Page 1

FormNo.3386-664RevA

Reelmaster

®

7000-D4-Wheel

DriveTractionUnit

ModelNo.03780—SerialNo.315000001andUp

ModelNo.03780A—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3386-664*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporatedwith

themuferassembly.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

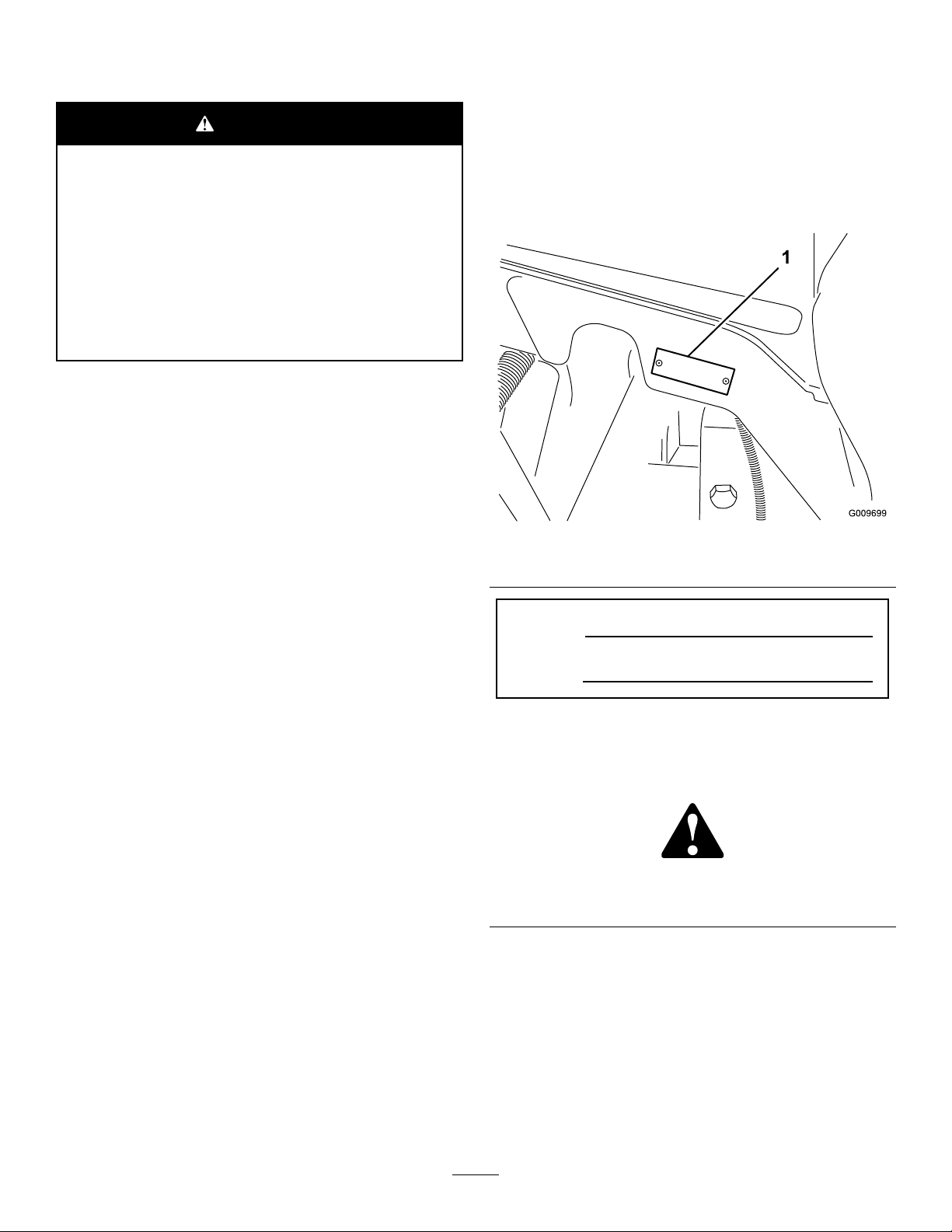

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontherightfrontframemember

oftheproduct.Writethenumbersinthespaceprovided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsingolfcourses,parks,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

SafetyandInstructionalDecals.................................7

Setup...........................................................................13

1AdjustingtheSupportRollers................................14

2ReplacingtheWarningDecalforCE

Compliance........................................................14

3InstallingtheHoodLockforCE

Compliance........................................................14

4InstallingtheCuttingUnits....................................15

5AdjustingtheTurfCompensationSpring.................19

6UsingtheCuttingUnitKickstand...........................19

7GreasingtheMachine...........................................20

8CheckingFluidLevels...........................................21

9UsingtheGaugeBar............................................21

ProductOverview.........................................................22

Controls...............................................................22

Specications........................................................28

TractionUnitSpecications.....................................28

Attachments/Accessories........................................28

Operation....................................................................29

CheckingtheEngineOilLevel.................................29

CheckingtheCoolingSystem...................................29

FillingtheFuelTank...............................................30

CheckingtheHydraulicFluidLevel...........................31

CheckingtheTirePressure......................................32

StartingandStoppingtheEngine..............................32

EngineSpeedSwitch...............................................32

CheckingtheInterlockSwitches...............................32

AdjustingtheLiftArmCounterbalance.....................33

AdjustingtheLiftArmTurnAroundPosition.............33

PushingorTowingtheMachine................................34

JackingPoints........................................................34

TieDowns............................................................34

OperatingCharacteristics........................................34

OperatingTips......................................................35

Maintenance.................................................................36

RecommendedMaintenanceSchedule(s)......................36

DailyMaintenanceChecklist....................................37

ServiceIntervalChart.............................................38

PremaintenanceProcedures........................................39

RemovingtheHood...............................................39

Lubrication...............................................................39

GreasingtheBearingsandBushings..........................39

EngineMaintenance..................................................41

ServicingtheAirCleaner.........................................41

ServicingtheEngineOilandFilter............................42

ServicingtheDieselParticulateFilter(DPF)...............42

ServicingtheDieselOxidationCatalyst

(DOC)..............................................................42

FuelSystemMaintenance...........................................43

FuelTank..............................................................43

FuelLinesandConnections.....................................43

ServicingtheWaterSeparator..................................43

ServicingtheFuelFilter...........................................43

FuelPickupTubeScreen.........................................44

ElectricalSystemMaintenance....................................44

ChargingandConnectingtheBattery........................44

BatteryCare...........................................................45

Fuses....................................................................46

DriveSystemMaintenance.........................................47

CheckingtheTorqueoftheWheelNuts.....................47

CheckingthePlanetaryGearDriveOil......................47

ChangingthePlanetaryGearDriveOil......................47

CheckingtheRearAxleLubricant.............................48

ChangingtheRearAxleLubricant.............................48

AdjustingtheTractionDriveforNeutral....................48

CheckingtheRearWheelToe-In..............................49

CoolingSystemMaintenance......................................50

ServicingtheEngineCoolingSystem........................50

BrakeMaintenance....................................................51

AdjustingtheServiceBrakes....................................51

BeltMaintenance......................................................51

ServicingtheAlternatorBelt....................................51

HydraulicSystemMaintenance....................................52

ChangingtheHydraulicFluid...................................52

ReplacingtheHydraulicFilters.................................52

CheckingtheHydraulicLinesandHoses....................52

CuttingUnitMaintenance...........................................53

BacklappingtheCuttingUnits..................................53

Storage........................................................................54

Engine..................................................................54

TractionUnit.........................................................54

3

Page 4

Safety

ThismachinemeetsorexceedsENISO5395:2013

(whenappropriatedecalsapplied),andANSIB71.4-2012

specicationsineffectatthetimeofproduction.

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheENISO5395:2013

andANSIB71.4-2012.

hair,looseclothing,orjewelrymaygettangledinmoving

parts.Donotoperatetheequipmentwhenbarefootor

wearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthattheoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andearprotection.Long

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

4

Page 5

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.T oguardagainst

overturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopesand

duringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheoperator'smanual.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsorover-speed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcylinders/reelsifnot

mowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-cylinder/multi-reelmachines,takecareas

rotatingonecylinder/reelcancauseothercylinders/reels

torotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.Wait

forallmovementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingthecylinders/reels.Weargloves

andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

5

Page 6

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•WhenoperatingamachinewithROPS(roll-over

protectionsystem)neverremovetheROPSandalways

usetheseatbelt.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Onanyhill,thereisthepossibilityoftippingorrolling

over,buttheriskincreasesastheslopeangleincreases.

Steephillsshouldbeavoided.

Cuttingunitsmustbeloweredwhengoingdownslopes

tomaintainsteeringcontrol

•Engagetractiondriveslowly,alwayskeepfootontraction

pedal,especiallywhentravelingdownhill.

Usereverseontractionpedalforbraking.

•Ifthemachinestallswhenclimbingaslope,donotturn

themachinearound.Alwaysbackslowly,straightdown

theslope.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifuidis

injectedintoskin.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsandreplacement

parts.Thewarrantymaybevoidedifusedwith

unapprovedattachments.

6

Page 7

SoundPowerLevel

VibrationLevel

Thisunithasaguaranteedsoundpowerlevelof101dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof83

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Hand-Arm

Measuredvibrationlevelforrighthand=0.3m/s

Measuredvibrationlevelforlefthand=0.3m/s

UncertaintyValue(K)=0.16m/s

2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBody

Measuredvibrationlevel=0.2m/s

UncertaintyValue(K)=0.1m/s

2

2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

2

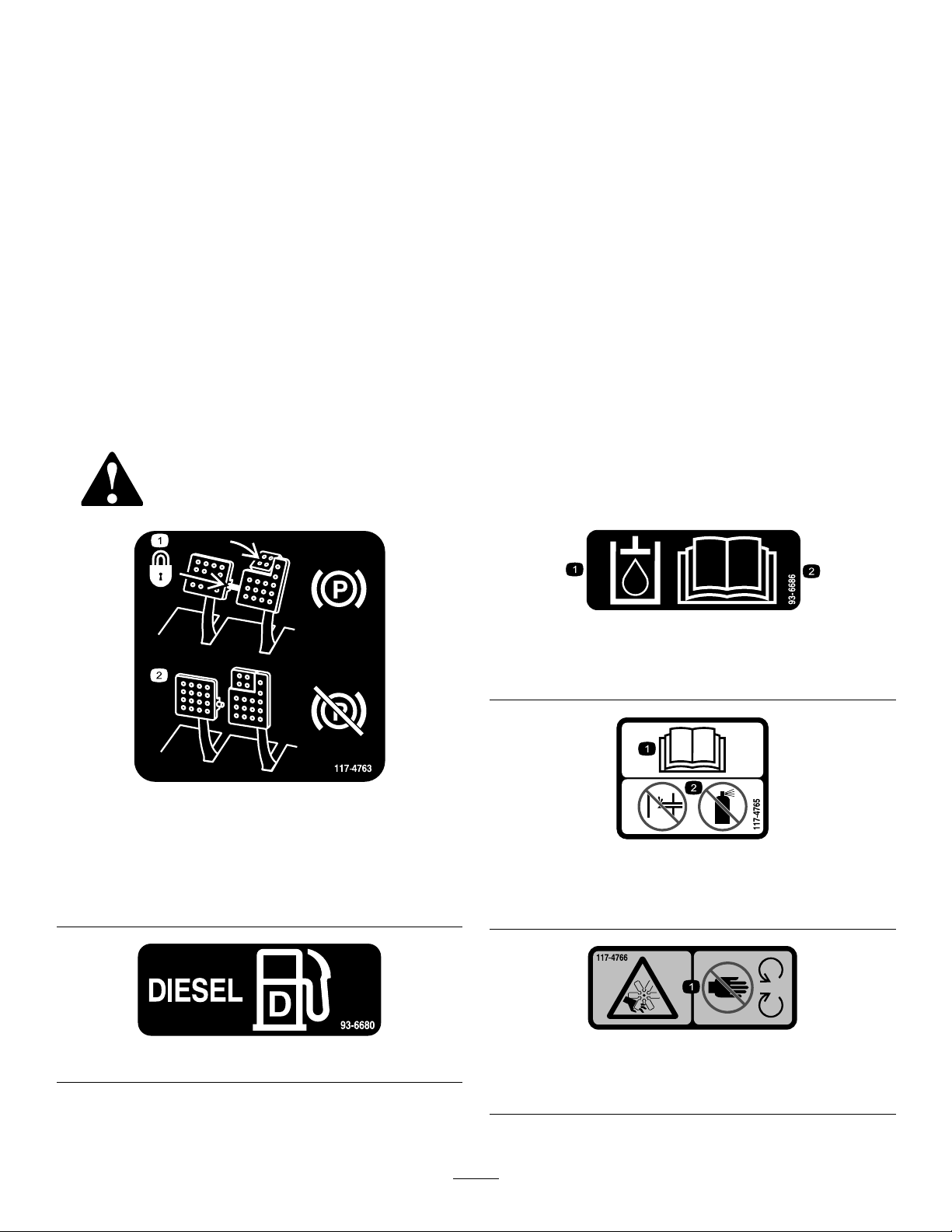

1.Toengagetheparking

brake,securethebrake

pedalswiththelockingpin,

presstheparkingbrake

pedalsandengagethetoe

pedal.

