Page 1

FormNo.3375-837RevC

18and22inchDPACuttingUnit

Reelmaster

ModelNo.03911—SerialNo.313000001andUp

ModelNo.03912—SerialNo.313000001andUp

ModelNo.03913—SerialNo.313000001andUp

®

3550SeriesTractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3375-837*C

Page 2

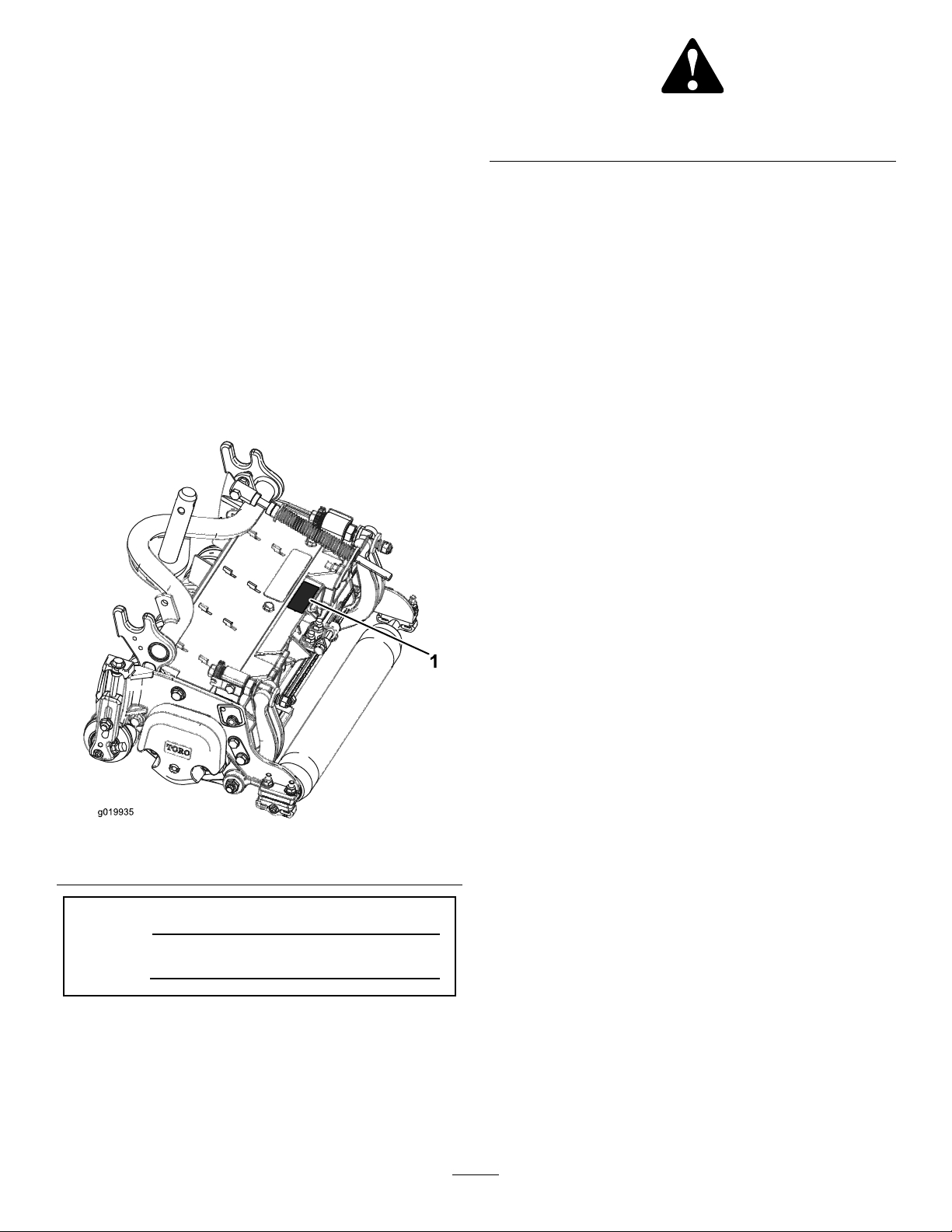

Figure2

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................3

SafetyandInstructionalDecals.................................3

Setup............................................................................4

1Inspection............................................................4

2CuttingUnitKickstand..........................................4

3AdjustingtheRearShield.......................................5

4RepositioningtheCounterWeights..........................5

ProductOverview..........................................................7

Specications.........................................................7

CuttingUnitAccessoriesandKits(seeparts

catalogforpartnumbers)......................................7

Operation.....................................................................8

Adjustments...........................................................8

HeightofCutChartTerms......................................10

HeightofCutChart................................................12

ServicingtheBedknife............................................16

Maintenance.................................................................18

Lubrication............................................................18

ServicingtheBedbar...............................................18

ServicingtheHDDualPointAdjusters

(DPA)...............................................................20

ServicingtheRoller.................................................21

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.T oreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitoperatorsmanualbeforeoperatingthe

cuttingunit.

•Read,understand,andfollowallinstructionsinthis

operatorsmanualbeforeoperatingthecuttingunit.

•Neverallowchildrentooperatethetractionunitor

cuttingunits.Donotallowadultstooperatetractionunit

orcuttingunitswithoutproperinstruction.Onlytrained

operatorswhohavereadthismanualshouldoperatethe

cuttingunits.

•Neveroperatethecuttingunitswhenundertheinuence

ofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydeviceordecalisillegibleordamaged,repairor

replaceitbeforeoperationiscommenced.Alsotighten

anyloosenuts,bolts,andscrewstoensurecuttingunitis

insafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperatecutting

unitswhilewearingsandals,tennisshoes,sneakersor

shorts.Also,donotwearloosettingclothingwhich

couldgetcaughtinmovingparts.Alwayswearlongpants

andsubstantialshoes.Wearingsafetyglasses,safetyshoes

andahelmetisadvisableandrequiredbysomelocal

ordinancesandinsuranceregulations.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbythecuttingunitreelblades.Keepall

bystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

cuttingunitfordamagedparts.Repairanydamagebefore

restartingandoperatingthecuttingunit.

•Lowerthecuttingunitstothegroundandremovekey

fromignitionswitchwhenevermachineisleftunattended.

•Besurecuttingunitsareinsafeoperatingconditionby

keepingnuts,boltsandscrewstight.

•Removekeyfromignitionswitchtopreventaccidental

startingoftheenginewhenservicing,adjustingorstoring

themachine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedT oroDistributor.

•Toensureoptimumperformanceandsafety ,always

purchasegenuineT ororeplacementpartsandaccessories

tokeeptheT oroallTORO.Neveruse"will-t"

replacementpartsandaccessoriesmadebyother

manufacturers.LookfortheT orologotoassure

genuineness.Usingunapprovedreplacementparts

andaccessoriescouldvoidthewarrantyofTheToro

Company.

SafetyandInstructionalDecals.

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93–6688

1.Warning—readthe

Operator’sManualbefore

performingmaintenance.

2.Cuttinghazardofhandor

foot—stoptheengineand

waitforallmovingpartsto

stop.

