Page 1

Form No. 3356-378 Rev A

Greensmaster® Flex 18 or Flex

21 Walk-Behind Mower

Model No. 04018 (Traction Unit) —Serial No. 270000001

and Up

Model No. 04206 (Cutting Unit) —Serial No. 270000001 and

Up

Model No. 04022 (Traction Unit) —Serial No. 260000001

and Up

Model No. 04202 (Cutting Unit) —Serial No. 260000001 and

Up

Register your product at www.Toro.com Original Instructions (EN)

Page 2

Warning

Model No.

CALIFORNIA

Pr oposition 65 W ar ning

T he engine exhaust fr om this pr oduct

contains chemicals kno wn to the State of

Calif or nia to cause cancer , bir th defects, or

other r epr oducti v e har m.

T his spark ignition system complies with Canadian

ICES-002

Introduction

R ead this infor mation carefully to lear n ho w to

operate and maintain y our product properly and

to a v oid injur y and product damag e . Y ou are

responsible for operating the product properly

and safely .

Y ou ma y contact T oro directly at www .T oro .com

for product and accessor y infor mation, help

finding a dealer , or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts ,

or additional infor mation, contact an A uthorized

Ser vice Dealer or T oro Customer Ser vice and ha v e

the model and serial n umbers of y our product

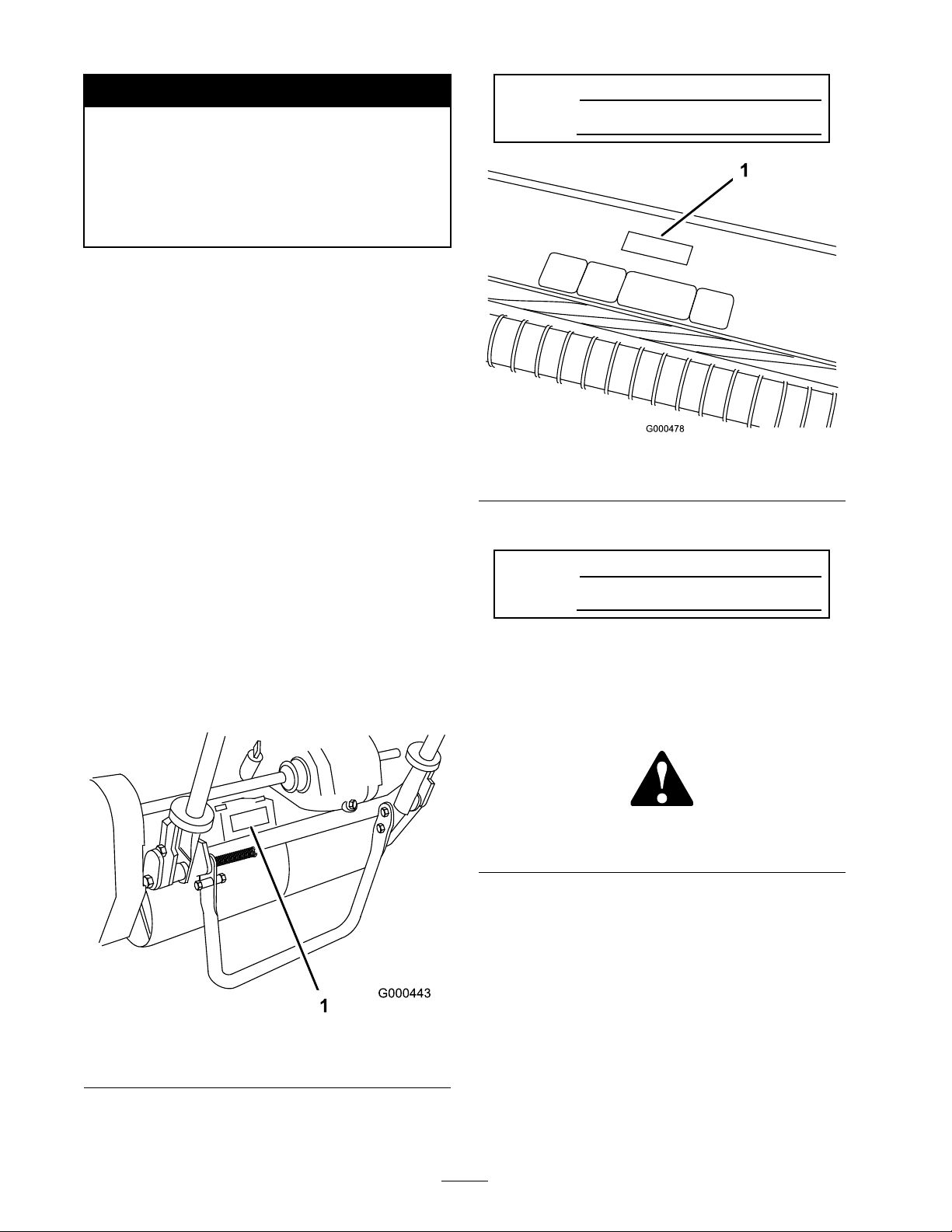

ready . Figure 1 and Figure 2 identify the location

of the model and serial n umbers on the product.

W rite the n umbers in the space pro vided.

Serial No.

Figure 2

1. Location of the model and serial numbers-Cutting Unit

Cutting unit:

Model No.

Serial No.

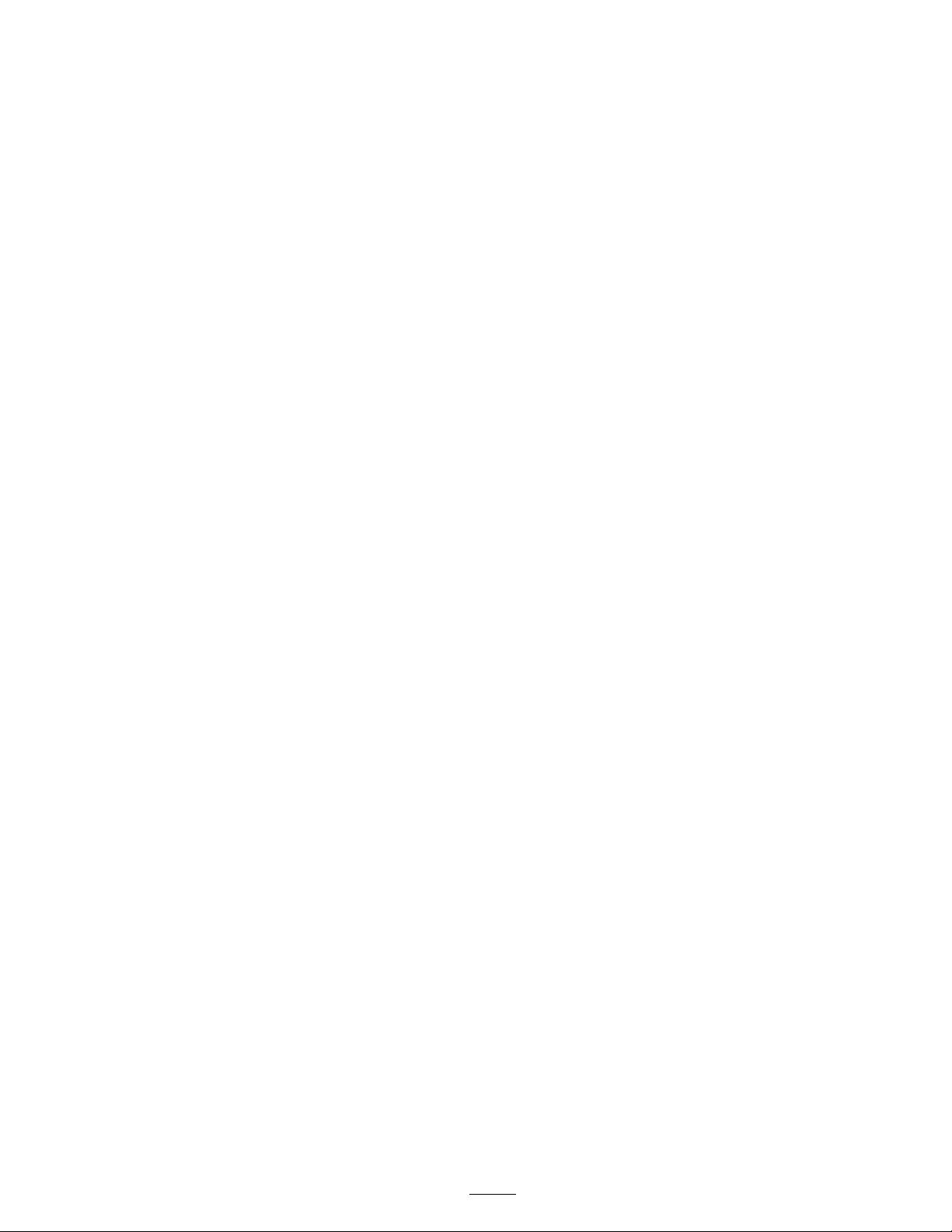

T his man ual identifies potential hazards and has

safety messag es identified b y the safety aler t

symbol ( Figure 3 ), whic h signals a hazard that ma y

cause serious injur y or death if y ou do not follo w

the recommended precautions .

Figure 1

1. Location of the model and serial numbers-Traction unit

T raction unit:

© 2006—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Figure 3

1. Safety alert symbol.

T his man ual uses tw o other w ords to highlight

infor mation. Impor tant calls attention to special

mec hanical infor mation and Note emphasizes

g eneral infor mation w or th y of special attention.

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safe Operating Practices . . . . . . . . . . . . . . . . . . . . . . 4

T oro Mo w er Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Contact us at www.Toro.com.

2

Printed in the USA.

