Page 1

FormNo.3363-382RevA

Reelmaster

®

4000-D2-Wheeland

4-WheelDriveTractionUnit

ModelNo.03706—SerialNo.310000001andUp

ModelNo.03707—SerialNo.310000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

G012278

1

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Introduction

Thismachineisaride-on,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedfor

cuttinggrassonwell-maintainedlawnsingolfcourses,

parks,sportselds,andoncommercialgrounds.Itis

notdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Figure1

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

Figure1),whichsignalsahazardthatmaycauseserious

(

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

Figure1

illustratesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2009—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SoundPowerLevel...............................................7

SoundPressureLevel...........................................7

VibrationLevel....................................................7

SafetyandInstructionalDecals.............................8

ProductOverview......................................................12

Controls.............................................................12

Specications.....................................................16

Attachments/Accessories...................................16

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Operation...................................................................17

CheckingtheEngineOilLevel............................17

CheckingtheCoolingSystem..............................17

AddingFuel.......................................................18

Checking/AddingHydraulicFluid......................19

CheckingtheReeltoBedknifeContact................20

CheckingtheTirePressure.................................20

RearBallast........................................................20

StartingandStopping.........................................20

BleedingtheFuelSystem....................................21

CheckingtheWarningIndicatorLights...............21

CheckingtheSafetyInterlockSystem..................21

PushingorTowingtheMachine..........................22

OperatingTips...................................................23

Maintenance...............................................................26

RecommendedMaintenanceSchedule(s)................26

DailyMaintenanceChecklist...............................27

Lubrication.............................................................27

GreasingtheBearingsandBushings....................27

EngineMaintenance...............................................29

ServicingtheAirCleaner....................................29

ChangingtheEngineOilandFilter.....................29

FuelSystemMaintenance.......................................30

DrainingtheFuelTank.......................................30

CheckingtheFuelLinesandConnections...........30

DrainingtheFuelFilter/WaterSeparator

......................................................................30

ReplacingtheFuelFilterCanister........................31

BleedingAirfromtheFuelInjectors...................31

ElectricalSystemMaintenance................................32

ServicingtheBattery...........................................32

DriveSystemMaintenance.....................................33

Checking/AdjustingtheRearWheel

Toe-in............................................................33

CheckingthePlanetaryGearDriveOil

Level..............................................................33

CoolingSystemMaintenance..................................34

RemovingDebrisfromtheCooling

System............................................................34

BrakeMaintenance.................................................35

AdjustingtheParkingBrakeandTraction

Switches.........................................................35

BeltMaintenance....................................................35

CheckingtheConditionandTensionofthe

AlternatorBelt...............................................35

HydraulicSystemMaintenance...............................36

DrainingWaterfromtheHydraulic

Reservoir........................................................36

ChangingtheHydraulicFluid.............................36

ChangingtheHydraulicFilter.............................36

ReplacingtheHydraulicSystemBreather............37

CheckingtheHydraulicLinesandHoses.............37

HydraulicSystemTestPorts...............................37

Storage.......................................................................38

PreparingtheTractionUnit................................38

PreparingtheEngine..........................................38

Schematics.................................................................39

ConditionsandProductsCovered.......................44

InstructionsforObtainingW arranty

Service...........................................................44

OwnerResponsibilities.......................................44

ItemsandConditionsNotCovered.....................44

Parts...................................................................44

NoteRegardingDeepCycleBattery

Warranty:.......................................................44

MaintenanceisatOwner’sExpense.....................44

GeneralConditions............................................44

Noteregardingenginewarranty:.........................44

CountriesOtherthantheUnitedStatesor

Canada...........................................................44

3

Page 4

Safety

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

ThismachinemeetsorexceedsCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004specicationsineffectattimeof

production,whenequippedwithrearweight.Refer

tothesectioninthismanualonInstallingRear

Weight.

Improperuseormaintenancebytheoperator

orownercanresultininjury.Toreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andear

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

•Readtheoperator’smanualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasize:

–theneedforcareandconcentrationwhen

workingwithride-onmachines;

–controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely .

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthattheoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

4

Page 5

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’ s

position;

–donotstoporstartsuddenlywhengoingupor

downhill;

–engagethetractionpedalslowly,alwayskeep

themachineingear,especiallywhentravelling

downhill;

–machinespeedsshouldbekeptlowonslopes

andduringtightturns;

–stayalertforhumpsandhollowsandother

hiddenhazards;

–donotturnsharply.Usecarewhenreversing;

–nevermowacrossthefaceoftheslope,unless

themowerisdesignedforthispurpose.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Usecarewhenpullingloadsorusingheavy

equipment.

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheOperator’sManual.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly ,

andfunctioningproperly .

•Donotchangetheenginegovernorsettingsor

over-speedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’sposition:

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthe

mower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Reducethethrottlesettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,

turnthefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcylinders/reels

ifnotmowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Thismachineisnotdesignedorequippedfor

on–roaduseandisa“slow–movingvehicle.”Ifyou

mustcrossortravelonapublicroad,youshould

beawareofandcomplywithlocalregulations,such

asrequiredlights,slowmovingvehiclesigns,and

reectors.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

–stoponlevelground;

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagedrivetoattachment:

–beforerefuelling;

Donotrunengineindoorsorinanenclosedarea.

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

5

Page 6

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Onmulti-cylinder/multi-reelmachines,takecare

asrotatingonecylinder/reelcancauseother

cylinders/reelstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.

Waitforallmovementtostopbeforeadjusting,

cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.

Cleanupoilorfuelspillage.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectthepositiverstand

negativelast.

•Usecarewhencheckingthecylinders/reels.Wear

glovesandusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Raisethecuttingunitswhendrivingfromonework

areatoanother.

•Donottouchtheengine,silencer/mufer,or

exhaustpipewhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Iftheenginestallsorlosesheadwayandcannotmake

ittothetopofaslope,donotturnthemachine

around.Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinor

nearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO,or

ANSIstandard.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

•Knowhowtostoptheenginequickly .

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

6

Page 7

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.Keep

everyoneaway.

•Toensuresafetyandaccuracy ,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.Maximumgovernedenginespeed

