Page 1

FormNo.3367-413RevA

Greensmaster

®

2000and2600

Walk-BehindMower

ModelNo.04036—SerialNo.311000001andUp

ModelNo.04037—SerialNo.311000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

Figure1

1.Safetyalertsymbol.

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Introduction

Thismachineisawalkbehind,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedfor

cuttinggrassonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.Itis

notdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Themodel

andserialnumbersarelocatedonaplateontherear

frame.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................5

SoundPressure.....................................................6

SoundPower........................................................6

Vibration(Model04036)......................................6

Vibration(Model04037)......................................6

SafetyandInstructionalDecals.............................7

Setup............................................................................9

1InstallingandAdjustingtheHandle....................9

2InstalltheLiftHandles.....................................11

3InstallingtheKickstand(Model04037

Only)..............................................................11

4InstallingtheTransportWheels........................12

5AdjustingtheCuttingUnit...............................13

6InstallingtheGrassBasket...............................13

ProductOverview......................................................14

Controls.............................................................14

Specications.....................................................15

Attachments/Accessories...................................15

Operation...................................................................16

ThinkSafetyFirst...............................................16

CheckingtheEngineOilLevel............................16

FillingtheFuelTank...........................................16

CheckingtheInterlockSwitchOperation............17

StartingandStoppingtheEngine........................17

DrivingtheMachineinTransport.......................17

PreparingtoMow...............................................18

Mowing..............................................................18

OperatingTips...................................................18

Maintenance...............................................................19

RecommendedMaintenanceSchedule(s)................19

DailyMaintenanceChecklist...............................20

Lubrication.............................................................21

GreasingtheMachine.........................................21

EngineMaintenance...............................................22

ServicingtheEngineOil.....................................22

ServicingtheAirCleaner....................................23

ReplacingtheSparkPlug....................................23

FuelSystemMaintenance.......................................24

CleaningtheFuelFilter.......................................24

ElectricalSystemMaintenance................................25

ServicingtheInterlockSwitch............................25

BrakeMaintenance.................................................25

AdjustingtheService/ParkingBrake...................25

BeltMaintenance....................................................27

AdjustingtheBelts.............................................27

ReplacingtheDifferentialBelt............................29

ControlsSystemMaintenance.................................30

AdjustingtheTractionControl...........................30

CuttingUnitMaintenance.......................................30

LevelingtheRearDrumtotheReel.....................30

AdjustingtheBedknifetotheReel......................31

AdjustingtheHeightofCut................................31

AdjustingtheGrassShieldHeight.......................32

AdjustingtheCut-OffBar..................................33

BedbarIdentication..........................................33

SettingtheMachinetoMatchTurf

Conditions.....................................................34

ServicingtheBedbar...........................................35

BacklappingtheReel..........................................35

Storage.......................................................................36

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004specicationsineffectatthetimeof

productionwhentheOperatorPresenceKit,PartNo.

105–5363isinstalled.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthe

languageoftheOperator’sManualitistheowner’s

responsibilitytoexplainthismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

•Alloperatorsormechanicsmustbetrained.Itisthe

owner’sresponsibilityfortrainingusers.

•Replacefaultysilencers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthatoperatorspresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andhearing

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly ,

andfunctioningproperly .

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperatorsposition:

4

Page 5

–stoponlevelground;

–disengagethecuttingunitandtractiondrive;

–settheparkingbrake;

–stoptheengine.

•Disengagedrivetocuttingunitwhentransportingor

notinuse.

•Stoptheengineanddisengagedrivetocuttingunit:

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustment.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Reducethethrottlesettingbeforestoppingengine

andclosethefuelshutoffvalveattheconclusion

ofmowing.

•Keephandsandfeetawayfromthecuttingunit.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopreelifnot

mowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,silencer

andfuelstorageareafreeofgrass,leaves,orexcessive

grease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Disengagedrives,disengagethecuttingunit,set

parkingbrake,stopengineanddisconnectsparkplug

wire.Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunit,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Removethesparkplugwirebeforemakingany

repairs.

•Usecarewhencheckingthereel.W earglovesand

usecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO ,or

ANSIstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlegasolinecarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.T oprevent

lossofcontrol:

–Donotoperateclosetosandtraps,ditches,

creeks,orotherhazards.

5

Page 6

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Reduceenginespeedandapplytheservicebrake

whengoingdownhilltokeepforwardspeedslow

andtomaintaincontrolofthemachine.

•Donottouchtheengine,mufer,orexhaustpipe

whiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenough

tocauseburns.

•Whenapersonorpetappearsunexpectedlyinor

nearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

MaintenanceandStorage

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecuttingunit

andanymovingparts.Keepeveryoneaway.

•Toensuresafetyandaccuracy,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.Maximumgovernedenginespeed

shouldbe3600±100RPM.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToroapprovedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

Vibration(Model04037)

Thisunitdoesnotexceedahand/armvibrationlevelof

4.50m/s

perEN1033andEN836.

2

,basedonmeasurementsofidenticalmachines

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operatorsearof84dBA,basedonmeasurementsof

identicalmachinesperEN836andISO11201.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof95

dBA,basedonmeasurementsofidenticalmachinesper

ISO11094.

Vibration(Model04036)

Thisunitdoesnotexceedahand/armvibrationlevelof

4.50m/s

perEN1033andEN836.

2

,basedonmeasurementsofidenticalmachines

6

Page 7

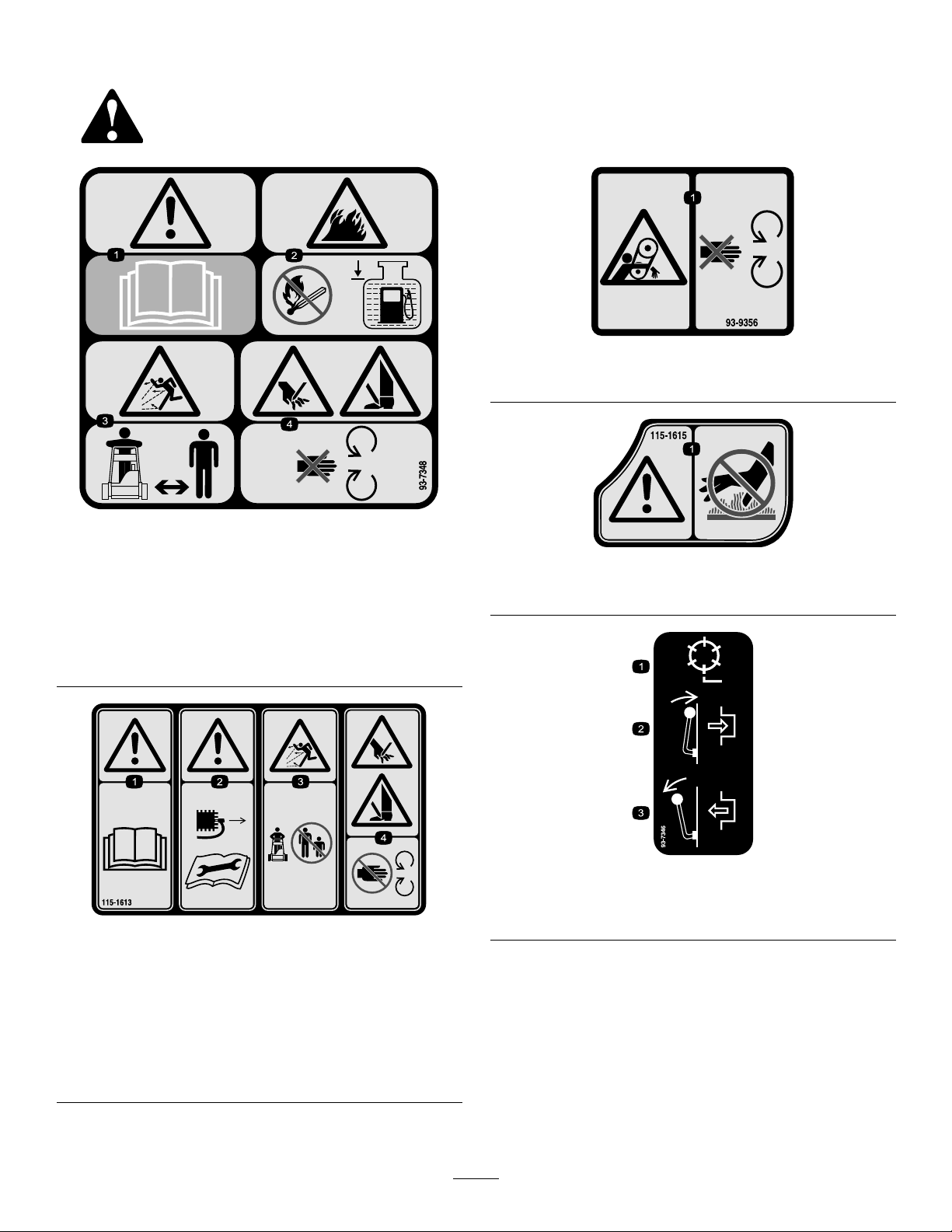

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-9356

1.Entanglementhazard—stayawayfrommovingparts.

