FormNo.3432-531RevC

Reelmaster

®

3555,3575,and3550

TractionUnit

ModelNo.03820—SerialNo.403446001andUp

ModelNo.03821—SerialNo.403446001andUp

ModelNo.03910—SerialNo.403446001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3432-531*

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Visitwww.Toro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g240238

Figure1

1.Modelandserialnumberlocation

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisaride-on,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesigned

forcuttinggrassonwell-maintainedturf.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

Engine-EmissionCertication.............................4

SafetyandInstructionalDecals..........................5

Setup......................................................................13

1InstallingtheCuttingUnits..............................14

2AdjustingtheTurfCompensation

Spring...........................................................17

3InstallingtheCEDecals.................................17

4InstallingtheHoodLatch(CEOnly)................17

5ReducingtheTirePressure............................18

6UsingtheCutting-UnitKickstand....................18

ProductOverview...................................................20

Controls...........................................................20

Specications..................................................23

Attachments/Accessories.................................23

BeforeOperation.................................................23

BeforeOperationSafety...................................23

PerformingDailyMaintenance..........................24

CheckingtheParkingBrake.............................24

FillingtheFuelTank..........................................24

AdjustingtheSeat............................................25

DuringOperation.................................................26

DuringOperationSafety...................................26

StartingtheEngine...........................................27

ShuttingOfftheEngine.....................................27

SettingtheReelSpeed.....................................27

AdjustingtheLift-ArmCounterbalance.............29

BleedingtheFuelSystem.................................29

UnderstandingtheDiagnosticLight..................30

UnderstandingtheDiagnosticACE

Display..........................................................30

CheckingtheInterlockSwitches.......................30

OperatingTips.................................................32

AfterOperation....................................................33

AfterOperationSafety......................................33

PushingorT owingtheMachine........................33

HaulingtheMachine.........................................34

IdentifyingtheTie-DownPoints........................34

Maintenance...........................................................35

MaintenanceSafety..........................................35

RecommendedMaintenanceSchedule(s)...........35

DailyMaintenanceChecklist.............................37

Pre-MaintenanceProcedures..............................38

RemovingtheHood..........................................38

RemovingtheBatteryCover.............................38

Lubrication..........................................................39

GreasingtheBearingsandBushings................39

EngineMaintenance...........................................40

EngineSafety...................................................40

CheckingtheEngine-OilLevel..........................40

ServicingtheAirCleaner..................................41

ChangingtheEngineOilandFilter....................42

FuelSystemMaintenance...................................42

ServicingtheFuelT ank.....................................42

InspectingtheFuelLinesand

Connections..................................................42

DrainingtheWaterSeparator...........................43

ChangingtheFuelFilterCanister......................43

BleedingAirfromtheInjectors..........................43

ElectricalSystemMaintenance...........................44

ElectricalSystemSafety...................................44

ServicingtheBattery.........................................44

CheckingtheFuses..........................................44

DriveSystemMaintenance..................................45

CheckingtheTirePressure...............................45

TorquingtheWheelNuts...................................45

AdjustingtheTractionDriveforNeutral.............45

CoolingSystemMaintenance..............................46

CoolingSystemSafety.....................................46

CheckingtheCoolingSystem...........................46

CleaningtheEngineCoolingSystem................47

BrakeMaintenance.............................................47

AdjustingtheParkingBrake..............................47

ServicingtheParkingBrakes............................47

BeltMaintenance................................................52

ServicingtheEngineBelts................................52

ControlsSystemMaintenance.............................53

AdjustingtheThrottle........................................53

HydraulicSystemMaintenance...........................53

HydraulicSystemSafety...................................53

CheckingtheHydraulicLinesand

Hoses............................................................53

CheckingtheHydraulicFluid............................53

HydraulicFluidSpecications...........................54

HydraulicFluidCapacity...................................54

ChangingtheHydraulicFluid............................54

ChangingtheHydraulicFilter............................55

CuttingUnitSystemMaintenance........................56

BladeSafety.....................................................56

CheckingtheReel-to-BedknifeContact............56

UsingtheOptionalGaugeBar..........................57

BacklappingtheCuttingUnits...........................57

Cleaning..............................................................58

WashingtheMachine.......................................58

Storage...................................................................59

StorageSafety..................................................59

PreparingtheTractionUnit...............................59

PreparingtheEngine........................................59

3

Safety

Thismachinehasbeendesignedinaccordance

withENISO5395(whenyoucompletethesetup

procedures)andANSIB71.4-2017.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeet

andofthrowingobjects.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

Engine-Emission

Certication

TheengineinthismachineisEP ATier4FinalandEU

StageVemissionscompliant.

4

SafetyandInstructionalDecals

99-3444

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

133-8062

93-7276

1.Explosionhazard—weareyeprotection.

2.Causticliquid/chemicalburnhazard—toperformrstaid,

ushwithwater.

3.Firehazard—nore,openames,orsmoking.

4.Poisonhazard—keepchildrenawayfromthebattery .

decal133-8062

decal110-9642

110-9642

1.Storedenergyhazard—readtheOperator'sManual.

2.Movethecotterpintotheholeclosesttotherodbracket

andthenremovetheliftarmandpivotyoke.

decal93-7276

decal117-3270

117-3270

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,hand;entanglement

hazard,belt—stayawayfrommovingparts,keepallguards

andshieldsinplace.

1.Transportspeed—fast

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

decal99-3444

99-3444

2.Mowingspeed—slow

decal120-0627

120-0627

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts,keepallguardsandshieldsinplace.

decal106-6755

106-6755

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

5

decal120-1683

120-1683

1.Warning—readtheOperator'sManual;alloperatorsshould

betrainedbeforeoperatingthemachine.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—driveslowlywhenturning;donotturnsharply

whiletravelingfast;lowerthecuttingunitswhendrivingdown

slopes;usearolloverprotectionsystemandweartheseatbelt.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,shutofftheengine,and

removethekeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersaway .

6.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

6

decal120-2105

120-2105

1.Lowerthecuttingunits.

2.Raisethecuttingunits.

3.Pulluptoengagethecuttingunits.

4.Pushdowntodisengagethecutting

units.

5.ReadtheOperator’sManualfor

informationonstartingtheengine—sit

intheoperator’sposition,turnthekey

totheenginepreheatposition,wait

untiltheenginepreheatlightturnsoff,

turnthekeytotheenginestartposition,

anddisengagetheparkingbrake.

6.ReadtheOperator’sManual

forinformationonstoppingthe

engine—disengagethecuttingunits,

turnthekeytotheenginestopposition,

removethekeyfromtheignition,and

engagetheparkingbrake.

7.Engine—Shutoff

8.Engine—Preheat

9.Engine—Start

10.Lights

11.Fast

12.Slow

1.8-bladereeladjustment

2.11-bladereeladjustment

decal121-7884

121-7884

3.ReadtheOperator’sManualforinformationonadjustingthe

reel.

7

decal133-4901

133-4901

1.8-bladereeladjustment

2.11-bladereeladjustment

3.ReadtheOperator’sManualforinformationonadjustingthe

reel.

8

Model03910

121-7928

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal121-7928

1.Warning—readtheOperator'sManual;alloperatorsshould

betrainedbeforeoperatingthemachine.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—donotturnsharplywhiletravelingfast;do

notdriveupordownslopesgreaterthan22°;lowerthecutting

unitswhendrivingdownslopes;usearolloverprotection

systemandweartheseatbelt.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,shutofftheengine,and

removethekeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersaway .

6.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

9

Models03820and03821AfxoverPartNo.120-1683forCE

138-1186

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal138-1186

1.Warning—readtheOperator'sManual;alloperatorsshould

betrainedbeforeoperatingthemachine.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—donotturnsharplywhiletravelingfast;do

notdriveupordownslopesgreaterthan16°;lowerthecutting

unitswhendrivingdownslopes;usearolloverprotection

systemandweartheseatbelt.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,shutofftheengine,and

removethekeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersaway .

6.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

10

Model03910

decal138-6980

138-6980

1.ReadtheOperator’sManual.

Models03820and03821

1.ReadtheOperator’sManual.

decal138-6981

138-6981

11

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard6.Keepbystandersaway

fromthebattery .