shouldbe2900RPM.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof105

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’s

earof86dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=0.38m/s

Measuredvibrationlevelforlefthand=0.34m/s

2

2

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

WholeBody

Measuredvibrationlevel=0.53m/s

2

7

Page 8

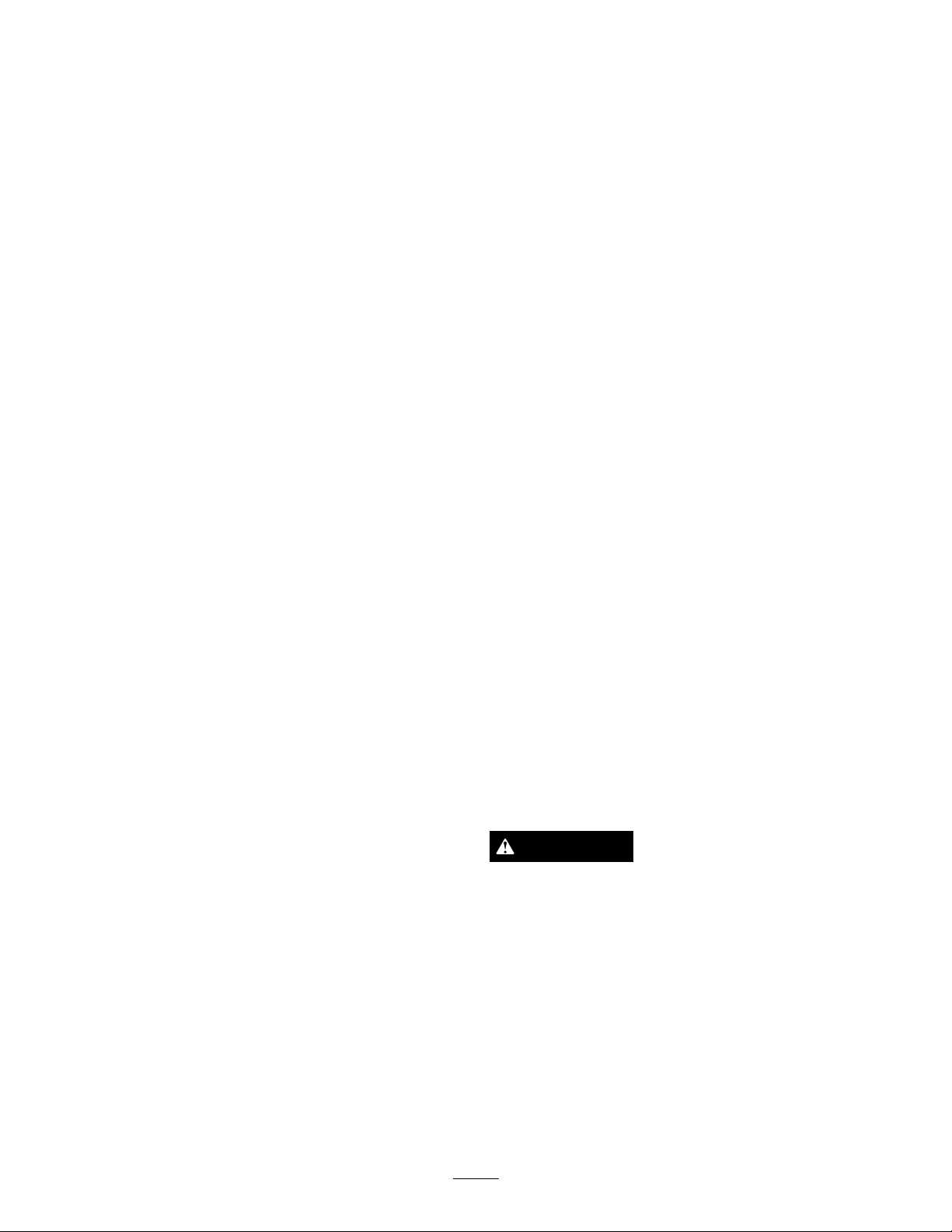

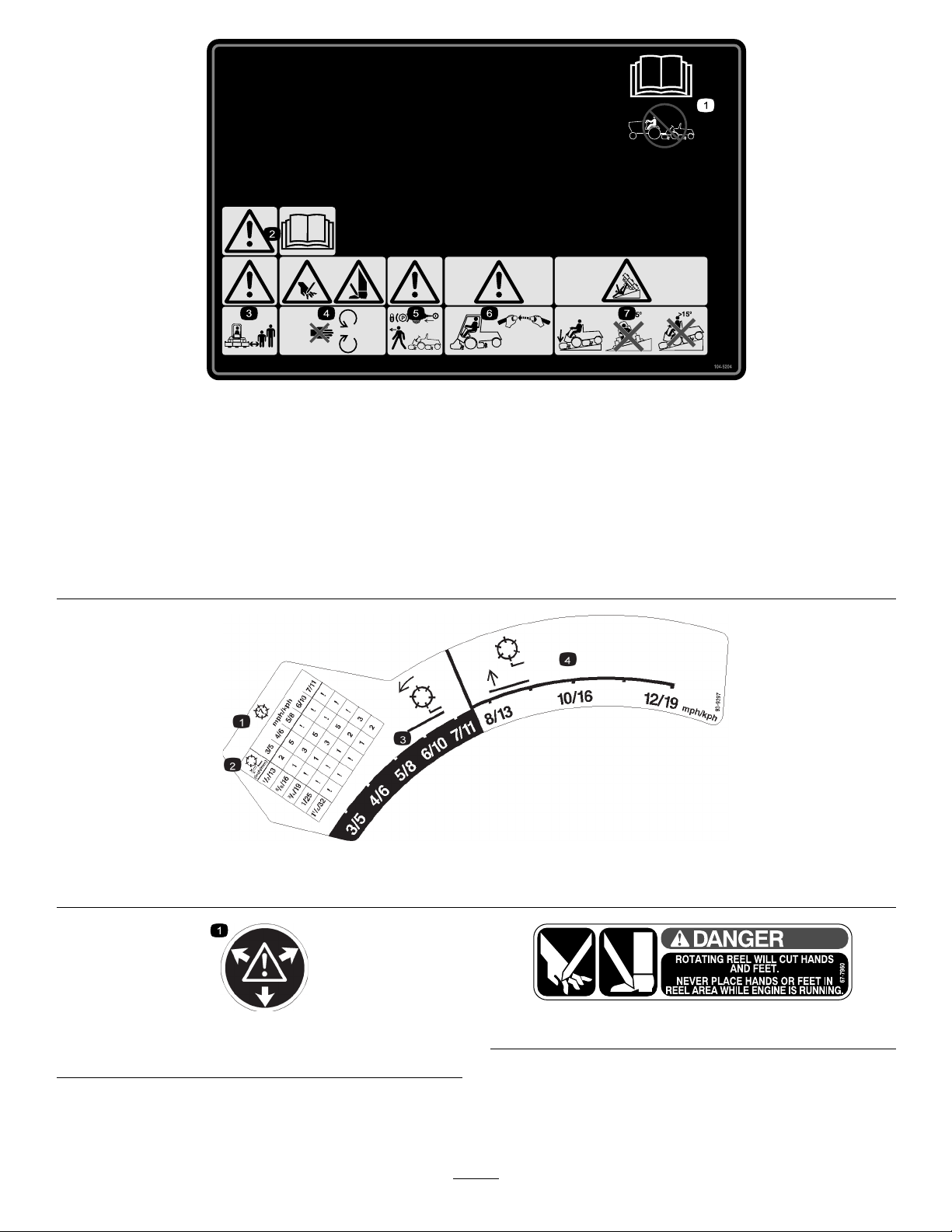

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

1.Temperaturelevel

2.Fourwheeldriveow

divider

3.On

4.Off

107-1819

5.Engine—stop7.Engine—preheat

6.Engine—start

1.ReadtheOperator’s

Manual;donottowthe

machine.

2.Warning—readthe

Operator’sManual.

3.Warning—keepbystanders

asafedistancefromthe

machine.

4.Cuttinghazardofhand

orfoot—stayawayfrom

movingparts.

104-5203

5.Warning—locktheparking

6.Warning—usearollover

8

brake,stoptheengine,and

removetheignitionkey

beforeleavingthemachine.

protectionsystemandwear

theseatbelt.

7.Tippinghazard—lowerthe

cuttingunitwhendriving

downslopes.

Page 9

104-5204forCE

(Afxoverpartno.104–5203forCE*

*ThissafetydecalincludesaslopewarningrequiredonthemachineforcompliancetotheEuropeanLawnMowerSafetyStandardEN836:1997.Theconservativemaximum

slopeanglesindicatedforoperationofthismachineareprescribedbyandrequiredbythisstandard.

1.ReadtheOperator’s

Manual;donottowthe

machine.

2.Warning—readthe

Operator’sManual.

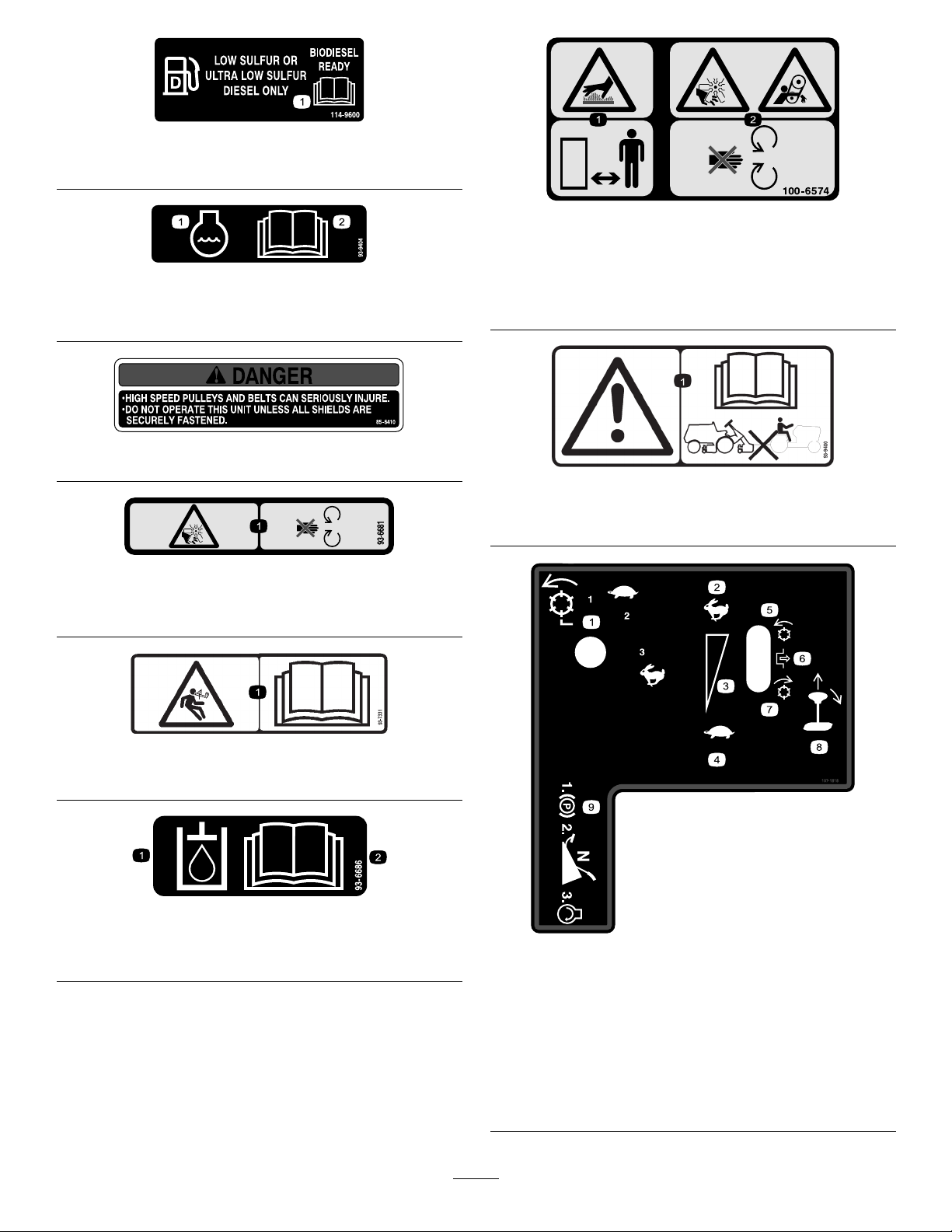

1.7-bladereel

3.Warning—keepbystanders

asafedistancefromthe

machine.

4.Cuttinghazardofhand

orfoot—stayawayfrom

movingparts.

2.Heightofcut

5.Warning—locktheparking

brake,stoptheengine,and

removetheignitionkey

beforeleavingthemachine.

6.Warning—usearollover

protectionsystemandwear

theseatbelt.

93-9397

3.Reel—mowingspeeds4.Reel—transportspeeds

7.Tippinghazard—lowerthe

cuttingunitwhendriving

downslopes.

