Page 1

FormNo.3392-160RevA

Verticutter

Reelmaster

ModelNo.03877—SerialNo.316000001andUp

®

6000-DSeriesCuttingUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3392-160*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheDeclarationofIncorporation(DOI)

atthebackofthispublication.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

SafetyandInstructionalDecals.................................3

Setup............................................................................4

1InspectingtheVerticutter.......................................5

2InstallingtheTransportRollers...............................5

3AdjustingtheBladeDepth.....................................5

4AdjustingtheRearGrassShield..............................6

5AdjustingtheRollerScrapers..................................6

6AdjustingtheTransportRollers...............................7

7MountingtheLiftBracketsandChains.....................7

8InstallingtheCounterweights.................................8

9InstallingtheVerticutterReels................................9

Operation....................................................................10

TrainingPeriod......................................................10

OperatingTips......................................................10

Maintenance.................................................................11

LubricatingtheV erticutter.......................................11

AdjustingtheReelBearings......................................11

ReplacingtheBlades...............................................12

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Safety

isadvisableandrequiredbysomelocalordinancesand

insuranceregulations.

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

Improperuseormaintenanceofthisequipmentcan

resultininjuryordeath.T oreducethepotentialfor

injuryordeath,complywiththefollowingsafety

instructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitOperator’ sManualbeforeoperatingthe

verticutters.

•Read,understand,andfollowallinstructionsinthis

Operator’sManualbeforeoperatingtheverticutters.

•Neverallowchildrentooperatethetractionunitorthe

verticutters.Donotallowadultstooperatethetraction

unitortheverticutterswithoutproperinstruction.Only

trainedoperatorswhohavereadthisOperator’sManual

shouldoperatetheverticutters.

•Neveroperatetheverticutterswhentired,ill,orunderthe

inuenceofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,a

safetydevice,oradecalisillegibleordamaged,repairor

replaceitbeforeresumingoperation.Also,tightenany

loosenuts,bolts,andscrewstoensurethattheverticutters

areinsafeoperatingcondition.

•Alwayswearsubstantial,slip-resistantfootwear.Always

wearlongpants.Wearingsafetyglassesandsafetyshoes

•Tiebacklonghair.Donotwearjewelry.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbythereelbladesofthecuttingunit.Keep

allbystandersawayfromtheworkingarea.

•Iftheverticutterbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

theverticutterfordamagedparts.Repairanydamage

beforestartingandoperatingtheverticutter.

•Lowertheverticutterstotheground,settheparking

brake,shutofftheengine,andremovethekeyfrom

theignitionswitchwheneveryouleavethemachine

unattended.

•Besurethattheverticuttersareinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

•Removethekeyfromtheswitchtopreventaccidental

startingoftheenginewhenservicing,adjusting,orstoring

themachine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedT oroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6688

1.Warning—readthe

Operator’sManualbefore

performingmaintenance.

2.Cuttinghazardofhandor

foot—shutofftheengine

andwaitforallmoving

partstostop.

