Page 1

FormNo.3374-295RevC

Reelmaster

®

7000-D4-Wheel

DriveTractionUnit

ModelNo.03708N—SerialNo.313000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisincorporated

withthemuferassembly.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:Thisengineisequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,

orgrass-coveredlandwithoutasparkarrester

mufermaintainedinworkingorder,ortheengine

constricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmay

havesimilarlaws.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontherightfrontframememberofthe

product.Writethenumbersinthespaceprovided.

Figure1

1.Modelandserialnumberlocation

Theenclosed

Engine Owner's Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Thismachineisaride-on,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedfor

cuttinggrassonwell-maintainedlawnsingolfcourses,

parks,sportselds,andoncommercialgrounds.Itis

notdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(

Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SafetyandInstructionalDecals.............................7

Setup.........................................................................11

1AdjustingtheSupportRollers...........................12

2InstallingtheCuttingUnits..............................12

3AdjustingtheTurfCompensation

Spring............................................................15

4UsingtheCuttingUnitKickstand.....................16

5GreasingtheMachine......................................16

6CheckingFluidLevels......................................17

ProductOverview......................................................17

Controls.............................................................17

Specications.....................................................21

TractionUnitSpecications................................21

Attachments/Accessories...................................21

Operation...................................................................22

CheckingtheEngineOilLevel............................22

CheckingtheCoolingSystem..............................23

FillingtheFuelTank...........................................23

CheckingtheHydraulicFluidLevel.....................25

CheckingtheTirePressure.................................26

StartingandStoppingtheEngine........................26

CheckingtheInterlockSwitches.........................26

SettingtheReelSpeed.........................................27

AdjustingtheLiftArmCounterbalance...............28

AdjustingtheLiftArmTurnAround

Position..........................................................28

PushingorTowingtheMachine..........................29

JackingPoints.....................................................29

TieDowns.........................................................29

UnderstandingtheDiagnosticLight....................29

DiagnosticAceDisplay.......................................30

CheckingtheInterlockSwitches.........................30

OperatingCharacteristics...................................31

EngineCoolingFanOperation...........................32

OperatingTips...................................................32

Maintenance...............................................................33

RecommendedMaintenanceSchedule(s)................33

DailyMaintenanceChecklist...............................34

ServiceIntervalChart.........................................35

PremaintenanceProcedures....................................36

RemovingtheHood...........................................36

Lubrication.............................................................36

GreasingtheBearingsandBushings....................36

EngineMaintenance...............................................38

ServicingtheAirCleaner....................................38

ServicingtheEngineOilandFilter......................39

AdjustingtheThrottle........................................39

FuelSystemMaintenance.......................................40

FuelTank...........................................................40

FuelLinesandConnections................................40

ServicingtheWaterSeparator.............................40

FuelPickupTubeScreen....................................40

BleedingAirfromtheInjectors...........................41

ElectricalSystemMaintenance................................41

ChargingandConnectingtheBattery..................41

BatteryCare.......................................................42

Fuses..................................................................43

DriveSystemMaintenance.....................................44

CheckingtheTorqueoftheWheel

Nuts...............................................................44

CheckingthePlanetaryGearDrive

Oil..................................................................44

ChangingthePlanetaryGearDrive

Oil..................................................................44

CheckingtheRearAxleLubricant.......................45

ChangingtheRearAxleLubricant.......................45

AdjustingtheTractionDriveforNeutral.............46

CheckingtheRearWheelT oe-In.........................46

CoolingSystemMaintenance..................................47

ServicingtheEngineCoolingSystem..................47

BrakeMaintenance.................................................48

AdjustingtheServiceBrakes...............................48

BeltMaintenance....................................................48

ServicingtheAlternatorBelt...............................48

HydraulicSystemMaintenance...............................49

ChangingtheHydraulicFluid.............................49

ReplacingtheHydraulicFilters...........................49

CheckingtheHydraulicLinesandHoses.............50

CuttingUnitMaintenance.......................................50

BacklappingtheCuttingUnits............................50

Cleaning.................................................................51

ServicingtheSparkArrestorMufer...................51

Storage.......................................................................52

Engine...............................................................52

TractionUnit......................................................52

Schematics.................................................................53

3

Page 4

Safety

ThismachinemeetsorexceedsANSIB71.4-2004

specicationsineffectatthetimeofproduction.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalertsymbol,

whichmeansCAUTION,WARNING,orDANGER"personalsafetyinstruction."Failuretocomplywiththe

instructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•Readtheoperator'smanualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andear

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthattheoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–machinespeedsshouldbekeptlowonslopes

andduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

4

Page 5

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheoperator'smanual.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly .

•Donotchangetheenginegovernorsettingsor

over-speedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator'sposition:

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator's

position.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcylinders/reels

ifnotmowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Onmulti-cylinder/multi-reelmachines,takecare

asrotatingonecylinder/reelcancauseother

cylinders/reelstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.

Cleanupoilorfuelspillage.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingthecylinders/reels.Wear

glovesandusecautionwhenservicingthem.

5

Page 6

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO,or

ANSIstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Raisethecuttingunitswhendrivingfromonework

areatoanother.

•Donottouchtheengine,silencer/mufer,or

exhaustpipewhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Onanyhill,thereisthepossibilityoftippingor

rollingover,buttheriskincreasesastheslopeangle

increases.Steephillsshouldbeavoided.

Cuttingunitsmustbeloweredwhengoingdown

slopestomaintainsteeringcontrol

•Engagetractiondriveslowly,alwayskeepfooton

tractionpedal,especiallywhentravelingdownhill.

Usereverseontractionpedalforbraking.

•Ifthemachinestallswhenclimbingaslope,do

notturnthemachinearound.Alwaysbackslowly,

straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

embankments,orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•WhenoperatingamachinewithROPS(roll-over

protectionsystem)neverremovetheROPSand

alwaysusetheseatbelt.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.

•Toensuresafetyandaccuracy ,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.

6

Page 7

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

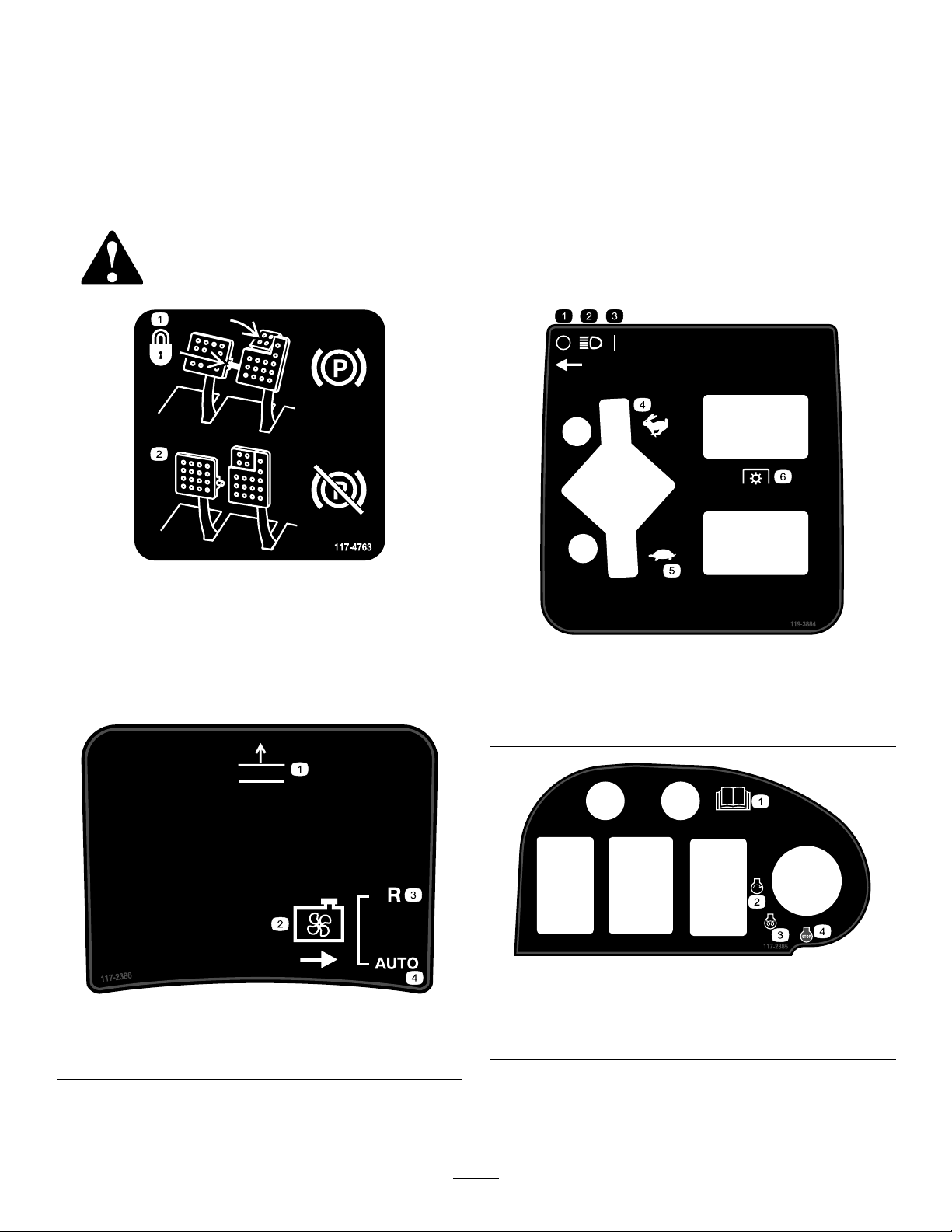

117-4763

1.Toengagetheparking

brake,securethebrake

pedalswiththelockingpin,

presstheparkingbrake

pedalsandengagethetoe

pedal.

117-2386

1.Raisedeck3.Reverse

2.Blowofffan

2.Todisengagetheparking

brake,disengagethe

lockingpinandreleasethe

pedals.

4.Automatic

119-3884

1.Off

2.Headlights

3.On6.PowerT ake-off(PTO)

1.ReadtheOperators

Manual.

