Page 1

Form No. 3350–280

5, 7, and 11 Blade Cutting Units

Reelmaster 4000-D Series

Model No. 03752—230000001 and Up

Model No. 03753—230000001 and Up

Model No. 03723—230000001 and Up

Model No. 03724—230000001 and Up

Model No. 03725—230000001 and Up

Model No. 03726—230000001 and Up

Operator ’s Manual

Eenglish (EN, GB)

Page 2

Contents

Introduction

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 3. . . . . . . . . . . . . . .

Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 3. . . . . . . . . . . . . . . . . . . .

Optional Accessories 4. . . . . . . . . . . . . . . . . . . . . .

Assembly 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Tipper Plates and Weights to the Cutting

Units 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Floatation Kit 6. . . . . . . . . . . . . . . . .

Installing the Fixed Head Kit 6. . . . . . . . . . . . . . . .

Securing the Cutting Units to the Lift Arms 6. . . .

Mounting the #4 and #5 Tipper Brackets 7. . . . . .

Mount the Roller Bumpers (Floatation Kit Only) 7

Mounting the Hydraulic Motors to the Cutting

Units 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Reel to Bedknife Contact 9. . . . . . .

Adjusting the Height-of-Cut for a Floating Cutting

Unit 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Method for Changing Height-of-Cut after Initial

Setup of a Floating Cutting Unit 11. . . . . . . . . . . .

Checking/Adjusting the Cutting Unit Attitude 12. .

Height-of-Cut Adjustment for a Fixed Cutting

Unit 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Skids and Front Roller

(Fixed Head Kit) 13. . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backlapping 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing the Bedknife/Bedbar 15. . . . . . . . . . . . . .

Servicing the Reel Assembly 16. . . . . . . . . . . . . . . .

Removing the Roller 18. . . . . . . . . . . . . . . . . . . . . .

Installing the Roller 19. . . . . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 20. .

Page

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. They are located on

the reel sideplate opposite the drive housing.

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard.

However, regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or

moderate injury if you do not follow the recommended

precautions.

This manual uses two other words to highlight

information. Important calls attention to special

mechanical information and Note: emphasizes general

information worthy of special attention.

2004 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Page 3

Safety

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any

area of potential danger. Replace any decal that is damaged or lost.

Part No. 67-7960

Part No. 93-6688 (for CE)

1. Danger—read the

operator’s manual before

performing maintenance.

2. Cutting hazard to hands,

fingers, and feet—stop the

engine before going near

rotating reels.

Specifications

General Specifications

5 Blade—1 to 3 in. (25 to 76 mm)

Height-of-cut

Height-of-cut adjustment

7 Blade—1/2 to 1-3/4 in. (9.5 to 45 mm)

11 Blade—3/8 to 3/4 in. (9.5 to 19 mm)

Quick adjustment and positive locking is provided by locking type cone nuts.

Gauge marks of 1/4 in. (6.3 mm) are provided as a reference for easy changes of

height-of-cut.

Part No. 85-6410

Part No. 93-7814 (for CE)

1. Entanglement hazard—stay away from moving parts.

Clip (variable to match

cutting conditions)

5 Blade Cutting Unit: .176 in. per mph (.352 in. at 2 MPH-1.32 in. at 7.5 mph)

7 Blade Cutting Unit : .126 in. per mph (.252 in. at 2 MPH-.945 in. at 7.5 mph)

11 Blade Cutting Unit: .080 in. per mph (.16 in. at 2 MPH-.600 in. at 7.5mph)

3

Page 4

Optional Accessories

Floatation Kit (1 per machine) Model No. 03760

Fixed Head Kit (1 per machine) Model No. 03762

Wiehle Roller Kit (1 per machine) Model No. 03740

Side Skid Kit (1 per machine) Model No. 03744

Full Roller Kit (1 per machine) Model No. 03742

Dethatching Unit, RH

(3 per machine)

Dethatching Unit, LH

(2 per machine)

Rear Roller Scraper Kit

(1 per cutting unit)

Front Full Roller Scraper Kit

(1 per cutting unit)

Note: The front roller or other optional accessories for the

front of the cutting unit are shipped separately. Use the

instructions and parts supplied with the selected options

for installation on the cutting unit.

Model No. 03732

Model No. 03730

Part No. 59-6090

Part No. 62-6220

Assembly

Note: Determine the left and right sides of the machine from the normal operating position.

Loose Parts

Note: Use this chart as a checklist to ensure that all parts have been received. Without these parts, total setup cannot be

completed.

Description Qty. Use

Decals 2 Affix to cutting unit for CE.

Operator’s manual 1 Read before operating.

Parts catalog 1

Registration card 1 Fill out and return to Toro.

The following parts are required to mount the cutting

units:

• 3 Right-Hand Cutting Units

• 2 Left-Hand Cutting Units

• 1 Front Roller or Skid Kit

• 1 Floatation Kit (includes 3 Weights, 1 Backlapping

Brush, and 1 Gauge Bar) or

Important Thoroughly read both Cutting Unit and

Traction Unit Operator Manuals. Failure to do so may

result in damage to the cutting unit and/or poor

performance.