3

Page 4

Setup

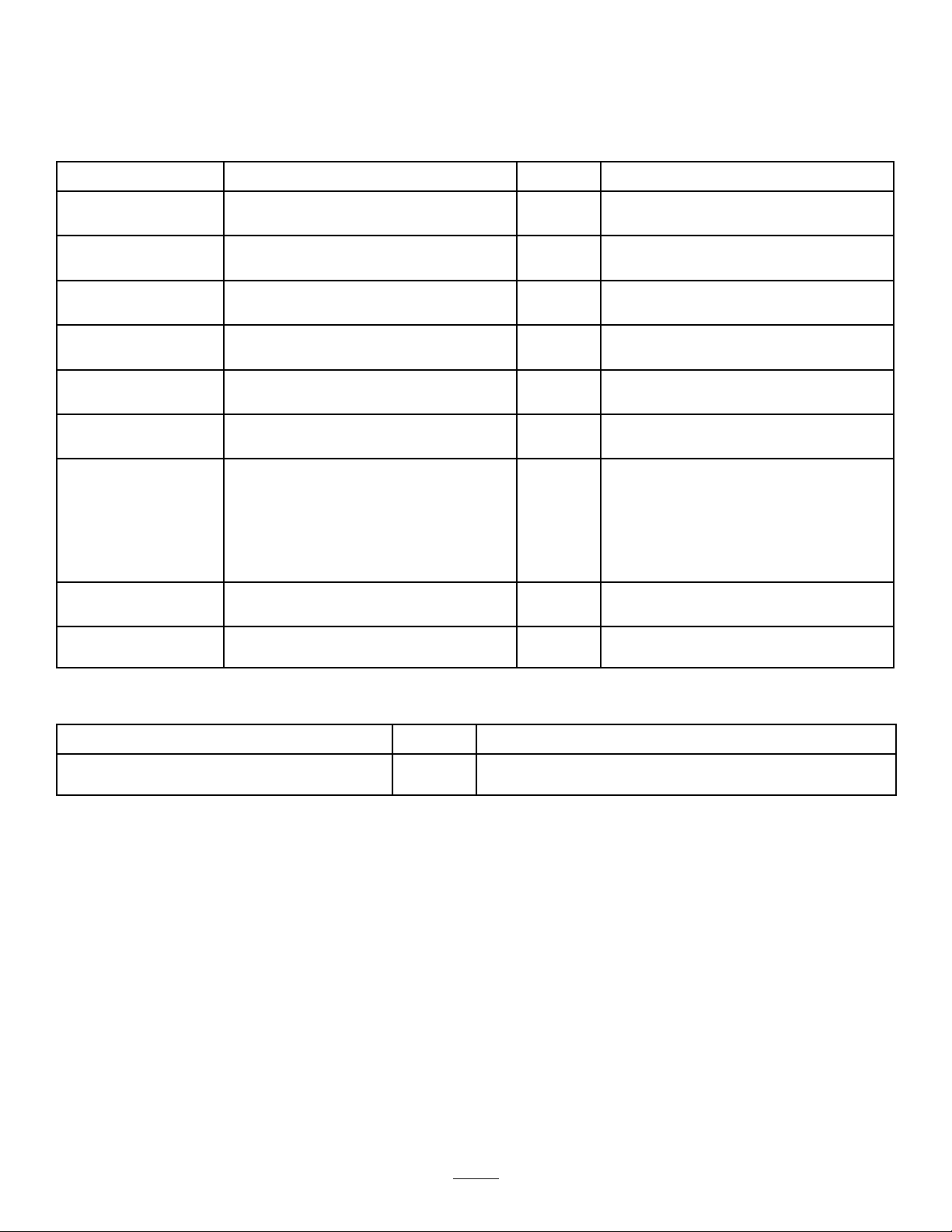

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Qty.

Nopartsrequired

Transportroller2Installthetransportrollers.

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Liftchain

Chainbracket

U-bolt1

Nut3

Washer1

Screw

Nopartsrequired

Screw

O-ring

–

–

–

–

–

1

1

1

–

1

1

Inspecttheverticutter.

Adjustthebladedepth.

Adjustthereargrassshield.

Adjusttherollerscrapers.

Adjustthetransportrollers.

Mounttheliftbracketsandchains.

Installthecounterweights.

Installtheverticutterreels.

Use

MediaandAdditionalParts

Description

Operator’sManual

PartsCatalog

Important:Withouttheseparts,totalsetupcannotbecompleted.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Qty.

1

1

Reviewthematerialandsaveitinanappropriateplace.

Use

4

Page 5

Note:Whenevertheverticutterhastobetippedtoexpose

theverticutterblades,usethekickstand(suppliedwith

tractionunit);refertoFigure2.

Figure2

1.Kickstand

2

InstallingtheTransportRollers

Partsneededforthisprocedure:

2Transportroller

Procedure

Secureatransport-rollerbrackettoeachside-platepinwith

acotterpin(Figure3).

1

InspectingtheVerticutter

NoPartsRequired

Procedure

1.Checkeachendofthereelforgrease.

Note:Greaseshouldbevisibleinthereelbearings

andtheinternalsplinesofthereelshaft.

2.Ensurethatallnutsandboltsaresecurelytightened.

3.Ensurethatthecarrier-framesuspensionoperates

freelyanddoesnotbindwhenmovedbackandforth.

Figure3

1.Transportroller

Note:Therollershouldbepositionedtotherearofthe

verticutter.

2.Cotterpin

3

AdjustingtheBladeDepth

NoPartsRequired

Procedure

Note:Themaximumrecommendedbladepenetrationdepth

is6mm(1/4inch).

1.Placetheverticutterreelonalevelsurface.

2.Place2gaugebars,whichhavethedesireddepthof

bladepenetrationbelowtheground,underthefront

andrearrollersoftheverticutterreel(oneachendof

thereel);refertoFigure4.