2.Nore,opename,or

smoking

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection.9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

10.Containslead;donot

discard

12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Righthoseguide(Models03820and

03821)

Lefthoseguide(Models03820and

03821)

Nopartsrequired

Warningdecal121-7928(machine

model03910)

Warningdecal138-1186(machine

models03820and03821)

CEdecal

Productionyeardecal1

Lockbracket1

Rivet2

Washer1

Screw(1/4x2inches)

Locknut(1/4inch)

Nopartsrequired

Cutting-unitkickstand

Qty.

1

Installthecuttingunits.

1

–

1

1

1

1

1

–

1Usethecutting-unitkickstand.

Adjusttheturfcompensationspring.

InstalltheCEdecals,ifrequired.

Installthehoodlatch(CEonly).

Reducethetirepressure.

Use

MediaandAdditionalParts

Description

Keys2

Operator'sManual

Engineowner’smanual1

Cuttingperformancepaper

Shim

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Qty.

Starttheengine.

1

1

1

Readthemanualsbeforeoperatingthemachine.

Usethepaperforadjustingthecuttingunitreel-to-bedknife

contact.

Usetheshimforadjustingthecuttingunitreel-to-bedknife

contact.

Use

13

1

InstallingtheCuttingUnits

Partsneededforthisprocedure:

1

Righthoseguide(Models03820and03821)

1

Lefthoseguide(Models03820and03821)

PreparingtheMachineandCutting

Units

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,shutofftheengine,andremove

thekeyfromtheignitionswitch.

2.Removethereelmotorsfromtheshipping

brackets.

3.Removeanddiscardtheshippingbrackets.

4.Removethecuttingunitsfromthecartons.

Assembleandadjustthemasdescribedinthe

cuttingunitOperator'sManual.

5.Makesurethatthecounterweight(Figure3)is

installedtotheproperendofthecuttingunitas

describedinthecuttingunitOperator'sManual.

PositioningtheTurfCompensating

Spring

Allthecuttingunitsareshippedwiththeturf

compensationspringmountedattherightsideofthe

cuttingunit.Ensurethattheturfcompensationspring

ismountedtothesamesideofthecuttingunitasthe

reeldrivemotor.

Note:Wheninstallingorremovingthecuttingunits,

makesurethatthehairpincotterisinstalledinthe

springrodholenexttotherodbracket.Otherwise,

installthehairpincotterintheholeintheendofthe

rod.

1.Removethe2carriageboltsandnutssecuring

therodbrackettothecuttingunittabs(Figure4).

g003949

Figure4

1.Turfcompensationspring3.Springtube

2.Rodbracket

2.Removetheangenutsecuringthespringtube

bolttothecarrierframetab(Figure4),and

removetheassembly.

3.Mountthespringtubebolttotheoppositetabon

thecarrierframeandsecureitwiththeange

nut.

Note:Positiontheboltheadtotheouterside

ofthetabasshowninFigure4.

g003967

Figure5

1.Oppositecarrierframetab

4.Mounttherodbrackettothecuttingunittabs

g019938

Figure3

1.Counterweight

withthecarriageboltsandnuts(Figure5).

2.Rodbracket

14

InstallingtheHoseGuide

Models03820and03821

Oncuttingunit4(leftfront)andcuttingunit5(right

front),usetherod-bracketmountingnutstoinstallthe

hoseguidestothefrontofthecutting-unittabs.The

hoseguidesshouldleantowardthecentercuttingunit

(Figure6,Figure7,andFigure8).

Figure6

1.Cuttingunit15.Cuttingunit5

2.Cuttingunit2

3.Cuttingunit3

4.Cuttingunit4

6.Reelmotor

7.Weight

g289454

Figure8

1.Hoseguides(eachmustleantowardthecentercuttingunit)

AligningtheCuttingUnitstothe

LiftArms

AllFrontCuttingUnits,andAnyRearCutting

Unitswitha1.2cm(3/4inch)orLowerHeight

g031275

ofCut

1.Loweralltheliftarmscompletely.

2.Removethesnapperpinandthecapfromthe

lift-armpivotyoke(Figure9).

1.Hoseguide(leftside

shown)

2.Rodbracket

g003975

Figure9

1.Snapperpin2.Cap

3.Forthefrontcuttingunits,slideacuttingunit

undertheliftarmwhileinsertingthecarrierframe

shaftupintothelift-armpivotyoke(Figure10).

g015160

Figure7

3.Nuts

15

Figure10

Note:Usetheslotifasteeringcuttingunitis

desiredorusetheholeifthecuttingunitistobe

lockedinposition(Figure9).

3.Securethelift-armchaintothechainbracket

withthesnapperpin(Figure12).

Note:Usethenumberofchainlinksspecied

inthecuttingunitOperator'sManual.

g020321

1.Liftarm3.Lift-armpivotyoke

2.Carrierframeshaft

AligningtheRearCuttingUnitsto

theLiftArms

CuttingUnitsadjustedfora1.2cm(3/4inch)

orHigherHeightofCut

1.Removethelynchpinandwashersecuringthe

lift-armpivotshafttotheliftarmandslidethe

lift-armpivotshaftoutoftheliftarm(Figure11).

Figure11

1.Lift-armshaftlynchpinandwasher

g003948

Figure12

1.Lift-armchain3.Snapperpin

2.Chainbracket

InstallingtheReelMotors

1.Coatthesplineshaftofthereelmotorwithclean

grease.

2.Lubricatethereel-motorO-ringwithoil,and

installitontothemotorange.

3.Installthemotorbyrotatingitclockwisesothat

themotorangesclearthelocknuts(Figure13).

Important:Ensurethatthereelmotorhoses

arenottwisted,kinked,oratriskofbeing

pinched.

g003979

2.Insertthelift-armyokeontothecarrierframe

shaft(Figure10).

3.Insertthelift-armshaftintotheliftarmand

secureitwiththewasherandlynchpin(Figure

11).

AssemblingtheCuttingUnitsto

theLiftArms

1.Insertthecapoverthecarrierframeshaftand

lift-armyoke.

2.Securethecapandthecarrierframeshafttothe

lift-armyokewiththesnapperpin.

g020322

Figure13

1.Reel-drivemotor2.Mountingnuts

16

4.Rotatethemotorcounterclockwiseuntilthe

angesencirclethenuts.

5.Torquethenutsto37to45N∙m(27to33ft-lb).

Note:Whenoperatingonroughterrain,

decreasethespringlengthby2.5cm(1/2inch).

Groundfollowingwillbeslightlydecreased.

2

AdjustingtheTurf

CompensationSpring

NoPartsRequired

Procedure

Theturfcompensationspring(Figure14)transfers

weightfromthefronttotherearroller.Thishelps

toreduceawavepatternintheturf,alsoknownas

marcellingorbobbing.

Important:Makespringadjustmentswiththe

cuttingunitmountedtothetractionunit,pointing

straightaheadandloweredtotheshopoor.

1.Makesurethatthehairpincotterisinstalledin

therearholeinthespringrod(Figure14).

3

InstallingtheCEDecals

Partsneededforthisprocedure:

1

Warningdecal121-7928(machinemodel03910)

Warningdecal138-1186(machinemodels03820and

1

03821)

1

CEdecal

1Productionyeardecal

Procedure

OnmachinesrequiringCEcompliance,applythe

productionyeardecal(PartNo.133-5615)nearthe

serialplate,theCEdecal(PartNo.93-7252)near

thehoodlock,andtheCEwarningdecal(PartNo.

121-7928formachinemodel03910andPartNo.

138-1186formachinemodels03820and03821)over

thestandardwarningdecal(PartNo.120-1683).

Figure14

1.Turfcompensationspring3.Springrod

2.Hairpincotter4.Hexnuts

2.Tightenthehexnutsonthefrontendofthe

springroduntilthecompressedlengthofthe

spring(Figure14)is12.7cm(5inches)for

5-inchcuttingunitsand15.8cm(6-1/4inches)

for7-inchcuttingunits.

