Page 1

FormNo.3404-369RevC

Greensmaster

®

Flex

™

2120TractionUnit

ModelNo.04044—SerialNo.316000001andUp

ModelNo.04045—SerialNo.316000001andUp

1820and

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3404-369*C

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

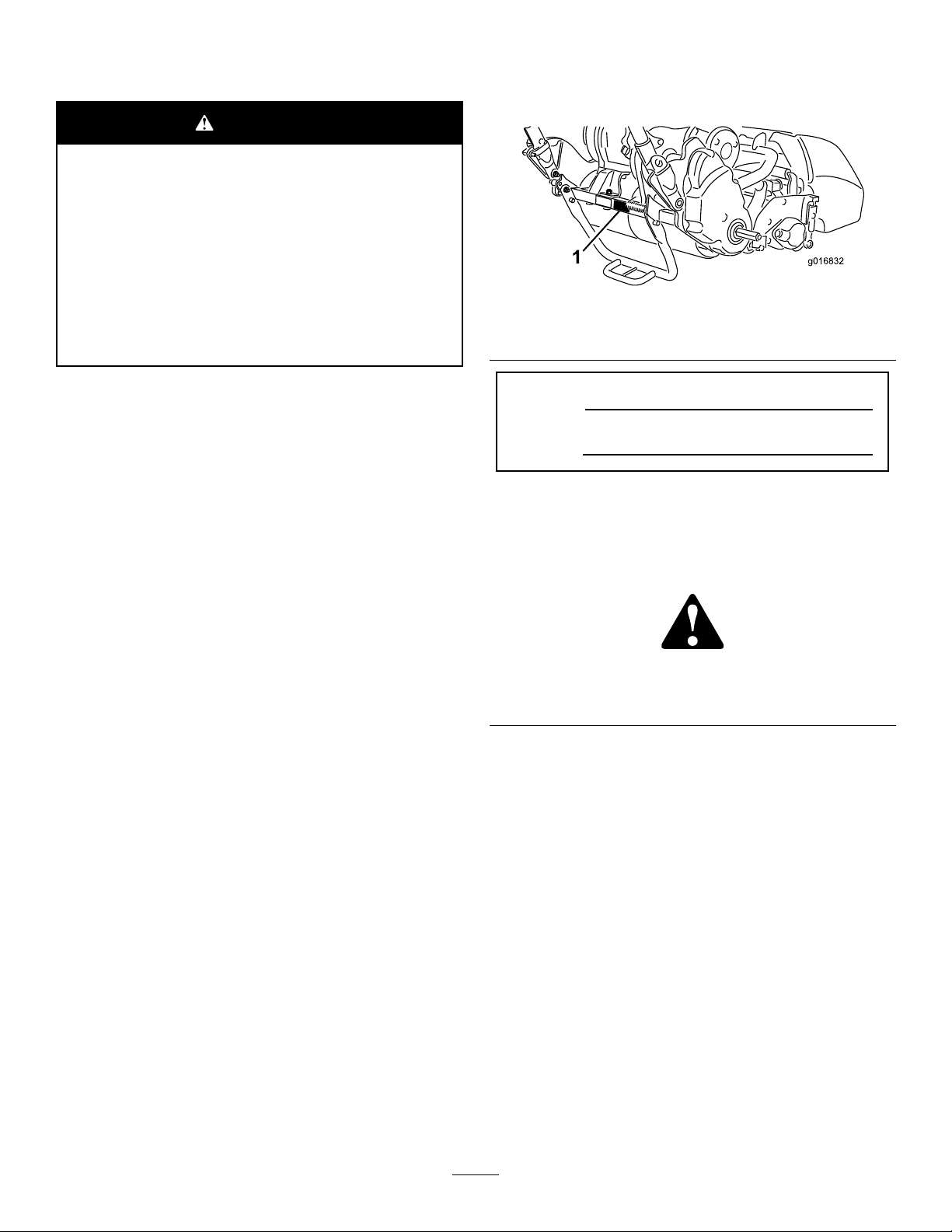

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g016832

Figure1

1.Locationofthemodelandserialnumbers-Tractionunit

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Operatingthismachinebetween1,524to2,438

m(5,000to8,000ft)abovesealevelrequiresthe

high-altitudekit.SeeyourAuthorizedToroDealer.

Introduction

Thismachineisawalk-behind,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesignedfor

cuttinggrassonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.It

isnotdesignedforcuttingbrush,mowinggrassand

othergrowthalongsidehighways,orforagricultural

uses.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

SafeOperatingPractices....................................4

ToroMowerSafety..............................................5

SoundPowerLevel............................................6

SoundPressureLevel........................................6

VibrationLevel....................................................6

SafetyandInstructionalDecals..........................7

Setup........................................................................9

1PreparingtheTractionUnit............................10

2InstallingtheCuttingUnittotheTraction

Unit...............................................................10

3InstallingtheHandleRetainers.......................11

4InstallingtheTransportWheels.......................11

5CheckingtheEngine-OilLevel.......................12

6InstallingtheGrassBasket.............................12

ProductOverview...................................................14

Controls...........................................................14

Specications..................................................18

Attachments/Accessories.................................18

Operation................................................................18

ThinkSafetyFirst..............................................18

CheckingtheEngine-OilLevel..........................18

FillingtheFuelTank..........................................18

AdjustingtheHandleHeight.............................20

AdjustingtheHandleAngle...............................20

AdjustingtheThrottleControl...........................20

StartingandShuttingOfftheEngine.................21

TransportingtheMachine.................................21

PreparingtoMow.............................................21

MowingTips.....................................................22

CheckingtheOperationoftheInterlock

Switches......................................................23

ReleasingtheTransmission..............................24

SettingtheMachinetoMatchTurf

Conditions.....................................................25

Maintenance...........................................................26

RecommendedMaintenanceSchedule(s)...........26

DailyMaintenanceChecklist.............................27

EngineMaintenance...........................................28

ServicingtheEngineOil....................................28

ServicingtheAirCleaner..................................29

ServicingtheSparkPlug...................................30

FuelSystemMaintenance...................................30

CleaningtheFuelCupandFuel-T ank

Screen..........................................................30

ReplacingtheFuelLine....................................31

ElectricalSystemMaintenance...........................31

ServicingtheTractionInterlockSwitch

......................................................................31

ServicingtheBrake-InterlockSwitch.................32

BrakeMaintenance.............................................32

AdjustingtheService/ParkingBrake.................32

BeltMaintenance................................................33

InspectingtheReel-DriveBelt...........................33

VisuallyInspectingtheReelClutch...................33

Engaging/Disengagingthe

Transmission-BeltT ensioner.........................34

ControlsSystemMaintenance.............................34

AdjustingtheTractionControl...........................34

AdjustingtheReelControl................................35

Storage...................................................................36

3

Page 4

Safety

Thismachinehasbeendesignedinaccordancewith

ENISO5395:2013andANSIB71.4-2012.

Improperuseormaintenancebytheoperatororowner

canresultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Hazardcontrolandaccidentpreventionare

dependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedinthe

operation,transport,maintenance,andstorageof

themachine.Improperuseormaintenanceofthe

machinecanresultininjuryordeath.Toreduce

thepotentialforinjuryordeath,complywiththe

followingsafetyinstructions.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertraining

materialcarefully.Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwith

theseinstructionstouseorservicethemachine.

Localregulationsmayrestricttheageofthe

operator.

•Nevermowwhilepeople,especiallychildren,or

petsarenearby.

•Keepinmindthattheoperatororuseris

responsibleforaccidentsorhazardsoccurringto

otherpeopleortheirproperty.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtopeople,or

damagetoproperty.

Preparation

•Whilemowing,alwayswearsubstantial,

slip-resistantfootwear,longtrousers,safety

glasses,andearprotection.Tiebacklonghair.

Donotwearjewelry.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichthe

machinemaythrow.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesigned

forthispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuel

whiletheengineisrunningorwhentheengine

ishot.

–Ifyouspillfuel,donotattempttostartthe

enginebutmovethemachineawayfromthe

spillandavoidcreatinganysourceofignition

untilthefuelvaporshavedissipated.

–Replaceallfueltanksandcontainercaps

securely.

•Replacefaultysilencers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Useonlyaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthatoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

Operation

•Donotoperatetheengineinaconnedspace

wheredangerouscarbonmonoxideandother

exhaustgassescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengage

allbladeattachmentclutches,shiftintoneutral,

andengagetheparkingbrake.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornear

roadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirect

dischargeofmaterialtowardbystandersnorallow

anyonenearthemachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesin

place.Besureallinterlocksareattached,adjusted

properly,andfunctioningproperly.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardof

personalinjury.

•Shutofftheengineanddisengagethedrivetothe

attachment:

4

Page 5

–Beforeleavingtheoperator’sposition

–Beforerefuelling

–Beforeremovingthegrassbasket

–Beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator's

position

–Beforeclearingblockages

–Beforechecking,cleaning,orworkingonthe

machine

–Afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemachinefor

damageandmakerepairsbeforerestarting

andoperatingtheequipment.

Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Reducethethrottlesettingbeforestoppingengine

and,iftheengineisprovidedwithafuelshut-off

valve,turnthevalveoffattheconclusionof

mowing.

•Keephandsandfeetawayfromthecuttingunit.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopreelsif

notmowing.

•Donotoperatethemachineifyouareill,tired,or

undertheinuenceofalcoholordrugs

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Disengagedrives,disengagethecuttingunit,

settheparkingbrake,shutofftheengine,and

disconnectthespark-plugwire.Waitforall

movementtostopbeforeadjusting,cleaning,or

repairing.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,andtheenginetohelpprevent

res.Cleanupoilorfuelspillage.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryandremovethespark-plug

wirebeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.