• 1 Fixed Head Kit (includes 3 Weights and 1

Backlapping Brush)

4

Page 5

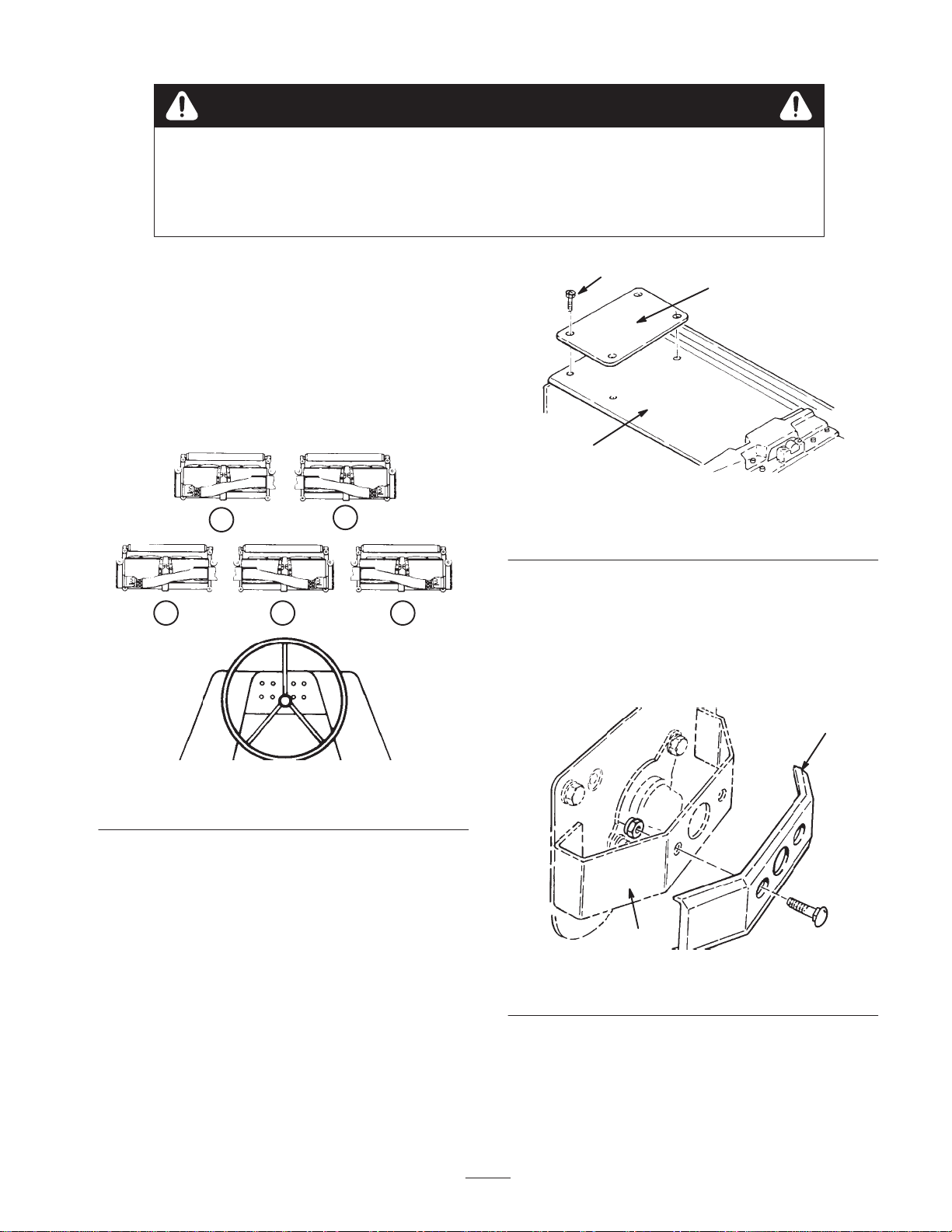

Caution

If you leave the key in the ignition switch, someone could accidently start the engine and

seriously injure you or other bystanders.

Remove the key from the ignition before installing, servicing, or making adjustments to the

cutting units.

Installing the Tipper Plates and

Weights to the Cutting Units

1. Refer to Figure 1 and layout all five cutting units on

the floor in front of the machine. Position 3 right-hand

cutting units (all three are alike) as #1, #3 and #5.

Position the left-hand #2 and #4 cutting units also

(both are alike).

FRONT

2

1

3

54

3

1

Figure 2

1. Inboard cutting unit cover

2. Tipper plate

Note: Do not install a tipper plate on the #1 cutting unit.

4. Mount one weight to each cutting unit guard (Fig. 3)

on the #1, #2 and #3 cuttings. Weights are located at

the opposite end of each cutting unit drive housing.

Use 1/2 in. carriage bolts provided with weights

(Fig. 3).

2

3. Flathead socket capscrew

Figure 1

Cutting Unit Layout

2. Install a front roller or skid kit to each cutting unit.

Installation instructions and cutting unit guards are

included with each kit.

3. On the #2 and #3 cutting units, remove 4 cover

capscrews located at the outside end of the cutting unit

drive housing. Discard cover screws. Mount a tipper

plate to front left-hand (#2) cutting unit and the front

right-hand (#3) cutting unit using flathead socket

screws and locknuts supplied with tipper plates

(Fig. 2).

1

2

Figure 3

1. Weight 2. Guard

5. On the #4 and #5 cutting units, remove 4 cover

capscrews located at the outside end of the cutting unit

drive housing. Discard cover screws. Tipper brackets

will be mounted at these locations after the #4 and #5

cutting units are mounted on lift arms (Fig. 2).

