Page 1

FormNo.3324-149RevA

Greensmaster

ModelNo.04052—SerialNo.200000001andUp

ModelNo.04052TE—SerialNo.200000001andUp

®

1000

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrestor,contactyour

AuthorizedServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,

orgrass-coveredlandwithoutasparkarrester

mufermaintainedinworkingorder,ortheengine

constricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmay

havesimilarlaws.

(Figure1),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Themodel

andserialnumbersarelocatedonaplateontherear

frame.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

©2000,2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................5

SoundPressure.....................................................6

Vibration..............................................................6

SafetyandInstructionalDecals.............................7

Setup............................................................................9

1InstallingandAdjustingtheHandle....................9

2InstallingtheTransportWheels

(Optional)......................................................10

3CheckingFluidLevels......................................10

4AdjustingtheCuttingUnit...............................10

5InstallingtheGrassBasket...............................11

ProductOverview......................................................11

Controls.............................................................11

Specications.....................................................12

Attachments/Accessories...................................12

Operation...................................................................13

ThinkSafetyFirst...............................................13

CheckingtheEngineOilLevel............................13

FillingtheFuelTank...........................................13

CheckingtheInterlockSwitchOperation............15

StartingandStoppingtheEngine........................15

DrivingtheMachineinTransport.......................15

PreparingtoMow...............................................15

Mowing..............................................................15

OperatingTips...................................................16

Maintenance...............................................................17

RecommendedMaintenanceSchedule(s)................17

DailyMaintenanceChecklist...............................18

Lubrication.............................................................19

GreasingtheMachine.........................................19

EngineMaintenance...............................................20

ServicingtheEngineOil.....................................20

ServicingtheAirCleaner....................................21

ReplacingtheSparkPlug....................................21

FuelSystemMaintenance.......................................22

CleaningtheFuelFilter.......................................22

BrakeMaintenance.................................................23

AdjustingtheService/ParkingBrake...................23

BeltMaintenance....................................................23

AdjustingtheBelts.............................................23

ReplacingtheDifferentialBelt............................25

ControlsSystemMaintenance.................................26

AdjustingtheTractionControl...........................26

CuttingUnitMaintenance.......................................27

LevelingtheRearDrumtotheReel.....................27

AdjustingtheBedknifetotheReel......................27

AdjustingtheHeightofCut................................28

AdjustingtheGrassShieldHeight.......................29

AdjustingtheCut-OffBar..................................29

ServicingtheBedbar..........................................29

BacklappingtheReel..........................................30

Storage.......................................................................31

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Training

•ReadtheOperator’sManualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthe

languageoftheOperator’sManualitistheowner’s

responsibilitytoexplainthismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

•Alloperatorsormechanicsmustbetrained.Itisthe

owner’sresponsibilityfortrainingusers.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andhearing

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Donotuseonslopesofmorethan15°.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–engageclutchslowly,alwayskeepmachinein

gear,especiallywhentravellingdownhill;

–machinespeedsshouldbekeptlowonslopes

andduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

–nevermowacrossthefaceoftheslope,unless

themowerisdesignedforthispurpose.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

4

Page 5

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly .

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’sposition:

–stoponlevelground;

–disengagethecuttingunitandtractiondrive;

–settheparkingbrake;

–stoptheengine.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Reducethethrottlesettingbeforestoppingengine

and,iftheengineisprovidedwithafuelshut-off

valve,turnthevalveoffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunit.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopreelsifnot

mowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandfuelstorageareafreeof

grass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Disengagedrives,disengagethecuttingunit,set

parkingbrake,stopengineanddisconnectsparkplug

wire.Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunit,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Removethesparkplugwirebeforemakingany

repairs.

•Usecarewhencheckingthereel.Wearglovesand

usecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO,or

ANSIstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlegasolinecarefully.Wipeupanyspills.

5

Page 6

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operator’searof83dBA,basedonmeasurementsof

identicalmachinesperEN836andISO11201.

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Thegrassbasketmustbeinplaceduringthemowing

operationformaximumsafety .Shuttheengineoff

beforeemptyingthebasket.

•Donottouchtheengine,mufer,orexhaustpipe

whiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenough

tocauseburns.

•Whenapersonorpetappearsunexpectedlyinor

nearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

Vibration

Thisunitdoesnotexceedahand/armvibrationlevel

of10.05m/s

machinesperEN1033andEN836.

2

,basedonmeasurementsofidentical

MaintenanceandStorage

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecuttingunit,

attachments,andanymovingparts.Keepeveryone

away.

•Toensuresafetyandaccuracy ,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.Maximumgovernedenginespeed

shouldbe3600RPM.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

104-051

93-7273

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhandorfoot—stayawayfrommoving

parts.

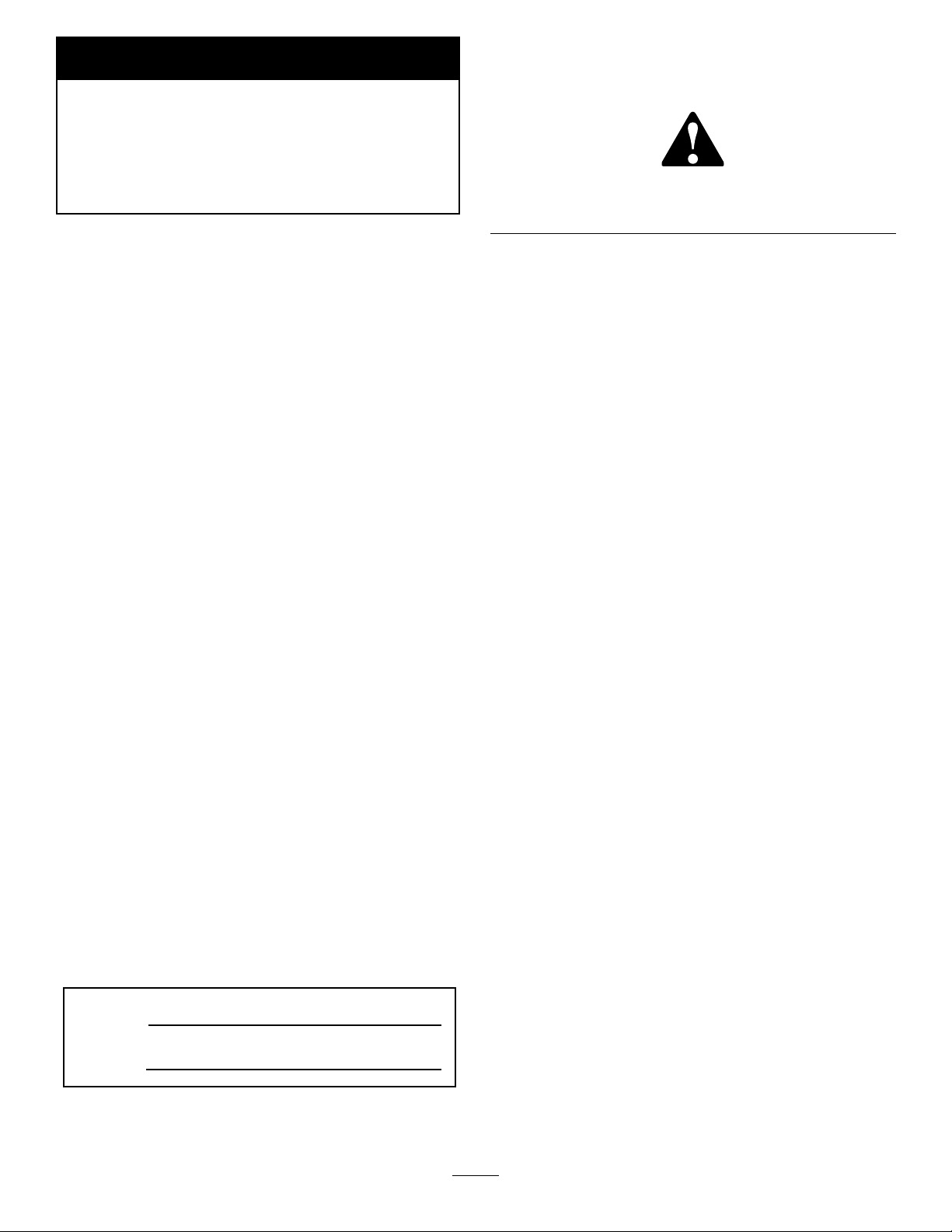

93-6098

93-8069

1.Hotsurface/burnhazard—stayasafedistancefromthe

hotsurface.