117-4763

93-6680

2.Todisengagetheparking

brake,disengagethe

lockingpinandreleasethe

pedals.

93-6686

1.Hydraulicoil

2.ReadtheOperator'sManual.

117-4765

1.ReadtheOperator'sManual.

2.Donotusestartingaids.

117-4766

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

7

Page 8

117–2718

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

1.Warning—wearhearingprotection.

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

98-4387

93-6688

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

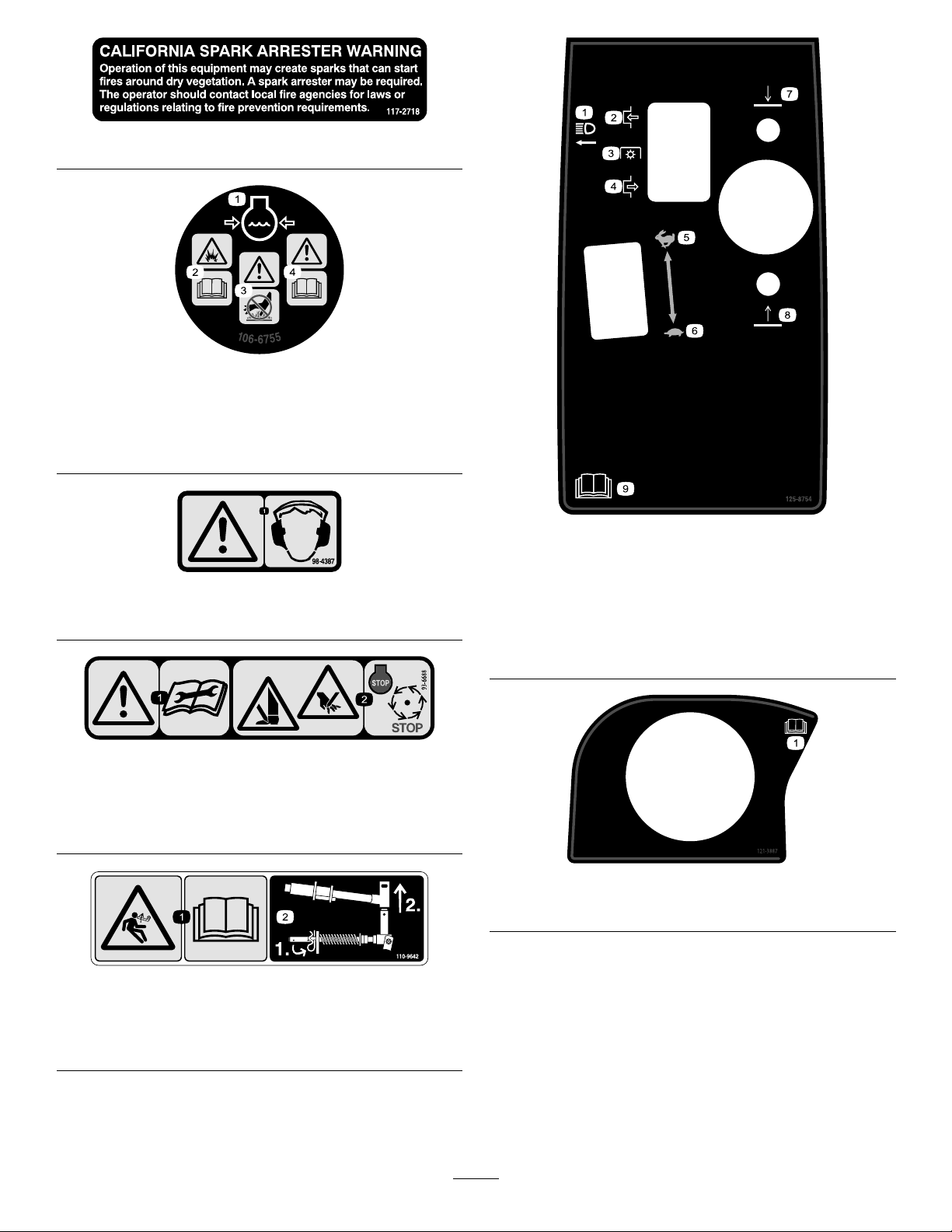

125–8754

1.Headlights

2.Engage7.Lowerthecuttingunits

3.Powertake-off(PTO)

4.Disengage

5.Fast

6.Slow

8.Raisethecuttingunits

9.ReadtheOperator’s

Manual.

110-9642

1.Storedenergyhazard—readtheOperator'sManual.

2.Movethecotterpintotheholeclosesttotherodbracket

andthenremovetheliftarmandpivotyoke.

121–3887

1.ReadtheOperator’sManual.

8

Page 9

121–3884

1.Engine—stop3.Engine—start

2.Engine—preheat

112-5019

93–6681

1.Cutting/dismembermenthazard—stayawayfrommoving

parts.