93-7348

1.Warning—readtheOperator’sManual.

2.Firehazard—nore,openames,orsmoking;whenadding

fueltothetank,leavespacebetweenthefuelandthetopof

thetank.

3.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

4.Cuttinghazardofhandorfoot—stayawayfrommoving

parts

115-1613

1.Warning—readthe

Operator’sManual.

2.Warning—remove

thesparkplugwire

beforeperformingany

maintenanceonthe

machine.

3.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

4.Cutting,dismemberment

hazardofhandor

foot—stayawayfrom

movingparts.

115-1615

1.Warning—donottouchthehotsurface.

93-7346

1.Reeldrive3.Disengage

2.Engage

7

Page 8

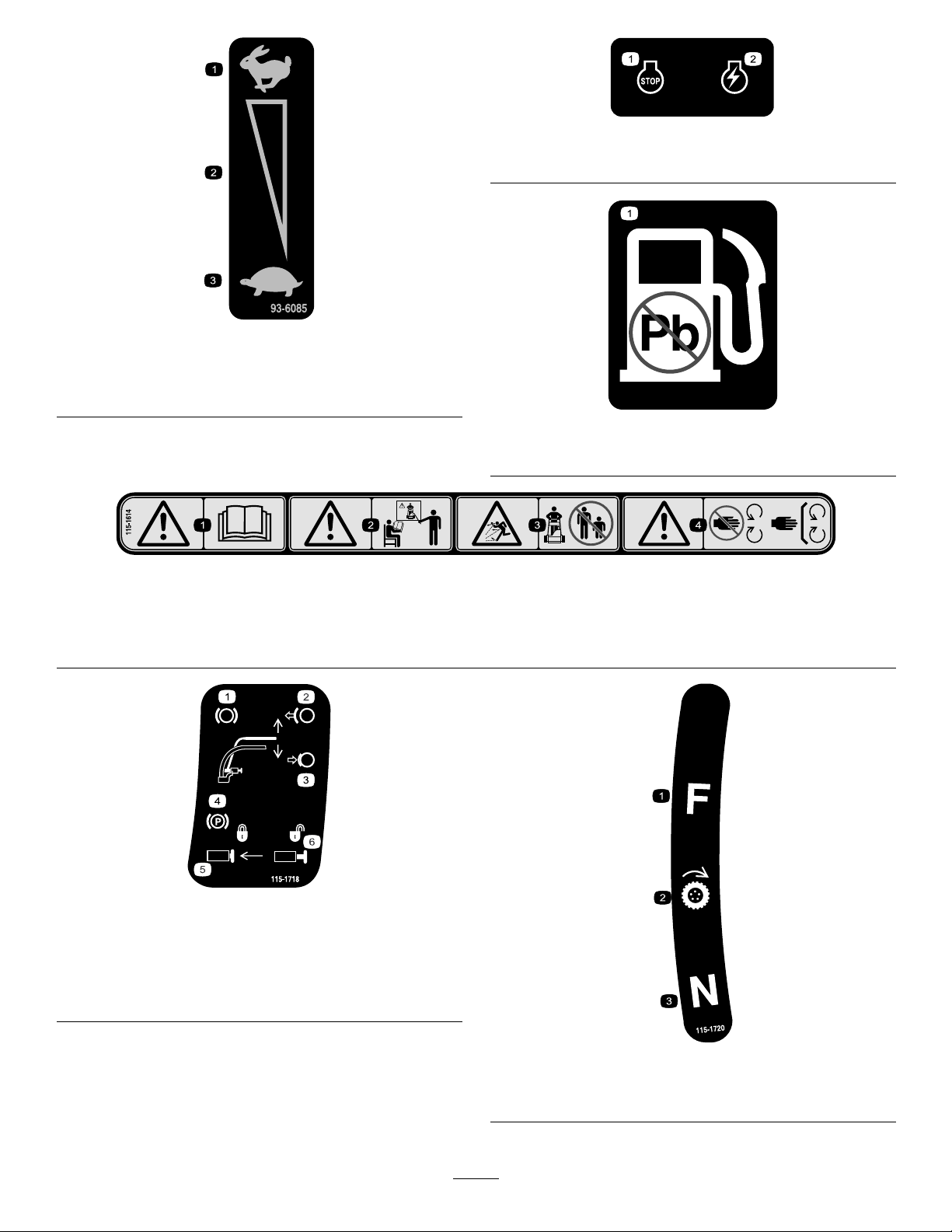

112-9408

1.Engine—stop2.Engine—run

93-6085

1.Fast

2.Continuousvariable

setting

3.Slow

93-9886

1.Useunleadedgasoline.

115-1614

1.Warning—readtheOperator’sManual.3.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethemachineunlessyouaretrained.

themachine.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.

115-1718

1.Brake4.Parkingbrake

2.Releasethehandleto

disengagethebrake

3.Compressthehandleto

engagethebrake

5.Pushintheswitchtolock

theparkingbrake

6.Pullouttheswitchto

unlocktheparkingbrake

115-1720

1.Forward3.Neutral

2.Drivewheel

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Handle1

Cabletie

Lifthandle

Clamp

Locknut8

Kickstandassembly1

Spring

Smallspacer

Largespacer2

Largebolt2

Smallbolt

Locknut2

Washer2

Wheelshaft,right

Wheelshaft,left

Transportwheels(obtainseparately)

Nopartsrequired

Grassbasket

Qty.

2

2

4

2

2

2

1

1

2

–

1Installthegrassbasket.

Installthehandle.

Installthelifthandles.

Installthekickstand(model04037only).

Installthetransportwheels.

Adjustthecuttingunit.

Use

MediaandAdditionalParts

Description

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterial

CerticateofCompliance

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

Use

1

1

1

1

1

Readorviewbeforeoperatingthemachine

9

Page 10

1

InstallingandAdjustingthe

Handle

Partsneededforthisprocedure:

1Handle

2

Cabletie

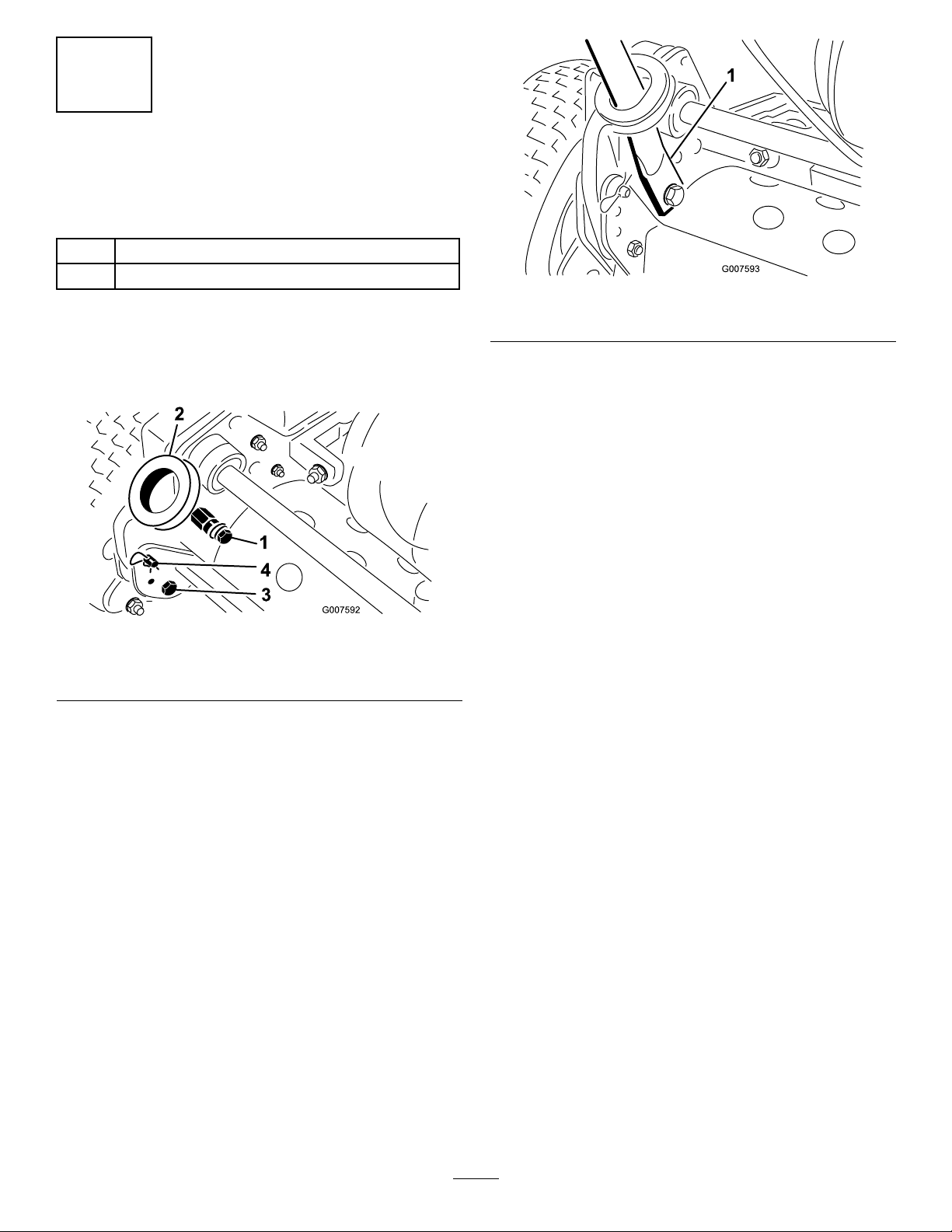

InstallingtheHandle

Figure3

1.Handleend

1.Removethebolt,washer,andlockwasherfromthe

mountingpinoneachsideofthemower(Figure2).