Reconnectthepositiverstandnegativelast.

•Usecarewhencheckingthereel.Weargloves

andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

Hauling

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usefullwidthrampsforloadingmachineinto

trailerortruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer,batterycompartment,andfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Checkthegrassbasketfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replace

allwornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toT oroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO,or

ANSIstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Knowhowtoshutofftheenginequickly.

•Handlegasolinecarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacethe

switchbeforeoperatingthemachine.

•Alwaysstandbehindthehandlewhenstartingand

operatingthemachine.

5

Page 6

•Whennearorcrossingroads,alwaysyieldthe

right-of-way.

•Thegrassbasketmustbeinplace,duringthe

mowingoperation,formaximumsafety.Shutthe

engineoffbeforeemptyingthebasket.

•Donottouchtheengine,mufer,orexhaustpipe

whiletheengineisrunningorsoonafterithas

shutoffbecausetheseareascouldbehotenough

tocauseburns.

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

Thisunithasaguaranteedsoundpowerlevelof

95dBA,whichincludesanUncertaintyV alue(K)

of1dBA.

Soundpowerlevelwasdeterminedaccordingto

theproceduresoutlinedinEN11094.

SoundPressureLevel

•Model04044

Thisunithasasoundpressurelevelatthe

operator’searof84dBA,whichincludesan

UncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccording

totheproceduresoutlinedinENISO5395:2013.

MaintenanceandStorage

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,

clothing,andanypartsofthebodyawayfromthe

cuttingunit,attachmentsandanymovingparts.

Keepeveryoneaway.

•Toensuresafetyandaccuracy,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.Themaximumgovernedengine

speedshouldbebetween3,190and3,340rpm.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

SoundPowerLevel

CAUTION

•Model04045

Thisunithasasoundpressurelevelatthe

operator’searof87dBA,whichincludesan

UncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccording

totheproceduresoutlinedinENISO5395:2013.

VibrationLevel

Hand-Arm

•Model04044

Measuredvibrationlevelforrighthand=2.86m/s

Measuredvibrationlevelforlefthand=3.24m/s

UncertaintyValue(K)=1.6m/s

•Model04045

Measuredvibrationlevelforrighthand=3.16m/s

Measuredvibrationlevelforlefthand=2.73m/s

UncertaintyValue(K)=1.6m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

2

2

2

2

2

2

Thismachineproducessoundlevelsthatcan

causehearinglossthroughextendedperiods

ofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

•Model04044

Thisunithasaguaranteedsoundpowerlevelof

96dBA,whichincludesanUncertaintyV alue(K)

of1dBA.

Soundpowerlevelwasdeterminedaccordingto

theproceduresoutlinedinEN11094.

•Model04045

6

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

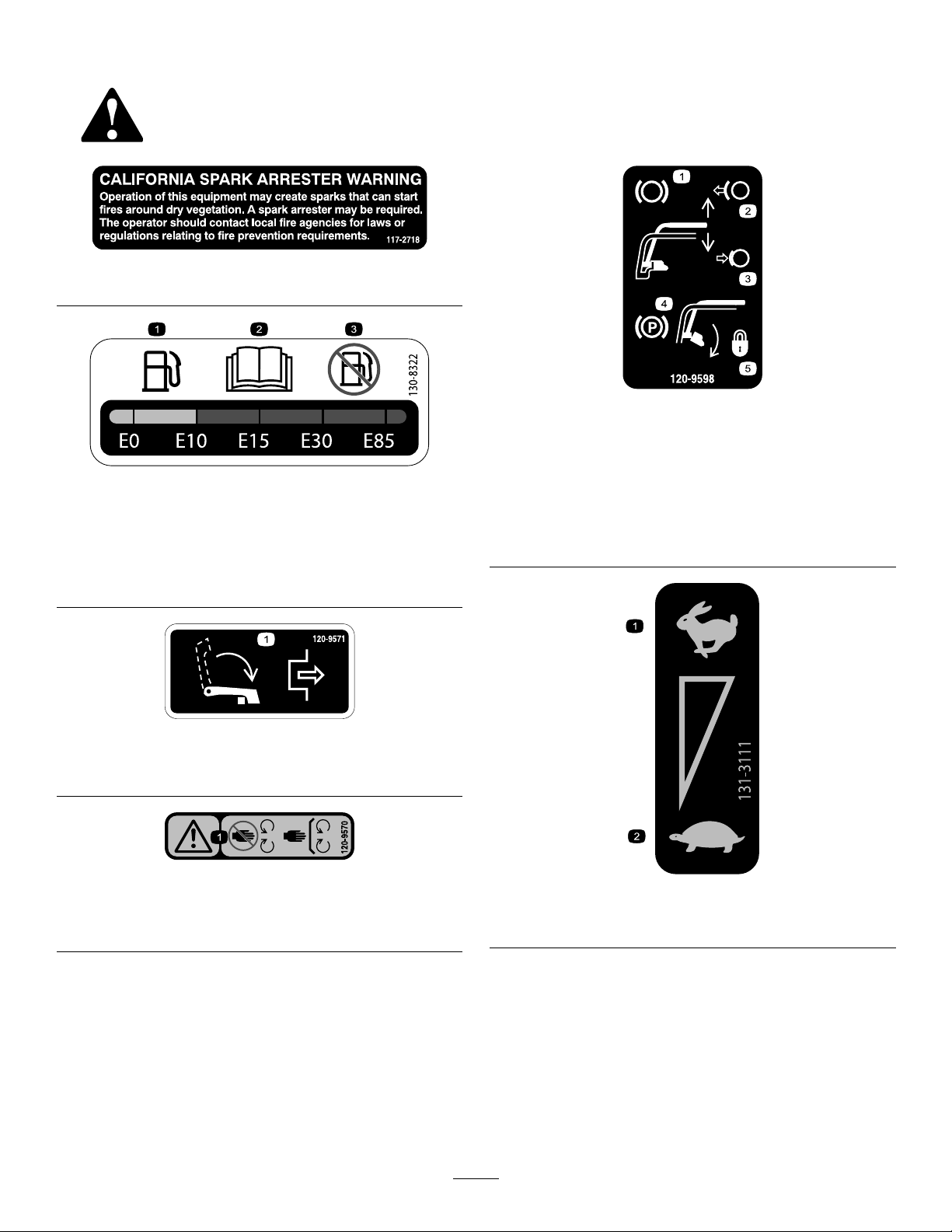

117–2718

130-8322

1.Onlyusegasolinethat

contains10%ethanolby

volume(E10)orless.

2.ReadtheOperator's

Manual.

3.Donotusegasolinethat

containsmorethan10%

ethanolbyvolume(E10).

decal117-2718

decal120-9598

120-9598

1.Brake4.Parkingbrake

decal130-8322

2.Releasehandleto

disengagethebrake.

3.Compressthehandleto

engagethebrake.

5.Rotatethelatchtolockthe

parkingbrake;compress

thehandletoreleasethe

latch.

120-9571

1.Lowerthelevertodisengagethetraction.

120-9570

1.Warning—stayawayfrommovingparts,keepallguards

andshieldsinplace.

