Page 1

FormNo.3426-959RevD

Reelmaster

ModelNo.03674—SerialNo.403430001andUp

®

5010-HTractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3426-959*D

Page 2

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheseparate

productspecicDeclarationofConformity(DOC)

sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner’smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Visitwww.Toro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

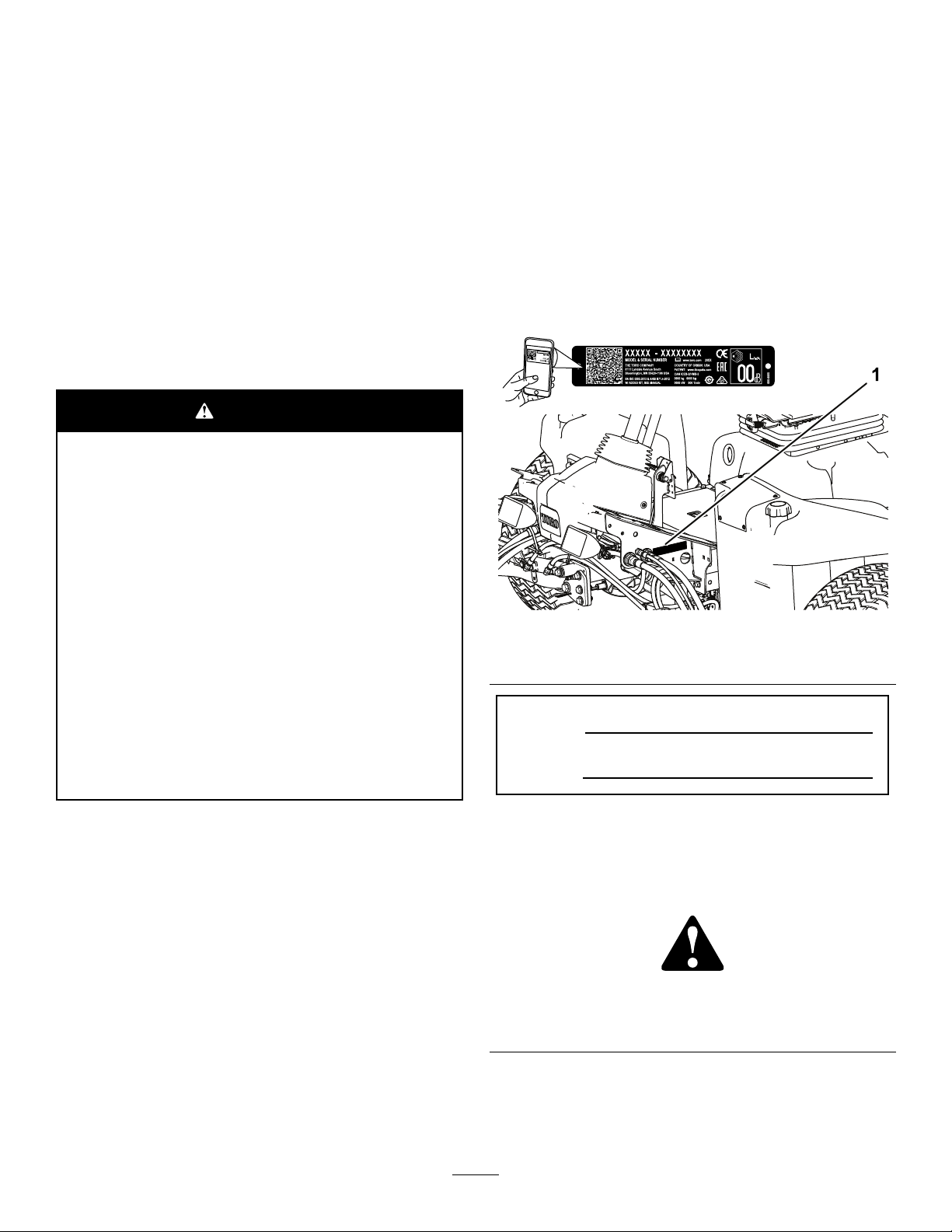

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberplate(if

equipped)toaccesswarranty,parts,andother

productinformation.

g259591

Figure1

1.Modelandserialnumberlocation

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisaride-on,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesigned

forcuttinggrassonwell-maintainedturf.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................9

1AdjustingtheTirePressure............................10

2AdjustingtheControl-ArmPosition.................10

3InstallingtheCuttingUnits..............................10

4MountingtheFinishingKits............................13

5AdjustingtheTurf-Compensation

Spring...........................................................14

6InstallingtheCEHoodLatch..........................15

7UsingtheCutting-UnitKickstand....................16

8ApplyingtheCEDecals.................................16

ProductOverview...................................................17

Controls...........................................................17

Specications..................................................24

Attachments/Accessories.................................24

BeforeOperation.................................................24

BeforeOperationSafety...................................24

PerformingDailyMaintenance..........................25

FillingtheFuelTank..........................................25

BreakingintheMachine...................................25

BleedingtheFuelSystem.................................25

DuringOperation.................................................26

DuringOperationSafety...................................26

StartingtheEngine...........................................28

ShuttingOfftheEngine.....................................28

SettingtheReelSpeed.....................................29

AdjustingtheLift-ArmCounterbalance.............30

AdjustingtheLift-ArmTurnaround

Position.........................................................30

UnderstandingtheDiagnosticLight..................30

CheckingtheInterlockSwitches.......................31

OperatingTips.................................................31

AfterOperation....................................................31

AfterOperationSafety......................................31

PushingorT owingtheMachine........................32

IdentifyingtheTie-DownPoints........................32

JackingPoints..................................................33

HaulingtheMachine.........................................33

Maintenance...........................................................34

MaintenanceSafety..........................................34

RecommendedMaintenanceSchedule(s)...........34

DailyMaintenanceChecklist.............................36

Lubrication..........................................................37

GreasingtheBearingsandBushings................37

EngineMaintenance...........................................39

EngineSafety...................................................39

ServicingtheAirCleaner..................................39

CheckingtheEngine-OilLevel..........................40

ServicingtheEngineOilandFilter....................40

FuelSystemMaintenance...................................41

DrainingtheFuelT ank......................................41

CheckingtheFuelLinesand

Connections..................................................41

ServicingtheWaterSeparator..........................41

ServicingtheFuel-PickupTube........................42

BleedingAirfromtheFuelInjectors...................42

ElectricalSystemMaintenance...........................43

ElectricalSystemSafety...................................43

ServicingtheBattery.........................................43

ReplacingtheFuses.........................................43

DriveSystemMaintenance..................................45

CheckingtheTirePressure...............................45

CheckingtheT orqueoftheWheel

Nuts..............................................................45

AdjustingtheTractionDriveforNeutral.............45

AdjustingtheRearWheelToe-in.......................45

CoolingSystemMaintenance..............................46

CoolingSystemSafety.....................................46

CheckingtheCoolingSystem...........................46

RemovingDebrisfromtheCooling

System..........................................................47

BrakeMaintenance.............................................48

AdjustingtheParkingBrakes............................48

AdjustingtheParking-BrakeLatch....................49

BeltMaintenance................................................49

TensioningtheAlternatorBelt...........................49

HydraulicSystemMaintenance...........................50

HydraulicSystemSafety...................................50

CheckingtheHydraulicLinesand

Hoses............................................................50

HydraulicFluidSpecication.............................50

CheckingtheLeveloftheHydraulic

Fluid..............................................................50

HydraulicFluidCapacity...................................51

ChangingtheHydraulicFluid............................51

ReplacingtheHydraulicFilter...........................52

TestingthePressureintheHydraulic

System..........................................................52

CuttingUnitSystemMaintenance........................53

BladeSafety.....................................................53

CheckingtheReel-to-BedknifeContact............53

BacklappingtheCuttingUnits...........................53

Storage...................................................................54

StorageSafety..................................................54

PreparingtheTractionUnit...............................54

PreparingtheEngine........................................54

3

Page 4

Safety

Thismachinehasbeendesignedinaccordance

withENISO5395(whenyoucompletethesetup

procedures)andANSIB71.4-2017.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepchildren,bystanders,andpetsoutofthe

operatingarea.Neverallowchildrentooperate

themachine.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeet

andofthrowingobjects.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93-6689

•Shutofftheengine,removethekey,waitforall

movementtostopbeforeyouleavetheoperator’s

position.Allowthemachinetocoolbefore

adjusting,servicing,cleaning,orstoringit.

Improperlyusingormaintainingthismachinecan

resultininjury .Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

decal93-6689

,which

1.Warning—donotcarrypassengers.

93–6696

1.Storedenergyhazard—readtheOperator'sManual.

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

decal106-6754

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fan;entanglementhazard,

belt—stayawayfrommovingparts.