7

Page 8

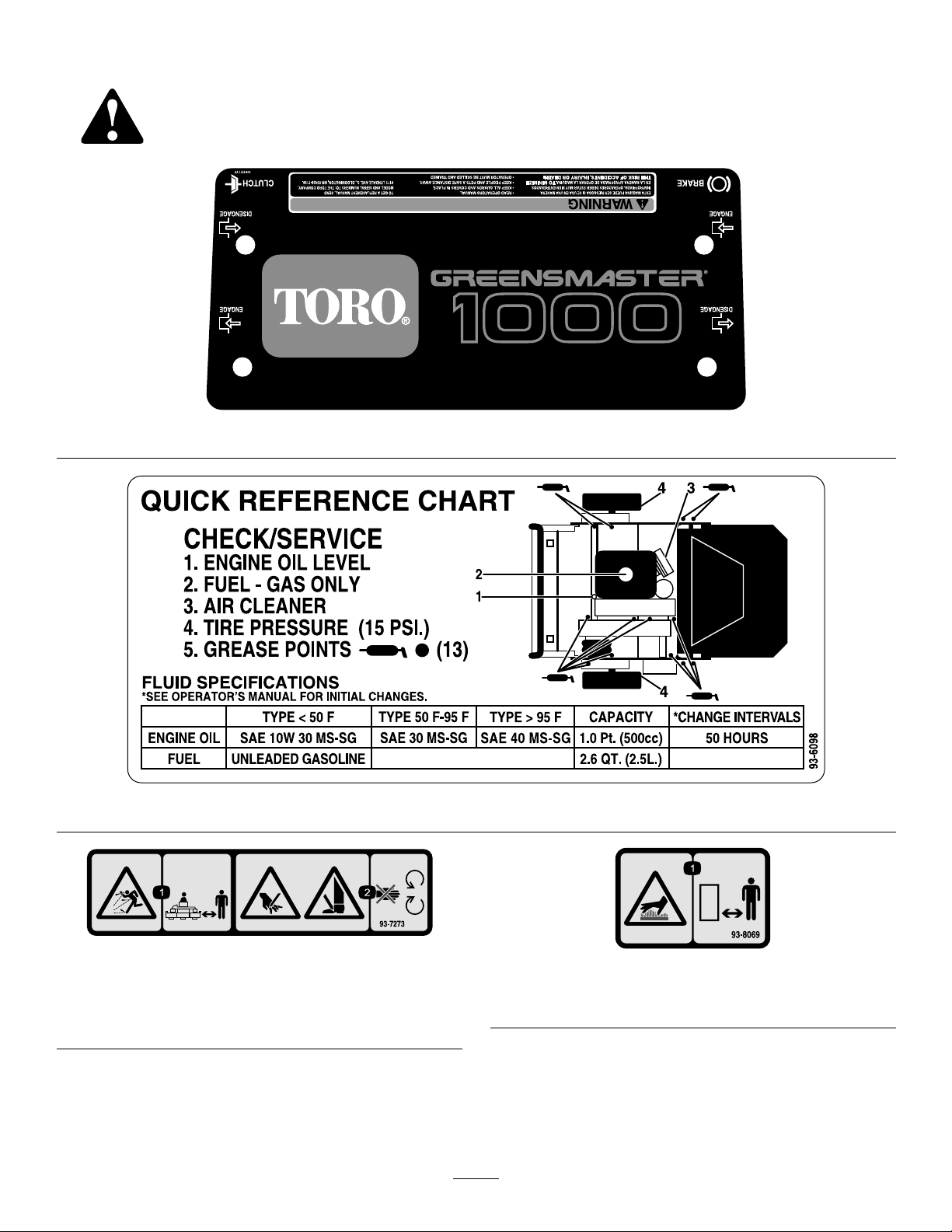

93-7348

1.Warning—readtheOperator’sManual.

2.Firehazard—nore,openames,orsmoking;whenadding

fueltothetank,leavespacebetweenthefuelandthetopof

thetank.

3.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

4.Cuttinghazardofhandorfoot—stayawayfrommoving

parts

93-9356

1.Entanglementhazard—stayawayfrommovingparts.

1.Fast

2.Continuousvariable

setting

1.Useunleadedgasoline.

93-6085

3.Slow

93-9886

1.Reeldrive3.Disengage

2.Engage

93-8064

1.Warning—readtheinstructionsbeforeservicingor

performingmaintenance.

2.Cuttinghazardofhandorfoot—stoptheengineandwait

formovingpartstostop.

93-7346

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Handle1

1

2

4

5

Cabletie

Transportwheels(obtainseparately)

Nopartsrequired

Grassbasket

MediaandAdditionalParts

Description

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterial

CerticateofCompliance

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

Qty.

2

2Installthetransportwheels.

–

1Installthegrassbasket.

1

1

1

1

1

Readorviewbeforeoperatingthemachine

Installthehandle.

Adjustthecuttingunit.

Use

Use

1

InstallingandAdjustingthe

Handle

Partsneededforthisprocedure:

1Handle

2

Cabletie

InstallingtheHandle

1.Removethebolt,washer,andlockwasherfromthe

mountingpinoneachsideofthemower(Figure2).