All Rights Reserved

Page 3

Sound Pressure for a Flex 18 . . . . . . . . . . . . . . . . 7

Sound P o w er for a Flex 18 . . . . . . . . . . . . . . . . . . . . 7

Vibration for a Flex 18 . . . . . . . . . . . . . . . . . . . . . . . . . 7

Sound Pressure for a Flex 21 . . . . . . . . . . . . . . . . 7

Sound P o w er for a Flex 21 . . . . . . . . . . . . . . . . . . . . 7

Vibration for a Flex 21 . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety and Instr uctional Decals . . . . . . . . . . . . 8

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1 Installing the Handle . . . . . . . . . . . . . . . . . . . . . . . 10

2 Installing the Kic kstand for Flex

18 Mo w ers Only . . . . . . . . . . . . . . . . 11

3 Adjusting the Handle . . . . . . . . . . . . . . . . . . . . . . 12

4 Installing the T ranspor t

W heels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5 Chec king Fluid Lev els . . . . . . . . . . . . . . . . . . . . . 13

6 Installing the Grass Bask et . . . . . . . . . . . . . . . 13

7 R eading the Man uals and Viewing

the Video . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Product Ov er view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

T hink Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chec king the Engine Oil Lev el . . . . . . . . . . . 18

Filling the Fuel T ank . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chec king the Interloc k Switc h

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Star ting and Stopping the

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

T ranspor t Operation . . . . . . . . . . . . . . . . . . . . . . . . . 20

Pre paring to Mo w . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Mo wing Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

R ecommended Maintenance

Sc hedule(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Daily Maintenance Chec klist . . . . . . . . . . . . . . 23

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Engine Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Ser vicing the Air Cleaner . . . . . . . . . . . . . . . . . . . 24

R e placing the Spark Plug . . . . . . . . . . . . . . . . . . . . 25

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cleaning the Fuel Filter . . . . . . . . . . . . . . . . . . . . . . 26

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . 26

Ser vicing the Interloc k Switc h . . . . . . . . . . . 26

Dri v e System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 27

Chec king the T ransmission Fluid

Lev el . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Changing the T ransmission

Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Brak e Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Adjusting the Ser vice/P arking

Brak e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Belt Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Adjusting the Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Controls System Maintenance . . . . . . . . . . . . . . . . . . . . 31

Adjusting the T raction

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Adjusting the R eel Control . . . . . . . . . . . . . . . . . 31

Cutting Unit Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Se parating the Cutting Unit from

the T raction Unit . . . . . . . . . . . . . . . 32

Adjusting the R ear R oller . . . . . . . . . . . . . . . . . . . 32

Adjusting the Bedknife to the

R eel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Adjusting the Height of Cut . . . . . . . . . . . . . . . 34

Adjusting the Cut-Off Bar . . . . . . . . . . . . . . . . . . 35

Setting the Mac hine to Matc h T urf

Conditions . . . . . . . . . . . . . . . . . . . . . . . . 36

Ser vicing the Bedbar . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Bac klapping the R eel . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Storag e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3

Page 4

Safety

T his mac hine meets or ex ceeds CEN standard

EN 836:1997, ISO standard 5395:1990, and ANSI

B71.4-1999 specifications in effect at the time of

production when the Operator Presence Kit, P ar t

No . 105-5333 is installed.

• T horoughly inspect the area where the

equipment is to be used and remo v e all objects

whic h ma y be thro wn b y the mac hine .

• W ar ning-Fuel is highly flammable . T ak e the

follo wing precautions:

– Store fuel in containers specifically designed

for this pur pose .

Improper use or maintenance b y the operator or

o wner can result in injur y . T o reduce the potential

for injur y , comply with these safety instr uctions

and alw a ys pa y attention to the safety aler t

symbol, whic h means CA UTION , W ARNING , or

D ANGER-“personal safety instr uction." F ailure

to comply with the instr uction ma y result in

personal injur y or death.

Safe Operating Practices

T he follo wing instr uctions are from the CEN

standard EN 836:1997, ISO standard 5395:1990,

and ANSI B71.4-1999.

Training

• R ead the Operator’ s Man ual and other training

material carefully . Be familiar with the

controls , safety signs , and the proper use of the

equipment.

• Nev er allo w c hildren or people unfamiliar with

these instr uctions to use or ser vice the mo w er .

Local regulations ma y restrict the ag e of the

operator .

– R efuel outdoors only and do not smok e

while refuelling .

– Add fuel before star ting the engine . Nev er

remo v e the cap of the fuel tank or add fuel

while the engine is r unning or when the

engine is hot.

– If fuel is spilled, do not attempt to star t the

engine but mo v e the mac hine a w a y from

the area of spillag e and a v oid creating any

source of ignition until fuel v apors ha v e

dissipated.

– R e place all fuel tanks and container caps

securely .

• R e place faulty silencers .

• Ev aluate the ter rain to deter mine what

accessories and attac hments are needed to

properly and safely perfor m the job . Only use

accessories and attac hments appro v ed b y the

man ufacturer .

• Chec k that operator’ s presence controls ,

safety switc hes and shields are attac hed and

functioning properly . Do not operate unless

they are functioning properly .

• Nev er mo w while people , especially c hildren,

or pets are nearb y .

• K ee p in mind that the operator or user is

responsible for accidents or hazards occur ring

to other people or their proper ty .

• T he o wner/user can prev ent and is responsible

for accidents or injuries occur ring to himself

or herself , other people , or proper ty .

Preparation

• W hile mo wing, alw a ys w ear substantial

footw ear , long trousers , hard hat, safety glasses ,

and ear protection. Long hair , loose clothing,

or jew elr y ma y g et tangled in mo ving par ts . Do

not operate the equipment when barefoot or

w earing open sandals .

Operation

• Do not operate the engine in a confined space

where dang erous carbon mono xide fumes can

collect.

• Mo w only in da ylight or in g ood ar tificial light.

• Before attempting to star t the engine ,

diseng ag e all blade attac hment clutc hes , shift

into neutral, and eng ag e the parking brak e .

• Do not use on slopes of more than 15°.

• R emember there is no suc h thing as a safe

slope . T ra v el on g rass slopes requires par ticular

care . T o guard ag ainst o v er tur ning:

– do not stop or star t suddenly when g oing

up or do wnhill;

– eng ag e clutc h slo wly , alw a ys k ee p mac hine

in g ear , especially when tra v elling do wnhill;

4

Page 5

– mac hine speeds should be k e pt lo w on

slopes and during tight tur ns;

– sta y aler t for humps and hollo ws and other

hidden hazards;

– nev er mo w across the face of the slope ,

unless the mo w er is designed for this

pur pose .

• Sta y aler t for holes in the ter rain and other

hidden hazards .

• W atc h out for traffic when crossing or near

roadw a ys .

• Stop the blades rotating before crossing

surfaces other than g rass .

• W hen using any attac hments , nev er direct

disc harg e of material to w ard b ystanders

nor allo w any one near the mac hine while in

operation.

• Nev er operate the mac hine with damag ed

guards , shields , or without safety protecti v e

devices in place . Be sure all interloc ks are

attac hed, adjusted properly , and functioning

properly .

• Do not c hang e the engine g o v er nor settings or

o v erspeed the engine . Operating the engine

at ex cessi v e speed ma y increase the hazard of

personal injur y .

• Before lea ving the operator’ s position:

– stop on lev el g round;

– diseng ag e the po w er tak e-off and lo w er the

attac hments;

– c hang e into neutral and set the parking

brak e;

– stop the engine .

• Diseng ag e dri v e to attac hments when

transpor ting or not in use .

• Stop the engine and diseng ag e dri v e to

attac hment

– before refuelling;

– before remo ving the g rass catc her/catc hers;

– before making height adjustment unless

adjustment can be made from the operator’ s

position.

– before clearing bloc kag es;

– before c hec king, cleaning or w orking on

the mo w er;

– after striking a foreign object or if an

abnor mal vibration occurs . Inspect the

mo w er for damag e and mak e re pairs before

restar ting and operating the equipment.

• R educe the throttle setting before stopping

engine and, if the engine is pro vided with a

fuel shut-off v alv e , tur n the v alv e off at the

conclusion of mo wing .

• K ee p hands and feet a w a y from the cutting

unit.

• Slo w do wn and use caution when making tur ns

and crossing roads and sidew alks . Stop reels if

not mo wing .

• Do not operate the mo w er under the influence

of alcohol or dr ugs

• Use care when loading or unloading the

mac hine into a trailer or tr uc k

• Use care when approac hing blind cor ners ,

shr ubs , trees , or other objects that ma y obscure

vision.

Maintenance and Storage

• K ee p all n uts , bolts and screws tight to be sure

the equipment is in safe w orking condition.

• Nev er store the equipment with fuel in the

tank inside a building where fumes ma y reac h

an open flame or spark.

• Allo w the engine to cool before storing in any

enclosure .

• T o reduce the fire hazard, k ee p the engine ,

silencer , batter y compar tment and fuel storag e

area free of g rass , lea v es , or ex cessi v e g rease .

• Chec k the g rass catc her frequently for w ear or

deterioration.

• K ee p all par ts in g ood w orking condition and

all hardw are and h y draulic fittings tightened.

R e place all w or n or damag ed par ts and decals .

• If the fuel tank has to be drained, do this

outdoors .

• Be careful during adjustment of the mac hine

to prev ent entrapment of the fing ers betw een

mo ving blades and fix ed par ts of the mac hine .

• Diseng ag e dri v es , diseng ag e the cutting unit,

set parking brak e , stop engine and disconnect

spark plug wire . W ait for all mo v ement to stop

before adjusting, cleaning or re pairing .

• Clean g rass and debris from cutting unit,

dri v es , m ufflers , and engine to help prev ent

fires . Clean up oil or fuel spillag e .

5

Page 6

• Carefully release pressure from components

with stored energ y .

• Disconnect batter y and remo v e spark plug

wire before making any re pairs . Disconnect

the neg ati v e ter minal first and the positi v e last.

R econnect positi v e first and neg ati v e last.

• Use care when c hec king the reel. W ear glo v es

and use caution when ser vicing them.

• K ee p hands and feet a w a y from mo ving par ts .

If possible , do not mak e adjustments with the

engine r unning .

Toro Mower Safety

T he follo wing list contains safety infor mation

specific to T oro products or other safety

infor mation that y ou m ust kno w that is not

included in the CEN , ISO , or ANSI standard.

T his product is capable of amputating hands and

feet and thro wing objects . Alw a ys follo w all safety

instr uctions to a v oid serious injur y or death.

Use of this product for pur poses other than its

intended use could pro v e dang erous to user and

b ystanders .

• Kno w ho w to stop the engine quic kly .

• Do not operate the mac hine while w earing

tennis shoes or sneak ers .

• W earing safety shoes and long pants is advisable

and required b y some local ordinances and

insurance regulations .

• Handle g asoline carefully . Wipe up any spills .

• Chec k the safety interloc k switc hes daily

for proper operation. If a switc h should

fail, re place the switc h before operating the

mac hine . After ev er y tw o years , re place

all interloc k switc hes in the safety system,

reg ardless if they are w orking properly or not.

• Alw a ys stand behind the handle when star ting

and operating the mac hine .

• T o star t and stop the engine:

– Open fuel shut-off v alv e .

– V erify that the traction and reel dri v e

control lev ers on handle are in Neutral

position.

– Mo v e on/off switc h to ON position, set

c hok e to full c hok e position (cold star t)

and throttle to half throttle .

– Pull star ter cord to star t engine .

– Mo v e throttle to Slo w and on/off switc h to

Off position to stop engine .

• T o transpor t mo w er from one area to another :

– Install transpor t wheels .

– Diseng ag e reel dri v e .

– Star t engine .

– Press do wn on handle to raise front of

mo w er and eng ag e traction dri v e .

• Before beginning mo wing operation:

– Diseng ag e traction dri v e .

– Stop engine .

– R emo v e transpor t wheels .

– Star t engine

– Eng ag e reel dri v e .

• Using the mac hine demands attention. T o

prev ent loss of control:

– Do not dri v e close to sand traps , ditc hes ,

creeks , or other hazards .

– R educe speed when making shar p tur ns .

A v oid sudden stops and star ts .

– W hen near or crossing roads , alw a ys yield

the right-of-w a y .

– Apply the ser vice brak es when g oing

do wnhill to k ee p forw ard speed slo w and

to maintain control of the mac hine .