decal120-9571

decal120-9570

decal131-311 1

131-3111

1.Fast

2.Slow

7

Page 8

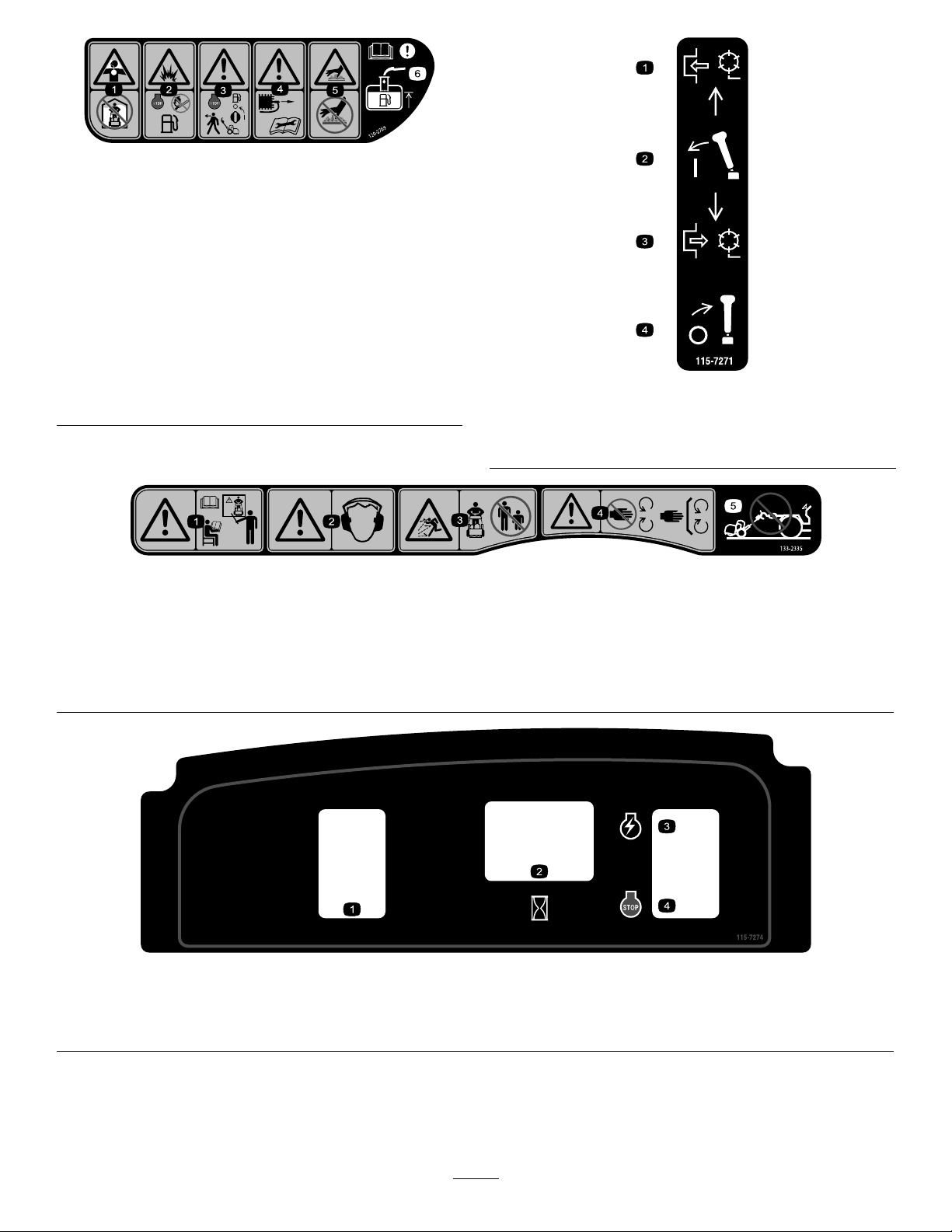

decal120-2769

120–2769

1.Toxicgasinhalation

hazard—donotoperate

indoors.

4.Warning—disconnectthe

spark-plugwireandread

theinstructionbefore

servicingorperforming

maintenance.

2.Explosionhazard—shut

offtheengineandkeep

awayfromopenames

5.Hotsurface/burn

hazard—donottouch

hotsurfaces.

whenrefueling.

3.Warning—shutoffthe

engineandturnoffthe

fuelbeforeleavingthe

machine.

6.Warning—readthe

Operator’sManual;when

addingfueltothetank,

onlylltothebottomof

thelltube.

1.Warning—readtheOperator’sManual;

donotoperatethemachineunlessyou

aretrained.

2.Warning—wearhearingprotection.

1.Engagethereel.3.Disengagethereel.

2.Engagethelever .4.Disengagethelever.

133–2335

3.Thrownobjecthazard—keep

bystandersasafedistancefromthe

machine.

4.Warning—stayawayfrommoving

parts;keepallguardsandshieldsin

place.

decal115-7271

115-7271

decal133-2335

5.Donottowthemachine.

1.Lights(optional)

2.Hourmeter

decal115-7274

115-7274

3.Engine—start

4.Engine—shutoff

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

CerticateofCompliance

Nopartsrequired

Bolt,3/8x3/4inch

Handleretainer2

Hairpincotter2

Transportwheels(OptionalTransport

WheelKit,Model04123)

Nopartsrequired

Grassbasket

Qty.

1

1

1

1

1

Readorviewthesematerialsbeforeoperatingthe

machine.

Qty.

–

2Installthecuttingunittothetractionunit.

2Installthetransportwheels.

–

1Installthegrassbasket.

Preparethetractionunit(optional).

Installthehandleretainers.

Checktheengine-oillevel.

Use

Use

9

Page 10

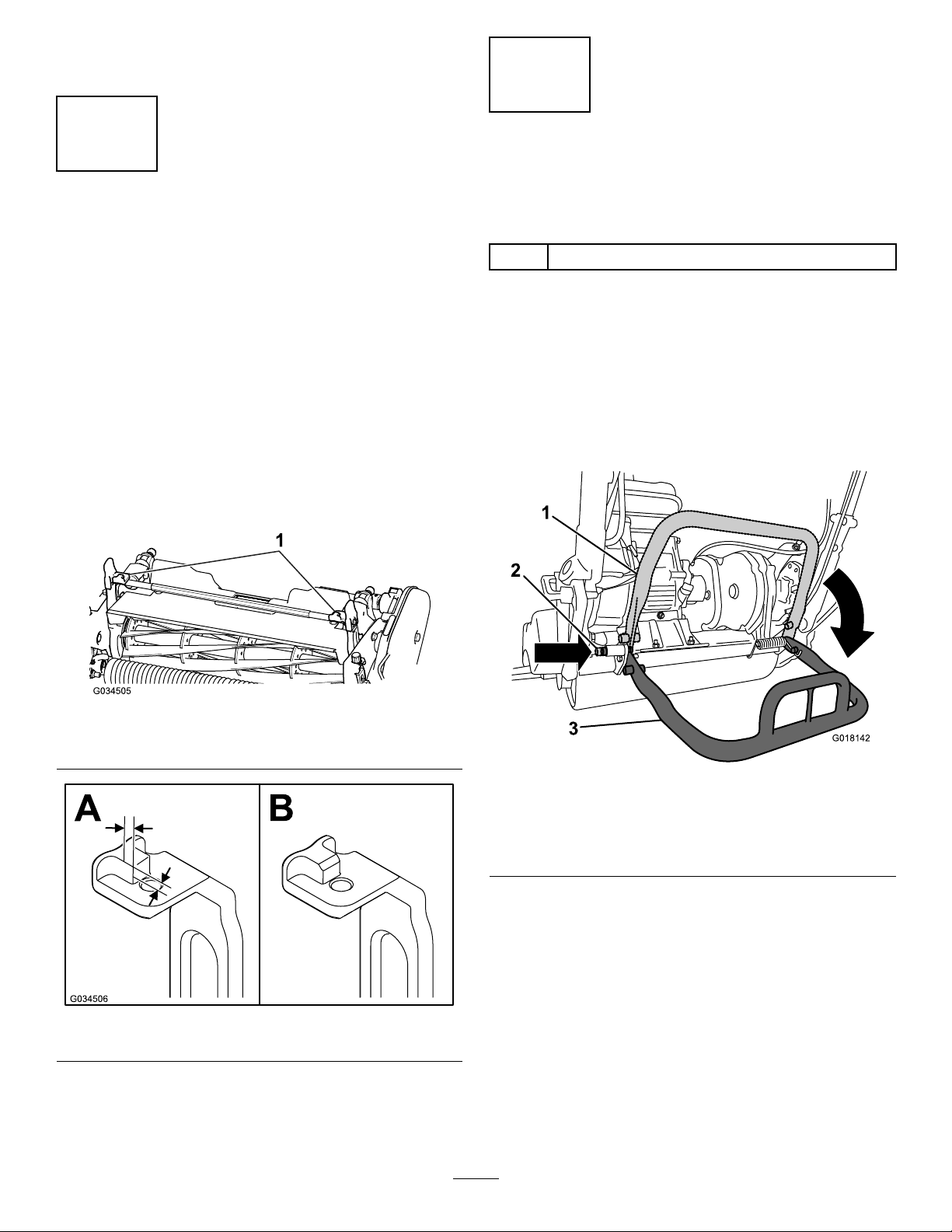

Note:Determinetheleftandrightsidesofthe

G018142

1

2

3

machinefromthenormaloperatingposition.

1

PreparingtheTractionUnit

Optional

NoPartsRequired

2

InstallingtheCuttingUnit totheTractionUnit

Partsneededforthisprocedure:

2

Bolt,3/8x3/4inch

Procedure

Procedure

Ifyouareinstallingcuttingunit04251,02452,04253,

or04254onthistractionunit,completethefollowing

steps:

1.Positionthecuttingunitonaat,levelsurface.

2.Onbothpitcharms(Figure3),measure2.28

mm(0.09inch)inonthetabsandgrinddown

thecornerasshowninFigure4.

Figure3

1.Pitcharms

1.Placethemachineonitsdrumsonalevel

surface.

2.Lowerthekickstandandpushinthelocking

pintolockthekickstandintheserviceposition

(Figure5).Allowthemachinetorestonthe

lockingpin.

g034505

g018142

Figure5

1.Kickstand—storage

position

2.Lockingpin

3.Pushthecuttingunitunderthetractionunitand

tothelefttoengagethetransmissioncoupling

(Figure6).

g034506

3.Painttherevealedmetaltopreventcorrosion.

