Page 1

FormNo.3367-381RevB

Greensmaster

®

Flex18orFlex21

Walk-BehindMower

ModelNo.04019—SerialNo.311000001andUp

ModelNo.04024—SerialNo.311000001andUp

ModelNo.04025—SerialNo.311000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Introduction

Thismachineisawalk-behind,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedfor

cuttinggrassonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.Itis

notdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

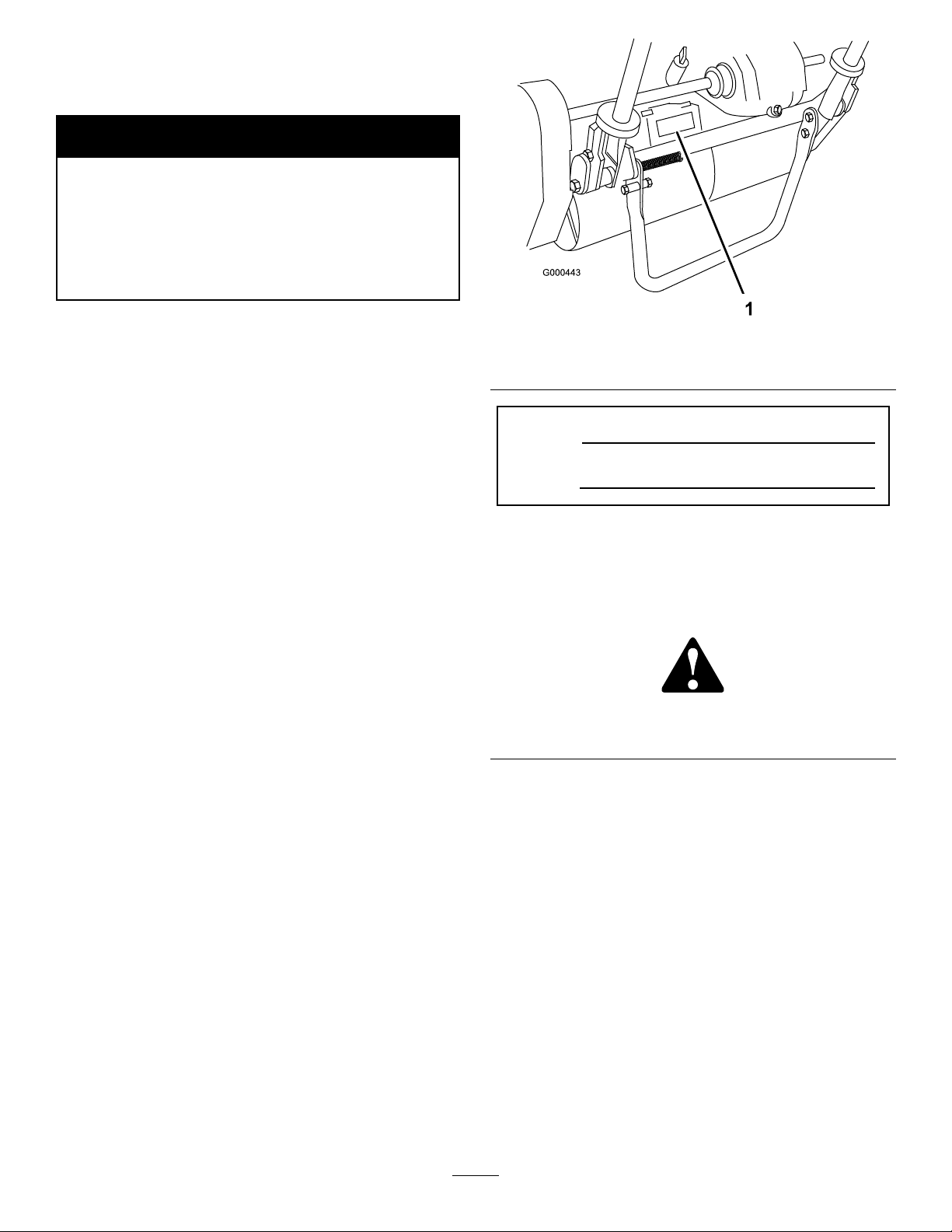

Figure1

1.Locationofthemodelandserialnumbers-Tractionunit

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .

Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................5

SoundPowerLevel-Flex18..................................6

SoundPressureLevel-Flex18...............................6

VibrationLevel-Flex18.......................................6

SoundPowerLevel-Flex21..................................6

SoundPressureLevel-Flex21...............................7

VibrationLevel-Flex21........................................7

SafetyandInstructionalDecals.............................7

Setup............................................................................9

1InstallingtheCuttingUnittotheTraction

Unit................................................................10

2InstallingtheHandle........................................11

3InstallingtheKickstandforFlex18Mowers

Only...............................................................11

4AdjustingtheHandle.......................................12

5InstallingtheTransportWheels........................12

6CheckingFluidLevels......................................13

7InstallingtheGrassBasket...............................13

ProductOverview......................................................15

Controls.............................................................15

Specications.....................................................16

Attachments/Accessories...................................16

Operation...................................................................17

ThinkSafetyFirst...............................................17

CheckingtheEngineOilLevel............................17

FillingtheFuelTank...........................................17

CheckingtheInterlockSwitchOperation............18

StartingandStoppingtheEngine........................18

TransportOperation..........................................18

PreparingtoMow...............................................19

MowingOperation.............................................19

Maintenance...............................................................21

RecommendedMaintenanceSchedule(s)................21

DailyMaintenanceChecklist...............................22

EngineMaintenance...............................................23

EngineOil..........................................................23

ServicingtheAirCleaner....................................24

ReplacingtheSparkPlug....................................24

FuelSystemMaintenance.......................................25

CleaningtheFuelFilter.......................................25

ElectricalSystemMaintenance................................26

ServicingtheInterlockSwitch............................26

DriveSystemMaintenance.....................................26

CheckingtheTransmissionFluidLevel...............26

ChangingtheTransmissionFluid........................27

BrakeMaintenance.................................................27

AdjustingtheService/ParkingBrake...................27

BeltMaintenance....................................................28

AdjustingtheBelts.............................................28

ControlsSystemMaintenance.................................31

AdjustingtheTractionControl...........................31

AdjustingtheReelControl..................................31

Storage.......................................................................32

3

Page 4

Safety

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

ThismachinemeetsorexceedsCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004specicationsineffectatthetimeof

productionwhentheOperatorPresenceKit,PartNo.

105-5333isinstalled.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalert

CAUTION,WARNING,orDANGER-“personalsafety

instruction."Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

symbol,whichmeans

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•ReadtheOperator’sManualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andear

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning-Fuelishighlyammable.Takethe

followingprecautions:

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly ,

andfunctioningproperly .

