Toro 03780, Reelmaster 7000-D Operator's Manual

FormNo.3398-993RevA

Reelmaster

®

7000-D4-Wheel

DriveTractionUnit

ModelNo.03780—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3398-993*A

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Figure1

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Theenclosedengineowner’smanualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughtheengine

manufacturer.

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsingolfcourses,parks,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontherightfrontframemember

oftheproduct.Writethenumbersinthespaceprovided.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

Engine-EmissionCertication..................................7

SafetyandInstructionalDecals.................................7

Setup...........................................................................13

1AdjustingtheSupportRollers................................14

2ReplacingtheWarningDecalforCE

Compliance........................................................14

3InstallingtheHoodLockforCE

Compliance........................................................14

4InstallingtheCuttingUnits....................................15

5AdjustingtheTurf-CompensationSpring................19

6UsingtheCutting-UnitKickstand...........................19

7GreasingtheMachine...........................................20

8CheckingtheFluidLevels.....................................21

9UsingtheGaugeBar............................................21

ProductOverview.........................................................22

Controls...............................................................22

Specications........................................................28

TractionUnitSpecications.....................................28

Attachments/Accessories........................................28

Operation....................................................................29

ThinkSafetyFirst...................................................29

CheckingtheLeveloftheEngineOil.........................29

CheckingtheCoolingSystem...................................30

FillingtheFuelTank...............................................30

CheckingtheLeveloftheHydraulicFluid..................31

CheckingtheTirePressure......................................32

StartingandStoppingtheEngine..............................32

EngineSpeedSwitch...............................................33

CheckingtheInterlockSwitches...............................33

AdjustingtheLift-ArmCounterbalance.....................34

AdjustingtheLift-ArmTurnaroundPosition..............34

PushingorTowingtheMachine...............................34

HaulingtheMachine...............................................36

IdentifyingtheJackingPoints...................................36

IdentifyingtheTie-DownPoints..............................36

OperatingCharacteristics........................................36

OperatingTips......................................................37

Maintenance.................................................................38

RecommendedMaintenanceSchedule(s)......................38

DailyMaintenanceChecklist....................................39

ServiceIntervalChart.............................................40

PremaintenanceProcedures........................................41

RemovingtheHood...............................................41

Lubrication...............................................................41

GreasingtheBearingsandBushings..........................41

EngineMaintenance..................................................43

ServicingtheAirCleaner.........................................43

ServicingtheEngineOilandFilter............................44

ServicingtheDieselParticulateFilter(DPF)...............44

ServicingtheDieselOxidationCatalyst

(DOC)..............................................................44

FuelSystemMaintenance...........................................45

DrainingtheFuelTank...........................................45

CheckingtheFuelLinesandConnections..................45

ServicingtheWaterSeparator..................................45

ServicingtheFuelFilter...........................................45

CleaningtheFuel-IntakeScreen...............................46

ElectricalSystemMaintenance....................................46

ChargingandConnectingtheBattery........................46

ServicingtheBattery...............................................47

LocatingtheFuses..................................................48

DriveSystemMaintenance.........................................49

CheckingtheTorqueoftheWheelNuts.....................49

CheckingthePlanetaryGearDriveOil......................49

ChangingthePlanetaryGearDriveOil......................49

CheckingtheOilLeveloftheRearAxle.....................50

ChangingtheOilintheRearAxle.............................50

CheckingtheLubricantintheGearBoxofthe

RearAxle...........................................................50

AdjustingtheTractionDriveforNeutral....................51

CheckingtheRear-WheelToe-In..............................51

CoolingSystemMaintenance......................................52

ServicingtheEngineCoolingSystem........................52

BrakeMaintenance....................................................53

AdjustingtheServiceBrakes....................................53

BeltMaintenance......................................................54

ServicingtheAlternatorBelt....................................54

HydraulicSystemMaintenance....................................54

ChangingtheHydraulicFluid...................................54

ReplacingtheHydraulicFilters.................................54

CheckingtheHydraulicLinesandHoses....................55

CuttingUnitMaintenance...........................................56

BacklappingtheCuttingUnits..................................56

Storage........................................................................57

PreparingtheEngine..............................................57

PreparingtheTractionUnit.....................................57

3

Safety

ThismachinemeetsorexceedsENISO5395:2013(when

appropriatedecalsapplied),andANSIB71.4-2012.

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheENISO5395:2013

andANSIB71.4-2012.

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Whilemowing,alwayswearappropriateclothing,

includingeyeprotection,substantial,slip-resistant

footwear,longtrousers,andearprotection.

•Tiebacklonghair.Donotwearjewelry.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthattheoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,useextreme

careinhandlingfuel.Fuelisextremelyammableandthe

vaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.T oguardagainst

overturning:

4

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopesand

duringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheoperator'smanual.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsorover-speed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcylinders/reelsifnot

mowing.

•Donotoperatethemachinewhenill,tired,orunderthe

inuenceofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallfastenerstighttobesurethattheequipmentis

insafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetheriskofre,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.Cleanupoil

orfuelspillage.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-cylinder/multi-reelmachines,takecareas

rotatingonecylinder/reelcancauseothercylinders/reels

torotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.Wait

forallmovementtostopbeforeadjusting,cleaningor

repairing.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingthecylinders/reels.Weargloves

andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

5

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Onanyhill,thereisthepossibilityoftippingorrolling

over,buttheriskincreasesastheslopeangleincreases.

Steephillsshouldbeavoided.

Cuttingunitsmustbeloweredwhengoingdownslopes

tomaintainsteeringcontrol

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtostoptheenginequickly.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•WhenoperatingamachinewithROPS(roll-over

protectionsystem)neverremovetheROPSandalways

usetheseatbelt.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Engagetractiondriveslowly,alwayskeepfootontraction

pedal,especiallywhentravelingdownhill.

Usereverseontractionpedalforbraking.

•Ifthemachinestallswhenclimbingaslope,donotturn

themachinearound.Alwaysbackslowly,straightdown

theslope.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifuidis

injectedintoskin.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsandreplacement

parts.Thewarrantymaybevoidedifusedwith

unapprovedattachments.

6

SoundPowerLevel

VibrationLevel

Thisunithasaguaranteedsoundpowerlevelof100dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof83

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

Hand-Arm

Measuredvibrationlevelforrighthand=0.3m/s

Measuredvibrationlevelforlefthand=0.3m/s

UncertaintyValue(K)=0.16m/s

2

2

2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBody

Measuredvibrationlevel=0.2m/s

UncertaintyValue(K)=0.1m/s

2

2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

Engine-EmissionCertication

TheengineinthismachineisEPATier4FinalandEUStage

3bcompliant.

