Toro 04054, 04055, 04056, Greensmaster 800, Greensmaster 1000 Operator's Manual

...

FormNo.3376-120RevB

Greensmaster

®

800,1000,and

1600Mower

ModelNo.04054—SerialNo.313000001andUp

ModelNo.04055—SerialNo.313000001andUp

ModelNo.04056—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3376-120*B

ThisproductcomplieswithallrelevantEuropeandirectives,

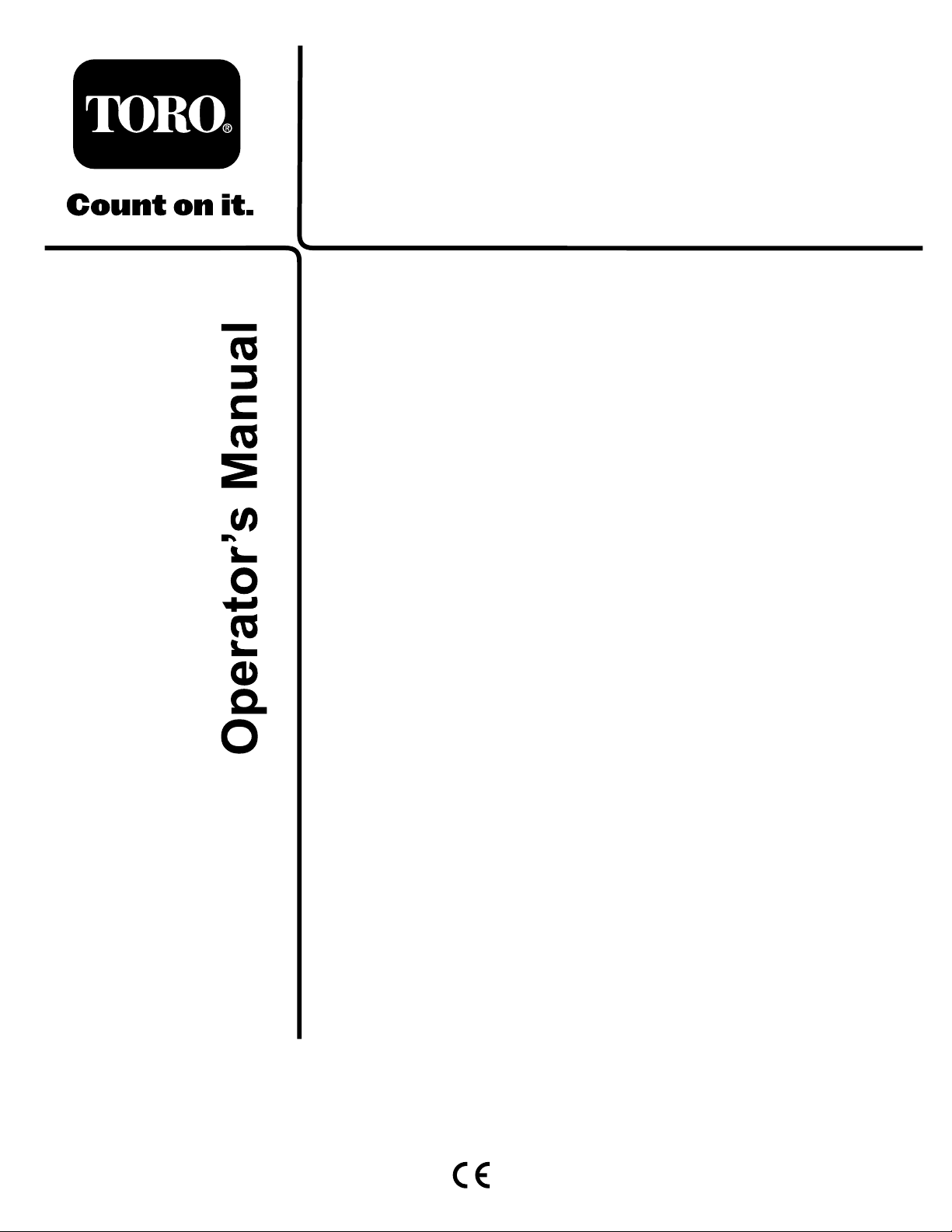

G019969

1

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporatedwith

themuferassembly.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Figure1

1.Locationofthemodelandserialnumbers-Tractionunit

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Introduction

Thismachineisawalk-behind,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedforcutting

grassonwell-maintainedlawnsinparks,golfcourses,sports

elds,andoncommercialgrounds.Itisnotdesignedfor

cuttingbrush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Thismanualusestwootherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................5

ForModel04054.....................................................6

ForModel04055.....................................................6

ForModel04056.....................................................6

SafetyandInstructionalDecals.................................7

Setup............................................................................9

