Page 1

FormNo.3375-301RevC

Reelmaster

®

6500-Dand6700-D

TractionUnit

ModelNo.03806—SerialNo.313000001andUp

ModelNo.03807—SerialNo.313000001andUp

ModelNo.03808—SerialNo.313000001andUp

ModelNo.03812—SerialNo.313000001andUp

ModelNo.03813—SerialNo.313000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Figure1

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Introduction

Thismachineisaride-on,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedfor

cuttinggrassonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.Itis

notdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

1.Locationofthemodelandserialnumbers

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................5

SoundPowerLevel...............................................6

SoundPowerLevel...............................................6

SoundPressureLevel...........................................6

VibrationLevel....................................................6

SafetyandInstructionalDecals.............................7

Setup.........................................................................14

1CheckingFluidLevels......................................14

2InstallingCuttingUnitsModels03860,03861

and03862.......................................................14

3InstallingCuttingUnitsModels03863and

03864.............................................................16

4MakingAlternateCuttingUnit

Adjustments...................................................21

5AddingRearBallast..........................................21

6InstallingCEDecals........................................21

7ReadingtheManualsandStoringAdditional

Parts...............................................................21

ProductOverview......................................................22

Controls.............................................................22

Specications.....................................................25

Attachments/Accessories...................................25

Operation...................................................................26

CheckingtheEngineOil.....................................26

CheckingtheCoolingSystem..............................26

FillingtheFuelTank...........................................27

CheckingtheHydraulicFluid..............................29

CheckingtheTirePressure.................................30

CheckingtheReeltoBedknifeContact................30

StartingandStopping.........................................30

BleedingtheFuelSystem....................................30

PushingorTowingtheMachine..........................31

CheckingtheInterlockSwitches.........................31

FaultMemoryandRetrieval................................33

HydraulicSolenoidValveFunctions....................33

OperatingTips...................................................34

Maintenance...............................................................35

RecommendedMaintenanceSchedule(s)................35

ServiceIntervalChart.........................................36

DailyMaintenanceChecklist...............................37

Lubrication.............................................................38

GreasingtheBearingsandBushings....................38

EngineMaintenance...............................................40

ServicingtheAirCleaner....................................40

ServicingtheEngineOilandFilter......................41

AdjustingThrottle..............................................41

FuelSystemMaintenance.......................................42

FuelTank...........................................................42

FuelLinesandConnections................................42

FuelFilter/WaterSeparator................................42

BleedingAirFromInjectors...............................43

ElectricalSystemMaintenance................................43

BatteryCare.......................................................43

Fuses..................................................................44

OptionalLighting...............................................44

DriveSystemMaintenance.....................................46

CheckingtheTorqueoftheWheelNutsor

Bolts..............................................................46

CheckingthePlanetaryGearDrive

Oil..................................................................46

ChangingthePlanetaryGearDrive

Oil..................................................................46

CheckingtheRearAxleLubricant.......................47

ChangingtheRearAxleLubricant.......................47

RearWheelT oe-In.............................................48

AdjustingtheTractionDriveforNeutral.............48

CoolingSystemMaintenance..................................49

RemovingDebris...............................................49

MaintainingtheCoolingSystem..........................49

BrakeMaintenance.................................................50

AdjustingtheServiceBrakes...............................50

BeltMaintenance....................................................50

CheckingtheAlternatorBelt...............................50

HydraulicSystemMaintenance...............................51

ChangingtheHydraulicFluid.............................51

ReplacingtheHydraulicFilter.............................51

CheckingtheHydraulicLinesandHoses.............51

HydraulicSystemTestPorts...............................52

CuttingUnitMaintenance.......................................53

CuttingUnitKickstandModels03863and

03864.............................................................53

Backlapping........................................................53

AdjustingtheCuttingUnitLoweringRate

......................................................................54

LiftedHeightofOuterFrontCuttingUnits

(EnablePosition)............................................55

AdjustingtheTraveloftheFrontThree

CuttingUnits..................................................56

Storage.......................................................................57

TractionUnit......................................................57

Engine...............................................................57

Schematics.................................................................58

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004specicationsineffectatthetimeof

productionwhenballastisadded;refertoAdding

RearBallastinSetUpsection.

Note:Theadditionofattachmentsmadeby

othermanufacturersthatdonotmeetAmerican

NationalStandardsInstitutecerticationwillcause

noncomplianceofthismachine.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlingdieselfuel.Itis

ammableandvaporsareexplosive.

Useonlyanapprovedcontainer.

•Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.Do

notsmoke.

•Neverrefuelordrainthemachineindoors.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalert

CAUTION,WARNING,orDANGER-“personalsafety

instruction.”Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

symbol,whichmeans

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

•Checkthatoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartengine

fromtheoperator'sposition.Alwaysuseseatbelts

whenROPSisprovided.

•Slowdownanduseextracareonhillsides.Besure

totravelintherecommendeddirectiononhillsides.

Turfconditionscanaffectthemachine'sstability.

Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neveroperatewithguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,

andfunctioningproperty.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,raisethecuttingunits,

disengagedrives,engageparkingbrake(ifprovided),

shutoffenginebeforeleavingtheoperator'sposition

foranyreasonincludingemptyingthegrassbaskets.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandearprotection.Longhair,looseclothing

orjewelrymaygettangledinmovingparts.

•Stopequipmentandinspectthemachineafter

strikingobjectsorifanabnormalvibrationoccurs.

Makenecessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

4

Page 5

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Stopreelsifnot

mowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedintheANSIstandards.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Disengagedrives,raisethecuttingunits,setparking

brake,stopengineandremovekey.Waitforall

movementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunits,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingthereels.W earglovesand

usecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.W ear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamageddecals.

Operation

•Sitontheseatwhenstartingandoperatingthe

machine.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,or

sneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Donottouchtheengine,mufer,orexhaustpipe

whiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenough

tocauseburns.

•Ifacuttingunitstrikesasolidobjectorvibrates

abnormally,stopimmediately ,turntheengineoff,

waitforallmotiontostop,andinspectthemachine

fordamage.Adamagedreelorbedknifemustbe

repairedorreplacedbeforeoperationiscontinued.

•Traverseslopescarefully.Donotstartorstop

suddenlywhentravelinguphillordownhill.

•Theoperatormustbeskilledandtrainedinhowto

driveonhillsides.Failuretousecautiononslopesor

hillsmaycauselossofcontrolandcausethevehicle

totiporroll,possiblyresultinginpersonalinjury

5

Page 6

ordeath.AlwaysusetheseatbeltandRollOver

ProtectionSystem(ROPS)together.

•Iftheenginestallsorlosesheadwayandcannotmake

ittothetopofaslope,donotturnthemachine

around.Alwaysbackslowly,straightdowntheslope.

SoundPowerLevel

Reelmaster6500

Thisunithasaguaranteedsoundpowerlevelof101

dBA,whichincludesanUncertaintyValue(K)of1dBA.

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

•Donotparkonslopesunlessthewheelsarechocked

orblocked.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunderhigh

pressure.Usepaperorcardboard,notyourhands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetratethe

skinandcauseseriousinjury.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitsandattachmentstotheground.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachmentsandanymovingparts.Keep

everyoneaway.

•Theenginemustbeshutoffbeforecheckingtheoil

oraddingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11094.

SoundPowerLevel

Reelmaster6700

Thisunithasaguaranteedsoundpowerlevelof103

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’ s

earof90dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=0.69m/s

Measuredvibrationlevelforlefthand=1.04m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

WholeBody

Measuredvibrationlevel=0.55m/s

2

2

2

2

•Tomakesureofoptimumperformanceand

continuedsafetycerticationofthemachine,use

onlygenuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

6

2

Page 7

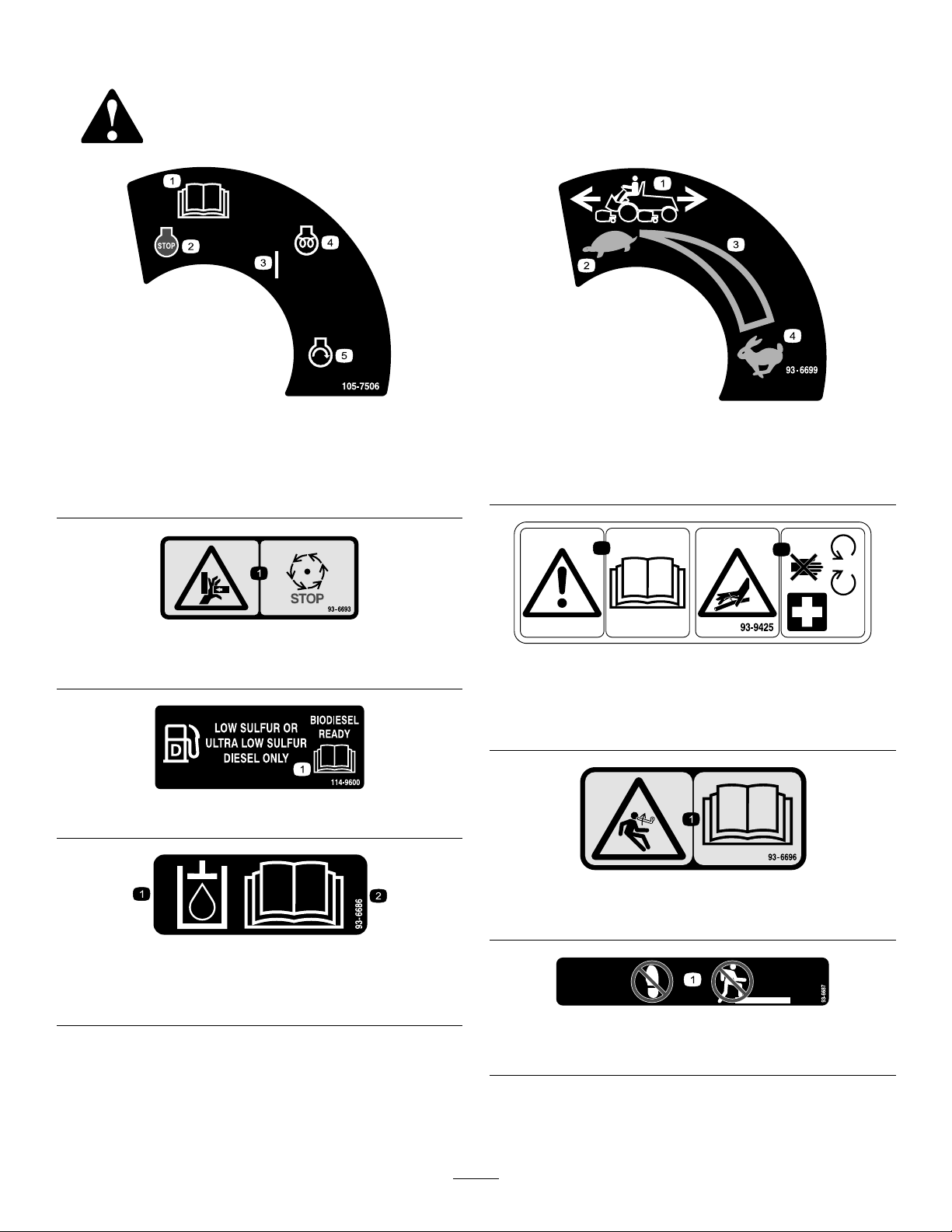

SafetyandInstructionalDecals

2

1

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

105-7506

1.ReadtheOperator's

Manual.

2.Engine—stop5.Engine—start

3.On

4.Engine—preheat

93-6693

1.Crushinghazardofhand—waitformovingpartstostop.

114–9600

93-6699

1.Machinespeed

2.Slow

3.Continuousvariable

setting

4.Fast

93-9425

1.ReadtheOperator'sManual.

2.Hydraulichosesareunderpressure—stayawayfrom

movingparts.

1.Hydraulicoil

2.ReadtheOperator'sManual.

93-6696

1.Storedenergyhazard—readtheOperator'sManual.

93-6686

93-6687

1.Donotstephere.

7

Page 8

93–6689

93-1263

1.Danger—donotsitontheplasticshroud.

93–6681

1.Cutting/dismembermenthazard—stayawayfrommoving

parts.

115-2047

1.Warning—donottouchthehotsurface.

93-1263

1.ReadtheOperator'sManual.

2.Toengagetheparkingbrake,connectthebrakepedals

withthelockingpin,pushdownonbothpedals,andpullthe

brakelatchout.

3.Toreleasetheparkingbrake,pressbothpedalsuntilthe

parkingbrakelatchretracts.

4.Danger—reelsenabled.

104-9298

1.ReadtheOperator'sManual.

1.ReadtheOperator'sManual.