Figure2

1.Mountingpins3.Boltandlocknut

2.Handlearms4.Hairpincotterandringpin

2.Removetheboltsandlocknutssecuringthebottom

ofthehandlearmstoeachsideofthemower

Figure2).

(

3.Removethehairpincottersandringpinssecuring

thehandlearmstotherearoftheframe(Figure2).

6.Securethehandleendstothemountingpinswiththe

bolts,washers,andlockwasherspreviouslyremoved

Figure3).

(

7.Securethebottomofhandlearmstoeachsideof

themowerwiththeboltsandlocknutspreviously

removed(Figure3).Ensurethatyouinstallthe

bushingsinthehandlearmmountingholes.

8.Securethehandlearmstotherearoftheframewith

thehairpincottersandringpinspreviouslyremoved

Figure3).

(

AdjustingtheHandle

1.Removethehairpincottersfromtheringpinson

eachsideofthemower(Figure2).

2.Whilesupportingthehandle,removetheringpins

fromeachsideandraiseorlowerthehandletothe

desiredoperatingposition(

3.Installtheringpinsandhairpincotters.

Figure2).

4.Insertthehandleendsthrutheholesinthehandle

armsandaligntheholeswiththemountingpins

Figure2).

(

5.Squeezethehandleendsinwardandinstallthemon

themountingpins(Figure3).

10

Page 11

2

3

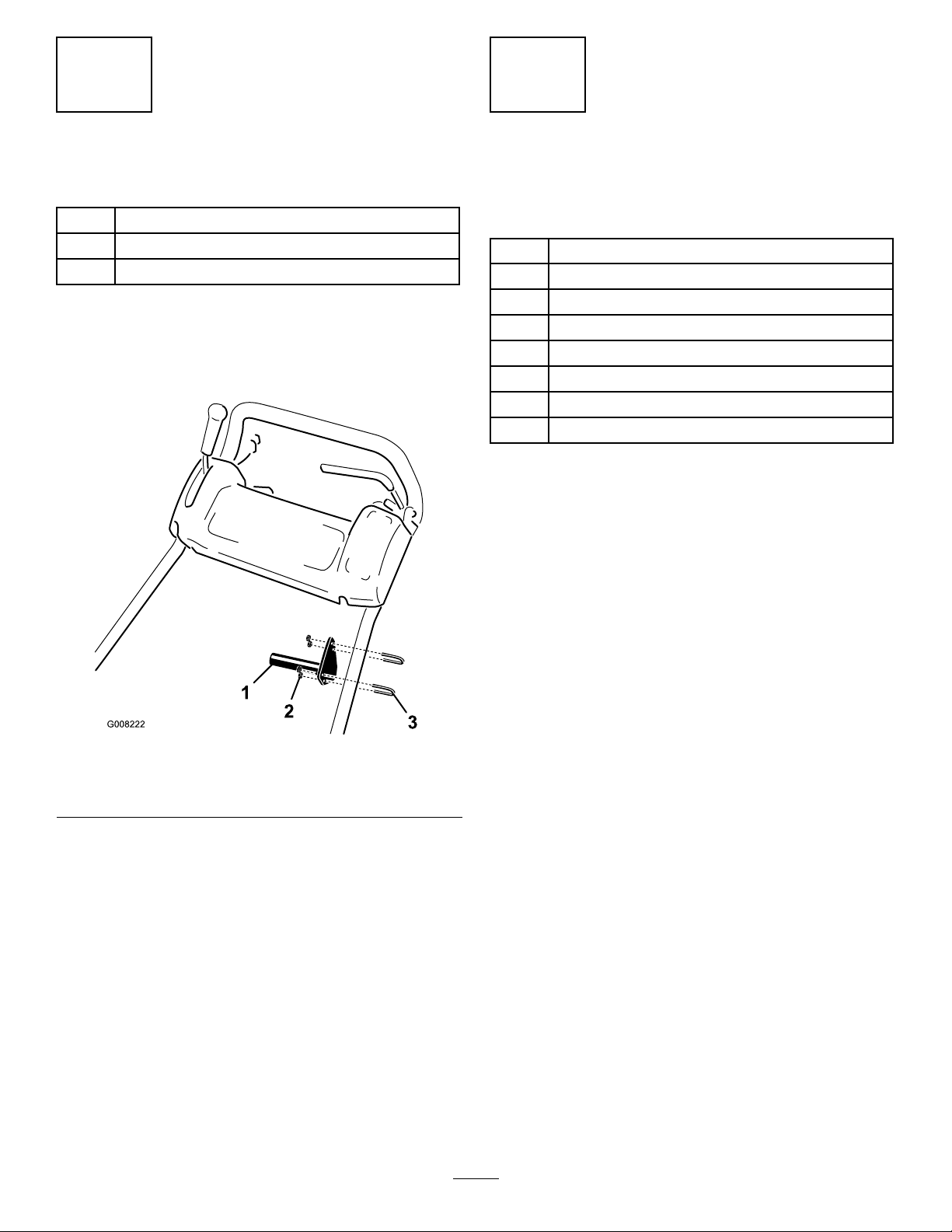

InstalltheLiftHandles

Partsneededforthisprocedure:

2

Lifthandle

4

Clamp

8Locknut

Procedure

1.Looselymountalifthandletoeachsideofthe

handlewith2clampsand4locknuts(Figure4).

InstallingtheKickstand(Model

04037Only)

Partsneededforthisprocedure:

1Kickstandassembly

2

Spring

2

Smallspacer

2Largespacer

2Largebolt

2

Smallbolt

2Locknut

2Washer

Procedure

1.Positionthekickstandbetweenthetabsontherear

oftheframe.

2.Installawasherontothesmallbolt.Installtheright

sideofthekickstandtotheframewiththeboltand

washer,thesmallspacer,andlocknut(

Ensuretheboltisinstalledfromtheinsideofthe

frameasshownin

Figure5.

Figure5).

Figure4

1.Lifthandle3.Clamp

2.Locknut

2.Positionthehandlesabout6inchesbelowthe

controlpanel(Figure4).Tightenthemountingnuts.

Note:Thelifthandlesmayberelocatedfor

operatorcomfort.

3.Securethecontrolcablestothehandle,belowthelift

handles,withcableties.

3.Installawasherontothelargebolt.

4.Installthespacerintothespringandinstallthelarge

boltintothespacer.

Important:Wheninstallingthespring,place

oneendofthespringundertherearframe

Figure5).

(

5.Installtheleftsideofthekickstandtotheframewith

theboltandwasher,thelargespacerandspring,and

locknut(Figure5).Ensuretheboltisinstalledfrom

theinsideoftheframeasshowninFigure5.