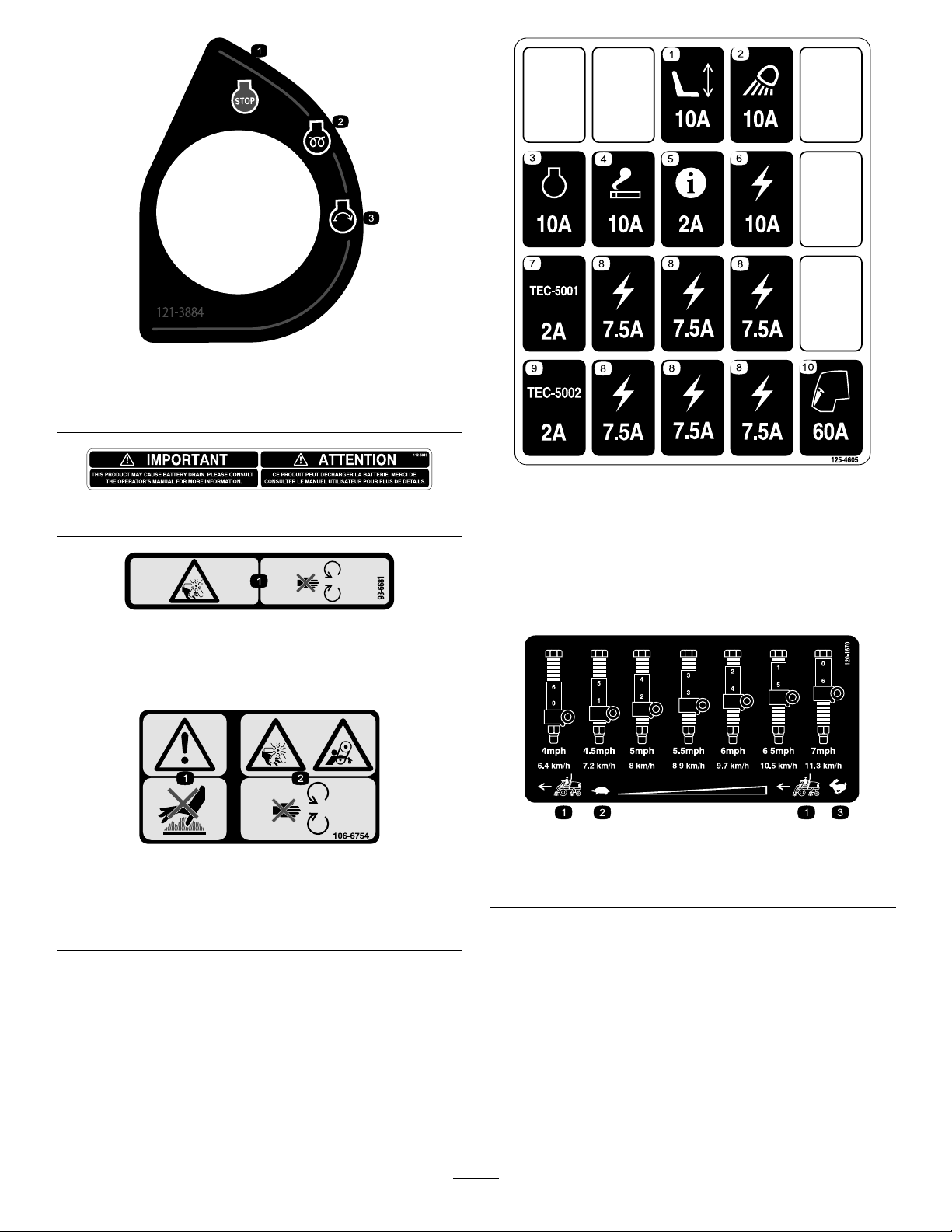

125–4605

1.Powerseat,10A6.Powersupplied,10A

2.Worklight,10A

3.Engine,10A8.Powersupplied,7.5A

4.Cigarettelighter,10A9.Controller,2A

5.Infocenter,2A

7.Controller,2A

10.Enginepreheat,60A

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

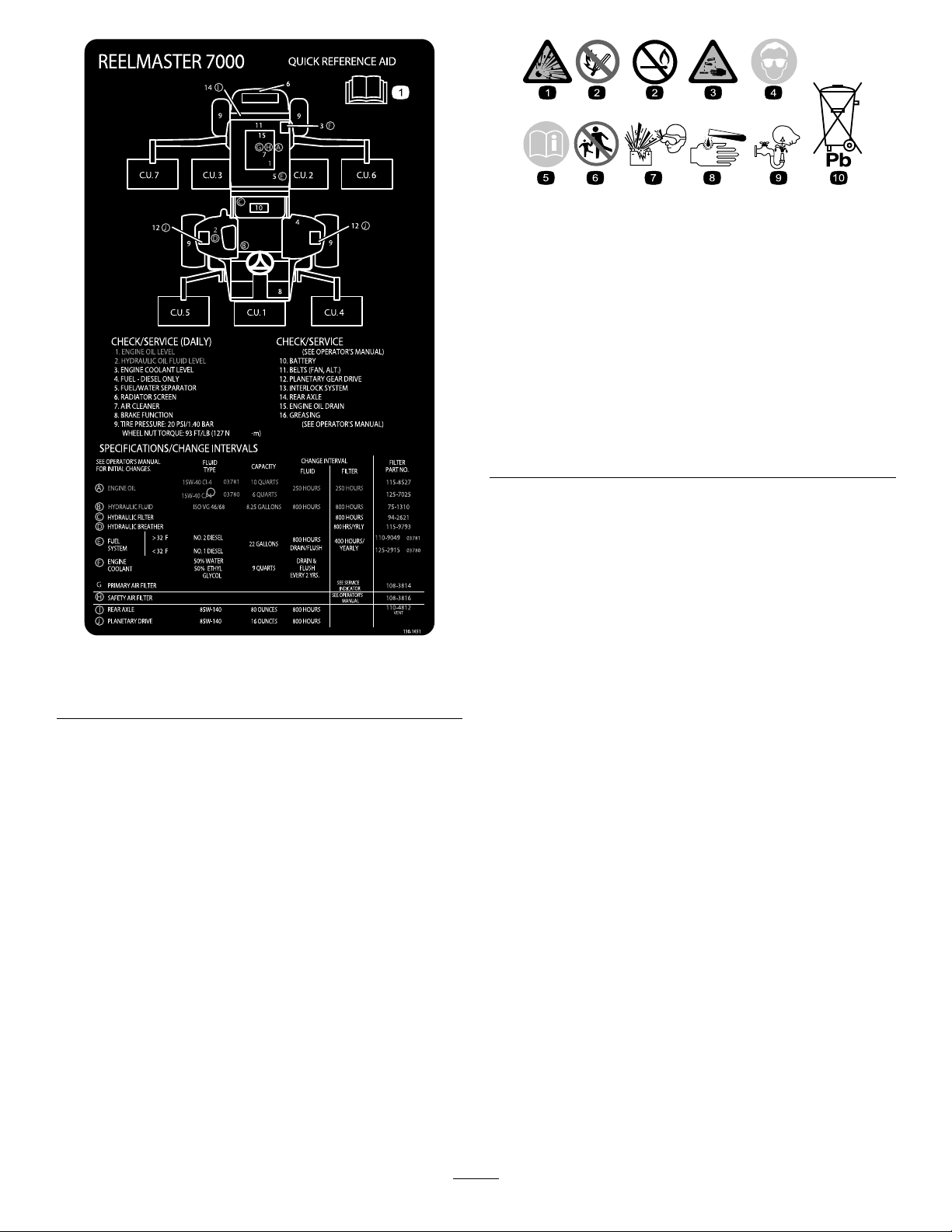

120-1670

1.Tractionunitspeed3.Fast

2.Slow

9

Page 10

BatterySymbols

Someorallofthesesymbolsareonyourbattery

130-1651

1.ReadtheOperator'sManualformoreinformationof

servicingthemachine.

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

10

Page 11

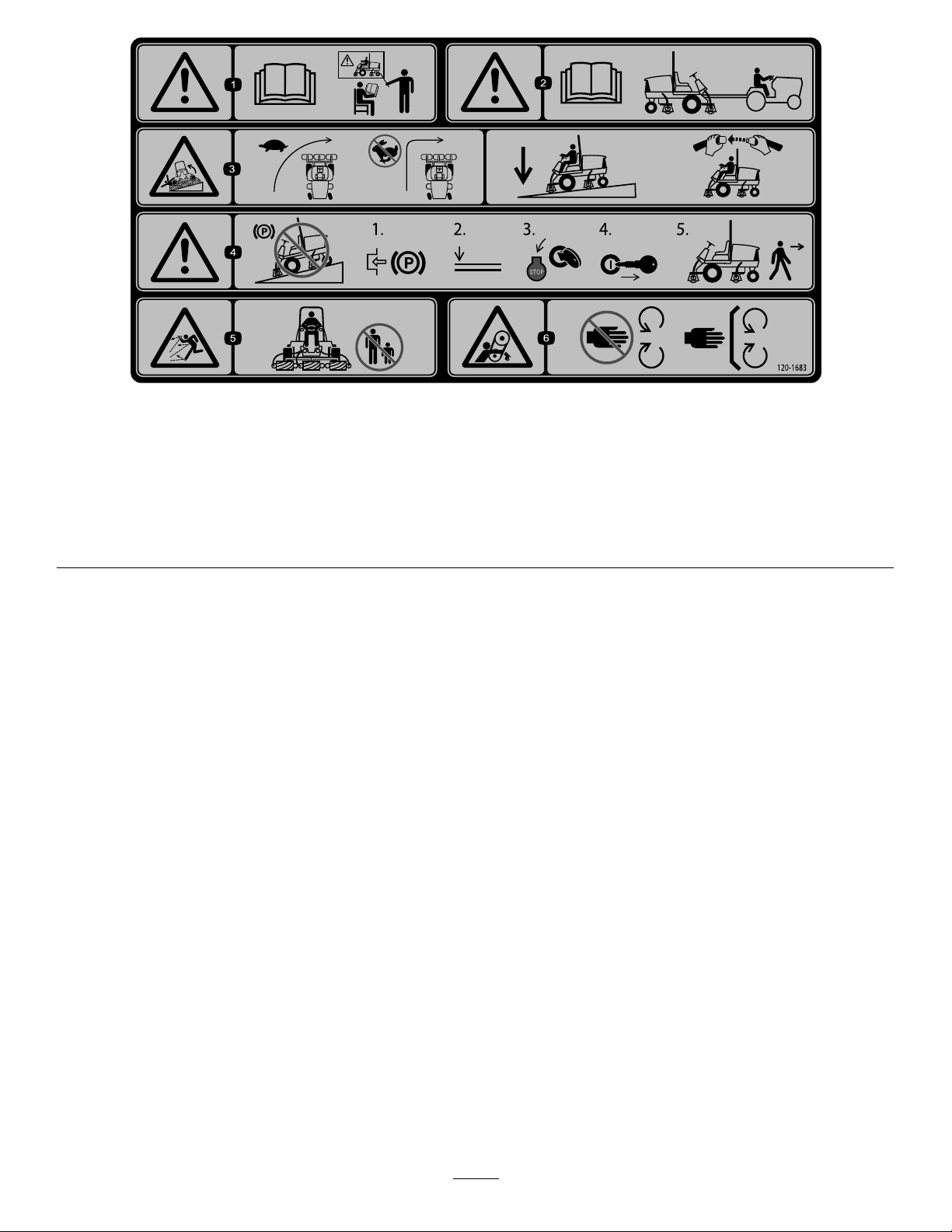

120-1683

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—slowmachinebeforeturning,donotturnat

highspeeds;lowerthecuttingunitwhendrivingdownslopes;

usearolloverprotectionsystemandweartheseatbelt

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

11

Page 12

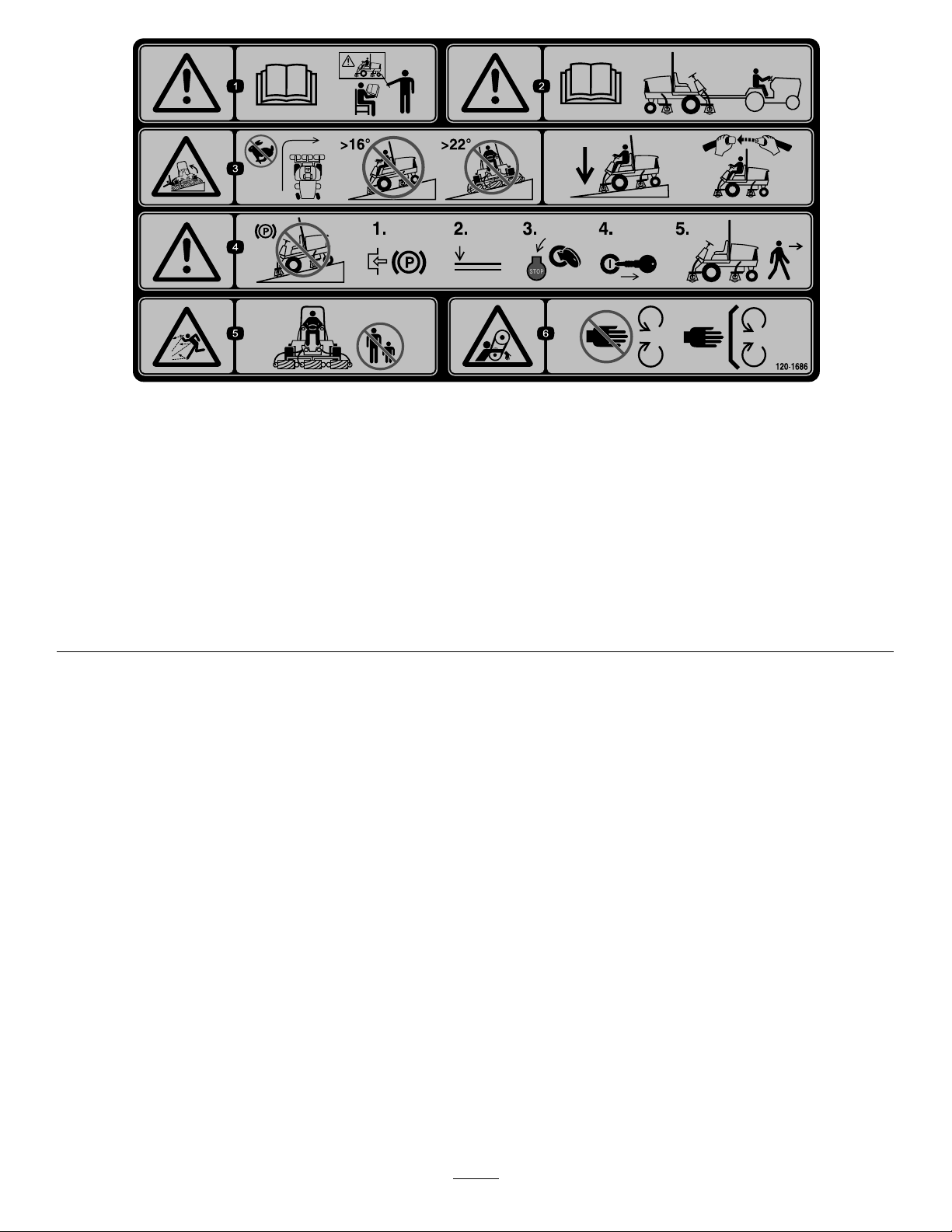

120-1686

Afxoverpartno.120–1683forCE*

*ThissafetydecalincludesaslopewarningrequiredonthemachinefrocompliancetotheEuropeanLawnMowerStandardENISO5395:2013.Theconservativemaximumslope

anglesindicatedforoperationofthismachineareprescribedbyandrequiredbythisstandard.

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—donotturnathighspeeds,donotupand

downslopesgreaterthan16degrees,donotmowacross

slopesgreaterthan22degrees;lowerthecuttingunitwhen

drivingdownslopes;usearolloverprotectionsystemand

weartheseatbelt

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

12

Page 13

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Nopartsrequired

Warningdecal1

Hoodlockbracket1

Rivet2

Screw,1/4x2inch

Flatwasher,1/4inch

Locknut,1/4inch

Fronthoseguide-R.H.1

Fronthoseguide-L.H.1

Nopartsrequired

Cuttingunitkickstand

Nopartsrequired

Nopartsrequired

Gaugebar

Qty.

Use

–

1

2

1

–

1

–

–

1

Adjustthesupportrollers

UsedonlyonmachinesrequiringCE

Compliance.

Usedonlyonmachinesrequiring

EuropeanCECompliance.

Installthecuttingunits

Adjusttheturfcompensationspring.

InstalltheCuttingUnitKickstand.

Greasethemachine.

Checktherearaxlelubricant,hydraulic

uid,andengineoillevels

Usethegaugebartoadjustthecutting

unit.

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

DeclarationofConformity

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Qty.