5

Page 6

1.Gaugebar(1/4inch)

Figure4

2.Adjustingbolt

Figure5

1.Reargrassshield2.Pivotcapscrew

2.Rotatethegrassshieldtothedesiredsetting,and

tightenthecapscrews(Figure5).

Note:Theverticutterbladesmustnottouchthe

gaugebars.

3.Turntheadjustingboltoneachheight-of-cutbracket

(Figure4)sothatthereelbladescomeincontactwith

thelevelsurfaceonbothends.

Note:Astheverticutterbladeswear,thediameterof

thereelwilldecreaseandthedepthsettingwillchange.

Checkthedepthsettingperiodicallytoensurethatthe

desiredsettingisachieved.

4

AdjustingtheRearGrass Shield

NoPartsRequired

Procedure

WARNING

Openingtherearshieldtoomuchcouldcause

personalinjuryduetothrowndebris.

Donotopentherearshieldsothatitishigherthan

leveltotheground.

5

AdjustingtheRollerScrapers

NoPartsRequired

Procedure

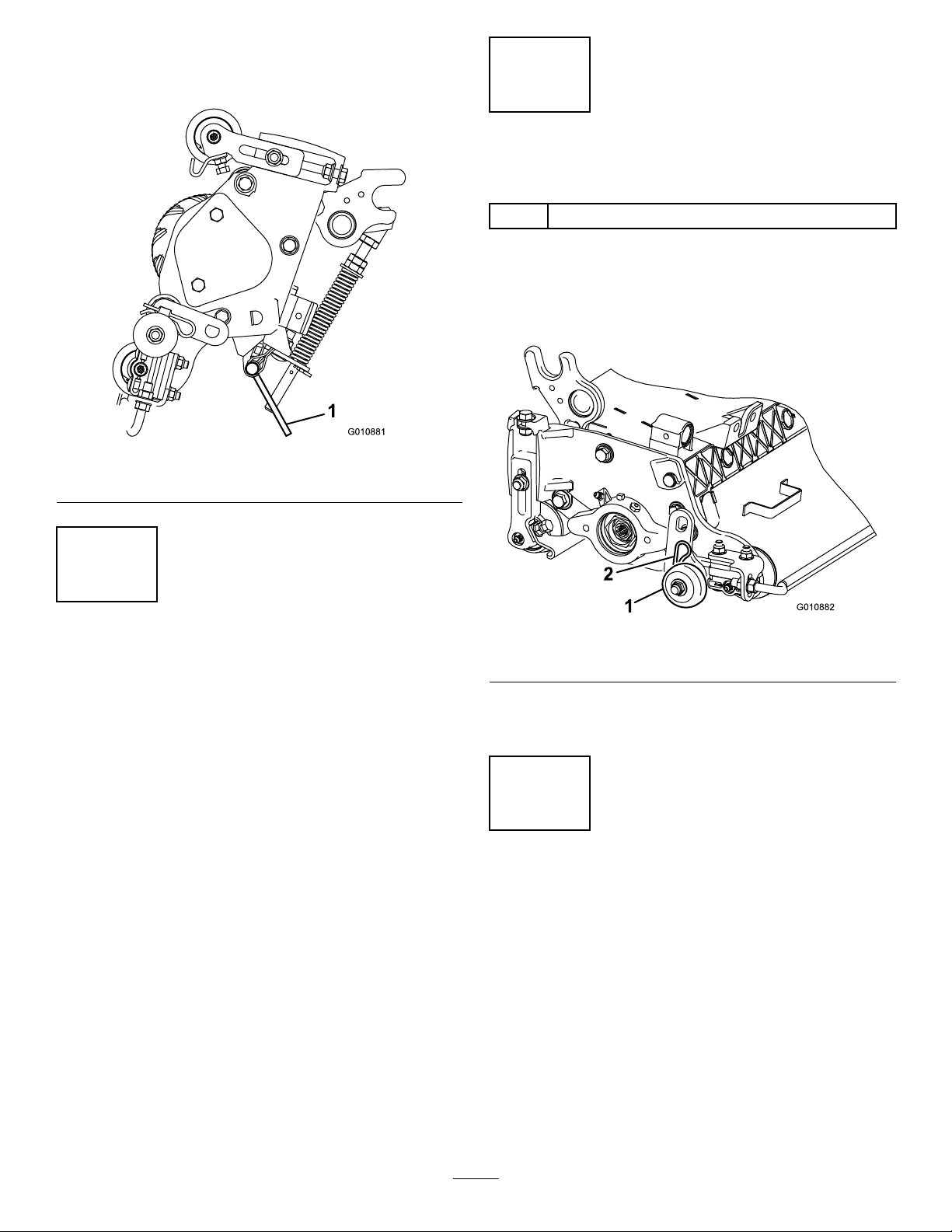

1.Loosentheangenutsthatsecuretherollerscrapers

(Figure6).