11

Page 12

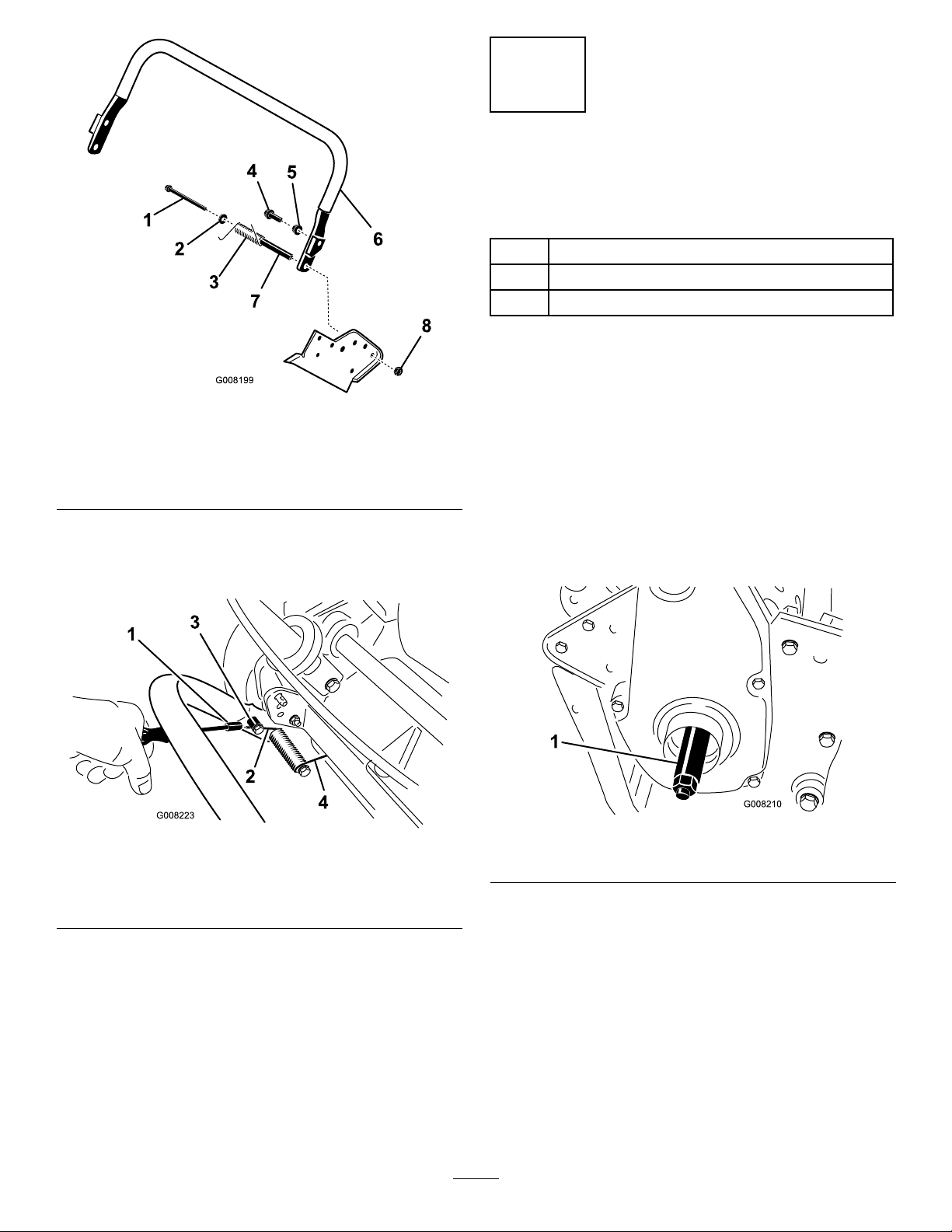

Figure5

1.Largebolt

2.Washer

3.Spring

4.Smallbolt

5.Smallspacer

6.Lefthandleend

7.Largespacer

8.Locknut

6.Placeanutrunnerovertheendofthespringpointing

towardstherearandmovetheendofthespringover

andunderthekickstandspacer(

Figure6).

4

InstallingtheTransport

Wheels

Partsneededforthisprocedure:

1

Wheelshaft,right

1

Wheelshaft,left

2

Transportwheels(obtainseparately)

Procedure

1.Pushthekickstanddownwithyourfootandpull

uponthehandletosupportthemoweronthekick

stand.

2.Apply#242Loctitetothethreadsofthewheel

shafts.

3.Threadtherightwheelshaftintothedrivepulleyon

therightsideofthemachine(

Note:Therightwheelshafthaslefthandthreads.

Figure7).

Figure6

1.Nutrunner3.Movethespringendunder

thekickstandspacer

2.Spring4.Springendunderframe

Figure7

1.Rightwheelshaft

4.Torquetheshaftto65to75ft-lb(88to101N-m).

5.Slidethewheelontotheaxle(Figure8).

6.Pivotthewheellockingclipawayfromcenterof

thewheelallowingittoslidefartherontotheaxle

(Figure8).

12

Page 13

Figure8

1.Lockingclip

7.Rotatewheelbackandforthuntilitslidescompletely

ontoaxleandlockingclipissecuredingrooveon

axleshaft.

6

InstallingtheGrassBasket

Partsneededforthisprocedure:

1

Grassbasket

Procedure

Graspbasketbytoplipandslideitontothebasket

mountingrods(Figure9).

8.Repeatprocedureonoppositesideofmachine.

9.Inatethetiresto12to15psi.(574to718Pa).

5

AdjustingtheCuttingUnit

NoPartsRequired

Procedure

Beforeoperatingthemachine,completethefollowing

adjustments:

•Levelthereardrumtothereel.

•Adjustthebedknifetothereel.

•Adjusttheheight-of-cut.

•Adjustthegrassshieldheight

1.Grassbasket

Figure9

2.Basketmountingrod

•Adjustthecutoffbar.

RefertotheCuttingUnitMaintenancesectionin

Maintenanceforinstructionsonperformingthese

procedures.

13

Page 14

ProductOverview

Controls

Figure10

1.Tractiondrivelever

2.Throttlecontrol5.Parkingbrake

3.On/offswitch

4.Servicebrake

theservicebraketoreleasetheparkingbrake.Youmust

releasethebrakebeforetractiondriveisengaged.

TractionDriveLever

Thetractiondrivelever(Figure10)islocatedonthe

frontrightsideofthecontrolpanel.Ithastwopositions:

NeutralandForward.Pushingtheleverforwardengages

thetractiondrive.

ThrottleControl

Thethrottlecontrol(Figure10)islocatedontopright

sideofthecontrolpanel.Theleverconnectstoand

operatesthrottlelinkagetothecarburetor.Theengine

speedcanbevariedfrom1600to3600RPM.

On/OffSwitch

Theon/offswitch(Figure10)islocatedonthetopof

thecontrolpanel.MoveswitchtotheOnpositionto

starttheengineandtheOffpositiontostoptheengine.

ServiceBrake

Theservicebrake(Figure10)islocatedontopleftside

ofcontrolpanel.Youcanusethebraketosloworstop

themachine.

Figure11

ReelDriveLever

Thereeldrivelever(Figure12)islocatedonthe

rightfrontcornerofthemachine.Theleverhastwo

positions:EngageandDisengage.Pulluponthelever

toengagethereelorpushitdowntodisengagethereel.

ParkingBrake

Theparkingbrake(Figure10&Figure11)islocatedat

thebaseoftheservicebrake.Fullyengagetheservice

brake,pushintheparkingbrakeknobandallowthe

servicebraketorestontheparkingbrakepin.Engage

Figure12

1.Reeldrivelever

14

Page 15

ChokeLever

Specications

Thechokelever(Figure13)islocatedonleftfrontof

theengine.Theleverhastwopositions:RunandChoke.

MovethelevertotheChokepositionwhenstarting

acoldengine.AfterenginestartsmovelevertoRun

position.

Figure13

1.Chokelever2.Fuelshutoffvalve

FuelShut-OffValve

Thefuelshutoffvalve(Figure13)islocatedonleft

frontofengine.Thevalvehastwopositions:Closed

andOpen.Movethelevertotheclosedpositionwhen

storingortransportingmachine.Openthevalvebefore

startingtheengine.

Model04036Model04037

Width

Height

Lengthwithbasket

Dryweight(with

basketandWiehle

roller;without

wheelsorgrooming

reel)

Widthofcut21inches(53cm)26inches(66cm)

Heightofcut1/8to1-1/4inches

Clip0.15inch(3.7mm)0.15inch(3.7mm)

EnginespeedLowidle–1600

36inches(91cm)41inches(104cm)

47inches(1 19cm)41-1/2inches

59inches(150cm)54-1/4inches

208lb(94kg.)229lb(104kg)

(0.3to3.2cm)

±100,Highidle–

3600±100

(105.4cm)

(137.8cm)

1/8to1-1/4inches

(0.3to3.2cm)

Lowidle–1600

±100,Highidle–

3600±100

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

RecoilStarter

Pullrecoilstarterhandle(Figure14)tostartengine.

Figure14

1.Recoilstarter2.Kickstand

Kickstand

Thekickstand(Figure14)ismountedtotherearof

machineandisusedtoraisetherearofmachinefor

installationorremovalofthetransportwheels.

15

Page 16

Operation

g014638

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

CheckingtheEngineOilLevel

Checktheengineoillevelbeforeeachuseorevery8

operatinghours,refertoCheckingtheEngineOilLevel

EngineMaintenance(page22).

in

FillingtheFuelTank

Important:Neverusemethanol,gasoline

containingmethanol,gasoholcontainingmore

than10%ethanol,gasolineadditives,premium

gasoline,orwhitegasbecausethefuelsystem

couldbedamaged.Donotmixoilwithgasoline.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1inch

(2.5cm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

WARNING

Figure15

1.Fueltankcap

1.Cleanaroundfueltankcapandremovecapfrom

tank(Figure15).

2.Usingunleadedgasoline,llfueltanknohigher

thantobottomoflterscreen.Donotoverll.

3.Installfueltankcapandwipeupanyspilledgasoline.

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

16

Page 17

DANGER

StartingandStoppingthe

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

CheckingtheInterlockSwitch

Operation

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

1.Pushthekickstanddownwithyourfootandpull

upandbackonthehandletoraisethewheelsoff

oftheground.

2.PlacetractionleverintoEngagepositionandengine

controlsinstartingposition.