Figure4

10

3.Kickstand—service

position

Page 11

Figure6

3

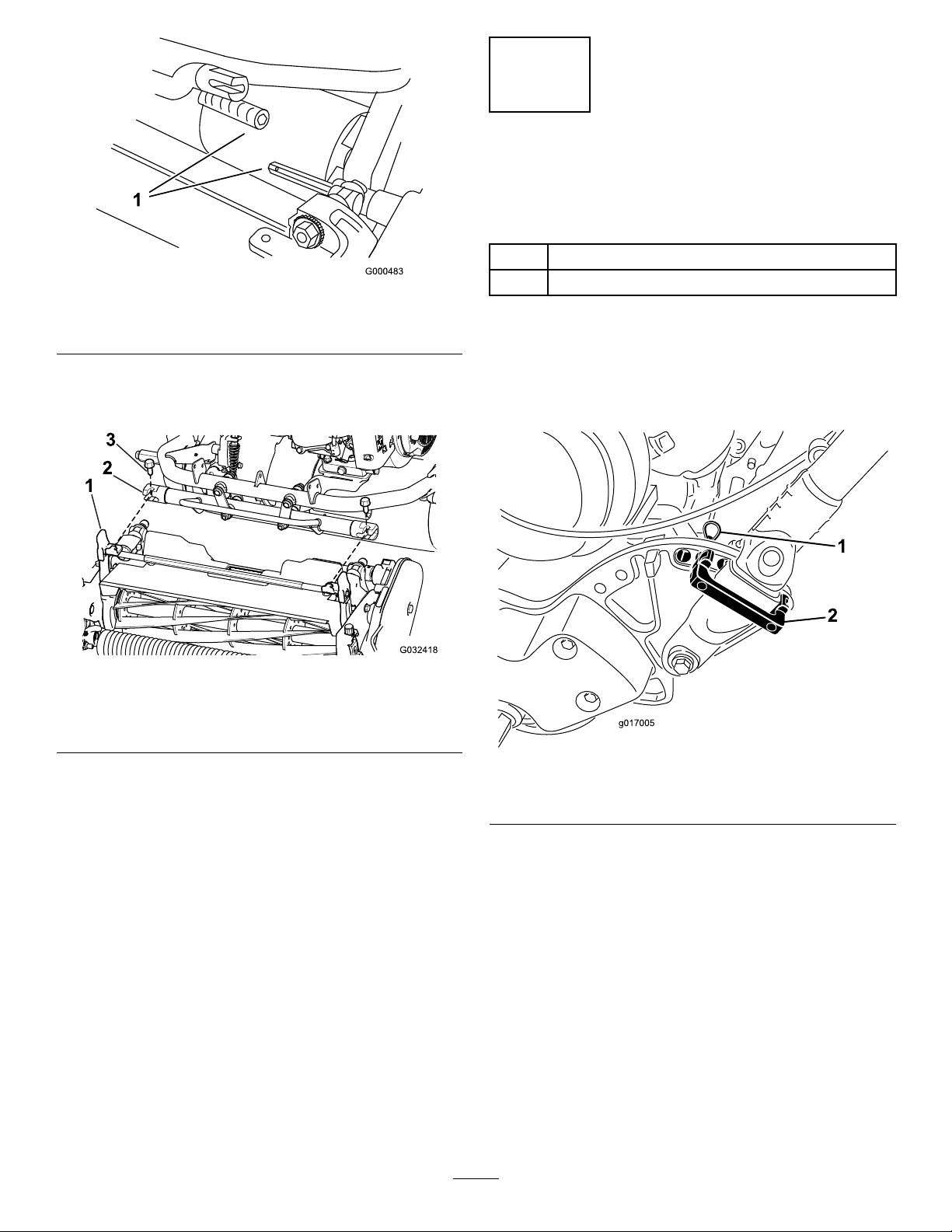

InstallingtheHandle Retainers

Partsneededforthisprocedure:

2Handleretainer

g000483

2Hairpincotter

1.Transmissioncoupling

4.Maneuverthetractionunitframe(Figure7)

forwarduntilitengagesthecuttingunitpivot

arms.

Figure7

1.Cuttingunitpivotarms

2.Tractionunitframe

5.Securethetractionunitframetothecuttingunit

pivotarmswith2bolts(3/8x3/4inch)(Figure7).

3.Bolts

Procedure

1.Whilesupportingthehandle,removethecable

tiessecuringthehandleclampstotheside

plates(Figure8).

g032418

g017005

Figure8

1.Hairpincotter2.Handleretainer

Note:Toremovethecuttingunit,justloosen

the2bolts(3/8x3/4inch)approximately1-1/2

turnsandrotatethepivotarmsout.

6.Pushdownonthekickstandtoreleasethe

spring-loadedlockingpinandallowthekick

standtorotateuptothestorageposition.

2.Pivotthehandletothedesiredoperating

position,insertahandleretaineroverthehandle

clampandintothematchingholesintheside

plate(Figure8).

3.Securetheclampinpositionwithahairpincotter

(Figure8).

4.Repeattheprocedureontheoppositesideof

thehandle.

5.Adjustthehandleheighttothedesiredposition;

refertoAdjustingtheHandleHeight(page20).

Note:Themachineisshippedwiththe

handleadjustedtothelowestposition.The

machineistraditionallyoperatedwiththehandle

telescopedouttoitsmaximumheight.

11

Page 12

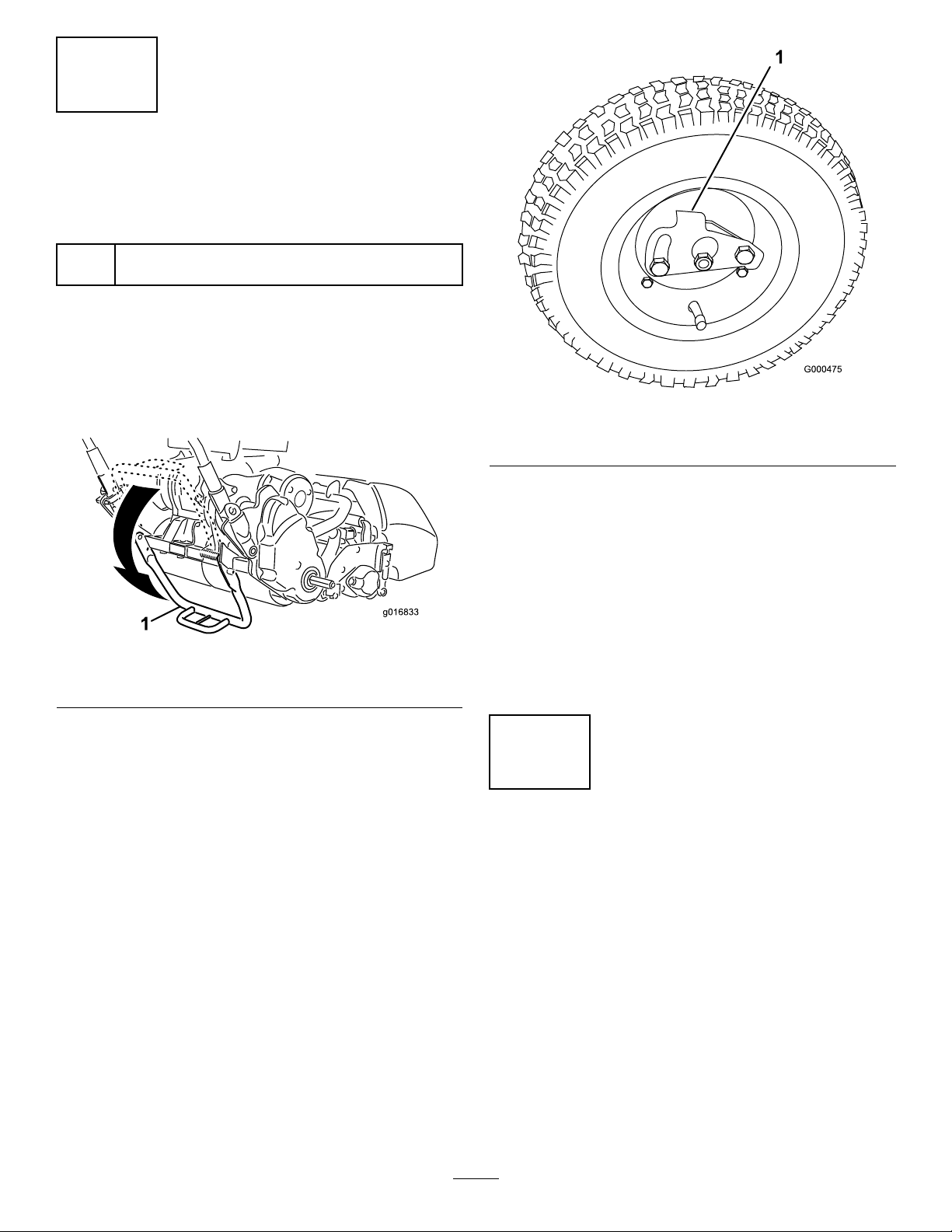

4

InstallingtheTransport

Wheels

Partsneededforthisprocedure:

Transportwheels(OptionalTransportWheelKit,

2

Model04123)

Procedure

1.Pushthekickstanddownwithyourfootinthe

centerofthekickstandandpulluponthe

lowercentermachinehandleuntilthekickstand

hasrotatedforward,overcenter(Figure9).

g000475

Figure10

1.Lockingclip

3.Rotatethewheelbackandforthuntilitslides

completelyontotheaxleandthelockingclipis

securedinthegrooveontheaxleshaft.

Figure9

1.Kickstand

2.Pressthewheellockingcliptowardthecenter

ofwheelandslidethewheelontothehexshaft

(Figure10).

4.Repeattheprocedureontheoppositesideof

themachine.

5.Inatethetiresto83to103kPa(12to15psi).

g016833

6.Carefullylowerthemachineoffthekickstand

bypushingforwardslowlyorbyliftingthelower

centerhandlesupport,allowingthekickstandto

springbacktoitsnormalposition.

5

CheckingtheEngine-Oil Level

NoPartsRequired

Procedure

Checktheengine-oillevel,refertoCheckingthe

Engine-OilLevel(page28).

12

Page 13

6

InstallingtheGrassBasket

Partsneededforthisprocedure:

1

Grassbasket

Procedure

1.Graspthebasketbythehandle(Figure11).

Figure11

1.Baskethooks

2.Guidethebasketlipbetweenthecuttingunit

sideplatesandoverthefrontroller(Figure1 1).

g032408

Figure12

1.Pitcharmcontactpoint

g032407

3.Installthebaskethooksovertheframeloop

(Figure11).

Important:Ifyoueverdropthebasket,examine

thepitcharmcontactpointsnearthelowerlip

ofthebasketfordamage(Figure12).Straighten

thembeforeusingthebasket.Usingthebasket

withbentpitcharmcontactpointsmaycause

contactbetweenthebasketandreelcausing

undesirednoiseand/ordamagetothebasketand

reel.

13

Page 14

ProductOverview

ThrottleControl

Thethrottlecontrol(Figure14andFigure15)is

locatedontheright,rearsideofthecontrolpanel.