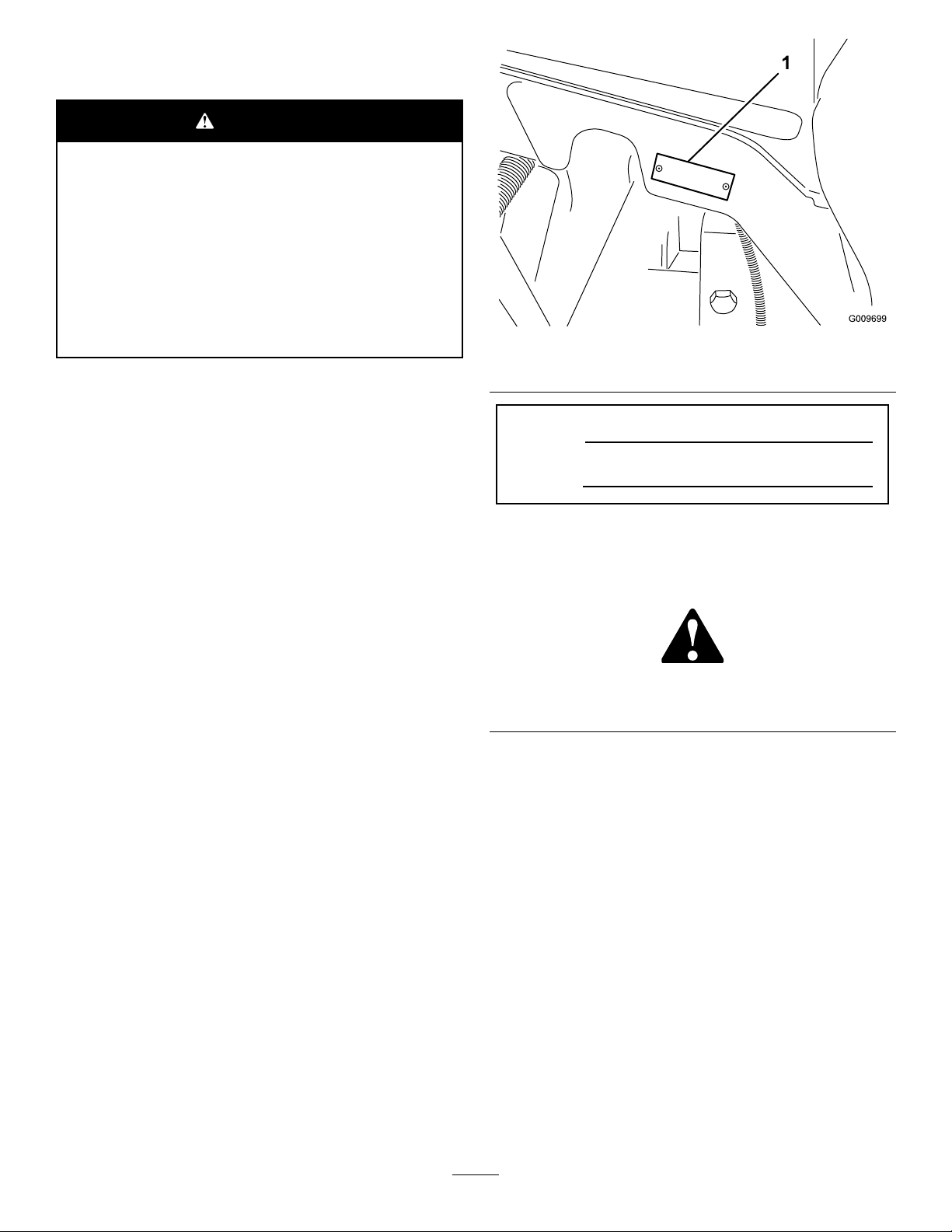

1.Toengagetheparking

brake,securethebrake

pedalswiththelockingpin,

presstheparkingbrake

pedalsandengagethetoe

pedal.

117-4763

93-6680

2.Todisengagetheparking

brake,disengagethe

lockingpinandreleasethe

pedals.

93-6686

1.Hydraulicoil

2.ReadtheOperator'sManual.

117-4765

1.ReadtheOperator'sManual.

2.Donotusestartingaids.

7

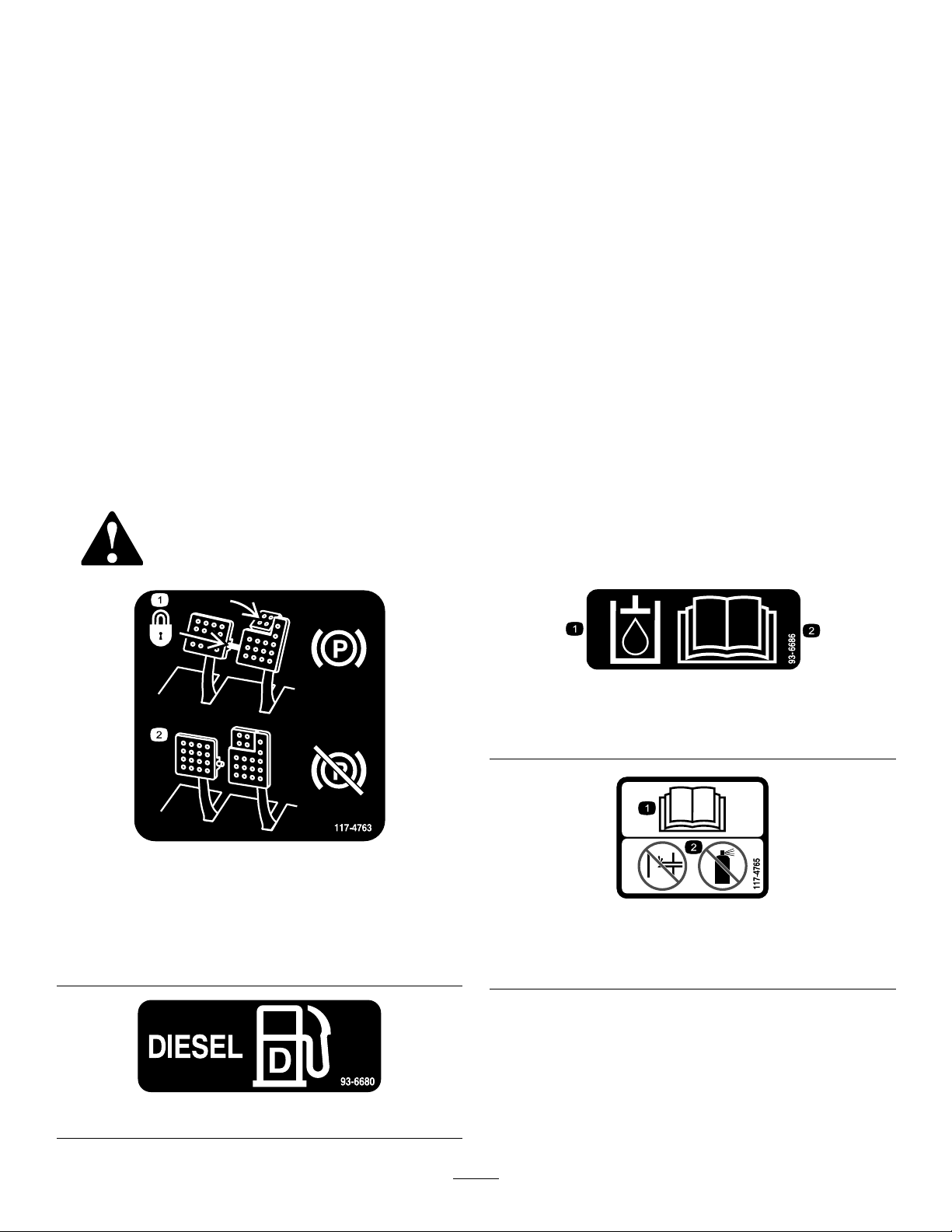

117-4766

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

117–2718

106-6755

110-9642

1.Storedenergyhazard—readtheOperator'sManual.