5

Page 6

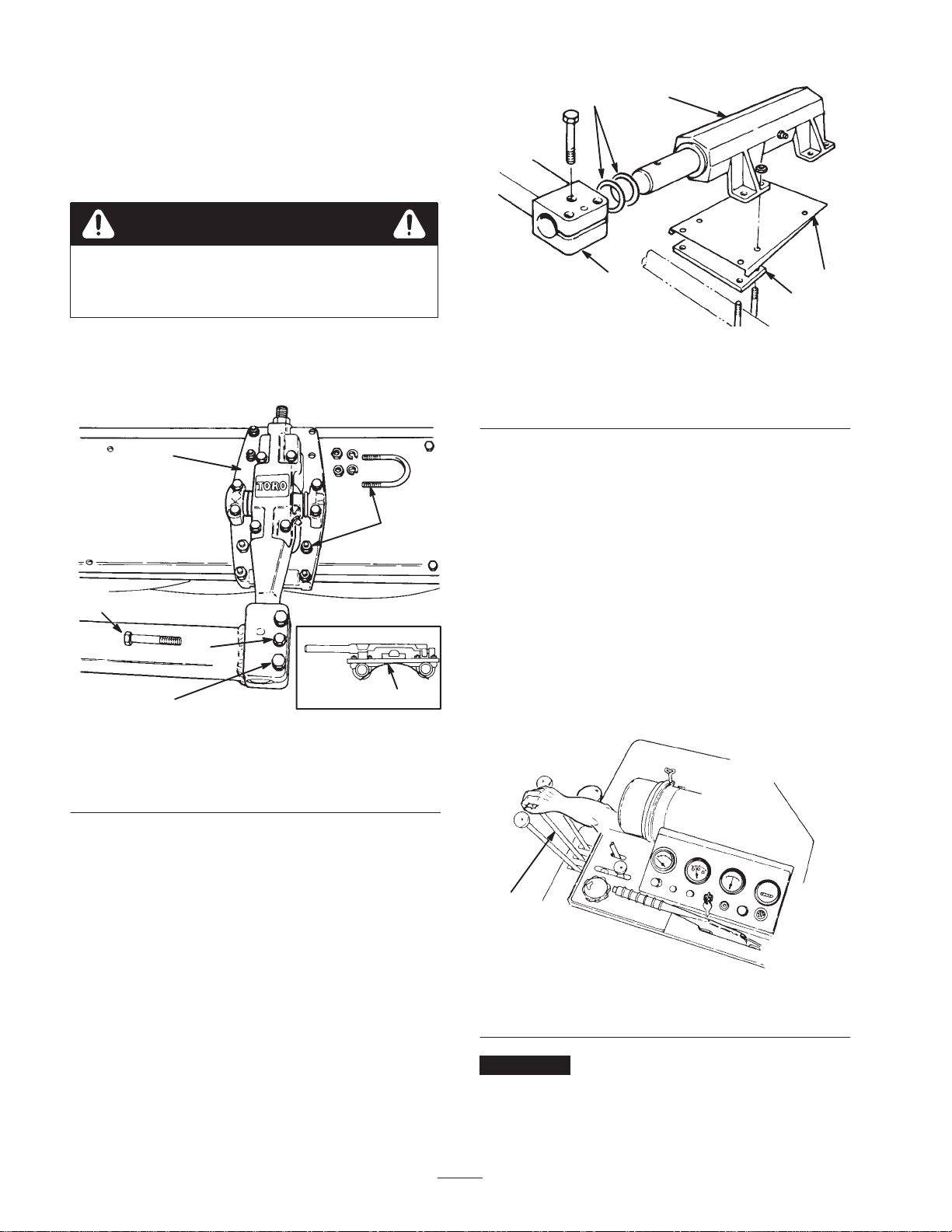

Installing the Floatation Kit

Mount a Flotation Kit Assembly (Fig. 4) to each cutting

unit with U-bolts, lock washers and nuts supplied with

kits. Male end of floatation assembly to be positioned

forward. Tighten U-bolts evenly.

Caution

2

1

Fingers can be pinched in the floatation u-joint.

Keep hands and fingers away from the u-joint.

Note: When installing floating head assembly to cutting

unit, make sure flap on bottom of assembly is positioned

to the inside of the cutting frame tubes (Fig. 4, inset).

1

2

6

5

3

1. Floatation kit assembly

2. U-bolts

3. Lift arm bolts

Figure 4

4. Flap

5. Capscrew and jam nut

6. Capscrew

4

5

4

Figure 5

1. Fixed head assembly

2. Thrust washer

(as required)

3. Cover plate

4. Attitude adjustment plate

5. Lift arm

Securing the Cutting Units to

the Lift Arms

1. Remove three metric bolts from each of the lift arms

(Fig. 5).

Note: The smaller diameter bolt goes through both the

pivot arm and the lift arm. Keep these bolts separate.

2. With the parking brake on, start the traction unit and

adjust the engine to half throttle. Be sure to release the

lift arm lock lever for the #1, #2 and #3 cutting units

and put the reel lift control for the #1, #2 and #3

cutting units in the lower position (Fig. 6). Release the

lever and let it return to the neutral position.

3

Installing the Fixed Head Kit

Note: Before mounting each fixed head assembly to

cutting unit, insert the pivot arm of assembly into the

appropriate lift arm block, align mounting holes and

determine how many thrust washers (if any) are required

to fill gap between assembly body and lift arm block. Add

required amount of washers to pivot arm before installing

fixed head assembly to lift arm.

