Page 1

FormNo.3362-355RevA

8and11BladeDPACuttingUnits

with7inchReels

Reelmaster

ModelNo.03681—SerialNo.290000001andUp

ModelNo.03682—SerialNo.290000001andUp

ModelNo.03696—SerialNo.290000001andUp

ModelNo.03697—SerialNo.290000001andUp

®

5510&5610TractionUnits

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

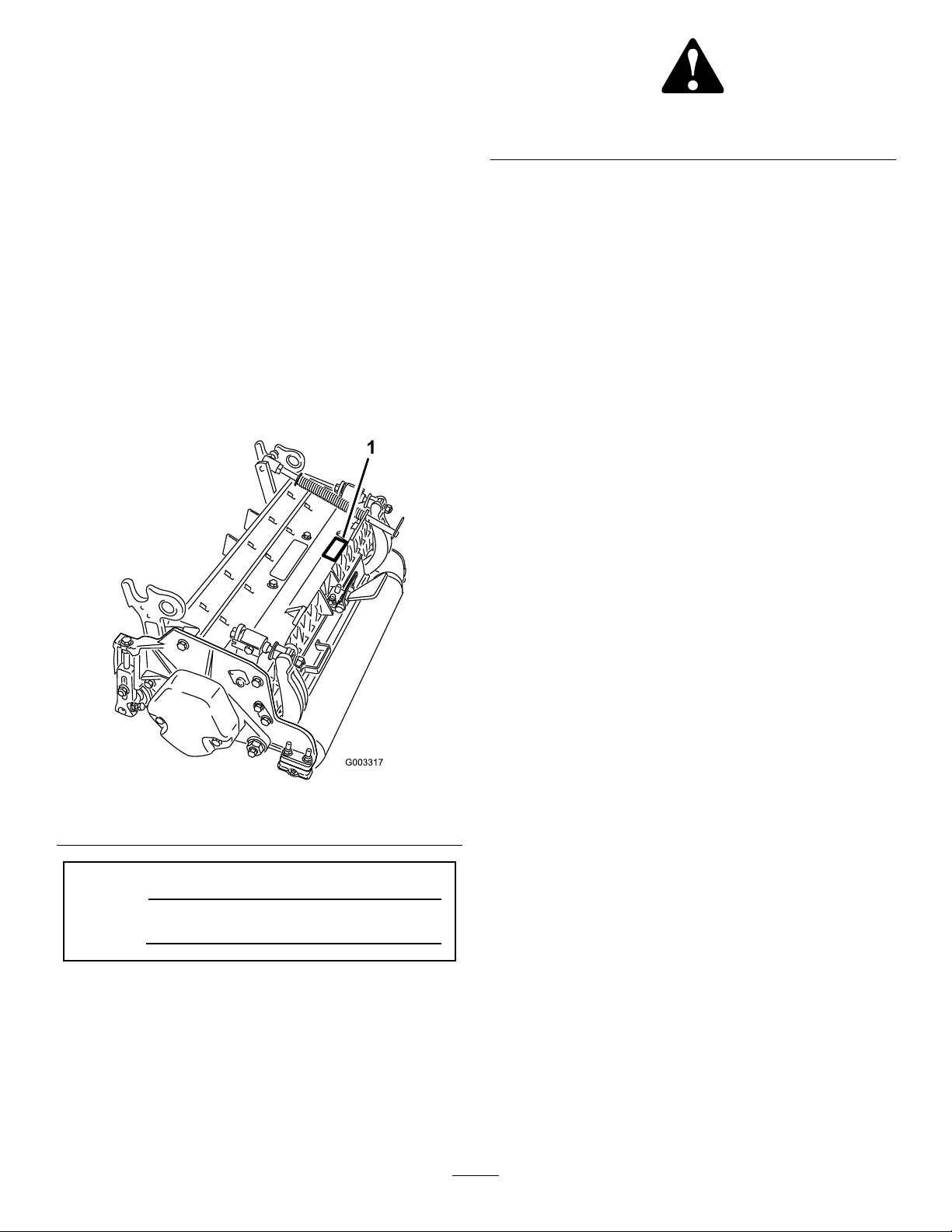

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Locationofthemodelandserialnumbers

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafetyandInstructionalDecals.............................3

Setup............................................................................4

1Inspection.........................................................4

2CuttingUnitKickstand......................................4

3AdjustingtheRearShield...................................5

4MounttheCounterWeights...............................5

ProductOverview........................................................7

Specications.......................................................7

CuttingUnitAccessoriesandKits(seeparts

catalogforpartnumbers)..................................8

Operation.....................................................................9

Adjustments.........................................................9

HeightofCutChartTerms.................................10

HeightofCutChart............................................11

ServicingBedknife.............................................13

Maintenance...............................................................15

Lubrication.........................................................15

AdjustingtheReelBearings................................15

ServicingtheBedbar...........................................16

ServicingtheRoller............................................17

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

©2009—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

advisableandrequiredbysomelocalordinancesand

insuranceregulations.

Hazardcontrolandaccidentpreventionare

dependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedinthe

operation,transport,maintenance,andstorageof

themachine.Improperuseormaintenanceofthe

machinecanresultininjuryordeath.Toreduce

thepotentialforinjuryordeath,complywiththe

followingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitandcuttingunitoperatorsmanual’ s

beforeoperatingthecuttingunit.