decal93-6696

decal93-7272

decal106-6755

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

4

Page 5

decalbatterysymbols

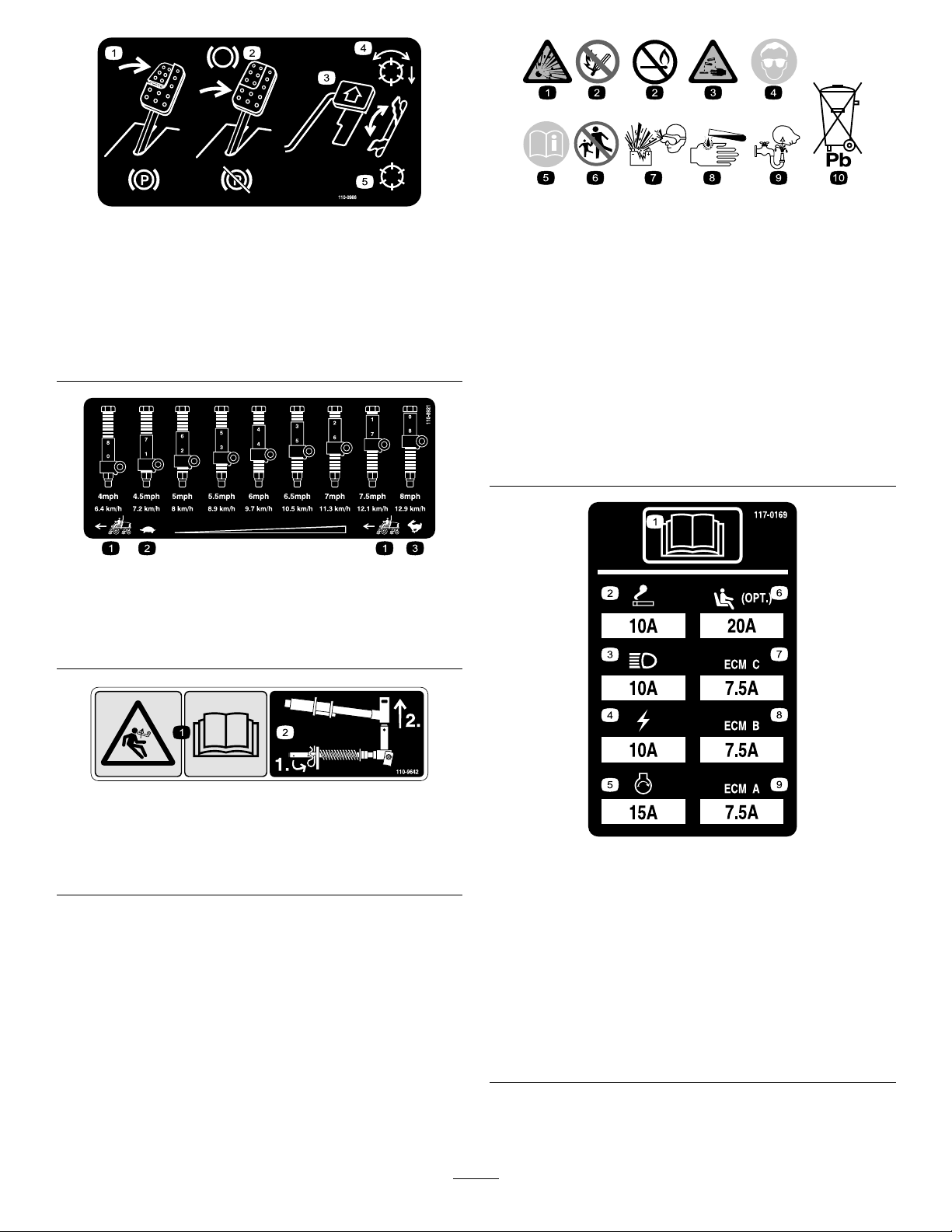

decal110-0986

110-0986

Someorallofthesesymbolsareonyourbattery .

BatterySymbols

1.Pressthebrakepedalandparkingbrakepedaltosetthe

parkingbrake.

2.Pressthebrakepedaltoapplythebrake.

3.Pressthetractionpedaltomovethemachineforward.

4.Reelenabledmode

5.Transportmode

110-8921

1.Tractionunitspeed

2.Slow

3.Fast

1.Explosionhazard6.Keepbystandersaway

fromthebattery .

2.Nore,opename,or

smoking

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection.9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

decal110-8921

10.Containslead;donot

discard

110-9642

1.Storedenergyhazard—readtheOperator'sManual.

2.Movethecotterpintotheholeclosesttotherodbracket

andthenremovetheliftarmandpivotyoke.

decal110-9642

r:\decal117-0169

117-0169

1.ReadtheOperator'sManual.

2.Lighter

3.Headlights

4.Electric

5.Enginestart

6.Airrideseatsuspension(optional)

7.EnginecomputermanagementC

8.EnginecomputermanagementB

9.EnginecomputermanagementA

5

Page 6

decal120-4158

120–4158

1.ReadtheOperator’s

Manual.

2.Engine—start4.Engine—stop

3.Engine—preheat

decal125-8754

125–8754

1.Headlights

2.Engage7.Lowerthecuttingunits

3.Powertake-off(PTO)

4.Disengage

5.Fast

6.Slow

8.Raisethecuttingunits

9.ReadtheOperator’s

Manual.

125-8818

1.Nore,openames,orsmoking.5.ReadtheOperator’sManual.

2.Weareyeprotection.6.Explosionhazard

3.Keepbystandersaway.

7.Containslead;donotdiscard.

4.Corrosiveliquidhazard8.ReadtheOperator’sManual;attention.

6

decal125-8818

Page 7

decal133-8062

decal127-2470

133-8062

127-2470

decal133-2930

133-2930

1.Warning—donotoperatethismachineunlessyouaretrained.4.Tippinghazard—driveslowlywhenturning;donotturnsharply

whiletravelingfast;onlydriveonslopeswiththecuttingunits

lowered;alwayswearaseatbelt.

2.Warning—wearhearingprotection.5.Warning—donotparkonslopes;engagetheparkingbrake,

lowerthecuttingunits,shutofftheengine,andremovethe

ignitionkeybeforeleavingthemachine.

3.Thrownobjecthazard—keepbystandersoutoftheoperating

area.

6.Warning—readtheOperator'sManual;donottowthe

machine.

7

Page 8

133-2931

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal133-2931

1.Warning—readtheOperator'sManual;donotoperatethis

machineunlessyouaretrained.

4.Tippinghazard—donotdriveacrossordownslopesgreater

than15°;onlydriveonslopeswiththecuttingunitslowered;

alwayswearaseatbelt.

2.Warning—wearhearingprotection.5.Warning—donotparkonslopes;engagetheparkingbrake,

lowerthecuttingunits,shutofftheengine,andremovethe

ignitionkeybeforeleavingthemachine.

3.Thrownobjecthazard—keepbystandersaway .

6.Warning—readtheOperator'sManual;donottowthe

machine.

1.ReadtheOperator'sManual.