Rotatethethrottletoregulatetheenginespeed.

g032409

Figure13

1.Tractionandreel-drive

engagementlever

2.Operator-presencecontrol7.Grassbasket

3.Handle

4.Servicebrake

5.Controlpanel

Controls

6.Fueltank

8.Cuttingunit

9.Transportwheelaxle

Figure15

1.Fullspeed

2.Slowspeed

TractionandReel-Drive

EngagementLever

Thetractionandreel-driveengagementlever(Figure

16)islocatedonthefrontrightsideofthecontrol

panel.Fortransportoperation,theleverhas2

positions:NEUTRALandFORWARD.Pushingthelever

forwardengagesthetractiondrive.

Note:Tomovetheleveryoumustrstengagethe

operator-presencecontrol.

g027738

Figure14

1.Openspaceforoptional

lights

2.Parking-brakelatch

3.Servicebrake

4.Handle8.Tractionandreel-drive

5.Operator-presencecontrol

6.On/offswitch

7.Throttlecontrol

engagementlever

g032410

14

Page 15

ServiceBrake

Theservicebrake(Figure17)islocatedontheleft

frontsideofthehandle.Pullingtheleverbackwill

applytheservicebrake.Y oumustreleasethebrake

beforeyouengagethetractiondrive.

Figure16

1.NEUTRAL3.Tractiondrive-engaged

2.Tractiondriveneutraland

reeldriveoff

(transport)

4.Tractiondriveandreel

driveengaged

Forreeloperation,theleverhas2positions:ENGAGE

andDISENGAGE.Movethetopofthelevertotheleft

thenforwardtoengagethereelandbeginmowing.

Pushthelevertotherighttodisengagethereel

andcontinueforwardmotionorpullbackonitto

disengageboththereelandthetractiondrive.

Note:Ifyoureleasetheoperator-presencecontrol,

theleverreturnstoneutralandthemachinestops.

g000494

1.Parking-brakelatch

Figure17

2.Servicebrake

g016853

Parking-BrakeLatch

Theparking-brakelatch(Figure17)isusedwiththe

servicebrake.Withtheservicebrakeengaged,rotate

theparking-brakelatchtowardthebrakehandleand

releasetheservicebrakeontothelatchtoholdthe

servicebrakeinplace.Pullthebrakelevertorelease

it.

On/OffSwitch

Theon/offswitch(Figure14)islocatedontopofthe

controlpanel.MovetheswitchtotheONpositionto

starttheengineandOFFtoshutofftheengine.

Operator-PresenceControl(OPC)

Theoperator-presencecontrol(Figure14)mustbe

engagedbeforeengagingthetractionlever.Releasing

theOPCduringoperationreturnsthemachineto

neutralbutdoesnotshutofftheengine.

15

Page 16

ChokeLever

g018267

g018268

Recoil-StarterHandle

Thechokelever(Figure18)islocatedontheengine.

Theleverhas2positions:RUNandCHOKE.Movethe

chokelevertothehalf-openpositionwhenstartinga

coldengine.Aftertheenginestarts,movethelever

totheRUNposition.

g018267

Figure18

1.ChokeleverintheCHOKEposition

Fuel-ShutoffValve

Thefuel-shutoffvalve(Figure19)islocatedonthe

engine.Thevalvehas2positions:CLOSEDandOPEN.

MovethelevertotheCLOSEDpositionwhenstoringor

transportingmachine.Openthevalvebeforestarting

theengine.Thefuelcupislocatedbelowtheshutoff

valve.

Pulltherecoil-starterhandle(Figure20)tostartthe

engine.

g018268

Figure20

1.Recoil-starterhandle

Kickstand

Thekickstand(Figure22)ismountedtotherearofthe

machineandisusedtoraisetherearofthemachine

forinstallingorremovingthetransportwheelsandfor

preventingthemachineforfallingontothehandle

whenyouremovethereel.

•Tousethekickstandtoinstallthetransportwheels,

lowerittothegroundandstepdownonthe

kickstandloopwhilepullingupandbackonthe

lowercentermachinehandle(Figure21).

1.Fuel-shutoffvalvein

closedposition

CAUTION

Themachineisheavyandcancauseback

strainifliftedimproperly.

Putfootpressuredownonlyonthe

kickstandloopandonlyusethelower

centermachinehandletoraisetheunit.

Attemptingtoraisetheunitontothe

kickstandanyotherwaycancauseinjury.

g016847

Figure19

2.Fuelcup

16

Page 17

g018793

G018142

1

2

3

Figure23

g018142

Figure21

1.Lowercentermachine

handle

2.Kickstandloop

Figure22

1.Kickstand2.Kickstandloop

1.Kickstand—STORAGE

position

2.Lockingpin

g018793

g016833

3.Kickstand—SERVICE

position

•Topreventtheunitfromtippingbackwardwhen

removingthereel,lowerthekickstandandpush

inthelockingpintolockitintheSERVICEposition

(Figure23).

17

Page 18

Specications

G009027

1

2

1820TractionUnit

Width

Height

Lengthwithbasket

NetWeight(with11

bladecuttingunit

andgrassbasket

installed)

Widthofcut46cm(18inches)

Heightofcut1.5to7.5mm(1/16to19/64inches)

ClipfrequencyAdjustable(refertoCuttingUnit

82.5cm(32-1/2inches)

104.8cm(41–1/4inches)

152.4cm(60inches)

117kg(258lb)

withMicro-Cutbedknife

Operator’sManual)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsin

thesafetysection.Knowingthisinformationcould

helpyouorbystandersavoidinjury.

CAUTION

Thismachineproducessoundlevelsthatcan

causehearinglossthroughextendedperiods

ofexposure.

2120TractionUnit

Width

Height

Lengthwithbasket

NetWeight(with11

bladecuttingunit

andgrassbasket

installed)

Widthofcut53.3cm(21inches)

Heightofcut1.5to7.5mm(1/16to19/64inches)

ClipfrequencyAdjustable(refertoCuttingUnit

90.1cm(35-1/2inches)

104.8cm(41–1/4inches)

152.4cm(60inches)

117.9kg(260lb)

withMicro-Cutbedknife

Operator’sManual)

Wearhearingprotectionwhenoperatingthis

machine.

g009027

Figure24

1.Weareyeprotection.2.Wearhearingprotection.

CheckingtheEngine-Oil Level

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability,T oro

deliversreplacementpartsdesignedtotheexact

engineeringspecicationofourequipment.Forpeace

ofmind,insistonTorogenuineparts.

Checktheengine-oillevelbeforeeachuseorevery

8operatinghours,refertoCheckingtheEngine-Oil

Level(page28).

FillingtheFuelTank

Thefueltankcapacityis3.0L(0.79gallons).

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

18

Page 19

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethegasolinevapors.Are

orexplosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•Donotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Neverllthefueltankinsideanenclosed

trailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

Neverbuymorethana30-daysupplyof

gasoline.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancause

seriousinjuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastank

orconditionerbottleopening.

•Avoidcontactwithskin;washoffspillage

withsoapandwater.

1.Cleanaroundthefuel-tankcapandremovethe

capfromthetank(Figure25).Usingunleaded

gasoline,llthefueltanknohigherthantothe

bottomofthelterscreen.Donotoverll.

19

Page 20

g018269

Figure25

1.Fuel-tankcap

2.Installthefuel-tankcapandwipeupanyspilled

gasoline.

AdjustingtheHandleAngle

1.Removethehairpincottersfromthehandle

retainersoneachsideofthemachine(Figure

27).

g018269

AdjustingtheHandle Height

Note:Themachineisshippedwiththehandle

adjustedtothelowestposition.Themachineis

traditionallyoperatedwiththehandletelescopedout

toitsmaximumheight.

1.Loosenthe3carriageboltsandnutssecuring

eachsideofthehandleinthehandleclamps

(Figure26).

g017005

Figure27

1.Hairpincotter2.Handleretainer

2.Whilesupportingthehandle,removethehairpin

cottersfromeachsideandpivotthehandleto

thedesiredoperatingposition(Figure27).

3.Installthehandleretainersandhairpincotters.

AdjustingtheThrottle Control

1.Removetheconsolecover.

2.Loosenthe2fastenerssecuringthethrottle

control(Figure28).

Figure26

1.Handleclamp

2.Nut

2.Pulluponthehandleslowlyandevenlyoneach

sideuntilitisinthedesiredoperatingposition.

3.Tightenthecarriageboltsandnutstolockthe

adjustment.

3.Carriagebolts

g016851

20

Page 21

Figure28

1.Fasteners2.Throttlecontrol

3.Adjustthethrottlecontroltothedesiredposition.

ShuttingOfftheEngine

1.Movethetractionandreeldrivecontrolsto

theDISENGAGEDposition,thethrottlecontrolto

SLOW,andtheon/offswitchtoOFF.

2.Pullthemoldedspark-plugwireoffofthespark

plugtopreventthepossibilityofaccidental

startingbeforestoringthemachine.

3.Closethefuel-shutoffvalvebeforestoringor

transportingthemachineinavehicle.

TransportingtheMachine

g027739

Note:Donotruntheenginewhiletransportingitin

atransporttrailerbecausedamagecanoccurtothe

machine.

Iftheoptionaltransportwheelsarenotgoingtobe

installed,proceedtostep4.

4.Tightenthethrottle-controlfasteners.

5.Installthepreviouslyremovedconsolecover.

StartingandShuttingOff theEngine

Note:Forillustrationsanddescriptionsofthecontrols

referencedinthissection,refertoControls(page14).

StartingtheEngine

Note:Ensurethatthespark-plugwireisinstalledon

thesparkplug.

1.Ensurethatthetractionandreel-driveleversare

intheDisengagedposition.