3.Attempttostartengine.

Theengineshouldnotstart.Ifenginestarts,the

interlockswitchneedsservice.Correctproblem

beforeoperating.RefertoServicingInterlock

Switch.

4.Carefullyliftuponhandletoreleasekickstand.

Engine

Note:Forillustrationsanddescriptionsofthecontrols

referencedinthissection,refertotheControlssection

inProductOverview.

StartingtheEngine

Note:Ensurethatthesparkplugwireisinstalledon

thesparkplug.

1.Ensurethatthetractionandreeldriveleversarein

theDisengagedposition.

Note:Theenginewillnotstartifthetractionlever

isintheEngagedposition.

2.Openthefuelshutoffvalveontheengine.

3.Movetheon/offswitchtotheOnposition.

4.MovethethrottlecontroltotheFastposition.

5.MovethechokeleverhalfwaybetweentheOnand

Offpositionswhenstartingacoldengine.The

chokemaynotberequiredwhenstartingawarm

engine.

6.Pulltherecoilstarterhandleoutuntilpositive

engagementresults,thenpullitvigorouslytostart

theengine.

Important:Donotpullrecoilropetoitslimit

orletgoofstarterhandlewhenropeispulled

outbecauseropemaybreakorrecoilassembly

maybedamaged.

7.MovethechoketotheOffpositionastheengine

warmsup.

StoppingtheEngine

1.Movethetractionandreeldrivecontrolstothe

Disengagedposition,thethrottlecontroltothe

Slowposition,andtheOn/OffswitchtotheOff

position.

2.Pullthesparkplugwireoffofthesparkplugto

preventthepossibilityofaccidentalstartingbefore

storingthemachine.

3.Closethefuelshutoffvalvebeforestoringor

transportingthemowerinavehicle.

DrivingtheMachinein

Transport

1.Pushthekickstanddownwithyourfootandpull

uponthehandletoraisetherearofmowerand

installthetransportwheels.

17

Page 18

2.Toreleasethekickstand,pulluponthehandle,

pushthemowerforward,andthenlowertherearof

mowerontothetransportwheels.

3.Ensurethatthetractionandreeldrivecontrolsare

intheDisengagedpositionandstarttheengine.

position,stoptheengineandpushthereeldrive

leverintotheDisengageposition.

5.Emptythegrassbasketofclippings,installthegrass

basket,andcommencetransportoperation.

4.SetthethrottlecontroltoSlow ,raisethefrontofthe

machineupslightly,graduallyengagethetraction

driveandslowlyincreasetheenginespeed.

5.Adjustthethrottletooperatethemoweratthe

desiredgroundspeedandtransportthemowerto

thedesireddestination.

PreparingtoMow

1.ReturnthetractioncontrollevertotheDisengage

position,thethrottletotheSlowposition,andstop

theengine.

2.Pushthekickstanddownwithyourfootandpull

upandbackonthehandletoraisethewheelsoff

oftheground.

3.Pushthelockingclipsonthewheelsoutofthe

groovesintheshafts.

4.Slidethewheelsoffoftheshafts.

5.Movetheunitoffofthekickstand.

OperatingTips

BeforeMowing

•Ensurethatthemoweriscarefullyadjustedand

issetevenlyonbothsidesofthereel.Improper

moweradjustmentismagniedmanytimesoverin

theappearanceoftheclippedturf.

•Removeallforeignobjectsfromtheturfpriorto

mowing.

•Ensurethateveryone,especiallychildrenandpets,

areclearoftheworkarea.

MowingT echniques

•Mowagreeninastraightbackandforthdirection,

acrossthegreen.

•Avoidcircularmowingorturningthemowerona

greenbecausescufngmayoccur.Turnthemower

offofthegreenbyraisingthecuttingreel(pushing

thehandledown)andturningonthetractiondrum.

Mowing

Properuseofthemachineprovidesthesmoothest

turfcuttingavailable.ReferalsotoOperatingTips

forfundamentalsuggestionstoobtaintheutmost

performancefromyourmower.

Important:Excessiveoperationofthecuttingunit

withtheabsenceofgrassclippings(lubricant)can

damagethecuttingunit.

1.Starttheengine,setthethrottleatreducedspeed,

pushdownonthehandletoraisethecuttingunit,

movethetractionlevertotheEngagedposition,

andtransportthemowerontocollarofthegreen.

2.MovethetractionlevertotheDisengagedposition

andmovethereeldrivelevertotheEngaged

position.

3.MovethetractionlevertotheEngagedposition,

increasethethrottlespeeduntilthemoweris

travelingatthedesiredgroundspeed,drivethe

mowerontothegreen,lowerthefrontofthe

mower,andcommenceoperation.

•Mowatanormalwalkingpace.Fastspeedsaves

verylittletimeandwillresultinaninferiormowing

job.

4.Whennishedmowing,driveoffofthegreen,

movethetractioncontrollevertotheDisengage

18

Page 19

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every200hours

Every300hours

Beforestorage

Important:Refertoyour

MaintenanceProcedure

•Changetheengineoil.

•Cleanthefuellter.

•Checktheinterlockswitchoperation.

•Checktheengineoillevel.

•Greasethemachine.(Greasethettingsimmediatelyaftereverywashingregardless

oftheintervallisted.)

•Cleanandoiltheaircleanerfoamelement.(Moreoftenindirtyordustyconditions)

•Changetheengineoil.(Morefrequentlyindustyordirtyconditions)

•Cleanthefuellter.

•Cleanorreplacethepaperairlterelement.(Moreoftenindirtyordustyconditions)

•Checkthesparkplug.

•Decarbontheengine.

•Changetheairlterpaperelement

•Checktheconditionandtensionofbelts.

•Paintchippedsurfaces.

•RefertoStorageSectionforadditionalinformation

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

19

Page 20

DailyMaintenanceChecklist

Important:Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation.

Checktheparking

brakeoperation.

Checkthefuel

level.

Checktheengine

oillevel.

Checktheair

lter.

Cleantheengine

coolingns.

Checkforunusual

enginenoises.

Checkforunusual

operatingnoises.

Checkthe

reel-to-bedknife

adjustment.

Checkthe

height-of-cut

adjustment.

Greaseallttings.

Touchup

damagedpaint.

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

20

Page 21

Lubrication

GreasingtheMachine

ServiceInterval:Every25hours

Lubricatethe13greasettingsonthemowerusing

aNo.2multipurposelithiumbasegrease.Ahand

operatedgreasegunisrecommendedforbestresults.

Thegreasettinglocationsareasfollows:

•2onthefrontroller(Figure16)

•2onthereelbearings(Figure16)

•2onthedrumaxles(Figure17)

•3onthedifferential(

•2onthereelcountershaftbearings(Figure18)

•2onthebeltidlerpivots(Figure19).

1.Wipeeachgreasettingwithacleanrag.

2.Pumpgreaseintoeachttinguntilitbeginstoget

difculttopumpthegun.

Important:Donotapplytoomuchpressureor

greasesealswillbecomepermanentlydamaged.

3.Wipeoffexcessgrease.

Figure17)

Figure18

Figure19

Figure16

Figure17

21

Page 22

EngineMaintenance

ServicingtheEngineOil

ServiceInterval:Aftertherst8hours—Changethe

engineoil.

Beforeeachuseordaily—Checkthe

engineoillevel.

Every50hours—Changetheengine

oil.(Morefrequentlyindustyordirty

conditions)

Crankcasecapacity:20oz.(.59l)

Theengineusesanyhigh-qualityoilhavingtheAmerican

PetroleumInstitute-APl-“serviceclassication"SF,

SG,SHorSJ .Oilviscosity-weight-mustbeselected

accordingtoambienttemperature.illustratesthe

temperature/viscosityrecommendations.

Figure20

Figure21

1.Oillevelgauge

2.Removetheoillevelgaugebyrotatingit

counterclockwise.

3.Wipetheoillevelgaugecleanandinsertitintothe

llerport.Donotscrewitintotheport.

4.Removethegaugeandchecktheleveloftheoil.

5.Ifthelevelislow,addonlyenoughoiltoraisethe

leveluntilitisbetweenthe“H”and“L”markson

thegauge(

Figure22).Donotoverll.

2.Drainplug

Note:Usingmultigradeoils(5W-20,10W-30,and

10W-40)willincreaseoilconsumption.Checktheoil

levelmorefrequentlywhenusingthem.

CheckingtheEngineOilLevel

1.Positionmowersotheengineislevelandclean

aroundoillevelgauge(Figure21).

Figure22

6.Installtheoillevelgaugeandwipeupanyspilledoil.

ChangingtheEngineOil

1.Startandruntheengineforafewminutestowarm

theengineoil.

2.Placeadrainpanattherearofmachine,underthe

drainplug(

3.Removethedrainplug.

22

Figure21).

Page 23

4.Pushdownonthehandletotipthemowerandthe

enginebackward,allowingmoreoiltorunintothe

drainpan.

5.Installthedrainplugandrellthecrankcasewiththe

properoil;refertoCheckingtheEngineOilLevel.