1

1

1

1

1

Readbeforeoperatingmachine

Readbeforeoperatingengine

Usetoreferencepartnumbers

Viewbeforeoperatingmachine

UseforCECompliance

Use

13

Page 14

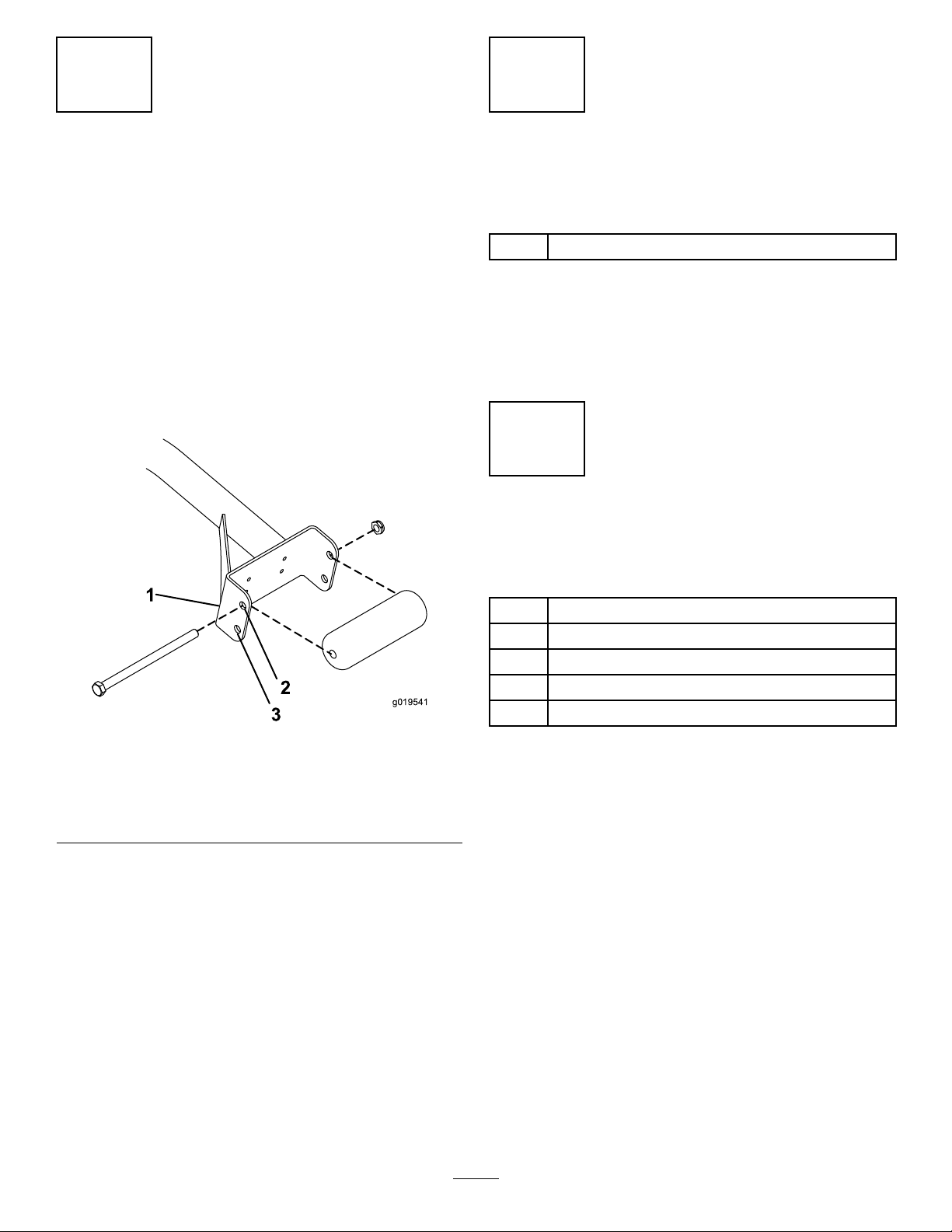

1

g019541

1

2

3

2

AdjustingtheSupportRollers

NoPartsRequired

Procedure

Dependingonwhatwidthcuttingunitsaretobeinstalledon

thetraction,adjustthesupportrollersasfollows:

•Ifusing27inchcuttingunits,therollersaretobeinstalled

intheuppermountingholesofsupportassembly

channels(Figure3).

•Ifusing32inchcuttingunits,therollersaretobe

installedinthelowermountingholesofsupportassembly

channels(Figure3).

ReplacingtheWarningDecal forCECompliance

Partsneededforthisprocedure:

1Warningdecal

Procedure

OnmachinesrequiringCECompliance,afxthewarning

decal,partno.120–1683overthewarningdecalpartno.

120–1686.

3

InstallingtheHoodLockfor CECompliance

Partsneededforthisprocedure:

Figure3

1.Supportassemblychannel3.Usethisholefor32inch

cuttingunits

2.Usethisholefor27inch

cuttingunits

1Hoodlockbracket

2Rivet

1

Screw,1/4x2inch

2

Flatwasher,1/4inch

1

Locknut,1/4inch

Procedure

1.Unhookthehoodlatchfromthehoodlatchbracket

(Figure4).

14

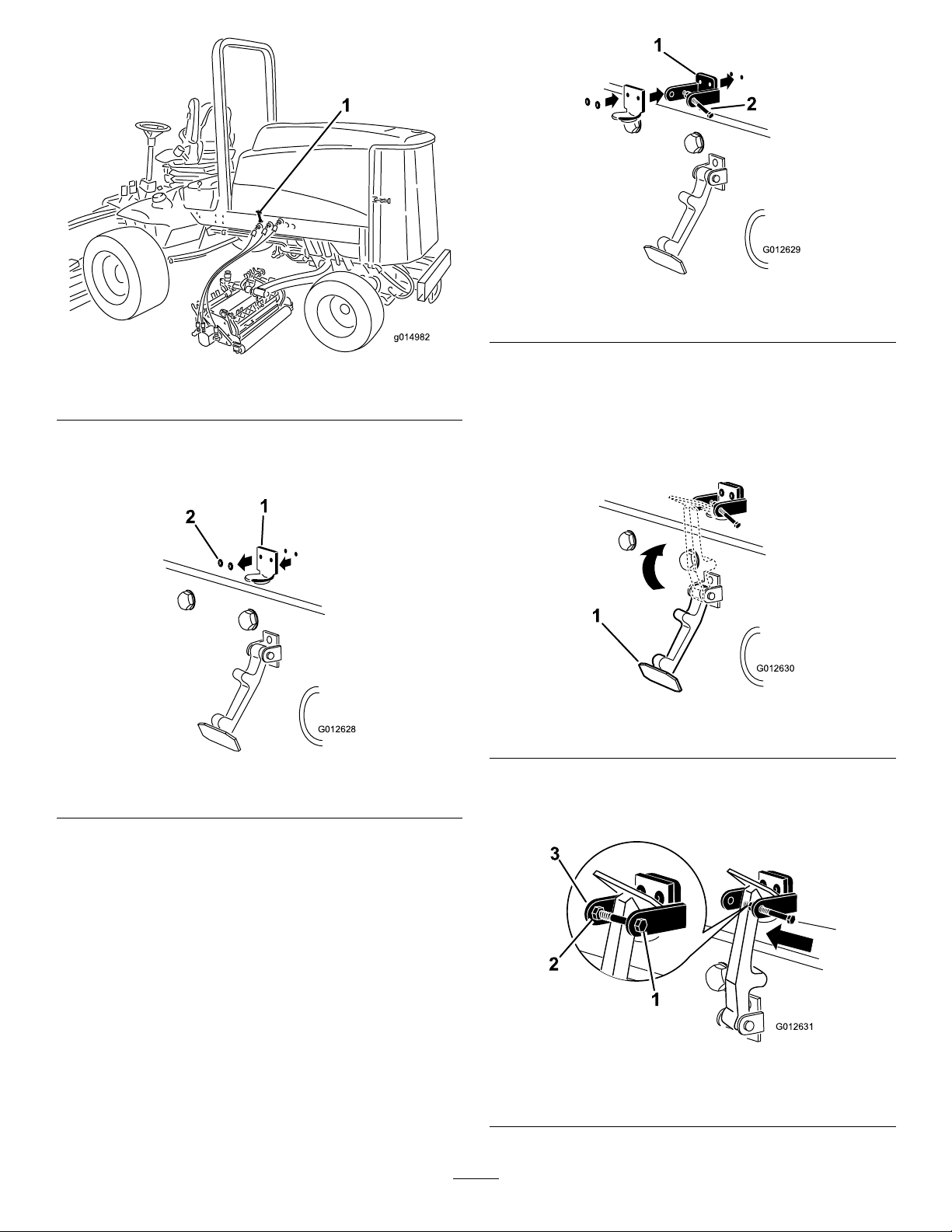

Page 15

G012628

1

2

G012629

1

2

Figure6

G012630

1

G012631

1

2

3

Figure4

1.Hoodlatch

2.Removethe(2)rivetssecuringthehoodlatchbracket

tothehood(Figure5).Removethehoodlatchbracket

fromthehood.

Figure5

1.Hoodlatchbracket2.Rivets

3.Whilealigningthemountingholes,positiontheCE

lockbracketandthehoodlatchbracketontothehood.

Thelockbracketmustbeagainstthehood(Figure5).

Donotremoveboltandnutassemblyfromthelock

bracketarm.

1.CElockbracket

2.Boltandnutassembly

4.Alignthewasherswiththeholesontheinsideofthe

hood.

5.Rivetthebracketsandthewasherstothehood(Figure

6).

6.Hookthelatchontothehoodlatchbracket(Figure7).

Figure7

1.Hoodlatch

7.Screwtheboltintotheotherarmofhoodlockbracket

tolockthelatchinposition(Figure8).Tightenbolt

securelybutdonottightennut.

1.Bolt

2.Nut

15

Figure8

3.Armofhoodlockbracket

Page 16

4

InstallingtheCuttingUnits

Partsneededforthisprocedure:

1Fronthoseguide-R.H.

1Fronthoseguide-L.H.

Procedure

1.Removethereelmotorsfromtheshippingbrackets.

2.Removetheshippingbracketsanddiscard.

3.Removethecuttingunitsfromthecartons.Assemble

andadjustasdescribedinthecuttingunitOperator's

Manual.

4.Makesurethecounterweight(Figure9)isinstalledto

theproperendofthecuttingunitasdescribedinthe

cuttingunitOperator'sManual.