2.Movethecotterpintotheholeclosesttotherodbracket

andthenremovetheliftarmandpivotyoke.

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

1.Warning—wearhearingprotection.

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

98-4387

93-6688

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

125–8754

1.Headlights

2.Engage7.Lowerthecuttingunits

3.Powertake-off(PTO)

4.Disengage

5.Fast

6.Slow

8.Raisethecuttingunits

9.ReadtheOperator’s

Manual.

1.ReadtheOperator’sManual.

8

121–3887

121–3884

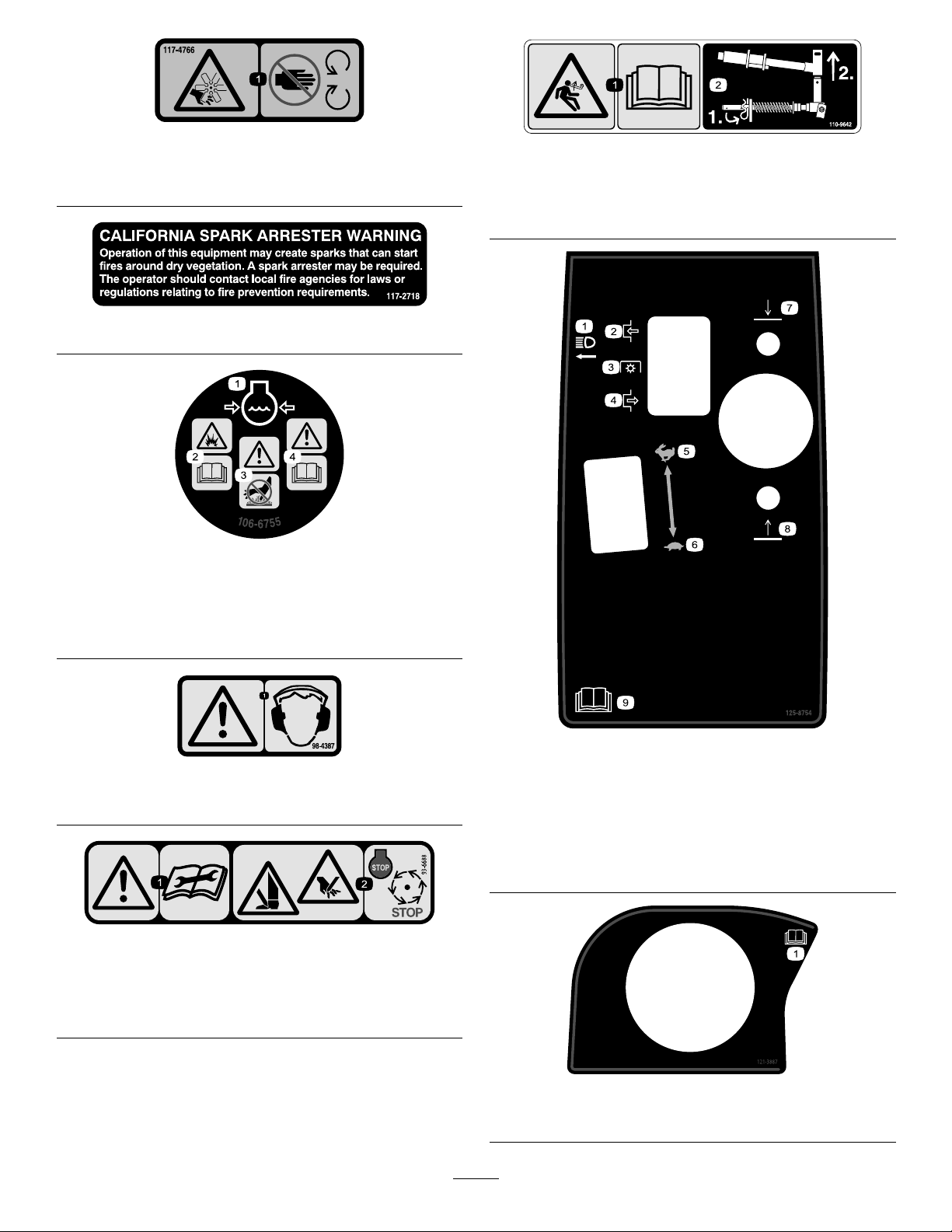

1.Engine—stop3.Engine—start

2.Engine—preheat

112-5019

93–6681

1.Cutting/dismembermenthazard—stayawayfrommoving

parts.