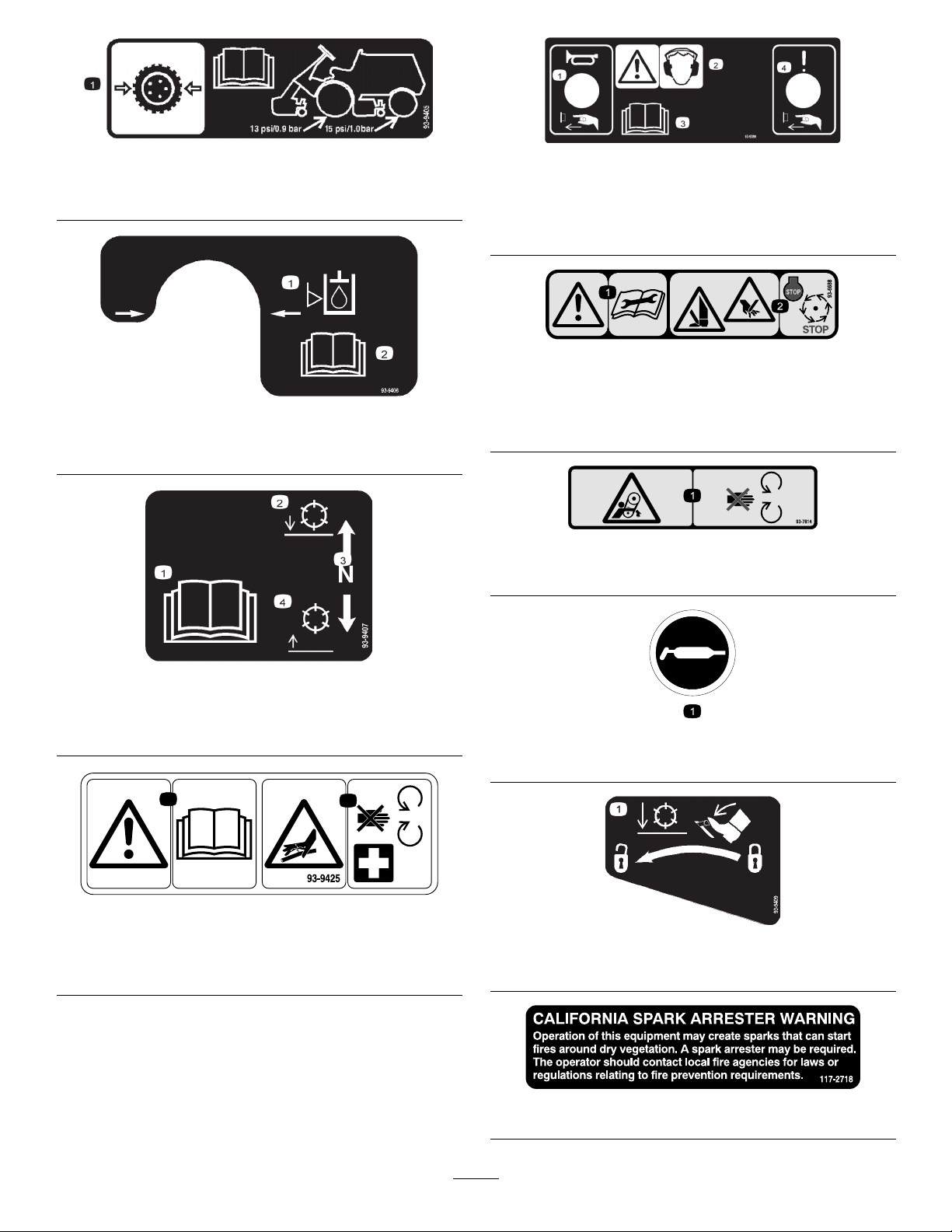

1.Warning—contentsunderpressure.

59-8440

67-7960

9

Page 10

114-9600

1.ReadtheOperator’sManual.

93-9404

1.Enginecoolant

2.ReadtheOperator’s

Manual.

85-6410

93-6681

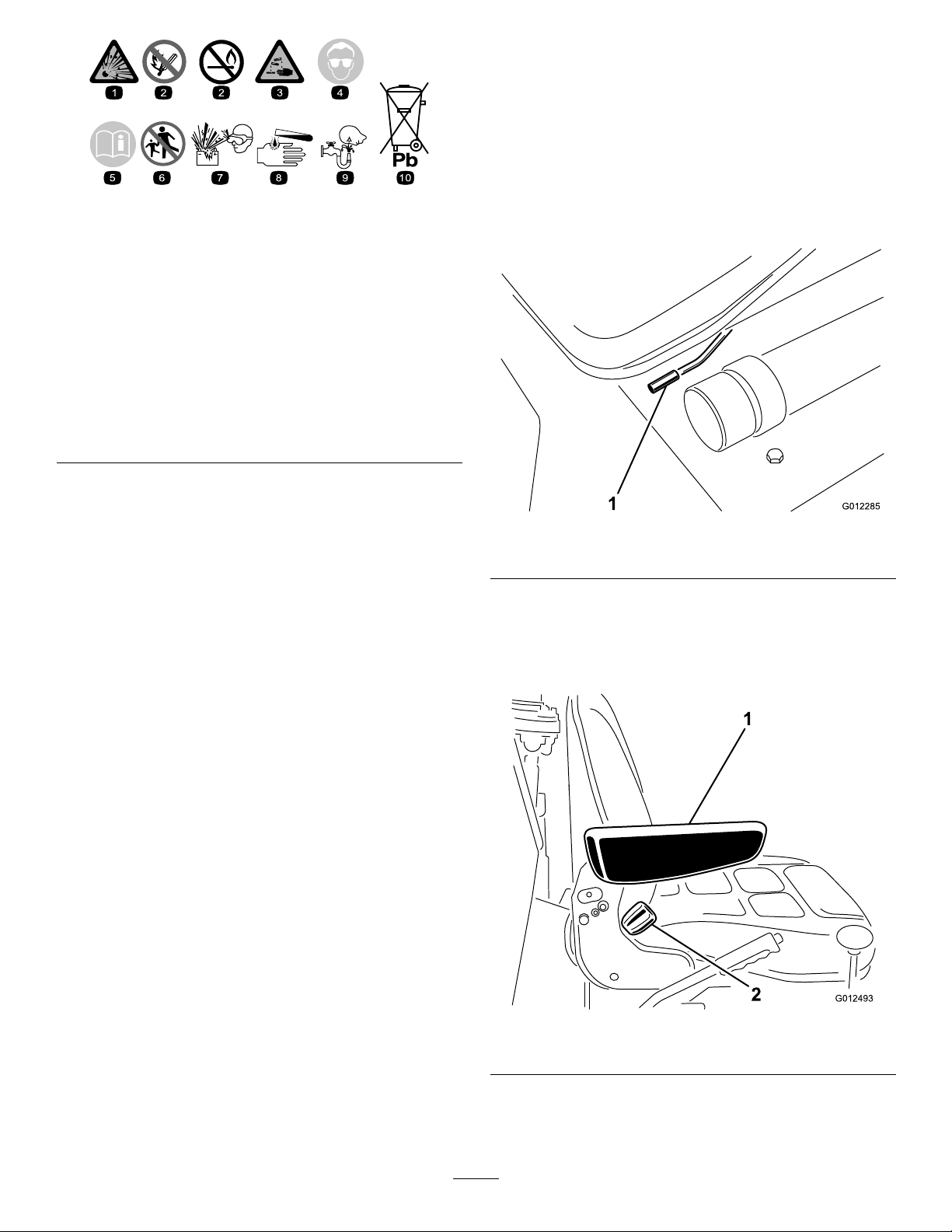

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

100-6574

1.Hotsurface/burnhazard—stayasafedistancefromthe

hotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts;keepallguards

andshieldsinplace.

93-9400

1.Warning—readtheOperator’sManual;donottowthe

machine.

93-7331

1.Storedenergyhazard—readtheOperator’sManual.

93-6686

1.Hydraulicoil

2.ReadtheOperator’sManual.

1.Reel—mowingspeeds,

slowtofast.

2.Fast7.Reel—backlapping

3.Continuousvariable

setting

4.Fast

5.Reel—mowing

10

107-1818

6.Disengage

8.Pullandmovethelever.

9.Settheparkingbrake,set

thecontrolstoneutral,and

starttheengine.

Page 11

93-9405

2

1

1.Tirepressure—readtheOperator’sManual;llthefront

tiresto13psi(0.9bar)andthereartiresto15psi(1.0bar).

93-9406

1.Hydraulicoillevel

2.ReadtheOperator’s

Manual.

93-9399

1.Horn—pressthebutton.

2.Warning—wearhearing

protection.

3.ReadtheOperator’s

Manual.

4.Failure/malfunction—

pressthebutton.

93-6688

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

93-9407

1.ReadtheOperator’s

Manual.

2.Lowerthereels.4.Raisethereels.

3.Neutral

93-9425

1.ReadtheOperator’sManual.

2.Hydraulichosesareunderpressure—stayawayfrom

movingparts.

58-6520

1.Grease

93-9409

1.Tounlockthereelsbeforeloweringthem,pressthepedal.

117–2718

11

Page 12

ProductOverview

G012285

1

G012493

1

2

Controls

SeatAdjustingLever

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

Theseatadjustinglever(Figure3)allows5.9inch(15

cm)foreandaftadjustmentin19/32inch(15mm)

increments.

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

Figure3

1.Seatadjustinglever

ArmRest

Pivotthearmrest(Figure4)upanddownforoperator

comfort.