3

Page 4

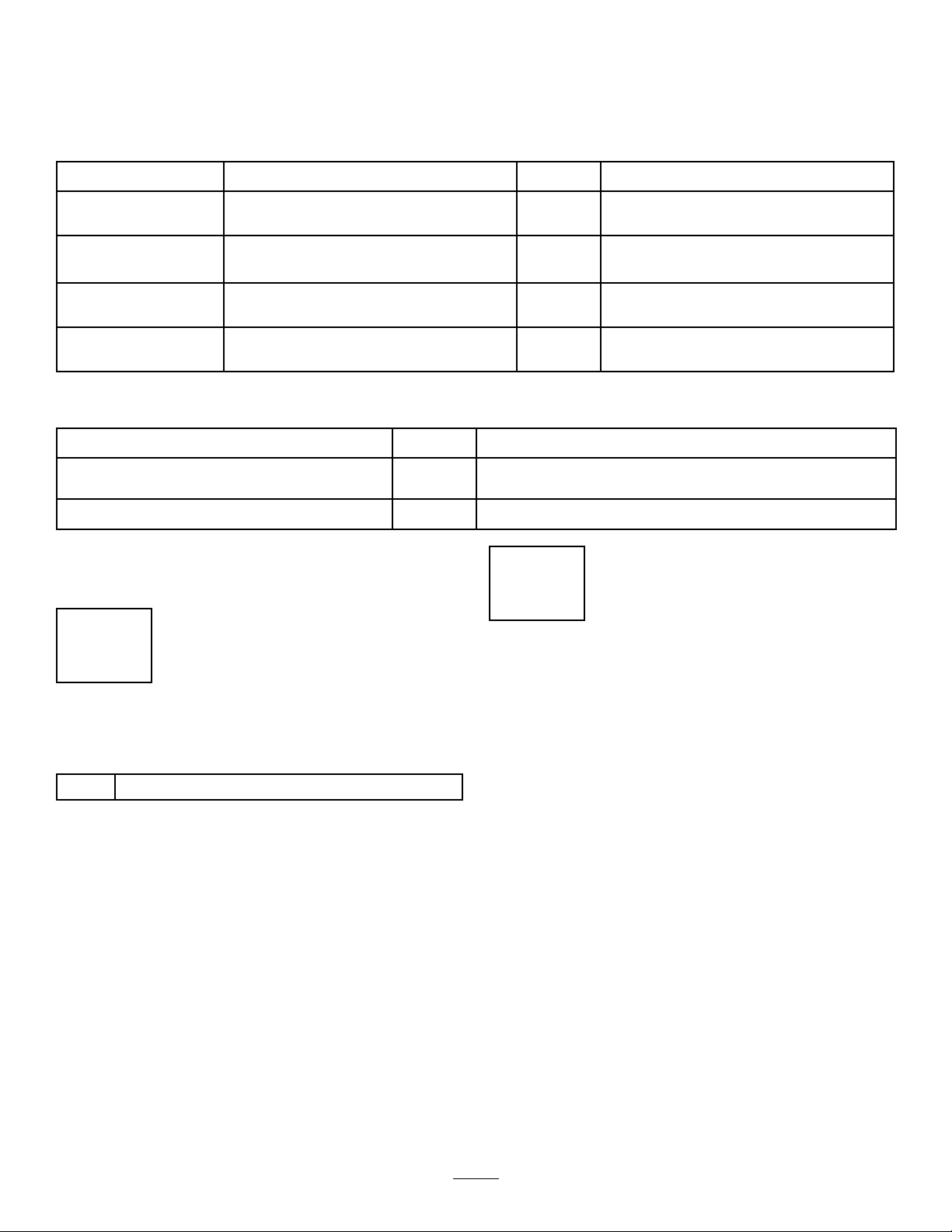

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Cuttingunit

Nopartsrequired

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Partscatalog1

Operator'sManual

O-ring

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

1Inspectthecuttingunit

–

–

–

Qty.

1

1Usewhenmountingreelmotortocuttingunit

Reviewthematerialandsaveinanappropriateplace:

Usethekickstandwhentippingthe

cuttingunit

Adjusttherearshield

Mountthecounterweights

Use

2

Use

1

Inspection

Partsneededforthisprocedure:

1

Cuttingunit

Procedure

Afterthecuttingunitisremovedfromthebox,inspectthe

following:

1.Checkeachendofthereelforgrease.Greaseshouldbe

visiblyevidentintheinternalsplinesofthereelshaft.

2.Ensurethatallnutsandboltsaresecurelytightened.

3.Makesurethecarrierframesuspensionoperatesfreely

anddoesnotbindwhenmovedbackandforth.

CuttingUnitKickstand

NoPartsRequired

Procedure

Wheneverthecuttingunithastobetippedtoexposethe

bedknife/reel,propuptherearofthecuttingunitwiththe

kickstand(suppliedwiththetractionunit)tomakesurethe

nutsonthebackendofthebedbaradjustingscrewsarenot

restingontheworksurface(Figure3).