decal138-6975

138-6975

8

Page 9

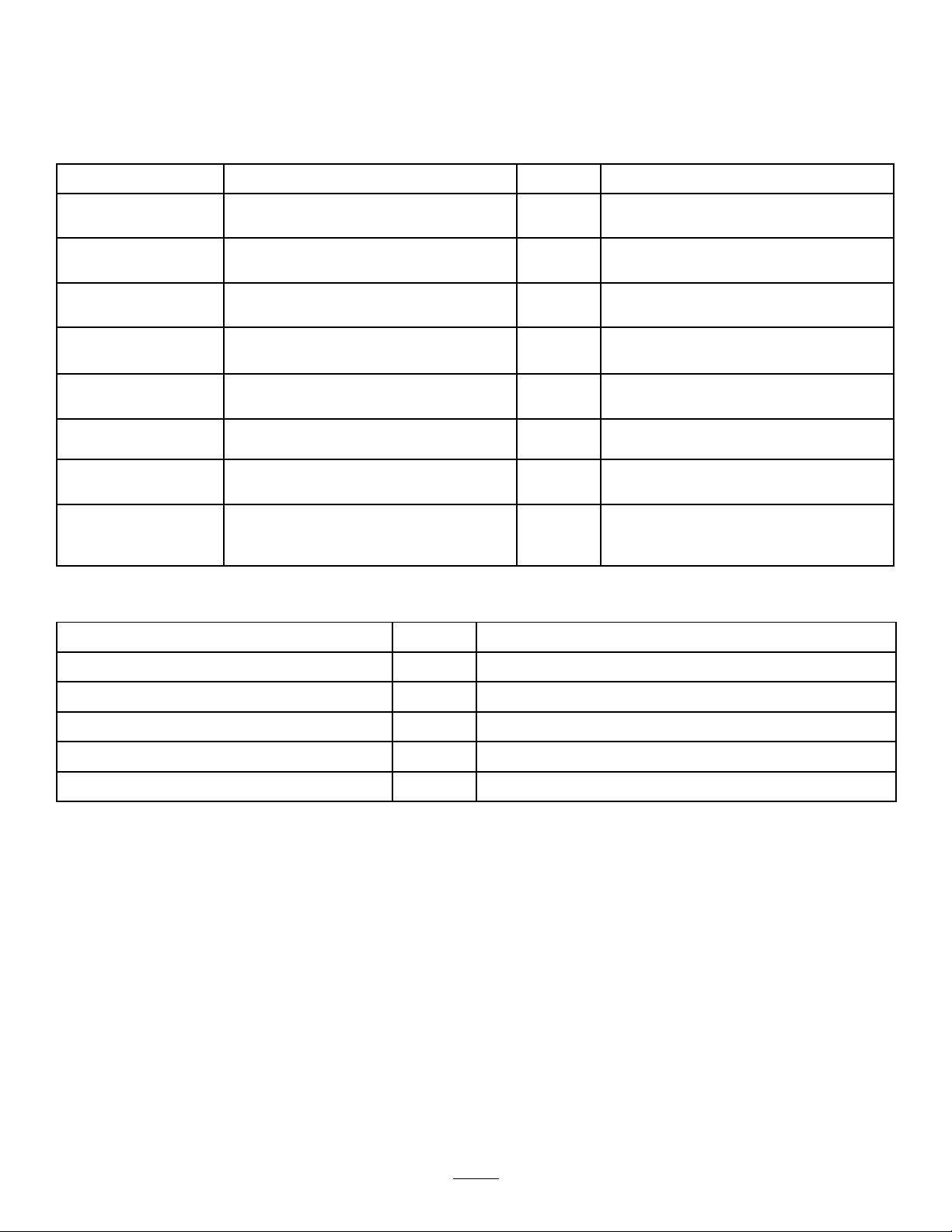

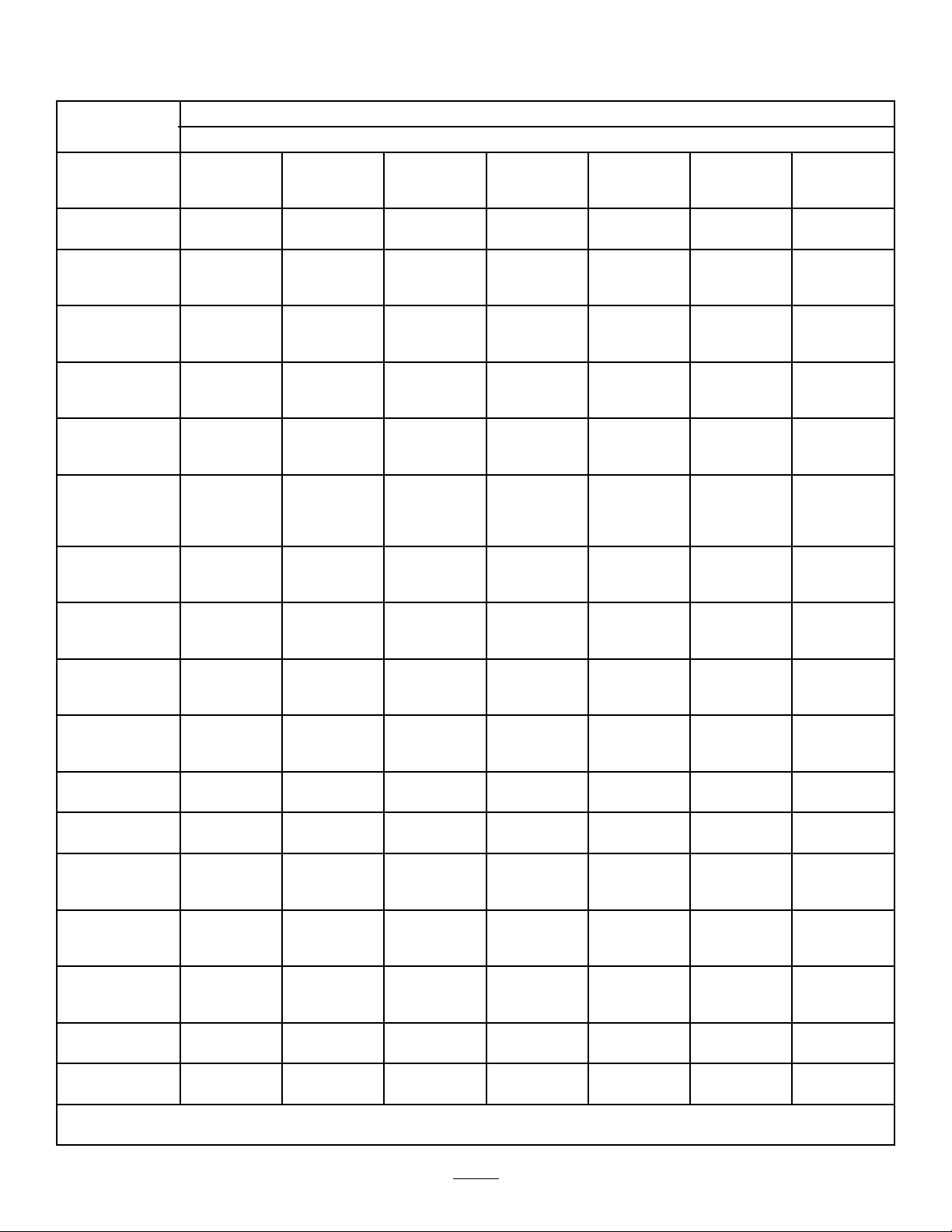

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

MediaandAdditionalParts

Nopartsrequired

Nopartsrequired

Cuttingunits

Finishingkit(soldseparately)

Nopartsrequired

Hood-latchassembly1

Washer1

Cutting-unitkickstand

Warningdecal1

CEdecal

Productionyeardecal1

Qty.

–

–

5

1

–

1Installthecutting-unitkickstand.

1

Adjustthetirepressure.

Adjustthecontrol-armposition.

Installthecuttingunits.

Mountthenishingkits(nishingkits

aresoldseparately).

Adjusttheturf-compensationspring.

InstalltheCEhoodlatch.

ApplytheCEdecals.

Use

Description

Key2

Operator'sManual

Engineowner’smanual1

DeclarationofConformity

Operatortrainingmaterial

Qty.

Starttheengine.

1

1

1

ReadtheOperator'sManualbeforeoperatingthemachine.

Usethemanualtoreferenceengineinformation.

Declarationofconformity

Reviewthematerialbeforeoperatingthemachine.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Use

9

Page 10

1

AdjustingtheTirePressure

NoPartsRequired

Procedure

Thetiresareover-inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.

Correctairpressureinthefrontandreartiresis83

to103kPa(12to15psi).

Important:Maintainevenpressureinalltiresto

ensureuniformcontactwiththeturf.

2

g004152

Figure3

1.Controlarm3.Bolts(2)

2.Retainingbrackets

AdjustingtheControl-Arm

Position

NoPartsRequired

Procedure

Thecontrol-armpositioncanbeadjustedforyour

comfort.

1.Loosenthe2boltssecuringthecontrolarmto

theretainingbracket(Figure3).

2.Rotatethecontrolarmtothedesiredposition

andtightenthe2bolts.

3

InstallingtheCuttingUnits

Partsneededforthisprocedure:

5

Cuttingunits

Procedure

CAUTION

Ifyoudonotdisconnectthepowertothe

cuttingunits,someonecouldaccidentally

startthecuttingunit,causingseriousinjury

tohandsandfeet.

Alwaysseparatethepower-disconnect

connectorsbeforeworkingonthecutting

units(Figure28).

1.Disconnectthepower-disconnectconnector;

refertoCutting-Unit-PowerDisconnect(page

18).

2.Removethecuttingunitsfromthecartons.

Assembleandadjustasdescribedinthecutting

unitOperator'sManual.

10

Page 11

3.Makesurethatthecounterweight(Figure4)is

installedtotheproperendofthecuttingunitas

describedinthecounterweightkitInstallation

Instructions.

C.Mountthespring-tubebolttotheopposite

tabonthecarrierframeandsecurewiththe

angenut.

Note:Positiontotheboltheadtotheouter

sideofthetabasshowninFigure6.

g003967

Figure6

Figure4

1.Counterweight

4.Mounttheturf-compensationspringtothesame

sideofthecuttingunitasthereel-drivemotor.

Positiontheturfcompensationasfollows:

Note:Allcuttingunitsareshippedwiththe

turf-compensationspringmountedtotheright

sideofthecuttingunit.

A.Removethe2carriageboltsandnuts

securingtherodbrackettothecutting-unit

tabs(Figure5).

1.Oppositecarrier-frametab

2.Rodbracket

D.Mounttherodbrackettothecutting-unit

tabswiththecarriageboltsandnuts(Figure

6).

Note:Wheninstallingorremovingthe

cuttingunits,makesurethatthehairpin

cotterisinstalledinthespringrodholenext

g027133

5.Lowerallliftarmscompletely .

6.Removethelynchpinfromtheliftarmpivot

totherodbracket.Otherwise,installthe

hairpincotterintheholeintheendofthe

rod.

yoke.Then,removethecap(Figure7).

Figure5

1.Turf-compensationspring3.Springtube

2.Rodbracket

B.Removetheangenutsecuringthespring

tubebolttothecarrier-frametab(Figure5)

Removetheassembly.

g003975

Figure7

1.Lynchpin

g003949

2.Cap

7.Forthefrontcuttingunits,slideacuttingunit

undertheliftarmwhileinsertingthecarrier-frame

shaftupintothelift-arm-pivotyoke(Figure8).

11

Page 12

Note:Usethenumberofchainlinksdescribed

inthecuttingunitOperator'sManual.

Figure10

g003948

Figure8

1.Liftarm3.Lift-arm-pivotyoke

2.Carrier-frameshaft

8.Usethefollowingprocedureontherearcutting

unitswhentheheightofcutisabove19mm

(3/4inch).

A.Removethelynchpinandwashersecuring

thelift-arm-pivotshafttotheliftarmand

slidethelift-arm-pivotshaftoutofthelift

arm(Figure9).

Figure9

1.Lift-armchain

g003977

2.Chainbracket

3.Pin

12.Coatthesplineshaftofthereelmotorwithclean

grease.

13.OilthereelmotorO-ringandinstallitontothe

motorange.

14.Installthemotorbyrotatingitclockwisesothat

themotorangesclearthebolts(Figure11).

Note:Rotatethemotorcounterclockwiseuntil

theangesencircletheboltsandthentighten

thebolts.

Important:Makesurethatthereel-motor

hosesarenottwisted,kinked,oratriskof

beingpinched.

g003979

1.Lynchpinandwasher

B.Insertthelift-armyokeontothecarrier-frame

shaft(Figure8).

C.Insertthelift-armshaftintotheliftarmand

secureitwiththewasherandlynchpin

(Figure9).

9.Insertthecapoverthecarrier-frameshaftand

lift-armyoke.

10.Securethecapandthecarrier-frameshaftto

thelift-armyokewiththesnapperpin(Figure7).

Note:Usetheslotifasteeringcuttingunitis

desiredorusetheholeifthecuttingunitisto

belockedinposition.

11.Securethelift-armchaintothechainbracket

withthesnapperpin(Figure10).

12

Page 13

1.Reel-drivemotor

Figure11

2.Mountingbolt(2)

g316995

Figure12

1.Centerfrontcuttingunit4.Frontleftcuttingunit

2.Leftrearcuttingunit

3.Rightrearcuttingunit6.Reelmotorlocation

1.Onthefrontleftcorneroftheframe(#4cutting

unitlocation),removetheextraangenuton

theboltsecuringthebulkheadbrackettothe

machine(Figure13).

2.Loosenthenutsonthenishingkithosetting,

insertthehoseintotheslotonthebulkhead

bracketandtightenthenuts.

5.Frontrightcuttingunit

Note:Whentighteningthenuts,useabackup

g027140

wrenchtopreventthehosefromtwistingor

kinking.

3.Inserttheconnectorplateontothe

bulkhead-mountingboltswiththeconnectors

positionedasshowninFigure13.

4.Securetheconnectorplateto1ofthemounting

boltswiththeangenutpreviouslyremoved.