Figure4

1.Armrest2.Backrestknob

12

Page 13

BackrestKnob

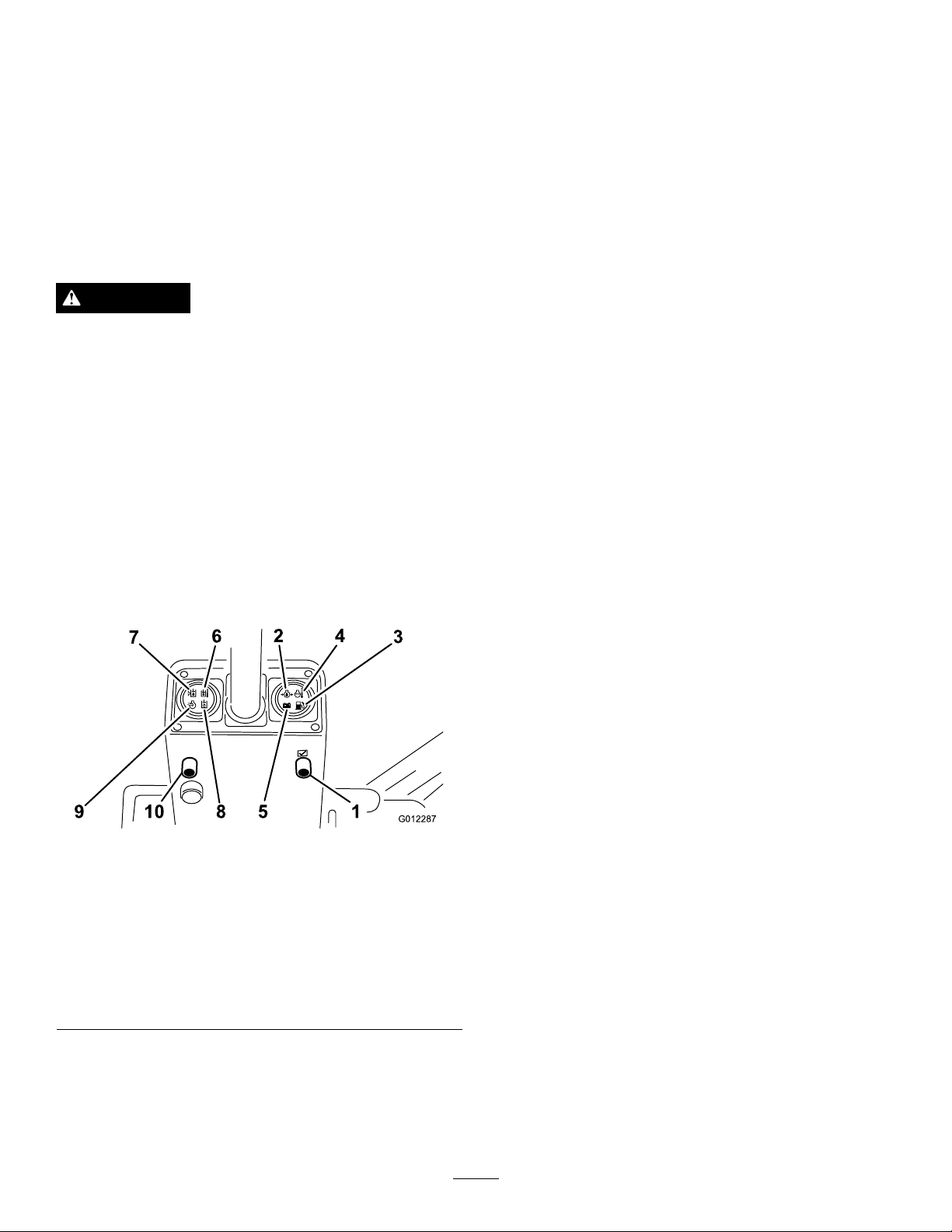

G01228 7

1589 10

7

6

2 4

3

EngineOilPressureWarning

Thebackrestknob(Figure4)adjustsbackrestangle

from5–20degrees.

SuspensionKnob

Thesuspensionknob,locatedbelowtheseatpan,allows

youtosettheseatfortheweightoftheoperator.

Note:Thebackrestandbottomseatcushionsare

removable.

CAUTION

Toensurethattheinterlockswitchoperates

properly,settheseatsuspensionfortheweightof

eachoperator.Ifthesuspensionisnotsetcorrectly,

theenginewillrunintermittentlyandtendtostall.

Tocorrectthis,setthesuspensionlighter.

WarningLightTestButton

Beforeoperatingmachine,pressthewarninglighttest

button(Figure5).Alllightsonthesteeringtower

shouldilluminate.Anylightthatdoesnotcomeon

indicatesanelectricalmalfunctionthatshouldbe

repairedimmediately.Oilpressureandelectricalno

chargeindicatorlightsilluminatewhenturningthekey

switchOn.

Dangerouslylowengineoilpressureisindicatedbyboth

awarningindicatorlightandaudiblesignal(

Figure5).

Whenthisoccurs,stoptheengineimmediatelyand

correcttheproblem.

FuelSystemWarning

Awarningindicatorlightandaudiblesignal(Figure5)

warnofexcesswaterinthefuelsystem.Removewater

fromthesystem.

CoolantTemperatureWarning

Ifenginecoolanttemperatureexceeds221°F(105°C)a

warningindicatorlight(Figure5)illuminatesandaudible

signalsounds.Theengineshutsdowniftemperature

ofcoolantexceeds230°F(110°C).Switchresets

automaticallywhensystemandenginecoolsdown.

ElectricalNoChargeWarning

Nochargetothebatteriesisindicatedbyawarning

indicatorlightandaudiblesignal(

Figure5).

HydraulicOilTemperatureWarning

Awarningindicatorlightandaudiblesignalwarn

Figure5)ofexcessivelyhighhydraulictemperature.

(

Figure5

1.Warninglighttestbutton6.Hydraulicoiltemperature

2.Engineoilpressure

warninglight

3.Fuelsystemwarning

4.Coolanttemperature

warning

5.Electricalnocharge

warning

warning

7.Hydraulicoillevelwarning

8.Hydraulicoillterwarning

9.Aircleanerwarning

10.Alarmsilencebutton

HydraulicandEngineIndicatorLights

Iftheselightscomeon(Figure5),stopthemachineand

makerepairsimmediately .

HydraulicOilLevelWarning

Awarningindicatorlightandaudiblesignal(Figure5)

warnoflowhydraulicoillevel.Ifoilleveldropsfurther,

theenginewillautomaticallybestopped.Enginecannot

berestarteduntiloilsupplyisbroughttoasafelevel.

HydraulicOilFilterWarning

Awarningindicatorlightandaudiblesignal(Figure5)

warnofacloggedhydrauliclter.

AirCleanerWarning

Awarningindicatorlightandaudiblesignal(Figure5)

warnthatthelteriscloggedandinneedofservice.

AlarmSilenceButton

Pressingbutton(Figure5)silencesalarm.Alarmsystem

willdisengageandautomaticallyresetwhentheproblem

iscorrectedorthealarmsilencebuttonispressed.

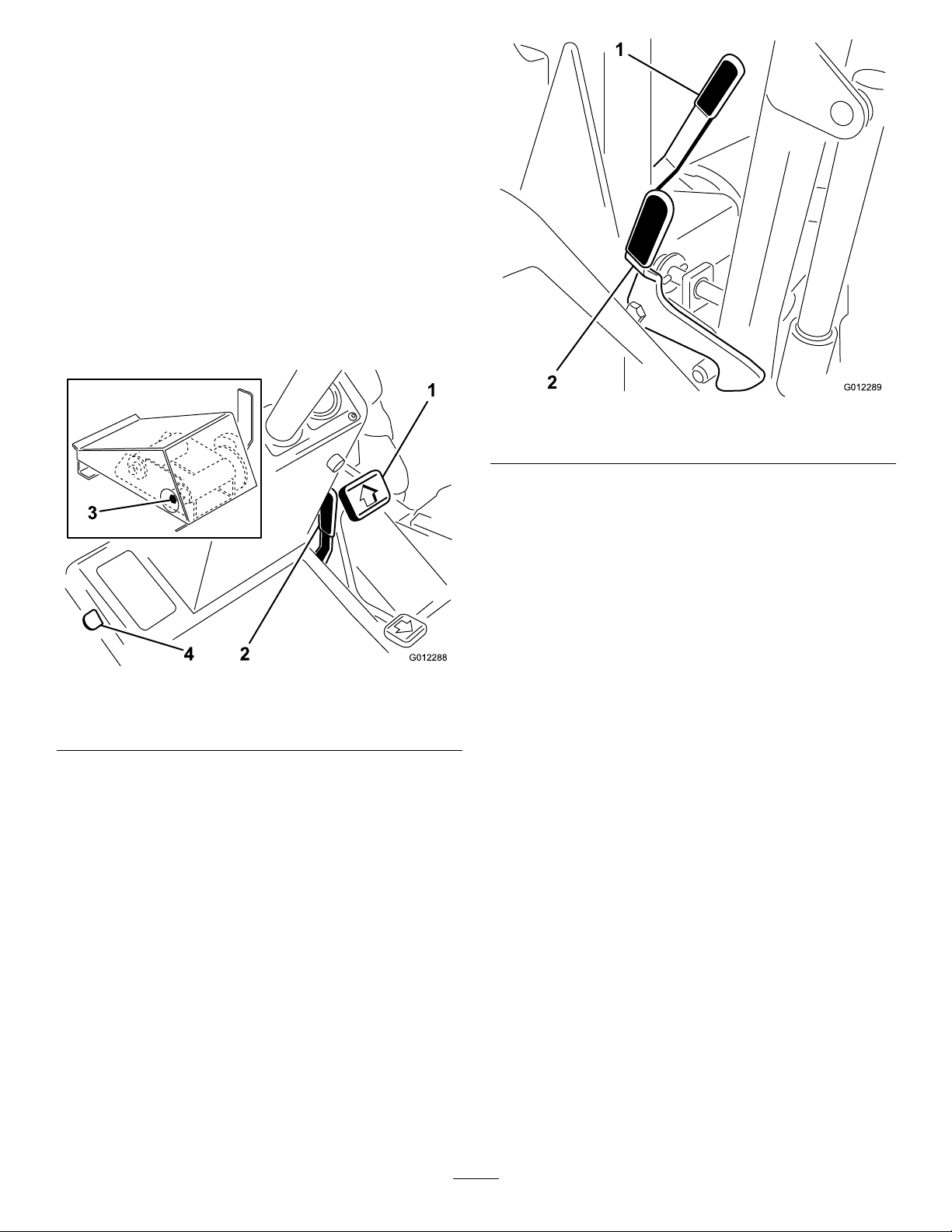

TractionPedal

Thetractionpedal(Figure6)controlsforwardand

reverseoperation.Pressthetopofthepedaltomove

13

Page 14

forwardandthebottomtomovebackward.Ground

G012288

4 2

1

3

G012289

1

2

speeddependsonhowfarthepedalispressed.For

maximumgroundspeed,fullypressthepedalwhilethe

throttleisintheFastposition.Formaximumpower

underloadorwhengoinguphill,keeptheenginerpm

highbyhavingthethrottleintheFastpositionandthe

tractionpedalheldstationaryagainstthegroundspeed

limiter.Iftheenginerpmbeginstodecreaseduetoload,

graduallyreducethetractionpedalpressureuntilthe

enginespeedisincreased.

Tostop,reducefootpressureonthetractionpedaland

allowittoreturntothecenterposition.Onextreme

downhillslopes,applypressuretothereversesideofthe

pedal,oroperatewithyourheelontheReverseandtoe

ontheForwardportionofthepedal.

Figure7

1.Centercuttingunitlatch2.Outsidecuttingunitlatch

Figure6

1.Tractionpedal

2.Speedlimiter

3.Camlevernut

4.Transportlatch

GroundSpeedLimiter

Thegroundspeedlimiter(Figure6)controlsthetraction

pedalmovement.Thelimiterleverhelpscontrolthe

rateofclipandeliminatessuddenspeedvariationsover

roughterrain.

Important:Thecamlevernut(

betightenedifthelimiterstopwillnotholdthe

tractionpedalinthedesiredposition.