2.Engine—start4.Engine—stop

4.Fast,throttle

5.Slow,throttle

117–2385

3.Engine—preheat

7

Page 8

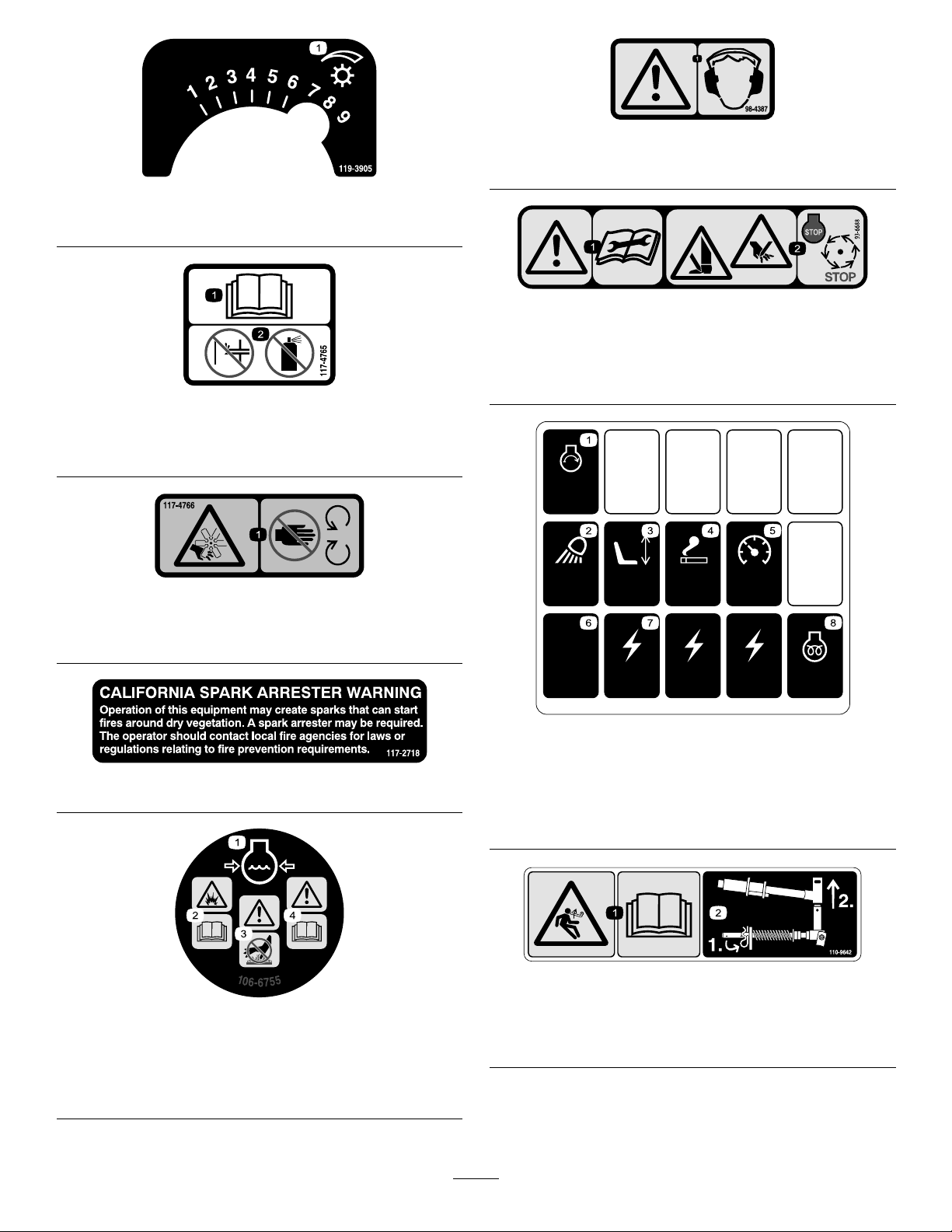

1.Reelspeed

120-1672

10A

20A

10A

10A

10A

2A

7.5A

7.5A

7.5A

TEC-5002

60A

98-4387

1.Warning—wearhearingprotection.

119-3905

93-6688

117-4765

1.ReadtheOperator'sManual.

2.Donotusestartingaids.

117-4766

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

117–2718

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

120-1672

1.Starter,20A5.Gauges,10A

2.Worklight,10A

3.Seat,10A

4.Powerpoint,10A8.Enginepreheat,60A

6.GM4500controller,2A

7.Powersupplied,7.5A

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

106-6755

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

110-9642

1.Storedenergyhazard—readtheOperator'sManual.

2.Movethecotterpintotheholeclosesttotherodbracket

andthenremovetheliftarmandpivotyoke.

8

Page 9

120-1683

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Warning—readtheOperator'sManualbeforetowingthe

machine.

3.Tippinghazard—slowmachinebeforeturning,donotturnat

highspeeds;lowerthecuttingunitwhendrivingdownslopes;

usearolloverprotectionsystemandweartheseatbelt

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingunits,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine.

6.Entanglementhazard,belt—stayawayfrommovingparts,

keepallguardsandshieldsinplace.

120-1681

1.5Bladecuttingunit3.11Bladecuttingunit

2.8Bladecuttingunit4.Mowandbacklap6.Machinespeed

5.ReadtheOperator'sManual.

9

Page 10

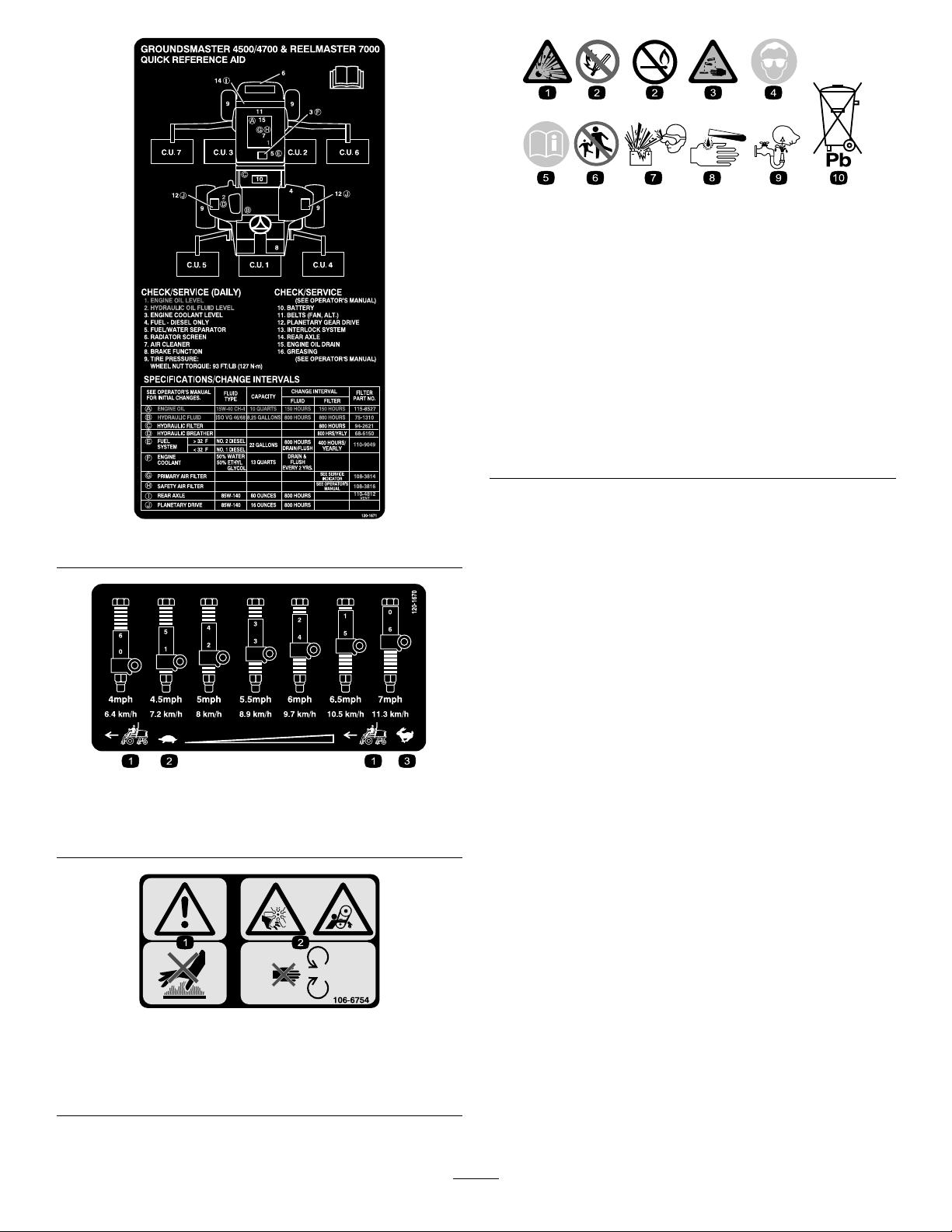

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

120-1671

120-1670

1.Tractionunitspeed3.Fast

2.Slow

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

10

Page 11

Setup

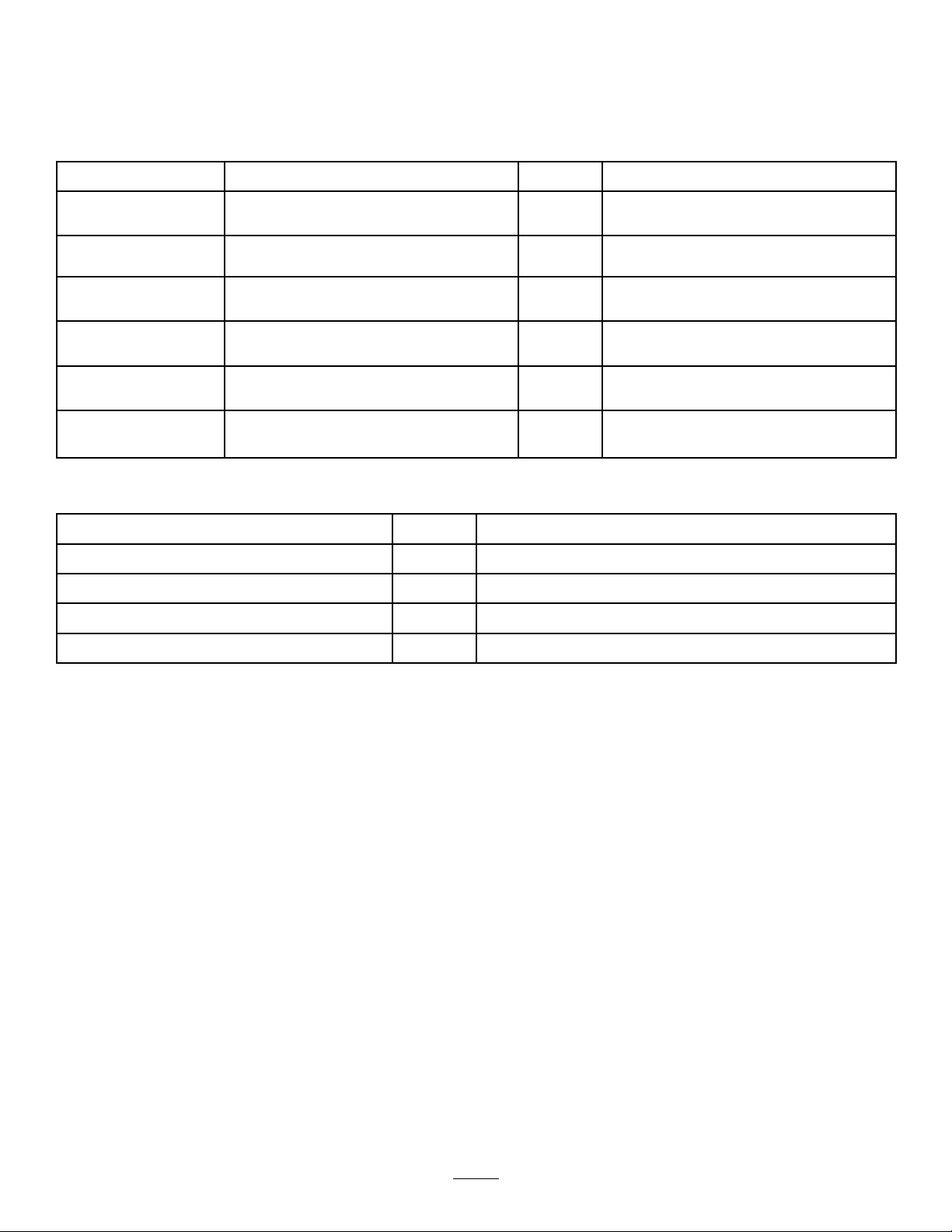

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

MediaandAdditionalParts

Description

Operator'sManual

EngineOperator'sManual

PartsCatalog

Nopartsrequired

Fronthoseguide-R.H.1

Fronthoseguide-L.H.1

Nopartsrequired

Cuttingunitkickstand

Nopartsrequired

Nopartsrequired

Qty.

1

1

1

Readbeforeoperatingmachine

Readbeforeoperatingengine

Usetoreferencepartnumbers

Qty.