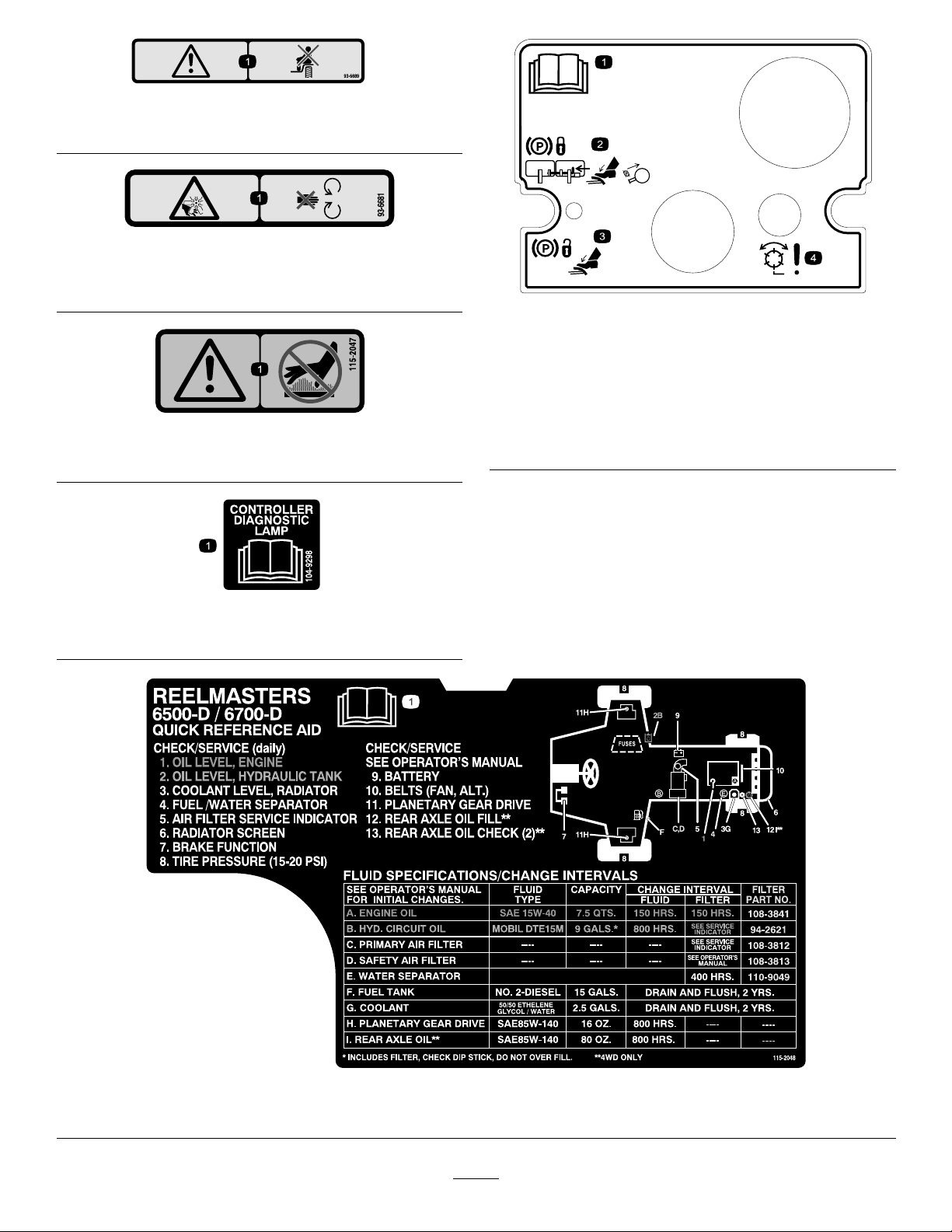

115-2048

8

Page 9

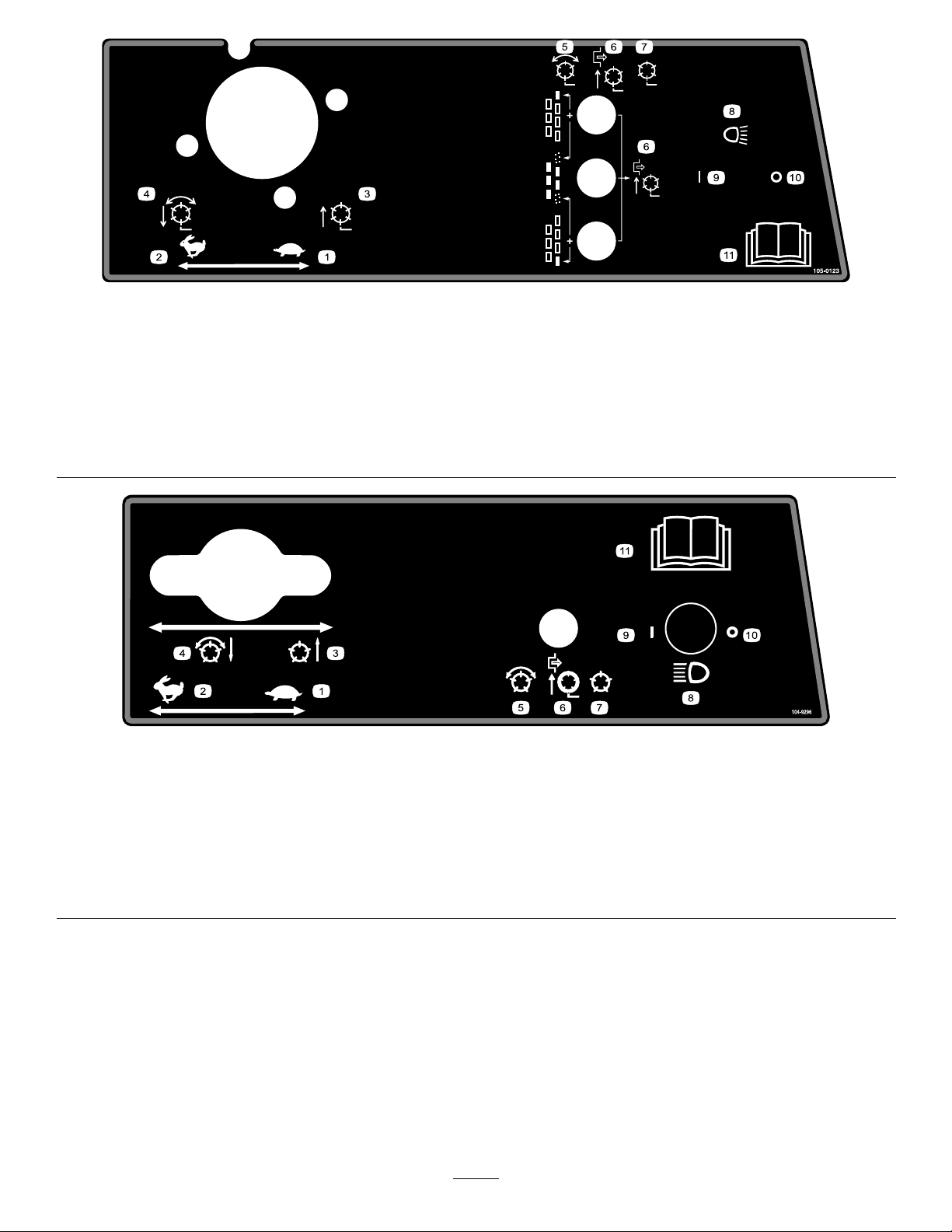

105-0123

Model03808and03813

1.Throttle—slow

2.Throttle—fast8.Headlights(optional)

3.Reelsraisedandoff9.Headlights—On

4.Reelsloweredandonwhenenabled—forwardandbacklap10.Headlights—Off

5.Reels—enabled

6.Reelsdisabled—liftonly

7.Reelsdisabled—liftandlower

11.ReadtheOperatorsManual.

104-9296

Models03806,03807and03812

1.Throttle—slow4.Reelsloweredandonwhen

2.Throttle—fast

3.Reelsraisedandoff6.Reelsdisabled—liftonly9.Headlights—On

enabled—forwardand

backlap

5.Reelsenabled

7.Reelsdisabled—liftand

lower

8.Headlights(optional)11.ReadtheOperator's

10.Headlights—Off

Manualforfurther

instructions.

9

Page 10

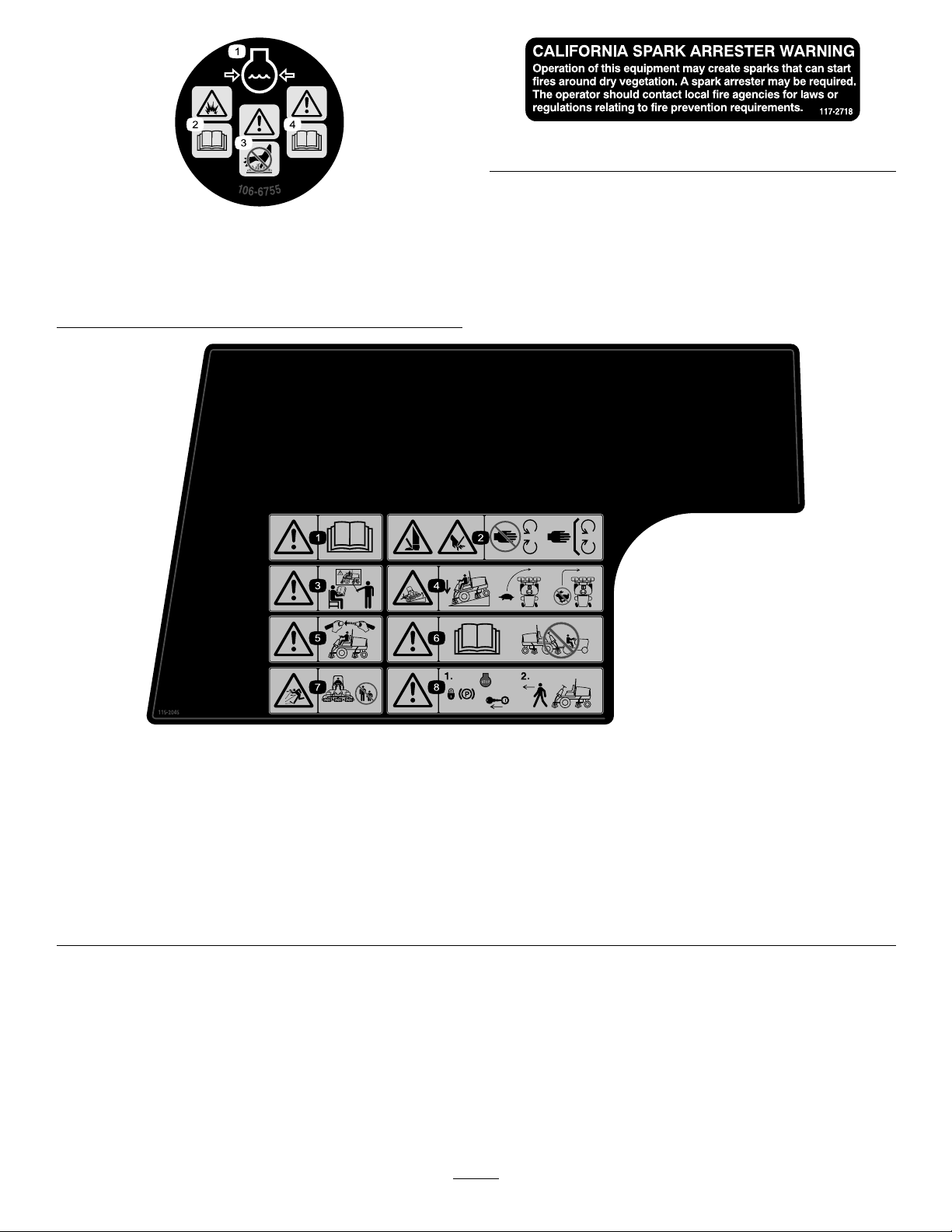

117–2718

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

115-2045

1.Warning—readtheOperator'sManual.

2.Cuttinghazardofhandorfoot—stayawayfrommovingparts;keepallguardsinplace.

3.Warning—donotoperatethismachineunlessyouaretrained.

4.Tippinghazard—lowerthecuttingunitwhendrivingdownslopes;slowmachinebeforeturning,donotturnathighspeeds.

5.Warning—weartheseatbeltwhenseatedintheoperator'sposition.

6.Warning—readtheOperator'sManual;donottowthemachine.

7.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

8.Warning—locktheparkingbrake,stoptheengineandremovetheignitionkeybeforeleavingthemachine.

10

Page 11

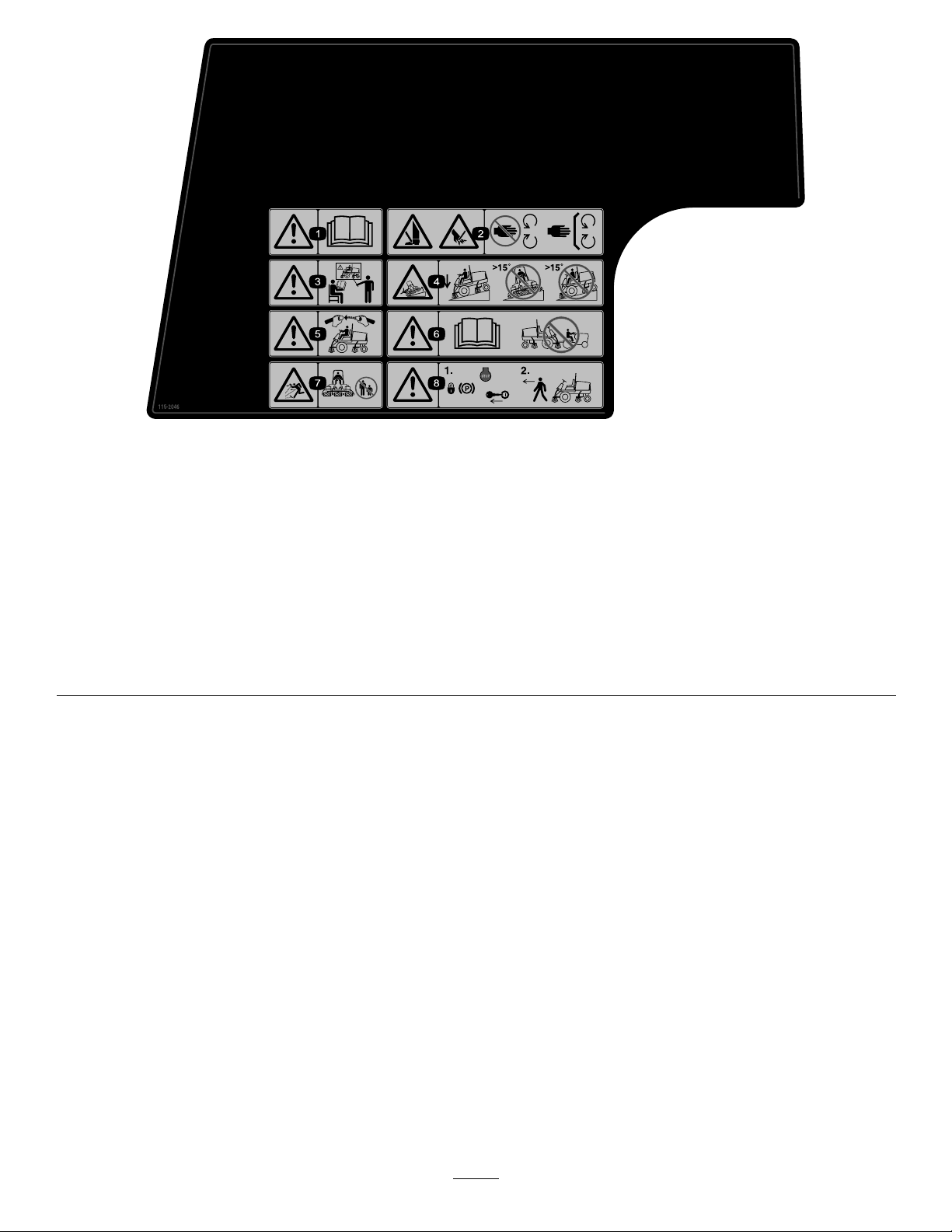

115-2046

(Afxoverpartno.115–2045forCE*)

*ThissafetydecalincludesaslopewarningrequiredonthemachineforcompliancetotheEuropeanLawnMowerSafetyStandardEN836:1997.Theconservativemaximum

slopeanglesindicatedforoperationofthismachineareprescribedbyandrequiredbythisstandard.