4

Page 5

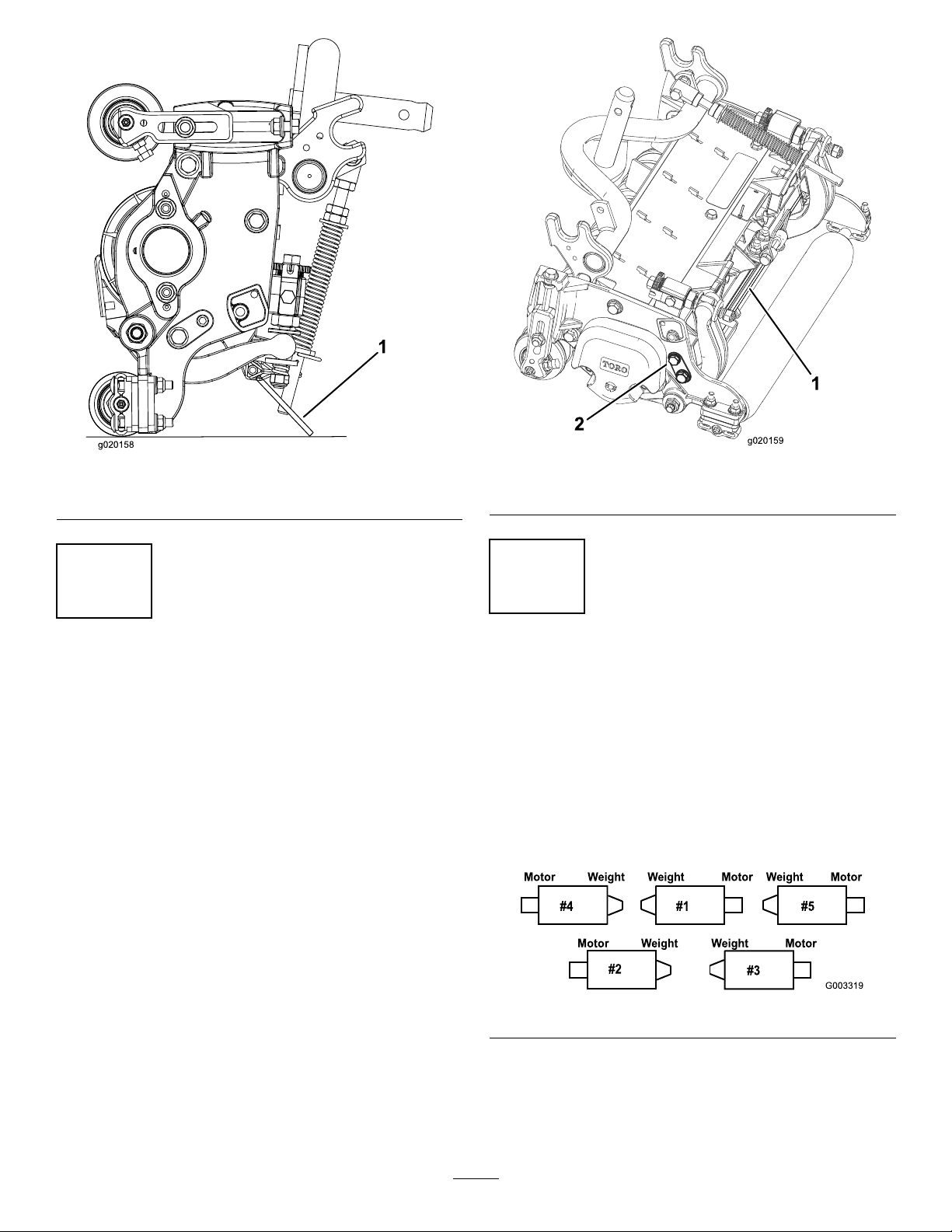

g020158

1.Cuttingunitkickstand

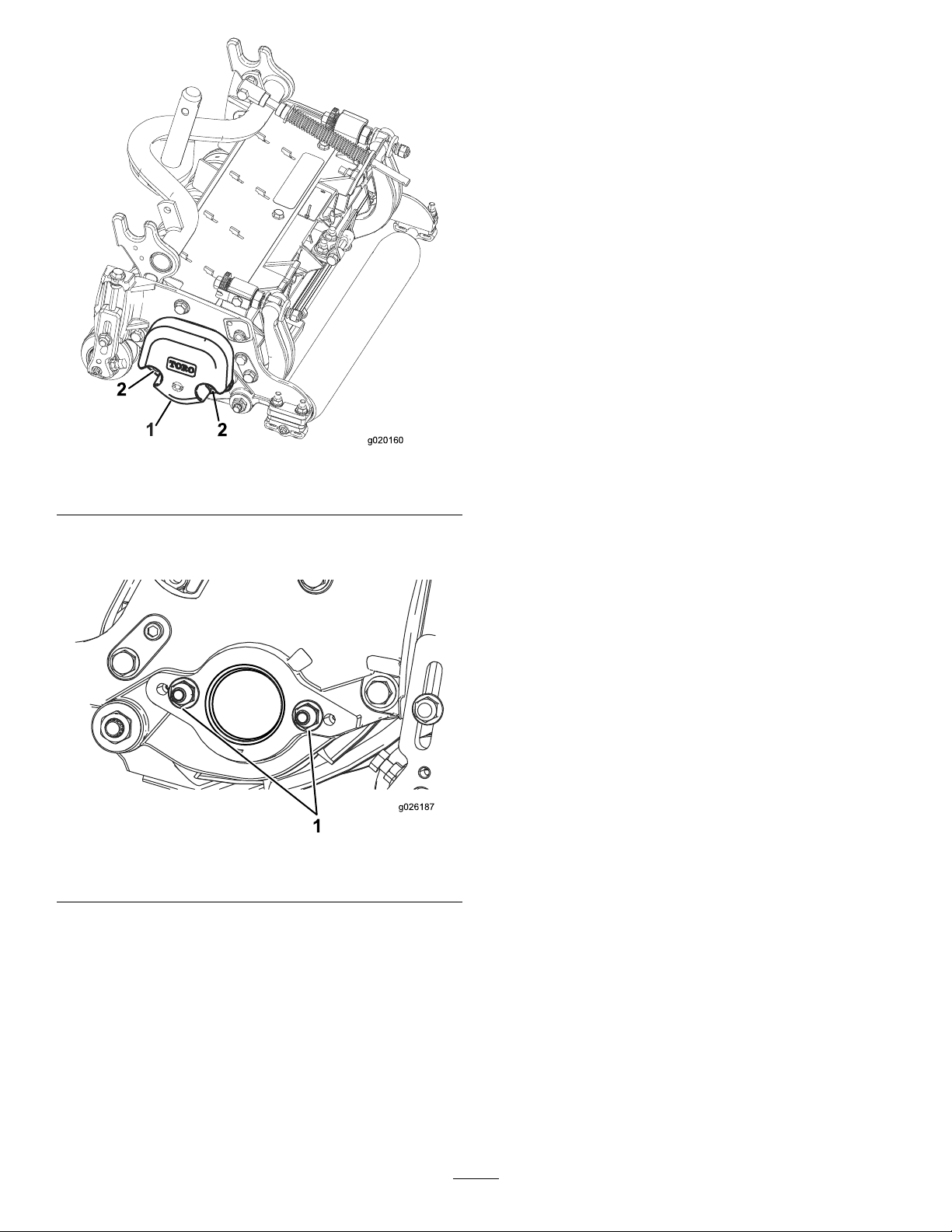

g020159

Figure3

1.Rearshield

Figure4

2.Capscrew

3

AdjustingtheRearShield

NoPartsRequired

Procedure

Undermostconditions,bestdispersionisattainedwhenthe

rearshieldisclosed(frontdischarge).Whenconditionsare

heavyorwet,rearshieldmaybeopened.

Toopentherearshield(Figure4),loosenthecapscrew

securingtheshieldtotheleftsideplate,rotatetheshieldto

theopenpositionandtightenthecapscrew.

4

RepositioningtheCounter Weights

NoPartsRequired

Procedure

Allcuttingunitsareshippedwiththecounterweightmounted

totheleftendofthecuttingunit.Usethefollowingdiagram

todeterminethepositionofthecounterweightsandreel

motors.

Figure5

1.Onthe#2and#4cuttingunits,removethe2lock

nutssecuringthecounterweighttotheleftendofthe

cuttingunit.Removethecounterweight(Figure6).