Use

–

–

1

–

–

Adjustthesupportrollers

Installthecuttingunits

Adjusttheturfcompensationspring.

InstalltheCuttingUnitKickstand.

Greasethemachine.

Checktherearaxlelubricant,hydraulic

uid,andengineoillevels

Use

OperatorTrainingMaterial

1

Viewbeforeoperatingmachine

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

11

Page 12

1

g019541

1

2

3

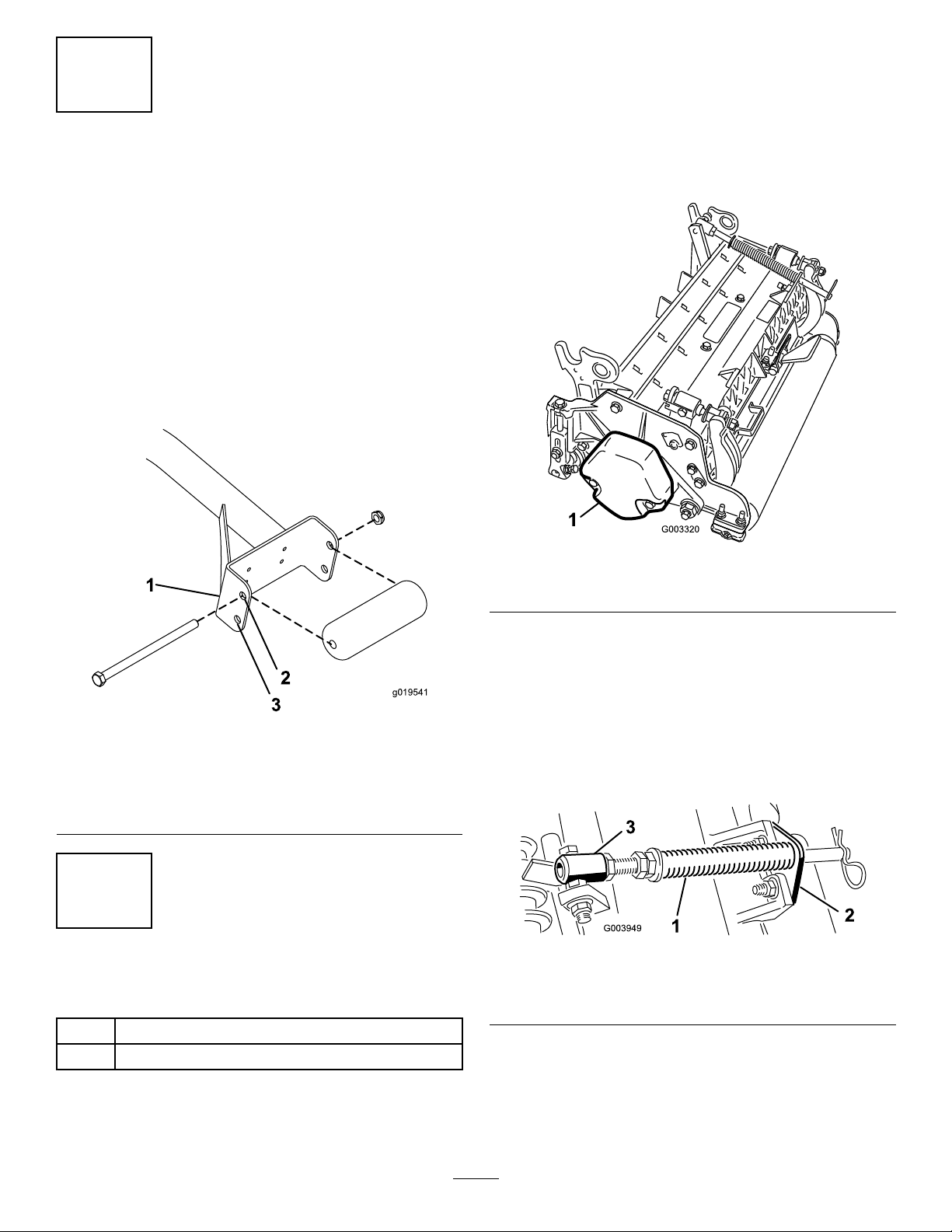

AdjustingtheSupportRollers

NoPartsRequired

Procedure

Dependingonwhatwidthcuttingunitsaretobeinstalled

onthetraction,adjustthesupportrollersasfollows:

•Ifusing27inchcuttingunits,therollersaretobe

installedintheuppermountingholesofsupport

assemblychannels(

•Ifusing32inchcuttingunits,therollersaretobe

installedinthelowermountingholesofsupport

assemblychannels(Figure3).

Figure3).

2.Removetheshippingbracketsanddiscard.

3.Removethecuttingunitsfromthecartons.Assemble

andadjustasdescribedinthecuttingunitOperator's

Manual.

4.Makesurethecounterweight(

totheproperendofthecuttingunitasdescribedin

thecuttingunitOperator'sManual.

Figure4)isinstalled

Figure3

1.Supportassemblychannel3.Usethisholefor32inch

cuttingunits

2.Usethisholefor27inch

cuttingunits

2

InstallingtheCuttingUnits

Partsneededforthisprocedure:

Figure4

1.Counterweight

5.Allthecuttingunitsareshippedwiththeturf

compensationspringmountedtotherightsideofthe

cuttingunit.Theturfcompensationspringmustbe

mountedtothesamesideofthecuttingunitasthe

reeldrivemotor.Repositiontheturfcompensation

asfollows:

A.Removethe2carriageboltsandnutssecuring

therodbrackettothecuttingunittabs(

Figure5

1.Turfcompensationspring3.Springtube

2.Rodbracket

Figure5).

1Fronthoseguide-R.H.

1Fronthoseguide-L.H.

Procedure

1.Removethereelmotorsfromtheshippingbrackets.

B.Removetheangenutsecuringthespringtube

bolttothecarrierframetab(Figure5)Remove

theassembly .

C.Mountthespringtubebolttotheoppositetab

onthecarrierframeandsecurewiththeange

12

Page 13

nut.Theboltheadistobepositionedtothe

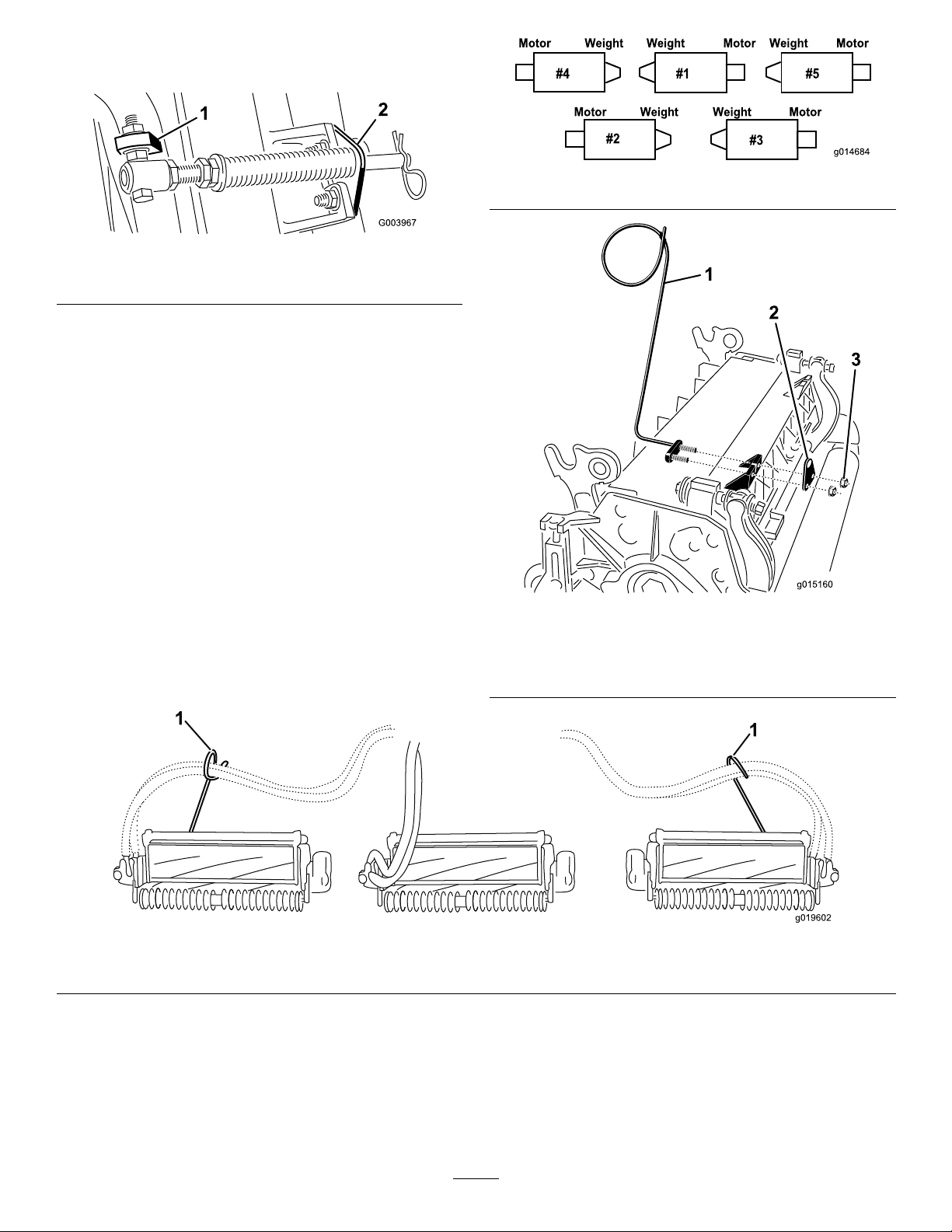

g019602

1

1

outersideofthetabasshowninFigure6.

Figure6

Figure7

1.Oppositecarrierframetab

2.Rodbracket

D.Mounttherodbrackettothecuttingunittabs

withthecarriageboltsandnuts(Figure6).Also,

onthecuttingunit,mountthelefthandhose

guidetothefrontofthecuttingunittabswhen

reinstallingtherodbracket(

Figure8).

Important:Onthe#4(leftfront)and#5

(rightfront)cuttingunits,usetherodbracket

mountingnutstoinstallthehoseguidesto

thefrontofthecuttingunittabs.Thehose

guidesshouldleantowardthecentercutting

unit(Figure7throughFigure9).

1.Hoseguide(Lefthand

shown)

2.Rodbracket

Figure8

3.Nuts

1.Hoseguides(eachmustleantowardthecentercuttingunit)

Note:Wheninstallingorremovingthecutting

units,makesurethehairpincotterisinstalled

inthespringrodholenexttotherodbracket.

Otherwise,thehairpincottermustbeinstalledin

theholeintheendoftherod.

Figure9

6.On27inchcuttingunitsonly ,increasethesteering

ontherearcuttingunitsbyremovingthe(2)pivot

spacers,hexsocketscrewsandangelocknuts

(Figure10)fromtherear(#2and#3)cuttingunit

carrierframes(Figure7).