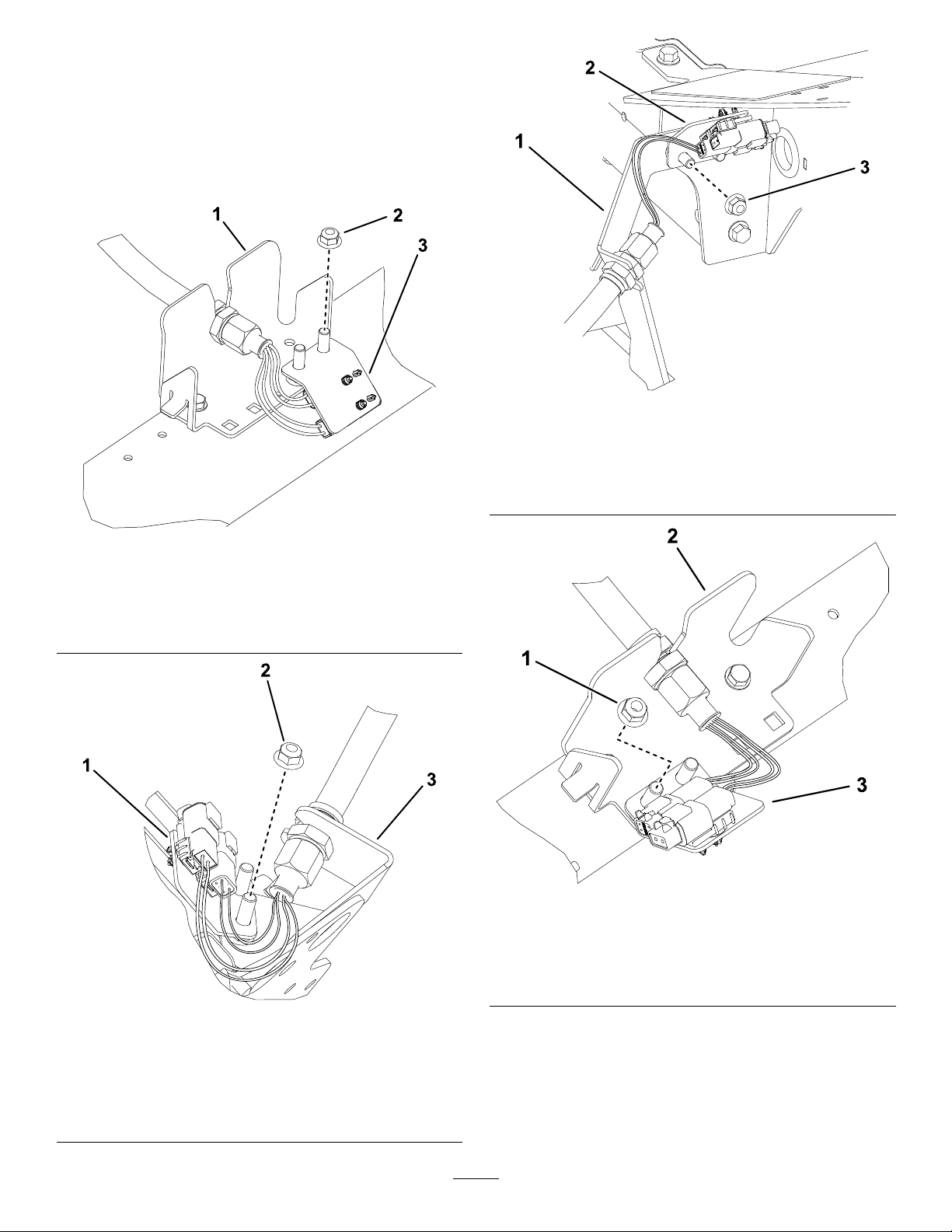

4

MountingtheFinishingKits

Partsneededforthisprocedure:

1

Finishingkit(soldseparately)

Procedure

Important:Toensurethatthehoseroutingis

appropriateandthehosesarenottwisted,mount

themotorstothecuttingunitsbeforemounting

thenishingkits.

Usethefollowingdiagramtodeterminethe

positionsofcuttingunitsandreelmotors.

5.Locatethewireharnessonthemachineand

plugthewireconnectorsintothewireconnectors

ofthenishingkit.

Figure13

Leftfrontcuttingunit(#4)

1.Extraangenut

2.Connectorplate

3.Bulkheadbracket

g316962

13

Page 14

6.Repeattheprocedureontheremaining4

bulkheadlocationsasshowninFigure14

throughFigure17.

Important:Theconnectorplatesare

positioneddifferentlyattheremaining

locationssothehosecanberoutedthrough

thebulkheadbracketandtothecuttingunit

withoutgettingtwistedorkinked.

g316996

Figure16

Rightfrontcuttingunitlocation(#5)

1.Bulkheadbracket

2.Extraangenut

Figure14

Leftrearcuttingunit(#2)

3.Connectorplate

1.Bulkheadbracket

2.Connectorplate

g316994

3.Extraangenut

g316998

Figure17

Rightrearcuttingunit(#3)

1.Connectorplate

2.Extraangenut

1.Extraangenut3.Connectorplate

2.Bulkheadbracket

g316976

Figure15

Centerfrontcuttingunit(#1)

(Undersideofmachineshown)

3.Bulkheadbracket

14

Page 15

5

6

Adjustingthe

Turf-CompensationSpring

NoPartsRequired

Procedure

Theturf-compensationspring(Figure18)transfers

theweightfromthefronttotherearroller.Thishelps

toreduceawavepatternintheturf,alsoknownas

marcellingorbobbing.

Important:Makespringadjustmentswiththe

cuttingunitmountedtothetractionunit,pointing

straightaheadandloweredtotheground.

1.Makesurethatthehairpincotterisinstalledin

therearholeinthespringrod(Figure18).

InstallingtheCEHood

Latch

Partsneededforthisprocedure:

1Hood-latchassembly

1Washer

Procedure

1.Unlatchandraisethehood.

2.Removetherubbergrommetfromtheholein

theleftsideofthehood(Figure19).

Figure18

1.Turf-compensationspring3.Springrod

2.Hairpincotter4.Hexnuts

2.Tightenthehexnutsonthefrontendofthe

springroduntilthecompressedlengthofthe

springis12.7cm(5inches)for5-inchcutting

unitsor15.9cm(6.25inches)for7-inchcutting

units(Figure18).

Note:Whenoperatingonroughterrain

decreasethespringlengthby12.7mm

(1/2inch).Groundfollowingwillbeslightly

decreased.

g027072

g003863

1.Rubbergrommet

3.Removethenutfromthehood-latchassembly

(Figure20).

1.Hoodlatch3.Rubberwasher

2.Nut4.Metalwasher

Figure19

g003946

Figure20

15

Page 16

4.Outsidethehood,insertthehookendofthe

latchthroughtheholeinthehood.Makesure

thattherubbersealingwasherremainsonthe

outsideofthehood.

5.Insidethehood,insertthemetalwasheronto

thelatchandsecurewiththenut.Makesure

thatthelatchengagestheframecatchwhenit

islocked.Usetheenclosedhood-latchkeyto

operatethehoodlatch.

7

UsingtheCutting-Unit

Kickstand

Partsneededforthisprocedure:

1

Cutting-unitkickstand

g004144

Figure22

1.Chainbracket3.Cutting-unitkickstand

2.Snapperpin

Procedure

Wheneveryouneedtotipthecuttingunittoexpose

thebedknife/reel,propuptherearofthecuttingunit

withthekickstandtomakesurethatthenutsonthe

backendofthebedbar-adjustingscrewsarenot

restingontheworksurface(Figure21).

Figure21

8

ApplyingtheCEDecals

Partsneededforthisprocedure:

1Warningdecal

1

CEdecal

1Productionyeardecal

Procedure

OnmachinesrequiringCEcompliance,applythe

productionyeardecal(PartNo.133-5615)nearthe

serialplate,theCEdecal(PartNo.93-7252)near

thehoodlock,andtheCEwarningdecal(PartNo.

133-2931)overthestandardwarningdecal(PartNo.

133-2930).

g003985

1.Cutting-unitkickstand

Securethekickstandtothechainbracketwiththe

snapperpin(Figure22).

16

Page 17

ProductOverview

1.Enginehood

2.Operator'sseat

3.Controlarm

4.Steeringwheel

Figure23

5.Seatadjustments

6.Frontcuttingunits

7.Rearcuttingunits

TractionPedal

Thetractionpedal(Figure25)controlstheforwardand

reverseoperation.Pressthetopofthepedaltomove

forwardandthebottomtomoverearward.Theground

speeddependsonhowfaryoupressthepedal.For

noload,maximumgroundspeed,fullypressthepedal

whilethethrottleisintheFASTposition.

Tostopthemachine,reducefootpressureonthe

tractionpedalandallowittoreturntothecenter

position.

Mow-SpeedLimiter

Whenthemow-speedlimiter(Figure25)isipped

upitcontrolsthemowspeedandallowsthecutting

unitstobeengaged.Eachspaceradjuststhemowing

speedby0.8km/h(0.5mph).Themorespacersyou

g260768

have,onthetopoftheboltthesloweryougo.For

transport,ipbackthemow-speedlimiterandyouwill

havemaximumtransportspeed.

Note:WhenmowingintheEconomymode,the

mowinggroundspeedisslightlyreduced.Remove1

spacertoachievethesamemowingspeedaswhen

mowinginthenormalmode.

Controls

Seat-AdjustingKnobs

Theseat-adjustinglever(Figure24)allowsyouto

adjusttheseatforeandaft.Theweight-adjusting

knobadjuststheseatforyourweight.Theweight

gaugeindicateswhentheseatisadjustedtoyour

weight.Theheight-adjustingknobadjuststheseat

foryourheight.

Figure24

BrakePedal

Pressthebrakepedal(Figure25)tostopthemachine.

ParkingBrake

Toengagetheparkingbrake,(Figure25)pushdown

onthebrakepedalandpressthetopforwardtolatch.

Toreleasetheparkingbrake,pressthebrakepedal

untiltheparking-brakelatchretracts.

g003954

1.Weightgauge3.Height-adjustingknob

2.Weight-adjustingknob

4.Adjustinglever(foreand

aft)

17

Page 18

KeySwitch

Thekeyswitch(Figure26)has3positions:OFF,

ON/PREHEAT,andSTART.

LowerMow/RaiseControlLever

Thislever(Figure26)raisesandlowersthecutting

unitsandalsostartsandstopsthecuttingunitswhen

thecuttingunitsareenabledintheMOWmode.Y ou

cannotlowerthecuttingunitswhenthemow/transport

leverisintheTRANSPORTposition.

HeadlightSwitch

Figure25

1.Tractionpedal4.Brakepedal

2.Mow-speedlimiter5.Parkingbrake

3.Spacers

6.Tilt-steeringpedal

Tilt-SteeringPedal

Totiltthesteeringwheeltowardyou,pressthefoot

pedal(Figure25)down,pullthesteeringtowertoward

youtothemostcomfortableposition,andthenrelease

thepedal.