• T he g rass bask et m ust be in place during

operation of the reels or thatc hers for

maxim um safety . Shut the engine off before

emptying the bask ets .

• Do not touc h the engine , m uffler , or exhaust

pipe while the engine is r unning or soon after

it has stopped because these areas could be hot

enough to cause bur ns .

• Sta y clear of the rotating screen at the side of

the engine to prev ent direct contact with y our

body or clothing .

• W hen a person or pet appears unexpectedly

in or near the mo wing area, stop mo wing .

Careless operation, combined with ter rain

angles , ricoc hets , or improperly positioned

guards can lead to thro wn object injuries . Do

not resume mo wing until the area is cleared.

Maintenance and Storage

• Chec k all fuel lines for tightness and w ear on a

regular basis . Tighten or re pair them as needed.

6

Page 7

• If the engine m ust be r unning to perfor m a

maintenance adjustment, k ee p hands , feet,

clothing, and any par ts of the body a w a y from

the cutting unit, attac hments , and any mo ving

par ts , especially the screen at the side of the

engine . K ee p ev er y one a w a y .

• T o ensure safety and accuracy , ha v e an

A uthorized T oro Distributor c hec k the

maxim um engine speed with a tac hometer .

Maxim um g o v er ned engine speed should be

3600 RPM.

• If major re pairs are ev er needed or if assistance

is desired, contact an A uthorized T oro

Distributor .

• Use only T oro-appro v ed attac hments and

re placement par ts . T he w ar ranty ma y be

v oided if used with unappro v ed attac hments .

Sound Pressure for a Flex 18

T his unit has a maxim um sound pressure lev el

at the operator’ s ear of 85 dB A, based on

measurements of identical mac hines per EN 11094

and EN 836.

Vibration for a Flex 21

T his unit does not ex ceed a hand/ar m vibration

lev el of 2.50 m/s

identical mac hines per EN 1033.

2

, based on measurements of

Sound Power for a Flex 18

T his unit has a guaranteed sound po w er lev el

of 96 dB A, based on measurements of identical

mac hines per EN 11094.

Vibration for a Flex 18

T his unit does not ex ceed a hand/ar m vibration

lev el of 2.50 m/s

identical mac hines per EN 1033.

2

, based on measurements of

Sound Pressure for a Flex 21

T his unit has a maxim um sound pressure lev el

at the operator’ s ear of 85 dB A, based on

measurements of identical mac hines per EN 11094

and EN 836.

Sound Power for a Flex 21

T his unit has a guaranteed sound po w er lev el

of 98 dB A, based on measurements of identical

mac hines per EN 11094.

7

Page 8

Safety and Instructional

Decals

Safety decals and instr uctions are easily visible to the operator and are located near any

area of potential dang er . R e place any decal that is damag ed or lost.

105-5309

1. Hot surface/burn hazard—keep a safe distance from the hot

surface.

93-7348

1. Warning—read the Operator’s Manual .

2. Fire hazard—no re, open ames, or smoking; when adding

fuel to the tank, leave space between the fuel and the top of

the tank.

3. Thrown object hazard—keep bystanders a safe distance from

the machine.

4. Cutting hazard of hand or foot—stay away from moving

parts

93-9356

1. Entanglement hazard—stay away from moving parts.

1. Fast

2. Continuous variable setting

93-6085

3. Slow

8

93-9886

1. Use unleaded gasoline.

Page 9

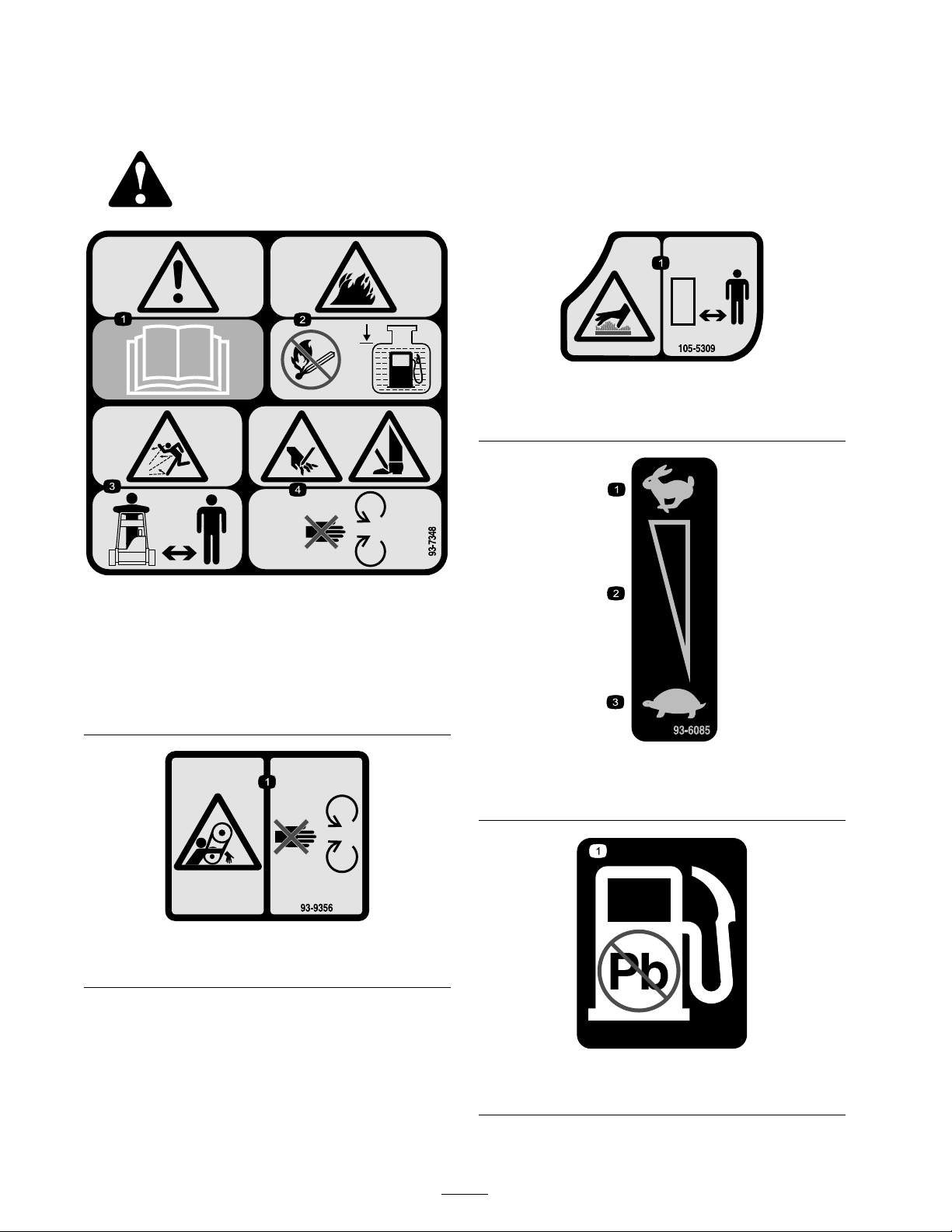

1. Parking brake

2. Disengage

104-2618

3. Engage

1. Traction drive 4. Forward

2. Reel drive 5. Lever engaged

3. Neutral 6. Lever disengaged

104-2617

93-8064

1. Warning—read the instructions before servicing or

performing maintenance.

2. Cutting hazard of hand or foot—stop the engine and wait

for moving parts to stop.

1. Read the Operator’s Manual .

105-2411

1. Transmission oil

104-2621

9

Page 10

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

1

2

3

4

5

6

7

Handle

Kickstand assembly

Spring

Small spacer

Large spacer 1

Large bolt (M8–1.25 x 100)

Small bolt (M8–1.25 x 030)

Locknut (M8 x 1.25)

Washer (M8)

No parts required

Transport wheels (Optional

Transport Wheel Kit, Model 04123)

No parts required

Grass basket

Operator’s Manual

Engine Operator’s Manual

Parts Catalog

Operator Video

Certicate of compliance

Description

Qty.

1

1

1

1

1

1

2

2

–

2

–

1

1

1

1

1

1

Install the handle.

Install the kickstand for Flex 18

Mowers Only.

Adjust the handle.

Install the transport wheels.

Check the engine oil and

transmission uid levels

Install the grass basket.

Read the manuals and watch

the video before operating the

machine.

Use

Note: Deter mine the left and right sides of the

mac hine from the nor mal operating position.

Step

1

Installing the Handle

Parts needed for this step:

1

Handle

Procedure

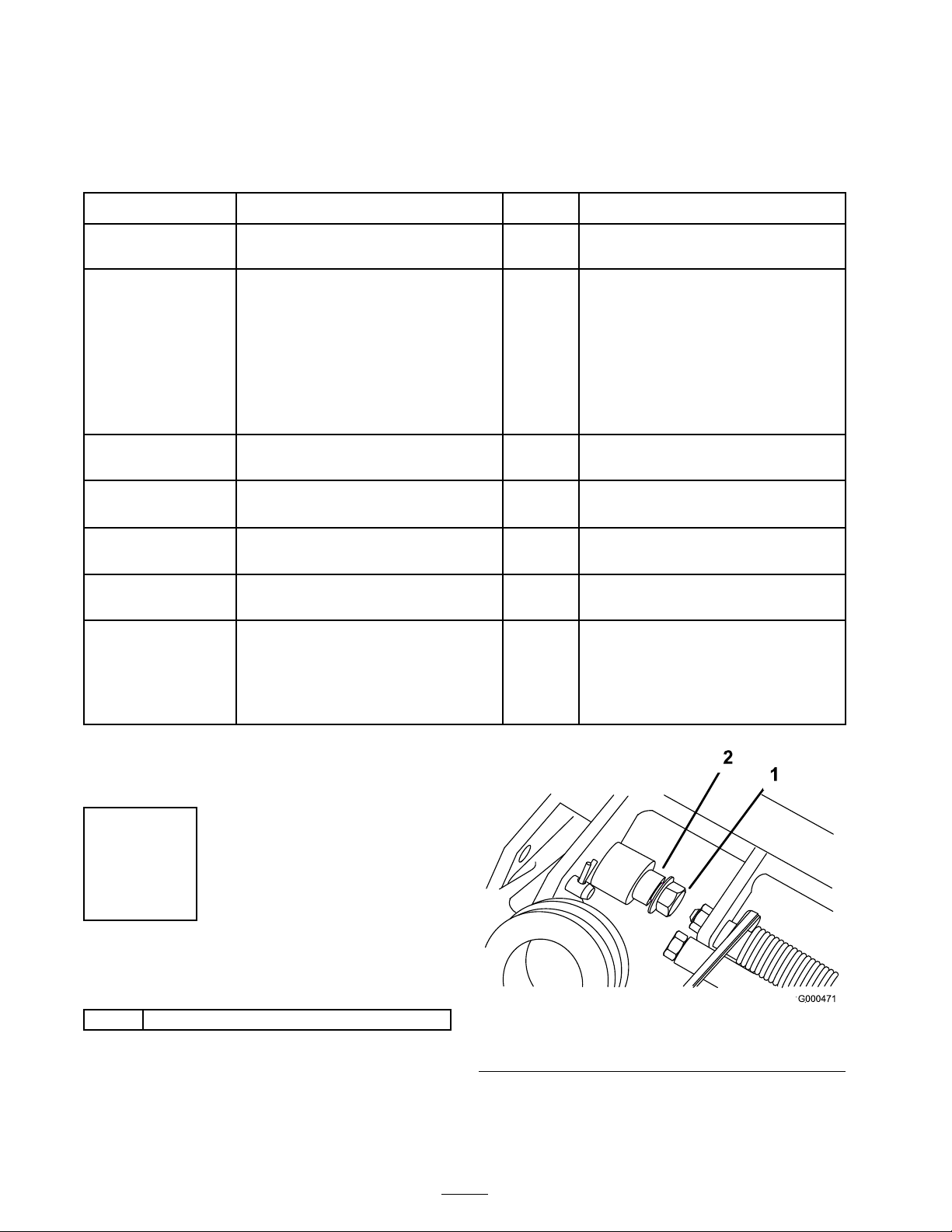

1. R emo v e the flang e loc k n ut from the bolt and

pi v ot pin on eac h side of the mo w er ( Figure 4 ).