13

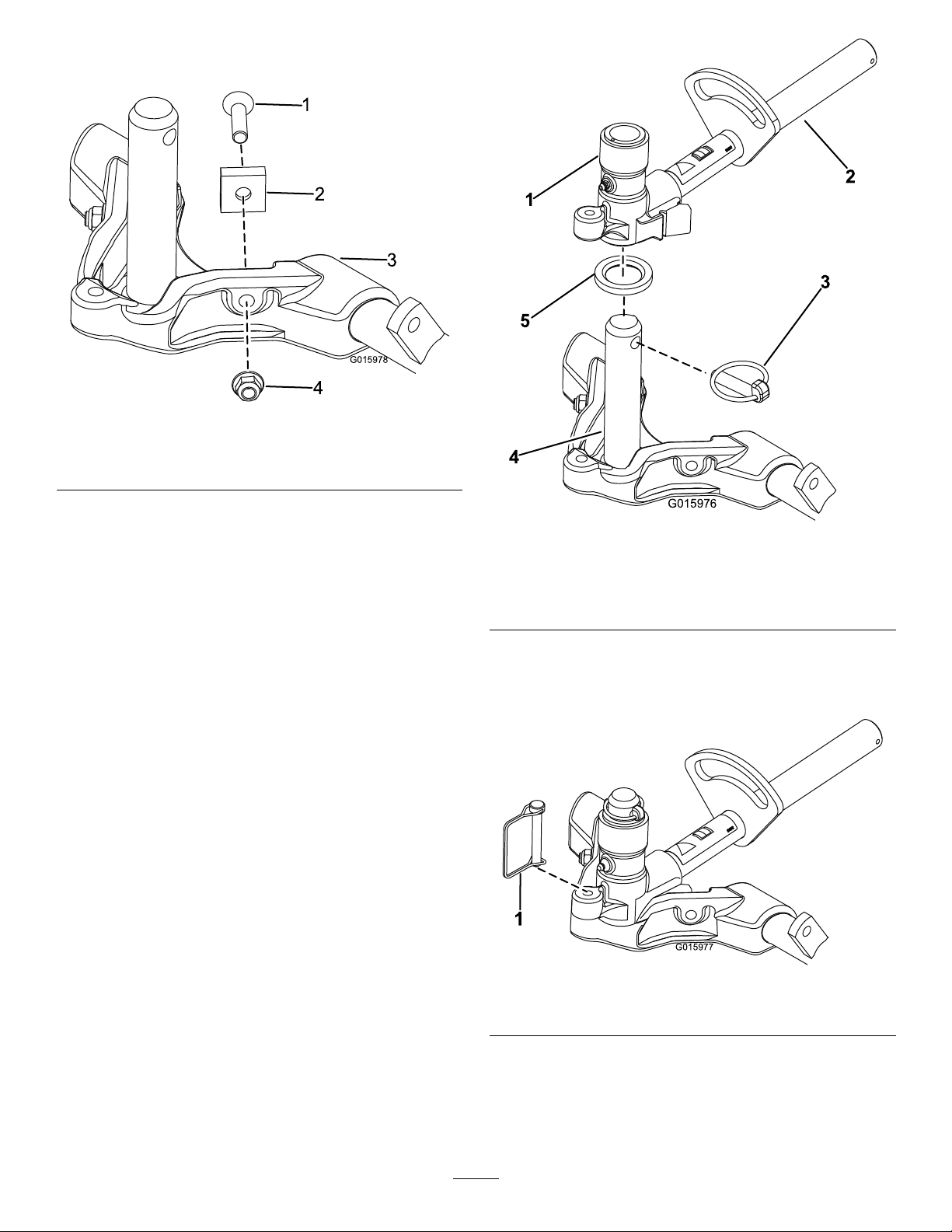

Page 14

Note:32inchcuttingunitsarenotequippedwith

1

2

3

4

G015978

G015976

1

2

3

4

5

1

G015977

pivotspacers.

Figure10

1.Hexsocketscrew

2.Pivotspacer4.Flangelocknut

3.Carrierframe

7.Loweralltheliftarmscompletely.

8.Coatthecarrierframeshaftwithcleangrease

Figure11).

(

9.Forthefrontcuttingunits,slideacuttingunitunder

theliftarmwhileinsertingthecarrierframeshaftup

intotheliftarmpivotyoke(

Figure11).Makesure

thethrustwasherisinpositiononthecarrierframe

shaft.

10.Securethecarrierframeshafttotheliftarmyoke

withtheKlikpin(Figure11).

Figure11

1.Liftarmpivotyoke4.Carrierframeshaft

2.Liftarm

3.Klikpin

5.Thrustwasher

11.Tolock(x)thesteeringonthecuttingunits,secure

thepivotyoketothecarrierframewiththesnapper

pin(Figure12).

Figure12

1.Snapperpin

Note:Fixedsteeringisrecommendedwhen

cuttingsidehills.

12.Usethefollowingprocedureontherearcuttingunits

whentheheightofcutisabove3/4inch.

14

Page 15

A.Removethelynchpinandwashersecuringthe

liftarmpivotshafttotheliftarmandslidethe

liftarmpivotshaftoutoftheliftarm(Figure13).

Figure13

1.Liftarmpivotshaftlynchpinandwasher

B.Inserttheliftarmyokeontothecarrierframe

shaft(Figure11).

C.Inserttheliftarmshaftintotheliftarm

andsecureitwiththewasherandlynchpin

Figure13).

(

13.Securetheliftarmchaintothechainbracketwith

thesnapperpin(Figure14).Usethenumberofchain

linksdescribedinthecuttingunitOperator'sManual.

Figure15

1.Reeldrivemotor2.Mountingbolts

3

Figure14

1.Liftarmchain3.Snapperpin

2.Chainbracket

14.Coatthesplineshaftofthereelmotorwithclean

grease.

15.OilthereelmotorO-ringandinstallitontothe

motorange.

16.Installthemotorbyrotatingitclockwisesothatthe

motorangesclearthebolts(Figure15).Rotatethe

motorcounterclockwiseuntiltheangesencirclethe

boltsthentightenthebolts.

AdjustingtheTurf

CompensationSpring

NoPartsRequired

Procedure

Theturfcompensationspring(Figure16)transfers

weightfromthefronttotherearroller.(Thishelps

toreduceawavepatternintheturf,alsoknownas

marcellingorbobbing.)

Important:Makespringadjustmentswiththe

cuttingunitmountedtothetractionunit,pointing

straightaheadandloweredtotheshopoor.

1.Makesurethehairpincotterisinstalledintherear

holeinthespringrod(

Note:Whenservicingthecuttingunit,movethe

hairpincottertothespringrodholenexttotheturf

compensationspring.

Figure16).

Important:Makesurethereelmotorhoses

arenottwisted,kinkedorintheriskofbeing

pinched.

15

Page 16

Figure16

1.Turfcompensationspring3.Springrod

2.Hairpincotter4.Hexnuts

Figure17

2.Tightenthehexnutsonthefrontendofthespring

roduntilthecompressedlengthofthespringis6.25

inches(15.9cm)(Figure16).

Note:Whenoperatingonroughterraindecrease

thespringlengthby1/2inch.Groundfollowingwill

beslightlydecreased.

Note:Theturfcompensationsettingwillneedto

beresetiftheHOCsettingortheAggressiveness

ofCutsettingischanged.

4

UsingtheCuttingUnit

Kickstand

Partsneededforthisprocedure:

1

Cuttingunitkickstand

1.Cuttingunitkickstand

Securethekickstandtothechainbracketwiththe

snapperpin(Figure18).

Figure18

Procedure

Wheneverthecuttingunithastobetippedtoexpose

thebedknife/reel,propuptherearofthecuttingunit

withthekickstandtomakesurethenutsontheback

endofthebedbaradjustingscrewsarenotrestingonthe

worksurface(Figure17).

1.Chainbracket3.Cuttingunitkickstand

2.Snapperpin

16

Page 17

ProductOverview

5

GreasingtheMachine

NoPartsRequired

Procedure

Beforethemachineisoperated,itmustbegreasedto

ensureproperlubrication.RefertoLubricationsection.

Failuretoproperlygreasethemachinewillresultin

prematurefailureofcriticalparts.