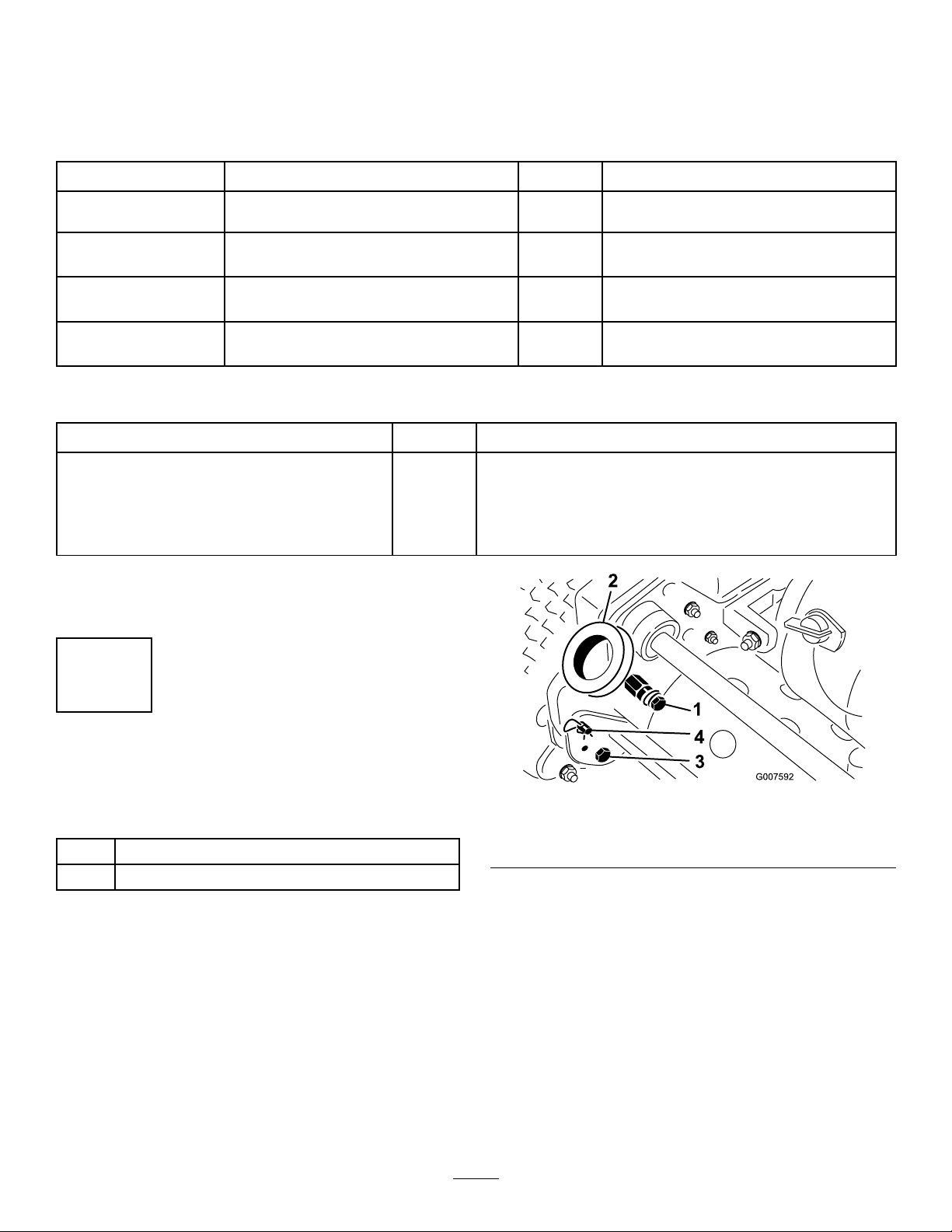

Figure2

1.Mountingpins3.Boltandlocknut

2.Handlearms4.Hairpincotterandringpin

2.Insertthehandleendsthrutheholesinthehandle

armsandaligntheholeswiththemountingpins

(Figure2).

Note:Hairpincottersandringpinsmayhave

toberemovedfromhandlearmstoallowhandle

installation(Figure2).

3.Squeezethehandleendsinwardandinstallthemon

themountingpins(Figure3).

9

Page 10

Figure3

1.Handleend

4.Securethehandleendstothemountingpinswiththe

bolts,washers,andlockwasherspreviouslyremoved

(Figure3).

5.Securethecablestothehandlewithcableties.

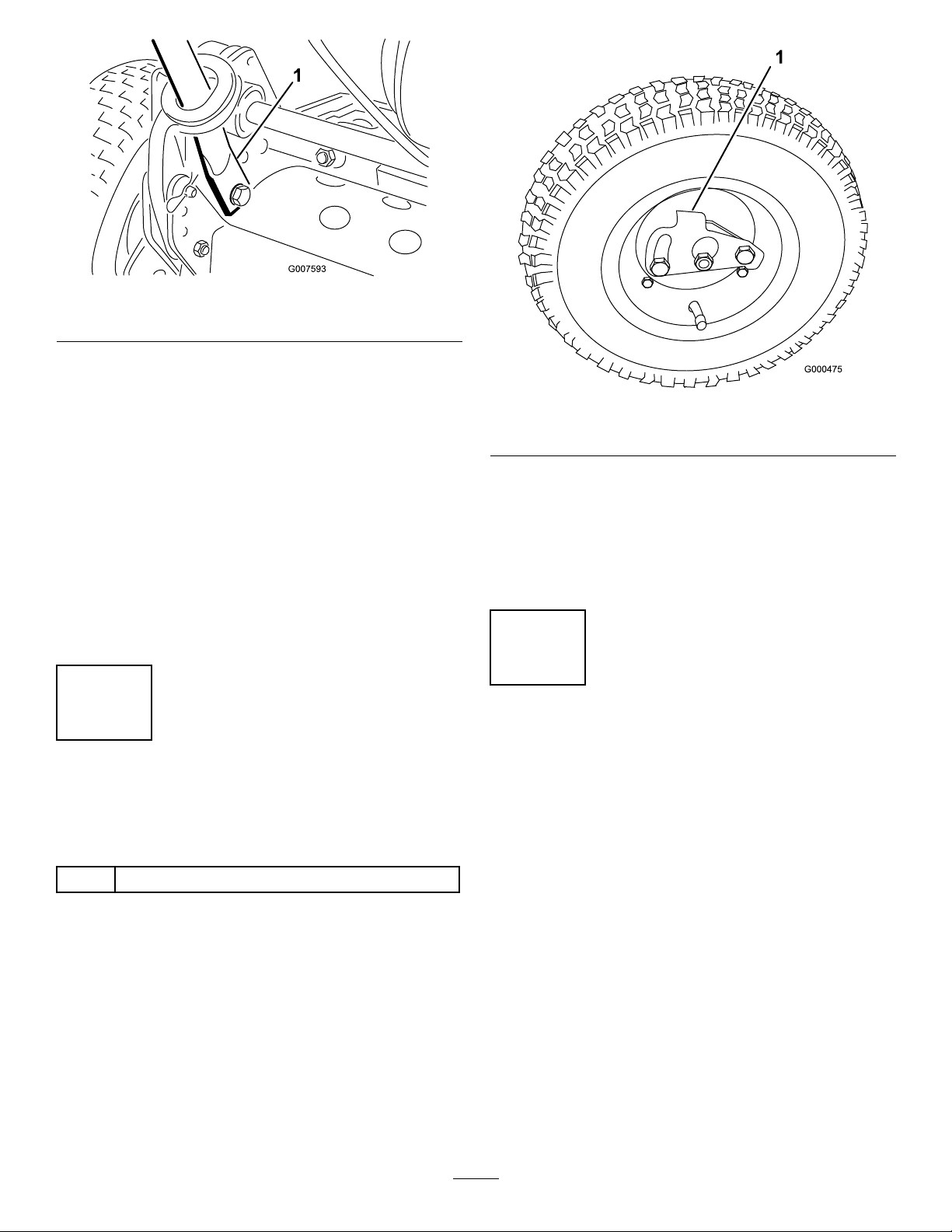

Figure4

1.Lockingclip

AdjustingtheHandle

1.Removethehairpincottersfromtheringpinson

eachsideofthemower(Figure2).

2.Whilesupportingthehandle,removetheringpins

fromeachsideandraiseorlowerthehandletothe

desiredoperatingposition(Figure2).

3.Installtheringpinsandhairpincotters.

2

InstallingtheTransport

Wheels(Optional)

Partsneededforthisprocedure:

2

Transportwheels(obtainseparately)

Procedure

4.Rotatewheelbackandforthuntilitslidescompletely

ontoaxleandlockingclipissecuredingrooveon

axleshaft.

5.Repeatprocedureonoppositesideofmachine.

6.Inatethetiresto12to15psi.(574to718Pa).

3

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checktheengineoillevel,refertoCheckingthe

EngineOilLevelinEngineMaintenance.

2.Checkthetransmissionuidlevel,refertoChecking

theTransmissionFluidLevelinDriveSystem

Maintenance.

1.Pushthekickstanddownwithyourfootandpull

uponthehandletosupportthemoweronthekick

stand.

2.ApplyNever–Seeztotheexposedendsoftheaxles

andslidethewheelontotheaxle(Figure4).

3.Pivotthewheellockingclipawayfromcenterof

thewheelallowingittoslidefartherontotheaxle

(Figure4).

10

Page 11

ProductOverview

4

AdjustingtheCuttingUnit

NoPartsRequired

Procedure

Beforeoperatingthemachine,completethefollowing

adjustments:

•Levelthereardrumtothereel.

•Adjustthebedknifetothereel.

•Adjusttheheight-of-cut.

•Adjustthegrassshieldheight

•Adjustthecut-offbar.