ServicingtheAirCleaner

ServiceInterval:Every25hours—Cleanandoiltheair

cleanerfoamelement.(Moreoftenin

dirtyordustyconditions)

Every100hours—Cleanorreplace

thepaperairlterelement.(More

oftenindirtyordustyconditions)

Every300hours—Changetheair

lterpaperelement

Important:Servicetheaircleanermoreoftenin

dirtyordustyconditions

1.Makesurethewireisoffofthesparkplug.

2.Removethewingnutssecuringtheaircleanercover

andremovethecover(

Figure23).

Figure24

1.Foamelement2.Paperelement

5.Checkconditionofthepaperelement.Cleanby

gentlytappingthelterorreplaceitasrequired.

Important:Donotusecompressedairtoclean

thepaperelement.

6.Installthefoamelement,paperelement,andair

cleanercover.

Important:Donotoperatetheenginewithout

theaircleanerelementbecauseextremeengine

wearanddamagewilllikelyresult.

Figure23

1.Aircleanercover

3.Cleanthecoverthoroughly .

4.Ifthefoamelementisdirty,removeitfromthepaper

element(Figure24)andcleanthoroughly,asfollows:

A.Washthefoamelementinasolutionofliquid

soapandwarmwater.Squeezeittoremovedirt,

butdonottwistitbecausethefoammaytear.

B.Drythefoamelementbywrappingitinaclean

rag.Squeezetheragandfoamelementtodry

it,butdonottwistit.

C.Saturatethefoamelementwithcleanengineoil.

Squeezetheelementtoremoveexcessoiland

todistributetheoilthoroughly.Anoildamp

elementisdesirable.

ReplacingtheSparkPlug

ServiceInterval:Every100hours

UseanNGKBPR5ESsparkplugorequivalent.The

correctairgapis0.028-0.032inch.

1.Pullthemoldedwireoffofthesparkplug(Figure25).

Figure25

1.Sparkplugwire

2.Cleanaroundthesparkplugandremoveitfromthe

cylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotsandblast,scrape,orclean

electrodesbecauseenginedamagecouldresult

fromgritenteringthecylinder.

23

Page 24

3.Settheairgapat0.028to0.032inch(0.05to0.07

cm)(Figure26).

FuelSystem

Maintenance

CleaningtheFuelFilter

ServiceInterval:Aftertherst25hours

Every50hours

Figure26

4.Installthecorrectlygappedsparkplugandtighten

itto17ft.-lb(23N-m).

5.Installthesparkplugwireonthesparkplug.

1.Closethefuelshutoffvalveandunscrewthebowl

fromthelterbody(

1.Shutoffvalve

2.Cleanthebowlandlterincleangasolineandinstall

it.

Figure27).

Figure27

2.Bowl

24

Page 25

ElectricalSystem

Maintenance

BrakeMaintenance

AdjustingtheService/Parking

ServicingtheInterlockSwitch

Usethefollowingprocedureiftheswitchneeds

adjustmentorreplacement.

1.Makesuretheengineisoffandthetractionlever

isdisengagedandrestingagainsttheneutralstop

Figure28).

(

Brake

Ifservice/parkingbrakeslipswhenoperated,an

adjustmentisrequired.

1.Engagetheservicebrake,pushinontheparking

brakeknobandallowtheservicebraketorestonthe

parkingbrakepin(

Figure29).

Figure28

1.Tractionlever3.Interlockswitch

2.Neutralstop

2.Loosentheinterlockswitchmountingfasteners

(Figure28).

3.Placea.032"thickshimbetweenthetractionlever

andtheinterlockswitch(Figure28).

4.Tighteninterlockswitchmountingfasteners.

Recheckgap.Thetractionlevermustnotcontact

theswitch.

5.Engagetractionleverandverifythattheswitchloses

continuity.Replaceifrequired.

4..032"Gap

Figure29

2.Usingaspringscale,pressrearwardontheservice

brakelever(Figure30).Theparkingbrakeshould

releasewhenaforceof30to40poundsisattained.

Iftheparkingbrakereleasesbefore30to40pounds

offorceisattained,anadjustmenttothebrakecable

isrequired.Proceedtostep3.

25

Page 26

Figure30

1.Rearpressureonservicebrakelever

(Bracketatthebaseoftheengineshown)

1.Service/parkingbrake

cable

Figure32

2.Frontjamnut

3.LoosentheretainersecuringtheV-beltcoverand

pivotthecoveropen(Figure31).

Figure31

1.V-beltcover2.Retainer

4.Toadjustthebrakecabletension,proceedasfollows.

•Todecreasethecabletension,loosenthefront

cablejamnutandtightentherearjamnut

Figure32).Repeatstepsoneandtwoand

(

readjustifrequired.

•Toincreasethecabletension,tightenthefront

cablejamnutandloosentherearjamnut

Figure32).Repeatstepsoneandtwoand

(

readjustifrequired.

5.Closethecoverandsecuretheretainer.

Note:Theadjustmentscanbeperformedon

thecableatthejamnutbracketsbythecontrol

paneloratthebracketatthebaseoftheengine.

26

Page 27

BeltMaintenance

Important:Donotovertensionthebelt.

B.Tightenthenuttolocktheadjustment.

AdjustingtheBelts

ServiceInterval:Every300hours—Checkthe

conditionandtensionofbelts.

Ensurethatthebeltsareproperlytensionedtoensure

properoperationofthemachineandunnecessarywear.

Checkbeltsfrequently.

AdjustingtheReelDriveBelt

1.Removethebeltcovermountingfastenersandbelt

covertoexposethebelt(

Figure33).

4.Installthebeltcoverbyplacingitinposition.

5.Whilemaintainingaslightgapbetweenthecover

sealandthesideplate,installeachmountingbolt

untilthethreadsengageintheinsert.Thegapallows

visualalignmentoftheboltstothethreadedinserts.

6.Afterallboltsareinstalled,tightenthemuntilthe

standoffsinsidethecovercontactthesideplate.Do

notovertighten.

AdjustingtheTractionDriveBelt

1.Removethebeltcovermountingfastenersandthe

beltcovertoexposethebelt(Figure35).

Figure33

1.Beltcover

2.Checkthetensionbypressingthebeltatmidspan

ofthepulleys(Figure34)with4to5lbofforce.The

beltshoulddeect1/4inch.

Figure34

1.Reeldrivebelt2.Idlerpulley

3.Completethefollowingtoadjustthebelttension:

Figure35

1.Tractiondrivebeltcover

2.Checkthetensionbypressingthebeltatmidspan

ofthepulleys(Figure36)with4to5lbofforce.The

beltshoulddeect1/4inch.

Figure36

1.Tractiondrivebelt2.Idlerpulley

A.Loosentheidlerpulleymountingnutandpivot

theidlerpulleydownwardagainstthebacksideof

thebeltuntilyouattainthedesiredbelttension

(Figure34).

3.Completethefollowingtoadjustthebelttension:

A.Loosentheidlerpulleymountingnutandpivot

theidlerpulleyclockwiseagainstthebacksideof

27

Page 28

thebeltuntilthedesiredbelttensionisattained

(Figure36).

Important:Donotovertensionthebelt.

B.Tightenthenuttolocktheadjustment.

4.Installthebeltcoverbyplacingitinposition.

5.Whilemaintainingaslightgapbetweenthecover

sealandthesideplate,installeachmountingbolt

untilthethreadsengageintheinsert.Thegapallows

visualalignmentoftheboltstothethreadedinserts.

6.Afterallboltsareinstalled,tightenthemuntilthe

stand-offsinsidethecovercontactthesideplate.Do

notovertighten.

AdjustingtheDifferentialBelt

1.Removetheboltssecuringthefrontandrearsections

ofthedifferentialcovertothedifferentialhousing

andslidethecoversectionsawaytoexposethebelt.

2.Checkthetensionbypressingthebeltatmidspan

ofthepulleys(Figure37)with5to6lbofforce.The

beltshoulddeect1/4inch.

AdjustingthePrimaryV-Belts

1.ToadjustthebelttensiononprimaryV-belts,rst

checktheadjustmentofthetractioncontrol.Refer

toAdjustingtheTractionControl.Ifunabletoattain

the4to5lbforcerequiredinadjustingthetraction

control,proceedtonextstep.

2.LoosentheretainersecuringtheV-beltcoverand

pivotthecoveropen(

1.V-beltcover2.Retainer

Figure38).

Figure38

Figure37

1.Differentialbelt

2.Idlerpulley

3.Completethefollowingtoadjustthebelttension:

A.Loosentheidlerpulleymountingnutandpivot

theidlerpulleyclockwiseagainstthebacksideof

thebeltuntilthedesiredbelttensionisattained

Figure37).

(

Important:Donotovertensionthebelt.

B.Tightenthenuttolocktheadjustment.

4.Installthebeltcoverbyplacingitinposition.