Note:Whenoperatinginturfconditionswheremuchdebris

orunusuallyheavythatchisencountered,opentherear

dischargeshieldtohelpallowthedebristodischargefrom

thereel.

1.Loosenthecapscrewsonthepivotofthegrassshield

(Figure5).

Figure6

1.Frontrollerscraper3.Transportroller

2.Rearrollerscraper

6

4.Cotterpin

Page 7

2.Movethescraperrodsinorouttoattain0.0to0.75

mm(0.0to0.03inch)clearancebetweenthescraper

andtheroller.

3.Ensurethatthescraperrodisparalleltotherollerand

tothelevelsurface.

4.Tightentheangenutstolocktheadjustment.

6

AdjustingtheTransport Rollers

NoPartsRequired

7

MountingtheLiftBracketsand Chains

Partsneededforthisprocedure:

1

Liftchain

1

Chainbracket

1U-bolt

3Nut

1Washer

1

Screw

Procedure

Beforeyoulowertheverticutterstotheshopoororremove

themfromthetractionunit,lowerthetransportrollers

(Figure6)toprotectthebladesfromhardsurfacecontact.

1.Removethecotterpinthatsecuresthetransportroller

brackettotheside-platepin.

2.Positionthetransportrollerasfollows:

•Lowertherollerbracketbeforetheverticutteris

loweredtotheshopoor.

•Raisetherollerbracketaftertheverticutterisraised

totheoperatingposition.

3.Securethetransportrollerbrackettotheside-platepin

withthecotterpin.

4.Repeattheprocedureontheoppositeendofthe

verticutter.

Procedure

MountachainbrackettoeachliftarmwithaU-boltand2

nuts.Positionthebracketsasfollows:

1.Onliftarms1,4,and5,positionthechainbracketsand

U-bolts38cm(15inches)behindthecenterlineofthe

pivotknuckle(Figure7).

Figure7

1.38cm(15inches)3.Liftarms1and5

2.Liftarm4

Note:Onliftarms1and5,thebracketsshouldbe

rotatedtotheright10°fromvertical(Figure7).

Note:Onliftarm4,thebracketshouldberotatedto

theleft10°fromvertical(Figure7).

7

Page 8

2.Onliftarms2and3,positionthebracketsandU-bolts

38cm(15inches)behindthecenterlineofthepivot

knuckle(Figure8).

Note:Rotatethebrackets10°totheoutboardside

ofthemachine.

4.TightenalltheU-boltnutsto52to65N∙m(38to48

ft-lb).

5.Mountaliftchaintoeachchainbracketwithascrew ,a

washer,andanut,positioningthemasshowninFigure

10.

Figure10

1.Liftchain2.Chainbracket

Figure8

1.38cm(15inches)2.Liftarm3

3.Onliftarms6and7,positionthebracketsandU-bolts

36.8cm(14-1/2inches)behindthecenterlineofthe

pivotknuckle(

8

InstallingtheCounterweights

NoPartsRequired

Procedure

Important:Whenloweringtheverticutterreels,take

caretopreventdamagetothereelbladesduetocontact

withaconcreteoororapavedsurface.Lowerthe

transportrollersbeforeloweringtheverticutterstoa

concreteoororapavedsurface.

Youcaninstalltheverticuttersatanyofthe7locationson

thetractionunit.Figure11showstheorientationofthe

hydraulicdrivemotorforeachofthelocations.Foranyof

thelocationsrequiringthemotortobemountedontheright

endoftheverticutters,installacounterweightontheleftend

oftheverticutters.Forthelocationsrequiringthemotorto

bemountedontheleftend,installacounterweightonthe

rightendoftheverticutters.