1.Warning—readtheOperator'sManual.

2.Cuttinghazardofhandorfoot—stayawayfrommovingparts;keepallguardsinplace.

3.Warning—donotoperatethismachineunlessyouaretrained.

4.Tippinghazard—lowerthecuttingunitwhendrivingdownslopes;donotmowonslopesgreaterthan15degrees.

5.Warning—weartheseatbeltwhenseatedintheoperator'sposition.

6.Warning—readtheOperator'sManual;donottowthemachine.

7.Thrownobjecthazard—keepbystandersasafedistancefromthemachine.

8.Warning—locktheparkingbrake,stoptheengineandremovetheignitionkeybeforeleavingthemachine.

11

Page 12

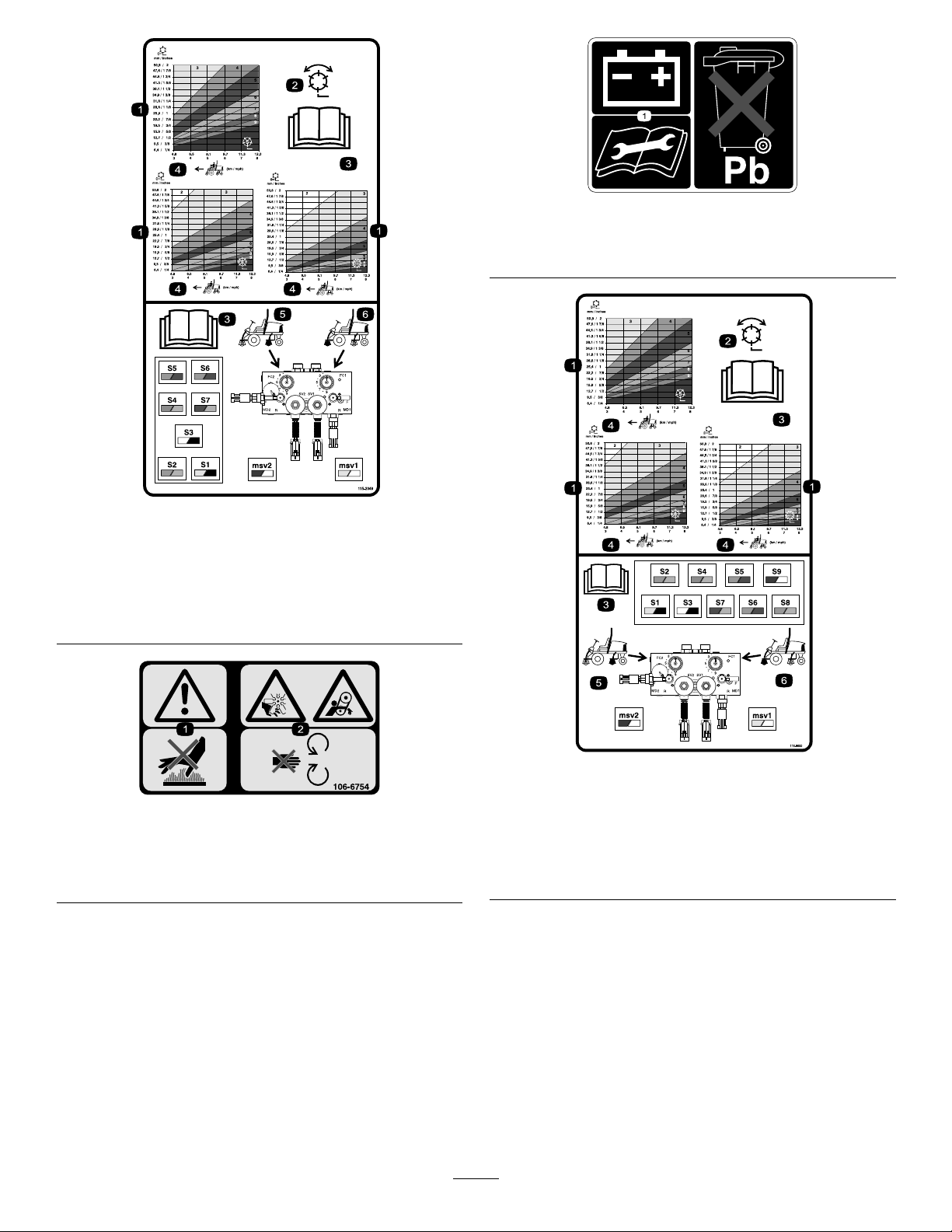

115-2049

Models03806,03807and03812

93-6668

1.ReadtheOperator'sManualforinformationonchargingthe

battery;containslead;donotdiscard.

1.Reel—heightofcut

2.Reel—mowandbacklap5.Rearreelscircuitcontrols

3.ReadtheOperator's

Manual.

4.Machinespeed

6.Frontreelscircuitcontrols

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

115-8000

Model03808and03813

1.Reel—heightofcut

2.Reel—mowandbacklap5.Rearreelscircuitcontrols

3.ReadtheOperator's

Manual.