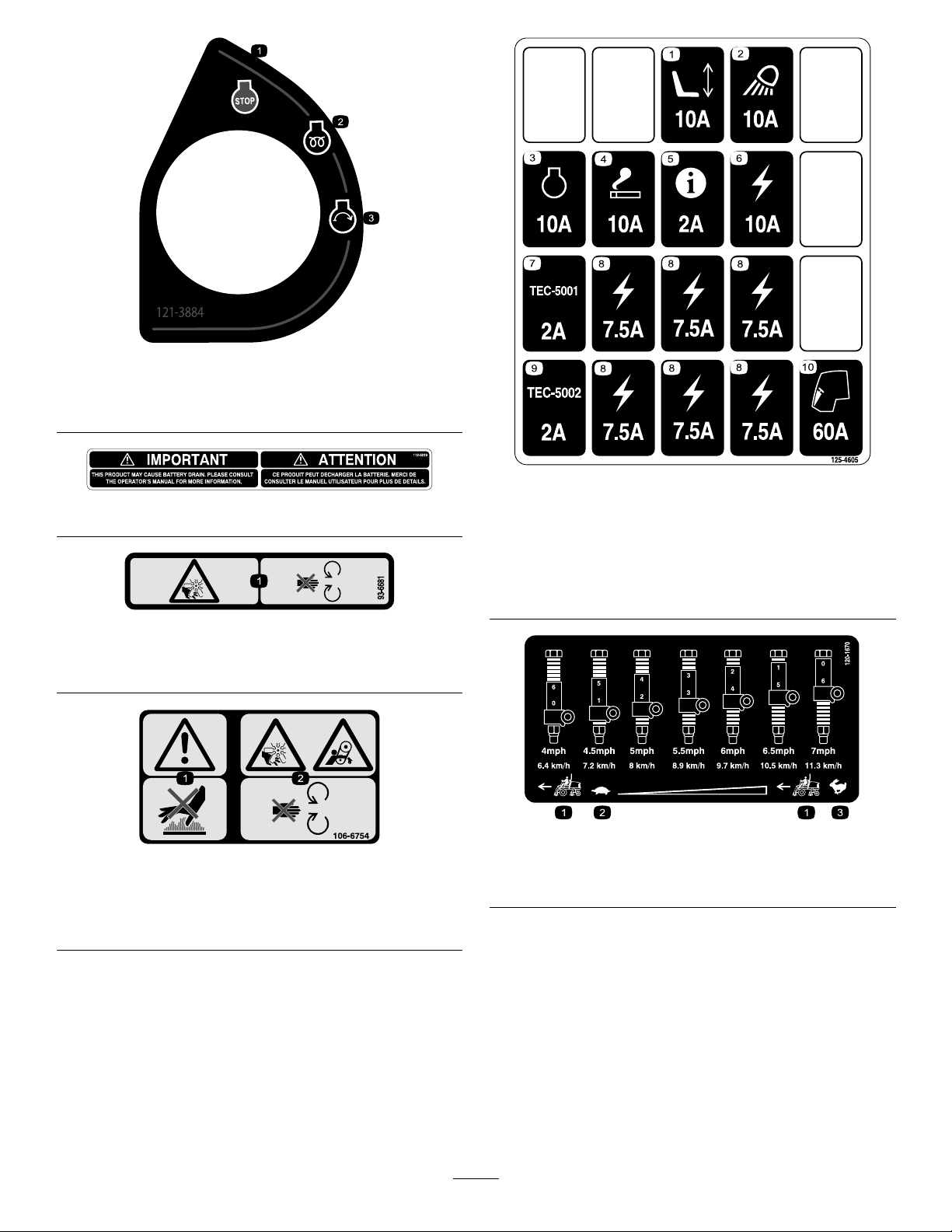

125–4605

1.Powerseat,10A6.Powersupplied,10A

2.Worklight,10A

3.Engine,10A8.Powersupplied,7.5A

4.Cigarettelighter,10A9.Controller,2A

5.Infocenter,2A

7.Controller,2A

10.Enginepreheat,60A

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

120-1670

1.Tractionunitspeed3.Fast

2.Slow

9

BatterySymbols

Someorallofthesesymbolsareonyourbattery

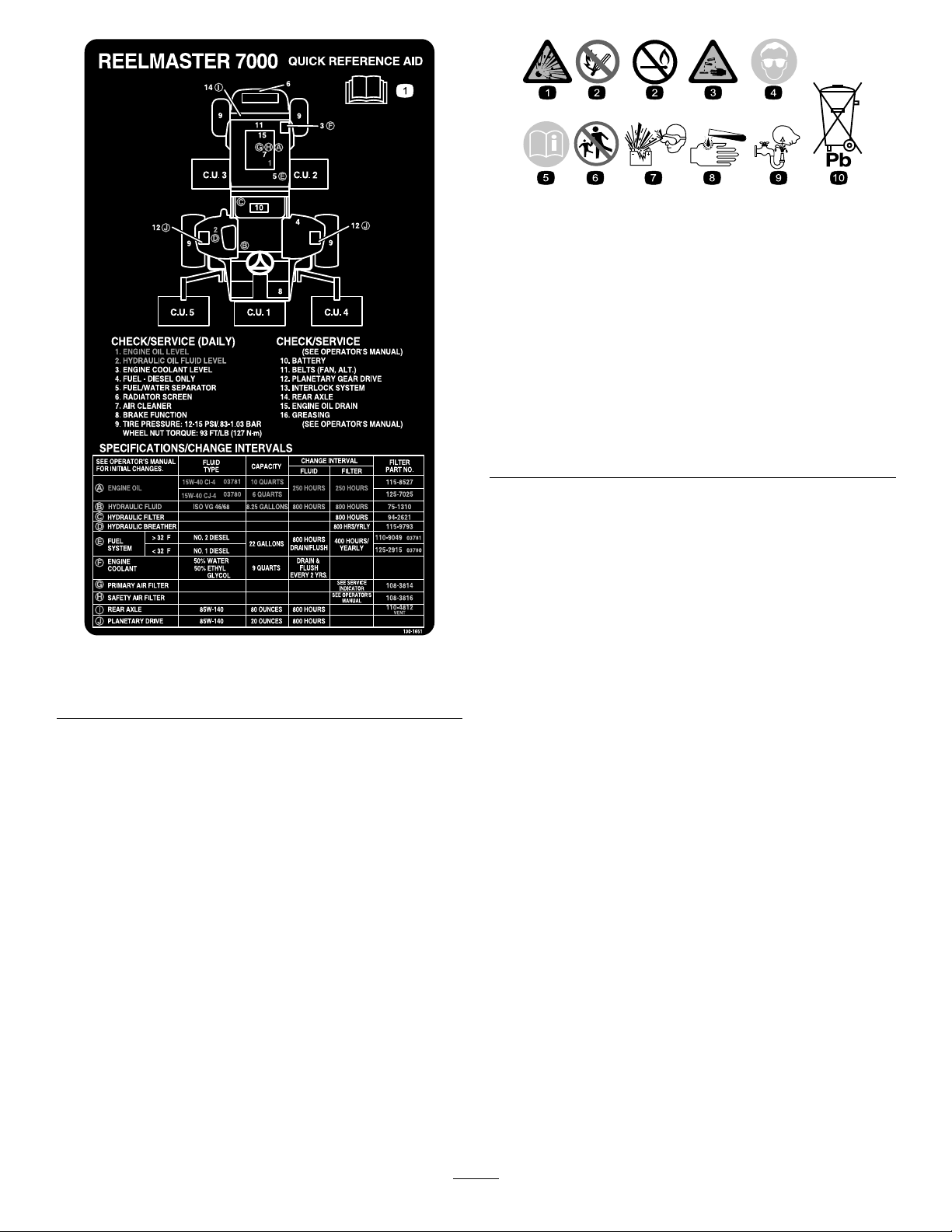

130-1651

1.ReadtheOperator'sManualformoreinformationof

servicingthemachine.