•Neverallowchildrentooperatethetractionunitor

cuttingunits.Donotallowadultstooperatetraction

unitorcuttingunitswithoutproperinstruction.

Onlytrainedoperatorswhohavereadthismanual

shouldoperatethetractionunitorcuttingunits.

•Neveroperatethecuttingunitswhenunderthe

inuenceofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisillegibleordamaged,

repairorreplaceitbeforeoperationiscommenced.

Alsotightenanyloosenuts,bolts,andscrewsto

ensurecuttingunitisinsafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperate

cuttingunitswhilewearingsandals,tennisshoes,

sneakersorshorts.Also,donotwearloosetting

clothingwhichcouldgetcaughtinmovingparts.

Alwayswearlongpantsandsubstantialshoes.

Wearingsafetyglasses,safetyshoesandahelmetis

•Removealldebrisorotherobjectsthatmightbe

pickedupandthrownbythecuttingunitreelblades.

Keepallbystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.

Checkcuttingunitfordamagedparts.Repairany

damagebeforerestartingandoperatingthecutting

unit.

•Lowerthecuttingunitstothegroundandremove

keyfromignitionswitchwhenevermachineisleft

unattended.

•Besurecuttingunitsareinsafeoperatingcondition

bykeepingnuts,boltsandscrewstight.

•Removekeyfromignitionswitchtoprevent

accidentalstartingoftheenginewhenservicing,

adjustingorstoringthemachine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedT oroDistributor.

•Toensureoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsand

accessoriestokeeptheToroallTORO.Neveruse

"will-t"replacementpartsandaccessories

madebyothermanufacturers.Lookforthe

Torologotoassuregenuineness.Usingunapproved

replacementpartsandaccessoriescouldvoidthe

warrantyofTheToroCompany.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-6688

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

3

Page 4

Setup

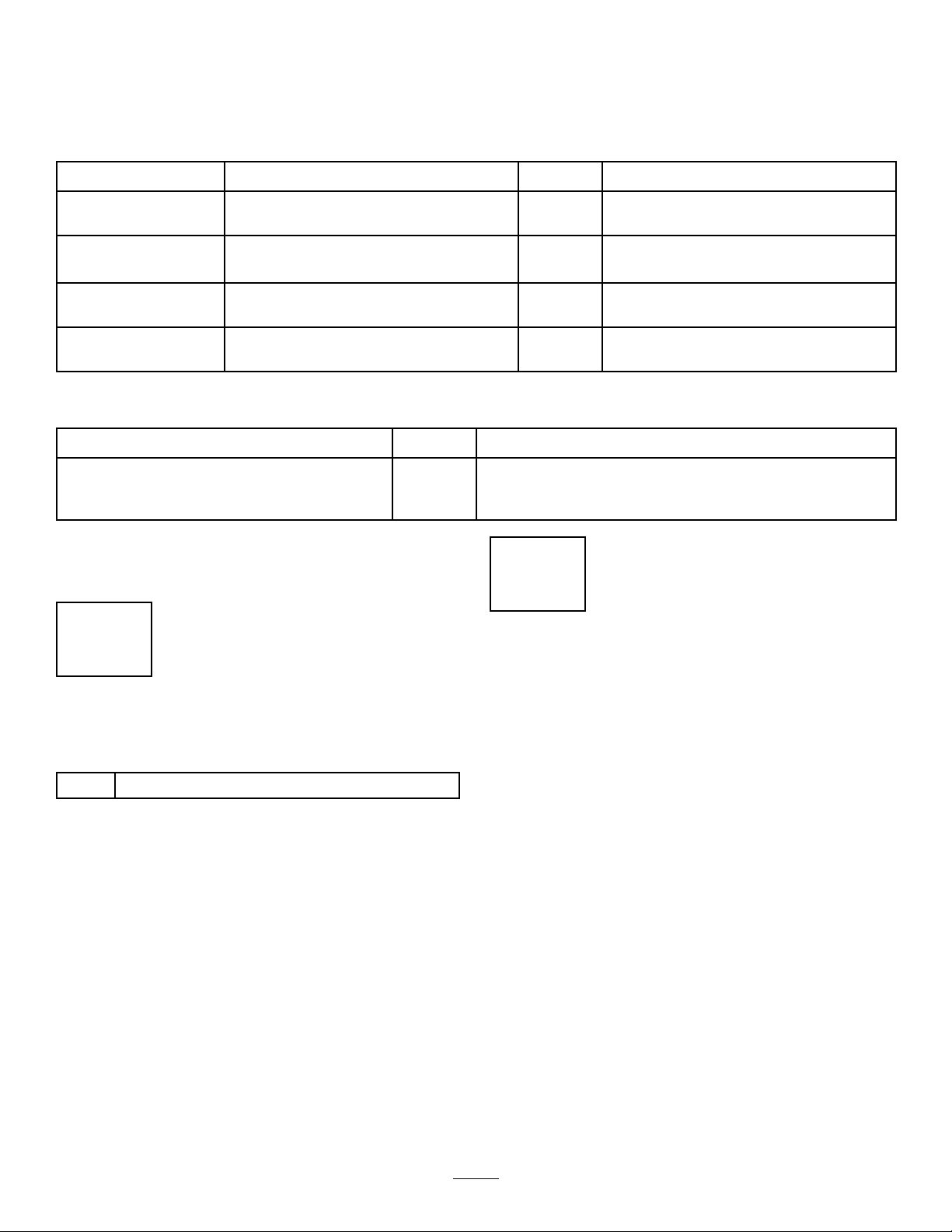

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Cuttingunit

Nopartsrequired

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Partscatalog1

Operator’sManual

CerticateofCompliance

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

Qty.