RefertotheCuttingUnitMaintenancesectionin

Maintenanceforinstructionsonperformingthese

procedures.

5

Controls

Figure6

1.Throttlecontrol

2.Tractiondrivelever

ThrottleControl

Thethrottlecontrol(Figure6)islocatedonrearright

sideofthecontrolpanel.Theleverconnectstoand

operatesthrottlelinkagetothecarburetor.Theengine

speedcanbevariedfrom1600to3600RPM.

3.Service/parkingbrake

4.Operatorpresencecontrol

(optional)

InstallingtheGrassBasket

Partsneededforthisprocedure:

1

Grassbasket

Procedure

Graspbasketbytoplipandslideitontothebasket

mountingrods(Figure5).

TractionDriveLever

Thetractiondrivelever(Figure6)islocatedonthefront

rightsideofthecontrolpanel.Ithastwopositions:

NeutralandForward.Pushingtheleverforwardengages

thetractiondrive.

Service/ParkingBrake

Theservice/parkingbrake(Figure6)islocatedonleft

frontsideofcontrolpanel.Youcanusethebraketo

sloworstopthemachine.Pullingtheleverbackover

centerwillsettheparkingbrake.Youmustreleasethe

brakebeforetractiondriveisengaged.

OperatorPresenceControl(Optional)

Ifequipped,theoperatorpresencecontrol(Figure6)

islocatedontherearofthehandle.Pushtheoperator

presencecontrolagainstthehandle.Ifequipped,the

operatorpresencecontrolmustbeengagedbefore

movingthetractiondriveleverortheenginewillstop.

1.Grassbasket

Figure5

2.Basketmountingrod

ReelDriveLever

Thereeldrivelever(Figure7)islocatedontheright

frontcornerofthemachine.Theleverhastwo

11

Page 12

positions:EngageandDisengage.Pulluponthelever

toengagethereelorpushitdowntodisengagethereel.

RecoilStarter

Pullrecoilstarterhandle(Figure9)tostartengine.

Figure7

1.Reeldrivelever

ChokeLever

Thechokelever(Figure8)islocatedonleftfrontofthe

engine.Theleverhastwopositions:RunandChoke.

MovethelevertotheChokepositionwhenstarting

acoldengine.AfterenginestartsmovelevertoRun

position.

Figure8

1.Chokelever2.Fuelshut-offvalve

Figure9

1.Recoilstarter

2.Kickstand

3.On/offswitch

Kickstand(Optional)

Thekickstand(Figure9)ismountedtotherearof

machineandisusedtoraisetherearofmachinefor

installationorremovalofthetransportwheels.

Specications

Width

Height

Lengthwithbasket

Dryweight(withbasketand

Wiehleroller;withoutwheels

orgroomingreel)

Widthofcut21inches(53cm)

Heightofcut5/64to1inch(0.2to2.5cm)

Clip0.16inch(0.4cm)

36inches(91cm)

47inches(1 19cm)

59inches(150cm)

208lb(94kg.)

FuelShut-OffValve

Thefuelshut-offvalve(Figure8)islocatedonleft

frontofengine.Thevalvehastwopositions:Closed

andOpen.Movethelevertotheclosedpositionwhen

storingortransportingmachine.Openthevalvebefore

startingtheengine.

On/OffSwitch

Theon/offswitch(Figure9)islocatedonthetopofthe

controlpanel.MoveswitchtotheOnpositiontostart

theengineandtheOffpositiontostoptheengine.

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

12

Page 13

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

CheckingtheEngineOilLevel

Checktheengineoillevelbeforeeachuseorevery8

operatinghours,refertoCheckingtheEngineOilLevel

inEngineMaintenance,page20.

FillingtheFuelTank

Important:Neverusemethanol,gasoline

containingmethanol,gasoholcontainingmore

than10%ethanol,gasolineadditives,premium

gasoline,orwhitegasbecausethefuelsystem

couldbedamaged.Donotmixoilwithgasoline.

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1

inch(2.5cm)belowthebottomoftheller

neck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofgasoline.

Figure10

1.Fueltankcap2.Fuelgauge

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

13

Page 14

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

1.Cleanaroundfueltankcapandremovecapfrom

tank(Figure10).

2.Usingunleadedgasoline,llfueltanknohigher

thantobottomoflterscreen.Donotoverll.

3.Installfueltankcapandwipeupanyspilledgasoline.

14

Page 15

CheckingtheInterlockSwitch

Operation

ServiceInterval:Beforeeachuseordaily

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

1.PlacetractionleverintoEngagepositionandengine

controlsinstartingposition.

2.Attempttostartengine.

Theengineshouldnotstart.Ifenginestarts,the

interlockswitchneedsservice.Correctproblem

beforeoperating.RefertoServicingInterlock

Switch.

StartingandStoppingthe

Engine

Note:Forillustrationsanddescriptionsofthecontrols

referencedinthissection,refertotheControlssection

inProductOverview.

StartingtheEngine

Note:Ensurethatthesparkplugwireisinstalledon

thesparkplug..

1.Ensurethatthetractionandreeldriveleversarein

theDisengagedposition.

Note:Theenginewillnotstartifthetractionlever

isintheEngagedposition.

2.Openthefuelshut-offvalveontheengine.

3.Movetheon/offswitchtotheOnposition.

4.MovethethrottlecontroltotheFastposition.

5.MovethechokeleverhalfwaybetweentheOnand

Offpositionswhenstartingacoldengine.The

chokemaynotberequiredwhenstartingawarm

engine.

6.Pulltherecoilstarterhandleoutuntilpositive

engagementresults,thenpullitvigorouslytostart

theengine.

outbecauseropemaybreakorrecoilassembly

maybedamaged.

7.MovethechoketotheOffpositionastheengine

warmsup.

StoppingtheEngine

1.Movethetractionandreeldrivecontrolstothe

Disengagedposition,thethrottlecontroltothe

Slowposition,andtheOn/OffswitchtotheOff

position.

2.Pullthesparkplugwireoffofthesparkplugto

preventthepossibilityofaccidentalstartingbefore

storingthemachine.

3.Closethefuelshut-offvalvebeforestoringor

transportingthemowerinavehicle.

DrivingtheMachinein

Transport

1.Pushthekickstanddownwithyourfootandpull

uponthehandletoraisetherearofmowerand

installthetransportwheels.

2.Toreleasethekickstand,pulluponthehandle,

pushthemowerforward,andthenlowertherearof

mowerontothetransportwheels.

3.Ensurethatthetractionandreeldrivecontrolsare

intheDisengagedpositionandstarttheengine.

4.SetthethrottlecontroltoSlow ,tipthefrontofthe

machineupgradually,engagethetractiondriveand

slowlyincreasetheenginespeed.

5.Adjustthethrottletooperatethemoweratthe

desiredgroundspeedandtransportthemowerto

thedesireddestination.

PreparingtoMow

1.ReturnthetractioncontrollevertotheDisengage

position,thethrottletotheSlowposition,andstop

theengine.

2.Pushthekickstanddownwithyourfootandpull

upandbackonthehandletoraisethewheelsoff

oftheground.

3.Pushthelockingclipsonthewheelsoutofthe

groovesintheshafts.

4.Slidethewheelsoffoftheshafts.

5.Movetheunitoffofthekickstand.

Mowing

Important:Donotpullrecoilropetoitslimit

orletgoofstarterhandlewhenropeispulled

Properuseofthemachineprovidesthesmoothest

turfcuttingavailable.ReferalsotoOperatingTips

15

Page 16

forfundamentalsuggestionstoobtaintheutmost

performancefromyourmower.

Important:Excessiveoperationofthecuttingunit

withtheabsenceofgrassclippings(lubricant)can

damagethecuttingunit.

1.Starttheengine,setthethrottleatreducedspeed,

pushdownonthehandletoraisethecuttingunit,

movethetractionlevertotheEngagedposition,

andtransportthemowerontocollarofthegreen.