4.Machinespeed

6.Frontreelscircuitcontrols

12

Page 13

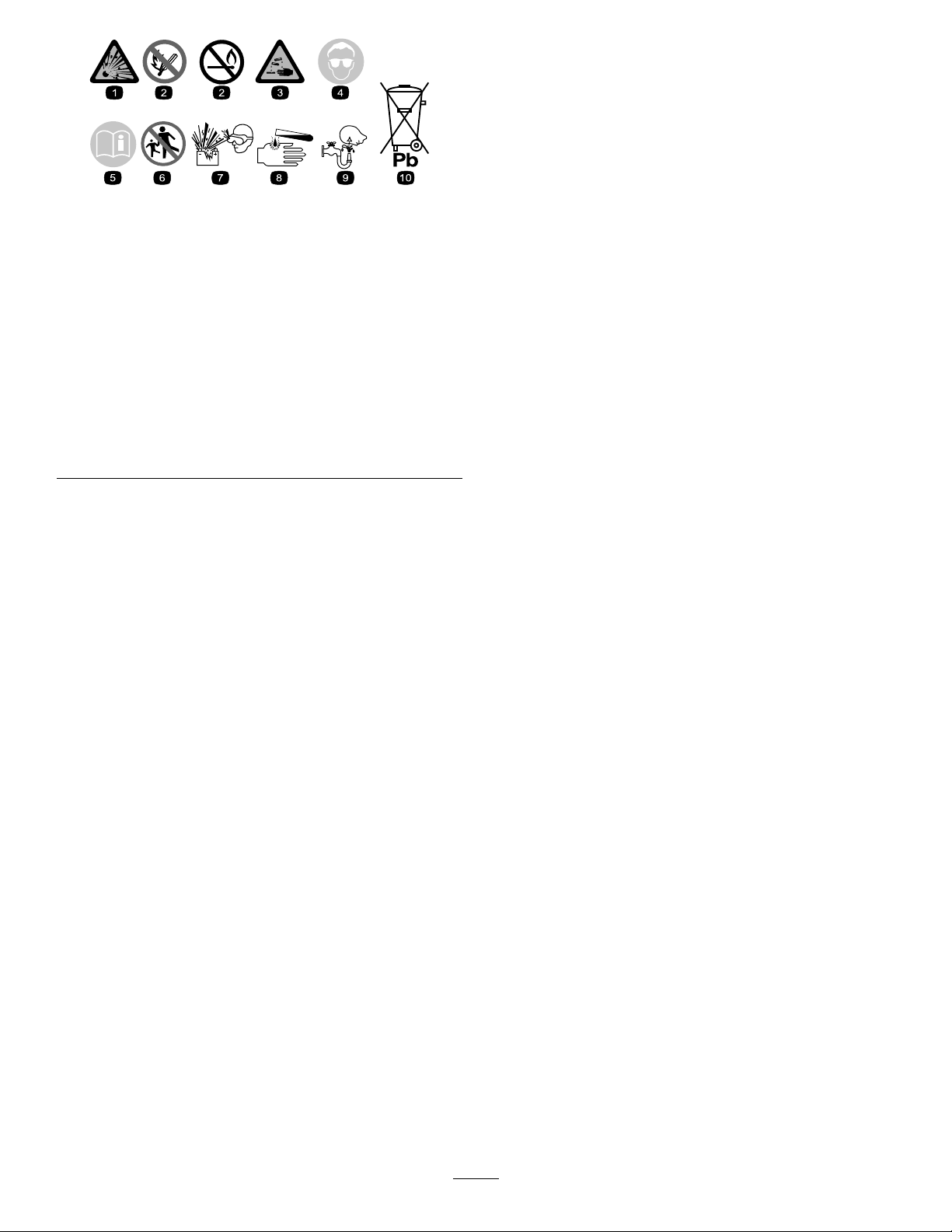

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

13

Page 14

Setup

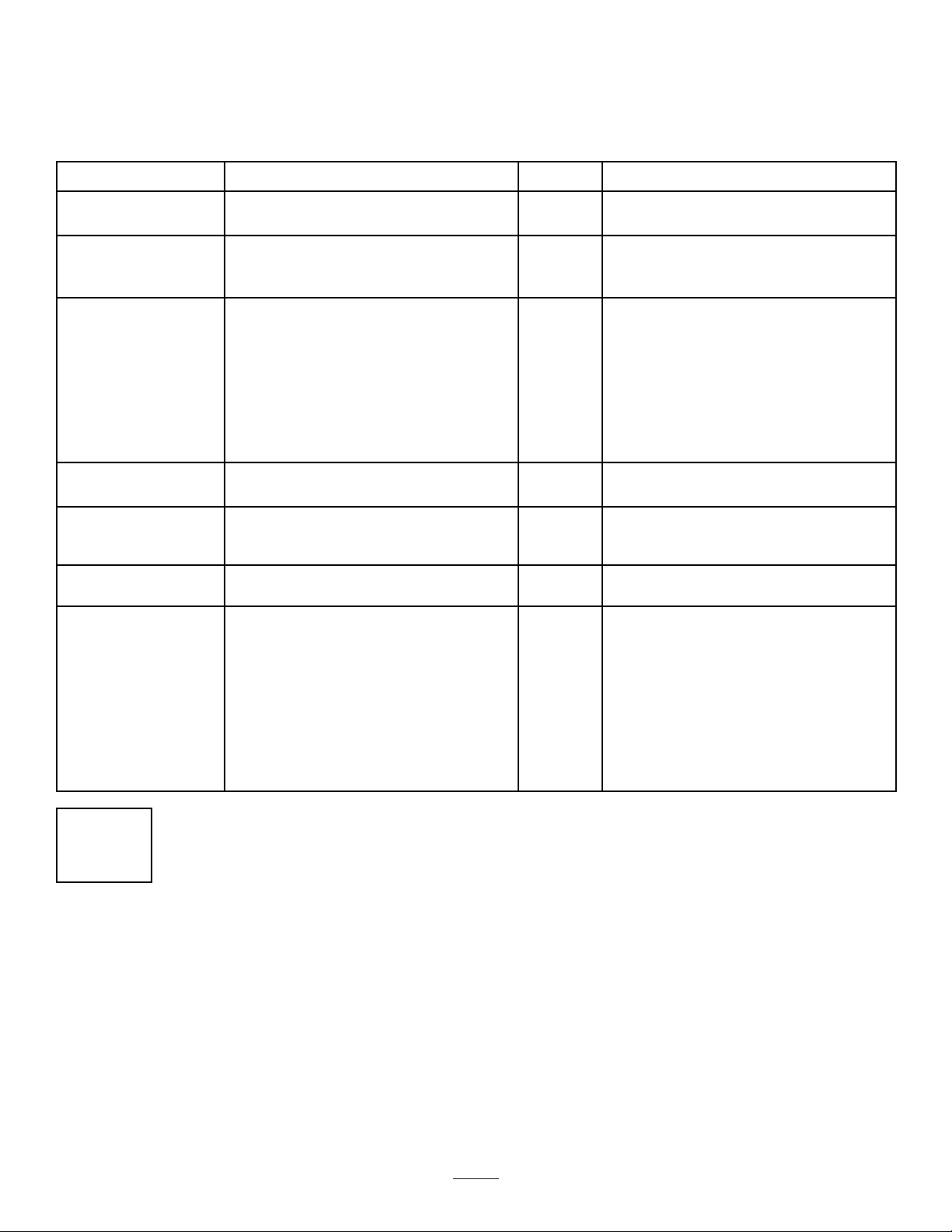

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

LargeO-ring14/10

Counterweight7/5

Steeringlockingpin7/5

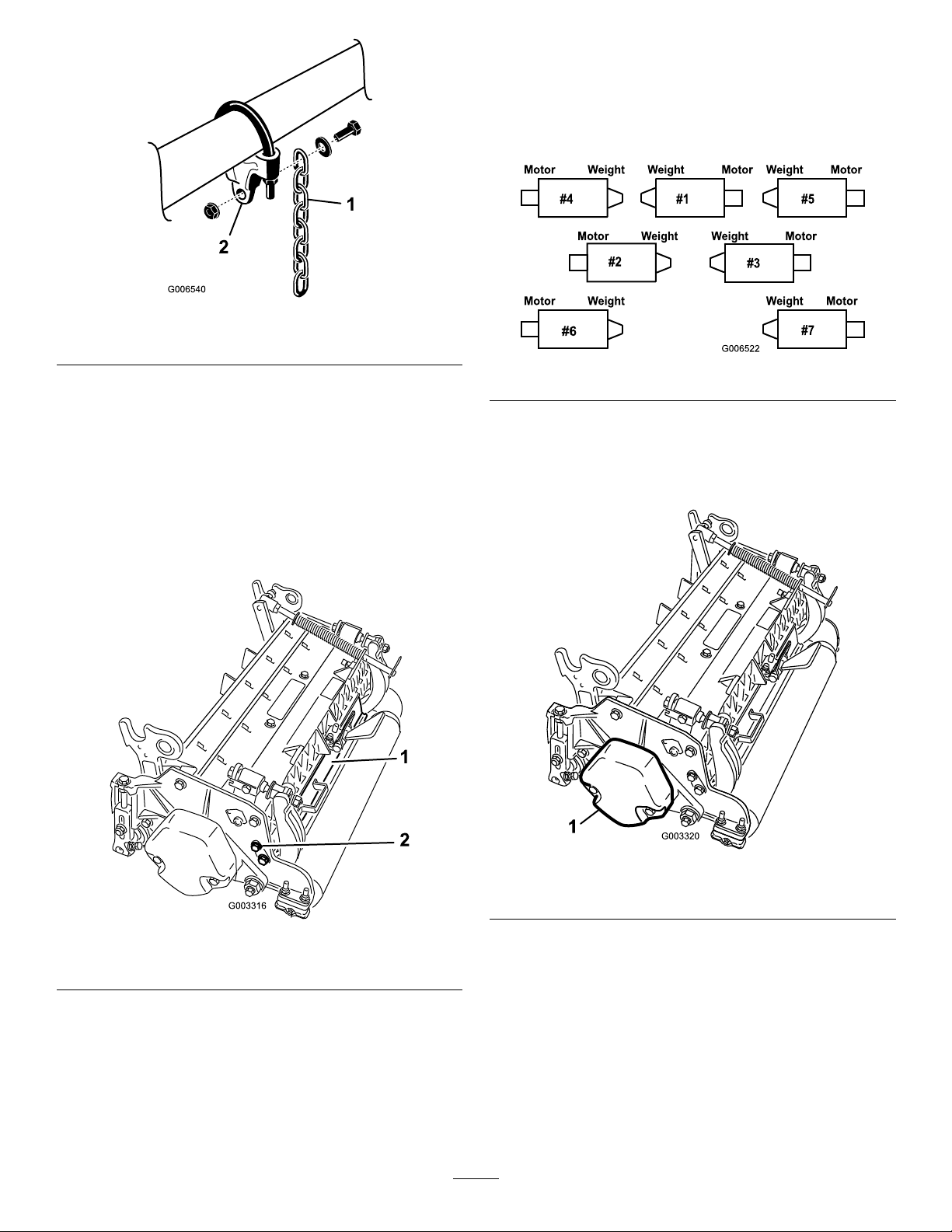

Liftchain5/7

Chainbracket5/7

U-bolt

Nut

Screw5/7

Washer

Nut

LargeO-ring5/7

Nopartsrequired

Calciumchloride(obtainseparately)

Rearweightkit,partnumber104–1478

(obtainseparately)

CEdecals

CEcerticate

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

DiagnosticACEdisplayoverlay

Ignitionkeysonring1

Hoodlockkey1

Screw

Wingnut2

10/14

100lb

Qty.

5/7

5/7

5/7

Use

–

–

1

4

2

1

1

1

1

1

2

Checkuidlevels.

Installcuttingunits.

Installcuttingunits.

Makecuttingunitadjustmentsifneeded.

Addrearballast(ifrequired).

InstalltheCEdecals.

Readthemanualsandviewthetraining

materialbeforeoperatingthemachine.

1

CheckingFluidLevels

NoPartsRequired

Procedure

Beforestartingtheengineforthersttime,checkthe

followinguidlevels:

•Engineoil

RefertoCheckingtheEngineOil.

•Enginecoolant

RefertoCheckingtheCoolingSystem.

•Hydraulicoil

RefertoCheckingtheHydraulicOil.

•Rearaxlelubricant

RefertoCheckingtheRearAxleLubricant.

14

Page 15

2

InstallingCuttingUnits

Models03860,03861and

03862

Partsneededforthisprocedure:

14/10LargeO-ring

7/5Counterweight

7/5Steeringlockingpin

MounttheCuttingUnits

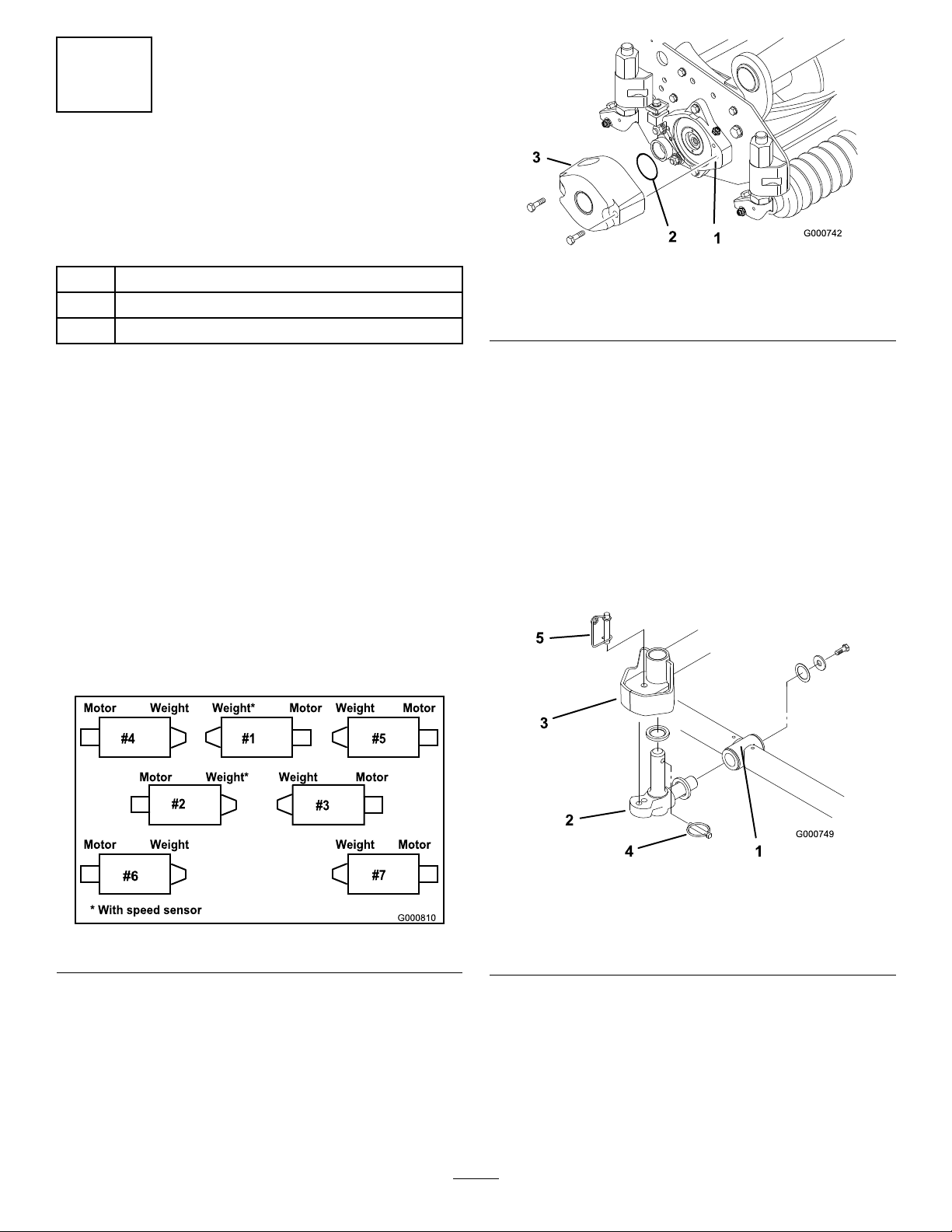

Cuttingunitmodels03860,03861,and03862canbe

installedatanyofthemountinglocationsonthetraction

unit.Figure3showstheorientationofthehydraulic

drivemotorforeachofthelocations.Foranyofthe

locationsrequiringthemotortobemountedontheright

endofthecuttingunit,installacounterweightonthe

leftendofthecuttingunit.Forthelocationsrequiring

themotortobemountedontheleftend,installa

counterweightontherightendofthecuttingunit.

Note:Counterweightmountingcapscrewsareshipped

installedontherightbearinghousingofthecutting

units.Thecapscrewsonleftbearinghousingaretobe

usedforsecuringthehydraulicmotor.

Figure4

1.Bearinghousing

2.Largeo-ring

Note:Beforeinstallingcuttingunitmotorsor

counterweights,lubricateinternalsplinesofcutting

unitreelshaftswithgrease.

4.Installacounterweightontoappropriateendofeach

cuttingunitwithcapscrewsprovided(

5.Thoroughlygreasethecuttingunitreelbearingsprior

toinstallationonthetractionunit.Greaseshould

beevidentattheinboardreelseals;refertoCutting

UnitOperator'sManualforgreasingprocedure.

6.Insertathrustwasherontohorizontalshaftofpivot

knuckleasshownin(

3.Counterweight

Figure4).

Figure5).

Figure3

1.Removecuttingunitsfromcartons.Assembleand

adjustperCuttingUnitOperator'sManual.

2.Removeprotectiveplugsfromeachendofcutting

unit.

3.LubricateandinstallalargeO-ringintobearing

housinggrooveoneachendofcuttingunit

Figure4&Figure7).

(

Figure5

1.Carrierframe

2.Pivotknuckle

3.Liftarmsteeringplate

7.Insertthehorizontalshaftofthepivotknuckleinto

themountingtubeofthecarrierframe(Figure5).

8.Securepivotknuckletocarrierframewithathrust

washer,atwasherandaangeheadcapscrew

(Figure5).

9.Insertathrustwasherontoverticalshaftofpivot

knuckle(Figure5).

15

4.Lynchpin

5.Steeringlockingpin

Page 16

10.Ifremoved,inserttheverticalshaftofthepivot

knuckleintoliftarmpivothub(Figure5).Guide

thepivotknuckleinplacebetweenthetworubber

centeringbumpersintheundersideoftheliftarm

steeringplate.

11.Insertthelynchpinintothecrossholeonthepivot

knuckleshaft(

Figure5).

12.Removenutsecuringturfcompensationspring

mountingbrackettocuttingunitstabilizerear

(Figure6).Inserttipperchainontocapscrewand

securewithnutremoved.

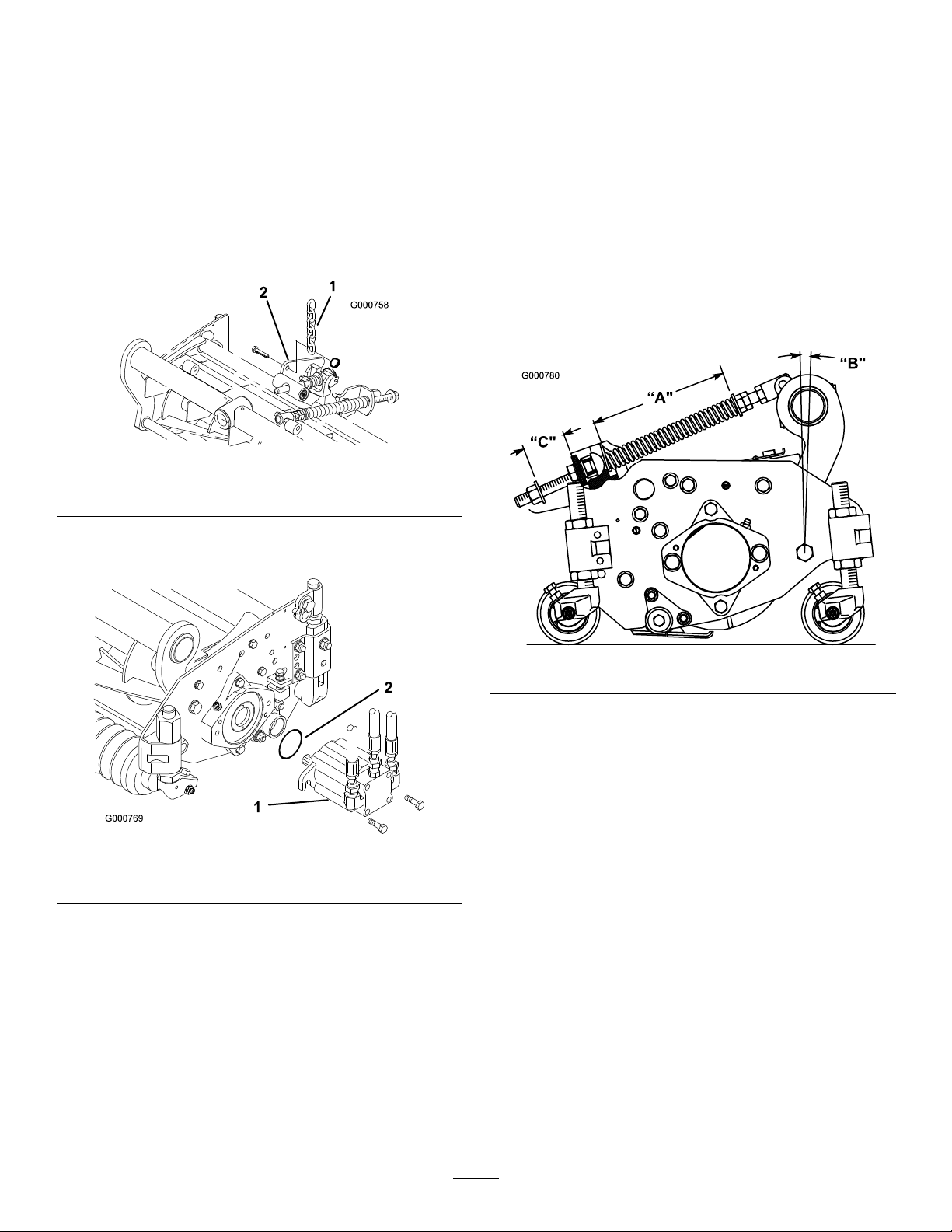

Figure6

1.Liftchain2.Cuttingunitstabilizerear

TheTurfCompensationSpring(Figure8),connecting

carrierframetocuttingunit,controlstheamountof

fore-aftrotationavailable,aswellastheamountof

groundclearanceintransportandturnaround.