1Inspectthecuttingunit

–

–

–

1

1

Reviewthematerialandsaveinanappropriateplace:

Usethekickstandwhentippingthe

cuttingunit

Adjusttherearshield

Mountthecounterweights

Use

Use

2

1

Inspection

Partsneededforthisprocedure:

1

Cuttingunit

Procedure

Afterthecuttingunitisremovedfromthebox,inspect

thefollowing:

1.Checkeachendofthereelforgrease.Greaseshould

bevisiblyevidentinthereelbearingsandinternal

splinesofthereelshaft.

2.Ensurethatallnutsandboltsaresecurelytightened.

3.Makesurethecarrierframesuspensionoperates

freelyanddoesnotbindwhenmovedbackandforth.

CuttingUnitKickstand

NoPartsRequired

Procedure

Wheneverthecuttingunithastobetippedtoexposethe

bedknife/reel,propuptherearofthecuttingunitwith

thekickstand(suppliedwiththetractionunit)tomake

surethenutsonthebackendofthebedbaradjusting

screwsarenotrestingontheworksurface(Figure3).

4

Page 5

1.Cuttingunitkickstand

Figure3

1.Rearshield

Figure4

2.Capscrew

3

AdjustingtheRearShield

NoPartsRequired

Procedure

Undermostconditions,bestdispersionisattained

whentherearshieldisclosed(frontdischarge).When

conditionsareheavyorwet,rearshieldmaybeopened.

Toopentherearshield(Figure4),loosenthecapscrew

securingtheshieldtotheleftsideplate,rotatetheshield

totheopenpositionandtightenthecapscrew .

4

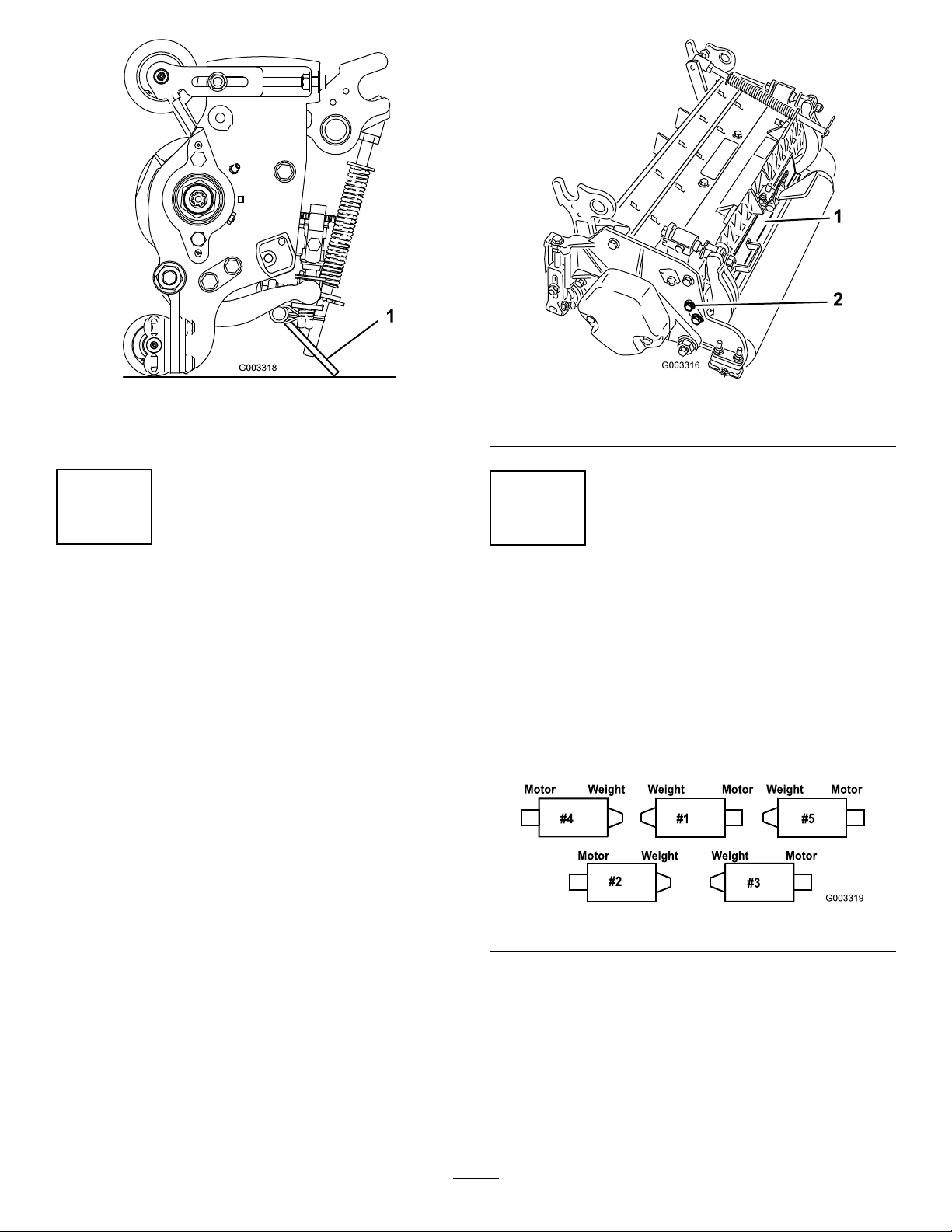

MounttheCounterWeights

NoPartsRequired

Procedure

Allcuttingunitsareshippedwiththecounterweight

mountedtotheleftendofthecuttingunit.Usethe

followingdiagramtodeterminethepositionofthe

counterweightsandreelmotors.