1InstallingandAdjustingtheHandle.........................9

2InstallingtheKickstand(ForGR800and

GR1600)...........................................................10

3InstallingtheTransportWheelShafts(For

GR1000andGR1600).........................................11

4InstallingtheTransportWheels(Optional)..............11

5AdjustingtheCuttingUnit....................................12

6InstallingtheGrassBasket....................................12

ProductOverview.........................................................13

Controls...............................................................13

Specications........................................................15

Attachments/Accessories........................................16

Operation....................................................................16

ThinkSafetyFirst...................................................16

CheckingtheEngineOilLevel.................................16

FillingtheFuelTank...............................................16

CheckingtheInterlockSwitchOperation...................17

StartingandStoppingtheEngine..............................18

DrivingtheMachineinTransport.............................18

PreparingtoMow...................................................18

PriortoMowing.....................................................18

MethodofMowing.................................................18

ControlOperation..................................................18

Maintenance.................................................................20

RecommendedMaintenanceSchedule(s)......................20

DailyMaintenanceChecklist....................................21

Lubrication...............................................................22

GreasingtheMachine.............................................22

EngineMaintenance..................................................23

ServicingtheEngineOil..........................................23

ServicingtheAirCleaner.........................................24

ReplacingtheSparkPlug.........................................24

FuelSystemMaintenance...........................................25

CleaningtheFuelFilter...........................................25

ElectricalSystemMaintenance....................................26

ServicingtheInterlockSwitch.................................26

BrakeMaintenance....................................................26

AdjustingtheService/ParkingBrake.........................26

BeltMaintenance......................................................28

AdjustingtheBelts.................................................28

ReplacingtheDifferentialBelt..................................30

ControlsSystemMaintenance.....................................31

AdjustingtheTractionControl.................................31

CuttingUnitMaintenance...........................................31

LevelingtheRearDrumtotheReel...........................31

AdjustingtheBedknifetotheReel............................32

AdjustingtheHeightofCut.....................................32

AdjustingtheGrassShieldHeight.............................33

AdjustingtheCut-OffBar.......................................34

BedbarIdentication..............................................34

SettingtheMachinetoMatchTurfConditions............35

ServicingtheBedbar...............................................36

BacklappingtheReel...............................................36

Storage........................................................................37

3

Safety

ThismachinemeetsorexceedsCENstandardEN836:1997,

ISOstandard5395:1990,andANSIB71.4-2004specications

ineffectatthetimeofproductionwhentheOperator

PresenceKit,PartNo.112-9282isinstalled.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalert

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandardEN

836:1997,ISOstandard5395:1990,andANSIB71.4-2004.

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,oranimals

arenearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andhearingprotection.

Longhair,looseclothing,orjewelrymaygettangled

inmovingparts.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Warning—Fuelishighlyammable.Takethefollowing

precautions:

–Storefuelincontainersspecicallydesignedforthis

–Refueloutdoorsonlyanddonotsmokewhile

–Addfuelbeforestartingtheengine.Neverremove

–Iffuelisspilled,donotattempttostarttheengine

symbol,whichmeansCaution,Warning,or

purpose.

refuelling.

thecapofthefueltankoraddfuelwhiletheengineis

runningorwhentheengineishot.

butmovethemachineawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilfuel

vaporshavedissipated.

–Secureallfueltanksandcontainercaps.

•Replacefaultysilencers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly .Donot

operateunlesstheyarefunctioningproperly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengine.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforeremovingthegrassbasket;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition;

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

4

•Reducethethrottlesettingbeforestoppingengineand,if

theengineisprovidedwithafuelshut-offvalve,turnthe

valveoffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunit.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopreelsifnotmowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,silencer,and

fuelstorageareafreeofgrass,leaves,orexcessivegrease.

•Checkthegrassbasketfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Disengagedrives,disengagethecuttingunit,setparking

brake,stopengineanddisconnectsparkplugwire.W ait

forallmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunit,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Removethesparkplugwirebeforemakinganyrepairs.

•Usecarewhencheckingthereel.Wearglovesanduse

cautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlegasolinecarefully .Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Alwaysstandbehindthehandlewhenstartingand

operatingthemachine.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotoperateclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

•Thegrassbasketmustbeinplace,duringthemowing

operation,formaximumsafety.Shuttheengineoff

beforeemptyingthebasket.

•Donottouchtheengine,mufer,orexhaustpipewhile

theengineisrunningorsoonafterithasstoppedbecause

theseareascouldbehotenoughtocauseburns.

•Whenapersonorpetappearsunexpectedlyinornear

themowingarea,stopmowing.Carelessoperation,

combinedwithterrainangles,ricochets,orimproperly

positionedguardscanleadtothrownobjectinjuries.Do

notresumemowinguntiltheareaiscleared.

MaintenanceandStorage

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunit,attachments,andany

movingparts.Keepeveryoneaway .

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.Maximumgovernedenginespeedshould

be3375±100RPM.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsandreplacement

parts.Thewarrantymaybevoidedifusedwith

unapprovedattachments.