Figure9

1.36.8cm(14-1/2inches)2.Liftarm7

8

Page 9

Figure11

1.Cuttingunit16.Cuttingunit6

2.Cuttingunit27.Cuttingunit7

3.Cuttingunit3

4.Cuttingunit4

5.Cuttingunit5

Note:Thecounterweightsareshippedinstalledtotheleft

endoftheverticutters.The2capscrews,shippedintheloose

partsbag,aretobeusedforsecuringthehydraulicmotor.

8.Reelmotor

9.Weight

9

3.Securepivotknuckletocarrierframewithathrust

washer,aatwasher,andaange-headcapscrew

(Figure12).

4.Insertathrustwasherontotheverticalshaftofthe

pivotknuckle(Figure12).

5.Ifremoved,inserttheverticalshaftofthepivotknuckle

intothelift-armpivothub(Figure12).

Note:Guidethepivotknuckleinplacebetweenthe

2rubbercenteringbumpersintheundersideofthe

lift-armsteeringplate.

6.Insertthelynchpinintothecrossholeonthe

pivot-knuckleshaft(Figure12).

7.Securethelift-armchaintothecuttingunitchain

bracket(Figure13)withthesnapperpinasfollows:

InstallingtheVerticutterReels

Partsneededforthisprocedure:

1

Screw

1

O-ring

Procedure

1.Insertathrustwasherontohorizontalshaftofpivot

knuckleasshowninFigure12.

Figure13

•Oncuttingunits1,4,5,6,and7,useonly6ofthe

chainlinks.

•Oncuttingunits2and3,useall7ofthechainlinks.

8.Coatthesplinesofthereelmotorwithcleangrease.

9.OilthereelmotorO-ringandinstallitontothemotor

ange.

10.Installthemotorbyrotatingitclockwisesothatthe

motorangesclearthecapscrews(Figure14).

Figure12

1.Carrierframe

2.Pivotknuckle

3.Lift-armsteeringplate

2.Insertthehorizontalshaftofthepivotknuckleintothe

mountingtubeofthecarrierframe(Figure12).

4.Lynchpin

5.Steeringlockingpin

9

Page 10

Operation

TrainingPeriod

Beforeoperatingtheverticutterreels,evaluatethe

performanceofthereelatthedesiredsetting.Operatethem

inaclear,unusedareatodetermineiftheywillachievethe

desiredresults.Adjustthemasdesired.

OperatingTips

•Operatethetractionunitatfullthrottle,fullreelspeed

(setting11)andbetween5to8km/h(3to5mph).

•Themaximumrecommendedbladepenetrationdepth

is6mm(1/4inch).

Figure14

1.Reeldrivemotor

Note:Rotatethemotorcounterclockwiseuntilthe

angesencirclethecapscrews;then,tightenthecap

screws.

Important:Ensurethatthereelmotorhosesare

nottwisted,kinkedorintheriskofbeingpinched.

Note:Ifaxedcuttingunitpositionisrequired,

insertthesteeringlockingpinintothepivotknuckle

mountinghole.

11.Hookthespringwirearoundthebottomofthesteering

lockingpin(Figure12).

2.Capscrew

•Powerrequirementstooperatetheverticutterreelswill

varywithturfandsoilconditions.Travelspeedmayneed

tobereducedinsomeconditions.

•Whenoperatinginturfconditionswithmuchdebrisor

unusuallyheavythatch,openthereardischargeshieldto

helpallowthedebristodischargefromthereel.

WARNING

Openingtherearshieldtoomuchcouldcause

personalinjuryduetothrowndebris.

Donotopentherearshieldsothatitishigherthan

leveltotheground.

10

Page 11

Maintenance

LubricatingtheVerticutter

Eachcuttingunithas7greasettingsthatyoumustlubricate

weeklywithNo.2lithiumgrease.Thelubricationpointsare

thefrontroller(2),therearroller(2),thereelbearings(2),and

thebed-knifeadjuster.

Important:Lubricatingthecuttingunitsimmediately

afterwashinghelpspurgewateroutofthebearingsand

increasesbearinglife.

1.Wipeeachgreasettingwithacleanrag.

2.Applygreaseuntilcleangreasecomesoutoftheroller

sealsandthebearingreliefvalve(Figure15).

AdjustingtheReelBearings

Toensurelonglifeofthereelbearings,periodicallycheckfor

anyreelendplay.Checkandadjustthebearingsasfollows:

1.Holdontothereelshaftandtrytomovethereel

assemblysidetoside(Figure16).

Figure16

1.Reelshaft

Figure15

1.Reliefvalve

3.Wipeanyexcessgreaseaway .