Figure5

1.Onthe#2and#4cuttingunits,removethe2cap

screwssecuringthecounterweighttotheleftend

ofthecuttingunit.Removethecounterweight

(Figure6).

5

Page 6

Figure6

1.Counterweight

2.Onrightendofcuttingunit,removetheplasticplug

fromthebearinghousing(Figure7).

3.Removethe2capscrewsfromtherightsideplate

(Figure7).

Figure7

1.Plasticplug

2.Capscrew(2)

4.Installthecounterweighttotherightendofthe

cuttingunitwiththe2screwspreviouslyremoved.

5.Looselyinstallthe2reelmotormountingcapscrews

totheleftsideplateofthecuttingunit(Figure7).

6

Page 7

ProductOverview

Specications

Tractors

HeightofCutCuttingheightisadjustedonthefrontrollerbytwoverticalscrewsandheldbytwolocking

HeightOfCutRangeStandardbenchheightofcutrangeis.250inch(3mm)to1.00inch(25mm).Benchheight

ReelWeldment

ReelBearings

PowerAttachment

FrameDiecastaluminumcrossmemberwiththreebolt-ondie-castaluminumsideplates.

Rollers

BedknifeReplaceablesingleedged,highcarbonsteelbedknifeisfastenedtoamachinedcastiron

BedknifeAdjustmentDualscrewadjustmenttothereel;detentscorrespondingto.0009inch(.023mm)bedknife

GrassShieldAdjustablerearshieldwithoptionaladjustablecut-offbartoimprovegrassdischargefrom

Counterweight

MaximumReelSpeed

Weight

ThesecuttingunitswillmountontheReelmaster5510&5610TractionUnits.

capscrews

ofcutrangewiththeHighHeightofCutKitinstalledis1.00inch(25mm)to2.00inches

(51mm).EffectiveHOCmayvarydependingonturfconditions,typeofbedknife,rollers

andattachmentsinstalled.

Reelsare7inches(18cm.)indiameter,22inches(56cm.)inlength.Highstrengthlow

alloysteelbladesarethruhardenedandimpactresistant.

Twodoublerowself-aligningballbearings,presstontoreelshaft.

Thereelmotorsfeaturequickdisconnectforremovalorinstallationontocuttingunit.The

cuttingunitscanbedrivenfromeitherend.

Thefrontrollerisa3inch(76mm)diameterplasticWiehleroller.Therearrollerisa3inch

(76mm)diametersteelfullroller.

bedbarwith8screws.TheEdgeMax®bedknifeisstandard.

movementforeachindexedposition.

reelinwetconditions.

Acastironweightmountedoppositetothedrivemotorbalancesthecuttingunit.

1650RPM.

8Blade–147lb.(67kg)11Blade–151lb.(69kg)

7

Page 8

CuttingUnitAccessoriesandKits(see

partscatalogforpartnumbers)

Note:Allaccessoriesandkitsare1percuttingunit

unlessotherwisespecied.

GrassBasketKit:Aseriesofclippingcollection

basketsattachedtothefrontofthecuttingunitsto

collectgrassclippings.

RearLiftCylinderKit:Collarsassembledonrear

cuttingunitliftarmcylinderstolimittheheightofthe

cuttingunits.Thisincreasestheareaforthereargrass

baskets.

RearRollerBrushKit:Ahighspeed,highcontact

brushthatkeepstherearrollerfreeofgrassanddebris,

whichmaintainsaconsistentheightofcutandprevents

clumping.Thisleadstoabetteraftercutappearance.

GroomerKit:Rotatingbladesassembledbehindthe

frontrollerwhichprovidethebestmethodforreducing

grainandspongyturfbystandingupthegrassbefore

cutting.Thegroomeralsoknocksoffdewfordecreased

stickinessandclumping,opensupcanopyforbetter

grassclippingintegration,andliftsgrassforaclean

crispcut.Theoveralldesignimprovesthequalityofcut

forhealthierturfgrasswhileimprovingtheaftercut

appearance

BroomerKit:Multiplebrushstripswovenintothe

helicalgroomerbladesimprovetheeffectivenessofthe

groomerkit.Performanceofthegroomerisenhanced

byenablingafullwidth"Brooming"effectofturfwhile

openingupcanopyforbettergrassclippingintegration.

Thecombinationofgroomerandbroomersystems

optimizethequalityofcutandaftercutappearancefor

moreconsistentplayingconditions.

Comb/ScraperKit:Axedcombinstalledbehindthe

frontrollerwhichhelpsreducegrainandspongyturfby

standingupthegrassbeforecutting.Ascraperforthe

frontWiehlerollerisincludedinthekit.

HighHOCKit:Newfrontrollerbracketsand

additionalspacersfortherearrollerallowsthecutting

unittoachieveheightsofcutabove1.00inch(25mm).