TheTurfCompensationSpringalsotransfersweight

fromthefronttorearroller.Thishelpstoreduceawave

patternintheturf,alsoknownasbobbing.

Important:Makespringadjustmentswithcutting

unitmountedtotractionunitandloweredtoshop

oor.

1.Tightenlocknutonrearofspringroduntilthegap

(C)betweenrearofspringbracketandfrontof

washeris1in.(25mm)(

Figure8).

13.Mountthemotortothedriveendofthecuttingunit

andsecurewithtwocapscrewsprovided(

Figure7

1.Motor

2.O-ring

Figure7).

Note:Ifxedcuttingunitpositionisrequired,

insertsteeringlockingpinintopivotknuckle

mountinghole(Figure5).

14.Hookspringwirearoundbottomofsteeringlocking

pin(Figure5).

AdjustTurfCompensationSpring

Figure8

2.Tightenhexnutsonfrontendofspringroduntilthe

compressedlength(A)ofspringis8in.(203mm)

Figure8).

(

Note:Whencuttingroughorundulatingturf,

increasecompressedlength(A)ofspringto8-1/2in.

(216mm)andgap(C)betweenrearofspringbracket

andfrontofwasherto1-1/2in.(38mm)(

Figure8).

Note:Ascompressedspringlength(A)decreases,

weighttransferfromfrontrollertorearroller

increasesandcarrierframe/cuttingunitrotation

angle(B)decreases.

Note:Asgap(C)betweenspringbracketand

washerincreases,cuttingunitgroundclearance

decreasesandcarrierframe/cuttingunitrotation

angle(B)increases.

Tractorsaresetupatthefactoryappropriatelyformost

fairwaymowingapplications.Thefollowingadjustment

isforne-tuningthemachinetotheapplication:

16

Page 17

3

InstallingCuttingUnits

Models03863and03864

Partsneededforthisprocedure:

5/7Liftchain

5/7Chainbracket

U-bolt

5/7

5/7Screw

5/7

5/7

5/7LargeO-ring

Nut

Washer

Nut

10/14

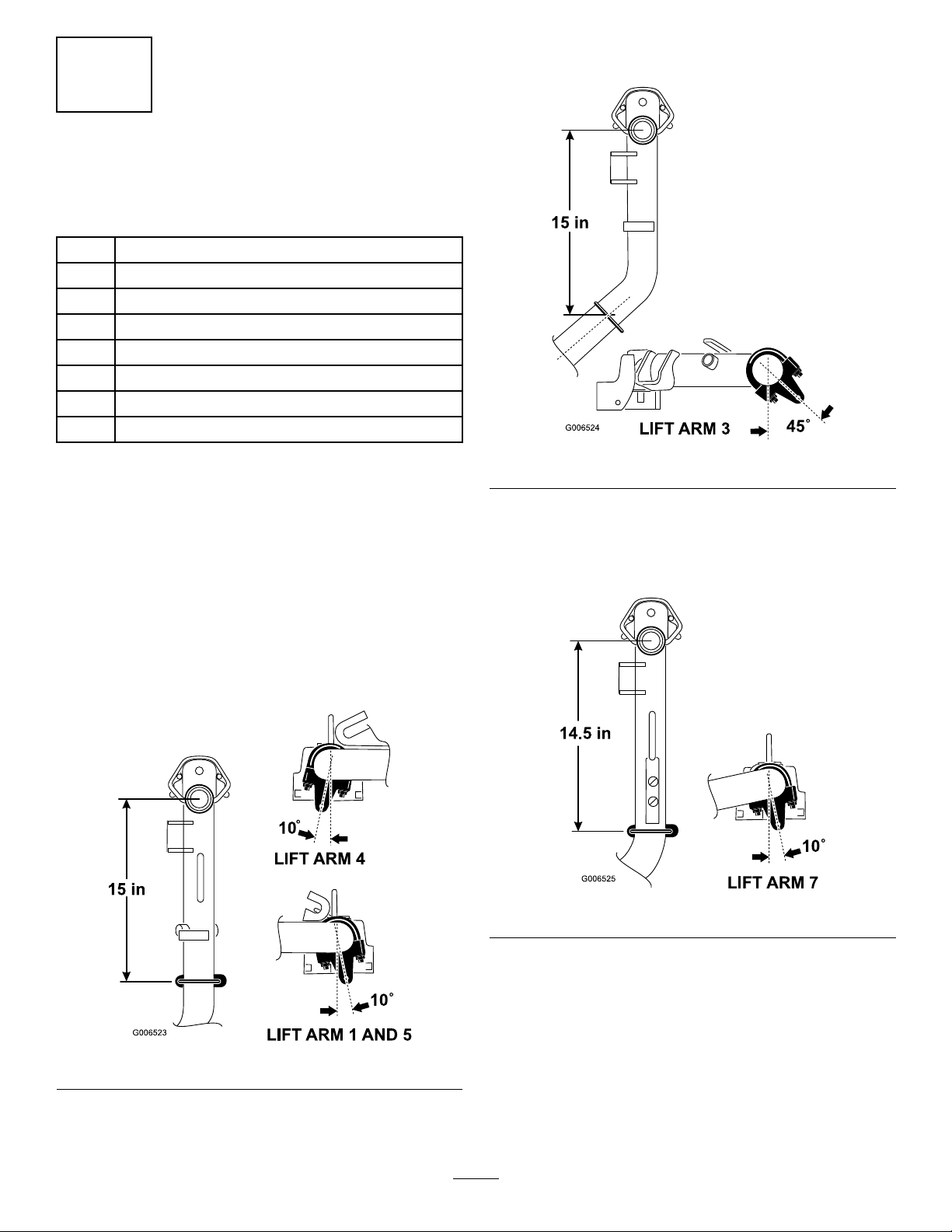

MounttheLiftBracketsandChains

knuckle(Figure10).Rotatethebrackets45degrees

totheoutboardsideofthemachine.

Figure10

MountachainbrackettoeachliftarmwithaU-boltand

2nuts.Positionthebracketsasfollows:

1.Onliftarms#1,#4and#5,positionthechain

bracketsandU-bolts15inchesbehindthecenter

lineofthepivotknuckle(

and#5thebracketsshouldberotatedtotheright

10degreesfromvertical(Figure9).Onliftarm#4

thebracketshouldberotatedtotheleft10degrees

fromvertical(Figure9).

Figure9).Onliftarms#1

3.Onliftarms#6and#7,positionthebracketsand

U-bolts14.5inchesbehindthecenterlineofthe

pivotknuckle(

degreestotheoutboardsideofthemachine.

4.TightenalltheU-boltnutsto38–48ft-lbs.

Figure11).Rotatethebrackets10

Figure11

Figure9

2.Onliftarms#2and#3,positionthebracketsand

U-bolts15inchesbehindthecenterlineofthepivot

5.Mountaliftchaintoeachchainbracketwithascrew ,

washerandnut,positioningasshowninFigure12

17

Page 18

Figure12

1.Liftchain2.Chainbracket

AdjusttheRearShield

Undermostconditions,bestdispersionisattained

whentherearshieldisclosed(frontdischarge).When

conditionsareheavyorwet,rearshieldmaybeopened.

MounttheCounterWeights

Allcuttingunitsareshippedwiththecounterweight

mountedtotheleftendofthecuttingunit.Usethe

followingdiagramtodeterminethepositionofthe

counterweightsandreelmotors.

Figure14

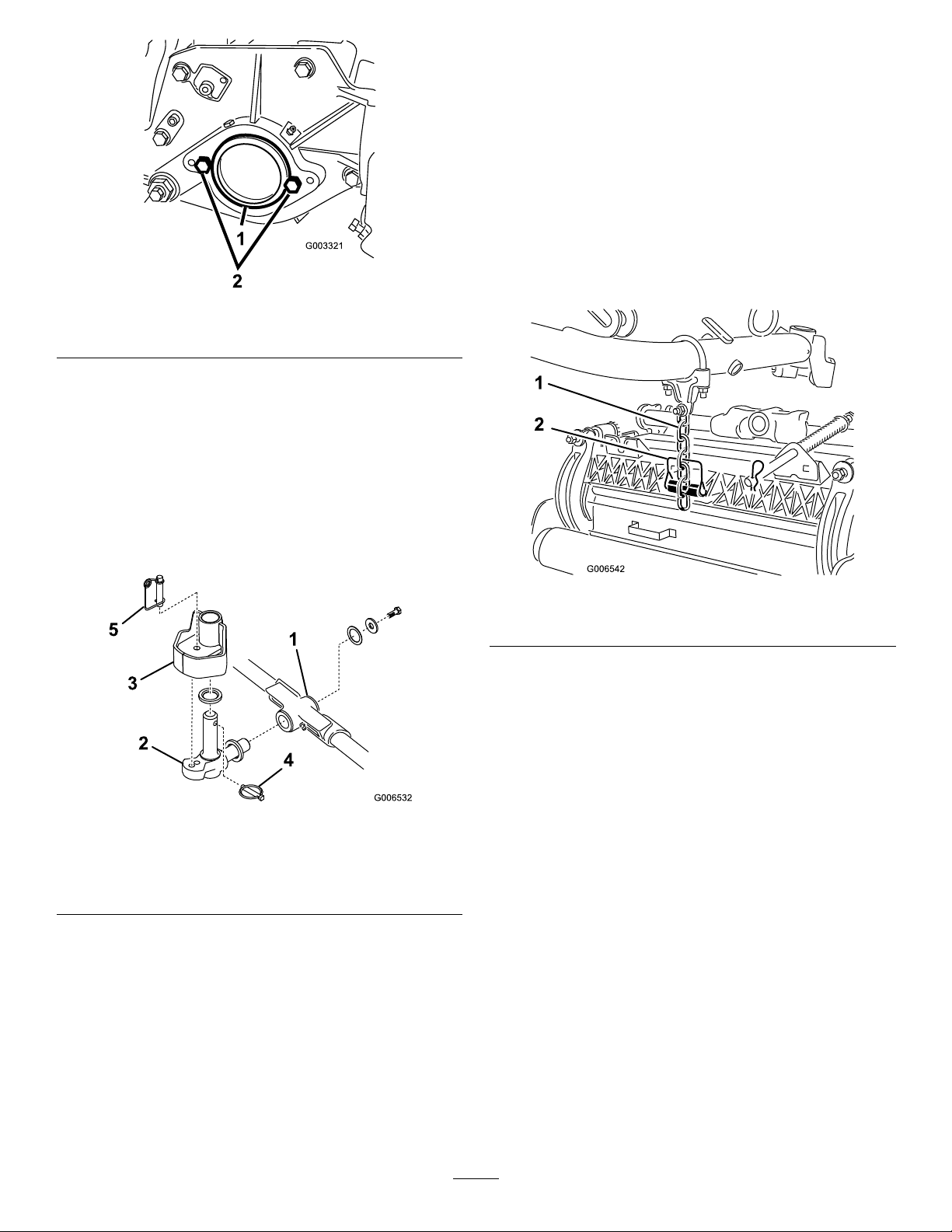

1.Onthe#2,#4and#6cuttingunits,removethe2

capscrewssecuringthecounterweighttotheleft

endofthecuttingunit.Removethecounterweight

Figure15).

(

Toopentherearshield(

Figure13),loosenthecapscrew

securingtheshieldtotheleftsideplate,rotatetheshield

totheopenpositionandtightenthecapscrew .

Figure13

1.Rearshield

2.Capscrew

Figure15

1.Counterweight

2.Onrightendofcuttingunit,removetheplasticplug

fromthebearinghousing(Figure16).

3.Removethe2capscrewsfromtherightsideplate

(Figure16).

18

Page 19

G003321

1

2

Figure16

thepivotknuckleinplacebetweenthetworubber

centeringbumpersintheundersideoftheliftarm

steeringplate.

6.Insertthelynchpinintothecrossholeonthepivot

knuckleshaft(Figure17).

7.Securetheliftarmchaintothecuttingunitchain

bracket(

Figure18)withthesnapperpinasfollows:

A.Oncuttingunits#1,4,5,6and7,onlyuse6of

thechainlinks.

B.Oncuttingunits#2and3,useall7ofthechain

links.

1.Plasticplug

2.Capscrew(2)

4.Installthecounterweighttotherightendofthe

cuttingunitwiththe2screwspreviouslyremoved.

5.Looselyinstallthe2reelmotormountingcapscrews

totheleftsideplateofthecuttingunit(Figure16).

MounttheCuttingUnits

1.Insertathrustwasherontohorizontalshaftofpivot

knuckleasshowninFigure17.

Figure17

Figure18

1.Liftchain2.Snapperpin

8.Coatthesplineofthereelmotorwithcleangrease.