4

InstallingtheHoodLatch

(CEOnly)

Partsneededforthisprocedure:

1Lockbracket

2Rivet

1Washer

1

g020164

Procedure

1.Unhookthehoodlatchfromthehood-latch

2.Removethe2rivetssecuringthehood-latch

Screw(1/4x2inches)

1

Locknut(1/4inch)

bracket.

brackettothehood(Figure15)andremovethe

hood-latchbracketfromthehood.

17

Figure15

g012630

Figure17

g012628

1.Hoodlatch

1.Hood-latchbracket2.Rivets

3.Whilealigningthemountingholes,positionthe

CElockbracketandthehood-latchbracketonto

thehood.

Note:Thelockbracketmustbeagainstthe

hood(Figure16).Donotremovetheboltand

nutfromthelock-bracketarm.

Figure16

7.Screwtheboltintotheotherarmofthehood-lock

brackettolockthelatchinposition(Figure18).

Note:Tightentheboltsecurelybutdonot

tightenthenut.

g012631

Figure18

1.Bolt

2.Nut

g012629

3.Armofhood-lockbracket

1.CElockbracket

4.Alignthewasherswiththeholesontheinsideof

thehood.

5.Rivetthebracketsandthewasherstothehood

(Figure16).

6.Hookthelatchontothehood-latchbracket

(Figure17).

2.Boltandnut

5

ReducingtheTirePressure

NoPartsRequired

Procedure

Thetiresareoverinatedatthefactoryforshipping

purposes.Reducethepressuretotheproperlevels

beforestartingthemachine;refertoCheckingtheTire

Pressure(page45).

18

6

UsingtheCutting-Unit

Kickstand

Partsneededforthisprocedure:

1

Cutting-unitkickstand

Procedure

Wheneveryoutipacuttingunittoexposethe

bedknife/reel,propuptherearofthecuttingunitwith

thekickstandtoensurethatthenutsonthebackend

ofthebedbaradjustingscrewsarenotrestingonthe

worksurface(Figure19).

g004144

Figure20

1.Chainbracket3.Cutting-unitkickstand

2.Snapperpin

Figure19

1.Cutting-unitkickstand

Securethekickstandtothechainbracketwiththe

snapperpin(Figure20).

g020158

19

ProductOverview

Mow/TransportSlide

Usingyourheel,movethemow/transportslide(Figure

22)tothelefttotransportandtotherighttomow.The

cuttingunitswillonlyoperateintheMOWposition

andnotlowerintheTRANSPORTposition.

Important:Themowspeedissetatthefactoryto

9.7km/h(6mph).Itcanbeincreasedordecreased

byadjustingthespeedstopscrew(Figure23).

1.Enginehood

2.Seat

3.Controlarm

4.Steeringwheel

Controls

Figure21

Figure22

5.Seatadjustmentlever

6.Frontcuttingunits

7.Rearcuttingunits

g216864

Figure23

1.Speedstopscrew

g008888

Tilt-SteeringLever

Pullthetilt-steeringlever(Figure22)backtotiltthe

steeringwheeltothedesiredposition.Thenpushthe

leverforwardtosecuretheposition.

IgnitionSwitch

Theignitionswitch(Figure24),usedtostart,shut

off,andpreheattheengine,has3positions:OFF,

ON/PREHEAT,andSTART.Rotatethekeytothe

ON/PREHEATpositionuntiltheglow-plugindicator

lightgoesout(approximately7seconds);thenrotate

thekeytotheST ARTpositiontoengagethestarter

motor.Releasethekeywhentheenginestarts.The

keymovesautomaticallytotheON/RUNposition.T o

shutofftheengine,rotatethekeytotheOFFposition.

Removethekeyfromtheswitchtopreventaccidental

starting.

g020079

1.Forwardtractionpedal

2.Reversetractionpedal4.Tilt-steeringlever

3.Mow/transportslide

TractionPedals

Presstheforwardtractionpedal(Figure22)tomove

forward.Pressreversetractionpedal(Figure22)to

movebackwardortoassistinstoppingwhenmoving

forward.Also,allowthepedaltomoveormoveitto

theNEUTRALpositiontostopthemachine.

20

Figure24

1.Parkingbrake

2.Ignitionswitch8.Temperaturelight

3.Enable/Disableswitch

4.Diagnosticlight

5.Lowermow/raisecontrol

lever

6.Hourmeter12.Alternatorlight

7.Oil-pressurelight

9.Lightswitch

10.Glow-plugindicatorlight

11.Throttle

EngineCoolantTemperature

WarningLight

Thetemperaturewarninglight(Figure24)glows

iftheenginecoolanttemperatureishigh.Atthis

temperature,thecuttingunitsaredisabled.Ifthe

coolanttemperaturerisesanother5.5°C(10°F),the

engineshutsofftopreventfurtherdamage.

Oil-PressureWarningLight

Theoil-pressurewarninglight(Figure24)glowsifthe

g019980

engineoilpressuredropsbelowasafelevel.

AlternatorLight

Thealternatorlight(Figure24)shouldbeoffwhen

theengineisrunning.Ifitison,checkthecharging

systemandrepairitasnecessary.

Glow-PlugIndicator

Theglow-plugindicatorlight(Figure24)glowswhen

theglowplugsareoperating.

Throttle

Movethethrottle(Figure24)forwardtoincreasethe

enginespeedandrearwardtodecreasetheengine

speed.

Enable/DisableSwitch

Usetheenable/disableswitch(Figure24)in

conjunctionwiththelowermow/raisecontrollever

tooperatethecuttingunits.Youcannotlowerthe

cuttingunitswhenthemow/transportleverisin

theTRANSPORTposition.

HourMeter

Thehourmeter(Figure24)indicatesthetotalhours

ofmachineoperation.Itstartstofunctionwhenever

thekeyswitchison.

LowerMow/RaiseControlLever

Thislever(Figure24)raisesandlowersthecutting

unitsandalsostartsandstopsthereelswhenthe

reelsareenabledinthemowmode.Youcannot

lowerthecuttingunitswhenthemow/transport

leverisintheTRANSPORTposition.

ParkingBrake

Whenevertheengineisshutoff,engagetheparking

brake(Figure24)topreventaccidentalmovementof

themachine.T oengagetheparkingbrake,pullup

onthelever.Theenginestopswhenyoupressthe

tractionpedalwiththeparkingbrakeengaged.

Note:Whenthecuttingunitsareenabled,youdonot

needtoholdtheleverintheforwardpositionwhilethe

cuttingunitsareloweredorraised.

21

DiagnosticLight

ReelSpeedControlKnob

Thediagnosticlight(Figure24)willilluminateifthe

systemrecognizesasystemfault.

FuelGauge

Thefuelgauge(Figure25)indicatestheamountof

fuelinthetank.

Figure25

1.Fuelgauge

PowerPoint

Thepowerpoint,locatedontheoutsideofthecontrol

panel,isa12Vpowersupplyforelectronicdevices

(Figure26).

Thereelspeedcontrolcontrolsthespeedofthe

cuttingunits(Figure27).Thereelspeedincreases

asyouturntheknobcounterclockwise.Refertothe

reelspeedchartdecal(Figure31),todeterminethe

properreelspeed.

g019982

g020248

Figure27

1.Backlaplever2.Reelspeedcontrolknob

1.Powerpoint

BacklapLever

Usethebacklapleverinconjunctionwiththelower

mow/raisecontrolleverforthereels(Figure27).

g019983

Figure26

22

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

DimensionsReelmaster3550Reelmaster3555Reelmaster3575

WidthofCut208cm(82inches)254cm(100inches)254cm(100inches)

OverallWidth239cm(94inches)284cm(112inches)284cm(1 12inches)

TransportWidth

OverallLength295cm(110inches)267cm(105inches)267cm(105inches)

HeighttotopofROPS188cm(74inches)201cm(79inches)206cm(81inches)

WheelBase

Weight(congured)900kg(1985lb)1034kg(2280lb)1 157kg(2550lb)

Weight(nocuttingunits)708kg(1560lb)751kg(1655lb)796kg(1755lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorauthorizedT orodistributororgoto

www.T oro.comforalistofallapprovedattachmentsandaccessories.

231cm(91inches)231cm(91inches)231cm(91inches)

151cm(59.5inches)152cm(60inches)152cm(60inches)

Toensureoptimumperformanceandcontinuedsafetycerticationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacementpartsandaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty .

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Beforemowing,alwaysinspectthemachineto

ensurethatthecuttingunitsareingoodworking

condition.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

23

PerformingDaily

FillingtheFuelTank

Maintenance

ServiceInterval:Beforeeachuseordaily

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page35).

CheckingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

1.Starttheengine,raisethecuttingunits,

disengagetheparkingbrake,andmovethe

machinetoanopenatarea.

2.Engagetheparkingbrake(Figure28).

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultra-low(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180days

toensurefuelfreshness.

Thefueltankcapacityisapproximately42L(1 1US

gallons).

Usesummer-gradedieselfuel(Number2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

dieselfuel(Number1-DorNumber1-D/2-Dblend)

below-7°C(20°F).Usingwinter-gradefuelatlower

temperaturesprovideslowerashpointandcoldow

characteristicswhichwilleasestartingandreduce

pluggingofthefuellter.

Usingsummer-gradefuelabove-7°C(20°F)will

contributetowardlongerfuel-pumplifeandincreased

powercomparedtowinter-gradefuel.

Themachineisbiodieselready.

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultra-lowsulfur.

Observethefollowingprecautions:

Figure28

3.Pressthetractionpedaltomovethemachine

forward.

Note:Ifthemachinemovesforwardwiththe

parkingbrakeengaged,adjustparkingbrake;

refertoAdjustingtheParkingBrake(page47).

Note:Movingthemachineforwardwiththe

parkingbrakeengagedwillcausetheengineto

shutoff.

4.Ifyouadjustedtheparkingbrake,repeatsteps

2and3.

Note:Ifthemachinemovesforwardwiththe

parkingbrakeengaged:servicetheparking

brakes,checkleftandrightbrakelinkagefor

damage,andcheckthebrakeleverpivotfor

damage;refertoServicingtheParkingBrakes

(page47).

5.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operator’sseat.

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

g332418

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,andgasketsincontactwith

fuelastheymaydegradeovertime.

•Expectpluggingofthefuellterforatimeafter

convertingtobiodieselblends.

•ContactyourauthorizedT orodistributorifyouwish

formoreinformationonbiodiesel.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekeyfromtheignition

switch.

2.Cleantheareaaroundthefuel-tankcap(Figure

29).

3.Removethefuel-tankcap.

4.Fillthetanktothebottomofthellerneck.Do

notoverllthetank.

5.Installthecap.

6.Topreventarehazard,wipeupanyfuelthat

mayhavespilled.

24

Figure29

1.Fuel-tankcap

AdjustingtheSeat

ChangingtheSeatPosition

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable.

1.Movetheleversidewaystounlocktheseat

(Figure30).

g008884

2.Slidetheseattothedesiredpositionandrelease

thelevertolockitinposition.

ChangingtheSeatSuspension

Youcanadjusttheseattoprovideasmoothand

comfortableride.Positiontheseatwhereyouare

mostcomfortable.

Toadjustit,turnthefrontknobineitherdirectionto

providethebestcomfort(Figure30).

ChangingtheBackPosition

Youcanadjustthebackoftheseattoprovidea

comfortableride.Positionthebackoftheseatwhere

itismostcomfortable.

Toadjustit,turntheknobundertherightarmrest,in

eitherdirection,toprovidethebestcomfort(Figure

30).

ChangingtheArmrestPosition

1.Backrestknob

2.Seat-positionadjustment

lever

g010515

Figure30

3.Seat-suspensionknob

4.Armrest-adjustingknob

Youcanadjustthearmreststoprovideacomfortable

ride.Positionthearmrestswheretheyaremost

comfortable.

Raisethearmrestandturntheknob,ineither

direction,toprovidethebestcomfort(Figure30).

25

DuringOperation

DuringOperationSafety

–Waitforallmovementtostop.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Donotcarrypassengersonthemachineandkeep

bystandersandchildrenoutoftheoperatingarea.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Keepyourhandsandfeetawayfromthecutting

units.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Stopthecuttingunitswheneveryouarenot

mowing.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,which

islethalifinhaled.

•Donotleavearunningmachineunattended.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Disengagethecuttingunit(s)andlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

RolloverProtectionSystem

(ROPS)Safety

•DonotremoveanyoftheROPScomponentsfrom

themachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Alwayswearyourseatbelt.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplacealldamagedROPScomponents.Donot

repairoralterthem.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Youareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey .

•Reviewtheslopeinstructions,listedbelow,for

operatingthemachineonslopes.Beforeyou

operatethemachine,reviewthesiteconditionsto

determinewhetheryoucanoperatethemachine

intheconditionsonthatdayandatthatsite.

Changesintheterraincanresultinachangein

slopeoperationforthemachine.

–Avoidstarting,stopping,orturningthemachine

onslopes.Avoidmakingsuddenchangesin

speedordirection.Maketurnsslowlyand

gradually.

–Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisin

question.

–Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhidden

hazards.T allgrasscanhideobstructions.

Uneventerraincouldoverturnthemachine.

–Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycause

themachinetolosetraction.

–Useextremecautionwhenoperating

themachineneardrop-offs,ditches,

26

embankments,waterhazards,orother

hazards.Themachinecouldsuddenlyrollover

ifawheelgoesovertheedgeortheedge

cavesin.Establishasafetyareabetweenthe

machineandanyhazard.

–Identifyhazardsatthebaseoftheslope.

Iftherearehazards,mowtheslopewitha

pedestrian-controlledmachine.

–Ifpossible,keepthecuttingunitsloweredto

thegroundwhileoperatingonslopes.Raising

thecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

StartingtheEngine

Youmayneedtobleedthefuelsystemifanyofthe

followingsituationshaveoccurred;refertoBleeding

theFuelSystem(page29):

•Initialstartupofanewengine

CAUTION

Contactwithmovingpartscouldresult

ininjury.

Shutofftheengineandwaitforall

movingpartstostopbeforechecking

foroilleaks,looseparts,andother

malfunctions.

ShuttingOfftheEngine

1.MovethethrottlecontroltotheIDLEposition.

2.MovethecuttingunitdriveswitchtoDISENGAGE.

3.RotatethekeytoOFF.

4.Removethekeytopreventaccidentalstarting.

SettingtheReelSpeed

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuel

systemcomponents;i.e.lterreplaced,etc.

1.Ensurethattheparkingbrakeisengagedand

thecuttingunitdriveswitchisintheDISENGAGE

position.

2.Removeyourfootfromthetractionpedaland

ensurethatthepedalisintheNEUTRALposition.

3.Movethethrottlelevertothe1/2throttleposition.

4.Insertthekeyintotheswitchandrotateitto

theON/PREHEATpositionuntiltheglow-plug

indicatorlightgoesout(approximately7

seconds);thenrotatethekeytotheSTART

positiontoengagethestartermotor.

Note:Releasethekeywhentheenginestarts.

ThekeywillmoveautomaticallytotheON/RUN

position.

Important:Topreventoverheatingofthe

startermotor,donotengagethestarterfor

longerthan15seconds.After10secondsof

continuouscranking,wait60secondsbefore

engagingthestartermotoragain.

Toachieveaconsistent,highqualityofcutanda

uniformafter-cutappearance,itisimportantthatyou

setthereelspeedcontrols(locatedundertheseat)

correctly.Adjustthereelspeedcontrolsasfollows:

1.Selecttheheightofcutatwhichthecuttingunits

areset.

2.Choosethedesiredgroundspeedbestsuited

forconditions.

3.Usethegraphonthereelspeedchartdecals

(Figure31andFigure32),todeterminethe

properreelspeedsetting.

5.Whentheengineisstartedforthersttime

orafteranoverhauloftheengine,operate

themachineinforwardandreversefor1to2

minutes.Alsooperatetheliftleverandcutting

unitdriveswitchtoensureproperoperationof

allparts.

Turnthesteeringwheeltotheleftandright

tochecksteeringresponse;thenshutoffthe

engineandcheckforoilleaks,looseparts,and

anyothernoticeablemalfunctions.