Figure6,Inset)can

CuttingUnitLiftControls

Thetwooutsidelevers(Figure8)raiseandlowerthetwo

outsidecuttingunits.Thecenterleverraisesandlowers

thetwofrontandthecentercuttingunits.Theengine

mustberunningtolowerthecuttingunits.Whenthe

cuttingunitsarelifted,thereelsautomaticallystop.Do

notallowtheleverstosnapbacktoneutral,orcutting

unitsmaynotoatfreely.

TransportLatches

Theselatchessecurethecuttingunitsintheupright

positionfortransportoperation.Thelatchforthe

frontcuttingunitsisfoot–operated(Figure6).The

hand-operatedlatchescontrolthecenterandoutside

cuttingunits(Figure7).

14

Page 15

G012290

1 2 3 4 5 6

10

11

9 8 7

Figure8

1.Cuttingunitliftcontrols

2.Mow/backlaplever

3.Throttle9.Parkingbrake

4.Engineoverridebutton10.Reelspeedcontrol

5.Fuelgauge

6.Hourmeter

7.Enginepreheatindicator

light

8.Keyswitch

11.4Wheeldriveswitch(4

wheeldriveonly)

KeySwitch

Threepositions:Off,On,andStart.Rotatethekey

Figure8)toStartandreleaseitwhentheenginebegins

(

running.Tostoptheengine,rotatethekeytoOff.

ParkingBrakeLever

Pullthislever(Figure8)uptolockthebrake.Torelease

thebrake,pulluponthelever,pressthebutton,and

lowerthelever.Thebrakemustbeengagedtostartthe

engine.Alwaysengagetheparkingbrakebeforegetting

offoftheseat.

Mow-BacklapLever

Movethislever(Figure8)forwardtoengagethecutting

units.Movethelevertothecentertostopthecutting

units.Tobacklapcuttingunits,lifttheleveroverstop

andholditintherearposition.

Important:Donotmoveleverdirectlybetweenthe

MowandBacklappositions.Pausebrieyinthe

Stopposition.

ReelSpeedControl

EngineOverrideButton

Whenthisbutton(Figure8)ispressed,theenginecan

beoperatedafterithasoverheatedandautomatically

beenstoppedbytheelectricalsafetysystem.Useonly

forshortintervals.

FuelLevelGauge

Gauge(Figure8)indicatestheamountoffuelintank.

HourMeter

Hourmeter(Figure8)indicatesthetotalhoursthat

machinehasbeenoperated.

Note:Linescirclinginthesmallwindowatleftsideof

gaugeindicatehourmeterisoperating.

EnginePreheatIndicatorLight

Thislight(Figure8)turnsonwhenthekeyismovedto

theOnposition.Glowplugsengagefor10seconds,

then,thelightgoesoffwhentheengineisreadytostart.

Rotatetheknob(Figure8)clockwisetoincreasethe

reelspeed,counter–clockwisetodecreasespeed.Usein

conjunctionwiththegroundspeedlimitertoachieve

theappropriaterateofclip.

ThrottleControl

Movethiscontrol(Figure8)forwardtoincreaseengine

speedandbackwardtodecreasespeed.

4WheelDriveSwitch(4wheeldrive

modelonly)

Movethisswitch(Figure8)forwardtoengage4wheel

drive.Moveittotherearpositiontodisengage4wheel

drive.

15

Page 16

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width,cuttingunitsraised

Width,cuttingunitslowered

Widthofcut,5cuttingunits137inches(348cm)

Widthofcut,4cuttingunits110inches(279cm)

Widthofcut,3cuttingunits83inches(211cm)

Widthofcut,1cuttingunit29.5inches(75cm)

Length

HeightwithROPS82inches(208cm)

HeightwithoutROPS55.5inches(141cm)

Weight(Dry)4360lb(1717kg)

Fueltankcapacity

91.5inches(232cm)

147inches(373cm)

110inches(282cm)

15USgallons(56.8l)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

16

Page 17

Operation

G012279

1

G012280

1

G012281

1

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CheckingtheEngineOilLevel

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityisapproximately8qt.(7.6L)with

thelter.

Figure10

1.Dipstick

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher

•Preferredoil:SAE15W-40(above0degreesF)

•Alternateoil:SAE10W -30or5W -30(all

temperatures)

ToroPremiumEngineoilisavailablefromyour

distributorineither15W -40or10W -30viscosity.

1.Parkthemachineonalevelsurface,stoptheengine,

settheparkingbrake,andremovethekeyfromthe

ignitionswitch.

2.Releasetheenginecoverlatchesandopenthehood.

4.Removedipstickandcheckoillevelondipstick.

TheoillevelshouldbeuptotheFullmark.

5.IftheoillevelisbelowtheFullmark,removethe

llcap(

Figure11)andaddoiluntillevelreaches

theFullmarkondipstick.

Donotoverll.

Figure11

1.Oilllcap

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultof

overllingorunderllingtheengineoil.

Figure9

1.Enginecoverlatch

3.Removethedipstick,wipeitclean,andinstallit

(Figure10).

6.Installtheoilllcap.

7.Closeenginecoverandsecurewiththelatches.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Capacityofsystemis3.7USgallons(14L).

1.Carefullyremovetheradiatorcap(Figure13)and

expansiontankcap(Figure12).

17

Page 18

CAUTION

G012282

1

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

wintergradefuelatlowertemperaturesprovideslower

ashpointandcoldowcharacteristicswhichwillease

startingandreducefuellterplugging.

Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

2.Checklevelofcoolantinradiator.Radiator

shouldbelledtothetopofthellerneckand

theexpansiontanklledtothemarksonitsside

Figure12).

(

Figure12

1.Expansiontank

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

3.Ifthecoolantlevelislow,adda50/50mixture

ofwaterandethyleneglycolanti–freeze.Donot

overll.

Important:Donotusewateronlyor

alcohol/methanolbasecoolants.

4.Installtheradiatorandexpansiontankcaps.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Fueltankcapacity:15USgallons(56.8L)

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-Dor

No.1-D/2-Dblend)belowthattemperature.Useof

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

18

Page 19

DANGER

G012283

2

1

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffandis

cold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1inch

(25mm)belowthebottomofthellerneck.

Thisemptyspaceinthetankallowsthefuelto

expand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

Figure13

1.Radiatorcap2.Fueltankcap

4.Fillthetankuntilthelevelistothebottomofthe

llerneckwithdieselfuel.

5.Installfueltankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.

Thiswillminimizepossiblebuildupofcondensation

insidethefueltank.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling .

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwith

itswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromafueldispenser

nozzle.

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundfueltankcap.

3.Removecapfromthefueltank(Figure13).

Checking/AddingHydraulic

Fluid

Thehydraulicsystemandreservoirislledatthefactory

withapproximately18.2USgallons(69L)ofhigh

qualityhydraulicuid.Thehydraulicuidreservoir

holds9.3USgallons(35.2L)ofthetotal.Checkthe

levelofthehydraulicuidbeforetheengineis

rststartedanddailythereafter.Therecommended

replacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorToro

distributorforpartnumbers.)

Alternateuids:IftheTorouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Wedo

notrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

product.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehind

theirrecommendation.

Anti-wearHydraulicFluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C65to71

cSt@100°C8.4to8.9

19

Page 20

ViscosityIndexASTM

G012284

1

G012313

1

D2270

PourPoint,ASTMD97-18°Fto-30°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

97to107

C.Removecoverandaddhydraulicoiluntilitis

evenwitharrowsonsightglass(Figure14).

CheckingtheReeltoBedknife

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemoilisavailablein2/3oz(20

ml)bottles.Onebottleissufcientfor4–6USgallons

(15-22L)ofhydraulicoil.Orderpartnumber44-2500

fromyourauthorizedTorodistributor.

1.Parkthemachineonalevelsurface.

2.Lookintothesightglass(

Figure14).Theoillevel

shouldbeevenwiththearrowswhenchecking

warmoil.Theoilwillbe1/4to1/2inch(6to12

mm)belowthearrowswhencold.

Contact

Eachdaybeforeoperating,checkreeltobedknife

contact,regardlessifthequalityofcuthadpreviously

beenacceptable.Theremustbelightcontactacross

thefulllengthofthereelandthebedknife(referto

AdjustingtheReeltoBedknifeinthecuttingunit

Operator’sManual).

CheckingtheTirePressure

Fornormalmowingconditionsandawidevarietyof

turfgrasses,usethesetirepressures:13psi(90kPa)

frontand15psi(103.4kPa)rear.However,whenturf

iseitherwetterordrierthannormal,tirepressure

mayneedtobechanged.Onhardturf,usehightire

pressure(18psi(124kPa)frontandrear).Whenturf

issoft,uselowpressure(9psi(62kPa)frontand12

psi(82.7kPa)rear).

Important:Maintainevenpressureintwofront

tires,i.e.,13psi(90kPa)andbothreartires,i.e.,15

psi(103.4kPa),toensureexcellentquality-of-cut.

Figure14

1.Sightglassarrows

3.Iftheoillevelislow ,addhydraulicoiltothe

reservoir,asfollows:

A.Removetheseatlockpin,raisetheseatandhold

itopenwiththesupportrod.

B.Cleanaroundreservoircover(Figure15).

Figure15

1.Reservoircover

RearBallast

ThisunitcomplieswiththeANSIB71.4–2004Standard

whenreartiresarelledwithcalciumchlorideandarear

wheelweightkit(PartNumber11-0440)isinstalled.

Important:Ifapunctureoccursinatirewith

calciumchloride,removeunitfromturfareaas

quicklyaspossible.T opreventpossibledamageto

turf,immediatelysoakaffectedareawithwater.

StartingandStopping

1.Sitontheseat,keepyourfootoffofthetraction

pedal.Ensurethattheparkingbrakeisengaged

Andthatthetractionpedalandmow/backlaplever

areinneutral.

2.TurnthekeyswitchtotheOnposition.Whenthe

glowplugindicatorlightgoesoff,theengineis

readytoStart.

3.TurnthekeytotheStartposition.Releasethekey

whentheenginestarts.

Tostop,disengageandmoveallcontrolstoneutraland

settheparkingbrake.Raiseandlatchallcuttingunits

20

Page 21

inthetransportposition.TurnthekeytotheOffand

G012391

1

2

G012291

1

G012292

1

removeitfromtheswitch.

BleedingtheFuelSystem

1.Parkthemachineonalevelsurface.Ensurethatthe

fueltankisatleasthalffull.