Engine-SpeedSwitch

Theengine-speedswitchhas2modestochangethe

enginespeed(Figure26).Bymomentarilytappingthe

switch,youcanchangetheenginespeedin100rpm

increments.Ifyouholdtheswitchdown,theengine

automaticallymovestoHighorLowidle,depending

onwhichendoftheswitchyoupress.

g003955

(Figure26).

Enable/DisableSwitch

Pivottheswitchdownwardtoturnontheheadlights

Usetheenable/disableswitch(Figure26)in

conjunctionwiththelowermow/raisecontrolleverto

operatethecuttingunits.

PowerPoint

Thepowerpointisa12Vpowersupplyforelectronic

devices(Figure27).

Figure26

1.Lowermow/raisecontrol

lever

2.Keyswitch5.Engine-speedswitch

3.InfoCenter

4.Enable/disableswitch

6.Headlightswitch

g004133

Figure27

1.Powerpoint

g021208

Cutting-Unit-PowerDisconnect

Beforeinstalling,removing,orworkingonthecutting

units,disconnectthecuttingunitsfromthepower

supplybyseparatingthecutting-unit-power-disconnect

connector(Figure28),locatedundertheseat.Plug

theconnectorbackinbeforeoperatingthemachine.

18

Page 19

1.Power-disconnectconnector

Figure28

g020650

Figure29

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•LeftButton,MenuAccess/BackButton—Press

thisbuttontoaccesstheInfoCentermenus.

Youcanuseittobackoutofanymenuyouare

currentlyusing.

g027134

•MiddleButton—Pressthisbuttontoscrolldown

menus.

•RightButton—Pressthisbuttontoopenamenu

wherearightarrowindicatesadditionalcontent.

CAUTION

Ifyoudonotdisconnectthepowertothe

cuttingunits,someonecouldaccidentally

startthecuttingunit,causingseriousinjury

tohandsandfeet.

Alwaysseparatethe

cutting-unit-power-disconnectconnectors

beforeworkingonthecuttingunits.

UsingtheInfoCenterLCDDisplay

TheInfoCenterLCDdisplayshowsinformationabout

yourmachinesuchastheoperatingstatus,various

diagnosticsandotherinformationaboutthemachine

(Figure29).Therearemultipledisplayscreensonthe

InfoCenter.Youcanswitchbetweenthescreens,at

anytime,bypressinganyoftheInfoCenterbuttons

andthenselectingtheappropriatedirectionalarrow.

Note:Thepurposeofeachbuttonmaychange

dependingonwhatisrequiredatthetime.Each

buttonislabeledwithanicondisplayingitscurrent

function.

19

Page 20

InfoCenterIconDescription

SERVICEDUE

Indicateswhenscheduledservice

shouldbeperformed

Hourmeter

Infoicon

Fast

InfoCenterIconDescription(cont'd.)

Battery

Motor/Generator(notcharging)

Motor/Generator(charging)

E-Reel

Slow

Fuellevel

Theglowplugsareactive.

Raisethecuttingunits.

Lowerthecuttingunits.

Sitintheseat.

Theparkingbrakeison.

Therangeishigh(transport).

Neutral

Therangeislow(mow).

FrontBacklap

RearBacklap

Thecuttingunitsarelowering.

Thecuttingunitsareraising.

PINpasscode

CANbus

InfoCenter

Badorfailed

Bulb

OutputofTECcontrollerorcontrol

wireinharness

Switch

Releasetheswitch.

Engine-coolanttemperature(°Cor

°F)

Temperature(hot)

ThePTOisengaged.

Notallowed

Starttheengine.

Stoptheengine.

Engine

Keyswitch

Changetotheindicatedstate.

Symbolsareoften

combinedtoform

sentences.Some

examplesareshown

below

PutthemachineintoNeutral.

Enginestartisdenied.

Engineshutdown

Enginecoolantistoohot.

Sitdownorsetparkingbrake

20

Page 21

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthe

menuaccessbuttonwhileatthemainscreen.This

bringsyoutothemainmenu.Refertothefollowing

tablesforasynopsisoftheoptionsavailablefrom

themenus:

MainMenu

MenuItemDescription

FaultsTheFaultsmenucontainsalist

ServiceTheServicemenucontains

DiagnosticsTheDiagnosticsmenu

SettingsTheSettingsmenuallows

AboutTheAboutmenuliststhe

Service

MenuItemDescription

Hours

Counts

Diagnostics

MenuItemDescription

CuttingUnitsIndicatestheinputs,qualiers,

Hi/LowRangeIndicatestheinputs,qualiers,

PTOIndicatestheinputs,qualiers,

oftherecentmachinefaults.

RefertotheServiceManualor

contactyourT oroDistributor

formoreinformationon

theFaultsmenuandthe

informationcontainedthere.

informationonthemachine

suchashoursofuse,counters,

andothersimilarnumbers.

displaysthestateofeach

machineswitch,sensor,and

controloutput.Y oucanuse

thistotroubleshootcertain

issuesasitquicklytellsyou

whichmachinecontrolsareon

andwhichareoff.

youtocustomizeandmodify

congurationvariablesonthe

InfoCenterdisplay.

modelnumber,serialnumber,

andsoftwareversionofyour

machine.

Liststhetotalnumberofhours

thatthemachine,engineand

PTOhavebeenon,aswell

asthenumberofhoursthe

machinehasbeentransported

andservicedue.

Listsnumerouscountsthe

machinehasexperienced.

andoutputsforraisingand

loweringthecuttingunits.

andoutputsfordrivingin

transportmode.

andoutputsforenablingthe

PTOcircuit.

EngineRun

Backlap

Settings

MenuItemDescription

Units

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

FrontBacklapReelSpeedControlsthespeedofthefront

RearBacklapReelSpeedControlsthespeedoftherear

ProtectedMenusAllowsthe

AutoIdle

BladeCountControlsthenumberofblades

MowSpeedControlsthegroundspeedfor

Heightofcut(HOC)Controlstheheightofcut

FReelRPMDisplaysthecalculatedreel

RReelRPMDisplaysthecalculatedreel

EconomyModeWhenactivated,theEconomy

Indicatestheinputs,qualiers,

andoutputsforstartingthe

engine.

Indicatestheinputs,qualiers

andoutputsforoperatingthe

backlapfunction.

Controlstheunitsusedonthe

InfoCenter.Themenuchoices

areEnglishorMetric.

Controlsthelanguageused

ontheInfoCenter*.

LCDdisplay.

LCDdisplay.

reelsinbacklapmode.

reelsinbacklapmode.

superintendent/mechanic

toaccessprotectedmenusby

inputtingapasscode.

Controlstheamountoftime

allowedbeforereturningthe

enginetolowidlewhenthe

machineisstationary.

onthereelforreelspeed.

determiningthereelspeed.

(HOC)fordeterminingthereel

speed.

speedpositionforthefront

reels.Thereelscanalsobe

manuallyadjusted.

speedpositionfortherear

reels.Thereelscanalsobe

manuallyadjusted.

Modelowerstheengine

speedwhilemowingtoreduce

noiseandfuelconsumption.

Thereelspeeddoesnot

change,butthemowspeedis

decreasedifthemowstopis

notadjustedaccordingly.

*Only"operator-faced"textistranslated.Faults,

Service,andDiagnosticsscreensare"service-faced.”

Titlesareintheselectedlanguage,butmenuitems

areinEnglish.

21

Page 22

About

MenuItemDescription

Model

SNListstheserialnumberofthe

MachineControllerRevisionListsthesoftwarerevisionof

CU1

CU2

CU3

CU4

CU5

GeneratorListsthesoftwarerevisionof

InfoCenterRevisionListsthesoftwarerevisionof

CANBus

Liststhemodelnumberofthe

machine.

machine.

themastercontroller .

Liststhesoftwarerevisionof

eachcuttingunit.

themotor/generator.

theInfoCenter.

Liststhemachine

communicationbusstatus.

ProtectedMenus

Thereare2additionaldisplayscreensand7operating

congurationsettingsthatareadjustablewithinthe

SettingsMenuoftheInfoCenter:AutoIdle,Blade

Count,MowSpeed,HeightofCut(HOC),FReel

RPM,RReelRPM,andEconomyMode.These

settingscanbelockedbyusingtheProtectedMenu.

Note:Atthetimeofdelivery ,theinitialpassword

codeisprogrammedbyyourdistributor.

AccessingtheProtectedMenu

7.Pressthemiddlebuttontoenterthecode.

8.Ifthecodehasbeenacceptedandtheprotected

menuhasbeenunlocked,“PIN”isbedisplayed

intheupperrightcornerofthedisplayscreen.

Note:Ifthepasscodehasbeenforgottenor

misplaced,pleasecontactyourdistributorfor

assistance.

ViewingandChangingthe

ProtectedMenuSettings

1.IntheProtectedMenu,scrolldowntoProtect

Settings.

2.Toviewandchangethesettingswithoutentering

apasscode,usetherightbuttontochangethe

ProtectSettingstoOFF.

3.Toviewandchangethesettingswitha

passcode,usetheleftbuttontochangethe

ProtectSettingstoON,setthepasscode,and

turnthekeytotheOFFpositionandthentothe

ONposition.

SettingtheAutoIdle

1.IntheSettingsMenu,scrolldowntoAutoIdle.

2.Presstherightbuttontochangetheautoidle

timebetweenOFF,8S,10S,15S,20S,and30S.

SettingtheBladeCount

1.IntheSettingsMenu,scrolldowntoBladeCount

2.Presstherightbuttontochangethebladecount

between5,8or1 1bladereels.

SettingsandDisplayScreens

ToaccesstheProtectedMenuSettingsandDisplay

Screens

1.FromtheMainMenu,scrolldowntotheSettings

Menuandpresstherightbutton.

2.IntheSettingsMenu,scrolldowntothe

ProtectedMenuandpresstherightbutton.

3.Toenterthepasscode,usethecenterbuttonto

settherstdigitthenpresstherightbuttonto

moveontothenextdigit.

4.Usethecenterbuttontosettheseconddigit

thenpresstherightbuttontomoveontothe

nextdigit.

5.Usethecenterbuttontosetthethirddigitthen

presstherightbuttontomoveontothenext

digit.