9.OilthereelmotorO-ringandinstallitontothe

motorange.

10.Installthemotorbyrotatingitclockwisesothat

themotorangesclearthecapscrews(

Figure19).

Rotatethemotorcounterclockwiseuntiltheanges

encirclethecapscrewsthentightenthecapscrews

1.Carrierframe

2.Pivotknuckle

3.Liftarmsteeringplate

4.Lynchpin

5.Steeringlockingpin

2.Insertthehorizontalshaftofthepivotknuckleinto

themountingtubeofthecarrierframe(Figure17).

3.Securepivotknuckletocarrierframewithathrust

washer,atwasherandaangeheadcapscrew

(Figure17).

4.Insertathrustwasherontoverticalshaftofpivot

knuckle(

Figure17).

5.Ifremoved,inserttheverticalshaftofthepivot

knuckleintoliftarmpivothub(

Figure17).Guide

Important:Makesurethereelmotorhoses

arenottwisted,kinkedorintheriskofbeing

pinched.

19

Page 20

Figure20

Figure19

1.Reeldrivemotor

2.Capscrew

Note:Ifxedcuttingunitpositionisrequired,

insertsteeringlockingpinintopivotknuckle

mountinghole(

Figure17).

11.Hookspringwirearoundbottomofsteeringlocking

pin(Figure17).

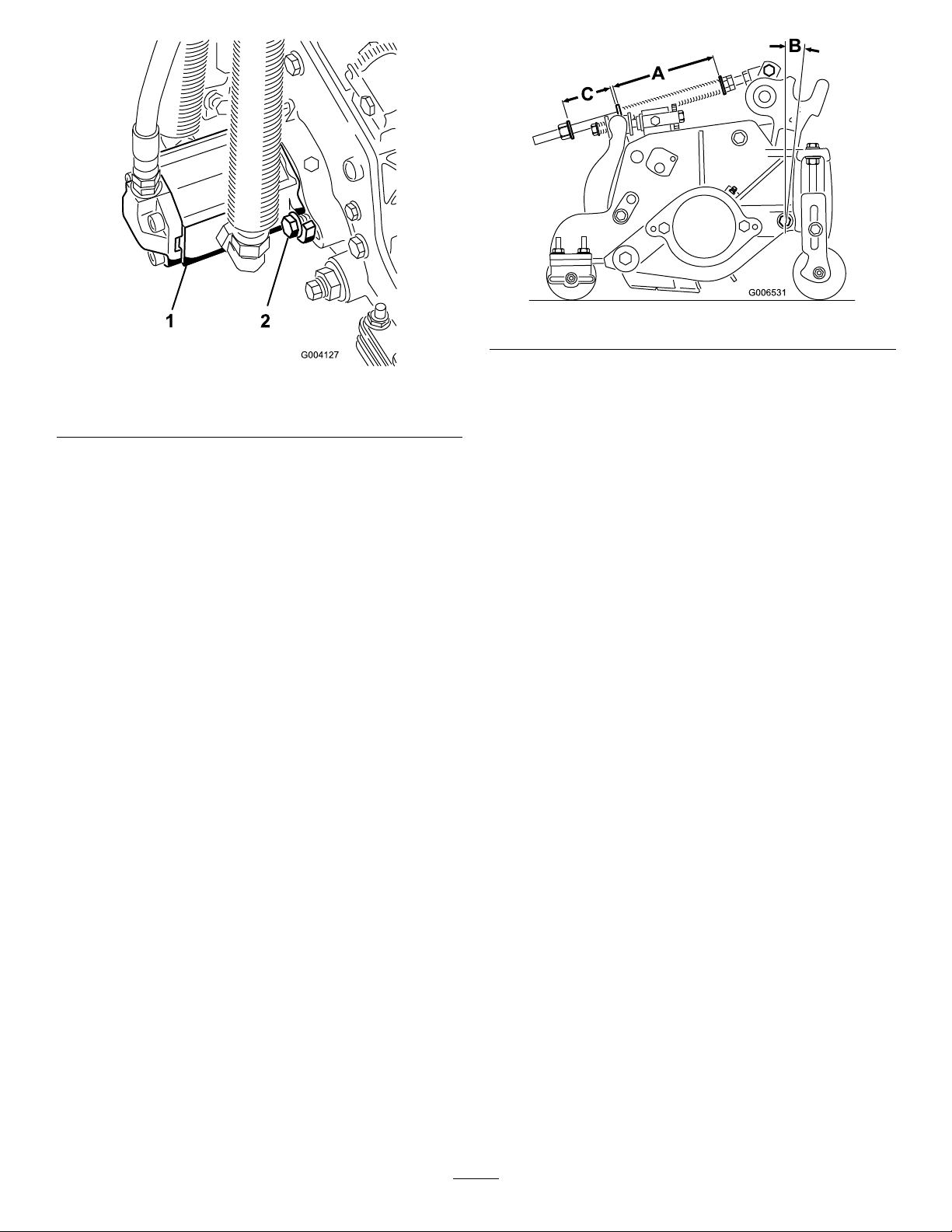

AdjusttheTurfCompensationSpring

Tractorsaresetupatthefactoryappropriatelyformost

fairwaymowingapplications.

Thefollowingadjustmentsareavailableforne-tuning

ofthemachinetotheapplication:

TheTurfCompensationSpring(Figure20)transfers

weightfromthefronttorearroller.Thishelpstoreduce

awavepatternintheturf,alsoknownasbobbing.

Important:Makespringadjustmentswithcutting

unitmountedtotractionunitandloweredtoshop

oor.

2.Tightenhexnutsonfrontendofspringroduntil

thecompressedlength(A)ofspringis6.25in.(159

mm)(Figure20).

Note:Whenoperatingonroughterrain,decrease

thespringlengthby1/2inch.Groundfollowingwill

beslightlydecreased.

Note:Ascompressedspringlength(A)decreases,

weighttransferfromfrontrollertorearroller

increasesandcarrierframe/cuttingunitrotation

angle(B)decreases.

Note:Asgap(C)betweenspringbracketand

washerincreases,cuttingunitgroundclearance

decreasesandcarrierframe/cuttingunitrotation

angle(B)increases.

Note:Whencuttingundulatingturf,increasethe

compressedspringlength(A)andthegapwidth(C)

1/2inch(

Figure20).

1.Tightenlocknutonrearofspringroduntilthegap

(C)betweenrearofspringbracketandfrontof

washeris2in.(51mm)(

Figure20).

20

Page 21

4

6

MakingAlternateCuttingUnit

Adjustments

NoPartsRequired

Procedure

Thefactorysetsthetractorappropriatelyformost

fairwaymowingapplications.Severaladjustmentsfor

ne-tuningthemachineforparticularapplicationsare

includedintheCuttingUnitMaintenancesectionas

follows:

•Adjustingthecuttingunitloweringrate

Adjuststhespeedatwhichthecuttingunitslower.

•Adjustingtheliftedheightoftheouterfrontcutting

units

Adjuststheturnaroundheightoftheouterfront

cuttingunitstoprovidegreaterclearanceon

contouredfairways.

•Adjustingthetravelofthefrontthreecuttingunits

InstallingCEDecals

Partsneededforthisprocedure:

4

CEdecals

2

CEcerticate

Procedure

IfyouwillbeusingthemachineinaCEcountry,install

thesuppliedCEdecalsoverthecorrespondingANSI

decalsontheproduct.StoretheCEcerticatesinasafe

location.

7

ReadingtheManualsand

StoringAdditionalParts

Adjuststhedownwardtravelofthefrontthree

cuttingunitstoallowforhighlycontouredfairways.

5

AddingRearBallast

Partsneededforthisprocedure:

100lb

Procedure

TocomplywithCENstandardEN836:1997,ISO

standard5395:1990,andtheANSIB71.4-2004

Standard,add100lb(45kg)ofcalciumchloride

ballasttotherearwheelsandinstalltherearweightkit

(PartNumber104-1478).

Calciumchloride(obtainseparately)

Rearweightkit,partnumber104–1478(obtain

1

separately)

Partsneededforthisprocedure:

1

Operator'sManual

1

EngineOperator'sManual

1

PartsCatalog

1

OperatorTrainingMaterial

1

DiagnosticACEdisplayoverlay

1Ignitionkeysonring

1Hoodlockkey

2

Screw

2Wingnut

Procedure

1.Readthemanuals.

2.ViewtheOperatorTrainingMaterial.

3.ThediagnosticACEdisplayoverlayisfordiagnosing

machinemalfunctions.Storeitinasafelocation.

Important:Ifapunctureoccursinatirewith

calciumchloride,removeunitfromturfareaas

quicklyaspossible.Topreventpossibledamageto

turf,immediatelysoakaffectedareawithwater.

21

Page 22

ProductOverview

g019447

1

2

3

4

5

6

7

8

9

Controls

TractionPedal

Thetractionpedal(Figure21)controlsforwardand

reverseoperation.Depresstopofpedaltomoveforward

andbottomtomovebackward.Groundspeeddepends

onhowfarpedalisdepressed.Fornoload,maximum

groundspeed,fullydepresspedalwhilethrottleisin

FAST.

Tostop,reducefootpressureontractionpedaland

allowittoreturntocenterposition.

•Themachineisbeingoperatedfasterthanthe

maximumspeedvalueinitiallyprogrammedintothe

ECU.

•Anelectricalmalfunctionhasbeendetected(open

orshortedoutput.

•Ahydraulicleakhasbeendetected(Onlyif

Turfdefenderleakdetectorisinstalledonmachine)

•Acommunicationserrorhasbeendetected(Onlyif

Turfdefenderleakdetectorisinstalledonmachine)

KeySwitch

Thekeyswitch(Figure21)hasthreepositions:OFF ,

ON/PreheatandSTART.

Speedometer

Thespeedometer(Figure21)indicatesgroundspeedat

whichmachineistraveling.

BrakePedals

Twobrakepedals(Figure21)operateindividualwheel

brakesforturningassistance,parking,andtoaidin

obtainingbettersidehilltraction.Lockingpinconnects

thepedalsforparkingbrakeoperationandtransport.

Figure21

1.Tractionpedal6.Parkingbrakelatch

2.Forwardspeedlimiter7.Lockingpin

3.Reddiagnosticlight8.Reversespeedlimiter

4.Speedometer

5.Brakepedals

9.Keyswitch

ForwardSpeedLimiter

Presettheforwardspeedlimiter(Figure21)tolimit

theamountthetractionpedalcanbedepressedinthe

forwarddirectiontomaintainaconstantmowingspeed.

RedDiagnosticLight

Thereddiagnosticlight(Figure21),locatedonsteering

tower,isusedtoconveyseveraldifferentmessages.

Whilestartingthemachine,thelightwillilluminatewhen

theglowplugsareon.

Ifthelightblinksduringoperation,itmayindicateany

ofthefollowing:

ParkingBrakeLatch

Aknobontheleftsideofconsoleactuatesparkingbrake

lock(Figure21).Toengageparkingbrake,connect

pedalswithlockingpin,pushdownonbothpedalsand

pullparkingbrakelatchout.Toreleaseparkingbrake,

depressbothpedalsuntilparkingbrakelatchretracts.

ReverseSpeedLimiter

Adjustthescrew(Figure21)tolimittheamountthe

tractionpedalcanbedepressedintherearwarddirection

tolimitspeed.

LowerMow/RaiseControlLever

(Joystick)

Thelever(Figure22andFigure23)raisesandlowersthe

cuttingunitsandalsostartsandstopsthereels.

FuelGauge

Thefuelgauge(Figure22andFigure23)indicateslevel

offuelintank.

EngineOilPressureWarningLight

Thislight(Figure22andFigure23)indicatesdangerously

lowengineoilpressure.

22

Page 23

G019448

1

2

3

4

5

6

7

8

9

10

11

Figure22

G019449

1

2

3

4

5

6

7

8

9

Model03808and03813

1.Throttlecontrol

2.Lowermow/raisecontrol

lever

3.Fuelgauge

4.Chargeindicator10.Enable/disableswitch

5.Engineoilpressure

warninglight

6.Enginecoolant

temperaturewarning

light

7.Glowplugindicatorlight

8.Enginecoolant

temperaturegauge

9.Enable/disableswitch(#7)

rightrear

(Master)

11.Enable/disableswitch(#6)

leftrear

ThrottleControl

Movethecontrol(Figure22andFigure23)forwardto

increaseenginespeed,rearwardtodecreasespeed.

EngineCoolantTemperatureWarning

Light

Thelight(Figure22andFigure23)illuminatesand

theengineshutsdownwhenthecoolantreachesa

dangerouslyhightemperature.

GlowPlugIndicatorLight

Figure23

Models03806,03807and03812

1.Throttlecontrol6.Enginecoolant

2.Lowermow/raisecontrol

lever

3.Fuelgauge8.Enginecoolant

4.Chargeindicator9.Enable/disableswitch

5.Engineoilpressure

warninglight

temperaturewarning

light

7.Glowplugindicatorlight

temperaturegauge

(Master)

Enable/DisableSwitches

Theenable/disableswitches(Figure22andFigure23)

areusedinconjunctionwiththelowermow/raise

controllever(Joystick)tooperatereels.Reelscanbe

raisedbutnotloweredwheninmidposition.

HourMeter

Thehourmeter(Figure24)showstotalhoursthat

machinehasbeenoperated.

Whentheindicatorlight(Figure22andFigure23)islit,

indicatesglowplugsareon.

ChargeIndicator

Thechargeindicator(Figure22andFigure23)

illuminateswhensystemchargingcircuitmalfunctions.

23

Page 24

G019525

1

1.Hourmeter

G019451

1

2

adjustsseatforoperatorsweight.Toadjustseatfore

andaft,pullleveronleftsideofseatassemblyoutward.

Aftermovingseattodesiredlocation,releaseleverto

lockseatintoposition.Toadjustforoperatorsweight,

turnspringtensionknob;clockwisetoincreasetension,

counterclockwisetodecreasespringtension.