2.Raisetheenginecover.

3.Opentheventplugonthefuellter/water

separator(

Figure16).

bleedscrew.LeavethekeyintheOnpositionuntil

asolidstreamoffuelowsoutaroundthescrew .

TightenthescrewandturnthekeytotheOff

position.

Note:Normally,theengineshouldstartafter

performingtheabovebleedingprocedures.

However,ifenginedoesnotstart,airmaybe

trappedbetweentheinjectionpumpandthe

injectors;refertoBleedingAirfromtheInjectors.

CheckingtheWarning

IndicatorLights

Eachdaybeforeoperating,ensurethatallwarning

lightsareworking.

Note:Analarmwillcontinuetosounduntilaproblem

iscorrectedoruntilyoupressthealarmsilencebutton.

Ifyouencounterasecondproblem,thealarmwillnot

soundbuttheindicatorlightwillilluminate.

Figure16

1.Fuellter/waterseparator

2.Ventplug

4.TurnthekeyintheignitionswitchtotheOn

position.Theelectricfuelpumpwillbegin

operation,therebyforcingairoutaroundthevent

plug.LeavethekeyintheOnpositionuntilasolid

streamoffuelowsoutaroundplug.Tightenthe

plugandturnkeytotheOffposition.

5.Opentheairbleedscrewonthefuelinjectionpump

Figure17).

(

Figure18

1.Warningindicatorlighttestbutton

CheckingtheSafetyInterlock

System

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly

causingpersonalinjury.

Figure17

1.Fuelinjectionpumpbleedscrew

6.TurnthekeyintheignitionswitchtotheOn

position.Theelectricfuelpumpwillbegin

operation,therebyforcingairoutaroundtheair

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

1.Inawideopenareafreeofdebrisandbystanders,

lowerthecuttingunitstotheground.Stopthe

engine.

21

Page 22

2.Sitontheseatandengagetheparkingbrake.

G012293

1

G012294

1

Turnthekeyandtrytostarttheenginewith

theMow-BacklapleverinboththeMowand

Backlappositions.Iftheenginecranks,thereisa

malfunctionthatmustberepairedimmediately.If

enginedoesnotcrank,thecuttingunitdriveswitch

isoperatingproperly.

3.Sitontheseatanddisengagetheparkingbrake.

Turnthekeyandtrytostartenginewiththe

Mow-BacklapleverintheStopposition.Ifthe

enginecranks,thereisamalfunctionthatmustbe

repairedimmediately.Ifenginedoesnotcrank,the

brakeswitchisoperatingproperly.

4.Engagetheparkingbrake,starttheengine,and

lowerthecuttingunits.MovetheMow-Backlap

levertotheMowposition.Raiseofftheseat;the

engineshouldstopwithinafewseconds,which

indicatestheinterlocksystemisoperating.Alsoraise

offtheseatwiththeleverintheBacklapposition.

Theengineshouldstop,indicatinginterlocksystem

isoperating.Ifenginedoesnotstop,thereisa

malfunctionthatmustberepairedimmediately.

Figure19

1.Retainerclip

2.Raisetheseatandsupportitinanduprightposition

withtheseatsupportrod(Figure20).

Note:Thereisa1to2seconddelaybetweenrising

offtheseatandengineshuttingoff.

5.Engagetheparkingbrake,movetheMow-Backlap

levertotheNeutralposition,starttheengine,

disengagetheparkingbrake,andraiseofftheseat.

Iftheenginestops,theinterlocksystemisoperating.

Ifenginedoesnotstop,thereisamalfunctionthat

mustberepairedimmediately .

PushingorTowingthe

Machine

Inanemergency,themachinecanbepushedortowed

foraveryshortdistance,byusingthetractionpump

by–passvalve.

Important:Donotpushortowthemachinefaster

than2-3mph(3-4.8km/h)becausethehydraulic

systemmaybedamaged.Ifthetractionunitmust

bemovedaconsiderabledistance,transportitona

truckortrailer.

Figure20

1.Seatsupportrod

3.Rotatetheby-passvalve90degrees(Figure21).

Openingthevalveopensaninternalpassageinthe

tractionpump,therebyby-passinghydraulicoil.

Becauseoilisby-passed,thetractionunitcanbe

movedwithoutdamagingthehydraulicsystem.

DANGER

Themachinewillrollwiththefrontwheelmotors

disengaged.Themachinemustbeonalevel

surfaceorthewheelsmustbeblocked.There

isnoeffectivebrakingwiththewheelmotors

disengaged.

1.Removetheretainerclipfromtheseatlockrod

(Figure19).

22

Page 23

G012295

1

Figure21

G0122961

MowingPreparation

Whenyouareattheareatobemowed,releasethe

front,centerandoutsidecuttingunittransportlatches,

lowerthecuttingunits,engagetheparkingbrake,and

stoptheengine.

CuttingUnitGrassDeectors

Adjustgrassdeectorstothehorizontalposition

Figure22),sotheclippingsdispersebackward;outand

(

awayfromthecuttingunits.Thiswillpreventclumps

ofclippings,especiallywetclippings,droppingoff

themachineorcuttingunits,whichaffectsthevisual

appearanceoftheturf.

Important:Ensurethattheparkingbrakeis

engagedbeforeopeningtheby-passvalve.

4.Beforestartingtheengine,closetheby-passvalve.

Donotstarttheenginewhenthevalveisopen.

Important:Runningthemachinewiththe

by-passvalveopenwillcausethehydraulic

systemtooverheat.

OperatingTips

Familiarization

Beforemowinggrasspracticeoperatinginanopen

area.Startandstoptheengine.Operateinforwardand

reverse.Lowerandraisecuttingunitssimultaneously

andindividually.Engageanddisengagereels.Operate

withallcuttingunitsdown,thenwithonlyanindividual

cuttingunit.Whenyoufeelfamiliarwiththemachine,

practiceoperatingaroundtreesandobstacles.Also

driveupanddownslopesusingbothmowingand

transportspeeds.

DANGER

Note:Generallyyoucanadjustthedeectorsdown

slightlyindrygrassandupslightlyinwetgrass.

Figure22

1.Grassdeector

Mowing

Matchthegroundspeedlimiter(Figure23)andreel

speedcontrolknob(Figure24)todesiredheight-of-cut;

refertoCuttingChartinMatchingtheGroundSpeed

andReelSpeed.Usethedecalatthesideofthesteering

columnasaguideonly.

Whenoperatingthemachine,alwaysusetheseat

beltandROPStogether.Donotuseaseatbelt

withoutaROPS.

WarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurif

themachineisoperatedwithamalfunction.Forshort

intervals,however,theemergencyengineoverride

buttoncanbeusedtooperatetheengineifitstops

becauseofoverheating.

23

Page 24

G012297

1

2

1.Groundspeedlimiter

G012298

1

Figure23

2.Tractionpedal

backuntilthecuttingunitsarefullyraised(asqueal

fromthehydraulicsystemmeansthecuttingunitsare

fullyraised).Lockthecuttingunitsinplacewiththe

transportlatches.Becarefulwhendrivingbetween

objectssoyoudonotaccidentallydamagethemachine

orcuttingunits.

MatchingGroundSpeedandReel

Speed

Varyreelspeed(whilemaintainingconstantground

speed)toestablishthebestqualityofcutforthearea

beingmowed.Reelspeedseithertoofastortooslow

forconditionsmayeffectthequalityofcut.Usethe

appropriatecuttingchart(below)andthedecalon

steeringconsoleasaguideforinitialadjustmentof

groundandreelspeeds.

RelateHOCandgroundspeedtorequiredreelspeed

settingona1thru5scaleonreelspeedknob.

Note:1=800RPM;2=900RPM;3=1000RPM;

4=1100RPM;and5=1200RPM.(Speedsare

approximate)

Figure24

1.Reelspeedcontrol

StarttheengineandmovethethrottletotheFast

position.Disengagetheparkingbrake.Tomove

forward,pressthetractionpedalforward(

Figure23).

MovetheMow-BacklaplevertotheMowposition.The

reelsarenowspinning.Maintaintractionpedalcontact

withthegroundspeedlimiter(Figure23)toensure

consistentclipandquality-of-cut.

CAUTION

Thisproductmayexceednoiselevelsof85dB(A)

attheoperatorposition.Earprotectorsare

recommendedforprolongedexposuretoreduce

thepotentialofpermanenthearingdamage.

Transport

Whenmowingiscomplete,movetheMow-Backlap

levertotheStopposition.Raisethecuttingunitsby

pullingbackontheliftcontrollevers.Holdthelevers

Note:Inthefollowingtables,N/RmeansNot

Recommended.

Note:Positions4and5areonlyattainablewitha

specialcoupler(PartNumber58-1530).Contactyour

ToroDealerforinformation.

RecommendedReelSpeedSettings:5BladeReel

HOC

113

1.25

1.5

2

2.5

RecommendedReelSpeedSettings:7BladeReel

HOC

1/2

5/8

3/4N/R

1

1.25

RecommendedReelSpeedSettings:11BladeReel

34

N/R

N/RN/R

N/RN/RN/R

N/RN/RN/RN/R

34

2

13

N/RN/R

N/RN/RN/R

GroundSpeedInMPH

5

5

13

234

GroundSpeedInMPH

5

5

13

N/RN/RN/R

5

123

6

N/RN/R

5

12

6

N/RN/R

5

12

7

N/R

1

7

N/R

24

Page 25

RecommendedReelSpeedSettings:11BladeReel

(cont'd.)

HOC

3/8

1/2N/R

5/8N/RN/R

3/4N/RN/RN/R

34

13

GroundSpeedInMPH

134

5

5

124

6

N/RN/R

12

7

N/R

25

Page 26

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•Checkthefanandalternatorbelttension.

•T orquethewheellugnuts.

•Changetheengineoilandlter.

•Checktheplanetarygeardriveoillevel.

•Changethehydrauliclter.

•Lubricatethereelspeedvalvewithoil.

•ChecktheengineRPM(idleandfullthrottle).

•Checktheengineoillevel.

•Checkthelevelofthecoolantinthecoolingsystem.

•Checkthehydraulicuidlevel.

•Checkthereeltobedknifecontact.

•Checkthewarningindicatorlights.

•Checkthesafetyinterlocksystem.

•Drainthefuellter/waterseparator.