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

10

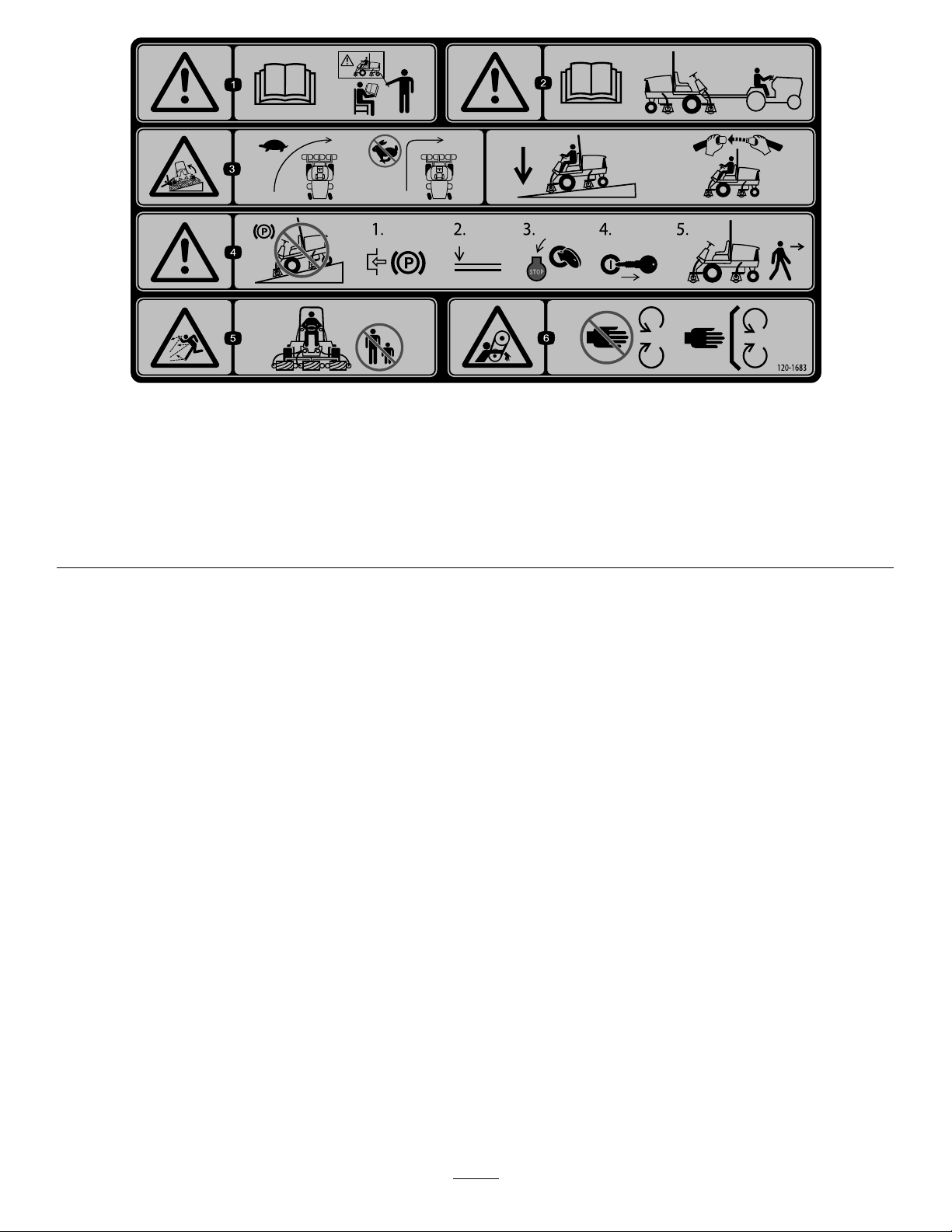

120-1683

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—slowmachinebeforeturning,donotturnat

highspeeds;lowerthecuttingunitwhendrivingdownslopes;

usearolloverprotectionsystemandweartheseatbelt

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

11

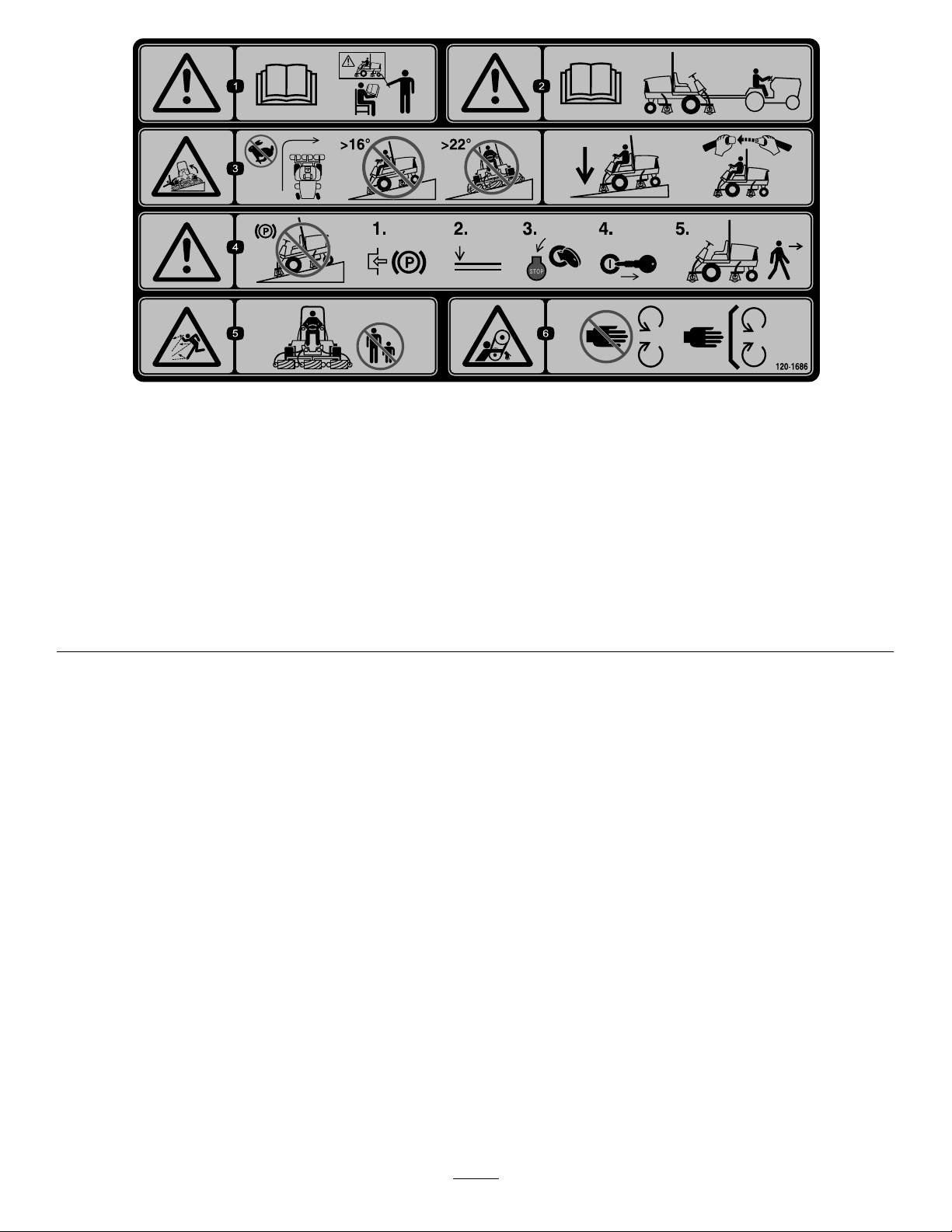

120-1686

Afxoverpartno.120–1683forCE*

*ThissafetydecalincludesaslopewarningrequiredonthemachinefrocompliancetotheEuropeanLawnMowerStandardENISO5395:2013.Theconservativemaximumslope

anglesindicatedforoperationofthismachineareprescribedbyandrequiredbythisstandard.

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—donotturnathighspeeds,donotupand