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’sposition:

–stoponlevelground;

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–disengagethepowertake-offandlowerthe

attachments;

4

Page 5

–changeintoneutralandsettheparkingbrake;

–stoptheengine.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Reducethethrottlesettingbeforestoppingengine

and,iftheengineisprovidedwithafuelshut-off

valve,turnthevalveoffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunit.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopreelsifnot

mowing.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Disengagedrives,disengagethecuttingunit,set

parkingbrake,stopengineanddisconnectsparkplug

wire.Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunit,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryandremovesparkplugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingthereel.W earglovesand

usecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandfuelstorageareafreeof

grass,leaves,orexcessivegrease.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO ,or

ANSIstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlegasolinecarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Alwaysstandbehindthehandlewhenstartingand

operatingthemachine.

5

Page 6

•Tostartandstoptheengine:

–Openfuelshut-offvalve.

–Verifythatthetractionandreeldrivecontrol

leversonhandleareinNeutralposition.

–Movetheon/offswitch,locatedonthecontrol

panel,toONposition,setchoketofullchoke

position(coldstart)andthrottletohalfthrottle.

–Pullstartercordtostartengine.

–MovethrottletoSlowandon/offswitchtoOff

positiontostopengine.

•Totransportmowerfromoneareatoanother:

–Installtransportwheels.

–Disengagereeldrive.

–Startengine.

–Pressdownonhandletoraisefrontofmower

andengagetractiondrive.

•Beforebeginningmowingoperation:

–Disengagetractiondrive.

–Stopengine.

–Removetransportwheels.

–Startengine

–Engagereeldrive.

•Usingthemachinedemandsattention.T oprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

•Thegrassbasketmustbeinplace,duringthe

mowingoperation,formaximumsafety.Shutthe

engineoffbeforeemptyingthebasket.

•Donottouchtheengine,mufer,orexhaustpipe

whiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenough

tocauseburns.

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

MaintenanceandStorage

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecuttingunit,

attachmentsandanymovingparts.Keepeveryone

away.

•Toensuresafetyandaccuracy,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.Maximumgovernedenginespeed

shouldbe3600RPM.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

SoundPowerLevel-Flex18

Thisunithasaguaranteedsoundpowerlevelof96dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11094.

SoundPressureLevel-Flex18

Thisunithasasoundpressurelevelattheoperator’s

earof84dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel-Flex18

Hand-Arm

Measuredvibrationlevelforrighthand=2.36m/s

Measuredvibrationlevelforlefthand=2.47m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

SoundPowerLevel-Flex21

Thisunithasaguaranteedsoundpowerlevelof97dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11094.

2

6

Page 7

SoundPressureLevel-Flex21

VibrationLevel-Flex21

Thisunithasasoundpressurelevelattheoperator’s

earof92dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

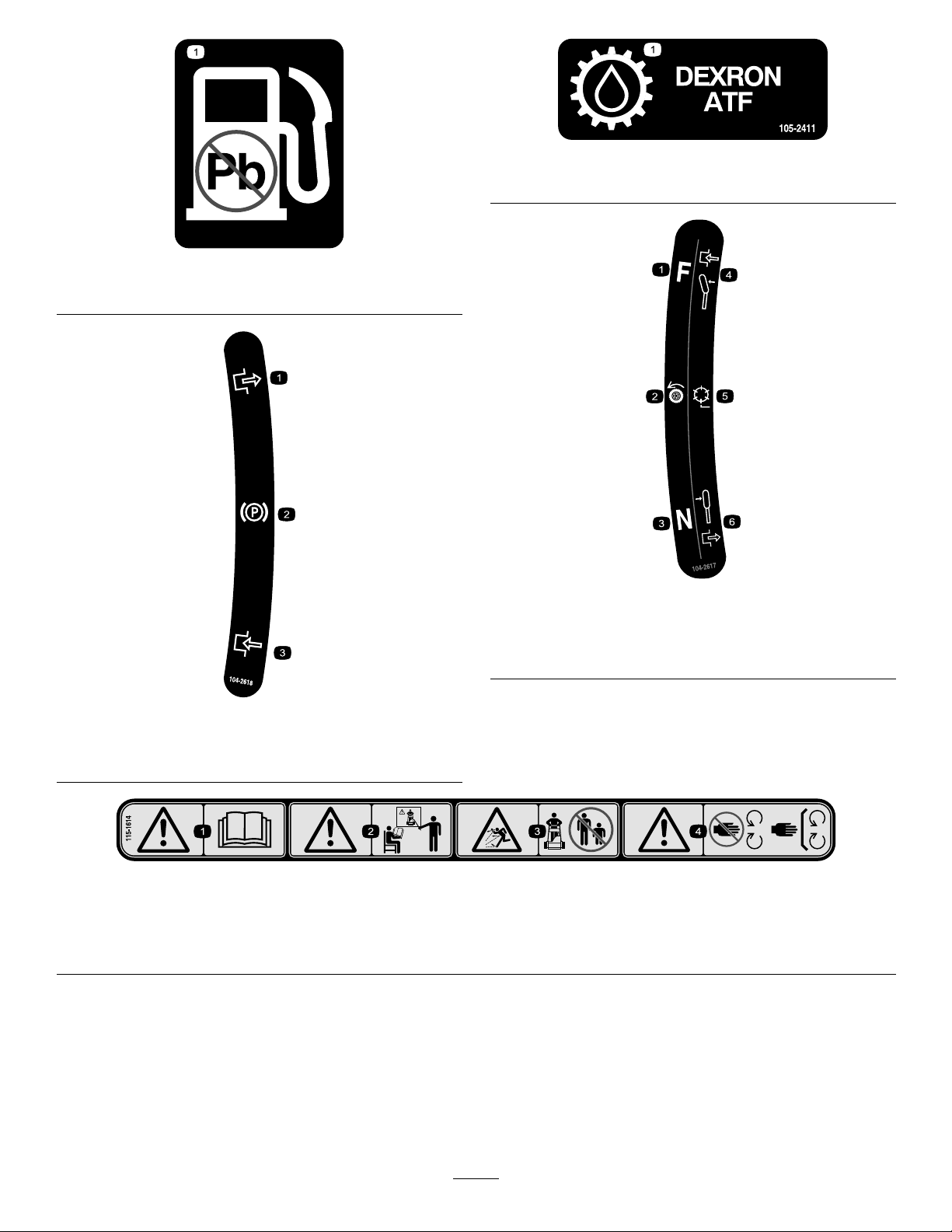

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

Hand-Arm

Measuredvibrationlevelforrighthand=2.36m/s

Measuredvibrationlevelforlefthand=2.47m/s

UncertaintyValue(K)=0.5m/s

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

115-1615

1.Warning—donottouchthehotsurface.

2

2

115-1613

1.Warning—readthe

Operator’sManual.

2.Warning—remove

thesparkplugwire

beforeperformingany

maintenanceonthe

machine.

1.Entanglementhazard—stayawayfrommovingparts.