Figure24

BacklapKnobs

Thebacklapknobs(Figure25)areusedin

conjunctionwithlowermow/raisecontrollever

forbacklappingoperation.RefertoBacklappingin

CuttingUnitMaintenance(page53).

Figure25

Figure26

1.Seatadjustingknob2.Seatadjustinglever

GreenDiagnosticLight

Themachineisequippedwithadiagnosticlightwhich

indicatesiftheelectroniccontrollerisfunctioning

correctly.Thegreendiagnosticlight(Figure27)is

locatedunderthecontrolpanel,nexttothefuseblock.

Whentheelectroniccontrollerisfunctioningcorrectly

andthekeyswitchismovedtotheONposition,the

controllerdiagnosticlightwillbeilluminated.Thelight

willblinkifthecontrollerdetectsamalfunctionin

theelectricalsystem.Thelightwillstopblinkingand

automaticallyresetwhenthekeyswitchisturnedtothe

OFFposition.

1.Backlapknobs2.Reelcontrolknobs

ReelSpeedControls

ControlsRPMoffrontandrearcuttingunits(Figure25).

#1positionisforbacklapping.Remainingsettingsare

formowingoperations.Seedecalunderseatforproper

settings.

Seat

Theseatadjustinglever(Figure26)allows4inchfore

andaftadjustment.Theseatadjustingknob(Figure26)

24

Page 25

G019452

1

TheDiagnosticACEdisplayisatooltohelptheuser

verifycorrectelectricalfunctionsofthemachine.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Figure27

1.Greendiagnosticlight

Whenthecontrollerdiagnosticlightblinks,oneofthe

followingproblemshasbeendetectedbythecontroller:

•Oneoftheoutputshasbeenshorted.

•Oneoftheoutputsisopencircuited.

Usingthediagnosticdisplay,determinewhichoutput

ismalfunctioning,refertoCheckingInterlock

Switches.

Ifthediagnosticlightisnotilluminatedwhenthe

keyswitchisintheOnposition,thisindicatesthat

theelectroniccontrollerisnotoperating.Possible

causesare:

•Loopbackisnotconnected.

•Thelightisburnedout.

Width-of-cut,model03806,

03807and03812

Width-of-cut,model03808and

03813

Overallwidth,Transport89inches(226cm)

Overallwidth,Operational110inches(279cm)

Overalllength120inches(305cm)

HeightWithROPSinstalled84inches(213cm)

Weight*,model038063200lb(1451kg)

Weight*,model03807and

03812

Weight*,model03808and

03813

*With5bladecuttingunitsandfulluidlevels.

96inches(244cm)

133inches(338cm)

3300lb(1496kg)

3950lb(1792kg)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

•Fusesareblown.

•Nobatterypower.

Checkelectricalconnections,inputfusesand

diagnosticlightbulbtodeterminemalfunction.

Makesureloopbackconnectorissecuredtowire

harnessconnector.

DiagnosticACEDisplay(Optional)

Themachineisequippedwithanelectroniccontroller

whichcontrolsmostmachinefunctions.Thecontroller

determineswhatfunctionisrequiredforvariousinput

switches(i.e.seatswitch,keyswitch,etc.)andturns

ontheoutputstoactuatesolenoidsorrelaysforthe

requestedmachinefunction.

Fortheelectroniccontrollertocontrolthemachineas

desired,eachoftheinputswitches,outputsolenoidsand

relaysmustbeconnectedandfunctioningproperly .

25

Page 26

Operation

g019453

1

G019454

1

G019455

1

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CheckingtheEngineOil

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityisapproximately7.5qt.(7l)with

thelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

Figure29

1.Dipstick

•APIClassicationLevelRequired:CH-4,CI-4or

higher.

•Preferredoil:SAE15W -40(above0°F)

•Alternateoil:SAE10W -30or5W-30(all

temperatures)

Note:ToroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity.See

thepartscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.Iftheoillevelisatorbelowthe“add”mark

onthedipstick,addoiltobringtheoilleveltothe“full”

mark.DONOTOVERFILL.Iftheoillevelisbetween

the“full”and“add”marks,nooiladditionisrequired.

1.Parkmachineonalevelsurface.Releasehoodlatch

andopenhood(

Figure28).

3.Ifoillevelislow,removellercap(Figure30)and

addoiluntillevelreachesFULLmarkondipstick.

Donotoverll.

Figure30

1.Fillercap

4.Installllercap.

5.Closehoodandsecurelatch.

Figure28

1.Hoodlatch

2.Removedipstick(Figure29),wipecleanandreinstall

dipstick.Pullitoutagainandcheckoillevelon

dipstick:OillevelshouldbeuptoFULLmarkon

dipstick.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Cleandebrisoffscreen,oilcoolerandfrontof

radiatordaily,moreoftenifconditionsareextremely

dustyanddirty;refertoRemovingDebrisin

CoolingSystemMaintenance(page49).

Thecoolingsystemislledwitha50/50solution

ofwaterandpermanentethyleneglycolantifreeze.

Checklevelofcoolantinradiatorandexpansiontank

26

Page 27

atthebeginningofeachdaybeforestartingtheengine.

1

G019456

Capacityofcoolingsystemis10quarts(9.4l).

CAUTION

Iftheenginehasbeenrunning,pressurizedhot

coolantcanescapeandcauseburnsiftheradiator

capisremoved.

Allowtheenginetocoolatleast15minutesoruntil

theradiatorcapiscoolenoughtotouchwithout

burninghands.

1.Carefullyremoveradiatorcapandexpansiontank

cap(Figure31).

2.Checklevelofcoolantinradiatorandinexpansion

Figure31).

tank(

Radiatorshouldbelledtothetopofthellerneck

andtheexpansiontanklledtotheFullmark.

Figure32

1.Ventplug

4.Installradiatorcapandexpansiontankcap.

5.Closehoodandsecurelatch.

FillingtheFuelTank

Figure31

1.Expansiontank

3.FillexpansiontanktotheFullmarkandradiator

tothetopofthellerneck.Donotoverllthe

expansiontank.

Note:Ifairistrappedissystem,removeventplug

Figure32),fromtopofradiatorsidetank,toallow

(

trappedairtoescape.Reinstallventplugusing

Teonthreadsealant.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1in.(25

mm)belowthebottomofthellerneck.This

emptyspaceinthetankallowsthefuelto

expand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Fueltankcapacity:15USgallons(57l)

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-Dor

No.1-D/2-Dblend)belowthattemperature.Useof

wintergradefuelatlowertemperaturesprovideslower

27

Page 28

ashpointandcoldowcharacteristicswhichwillease

startingandreducefuellterplugging.

Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuelthat

spills.

•Neverllthefueltankinsideanenclosedtrailer.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblendsd.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwith

itswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundfueltankcap.

3.Removecapfromthefueltank(Figure33).

28

Page 29

1

G019457

Note:Manyhydraulicuidsarealmostcolorless,

1

G019458

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz.(20ml)

bottles.Onebottleissufcientfor4-6gal(15-221)

ofhydraulicoil.Orderpartno.44-2500fromyour

authorizedTorodistributor.

BiodegradableHydraulicFluid-Mobil224H

ToroBiodegradableHydraulicFluid(Availablein5gallon

pailsor55gallondrums.SeepartscatalogorT orodistributor

forpartnumbers.)

Alternateuid:MobilEAL224H

Figure33

1.Fueltankcap

4.Fillthetankuntilthelevelistothebottomofthe

llerneckwithdieselfuel.

5.Installfueltankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.

Thiswillminimizepossiblebuildupofcondensation

insidethefueltank.

CheckingtheHydraulicFluid

ServiceInterval:Beforeeachuseordaily

Themachinesreservoirislledatthefactorywith

approximately8.5U.S.gallons(32l)ofhighquality

hydraulicuid.Checkthelevelofthehydraulicuid

beforetheengineisrststartedanddailythereafter.

Therecommendedreplacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Note:Thisisvegetable-oilbasedbiodegradableoil

testedandapprovedbyToroforthismodel.Thisuid

isnotasresistanttohightemperaturesasstandard

uid,soinstallanoilcoolerifrequiredbytheoperator

manualandfollowrecommendeduidchangeintervals

withthisuid.Contaminationbymineral-based

hydraulicuidswillchangethebiodegradabilityand

toxicityofthisoil.Whenchangingfromstandarduid

tothebiodegradabletype,becertaintofollowthe

approvedushingprocedure.ContactyourlocalT oro

Distributorfordetails.

1.Positionmachineonalevelsurface,lowerthe

cuttingunitsandstoptheengine.

2.Cleanareaaroundllerneckandcapofhydraulic

Figure34).Removecapfromllerneck.

tank(

Alternateuids:IftheTorouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Wedo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

productNote:Torowillnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souseonly

productsfromreputablemanufacturerswhowillstand

behindtheirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

Figure34

1.Hydraulictankcap

3.Removedipstickfromllerneckandwipeitwith

acleanrag.Insertdipstickintollerneck;then

removeitandchecklevelofuid.Fluidlevelshould

bewithin1/4inchofmarkondipstick.

4.Iflevelislow ,addappropriateuidtoraiselevel

tofullmark.

5.Installdipstickandcapontollerneck.

29

Page 30

CheckingtheTirePressure

BleedingtheFuelSystem

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.Correct

airpressureinthefrontandreartiresis15-20psi.

Important:Maintainevenpressureinalltiresto

ensureagoodquality-of-cutandpropermachine

performance.Donotunderinate.

CheckingtheReeltoBedknife

Contact

ServiceInterval:Beforeeachuseordaily

Eachdaybeforeoperating,checkreeltobedknife

contact,regardlessifqualityofcuthadpreviouslybeen

acceptable.Theremustbelightcontactacrossthefull

lengthofthereelandbedknife(refertoAdjustingReel

toBedknifeinCuttingUnitOperator'sManual).

StartingandStopping

1.Sitontheseat,keepfootofftractionpedal.

Ensureparkingbrakeisengaged,tractionpedal

isinNeutral,throttleisinSlowpositionandthe

Enable/DisableswitchisintheDisableposition.

2.TurnignitionswitchtoOn/Preheatposition.

Anautomatictimerwillcontrolpreheatfor

approximately6seconds.Afterpreheat,turnkey

toStartposition.Cranktheenginefornolonger

than15seconds.Releasekeywhenenginestarts.

Ifadditionalpreheatisrequired,turnkeytoOff

positionthentoOn/Preheatposition.Repeat

processasrequired.

1.Parkthemachineonalevelsurface.Makesurefuel

tankisatleasthalffull.

2.Unlatchandraisehood.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1in.

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsthefuel

toexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

3.Openventplugonthefuellter/waterseparator

(Figure35).

3.Runengineatidlespeedorpartialthrottleuntil

enginewarmsup.

4.Tostop,moveallcontrolstoNeutralandsetparking

brake.Returnthrottletotheidleposition,turnkey

toOFFandremoveitfromswitch.

Important:Allowenginetoidlefor5minutes

beforeshuttingitoffafterafullloadoperation.

Failuretodosomayleadtoturbo-charger

trouble.

Note:Werecommendthatanytimethemachineis

parked(shortorlongterm)thecuttingunitsshould

beloweredtotheground.Thisrelievespressure

fromtheliftcircuitandeliminatestheriskofthe

cuttingunitsaccidentallyloweringtotheground.

Figure35

1.Fuellter/waterseparator

4.TurnkeyinignitionswitchtotheOnposition.

Electricfuelpumpwillbeginoperation,thereby

forcingairoutaroundventplug.LeavekeyinOn

positionuntilasolidstreamoffuelowsoutaround

plug.TightenplugandturnkeytoOFF .

5.Opentheairbleedscrewonthefuelinjectionpump

(Figure36).

30

2.Ventplug

Page 31

g019459

Figure36

Figure37

1.Bypassvalve

1.Fuelinjectionpumpbleedscrew

6.TurnkeyinignitionswitchtotheOnposition.

Electricfuelpumpwillbeginoperation,thereby

forcingairoutaroundairbleedscrew .Leavekeyin

Onpositionuntilasolidstreamoffuelowsout

aroundscrew .TightenscrewandturnkeytoOff.

Note:Normally,engineshouldstartafterabove

bleedingproceduresarefollowed.However,if

enginedoesnotstart,airmaybetrappedbetween

injectionpumpandinjectors;refertoBleedingAir

FromInjectorsintheMaintenanceSection.

PushingorTowingthe

Machine

Inanemergency,themachinecanbemovedby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.

Important:Donotpushortowthemachine

fasterthan2-3mph(3-4.8km/h)becauseinternal

transmissiondamagemayoccur.Thebypassvalve

mustbeopenwheneverthemachineispushedor

towed.

1.Thebypassvalveislocatedontopofvariable

displacementpump(

90°,ineitherdirection,toopenandallowoilto

bypassinternally.Becauseuidisbypassed,the

machinecanbemovedslowlywithoutdamaging

thetransmission.

Figure37).Rotatethevalve

2.Closethebypassvalvebeforestartingtheengine.

However,donotexceed5-8ft.-lb.(7-11N·m)

torquetoclosethevalve.

Important:Runningtheenginewiththe

bypassvalveopenwillcausethetransmission

tooverheat.

CheckingtheInterlock

Switches

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thepurposeoftheinterlockswitchesaretoprevent

theenginefromcrankingorstartingunlessthetraction

pedalisinNeutral,theEnable/Disableswitchisin

DisableandtheLowerMow/Raisecontrolisinthe

neutralposition.Inaddition,theenginewillstopwhen

thetractionpedalisdepressedwitheithertheoperator

offtheseatortheparkingbrakeengaged.

Toverifyinterlockswitchfunction:

ServiceInterval:Beforeeachuseordaily

1.Parkmachineonalevelsurface,lowerthecutting

units,stoptheengineandengagetheparkingbrake.