5

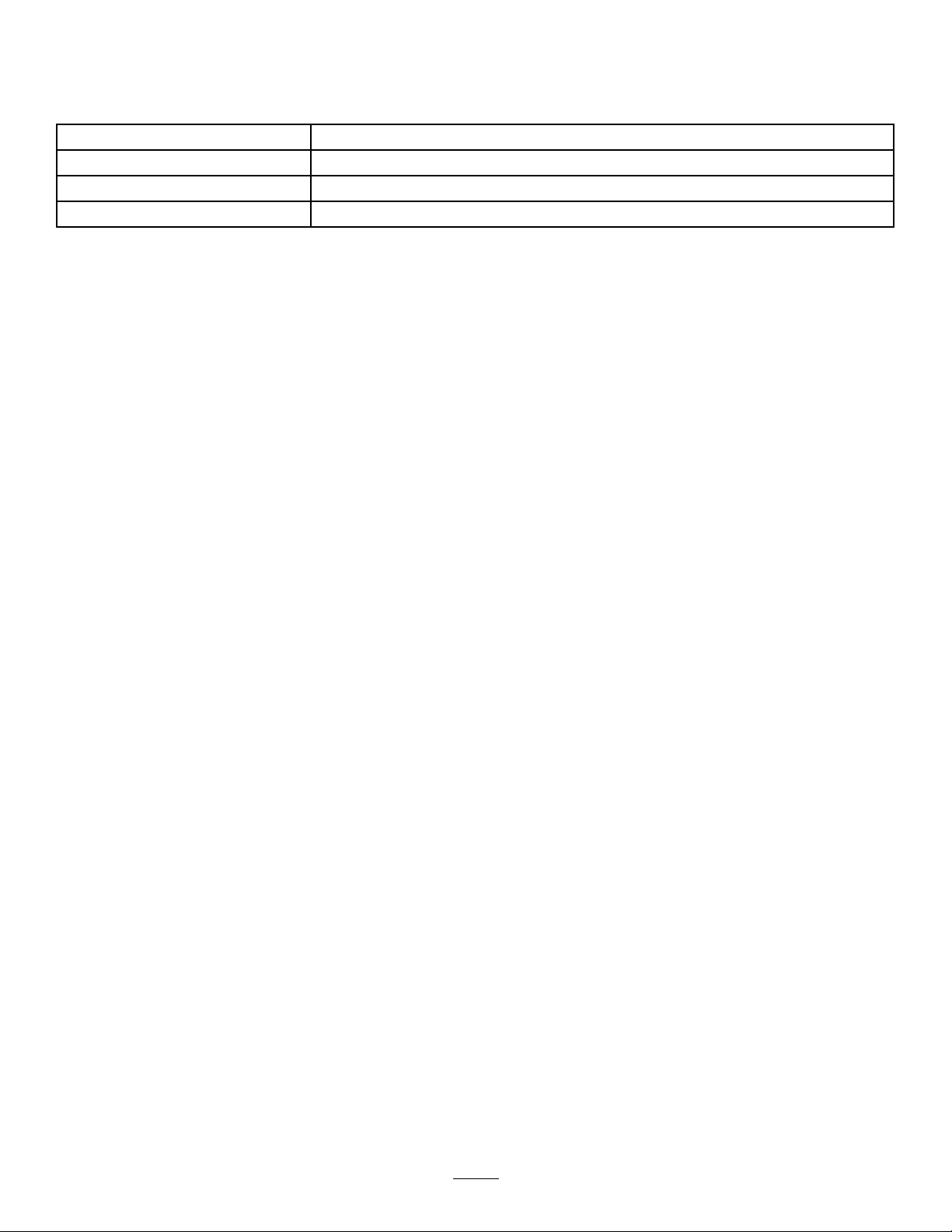

Page 6

2

2

g020160

Figure6

g026187

1.Counterweight

2.Locknuts

2.Removethe2locknutsfromtherightsideplate

(Figure7).

Figure7

1.Locknut(2)

3.Installthecounterweighttotherightendofthe

cuttingunitandsecurewiththe2locknutspreviously

removed.

4.Installthe2reelmotormountinglocknutstotheleft

sideplateofthecuttingunit(Figure7).

6

Page 7

ProductOverview

Specications.

ModelNumberNetWeight

03911

03912

03913

39kg(86lb.)

40kg(88lb.)

43kg(94lb.)

CuttingUnitAccessoriesandKits(see partscatalogforpartnumbers)

Note:Allaccessoriesandkitsare1percuttingunitunless

otherwisespecied.

GrassBasketKit:Aseriesofclippingcollectionbaskets

attachedtothefrontofthecuttingunitstocollectgrass

clippings.

RearRollerBrushKit:Ahighspeed,highcontactbrush

thatkeepstherearrollerfreeofgrassanddebris,which

maintainsaconsistentheightofcutandpreventsclumping.

Thisleadstoabetterafter-cutappearance.

GroomerKit:Rotatingbladesassembledbehindthefront

rollerwhichprovidethebestmethodforreducinggrain

andspongyturfbystandingupthegrassbeforecutting.

Thegroomeralsoknocksoffdewfordecreasedstickiness

andclumping,opensupcanopyforbettergrassclipping

integration,andliftsgrassforacleancrispcut.Theoverall

designimprovesthequalityofcutforhealthierturfgrass

whileimprovingtheaftercutappearance

BroomerKit:Multiplebrushstripswovenintothehelical

groomerbladesimprovetheeffectivenessofthegroomerkit.

Performanceofthegroomerisenhancedbyenablingafull

width"Brooming"effectofturfwhileopeningupcanopy

forbettergrassclippingintegration.Thecombinationof

groomerandbroomersystemsoptimizethequalityofcutand

after-cutappearanceformoreconsistentplayingconditions.

Comb/ScraperKit:Axedcombinstalledbehindthefront

rollerwhichhelpsreducegrainandspongyturfbystanding

upthegrassbeforecutting.AscraperforthefrontWiehle

rollerisincludedinthekit.

HighHOCKit:Newfrontrollerbracketsandadditional

spacersfortherearrollerallowsthecuttingunittoachieve

heightsofcutabove25mm(1.00inch).Thenewfrontroller

bracketsalsomovethefrontrolleroutfarthertoimprove

after-cutappearanceattheseheightsofcut.

ShoulderRoller:Helpsreduceover-lapmarksforwarm

seasongrasses(Bermuda,Zoysia,Paspalum).

CollarKit(4neededperroller):Helpsreduceoverlap

marksforwarmseasongrasses(Bermuda,Zoysia,Paspalum).

Thiskitisinstalledontheouterthreegroovesoftheexisting

Wiehleroller,butisnotasaggressiveastheShoulderroller.

LongRearRoller:Helpsreduceover-lapmarksand

mismatchbetweencuttingunitsforwarmseasongrasses

(Bermuda,Zoysia,Paspalum).

FullFrontRoller:Helpsproducemorepronouncedstriping

(repeatedcuttinginthesamedirection/path),however,

effectiveheightofcutisraisedandqualityofcutisreduced.

Scrapers(Wiehle,Shoulder,RearRoller,FullFront

Roller):Fixedscrapersforalloptionalrollersareavailable

forreducinggrassbuilduponrollerswhichcanaffectheight

ofcutsettings.

RollerRebuildKit:Includesallthebearings,bearingnuts,

innersealsandoutersealsrequiredtorebuildaroller.

RollerRebuildT oolKit:Includesallthetoolsand

installationinstructionsrequiredtorebuildaroller.