Figure 4

1. Flange lock nut

2. Pivot pin

2. Inser t the handle ends through the slots in the

handle suppor t ar ms ( Figure 5 ).

10

Page 11

Figure 5

1. Left handle end

2. Support arm

3. Pivot pin

4. Locknut

3. Squeeze the handle ends inw ard and install

them on the ste p of the pi v ot pin ( Figure 5 ).

4. Secure the handle to the bolt and pi v ot pin

with the flang e loc k n ut ( Figure 5 ).

5. Locate cable tie loosely securing throttle

cable to wire har ness . P osition cable tie

appro ximately one inc h behind transmission

and tighten cable tie .

the kic kstand to the frame with the bolt

and w asher , the small spacer , and loc kn ut

(M8–1.25) ( Figure 6 ). Ensure the bolt is

installed from the inside of the frame as sho wn

in Figure 6 .

3. Install a w asher (M8) onto the larg e bolt

(M8–1.25 x 100).

4. Install the spacer into the spring and install the

larg e bolt (M8–1.25 x 100) into the spacer .

Important: W hen installing the spring ,

place one end of the spring under the r ear

frame ( Figur e 6 ).

5. Install the left side of the kic kstand to the

frame with the bolt and w asher , the larg e

spacer and spring, and loc kn ut (M8–1.25)

( Figure 6 ). Ensure the bolt is installed from the

inside of the frame as sho wn in Figure 6 .

Step

2

Installing the Kickstand for

Flex 18 Mowers Only

Parts needed for this step:

1

Kickstand assembly

1

Spring

1

Small spacer

1 Large spacer

1

Large bolt (M8–1.25 x 100)

1

Small bolt (M8–1.25 x 030)

2

Locknut (M8 x 1.25)

2

Washer (M8)

Procedure

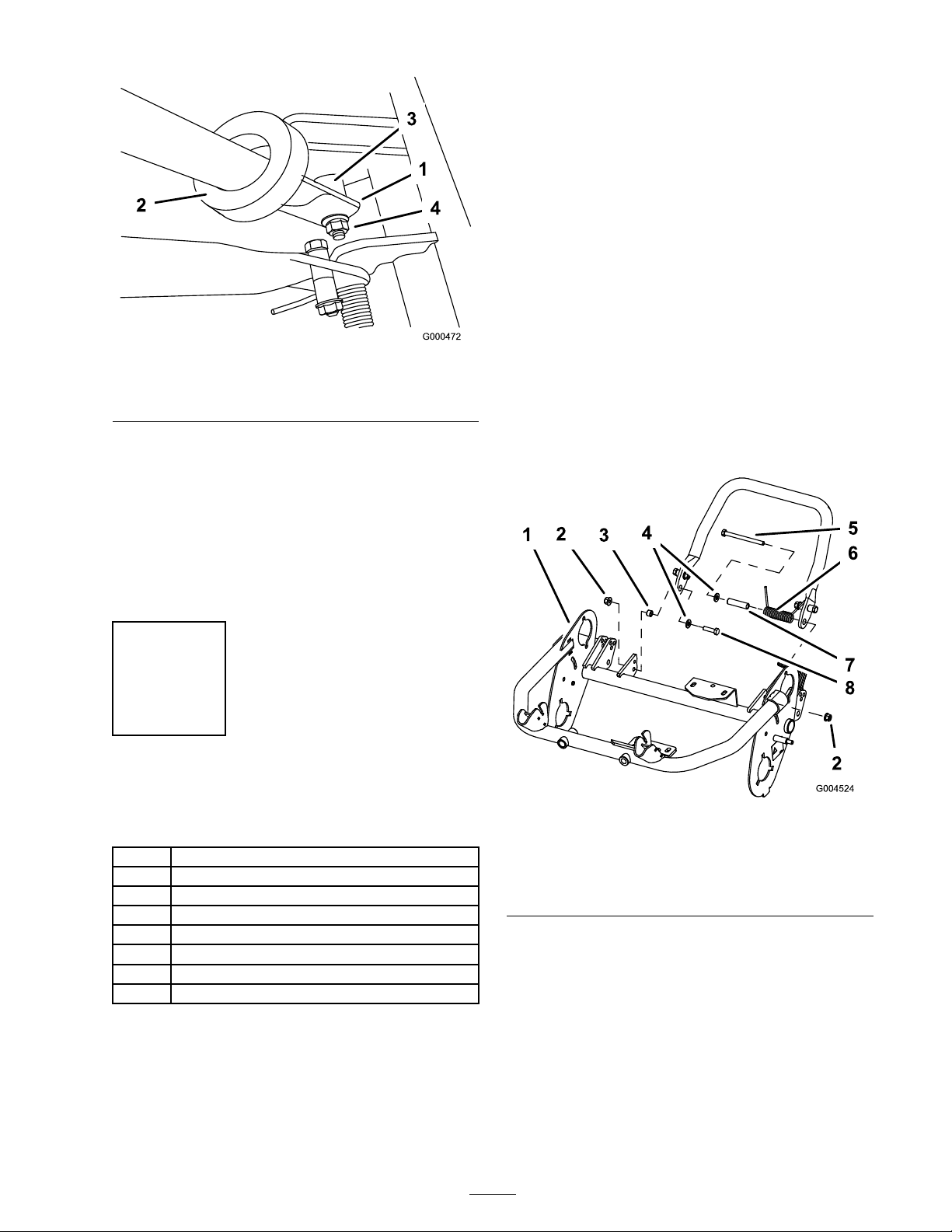

1. P osition the kic kstand betw een the tabs on the

rear of the frame .

2. Install a w asher (M8) onto the small bolt

(M8–1.25 x 030). Install the right side of

Figure 6

1. Left handle end

2. Locknut (M8–1.25)

3. Small spacer

4. Washer (M8) 8. Ssmall bolt (M8–1.25 x

5. Large bolt (M8–1.25 x 100)

6. Spring

7. Large spacer

030)

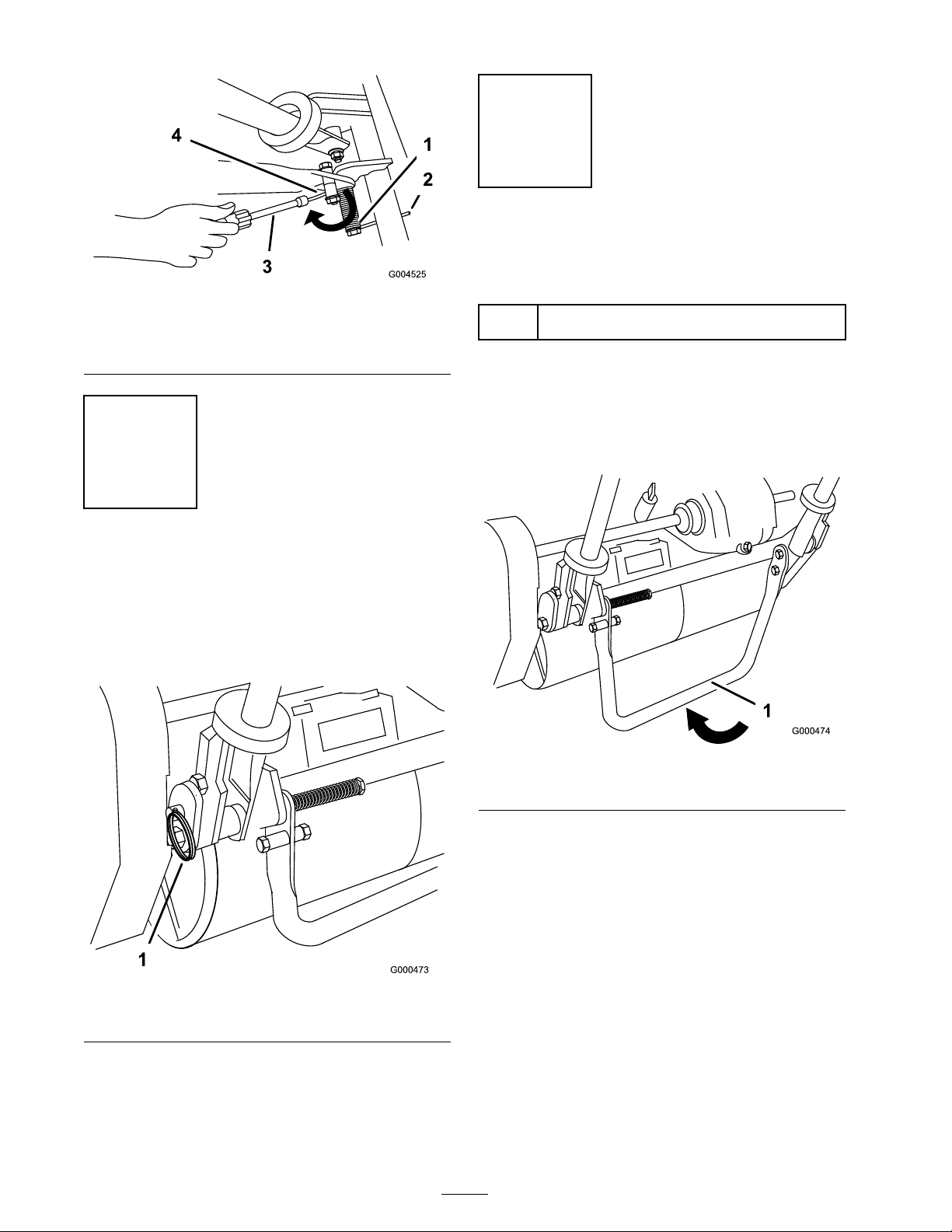

6. Place a n ut r unner o v er the end of the spring

pointing to w ards the rear and mo v e the end of

the spring o v er and under the kic kstand spacer

( Figure 7 ).

11

Page 12

Step

4

Installing the Transport

Wheels

Figure 7

1. Spring

2. Spring end under the frame 4. Move the spring end under

3. Nut runner

the kickstand spacer.