3.Thrownobject

hazard—keepbystanders

asafedistancefromthe

machine.

4.Cutting,dismemberment

hazardofhandor

foot—stayawayfrom

movingparts.

93-9356

1.Fast

2.Continuousvariable

setting

93-6085

3.Slow

1.Engine—stop2.Engine—run

7

112-9408

Page 8

1.Useunleadedgasoline.

105-2411

1.Transmissionoil

93-9886

104-2617

1.Tractiondrive4.Forward

2.Reeldrive5.Leverengaged

3.Neutral6.Leverdisengaged

104-2618

1.Parkingbrake3.Engage

2.Disengage

115-1614

1.Warning—readtheOperator’sManual.3.Thrownobjecthazard—keepbystandersasafedistancefrom

2.Warning—donotoperatethemachineunlessyouaretrained.

themachine.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Qty.

Bolt,M10x25mm2Installthecuttingunittothetractionunit

Handle1Installthehandle.

Kickstandassembly1

Spring

Smallspacer

Largespacer1

Largebolt(M8–1.25x100)

Smallbolt(M8–1.25x030)

Locknut(M8x1.25)

Washer(M8)

Nopartsrequired

Transportwheels(OptionalTransport

WheelKit,Model04123)

Nopartsrequired

Grassbasket

1

1

InstallthekickstandforFlex18Mowers

1

1

2

2

–

2Installthetransportwheels.

–

1Installthegrassbasket.

Only.

Adjustthehandle.

Checktheengineoilandtransmission

uidlevels

Use

MediaandAdditionalParts

Description

Operator’sManual

EngineOperator’sManual

PartsCatalog

OperatorTrainingMaterial

CerticateofCompliance

Qty.

Use

1

1

1

1

1

Readorviewbeforeoperatingthemachine

9

Page 10

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

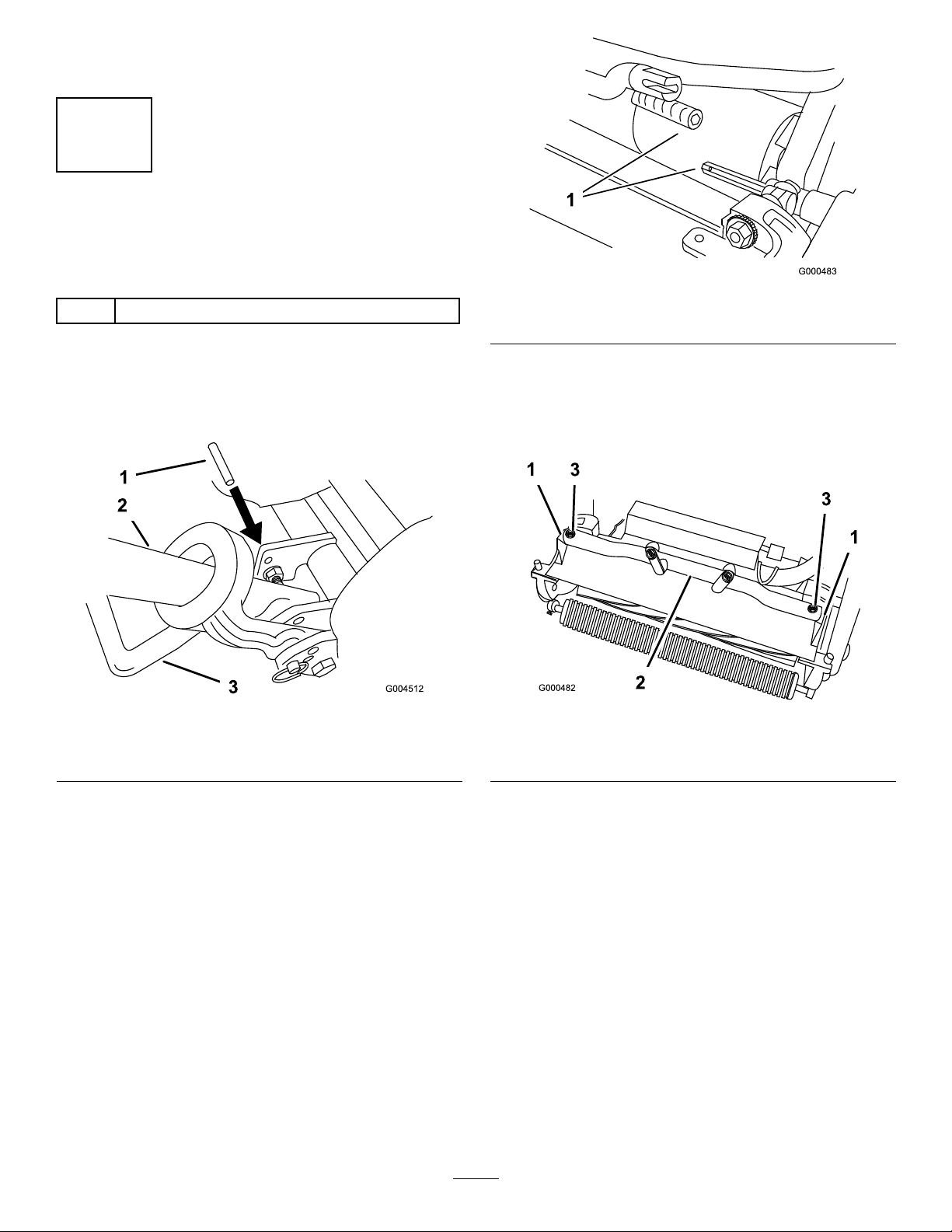

1

InstallingtheCuttingUnitto

theTractionUnit

Partsneededforthisprocedure:

2Bolt,M10x25mm

1.Placethemoweronitsdrumsonalevelsurface.

2.Lowerkickstand.Inserta1/4"dia.pinorequivalent

intoframeholeabovekickstandmountingbolt

(Figure3).

Figure3

1.1/4"Pin

2.Handle

3.Kickstand

Figure4

1.Transmissioncoupling

4.Rotatethetractionunitframe(Figure5)forward

untilitengagesthecuttingunitpivotarms.

5.Securethetractionunitframetothecuttingunit

pivotarmswith(2)M10x25mmbolts(Figure5)

Figure5

1.Cuttingunitpivotarms

2.Tractionunitframe

3.Bolts

3.Pushthecuttingunitunderthetractionunitand

thentothelefttoengagethetransmissioncoupling

(Figure4).