7

Page 8

Operation

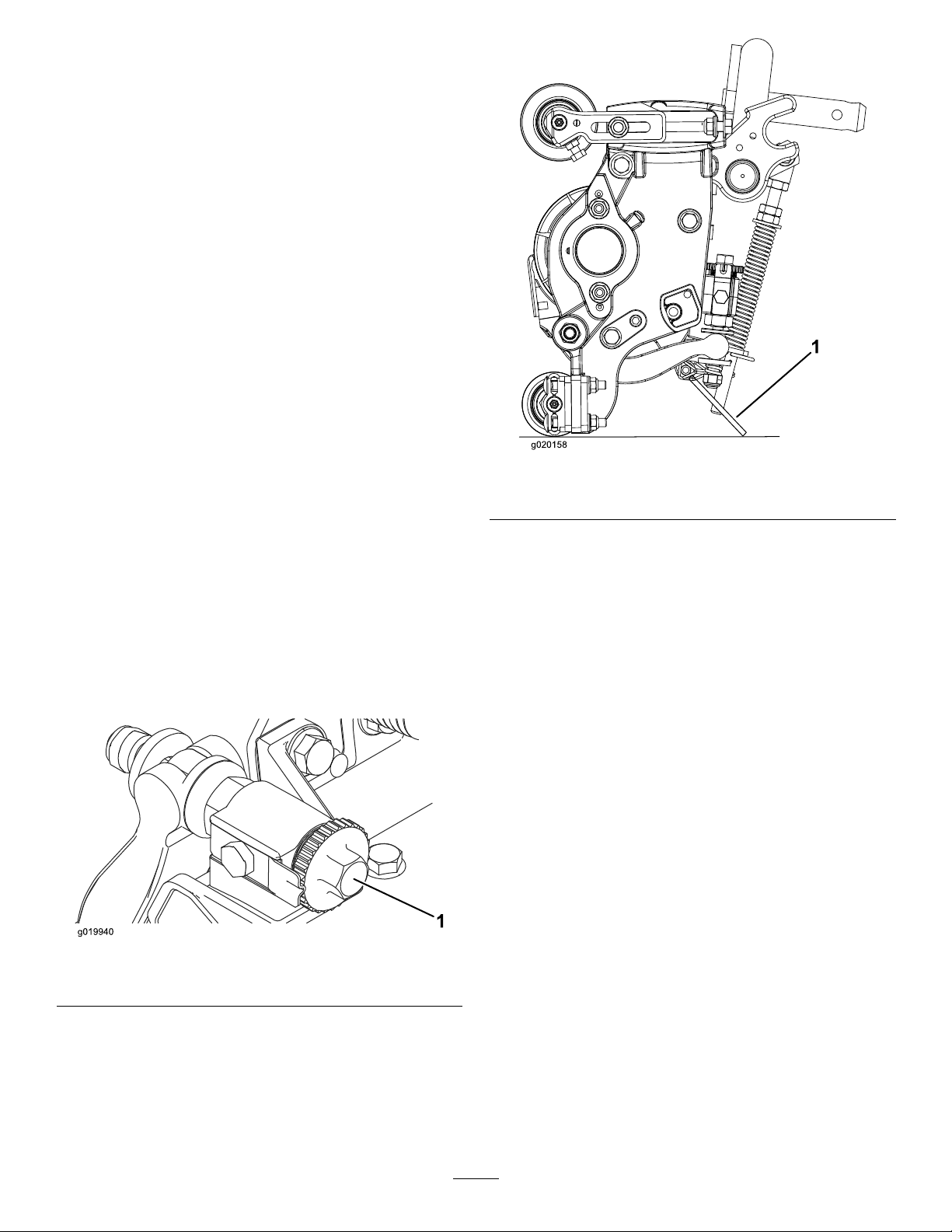

g020158

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Adjustments

AdjustingtheBedknifetotheReel

Usethisproceduretosetthebedknifetothereelandtocheck

theconditionofthereelandbedknifeandtheirinteraction.

Aftercompletingthisprocedure,alwaystestthecutting

unitperformanceunderyoureldconditions.Youmay

needtomakefurtheradjustmentstoobtainoptimalcutting

performance.

Important:Donotovertightenthebedknifetothereel

oryouwilldamageit.

•Afterbacklappingthecuttingunitorgrindingthereel,you

mayneedtomowwiththecuttingunitforafewminutes

andthenperformthisproceduretoadjustthebedknifeto

thereelasthereelandbedknifeadjusttoeachother.

•Youmayneedadditionaladjustmentsiftheturfis

extremelydenseoryourcuttingheightisverylow .

Youwillneedthefollowingtoolstocompletethisprocedure:

•Shim0.05mm(0.002inch)—Toropartnumber125-5611

•Cuttingperformancepaper—Toropartnumber125-5610

1.Positionthecuttingunitonaat,levelworksurface.

Turnthebedbaradjustingscrewscounterclockwiseto

ensurethatthebedbardoesnotcontactthereel(Figure

8).

Figure9

1.Cuttingunitkickstand

3.Rotatethereelsothatabladecrossesthebedknife

approximately25mm(1inch)infromtheendofthe

bedknifeontherighthandsideofthecuttingunit.

Puttinganidentifyingmarkonthisbladewillmake

subsequentadjustmentseasier.Insertthe0.05mm

(0.002inch)shimbetweenthemarkedreelbladeand

thebedknifeatthepointwherethebladecrossesthe

bedknife.

4.Turntherightbedbaradjusterclockwiseuntilyoufeel

lightpressure(i.e.drag)ontheshim,thenbackoffthe

bedbaradjustertwoclicksandremovetheshim.(Since

adjustingonesideofthecuttingunitaffectstheother

side,thetwoclickswillprovideclearanceforwhenthe

othersideisadjusted)

Figure8

1.Bedbaradjustingscrew

2.Tipthemower,toexposethebedknifeandreel.

Important:Makesurenutsonbackendofbedbar

adjustingscrewsarenotrestingonthework

surface(Figure9).

Note:Ifstartingwithalargegap,bothsidesshould

initiallybedrawncloserbyalternatelytighteningthe

rightandlefthandsides.

5.Slowlyrotatethereelsothatthesamebladethatyou

checkedontherightsideiscrossingthebedknife

approximately25mm(1inch)infromtheendofthe

bedknifeonthelefthandsideofthecuttingunit.

6.Turntheleftbedbaradjusterclockwiseuntiltheshim

canbeslidthroughthereeltobedknifegapwithlight

drag.

7.Returntotherightsideandadjustasnecessarytoget

lightdragontheshimbetweenthesamebladeand

bedknife.

8.Repeatsteps6and7untiltheshimcanbeslidthrough

bothgapswithslightdrag,butoneclickinonboth

8

Page 9

sidespreventstheshimfrompassingthroughonboth

g020161

g020162

sides.Thebedknifeisnowparalleltothereel.

Note:Thisprocedureshouldnotbeneededondaily

adjustments,butshouldbedoneaftergrindingor

disassembly.

9.Fromthisposition(i.e.oneclickinandshimnot

passingthrough)turnthebedbaradjustersclockwise

twoclickseach.

Note:Eachclickturnedmovesthebedknife0.018

mm(0.0007inches).Donotovertightenthe

adjustingscrews.

10.Testthecuttingperformancebyinsertingalongstrip

ofcuttingperformancepaper(T oropartnumber

125-5610)betweenreelandbedknife,perpendicular

tothebedknife(Figure10).Slowlyrotatethereel

forward;itshouldcutthepaper.