6.Usethecenterbuttontosetthefourthdigitthen

presstherightbutton.

SettingtheMowSpeed

1.IntheSettingsMenu,scrolldowntoMowSpeed.

2.PresstherightbuttontoselectMowSpeed.

3.Usethecenterandrightbuttontoselectthe

appropriatemowspeedsetonthemechanical

mow-speedlimiteronthetractionpedal.

4.Presstheleftbuttontoexitmowspeedandsave

thesetting.

SettingtheHeightofCut(HOC)

1.IntheSettingsMenu,scrolldowntoHOC.

2.PresstherightbuttontoselectHOC.

3.Usethecenterandrightbuttontoselectthe

appropriateHOCsetting.(Iftheexactsettingis

notdisplayed,selectthenearestHOCsetting

fromthelistdisplayed).

4.PresstheleftbuttontoexitHOCandsavethe

setting.

22

Page 23

SettingtheFrontandRearReel

Speeds

Althoughthefrontandrearreelspeedsarecalculated

byinputtingthenumberofblades,mowspeedand

HOCintotheInfoCenter,thesettingcanbemanually

changedtoaccommodatefordifferentmowing

conditions.

1.TochangetheReelSpeedSettings,scrolldown

totheFReelRPM,RReelRPM,orboth.

2.Presstherightbuttontochangethereelspeed

value.Asthespeedsettingischanged,the

displaycontinuestoshowthecalculatedreel

speedbasedonbladecount,mowspeedand

HOCwhichwaspreviouslyentered,butthenew

valuealsoisdisplayed.

SettingtheEconomyMode

1.FromtheMainMenu,usethecenterbuttonto

scrolldowntotheSettingsMenu.

2.Presstherightbuttontoselect.

3.IntheSettingsMenu,usethecenterbuttonto

scrolldowntotheEconomyMode.

4.PresstherightbuttontoselecttheONfunction.

5.Presstheleftbuttontosavethesettingandexit

thesettings.

ToAccessProtectedDisplay

Screens

Fromthemainscreen,pressthecenterbuttononce,

whenthearrowsappearabovethebuttons,press

thecenterbuttonagaintoscrollthroughthedisplay

screens.

PressthecenterbuttonagaintoaccesstheeReel

informationscreendisplayingthereelcurrentandthe

speedforeachofthe5cuttingunits.

Pressthecenterbuttonagaintoaccesstheenergy

modescreendisplayingthecomponents,energyow

andthedirectionwhileinoperation.

23

Page 24

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

TransportWidth

Widthofcut254cm(100inches)

Length

Heightw/ROPS160cm(63inches)

Weight

EngineKubota24.8hp

Fueltankcapacity

Transportspeed

Mowingspeed

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

228cm(90inches)

282cm(111inches)

1259kg(2,776lb)

53L(14USgallons)

0to16km/h(0to10mph)

0to13km/h(0to8mph)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alwaysshutofftheengine,removethekey,wait

forallmovingpartstostop,andallowthemachine

tocoolbeforeadjusting,servicing,cleaning,or

storingthemachine.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Beforemowing,alwaysinspectthemachineto

ensurethatthecuttingunitsareingoodworking

condition.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

24

Page 25

PerformingDaily

Maintenance

ServiceInterval:Beforeeachuseordaily

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page34).

FillingtheFuelTank

FuelTankCapacity

53L(14USgallons)

FuelSpecication

AddingFuel

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,shutofftheengine,andremove

thekey .

2.Usingacleanrag,cleantheareaaroundthe

fuel-tankcap.

3.Removethecapfromthefueltank(Figure30).

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180days

toensurefuelfreshness.

Usesummergradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwintergrade(No.

1-DorNo.1-D/2-Dblend)belowthattemperature.

Useofwintergradefuelatlowertemperatures

provideslowerashpointandcoldowcharacteristics

whicheasesstartingandreducesfuellterplugging.

Useofsummergradefuelabove-7°C(20°F)

contributestowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautiondamagestheengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatime

afterconvertingtobiodieselblended.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

g021210

Figure30

1.Fuel-tankcap

4.Fillthetankuntilthelevelistothebottomofthe

llerneckwithdieselfuel.

5.Installfuel-tankcaptightlyafterllingtank.

Note:Ifpossible,llthefueltankaftereachuse.

Thisminimizespossiblebuildupofcondensation

insidethefueltank.

BreakingintheMachine

Toensureoptimumperformanceoftheparkingbrake

system,burnish(breakin)thebrakesbeforeuse.

Settheforwardtractionspeedto6.4km/h(4mph)

tomatchthereversetractionspeed(all8spacers

movedtothetopofthemow-speedcontrol).With

theengineathighidle,proceedforwardwiththe

mow-speed-controlstopengagedandridethebrake

for15seconds.Proceedbackwardatfullreverse

speedandridethebrakefor15seconds.Repeat

this5timeswaiting1minutebetweeneachforward

andreversecycletoavoidoverheatingthebrakes.

Anadjustmenttothebrakesmayberequiredafter

break-in;refertoAdjustingtheParkingBrakes(page

48).

BleedingtheFuelSystem

Youmustbleedthefuelsystembeforestartingthe

engineifanyofthefollowingsituationshaveoccurred:

•Initialstart-upofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuel

systemcomponents;i.e.,lterreplaced,separator

serviced,etc.

25

Page 26

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis6

to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisemptyspaceinthe

tankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

1.Parkthemachineonalevelsurfaceandensure

thatthefueltankisatleasthalffull.

2.Openthehood.

3.Opentheair-bleedscrewonthefuel-injection

pump(Figure31)witha12mmwrench.

Figure31

1.Bleedscrew

4.TurnthekeytotheONposition.Theelectricfuel

pumpbeginsoperation,therebyforcingairout

aroundtheairbleedscrew.Leavethekeyinthe

ONpositionuntilasolidstreamoffuelowsout

aroundthescrew.

5.TightenthescrewandturnthekeytotheOFF

position.

Note:Normally,theengineshouldstartafterthe

abovebleedingproceduresarefollowed.However,if

enginedoesnotstart,airmaybetrappedbetween

injectionpumpandinjectors;refertoBleedingAir

fromtheFuelInjectors(page42).

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Donotcarrypassengersonthemachineand

keepbystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Keepyourhandsandfeetawayfromthecutting

units.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

g003993

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Stopthecuttingunitswheneveryouarenot

mowing.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Neverrunanengineinanareawhereexhaust

gassesareenclosed.

•Neverleavearunningmachineunattended.

26

Page 27

•Beforeleavingtheoperatingposition(includingto

emptythecatchersortounclogthecuttingunits),

dothefollowing:

–Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisin

question.

–Parkthemachineonlevelground.

–Disengagethecuttingunitsandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

RolloverProtectionSystem

(ROPS)Safety

•DonotremoveanyoftheROPScomponentsfrom

themachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Alwayswearyourseatbelt.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

–Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhidden

hazards.T allgrasscanhideobstructions.

Uneventerraincouldoverturnthemachine.

–Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycause

themachinetolosetraction.

–Useextremecautionwhenoperating

themachineneardrop-offs,ditches,

embankments,waterhazards,orother

hazards.Themachinecouldsuddenlyrollover

ifawheelgoesovertheedgeortheedge

cavesin.Establishasafetyareabetweenthe

machineandanyhazard.

–Identifyhazardsatthebaseoftheslope.

Iftherearehazards,mowtheslopewitha

pedestrian-controlledmachine.

–Ifpossible,keepthecuttingunitsloweredto

thegroundwhileoperatingonslopes.Raising

thecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplacealldamagedROPScomponents.Donot

repairoralterthem.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Y ouareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey .

•Reviewtheslopeinstructions,listedbelow,for

operatingthemachineonslopes.Beforeyou

operatethemachine,reviewthesiteconditionsto

determinewhetheryoucanoperatethemachine

intheconditionsonthatdayandatthatsite.

Changesintheterraincanresultinachangein

slopeoperationforthemachine.

–Avoidstarting,stopping,orturningthemachine

onslopes.Avoidmakingsuddenchangesin

speedordirection.Maketurnsslowlyand

gradually.

27

Page 28

StartingtheEngine

Important:Youmustbleedthefuelsystembefore

startingtheengineifyouarestartingtheengine

forthersttime,theenginehasshutoffdueto

lackoffuel,oryouhaveperformedmaintenance

onthefuelsystem;refertoBleedingtheFuel

System(page25).

1.Sitontheseat,keepyourfootoffthetraction

pedalsothatitisinNEUTRAL,engagetheparking

brake,settheengine-speedswitchtotheFAST

position,andensurethattheEnable/Disable

switchisintheDISABLEposition.

2.TurnthekeytotheON/PREHEA Tposition.

Anautomatictimercontrolstheglowplug

preheatfor6seconds.

3.Afterpreheatingtheglowplugs,turnthekeyto

theSTARTposition.

Cranktheenginefornolongerthan15seconds.

Releasethekeywhentheenginestarts.If

additionalpreheatingisrequired,turnthekeyto

theOFFpositionandthentotheON/PREHEA T

position.Repeatthisprocessasrequired.

4.Runtheengineatlowidlespeeduntilitwarms

up.

ShuttingOfftheEngine

1.MoveallcontrolstoNEUTRAL,engagethe

parkingbrake,movethethrottletotheLOWIDLE

positionandallowtheenginetoreachlowidle

speed.

Important:Allowtheenginetoidlefor5

minutesbeforeshuttingitoffafterafull

loadoperation.Failuretodosomayleadto

troubleonaturbo-chargedengine.

2.TurnthekeytotheOFFpositionandremoveit

fromtheswitch.

28

Page 29

SettingtheReelSpeed

Toachieveaconsistent,highquality-of-cutandauniformaftercutappearance,itisimportantthatyousetthe

reelspeedtothepropersetting.Adjustthereelspeedasfollows:

1.IntheInfoCenter,underthesettingsmenu,enterthebladecount,mowspeed,andHOCtocalculate

theproperreelspeed.

2.Iffurtheradjustmentsarerequired,inthesettingsmenu,scrolldowntotheFReelRPM,RReelRPM,or

both.

3.Presstherightbuttontochangethereelspeedvalue.Asthespeedsettingischanged,thedisplay

continuestoshowthecalculatedreelspeedbasedonbladecount,mowspeed,andHOC,butthenew

valueisalsodisplayed.