27

Figure31

Model03820and03910

decal121-7884

1.8-bladereeladjustment

2.11-bladereeladjustment

3.ReadtheOperator’sManualforinformationonadjustingthe

reel.

decal133-4901

Figure32

Model03821

1.8-bladereeladjustment

2.11-bladereeladjustment

4.Tosetthereelspeed,rotatetheknob(Figure

33)untiltheindicatorarrowisinlinewiththe

numberdesignatingthedesiredsetting.

3.ReadtheOperator’sManualforinformationonadjustingthe

reel.

28

Figure34

g034346

Figure33

1.Reelspeedcontrolknob

Note:Thereelspeedcanbeincreasedor

decreasedtocompensateforturfconditions.

Whenusingbaskets,increasethereelspeedto

improvecollectionperformance.

AdjustingtheLift-Arm

Counterbalance

Youcanadjustthecounterbalanceontheliftarmsof

therearcuttingunitstocompensatefordifferentturf

conditionsandtomaintainauniformheightofcutin

roughconditionsorinareasofthatchbuildup.

Youcanadjusteachcounterbalancespringto1of

4settings.Eachincrementincreasesordecreases

counterbalanceonthecuttingunitby2.3kg(5lb).

Youcanpositionthespringsonthebacksideofthe

rstspringactuatortoremoveallcounterbalance

(fourthposition).

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekeyfromtheignition

switch.

2.Insertatubeorsimilarobjectontothelong

springendtorelievethespringtensionduring

theadjustment(Figure34).

1.Spring

2.Springactuator

g020259

4.Movethespringactuatortothedesiredhole

locationandsecureitwiththeboltandthe

locknut.

5.Repeattheprocedureontheremainingspring.

3.Additionalholelocations

BleedingtheFuelSystem

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Ensurethatthefueltankisatleasthalffull.

3.Unlatchandraisethehood.

4.Opentheair-bleedscrewonthefuel-injection

pump(Figure35).

g008891

Figure35

CAUTION

Thespringsareundertensionandcould

causepersonalinjury.

Usecautionwhenadjustingthem.

3.Whilerelievingthespringtension,removethe

boltandlocknutsecuringthespringactuatorto

thebracket(Figure34).

1.Fuel-injectionpumpbleedscrew

5.TurnthekeyintheignitionswitchtotheON

position.Theelectricfuelpumpwillbegin

operation,therebyforcingairoutaroundthe

air-bleedscrew.

Note:LeavethekeyintheONpositionuntila

solidstreamoffuelowsoutaroundthescrew.

29

6.Tightenthescrewandturntheignitionkeyto

OFF.

Note:Normallytheengineshouldstartafterthe

abovebleedingproceduresarefollowed.However,if

theenginedoesnotstart,airmaybetrappedbetween

theinjectionpumpandinjectors;refertoBleedingAir

fromtheInjectors(page43).

•Fusesareblown.

•Itisnotfunctioningcorrectly.

Checktheelectricalconnections,inputfuses,and

diagnosticlightbulbtodeterminethemalfunction.

Ensurethattheloop-backconnectorissecuredto

thewireharnessconnector.

Understandingthe

DiagnosticLight

Themachineisequippedwithadiagnosticlight

thatindicatesiftheelectroniccontrollersensesan

electronicmalfunction.Thediagnosticlightislocated

onthecontrolpanel(Figure36).Whentheelectronic

controllerisfunctioningcorrectlyandyoumovethe

keyswitchtotheONposition,thecontrollerdiagnostic

lightturnsonfor3secondsandturnofftoindicate

thatthelightisworkingproperly.Iftheengineshuts

off,thenthelightturnsonsteadyuntiltheyouchange

keyposition.Thelightblinksifthecontrollerdetectsa

malfunctionintheelectricalsystem.Thelightstops

blinkingandautomaticallyresetswhenyouturnthe

keyswitchtotheOFFpositiononcethefaulthasbeen

resolved.

Figure36

1.Diagnosticlight

Understandingthe

DiagnosticACEDisplay

Themachineisequippedwithanelectroniccontroller

whichcontrolsmostmachinefunctions.Thecontroller

determineswhatfunctionisrequiredforvariousinput

switches(i.e.,seatswitch,keyswitch,etc.)andturns

ontheoutputstoactuatesolenoidsorrelaysforthe

requestedmachinefunction.

Fortheelectroniccontrollertocontrolthemachineas

desired,eachoftheinputswitches,outputsolenoids,

andrelaysmustbeconnectedandfunctioning

properly.

UsetheDiagnosticACEdisplaytohelpverifyand

correctelectricalfunctionsofthemachine.

CheckingtheInterlock

Switches

ServiceInterval:Beforeeachuseordaily

Thepurposeoftheinterlockswitchesistopreventthe

enginefromcrankingorstartingunlessthetraction

pedalisintheNEUTRALposition,theEnable/Disable

switchisintheDISABLEposition,andtheLower

Mow/RaisecontrolisintheNEUTRALposition.In

g020251

addition,theengineshouldshutoffwhenyoupress

thetractionpedalwithnooneintheseatorifthe

parkingbrakeisengaged.

Whenthecontrollerdiagnosticlightblinks,1of

thefollowingproblemshasbeendetectedbythe

controller:

•Anoutputhasbeenshorted.

•Anoutputisopencircuited.

Usingthediagnosticdisplay,determinewhichoutput

ismalfunctioning;refertoCheckingtheInterlock

Switches(page30).

Ifthediagnosticlightisnotilluminatedwhenthekey

switchisintheONposition,thisindicatesthatthe

electroniccontrollerisnotoperating.Possiblecauses

areasfollows:

•Theloop-backisnotconnected.

•Thelightisburnedout.

CAUTION

Ifsafetyinterlockswitchesaredisconnected

ordamaged,themachinecouldoperate

unexpectedly,causingpersonalinjury .

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

VerifyingtheInterlockSwitch

Function

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,and

shutofftheengine.

30

2.Removethecoverfromthecontrolpanel.

3.Locatethewireharnessandloop-back

connector(Figure37).

Figure37

1.Loop-backconnector

4.Carefullyunplugtheloop-backconnectorfrom

theharnessconnector.

5.ConnecttheDiagnosticACEdisplayconnector

totheharnessconnector(Figure38).

Note:Ensurethatthecorrectoverlaydecalis

positionedontheDiagnosticACEdisplay.

DiagnosticACE,tochangeLEDto“inputs

displayed.”

TheDiagnosticACEilluminatestheLED

associatedwitheachoftheinputswhenthat

inputswitchisclosed.

8.Individually,changeeachoftheswitchesfrom

opentoclosed(i.e.,sitontheseat,engage

thetractionpedal,etc.),andnotethatthe

appropriateLEDontheDiagnosticACEblinks

onandoffwhenthecorrespondingswitchis

closed.Repeatthisforallswitchesthatyoucan

changebyhand.

9.Ifaswitchisclosedandtheappropriate

LEDdoesnotturnon,checkallwiringand

connectionstotheswitchand/orcheckthe

switcheswithanohmmeterormultimeter.

g020260

Replaceanymalfunctioningswitchesandrepair

anymalfunctioningwiring.

Note:TheDiagnosticACEalsohastheability

todetectwhichoutputsolenoidsorrelaysare

turnedon.Thisisaquickwaytodetermineifa

machinemalfunctioniselectricalorhydraulic.

VerifyingOutputFunction

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

Figure38

1.DiagnosticACE

6.TurnthekeyswitchtotheONposition,butdo

notstartthemachine.

Note:Theredtextontheoverlaydecalrefers

toinputswitchesandthegreentextrefersto

outputs.

7.The“inputsdisplayed”LED,onthelowerright

columnoftheDiagnosticACE,shouldbe

illuminated.Ifthe“outputsdisplayed”LED

isilluminated,pressthetogglebutton,on

2.Removetheaccesspanelfromthesideofthe

controlarm.

3.Locatethewireharnessandconnectorsnear

thecontroller.

4.Carefullyunplugtheloop-backconnectorfrom

theharnessconnector.

5.ConnecttheDiagnosticACEconnectortothe

harnessconnector.

Note:Makesurethatthecorrectoverlaydecal

ispositionedontheDiagnosticACE.