•Removedebrisfromthescreen,oilcoolers,andradiator(morefrequentlyindirty

operatingconditions).

•Checkthehydrauliclinesandhosesforleaks,kinkedlines,loosemountingsupports,

wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings.(Greasethemimmediatelyaftereverywashing

regardlessoftheintervallisted.)

•Checktheconditionofandcleanthebattery .

•Checkthebatterycableconnections.

Every100hours

Every150hours

Every200hours

Every400hours

Every800hours

Every1,500hours

Beforestorage

•Inspectthecoolingsystemhoses.

•Checktheconditionandtensionofthealternatorbelt.

•Drainwaterfromthehydraulicreservoir.

•Changetheengineoilandlter.

•Servicetheaircleaner.(Morefrequentlyinextremelydirtyordustyconditions)

•T orquethewheellugnuts.

•Drainmoisturefromthefuelandhydraulicuidtanks.

•Checkthecuttingunitreeldrivebelts.

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacethefuelltercanister.

•ChecktheengineRPM(idleandfullthrottle).

•Drainandcleanthefueltank

•Checktherearwheeltoe-in.

•Checktheplanetarygeardriveoillevel.

•Flushandreplacethecoolingsystemuid.

•Changethehydrauliclter.

•Changethehydraulicsystembreather.(Moreofteninextremelydustyordirty

conditions)

•Packtherearwheelbearings

•Adjusttheenginevalves(refertotheengineOperator’sManual)

•Changethehydraulicuid.

•Drainandcleanthefueltank

Every2years

•Replaceallmovinghoses.

26

Page 27

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checktheengineoilandfuellevel.

Checkcoolingsystemuidlevel.

Drainthewater/fuelseparator .

Checktheairlterrestrictionindicator.

Checktheradiator ,oilcooler ,andscreenfordebris.

Cleantractionpedallockout

Checkunusualenginenoises.

Checkunusualoperatingnoises.

Checkthehydraulicsystemoillevel.

Checkhydraulichosesfordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrumentoperation.

Checkwarninglampsoperation

Checkthereel-to-bedknifeadjustment.

Checktheheight-of-cutadjustment.

Lubricateallgreasettings.

Touch-updamagedpaint.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

1

2

Sat.Sun.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

Thegreasettinglocationsandquantitiesareasfollows:

•Liftarms(5)(

Figure25)

GreasingtheBearingsand

Bushings

Ifyouoperatethemachineundernormalconditions,

lubricateallgreasettingsforthebearingsandbushings

afterevery50hoursofoperationwithNo.2General

PurposeLithiumBaseGrease.Lubricatebearingsand

bushingsimmediatelyaftereverywashing,regardless

oftheintervallisted.

27

Page 28

G012299

Figure25

G012300

G012301

G012302

•Rearaxle(6)(Figure26)

Figure27

•Cuttingunitreelandrollerbearings(Figure28)

Figure26

•Floatingorxedheadkitpivots(Figure27)

Figure28

•Reelcontrolvalve(notshown),locatedunderright

handconsole.

28

Page 29

EngineMaintenance

G012303

1 2

G01230 4

1 2

G012305

1

ServicingtheAirCleaner

ServiceInterval:Every200hours(Morefrequentlyin

extremelydirtyordustyconditions)

Checktheaircleanerbodyfordamagewhichcould

causeanairleak.Replaceifdamaged.Checkthewhole

intakesystemforleaks,damageorloosehoseclamps.

Changingtheairlterbeforeitisnecessaryonly

increasesthechanceofdirtenteringtheenginewhen

thelterisremoved.

Important:Besurethecoverisseatedcorrectly

andsealswiththeaircleanerbody.

1.Removetheknobssecuringtherearscreentothe

frame(

Figure29).Removethescreen.

3.Removethecoverfromtheaircleanerbody.Before

removingthelter,uselowpressureair(40psi,

cleananddry)tohelpremovelargeaccumulations

ofdebrispackedbetweentheoutsideofthelter

andthecanister.Avoidusinghighpressureair

whichcouldforcedirtthroughthelterintothe

intaketract.

Thiscleaningprocesspreventsdebrisfrommigrating

intotheintakewhentheprimarylterisremoved.

4.Removeandreplacetheprimarylter.

Cleaningoftheusedelementisnotrecommended

duetothepossibilityofdamagetotheltermedia.

Inspectthenewlterforshippingdamage,checking

thesealingendofthelterandthebody.Donot

useadamagedelement.Insertthenewlterby

applyingpressuretotheouterrimoftheelementto

seatitinthecanister.Donotapplypressuretothe

exiblecenterofthelter.

5.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthe

cover,cleanthecavityandreplacetheoutletvalve.

Figure29

1.Rearscreen2.Knob

2.Releasethelatchessecuringtheaircleanercoverto

theaircleanerbody(Figure30).

6.Installthecoverorientingtherubberoutletvalvein

adownwardposition—betweenapproximately5:00

to7:00whenviewedfromtheend.

7.SecurethelatchesAndreplaceandsecuretherear

screen.

ChangingtheEngineOiland

Filter

ServiceInterval:Aftertherst50hours

Every150hours

1.Removethedrainplug(Figure31)andlettheoil

owintoadrainpan.

Figure30

1.Aircleanerbody2.Aircleanercover

Figure31

1.Oildrainplug

2.Whentheoilstops,installthedrainplug.

29

Page 30

3.Removetheoillter(Figure32).

G012306

1

FuelSystem

Maintenance

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

Figure32

1.Oillter

4.Applyalightcoatofcleanoiltothenewlterseal.

5.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn.

Important:Donotover-tightenthelter.

6.Addoiltothecrankcase;refertoCheckingthe

EngineOilin

Operation(page17).

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to1/2

in.(6to13mm)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

DrainingtheFuelTank

ServiceInterval:Every800hours

Beforestorage

Drainandcleanthefueltankifthefuelsystembecomes

contaminatedorifthemachineistobestoredforan

extendedperiod.Usecleanfueltoushoutthetank.

CheckingtheFuelLinesand

Connections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

Inspectthefuellinesfordeterioration,damage,orloose

connections.

DrainingtheFuelFilter/Water

Separator

ServiceInterval:Beforeeachuseordaily

1.Placeacleancontainerunderthefuellter

(Figure33).

2.Loosenthedrainplugonthebottomofthelter

canisterandallowittodrain.

30

Page 31

G012390

1

2

Figure33

G012307

1

1.Waterseparatorltercanister

3.Tightenthedrainplug.

ReplacingtheFuelFilter

Canister

ServiceInterval:Every400hours

1.Cleantheareawheretheltercanistermounts

Figure33).

(

2.Removetheltercanisterandcleanthemounting

surface.

3.Lubricatethegasketontheltercanisterwithclean

oil.

4.Installthenewltercanisterbyhanduntilthe

gasketcontactsmountingsurface,thenrotateitan

additional1/2turn.

Figure34

1.Fuelinjectors

2.MovethrottletotheFastposition.

3.TurnthekeyinthekeyswitchtotheStartposition

andwatchthefuelowaroundtheconnector.The

enginewillcrank.Whenyouobserveasolidowof

fuel,turnthekeytotheOffposition.

4.Tightenthepipeconnectorsecurely.

5.Repeatsteps1through4ontheremainingnozzles.

BleedingAirfromtheFuel

Injectors

Note:Thisprocedureshouldbeusedonlyifthe

fuelsystemhasbeenpurgedofairthroughnormal

primingproceduresandtheenginewillnotstart;refer

toBleedingtheFuelSysteminOperation(page17).

1.LoosenthepipeconnectiontotheNo.1nozzleand

holderassembly(Figure34).

31

Page 32

ElectricalSystem

Maintenance

Important:Beforeweldingonthemachine,

disconnectbothcablesfromthebattery,bothwire

harnessplugsfromtheelectroniccontrolmodule,

andtheterminalconnectorfromthealternatorto

preventdamagetotheelectricalsystem.

ServicingtheBattery

WARNING

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metaltractorcomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

WARNING

Incorrectbatterycableroutingcoulddamagethe

tractorandcablescausingsparks.Sparkscancause

thebatterygassestoexplode,resultinginpersonal

injury.

•Always

cablebeforedisconnectingthepositive(red)

cable.

•Always

beforeconnectingthenegative(black)cable.

Checkthebatteryconditionweeklyorafterevery50

hoursofoperation.Keeptheterminalsandtheentire

batterycasecleanbecauseadirtybatterywilldischarge

slowly.Tocleanthebattery,washtheentirecasewitha

solutionofbakingsodaandwater.Rinseitwithclear

water.Coatthebatterypostsandcableconnectorswith

Grafo112X(skin-over)grease(ToroPartNo.505-47)

orpetroleumjellytopreventcorrosion.

disconnect

connect

thenegative(black)battery

thepositive(red)batterycable

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfromit.

32

Page 33

DriveSystem

G012319

1

2

G012300

G012321

1

Maintenance

CheckingthePlanetaryGear

DriveOilLevel

ServiceInterval:Aftertherst50hours

Checking/AdjustingtheRear

WheelToe-in

ServiceInterval:Every800hours

1.Measurethecenter-to-centerdistance(ataxleheight)

atfrontandrearofthesteeringtires(Figure35).The

frontmeasurementmustbe1/8inch(3mm)less

thantherearmeasurement.

Figure35

2.Loosentheclampsatbothendsofthetierods

(Figure36).

Every800hours

Theoilcapacityisapproximately30oz(885ml)ofhigh

qualitySAE80–90weightGearLube(ISO150/220).

1.Parkthemachineonalevelsurfacewiththe

check/drainplughole(

9o’clockposition.

1.Check/drainplug

2.Removethecheck/drainplug.Theoillevelshould

beatthebottomofthehole;ifnot,addoil.

Figure37)atthe3o’clockor

Figure37

Figure36

1.Clamp

3.Rotateeachtierodtomovethefrontofthetire

inwardoroutward.

4.Tightenthetierodclampswhentheadjustmentis

correct.

Note:Ensurethatthetierodclampsarepositioned

sotheydonotinterferewiththesteeringlinkage.

2.Tierod

3.Replacethecheck/drainplug.

33

Page 34

CoolingSystem

G012303

1 2

G012309

3

1 2

Maintenance

Capacityofthecoolingsystemis3.7USgallons(14L).