Note:Theenginewillnotstartifthetraction

leverisintheengagedposition.

2.Movetheon/offswitchtotheONposition.

3.MovethethrottlecontroltotheFASTposition.

4.Openthefuel-shutoffvalveontheengine.

5.Movethechokelevertothehalf-openposition

whenstartingacoldengine.Thechokemaynot

berequiredwhenstartingawarmengine.

6.Pulltherecoilstarterhandleoutuntilpositive

engagementresults,thenpullitvigorouslyto

starttheengine.Openthechokeastheengine

warmsup.

Important:Donotpulltherecoilropeto

itslimitorletgoofthestarterhandlewhen

theropeispulledoutbecausetherope

maybreakortherecoilassemblymaybe

damaged.

1.Pushthekickstanddownwithyourfootandpull

uponthehandlesupportuntilthekickstandhas

rotatedforward,overcenter.

2.Installthetransportwheels.

3.T oreleasethekickstand,pulluponthehandle

andlowertherearofthemachineontothe

transportwheels.

4.Ensurethatthetractionandreeldrivecontrols

areintheDISENGAGEDpositionandstartthe

engine.

5.SetthethrottlecontroltoSLOW,tipthefrontof

themachineup,graduallyengagethetraction

drive,andslowlyincreasetheenginespeed.

6.Adjustthethrottletooperatethemachineat

thedesiredgroundspeedandtransportthe

machinetothedesireddestination.

PreparingtoMow

1.Returnthetractioncontrollevertothe

DISENGAGEDposition,thethrottletotheSLOW

position,andshutofftheengine.

2.Pushthekickstanddownwithyourfootandpull

uponthehandlesupportuntilthekickstandhas

rotatedforward,overcenter.

3.Removethetransportwheels.

4.Carefullylowerthemachineoffthekickstand.

Ensurethatthemachineiscarefullyadjustedandthat

itissetevenlyonbothsidesofthereel.Improper

machineadjustmentismagniedintheappearance

oftheclippedturf.Removeallforeignobjectsfrom

theturfpriortomowing.Makesurethateveryone,

21

Page 22

especiallychildrenandpets,areclearofthework

area.

MowingTips

Important:Grassclippingsactasalubricant

whenmowing.Excessiveoperationofthecutting

unitwiththeabsenceofgrassclippingscan

damagethecuttingunit.

•Thegreensshouldbemowedinastraightback

andforthdirectionacrossthegreen.

•Avoidcircularmowingorturningthemachineon

thegreensareastopreventscufng.

•Turningthemachineshouldbedoneoffthegreen

byraisingthecuttingreel(pushingthehandle

down)andturningonthetractiondrum.

•Mowingshouldbedoneatanormalwalkingpace.

Fastspeedssavesverylittletimeandresultsin

aninferiormowingjob.

•Toassistinmaintainingastraightlineacross

thegreenandtokeepthemachineanequal

distancefromtheedgeofthepreviouscut,usethe

alignmentstripesonthebasket(Figure29).

OperatingtheControlswhile

Mowing

1.Starttheengine,setthethrottletoareduced

speed,pushdownonthehandletoraisethe

cuttingunit,presstheoperator-presencecontrol,

movethetractionlevertotheENGAGEDposition

andtransportthemachineontothecollarofthe

green(Figure30).

2.MovethetractionlevertotheDISENGAGED

positionandengagethereel-drivelever(Figure

30).

Figure29

1.Alignmentstripes

OperatingtheMachineinLow

LightConditions

Whenoperatingthemachineinlowlightconditions,

usetheoptionalLEDLightKit,availablefromyour

AuthorizedT oroDistributor.

Important:Donotuseotherlightsystemswith

thismachineastheywillnotoperateproperlywith

theengineACoutput.

g000494

Figure30

1.Tractiondrive—neutral3.Tractiondrive—engaged

g016840

2.Tractiondriveneutraland

reeldriveoff

3.MovethetractionlevertotheENGAGEDposition,

increasethethrottlespeeduntilthemachineis

travelingatthedesiredgroundspeed,drivethe

machineoutontothegreenarea,lowerthefront

ofthemachinedown,andcommenceoperation

(Figure30).

(transport)

4.Tractiondriveandreel

driveengaged

OperatingtheControlsafter

Mowing

1.Driveoffthegreen,movethereeldriveand

tractioncontrolleverstotheDISENGAGED

position,andshutofftheengine.

22

Page 23

2.Emptythegrassbasketofclippings,installthe

grassbasketonthemachine,andcommence

thetransportoperation.

CheckingtheOperationof theInterlockSwitches

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifthesafetyinterlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

CheckingtheOperator-Presence

Control(OPC)InterlockSwitch

4.WiththeOPCpressedandthetractionlever

engaged,releasetheOPC(Figure31).The

tractionlevershoulddisengage.Ifthetraction

leverdoesnotdisengage,theinterlocksystem

needsservice.Correcttheproblembefore

operating;refertoServicingtheTraction

InterlockSwitch(page31).

5.WiththeOPCpressedandtheshiftlevermoved

totheleft,engagethetractionandreeldrive,

releasetheOPC(Figure31).Thetractionlever

shoulddisengage.Ifthetractionleverdoesnot

disengage,theinterlocksystemneedsservice.

Correcttheproblembeforeoperating.;referto

ServicingtheTractionInterlockSwitch(page31)

orAdjustingtheReelControl(page35).

6.WiththeOPCpressedandtheshiftlevermoved

tothelefttoengagethetractionandreeldrive,

movetheshiftlevertotherighttodisengage

thereeldrive(Figure31).Thereeldriveshould

disengage.Ifthereeldrivedoesnotdisengage,

theinterlocksystemneedsservice.Correctthe

problembeforeoperating.;refertoAdjustingthe

ReelControl(page35).

7.Carefullylowerthemachineoffthekickstand.

1.Pushthekickstanddownwithyourfootandpull

uponthehandlesupportuntilthekickstandhas

rotatedforward,overcenter.

2.Starttheengine.

3.WiththeOPCreleased,attempttoengagethe

tractionlever(Figure31).Thetractionlever

shouldnotengage.Ifthetractionleverengages,

theinterlocksystemneedsservice.Correctthe

problembeforeoperating;refertoServicingthe

TractionInterlockSwitch(page31).

CheckingtheTractionInterlock

Switch

1.Pushthekickstanddownwithyourfootandpull

uponthehandlesupportuntilthekickstandhas

rotatedforward,overcenter.

2.WiththeOPCpressed,thetractionlever

engaged,andtheenginecontrolsinthestarting

position(Figure31).Attempttostarttheengine.

Theengineshouldnotstart.Iftheenginestarts,

theinterlockswitchneedsservice.Correctthe

problembeforeoperating.RefertoServicingthe

TractionInterlockSwitch(page31).

3.Carefullylowerthemachineoffthekickstand.

1.Operator-presencecontrol

(OPC)

2.Tractionlever

g032412

Figure31

3.Brakelever

23

Page 24

CheckingtheBrake-Interlock

Switch

1.Pushthekickstanddownwithyourfootandpull

uponthehandlesupportuntilthekickstandhas

rotatedforward,overcenter.

2.Withthetractionleverdisengaged,theservice

brakeengaged,andtheenginecontrolsin

thestartingposition(Figure31),attemptto

starttheengine.Theengineshouldstart.If

theenginedoesnotstart,theinterlockswitch

needsservice.Correcttheproblembefore

operatingthemachine;refertoServicingthe

Brake-InterlockSwitch(page32).

3.Withtheenginerunning,engagetheservice

brake(nottheparkingbrake),presstheOPC,

andengagethetractionlever(Figure31).The

engineshouldlabortoovercomethebrake

butshouldnotshutoff.Iftheengineshutsoff

immediately,theinterlockswitchneedsservice.

Correcttheproblembeforeoperatingthe

machine;refertoServicingtheBrake-Interlock

Switch(page32).

4.Withtheenginerunning,engagethe

parking-brakelatch,presstheOPC,andengage

thetractionlever(Figure31).Theengineshould

shutoff.Iftheenginedoesnotshutoff,the

interlockswitchneedsservice.Correctthe

problembeforeoperating;refertoServicingthe

Brake-InterlockSwitch(page32).

5.Carefullylowerthemachineoffthekickstand.

ReleasingtheTransmission

Ifthemachinebecomesdisabled,youcandisengage

thedrumfromthetransmissiontoallowthemachine

tobemaneuvered.

1.Ontherightrearcornerofthemachine,locate

thetractionengage/disengagelevernexttothe

drivehousingdrum(Figure32).

Figure32

1.Traction

engage/disengage

lever—engaged

2.Rotatetheleverrearwardtodisengagethe

transmissionfromthedrum.

2.Traction

engage/disengage

lever—disengaged

g032413

CAUTION

Notcarefullyrotatingthelevermay

causethespring-loadedlevertostrike

yourhand.

Carefullyrotatethelever.

3.Movethemachineasneeded.

Important:Ifpossible,donottowthe

machine.Ifitisabsolutelynecessary ,do

nottowatanyspeedgreaterthan4.8kph(3

mph);alwaysdisengagethetransmission

fromthedrum.Failingtodosowilllikely

damagethemachine.

4.Whennished,rotatetheleverforwardto

engagethetransmissiontothedrum.

Note:Thebrakeisstilloperationalwiththe

transmissiondisengagedfromthedrum.

24

Page 25

SettingtheMachinetoMatchTurfConditions

Usethefollowingtabletosetthemachinetomatchturfconditions.