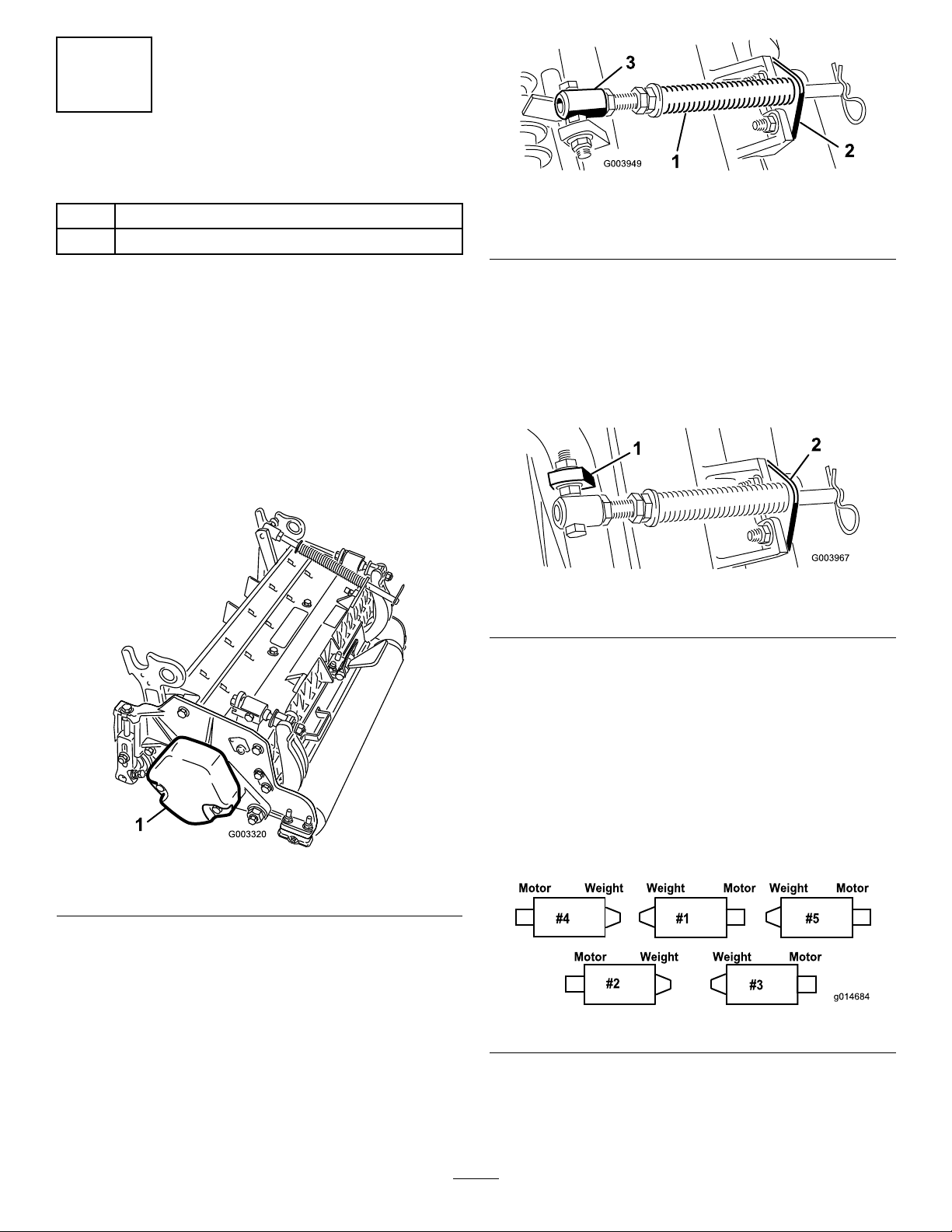

Figure10

1.Turfcompensationspring3.Springtube

2.Rodbracket

B.Removetheangenutsecuringthespringtube

bolttothecarrierframetab(Figure10)Remove

theassembly.

C.Mountthespringtubebolttotheoppositetabon

thecarrierframeandsecurewiththeangenut.

Theboltheadistobepositionedtotheouterside

ofthetabasshowninFigure11.

Figure11

1.Oppositecarrierframetab

2.Rodbracket

Figure9

1.Counterweight

5.Allthecuttingunitsareshippedwiththeturf

compensationspringmountedtotherightsideofthe

cuttingunit.Theturfcompensationspringmustbe

mountedtothesamesideofthecuttingunitasthe

reeldrivemotor.Repositiontheturfcompensation

asfollows:

A.Removethe2carriageboltsandnutssecuringthe

rodbrackettothecuttingunittabs(Figure10).

D.Mounttherodbrackettothecuttingunittabs

withthecarriageboltsandnuts(Figure11).Also,

onthecuttingunit,mountthelefthandhose

guidetothefrontofthecuttingunittabswhen

reinstallingtherodbracket(Figure13).

Important:Onthe#4(leftfront)and#5

(rightfront)cuttingunits,usetherodbracket

mountingnutstoinstallthehoseguidesto

thefrontofthecuttingunittabs.Thehose

guidesshouldleantowardthecentercutting

unit(Figure12throughFigure14).

Figure12

16

Page 17

Figure13

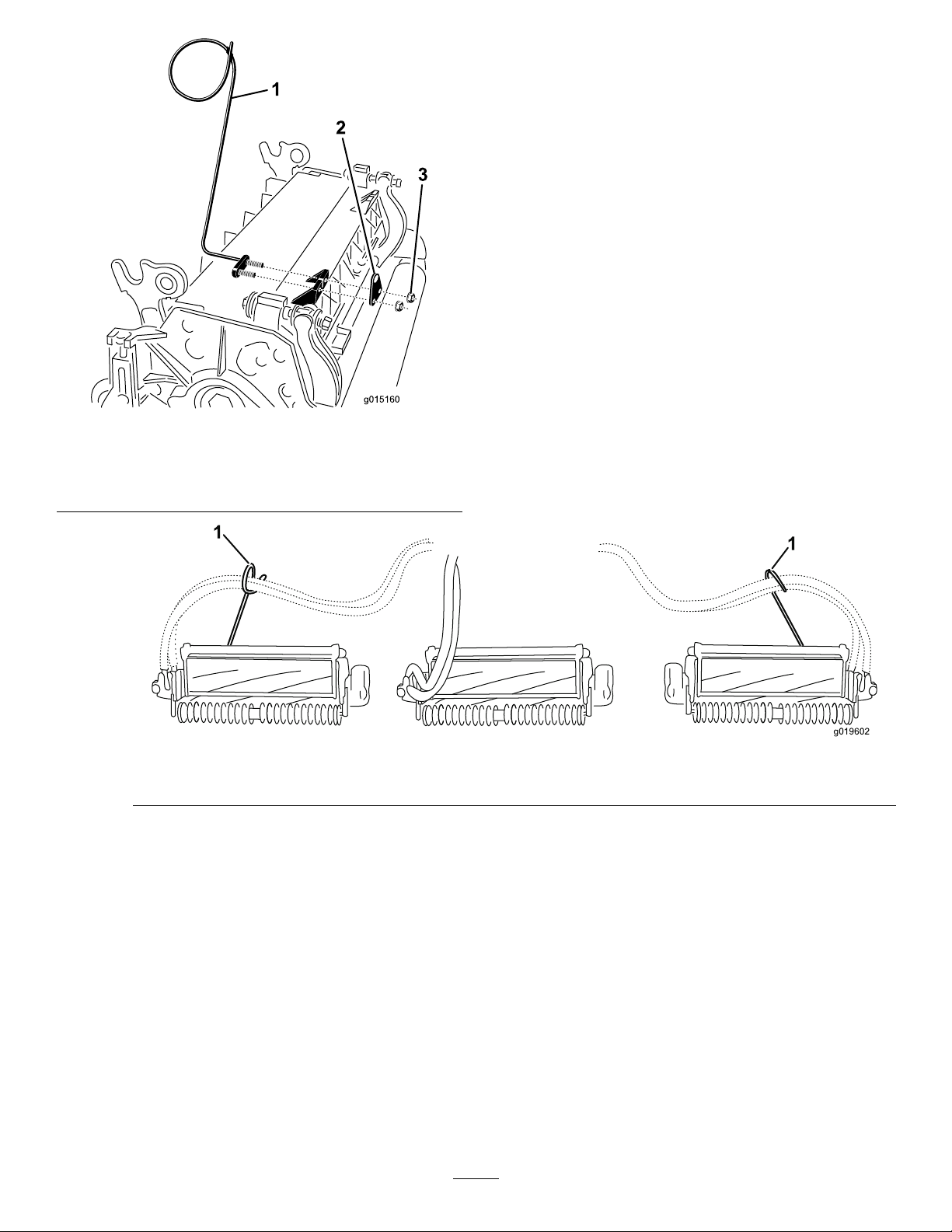

g019602

1

1

1.Hoseguide(Lefthand

shown)

2.Rodbracket

1.Hoseguides(eachmustleantowardthecentercuttingunit)

3.Nuts

Note:Wheninstallingorremovingthecutting

units,makesurethehairpincotterisinstalled

inthespringrodholenexttotherodbracket.

Otherwise,thehairpincottermustbeinstalledin

theholeintheendoftherod.

Figure14

6.Increasethesteeringontherearcuttingunitsby

removingthe(2)pivotspacers,hexsocketscrewsand

angelocknuts(Figure15)fromtherear(#2and#3)

cuttingunitcarrierframes(Figure12).

17

Page 18

1

2

3

4

G015978

Figure15

G015976

1

2

3

4

5

1

G015977

9.Forthefrontcuttingunits,slideacuttingunitunder

theliftarmwhileinsertingthecarrierframeshaftup

intotheliftarmpivotyoke(Figure16).Makesurethe

thrustwasherisinpositiononthecarrierframeshaft.

10.Securethecarrierframeshafttotheliftarmyokewith

theKlikpin(Figure16).

11.Tolock(x)thesteeringonthecuttingunits,secure

thepivotyoketothecarrierframewiththesnapper

pin(Figure17).

1.Hexsocketscrew

2.Pivotspacer4.Flangelocknut

3.Carrierframe

7.Loweralltheliftarmscompletely.

8.Coatthecarrierframeshaftwithcleangrease(Figure

16).

Figure17

1.Snapperpin

Note:Fixedsteeringisrecommendedwhen

cuttingsidehills.

12.Usethefollowingprocedureontherearcuttingunits

whentheheightofcutisabove3/4inch.

A.Removethelynchpinandwashersecuringthelift

armpivotshafttotheliftarmandslidethelift

armpivotshaftoutoftheliftarm(Figure18).

1.Liftarmpivotshaftlynchpinandwasher

Figure18

B.Inserttheliftarmyokeontothecarrierframe

Figure16

1.Liftarmpivotyoke4.Carrierframeshaft

2.Liftarm

3.Klikpin

5.Thrustwasher

13.Securetheliftarmchaintothechainbracketwiththe

shaft(Figure16).

C.Inserttheliftarmshaftintotheliftarmandsecure

itwiththewasherandlynchpin(Figure18).

snapperpin(Figure19).Usethenumberofchainlinks

describedinthecuttingunitOperator'sManual.

18

Page 19

Figure19

1.Liftarmchain3.Snapperpin

2.Chainbracket

14.Coatthesplineshaftofthereelmotorwithclean

grease.

15.OilthereelmotorO-ringandinstallitontothemotor

ange.

16.Installthemotorbyrotatingitclockwisesothatthe

motorangesclearthebolts(Figure20).Rotatethe

motorcounterclockwiseuntiltheangesencirclethe

boltsthentightenthebolts.

Important:Makesurethereelmotorhosesare

nottwisted,kinkedorintheriskofbeingpinched.

5

AdjustingtheTurf CompensationSpring

NoPartsRequired

Procedure

Theturfcompensationspring(Figure21)transfersweight

fromthefronttotherearroller.(Thishelpstoreduceawave

patternintheturf,alsoknownasmarcellingorbobbing.)

Important:Makespringadjustmentswiththecutting

unitmountedtothetractionunit,pointingstraight

aheadandloweredtotheshopoor.

1.Makesurethehairpincotterisinstalledintherearhole

inthespringrod(Figure21).

Note:Whenservicingthecuttingunit,movethe

hairpincottertothespringrodholenexttotheturf

compensationspring.

Figure20

1.Reeldrivemotor2.Mountingbolts

Figure21

1.Turfcompensationspring3.Springrod

2.Hairpincotter4.Hexnuts

2.Tightenthehexnutsonthefrontendofthespringrod

untilthecompressedlengthofthespringis6.25inches

(15.9cm)(Figure21).

Note:Whenoperatingonroughterraindecreasethe

springlengthby1/2inch.Groundfollowingwillbe

slightlydecreased.

Note:Theturfcompensationsettingwillneedtobe

resetiftheHOCsettingortheAggressivenessofCut

settingischanged.

19

Page 20

6

UsingtheCuttingUnit

Kickstand

Partsneededforthisprocedure:

1

Cuttingunitkickstand

Procedure

Wheneverthecuttingunithastobetippedtoexposethe

bedknife/reel,propuptherearofthecuttingunitwiththe

kickstandtomakesurethenutsonthebackendofthe

bedbaradjustingscrewsarenotrestingontheworksurface

(Figure22).

Figure23

1.Chainbracket3.Cuttingunitkickstand

2.Snapperpin

Figure22

1.Cuttingunitkickstand

Securethekickstandtothechainbracketwiththesnapper

pin(Figure23).

7

GreasingtheMachine

NoPartsRequired

Procedure

Beforethemachineisoperated,itmustbegreasedtoensure

properlubrication.RefertoLubricationsection.Failureto

properlygreasethemachinewillresultinprematurefailureof

criticalparts.