2.Ifthereisanyendplay,proceededasfollows:

A.Loosentheexternalsetscrewthatsecuresthe

bearingadjustingnuttothebearinghousing

locatedontheleftsideofthecuttingunit(Figure

17).

B.Usea1-3/8inchsocketwrenchtoslowlytighten

thebearingadjustmentnutuntilthereisnoend

playinthereel.Ifadjustingthenutdoesnot

eliminatereelendplay,replacethereelbearings.

Important:Thereelbearingsdonotrequire

preload.Overtighteningthebearingadjuster

nutwilldamagethereelbearings.

Figure17

1.Setscrew

3.Tightenthesetscrewthatsecuresthebearingadjusting

nuttothebearinghousing.Torquethesetscrewto136

to169N∙cm(12to15in-lb).

11

2.Bearingadjustingnut

Page 12

ReplacingtheBlades

5.Continuetoinstallspacersandbladesinthismanner

untilthefullcomplementofbladeshavebeeninstalled.

RemovingtheBladesfromtheShaft

1.Securetheendoftheverticuttershaftthathasonly1

washerand1nutinavise.

2.Onotherendoftheshaft,rotatethenut

counterclockwiseandremovethenut.

WARNING

Thebladesareextremelysharpandmayhave

burrsthatwillcutyourhands.

Usecautionwhenremovingthebladesfrom

theshaft.

3.Removethesmallspacer,thewasher,theblades,and

thelargespacers.

Important:Donotinverttheverticutterreelblades

whendisassemblingorreversetheorderwhen

assemblingthem.Notetheverticutterbladesindex

hole.Theindexholeisprovidedforassemblyinorderto

obtaintheproperhelixfortheverticutterreel.

InstallingtheBlades

Note:Whenproperlyassembled,thebladesare

staggeredinsuchamannerastoappearlikeahelix.

6.Installthesmallspacertotheshaft.

7.ApplyblueLoctite242tothenut.

8.Installthenutontotheshaft,(machinedsideofthenut

towardthespacer)andtightenitto108to136N∙m

(80to100ft-lb).

1.Cleanandlubricatethesquareshaftwithalightcoating

ofgrease.

2.Installablade.

3.Installaspacer.

Important:Donotinvertthebladeswhen

installingthemontheshaft.Ifthebladesare

inverted,thebladesthatareinuse(rounded)will

bemixedwiththesharpendsofthebladesthat

werenotinuse.Thiswillcauseunsatisfactory

performanceintheverticutterreelunit.Pay

closeattentionwhenremovingandinstallingthe

verticutterblades.

4.Installthenextbladeclockwisesothattheindex

referencehole(Figure18)isnotalignedwiththerst

bladeholeby1atoftheshaft.

1.Indexreferencehole

Figure18

12

Page 13

Notes:

13

Page 14

DeclarationofIncorporation

TheT oroCompany,811 1LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

03877316000001andUpVerticutter

SerialNo.

ProductDescriptionInvoiceDescription

7"VERTICUTTER-RM6000

GeneralDescription

Verticutter

Directive

2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

MarcelDutrieux

ManagerEuropeanProductIntegrity

ToroEuropeNV

Nijverheidsstraat5

2260Oevel

DavidKlisBelgium

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

January12,2016

Tel.+3216386659

14

Page 15

InternationalDistributorList

Distributor:

AgrolancKft

AsianAmericanIndustrial(AAI)

B-RayCorporation

BrisaGoodsLLC

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

FatDragon

FemcoS.A.Guatemala

FIVEMANSNew-T echCo.,LtdChina

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260T oroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India00914424494387ValtechMorocco212537663636

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

Country:

Hungary3627539640

HongKong85224977804

Korea82325512076

Mexico12104952417

PuertoRico7877888383

NorthernIreland442890813121

China

Estonia3723846060

Japan81726325861Riversa

Turkey902163365993

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

5062391138

94112746100

442890813121ParklandProductsLtd.NewZealand6433493760

8861080841322

5024423277

86-10-63816136

30109350054

4635100000

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

Lely(U.K.)Limited

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

Country:

Japan81332522285

Argentina541 148219999

Russia749541 16120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

UnitedKingdom441480226800

France33130817700

India911292299901

PhoneNumber:

5712364079

420255704220

420255704220

34952837500

35722434131

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0269RevK

Page 16

TheT oroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser .

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevD

Loading...

Loading...