Mount a Fixed Head Kit Assembly (Fig. 5) to each cutting

unit with a cover plate, attitude adjustment plate, U-bolts,

lockwashers and nuts supplied with kits. Male end of

floatation assembly to be positioned forward. Tighten

U-bolts evenly.

1

Figure 6

1. Reel lift control

Important Do not allow lever to snap back into the

neutral position or the lift arms may not go into float.

6

Page 7

3. Stop the traction unit and remove the key. Manually

pull the lift arms, one at a time, to floor level. Repeat

this procedure for the #4 and #5 cutting units.

Caution

Without the cutting units installed, restarting the

engine will result in the lift arms raising.

Mount the Roller Bumpers

(Floatation Kit Only)

Note: Roller bumpers are required only when operating

cutting units in the float position and front rollers are

installed.

1. Locate mounting position of roller bumpers (Fig. 8) on

each side of frame tube in front of #1 cutting unit.

4. Roll the appropriate cutting unit to lift arm and match

the male end of pivot arm with hole in lift arm.

Note: It may be necessary to spread slotted block on lift

arm slightly to slide pivot arm fully into hole.

5. Reinstall 3 lift arm bolts but do not tighten (Fig. 5).

Mounting the #4 and #5 Tipper

Brackets

1. Loosely secure the hydraulic hoses to the underside of

each tipper bracket with hose clamps, spacers, clamp

plate, lock washers, and capscrew as shown in

Figure 7.

1

2

2. Loosely secure a roller bumper to each side of frame

tube, as shown in Figure 8, with U-bolts and locknuts.

3. Align the center of each bumper with the respective

end of the roller on the #1 cutting unit and tighten the

locknuts.

2

1

1

Figure 8

1. Roller bumpers 2. Frame tube

3

4

Figure 7

1. Tipper bracket

2. Hose clamp

2. Mount tipper brackets to cutting units with capscrews

and locknuts.

Important Raise and lower each cutting unit to ensure

that there is no binding of hoses during operation.

3. Tighten capscrews securing hose clamps to tipper

brackets.

3. Spacer

4. Clamp plate

7

Page 8

Mounting the Hydraulic Motors

to the Cutting Units

3. Insert the reel drive motor pulley through the housing

and slip the cutting unit drive belt over the pulley

(Fig. 11).

1. Remove locknuts, bolts, shipping cover, and drive

plate shield (Fig. 9) from the cutting unit.

2

1

Figure 9

1. Shipping cover 2. Drive plate shield

1

2

3

Figure 11

1. Hydraulic motor

2. Motor pulley

4. Insert the 2 reel drive motor mounting bolts (heads on

inside of the drive housing—flat washer on top bolt)

through the reel motor flange holes. Thread the

locknuts onto the bolts. Rotate reel motor upward in

the slotted hole in the housing to tension the drive belt

and tighten the fasteners (Fig. 12) to approx. 25 ft. lb.

(34 Nm).

Note: Proper belt tension is achieved when belt deflects

approximately 1/8 in. (3 mm) at mid-point when 7 lb. of

force is applied. (Fig. 12).

3. Drive belt

2. Discard shipping cover and install the drive plate

shield onto the reel drive motor flange (Fig. 10). Be

sure the widest portion of the shield is at the top.

2

1

Figure 10

1. Drive plate shield 2. Reel drive motor flange

Note: Check to see that motor pulley set screws are tight

on motor shaft before installing motor onto cutting unit

(Fig. 11).

1

Figure 12

1. Reel motor fasteners

Important Rotate motors by hand only. Never place a

bar between hose fittings on hydraulic motors—motor

damage may result.

5. Install the gasket and drive housing cover after making

sure the ends of the gasket are at the bottom of the

housing to allow for drainage.

Important When hydraulic motors have been mounted

to the cutting units, make sure hydraulic hoses lay flat and

do not contact the frame of the machine when the cutting

units are in the raised position. There should also be

sufficient slack so hoses are above and not in contact with

the floatation kit. If hoses appear twisted once the

8

Page 9

hydraulic motors have been mounted and the belts

tightened, loosen swivel nuts at the motor and reposition

hoses. This can greatly increase the life of the hoses. With

cutting units down, all cutting unit hoses should have a

flat natural lay and be free from twist.

6. Tighten tipper bracket clamps on #4 and #5 cutting

units (Fig. 7).

Note: Refer to the Traction Unit Operator ’s Manual for

instructions on setting the adjustable hydraulic

counterbalance, if so equipped.

3. If there is excessive contact, turn the adjusting knobs

counterclockwise until no contact is noticed. Then

equally turn both adjusting knobs clockwise, until light

contact is felt and heard between the reel and

bedknife. Final adjustment should always be in the

tightening (clockwise) direction.

4. Tighten adjuster locking nuts when completed making

adjustments.

Caution

Caution

Before adjusting reel to bedknife, raise and fully

latch cutting units. Remove key from the ignition

switch. Keep others off machine while adjusting

cutting units.

Adjusting the Reel to Bedknife

Contact

Before adjusting height-of-cut and each day before

operating, check reel to bedknife contact, regardless if

quality of cut had previously been acceptable.

Note: A 3/4 in. wrench is required for making the reel to

bedknife adjustment.

1. Slowly and carefully rotate the reel, listening for light

contact across the full length of the reel and bedknife.

2. If there is no contact, loosen the adjuster locking nut

on each adjuster (Fig. 13). Then, equally turn each

adjuster knob clockwise until light contact is felt and

heard.