downslopesgreaterthan16degrees,donotmowacross

slopesgreaterthan22degrees;lowerthecuttingunitwhen

drivingdownslopes;usearolloverprotectionsystemand

weartheseatbelt

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

12

Setup

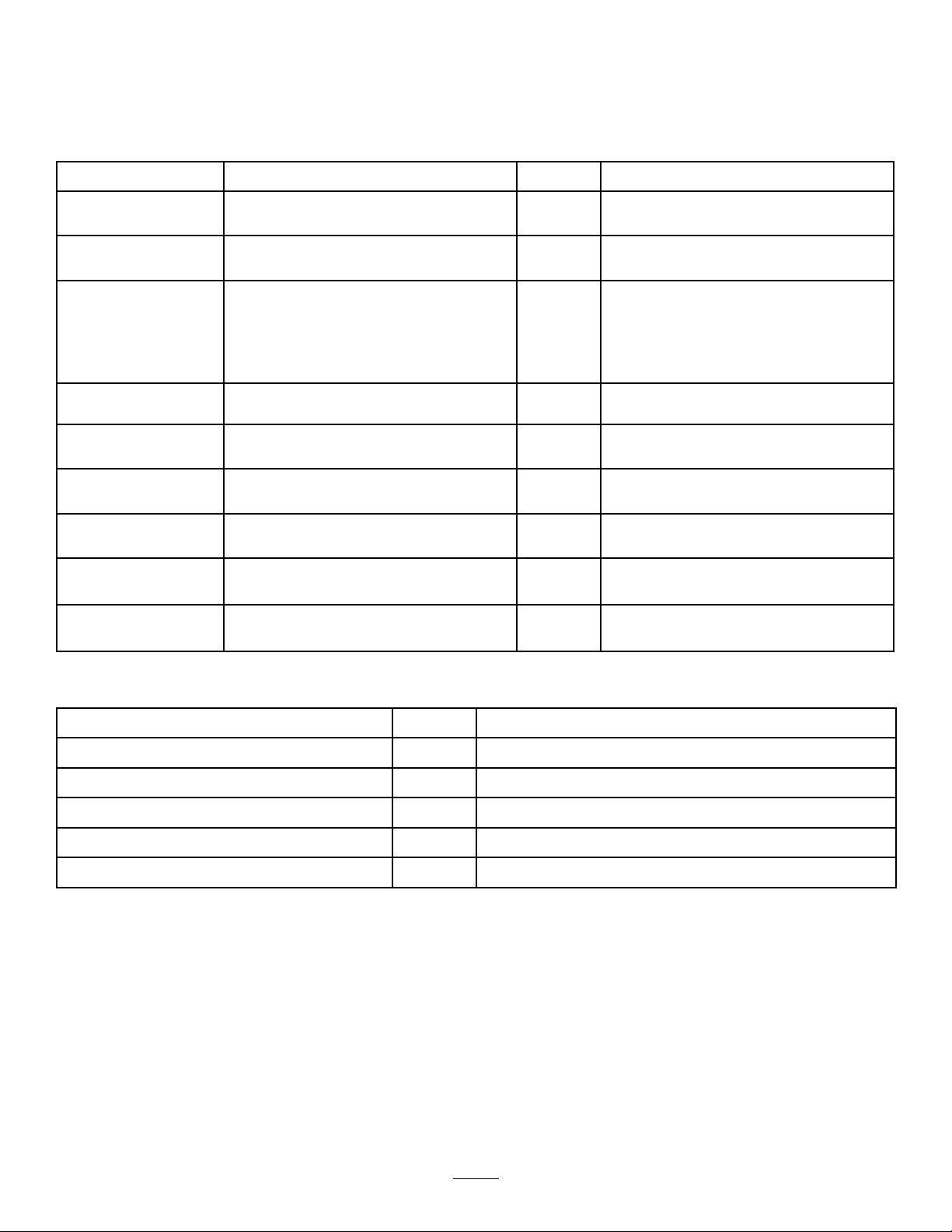

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Nopartsrequired

Warningdecal1

Hood-lockbracket1

Rivet2

Screw,1/4x2inch

Flatwasher,1/4inch

Locknut,1/4inch

Fronthoseguide,right1

Fronthoseguide,left

Nopartsrequired

Cutting-unitkickstand

Nopartsrequired

Nopartsrequired

Gaugebar

Qty.

–

1

2

1

1

–

1Usethecutting-unitkickstand.

–

–

1

Adjustthesupportrollers.

ReplacethedecalforCECompliance.

InstallthehoodlockforEuropeanCE

Compliance.

Installthecuttingunits.

Adjusttheturf-compensationspring.

Greasethemachine.

Checkthelevelsoftherearaxle

lubricant,hydraulicuid,andengineoil.

Usethegaugebartoadjustthecutting

unit.

Use

MediaandAdditionalParts

Description

Operator'sManual

Engineoperator'smanual1

PartsCatalog

Operatortrainingmaterial

DeclarationofConformity

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Qty.

1

1

1

1

Readthemanualbeforeoperatingthemachine.

Readthemanualbeforeoperatingtheengine.

Usethecatalogtoreferencepartnumbers.

Viewthetrainingmaterialbeforeoperatingthemachine.

ThisdocumentindicatesCEcompliance.

Use

13

1

g019541

1

2

3

2

AdjustingtheSupportRollers

NoPartsRequired

Procedure

Dependingonwhatwidthcuttingunitsaretobeinstalledon

thetraction,adjustthesupportrollersasfollows:

•Ifusing27inchcuttingunits,therollersaretobeinstalled

intheuppermountingholesofsupportassembly

channels(Figure3).

•Ifusing32inchcuttingunits,therollersaretobe

installedinthelowermountingholesofsupportassembly

channels(Figure3).

ReplacingtheWarningDecal forCECompliance

Partsneededforthisprocedure:

1Warningdecal

Procedure

OnmachinesrequiringCECompliance,afxtheCEwarning

decal,PartNo.120-1683overthestandardwarningdecal,

PartNo.120-1686.

3

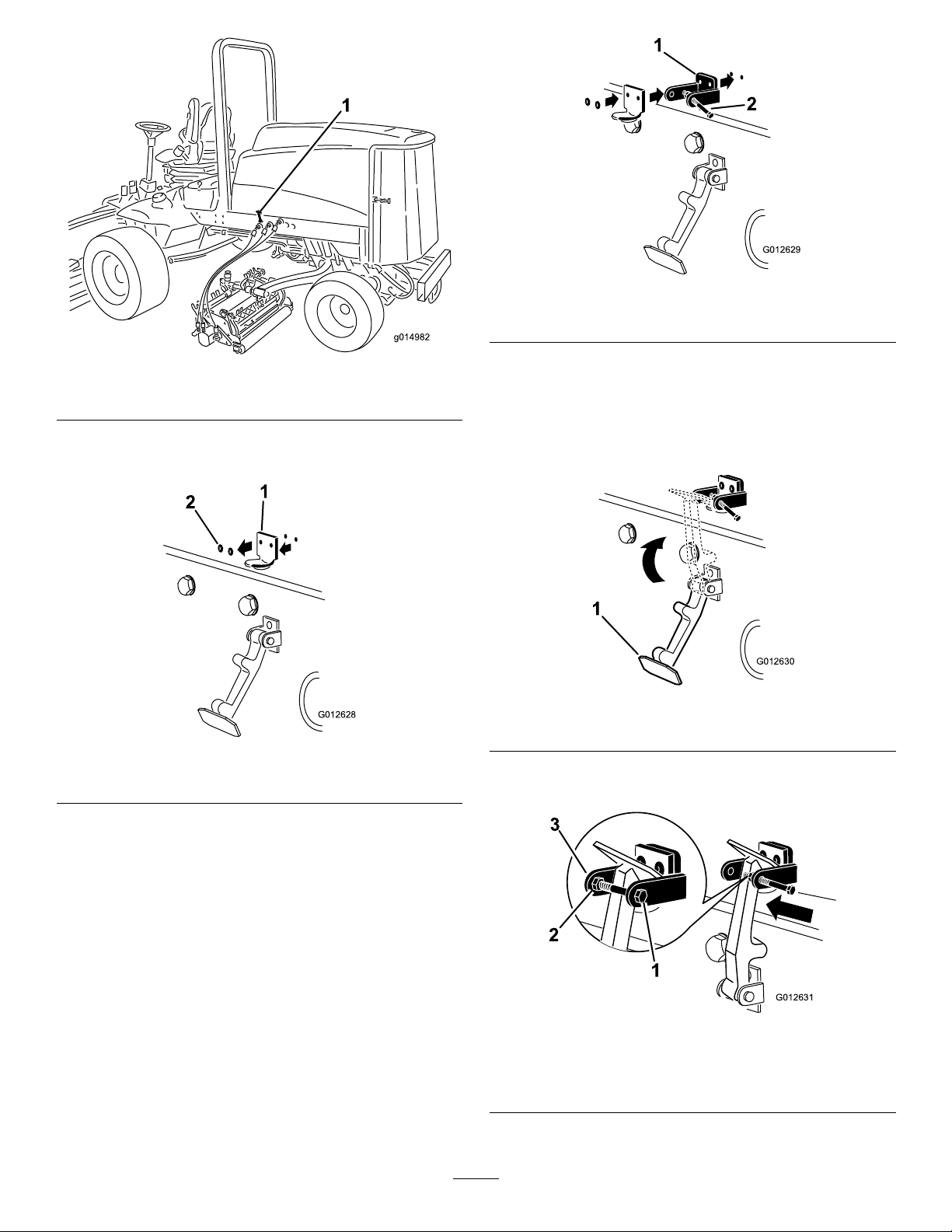

InstallingtheHoodLockfor CECompliance

Partsneededforthisprocedure:

Figure3

1.Supportassemblychannel3.Usethisholefor32inch

cuttingunits.

2.Usethisholefor27inch

cuttingunits.

1Hood-lockbracket

2Rivet

1

Screw,1/4x2inch

2

Flatwasher,1/4inch

1

Locknut,1/4inch

Procedure

1.Unhookthehoodlatchfromthehood-latchbracket

(Figure4).

14

G012628

1

2

G012629

1

2

Figure6

G012630

1

G012631

1

2

3

Figure4

1.Hoodlatch

2.Removethe2rivetssecuringthehood-latchbracketto

thehood(Figure5).

Figure5

1.Hood-latchbracket2.Rivets

1.CElockbracket

2.Boltandnutassembly

5.Alignthewasherswiththeholesontheinsideofthe

hood.

6.Rivetthebracketsandthewasherstothehood(Figure

6).

7.Hookthelatchontothehood-latchbracket(Figure7).

Figure7

1.Hoodlatch

8.Screwtheboltintotheotherarmofhood-lockbracket

tolockthelatchinposition(Figure8).

3.Removethehood-latchbracketfromthehood.

4.Whilealigningthemountingholes,positiontheCE

lockbracketandthehood-latchbracketontothehood.

Note:Thelockbracketmustbeagainstthehood

(Figure5).

Donotremoveboltandnutassemblyfromthe

lock-bracketarm.

Figure8

1.Bolt

2.Nut

3.Armofthehood-lock

bracket

9.Tightentheboltsecurelybutdonottightenthenut.

15

4

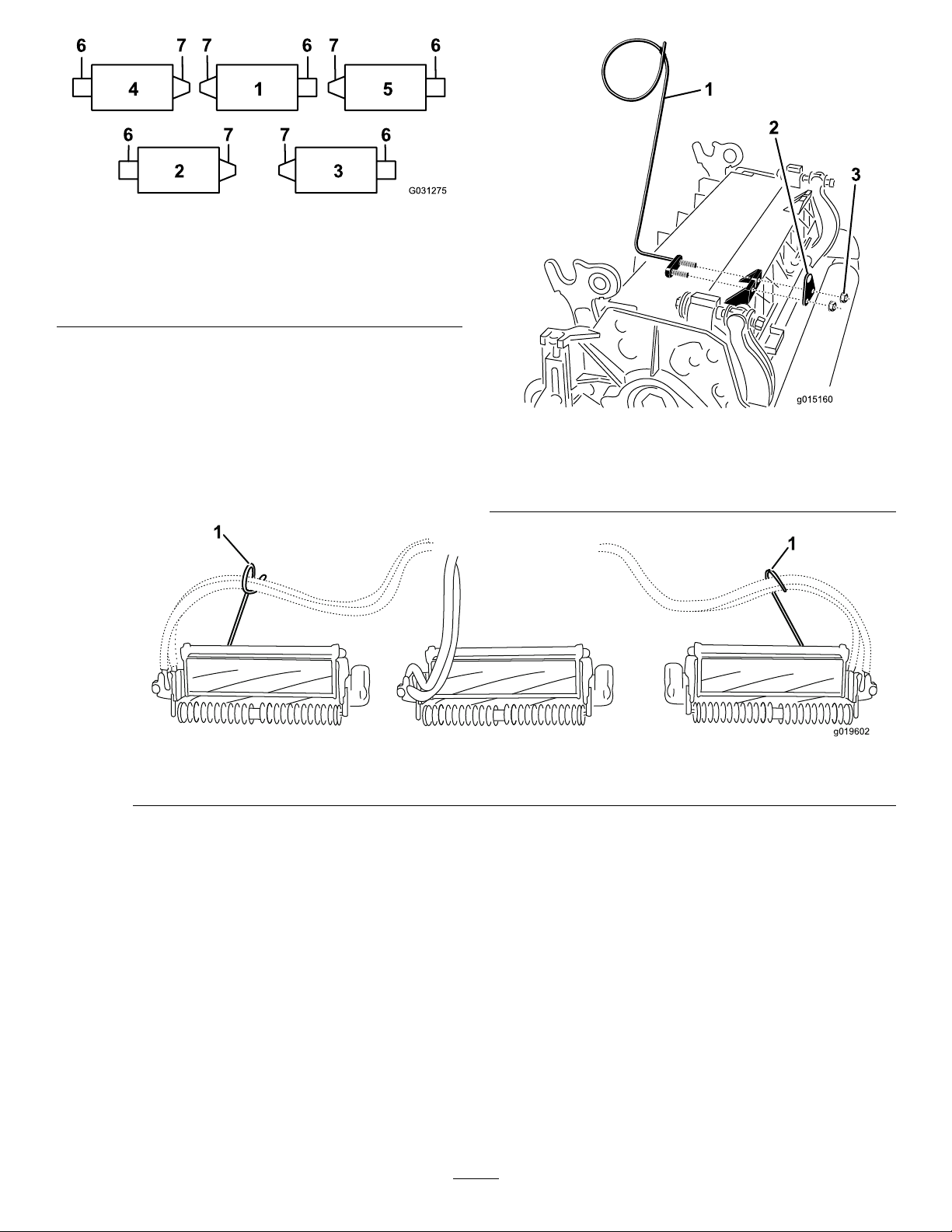

InstallingtheCuttingUnits

Partsneededforthisprocedure:

1Fronthoseguide,right

1

Fronthoseguide,left

Procedure

1.Removethereelmotorsfromtheshippingbrackets.

2.Removetheshippingbracketsanddiscard.

3.Removethecuttingunitsfromthecartons.

4.Assembleandadjustasdescribedinthecuttingunit

Operator'sManual.

5.Makesurethatthecounterweight(Figure9)isinstalled

totheproperendofthecuttingunitasdescribedinthe

cuttingunitOperator'sManual.

Figure10

1.Turfcompensationspring3.Springtube

2.Rodbracket

B.Removetheangenutsecuringthespring-tube

bolttothecarrier-frametab(Figure10)

C.Removetheassembly.

D.Mountthespring-tubebolttotheoppositetabon

thecarrierframeandsecurewiththeangenut.

Note:Theboltheadistobepositionedtothe

outersideofthetabasshowninFigure11.