20

Page 21

8

CheckingFluidLevels

NoPartsRequired

Procedure

1.Checktherearaxlelubricantlevelbeforetheengineis

rststarted,refertoCheckingtheRearAxleLubricant

inDriveSystemMaintenance.

2.Checkthehydraulicuidlevelbeforetheengineisrst

started,refertoCheckingtheHydraulicFluidLevelin

Operation.

3.Checktheengineoillevelbeforeandaftertheengineis

rststarted,refertoCheckingtheEngineOilLevelin

Operation.

9

Figure24

1.Gaugebar4.Holesusedforsetting

GroomerHOG

2.Heightadjustingscrew5.Holenotused

3.Nut

UsingtheGaugeBar

Partsneededforthisprocedure:

1

Gaugebar

Procedure

Usethegaugebartoadjustthecuttingunit.Referto

theCuttingUnitOperator'sManualfortheadjustment

procedures(Figure24).

21

Page 22

ProductOverview

Controls

BrakePedals

Twofootpedals(Figure25)operateindividualwheelbrakes

forturningassistanceandtoaidinobtainingbettersidehill

traction.

PedalLockingLatch

Thepedallockinglatch(Figure25)connectsthepedals

togethertoengagetheparkingbrake.

ParkingBrakePedal

Toengagetheparkingbrake,(Figure25)connectthepedals

togetherwiththepedallockinglatch,pushdownontheright

brakepedalwhileengagingthetoepedal.Toreleasethe

parkingbrake,pressoneofthebrakepedalsuntiltheparking

brakelatchretracts.

MowSpeedLimiter

Whenthemowspeedlimiter(Figure26)isippedupitwill

controlthemowspeedandallowthecuttingunitstobe

engaged.Eachspaceradjuststhemowingspeedby½mile

perhour.Themorespacersyouhave,onthetopofthebolt

thesloweryouwillgo.Fortransport,ipbackthemowspeed

limiterandyouwillhavemaximumtransportspeed.

SpeedLimiterScrews

Adjustthescrew(s)(Figure26)tolimittheamountthe

tractionpedalcanbedepressedintheforwardorreverse

directiontolimitspeed.

Important:Thespeedlimiterscrewmuststopthe

tractionpedalbeforethepumpreachesfullstrokeor

damagetothepumpmayoccur.

Figure25

1.Brakepedal4.Tractionpedal

2.Pedallockinglatch5.Tiltsteeringpedal

3.Parkingbrakepedal

TractionPedal

Thetractionpedal(Figure25)controlsforwardandreverse

operation.Depressthetopofthepedaltomoveforwardand

thebottomtomovebackward.Groundspeeddependson

howfarthepedalisdepressed.Fornoload,maximumground

speed,fullydepressthepedalwhilethethrottleisinFast.

Tostop,reduceyourfootpressureonthetractionpedaland

allowittoreturntothecenterposition.

TiltSteeringPedal

Totiltthesteeringwheeltowardsyou,pressthefootpedal

(Figure25)down,andpullthesteeringtowertowardyouto

themostcomfortablepositionandthenreleasethepedal.

Figure26

1.Reversespeedlimiter

screw

2.Forwardspeedlimiter

screw

3.Spacers

4.Mowspeedlimiter

LowerMow/RaiseControlLever

Thislever(Figure27)raisesandlowersthecuttingunitsand

alsostartsandstopsthecutterheadswhenthecutterheads

areenabledinthemowmode.Thecutterheadscannotbe

loweredwhenthemow/transportleverisinthetransport

position.

KeySwitch

Thekeyswitch(Figure27)hasthreepositions:Off,

On/Preheat,andStart.

InfoCenter

TheInfoCenterLCDdisplayshowsinformationaboutyour

machinesuchastheoperatingstatus,variousdiagnosticsand

otherinformationaboutthemachine(Figure27).

PTOSwitch

ThePTOswitch(Figure27)hastwopositions:Out(start)

andIn(stop).PullthePTObuttonouttoengagethecutting

22

Page 23

unitblades.Pushinthebuttontodisengagethecuttingunit

1

2

3

4

5

6

G021208

blades.

Figure27

1.Lowermow/raisecontrol

lever

2.Keyswitch5.Enginespeedswitch

3.InfoCenter

4.PTOswitch

6.Headlightswitch

EngineSpeedSwitch

Theenginespeedswitch(Figure27)hastwomodesto

changetheenginespeed.Bymomentarilytappingtheswitch,

theenginespeedcanbeincreasedordecreasedin100rpm

increments.Byholdingtheswitchdowntheenginewill

automaticallymovetoHighorLowidle,dependingonwhich

endoftheswitchisdepressed.

HeadlightSwitch

Pivottheswitchdownwardtoturnontheheadlights(Figure

27).

PowerPoint

Thepowerpoint(Figure28)isusedtopoweroptional12

voltelectricalaccessories.

Figure28

1.Powerpoint2.Bagholder

BagHolder

Usethebagholder(Figure28)forstorage.

BacklapLevers

Usethebacklapleversforbacklappingthereels(Figure29).

Figure29

1.Frontbacklaplever2.Rearbacklaplever

23

Page 24

SeatAdjustments

1

g020650

2

3

4

TORO

UsingtheInfoCenterLCDDisplay

ForeandAftAdjustingLever

Pulloutonthelevertoslidetheseatforeoraft(Figure30).

SeatArmRestAdjustingKnob

Rotatetheknobtoadjusttheseatarmrestangle(Figure30).

SeatBackAdjustingLever

Movethelevertoadjusttheseatbackangle(Figure30).

Weightgauge

Indicateswhentheseatisadjustedtotheweightofthe

operator(Figure30).Heightadjustmentismadeby

positioningthesuspensionwithintherangeofthegreen

region.

TheInfoCenterLCDdisplayshowsinformationaboutyour

machinesuchastheoperatingstatus,variousdiagnostics

andotherinformationaboutthemachine(Figure31)There

isasplashscreenandmaininformationscreenofthe

InfoCenter.Youcanswitchbetweenthesplashscreenand

maininformationscreen,atanytime,bypressinganyof

theInfoCenterbuttonsandthenselectingtheappropriate

directionalarrow .

Figure31

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•LeftButton,MenuAccess/BackButton—pressthis

buttontoaccesstheInfoCentermenus.Youcanuseitto

backoutofanymenuyouarecurrentlyusing.

•MiddleButton—usethisbuttontoscrolldownmenus.

•RightButton—usethisbuttontoopenamenuwherea

rightarrowindicatesadditionalcontent.

Figure30

1.Weightgauge

2.Weightadjustinglever5.Armrestadjustingknob

3.ForeandAftadjusting

lever

WeightAdjustingLever

4.Seatbackadjustinglever

Adjustforoperatorweight(Figure30).Pulluponthelever

toincreasetheairpressureandpushdowntodecreasetheair

pressure.Theproperadjustmentisattainedwhentheweight

gaugeisinthegreenregion.

•ManualFanReversal—activatedbypressingtheleftand

rightbuttonssimultaneously.

•Beeper—activatedwhenloweringthedecksorfor

advisoriesandfaults.

Note:Thepurposeofeachbuttonmaychange

dependingonwhatisrequiredatthetime.Eachbutton

willbelabeledwithanicondisplayingitscurrentfunction.

24

Page 25

InfoCenterIconDescription

InfoCenterIconDescription(cont'd.)

SERVICEDUE

Indicateswhenscheduledservice

shouldbeperformed

EngineRPM/status—indicatesthe

engineRPM

Infoicon

Fast

Slow

FanReversal—indicateswhenthe

fanisreversed

Stationaryregenerationrequired

Airintakeheaterisactive

Stoporshutdown

Engine

Keyswitch

Indicateswhenthecuttingunitsare

beinglowered

Indicateswhenthecuttingunitsare

beingraised

PINpasscode

HydraulicOilT emperature-indicates

thehydraulicoiltemperature

CANbus

InfoCenter

Badorfailed

Raisecuttingunits

Lowercuttingunits

Operatormustsitinseat

ParkingBrakeIndicator—indicates

whentheparkingbrakeisOn

IdentiestherangeasHigh

Neutral

IdentiestherangeasLow

CoolantTemperature-indicatesthe

enginecoolanttemperatureineither

°Cor°F

Temperature(hot)

Deniedornotallowed

Bulb

OutputofTECcontrollerorcontrol

wireinharness

High:overallowedrange

Low:underallowedrange

Outofrange

/

Switch

Operatormustreleaseswitch

Operatorshouldchangetoindicated

state

Symbolsareoften

combinedtoform

sentences.Some

examplesareshown

below

Operatorshouldputmachinein

neutral

PTOisengaged

EngineStart

Enginestartdenied

Engineshutdown

Enginecoolanttoohot

25

Page 26

InfoCenterIconDescription(cont'd.)

Hydraulicoiltoohot

DPFashaccumulationnotication.

RefertoServicingtheDiesel

ParticulateFilter(DPF)inthe

maintenancesectionfordetails.

Sitdownorsetparkingbrake

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthemenuaccess

buttonwhileatthemainscreen.Thiswillbringyoutothe

mainmenu.Refertothefollowingtablesforasynopsisof

theoptionsavailablefromthemenus:

MainMenu

MenuItemDescription

FaultsTheFaultsmenucontains

alistoftherecentmachine

faults.RefertotheService

ManualoryourAuthorized

ToroDistributorformore

informationontheFaults

menuandtheinformation

containedthere.

ServiceTheServicemenucontains

informationonthemachine

suchashoursofusecounters

andothersimilarnumbers.

DiagnosticsTheDiagnosticsmenu

displaysthestateofeach

machineswitch,sensorand

controloutput.Y oucanuse

thistotroubleshootcertain

issuesasitwillquicklytellyou

whichmachinecontrolsareon

andwhichareoff.

SettingsTheSettingsmenuallows

youtocustomizeandmodify

congurationvariablesonthe

InfoCenterdisplay.

AboutTheAboutmenuliststhe

modelnumber,serialnumber,

andsoftwareversionofyour

machine.

Service

MenuItemDescription

Hours

Counts

Diagnostics

MenuItemDescription

CuttingUnitsIndicatestheinputs,qualiers

Hi/LowRangeIndicatestheinputs,qualiers

PTOIndicatestheinputs,qualiers

EngineRun

Backlap

Settings

MenuItemDescription

Units

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

FrontBacklapReelSpeedControlsthespeedofthefront

RearBacklapReelSpeedControlsthespeedoftherear

ProtectedMenusAllowsthe

AutoIdle

BladeCountControlsthenumberofblades

MowSpeedControlsthegroundspeedfor

Heightofcut(HOC)Controlstheheightofcut

Liststhetotalnumberofhours

thatthemachine,engineand

PTOhavebeenon,aswell

asthenumberofhoursthe

machinehasbeentransported

andservicedue.

Listsnumerouscountsthe

machinehasexperienced.

andoutputsforraisingand

loweringthecuttingunits.

andoutputsfordrivingin

transportmode.

andoutputsforenablingthe

PTOcircuit.

Indicatestheinputs,qualiers

andoutputsforstartingthe

engine.

Indicatestheinputs,qualiers

andoutputsforoperatingthe

backlapfunction.

Controlstheunitsusedonthe

InfoCenter.Themenuchoices

areEnglishorMetric

Controlsthelanguageused

ontheInfoCenter*.

LCDdisplay.

LCDdisplay.

reelsinbacklapmode.

reelsinbacklapmode.

superintendant/mechanic

toaccessprotectedmenusby

inputtingapasscode.

Controlstheamountoftime

allowedbeforereturningthe

enginetolowidlewhenthe

machineisstationary.

onthereelforreelspeed.

determiningthereelspeed.

(HOC)fordeterminingthereel

speed.