2

Sharp edges on the cutting units can cut or pinch

hands or fingers.

• When adjusting the cutting units, wear heavy

gloves.

• Use care when turning the reels by hand.

Important Adjusted correctly, the reel will cut paper

(approx. .03 in. thick) across its entire length.

The cutting units will provide optimum mowing

performance when adjusted and maintained correctly.

Keeping a precise reel to bedknife adjustment (light

contact), at each end of the cutting unit will produce a

continual self-sharpening action. Therefore, sharp cutting

edges are maintained, good quality of cut ensured, and the

need for corrective re-sharpening reduced.

Important Cutting units with excessive contact

between the reel and bedknife are noisy, consume

excessive power, shorten component life and result in

overall poor performance. Light contact between the reel

and bedknife, once the cutting unit is warmed up, provides

optimum mowing performance and component life.

Adjusting the Height-of-Cut for

a Floating Cutting Unit

1

Figure 13

1. Adjuster locking nut 2. Adjustment knob

Adjusting the Reel to Bedknife Contact

Adjust reel to bedknife contact on all cutting units. Refer

to Adjusting the Reel to Bedknife Contact, page 9.

Leveling the Rear Roller to the Reel

1. Start engine and lower the cutting units onto a flat

surface such as a piece of 3/4 in. or 1 in. plywood (at

least 20 in. x 30 in. in size). Stop engine and remove

key from switch. Lock cutting units in the fixed

position, by loosening the jam nut on lockout pin

(Fig. 14) and screwing pin into hole in pivot arm

(Fig. 15). Tighten nut to secure lockout. Raise the

front rollers up so they do not contact the flat surface.

9

Page 10

1

2

Figure 14

Cutting Unit Float Position

1. Lockout pin 2. Jam nut

2. Insert a piece of bar stock 25–28 in. (70 cm) long

(Fig. 16), and approximately 3/8 in. (9.5 mm) thicker

than the desired height-of-cut, under the reel and up

against the bedknife cutting edge (Fig. 16). The reel

(not bedknife) must contact the bar stock along its full

length.

Note: Using a bar 3/8 in. (9.5 mm) thicker than

height-of-cut provides proper bedknife attitude (heeled

“up” in back) required for excellent low height-of-cut

performance.

contact after the jam nuts have been tightened. Check

roller contact by trying to slide paper between the

roller and the flat surface.

3/8

Figure 16

Leveling the Rear Roller to the Reel

4. Rear roller is now leveled to the reel.

Adjusting the Final Height-of-Cut Using

the Gauge Bar

1 2

Figure 15

Cutting Unit Fixed Position

1. Lockout pin 2. Jam nut

3. Loosen rear roller jam nuts and adjusting knobs and

push roller down against flat surface. At this point the

reel should be contacting the bar stock and the rear

roller contacting the flat surface. Contact should exist

along the entire length of the reel and rear roller.

Tighten rear roller adjustment knobs and jam nuts.

Recheck to be sure roller and reel are both still making

1. Raise cutting units and lock in the transport position.

Shut off the engine and remove the key.

2. Use gauge bar (Toro Part No. 98-1852) to set final

height-of-cut by adjusting front roller only.

Note: Position long cone nut (Fig. 17) on bottom for

heights of 1-1/4 in. or higher. Position short cone nut on

bottom for heights of below 1-1/4 in.

10

Page 11

2

1

Figure 17

1. Long cone nut 2. Short cone nut

3. Loosen the gauge bar jam nut and adjust the first

screw to set dimension between underside of screw

head and gauge bar for desired height-of-cut. (Fig. 18).

Tighten the jam nut to secure the adjustment. Hook

screw head over cutting edge of bedknife and position

bar against bottom of front roller (Fig. 19).

4. Loosen front roller nuts and adjust both ends of the

front roller until it contacts gauge bar at both ends.

With the gauge bar held firmly against the bottom of

the rollers, adjust the front roller so the screw head just

slips over the lip of the bedknife (Fig. 19). Tighten the

front roller nuts.

98-1852

Figure 19

Final Height-of-Cut Adjustment Using Gauge Bar

Important When set properly, the front and rear

rollers will contact the gauge bar and the screw head will

be snug over the bedknife cutting edge when checked at

both ends of the reel.

98-1852

Figure 18

Gauge Bar Assembly

5. Loosen lockout pin so cutting unit can float freely

(Fig. 14).

Quick Method for Changing

Height-of-Cut after Initial Setup

of a Floating Cutting Unit

If the reel to bedknife adjustment has been set and the rear

roller leveled to the reel, the cutting unit may be quickly

changed from one height-of-cut to another by using the

gauge bar (Part No. 98-1852) and adjusting the front roller

only. In many cases, an entire machine can be done

quickly by using the gauge bar to set the front roller of

one cutting unit. The remaining cutting units can then be

set by loosening their front roller jam nuts and turning

each front roller adjustment knob the same number of

turns and in the same direction as the first unit.

11

Page 12

Checking/Adjusting the

Cutting Unit Attitude

1. Place an angle indicator, Toro Part No. 99-3503, on the

bedknife and record the bedknife angle (Fig. 20).

1

3

1

2

1. First screw

2. Second screw

4

Figure 21

3. Gauge bar angle

4. Front roller

Figure 20

1. Bedknife angle

2. Using a two-screw gauge bar, Toro Part No. 98-1852,

set the first screw to the desired height-of-cut.