Step

3

Adjusting the Handle

No Parts Required

Procedure

1. R emo v e hair pin cotters from ring pins on eac h

side of mo w er ( Figure 8 ).

Parts needed for this step:

Transport wheels (Optional Transport Wheel

2

Kit, Model 04123)

Procedure

1. Push kic k stand do wn with foot and pull up

on handle suppor t until kic k stand has rotated

forw ard, o v er center ( Figure 9 ).

Figure 8

1. Ring pins

2. W hile suppor ting handle , remo v e ring pins

from eac h side and raise or lo w er handle to

desired operating position ( Figure 8 ).

3. R einstall ring pins and hair pin cotters .

Figure 9

1. Kick stand

2. Press wheel loc king clip to w ard the center

of wheel and slide wheel onto hex shaft

( Figure 10 ).

12

Page 13

Figure 10

1. Locking clip

3. R otate wheel bac k and for th until it slides

completely onto axle and loc king clip is secured

in g roo v e on axle shaft.

Step

6

Installing the Grass Basket

Parts needed for this step:

1

Grass basket

Procedure

Grasp bask et b y top lip and slide bask et frame into

the recei v ers ( Figure 11 ).

4. R e peat procedure on opposite side of mac hine .

5. Inflate the tires to 12-15 psi.

6. Carefully lift up on handle suppor t to release

kic k stand.

Step

5

Checking Fluid Levels

No Parts Required

Procedure

1. Chec k the engine oil lev el, refer to Chec king

the Engine Oil Lev el in Engine Maintenance ,

pag e 24 .

2. Chec k the transmission fluid lev el, refer to

Chec king the T ransmission Fluid Lev el in

Dri v e System Maintenance , pag e 27 .

Figure 11

1. Grass basket 2. Basket receivers

13

Page 14

Step

7

Reading the Manuals and

Viewing the Video

Parts needed for this step:

1

Operator’s Manual

1

Engine Operator’s Manual

1

Parts Catalog

1

Operator Video

1

Certicate of compliance

Procedure

1. R ead the man uals .

2. View the Operator video .

3. Store the documentation in a safe place .

14

Page 15

Product Overview

Figure 12

1. Handle

2. Control panel 6. Grass basket

3. Engine

4. Transport wheels

Controls

5. Cutting unit

7. Fuel tank

operates throttle linkag e to carburetor . Engine

speed can be v aried from 2400 RPM to 3600 RPM.

Traction and Reel Drive Engagement

Lever

T he traction and reel dri v e eng ag ement lev er

( Figure 13 ) is located on front right side of control

panel. T raction lev er has tw o positions: Neutral

and F orw ard. Pushing lev er forw ard eng ag es

traction dri v e .

T he reel dri v e lev er has tw o positions: Eng ag e and

Diseng ag e . Mo v e top of lev er to the left to eng ag e

reel or bac k to neutral to diseng ag e reel.

Service/Parking Brake

T he ser vice/parking brak e ( Figure 13 ) is located

on left front side of control panel. Pulling the lev er

bac k o v er center will set the parking brak e . Brak e

m ust be released before traction dri v e is eng ag ed.

Operator Presence Control

T he optional operator presence control m ust be

eng ag ed before eng aging the traction lev er or the

engine will stop .

Choke Lever

Figure 13

1. Throttle control 3. Service/parking brake

2. Traction & reel drive

engagement lever

Throttle Control

T he throttle control ( Figure 13 ) is located on rear

right side of control panel. Lev er connects to and

T he c hok e lev er ( Figure 14 ) is located on left

front of engine . Lev er has tw o positions: R un and

Chok e . Mo v e the c hok e lev er to the half-open

position when star ting a cold engine . After engine

star ts mo v e lev er to R un position.

Figure 14

1. Choke lever 2. Fuel shut-off valve

15

Page 16

Fuel Shut-Off Valve

T he fuel shut-off v alv e ( Figure 14 ) is located on

left front of engine . V alv e has tw o positions:

Closed and Open. Mo v e lev er to closed position

when storing or transpor ting mac hine . Open v alv e

before star ting engine .

Recoil Starter

Pull recoil star ter handle ( Figure 15 ) to star t engine .

Figure 16

1. Kick stand

Figure 15

1. Recoil starter

2. On/off switch

3. Hour meter

On/Off Switch

T he on/off switc h ( Figure 15 ) is located on rear

of engine . Mo v e switc h to On position to star t

engine and Off to stop engine .

Hour Meter

T he hour meter ( Figure 15 ) located on rear of

engine , indicates the total hours of mac hine

operation.

Kickstand

T he kic kstand ( Figure 16 ) is mounted to rear of

mac hine and is used to raise rear of mac hine for

installation or remo v al of transpor t wheels .

16

Page 17

Specications

Width 35-1/2 inches

Height 41–1/4 inches

Length with

basket

Weight with full

uids and basket

Dry weight with

basket

Engine

Fuel capacity

Ground speed Mowing speed:

Width of cut

Height of cut 1/16 to 19/64

Clip frequency 11 blade

Flex 21 Flex 18

(90.1 cm)

(104.8 cm)

61–1/2 inches

(156.2 cm)

267lb (121 kg) 261lb (118 kg)

256lb (116 kg) 250lb (113 kg)

Kawasaki,

4-cycle, 3.7 (2.7

kw) air cooled

OHV engine,

3600 RPM, 7.57

cu inch (124 cc)

displacement,

cast iron

cylinder sleeve;

electronic

ignition

with integral

lighting coil;

maximum noise

suppression

mufer; 85 dB(A)

at operator’s ear

2.64 qt. (2.5

l); regular

grade unleaded

gasoline

1.3 to 3.3 MPH

(2.1 to 5.3

km/h)Transport

speed: 4.9

MPH (7.9 km/h)

maximum

21 inches (53.3

cm)

inches (1.5

to 7.5 mm)

with Micro-Cut

bedknife

(standard): .14

in.

32 inches (81.3

cm)

41–1/2 inches

(105.4 cm)

61 inches (155

cm)

Kawasaki,

4-cycle, 3.7 (2.7

kw) air cooled

OHV engine,

3600 RPM, 7.57

cu inch (124 cc)

displacement,

cast iron

cylinder sleeve;

electronic

ignition

with integral

lighting coil;

maximum noise

suppression

mufer; 85 dB(A)

at operator’s ear

2.64 qt. (2.5

l); regular

grade unleaded

gasoline

Mowing speed:

1.3 to 3.3 MPH

(2.1 to 5.3

km/h)Transport

speed: 4.9

MPH (7.9 km/h)

maximum

18 inches (45.7

cm)

1/16 to 19/64

inches (1.5

to 7.5 mm)

with Micro-Cut

bedknife

11 blade

(standard): .14

inch

g o to www .T oro .com for a list of all appro v ed

attac hments and accessories .

Attachments/Accessories

A selection of T oro appro v ed attac hments and

accessories are a v ailable for use with the mac hine

to enhance and expand its capabilities . Contact

y our A uthorized Ser vice Dealer or Distributor or

17

Page 18

Operation

Note: Deter mine the left and right sides of the

mac hine from the nor mal operating position.

Think Safety First

Please carefully read all of the safety instr uctions

and decals in the safety section. Kno wing this

infor mation could help y ou or b ystanders a v oid

injur y .

Checking the Engine Oil

Level

Chec k the engine oil lev el before eac h use or ev er y

8 operating hours , refer to Chec king the Engine

Oil Lev el in Engine Maintenance , pag e 24 .

Filling the Fuel Tank

Important: Nev er use methanol, gasoline

containing methanol, gasohol containing

mor e than 10% ethanol, gasoline additi v es,

pr emium gasoline, or white gas because the

fuel system could be dama ged. Do not mix

oil with gasoline.

Gasoline is har mful or f atal if s w allo w ed.

Long-ter m exposur e to v apor s can cause

serious injur y and illness.

• A v oid pr olonged br eathing of v apor s.

• K eep f ace a w ay fr om nozzle and gas tank

or conditioner opening .

• K eep gas a w ay fr om ey es and skin.

Figure 17

1. Fuel tank cap 2. Fuel gauge

18

Page 19

In cer tain conditions, gasoline is extr emel y

flamma ble and highl y explosi v e. A fir e or

explosion fr om gasoline can bur n y ou and

other s and can dama ge pr oper ty .

• Fill the fuel tank outdoor s, in an open

ar ea, when the engine is cold. W ipe up

an y gasoline that spills.

• Do not fill the fuel tank completel y full.

Add gasoline to the fuel tank until the

lev el is 1/4 to 1/2 inch (6 to 13 mm)

belo w the bottom of the filler neck. T his

empty space in the tank allo ws gasoline

to expand.

• Nev er smok e when handling gasoline,

and stay a w ay fr om an open flame or

wher e gasoline fumes may be ignited by

a spar k.

• Stor e gasoline in an appr o v ed container

and k eep it out of the r each of childr en.

Nev er buy mor e than a 30-day suppl y of

gasoline.

• Al w ays place gasoline container s on the

g r ound a w ay fr om y our v ehicle bef or e

filling .

g asoline , fill fuel tank no higher than to bottom

of filter screen. Do not o v erfill.

2. Install fuel tank cap and wipe up any spilled

g asoline .

Checking the Interlock

Switch Operation

If safety inter lock s witches ar e disconnected

or dama ged the machine could operate

unexpectedl y causing per sonal injur y .

• Do not tamper with the inter lock

s witches.

• Check the operation of the inter lock

s witches dail y and r eplace an y dama ged

s witches bef or e operating the machine.

• R eplace s witches ev er y tw o y ear s

r egardless of whether they ar e operating

pr oper l y or not.

1. Push kic k stand do wn with foot and pull up

on handle suppor t until kic k stand has rotated

forw ard, o v er center ( Figure 18 ).

• Do not fill gasoline container s inside

a v ehicle or on a tr uck or trailer bed

because interior car pets or plastic tr uck

bed liner s may insulate the container and

slo w the loss of an y static charge.

• W hen practical, r emo v e gas-po w er ed

equipment fr om the tr uck or trailer and

r efuel the equipment with its wheels on

the g r ound.

• If this is not possible, then r efuel such

equipment on a tr uck or trailer fr om a

por ta ble container , rather than fr om a

gasoline dispenser nozzle.

• If a gasoline dispenser nozzle must be

used, k eep the nozzle in contact with the

rim of the fuel tank or container opening

at all times until fueling is complete.

1. Clean around fuel tank cap and remo v e

cap from tank ( Figure 17 ). Using unleaded

Figure 18

1. Kick stand

2. Place traction lev er into Eng ag e position and

engine controls in star ting position.

3. Attempt to star t engine . Engine should not

star t. If engine star ts , the interloc k switc h

needs ser vice . Cor rect problem before

operating . R efer to Ser vicing Interloc k Switc h.

4. Carefully lift up on handle to release kic k stand.

19

Page 20

Starting and Stopping the

Engine

Note: F or illustrations and descriptions of

the controls referenced in this section, refer to

Controls , pag e 15 .