2.Opencontrolpanelcover.Locatewireharnessand

loopbackconnector.Carefullyunplugloopback

connectorfromharnessconnector(

31

Figure38).

Page 32

correspondingswitchisclosed.Repeatoneach

switchthatispossibletobechangedbyhand.

7.IfswitchisclosedandappropriateLEDdoesnot

turnon,checkallwiringandconnectionstoswitch

and/orcheckswitcheswithanohmmeter.Replace

anydamagedswitchesandrepairanydamaged

wiring.

Figure38

1.Loop-backconnector

3.ConnecttheDiagnosticACEdisplayconnector

totheharnessconnector(

Figure39).Makesure

correctoverlaydecalispositionedonDiagnostic

ACEdisplay.

Figure39

1.DiagnosticACE

4.TurnthekeyswitchtotheOnposition,butdonot

startmachine.

Note:Theredtextontheoverlaydecalrefersto

inputswitchesandthegreentextreferstooutputs.

5.The“inputsdisplayed”LED,onlowerrightcolumn

oftheDiagnosticACE,shouldbeilluminated.If

“outputsdisplayed”LEDisilluminated,pressand

releasethetogglebutton,onDiagnosticACE,to

changeLEDto“inputsdisplayed”.Donothold

buttondown.

6.TheDiagnosticACEwillilluminatetheLED

associatedwitheachoftheinputswhenthatinput

switchisclosed.

Individually,changeeachoftheswitchesfrom

opentoclosed(i.e.,sitonseat,engagetraction

pedal,etc.),andnotethattheappropriateLED

onDiagnosticACEwillblinkonandoffwhen

TheDiagnosticACEalsohastheabilitytodetect

whichoutputsolenoidsorrelaysareturnedon.This

isaquickwaytodetermineifamachinemalfunction

iselectricalorhydraulic.

Toverifyoutputfunction:

1.Parkmachineonalevelsurface,lowerthecutting

units,stoptheengineandengagetheparkingbrake.

2.Opencontrolpanelcover.Locatewireharness

andconnectorsnearcontroller.Carefullyunplug

loopbackconnectorfromharnessconnector.

3.ConnecttheDiagnosticACEconnectortothe

harnessconnector.Makesurecorrectoverlaydecal

ispositionedonDiagnosticACE.

4.TurnthekeyswitchtotheOnposition,butdonot

startmachine.

Note:Theredtextontheoverlaydecalrefersto

inputswitchesandthegreentextreferstooutputs.

5.The“outputsdisplayed”LED ,onlowerright

columnofDiagnosticACE,shouldbeilluminated.

If“inputsdisplayed”;LEDisilluminated,pressthe

togglebutton,onDiagnosticACE,tochangeLED

to“outputsdisplayed.”

Note:Itmaybenecessarytotogglebetween

“inputsdisplayed”and“outputsdisplayed”several

timestodothefollowingstep.Totogglebackand

forth,presstogglebuttononce.Thismaybedone

asoftenasrequired.Donotholdthebutton.

6.Sitontheseatandattempttooperatethedesired

functionofthemachine.Theappropriateoutput

LED'sshouldilluminatetoindicatethattheECU

isturningonthatfunction.(RefertoHydraulic

SolenoidValveFunctionstobecertainofthe

speciedoutputLEDs.)

Note:IfanyoutputLEDisblinking,this

indicatesanelectricalproblemwiththatOUTPUT.

Repair/replacedefectiveelectricalpartsimmediately .

ToresetablinkingLED,turnthekeyswitch“Off”,

thenback“On”andclearthecontrollersfault

memory(RefertoClearingtheFaultMemoryin

FaultMemoryandRetrieval).

IfnooutputLEDsareblinking,butthecorrect

outputLED'sdonotilluminate,verifythatthe

32

Page 33

requiredinputswitchesareinthenecessary

positionstoallowthatfunctiontooccur.Verify

correctswitchfunction.

IftheoutputLEDsareonasspecied,butthe

machinedoesnotfunctionproperly,thisindicatesa

non-electricalproblem.Repairasnecessary.

TooldisplayonOutputstoseefault.The

Problemcircuitwillbeashing.Recordswill

repeatuntilkeyisturnedoff.Unitwillnotstart

inthismode.

ClearingtheFaultMemory(DiagnosticT ool

notrequired)

Note:Duetoelectricalsystemconstraints,

theoutputLED'sfor“Start”,“Preheat”and

“ETR/ALT”maynotblinkeventhoughan

electricalproblemmayexistforthosefunctions.If

themachineproblemappearstobewithoneof

thesefunctions,becertaintochecktheelectrical

circuitwithavolt/ohmmetertoverifythatno

electricalproblemexiststothesefunctions.

Ifeachinputswitchisinthecorrectposition

andfunctioningcorrectly,buttheoutputLEDs

arenotcorrectlyilluminated,thisindicatesan

ECUproblem.Ifthisoccurs,contactyourT oro

Distributorforassistance.

FaultMemoryandRetrieval

IftheControllersensesafaultononeoftheoutput

solenoids,itwillashthemachinesdiagnosticLamp

(ReelDiagnosticLamponconsoleorGreenDiagnostic

Lampunderconsole)andstorethefaultintothe

Controllers(ECU)memory.Thefaultcanthenbe

retrievedandviewedwiththeDiagnosticACEhand

heldtooloralaptop/PCatanytime.TheController

willstoreone(1)faultatatimeandwillnotstore

anotherdifferentfaultuntiltherstfaultiscleared.

7.RotateignitionkeytoOffposition.

8.TurnBacklapSwitchtotheFrontorRearBacklap

position.

9.TurntheReelControlSwitchtoEnableposition.

10.MovetheJoysticktotheRaisepositionandhold.

11.TurntheignitionkeytoOn,andcontinuetohold

theJoystickintheRaisepositionuntiltheReel

ControlLampstartstoash(approx.2seconds).

12.ReleasetheJoystickandturntheKeyOff.Memory

isnowcleared.

13.TurntheBacklapSwitchtoOffandEnableSwitch

toDisableposition.

Important:TheDiagnosticACEdisplaymust

notbeleftconnectedtothemachine.Itis

notdesignedtowithstandtheenvironment

ofthemachine'severydayuse.Whendone

usingDiagnosticACE,disconnectitfromthe

machineandreconnectloopbackconnectorto

harnessconnector.Machinewillnotoperate

withoutloopbackconnectorinstalledon

harness.StoreDiagnosticACEindry,secure

locationinshop,notonmachine.

RetrievingFaultInformation

RetrievingStoredFaults(Donotsitinseat)

1.RotateignitionkeytoOffposition.

2.ConnecttheHandheldDiagnosticTooltothe

desiredControllerLoopbackConnector(usethe

properoverlay).

3.MovetheJoysticktotheRaisepositionandhold.

4.RotateignitionkeytoOnposition,andcontinueto

holdtheJoystickinRaisepositionuntilthetopleft

DiagnosticToollightcomeson(approx.2seconds).

5.ReleasetheJoysticktothecenterposition.

6.HandheldToolwillnowplaybackthefaultretained

intheControllermemory.

Important:Thedisplaywillshoweight(8)

individualrecordswiththefaultdisplayedon

the8threcord.Eachrecordwillbedisplayed

for10seconds.BesuretohavetheDiagnostic

HydraulicSolenoidValve

Functions

Usethelistbelowtoidentifyanddescribethedifferent

functionsofthesolenoidsinthehydraulicmanifold.

Eachsolenoidmustbeenergizedtoallowfunctionto

occur.

Solenoid

MSV1

MSV2

SV4Liftfrontwingcuttingunits

SV3Liftfrontcentercuttingunit

SV5Liftrearcuttingunits

SV1Pressurizeraise/lower

SV2Direction:ON=Raise,

SV6Leftrearwingcuttingunit

Function

Frontreelcircuit

Rearreelcircuit

hydrauliccircuit

OFF=Lower

33

Page 34

Solenoid

SV7

SV8

Function

Rightrearwingcuttingunit

LoadHolding

On.Themachineshouldnotbestarteduntilthe

glowplugcycleiscomplete.

Mowing

OperatingTips

Familiarization

Beforemowinggrass,practiceoperatingmachinein

anopenarea.Startandstoptheengine.Operatein

forwardandreverse.Lowerandraisecuttingunitsand

engageanddisengagereels.Whenyoufeelfamiliarwith

themachine,practiceoperatingupanddownslopes

atdifferentspeeds.

Thebrakescanbeusedtoassistinturningthemachine.

However,usethemcarefully,especiallyonsoftor

wetgrassconditionsbecausetheturfmaybetorn

accidentally.Individualturningbrakesmayalsobeused

tohelpmaintaintraction.Forexample,insomeslope

conditions,theuphillwheelslipsandlosestraction.If

thissituationoccurs,depressuphillturnpedalgradually

andintermittentlyuntiltheuphillwheelstopsslipping,

thus,increasingtractiononthedownhillwheel.

Important:Beforemowinggrass,practice

operatingthemachineinturns.Turfdamagein

turnsmayoccurespeciallyundersoftorwetgrass

conditionsiftheturniscompletedatahighspeed

oratasmallturningradius.Maintainaspeed

below3mphduringaturnandaturningradius

greaterthan8feettominimizeturfdamagefrom

tiresorcuttingunits.Mountingthecuttingunits

withthesteeringpininthefrontmountingholewill

allowthecuttingunittosteeritselfasthetraction

unitturnsprovidingoptimummaneuverabilityand

cuttingperformanceinturns.Duringcross-cutting

offairways,ateardropshapeturnisrecommended

toincreasecuttingproductivityandminimizeturf

damage.

StartengineandmovethrottletoFASTso

engineisrunningatmaximumspeed.Movethe

Enable/DisableswitchtoENABLEandusethe

LOWERMOW/RAISElevertocontrolthecutting

units(frontcuttingunitsaretimedtolowerbefore

therearcuttingunits).Tomoveforwardandcut

grass,presstractionpedalforward.Maintainaspeed

whichdoesnotresultintheReelControlLightbeing

illuminated.Graduallyincreaseordecreasetraction

speedtoensureproperclipismaintained.

Transport

MovetheEnable/DisableswitchtoJoyStickDisable

(midposition),lockbrakepedalstogetherandraisethe

cuttingunitstothetransportposition.Becarefulwhen

drivingbetweenobjectssoyoudonotaccidentally

damagethemachineorcuttingunits.Useextracare

whenoperatingmachineonslopes.Driveslowlyand

avoidsharpturnsonslopestopreventrollovers.The

cuttingunitsshouldbeloweredwhengoingdownhill

forsteeringcontrol.

DANGER

Whenoperatingthemachine,alwaysusetheseat

beltandROPStogether.Donotuseaseatbelt

withoutaROPS.

WarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurif

themachineisoperatedwithamalfunction.

Important:TheRedDiagnosticLight,onthe

steeringtower,indicateswhentheglowplugsare

34

Page 35

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Checkthetorqueofthewheelnutsorbolts(aftertherst1–4hoursofoperation

andthenafter10hoursofoperation).

•Changetheengineoilandoillter.

•Changetheplanetarygeardriveoil.

•Changetherearaxlelubricant.

•Checktheengineoillevel.

•Checkandcleanthecoolingsystem.

•Checkthehydraulicuidlevel.

•Checkthetirepressure.

•Checkthereeltobedknifecontact.

•Checktheinterlockswitches.

•Drainthefuellter/waterseparator.

•Removedebrisfromtherearscreen,oilcooler,andradiator(morefrequentlyin

dirtyconditions).

•Inspectthehydrauliclinesandhosesforleaks,kinkedlines,loosemounting

supports,wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings.

•Checktheconditionofthebattery.

•Inspectandtightenthecoolingsystemhosesandconnections.

•Checktheconditionandtensionofthealternatorbelt.

Every150hours

Every200hours

Every400hours

Every800hours

Every2years

Important:Refertoyourengine

•Changetheengineoilandoillter.

•Checkthetorqueofthewheelnutsorbolts.

•Servicetheaircleaner.(Servicetheaircleanerearlieriftheaircleanerindicator

showsred.Serviceitmorefrequentlyinextremelydirtyordustyconditions.)

•Checkthefuellinesandconnections.

•Replacethefuelltercanister.

•Checktheplanetarygeardriveoil(Also,checkifexternalleakageisobserved)

•Checktherearaxlelubricantlevel.

•Changetheplanetarygeardriveoil.(Oryearly,whichevercomesrst)

•Changetherearaxlelubricant.

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Drainandcleanthefueltank.

•Drainandushthecoolingsystem.

•Replaceallmovinghoses.

•Drain/ushthehydraulictank.

Operator's Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

35

Page 36

ServiceIntervalChart

g023347

Figure40

36

Page 37

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Checksafetyinterlockoperation.

Checkbrakeoperation.

Checkengineoilandfuellevel.

Checkcoolingsystemuidlevel.

Drainthewater/fuelseparator.

Checktheairlterrestrictionindicator.

Checktheradiatorandscreenfordebris.

Checkunusualenginenoises.

Checkunusualoperatingnoises.

Checkthetransmissionoillevel.

Checkthehydraulicsystemoillevel.

Checkthehydrauliclterindicator.

Checkthehydraulichosesfordamage.

Checkforuidleaks.

Checkthetirepressure.

Checkinstrumentoperation.

Checkthereel-to-bedknifeadjustment.

Checktheheight-of-cutadjustment.

Lubricateallgreasettings.

Touchupdamagedpaint.

1

2

3

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

2.Checkwiththeenginerunningandoilatoperatingtemperature.

3.Immediatelyaftereverywashing,regardlessoftheintervallisted

37

Page 38

Lubrication

g019485

g019486

g019487

g019495

GreasingtheBearingsand

Bushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Ifmachineisoperatedundernormalconditions,

lubricateallbearingsandbushingsafterevery50hours

ofoperationorimmediatelyaftereverywashing.

Thegreasettinglocationsandquantitiesare:

•Cuttingunitcarrierframeandpivot(2ea.)

Figure41).

(

Figure42