3. Place the gauge bar across the front and rear rollers.

The first screw head needs to fit snugly over the edge

of the bedknife while the gauge bar contacts the rollers

(Fig. 21).

4. Adjust the second screw to contact the bedknife.

5. Place an angle indicator on the gauge bar and record

the gauge bar angle (Fig. 21).

6. Bedknife Angle (step 1) – Gauge Bar Angle (step 5) =

Cutting Unit Attitude (degrees)

7. For adjusting the cutting unit attitude, adjust the

second screw for the desired attitude, then repeat the

height-of-cut adjustment for a floating cutting unit;

refer to Leveling the Rear Roller to the Reel, page 9.

Change the bar stock thickness for leveling the rear

roller in order to accommodate your desired cutting

unit attitude.

12

Page 13

Height-of-Cut Adjustment for a

Fixed Cutting Unit

1. Adjust reel to bedknife contact.

2. Loosen nuts securing skids or front roller and raise to

highest position.

3. Loosen jam nuts securing rear roller. Lower roller

beyond desired height-of-cut (ensures proper bedknife

attitude).

4. Lower cutting unit onto a flat surface, such as a 1 in. x

20 in. x 30 in. piece of plywood. Shut off engine and

remove the key.

5. Insert piece of bar stock (Fig. 16) 25–28 in. (70 cm)

long with thickness equal to desired height-of-cut,

under entire length of the reel, next to bedknife.

6. Adjust rear roller adjustment knobs and jam nuts until

full length of the rear roller contacts the flat surface

and the full length of the reel (not bedknife) contacts

the bar stock. Tighten rear roller knobs and jam nuts.

Adjusting the Skids and Front

Maintenance

Note: Determine the left and right sides of the machine

from the normal operating position.

Lubrication

Before and after greasing, wipe each grease fitting with a

clean rag. Use a hand-operated grease gun and #2 general

purpose grease to lubricate the eight grease fittings.

Applying too much pressure will ruin the seals and

leaking grease could cause damage to grass.

Important Before washing the machine, shut off the

engine and remove the key. Lubricate the reels and rollers

immediately after washing the machine. This helps to

minimize water entering the reel and roller bearings.

Roller (Fixed Head Kit)

After skid kit or front rollers are installed (installation

instructions are included with each option) make the

following adjustments to prevent them from pushing down

uncut grass or scalping on undulating terrain:

1. Lock each cutting unit in the fixed position (Refer to

Cutting Unit Orientation, Fig. 15). Set the reel to

bedknife adjustment and height-of-cut adjustment.

2. Position the cutting units on a flat, level surface (1 in.

(25 mm) thick piece of plywood).

3. Skids and front rollers used to prevent scalping should

not ride on the ground. Adjust each skid or front roller

so it is 1/8–1/4 in. (3–6 mm) or higher above the level

surface. Allow greater clearance at the higher

height-of-cut settings.

4. Proper adjustment is achieved when the cutting unit

does not scalp the grass in normal mowing conditions

and yet is set high enough not to mar the turf and

create undue wear on the skids or rollers.

Note: Skids are used only with the cutting unit in the

fixed position. Front rollers may be used with the cutting

unit in either the fixed or floating position.

Figure 22

Important If the cutting units are washed in the raised

position, be sure to lower them to the ground after

washing. This allows water to drain from the ends of the

rollers and reel bearing housings.

1. Lubricate the reel shaft and roller bearings with 3 or 4

pumps of grease. Daily lubrication of these fittings

purges water and other contaminants, increasing

service life and maintaining excellent quality-of-cut.

Note: When greasing roller bearings, grease forced from

bearings will not be visible around the roller shaft.

13

Page 14

Figure 23

starting the engine raise the grass deflector on the #1

cutting unit (center) and tighten fasteners to retain the

deflector in the raised position.

Operator Duties

1. Sit on the seat and engage parking brake.

2. Turn reel speed knob counterclockwise to slowest (#1)

position.

3. Start the engine and run at minimum throttle. Lower

either:

• The center 3 cutting units (#1, 2 & 3 ) or

2. Lubricate the floatation kit pivots and fixed head kit

pivots with one pump of grease weekly.

Figure 24

Backlapping

Danger

During the backlap operation the reels are under

power. Contact with rotating reels can result in

personal injury.

• Do not adjust the cutting units while the engine

and reels are operating.

• Instruct the operator to stop the reels and shut

the engine off when an adjustment is necessary.

• Left-hand (#4) cutting unit or

• Right-hand (#5) cutting unit

The center 3 cutting units run and shut off together.

With the #4 & #5 cutting units up and latched

(automatically shut off) and the #1, #2 & #3 cutting

units down, backlap the center (#1) cutting unit from

the rear of the machine with the long handled brush.

Backlap the #2 and #3 cutting units from the front of

the machine.

4. Wait for second person’s instruction to engage reels in

backlap mode. Pull up on control lever and turn the

reel speed knob counterclockwise to the backlap

position.

5. Follow the second person’s instructions. Be prepared

to stop reels and engine quickly in case of an

emergency.

Duties for Second Person

1. Instruct operator when to start and stop reels.

Danger

Contact with the reel or other moving parts can

result in personal injury.

• Stay away from the reel while backlapping.

• Never use a short handled paint brush to apply

backlapping compound.

Use a good grade of medium grit (80 courseness) lapping

compound with a water soluble carrier so the compound

will be easily washed away after completion of the

operation. Dry lapping compound should be mixed with

liquid detergent until it has a free-flowing consistency.