5

ForModel04054

ForModel04056

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof95dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof85

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforlefthand=4.00m/s

Measuredvibrationlevelforrighthand=2.87m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof95dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof85

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=3.35m/s

Measuredvibrationlevelforlefthand=2.59m/s

UncertaintyValue(K)=1.7m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

2

2

ForModel04055

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof95dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof84

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=2.52m/s

Measuredvibrationlevelforlefthand=2.39m/s

2

2

UncertaintyValue(K)=1.3m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

2

6

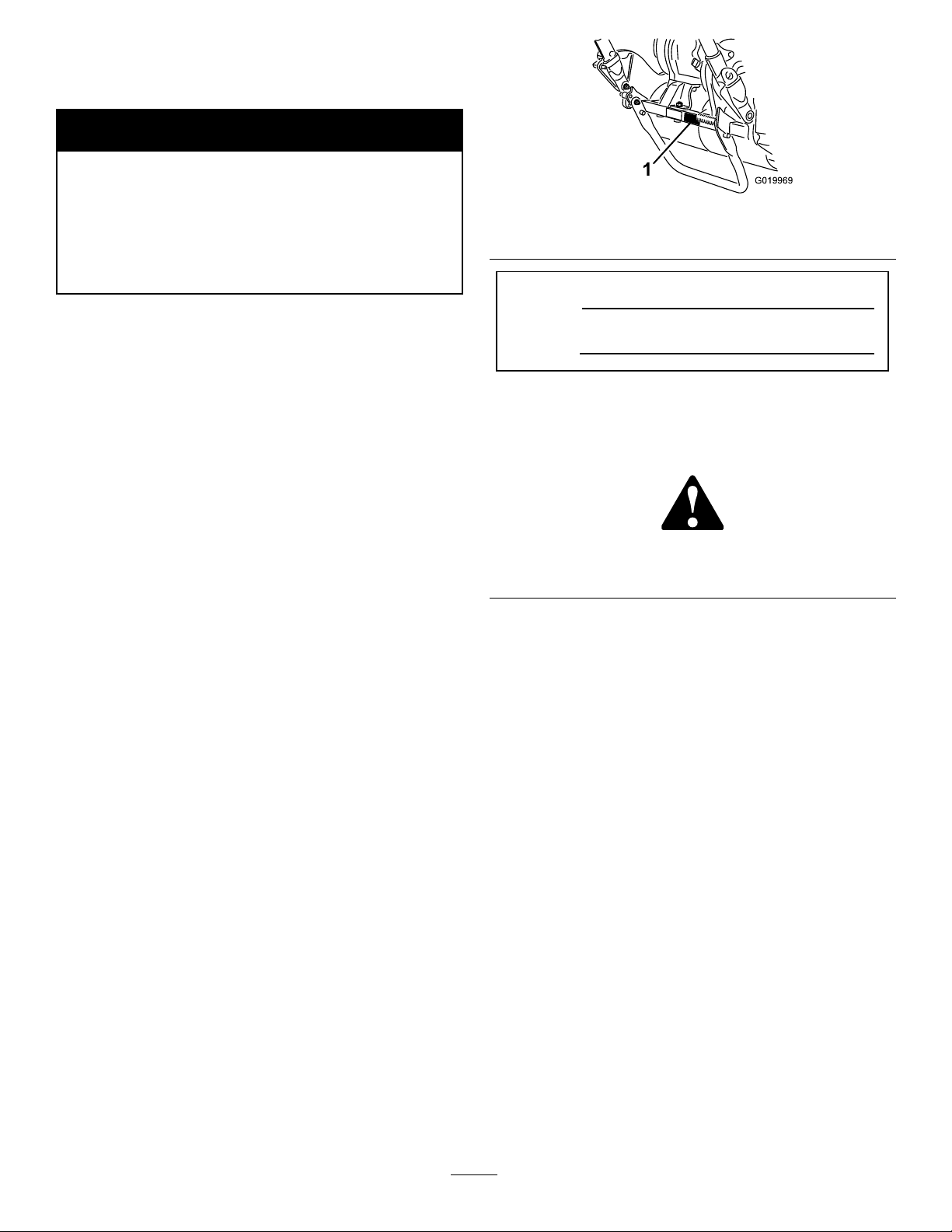

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

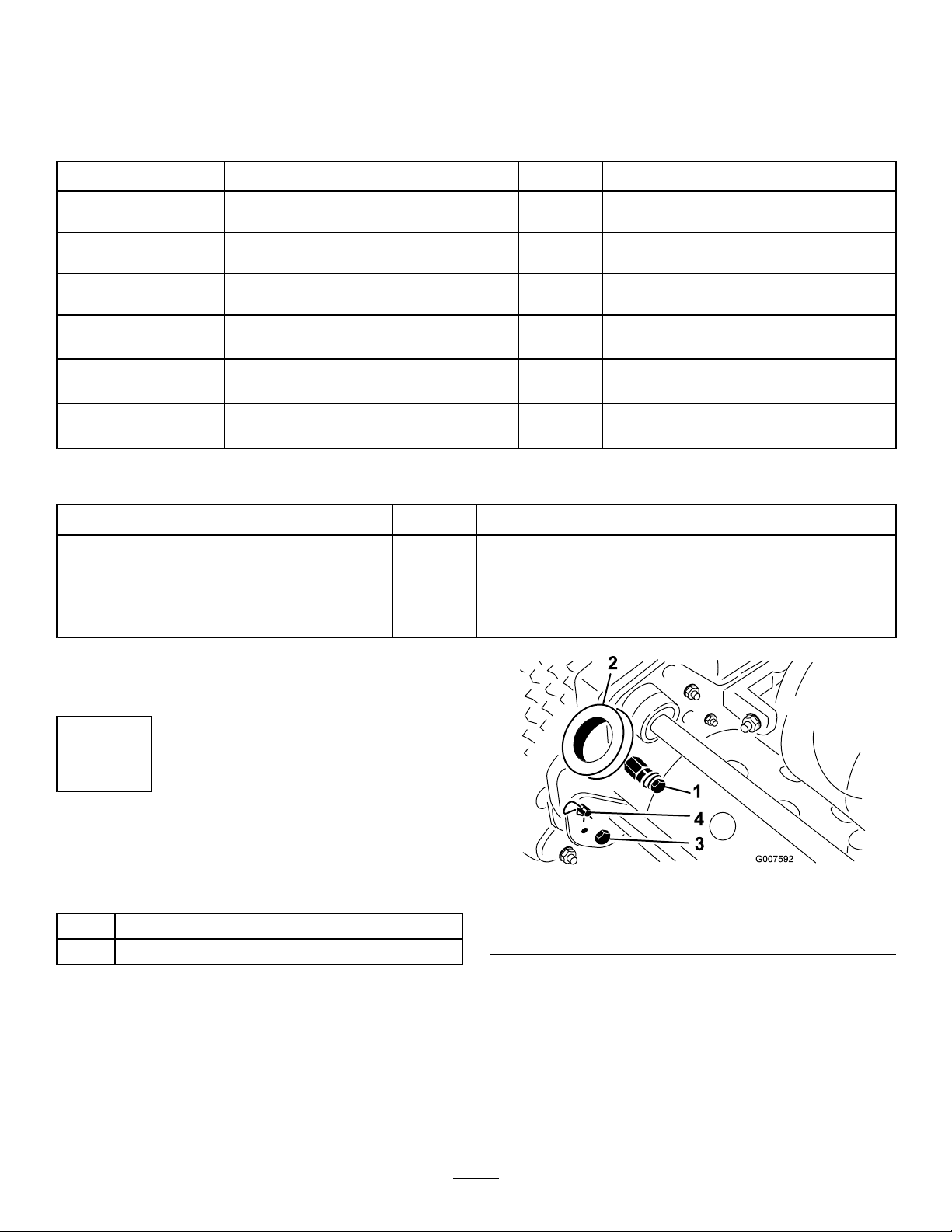

120–2769

1.Toxicgasinhalation

hazard—donotoperate

indoors.

2.Explosionhazard—stop

theengineandkeepaway

fromopenameswhen

refueling.

3.Warning—stoptheengine

andturnoffthefuelbefore

leavingthemachine.

4.Warning—disconnectthe

sparkplugwireandread

theinstructionbefore

servicingorperforming

maintenance.

5.Hotsurface/burn

hazard—donottouch

hotsurfaces.

6.Warning—readthe

Operator’sManual;when

addingfueltothetank,

onlylltothebottomof

thelltube.

93-9356

1.Entanglementhazard—stayawayfrommovingparts.

93-6085

1.Fast

2.Continuousvariable

setting

3.Slow

93-8064

1.Warning—readtheinstructionsbeforeservicingor

performingmaintenance.

2.Cuttinghazardoffootorhand—stoptheengineandwait

formovingpartstostop.