Note:Whentighteningthepivotarmmounting

fasteners,useanadjustableendwrenchtoholdthe

pivotarmparalleltothesideplate(Figure6)

10

Page 11

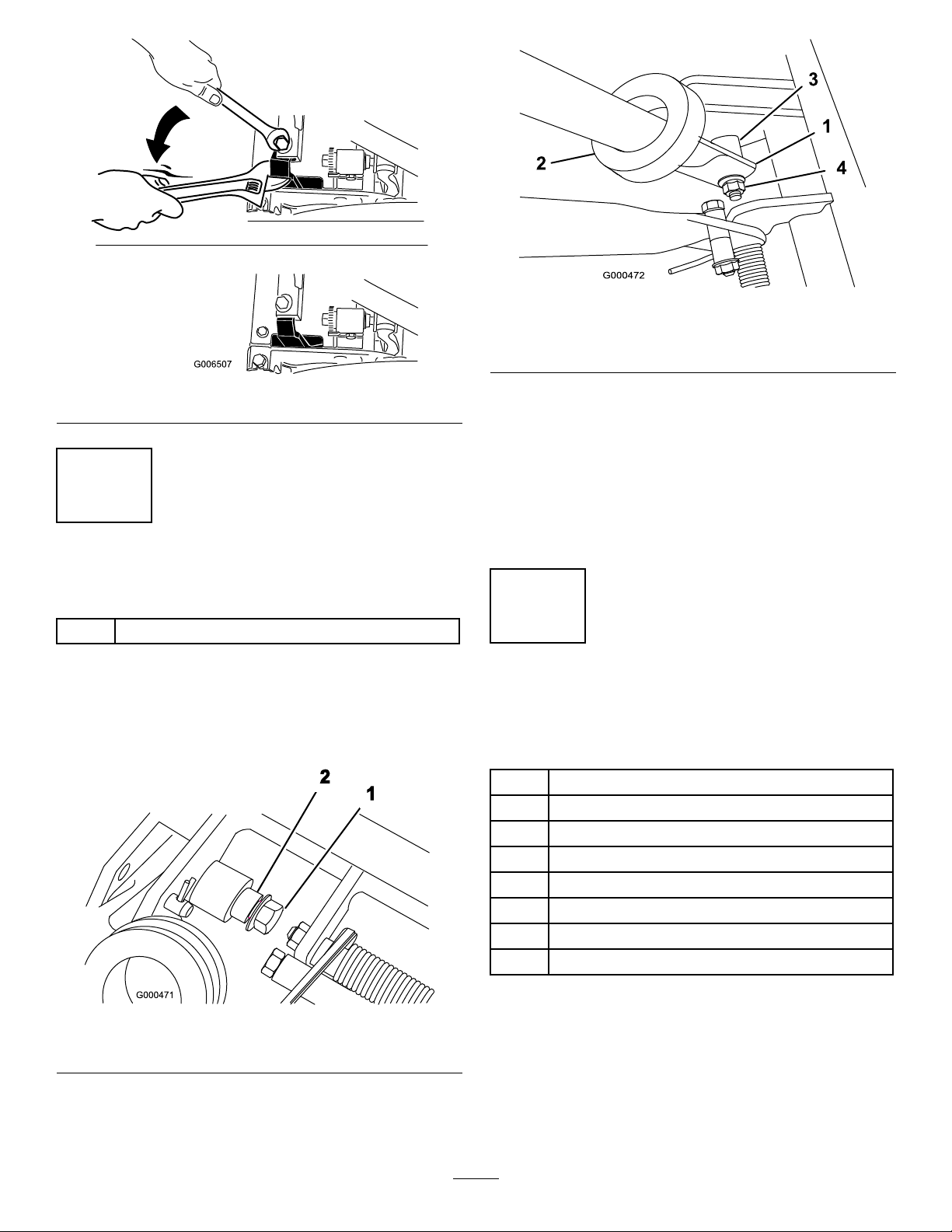

1.Lefthandleend

2.Supportarm

Figure8

3.Pivotpin

4.Locknut

Figure6

2

InstallingtheHandle

Partsneededforthisprocedure:

1Handle

Procedure

1.Removetheangelocknutfromtheboltandpivot

pinoneachsideofthemower(

Figure7).

3.Squeezethehandleendsinwardandinstallthemon

thestepofthepivotpin(

4.Securethehandletotheboltandpivotpinwiththe

angelocknut(Figure8).

5.Locatecabletielooselysecuringthrottlecableto

wireharness.Positioncabletieapproximatelyone

inchbehindtransmissionandtightencabletie.

Figure8).

3

InstallingtheKickstandfor

Flex18MowersOnly

Partsneededforthisprocedure:

1Kickstandassembly

1

Spring

1

Smallspacer

1Largespacer

1

Largebolt(M8–1.25x100)

1

Smallbolt(M8–1.25x030)

2

Locknut(M8x1.25)

2

Washer(M8)

Figure7

1.Flangelocknut2.Pivotpin

2.Insertthehandleendsthroughtheslotsinthehandle

supportarms(Figure8).

Procedure

1.Positionthekickstandbetweenthetabsontherear

oftheframe.

2.Installawasher(M8)ontothesmallbolt(M8–1.25

x030).Installtherightsideofthekickstandtothe

11

Page 12

framewiththeboltandwasher,thesmallspacer,

andlocknut(M8–1.25)(Figure9).Ensurethebolt

isinstalledfromtheinsideoftheframeasshown

Figure9.

in

3.Installawasher(M8)ontothelargebolt(M8–1.25x

100).

4.Installthespacerintothespringandinstallthelarge

bolt(M8–1.25x100)intothespacer.

Important:Wheninstallingthespring,place

oneendofthespringundertherearframe

Figure9).

(

5.Installtheleftsideofthekickstandtotheframe

withtheboltandwasher,thelargespacerandspring,

andlocknut(M8–1.25)(Figure9).Ensurethebolt

isinstalledfromtheinsideoftheframeasshown

Figure9.

in

Figure10

1.Spring

2.Springendunderthe

frame

3.Nutrunner

4.Movethespringendunder

thekickstandspacer.

4

AdjustingtheHandle

NoPartsRequired

Procedure

1.Removehairpincottersfromringpinsoneachside

ofmower(Figure11).

Figure9

1.Lefthandleend5.Largebolt(M8–1.25x

2.Locknut(M8–1.25)6.Spring

3.Smallspacer

4.Washer(M8)8.Ssmallbolt(M8–1.25x

100)

7.Largespacer

030)

6.Placeanutrunnerovertheendofthespringpointing

towardstherearandmovetheendofthespringover

andunderthekickstandspacer(Figure10).

Figure11

1.Ringpins

2.Whilesupportinghandle,removeringpinsfrom

eachsideandraiseorlowerhandletodesired

operatingposition(Figure11).

3.Reinstallringpinsandhairpincotters.

12

Page 13

5

InstallingtheTransport

Wheels

Partsneededforthisprocedure:

Transportwheels(OptionalTransportWheelKit,

2

Model04123)

Procedure

1.Pushkickstanddownwithfootandpullupon

handlesupportuntilkickstandhasrotatedforward,

overcenter(Figure12).