Figure11

1.Oppositecarrierframetab

2.Rodbracket

Figure9

1.Counterweight

6.Allofthecuttingunitsareshippedwiththeturf

compensationspringmountedtotherightsideofthe

cuttingunit.Theturfcompensationspringmustbe

mountedtothesamesideofthecuttingunitasthe

reeldrivemotor.Repositiontheturfcompensation

asfollows:

A.Removethe2carriageboltsandnutssecuringthe

rodbrackettothecutting-unittabs(Figure10).

E.Mounttherodbrackettothecuttingunittabs

withthecarriageboltsandnuts(Figure11).On

thecuttingunit,mountthelefthoseguidetothe

frontofthecuttingunittabswhenreinstallingthe

rodbracket(Figure13).

Important:OnCuttingUnit4(leftfront)

andCuttingUnit5(rightfront),usethe

rod-bracketmountingnutstoinstallthehose

guidestothefrontofthecutting-unittabs.

Thehoseguidesshouldleantowardthecenter

cuttingunit(Figure12throughFigure14).

16

Figure12

g019602

1

1

1.Cuttingunit15.Cuttingunit5

2.Cuttingunit2

3.Cuttingunit3

4.Cuttingunit4

6.Reelmotor

7.Weight

Figure13

1.Hoseguides(eachmustleantowardthecentercuttingunit)

Note:Wheninstallingorremovingthecutting

units,makesurethatthehairpincotterisinstalled

inthespring-rodholenexttotherodbracket.

Otherwise,thehairpincottermustbeinstalledin

theholeintheendoftherod.

1.Hoseguide(leftside

shown)

2.Rodbracket

Figure14

3.Nuts

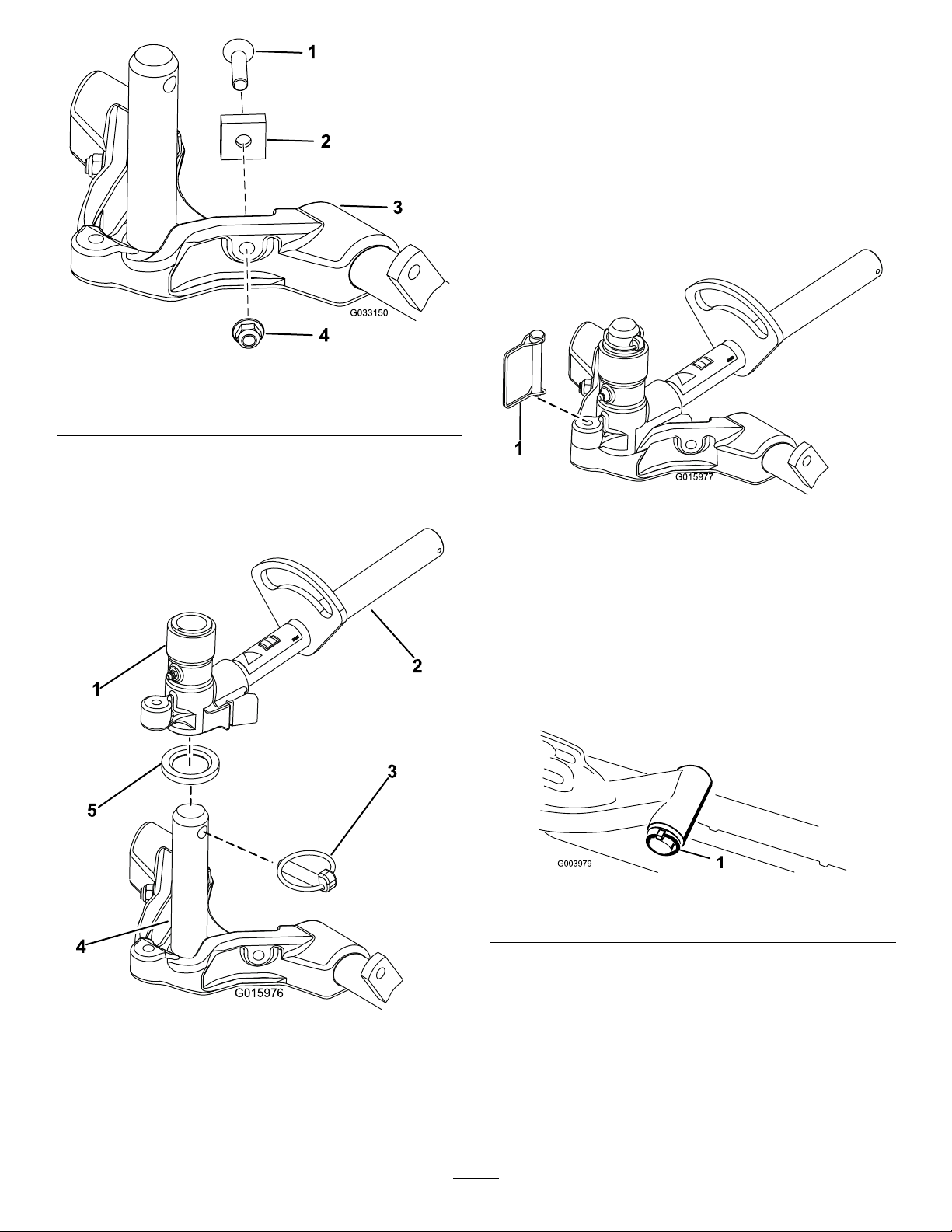

7.Increasethesteeringontherearcuttingunitsby

removingthe2pivotspacers,hex-socketscrews,and

angelocknuts(Figure15)fromthecarrierframesof

therearcuttingunits(CuttingUnits2and3);referto

Figure12.

17

Figure15

G015976

1

2

3

4

5

1

G015977

10.Forthefrontcuttingunits,slideacuttingunitunder

theliftarmwhileinsertingtheshaftofthecarrier

frameupintothelift-armpivotyoke(Figure16).Make

surethatthethrustwasherisinpositiononthecarrier

frameshaft.

11.Securethecarrier-frameshafttothelift-armyokewith

theklikpin(Figure16).

12.Tolock(x)thesteeringonthecuttingunits,secure

thepivotyoketothecarrierframewiththesnapper

pin(Figure17).

1.Hex-socketscrew

2.Pivotspacer4.Flangelocknut

3.Carrierframe

8.Loweralloftheliftarmscompletely.

9.Coatthecarrier-frameshaftwithcleangrease(Figure

16).

Figure17

1.Snapperpin

Note:Fixedsteeringisrecommendedwhen

cuttingonsidehills.

13.Usethefollowingprocedureontherearcuttingunits

whentheheightofcutisabove19mm(3/4inch).

A.Removethelynchpinandwashersecuringthe

lift-armpivotshafttotheliftarmandslidethe

lift-armpivotshaftoutoftheliftarm(Figure18).

1.Lift-armpivot-shaftlynchpinandwasher

Figure18

B.Insertthelift-armyokeontothecarrierframe

shaft(Figure16).

1.Lift-armpivotyoke4.Carrier-frameshaft

2.Liftarm

3.Klikpin

Figure16

5.Thrustwasher

C.Insertthelift-armshaftintotheliftarmand

secureitwiththewasherandthelynchpin(Figure

18).

14.Securethelift-armchaintothechainbracketwiththe

snapperpin(Figure19).

Note:Usethenumberofchainlinksdescribedinthe

cuttingunitOperator'sManual.

18

Loading...

Loading...