Alwaysprotectthecoolingsystemwitha50/50solution

ofwaterandethyleneglycolanti-freeze.Donotuse

wateronlyinthecoolingsystem.

•Afterevery100operatinghours,tightenhose

connections.Replaceanydeterioratedhoses.

•Afterevery800operatinghours,drainandushthe

coolingsystem.Addanti-freeze(refertoChecking

theCoolingSystem).

RemovingDebrisfromthe

CoolingSystem

ServiceInterval:Beforeeachuseordaily—Remove

debrisfromthescreen,oilcoolers,

andradiator(morefrequentlyindirty

operatingconditions).

1.Turntheengineoffandremovethekeyfromthe

ignitionswitch.

2.Releasethefrontenginecoverlatchesandraisethe

enginecover.

3.Thoroughlycleanalldebrisoutoftheenginearea.

4.Removetheknobssecuringtherearscreentothe

frameandremovethescreen(

Figure38).

Figure39

1.Oilcooler3.Inlinefuellter

2.Radiator

6.Pivotoilcoolerbackintopositionandinstallrear

screen.

7.Lowertheenginecoverandsecurethelatches.

Figure38

1.Rearscreen2.Knob

5.Liftupontheoilcoolerhandlesandpivotitrearward

inthemountingslot.Cleanbothsidesoftheoil

cooler,radiatorandrearengineareathoroughlywith

compressedair(Figure39).

34

Page 35

BrakeMaintenance

G01231 1

3 3

4

5

1

2

G012310

1

2

AdjustingtheParkingBrake

andTractionSwitches

BeltMaintenance

Checktheconditionandtensionofthealternatorbelt

aftertherstdayofoperationandevery100operating

hoursthereafter.

Intime,theparkingbrakecablemaystretch,causing

theenginenottostart.Ifthishappens,adjustthecable

Figure40).

(

Figure40

1.Parkingbrake4.Tractionswitches

2.Brakecable5.Tractionpedal

3.U-bracketnuts

CheckingtheConditionand

TensionoftheAlternatorBelt

ServiceInterval:Every100hours

•Propertensionwillallowa3/8inch(10mm)

deectionwhenaforceof10lb(4.5kg)isapplied

onthebeltmidwaybetweenthepulleys.

•Ifthedeectionisnot3/8inch(10mm),loosenthe

alternatormountingbolts(Figure41).Increaseor

decreasethealternatorbelttensionandtightenthe

bolts.Checkdeectionofbeltagaintoensurethat

thetensioniscorrect.

1.Pullthebrakelevertothe3rdclick.

2.Pullthebrakeleveruponeadditionalclick.

3.AdjustthefourU-bracketnutsequallysothespring

hastension.

Note:Thisadjustmentaffectsoperationoftraction

switches.

4.AdjustthefourU-bracketnutssoenginewillstart

andrunwhenhandbrakeisatthefourthclick,but

willnotstartorrunwhenhandbrakeisatthesecond

click.

Figure41

1.Alternator2.Mountingbolt

35

Page 36

HydraulicSystem

G012314

1

G012284

1

Maintenance

DrainingWaterfromthe

HydraulicReservoir

ServiceInterval:Every100hours

Beforedraining,allowmachinetosetabout8hoursto

allowwatertosettletobottomofreservoir.

1.Openthedrainplug(Figure42)one-halfturnand

allowtheuidtoowintodrainpanuntilyoudo

notnoticewaterinthehydraulicuid.

3.Installthereservoircover,lowertheseat,andsecure

itwiththelockpin.

4.Starttheengine,runitslowly,anduseallofthe

hydrauliccontrolstodistributehydraulicuid

throughoutthesystem.Alsocheckforleaks,then

stoptheengine.

5.Withcuttingunitsupandoilwarm,lookintothe

sightglass(Figure43).Ifthehydraulicuidisnot

evenwiththearrows,addenoughuidtoraiseitto

theproperlevel.Donotllfulliftheuidiscold.

Figure42

1.Drainplug

2.Tightenthedrainplugandaddhydraulicuid;refer

toCheckingandAddingHydraulicFluid.

ChangingtheHydraulicFluid

ServiceInterval:Every1,500hours/Every2years

(whichevercomesrst)

Ifuidbecomescontaminated,contactyourlocal

Torodistributorbecausethesystemmustbeushed.

Contaminateduidlooksmilkyorblackwhencompared

tocleanoil.

1.Removethedrainplug(Figure42)fromthe

reservoirandletthehydraulicoilowintoadrain

pan.Tightentheplugwhenthehydraulicoilstops

draining.

2.Fillthereservoirwithhydraulicuid;referto

Checking/AddingtheHydraulicFluid.

Important:Useonlythehydraulicuids

specied.Otheruidscouldcausesystem

damage.

Figure43

1.Sightglassarrows

ChangingtheHydraulicFilter

ServiceInterval:Aftertherst50hours

Every800hours/Yearly(whichever

comesrst)

UseTororeplacementlterPartNo.86-6110.

Important:Useofanyotherltersmayvoidthe

warrantyonsomecomponents.

Note:Undercertainconditions,abypassvalvein

theltermountingplateallowsoiltobypassthelter.

Beforethelterstartstobypass,awarninglightonthe

steeringconsolewillilluminate.Thewarninglightmay

comeonmomentarilywhentheoiliscold.Ifthelight

doesnotgooutaftertheoiliswarm,thelterisclogged

oranelectricalproblemexists.Correcttheproblem

beforecommencingoperation.

1.Removetheseatlockpin,raisetheseat,andholdit

openwiththesupportrod.Also,removethepanel

(securedwithmagnets)aheadoftheseat.

2.Cleanaroundtheltermountingarea(

Placeadrainpanunderthelterandremovethe

lter.

Figure44).

36

Page 37

G012315

1

G012316

1

CheckingtheHydraulicLines

G012317

2

1

andHoses

Daily,checkhydrauliclinesandhosesforleaks,kinked

lines,loosemountingsupports,wear,loosettings,

weatherdeterioration,andchemicaldeterioration.Make

allnecessaryrepairsbeforeoperating.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

Figure44

3.Lubricatethenewltergasketandllthenewlter

withhydraulicoil.

4.Ensurethattheltermountingareaisclean.Screw

thelteronuntilthegasketcontactsthemounting

plate,thentightenthelterone-halfturn.

5.Starttheengineandletitrunslowlyforabouttwo

minutestopurgeairfromthesystem.Stopthe

engineandcheckforleaks.

6.Lookintosightglass(

Figure43).Thehydraulicoil

levelshouldbeevenwitharrowswhenoiliswarm.

Iflevelislow,addhydraulicoiltothereservoir.

ReplacingtheHydraulic

SystemBreather

ServiceInterval:Every800hours/Yearly(whichever

comesrst)(Moreofteninextremely

dustyordirtyconditions)

1.Releasethelatchesandopentheenginecover.

2.Cleanaroundthebreatherandunscrewitwitha

wrench(

Figure45).

•Makesureallhydraulicuidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

•Getimmediatemedicalhelpifuidisinjected

intoskin.

HydraulicSystemTestPorts

Thetestports(Figure46andFigure47)areusedtotest

thehydrauliccircuits.Checkallpressureswhenengine

isatfullspeedandhydraulicoilisatnormaloperating

temperature.ContactyourlocalTorodistributorfor

assistance.

Figure45

1.Breather

1.Tractionforward

Figure46

2.Tractionreverse

3.Installanewbreather.

4.Closetheenginecoverandlatchitsecurely.

37

Page 38

G012318

5 2 1 4

3

Figure47

1.Liftreliefcircuit4.Cuttingunitcircuit

2.Chargepressurecircuit5.Steeringcircuit

3.Cuttingunit

counterbalance

Storage

PreparingtheTractionUnit

1.Thoroughlycleanthetractionunit,cuttingunits,

andengine.

2.Checkthetirepressure.

3.Checkallfastenersforloosenessandtightenthem

asnecessary.

4.Greaseallgreasettingsandpivotpoints.Wipeup

anyexcesslubricant.

5.Lightlysandandusetouch-uppaintonpaintedareas

thatarescratched,chipped,orrusted.Repairany

dentsinthemetalbody.

6.Servicethebatteryandcablesasfollows:

A.Removethebatteryterminalsfromthebattery

posts.

•TractionForwardandReverse(Figure46)(behind

thewheelmotors)hasanormalreliefsettingof

approximately5300psiand50to150psicharge

pressure.Useagaugewith7500to10,000psifull

scalerating.

•CuttingunitCounterbalancehasadjustablepressure:

HotOil:500–550psi NormalSetting

ColdOil:600–650psi

HotOil:550+psi MaximumHillClimbingSetting

ColdOil:650+psi

Setting

Liftcircuitreliefpressureisapproximately2650psiwhen

counterbalancesettingis550psi.

HotOil:500psi MaximumQualityofCut

ColdOil:600psi

Note:Changesincounterbalancesettingwilleffect

theliftcircuitreliefpressure.

•CuttingUnitCircuithasanormalreliefsettingof

approximately2700–3000psi.

•SteeringCircuithasanormalreliefsettingof

approximately1500psi.

•Lift/reliefCircuithasanormalreliefsettingof

approximately2650–2750psi.

•ChargePressureCircuithasanormalreliefsettingof

approximately100–150psi.

B.Cleanthebattery,terminals,andpostswitha

wirebrushandbakingsodasolution.

C.Coatthecableterminalsandbatterypostswith

Grafo112Xskin-overgrease(ToroPartNo.

505-47)orpetroleumjellytopreventcorrosion.

D.Slowlyrechargethebatteryevery60daysfor24

hourstopreventleadsulfationofthebattery.

PreparingtheEngine

1.Draintheengineoilfromtheoilpanandreplace

thedrainplug.

2.Removeanddiscardtheoillter.Installanewoil

lter.

3.Relltheoilpanwithdesignatedquantityofmotor

oil.

4.Starttheengineandrunitatidlespeedfor

approximatelytwominutes.

5.Stoptheengine.

6.Thoroughlydrainallfuelfromthefueltank,lines,

andthefuellter/waterseparatorassembly.

7.Flushthefueltankwithfresh,cleandieselfuel.

8.Secureallfuelsystemttings.

9.Thoroughlycleanandservicetheaircleaner