26

Page 27

FReelRPMDisplaysthecalculatedreel

RReelRPMDisplaysthecalculatedreel

speedpositionforthefront

reels.Thereelscanalsobe

manuallyadjusted.

speedpositionfortherear

reels.Thereelscanalsobe

manuallyadjusted.

*Only"operator-faced"textistranslated.Faults,Service,and

Diagnosticsscreensare"service-faced".Titleswillbeinthe

selectedlanguage,butmenuitemsareinEnglish.

About

MenuItemDescription

Model

SNListstheserialnumberofthe

MachineControllerRevisionListsthesoftwarerevisionof

InfoCenterRevisionListsthesoftwarerevisionof

CANBus

Liststhemodelnumberofthe

machine.

machine.

themastercontroller .

theInfoCenter.

Liststhemachine

communicationbusstatus.

TheabilitytoviewandchangethesettingsintheProtected

Menucanbechanged.OncetheProtectedMenuhasbeen

accessed,scrolldowntoProtectSettings.Usingtheright

button,changingProtectSettingstoOFFwillallowthe

abilitytoviewandchangethesettingsintheProtectedMenu

withoutenteringthepasscode.ChangingProtectSettingsto

ONwillhidetheprotectedoptionsandwillrequireenteringa

passcodetochangethesettingintheProtectedMenu.After

thepasscodehasbeenset,thekeyswitchmustbeturnedoff

andbackontoenableandsavethisfeature.

Note:Ifthepasscodehasbeenforgottenormisplaced,

pleasecontactyourdistributorforassistance.

ToSettheAutoIdle

•IntheSettingsMenu,scrolldowntoAutoIdle.

•Presstherightbuttontochangetheautoidletime

betweenOFF,8S,10S,15S,20S,&30S.

ToSettheBladeCount

•IntheSettingsMenu,scrolldowntoBladeCount

•Presstherightbuttontochangethebladecountbetween

5,8or11bladereels.

ProtectedMenus

Thereare8operatingcongurationsettingsthatareadjustable

withintheSettingsMenuoftheInfoCenter:autoidletime

delay,BladeCount,MowSpeed,HeightofCut(HOC),F

ReelRPMandRReelRPM.Thesesettingscanbelocked

byusingtheProtectedMenu.

Note:Atthetimeofdelivery,theinitialpasswordcodeis

programmedbyyourdistributor.

AccessingtheProtectedMenuSettings

ToaccesstheProtectedMenuSettings

•FromtheMainMenu,scrolldowntotheSettingsMenu

andpresstherightbutton.

•IntheSettingsMenu,scrolldowntotheProtectedMenu

andpresstherightbutton.

•Toenterthepasscode,usethecenterbuttontosetthe

rstdigitthenpresstherightbuttontomoveontothe

nextdigit.

•Usethecenterbuttontosettheseconddigitthenpress

therightbuttontomoveontothenextdigit.

•Usethecenterbuttontosetthethirddigitthenpressthe

rightbuttontomoveontothenextdigit.

•Usethecenterbuttontosetthefourthdigitthenpress

therightbutton.

•Pressthemiddlebuttontoenterthecode.

•Ifthecodehasbeenacceptedandtheprotectedmenuhas

been“Unlocked”,“PIN”willbedisplayedintheupper

rightcornerofthedisplayscreen.

ToSettheMowSpeed

•IntheSettingsMenu,scrolldowntoMowSpeed.

•Presstherightbuttontoselectmowspeed.

•Usethecenterandrightbuttontoselecttheappropriate

mowspeedsetonthemechanicalmowspeedlimiteron

thetractionpedal.

•Presstheleftbuttontoexitmowspeedandsavethe

setting.

ToSettheHeightofCut(HOC)

•IntheSettingsMenu,scrolldowntoHOC.

•PresstherightbuttontoselectHOC.

•Usethecenterandrightbuttontoselecttheappropriate

HOCsetting.(Iftheexactsettingisnotdisplayed,select

thenearestHOCsettingfromthelistdisplayed).

•PresstheleftbuttontoexitHOCandsavethesetting.

27

Page 28

ToSettheFrontandRearReelSpeeds

Specications

Althoughthefrontandrearreelspeedsarecalculatedby

inputtingthenumberofblades,mowspeedandHOCinto

theInfoCenter,thesettingcanbemanuallychangedto

accommodatefordifferentmowingconditions.

•TochangetheReelSpeedSettings,scrolldowntotheF

ReelRPM,RReelRPMorboth.

•Presstherightbuttontochangethereelspeedvalue.As

thespeedsettingischanged,thedisplaywillcontinueto

showthecalculatedreelspeedbasedonbladecount,

mowspeedandHOCwhichwaspreviouslyentered,but

thenewvaluewillalsobedisplayed.

StationaryRegeneration

IftheStationaryRegenerationiconappearsontheInfoCenter,

refertotheServiceManualorcontactyourToroDistributor

forthemaintenanceprocedure.

DPFAshLevel

TheDPFashlevelmaybecheckedbyenteringthePINas

describedinAccessingtheProtectedMenuSettingsand

navigatingtotheservicesection.

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

TractionUnitSpecications

Widthofcut,27inchcutting

units

Widthofcut,32inchcutting

units

Overallwidth,27inchcutting

unitsdown

Overallwidth,32inchcutting

unitsdown

Overallwidth,cuttingunitsup

(transport)

Overalllength370cm(145.8inches)

HeightwithROPS220cm(87inches)

TrackWidth,front229cm(90inches)

TrackWidth,rear

Wheelbase

NetWeight(withnocutting

unitsandnouids)

307cm(121inches)

320cm(126inches)

345cm(136inches)

358cm(141inches)

239cm(94inches)

141cm(55.5inches)

171cm(67-1/2inches)

1574kg(3470lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

28

Page 29

Operation

3.Removethedipstick,wipeitclean,installthedipstick

intothetube,andpullitoutagain.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoany

maintenance.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Thecrankcasecapacityisapproximately5.7liters(6quarts)

withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CJ-4orhigher.

•Preferredoil:SAE15W -40(above0°F)

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

Important:UsingnonCJ-4orhigheroilwillcause

DPFplugginganddamagetheengine.

Theoillevelshouldbeinthesaferange(Figure32).

Figure32

1.Dipstick

4.Iftheoilisbelowthesaferange,removethellcap

(Figure32)andaddoiluntilthelevelreachestheFULL

mark.Donotoverll.

Note:Whenusingdifferentoil,drainalloldoilfrom

thecrankcasebeforeaddingnewoil.

5.Installtheoilllcapanddipstick.

6.Closetheenginecoverandsecureitwiththelatches.

2.Oilllcap

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Checklevelofcoolantatthebeginningofeachday.Capacity

ofsystemis12.3liters(13quarts).

1.Carefullyremovetheradiatorcap.

CAUTION

Note:ToroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity .Seethe

partscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifit

hasalreadybeenrun,allowtheoiltodrainbackdownto

thesumpforatleast10minutesbeforechecking.Ifthe

oillevelisatorbelowthe‘add’markonthedipstick,add

oiltobringtheoilleveltothe‘full’mark.Donotoverll.

Iftheoillevelisbetweenthe‘full’and‘add’marks,nooil

additionisrequired.

1.Parkthemachineonalevelsurface.

2.Unlocktheenginecoverlatchesandopentheengine

cover.

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeandcause

burns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

29

Page 30

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofupto

B7(7%biodiesel,93%petrodiesel).Thepetrodieselportion

mustbeultralowsulfur.Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

Figure33

1.Expansiontank

2.Checkthecoolantlevelintheradiator.Theradiator

shouldbelledtothetopofthellerneckandthe

expansiontanklledtotheFULLmark(Figure33).

3.Ifthecoolantislow ,adda50/50mixtureofwaterand

ethyleneglycolantifreeze.Donotusewateronlyor

alcohol/methanolbasecoolants.

4.Installtheradiatorcapandexpansiontankcap.

FillingtheFuelTank

Fueltankcapacity:83liters(22gallons).

Useonlyclean,freshdieselfuelwithultralow(<15

ppm)sulfurcontentmeetingASTMD975orEN590

specications.Theminimumcetaneratingshouldbe40.

Purchasefuelinquantitiesthatcanbeusedwithin180days

toensurefuelfreshness.

Important:Useofnon-ultralowsulfurfuelwillcause

damagetotheengineemissionsystem.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishmoreinformation

onbiodiesel.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Useofwintergrade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

fuellterplugging.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatemachinewithoutentireexhaust

systeminplaceandinproperworkingcondition.

30

Page 31

DANGER

CheckingtheHydraulicFluid

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafueldispensernozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundfueltankcap.

3.Removecapfromthefueltank(Figure34).

Level

ServiceInterval:Beforeeachuseordaily

Themachinesreservoirislledatthefactorywith

approximately28.4liters(7.5U.S.gallons)ofhighquality

hydraulicuid.Checkthelevelofthehydraulicuid

beforetheengineisrststartedanddailythereafter.The

recommendedreplacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein

5gallonpailsor55gallondrums.SeepartscatalogorToro

distributorforpartnumbers.)

Alternateuids:IftheT orouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.W edonot

recommendtheuseofsyntheticuid.Consultwithyour

lubricantdistributortoidentifyasatisfactoryproductNote:

Torowillnotassumeresponsibilityfordamagecausedby

impropersubstitutions,souseonlyproductsfromreputable

manufacturerswhowillstandbehindtheirrecommendation.

HighViscosityIndex/LowPourPointAnti-wear

HydraulicFluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

Figure34

1.Fueltankcap

4.Fillthetankuntilthelevelistothebottomoftheller

neckwithdieselfuel.

5.Installfueltankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.This

willminimizepossiblebuildupofcondensationinside

thefueltank.

PremiumBiodegradableHydraulicFluid-MobilEAL

EnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyT oro.This

uidiscompatiblewiththeelastomersusedinToro

hydraulicsystemsandissuitableforawide-range

oftemperatureconditions.Thisuidiscompatible

withconventionalmineraloils,butformaximum

biodegradabilityandperformancethehydraulicsystem

shouldbethoroughlyushedofconventionaluid.The

oilisavailablein19liter(5gallon)containersor55gallon

drumsfromyourMobilDistributor.

Note:Manyhydraulicuidsarealmostcolorless,makingit

difculttospotleaks.Areddyeadditiveforthehydraulic

systemoilisavailablein20mlm(2/3ounce)bottles.One

bottleissufcientfor15-221iters(4-6gallons)ofhydraulic

oil.Orderpartno.44-2500fromyourauthorizedToro

distributor.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andremovethekey.

2.Cleantheareaaroundthellerneckandcapofthe

hydraulictank(Figure35).Removethecapfromthe

llerneck.

31

Page 32

g020704

2.Movetheenginespeedswitchtothelowidleposition.

3.TurntheignitionkeytotheRunposition.Theglow

indicatorwilllight.

4.Whentheglowindicatordims,turntheignitionkeyto

theStartposition.Releasethekeyimmediatelywhen

theenginestartsandallowittoreturntotheRun

position.Adjusttheenginespeed.

Important:Donotrunthestartermotormore

than15secondsatatimeorprematurestarter

failuremayresult.Iftheenginefailstostartafter15

seconds,turnthekeytotheOffposition,recheck

thecontrolsandprocedures,wait15additional

seconds,andrepeatthestartingprocedure.

Whenthetemperatureislessthan-7°C(20°F),the

startermotorcanberunfor30secondsonthen60

secondsofffor2attempts.

Figure35

1.Hydraulictankcap

3.Removethedipstickfromthellerneckandwipeit

withacleanrag.Insertthedipstickintothellerneck;

thenremoveitandchecktheuidlevel.Theuidlevel

shouldbebetweenthetwomarksonthedipstick.

4.Ifthelevelislow ,addtheappropriateuidtoraisethe

leveltotheuppermark.