6.TurnthekeyswitchtotheONposition,butdo

g004140

notstartthemachine.

Note:Theredtextontheoverlaydecalrefers

toinputswitchesandthegreentextrefersto

outputs.

7.The“outputsdisplayed”LED,onlower

rightcolumnofDiagnosticACE,shouldbe

illuminated.Ifthe“inputsdisplayed”LEDis

illuminated,pressthetogglebutton,onthe

DiagnosticACE,tochangetheLEDto“outputs

displayed”.

Note:Itmaybenecessarytotogglebetween

“inputsdisplayed”and“outputsdisplayed”

severaltimestodothefollowingstep.T otoggle

31

backandforth,pressthetogglebuttononce.

Thismaybedoneasoftenasrequired.Donot

holdthebutton.

8.Sitontheseatandattempttooperatethe

desiredfunctionofthemachine.Theappropriate

outputLEDsshouldilluminatetoindicatethat

theECMisturningonthatfunction.

Note:IfthecorrectoutputLEDsdonot

illuminate,verifythattherequiredinputswitches

areinthenecessarypositionstoallowthat

functiontooccur.Verifycorrectswitchfunction.

IftheoutputLEDsareonasspecied,but

themachinedoesnotfunctionproperly ,this

indicatesanon-electricalproblem.Repairas

necessary.

Note:Ifeachoutputswitchisinthecorrect

positionandfunctioningcorrectly,buttheoutput

LEDsarenotcorrectlyilluminated,thisindicates

anECMproblem.Ifthisoccurs,contactyour

authorizedT orodistributorforassistance.

Important:TheDiagnosticACEdisplay

mustnotbeleftconnectedtothemachine.It

isnotdesignedtowithstandtheenvironment

oftheeverydayuseofthemachine.When

youarenishedusingtheDiagnosticACE,

disconnectitfromthemachineandconnect

theloop-backconnectortotheharness

connector.Themachinedoesnotoperate

withouttheloop-backconnectorinstalledon

theharness.StoretheDiagnosticACEina

dry,securelocationintheshop,notonthe

machine.

OperatingTips

BecomingFamiliarwiththe

Machine

Beforemowinggrass,practiceoperatingthemachine

inanopenarea.Startandshutofftheengine.

Operateinforwardandreverse.Lowerandraise

thecuttingunitsandengageanddisengagethe

cuttingunits.Whenyoufeelfamiliarwiththemachine,

practiceoperatingupanddownslopesatdifferent

speeds.

UnderstandingtheWarning

System

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurif

youoperatethemachinewithamalfunction.

MowingGrass

StarttheengineandmovethethrottletotheFAST

position.MovetheEnable/Disableswitchtothe

ENABLEpositionandusetheLowerMow/Raiselever

tocontrolthecuttingunits(thefrontcuttingunits

aretimedtolowerbeforetherearcuttingunits).To

moveforwardandcutgrass,pressthetractionpedal

forward.

DrivingtheMachineinTransport

Mode

MovetheEnable/DisableswitchtotheDISABLE

positionandraisethecuttingunitstothetransport

position.MovetheMow/Transportlevertothe

TRANSPORTposition.Becarefulwhendrivingbetween

objectssothatyoudonotaccidentallydamagethe

machineorthecuttingunits.Useextracarewhen

operatingthemachineonslopes.Driveslowlyand

avoidsharpturnsonslopestopreventrollovers.

32

AfterOperation

AfterOperationSafety

•ToroPartNo.354-79,diagnostic-ttingcap

•ToroPartNo.95-8843,hydraulichose

•ToroPartNo.95-0985,couplertting(2)

•ToroPartNo.340-77,hydraulictting(2)

GeneralSafety

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Cleangrassanddebrisfromthecuttingunits,

drives,mufers,coolingscreens,andengine

compartmenttohelppreventres.Cleanupoilor

fuelspills.

•Disengagethedrivetotheattachmentwhenever

youarehaulingornotusingthemachine.

•Maintainandcleantheseatbelt(s)asnecessary.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

PushingorTowingthe

Machine

Inanemergency,youcanmovethemachine

byactuatingthebypassvalveinthevariable

displacementhydraulicpumpandinstallinga

hydraulichosetobypassthecheckvalve,andthen

pushingortowingthemachine.

Important:Donotpushortowthemachinefaster

than3to4.8km/h(2to3mph)orformorethan

0.4km(1/4mile),becauseinternaltransmission

damagemayoccur.Thebypassvalvemustbe

openwheneveryoupushortowthemachine.

Additionally,youneedtoinstallahydraulichose

tobypassthecheckvalvewheneveryoupushor

towthemachineinreverse.

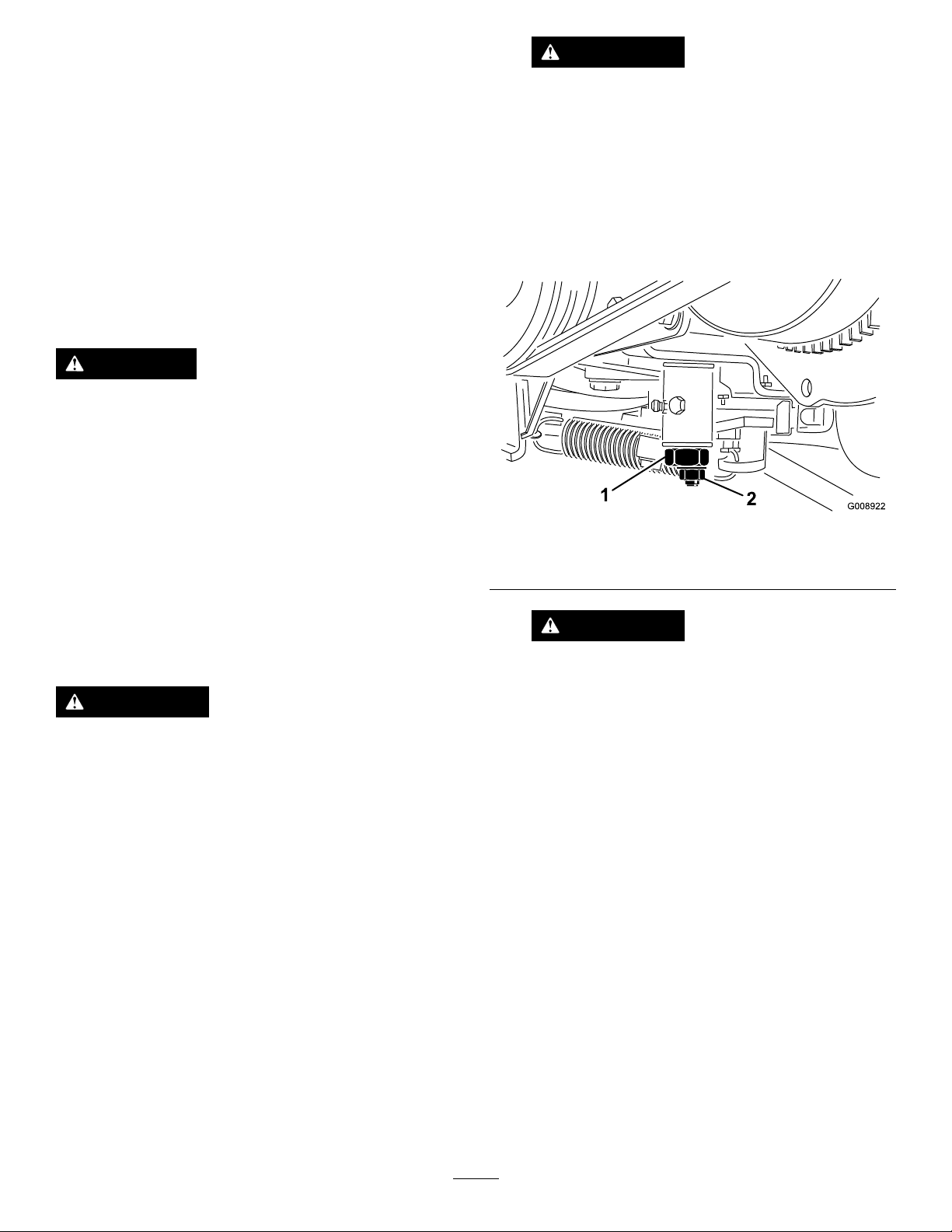

1.Installadiagnosticttingintheunmarkedport

locatedbetweenportsM8andP2ontherear

tractionmanifold(Figure39).