Figure10

Note:Shouldexcessivereeldragbeevident,itwillbe

eithernecessarytobacklaporregrindthecuttingunit

toachievethesharpedgesneededforprecisioncutting.

Figure11

1.Spacer3.Sideplatemountingange

2.Rollerbracket

2.Raiserearofcuttingunitandplaceablockunder

bedknife.

3.Remove(2)nutssecuringeachrollerbracketandspacer

toeachsideplatemountingange.

4.Lowerrollerandscrewsfromsideplatemounting

angesandspacers.

5.Placespacersontoscrewsonrollerbrackets.

6.Re-securerollerbracketandspacerstounderside

ofsideplatemountingangeswithnutspreviously

removed.

7.Verifythatbedknifetoreelcontactiscorrect.Tip

mowertoexposefrontandrearrollersandbedknife.

Note:Thepositionoftherearrollertothereel

iscontrolledbythemachiningtolerancesofthe

assembledcomponentsandparallelingisnotrequired.

Alimitedamountofadjustmentispossiblebysetting

thecuttingunitonasurfaceplateandlooseningthe

sideplatemountingcapscrews(Figure12).Adjustand

retightencapscrews.Torquethecapscrewsto37-45

N-m(27-33ft-lb).

AdjustingtheRearRoller

1.Adjusttherearrollerbrackets(Figure11)tothedesired

heightofcutrangebypositioningtherequiredamount

ofspacersbelowthesideplatemountingange(Figure

11)pertheHOCChart.

Figure12

1.Sideplatemountingcapscrews

9

Page 10

HeightofCutChartTerms

g020164

HeightofCutSetting(HOC)

ThedesiredHeightofCut.

BenchSetHeightofCut

Theheightatwhichthetopedgeofthebedknifeissetabove

aatlevelsurfacethatcontactsthebottomofboththefront

andrearroller.

EffectiveHeightofCut

Thisistheactualheightthegrasshasbeencut.Foragiven

benchsetheightofcut,theactualheightofcutwillvary

dependingonthetypeofgrass,timeofyear,turfandsoil

conditions.Thecuttingunitsetup(aggressivenessofcut,

rollers,bedknives,attachmentsinstalled,turfcompensation

settings,etc.)willalsoaffecttheeffectiveheightofcut.Check

theeffectiveheightofcutusingtheTurfEvaluator,Model

04399regularlytodeterminethedesiredbenchsetheight

ofcut.

AggressivenessofCut

Zoysia)whilecoolseasongrasses(Bent,Bluegrass,Rye)may

requirenormaltomoreaggressivesetups.Moreaggressive

setupscutmoregrassoffbyallowingthespinningreeltopull

moregrassupintothebedknife.

RearSpacers

Thenumberofrearspacersdeterminestheaggressiveness

ofcutforthecuttingunit.Foragivenheightofcut,adding

spacers,belowthesideplatemountingange,increasesthe

aggressivenessofthecuttingunit.Allcuttingunitsona

givenmachinemustbesettothesameaggressivenessofcut

(Numberofrearspacers,partno.119–0626),otherwisethe

after-cutappearancecouldbenegativelyaffected(Figure13).

TurfCompensationSettings

Theturfcompensationspringtransferstheweightfromthe

fronttotherearroller.(Thishelpstoreduceawavepattern

intheturf,alsoknownasmarcellingorbobbing.)

Important:Makespringadjustmentswiththecutting

unitmountedtothetractionunit,pointingstraight

aheadandloweredtotheshopoor.

1.Makesurethehairpincotterisinstalledintherearhole

inthespringrod(Figure14).

CuttingunitAggressivenessofCuthasasignicantimpact

ontheperformanceofthecuttingunit.Aggressivenessof

Cutreferstotheangleofthebedkniferelativetotheground

(Figure13).

Figure13

1.Rearspacers

2.Sideplatemountingange

Thebestcuttingunitsetupisdependentonyourturf

conditionsanddesiredresults.Experiencewiththecutting

unitonyourturfwilldeterminethebestsettingtouse.

Aggressivenessofcutmaybeadjustedthroughoutthecutting

seasontoallowforvariousturfconditions.

Ingeneral,lesstonormalaggressivesettingsaremore

appropriateforwarmseasongrasses(Bermuda,Paspalum,

3.Aggressivenessofcut

Figure14

1.Turfcompensationspring3.Springrod

2.Hairpincotter4.Hexnuts

2.Tightenthehexnutsonthefrontendofthespringrod

untilthecompressedlengthofthespringis5inches

(12.7cm)(Figure14).

Note:Whenoperatingonroughterraindecreasethe

springlengthby1.3cm(1/2inch).Groundfollowing

willbeslightlydecreased.

Note:Theturfcompensationsettingwillneedtobe

resetiftheHOCsettingortheAggressivenessofCut

settingischanged.

10

Page 11

ChainLinks

Thelocationatwhichtheliftarmchainisattacheddetermines

therearrollerpitchangle(Figure15).

Figure15

1.Liftchain

2.U-Bracket

3.Bottomhole

11

Page 12

Groomer

Thesearetherecommendedheightofcutsettingswhenagroomerkitisinstalledonthecuttingunit.

HeightofCutChart

HOCSettingAggressivenessofCutNo.ofRearSpacersNo.ofChainLinksWithGroomerkits

0.64cm(0.250inches)

0.95cm(0.375inches)

1.27cm(0.500inches)

1.56cm(0.625inches)

1.91cm(0.750inches)

2.22cm(0.875inches)

2.54cm(1.000inch)

2.86cm(1.125inches)*

3.18cm(1.250inches)*

3.49cm(1.375inches)*

3.81cm(1.500inches)*

+IndicatestheU-bracket,onliftarm,ispositionedinthebottomhole(Figure15).

*HighHOCKit(PartNo.1 10-9600)mustbeinstalled.FrontHOCbracketmustbepositionedinthetopsideplatehole.

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

0

0

1

0

1

2

0

1

2

1

2

3

2

3

4

2

3

4

3

4

5

4

5

6

4

5

6

4

5

6

5

6

7

4

4

3

4

3+

3+

4

4

3+

4

4

3+

4

3+

3+

4

3

3

4

3+

3+

4

3+

3

4

3+

3

4

4

3+

4

3+

3+

installed

Y

Y

-

Y

Y

-

Y

Y

Y

Y

Y

-

Y

Y

-

Y

Y

-

Y

Y

-

-

-

-

-

-

-

-

-

-

-

-

-

Note:Changingonechainlinkwillchangetherearrollerpitchanglemovementby7.0degrees.

Note:ChangingtheU-bracket,ontheliftarm,tothebottomholewilladd3.5degreestotherearrollerpitchangle

12

Page 13

AdjustingtheHeightofCut

g020166

Note:Forheightsofcutgreaterthan2.54cm(1.000inch)

theHighHeightofCutKitmustbeinstalled.

1.Loosenlocknutssecuringheight-of-cutbracketsto

cuttingunitsideplates(Figure16).

Figure16

1.Adjustingscrew

2.Locknut

2.Loosennutongaugebar(Figure17)andsetadjusting

screwtodesiredheight-of-cut.Distancebetween

bottomofscrewheadandfaceofbarisheight-of-cut.