Bedbars:StandardandOptional(Flex/eFlex2120Machines)

PartNumberDescriptionAggressiveness

106-2468-01Non-AggressiveLess

99-3794-03AggressiveMoreBlack

Bedbars:StandardandOptional(Flex/eFlex1820Mowers)

110-2282-01Non-AggressiveLess

110-2281-03AggressiveMoreBlack

Bedknives:StandardandOptional(Flex/eFlex2120Machines)

PartNumberDescription

115-1880Microcut-EdgeMax

93-4262Microcut

108-4303ExtendedMicrocut

115-1881Tournament-EdgeMax

93-4263T ournament

108-4302ExtendedTournament

93-4264

Bedknives:StandardandOptional(Flex/eFlex1820Machines)

117-1530Microcut-EdgeMax

98-7261Microcut

110-2300ExtendedMicrocut

98-7260T ournament

117-1532Tournament-EdgeMax

110-2301

LowCut6.4mm(0.25inch)andup

LowCut6.4mm(0.25inch)andup

Height-of-cutRangeComments

1.6to3.2mm(0.062to0.125inch)Standard

1.6to3.2mm(0.062to0.125inch)

1.6to3.2mm(0.062to0.125inch)

3.2to6.4mm(0.125to0.25inch)

3.2to6.4mm(0.125to0.25inch)

3.2to6.4mm(0.125to0.25inch)

1.6to3.2mm(0.062to0.125inch)Standard

1.6to3.2mm(0.062to0.125inch)

1.6to3.2mm(0.062to0.125inch)

3.2to6.4mm(0.125to0.25inch)

3.2to6.4mm(0.125to0.25inch)

Comments

Red,Standard

Red,Standard

Lessaggressive

Lessaggressive

Lessaggressive

Rollers(Flex/eFlex2120Machines)

PartNumberDescription

04255NarrowWiehle

04256WideWiehle

04257FullRoller

04258NarrowWiehle—Long

04267Paspalum

115-7356RearRoller

120-9595RearRoller

Rollers(Flex/eFlex1820Machines)

120-9607NarrowWiehle

120-9609WideWiehle

120-9611FullRoller

121-4681NarrowWiehle—Long

120-9605RearRoller

Diameter/MaterialComments

6.4cm(2.5inches)/Aluminum

6.4cm(2.5inches)/Aluminum

6.4cm(2.5inches)/Steel

6.4cm(2.5inches)/AluminumMoreedgesupport;4.3cm(1.7inches)longer

6.4cm(2.5inches)/AluminumLesspenetration,softenednarrowspacedgrooves

5.1cm(2.0inches)/AluminumStandardrear

5.1cm(2.0inches)/SteelSteelrear

6.4cm(2.5inches)/Aluminum

6.4cm(2.5inches)/Aluminum

6.4cm(2.5inches)/Steel

6.4cm(2.5inches)/AluminumMoreedgesupport;4.3cm(1.7inches)longer

5.1cm(2.0inches)/AluminumStandardrear

Narrowspacedgrooves

Morepenetration,widespacedgrooves

Leastpenetration

Narrowspacedgrooves

Morepenetration,widespacedgrooves

Leastpenetration

25

Page 26

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:WhenusingthemachineinconjunctionwiththeTransPro80,alwaysusethestopsonthe

trailerwhenservicingthemachine.Overtippingcanresultinfuelspillage.

ThestopontheRailRampKitrequiresabroomhandleorsimilaritemtobeinsertedthroughthe

holesbehindthewheels.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst20hours

Beforeeachuseordaily

Every50hours

Every100hours

Every500hours

Every1,000hours

Beforestorage

MaintenanceProcedure

•Changetheengineoil.

•Cleanthefuelcupandfuel-tankscreen.

•Checktheoperationoftheinterlockswitches.

•Checktheengine-oillevel.

•Changetheengineoil.

•Cleantheaircleaner(moreoftenindirtyordustyconditions).

•Replacethepaperairlterelement(moreoftenindirtyordustyconditions).

•Checkthesparkplug.

•Cleanthefuelcupandfuel-tankscreen.

•Replacetheclutchoil.

•Cleanthecarburetor.

•Inspecttheintakeandexhaustvalves.Adjustasnecessary.

•Replacethefuelline.

•Inspectthereel-drivebelt.

•Inspectthetransmissionbearingsandreplaceasnecessary.

•Paintchippedsurfaces.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

26

Page 27

DailyMaintenanceChecklist

Important:Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation.

Checkthe

parkingbrake

operation.

Checkthatpivot

jointsoperate

freely.

Checkthefuel

level.

Checktheengine

oillevel.

Checktheair

lter.

Cleantheengine

coolingns.

Checkfor

unusualengine

noises.

Checkfor

unusual

operatingnoises.

Checkthe

reel-to-bedknife

adjustment.

Checkthe

height-of-cut

adjustment.

Touchup

damagedpaint.

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

27

Page 28

EngineMaintenance

g018270

1

2

ServicingtheEngineOil

Fillthecrankcasewithapproximately0.6L(20

oz)oftheproperviscosityoilbeforestarting.Use

ahigh-qualityoilhavingtheAmericanPetroleum

Institute(API)serviceclassicationSEorhigher.

Selecttheproperoilviscosity(weight)basedon

theambienttemperature.Figure33illustratesthe

temperature/viscosityrecommendations.

g018270

Figure34

Figure33

Note:Usingmulti-gradeoils(5W-20,10W-30and

10W-40)willincreaseoilconsumption.Checktheoil

levelmorefrequentlywhenusingthem.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Thebesttimetochecktheengineoiliswhen

theengineiscool,beforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.IftheoillevelisatorbelowtheLmarkon

thedipstick,addoiltobringtheoilleveltotheHmark.

Donotoverll.IftheoillevelisbetweentheHand

Lmarks,donotaddoil.

1.Oil-levelgauge

3.Removetheoil-levelgaugebyrotatingit

counterclockwise(Figure34).

4.Wipetheoil-levelgaugecleanandinsertitinto

thellerport.Donotscrewthegaugeintothe

port.Thenremoveitandcheckthelevelofthe

oil.Ifthelevelislow,addonlyenoughoilto

g016841

raisetheleveluntilitisbetweentheHandL

marksonthegauge(Figure35).Checkthelevel

oftheoil.Donotoverll.

5.Installtheoil-levelgaugeandwipeupany

spilledoil.

2.Drainplug

g007620

Figure35

1.Removethetransportwheels(ifinstalled).

2.Positionthemachinesothattheengineislevel

andcleanaroundtheoil-levelgauge(Figure34).

ChangingtheEngineOil

ServiceInterval:Aftertherst20hours

Every50hours

1.Startandruntheengineforafewminutesto

warmtheengineoil.

2.Attherearofthemachine,placeadrainpan

underthedrainplug(Figure34).Loosenthe

drainplug.

3.Pushdownonthehandletotipthemachineand

enginebackward,allowingalltheoiltoruninto

thedrainpan.

28

Page 29

4.Installthedrainplugandrellthecrankcase

g018271

1

withthespeciedoil.

5.Wipeupanyspilledoil.

6.Disposeoftheusedoilproperly .Recycle

accordingtolocalcodes.

ServicingtheAirCleaner

ServiceInterval:Every50hours

1.Disconnectthewirefromthesparkplug.

2.Removethewingnutsecuringtheair-cleaner

covertotheaircleanerandremovethecover.

Cleanthecoverthoroughly(Figure36and

Figure37).

g016845

Figure37

Figure36

1.Air-cleanercover

3.Ifthefoamelementisdirty,removeitfromthe

paperelement(Figure37).Cleanitthoroughly.

A.Washthefoamelementinasolutionof

liquidsoapandwarmwater.Squeezeitto

removethedirt,butdonottwistitbecause

thefoammaytear.

B.Drybywrappinginacleanrag.Squeeze

theragandfoamelementtodry,butdonot

twistbecausethefoammaytear.

C.Saturatetheelementwithcleanengineoil.

Squeezetheelementtoremovetheexcess

oilandtodistributetheoilthoroughly.

Note:Anelementdampwithoilis

desirable.

1.Wingnut4.Foamelement

2.Air-cleanercover5.Paperelement

3.Wingnut6.Air-cleanerbase

g018271

4.Whenservicingthefoamelement,checkthe

conditionofthepaperelement.Replaceas

required.

Note:Donotusecompressedairtocleanthe

paperelement.

5.Installthefoamelement,paperelement,and

air-cleanercover.

Important:Donotoperatetheengine

withouttheair-cleanerelementbecause

extremeenginewearanddamagewillresult.

29

Page 30

ServicingtheSparkPlug

g018272

1

FuelSystem

ServiceInterval:Every100hours

UseanNGKBR6HSsparkplugorequivalent.The

correctairgapis0.6to0.7mm(0.024to0.028inch).

1.Pullthemoldedwireoffthesparkplug(Figure

38).

Figure38

Maintenance

CleaningtheFuelCupand Fuel-TankScreen

ServiceInterval:Aftertherst20hours

Every100hours/Monthly(whichevercomes

rst)

1.Closethefuelshutoffvalveandunscrewthe

fuelcupfromthelterbody(Figure40).

Note:A17mm,12pointsockettsoverthe

bodyofthefuelcupandaidsintheremoval.

g018272

1.Spark-plugwire

2.Cleanaroundthesparkplugandremovethe

plugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotsandblast,scrape,

orcleantheelectrodesbecauseengine

damagecouldresultfromgritenteringthe

cylinder.

3.Settheairgapat0.6to0.7mm(0.024to0.028

inch)asshowninFigure39.Installthecorrectly

gappedsparkplugandtightenitrmlyto23

N∙m(17ft-lb).