Starting the Engine

Note: Mak e sure spark plug wire is installed on

spark plug .

1. Mak e sure traction and reel dri v e lev ers are in

Diseng ag ed position.

Note: Engine will not star t if traction lev er is

in the eng ag ed position.

2. Open the fuel shut-off v alv e on the engine .

3. Mo v e the on/off switc h to the On position.

4. Mo v e the throttle control to the F ast position.

5. Mo v e the c hok e lev er to the half-open position

when star ting a cold engine . T he c hok e ma y

not be required when star ting a w ar m engine .

2. T o release kic kstand, pull up on handle and

lo w er rear of mo w er onto transpor t wheels .

3. Ensure traction and reel dri v e controls are in

Diseng ag e position and star t engine .

4. Set throttle control to Slo w , tip front of

mac hine up g radually eng ag e traction dri v e and

slo wly increase engine speed.

5. Adjust throttle to operate mo w er at desired

g round speed and transpor t mo w er to desired

destination.

Preparing to Mow

1. R etur n traction control lev er to Diseng ag e ,

throttle to Slo w and stop engine .

2. Push kic k stand do wn with foot and pull up

on handle suppor t until kic k stand has rotated

forw ard, o v er center .

3. R emo v e transpor t wheels .

4. R elease kic kstand.

6. Pull the recoil star ter handle out until positi v e

eng ag ement results , then pull it vig orously to

star t the engine . Open the c hok e as engine

w ar ms up .

Important: Do not pull r ecoil r ope to its

limit or let go of star ter handle when r ope

is pulled out because r ope may br eak or

r ecoil assembl y may be dama ged.

Stopping the Engine

1. Mo v e the traction and reel dri v e controls to

the Diseng ag ed position, the throttle control

to Slo w , and the on/off switc h to Off .

2. Pull the molded spark plug wire off of the spark

plug to prev ent the possibility of accidental

star ting before storing mac hine .

3. Close the fuel shut-off v alv e before storing or

transpor ting mo w er in a v ehicle .

Transport Operation

Note: Do not r un the mo w er engine while

transpor ting it in a transpor t trailer because

damag e can occur to the mo w er .

1. Push kic k stand do wn with foot and pull up

on handle suppor t until kic k stand has rotated

forw ard, o v er center .

Mowing Operation

Proper use of the mac hine pro vides the smoothest

turf cutting a v ailable .

Important: Grass clippings act as a

lubricant when mo wing . Ex cessi v e operation

of the cutting unit with the a bsence of g rass

clippings can dama ge the cutting unit.

Prior to Mowing

Be sure the mo w er is carefully adjusted and is set

ev enly on both sides of the reel. Improper mo w er

adjustment is magnified in the appearance of the

clipped turf . R emo v e all foreign objects from turf

prior to mo wing . Mak e sure ev er y one , especially

c hildren and pets , are clear of the w ork area.

Method of Mowing

T he g reens should be mo w ed in a straight bac k

and for th direction across the g reen. A v oid

circular mo wing or tur ning the mo w er on g reens

areas since scuffing ma y occur . T ur ning the mo w er

should be done off the g reen b y raising the cutting

reel (pushing the handle do wn) and tur ning on

the traction dr um. Mo wing should be done at a

nor mal w alking pace . F ast speeds sa v es v er y little

time and will result in an inferior mo wing job .

20

Page 21

T o assist in maintaining a straight line across

the g reen and to k ee p the mac hine an equal

distance from the edg e of the previous cut, use the

alignment stripes on the bask et ( Figure 19 ).

Figure 19

1. Alignment stripes

Control Operation

T o operate the controls while mo wing:

1. Star t the engine , set the throttle at reduced

speed, push do wn on handle to raise cutting

unit, mo v e traction lev er to Eng ag ed position

and transpor t mo w er onto collar of g reen

( Figure 20 ).

2. Mo v e traction lev er to Diseng ag ed position

and Eng ag e reel dri v e lev er ( Figure 20 ).

Figure 20

1. Traction drive -neutral 3. Traction drive-engaged

2. Traction drive neutral &

reel drive off

(transport)

4. Traction drive & reel drive

engaged

3. Mo v e traction lev er to Eng ag ed position,

increase throttle speed until the mo w er is

tra v eling at the desired g round speed, dri v e the

mo w er out onto the g reen area, lo w er the front

of the mo w er do wn and commence operation

( Figure 20 ).

After Mowing

1. Dri v e off g reen, mo v e reel dri v e and traction

control lev ers to Diseng ag e and stop the

engine .

2. Empty the g rass catc her of clippings , install

g rass catc her and commence transpor t

operation.

21

Page 22

Maintenance

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

After the rst 8 operating

hours

After the rst 25

operating hours

Before each use or daily

Every 25 hours

Every 50 hours

Every 100 hours

Every 200 hours

Every 1,500 hours

Before storage

Every 2 years

Maintenance Procedure

• Change the engine oil.

• Clean the fuel lter.

• Change the transmission uid.

• Check the engine oil level.

• Clean the air cleaner (more often in dirty or dusty conditions).

• Change the engine oil.

• Clean the fuel lter.

• Check the transmission uid level.

• Clean or replace the paper air lter element (more often in dirty or dusty

conditions).

• Check the spark plug.

• Decarbon the engine.

• Replace the interlock switch.

• Change the transmission uid.

• Paint chipped surfaces.

• Change the transmission uid.

Important: R efer to y our engine operator’ s man ual f or additional maintenance pr ocedur es.

22

Page 23

Daily Maintenance Checklist

Important: Duplicate this pa ge f or r outine use.

Maintenance

Check Item

Check the

safety interlock

operation.

Check the

parking brake

operation.

Check that pivot

joints operate

freely.

Check the fuel

level.

Check the engine

oil level.

Check the air

lter.

Clean the engine

cooling ns.

Check for

unusual engine

noises.

Check for

unusual

operating noises.

Check the

reel-to-bedknife

adjustment.

Check the

height-of-cut

adjustment.

Touch up

damaged paint.

For the week of:

Mon. Tues.

Wed. Thurs.

Fri.

Sat. Sun.

Notation for Areas of Concern

Inspection performed by:

Item Date

Information

23

Page 24

Engine Maintenance

Engine Oil

Chec k the engine oil lev el eac h time the mo w er

is used or after ev er y 8 operating hours . Chang e

the oil after the first 8 operating hours and ev er y

50 hours thereafter . More frequent oil c hang es

are required in dusty or dir ty conditions . T he

crankcase m ust be filled with appro ximately

20 fluid ounces of proper viscosity oil before

staring . T he engine uses any high-quality oil

ha ving the American P etroleum Institute - APl

- “ser vice classification" SF , SG , SH or SJ . Oil

viscosity - w eight - m ust be selected according

to ambient temperature . Figure 21 illustrates the

temperature/viscosity recommendations .

Figure 22

1. Oil level gauge 2. Drain plug

2. R emo v e oil lev el g aug e b y rotating it

countercloc kwise .

Figure 21

Note: Using m ulti-g rade oils (5W -20, 10W -30,

and 10W -40) will increase oil consumption. Chec k

the oil lev el more frequently when using them.

Checking the Engine Oil Level

1. P osition mo w er so the engine is lev el and clean

around oil lev el g aug e ( Figure 22 ).

3. Wipe oil lev el g aug e clean and inser t it into

filler por t. Do not screw into por t. T hen

remo v e and c hec k lev el of oil. If lev el is lo w ,

add only enough oil to raise lev el to bottom

of filler opening . R ec hec k lev el of oil. Do not

o v erfill.

4. R einstall oil lev el g aug e and wipe up any spilled

oil.

Changing the Engine Oil

1. Star t and r un engine for a few min utes to

w ar m the engine oil.

2. Place a drain pan at rear of mac hine under

drain plug ( Figure 22 ). R emo v e drain plug .

3. Push do wn on handle to tip mo w er and engine

bac kw ard, allo wing all oil to r un into drain pan.

4. Install drain plug and refill crankcase with the

specified oil; refer to Chec king the Oil Lev el.

Servicing the Air Cleaner

Nor mally , clean air cleaner foam element after

ev er y 25 operating hours . More frequent cleaning

is required when mo w er is operated in dusty or

dir ty conditions .

1. Mak e sure wire is off spark plug .

24

Page 25

2. R emo v e wing n uts securing air cleaner co v er

to air cleaner and remo v e co v er . Clean co v er

thoroughly ( Figure 23 ).

Figure 23

1. Air cleaner cover

3. If foam element is dir ty , remo v e it from paper

element ( Figure 24 ). Clean thoroughly .

A. W ash foam element in a solution of liquid

soap and w ar m w ater . Squeeze to remo v e

dir t, but do not twist because the foam ma y

tear .

B . Dr y b y wrapping in a clean rag . Squeeze

rag and foam element to dr y , but do not

twist because the foam ma y tear .

C . Saturate element with clean engine oil.

Squeeze element to remo v e ex cess oil and

to distribute oil thoroughly . An oil damp

element is desirable .

Figure 24

1. Foam element 2. Paper element

4. W hen ser vicing foam element, c hec k condition

of paper element. Clean or re place ev er y 100

hours or as required.

5. Install foam element, paper element, and air

cleaner co v er .

Important: Do not operate the engine

without the air cleaner element because

extr eme engine w ear and dama ge will

lik el y r esult.

Replacing the Spark Plug

Use an NGK BPR 5ES spark plug or equi v alent.

Cor rect air g ap is 0.028-0.032 inc h R emo v e plug

after ev er y 100 operating hours and c hec k its

condition.

1. Pull molded wire off spark plug ( Figure 25 ).

25

Page 26

Figure 25

1. Spark plug wire

2. Clean around spark plug and remo v e plug

from cylinder head.

Important: R eplace a crack ed, f ouled,

or dir ty spar k plug . Do not sand blast,

scrape, or clean electr odes because engine

dama ged could r esult fr om g rit entering

the cylinder .

3. Set air g ap at 0.028-0.032 inc h ( Figure 26 ).

Install cor rectly g apped spark plug and tighten

fir mly to 17 ft.-lb .

Figure 27

1. Shut-off valve 2. Bowl

2. Clean bo wl and filter in clean g asoline and

install.

Electrical System

Maintenance

Servicing the Interlock

Switch

Use the follo wing procedure if the switc h needs

adjustment or re placement.

1. Mak e sure the engine is off and traction lev er

is Diseng ag ed.

2. Eng ag e traction lev er until it contacts neutral

stop ( Figure 28 ).

Figure 26

Fuel System

Maintenance

Cleaning the Fuel Filter

Initially , clean fuel filter after the first 25 hours of

operation; thereafter clean after ev er y 50 hours

operation.

1. Close fuel shut off v alv e and unscrew bo wl

from filter body ( Figure 27 ).

Figure 28

1. Traction lever 3. Interlock switch

2. Neutral stop

26

4. .032" Gap

Page 27

3. Loosen interloc k switc h mounting fasteners

( Figure 28 ).