Thenewfrontrollerbracketsalsomovethefrontroller

outfarthertoimproveafter-cutappearance.

ShoulderRoller:Helpsreduceover-lapmarksfor

warmseasongrasses(Bermuda,Zoysia,Paspalum).

CollarKit(6perneededperroller):Helpsreduceover

lapmarksforwarmseasongrasses(Bermuda,Zoysia,

Paspalum).ThiskitisinstalledontheexistingWiehle

roller,butisnotasaggressiveastheShoulderroller.

ShortRearRoller:Helpsreducedoublerollermarks

forcoolseasongrasses(Bent,Bluegrass,Rye).

FullFrontRoller:Helpsproducemorepronounced

striping(repeatedcuttinginthesamedirection/path),

however,effectiveheightofcutisraisedandqualityof

cutisreduced.

Scrapers(Wiehle,Shoulder,Rearroller,FullFront

Roller):Fixedscrapersforalloptionalrollersare

availableforreducinggrassbuilduponrollerswhich

canaffectheightofcutsettings.

RollerRebuildKit:Includesallthebearings,bearing

nuts,innersealsandoutersealsrequiredtorebuilda

roller.

RollerRebuildToolKit:Includesallthetoolsandthe

installationinstructionsrequiredtorebuildarollerwith

therollerrebuildkit.

8

Page 9

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Adjustments

AdjustingtheBedknifetotheReel

Bedknifetoreeladjustmentisaccomplishedby

looseningortighteningbedbaradjustingscrews,located

ontopofmower.

1.Positionmachineonaat,levelworksurface.Make

surereelcontactisremovedbyturningbedbar

adjustingscrewscounterclockwise(Figure8).

Figure8

1.Bedbaradjustingscrew

2.Tiltmoweronback,ontothecuttingunitkickstand,

toexposebedknifeandreel.

Important:Makesurenutsonbackendof

bedbaradjustingscrewsarenotrestingonthe

worksurface(Figure8).

Figure9

4.Checkforlightcontactatotherendofreelusing

paperandadjustasrequired.

5.Afteradjustmentisaccomplished,checktoseeif

reelcanpinchpaperwheninsertedfromthefront

andcutpaperwheninsertedatarightangletothe

bedknife(Figure9).Itshouldbepossibletocut

paperwithminimumcontactbetweenthebedknife

andthereelblades.Ifexcessivecontact/reeldrag

isevidentitwillbeeithernecessarytobacklapor

regrindthecuttingunittoachievethesharpedges

neededforprecisioncutting(RefertotheToro

manualforSharpeningReelandRotaryMowers,

FormNo.80-300PT).

AdjustingtheRearRoller

1.Adjusttherearrollerbrackets(Figure10)tothe

desiredheightofcutrangebypositioningthe

requiredamountofspacersbelowthesideplate

mountingange(Figure10)pertheHOCChart.

3.Atoneendofreel,insertastripofnewspaper

betweenreelandbedknife(Figure9).Whileslowly

rotatingreelforward,turnbedbaradjustingscrew

(Figure8)clockwise(onsameendofreel,one

clickatatime,untilpaperispinchedlightly,when

insertedfromthefront,paralleltothebedknife.A

slightdragwillbenotedasthepaperispulled.

Note:Eachtimeadjustingscrewisrotatedone

clickclockwise,bedknifemoves.0009in(.023mm).

closertoreel.Donotovertightentheadjusting

screws.

Figure10

1.Spacer3.Sideplatemountingange

2.Rollerbracket

2.Raiserearofcuttingunitandplaceablockunder

bedknife.

3.Remove(2)nutssecuringeachrollerbracketand

spacertoeachsideplatemountingange.

4.Lowerrollerandscrewsfromsideplatemounting

angesandspacers.

5.Placespacersontoscrewsonrollerbrackets.

9

Page 10

6.Re-securerollerbracketandspacerstounderside

ofsideplatemountingangeswithnutspreviously

removed.

7.Verifythatbedknifetoreelcontactiscorrect.Tip

mowertoexposefrontandrearrollersandbedknife.

Note:Thepositionoftherearrollertothe

reeliscontrolledbythemachiningtolerances

oftheassembledcomponentsandparallelingis

notrequired.Alimitedamountofadjustmentis

possiblebysettingthecuttingunitonasurface

plateandlooseningthesideplatemountingcap

screws(Figure11).Adjustandretightencapscrews.

Torquethecapscrewsto27-33ft-lb.

Figure11

1.Sideplatemountingcapscrews

allowingthespinningreeltopullmoregrassupinto

thebedknife.

Figure12

1.Rearspacers

2.Sideplatemountingange

3.Aggressivenessofcut

RearSpacers

Thenumberofrearspacersdeterminesthe

aggressivenessofcutforthecuttingunit.Foragiven

heightofcut,addingspacers,belowthesideplate

mountingange,increasestheaggressivenessofthe

cuttingunit.Allcuttingunitsonagivenmachinemust

besettothesameaggressivenessofcut(Numberof

rearspacers,partno.106-3925),otherwisetheafter-cut

appearancecouldbenegativelyaffected(Figure12).

HeightofCutChartTerms

HeightofCutSetting(HOC)

ThedesiredHeightofCut.