3.Height-of-cutbracket

Figure18

Important:Whensetproperly,therearandfront

rollerswillcontactthegaugebarandthescrew

willbesnugagainstthebedknife.Thisensures

thattheheight-of-cutisidenticalatbothendsof

thebedknife.

5.Tightennutstosecureadjustment.Donotovertighten

nut.Tightenenoughtoremoveplayfromwasher.

Usethefollowingcharttodeterminewhichbedknifeis

bestsuitedforthedesiredheightofcut.

Figure17

1.Gaugebar4.Holesusedforsetting

GroomerHOG

2.Heightadjustingscrew5.Holenotused

3.Nut

3.Hookthescrewheadoncuttingedgeofbedknifeand

restrearendofbaronrearroller(Figure18).

4.Rotatetheadjustingscrewuntilthefrontrollercontacts

thegaugebar(Figure18).Adjustbothendsofroller

untilentirerollerisparalleltothebedknife.

13

Page 14

PremiumLowHOCBedknife

Bedknife/HeightofCutChart

ReelSize

18inch,11

blade(Production)

18inch,8blade(Optional)

22inch,8blade(Optional)

LowHOCBedknife

ReelSize

18inch,8&11blade

(Optional)

22inch,8blade(Optional)

EdgeMax®LowHOCBedknife

ReelSize

18inch,1 1blade(Optional)

18inch,8blade(Optional)

22inch,8blade(Optional)

EdgeMax®Bedknife

ReelSize

18inch,8blade(Production)

18inch,11blade(Optional)

22inch,8blade(Production)

PartNo.

125–2770

125–2771

PartNo.

121-3167

110-4084

PartNo.

130–4745

127–7132

PartNo.

121–3165

108-9095

BedknifeLipHeightHeightofCut

5.6mm

(.220inch)

BedknifeLipHeightHeightofCut

5.6mm

(.220inch)

BedknifeLipHeightHeightofCut

5.6mm

(.220inch)

BedknifeLipHeightHeightofCut

6.9mm

(.270inch)

6.4–12.7mm

(.250-.500inch)

.6.4–12.7mm

(.250-.500inch))

6.4–12.7mm

(.250-.500inch)

9.5–38.1mm

(.375-1.50inches)

StandardBedknife

ReelSize

18inch,8&11blade

(Optional)

22inch,8blade(Optional)

PartNo.

121–3166

108-9096

*WarmseasongrassesmayrequiretheLowHOC

bedknifefor12.7mm(.500inches)andbelow.

Figure19

1.BedknifeLipHeight*

CuttingUnitCharacteristics

Thedualknobbedknife-to-reeladjustmentsystem

incorporatedinthiscuttingunitsimpliestheadjustment

procedureneededtodeliveroptimummowingperformance.

Thepreciseadjustmentpossiblewiththedualknob/bedbar

designgivesthenecessarycontroltoprovideacontinual

self-sharpeningaction-thusmaintainingsharpcuttingedges,

BedknifeLipHeightHeightofCut

6.9mm

(.270inch)

9.5–38.1mm

(.375-1.50inches)*

ensuringgoodquality-of-cut,andgreatlyreducingtheneed

forroutinebacklapping.

DailyAdjustmentsofCuttingUnit

Priortomowingeachday,orasrequired,checkeachcutting

unittoverifyproperbedknife-to-reelcontact.Thismustbe

performedeventhoughthequalityofcutisacceptable.

1.Slowlyrotatethereelinareversedirection,listening

forreel-to-bedknifecontact.

Note:Theadjustmentknobshavedetents

correspondingto0.018mm(0.0007inch)bedknife

movementforeachindexedposition.Referto

AdjustingtheBedknifetotheReel.

2.Testthecuttingperformancebyinsertingalongstrip

ofcuttingperformancepaper(T oropartnumber

125-5610)betweenreelandbedknife,perpendicular

tothebedknife(Figure20).Slowlyrotatethereel

forward;itshouldcutthepaper.

14

Page 15

Figure20

Note:Ifexcessivecontact/reeldragisevidentitwill

beeithernecessarytobacklap,refacethefrontofthe

bedknife,orregrindthecuttingunittoachievethe

sharpedgesneededforprecisioncutting(Refertothe

ToroManualforSharpeningReelandRotaryMowers,

FormNo.09168SL).

Important:Lightcontactispreferredatalltimes.

Ifyoudonotmaintainlightcontact,thebedknife

andreeledgeswillnotsufcientlyself-sharpen

andwilldullafteraperiodofoperation.Ifyou

maintainexcessivecontact,thebedknifeandreel

willwearquicker,wearunevenly,andthequality

ofcutmaybeadverselyaffected.

Note:Afterextendedrunning,aridgewilleventually

developatbothendsofthebedknife.Roundoffor

lethesenotchesushwiththecuttingedgeofthe

bedknifetoensuresmoothoperation.

Note:Overtime,thechamfer(Figure21)willneedto

beregroundasitisonlydesignedtolast40%ofthe

bedknifelife.

Figure21

Note:Donotmakethelead-inchamfertoolargeas

itmaycauseturftufting.

15

Page 16

ServicingtheBedknife

Thebedknifeservicelimitsarelistedinthefollowingcharts.

Important:Operatingthecuttingunitwiththebedknifebelowthe“servicelimit”mayresultinpoorafter-cut

appearanceandreducethestructuralintegrityofthebedknifeforimpacts.

BedknifeServiceLimitChart

PremiumLowHOCBedknife

ReelSize

18inch,11blade(Production)

18inch,8blade(Optional)

22inch,8blade(Optional)

LowHOCBedknife

ReelSize

18inch,8&1 1blade(Optional)

22inch,8blade(Optional)

EdgeMax®LowHOCBedknife

ReelSize

18inch,11blade(Optional)

18inch,8blade(Optional)

22inch,8blade(Optional)

EdgeMax®Bedknife

ReelSize

18inch,8blade(Production)

18inch,1 1blade(Optional)

22inch,8blade(Production)

PartNo.

125-2770

125-2771

PartNo.

121-3167

110-4084

PartNo.

130–4745

127–7132

PartNo.

121–3165

108-9095

BedknifeLipHeightServiceLimit*GrindAngles

5.6mm

(.220inch)

BedknifeLipHeightServiceLimit*GrindAngles

5.6mm

(.220inch)

BedknifeLipHeightServiceLimit*GrindAngles

5.6mm

(.220inch)

BedknifeLipHeightServiceLimit*GrindAngles

6.9mm

(.270inch)

4.8mm

(.190inch)

4.8mm

(.190inch)

4.8mm

(.190inch)

4.8mm

(.190inch)

Top/FrontAngles

10/5Degrees

Top/FrontAngles

5/5Degrees

Top/FrontAngles

10/5Degrees

Top/FrontAngles

5/5Degrees

StandardBedknife

22inch,8blade(Optional)

ReelSize

18inch,8&11blade

(Optional)

PartNo.