5.Whilemaintainingaslightgapbetweenthecover

sealandthesideplate,installeachmountingbolt

untilthethreadsengageintheinsert.Thegapallows

visualalignmentoftheboltstothethreadedinserts.

6.Afterallboltsareinstalled,tightenthemuntilthe

stand-offsinsidethecovercontactthesideplate.Do

notovertighten.

3.Toincreasebelttension,loosentheenginemounting

boltsandmoveenginebackwardsintheslots.

Important:Donotovertensionthebelt.

4.Tightenthemountingbolts.

Note:Thedistancebetweenthecentersofthe

driverandthedrivenpulleysshouldbeapproximately

5.18inches(13.15cm)afternewV-beltsareinstalled.

5.AftertensioningtheprimaryV-belts,checkthe

alignmentoftheengineoutputshaftpulleyandthe

countershaftpulleywithastraightedge.

6.Ifthepulleysaremisaligned,loosenthescrews

securingtheenginemountingbasetothemower

frameandslidetheenginefromsidetosideuntilthe

pulleysarealignedwithin0.030inch(0.07cm).

28

Page 29

Figure39

1.PrimaryV-belts3.Idlerpulley

2.Beltguide

1.Differentialcoversections

2.Frontclutchhousing

Figure40

3.Rightrearbearinghousing

7.Tightenthemountingscrewsandcheckthe

alignment.

8.Topushorpullthemachineeasierwithoutstarting

theengine,adjustthebeltguide(Figure39,inset)

asfollows:

A.Engagetheclutch.

B.Loosenthenutsecuringtheidlerpulleyandbelt

guidetotheidlerarm.

C.Rotatethebeltguideclockwiseuntilagapof

approximately0.06inch(0.15cm)isobtained

betweentheguidengerandthebacksideofthe

drivebelts.

D.Tightentheboltandlocknutsecuringtheidler

pulleyandbeltguidetotheidlerarm.

9.Closethecoverandsecuretheretainer.

ReplacingtheDifferentialBelt

1.Removetheboltssecuringthetractiondriveandreel

drivebeltcoverstotherightsideplateandremove

thebeltcovers.

5.Loosentheidlerpulleymountingnutonthe

differentialidlerpulleyandpivottheidlerpulley

counterclockwiseawayfromthebacksideofthebelt

toreleasethebelttension.

6.Removethe2boltsandlocknutssecuringthefront

clutchhousingtothesideplate(

Figure40).

7.Rotatethehousing180°sothebottomofthe

housingpointsupward.

8.Removethe2boltsandlocknutssecuringtheright

rearbearinghousingtothesideplate(

Figure40).

9.Rotatethehousing180°sothebottomofthe

housingpointsupward.Removeoldbelt.

10.Slidethenewbeltovertherotatedhousingcovers,

thedifferentialcoversections,andontothe

differentialpulleys.

11.Ensurethattheidlerpulleyispositionedagainstthe

backsideofbelt.

12.Rotatebothhousingsbackintotheuprightposition

andsecurethemtothesideplatewiththeboltsand

nutspreviouslyremoved.

2.Loosentheidlerpulleymountingnut,oneachidler

pulley,andpivoteachidlerpulleycounterclockwise

awayfromthebacksideofeachbelttoreleasebelt

tension.

3.Removethebelts.

4.Removetheboltssecuringthefrontandrearsections

ofthedifferentialcovertothedifferentialhousing

andslidethecoversectionsawaytoexposethebelt

(Figure40).

13.Adjustthedifferentialbelttension;refertoAdjusting

theDifferentialBelt.

14.Adjustthebelttensiononthetractiondriveandreel

drivebelts;refertoAdjustingtheTractionDrive

Belt,andAdjustingtheReelDriveBelt

15.Installthedifferential,tractiondrive,andreeldrive

covers.

29

Page 30

ControlsSystem

Maintenance

CuttingUnitMaintenance

LevelingtheRearDrumtothe

AdjustingtheTractionControl

Iftractioncontroldoesnotengageoritslipsduring

operation,anadjustmentisrequired.

1.MovethetractioncontroltotheDisengaged

position.

2.LoosentheretainersecuringtheV-beltcoverand

pivotthecoveropen(

3.Toincreasethecabletension,loosenthefront

cablejamnutandtightenthebackcablejamnut

(Figure41)untilaforceof7to9lbisrequiredto

engagethetractioncontrol.Measuretheforceatthe

controlknob.

Figure38).

Reel

1.Positionthemachineonaat,levelsurface,

preferablyaprecisionsteelworkplate.

2.Placea1/4x1inch(0.6x2.5cm)atsteelstrip,

approximately29inches(73.6cm)long,underthe

reelbladesandagainstthefrontedgeofthebedknife

topreventthebedbarfromrestingonthework

surface.

3.Raisethefrontrollersoonlythereardrumandreel

areonthesurface.

4.Firmlypressdownonthemachineabovethereelso

allreelbladescontactthesteelstrip.

5.Whilepressingdownonthereel,slideafeelergauge

underoneendofthedrum,thenchecktheother

endofthedrum.

Ifthereisagapbetweenthedrumandthework

surface,greaterthan0.010inch(.025cm),oneither

end,adjustthedrum(proceedtostep6).Ifthegap

islessthan0.010inch(.025cm)noadjustmentis

required.

Figure41

1.Tractioncable2.Frontjamnut

4.Tightenfrontcablejamnut.

5.Closethecoverandsecuretheretainer.

6.Checkthetractioncontroloperation.

6.Removetherearbeltcoverfromtherightsideof

themachine(

1.Tractiondrivebeltcover

7.Rotatethedrivenpulleyuntiltheholesalignwiththe

4rollerbearingangescrews(Figure43).

Figure42).

Figure42

30

Page 31

Figure43

1.Drivenpulley3.IdlerPulley

2.4holes

8.Loosenthe4rollerbearingscrewsandthescrew

securingtheidlerpulley .

9.Raiseorlowertherightsideoftherollerassembly

untilthegapislessthan0.010inch(.025cm).

10.Tightentherollerbearingscrews.

11.Adjustthebelttensionandtightentheidlerpulley

mountingscrew(Figure43).

AdjustingtheBedknifetothe

Reel

Thebedknifetoreeladjustmentisaccomplishedby

looseningortighteningthebedbaradjustingscrews,

locatedontopofthemower.

1.Positionthemachineonaat,levelworksurface.

2.Ensurethatthereelcontactisremovedbyturning

thebedbaradjustingscrewscounterclockwise

(Figure44).

sameendofreel,oneclickatatime,untilthepaper

ispinchedlightly,wheninsertedfromthefront,

paralleltothebedknife,whichresultsinaslightdrag

whenpaperispulled(

Note:Eachtimetheadjustingscrewisrotatedone

clickclockwise,thebedknifemoves0.0007inch

(0.0017cm)closertothereel.Donotovertighten

theadjustingscrews.

5.Checkforlightcontactattheotherendofthereel

usingpaperandadjustitasrequired.

6.Aftertheadjustmentisaccomplished,checktosee

ifthereelcanpinchpaperwheninsertedfromthe

frontandcutpaperwheninsertedatarightangleto

thebedknife(

paperwithminimumcontactbetweenthebedknife

andthereelblades.Shouldexcessivereeldragbe

evident(morethan7inch-lb(0.79N•m),either

backlaporgrindthecuttingunittoachievethesharp

edgesneededforprecisioncutting;refertotheToro

reelsharpeningmanual.

Figure45).Itshouldbepossibletocut

Figure44)

Figure45

AdjustingtheHeightofCut

Figure44

1.Bedbaradjustingscrew

3.Tiltthemowerbackonthehandletoexposethe

bedknifeandreel.

4.Ononeendofthefrontsideofthereel,insertalong

stripofnewspaperbetweenthereelandbedknife

(Figure45).Whileslowlyrotatingthereelforward,

turnthebedbaradjustingscrewclockwise(onthe

1.Verifythattherearrollerislevelandthatthe

bedknifetoreelcontactiscorrect.Tipthemower

backonthehandletoexposethefrontandrear

rollersandthebedknife.

2.Loosenthelocknutssecuringtheheight-of-cutarms

totheheight-of-cutbrackets(Figure46).

31

Page 32

Figure46

1.Height-of-cutarm

2.Height-of-cutbracket

3.Locknut

4.Adjustingscrew

3.Loosenthenutonthegaugebar(Figure47)andset

theadjustingscrewtothedesiredheight-of-cut.The

distancebetweenthebottomofthescrewheadand

thefaceofthebaristheheight-of-cut.

ensurestheheight-of-cutisidenticalatboth

endsofthebedknife.

7.Tightennutstolocktheadjustment.

Important:T oavoidscalpingonundulating

turf,ensurethattherollersupportsare

positionedrearward(therollerclosertothereel).

Note:Thefrontrollercanbeputinthreedifferent

positions(

Figure49),dependingontheapplication

andneedsoftheuser.

•Usethefrontpositionwhenagroomeris

installed.

•Usethemiddlepositionwithoutagroomer.

•Usethethirdpositioninextremelyundulating

turfconditions.