Figure40

1.Shutoffvalve

2.Cleanthefuelcupincleanfuelandinstallit.

3.Unscrewandremovethefuel-tankcapfromthe

fueltank(Figure41).

2.Fuelcup

g016847

1.Center-electrodeinsulator

2.Sideelectrode

Figure39

3.Airgap—0.6to0.7mm

(0.024to0.028inch)

g016950

g016857

Figure41

1.Fuel-tankcap2.Fuel-tankscreen

30

Page 31

4.Removethefuel-tankscreenfrominsidethe

fueltank.

ElectricalSystem

5.Cleanthescreenincleanfuelandinstallitin

thetank.

6.Installthefuel-tankcaptothefueltank.

ReplacingtheFuelLine

ServiceInterval:Every1,000hours

Iffuelleaksfromtheline,replaceitimmediately.

Maintenance

ServicingtheTraction InterlockSwitch

Usethefollowingprocedureiftheswitchneeds

adjustmentorreplacement.

1.Makesurethattheengineisoff.

2.Removethecontrolpanel.

3.Engagethetractionlever.

Figure42

1.Tractionlever2.Interlockswitch

4.Loosentheinterlockswitchmountingfasteners

(Figure42).

5.Placea1.6mm(0.062inch)thickshimbetween

thetractionleverandtheinterlockswitch(Figure

42).

6.Tightentheinterlockswitchmountingfasteners.

7.Engagethetractionleverandcheckthegap.

Thenormaloperatingrangeisbetween0.76to

3.05mm(0.03to0.12inch).Withthetraction

leverengaged,verifythattheswitchloses

continuity.Replacetheswitchifrequired.

g016912

31

Page 32

Servicingthe

3

Brake-InterlockSwitch

BrakeMaintenance

1.Makesurethattheengineisoff.

2.Removethecontrolpanel.

3.Engagetheservice-brakeleverandengagethe

parking-brakelatch.

4.Loosentheinterlockswitchmountingfasteners

(Figure43).

Adjustingthe Service/ParkingBrake

Iftheservice/parkingbrakeslipswhenoperated,

adjustthecableasfollows:

1.Movetheservice/parkingbrakelevertotheOFF

position.

2.Removethecontrolpanel.

3.T oincreasethecabletension,loosentheupper

cablejamnutandtightenthelowercablejam

nut(Figure44)untilaforceof156N(35lb)

appliedtothebrakeleverhandleisrequiredto

releasetheparking-brakelatch.Donotover

adjustitorthebrakebandmaydrag.

Figure43

1.Parking-brakelatch

2.Interlockswitch

5.Placea1.6mm(0.062inch)thickshimbetween

theparking-brakelatchandtheinterlockswitch

(Figure43).

6.Tighteninterlockswitchmountingfasteners.

Checkthegap.Thelatchmustnotcontactthe

switch.

7.Engagethebrakeleverandrotatethelatch.

Verifythattheswitchlosescontinuity.Replace

theswitchifrequired.

3.Service-brakelever

g016913

g016920

Figure44

1.Jamnuts

2.Service-brakecable

32

Page 33

BeltMaintenance

g018273

InspectingtheReel-Drive Belt

D.Makesurethatthecompressionspringis

applyingthepropertensiononthebelt.

E.Tightenthebearinghousingmountingnut.

F.Installthebeltcover.

ServiceInterval:Every1,000hours

1.Loosentheangeboltsecuringthebeltcover

andremovethebeltcovertoexposethebelt

(Figure45).

Figure45

1.Beltcover

2.T oadjustthebelttension:

A.Loosenthebearinghousingmountingnut

(Figure46).

VisuallyInspectingtheReel Clutch

Removetherubberplug(Figure47)fromtheholein

thefrontofthetransmissiontovisuallyinspectthe

reelclutchwhenmakingadjustments.

Important:Replacetheplugwhennishedto

preventwateranddebrisfromcontaminatingthe

clutch.

g018273

Figure46

1.Bearinghousingmounting

nut

2.Reel-drivebelt

B.Usinga16mm(5/8inch)wrench,rotate

thebearinghousingtomakesurethatit

operatesfreely.

C.Cleananydebrisfrominsidethebelt

compartmentandfromaroundthe

compressionspring(Figure46).

3.Compressionspring

g016949

Figure47

1.Rubber-holeplug

g017116

2.Engage/disengageshaft

33

Page 34

Engaging/Disengaging

1

2

G019886

ControlsSystem

theTransmission-Belt

Tensioner

Thetransmissionbeltistensionedbyaspringloaded

idlerpulley.Ifyoumustengageordisengagethe

belttension,usea3/8inchwrenchtorotatethe

engage/disengageshaft(Figure47)tothedesired

position.Rotatingtheshaft1/4turnclockwise

disengagestheidlerfromthebelt(Figure48).

Note:Thebelttensionmustbedisengagedpriorto

removingthetransmissioncover.

Figure48

1.Engaged2.Disengaged

Maintenance

AdjustingtheTraction Control

ServiceInterval:Every500hours—Replacethe

clutchoil.

Ifthetractioncontroldoesnotengageorslipsduring

operation,thetractioncontrolmayneedadjusting.

1.MovethetractioncontroltotheENGAGED

position.

2.Measurethedistancefromthepinoneither

endofthetraction-controlspring(Figure49);if

itisnotwithin7.3to7.6cm(2-7/8to3inches),

adjusttheclutchaccordingtothestepsbelow.

g019886

g032417

Figure49

1.Measurethisdistance;

shouldbe7.3to7.6cm

(2-7/8to3inches)

2.Traction-controlspring5.Jamnut

3.Clevispin

A.Disengagethetraction-controllever.

B.Loosenthejamnutontheturnbuckleand

34

removetheclevispin,disconnectingthe

springfromtheturnbuckle(Figure49).

C.Turntheturnbuckleinorouttoadjustthe

lengthasneeded.

4.Turnbuckle

Page 35

D.Installtheturnbuckletothespringusingthe

G027790

1

2

3

clevispin.

E.MovethetractioncontroltotheENGAGED

position.

F.Measurethedistancefromthepinoneither

endofthetraction-controlspring(Figure

49);repeatstepsAthroughFuntilitis

within7.3to7.6cm(2-7/8to3inches).

AdjustingtheReelControl

Ifthereelcontroldoesnotproperlyengage,an

adjustmentisrequired.

1.Ensurethatthereelcontrolisdisengaged.

2.Atthetransmissionbulkhead,adjustthe

reel-controlcable(Figure50)toattainaspring

lengthof70.6to72.4mm(2.78to2.85inches).

g027790

Figure51

1.Jamnuts3.Reel-controlcable

2.Traction-controlcable

4.Atthecontrolhandlebulkhead,tightenthe

reel-controlcableenoughtoremovetheslack

fromthecablewithoutextendingthespring.

5.Checktheoperationasfollows:

Figure50

1.Reel-controlcable2.Jamnuts

3.Atthecontrolhandlebulkhead,loosenthe

reel-controlcableuntilthereisslackinthecable

(Figure51).

•Verifythatthereelclutchteethdisengage

whentheclutchisreleasedandthereel

clutchteethdonotbottomoutwhen

engaged.

Note:Removetherubberplug(Figure47)

fromtheholeinthefrontofthetransmission

toviewreelclutch.

•Thereelstoppingtimemustbelessthan7

secondswiththereeltobedknifebackedoff.

•RefertotheServiceManualorcontact

g017020

yourauthorizedT orodistributorforfurther

assistance.

35

Page 36

Storage

1.Removeanygrassclippings,dirt,andgrime

fromtheexternalpartsoftheentiremachine,

especiallytheengine.Cleanthedirtandchaff

fromtheoutsideoftheenginecylinder-headns

andtheblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressure

washthemachine.Avoidexcessiveuseof

water,especiallyneartheshiftleverplate,

andtheengine.

2.Forlong-termstorage(morethan30days)add

stabilizer/conditioneradditivetothefuelinthe

tank.

A.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

B.Eithershutofftheengine,allowittocool,

anddrainthefueltank,oroperatethe

engineuntilitshutsoff.

C.Starttheengineandrunituntilitshuts

off.Repeat,onCHOKE,untiltheengineno

longerstarts.

D.Disposeoffuelproperly .Recycleaccording

tolocalcodes.

Note:Donotstorestabilizer/conditioned

fuelover90days.

3.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatiswornor

damaged.

4.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourauthorizedT orodistributor.

5.Storethemachineinaclean,drygarageor

storagearea.Coverthemachinetoprotectit

andkeepitclean.

36

Page 37

Notes:

Page 38

Notes:

Page 39

InternationalDistributorList

Distributor:

AgrolancKft

AsianAmericanIndustrial(AAI)

B-RayCorporation

BrisaGoodsLLC

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

FatDragon

FemcoS.A.Guatemala

FIVEMANSNew-T echCo.,LtdChina

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India00914424494387ValtechMorocco212537663636

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

Country:

Hungary3627539640

HongKong85224977804

Korea82325512076

Mexico12104952417

PuertoRico7877888383

NorthernIreland442890813121

China

Estonia3723846060

Japan81726325861Riversa

Turkey902163365993

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

5062391138

94112746100

442890813121ParklandProductsLtd.NewZealand6433493760

8861080841322

5024423277

86-10-63816136

30109350054

4635100000

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

Lely(U.K.)Limited

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

Country:

Japan81332522285

Argentina541 148219999

Russia749541 16120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

UnitedKingdom441480226800

France33130817700

India911292299901

PhoneNumber:

5712364079

420255704220

420255704220

34952837500

35722434131

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy .Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMA TION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofY ourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0269RevK

Page 40

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevC

Loading...

Loading...