2.MovethetractionlevertotheDisengagedposition

andmovethereeldrivelevertotheEngaged

position.

3.MovethetractionlevertotheEngagedposition,

increasethethrottlespeeduntilthemoweris

travelingatthedesiredgroundspeed,drivethe

mowerontothegreen,lowerthefrontofthe

mower,andcommenceoperation.

4.Whennishedmowing,driveoffofthegreen,

movethetractioncontrollevertotheDisengage

position,stoptheengineandpushthereeldrive

leverintotheDisengageposition.

5.Emptythegrasscatcherofclippings,installthe

grasscatcher,andcommencetransportoperation.

OperatingTips

BeforeMowing

•Ensurethatthemoweriscarefullyadjustedand

issetevenlyonbothsidesofthereel.Improper

moweradjustmentismagniedmanytimesoverin

theappearanceoftheclippedturf.

•Removeallforeignobjectsfromtheturfpriorto

mowing.

•Ensurethateveryone,especiallychildrenandpets,

areclearoftheworkarea.

MowingTechniques

•Mowagreeninastraightbackandforthdirection,

acrossthegreen.

•Avoidcircularmowingorturningthemowerona

greenbecausescufngmayoccur.Turnthemower

offofthegreenbyraisingthecuttingreel(pushing

thehandledown)andturningonthetractiondrum.

•Mowatanormalwalkingpace.Fastspeedsaves

verylittletimeandwillresultinaninferiormowing

job.

16

Page 17

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

Every300hours

Beforestorage

Important:Refertoyour

MaintenanceProcedure

•Changetheengineoil.

•Cleanthefuellter.

•Checktheinterlockswitchoperation.

•Checktheengineoillevel.

•Greasethemachine.

•Cleanandoiltheaircleanerfoamelement.(Moreoftenindirtyordustyconditions)

•Changetheengineoil.(Morefrequentlyindustyordirtyconditions)

•Cleanthefuellter.

•Cleanorreplacethepaperairlterelement.(Moreoftenindirtyordustyconditions)

•Checkthesparkplug.

•Decarbontheengine.

•Changetheairlterpaperelement

•Paintchippedsurfaces.

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

17

Page 18

DailyMaintenanceChecklist

Important:Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation.

Checktheparking

brakeoperation.

Checkthefuel

level.

Checktheengine

oillevel.

Checktheair

lter.

Cleantheengine

coolingns.

Checkforunusual

enginenoises.

Checkforunusual

operatingnoises.

Checkthe

reel-to-bedknife

adjustment.

Checkthe

height-of-cut

adjustment.

Greaseallttings.

Touchup

damagedpaint.

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

18

Page 19

Lubrication

GreasingtheMachine

ServiceInterval:Every25hours

Lubricatethe13greasettingsonthemowerusing

aNo.2multipurposelithiumbasegrease.Ahand

operatedgreasegunisrecommendedforbestresults.

Thegreasettinglocationsareasfollows:

•2onthefrontroller(Figure11)

•2onthereelbearings(Figure11)

•2onthedrumaxles(Figure12)

•3onthedifferential(Figure12)

•2onthereelcountershaftbearings(Figure13)

•2onthebeltidlerpivots(Figure14)

1.Wipeeachgreasettingwithacleanrag.

2.Pumpgreaseintoeachttinguntilitbeginstoget

difculttopumpthegun.

Important:Donotapplytoomuchpressureor

greasesealswillbecomepermanentlydamaged.

3.Wipeoffexcessgrease.

Figure13

Figure14

Figure11

Figure12

19

Page 20

EngineMaintenance

ServicingtheEngineOil

ServiceInterval:Aftertherst8hours—Changethe

engineoil.

Beforeeachuseordaily—Checkthe

engineoillevel.

Every50hours—Changetheengine

oil.(Morefrequentlyindustyordirty

conditions)

Thecrankcasemustbelledwithapproximately20

uidouncesofproperviscosityoilbeforestaring.The

engineusesanyhigh-qualityoilhavingtheAmerican

PetroleumInstitute-APl-“serviceclassication"SF,

SG,SHorSJ.Oilviscosity-weight-mustbeselected

accordingtoambienttemperature.illustratesthe

temperature/viscosityrecommendations.

Figure16

1.Oillevelgauge

2.Removetheoillevelgaugebyrotatingit

counterclockwise.

2.Drainplug

Figure15

Note:Usingmulti-gradeoils(5W-20,10W-30,and

10W-40)willincreaseoilconsumption.Checktheoil

levelmorefrequentlywhenusingthem.

CheckingtheEngineOilLevel

1.Positionmowersotheengineislevelandclean

aroundoillevelgauge(Figure16).

3.Wipetheoillevelgaugecleanandinsertitintothe

llerport.Donotscrewitintotheport.

4.Removethegaugeandchecktheleveloftheoil.

5.Ifthelevelislow,addonlyenoughoiltoraisethe

leveluntilitisbetweentheHandLmarksonthe

gauge(Figure17).Donotoverll.

Figure17

6.Installtheoillevelgaugeandwipeupanyspilledoil.

ChangingtheEngineOil

1.Startandruntheengineforafewminutestowarm

theengineoil.

2.Placeadrainpanattherearofmachine,underthe

drainplug(Figure16).

3.Removethedrainplug.

20

Page 21

4.Pushdownonthehandletotipthemowerandthe

enginebackward,allowingmoreoiltorunintothe

drainpan.

5.Installthedrainplugandrellthecrankcasewiththe

properoil;refertoCheckingtheEngineOilLevel.

ServicingtheAirCleaner

ServiceInterval:Every25hours—Cleanandoiltheair

cleanerfoamelement.(Moreoftenin

dirtyordustyconditions)

Every100hours—Cleanorreplace

thepaperairlterelement.(More

oftenindirtyordustyconditions)

Every300hours—Changetheair

lterpaperelement

Important:Servicetheaircleanermoreoftenin

dirtyordustyconditions

1.Makesurethewireisoffofthesparkplug.

2.Removethewingnutssecuringtheaircleanercover

andremovethecover(Figure18).

Figure19

1.Foamelement2.Paperelement

5.Checkconditionofthepaperelement.Cleanby

gentlytappingthelterorreplaceitasrequired.

Important:Donotusecompressedairtoclean

thepaperelement.

6.Installthefoamelement,paperelement,andair

cleanercover.

Important:Donotoperatetheenginewithout

theaircleanerelementbecauseextremeengine

wearanddamagewilllikelyresult.

Figure18

1.Aircleanercover

3.Cleanthecoverthoroughly .

4.Ifthefoamelementisdirty,removeitfromthepaper

element(Figure19)andcleanthoroughly,asfollows:

A.Washthefoamelementinasolutionofliquid

soapandwarmwater.Squeezeittoremovedirt,

butdonottwistitbecausethefoammaytear.

B.Drythefoamelementbywrappingitinaclean

rag.Squeezetheragandfoamelementtodry

it,butdonottwistit.

C.Saturatethefoamelementwithcleanengineoil.

Squeezetheelementtoremoveexcessoiland

todistributetheoilthoroughly.Anoildamp

elementisdesirable.

ReplacingtheSparkPlug

ServiceInterval:Every100hours

UseanNGKBPR5ESsparkplugorequivalent.The

correctairgapis0.028-0.032inch.

1.Pullthemoldedwireoffofthesparkplug(Figure20).

Figure20

1.Sparkplugwire

2.Cleanaroundthesparkplugandremoveitfromthe

cylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotsandblast,scrape,orclean

electrodesbecauseenginedamagecouldresult

fromgritenteringthecylinder.

21

Page 22

3.Settheairgapat0.028to0.032inch(0.05to0.07

cm)(Figure21).