Figure13

1.Lockingclip

3.Rotatewheelbackandforthuntilitslidescompletely

ontoaxleandlockingclipissecuredingrooveon

axleshaft.

Figure12

1.Kickstand

2.Presswheellockingcliptowardthecenterofwheel

andslidewheelontohexshaft(Figure13).

4.Repeatprocedureonoppositesideofmachine.

5.Inatethetiresto12-15psi.

6.Carefullyliftuponhandlesupporttoreleasekick

stand.

6

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checktheengineoillevel,refertoCheckingthe

EngineOilLevel.

2.Checkthetransmissionuidlevel,refertoChecking

theTransmissionFluidLevel.

13

Page 14

7

InstallingtheGrassBasket

Partsneededforthisprocedure:

1

Grassbasket

Procedure

Graspbasketbytoplipandslidebasketframeintothe

receivers(Figure14).

1.Grassbasket

Figure14

2.Basketreceivers

14

Page 15

ProductOverview

G009976

1

2

3

4

5

Figure15

1.Handle

2.Controlpanel6.Grassbasket

3.Engine7.Fueltank

4.Transportwheels

Controls

5.Cuttingunit

TractionandReelDriveEngagement

Lever

Thetractionandreeldriveengagementlever(Figure16)

islocatedonfrontrightsideofcontrolpanel.Traction

leverhastwopositions:NeutralandForward.Pushing

leverforwardengagestractiondrive.

Thereeldriveleverhastwopositions:Engageand

Disengage.Movetopoflevertothelefttoengagereel

orbacktoneutraltodisengagereel.

Service/ParkingBrake

Theservice/parkingbrake(Figure16)islocatedonleft

frontsideofcontrolpanel.Pullingtheleverbackover

centerwillsettheparkingbrake.Brakemustbereleased

beforetractiondriveisengaged.

On/OffSwitch

Theon/offswitch(Figure16)islocatedontopof

controlpanel.MoveswitchtoOnpositiontostart

engineandOfftostopengine.

HourMeter

Thehourmeter(Figure16),locatedontopofthe

controlpanel,indicatesthetotalhoursofmachine

operation.

OperatorPresenceControl

Figure16

1.Throttlecontrol

2.Traction&reeldrive

engagementlever

3.Service/parkingbrake

4.On/offswitch

5.Hourmeter

ThrottleControl

Thethrottlecontrol(Figure16)islocatedonrearright

sideofcontrolpanel.Leverconnectstoandoperates

throttlelinkagetocarburetor.Enginespeedcanbe

variedfrom2400RPMto3600RPM.

Theoptionaloperatorpresencecontrolmustbeengaged

beforeengagingthetractionleverortheenginewillstop.

ChokeLever

Thechokelever(Figure17)islocatedonleftfrontof

engine.Leverhastwopositions:RunandChoke.Move

thechokelevertothehalf-openpositionwhenstarting

acoldengine.AfterenginestartsmovelevertoRun

position.

1.Chokelever2.Fuelshut-offvalve

Figure17

15

Page 16

FuelShut-OffValve

G009975

1

Kickstand

Thefuelshut-offvalve(Figure17)islocatedonleft

frontofengine.Valvehastwopositions:Closedand

Open.Movelevertoclosedpositionwhenstoring

ortransportingmachine.Openvalvebeforestarting

engine.

RecoilStarter

Pullrecoilstarterhandle(Figure18)tostartengine.

Thekickstand(Figure19)ismountedtorearofmachine

andisusedtoraiserearofmachineforinstallationor

removaloftransportwheels.

Figure19

1.Kickstand

Specications

Attachments/Accessories

Figure18

1.Recoilstarter

Flex21Flex18

Width

Height

Lengthwithbasket

Netweight

Widthofcut21inches(53.3cm)18inches(45.7cm)

Heightofcut1/16to19/64inches(1.5to7.5mm)with

Clipfrequency11blade(standard):.14inch11blade(standard):.14inch

35-1/2inches(90.1cm)32inches(81.3cm)

41–1/4inches(104.8cm)41–1/2inches(105.4cm)

61–1/2inches(156.2cm)61inches(155cm)

Model04024–185lb(84kg)Model04019–175lb(79kg)

Model04202–82lb(37kg)Model04206–82lb(37kg)

Model04025–185lb(84kg)Model04207–89lb(40kg)

Model04208–89lb(40kg)

Micro-Cutbedknife

1/16to19/64inches(1.5to7.5mm)withMicro-Cut

bedknife

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

16

Page 17

Operation

g014638

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyouorbystandersavoidinjury.

CheckingtheEngineOilLevel

Checktheengineoillevelbeforeeachuseorevery8

operatinghours,refertoCheckingtheEngineOilLevel.

FillingtheFuelTank

Important:Neverusemethanol,gasoline

containingmethanol,gasoholcontainingmore

than10%ethanol,gasolineadditives,premium

gasoline,orwhitegasbecausethefuelsystem

couldbedamaged.Donotmixoilwithgasoline.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsgasoline

toexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

Figure20

1.Fueltankcap

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Cleanaroundfueltankcapandremovecapfrom

tank(Figure20).Usingunleadedgasoline,llfuel

tanknohigherthantobottomoflterscreen.Do

notoverll.

2.Installfueltankcapandwipeupanyspilledgasoline.

17

Page 18

CheckingtheInterlockSwitch

Operation

5.Iftheenginedoesnotshutoff,theinterlock

switchneedsservice.Correcttheproblembefore

operating.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

TractionInterlockSwitch

1.Pushkickstanddownwithfootandpullupon

handlesupportuntilkickstandhasrotatedforward,

overcenter(Figure21).

6.Carefullyliftuponhandletoreleasekickstand.

StartingandStoppingthe

Engine

Note:Forillustrationsanddescriptionsofthecontrols

referencedinthissection,refertotheControlws

sectioninOperation.

StartingtheEngine

Note:Makesuresparkplugwireisinstalledonspark

plug.

1.Makesuretractionandreeldriveleversarein

Disengagedposition.

Note:Enginewillnotstartiftractionleverisin

theengagedposition.

2.Openthefuelshut-offvalveontheengine.

3.Movetheon/offswitchtotheOnposition.

4.MovethethrottlecontroltotheFastposition.

Figure21

1.Kickstand

2.PlacetractionleverintoEngagepositionandengine

controlsinstartingposition.

3.Attempttostartengine.Engineshouldnotstart.

Ifenginestarts,theinterlockswitchneedsservice.

Correcttheproblembeforeoperating.Referto

ServicingInterlockSwitch.

4.Carefullyliftuponhandletoreleasekickstand.

BrakeInterlockSwitch

1.Pushkickstanddownwithfootandpullupon

handlesupportuntilkickstandhasrotatedforward,

overcenter(Figure21).

5.Movethechokelevertothehalf-openposition

whenstartingacoldengine.Thechokemaynotbe

requiredwhenstartingawarmengine.