6

CheckingFluidLevels

NoPartsRequired

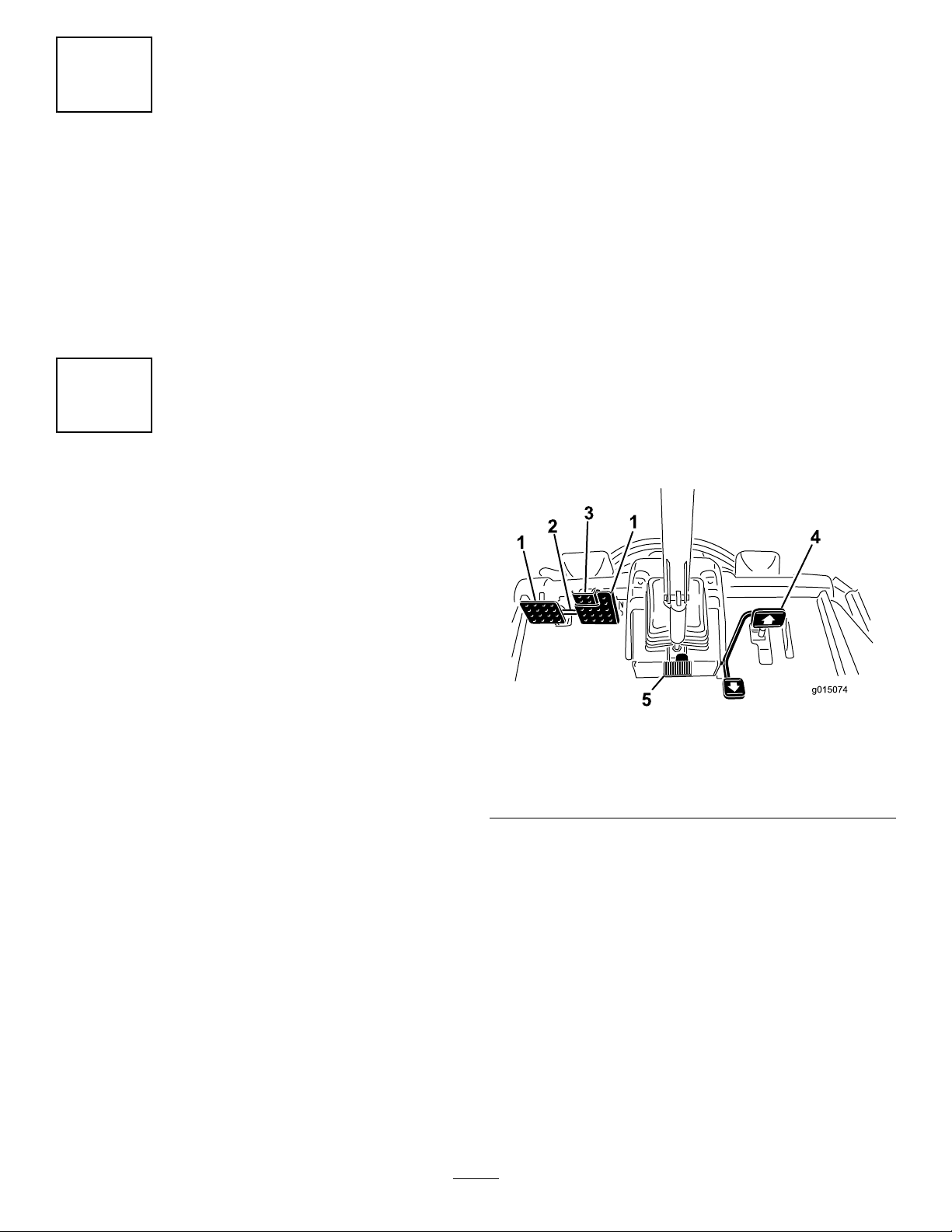

Controls

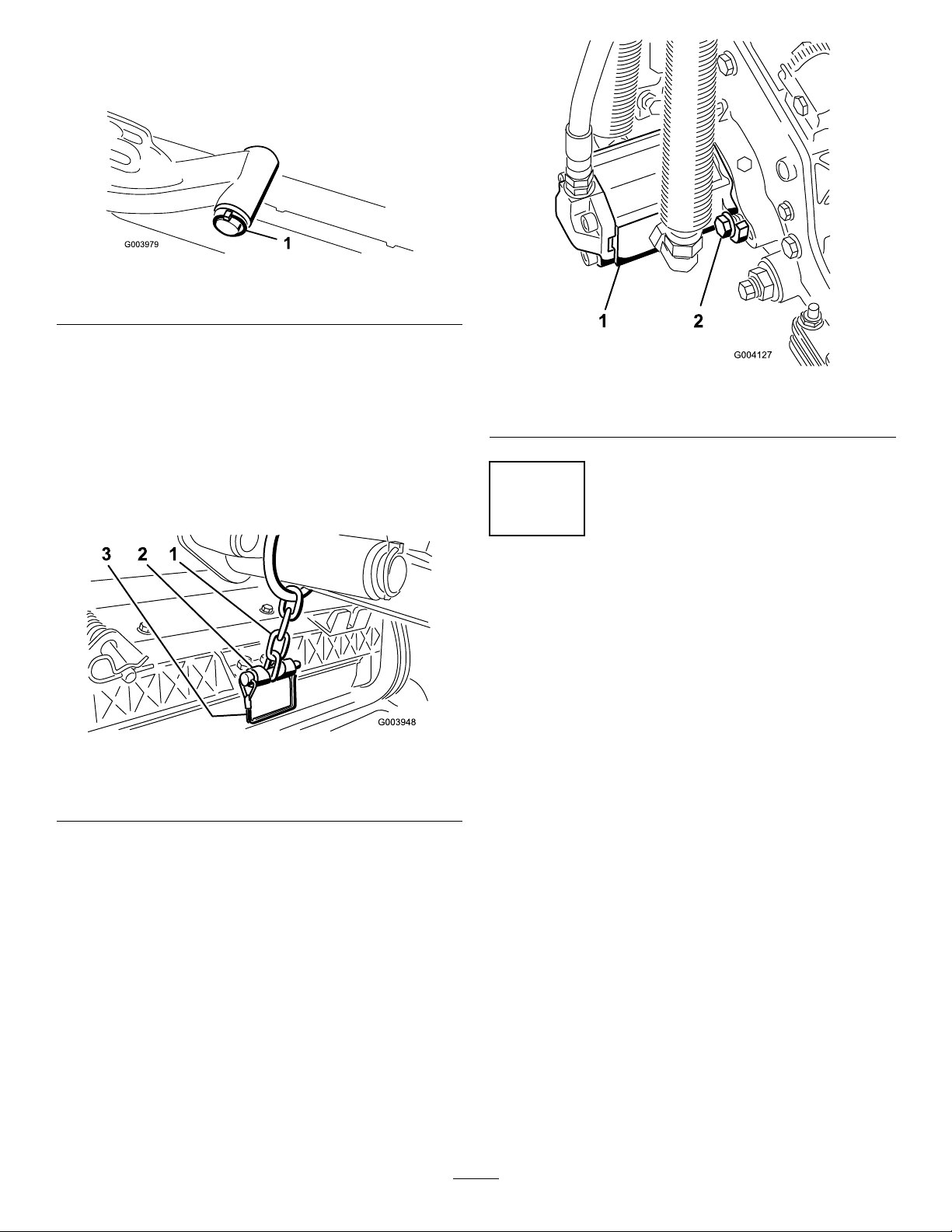

BrakePedals

Twofootpedals(Figure19)operateindividualwheel

brakesforturningassistanceandtoaidinobtaining

bettersidehilltraction.

PedalLockingLatch

Thepedallockinglatch(Figure19)connectsthepedals

togethertoengagetheparkingbrake.

ParkingBrakePedal

Toengagetheparkingbrake,(Figure19)connectthe

pedalstogetherwiththepedallockinglatch,pushdown

ontherightbrakepedalwhileengagingthetoepedal.To

releasetheparkingbrake,pressoneofthebrakepedals

untiltheparkingbrakelatchretracts.

Procedure

1.Checktherearaxlelubricantlevelbeforetheengine

isrststarted,refertoCheckingtheRearAxle

LubricantinDriveSystemMaintenance.

2.Checkthehydraulicuidlevelbeforetheengineis

rststarted,refertoCheckingtheHydraulicFluid

LevelinOperation.

3.Checktheengineoillevelbeforeandaftertheengine

isrststarted,refertoCheckingtheEngineOil

LevelinOperation.

Figure19

1.Brakepedal4.Tractionpedal

2.Pedallockinglatch5.Tiltsteeringpedal

3.Parkingbrakepedal

TractionPedal

Thetractionpedal(Figure19)controlsforwardand

reverseoperation.Depressthetopofthepedaltomove

forwardandthebottomtomovebackward.Ground

speeddependsonhowfarthepedalisdepressed.For

noload,maximumgroundspeed,fullydepressthepedal

whilethethrottleisinFast.

Tostop,reduceyourfootpressureonthetractionpedal

andallowittoreturntothecenterposition.

TiltSteeringPedal

Totiltthesteeringwheeltowardsyou,pressthefoot

pedal(Figure19)down,andpullthesteeringtower

17

Page 18

towardyoutothemostcomfortablepositionandthen

releasethepedal.

MowSpeedLimiter

ChargeIndicator

Thechargeindicator(Figure21)illuminateswhenthe

systemchargingcircuitmalfunctions.

Whenthemowspeedlimiter(Figure20)isippedupit

willcontrolthemowspeedandallowthecuttingunits

tobeengaged.Eachspaceradjuststhemowingspeed

by½mileperhour.Themorespacersyouhave,onthe

topoftheboltthesloweryouwillgo.Fortransport,ip

backthemowspeedlimiterandyouwillhavemaximum

transportspeed.

SpeedLimiterScrews

Adjustthescrew(s)(Figure20)tolimittheamountthe

tractionpedalcanbedepressedintheforwardorreverse

directiontolimitspeed.

Important:Thespeedlimiterscrewmuststopthe

tractionpedalbeforethepumpreachesfullstroke

ordamagetothepumpmayoccur.

KeySwitch

Thekeyswitch(Figure21)hasthreepositions:Off,

On/Preheat,andStart.

PTOSwitch

ThePTOswitch(Figure21)hastwopositions:Out

(start)andIn(stop).PullthePTObuttonouttoengage

thecuttingunitblades.Pushinthebuttontodisengage

thecuttingunitblades.

Figure20

1.Reversespeedlimiter

screw

2.Forwardspeedlimiter

screw

3.Spacers

4.Mowspeedlimiter

DiagnosticLight

Thediagnosticlight(Figure21)willilluminateshoulda

systemfaultberecognized.

EngineCoolantTemperatureGauge

Duringnormaloperatingconditionsthegauge

(Figure21)shouldbeinthegreenrange.Checkthe

coolingsystemifthegaugegoestotheyelloworred

range.

EngineOilPressureWarningLight

Thelight(Figure21)illuminateswhentheengineoil

pressureisdangerouslylow .

Figure21

1.Diagnosticlight

2.Enginecoolant

temperaturegauge

3.Engineoilpressure

warninglight

4.Chargeindicator10.Glowplugindicatorlight

5.Keyswitch11.Enginecoolant

6.PTOswitch

7.Liftswitch

8.Throttlecontrol

9.Lightswitch

temperaturewarning

light

LiftSwitch

Theliftswitch(Figure21)raisesandlowersthecutting

units.Presstheswitchforwardtolowerthecuttingunits

andbackwardtoraisethecuttingunits.Whenstarting

18

Page 19

themachine,withthecuttingunitsinthedownposition,

presstheliftswitchdowntoallowthecuttingunitsto

oatandmow .

hastwopositionsR(manualreverse)andAuto(normal).

RefertoEngineCoolingFanOperationintheOperation

Sectionofmanual.

ThrottleControl

Movethecontrol(Figure21)forwardtoincreasethe

enginespeedandrearwardtodecreasethespeed.

LightSwitch

Presstheloweredgeoftheswitch(Figure21)toturnon

thelights.Presstheupperedgeoftheswitchtoturn

offthelights.

GlowPlugIndicatorLight

Whenlit,theglowplugindicatorlight(Figure21)

indicatesthattheglowplugsareon.

EngineCoolantTemperatureWarning

Light

Thelight(Figure21)illuminatesandthecuttingunits

shutdown(PTOdisengages).Ifthetemperature

continuestorisetheenginewillshutdown.

PowerPoint

BagHolder

Usethebagholder(Figure22)forstorage.

HourMeter

Thehourmeter(Figure22)showsthetotalhoursthat

themachinehasbeenoperated.

BacklapLevers

Usethebacklapleversforbacklappingthereels

Figure23).

(

Thepowerpoint(Figure22)isusedtopoweroptional

12voltelectricalaccessories.

Figure22

1.Powerpoint3.Bagholder

2.Enginecoolingfanswitch

4.Hourmeter

Figure23

1.Frontbacklaplever2.Rearbacklaplever

ReelSpeedControl

Thereelspeedcontrolregulatesthespeedofthefront

andrearcuttingunits(Figure24).Thereelspeed

increasesastheknobisturnedclockwise.

EngineCoolingFanSwitch

Themachineisequippedwithahydraulicallydrivenauto

reversingenginecoolingfan.Thefanswitch(Figure22)

19

Page 20

1.Reelspeedcontrols

Weightgauge

Indicateswhentheseatisadjustedtotheweightofthe

operator(Figure26).Heightadjustmentismadeby

positioningthesuspensionwithintherangeofthegreen

region.

Figure24

FuelGauge

Thefuelgauge(Figure25)indicatestheleveloffuelin

thetank.

Figure25

1.Fuelgauge

SeatAdjustments

ForeandAftAdjustingLever

Pulloutonthelevertoslidetheseatforeoraft

(Figure26).

Figure26

1.Weightgauge

2.Weightadjustinglever5.Armrestadjustingknob

3.ForeandAftadjusting

lever

4.Seatbackadjustinglever

WeightAdjustingLever

Adjustforoperatorweight(Figure26).Pulluponthe

levertoincreasetheairpressureandpushdownto

decreasetheairpressure.Theproperadjustmentis

attainedwhentheweightgaugeisinthegreenregion.

SeatArmRestAdjustingKnob

Rotatetheknobtoadjusttheseatarmrestangle

(Figure26).

SeatBackAdjustingLever

Movethelevertoadjusttheseatbackangle(Figure26).

20

Page 21

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

TractionUnitSpecications

Widthofcut121inches(307cm)

Overallwidth,cuttingunits

down

Overallwidth,cuttingunitsup

(transport)

Overalllength145.8inches(370cm)

HeightwithROPS87inches(220cm)

TrackWidth,front90inches(229cm)

TrackWidth,rear

Wheelbase

NetWeight(withnocutting

unitsandnouids)

Attachments/Accessories

136inches(345cm)

94inches(239cm)

55.5inches(141cm)

67-1/2inches(171cm)

3470lb(1574kg)

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

21

Page 22

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

1.Parkthemachineonalevelsurface.

2.Unlockthehoodlatchesandopenthehood

Figure27).

(

Removethekeyfromtheignitionbeforeyoudo

anymaintenance.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Thecrankcasecapacityisapproximately10qt.(9.5l)

withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher.

•Preferredoil:SAE15W -40(above0°F)

•Alternateoil:SAE10W -30or5W -30(all

temperatures)

Note:ToroPremiumEngineoilisavailable

fromyourdistributorineither15W-40or10W-30

viscosity.Seethepartscatalogforpartnumbers.

Figure27

1.Hoodlatch

3.Removethedipstick,wipeitclean,installthe

dipstickintothetube,andpullitoutagain.