FuelSystem

Maintenance

CleaningtheFuelFilter

ServiceInterval:Aftertherst25hours

Every50hours

Figure21

4.Installthecorrectlygappedsparkplugandtighten

itto17ft.-lb(23N-m).

5.Installthesparkplugwireonthesparkplug.

1.Closethefuelshutoffvalveandunscrewthebowl

fromthelterbody(Figure22).

Figure22

1.Shut-offvalve

2.Cleanthebowlandlterincleangasolineandinstall

it.

2.Bowl

22

Page 23

BrakeMaintenance

BeltMaintenance

AdjustingtheService/Parking

Brake

Ifservice/parkingbrakeslipswhenoperated,an

adjustmentisrequired.

1.Moveservice/parkingbrakelevertotheOff

position.

2.LoosentheretainersecuringtheV-beltcoverand

pivotthecoveropen.

3.Toincreasethecabletension,loosenthefront

cablejamnutandtightenthebackcablejamnut

(Figure23)untilaforceof3to5lb(1.5to2.3kg)

isrequiredtoengagethebrake.Measuretheforce

attheleverknob.Donotover-adjustitsothatthe

brakebanddrags.

AdjustingtheBelts

Ensurethatthebeltsareproperlytensionedtoensure

properoperationofthemachineandunnecessarywear.

Checkbeltsfrequently.

AdjustingtheReelDriveBelt

1.Removethebeltcovermountingfastenersandbelt

covertoexposethebelt(Figure24).

Figure24

1.Beltcover

Figure23

1.Tractioncable

4.Closethecoverandsecuretheretainer.

2.Service/parkingbrake

cable

2.Checkthetensionbypressingthebeltatmidspan

ofthepulleys(Figure25)with3to5lbofforce.The

beltshoulddeect1/4inch(0.63cm).

Figure25

1.Reeldrivebelt2.Idlerpulley

3.Completethefollowingtoadjustthebelttension:

A.Loosentheidlerpulleymountingnutandpivot

theidlerpulleyclockwiseagainstthebacksideof

thebeltuntilyouattainthedesiredbelttension

(Figure25).

Important:Donotovertensionthebelt.

B.Tightenthenuttolocktheadjustment.

23

Page 24

4.Installthebeltcoverbyplacingitinposition.

B.Tightenthenuttolocktheadjustment.

5.Whilemaintainingaslightgapbetweenthecover

sealandthesideplate,installeachmountingbolt

untilthethreadsengageintheinsert.Thegapallows

visualalignmentoftheboltstothethreadedinserts.

6.Afterallboltsareinstalled,tightenthemuntilthe

stand-offsinsidethecovercontactthesideplate.Do

notovertighten.

AdjustingtheTractionDriveBelt

1.Removethebeltcovermountingfastenersandthe

beltcovertoexposethebelt(Figure26).

4.Installthebeltcoverbyplacingitinposition.

5.Whilemaintainingaslightgapbetweenthecover

sealandthesideplate,installeachmountingbolt

untilthethreadsengageintheinsert.Thegapallows

visualalignmentoftheboltstothethreadedinserts.

6.Afterallboltsareinstalled,tightenthemuntilthe

stand-offsinsidethecovercontactthesideplate.Do

notovertighten.

AdjustingtheDifferentialBelt

1.Removetheboltssecuringthefrontandrearsections

ofthedifferentialcovertothedifferentialhousing

andslidethecoversectionsawaytoexposethebelt.

2.Checkthetensionbypressingthebeltatmidspan

ofthepulleys(Figure28)with4to6lbofforce.The

beltshoulddeect1/4inch(0.63cm).

Figure26

1.Tractiondrivebeltcover

2.Checkthetensionbypressingthebeltatmidspanof

thepulleys(Figure27)with3to5lb(1.5to2.3kg)

offorce.Thebeltshoulddeect1/4inch(0.63cm).

Figure27

1.Tractiondrivebelt2.Idlerpulley

3.Completethefollowingtoadjustthebelttension:

A.Loosentheidlerpulleymountingnutandpivot

theidlerpulleyclockwiseagainstthebacksideof

thebeltuntilthedesiredbelttensionisattained

(Figure27).

Important:Donotovertensionthebelt.

Figure28

1.Differentialbelt

2.Idlerpulley

3.Completethefollowingtoadjustthebelttension:

A.Loosentheidlerpulleymountingnutandpivot

theidlerpulleyclockwiseagainstthebacksideof

thebeltuntilthedesiredbelttensionisattained

(Figure28).

Important:Donotovertensionthebelt.

B.Tightenthenuttolocktheadjustment.

4.Installthebeltcoverbyplacingitinposition.

5.Whilemaintainingaslightgapbetweenthecover

sealandthesideplate,installeachmountingbolt

untilthethreadsengageintheinsert.Thegapallows

visualalignmentoftheboltstothethreadedinserts.

6.Afterallboltsareinstalled,tightenthemuntilthe

stand-offsinsidethecovercontactthesideplate.Do

notovertighten.

24

Page 25

AdjustingthePrimaryV-Belts

1.ToadjustthebelttensiononprimaryV -belts,rst

checktheadjustmentofthetractioncontrol.Refer

toAdjustingtheTractionControl.Ifunabletoattain

the3to5lb(1.5to2.3kg)forcerequiredinadjusting

thetractioncontrol,proceedtonextstep.

2.LoosentheretainersecuringtheV-beltcoverand

pivotthecoveropen(Figure29).

Figure29

1.V-beltcover2.Retainer

Figure30

1.PrimaryV-belts3.Idlerpulley

2.Beltguide

7.Tightenthemountingscrewsandcheckthe

alignment.

8.Topushorpullthemachineeasierwithoutstarting

theengine,adjustthebeltguide(Figure30,inset)

asfollows:

A.Engagetheclutch.

3.Toincreasebelttension,loosentheenginemounting

boltsandmoveenginebackwardsintheslots.

Important:Donotovertensionthebelt.

4.Tightenthemountingbolts.

Note:Thedistancebetweenthecentersofthe

driverandthedrivenpulleysshouldbeapproximately

5.18inches(13.15cm)afternewV-beltsareinstalled.

5.AftertensioningtheprimaryV-belts,checkthe

alignmentoftheengineoutputshaftpulleyandthe

countershaftpulleywithastraightedge.

6.Ifthepulleysaremisaligned,loosenthescrews

securingtheenginemountingbasetothemower

frameandslidetheenginefromsidetosideuntilthe

pulleysarealignedwithin0.030inch(0.07cm).

B.Loosentheboltsecuringtheidlerpulleyandbelt

guidetotheidlerarm.

C.Rotatethebeltguideclockwiseuntilagapof

approximately0.06inch(0.15cm)isobtained

betweentheguidengerandthebacksideofthe

drivebelts.

D.Tightentheboltandlocknutsecuringtheidler

pulleyandbeltguidetotheidlerarm.

9.Closethecoverandsecuretheretainer.

ReplacingtheDifferentialBelt

1.Removetheboltssecuringthetractiondriveandreel

drivebeltcoverstotherightsideplateandremove

thebeltcovers.

2.Loosentheidlerpulleymountingnut,oneachidler

pulley,andpivoteachidlerpulleycounterclockwise

awayfromthebacksideofeachbelttoreleasebelt

tension.

3.Removethebelts.

4.Removetheboltssecuringthefrontandrearsections

ofthedifferentialcovertothedifferentialhousing

andslidethecoversectionsawaytoexposethebelt

(Figure31).

25

Page 26

Figure31

1.Differentialcoversections

2.Frontclutchhousing

5.Loosentheidlerpulleymountingnutonthe

differentialidlerpulleyandpivottheidlerpulley

counterclockwiseawayfromthebacksideofthebelt

toreleasethebelttension.

6.Removethe2boltsandlocknutssecuringthefront

clutchhousingtothesideplate(Figure31).