6.Pulltherecoilstarterhandleoutuntilpositive

engagementresults,thenpullitvigorouslytostart

theengine.Openthechokeasenginewarmsup.

Important:Donotpullrecoilropetoitslimit

orletgoofstarterhandlewhenropeispulled

outbecauseropemaybreakorrecoilassembly

maybedamaged.

StoppingtheEngine

1.Movethetractionandreeldrivecontrolstothe

Disengagedposition,thethrottlecontroltoSlow,

andtheon/offswitchtoOff.

2.Pullthemoldedsparkplugwireoffofthespark

plugtopreventthepossibilityofaccidentalstarting

beforestoringmachine.

3.Closethefuelshut-offvalvebeforestoringor

transportingmowerinavehicle.

2.Starttheengine.

3.MovethebrakelevertotheEngageposition.

4.MovetractionleverintoEngageposition,engine

mustshutoff.

TransportOperation

Note:Donotrunthemowerenginewhiletransporting

itinatransporttrailerbecausedamagecanoccurto

themower.

18

Page 19

Ifoptionaltransportwheelsarenotgoingtobe

installed,proceedtostep4.

1.Pushkickstanddownwithfootandpullupon

handlesupportuntilkickstandhasrotatedforward,

overcenter.

2.Installthetransportwheels.

3.Toreleasekickstand,pulluponhandleandlower

rearofmowerontotransportwheels.

4.Ensuretractionandreeldrivecontrolsarein

Disengagepositionandstartengine.

5.SetthrottlecontroltoSlow ,tipfrontofmachineup

graduallyengagetractiondriveandslowlyincrease

enginespeed.

6.Adjustthrottletooperatemoweratdesiredground

speedandtransportmowertodesireddestination.

PreparingtoMow

1.ReturntractioncontrollevertoDisengage,throttle

toSlowandstopengine.

2.Pushkickstanddownwithfootandpullupon

handlesupportuntilkickstandhasrotatedforward,

overcenter.

byraisingthecuttingreel(pushingthehandledown)

andturningonthetractiondrum.Mowingshouldbe

doneatanormalwalkingpace.Fastspeedssavesvery

littletimeandwillresultinaninferiormowingjob.

Toassistinmaintainingastraightlineacrossthegreen

andtokeepthemachineanequaldistancefromthe

edgeofthepreviouscut,usethealignmentstripeson

thebasket(Figure22).

Figure22

1.Alignmentstripes

3.Removetransportwheels.

4.Releasekickstand.

MowingOperation

Properuseofthemachineprovidesthesmoothestturf

cuttingavailable.

Important:Grassclippingsactasalubricant

whenmowing.Excessiveoperationofthecutting

unitwiththeabsenceofgrassclippingscan

damagethecuttingunit.

PriortoMowing

Besurethemoweriscarefullyadjustedandissetevenly

onbothsidesofthereel.Impropermoweradjustment

ismagniedintheappearanceoftheclippedturf.

Removeallforeignobjectsfromturfpriortomowing.

Makesureeveryone,especiallychildrenandpets,are

clearoftheworkarea.

ControlOperation

Tooperatethecontrolswhilemowing:

1.Starttheengine,setthethrottleatreducedspeed,

pushdownonhandletoraisecuttingunit,move

tractionlevertoEngagedpositionandtransport

mowerontocollarofgreen(

2.MovetractionlevertoDisengagedpositionand

Engagereeldrivelever(

Figure23).

Figure23).

MethodofMowing

Thegreensshouldbemowedinastraightbackand

forthdirectionacrossthegreen.Avoidcircularmowing

orturningthemowerongreensareassincescufngmay

occur.Turningthemowershouldbedoneoffthegreen

19

Page 20

Figure23

1.Tractiondrive-neutral3.Tractiondrive-engaged

2.Tractiondriveneutral&

reeldriveoff

(transport)

4.Tractiondrive&reeldrive

engaged

3.MovetractionlevertoEngagedposition,increase

throttlespeeduntilthemoweristravelingatthe

desiredgroundspeed,drivethemoweroutontothe

greenarea,lowerthefrontofthemowerdownand

commenceoperation(

Figure23).

AfterMowing

1.Driveoffgreen,movereeldriveandtractioncontrol

leverstoDisengageandstoptheengine.

2.Emptythegrasscatcherofclippings,installgrass

catcherandcommencetransportoperation.

20

Page 21

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst25hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every800hours

Beforestorage

MaintenanceProcedure

•Changetheengineoil.

•Cleanthefuellter.

•Changethetransmissionuid.

•Checktheengineoillevel.

•Cleantheaircleaner(moreoftenindirtyordustyconditions).

•Changetheengineoil.

•Cleanthefuellter.

•Checkthetransmissionuidlevel.

•Checkthepaperairlterelementandreplaceasrequired(moreoftenindirtyor

dustyconditions).

•Checkthesparkplug.

•Changethetransmissionuid.(Or2years,whicheveroccursrst)

•Paintchippedsurfaces.

Important:Refertoyourengineoperator’smanualforadditionalmaintenanceprocedures.

21

Page 22

DailyMaintenanceChecklist

Important:Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation.

Checktheparking

brakeoperation.

Checkthatpivot

jointsoperate

freely.

Checkthefuel

level.

Checktheengine

oillevel.

Checktheair

lter.

Cleantheengine

coolingns.

Checkforunusual

enginenoises.

Checkforunusual

operatingnoises.

Checkthe

reel-to-bedknife

adjustment.

Checkthe

height-of-cut

adjustment.

Touchup

damagedpaint.

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

Information

22

Page 23

EngineMaintenance

EngineOil

Thecrankcasemustbelledwithapproximately20

uidouncesofproperviscosityoilbeforestaring.The

engineusesanyhigh-qualityoilhavingtheAmerican

PetroleumInstitute-APl-“serviceclassication"SF,

SG,SHorSJ .Oilviscosity-weight-mustbeselected

accordingtoambienttemperature.Figure24illustrates

thetemperature/viscosityrecommendations.

Figure25

1.Oillevelgauge

2.Removeoillevelgaugebyrotatingit

counterclockwise.

2.Drainplug

Figure24

Note:Usingmulti-gradeoils(5W-20,10W-30,and

10W-40)willincreaseoilconsumption.Checktheoil

levelmorefrequentlywhenusingthem.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifit

hasalreadybeenrun,allowtheoiltodrainbackdown

tothesumpforatleast10minutesbeforechecking.If

theoillevelisatorbelowthe“L”markonthedipstick,

addoiltobringtheoilleveltothe“H”mark.DONOT

OVERFILL.Iftheoillevelisbetweenthe“H”and“L”

marks,nooiladditionisrequired.

1.Removethetransportwheels(ifinstalled),position

themowersotheengineislevelandcleanaroundoil

levelgauge(

Figure25).