AggressivenessofCut

CuttingunitAggressivenessofCuthasasignicant

impactontheperformanceofthecuttingunit.

AggressivenessofCutreferstotheangleofthe

bedkniferelativetotheground(Figure12).

Thebestcuttingunitsetupisdependentonyour

turfconditionsanddesiredresults.Experiencewith

thecuttingunitonyourturfwilldeterminethebest

settingtouse.Aggressivenessofcutmaybeadjusted

throughoutthecuttingseasontoallowforvariousturf

conditions.

Ingeneral,lesstonormalaggressivesettingsare

moreappropriateforwarmseasongrasses(Bermuda,

Paspalum,Zoysia)whilecoolseasongrasses(Bent,

Bluegrass,Rye)mayrequirenormaltomoreaggressive

setups.Moreaggressivesetupscutmoregrassoffby

ChainLinks

Thelocationatwhichtheliftarmchainisattached

determinestherearrollerpitchangle(Figure13).

Figure13

1.Liftchain

2.UBracket

3.Bottomhole

Groomer

Thesearetherecommendedheightofcutsettings

whenagroomerkitisinstalledonthecuttingunit.

10

Page 11

HeightofCutChart

HOCSettingAggressivenessofCutNo.ofRearSpacersNo.ofChainLinksWithGroomerkits

0.250"Less

0.375"Less

0.500"Less

0.625"Less

0.750"Less

0.875"Less

1.000"Less

1.125"Less

1.250"*

1.375"*

1.500"*

1.625"*

1.750"*

1.875"*

2.000"*

+IndicatestheUbracket,onliftarm,ispositionedinthebottomhole(Figure13).

*HighHOCKit(PartNo.110-9600)mustbeinstalled.FrontHOCbracketmustbepositionedinthetopsideplatehole.

Normal

More

Normal

More

Normal

More

Normal

More

Normal

More

Normal

More

Normal

More

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

0

0

1

0

1

2

0

1

2

1

2

3

2

3

4

2

3

4

3

4

5

4

5

6

4

5

6

4

5

6

5

6

7

6

7

8

6

7

8

7

8

9

7

8

9

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

4+

5

5

5

5

5

5

5

5

5

5

5

5

4

4

4

4

4

5

4

5

5

5

5

5

installed

Y

Y

-

Y

Y

-

Y

Y

Y

Y

Y

-

Y

Y

-

Y

Y

-

Y

Y

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Note:Changingonechainlinkwillchangetherearrollerpitchanglemovementby4.5degrees.

Note:ChangingtheUbracket,ontheliftarm,tothebottomholewilladd2.3degreestotherearrollerpitchangle

11

Page 12

AdjustingtheHeightofCut

Note:Forheightsofcutgreaterthan1.00"theHigh

HeightofCutKitmustbeinstalled.

1.Loosenlocknutssecuringheight-of-cutarmsto

cuttingunitsideplates(Figure14).

Figure16

Figure14

1.Height-of-cutarm

2.Locknut

3.Adjustingscrew

2.Loosennutongaugebar(Figure15)andset

adjustingscrewtodesiredheight-of-cut.Distance

betweenbottomofscrewheadandfaceofbaris

height-of-cut.

Figure15

1.Gaugebar4.Holesusedforsetting

2.Heightadjustingscrew5.Holenotused

3.Nut

GroomerHOG

Important:Whensetproperly,therearand

frontrollerswillcontactthegaugebarandthe

screwwillbesnugagainstthebedknife.This

ensuresthattheheight-of-cutisidenticalat

bothendsofthebedknife.

5.Tightennutstosecureadjustment.Donot

overtightennut.Tightenenoughtoremoveplay

fromwasher.

Usethefollowingcharttodeterminewhich

bedknifeisbestsuitedforthedesiredheightofcut.

Bedknife/HeightofCutChart

Bedknife

LowHOC

(Optional)

EdgeMax®

(Production)

Standard

(Optional)

HeavyDuty

(Optional)

PartNo.

110-4084.220.250-.375"

108-9095.270.375-1.50"

108-9096.270.375-2.0"

110-4074.370.500-2.0"

BedknifeLip

Height*

HeightofCut

3.Hookthescrewheadoncuttingedgeofbedknife

andrestrearendofbaronrearroller(Figure16).

4.Rotatetheadjustingscrewuntilthefrontroller

contactsthegaugebar(Figure16).Adjustbothends

ofrolleruntilentirerollerisparalleltothebedknife.

Figure17

1.BedknifeLipHeight*

12

Page 13

CuttingUnitCharacteristics

Thedualknobbedknife-to-reeladjustmentsystem

incorporatedinthiscuttingunitsimpliesthe

adjustmentprocedureneededtodeliveroptimum

mowingperformance.Thepreciseadjustment

possiblewiththedualknob/bedbardesigngivesthe

necessarycontroltoprovideacontinualself-sharpening

action-thusmaintainingsharpcuttingedges,ensuring

goodquality-of-cut,andgreatlyreducingtheneedfor

routinebacklapping.

DailyAdjustmentsofCuttingUnit

Priortomowingeachday ,orasrequired,eachcutting

unitmustbecheckedtoverifyproperbedknife-to-reel

contact.Thismustbeperformedeventhough

qualityofcutisacceptable.

1.Lowerthecuttingunitsontoahardsurface,shutoff

theengine,andremovetheignitionkey.