3.Rightrearbearinghousing

ControlsSystem

Maintenance

AdjustingtheTractionControl

Iftractioncontroldoesnotengageoritslipsduring

operation,anadjustmentisrequired.

1.MovethetractioncontroltotheDisengaged

position.

2.LoosentheretainersecuringtheV-beltcoverand

pivotthecoveropen(Figure29).

3.Toincreasethecabletension,loosenthefront

cablejamnutandtightenthebackcablejamnut

(Figure32)untilaforceof3to5lb(1.5to2.3kg)is

requiredtoengagethetractioncontrol.Measurethe

forceatthecontrolknob.

Measuretheforceatthecontrolknob.

7.Rotatethehousing180°sothebottomofthe

housingpointsupward.

8.Removethe2boltsandlocknutssecuringtheright

rearbearinghousingtothesideplate(Figure31).

9.Rotatethehousing180°sothebottomofthe

housingpointsupward.Removeoldbelt.

10.Slidethenewbeltovertherotatedhousingcovers,

thedifferentialcoversections,andontothe

differentialpulleys.

11.Ensurethattheidlerpulleyispositionedagainstthe

backsideofbelt.

12.Rotatebothhousingsbackintotheuprightposition

andsecurethemtothesideplatewiththeboltsand

nutspreviouslyremoved.

13.Adjustthedifferentialbelttension;refertoAdjusting

theDifferentialBelt.

14.Adjustthebelttensiononthetractiondriveandreel

drivebelts;refertoAdjustingtheTractionDrive

Belt,andAdjustingtheReelDriveBelt

Figure32

1.Tractioncable2.Frontjamnut

4.Tightenfrontcablejamnut.

5.Closethecoverandsecuretheretainer.

6.Checkthetractioncontroloperation.

15.Installthedifferential,tractiondrive,andreeldrive

covers.

26

Page 27

CuttingUnitMaintenance

LevelingtheRearDrumtothe

Reel

1.Positionthemachineonaat,levelsurface,

preferablyaprecisionsteelworkplate.

2.Placea1/4x1inch(0.6x2.5cm)atsteelstrip,

approximately29inches(73.6cm)long,underthe

reelbladesandagainstthefrontedgeofthebedknife

topreventthebedbarfromrestingonthework

surface.

3.Raisethefrontrollersoonlythereardrumandreel

areonthesurface.

4.Firmlypressdownonthemachineabovethereelso

allreelbladescontactthesteelstrip.

5.Whilepressingdownonthereel,slideafeelergauge

underoneendofthedrum,thenchecktheother

endofthedrum.

Ifthereisagapbetweenthedrumandthework

surface,greaterthan0.010inch(.025cm),oneither

end,adjustthedrum(proceedtostep6).Ifthegap

islessthan0.010inch(.025cm)noadjustmentis

required.

Figure34

1.Drivepulley3.IdlerPulley

2.4holes

8.Loosenthe4rollerbearingscrewsandthescrew

securingtheidlerpulley .

9.Raiseorlowertherightsideoftherollerassembly

untilthegapislessthan0.010inch(.025cm).

10.Tightentherollerbearingscrews.

11.Adjustthebelttensionandtightentheidlerpulley

mountingscrew(Figure34).

AdjustingtheBedknifetothe

Reel

6.Removetherearbeltcoverfromtherightsideof

themachine(Figure33).

Figure33

1.Tractiondrivebeltcover

7.Rotatethedrivepulleyuntiltheholesalignwiththe

4rollerbearingangescrews(Figure34).

Thebedknifetoreeladjustmentisaccomplishedby

looseningortighteningthebedbaradjustingscrews,

locatedontopofthemower.

1.Positionthemachineonaat,levelworksurface.

2.Ensurethatthereelcontactisremovedbyturning

thebedbaradjustingscrewscounterclockwise

(Figure35).

Figure35

1.Bedbaradjustingscrew

3.Tiltthemowerbackonthehandletoexposethe

bedknifeandreel.

4.Ononeendofthefrontsideofthereel,insertalong

stripofnewspaperbetweenthereelandbedknife

(Figure36).Whileslowlyrotatingthereelforward,

27

Page 28

turnthebedbaradjustingscrewclockwise(onthe

sameendofreel,oneclickatatime,untilthepaper

ispinchedlightly ,wheninsertedfromthefront,

paralleltothebedknife,whichresultsinaslightdrag

whenpaperispulled(Figure35).

Figure36

Note:Eachtimetheadjustingscrewisrotatedone

clickclockwise,thebedknifemoves0.0007inch

(0.0017cm)closertothereel.Donotovertighten

theadjustingscrews.

Figure37

1.Height-of-cutarm

2.Height-of-cutbracket

3.Locknut

4.Adjustingscrew

3.Loosenthenutonthegaugebar(Figure38)andset

theadjustingscrewtothedesiredheight-of-cut.The

distancebetweenthebottomofthescrewheadand

thefaceofthebaristheheight-of-cut.

5.Checkforlightcontactattheotherendofthereel

usingpaperandadjustitasrequired.

6.Aftertheadjustmentisaccomplished,checktosee

ifthereelcanpinchpaperwheninsertedfromthe

frontandcutpaperwheninsertedatarightangleto

thebedknife(Figure36).Itshouldbepossibletocut

paperwithminimumcontactbetweenthebedknife

andthereelblades.Shouldexcessivereeldragbe

evident(morethan7inch-lb(0.79N-m)),either

backlaporgrindthecuttingunittoachievethesharp

edgesneededforprecisioncutting;refertotheToro

reelsharpeningmanual.

AdjustingtheHeightofCut

1.Verifythattherearrollerislevelandthatthe

bedknifetoreelcontactiscorrect.Tipthemower

backonthehandletoexposethefrontandrear

rollersandthebedknife.

2.Loosenthelocknutssecuringtheheight-of-cutarms

totheheight-of-cutbrackets(Figure37).

Figure38

1.Gaugebar

2.Heightadjustingscrew

3.Nut

4.Hookthescrewheadonthecuttingedgeofthe

bedknifeandresttherearendofthebarontherear

roller(Figure39).

Figure39

5.Rotatetheadjustingscrewuntiltherollercontacts

thefrontofthegaugebar.

6.Adjustbothendsoftherolleruntiltheentireroller

isparalleltothebedknife.

28

Page 29

Important:Whensetproperly,therearand

frontrollerswillcontactthegaugebarandthe

screwwillbesnugagainstthebedknife.This

ensurestheheight-of-cutisidenticalatboth

endsofthebedknife.

7.Tightennutstolocktheadjustment.

Important:Toavoidscalpingonundulating

turf,ensurethattherollersupportsare

positionedrearward(therollerclosertothereel).

cm).Loosentheboltsandnutssecuringeachendof

theshieldtothesideplateandadjusttheshieldto

thecorrectheight.

3.Tightenthefasteners.

Note:Theshieldcanbeloweredfordrier

conditions(clippingsyovertopofbasket)orraised

toallowforheavywetgrassconditions(clippings

builduponrearofbasket).

Note:Thefrontrollercanbeputinthreedifferent

positions(Figure40),dependingontheapplication

andneedsoftheuser.

•Usethefrontpositionwhenagroomeris

installed.

•Usethemiddlepositionwithoutagroomer.

•Usethethirdpositioninextremelyundulating

turfconditions.

Figure40

AdjustingtheCut-OffBar

Adjustthecut-offbartoensurethattheclippingsare

cleanlydischargedfromthereelarea.

1.Loosenthescrewssecuringthetopbar(Figure42)

tocuttingunit.

Figure42

1.Cut-offbar

2.Inserta0.060inch(0.15cm)feelergaugebetween

thetopofthereelandthebarandtightenthescrews.

3.Ensurethatthebarandreelareequaldistanceapart

acrosstheentirereel.