Note:Thereelspeedmayneedtobeincreasedordecreasedtocompensateforvaryingturfconditions.

Figure32

5inch(127mm)ReelSpeedChart

Figure33

7inch(178mm)ReelSpeedChart

g031995

g031996

29

Page 30

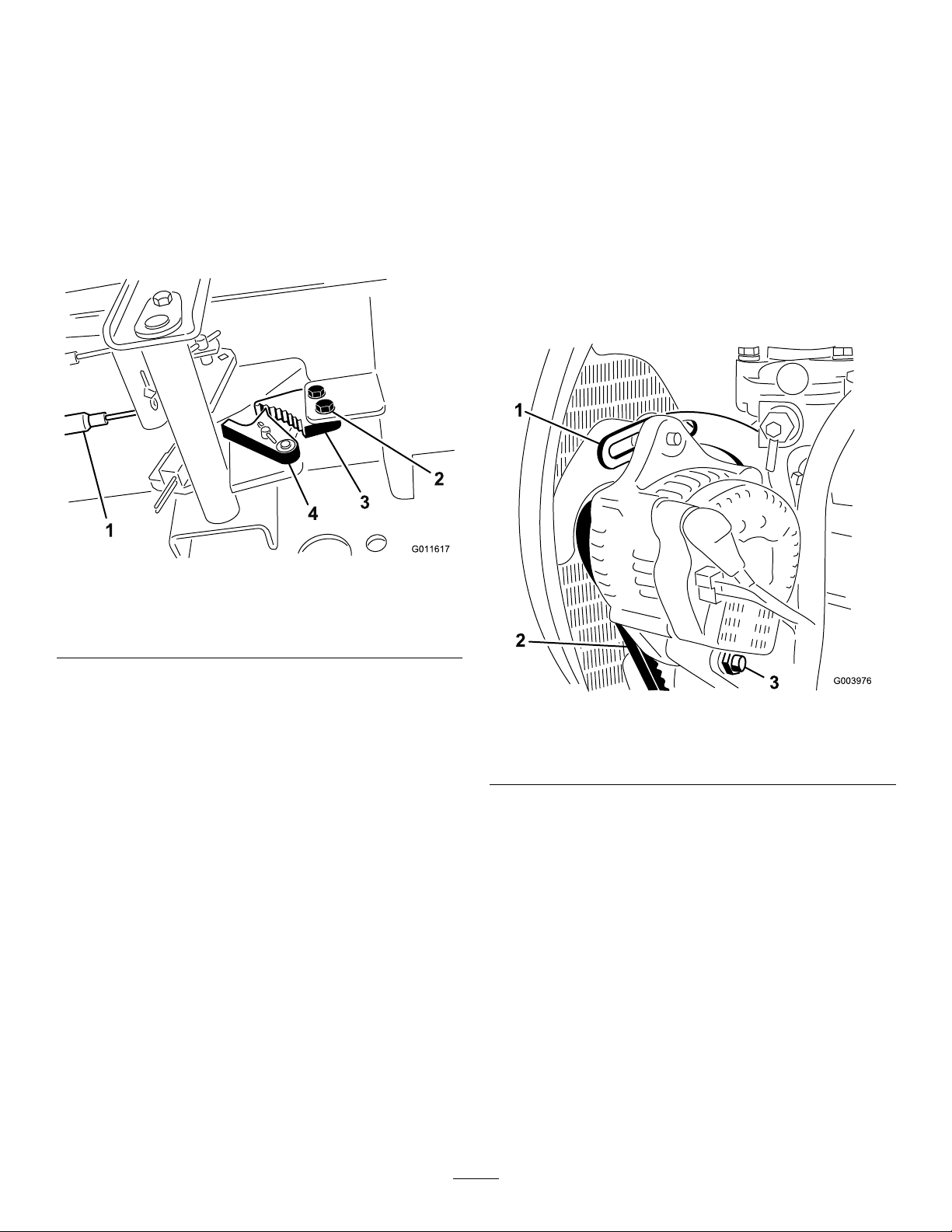

AdjustingtheLift-Arm

Counterbalance

Youcanadjustthecounterbalanceontherear

cutting-unitliftarmstocompensatefordifferentturf

conditionsandtomaintainauniformheightofcutin

theroughconditionsorinareasofthatchbuildup.

Youcanadjusteachcounterbalancespringto1of

4settings.Eachincrementincreasesordecreases

counterbalanceonthecuttingunitby2.3kg(5lb).

Youcanpositionthespringsonthebacksideofthe

rstspringactuatortoremoveallcounterbalance

(fourthposition).

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Insertatubeorsimilarobjectontothelong

springendandpivotitaroundthespringactuator

tothedesiredposition(Figure34).

CAUTION

Thespringsareundertensionandcould

causepersonalinjury.

turnaroundheightormovetheswitchupto

decreasethelift-armturnaroundheight(Figure

35).

g012154

Figure35

1.Switch2.Lift-armsensingdevice

4.Tightenthemountingscrews.

Usecautionwhenadjustingthesprings.

Figure34

1.Spring2.Springactuator

3.Repeattheprocedureontheotherspring.

AdjustingtheLift-Arm

TurnaroundPosition

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Thelift-armswitchislocatedunderneaththe

hydraulictankbehindthefront,rightliftarm

(Figure35).

3.Loosentheswitch-mountingscrewsand

movetheswitchdowntoincreasethelift-arm

Understandingthe

DiagnosticLight

Themachineisequippedwithadiagnosticlight,which

indicatesifthemachinedetectsamalfunction.The

diagnosticlightislocatedontheInfoCenter,above

thedisplayscreen(Figure36).Whenthemachine

isfunctioningproperlyandthekeyswitchismoved

totheON/RUNposition,thediagnosticlightturnson

brieytoindicatethatthelightisworkingproperly.

Whenamachineadvisorymessageappears,thelight

illuminateswhenthemessageispresent.Whena

g019276

faultmessageappears,thelightblinksuntilthefault

isresolved.

g021272

Figure36

1.Diagnosticlight

30

Page 31

CheckingtheInterlock

OperatingTips

Switches

Thepurposeoftheinterlockswitchesistopreventthe

enginefromcrankingorstartingunlessthetraction

pedalisintheNEUTRALposition,theEnable/Disable

switchisintheDISABLEposition,andtheLower

Mow/RaisecontrolisintheNEUTRALposition.In

addition,theengineshouldstopwhenyoupress

thetractionpedalwhileyouareofftheseatorifthe

parkingbrakeisengaged.

CAUTION

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

VerifyingtheInterlock-Switch

Function

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,shutofftheengine,engagethe

parkingbrake,andremovethekey.

2.TurnthekeytotheONposition,butdonotstart

themachine.

3.Locatetheappropriateswitchfunctioninthe

diagnosticsmenuontheInfoCenter.

4.Individually,changeeachoftheswitchesfrom

opentoclosed(i.e.,sitonseat,engagetraction

pedal,etc.),andnotethattheappropriatestate

oftheswitchchanges.

Note:Repeatthisforallswitchesthatyoucan

changebyhand.

5.Ifaswitchisclosedandtheappropriate

indicatordoesnotchange,checkallwiringand

connectionstotheswitchand/orcheckthe

switcheswithanohmmeter.

BecomingFamiliarizedwiththe

Machine

Beforemowinggrass,practiceoperatingthemachine

inanopenarea.Startandshutofftheengine.

Operateinforwardandreverse.Lowerandraisethe

cuttingunitsandengageanddisengagethereels.

Whenyoufeelfamiliarwiththemachine,practice

operatingupanddownslopesatdifferentspeeds.

UnderstandingtheWarning

System

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurif

youoperatethemachinewithamalfunction.

Mowing

Starttheengineandmovetheengine-speedswitch

totheFASTposition.MovetheEnable/Disableswitch

totheENABLEpositionandusetheLowerMow/Raise

levertocontrolthecuttingunits(thefrontcuttingunits

aretimedtolowerbeforetherearcuttingunits).To

moveforwardandcutgrass,pressthetractionpedal

forward.

TransportingtheMachine

MovetheEnable/DisableswitchtotheDISABLE

positionandraisethecuttingunitstotheTRANSPORT

position.MovetheMow/Transportlevertothe

TRANSPORTposition.Becarefulwhendrivingbetween

objectssoyoudonotaccidentallydamagethe

machineorcuttingunits.Useextracarewhen

operatingthemachineonslopes.Driveslowlyand

avoidsharpturnsonslopestopreventrollovers.

Lowerthecuttingunitswhengoingdownhillfor

steeringcontrol.

AfterOperation

AfterOperationSafety

Note:Replaceanyfaultyswitchesandrepair

anyfaultywiring.

Note:TheInfoCenterdisplayalsohastheabilityto

detectwhichoutputsolenoidsorrelaysareturned

on.Thisisaquickwaytodetermineifamachine

malfunctioniselectricalorhydraulic.

GeneralSafety

•Shutofftheengine,removethekey,andwait

forallmovementtostopbeforeyouleavethe

operator’sposition.Allowthemachinetocool

beforeadjusting,servicing,cleaning,orstoringit.

•Cleangrassanddebrisfromthecuttingunits,

drives,mufers,coolingscreens,andengine

31

Page 32

compartmenttohelppreventres.Cleanupoilor

fuelspills.

•Disengagethedrivetotheattachmentwhenever

youarehaulingornotusingthemachine.

•Maintainandcleantheseatbelt(s)asnecessary.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

PushingorTowingthe

Machine

Inanemergency ,youcanmovethemachine

byactuatingthebypassvalveinthevariable

displacementhydraulicpumpandpushingortowing

themachine.

Important:Donotpushortowthemachinefaster

than3to4.8km/h(2to3mph)becauseinternal

transmissiondamagemayoccur.Thebypass

valvemustbeopenwheneveryoupushortow

themachine.

1.Rotatethebypass-valvebolt1-1/2turnstoopen

andallowoiltobypassinternally(Figure37).

IdentifyingtheTie-Down

Points

•Front—theholeintherectangularpad,underthe

axletube,insideeachfronttire(Figure38)

g031851

Figure38

1.Fronttie-down

Note:Thebypassvalveislocatedontheleft

sideofthehydrostat.Bybypassingtheuid,you

canmovethemachineslowlywithoutdamaging

thetransmission.