5.Installthedipstickandcapontothellerneck.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Thecorrectair

pressureinthetiresis83-103kPa(12–15psi).Checkthe

tirepressuredaily.

Important:Maintaintherecommendedpressureinall

tirestoensureagoodquality-of-cutandpropermachine

performance.Donotunder-inate.

CAUTION

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,

looseparts,andothermalfunctions.

StoppingtheEngine

Important:Allowenginetoidlefor5minutesbefore

shuttingitoffafterafullloadoperation.Thisallowsthe

turbochargertocooldownbeforeshuttingtheengine

off.Failuretodosomayleadtoturbo-chargertrouble.

Note:Lowercuttingunitstothegroundwhenevermachine

isparked.Thisrelievesthehydraulicloadfromthesystem,

preventswearonsystempartsandalsopreventsaccidental

loweringofthecuttingunits.

1.Returntheenginespeedtolowidle.

2.MovethePTOswitchtotheOffposition.

3.Settheparkingbrake.

4.RotatetheignitionkeytoOff.

5.Removethekeyfromtheswitchtopreventaccidental

starting.

StartingandStoppingthe Engine

StartingtheEngine

Important:Thefuelsystemmustbebledifanyofthe

followingsituationshaveoccurred:

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuelsystem

components.

1.Removeyourfootfromthetractionpedalandensure

thatitisinneutral.Ensurethattheparkingbrakeisset.

EngineSpeedSwitch

Theenginespeedswitchhastwomodestochangetheengine

speed.Bymomentarilytappingtheswitch,theenginespeed

canbeincreasedordecreasedin100rpmincrements.By

holdingtheswitchdowntheenginewillautomaticallymove

toHighorLowidle,dependingonwhichoftheswitchis

depressed.

CheckingtheInterlock Switches

ServiceInterval:Beforeeachuseordaily

32

Page 33

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Themachinehasinterlockswitchesintheelectricalsystem.

Theseswitchesaredesignedtostoptheenginewhenoperator

getsoffoftheseatwhenthetractionpedalisdepressed.

However,theoperatormaygetoffoftheseatwhiletheengine

isrunningandthetractionpedalisinneutral.Althoughthe

enginewillcontinuetorunifthePTOswitchisdisengaged

andthetractionpedalisreleased,itisstronglyrecommended

thattheenginebestoppedbeforerisingfromtheseat.

Tochecktheoperationoftheinterlockswitches,perform

thefollowingprocedure:

1.Drivethemachineslowlytoalarge,relativelyopen

area.Lowerthecuttingunit,stoptheengine,andapply

theparkingbrake.

2.Sitontheseatanddepressthetractionpedal.Tryto

starttheengine.Theengineshouldnotcrank.Ifthe

enginecranks,thereisamalfunctionintheinterlock

systemthatshouldbecorrectedbeforebeginning

operation.

3.Sitontheseatandstarttheengine.Risefromtheseat

andmovethePTOswitchtoOn.ThePTOshould

notengage.IfthePTOengages,thereisamalfunction

intheinterlocksystemthatshouldbecorrectedbefore

beginningoperation.

4.Sitontheseat,engagetheparkingbrakeandstartthe

engine.Movethetractionpedaloutoftheneutral

position.Theengineshouldkill.Iftheenginedoesnot

kill,thereisamalfunctionintheinterlocksystemthat

shouldbecorrectedbeforebeginningoperation.

AdjustingtheLiftArm Counterbalance

Youcanadjustthecounterbalanceontherearcuttingunit

liftarmstocompensatefordifferentturfconditionsandto

maintainauniformheight-of-cutintheroughconditionsor

inareasofthatchbuildup.

2.Insertatubeorsimilarobjectontothelongspring

endtorelievethespringtensionduringtheadjustment

(Figure36).

CAUTION

Thespringsareundertension.

Usecautionwhenadjustingthem.

3.Whilerelievingthespringtension,removethebolt

andlocknutsecuringthespringactuatortothebracket

(Figure36).

Figure36

1.Spring2.Springactuator

4.Movethespringactuatortothedesiredholelocation

andsecurewithlocknut.

5.Repeattheprocedureontheremainingspring.

AdjustingtheLiftArmTurn AroundPosition

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,engagetheparking

brakes,andremovethekeyfromignitionswitch.

2.Theliftarmswitchislocatedbehindthefrontright

liftarm(Figure37).

Youcanadjusteachcounterbalancespringtooneof

foursettings.Eachincrementincreasesordecreases

counterbalanceonthecuttingunitby2.3kg(5lb).The

springscanbepositionedonthebacksideofthespring

actuatortoremoveallcounterbalance(forthposition).

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,engagetheparking

brakes,andremovethekeyfromignitionswitch.

33

Page 34

Figure37

1.Switch

3.Loosentheswitchmountingscrews(Figure37)and

movetheswitchuptoincreasetheliftarmturnaround

heightormovetheswitchdowntodecreasethelift

armturnaroundheight.Tightenthemountingscrews.

Figure38

1.Bypassvalve

3.Rotatethebypassvalve90°(1/4turn)backbefore

startingtheengine.Donotexceed7-11N·m

(5-8ft.-lb.)torquetoclosethevalve.

JackingPoints

•Onthefrontofthemachineontheframeontheinside

ofeachdrivetire

•Ontherearofthemachineatthecenteroftheaxle

PushingorTowingthe Machine

Inanemergency,themachinecanbemovedforwardby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.Donot

pushortowthemachineformorethan1/4mile(0.4km).

Important:Donotpushortowthemachinefasterthan

3-4.8km/h(2-3MPH)becauseinternaltransmission

damagemayoccur.Thebypassvalvemustbeopen

wheneverthemachineispushedortowed.

Important:Ifthemachinemusttobepushedor

towedinreverse,thecheckvalveinthefour-wheel

drivemanifoldmustalsobebypassed.T obypassthe

checkvalve,connectahoseassembly(HosePartNo.

95-8843,CouplerFittingNo.95-0985[Qty.2],and

HydraulicFittingNo.340-77[Qty.2])tothereverse

tractionpressuretestportandthereversefour-wheel

drivepressureport.

1.Openhoodandremovethecentershroud

2.Rotatethebypassvalve90°(1/4turn)ineither

directiontoopenandallowoiltobypassinternally

(Figure38).Becauseuidisbypassed,themachinecan

beslowlymovedwithoutdamagingthetransmission.

Notethepositionofthevalvewhenopeningorclosing.

TieDowns

•Oneachsideoftheframeunderthefrontsteps

•Therearbumper

OperatingCharacteristics

Practicedrivingthemachinebecauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthanmany

turfmaintenancemachines.Somepointstoconsider

whenoperatingthetractionunitandcuttingunitsarethe

transmission,enginespeed,loadonthecuttingbladesand

theimportanceofthebrakes.

Tomaintainenoughpowerforthetractionunitwhile

operating,regulatethetractionpedaltokeeptheengineRPM

highandsomewhatconstant.Agoodruletofollowisto

decreasethegroundspeedastheloadonthecuttingunits

increases,andincreasethegroundspeedastheloaddecreases.

Therefore,allowthetractionpedaltomovebackwardasthe

engineRPMdecreases,anddepressthepedalslowlyasthe

RPMincreases.Bycomparison,whendrivingfromonework

areatoanother,withnoloadandcuttingunitraised,havethe

throttleintheFastpositionanddepressthetractionpedal

slowlybutfullytoattainmaximumgroundspeed.

Anothercharacteristictoconsideristheoperationofthe

pedalsthatareconnectedtothebrakes.Thebrakescanbe

usedtoassistinturningthemachine.However,usethem

carefully,especiallyonsoftorwetgrassbecausetheturf

maybetornaccidentally.Anotherbenetofthebrakesisto

34

Page 35

maintaintraction.Forexample,insomeslopeconditions,the

uphillwheelslipsandlosestraction.Ifthissituationoccurs,

depresstheuphillturnpedalgraduallyandintermittentlyuntil

theuphillwheelstopsslipping,thus,increasingtractionon

thedownhillwheel.

Useextracarewhenoperatingthemachineonslopes.Make

surethattheseatlatchisproperlysecuredandtheseatbelt

isbuckled.Driveslowlyandavoidsharpturnsonslopesto

preventrollovers.Forsteeringcontrol,thecuttingunitmust

beloweredwhengoingdownhill.

Important:Allowenginetoidlefor5minutesbefore

shuttingitoffafterafullloadoperation.Thisallowsthe

turbochargertocooldownbeforeshuttingtheengine

off.Failuretodosomayleadtoturbo-chargertrouble.

Beforestoppingtheengine,disengageallcontrolsandmove

thethrottletoSlow .MovingthethrottletoSlowreduceshigh

engineRPM,noise,andvibration.TurnthekeytoOffto

stoptheengine.

OperatingTips

Familiarization

Beforemowinggrass,practiceoperatingthemachineinan

openarea.Startandstoptheengine.Operateinforwardand

reverse.Lowerandraisethecuttingunitsandengageand

disengagethereels.Whenyoufeelfamiliarwiththemachine,

practiceoperatingupanddownslopesatdifferentspeeds.

WarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurifyou

operatethemachinewithamalfunction.

Mowing

StarttheengineandmovetheenginespeedswitchtotheFast

position.MovetheMowSpeedLimitertothemowposition.

MovethePTOswitchtotheONpositionandusetheLift

Switchtocontrolthecuttingunits(thefrontcuttingunits

aretimedtolowerbeforetherearcuttingunits).Tomove

forwardandcutgrass,pressthetractionpedalforward.

Transport

MovethePTOswitchtotheOFFpositionandraisethe

cuttingunitstothetransportposition.MovetheMowSpeed

Limitertothetransportposition.Becarefulwhendriving

betweenobjectssoyoudonotaccidentallydamagethe

machineorcuttingunits.Useextracarewhenoperatingthe

machineonslopes.Driveslowlyandavoidsharpturnson

slopestopreventrollovers.Lowerthecuttingunitswhen

goingdownhillforsteeringcontrol.

35

Page 36

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

Every250hours

MaintenanceProcedure

•Torquethewheelnuts.

•Changetheplanetarygeardriveoil.

•Changetherearaxlelubricant.

•Changethehydrauliclters.

•Checktheengineoillevel.

•Checkthecoolingsystem.

•Checkthehydraulicuidlevel.

•Checkthetirepressure.

•Checktheinterlockswitches.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Drainwaterorothercontaminantsfromfuellter/waterseparator.

•Removedebrisfromtheenginearea,oilcooler,andradiator.

•Inspectthehydrauliclinesandhosesforleaks,kinkedlines,loosemounting

supports,wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings.

•Checkthebatterycondition.

•Checktheconditionandtensionofthealternatorbelt.

•Torquethewheelnuts.

•Changetheengineoilandlter.

Every400hours

Every800hours

Every6,000hours

Beforestorage

Yearly

Important:Refertoyourengine

procedures.

•Servicetheaircleaner.(Servicetheaircleanerearlieriftheaircleanerindicator

showsred.Serviceitmorefrequentlyinextremelydirtyordustyconditions.)

•Checkthefuellinesandconnections.

•Replacethefuelltercanister.

•Replacetheenginefuellter.

•Checktheplanetarygeardriveoillevel(Also,checkifexternalleakageisobserved).

•Checktherearaxlelubricantlevel.

•Drainandcleanthefueltank.

•Changetheplanetarygeardriveoil.(Oryearly,whichevercomesrst)

•Changetherearaxlelubricant.

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Changethehydrauliclters.

•Servicethedieseloxidationcatalyst(DOC)(orasrequired)

•Drainandcleanthefueltank.

•Checkthetirepressure.

•Checkallfasteners.

•Greaseoroilallgreasettingsandpivotpoints.

•Paintchippedsurfaces.

•Checkthefuellinesandconnections.

Operator's Man ual

andcuttingunit

Operator's Man ual

foradditionalmaintenance

36

Page 37

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation

Checkthebrake