1.Reeldrive3.Disengage

2.Engage

93-7346

7

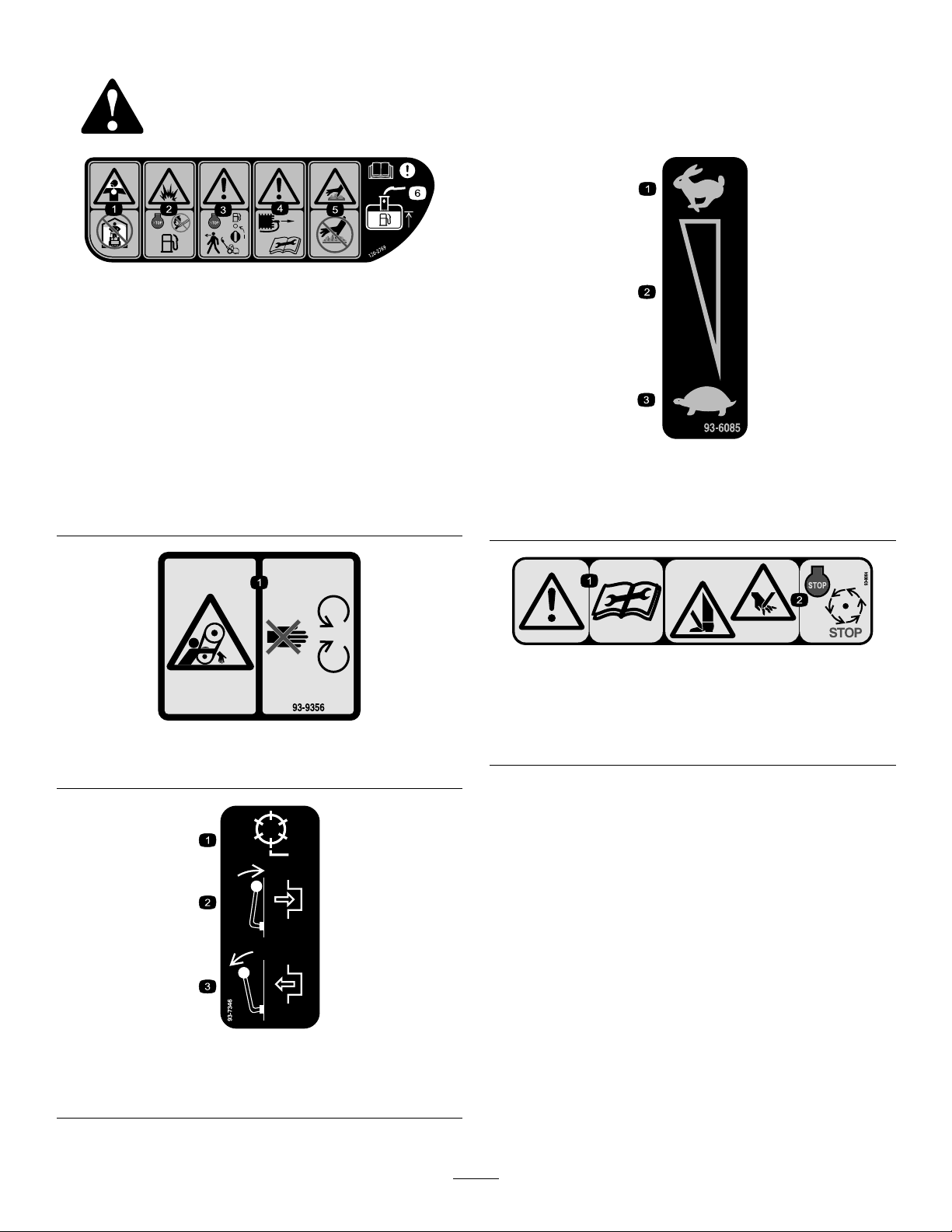

115-1614

1.Warning—readtheOperator'sManual.3.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethemachineunlessyouaretrained.

themachine.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.

115-1720

1.Forward3.Neutral

2.Drivewheel

120-2727

1.Brake—toengage,pullthe

levertowardthehandle;

todisengage,releasethe

lever.

2.Parkingbrake—tolock,

pullthelevertowardthe

handle,pressthebutton

inandreleasethelever

againstthelockingbutton;

torelease,pullthelever

towardthehandleuntil

thebuttonreleasesand

releasethelever..

106-8120

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhandandfoot—stayawayfrommoving

parts.

8

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

CerticateofCompliance

Handle1

Cabletie

Kickstandassembly1

Spring

Wheelshaft,right

Wheelshaft,left

Transportwheels(optional)

Nopartsrequired

Grassbasket

Qty.

1

1

1

1

1

Readorviewbeforeoperatingthemachine

Qty.

4

1

1

1

2

–

1Installthegrassbasket.

Installthehandle.

Installthekickstand.

Installthetransportwheelshafts.

Installthetransportwheels(optional).

Adjustthecuttingunit.

Use

Use

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

InstallingandAdjustingthe Handle

Partsneededforthisprocedure:

1Handle

4

Cabletie

InstallingtheHandle

1.Removetheboltsandlocknutssecuringthebottomof

thehandlearmstoeachsideofthemower(Figure3).