Figure39

1.Reartractionmanifold

(behindfrontleftwheel)

2.Connectahydraulichosebetweenthe

diagnosticttinginstalledinthereartraction

manifoldandthereversetractionpressuretest

port(Figure40).

2.Unmarkedport

Note:Usethehydraulicttingsandcoupler

ttingsasneededtoinstallthehose.

g033131

Ifyouneedtopushortowyourmachine,youwill

likelyneedtomoveitbothforwardandinreverse.

Toensurethatthedrivesystemdoesnotbecome

damagedfrompushingortowing,itisbesttoprepare

themachineforbothforwardandreversepushingor

towing.

PreparingtheMachineforPushing

orTowinginReverse

Important:Ifyouneedtopushortowthe

machineinreverse,youmustrstbypassthe

checkvalveinthe4-wheel-drivemanifold.

ThefollowingT oropartsareneededtobypassthe

checkvalve:

•ToroPartNo.59-7410,diagnostictting

1.Reversetractionpressure

33

g033132

Figure40

2.Hydraulicuidreturnlter

testport

3.Rotatethebypassvalve90°(1/4turn)ineither

directiontoopenitandallowuidtobypass

internally(Figure41).

Note:Becausetheuidbypassesthe

transmission,youcanmovethemachineslowly

withoutdamagingthetransmission.

Notethepositionofthevalvewhenopeningand

closingit.

Figure41

forwardslowlywithoutdamagingthe

transmission.

Notethepositionofthevalvewhenopeningand

closingit.

3.Rotatethebypassvalve90°(1/4turn)back

beforestartingtheengine.

Note:Donotexceed7to11N∙m(5to8ft-lb)

torquetoclosethevalve.

HaulingtheMachine

•Usefull-widthrampsforloadingthemachineonto

atrailerortruck.

•Tiethemachinedownsecurely.

IdentifyingtheTie-Down

Points

g009703

1.Bypassvalve

4.Whenyouarenishedpushingortowingthe

machine,removethehydraulichosethatyou

installed.

5.Installtheexistingcapontothereversetraction

pressuretestport.

6.Installthediagnostic-ttingcapontothetting

thatyouinstalledonthemanifold.

7.Rotatethebypassvalve90°(1/4turn)back

beforestartingtheengine.

Note:Donotexceed7to11N∙m(5to8ft-lb)

torquetoclosethevalve.

PushingorTowingtheMachine

ForwardOnly

Ifyouneedtopushortowthemachineforwardonly,

youcanjustrotatethebypassvalve.

Important:Ifyouneedtopushortowthe

machineinreverse,refertoPreparingtheMachine

forPushingorTowinginReverse(page33).

g198911

Figure42

1.Tie-downloops

1.Openthehoodandremovethecentershroud.

2.Rotatethebypassvalve90°(1/4turn)ineither

directiontoopenitandallowuidtobypass

internally(Figure41).

Note:Becausetheuidbypassesthe

transmission,youcanmovethemachine

34

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Downloadafreecopyoftheelectricalorhydraulicschematicbyvisitingwww.Toro.comandsearching

foryourmachinefromtheManualslinkonthehomepage.

Important:Refertoyourengineowner’smanualandcuttingunitOperator'sManualforadditional

maintenanceprocedures.

MaintenanceSafety

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Disengagethecuttingunit(s)andlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovementtostop.

•Allowmachinecomponentstocoolbefore

performingmaintenance.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst10hours

MaintenanceProcedure

•Torquethewheelnuts.

•Torquethewheelnuts.

•Checktheconditionandtensionofallbelts.

•Supportthemachinewithjackstandswhenever

youworkunderthemachine.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallwornordamageddecals.

•Toensuresafe,optimalperformanceofthe

machine,useonlygenuineT ororeplacement

parts.Replacementpartsmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty .

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

Every150hours

Every200hours

•Changetheoilandoillter.

•Inspecttheseatbelt(s)forwear,cuts,andotherdamage.Replacetheseatbelt(s)if

anycomponentdoesnotoperateproperly.

•Checktheparkingbrake.

•Checktheinterlocksystem.

•Checktheengine-oillevel.

•Drainthewaterseparator.

•Checkthetirepressure.

•Checktheengine-coolantlevel.

•Cleandebrisoffoftheradiator.

•Checkthehydrauliclinesandhoses.

•Checkthelevelofthehydraulicuid.

•Checkthereel-to-bedknifecontact.

•Checktheelectrolytelevel(ifmachineisinstorage,checkevery30days).

•Lubricateallbearingsandbushings(dailywhenconditionsaredustyanddirty).

•Checktheconditionandtensionofallbelts.

•Changetheoilandoillter.

•Servicetheaircleaner(morefrequentlyinextremelydustyordirtyconditions).

•Torquethewheelnuts.

•Checktheadjustmentoftheparkingbrake.

35

MaintenanceService

Every400hours

Every800hours

Interval

MaintenanceProcedure

•Checkthefuellinesandconnections.

•Replacethefuelltercanister.

•Servicetheparkingbrakes.

•Ifyouarenotusingtherecommendedhydraulicuidorhaveeverlledthereservoir

withanalternativeuid,changethehydraulicuid.

•Ifyouarenotusingtherecommendedhydraulicuidorhaveeverlledthereservoir

withanalternativeuid,replacethehydrauliclter.

Every1,000hours

Every2,000hours

Every2years

•Ifyouareusingtherecommendedhydraulicuid,replacethehydrauliclter.

•Ifyouareusingtherecommendedhydraulicuid,changethehydraulicuid.

•Drainandcleanthefueltank.

36

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlock

operation.

Checkthebrakeoperation.

Checktheengine-oillevel.

Checkthecoolingsystem

uidlevel.

Drainthewater/fuel

separator.

Checktheairlter,dustcup,

andburpvalve.

Checkforunusualengine

1

noises.

Checktheradiatorfordebris.

Checkforunusualoperating

noises.

Checkthehydraulicsystem

uidlevel.

Checkthehydraulichoses

fordamage.

Checkforuidleaks.

Checkthefuellevel.

Checkthetirepressure.

Checktheinstrument

operation.

Checktheheight-of-cut

adjustment.

Lubricateallthegrease

2

ttings.

Touch-upanydamaged

paint.

Washthemachine.

1

Checktheglowplugandinjectornozzlesifstartingishard,thereisexcesssmoke,orroughrunningisnoted.

2

Immediatelyaftereverywashing,regardlessoftheintervallisted.

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

2

3

4

5

Information

37

Pre-Maintenance

Procedures

RemovingtheHood

1.Unlatchandraisethehood.

2.Removethehairpincottersecuringthehood

pivottothemountingbrackets(Figure43).

Figure43

1.Hairpincotter

g034350

Figure44

1.Batterycover

g008908

3.Slidethehoodtotherightside,lifttheother

side,andpullitoutofthebrackets.

Note:Reversetheproceduretoinstallthehood.

RemovingtheBattery

Cover

Loosentheknobsandremovethebatterycover

(Figure44).

Note:RefertoServicingtheBattery(page44)for

moreinformation.

38

Lubrication

GreasingtheBearingsand

Bushings

ServiceInterval:Every50hours(dailywhen

conditionsaredustyanddirty).

Parkthemachineonalevelsurface,lowerthecutting

units,engagetheparkingbrake,shutofftheengine,

andremovethekeyfromtheignitionswitch.

LubricatethegreasettingsregularlywithNo.2

lithiumgrease.Lubricatethebearingsandbushings

dailywhenoperatingconditionsareextremelydusty

anddirty.Dustyanddirtyoperatingconditionscould

causedirttogetintothebearingsandbushings,

resultinginacceleratedwear.Lubricatethegrease

ttingsimmediatelyaftereverywashing,regardless

oftheintervalspecied.

Thegreasettinglocationsandquantitiesareas

follows:

g034347

Figure46

•Rearlift-armpivotsandliftcylinders(3eachside);

refertoFigure47.