4. Place a .032" thic k shim betw een the traction

lev er and the interloc k switc h ( Figure 28 ).

5. Tighten interloc k switc h mounting fasteners .

R ec hec k g ap . T he traction lev er m ust not

contact the switc h.

6. Eng ag e traction lev er and v erify that the switc h

loses contin uity . R e place if required.

Important: R eplace inter lock s witch

ev er y 2 y ear s.

Drive System

Figure 29

1. Check/ll plug 2. Drain plug

Maintenance

Checking the Transmission

Fluid Level

T he transmission is filled at the factor y with

appro ximately 94 fluid ounces of Mobil Dexron

lll automatic transmission fluid. Chec k fluid lev el

before the engine is first star ted and ev er y 50

hours thereafter .

Note: T he seals used in the transmission are

inter nally lubricated with g rease . During initial

operation of mo w er , slight w ee ping of g rease from

these seals will occur . Wipe off ex cess g rease .

Important: Use onl y Mobil Dexr on lll or

equi v alent transmission fluids. Other fluids

could cause system dama ge.

1. Place the mo w er on its dr ums on a lev el

surface .

2. R emo v e the c hec k/fill plug from the right-hand

side of the transmission ( Figure 29 ).

3. Install the plug .

Changing the Transmission

Fluid

Chang e the transmission fluid after the first 25

hours of operation and ev er y 2 years or 1500

hours , whic h ev er occurs first thereafter .

Important: Use onl y Mobil Dexr on lll or

equi v alent transmission fluids. Other fluids

could cause system dama ge.

1. Place a drain pan at the rear of the mac hine .

2. R emo v e the drain plug from the rear of the

transmission ( Figure 30 ).

T he oil lev el should come to the bottom of

the fill hole . If it does not, add enough of

the proper oil type until the lev el reac hes the

bottom of the fill hole .

Figure 30

1. Check/ll plug 2. Drain plug

3. Push do wn on the handle and tip the mac hine

bac k. R emo v e the c hec k/fill plug from the

right-hand side of the transmission ( Figure 30 ).

27

Page 28

4. W hen the fluid is drained, install the drain plug .

Reel Drive Belt (Reel)

5. Place the mo w er on its dr ums on a lev el

surface .

6. Fill the transmission with appro ximately 94

fluid ounces of the proper type of transmission

fluid until the lev el reac hes the bottom of

the c hec k/fill hole; refer to Chec king the

T ransmission Fluid.

7. Install the c hec k/fill plug .

Brake Maintenance

Adjusting the

Service/Parking Brake

If ser vice/park brak e slips when operated, an

adjustment is required.

1. Mo v e ser vice/parking brak e lev er to Off

position.

2. T o increase cable tension, loosen front cable

jam n ut and tighten bac k cable jam n ut

( Figure 31 ) until a force of 6-9 lb . is required

to eng ag e brak e . F orce to be measured at lev er

knob . Do not o v er adjust, or brak e band ma y

drag .

1. R emo v e the belt co v er mounting fasteners and

belt co v er to expose belt ( Figure 32 ).

Figure 32

1. Belt cover

2. Chec k tension b y de pressing belt ( Figure 33 )

at mid span of pulleys with 4 ± 1 lb . of force .

Belt should deflect 1/4 inc h (6 mm). If the

deflection is incor rect, proceed to next ste p .

Figure 31

1. Traction cable 2. Service/parking brake cable

Belt Maintenance

Adjusting the Belts

Mak e sure belts are properly tensioned to assure

proper operation of the mac hine and unnecessar y

w ear . Chec k belts frequently .

Figure 33

1. Reel drive belt 3. Driven pulley

2. Drive pulley

3. T o adjust belt tension:

A. Loosen the bearing housing mounting n uts

( Figure 34 ).

28

Page 29

Figure 34

1. Reel drive belt 2. Bearing housing mounting

nuts

B . Using a 3/8 inc h dri v e tor que wrenc h,

rotate the bearing housing with 35-40 in.-lb .

of tor que to set belt tension ( Figure 35 )

Figure 36

1. Belt cover

2. Chec k tension b y de pressing belt ( Figure 37 )

at mid span of pulleys with 4 ± 1 lb . of force .

Belt should deflect 1/4 inc h (6 mm). If the

deflection is incor rect, proceed to next ste p .

Figure 35

1. Bearing housing 2. 3/8" Torque wrench here

C . W hile holding the tor que wrenc h setting,

tighten the bearing housing mounting n uts

( Figure 34 ). Do not o v er -tension belt.

D . Install belt co v er .

Reel Drive Belt (Transmission coupler)

1. R emo v e the belt co v er mounting fasteners and

belt co v er to expose belt ( Figure 36 ).

Figure 37

1. Reel drive belt

3. T o adjust belt tension:

A. Loosen the bearing housing mounting n uts

( Figure 38 ).

29

Page 30

Figure 38

1. Reel drive belt 2. Bearing housing mounting

nuts

B . Using a 3/8 inc h dri v e tor que wrenc h,

rotate the bearing housing with 35-40 in.-lb .

of tor que to set belt tension ( Figure 39 ).

Figure 39

1. Bearing housing 2. 3/8" Torque wrench here

Figure 40

1. Traction drive belt cover

2. Chec k tension b y de pressing belt ( Figure 41 )

at mid span of pulleys with 4 ± 1 lb of force .

Belt should deflect 1/4 inc h (6 mm). If the

deflection is incor rect, proceed to next ste p .

C . W hile holding the tor que wrenc h setting,

tighten the bearing housing mounting n uts

( Figure 38 ). Do not o v er -tension belt.

D . Install belt co v er .

Traction Drive Belt

1. R emo v e belt co v er mounting fasteners and belt

co v er to expose belt ( Figure 40 ).

Figure 41

1. Traction drive belt

3. T o adjust belt tension:

A. On bac k side of side plate , loosen the bolt

securing the idler brac k et to the side plate

( Figure 42 ).

30

Page 31

Figure 42

1. Tang washer 2. Idler bracket bolt

B . Using a 3/8 inc h dri v e tor que wrenc h,

rotate the idler brac k et with 35-40 in.-lb . of

tor que to set the belt tension ( Figure 43 ).

W hile holding the tor que wrenc h setting,

tighten the idler brac k et mounting bolt

(T he tang w asher is installed to prev ent the

belt from slipping .). Do not o v er -tension

the belt.

Controls System

Maintenance

Adjusting the Traction

Control

If traction control does not eng ag e or it slips

during operation, an adjustment is required.

1. Mo v e traction control to Diseng ag ed position.

2. T o increase cable tension, loosen front cable

jam n ut and tighten bac k cable jam n ut

( Figure 44 ) until a force of 12-16 lb . is required

to eng ag e traction control.

Measure the force at the control knob .

Figure 43

1. Traction drive belt 3. 3/8 inch Torque wrench

here

2. Idler bracket

C . Install the belt co v er .

Figure 44

1. Traction cable 2. Service/parking brake cable

3. Tighten front cable jam n ut.

4. Chec k control operation.

Adjusting the Reel Control

If reel control does not eng ag e or it slips during

operation, an adjustment is required.

1. Mak e sure traction control is properly adjusted;

refer to Adjusting the T raction Control.

2. T o increase cable tension, loosen front cable

jam n ut and tighten bac k cable jam n ut

( Figure 45 ) (located on top of g ear bo x)

until the reel cable force adds 7 to 10 lbs . of

additional handle force measured at the control

knob .

Note: If traction control handle force is

12 lbs ., the combined traction and reel force

should be 19 to 22 lbs .

31

Page 32

Figure 45

1. Reel control cable

3. Tighten front cable jam n ut.

4. Chec k control operation.

Cutting Unit

Figure 47

1. Cutting unit pivot arms

2. Traction unit frame tube

3. Bolts

5. R otate pi v ot ar ms forw ard ( Figure 47 ) and rest

traction unit on restrained kic kstand.

Maintenance

Separating the Cutting Unit

from the Traction Unit

1. Place the mo w er on its dr ums on a lev el

surface .

2. Lo w er kic k stand. Inser t a 1/4" dia. pin or

equi v alent into frame hole abo v e kic k stand

mounting bolt ( Figure 46 ).

6. Pull cutting unit forw ard about 2 inc h

(51 mm) and then to the right to diseng ag e the

transmission coupling ( Figure 48 ).

Figure 48

1. Transmission coupling

7. R ev erse procedure to install cutting unit.

Adjusting the Rear Roller

Figure 46

1. 1/4" Pin 3. Kick stand

2. Handle

3. R emo v e g rass bask et.

4. R emo v e (2) bolts securing cutting unit pi v ot

ar ms to traction unit frame tube ( Figure 47 ).

1. Adjust the rear roller brac k ets to the lo w or

high position de pending on desired height of

cut rang e ( Figure 49 and Figure 50 ).

• P osition the spacer abo v e the side plate

mounting flang e (factor y setting) when

height of cut settings rang e from 1/16 to

1/4" (Fig . 10).

32

Page 33

Figure 49

1. Spacer

2. Sideplate mounting ange

3. Roller bracket

• P osition the spacer belo w the side plate

mounting flang e when height of cut

settings rang e from 1/8" to 1" ( Figure 50 ).

Note: T he position of the rear roller to the

reel is controlled b y the mac hining tolerances

of the assembled components and paralleling is

not required. A limited amount of adjustment

is possible b y setting the cutting unit on a

surface plate and loosening the side plate

mounting bolts ( Figure 51 ). Adjust and

re-tighten bolts .

Figure 51

1. Sideplate mounting bolts

Figure 50

1. Sideplate mounting ange 3. Roller bracket

2. Spacer

2. T o adjust rear roller proceed as follo ws:

• Raise rear of cutting unit and place a bloc k

under bedknife .

• R emo v e (2) n uts securing eac h roller

brac k et and spacer to eac h side plate

mounting flang e .

• Lo w er roller and screws from side plate

mounting flang es and spacers .

• Place spacers onto screws on roller

brac k ets .

• R e-secure roller brac k et and spacers to

underside of side plate mounting flang es

with n uts previously remo v ed.

Important: W henev er the cutting unit

has to be tipped to expose bedknife/r eel,

pr op up r ear of cutting unit to mak e sur e

n uts on back end of bedbar adjusting

scr ews ar e not r esting on w or k surf ace.

Adjusting the Bedknife to

the Reel

Bedknife to reel adjustment is accomplished b y

loosening or tightening bedbar adjusting screws ,

located on top of mo w er .

1. P osition mac hine on a flat, lev el w ork surface .

2. Mak e sure reel contact is remo v ed b y tur ning

bedbar adjusting screws countercloc kwise

( Figure 52 ).

3. V erify that the bedknife to reel contact is

cor rect. Tip mo w er to expose front and rear

rollers and bedknife .

33

Page 34

Figure 52

1. Bedbar adjusting screw

3. Tilt mo w er on bac k to expose bedknife and

reel.