3.Wipeoillevelgaugecleanandinsertitintoller

port.Donotscrewintoport.Thenremoveand

checklevelofoil.Iflevelislow,addonlyenough

oiltoraiseleveluntilitisbetweenthe“H”and“L”

marksonthegauge(

oil.Donotoverll.

4.Reinstalloillevelgaugeandwipeupanyspilledoil.

Figure26).Rechecklevelof

Figure26

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every50hours

1.Startandrunengineforafewminutestowarmthe

engineoil.

2.Placeadrainpanatrearofmachineunderdrainplug

(Figure25).Removedrainplug.

23

Page 24

3.Pushdownonhandletotipmowerandengine

backward,allowingalloiltorunintodrainpan.

4.Installdrainplugandrellcrankcasewiththe

speciedoil;refertoCheckingtheOilLevel.

ServicingtheAirCleaner

ServiceInterval:Every25hours

Every100hours

1.Makesurewireisoffsparkplug.

2.Removewingnutssecuringaircleanercovertoair

cleanerandremovecover.Cleancoverthoroughly

Figure27).

(

Figure27

1.Aircleanercover

Figure28

1.Foamelement2.Paperelement

4.Whenservicingfoamelement,checkconditionof

paperelement.Replaceasrequired.

Note:Donotusecompressedairtocleanthepaper

element.

5.Installfoamelement,paperelement,andaircleaner

cover.

Important:Donotoperatetheenginewithout

theaircleanerelementbecauseextremeengine

wearanddamagewilllikelyresult.

ReplacingtheSparkPlug

ServiceInterval:Every100hours

UseanNGKBPR5ESsparkplugorequivalent.Correct

airgapis0.028-0.032inch.

3.Iffoamelementisdirty,removeitfrompaper

element(

Figure28).Cleanthoroughly.

A.Washfoamelementinasolutionofliquidsoap

andwarmwater.Squeezetoremovedirt,butdo

nottwistbecausethefoammaytear.

B.Drybywrappinginacleanrag.Squeezeragand

foamelementtodry,butdonottwistbecause

thefoammaytear.

C.Saturateelementwithcleanengineoil.Squeeze

elementtoremoveexcessoilandtodistributeoil

thoroughly.Anoildampelementisdesirable.

1.Pullmoldedwireoffsparkplug(Figure29).

Figure29

1.Sparkplugwire

2.Cleanaroundsparkplugandremoveplugfrom

cylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotsandblast,scrape,orclean

24

Page 25

electrodesbecauseenginedamagedcouldresult

fromgritenteringthecylinder.

3.Setairgapat0.028-0.032inch(Figure30).Install

correctlygappedsparkplugandtightenrmlyto

17ft.-lb(23N-m).

Figure30

FuelSystem

Maintenance

CleaningtheFuelFilter

ServiceInterval:Aftertherst25hours

Every50hours

1.Closefuelshutoffvalveandunscrewbowlfrom

lterbody(

1.Shut-offvalve

Figure31).

Figure31

2.Bowl

2.Cleanbowlandlterincleangasolineandinstall.

25

Page 26

ElectricalSystem

DriveSystem

Maintenance

ServicingtheInterlockSwitch

Usethefollowingprocedureiftheswitchneeds

adjustmentorreplacement.

1.Makesuretheengineisoffandtractionleveris

Disengaged.

2.Engagetractionleveruntilitcontactsneutralstop

Figure32).

(

Figure32

1.Tractionlever3.Interlockswitch

2.Neutralstop

3.Looseninterlockswitchmountingfasteners

Figure32).

(

4..032"Gap

Maintenance

CheckingtheTransmission

FluidLevel

ServiceInterval:Every50hours

Thetransmissionislledatthefactorywith

approximately94uidouncesofMobilDexronlll

automatictransmissionuid.

Note:Thesealsusedinthetransmissionareinternally

lubricatedwithgrease.Duringinitialoperationof

mower,slightweepingofgreasefromthesesealswill

occur.Wipeoffexcessgrease.

Important:UseonlyMobilDexronlllorequivalent

transmissionuids.Otheruidscouldcause

systemdamage.

1.Placethemoweronitsdrumsonalevelsurface.

2.Removethecheckplugfromtheright-handsideof

thetransmission(

Theoillevelshouldcometothebottomofthell

hole.Ifitdoesnot,removethellplugfromthetop

ofthetransmissionandaddenoughoftheproperoil

typeuntilthelevelreachesthebottomofthecheck

hole.Donotremovetheventpipe.

Figure33).

4.Placea.032"thickshimbetweenthetractionlever

andtheinterlockswitch(Figure32).

5.Tighteninterlockswitchmountingfasteners.

Recheckgap.Thetractionlevermustnotcontact

theswitch.

6.Engagetractionleverandverifythattheswitchloses

continuity.Replaceifrequired.

Figure33

1.Fillplug3.Drainplug

2.Checkplug

3.Installtheplugs.

26

Page 27

ChangingtheTransmission

Fluid

BrakeMaintenance

ServiceInterval:Aftertherst25hours

Every800hours(Or2years,

whicheveroccursrst)

Important:UseonlyMobilDexronlllorequivalent

transmissionuids.Otheruidscouldcause

systemdamage.

1.Placeadrainpanattherearofthemachine.

2.Removethedrainplugfromtherearofthe

transmission(

Figure34).

AdjustingtheService/Parking

Brake

Note:Theservice/parkingbrakeisaholdingbrakenot

astoppingbrake.Itisdesignedtoholdthemachineon

a17degreeslopewithoutmoving.

Ifservice/parkbrakeslipswhenoperated,anadjustment

isrequired.

1.Moveservice/parkingbrakelevertoOffposition.

2.Toincreasecabletension,loosenfrontcablejamnut

andtightenbackcablejamnut(

forceof11–14lb.(5-6.3kg)isrequiredtoengage

brake.Forcetobemeasuredatleverknob.Donot

overadjust,orbrakebandmaydrag.

Figure35)untila

Figure34

1.Fillplug3.Drainplug

2.Checkplug

3.Pushdownonthehandleandtipthemachineback.

Removethecheckplugfromtheright-handsideof

thetransmission(Figure34).

4.Whentheuidisdrained,installthedrainplug.

5.Placethemoweronitsdrumsonalevelsurface.

6.Removethellplugfromthetopofthetransmission

Figure34).Donotremovetheventpipe.

(

7.Fillthetransmissionwithapproximately94uid

ouncesofthepropertypeoftransmissionuiduntil

thelevelreachesthebottomofthecheckhole;refer

toCheckingtheTransmissionFluid.

8.Installthellandcheckplugs.

1.Tractioncable

Figure35

2.Service/parkingbrake

cable

27

Page 28

BeltMaintenance

AdjustingtheBelts

Makesurebeltsareproperlytensionedtoassureproper

operationofthemachineandunnecessarywear.Check

beltsfrequently .