2.Slowlyrotatethereelinareversedirection,

listeningforreel-to-bedknifecontact.Ifnocontact

isevident,turnthebedknifeadjustingknobs

clockwise,oneclickatatime,untillightcontactis

feltandheard.

Note:Theadjustmentknobshavedetents

correspondingto0.0009in.(0.023mm)bedknife

movementforeachindexedposition.

3.Ifexcessivecontactisfelt,turnthebedknife

adjustingknobscounterclockwise,oneclickat

atimeuntilnocontactisevident.Thenturn

thebedknifeadjustingknobsoneclickatatime

clockwise,untillightcontactisfeltandheard.

Important:Lightcontactispreferredatall

times.Iflightcontactisnotmaintained,

thebedknife/reeledgeswillnotsufciently

self-sharpenanddullcuttingedgeswillresult

afteraperiodofoperation.Ifexcessivecontact

ismaintained,bedknife/reelwearwillbe

accelerated,unevenwearcanresult,andquality

ofcutmaybeadverselyaffected.

Note:Overtime,thechamfer(Figure18)willneed

toberegroundasitisonlydesignedtolast40%

ofthebedknifelife.

Figure18

1.Lead-inchamferonrightendofbedknife

Note:Donotmakelead-inchamfertoolargeas

itmaycauseturftufting.

ServicingBedknife

Thebedknifeservicelimitsarelistedinthefollowing

charts.

Important:Operatingthecuttingunitwiththe

bedknifebelowthe“servicelimit”mayresultin

poorafter-cutappearanceandreducethestructural

integrityofthebedknifeforimpacts.

BedknifeServiceLimitChart

Bedknife

LowHOC

(Optional)

EdgeMax®

(Production)

Standard

(Optional)

HeavyDuty

(Optional)

PartNo.

110-4084.220.190"

108-9095.270.190"

108-9096.270.190"

110-4074.370.190"

BedknifeLip

Height*

Service

Limit*

Note:Asthereelbladescontinuetorunagainst

thebedknife,aslightburrwillappearonthefront

cuttingedgesurfacealongthefulllengthofthe

bedknife.Ifaleisoccasionallyrunacrossthe

frontedgetoremovethisburr,improvedcutting

canbeobtained.

Afterextendedrunning,aridgewilleventually

developatbothendsofthebedknife.Thesenotches

mustberoundedofforledushwiththecutting

edgeofthebedknifetoensuresmoothoperation.

13

Page 14

Note:Therecommendedtopandfrontbedknifegrind

angleis3to7degrees(Figure19).

Figure19

1.BedknifeServiceLimit*

Note:Allbedknifeservicelimitmeasurements

referencethebottomofthebedknife(Figure20)

Figure20

14

Page 15

Maintenance

Lubrication

Eachcuttingunithas(6)greasettings(Figure21)that

mustbelubricatedregularlywithNo.2GeneralPurpose

LithiumBaseGrease.

Thelubricationpointsarefrontroller(2),rearroller(2)

andreelbearing(2).

Note:Lubricatingcuttingunitsimmediatelyafter

washinghelpspurgewateroutofbearingsand

increasesbearinglife.

1.Wipeeachgreasettingwithacleanrag.

2.Applygreaseuntilcleangreaseisseencomingoutof

rollersealsandbearingreliefvalve.

3.Wipeexcessgreaseaway .

Figure22

1.Bedknifeadjustingknob

2.Usingaragorthicklypaddedglove,holdontothe

reelbladeandtrytomovethereelassemblysideto

side(Figure23).

Figure21

1.Reliefvalve

AdjustingtheReelBearings

Toensurelonglifeofthereelbearings,periodically

checkifreelendplayexists.Thereelbearingscanbe

checkedandadjustedasfollows:

1.Loosenreeltobedknifecontactbyturning

thebedknifeadjustingknobs(Figure22)

counterclockwiseuntilnocontactexists.

Figure23

3.Ifendplayexists,proceededasfollows:

A.Loosenexternalsetscrewsecuringbearing

adjustingnuttobearinghousinglocatedonthe

leftsideofthecuttingunit(Figure24).

Figure24

B.Usinga1-3/8"socketwrench,slowlytightenthe

reelbearingadjustmentnutuntilnoendplayof

thereelexists.Ifadjustingnutdoesnoteliminate

reelendplay,replacereelbearings.

15

Page 16

Note:Reelbearingsdonotrequirepreload.

Overtighteningreelbearingadjusternutwill

damagereelbearings.

4.Retightensetscrewsecuringbearingadjustingnutto

bearinghousing.Torqueto12-15in-lb.

ServicingtheBedbar

RemovingtheBedbar

1.Turnbedbaradjusterscrews,counterclockwise,to

backbedknifeawayfromreel(Figure25).

Figure25

1.Bedbaradjustingscrew3.Bedbar

2.Springtensionnut

2.Backoutthespringtensionnut,untilthewasheris

nolongertensionedagainstthebedbar(Figure25).

3.Oneachsideofthemachine,loosenthelocknut

securingthebedbarbolt(Figure26).

4.Washer

Figure27

1.Bedbarbolt

2.Nut4.Nylonwasher

3.Steelwasher

AssemblingtheBedbar

1.Installbedbar,positioningmountingearsbetween

washerandbedbaradjuster.