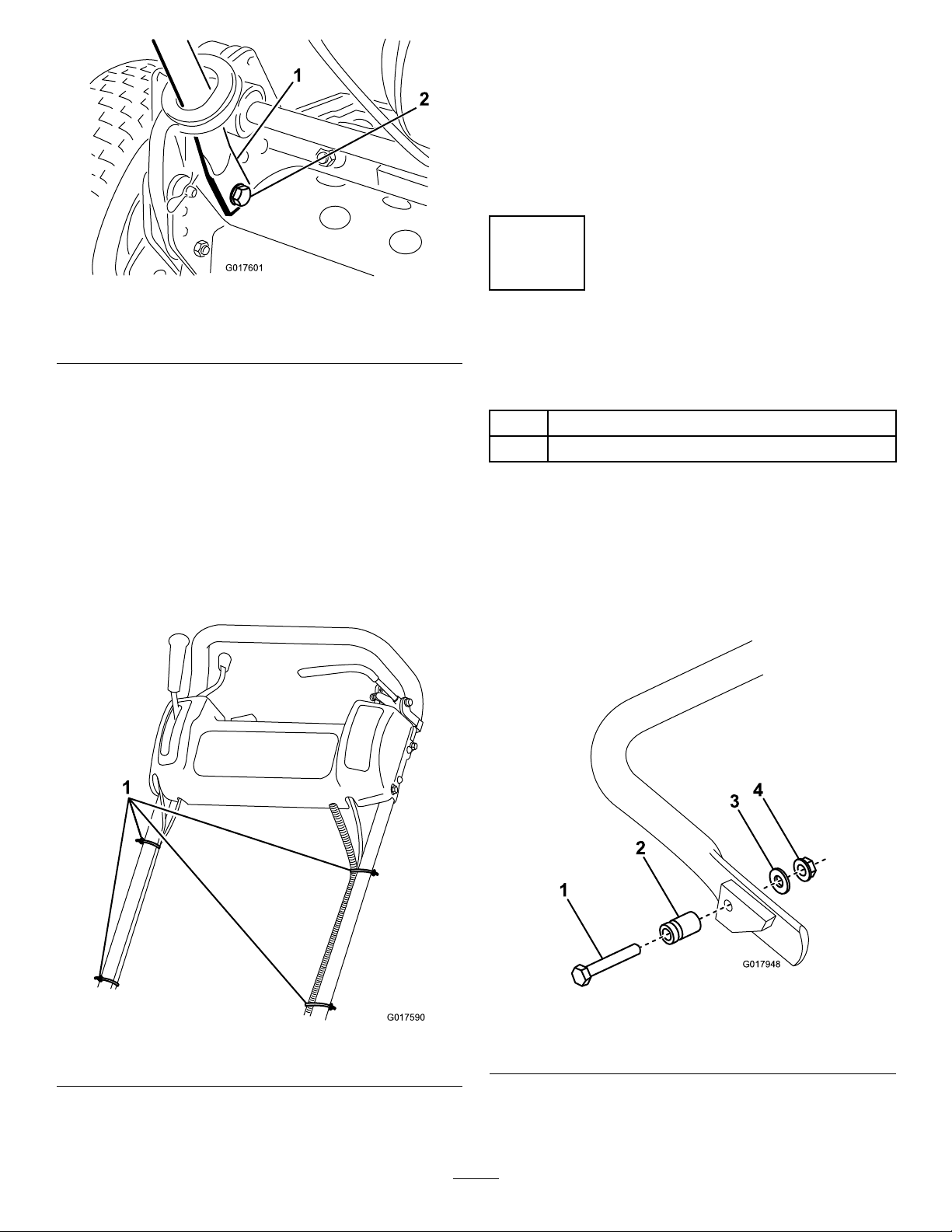

Figure3

1.Mountingpins3.Boltandlocknut

2.Handlearms4.Hairpincotterandringpin

2.Removethehairpincottersandringpinssecuringthe

handlearmstotherearoftheframe(

3.Insertthehandleendsthroughtheholesinthehandle

armsandaligntheholeswiththemountingpins

(Figure3).

4.Squeezethehandleendsinwardandinstallthemonthe

mountingpins(Figure4).

Figure3).

9

2

G017601

G017590

1

AdjustingtheHandle

G017948

1

2

3

4

1.Removethehairpincottersfromtheringpinsoneach

sideofthemower(Figure3).

2.Whilesupportingthehandle,removetheringpins

fromeachsideandraiseorlowerthehandletothe

desiredoperatingposition(

3.Installtheringpinsandhairpincotters.

Figure3).

Figure4

1.Handleend

2.Bolt,washer,andlockwasher

5.Securethehandleendstothemountingpinswiththe

bolts,washers,andlockwashersprovided(Figure4).

6.Securethebottomofthehandlearmstoeachside

ofthemowerwiththeboltsandlocknutspreviously

removed(Figure4).Ensurethatyouinstallthe

bushingsinthehandlearmmountingholes.

7.Securethehandlearmstotherearoftheframewith

thehairpincottersandringpinspreviouslyremoved

(Figure4).

8.Securethecablesandwireharnesstothehandlewith

cableties(

Figure5).