Theoillevelshouldbeinthesaferange(

Figure28

1.Dipstick

Figure28).

Note:Thebesttimetochecktheengineoilis

whentheengineiscoolbeforeithasbeenstarted

fortheday .Ifithasalreadybeenrun,allowthe

oiltodrainbackdowntothesumpforatleast10

minutesbeforechecking.Iftheoillevelisator

belowthe‘add’markonthedipstick,addoilto

bringtheoilleveltothe‘full’mark.Donotoverll.

Iftheoillevelisbetweenthe‘full’and‘add’marks,

nooiladditionisrequired.

4.Iftheoilisbelowthesaferange,removethellcap

(Figure29)andaddoiluntilthelevelreachesthe

FULLmark.Donotoverll.

22

Page 23

Figure29

1.Oilllcap

Note:Whenusingdifferentoil,drainalloldoil

fromthecrankcasebeforeaddingnewoil.

Figure30

5.Installtheoilllcapanddipstick.

6.Closethehoodandsecureitwiththelatches.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Checklevelofcoolantatthebeginningofeachday.

Capacityofsystemis13qt.(12.3l).

1.Carefullyremovetheradiatorcap.

CAUTION

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

1.Expansiontank

2.Checkthecoolantlevelintheradiator.Theradiator

shouldbelledtothetopofthellerneckandthe

expansiontanklledtotheFULLmark(Figure30).

3.Ifthecoolantislow ,adda50/50mixtureofwater

andethyleneglycolantifreeze.Donotusewater

onlyoralcohol/methanolbasecoolants.

4.Installtheradiatorcapandexpansiontankcap.

FillingtheFuelTank

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Fueltankcapacity:22gallons(83l).

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-Dor

No.1-D/2-Dblend)belowthattemperature.Useof

wintergradefuelatlowertemperaturesprovideslower

ashpointandcoldowcharacteristicswhichwillease

startingandreducefuellterplugging.

Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

23

Page 24

WARNING

DANGER

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineiscold.Wipe

upanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1in.(25

mm)belowthetopofthetank,nottheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana180-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

1.Removethefueltankcap(Figure31).

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

Figure31

1.Fueltankcap

2.Fillthetanktoabout1inch(25mm)belowthetop

ofthetank,notthellerneck,withNo.2diesel

fuel.Theninstallthecap.

Note:Ifpossible,llthefueltankaftereachuse.

Thiswillminimizepossiblebuildupofcondensation

insidethefueltank.

24

Page 25

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwith

itswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

140to160

PremiumBiodegradableHydraulicFluid-Mobil

EALEnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyT oro.

Thisuidiscompatiblewiththeelastomersused

inT orohydraulicsystemsandissuitablefora

wide-rangeoftemperatureconditions.Thisuidis

compatiblewithconventionalmineraloils,butfor

maximumbiodegradabilityandperformancethe

hydraulicsystemshouldbethoroughlyushedof

conventionaluid.Theoilisavailablein5gallon

(19l)containersor55gallondrumsfromyour

MobilDistributor.

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz.(20ml)

bottles.Onebottleissufcientfor4-6gal(15-221)

ofhydraulicoil.Orderpartno.44-2500fromyour

authorizedTorodistributor.

CheckingtheHydraulicFluid

Level

ServiceInterval:Beforeeachuseordaily

Themachinesreservoirislledatthefactorywith

approximately7.5U .S.gallons(28.4l)ofhighquality

hydraulicuid.Checkthelevelofthehydraulicuid

beforetheengineisrststartedanddailythereafter.

Therecommendedreplacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid

(Availablein5gallonpailsor55gallondrums.Seeparts

catalogorTorodistributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Wedo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

productNote:Torowillnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souseonly

productsfromreputablemanufacturerswhowillstand

behindtheirrecommendation.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andremovethekey.

2.Cleantheareaaroundthellerneckandcapofthe

hydraulictank(

Figure32).Removethecapfrom

thellerneck.

HighViscosityIndex/LowPourPointAnti-wear

HydraulicFluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

cSt@100°C7.9to8.5

Figure32

1.Hydraulictankcap

25

Page 26

3.Removethedipstickfromthellerneckandwipe

itwithacleanrag.Insertthedipstickintotheller

neck;thenremoveitandchecktheuidlevel.The

uidlevelshouldbebetweenthetwomarksonthe

dipstick.

4.Ifthelevelislow ,addtheappropriateuidtoraise

theleveltotheuppermark.

5.Installthedipstickandcapontothellerneck.

Whenthetemperatureislessthan20°F(-7°C),the

startermotorcanberunfor30secondsonthen60

secondsofffor2attempts.

CAUTION

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,loose

parts,andothermalfunctions.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.The

correctairpressureinthetiresis12–15psi(83-103

kPa).Checkthetirepressuredaily.

Important:Maintaintherecommendedpressure

inalltirestoensureagoodquality-of-cut

andpropermachineperformance.Donot

under-inate.

StartingandStoppingthe

Engine

StartingtheEngine

Important:Thefuelsystemmustbebledifanyof

thefollowingsituationshaveoccurred:

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuel

systemcomponents.

StoppingtheEngine

Important:Allowenginetoidlefor5minutes

beforeshuttingitoffafterafullloadoperation.

Thisallowstheturbochargertocooldownbefore

shuttingtheengineoff.Failuretodosomaylead

toturbo-chargertrouble.

Note:Lowercuttingunitstothegroundwhenever

machineisparked.Thisrelievesthehydraulicloadfrom

thesystem,preventswearonsystempartsandalso

preventsaccidentalloweringofthecuttingunits.

1.MovethethrottlecontrolbackwardtotheSlow

position.

2.MovethePTOswitchtotheOffposition.

3.Settheparkingbrake.

4.RotatetheignitionkeytoOff.

5.Removethekeyfromtheswitchtoprevent

accidentalstarting.

CheckingtheInterlock

Switches

1.Removeyourfootfromthetractionpedaland

ensurethatitisinneutral.Ensurethattheparking

brakeisset.

2.Movethethrottlecontroltothelowidleposition.

3.TurntheignitionkeytotheRunposition.Theglow

indicatorwilllight.

4.Whentheglowindicatordims,turntheignitionkey

totheStartposition.Releasethekeyimmediately

whentheenginestartsandallowittoreturnto

theRunposition.Movethethrottlecontroltothe

desiredposition.

Important:Donotrunthestartermotor

morethan15secondsatatimeorpremature

starterfailuremayresult.Iftheenginefailsto

startafter15seconds,turnthekeytotheOff

position,recheckthecontrolsandprocedures,

wait15additionalseconds,andrepeatthe

startingprocedure.

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Themachinehasinterlockswitchesintheelectrical

system.Theseswitchesaredesignedtostoptheengine

whenoperatorgetsoffoftheseatwhenthetraction

pedalisdepressed.However,theoperatormaygetoff

oftheseatwhiletheengineisrunningandthetraction

pedalisinneutral.Althoughtheenginewillcontinue

torunifthePTOswitchisdisengagedandthetraction

26

Page 27

pedalisreleased,itisstronglyrecommendedthatthe

enginebestoppedbeforerisingfromtheseat.

Tochecktheoperationoftheinterlockswitches,

performthefollowingprocedure:

neutralposition.Theengineshouldkill.Ifthe

enginedoesnotkill,thereisamalfunctioninthe

interlocksystemthatshouldbecorrectedbefore

beginningoperation.

1.Drivethemachineslowlytoalarge,relativelyopen

area.Lowerthecuttingunit,stoptheengine,and

applytheparkingbrake.

2.Sitontheseatanddepressthetractionpedal.Try

tostarttheengine.Theengineshouldnotcrank.

Iftheenginecranks,thereisamalfunctioninthe

interlocksystemthatshouldbecorrectedbefore

beginningoperation.

3.Sitontheseatandstarttheengine.Risefromthe

seatandmovethePTOswitchtoOn.ThePTO

shouldnotengage.IfthePTOengages,thereisa

malfunctionintheinterlocksystemthatshouldbe

correctedbeforebeginningoperation.

4.Sitontheseat,engagetheparkingbrakeandstart

theengine.Movethetractionpedaloutofthe

SettingtheReelSpeed

Toachieveaconsistent,highquality-of-cutanda

uniformaftercutappearance,itisimportantthatyou

setthereelspeedcontrols(locatedundertheseat)

correctly.Adjustthereelspeedcontrolsasfollows:

1.Selecttheheight-of-cutatwhichthecuttingunits

areset.

2.Choosethedesiredgroundspeedbestsuitedfor

conditions.

3.Usingtheappropriategraphonthedecal(

determinetheproperreelspeedsetting.

Figure33)

Figure33

1.5bladecuttingunit3.1 1bladecuttingunit

2.8bladecuttingunit4.Mowandbacklap6.Machinespeed

5.ReadtheOperator'sManual.

Tosetthereelspeed,rotateknobs(Figure34)until

theindicatorarrowsareinlinewiththenumber

designatingthedesiredsetting.

Note:Thereelspeedcanbeincreasedordecreased

tocompensateforturfconditions.

27

Page 28

Figure35

1.Spring2.Springactuator

Figure34

1.Reelspeedcontrolknob

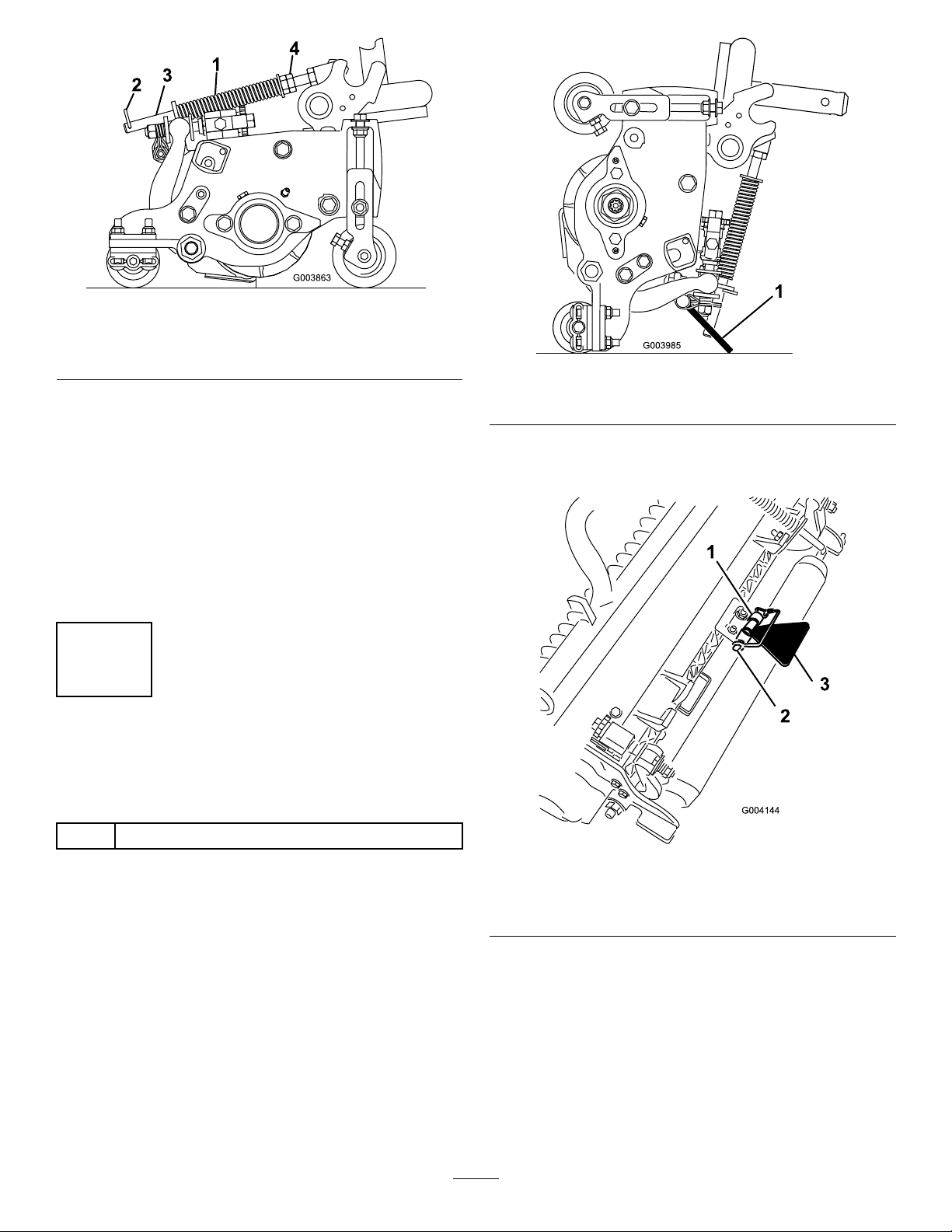

AdjustingtheLiftArm

Counterbalance

Youcanadjustthecounterbalanceontherear

cuttingunitliftarmstocompensatefordifferentturf

conditionsandtomaintainauniformheight-of-cutin

theroughconditionsorinareasofthatchbuildup.