4. At one end of reel, inser t a long strip

of newspaper betw een reel and bedknife

( Figure 53 ). W hile slo wly rotating reel forw ard,

tur n bedbar adjusting screw cloc kwise (on same

end of reel) ( Figure 52 ), one clic k at a time ,

until paper is pinc hed lightly , when inser ted

from the front, parallel to the bedknife . A

slight drag will be noted as the paper is pulled.

angle to the bedknife ( Figure 53 ). It should be

possible to cut paper with minim um contact

betw een the bedknife and the reel blades .

Should ex cessi v e reel drag be evident it will

be either necessar y to bac klap or reg rind the

cutting unit to ac hiev e the shar p edg es needed

for precision cutting (see T oro reel shar pening

man ual).

Adjusting the Height of Cut

F or heights of cut g reater than .500", the high

height of cut kit m ust be installed.

1. Loosen loc kn uts securing height-of-cut ar ms

to cutting unit side plates ( Figure 54 ).

Figure 53

Note: Eac h time adjusting screw is rotated

one clic k cloc kwise , the bedknife mo v es .0007

inc h closer to reel. Do not o v er tighten the

adjusting screws .

5. Chec k for light contact at other end of reel

using paper and adjust as required.

6. After adjustment is accomplished, c hec k to see

if reel can pinc h paper when inser ted from the

front and cut paper when inser ted at a right

Figure 54

1. Rear roller bracket 3. Locknut

2. Height-of-cut arm 4. Adjusting screw

2. Loosen n ut on g aug e bar ( Figure 55 ) and

set adjusting screw to desired height-of-cut.

Distance betw een bottom of screw head and

face of bar is height-of-cut.

34

Page 35

Figure 55

1. Gauge bar

2. Height adjusting screw

3. Nut

3. Hook screw head on cutting edg e of bedknife

and rest rear end of bar on rear roller

( Figure 56 ).

1. Loosen screws securing top bar ( Figure 57 ) to

cutting unit.

Figure 57

1. Cut-off bar

2. Inser t .060 inc h feeler g aug e betw een top

of reel and bar and tighten screws . Ensure

bar and reel are equal distance apar t across

complete reel.

Figure 56

4. R otate adjusting screw until roller contacts

front of g aug e bar . Adjust both ends of roller

until entire roller is parallel to the bedknife .

Important: W hen set pr oper l y , the r ear

and fr ont r oller s will contact the gauge

bar and the scr ew will be sn ug a gainst

the bedknife. T his ensur es that the

height-of-cut is identical at both ends of

the bedknife.

5. Tighten n uts to secure adjustment. Do not

o v er tighten n ut. Tighten enough to remo v e

pla y from w asher .

Note: Use the follo wing c har t to deter mine

whic h bedknife is best suited for the desired

height of cut.

Note: T he bar is adjustable to compensate

for c hang es in turf conditions . T he bar should

be adjusted closer to reel when turf is extremely

dr y . By contrast, adjust bar fur ther a w a y from

reel when turf conditions are w et. T he bar

should be parallel to reel to ensure optim um

perfor mance and should be adjusted whenev er

reel is shar pened on a reel g rinder .

Adjusting the Cut-Off Bar

Adjust cut-off bar to assure clippings are cleanly

disc harg ed from the reel area:

35

Page 36

Setting the Machine to

Match Turf Conditions

Use the follo wing table to set the mac hine to

matc h turf conditions .

Flex Greensmower Cutting Unit Set-up Matrix

Bedbars: Standard and Optional

Part Number

106-2468-01

99-3794-03

110-2282-01

110-2281-03

Bedknives: Standard and Optional

Part Number

93-4262

93-4263

93-4264 Low Cut

108-4303

98-7261

98-7260

110-2300

110-2301 Low Cut

Description

Standard Flex 21

Aggressive

Standard Flex 18

Aggressive

Description

Microcut

Tournament

Extended Microcut Flex 21 0.062 - 0.125 inches

Microcut

Tournament

Extended Microcut Flex 18 0.062 - 0.125 inches

Mower

Flex 21

Flex 18

Mower

Flex 21 0.062 - 0.125 inches Standard

Flex 21 0.125 -0.25 inches

Flex 21 0.25 inches and up

Flex 18 0.062 - 0.125 inches Standard

Flex 18 0.125 -0.25 inches

Flex 18 0.25 inches and up

Aggressiveness

Less

More

Less

More

Height of Cut Range

Comments

Standard

Standard

Comments

Less Aggressive

Less Aggressive

Rollers: Standard and Optional

Part Number

107-9037

107-9038

107-9039

107-9036

106-6945

110-2304

110-2305

110-2306

110-2303

Description

Narrow Wiehle Flex 21 2.5 inches Aluminum Standard Front

Wide Wiehle Flex 21 2.5 inches Aluminum

Full Roller Flex 21 2.5 inches Steel

Rear Roller Flex 21 2.0 inches Aluminum Standard Rear

Rear Roller Flex 21 2.0 inches Steel Steel Rear

Narrow Wiehle Flex 18 2.5 inches Aluminum Standard Front

Wide Wiehle Flex 18 2.5 inches Aluminum

Full Roller Flex 18 2.5 inches Steel

Rear Roller Flex 18 2.0 inches Aluminum Standard Rear

Mower

Diameter/Material

Comments

More Penetration

Least Penetration

More Penetration

Least Penetration

36

Page 37

Use the follo wing table and Figure 58 to set the

rate of clip .

Clip (Refer to Figure 58 for pulley locations.)

Drive pulley number of

teeth

27 22

22 22

22 27

Driven pulley number

of teeth

T he reel is shipped with one 27 tooth and one

22 tooth pulley . T o g et a .16 inc h clip , y ou m ust

purc hase a 22 tooth pulley . T he clip can only be

c hang ed on the reel dri v e ( Figure 58 ). Do not

c hang e the dri v e ratio on the g earbo x pulleys .

11 Blade Clip 8 Blade Clip

.14 inches (standard)

.16 inches .24 inches

.21 inches .29 inches

Figure 59

1. Bedbar adjusting screw

2. Spring tension nut

3. Bedbar

4. Jam nut

5. Bedbar bolt

.19 inches

Figure 58

1. Reel drive belt 3. Driven pulley

2. Drive pulley

Servicing the Bedbar

Removing the Bedbar

1. T ur n the bedbar adjuster screw ,

countercloc kwise , to bac k the bedknife

a w a y from reel ( Figure 59 ).

2. Bac k out the spring tension n ut, until the

w asher is no long er tensioned ag ainst the

bedbar ( Figure 60 ).

3. On eac h side of the mac hine , loosen the jam

n ut securing the bedbar bolt ( Figure 60 ).

Figure 60

1. Bedbar bolt

2. Nut

4. R emo v e eac h bedbar bolt allo wing bedbar to be

pulled do wnw ard and remo v ed from mac hine .

Account for 2 nylon and 2 stamped steel

w ashers on eac h end of bedbar ( Figure 61 ).

37

Page 38

Figure 61

1. Bedbar bolt

2. Steel washer 4. Nylon washer

3. Nut

Assembling the Bedbar

1. Install bedbar , positioning mounting ears

betw een w asher and bedbar adjuster .

2. Secure bedbar to eac h side plate with bedbar

bolts (jam n uts on bolts) and 8 w ashers . A

nylon w asher is to be positioned on eac h side

of side plate boss . Place a steel w asher outside

eac h of the nylon w ashers . T or que bolts to

240-320 in.-lb .

3. Tighten the jam n ut until the end pla y is

remo v ed from the outside thr ust w ashers . Do

not o v er tighten.

Note: It is acce ptable that the inside thr ust

w ashers on the cutting unit ma y remain loose .

4. Tighten spring tension n ut until spring is

collapsed, then bac k off 1/2 tur n.

5. Adjust bedbar; refer to Adjusting the Bedknife

to the R eel.

Backlapping the Reel

1. R emo v e plug from the reel dri v e co v er on the

left side of reel assembly ( Figure 62 )

Figure 62

1. Reel drive cover plug

2. Inser t a 18 mm soc k et onto hex flang e n ut on

left end of reel shaft.

3. Bac klap according to the procedure in the T oro

Shar pening R eel and R otar y Mo w ers Man ual,

F or m No . 80-300 PT .

Contact with the r eel or other mo ving

par ts can r esult in per sonal injur y .

• Stay a w ay fr om the r eel while

backlapping .

• Nev er use a shor t handled paint

br ush f or backlapping . P ar t No.

29-9100 Handle assembl y complete

or indi vidual par ts ar e a v aila ble

fr om y our local Authoriz ed T or o

Distributor .

Note: F or a better cutting edg e , r un a file

across the front face of the bedknife when

the lapping operation is completed. T his will

remo v e any bur rs or rough edg es that ma y

ha v e built up on the cutting edg e .

4. R einstall plug when bac klap operation is

completed.

38

Page 39

Storage

1. R emo v e g rass clippings , dir t, and g rime from

the exter nal par ts of the entire mac hine ,

especially the engine . Clean dir t and c haff from

the outside of the engine’ s cylinder head fins

and blo w er housing .

Important: Y ou can w ash the machine

with mild detergent and w ater . Do

not pr essur e w ash the machine. A v oid

ex cessi v e use of w ater , especiall y near the

shift lev er plate, and engine.

2. F or long-ter m storag e (more than 90 da ys) add

stabilizer/conditioner additi v e to fuel in the

tank.

A. R un the engine to distribute conditioned

fuel through the fuel system (5 min utes).

B . Either stop engine , allo w it to cool, and

drain the fuel tank, or operate the engine

until it stops .

C . R estar t the engine and r un it until it stops .

R e peat, on Chok e , until the engine will not

restar t.

D . Dispose of fuel properly . R ecycle as per

local codes .

Note: Do not store stabilizer/conditioned

g asoline o v er 90 da ys .

3. Chec k and tighten all bolts , n uts , and screws .

R e pair or re place any par t that is damag ed or

defecti v e .

4. P aint all scratc hed or bare metal surfaces . P aint

is a v ailable from y our A uthorized Ser vice

Dealer .

5. Store the mac hine in a clean, dr y g arag e or

storag e area. Co v er the mac hine to protect it

and k ee p it clean.

39

Page 40

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its afliate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your

Toro Commercial Product (“Product") to be free from defects

in materials or workmanship for two years or 1500 operational

hours*, whichever occurs rst. Where a warrantable condition

exists, we will repair the Product at no cost to you including

diagnosis, labor, parts, and transportation. This warranty

begins on the date the Product is delivered to the original retail

purchaser.

* P r o d u c t e q u i p p e d w i t h h o u r m e t e r

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from

whom you purchased the Product as soon as you believe a

warrantable condition exists.

If you need help locating a Commercial Products Distributor

or Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: commercial.service@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required

maintenance and adjustments stated in your operator’s manual.

Failure to perform required maintenance and adjustments can be

grounds for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modied, or unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in

an abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used

up, during normal Product operation include, but are not

limited to, blades, reels, bedknives, tines, spark plugs, castor

wheels, tires, lters, belts, and certain sprayer components

such as diaphragms, nozzles, and check valves, etc.

• Failures caused by outside inuence. Items considered to be

outside inuence include, but are not limited to, weather,