AdjustingtheGrassShield

Height

Adjusttheshieldtoensurepropergrassclipping

dischargeintothebasket.

1.Measurethedistancefromtopofthefrontsupport

rodtothefrontlipoftheshieldateachendofthe

cuttingunit(Figure41).

Figure41

1.Supportrod2.Shield

2.Theheightoftheshieldfromthesupportrodfor

normalcuttingconditionsshouldbe4inches(10

Note:Thebarisadjustabletocompensatefor

changesinturfconditions.Adjustthebarcloserto

thereelwhentheturfisextremelywet.Bycontrast,

adjustthebarfurtherawayfromthereelwhenturf

conditionsaredry.Thebarshouldbeparalleltothe

reeltoensureoptimumperformance.Adjustthebar

whenevertheshieldheightisadjustedorwhenthe

reelissharpenedonareelgrinder.

ServicingtheBedbar

RemovingtheBedbar

1.Turnthebedbaradjusterscrew,counterclockwise,

untilthechannelbottomsoutintheadjusterframe

(Figure43).

29

Page 30

Figure43

1.Bedbaradjustingscrew4.Bedbar

2.Springtensionscrew5.Channel

3.Thrustwasher

6.Adjusterframe

2.Usinga7/8inchstandardwrench,backoutthe

springtensionscrewuntilthethrustwasherisno

longertensionedagainstthebedbar(Figure43).

3.Oneachsideofthemachine,loosenthejamnut

securingthebedbarbolt(Figure44).

BacklappingtheReel

1.Removetheplugintherightreeldrivecover

(Figure45).

Figure45

1.Coverplug

2.Inserta1/2inchsocketextension,connectedtothe

backlappingmachine,intothesquareholeinthe

centerofthereelpulley .

Figure44

1.Jamnut2.Bedbarbolt

4.Removeeachbedbarboltallowingthebedbartobe

pulleddownwardandremovedfromthemachine.

Savethe2nylonand2stampedsteelwasherson

eachendofbedbar(Figure44).

InstallingtheBedbar

1.Installthebedbar,positioningthemountingears

betweenthethrustwasherandthechannelonthe

bedbaradjuster.

2.Securethebedbartoeachsideplatewiththebedbar

bolts(angenutsonthebolts)and8washers.

Positionanylonwashereachsideofthesideplate

boss.Placeasteelwasheroutsideeachofthenylon

washers.

3.BacklapaccordingtotheprocedureintheToro

SharpeningReelandRotaryMowersManual,FormNo.

80-300PT .

Contactwiththereelorothermovingpartscan

resultinpersonalinjury.

•Stayawayfromthereelwhilebacklapping.

•Neveruseashorthandledpaintbrushfor

backlapping.PartNo.29-9100Handle

assemblycompleteorindividualpartsare

availablefromyourlocalAuthorizedToro

Distributor.

Note:Forabettercuttingedge,runaleacross

thefrontfaceofthebedknifewhenthelapping

operationiscompleted.Thiswillremoveanyburrs

orroughedgesthatmayhavebuiltuponthecutting

edge.

4.Installthepluginthecoverwhennished.

3.Torqueboltsto240to320inch-lb(27to36N-m).

4.Tightenthejamnutsuntilthethrustwashersjust

rotatefreely .

5.Adjustthebedbar;refertoAdjustingtheBedknife

totheReel.

30

Page 31

Storage

1.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheentiremachine,especiallythe

engine.Cleandirtandchafffromtheoutsideofthe

engine’scylinderheadnsandblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressurewash

themachine.Avoidexcessiveuseofwater,

especiallyneartheshiftleverplate,andengine.

2.Forlong-termstorage(morethan90days)add

stabilizer/conditioneradditivetofuelinthetank.

A.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

B.Eitherstopengine,allowittocool,anddrainthe

fueltank,oroperatetheengineuntilitstops.

C.Restarttheengineandrunituntilitstops.

Repeat,onChoke,untiltheenginewillnot

restart.

D.Disposeoffuelproperly.Recycleasperlocal

codes.

Note:Donotstorestabilizer/conditioned

gasolineover90days.

3.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanypartthatisdamagedordefective.

4.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

5.Storethemachineinaclean,drygarageorstorage

area.Coverthemachinetoprotectitandkeepit

clean.

31

Page 32

Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affi liate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Commercial Product (“Product”) to be free from defects in materials or workmanship for two years or 1500 operational hours*,

whichever occurs fi rst. This warranty is applicable to all products

with the exception of Aerators (refer to separate warranty statements for these products). Where a warrantable condition exists,

we will repair the Product at no cost to you including diagnosis,

labor, parts, and transportation. This warranty begins on the date

the Product is delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists. If you need help locating a Commercial Products

Distributor or Authorized Dealer, or if you have questions regarding your warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801

E-mail: commercial.warrnty@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your Operator’s Manual.

Failure to perform required maintenance and adjustments can be

grounds for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

warranty does not cover the following:

Product failures which result from the use of non-Toro

•

replacement parts, or from installation and use of add-on,

or modifi ed non-Toro branded accessories and products. A

separate warranty may be provided by the manufacturer of

these items.

Product failures which result from failure to perform recom-

•

mended maintenance and/or adjustments. Failure to properly

maintain your Toro product per the Recommended Maintenance listed in the Operator’s Manual can result in claims for

warranty being denied.

Product failures which result from operating the Product in an

•

abusive, negligent or reckless manner.

Parts subject to consumption through use unless found to be

•

defective. Examples of parts which are consumed, or used

up, during normal Product operation include, but are not limited to, brakes pads and linings, clutch linings, blades, reels,

bed knives, tines, spark plugs, castor wheels, tires, fi lters,

belts, and certain sprayer components such as diaphragms,

nozzles, and check valves, etc.

Failures caused by outside infl uence. Items considered to be

•

outside infl uence include, but are not limited to, weather, stor-

age practices, contamination, use of unapproved coolants,

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfi ed with your Distributor’s service or

have diffi culty obtaining guarantee information, contact the Toro importer.

lubricants, additives, fertilizers, water, or chemicals, etc.

Normal noise, vibration, wear and tear, and deterioration.

•

Normal “wear and tear” includes, but is not limited to, dam-

•

age to seats due to wear or abrasion, worn painted surfaces,

scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are warranted for the period of time up to the scheduled replacement time

for that part. Parts replaced under this warranty are covered for the

duration of the original product warranty and become the property

of Toro. Toro will make the fi nal decision whether to repair any ex-

isting part or assembly or replace it. Toro may use remanufactured

parts for warranty repairs.

Note Regarding Deep Cycle Battery Warranty:

Deep cycle batteries have a specifi ed total number of kilowatt-

hours they can deliver during their lifetime. Operating, recharging,

and maintenance techniques can extend or reduce total battery

life. As the batteries in this product are consumed, the amount

of useful work between charging intervals will slowly decrease

until the battery is completely worn out. Replacement of worn out

batteries, due to normal consumption, is the responsibility of the

product owner. Battery replacement may be required during the

normal product warranty period at owner’s expense.

Maintenance is at Owner’s Expense

Engine tune-up, lubrication cleaning and polishing, replacement of

fi lters, coolant, and completing Recommended Maintenance are

some of the normal services Toro products require that are at the

owner’s expense.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fi tness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you. This

warranty gives you specifi c legal rights, and you may also have

other rights which vary from state to state.

Note regarding engine warranty:

The Emissions Control System on your Product may be covered

by a separate warranty meeting requirements established by the

U.S. Environmental Protection Agency (EPA) and/or the California

Air Resources Board (CARB). The hour limitations set forth above

do not apply to the Emissions Control System Warranty. Refer to

the Engine Emission Control Warranty Statement printed in your

Operator’s Manual or contained in the engine manufacturer’s

documentation for details.

Part No. 374-0031 Rev. D

Loading...

Loading...