Youcanadjusteachcounterbalancespringtooneof

foursettings.Eachincrementincreasesordecreases

counterbalanceonthecuttingunitby5lb(2.3kg).The

springscanbepositionedonthebacksideofthespring

actuatortoremoveallcounterbalance(forthposition).

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,engagetheparking

brakes,andremovethekeyfromignitionswitch.

4.Movethespringactuatortothedesiredhole

locationandsecurewithlocknut.

5.Repeattheprocedureontheremainingspring.

AdjustingtheLiftArmTurn

AroundPosition

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,engagetheparking

brakes,andremovethekeyfromignitionswitch.

2.Theliftarmswitchislocatedbehindthefrontright

liftarm(Figure36).

2.Insertatubeorsimilarobjectontothelong

springendtorelievethespringtensionduringthe

adjustment(

Figure35).

CAUTION

Thespringsareundertension.

Usecautionwhenadjustingthem.

3.Whilerelievingthespringtension,removethebolt

andlocknutsecuringthespringactuatortothe

bracket(Figure35).

Figure36

1.Switch

3.Loosentheswitchmountingscrews(Figure36)

andmovetheswitchuptoincreasetheliftarm

28

Page 29

turnaroundheightormovetheswitchdownto

decreasetheliftarmturnaroundheight.Tighten

themountingscrews.

JackingPoints

•Onthefrontofthemachineontheframeonthe

insideofeachdrivetire

PushingorTowingthe

Machine

Inanemergency,themachinecanbemovedforwardby

actuatingthebypassvalveinthevariabledisplacement

hydraulicpumpandpushingortowingthemachine.

Donotpushortowthemachineformorethan1/4

mile(0.4km).

Important:Donotpushortowthemachine

fasterthan2-3MPH(3-4.8km/h)becauseinternal

transmissiondamagemayoccur.Thebypassvalve

mustbeopenwheneverthemachineispushedor

towed.

Important:Ifthemachinemusttobepushedor

towedinreverse,thecheckvalveinthefour-wheel

drivemanifoldmustalsobebypassed.T obypass

thecheckvalve,connectahoseassembly(Hose

PartNo.95-8843,CouplerFittingNo.95-0985

[Qty.2],andHydraulicFittingNo.340-77[Qty.2])

tothereversetractionpressuretestportandthe

reversefour-wheeldrivepressureport.

1.Openhoodandremovethecentershroud

•Ontherearofthemachineatthecenteroftheaxle

TieDowns

•Oneachsideoftheframeunderthefrontsteps

•Therearbumper

UnderstandingtheDiagnostic

Light

Themachineisequippedwithadiagnosticlightwhich

indicatesiftheelectroniccontrollersensesanelectronic

malfunction.Thediagnosticlightislocatedonthe

controlarm(

isfunctioningcorrectlyandthekeyswitchismovedto

theOnposition,thecontrollerdiagnosticlightwillturn

ONfor3secondsandturnOFFtoindicatethelight

isworkingproperly .Ifthemachinekillsthelightwill

turnonsteadyuntilthekeypositionischanged.The

lightwillblinkifthecontrollerdetectsamalfunctionin

theelectricalsystem.Thelightwillstopblinkingand

automaticallyresetwhenthekeyswitchisturnedtothe

Offpositiononcethefaulthasbeenresolved.

Figure38).Whentheelectroniccontroller

2.Rotatethebypassvalve90°(1/4turn)ineither

directiontoopenandallowoiltobypassinternally

Figure37).Becauseuidisbypassed,themachine

(

canbeslowlymovedwithoutdamagingthe

transmission.Notethepositionofthevalvewhen

openingorclosing.

Figure37

1.Bypassvalve

Figure38

1.Diagnosticlight

Whenthecontrollerdiagnosticlightblinks,oneofthe

followingproblemshasbeendetectedbythecontroller:

•Oneoftheoutputshasbeenshorted.

•Oneoftheoutputsisopencircuited.

3.Rotatethebypassvalve90°(1/4turn)backbefore

startingtheengine.Donotexceed5-8ft.-lb.

(7-11N·m)torquetoclosethevalve.

Usingthediagnosticdisplay,determinewhichoutput

ismalfunctioning;refertoCheckingtheInterlock

Switches.

29

Page 30

Ifthediagnosticlightisnotilluminatedwhenthekey

switchisintheOnposition,thisindicatesthatthe

electroniccontrollerisnotoperating.Possiblecauses

areasfollows:

•Loop-backisnotconnected.

•Thelightisburnedout.

•Fusesareblown.

•Itisnotfunctioningcorrectly.

Checktheelectricalconnections,inputfuses,and

diagnosticlightbulbtodeterminethemalfunction.

Ensurethattheloop-backconnectorissecuredtothe

wireharnessconnector.

DiagnosticAceDisplay

Themachineisequippedwithanelectroniccontroller

whichcontrolsmostmachinefunctions.Thecontroller

determineswhatfunctionisrequiredforvariousinput

switches(i.e.seatswitch,keyswitch,etc.)andturns

ontheoutputstoactuatesolenoidsorrelaysforthe

requestedmachinefunction.

VerifyingtheInterlockSwitchFunction

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andengagethe

parkingbrake.

2.Removetheaccesspanellocatedbeneaththefront

oftheseat(

3.Locatethewireharnessandconnectorsnearthe

controller(Figure39).

1.Wireharnessandconnectors

Figure39).

Figure39

Fortheelectroniccontrollertocontrolthemachineas

desired,eachoftheinputswitches,outputsolenoids,

andrelaysmustbeconnectedandfunctioningproperly .

UsetheDiagnosticACEdisplaytohelpverifyand

correctelectricalfunctionsofthemachine.

CheckingtheInterlock

Switches

Thepurposeoftheinterlockswitchesistopreventthe

enginefromcrankingorstartingunlessthetraction

pedalisintheNeutralposition,thePTOswitchisin

theOFFposition,andtheliftswitchisintheNeutral

position.Inaddition,theengineshouldstopwhenthe

tractionpedalispressedwithoperatoroffoftheseator

iftheparkingbrakeisleftengaged.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

4.Carefullyunplugloopbackconnectorfromharness

connector.

5.ConnecttheDiagnosticACEdisplayconnectorto

theharnessconnector(

Note:Makesurecorrectoverlaydecalispositioned

onDiagnosticACEdisplay.

1.DiagnosticACE

Figure40).

Figure40

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

6.TurnthekeyswitchtotheOnposition,butdonot

startthemachine.

Note:Theredtextontheoverlaydecalrefersto

inputswitchesandthegreentextreferstooutputs.

30

Page 31

7.The“inputsdisplayed”LED ,onthelower

rightcolumnoftheDiagnosticACE,shouldbe

illuminated.Ifthe“outputsdisplayed”LEDis

illuminated,pressthetogglebutton,onDiagnostic

ACE,tochangeLEDto“inputsdisplayed”.

TheDiagnosticACEwillilluminatetheLED

associatedwitheachoftheinputswhenthatinput

switchisclosed.

8.Individually,changeeachoftheswitchesfrom

opentoclosed(i.e.,sitonseat,engagetraction

pedal,etc.),andnotethattheappropriateLED

onDiagnosticACEwillblinkonandoffwhen

correspondingswitchisclosed.Repeatthisforall

switchesthatyoucanchangebyhand.

9.IfaswitchisclosedandtheappropriateLEDdoes

notturnon,checkallwiringandconnectionsto

theswitchand/orchecktheswitcheswithanohm

meter.Replaceanydefectiveswitchesandrepair

anydefectivewiring.

Note:TheDiagnosticACEalsohastheabilityto

detectwhichoutputsolenoidsorrelaysareturned

on.Thisisaquickwaytodetermineifamachine

malfunctioniselectricalorhydraulic.

VerifyingOutputFunction

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,andengagethe

parkingbrake.

2.Removetheaccesspanellocatedbeneaththefront

oftheseat.

3.Locatewireharnessandconnectorsnearcontroller.

4.Carefullyunplugloopbackconnectorfromharness

connector.

5.ConnecttheDiagnosticACEconnectortothe

harnessconnector.

Note:Makesurecorrectoverlaydecalispositioned

onDiagnosticACE.

6.TurnthekeyswitchtotheONposition,butdonot

startmachine.

Note:Theredtextontheoverlaydecalrefersto

inputswitchesandthegreentextreferstooutputs.

7.The“outputsdisplayed”LED,onlowerright

columnofDiagnosticACE,shouldbeilluminated.

Ifthe“inputsdisplayed”LEDisilluminated,press

thetogglebutton,ontheDiagnosticACE,to

changetheLEDto“outputsdisplayed”.

Note:Itmaybenecessarytotogglebetween

“inputsdisplayed”and“outputsdisplayed”several

timestodothefollowingstep.Totogglebackand

forth,pressthetogglebuttononce.Thismaybe

doneasoftenasrequired.Donotholdthebutton.

8.Sitontheseatandattempttooperatethedesired

functionofthemachine.Theappropriateoutput

LEDsshouldilluminatetoindicatethattheECMis

turningonthatfunction.

Note:IfthecorrectoutputLEDsdonotilluminate,

verifythattherequiredinputswitchesareinthe

necessarypositionstoallowthatfunctiontooccur.

Verifycorrectswitchfunction.

IftheoutputLEDsareonasspecied,butthe

machinedoesnotfunctionproperly,thisindicatesa

non-electricalproblem.Repairasnecessary.

Note:Ifeachoutputswitchisinthecorrectposition

andfunctioningcorrectly,buttheoutputLEDsarenot

correctlyilluminated,thisindicatesanECMproblem.If

thisoccurs,contactyourToroDistributorforassistance.

Important:TheDiagnosticACEdisplaymust

notbeleftconnectedtothemachine.Itisnot

designedtowithstandtheenvironmentofthe

machine'severydayuse.Whendoneusingthe

DiagnosticACE,disconnectitfromthemachine

andconnectloop-backconnectortoharness

connector.Themachinewillnotoperatewithout

loopbackconnectorinstalledontheharness.Store

theDiagnosticACEindry,securelocationinthe

shop,notonthemachine.