ReelDriveBelt(Reel)

1.Removethebeltcovermountingfastenersandbelt

covertoexposebelt(Figure36).

Figure36

1.Beltcover

Figure38

1.Reeldrivebelt2.Bearinghousingmounting

nuts

B.Usinga3/8inchdrivetorquewrench,rotatethe

bearinghousingwith35-40in.-lb.(4-4.5N-m)of

torquetosetbelttension(Figure39)

2.Checktensionbydepressingbelt(Figure37)atmid

spanofpulleyswith4±1lb.offorce.Beltshould

deect3/16to5/16inch(4.8to7.9mm).Ifthe

deectionisincorrect,proceedtonextstep.

Figure37

1.Reeldrivebelt3.Drivenpulley

2.Drivepulley

3.Toadjustbelttension:

A.Loosenthebearinghousingmountingnuts

(

Figure38).

Figure39

1.Bearinghousing

2.3/8"Torquewrenchhere

C.Whileholdingthetorquewrenchsetting,tighten

thebearinghousingmountingnuts(

Donotover-tensionbelt.

D.Installbeltcover.

Figure38).

28

Page 29

ReelDriveBelt(Transmissioncoupler)

1.Removethebeltcovermountingfastenersandbelt

covertoexposebelt(Figure40).

Figure42

1.Reeldrivebelt2.Bearinghousingmounting

nuts

Figure40

1.Beltcover

2.Checktensionbydepressingbelt(Figure41)atmid

spanofpulleyswith4±1lb.offorce.Beltshould

deect3/16to5/16inch(4.8to7.9mm).Ifthe

deectionisincorrect,proceedtonextstep.

Figure41

1.Reeldrivebelt

B.Usinga3/8inchdrivetorquewrench,rotatethe

bearinghousingwith35-40in.-lb.(4-4.5N-m)of

torquetosetbelttension(

Figure43

1.Bearinghousing

Figure43).

2.3/8"Torquewrenchhere

C.Whileholdingthetorquewrenchsetting,tighten

thebearinghousingmountingnuts(Figure42).

Donotover-tensionbelt.

D.Installbeltcover.

3.Toadjustbelttension:

A.Loosenthebearinghousingmountingnuts

Figure42).

(

29

Page 30

TractionDriveBelt

1.Removebeltcovermountingfastenersandbelt

covertoexposebelt(Figure44).

Figure46

1.Tangwasher2.Idlerbracketbolt

Figure44

1.Tractiondrivebeltcover

2.Checktensionbydepressingbelt(Figure45)atmid

spanofpulleyswith4±1lbofforce.Beltshould

deect3/16to5/16inch(4.8to7.9mm).Ifthe

deectionisincorrect,proceedtonextstep.

Figure45

1.Tractiondrivebelt

B.Usinga3/8inchdrivetorquewrench,rotatethe

idlerbracketwith35-40in.-lb.oftorquetoset

thebelttension(Figure47).Whileholdingthe

torquewrenchsetting,tightentheidlerbracket

mountingbolt(Thetangwasherisinstalled

topreventthebeltfromslipping.).Donot

over-tensionthebelt.

Figure47

1.Tractiondrivebelt

2.Idlerbracket

3.3/8inchT orquewrench

here

3.Toadjustbelttension:

A.Onbacksideofsideplate,loosenthebolt

securingtheidlerbrackettothesideplate

(Figure46).

C.Installthebeltcover.

30

Page 31

ControlsSystem

Maintenance

AdjustingtheTractionControl

Iftractioncontroldoesnotengageoritslipsduring

operation,anadjustmentisrequired.

1.MovetractioncontroltoDisengagedposition.

2.Toincreasecabletension,loosenfrontcablejamnut

andtightenbackcablejamnut(

forceof10-13lbs.(4.5-5.8kg)isrequiredtoengage

tractioncontrol.

Measuretheforceatthecontrolknob.

Figure48

1.Tractioncable

3.Tightenfrontcablejamnut.

2.Service/parkingbrake

Figure48)untila

cable

Figure49

1.Reelcontrolcable

3.Tightenfrontcablejamnut.

4.Checkcontroloperation.

4.Checkcontroloperation.

AdjustingtheReelControl

Ifreelcontroldoesnotengageoritslipsduring

operation,anadjustmentisrequired.

1.Makesuretractioncontrolisproperlyadjusted;refer

toAdjustingtheTractionControl.

2.Toincreasecabletension,loosenfrontcablejamnut

andtightenbackcablejamnut(Figure49)(located

ontopofgearbox)untilthereelcableforceadds

7to10lbs.(3-4.5kg)ofadditionalhandleforce

measuredatthecontrolknob.

Note:Iftractioncontrolhandleforceis12lbs.,(5.4

kg)thecombinedtractionandreelforceshouldbe

19to22lbs.(8.6-10N-m).

31

Page 32

Storage

1.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheentiremachine,especiallythe

engine.Cleandirtandchafffromtheoutsideofthe

engine’scylinderheadnsandblowerhousing.

Important:Youcanwashthemachinewith

milddetergentandwater.Donotpressurewash

themachine.Avoidexcessiveuseofwater,

especiallyneartheshiftleverplate,andengine.

2.Forlong-termstorage(morethan90days)add

stabilizer/conditioneradditivetofuelinthetank.

A.Runtheenginetodistributeconditionedfuel

throughthefuelsystem(5minutes).

B.Eitherstopengine,allowittocool,anddrainthe

fueltank,oroperatetheengineuntilitstops.

C.Restarttheengineandrunituntilitstops.

Repeat,onChoke,untiltheenginewillnot

restart.

D.Disposeoffuelproperly.Recycleasperlocal

codes.

Note:Donotstorestabilizer/conditioned

gasolineover90days.

3.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanypartthatisdamagedordefective.

4.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

5.Storethemachineinaclean,drygarageorstorage

area.Coverthemachinetoprotectitandkeepit

clean.

32

Page 33

Notes:

33

Page 34

Notes:

34

Page 35

Notes:

35

Page 36

TheToroT otalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

®

Companyanditsafliate,ToroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator’sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakes

padsandlinings,clutchlinings,blades,reels,bedknives,tines,

sparkplugs,castorwheels,tires,lters,belts,andcertainsprayer

componentssuchasdiaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.Torowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.T oromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesinthis

productareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementof

ItemsandConditionsNotCoveredlters,coolant,andcompleting

RecommendedMaintenancearesomeofthenormalservicesT oro

productsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty .

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.Somestatesdonotallowexclusions

ofincidentalorconsequentialdamages,orlimitationsonhowlongan

impliedwarrantylasts,sotheaboveexclusionsandlimitationsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty.RefertotheEngine

EmissionControlWarrantyStatementprintedinyourOperator’sManual

orcontainedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatT oroWarrantyCompany.

374-0253RevA

Loading...

Loading...