Figure47

1.Gaugebar

2.Heightadjustingscrew

3.Nut

4.Hookthescrewheadonthecuttingedgeofthe

bedknifeandresttherearendofthebarontherear

roller(

Figure48).

Figure48

5.Rotatetheadjustingscrewuntiltherollercontacts

thefrontofthegaugebar.

6.Adjustbothendsoftherolleruntiltheentireroller

isparalleltothebedknife.

Figure49

AdjustingtheGrassShield

Height

Adjusttheshieldtoensurepropergrassclipping

dischargeintothebasket.

1.Measurethedistancefromtopofthefrontsupport

rodtothefrontlipoftheshieldateachendofthe

cuttingunit(Figure50).

Figure50

1.Supportrod2.Shield

Important:Whensetproperly,therearand

frontrollerswillcontactthegaugebarandthe

screwwillbesnugagainstthebedknife.This

2.Theheightoftheshieldfromthesupportrodfor

normalcuttingconditionsshouldbe4inches(10

cm).Loosentheboltsandnutssecuringeachendof

32

Page 33

theshieldtothesideplateandadjusttheshieldto

thecorrectheight.

3.Tightenthefasteners.

Note:Theshieldcanbeloweredfordrier

conditions(clippingsyovertopofbasket)orraised

toallowforheavywetgrassconditions(clippings

builduponrearofbasket).

AdjustingtheCut-OffBar

Adjustthecut-offbartoensurethattheclippingsare

cleanlydischargedfromthereelarea.

BedbarIdentication

Todetermineifthebedbarisstandardoraggressive,

checktheleftbedbarmountingears.Ifthemounting

earsareroundeditisastandardbedbar.Ifthemounting

earshaveanotchinthem,itisanaggressivebedbar

(Figure52).

1.Loosenthescrewssecuringthetopbar(

Figure51)

tocuttingunit.

Figure51

1.Cut-offbar

2.Inserta0.060inch(0.15cm)feelergaugebetween

thetopofthereelandthebarandtightenthescrews.

3.Ensurethatthebarandreelareequaldistanceapart

acrosstheentirereel.

Note:Thebarisadjustabletocompensatefor

changesinturfconditions.Adjustthebarcloserto

thereelwhentheturfisextremelywet.Bycontrast,

adjustthebarfurtherawayfromthereelwhenturf

conditionsaredry.Thebarshouldbeparalleltothe

reeltoensureoptimumperformance.Adjustthebar

whenevertheshieldheightisadjustedorwhenthe

reelissharpenedonareelgrinder.

1.Standardbedbar

Figure52

2.Aggressivebedbar

33

Page 34

SettingtheMachinetoMatch

TurfConditions

Usethefollowingtabletosetthemachinetomatch

turfconditions.

GreensmowerCuttingUnitSetUpMatrix

Bedbars:StandardandOptional

PartNumberDescriptionMowerAggressiveness

112-9281-01

112-9279-03Aggressive

112-9280-01

110-9278-03Aggressive

Bedknives:StandardandOptional

PartNumberDescriptionMower

93-4262Microcut

93-4263T ournament

93-4264

112-9275Microcut

94-5885T ournament

104-2646

StandardGreensmaster2000

Greensmaster2000

StandardGreensmaster2600

Greensmaster2600

Greensmaster2000

Greensmaster2000

LowCutGreensmaster2000

Greensmaster2600

Greensmaster2600

HighCutGreensmaster2600

Less

More

Less

More

HeightofCutRangeComments

<0.125inches

0.125-0.25inches

0.25inchesandup

<0.125inches

0.125-0.25inches

0.25inchesandupTees

Comments

StandardGreensmaster2000

StandardGreensmaster2600

StandardGreensmaster2000

StandardGreensmaster2600

93-9015

Rollers:StandardandOptional

PartNumberDescriptionMower

99-6241NarrowWiehle

88-6790WideWiehle

104-2642FullRoller

71-1550WiehleRoller

93-9045WiehleRoller

52-3590

93-9039NarrowWiehle

95-0930FullRoller

ClipKit

PartNumberDescriptionMower

65–9000

LowCutGreensmaster2600

SwagedRollerGreensmaster2000

ClipKitGreensmaster2000

0.25inchesandup

Diameter/MaterialComments

Greensmaster2000

Greensmaster2000

Greensmaster20002.0"Steel

Greensmaster20002.0inchesCastIron

Greensmaster2000

Greensmaster2600

Greensmaster26002.5inchesSteel

&Greensmaster

2600

2.0inchesAluminum

2.0inchesAluminumMorePenetration,0.43

2.5inchesAluminum

2.5inchesAluminum

2.5inchesAluminum

Standard,0.2Spacing

Spacing

LeastPenetration

MorePenetration,0.43

Spacing

24inchesWideforEdge

Support

Standard

LeastPenetration

Comments

Decreaseclipto0.25"

34

Page 35

ServicingtheBedbar

BacklappingtheReel

RemovingtheBedbar

1.Turnbedbaradjusterscrew,counterclockwise,to

backbedknifeawayfromreel(Figure53).

Figure53

1.Bedbaradjustingscrew3.Bedbar

2.Springtensionnut

2.Backoutthespringtensionnut,untilthewasheris

nolongertensionedagainstthebedbar(Figure53).

3.Oneachsideofthemachine,loosenthejamnut

securingthebedbarbolt(Figure54).

1.Removetheplugintherightreeldrivecover

(Figure55).

Figure55

1.Coverplug

2.Inserta1/2inchsocketextension,connectedtothe

backlappingmachine,intothesquareholeinthe

centerofthereelpulley .

3.BacklapaccordingtotheprocedureintheToro

SharpeningReelandRotaryMowersManual,FormNo.

80-300PT .

Figure54

1.Jamnut2.Bedbarbolt

4.Removeeachbedbarboltallowingthebedbartobe

pulleddownwardandremovedfromthemachine.

Savethe2nylonand2stampedsteelwasherson

eachendofbedbar(

Figure54).

InstallingtheBedbar

1.Installthebedbar,positioningthemountingears

betweenthewasherandthebedbaradjuster.

2.Securethebedbartoeachsideplatewiththebedbar

bolts(jamnutsonthebolts)and8washers.Position

anylonwasheroneachsideofthesideplateboss.

Placeasteelwasheroutsideeachofthenylon

washers.

3.Torqueboltsto240to320inch-lb(27to36N-m).

4.Tightenthejamnutsuntilthethrustwashersjust

rotatefreely .

5.Tightenthespringtensionnutuntilthespringis

collapsed,thenbackitoff1/2turn.

6.Adjustthebedbar;refertoAdjustingtheBedknife

totheReel.

DANGER

Contactwiththereelorothermovingpartscan

resultinpersonalinjury.

•Stayawayfromthereelwhilebacklapping.

•Neveruseashorthandledpaintbrushfor

backlapping.PartNo.29-9100Handle

assemblycompleteorindividualpartsare

availablefromyourlocalAuthorizedT oro

Distributor.

Note:Forabettercuttingedge,runaleacross

thefrontfaceofthebedknifewhenthelapping

operationiscompleted.Thiswillremoveanyburrs

orroughedgesthatmayhavebuiltuponthecutting

edge.

4.Installthepluginthecoverwhennished.

35

Page 36

Storage

1.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheentiremachine,especiallythe

engine.Cleandirtandchafffromtheoutsideofthe

engine’scylinderheadnsandblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressurewash

themachine.Avoidexcessiveuseofwater,

especiallyneartheshiftleverplate,andengine.

2.Forlong-termstorage(morethan90days)add

stabilizer/conditioneradditivetofuelinthetank.

A.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

B.Eitherstopengine,allowittocool,anddrainthe

fueltank,oroperatetheengineuntilitstops.

C.Restarttheengineandrunituntilitstops.

Repeat,onChoke,untiltheenginewillnot

restart.

D.Disposeoffuelproperly.Recycleasperlocal

codes.

Note:Donotstorestabilizer/conditioned

gasolineover90days.

3.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanypartthatisdamagedordefective.

4.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

5.Storethemachineinaclean,drygarageorstorage

area.Coverthemachinetoprotectitandkeepit

clean.

36

Page 37

Notes:

37

Page 38

Notes:

38

Page 39

Notes:

39

Page 40

TheToroT otalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

®

Companyanditsafliate,ToroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator’sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakes

padsandlinings,clutchlinings,blades,reels,bedknives,tines,

sparkplugs,castorwheels,tires,lters,belts,andcertainsprayer

componentssuchasdiaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.Torowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesinthis

productareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementof

ItemsandConditionsNotCoveredlters,coolant,andcompleting

RecommendedMaintenancearesomeofthenormalservicesT oro

productsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.Somestatesdonotallowexclusions

ofincidentalorconsequentialdamages,orlimitationsonhowlongan

impliedwarrantylasts,sotheaboveexclusionsandlimitationsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementprintedinyourOperator’sManual

orcontainedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

374-0253RevA

Loading...

Loading...