OperatingCharacteristics

Practicedrivingthemachinebecauseithasahydrostatic

transmissionanditscharacteristicsaredifferentthan

manyturfmaintenancemachines.Somepointsto

considerwhenoperatingthetractionunitandcutting

unitsarethetransmission,enginespeed,loadonthe

cuttingbladesandtheimportanceofthebrakes.

Tomaintainenoughpowerforthetractionunitwhile

operating,regulatethetractionpedaltokeeptheengine

RPMhighandsomewhatconstant.Agoodruleto

followistodecreasethegroundspeedastheloadon

thecuttingunitsincreases,andincreasetheground

speedastheloaddecreases.

Therefore,allowthetractionpedaltomovebackward

astheengineRPMdecreases,anddepressthepedal

slowlyastheRPMincreases.Bycomparison,when

drivingfromoneworkareatoanother,withnoload

andcuttingunitraised,havethethrottleintheFast

positionanddepressthetractionpedalslowlybutfully

toattainmaximumgroundspeed.

Anothercharacteristictoconsideristheoperation

ofthepedalsthatareconnectedtothebrakes.The

31

Page 32

brakescanbeusedtoassistinturningthemachine.

However,usethemcarefully,especiallyonsoftor

wetgrassbecausetheturfmaybetornaccidentally .

Anotherbenetofthebrakesistomaintaintraction.

Forexample,insomeslopeconditions,theuphillwheel

slipsandlosestraction.Ifthissituationoccurs,depress

theuphillturnpedalgraduallyandintermittentlyuntil

theuphillwheelstopsslipping,thus,increasingtraction

onthedownhillwheel.

Useextracarewhenoperatingthemachineonslopes.

Makesurethattheseatlatchisproperlysecuredandthe

seatbeltisbuckled.Driveslowlyandavoidsharpturns

onslopestopreventrollovers.Forsteeringcontrol,the

cuttingunitmustbeloweredwhengoingdownhill.

Important:Allowenginetoidlefor5minutes

beforeshuttingitoffafterafullloadoperation.

Thisallowstheturbochargertocooldownbefore

shuttingtheengineoff.Failuretodosomaylead

toturbo-chargertrouble.

Beforestoppingtheengine,disengageallcontrolsand

movethethrottletoSlow .MovingthethrottletoSlow

reduceshighengineRPM,noise,andvibration.Turn

thekeytoOfftostoptheengine.

EngineCoolingFanOperation

Theenginecoolingfanswitchhastwopositionsfor

controllingtheoperationofthefan.Thetwopositions

areRandAuto.Thefanhastheabilitytoreverse

toblowdebrisoffoftherearscreen.Undernormal

operatingconditions,theswitchshouldbeintheAuto

position.InAuto,thefanspeedwillbecontrolled

bythecoolantorhydraulicoiltemperatureandwill

automaticallyreversetoblowdebrisoffoftherear

screen.Areversecycleisautomaticallyinitiatedwhen

eitherthecoolantorhydraulictemperaturereaches

acertainpoint.Bypressingthefanswitchforward

intotheRposition,thefanwillcompleteamanually

initiatedreversecycle.Itisrecommendedtoreversethe

fanwhentherearscreeniscloggedorpriortoentering

theshoporthestoragearea.

WarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurif

youoperatethemachinewithamalfunction.

Mowing

StarttheengineandmovethethrottletotheFast

position.MovetheMowSpeedLimitertothemow

position.MovethePTOswitchtotheONposition

andusetheLiftSwitchtocontrolthecuttingunits(the

frontcuttingunitsaretimedtolowerbeforetherear

cuttingunits).Tomoveforwardandcutgrass,press

thetractionpedalforward.

Transport

MovethePTOswitchtotheOFFpositionandraise

thecuttingunitstothetransportposition.Movethe

MowSpeedLimitertothetransportposition.Be

carefulwhendrivingbetweenobjectssoyoudonot

accidentallydamagethemachineorcuttingunits.Use

extracarewhenoperatingthemachineonslopes.Drive

slowlyandavoidsharpturnsonslopestopreventroll

overs.Lowerthecuttingunitswhengoingdownhill

forsteeringcontrol.

OperatingTips

Familiarization

Beforemowinggrass,practiceoperatingthemachine

inanopenarea.Startandstoptheengine.Operatein

forwardandreverse.Lowerandraisethecuttingunits

andengageanddisengagethereels.Whenyoufeel

familiarwiththemachine,practiceoperatingupand

downslopesatdifferentspeeds.

32

Page 33

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst200hours

Beforeeachuseordaily

Every50hours

Every100hours

Every200hours

MaintenanceProcedure

•Torquethewheelnuts.

•Changetheengineoilandlter.

•Changetheplanetarygeardriveoil.

•Changetherearaxlelubricant.

•Changethehydrauliclters.

•Checktheengineoillevel.

•Checkthecoolingsystem.

•Checkthehydraulicuidlevel.

•Checkthetirepressure.

•Checktheinterlockswitches.

•Checktheoperationoftheinterlockswitches.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Drainwaterorothercontaminantsfromfuellter/waterseparator .

•Removedebrisfromtheenginearea,oilcooler,andradiator.

•Inspectthehydrauliclinesandhosesforleaks,kinkedlines,loosemounting

supports,wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings.

•Checkthebatterycondition.

•Checktheconditionandtensionofthealternatorbelt.

•Torquethewheelnuts.

•Cleanthesparkarrestormufer.

Every400hours

Every800hours

Beforestorage

Yearly

Important:Refertoyourengine

maintenanceprocedures.

•Servicetheaircleaner.(Servicetheaircleanerearlieriftheaircleanerindicator

showsred.Serviceitmorefrequentlyinextremelydirtyordustyconditions.)

•Changetheengineoilandlter.

•Checkthefuellinesandconnections.

•Replacethefuelltercanister.

•Checktheplanetarygeardriveoillevel(Also,checkifexternalleakageisobserved)

•Checktherearaxlelubricantlevel.

•Drainandcleanthefueltank.

•Changetheplanetarygeardriveoil.(Oryearly,whichevercomesrst)

•Changetherearaxlelubricant.

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Changethehydrauliclters.

•Drainandcleanthefueltank.

•Checkthetirepressure.

•Checkallfasteners.

•Greaseoroilallgreasettingsandpivotpoints.

•Paintchippedsurfaces.

•Checkthefuellinesandconnections.

Operator's Man ual

andcuttingunit

Operator's Man ual

foradditional

33

Page 34

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation

Checkthebrake

operation

Checktheengine

oilandfuellevel

Checkthecooling

systemuidlevel

Drainthe

water/fuel

separator

Checktheair

lterrestriction

indicator

Checkthe

radiator,oilcooler,

andscreenfor

debris

Checkunusual

enginenoises

Checkunusual

operatingnoises

Checkthe

hydraulicsystem

oillevel

Checkhydraulic

hosesfordamage

Checkforuid

leaks

Checkthetire

pressure

Checkthe

instrument

operation

Checkthe

reel-to-bedknife

adjustment

Checkthe

height-of-cut

adjustment

Lubricateall

greasettings

2

1

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

Touch-up

damagedpaint.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted.

34

Page 35

ServiceIntervalChart

Figure41

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

35

Page 36

Premaintenance

Lubrication

Procedures

GreasingtheBearingsand

RemovingtheHood

1.Releasehoodlatches(Figure42)andpivotopenthe

hood.

Figure42

1.Hoodlatch(2)

Bushings

ServiceInterval:Every50hours

Themachinehasgreasettingsthatmustbelubricated

regularlywithNo.2GeneralPurposeLithiumBase

Grease.Ifthemachineisoperatedundernormal

conditions,lubricateallbearingsandbushingsafter

every50hoursofoperationorimmediatelyafterevery

washing.

Thegreasettinglocationsandquantitiesareasfollows:

•Brakeshaftpivotbearings(5)(

Figure43)

2.Removethecotterpinssecuringtherearhood

bracketstotheframepinsandliftoffthehood.

Figure43

•Rearaxlepivotbushings(2)(Figure44)

Figure44

36

Page 37

•Steeringcylinderballjoints(2)(Figure45)

Figure45

•Cuttingunitcarrierframe(2percuttingunit)

(Figure47)

•Cuttingunitliftarmpivot(1percuttingunit)

Figure47)

(

Figure47

1.T opttingonkingpin

•Tierodballjoints(2)(Figure45)

•Kingpinbushings(2)(Figure45).Thetoptting

onthekingpinshouldonlybelubricated

annually(2pumps).

•Liftarmbushings(1percuttingunit)(

Figure46)

Figure46

•Liftcylinderbushings(2percuttingunit)(Figure46)

•Liftarmpivotbushings(1percuttingunit)

(Figure47)

37

Page 38

EngineMaintenance

whichcouldforcedirtthroughthelterintothe

intaketract.

ServicingtheAirCleaner

ServiceInterval:Every400hours

Checktheaircleanerbodyfordamagewhichcould

causeanairleak.Replaceifdamaged.Checkthewhole

intakesystemforleaks,damageorloosehoseclamps.

Servicetheaircleanerlteronlywhentheservice

indicator(

beforeitisnecessaryonlyincreasesthechanceofdirt

enteringtheenginewhenthelterisremoved.

1.Aircleanerindicator

Figure48)requiresit.Changingtheairlter

Figure48

Thiscleaningprocesspreventsdebrisfrommigrating

intotheintakewhentheprimarylterisremoved.

3.Removeandreplacetheprimarylter(Figure50).

Cleaningoftheusedelementisnotrecommended

duetothepossibilityofdamagetotheltermedia.

Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.Donot

useadamagedelement.Insertthenewlterby

applyingpressuretotheouterrimoftheelementto

seatitinthecanister.Donotapplypressuretothe

exiblecenterofthelter.

Figure50

1.Aircleanerprimarylter

Important:Besurethecoverisseatedcorrectly

andsealswiththeaircleanerbody.

1.Pullthelatchoutwardandrotatetheaircleaner

covercounterclockwise(

1.Aircleanerindicator3.Aircleanercover

2.Aircleanerlatch

Figure49).

Figure49

2.Removethecoverfromtheaircleanerbody .Before

removingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulations

ofdebrispackedbetweenoutsideofprimarylter

andthecanister.Avoidusinghighpressureair

Important:Neverattempttocleanthesafety

lter(Figure51).Replacethesafetylterwitha

newoneaftereverythreeprimarylterservices.

Figure51

1.Aircleanersafetylter

4.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthe

cover,cleanthecavityandreplacetheoutletvalve.

5.Installthecoverorientingtherubberoutletvalvein

adownwardposition—betweenapproximately5:00

to7:00whenviewedfromtheend.

6.Resettheindicator(

Figure48)ifitshowsred.

38

Page 39

ServicingtheEngineOiland

AdjustingtheThrottle

Filter

ServiceInterval:Aftertherst50hours

Every400hours

Changetheoilandlterinitiallyaftertherst50hours

ofoperation;thereafterchangetheoilandlterevery

400hours.

1.Removethereardrainplug(Figure52)andletthe

oilowintoadrainpan.Whentheoilstops,install

thedrainplug.

Adjustthethrottlecable(Figure54)sothatthegovernor

leverontheenginecontactsthehighspeedsetboltat

thesamepointthatthethrottlecablecontactstheendof

theslotinthecontrolarm.

Figure54

1.Throttlecable

Figure52

1.Engineoildrainplug

2.Removetheoillter(Figure53).Applyalightcoat

ofcleanoiltothenewltersealbeforescrewingit

on.Donotovertighten.

Figure53

1.Engineoillter

3.Addoiltothecrankcase;refertoCheckingthe

EngineOilinOperation.

39

Page 40

FuelSystem

ServicingtheWaterSeparator

Maintenance

DANGER