Two people are required to perform backlapping. Good

communication between one another is necessary and

caution should be used when making each move. With one

person on the seat to operate the controls (operator) the

other performs the backlapping operation. Note: Before

2. Dip 3 in. (76 mm) paint brush attached to Toro Part

No. 29-9200 Handle Assembly into lapping

compound. Stand clear and instruct operator to engage

reel into backlap mode.

3. Apply lapping compound evenly over full length of the

reel, ensuring that all reel blades are covered.

Whenever noise of reel against the bedknife begins to

disappear or, an uneven concentration of material

appears on the reel, redistribute the compound with the

brush.

14

Page 15

4. When it becomes necessary to adjust the reel to the

bedknife, instruct the operator to disengage the reel,

stop the engine and remove the key from the ignition

switch. Then proceed with the adjustment only after

the reels have stopped rotating.

5. Backlap each reel until the cutting edges are sharp,

even, and consistent on all blades. Achieve a minimum

of 1/32 in. (0.79 mm) land area on newly sharpened

reel assemblies. Normally, a reel need only be

backlapped for approximately 3 minutes.

3

2

6. Upon completion, stop the reel and turn off the engine.

Remove the key from the ignition switch. Wash the

unit thoroughly with a low pressure stream of water to

remove all lapping material. Allow the reel to dry and

lubricate the grease fittings.

7. Check sharpness of the reel and bedknife with strips of

newspaper. With light reel to bedknife contact, the

paper should be cleanly sheared across the entire width

of the reel. If the paper is not sheared acceptably,

continue backlapping.

8. After backlapping the #1, #2 and #3 cutting units, raise

and latch these units and proceed with the #4 and #5

cutting units.

Note: See the Toro Sharpening Manual (Part No. 80-300)

for additional backlapping/sharpening information.

Servicing the Bedknife/Bedbar

Note: The bedbar on each cutting unit has a precision

ground mounting surface to provide an excellent fit with a

bedknife. Backlapping of replacement bedknives is often

sufficient to achieve an excellent cutting edge with

minimum material removed.

1

Figure 25

1. Shoulder bolts (2 each

side)

2. Bushing

3. Spacer

2. Remove the mounting screws for the bedknife and

separate the bedknife from the bar (Fig. 26). Discard

the screws.

1

Removing the Bedknife/Bedbar

1. Remove the shoulder bolts, bushings, and spacers from

each end of the unit and remove the bedbar/bedknife

assembly (Fig. 25).

3

1. Bedbar

2. Bedknife

3. Bedknife mounting screws

15

2

Figure 26

4. Bedknife mounting

4

components

Page 16

Installing the Bedknife/Bedbar

1. Thoroughly clean the bedknife mounting face on the

bedbar of all rust and scale. Remove any material on

the mounting face of the bedbar that will affect a good

match-up with the bedknife.

2. Before installation, apply a coating of Never Seez, or

any material that will ease future disassembly of the

bedknife mounting screws to the threads before

installation.

3. Use a torque wrench and Part No. 51-0880 special tool

to finish tightening the screws (Fig. 27). Torque the

screws to 250 in.-lb. (28 Kgm) beginning with the

center screw and tightening alternate screws toward

each end to ensure that the bedknife will be flat

against the bedbar.

4

3

1

4. Install the bedbar/bedknife assembly to the cutting

unit.

1

2

3

Figure 27

1. Torque wrench

2. Tool—Toro Part No.

51-0880

3. T orque from center out

1

2

Figure 28

1. Guard

2. Mounting fasteners

3. Bedbar mounting

assembly

4. Adjusting assembly

5. Dust cap

2. Remove the shoulder bolts, bushings, and spacers from

each end of the unit and remove the bedbar/bedknife

assembly (Fig. 29).

3. Remove the inboard locknut from the adjuster pin, the

fasteners for the bracket, and the adjusting handle

assembly from the sideplate (Fig. 29).

5

6

Servicing the Reel Assembly

Removing the Reel Assembly

1. Remove the guards from each end of the cutting unit

and the front and rear roller assemblies (Fig. 28).

1. Locknut

2. Belleville washer

3. Shoulder bolt

16

2

4

1

3

Figure 29

4. Bearing housing

5. Reel shaft

6. Flange bushings

Page 17

4. Disassemble the cone nut from the shoulder bolt

securing the bearing housing to the sideplate, remove

the Belleville washer and bolt, and slide the bearing

housing off of the reel shaft (Fig. 30).

5. Remove the cover from the drive housing and remove

the drive belt from the housing (Fig. 30).

1

6

5

4

2

2

Figure 30

1. Drive housing (cover

removed)

2. Drive Belt

6. Remove the reel capscrew, toothed washer, and pulley

washer from the reel shaft (Fig. 31).

Note: The capscrew is assembled with a thread locking

compound.

7

1

3

Figure 31

1. Reel capscrew

2. Pulley washer

3. Driven pulley

4. Drive housing

5. Adjusting handle

assembly

6. Woodruff key

7. Drive housing fasteners

7. Using a puller, remove the driven pulley from the reel

shaft (Fig. 31). Remove the woodruff key from the reel

shaft.

8. Remove the adjustment assembly and cone nut,

Belleville washer, and shoulder bolt securing the

housing to the sideplate (Fig. 31). Remove the

housing.