2

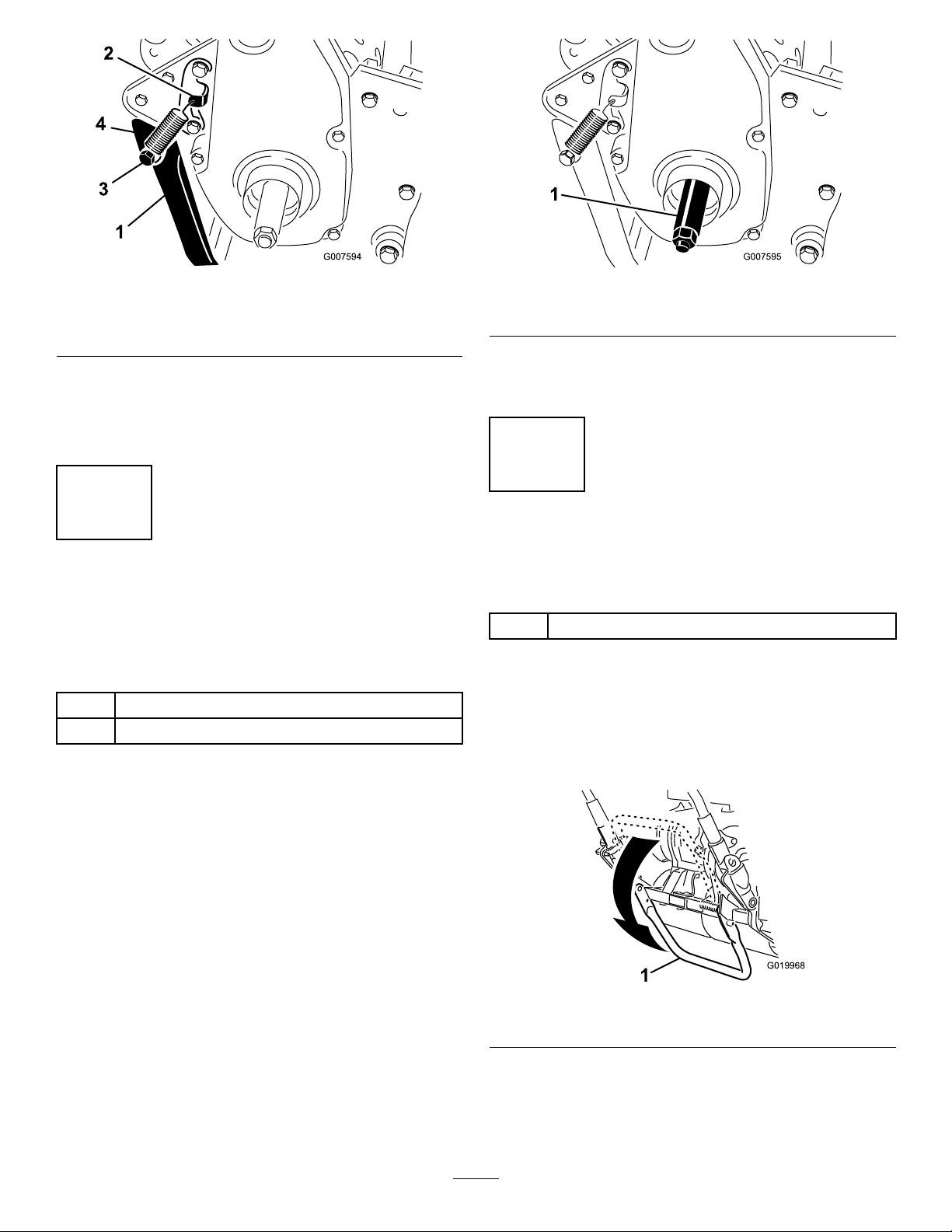

InstallingtheKickstand(For GR800andGR1600)

Partsneededforthisprocedure:

1Kickstandassembly

1

Spring

Procedure

Note:Thefastenersareshippedlooselyinstalledonthe

kickstandassembly.

1.OntheGR1600only,connectthespringstudtothe

righthandsideofthekickstand(Figure6)usingthe

bolt,washer,andange-headnutprovided.

1.Cableties

Figure5

1.Bolt3.Washer

2.Springstud

2.Hookthespringintotheholeinthespringbracketand

ontothespringstudwhilealigningthekickstandwith

themountingholesintherearframe(

10

Figure6

4.Flange-headnut

Figure7).

Figure7

G019968

1

Figure8

1.Kickstand

2.Springbracket4.Spring

3.Mountthekickstandtoeachsideoftheframewith

abolt,lockwasher,spacer,atwasherandlocknut

(Figure7).Positionthespacerinthekickstand

mountinghole.

3.Springstud

3

InstallingtheTransportWheel Shafts(ForGR1000and GR1600)

Partsneededforthisprocedure:

1

Wheelshaft,right

1

Wheelshaft,left

Procedure

1.Rightwheelshaft

4.Torquetheshaftto65to75ft-lb(88to101N-m).

5.Repeatontheleftside.