121–3166

108-9096

BedknifeLipHeightServiceLimit*GrindAngles

6.9mm

(.270inch)

4.8mm

(.190inch)

Top/FrontAngles

5/5Degrees

16

Page 17

RecommendedT opandFrontBedknifeGrindAngles

g025579

2

3

(Figure22).

Figure22

1.Bedknifeservicelimit*

2.Topgrindangle

3.Frontgrindangle

Note:Allbedknifeservicelimitmeasurementsreferencethe

bottomofthebedknife(Figure23)

Figure23

17

Page 18

Maintenance

g020156

Lubrication

Eachcuttingunithas(4)greasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBaseGrease.

Thelubricationpointsarethefrontroller(2)andtherear

roller(2).Also,afterevery250hoursorwheneverthereel

motorisremovedfromthecuttingunit,applygreasetothe

splineinsert(Figure24).

Note:Lubricatingcuttingunitsimmediatelyafter

washinghelpspurgewateroutofbearingsandincreases

bearinglife.

Figure25

1.Bedbaradjustingscrew3.Bedbar

2.Springtensionnut

4.Washer

1.Wipeeachgreasettingwithacleanrag.

2.Greasethettingsandsplineinsert.

3.Wipeexcessgreaseaway.

Figure24

Greasettinglocationsshownforleftside

2.Backoutthespringtensionnut,untilthewasherisno

longertensionedagainstthebedbar(Figure25).

3.Oneachsideofthemachine,loosenthelocknut

securingthebedbarbolt(Figure26).

Figure26

1.Bedbarbolt2.Locknut

4.Removeeachbedbarboltallowingbedbartobepulled

downwardandremovedfrommachinebolt(Figure

26).Accountfor2nylonand1stampedsteelwashers

oneachendofbedbar(Figure27).

ServicingtheBedbar

RemovingtheBedbar

1.Turnbedbaradjusterscrewscounterclockwisetoback

thebedknifeawayfromreel(Figure25).

Figure27

1.Bedbarbolt

2.Nut4.Nylonwasher

AssemblingtheBedbar

1.Installbedbar,positioningmountingearsbetween

washerandbedbaradjuster.

2.Securebedbartoeachsideplatewithbedbarbolts

(nutsonbolts)and6washers.Anylonwasheristobe

positionedoneachsideofsideplateboss.Placeasteel

18

3.Steelwasher

Page 19

washeroutsideeachofthenylonwashers(Figure27).

Torquebedbarboltsto27-33(37-45N-m).Tighten

thelocknutsequally ,oneachside,untiltheoutersteel

washerscannotberotatedbyhand.Then,loosenthe

locknutsuntiltheoutersteelwashersjustrotateby

hand,yetthebedbarendplayisremoved.

Note:Overtighteningthelocknutscandeecttheside

platesandbedbarwhichcanaffectthereel/bedknife

contact.

Note:Thewashersontheinsidemayhaveagap.

3.Tightenspringtensionnutuntilspringiscollapsed,

thenbackoff1/2turn(Figure28).

Note:Donotovertightenasdamagetothespring

mayoccur.

Figure28

1.Spring2.Springtensionnut

19

Page 20

ServicingtheHDDualPoint

1

2

3

4

5

6

7

8

9

10

11

G016355

Adjusters(DPA)

1.Removeallparts(refertoInstallationInstructionsforHD

DPAKitModelNo.120–7230andtoFigure29).

2.ApplyNeverSeizetotheinsideofthebushingareaon

cuttingunitcenterframe(Figure29).

3.Alignthekeysonangebushingstotheslotsinthe

frameandinstallthebushings(Figure29).

4.Installawavewasherontotheadjustershaftandslide

theadjustershaftintotheangebushingsinthecutting

unitframe(Figure29).

5.Securetheadjustershaftwithaatwasherandlock

nut(Figure29).T orquethelocknutto15to20ft-lb

(20to27N-m).

Note:Thebedbaradjustershafthasleft-handthreads.

6.ApplyNeverSeizelubricanttothethreadsofthe

bedbaradjusterscrewthattintotheadjustershaft.

Threadbedbaradjusterscrewintotheadjustershaft.

7.Looselyinstallthehardenedwasher,springandspring

tensionnutontoadjusterscrew .

8.Installthebedbar,positioningthemountingears

betweenwasherandbedbaradjuster.

9.Securethebedbartoeachsideplatewiththebedbar

bolts(nutsonbolts)and6washers.Anylonwasheris

tobepositionedoneachsideofsideplateboss.Placea

steelwasheroutsideeachofthenylonwashers(Figure

29).T orquebedbarboltsto27-33ft.-lb(37-45N-m).

Tightenthelocknutsequally ,oneachside,untilthe

outersteelwasherscannotberotatedbyhand.Then,

loosenthelocknutsuntiltheoutersteelwashersjust

rotatebyhand,yetthebedbarendplayisremoved

(Figure27).

10.Tightenthenutoneachbedbaradjusterassembly

untilthecompressionspringisfullycompressed,then

loosennut1/2turn(Figure28).

11.Repeattheprocedureontheotherendofthecutting

unit.

12.Adjustthebedknifetothereel.

Figure29

1.Shaftadjuster4.ApplyNeverSeizehere7.ApplyNeverSeizehere10.Compressionspring

2.Wavewasher5.Flatwasher8.Bedbaradjusterscrew

3.Flangebushing6.Locknut9.Hardenedwasher

20

11.Springtensionnut

Page 21

ServicingtheRoller

ARollerRebuildKit,PartNo.114–5430anda

RollerRebuildT oolKit,PartNo.115–0803(Figure

30)areavailableforservicingtheroller.TheRoller

RebuildKitincludesallthebearings,bearingnuts,

innersealsandoutersealstorebuildaroller.

TheRollerRebuildToolKitincludesallthetoolsandthe

installationinstructionsrequiredtorebuildaroller.Referto

yourpartscatalogorcontactyourdistributorforassistance.

Figure30

1.Rebuildkit(PartNo.114–5430)

2.Rebuildtoolkit(PartNo.1 15–0803)

3.Innerseal8.Washer

4.Bearing

5.Outerseal

6.Bearingnut

7.Innersealtool

9.Bearing/outersealtool

21

Page 22

Notes:

22

Page 23

DeclarationofIncorporation

TheT oroCompany,8111LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

03911313000001andUp

03912313000001andUp

03913313000001andUp

SerialNo.

ProductDescriptionInvoiceDescription

18-inch,8-bladeDP ACutting

UnitforReelmaster3550

SeriesTractionUnit

18-inch,11-bladeDPA

CuttingUnitforReelmaster

3550SeriesTractionUnit

22-inch,8-bladeDP ACutting

UnitforReelmaster3550

SeriesTractionUnit

RM355018”8BLDDP A

CUTTINGUNIT

RM355018”1 1BLDDPA

CUTTINGUNIT

RM355022”8BLDDP A

CUTTINGUNIT

GeneralDescription

CuttingUnit

CuttingUnit

CuttingUnit

Directive

2000/14/EC

2006/42/EC

2000/14/EC

2006/42/EC

2000/14/EC

2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

PeterT etteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

May29,2012

Fax003214581911

23

Page 24

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.Torowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevB

Loading...

Loading...