9. Slide the reel assembly out of the slots in the

sideplates.

10.To remove the bearing and seals from the drive

housing, remove the retaining ring from the inside of

the housing. Pry the outer seal out of the belt drive

case side. Press the bearing and rear seal out from the

outer side of the housing.

11. To remove the bearing and seal from the bearing

housing, remove the dust cap (Fig. 28) and press the

bearing and seal out of the housing.

17

Page 18

Installing the Reel Assembly

1. Inspect the flange bushings in the mounting holes for

the drive housing and bearing housing for wear

(Fig. 29). Replace, if necessary.

2. Assemble the outer seal (lip facing in to retain grease)

into the drive housing using Loctite 242 retaining

compound on the outer diameter. Apply a light coat of

oil to the seal lips and insert the bearing assembly

through the seal from the opposite side (Fig. 32).

Figure 32

3. Apply a light coating of oil to the inner seal lips and

install (lip facing away from the bearing and toward

the reel) in the housing. Install the retaining ring to

secure the assembly in the housing (Fig. 32).

10.Ensure the slot in the pulley washer is aligned with the

roll pin in the pulley and install the washer, toothed

washer, and reel capscrew (Fig. 31). Apply a medium

strength thread locking compound to the reel capscrew

during assembly. Torque the capscrew to 45–55 ft.-lb.

11. Install the reel adjustment assemblies to each

sideplate. Install roll pins before tightening fasteners.

12.Install the bedbar/bedknife assembly.

13.Install the front and rear roller assemblies or skids.

14.Adjust the reel to the bedknife; refer to Adjusting the

Reel to the Bedknife, page 9. Adjust the

height-of-cut; refer to Adjusting the Height-of-Cut,

page 9.

Removing the Roller

The roller assemblies can be removed by the following

methods:

1. Remove the fasteners securing the guard and roller

adjustment housing to the side plate (Fig. 33) or

unscrew the upper cone nut and drop the threaded rod

out of the adjustment housing (Fig. 34).

4. Apply a light coat of oil to the seal lips of the seal for

the bearing housing and install (lip facing away from

the bearing) over the bearing assembly (Fig. 32).

5. Insert the bearing and seal in the housing and install

the dust cap into the housing.

6. Assemble the reel assembly to the frame. Ensure the

shield washer is installed on the drive housing end of

the reel shaft. Align the drive pin on reel shaft with the

slot in the bearing and slide the drive housing onto the

shaft.

7. Insert the shoulder bolt through the Belleville washer

and rear housing mounting hole. Slide the bolt through

the sideplate mounting hole (Fig. 29). Install the cone

nut locknut onto the bolt. Tighten the cone nut to

45–55 ft.-lb.

8. Align the drive pin on the reel shaft with the notch in

the bearing inner race and slide the bearing housing

over the opposite end of the reel shaft. Insert the

shoulder bolt and Belleville washer through the rear

bearing housing mounting hole. Slide the bolt through

the sideplate mounting hole. Install the cone onto the

bolt. Tighten the cone nut to 45–55 ft.-lb.

9. Install the woodruff key in the drive housing end of the

reel shaft and install the driven pulley onto the shaft.

2

1

1. Guard

2. Roller adjusting housing

3

4

Figure 33

3. Sideplate

4. Mounting fasteners

18

Page 19

2

3

1

Figure 34

1. Cone nut

2. Rod and collar assembly

2. The threaded rod and collar assembly can be removed

from the roller by sliding it off the shaft at both ends

(Fig. 34).

3. Flex locknut

Installing the Roller

Important When assembling a new roller to the

cutting unit, mount the roller so that the roller shaft

locknut is on the right side of the cutting unit (Fig. 34) (as

viewed by the operator sitting on the seat of the machine).

This prevents the locknut from loosening during

operation.

19

Page 20

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Commercial Product (“Product”) to be free from defects in

materials or workmanship for two years or 1500 operational

hours*, whichever occurs first. Where a warrantable condition

exists, we will repair the Product at no cost to you including

diagnosis, labor, parts, and transportation. This warranty begins

on the date the Product is delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists.

If you need help locating a Commercial Products Distributor or

Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: commercial.service@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your operator’s manual. Failure

to perform required maintenance and adjustments can be grounds

for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in an

abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up,

during normal Product operation include, but are not limited to,

blades, reels, bedknives, tines, spark plugs, castor wheels,

tires, filters, belts, etc.

• Failures caused by outside influence. Items considered to be

outside influence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, or chemicals, etc.

• Normal “wear and tear” items. Normal “wear and tear”

includes, but is not limited to, damage to seats due to wear or

abrasion, worn painted surfaces, scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are

warranted for the period of time up to the scheduled replacement

time for that part.

Parts replaced under this warranty become the property of Toro.

Toro will make the final decision whether to repair any existing part

or assembly or replace it. Toro may use factory remanufactured

parts rather than new parts for some warranty repairs.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty . Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for use are

limited to the duration of this express warranty.

Some states d o n o t a l l o w exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note regarding engine warranty: The Emissions Control

System on your Product may be covered by a separate warranty

meeting requirements established by the U.S. Environmental

Protection Agency (EPA) and/or the California Air Resources

Board (CARB). The hour limitations set forth above do not apply to

the Emissions Control System Warranty. Refer to the Engine

Emission Control Warranty Statement printed in your operator’s

manual or contained in the engine manufacturer’s documentation

for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country , province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0031 Rev. a

Loading...

Loading...