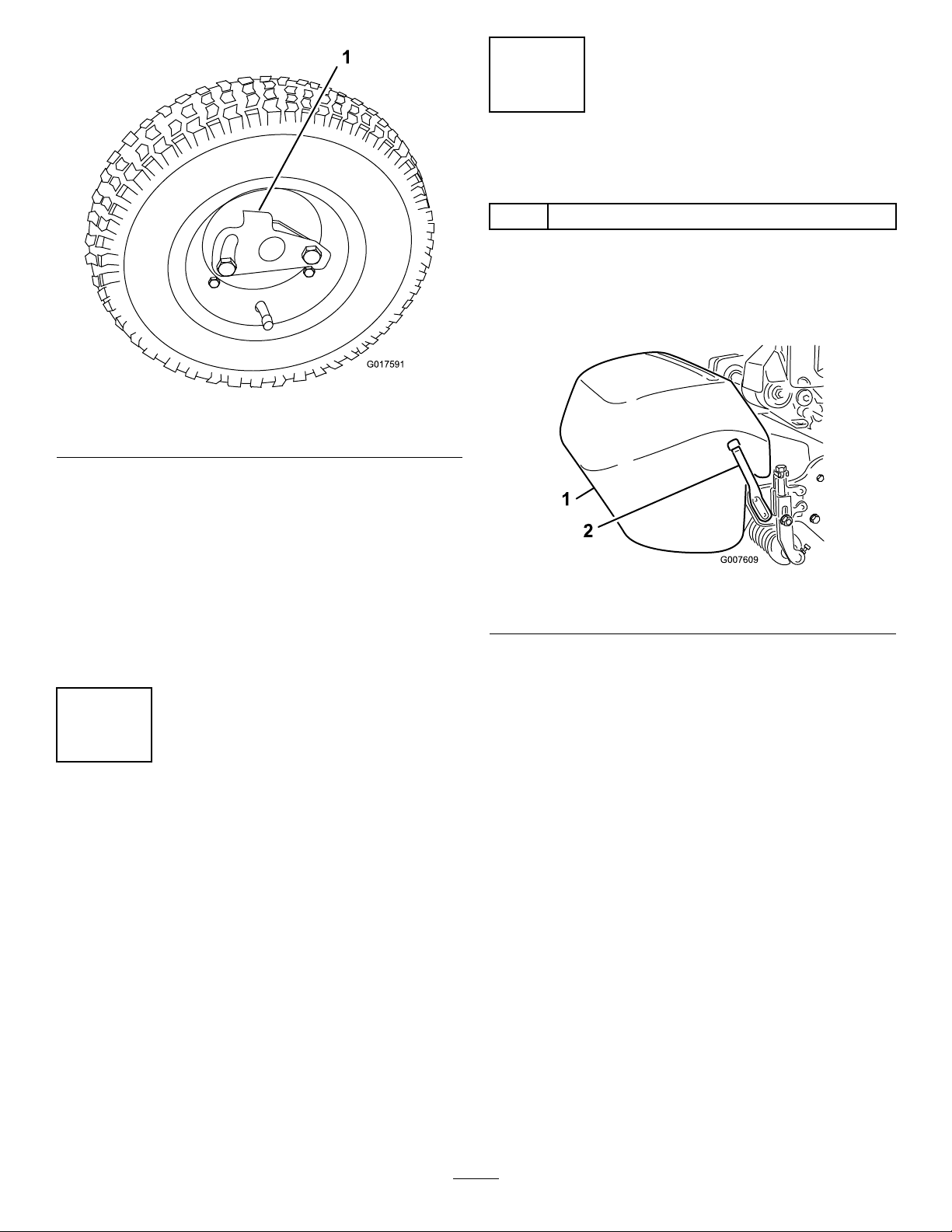

4

InstallingtheTransport Wheels(Optional)

Partsneededforthisprocedure:

2

Transportwheels(optional)

Procedure

1.Pushthekickstanddownwithyourfootinthecenter

ofthekickstandandpulluponthemachinehandle

untilthekickstandhasrotatedforward,overcenter

(Figure9).

1.Pushthekickstanddownwithyourfootandpullup

onthehandletosupportthemoweronthekickstand.

2.Apply#242Loctitetothethreadsofthewheelshafts.

3.Threadtherightwheelshaftintothedrivepulleyon

therightsideofthemachine(Figure8).

Note:Therightwheelshafthaslefthandthreads.

Figure9

1.Kickstand

2.Pressthewheellockingcliptowardthecenterofthe

wheelontothewheelshaft(Figure10).

11

G017591

Figure10

1.Lockingclip

3.Rotatethewheelbackandforthuntilitslides

completelyontotheaxleandthelockingclipissecured

inthegrooveontheaxleshaft.

4.Repeattheprocedureontheoppositesideofthe

machine.

5.Inatethetiresto12to15psi.(574to718Pa).

6.Carefullylowerthemachineoffthekickstandby

pushingforwardslowly,allowingthekickstandto

springbacktoitsnormalposition.

6

InstallingtheGrassBasket

Partsneededforthisprocedure:

1

Grassbasket

Procedure

Graspthebasketbythetoplipandslideitontothebasket

mountingrods(Figure11).

Figure11

1.Grassbasket

Note:Model04056only—Whencuttinginhigher

heights-of-cut,thebasketmaybeloweredbyremovingeach

basketmountingrodandinstallingeachontheoppositeside

ofthemachine.

2.Basketmountingrod

5

AdjustingtheCuttingUnit

NoPartsRequired

Procedure

Beforeoperatingthemachine,completethefollowing

adjustments:

•LevelingtheRearDrumtotheReel(page31).

•AdjustingtheBedknifetotheReel(page32).

•AdjustingtheHeightofCut(page32).

•

AdjustingtheGrassShieldHeight(page33).

•AdjustingtheCut-OffBar(page34).

RefertotheCuttingUnitMaintenancesectioninMaintenance

forinstructionsonperformingtheseprocedures.

12

Loading...

Loading...