2.Securebedbartoeachsideplatewithbedbarbolts

(nutsonbolts)and6washers.Anylonwasheristo

bepositionedoneachsideofsideplateboss.Place

asteelwasheroutsideeachofthenylonwashers

(Figure27).Torquebedbarboltsto27-33ft.-lb.

Tightenlocknutsuntiltheoutsidesteelwasher

stopsrotatingandendplayisremovedbutdonot

overtightenordeectsideplates.Washersoninside

mayhaveagap.

Figure26

1.Bedbarbolt2.Locknut

4.Removeeachbedbarboltallowingbedbartobe

pulleddownwardandremovedfrommachinebolt

(Figure26).Accountfor2nylonand1stampedsteel

washersoneachendofbedbar(Figure27).

3.Tightenspringtensionnutuntilspringiscollapsed,

thenbackoff1/2turn(Figure28).

Figure28

1.Springtensionnut2.Spring

16

Page 17

ServicingtheRoller

ARollerRebuildKit,PartNo.114–5430andaRoller

RebuildToolKit,PartNo.115–0803(Figure29)are

availableforservicingtheroller.TheRollerRebuildKit

includesallthebearings,bearingnuts,innersealsand

outersealstorebuildaroller.TheRollerRebuildTool

Kitincludesallthetoolsandtheinstallationinstructions

requiredtorebuildarollerwiththerollerrebuildkit.

Refertoyourpartscatalogorcontactyourdistributor

forassistance.

Figure29

1.Rebuildkit(PartNo.114–5430)

2.Rebuildtoolkit(PartNo.115–0803)

3.Innerseal8.Washer

4.Bearing

5.Outerseal

6.Bearingnut

7.Innersealtool

9.Bearing/outersealtool

17

Page 18

Notes:

18

Page 19

Notes:

19

Page 20

Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affi liate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Commercial Product (“Product”) to be free from defects in materials or workmanship for two years or 1500 operational hours*,

whichever occurs fi rst. This warranty is applicable to all products

with the exception of Aerators (refer to separate warranty statements for these products). Where a warrantable condition exists,

we will repair the Product at no cost to you including diagnosis,

labor, parts, and transportation. This warranty begins on the date

the Product is delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists. If you need help locating a Commercial Products

Distributor or Authorized Dealer, or if you have questions regarding your warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801

E-mail: commercial.warrnty@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your Operator’s Manual.

Failure to perform required maintenance and adjustments can be

grounds for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

warranty does not cover the following:

Product failures which result from the use of non-Toro

•

replacement parts, or from installation and use of add-on,

or modifi ed non-Toro branded accessories and products. A

separate warranty may be provided by the manufacturer of

these items.

Product failures which result from failure to perform recom-

•

mended maintenance and/or adjustments. Failure to properly

maintain your Toro product per the Recommended Maintenance listed in the Operator’s Manual can result in claims for

warranty being denied.

Product failures which result from operating the Product in an

•

abusive, negligent or reckless manner.

Parts subject to consumption through use unless found to be

•

defective. Examples of parts which are consumed, or used

up, during normal Product operation include, but are not limited to, brakes pads and linings, clutch linings, blades, reels,

bed knives, tines, spark plugs, castor wheels, tires, fi lters,

belts, and certain sprayer components such as diaphragms,

nozzles, and check valves, etc.

Failures caused by outside infl uence. Items considered to be

•

outside infl uence include, but are not limited to, weather, stor-

age practices, contamination, use of unapproved coolants,

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfi ed with your Distributor’s service or

have diffi culty obtaining guarantee information, contact the Toro importer.

lubricants, additives, fertilizers, water, or chemicals, etc.

Normal noise, vibration, wear and tear, and deterioration.

•

Normal “wear and tear” includes, but is not limited to, dam-

•

age to seats due to wear or abrasion, worn painted surfaces,

scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are warranted for the period of time up to the scheduled replacement time

for that part. Parts replaced under this warranty are covered for the

duration of the original product warranty and become the property

of Toro. Toro will make the fi nal decision whether to repair any ex-

isting part or assembly or replace it. Toro may use remanufactured

parts for warranty repairs.

Note Regarding Deep Cycle Battery Warranty:

Deep cycle batteries have a specifi ed total number of kilowatt-

hours they can deliver during their lifetime. Operating, recharging,

and maintenance techniques can extend or reduce total battery

life. As the batteries in this product are consumed, the amount

of useful work between charging intervals will slowly decrease

until the battery is completely worn out. Replacement of worn out

batteries, due to normal consumption, is the responsibility of the

product owner. Battery replacement may be required during the

normal product warranty period at owner’s expense.

Maintenance is at Owner’s Expense

Engine tune-up, lubrication cleaning and polishing, replacement of

fi lters, coolant, and completing Recommended Maintenance are

some of the normal services Toro products require that are at the

owner’s expense.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fi tness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you. This

warranty gives you specifi c legal rights, and you may also have

other rights which vary from state to state.

Note regarding engine warranty:

The Emissions Control System on your Product may be covered

by a separate warranty meeting requirements established by the

U.S. Environmental Protection Agency (EPA) and/or the California

Air Resources Board (CARB). The hour limitations set forth above

do not apply to the Emissions Control System Warranty. Refer to

the Engine Emission Control Warranty Statement printed in your

Operator’s Manual or contained in the engine manufacturer’s

documentation for details.

Part No. 374-0031 Rev. D

Loading...

Loading...