•Steeringpivot(Figure45)

Figure45

•Frontlift-armpivotsandliftcylinders(3each);

refertoFigure46.

g200803

Figure47

•Cuttingunitpivots(2each);refertoFigure48.

g008897

Figure48

•Neutraladjustmechanism(Figure49)

39

g020393

Figure49

EngineMaintenance

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Donotchangethegovernorspeedoroverspeed

theengine.

g008901

CheckingtheEngine-Oil

•Mow/transportslide(Figure50)

Figure50

•Belttensionpivot(Figure51)

Figure51

Level

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeand

aftertheengineisrststarted.

Crankcasecapacityisapproximately3.8L(4USqt)

withthelter.

g008902

g008903

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher.

•Preferredoil:SAE15W-40(above0ºF(-17ºC))

•Alternateoil:SAE10W-30or5W-30(all

temperatures)

Note:ToroPremiumEngineOilisavailablefromyour

distributorineither15W-40or10W-30viscosity.

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.IftheoillevelisatorbelowtheAddmark

onthedipstick,addoiltobringtheoilleveltothe

Fullmark.Donotoverlltheengine.Iftheoillevel

isbetweentheFullandAddmarks,nooiladdition

isrequired.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Removethedipstick(Figure52)andwipeitwith

acleanrag.

40

Figure52

1.Dipstick

3.Pushthedipstickdownintothedipsticktubeand

makesurethatitisseatedfully .Pullthedipstick

outandchecktheoillevel.

4.Iftheoillevelislow,removetheoil-llcap

(Figure53)andgraduallyaddsmallquantitiesof

oil,checkingthelevelfrequently,untilthelevel

reachestheFullmarkonthedipstick.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Releasethelatchessecuringtheair-cleaner

covertotheair-cleanerbody(Figure54).

3.Removethecoverfromtheair-cleanerbody

(Figure54).

4.Beforeremovingthelter,uselow-pressureair

(276kPa[40psi],cleananddry)tohelpremove

g008881

largeaccumulationsofdebrispackedbetween

outsideofprimarylterandthecanister.

Note:Avoidusinghigh-pressureair,which

couldforcedirtthroughthelterintotheintake

tract.Thiscleaningprocesspreventsdebris

frommigratingintotheintakewhenyouremove

theprimarylter.

5.Removeandreplacethelter(Figure54).

Donotcleantheusedelementbecauseitcould

damagetheltermedia.

Figure53

1.Oil-llcap

5.Installtheoil-llcapandclosethehood.

ServicingtheAirCleaner

ServiceInterval:Every200hours(morefrequentlyin

extremelydustyordirtyconditions).

•Checktheair-cleanerbodyfordamagewhich

couldcauseanairleak.Replaceitifitisdamaged.

Checkthewholeintakesystemforleaks,damage,

orloosehoseclamps.

•Servicetheaircleanerattherecommended

serviceintervalorearlierifengineperformance

suffersduetoextremelydusty ,dirtyconditions.

Changingtheairlterbeforeitisnecessaryonly

increasesthechanceofdirtenteringtheengine

whenyouremovethelter.

•Besurethatthecoverisseatedcorrectlyand

sealswiththeair-cleanerbody .

g008882

g002401

Figure54

1.Air-cleanercover2.Filter

6.Inspectthenewlterforshippingdamage,

checkingthesealingendofthelterandthe

body.

Important:Donotuseadamagedelement.

7.Insertthenewlterbyapplyingpressuretothe

outerrimoftheelementtoseatitinthecanister.

Important:Donotapplypressuretothe

exiblecenterofthelter.

8.Cleanthedirt-ejectionportlocatedinthe

removablecover.

9.Removetherubberoutletvalvefromthecover,

cleanthecavityandreplacetheoutletvalve.

41

10.Installthecoverorientingtherubberoutletvalve

inadownwardposition—betweenapproximately

5o’clockto7o’clockwhenviewedfromtheend.

11.Securethecoverlatches.

ChangingtheEngineOil

andFilter

FuelSystem

Maintenance

ServicingtheFuelTank

ServiceInterval:Every2years—Drainandcleanthe

fueltank.

ServiceInterval:Aftertherst50hours

Every150hours

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Removeeitherdrainplug(Figure55)andlet

theoilowintoadrainpan.Whentheoilstops

owing,installthedrainplug.

Figure55

1.Engine-oildrainplugs

3.Removetheoillter(Figure56).

Parkthemachineonalevelsurface,lowerthecutting

units,engagetheparkingbrake,shutofftheengine,

andremovethekey.

Drainandcleanthetankifthefuelsystembecomes

contaminatedorifthemachinewillbestoredforan

extendedperiodoftime.Usecleanfueltoushout

thetank.

InspectingtheFuelLines

andConnections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

Parkthemachineonalevelsurface,lowerthecutting

units,engagetheparkingbrake,shutofftheengine,

g020086

andremovethekeyfromtheignitionswitch.

Inspectthefuellinesandconnectionsfordeterioration,

damage,orlooseconnections.

Figure56

1.Engineoillter

4.Applyalightcoatofcleanoiltothenewlter

seal,andinstallthelter.

Important:Donotovertightenthelter.

5.Addoiltothecrankcase;refertoCheckingthe

Engine-OilLevel(page40).

g022147

42

DrainingtheWater

BleedingAirfromthe

Separator

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekeyfromtheignition

switch.

2.Placeacleancontainerunderthefuellter.

3.Loosenthedrainvalveonthebottomofthelter

canister(Figure57).

Figure57

Injectors

Note:Usethisprocedureonlyifthefuelsystemhas

beenpurgedofairthroughnormalprimingprocedures

andtheenginedoesnotstart;refertoBleedingthe

FuelSystem(page29).

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,and

shutofftheengine.

2.LoosenthepipeconnectiontotheNo.1nozzle

andholderassembly.

g008913

Figure58

g009880

1.Fuelinjectors

1.Waterseparator/lter

canister

2.Ventplug

4.Tightenthevalveafterdraining.

3.Drainvalve

ChangingtheFuelFilter

Canister

ServiceInterval:Every400hours

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekeyfromtheignition

switch.

2.Cleantheareawheretheltercanistermounts

(Figure57).

3.Removetheltercanisterandcleanthe

mountingsurface.

4.Lubricatethegasketontheltercanisterwith

cleanoil.

3.MovethethrottletotheFASTposition.

4.TurnthekeyinthekeyswitchtotheSTART

positionandwatchthefuelowaroundthe

connector.TurnthekeytotheOFFposition

whenthereisacontinuousow.

5.Tightenthepipeconnectorsecurely.

6.Repeattheprocedureontheremainingnozzles.

5.Installtheltercanisterbyhanduntilthegasket

contactsthemountingsurface;thenrotateitan

additional1/2turn.

43

ElectricalSystem

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

ServicingtheBattery

ServiceInterval:Every25hours—Checkthe

electrolytelevel(ifmachineisin

storage,checkevery30days).

Parkthemachineonalevelsurface,lowerthecutting

units,engagetheparkingbrake,shutofftheengine,

andremovethekeyfromtheignitionswitch.

WARNING

Incorrectbatterycableroutingcoulddamage

thetractorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

Ifcorrosionoccursattheterminals,disconnectthe

cables,negative(–)cablerst,andscrapetheclamps

andterminalsseparately.Connectthecables,positive

(+)cablerst,andcoattheterminalswithpetroleum

jelly.

CheckingtheFuses

Thefusesintheelectricalsystemarelocatedunder

thecontrolpanel.

Maintainthebatteryelectrolytelevelandkeepthetop

ofthebatteryclean.Storethemachinewherethe

temperatureiscoolerratherthanwarmertoprevent

thebatteryfromdischargingmorerapidly .

Maintainthecelllevelwithdistilledordemineralized

water.Donotllthecellsabovethebottomofthesplit

ringinsideeachcell.Installthellercapswiththe

ventspointingtotherear(towardthefueltank).

DANGER

Batteryelectrolytecontainssulfuricacid

whichisfatalifconsumedandcausessevere

burns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyes,orclothing.Weareye

protectiontoshieldyoureyesandrubber

glovestoprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.