Figure37

1.Bypass-valvebolt

2.Closethebypassvalvebeforestartingthe

engine.However,donotexceed7to1 1N∙m(5

to8ft-lb)torquetoclosethevalve.

•Rear—eachsideofthemachineontherearframe

(Figure39)

g003995

g027077

Figure39

1.Reartie-down

Important:Runningtheenginewiththe

bypassvalveopencausesthetransmission

tooverheat.

32

Page 33

JackingPoints

Note:Usejackstandstosupportthemachinewhen

required.

•Front—rectangularpad,undertheaxletube,

insideeachfronttire(Figure40).

Figure40

1.Frontjackingpoint

•Rear—rectangularaxletubeontherearaxle.

HaulingtheMachine

•Usefull-widthrampsforloadingthemachineonto

atrailerortruck.

•Tiethemachinedownsecurely.

g031850

33

Page 34

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

MaintenanceSafety

•Beforeadjusting,cleaning,servicing,orleaving

themachine,dothefollowing:

–Parkthemachineonalevelsurface.

–Movethethrottleswitchtothelow-idleposition.

–Disengagethecuttingunits.

–Lowerthecuttingunits.

–Ensurethatthetractionisinneutral.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

MaintenanceProcedure

•T orquethewheellugnutsto94to122N∙m(70to90ft-lb).

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Usejackstandstosupportthemachineor

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallwornordamageddecals.

•Toensuresafe,optimalperformanceofthe

machine,useonlygenuineT ororeplacement

parts.Replacementpartsmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty .

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

Every100hours

Every150hours

•Checktheconditionandtensionofthealternatorbelt.

•T orquethewheellugnutsto94to122N∙m(70to90ft-lb).

•Changetheengineoilandlter.

•Checktheenginespeed(idleandfullthrottle).

•Inspecttheseatbelt(s)forwear,cuts,andotherdamage.Replacetheseatbelt(s)if

anycomponentdoesnotoperateproperly.

•Checktheoperationoftheinterlockswitches.

•Checktheengine-oillevel.

•Drainwaterorothercontaminantsfromthewaterseparator.

•Checkthetirepressure.

•Checkthecoolingsystem.

•Removedebrisfromthescreen,oilcoolers,andradiator.(Morefrequentlyindirty

operatingconditions).

•Checkthehydrauliclinesandhoses.

•Checkthelevelofthehydraulicuid.

•Checkthereeltobedknifecontact.

•Greasethebearingsandbushings(andimmediatelyaftereverywashing).

•Cleanthebatteryandchecktheconditionofit(orweekly,whichevercomesrst).

•Checkthebattery-cableconnections.

•Inspectthecoolingsystemhoses.

•Checktheconditionandtensionofthealternatorbelt.

•Changetheengineoilandlter.

Every200hours

Every250hours

•Drainmoisturefromthefuelandhydraulicuidtanks.

•T orquethewheellugnutsto94to122N∙m(70to90ft-lb).

34

Page 35

MaintenanceService

Every400hours

Every800hours

Interval

MaintenanceProcedure

•Servicetheaircleaner.Servicetheaircleanerearlieriftheserviceindicatorshows

red.Serviceitmorefrequentlyinextremelydirtyordustyconditions.

•Checkthefuellinesandconnectionsfordeterioration,damage,orloose

connections.(Oryearly,whichevercomesrst).

•Replacethefuel-ltercanister.

•Checktheenginespeed(idleandfullthrottle).

•Drainandcleanthefueltank.

•Checktherearwheeltoe-in.

•Ifyouarenotusingtherecommendedhydraulicuidorhaveeverlledthereservoir

withanalternativeuid,changethehydraulicuid.

•Ifyouarenotusingtherecommendedhydraulicuidorhaveeverlledthereservoir

withanalternativeuid,replacethehydrauliclters.

•Packtherearwheelbearings(2wheeldrivemachinesonly).

•Adjusttheenginevalves(refertotheengineowner’smanual).

Every1,000hours

Every2,000hours

Beforestorage

Every2years

•Ifyouareusingtherecommendedhydraulicuid,replacethehydrauliclters.

•Ifyouareusingtherecommendedhydraulicuid,changethehydraulicuid.

•Drainandcleanthefueltank.

•Flushandreplacethecoolingsystemuid.

•Replaceallmovinghoses.

35

Page 36

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Maintenance

CheckItem

Checkthe

safetyinterlock

operation.

Checkthebrake

operation.

Checkthelevels

oftheengineoil

andfuel.

Checkthe

cooling-system

uidlevel.

Drainthe

water/fuel

separator.

Checkthe

air-lterservice

indicator.

Checkthe

radiator,oil

cooler,and

screenfordebris.

Checkfor

unusualengine

1

noises.

Checkfor

unusual

operatingnoises.

Checktheuid

levelofthe

hydraulicsystem.

Checkthe

hydraulichoses

fordamage.

Checkforuid

leaks.

Checkthetire

pressure.

Checkthe

instrument

operation.

Checkthe

reel-to-bedknife

adjustment.

Checkthe

height-of-cut

adjustment.

Lubricateall

greasettings.

Touch-up

damagedpaint.

1.Checktheglowplugandinjectornozzlesiftheenginestartshard,producesexcesssmoke,orrunsrough.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

2

Sat.Sun.

36

Page 37

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

2

3

4

5

6

7

8

Information

Important:Refertoyourengineowner’smanualandcuttingunitOperator'sManualforadditional

maintenanceprocedures.

Note:T oobtainanelectricalschematicorahydraulicschematicforyourmachine,visitwww.Toro.com.

Lubrication

GreasingtheBearingsand

Bushings

ServiceInterval:Every50hours(andimmediately

aftereverywashing).

Lubricateallgreasettingsforthebearingsand

bushingswithNo.2lithiumgrease.

Thegreasettinglocationsandquantitiesareas

follows:

•PumpdriveshaftU-joint(3)(Figure41)

Figure41

(Shownwiththemotor/generatorcoverremoved)

•Cutting-unitlift-armcylinders(2each)(Figure42)

g012150

Figure42

•Lift-armpivots(1each)(Figure42)

•Cutting-unitcarrier-frameandpivot(2each)

(Figure43)

g027142

g003960

Figure43

•Lift-arm-pivotshaft(1each)(Figure44)

37

Page 38

Figure44

g004157

•Rearaxletierod(2)(Figure45)

Figure45

•Axle-steeringpivot(1)(Figure46)

g003966

Figure47

•Brakepedal(1)(Figure48)

g011615

Figure48

g003987

Figure46

•Steering-cylinderballjoints(2)(Figure47)

g004169

38

Page 39

EngineMaintenance

removelargeaccumulationsofdebrispacked

betweenoutsideofthelterandthecanister.

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Donotchangethegovernorspeedoroverspeed

theengine.

ServicingtheAirCleaner

ServiceInterval:Every400hours—Servicetheair

cleaner.Servicetheaircleaner

earlieriftheserviceindicatorshows

red.Serviceitmorefrequentlyin

extremelydirtyordustyconditions.

Checktheair-cleanerbodyfordamagewhichcould

causeanairleak.Replaceifdamaged.Checkthe

wholeintakesystemforleaks,damage,orloosehose

clamps.

Servicetheair-cleanerlteronlywhentheservice

indicatorrequiresit(Figure49).Changingtheairlter

beforeitisnecessaryonlyincreasesthechanceof

dirtenteringtheenginewhenyouremovethelter.

Important:Makesurethatthecoverisseated

correctlyandsealswiththeair-cleanerbody.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,engagetheparkingbrake,shutoff

theengine,andremovethekey.

2.Releasethelatchessecuringtheair-cleaner

covertotheair-cleanerbody(Figure49).

Important:Avoidusinghigh-pressureair,

whichcouldforcedirtthroughthelterinto

theintaketract.

Note:Thiscleaningprocesspreventsdebris

frommigratingintotheintakewhenyouremove

thelter.

5.Removeandreplacethelter(Figure50).

Note:Donotcleantheusedelementduetothe

possibilityofdamagingtheltermedia.

g027080

Figure50

1.Air-cleanercover

2.Air-cleanerlter

3.Air-cleanerindicator

6.Inspectthenewlterforshippingdamage,

checkingthesealingendofthelterandthe

body.

Figure49

1.Air-cleanercover3.Air-cleanerservice

indicator

2.Air-cleaner-coverlatch

3.Removethecoverfromtheair-cleanerbody .

4.Beforeremovingthelter,uselow-pressure

air—275kPa(40psi),cleananddry—tohelp

Important:Donotuseadamagedelement.

7.Insertthenewlterbyapplyingpressuretothe

outerrimoftheelementtoseatitinthecanister.

Important:Donotapplypressuretothe

exiblecenterofthelter.

8.Cleanthedirt-ejectionportlocatedinthe

removablecover.Removetherubberoutlet

valvefromthecover,cleanthecavity,and

replacetheoutletvalve.

9.Installthecoverorientingtherubberoutletvalve

g027079

inadownwardposition—betweenapproximately

5o’clockto7o’clockwhenviewedfromtheend.

10.Securethelatches.

39

Page 40

CheckingtheEngine-Oil

Level

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeand

aftertheengineisrststarted.

Crankcasecapacityisapproximately3.3L(3.5US

qt)withthelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher

•Preferredoil:SAE15W-40(above0°F)

•Alternateoil:SAE10W-30or5W-30(all

temperatures)

ToroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W-30viscosity.

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,shutofftheengine,andremove

thekey .

5.IftheoillevelisbelowtheFULLmark,remove

thellcap(Figure52),andaddoiluntillevel

reachestheFULLmarkonthedipstick.

g004134

Figure52

1.Oil-llcap

2.Openthehood.

3.Removethedipstick,wipeitclean,andinstall

it(Figure51).

Figure51

Donotoverll.

Important:Makesurethatyoukeepthe

engine-oillevelbetweentheupperandlower

limitsontheoilgauge.Enginefailuremay

occurasaresultofoverllingorunder

llingtheengineoil.

6.Installtheoil-llcapandclosethehood.

ServicingtheEngineOil

andFilter

ServiceInterval:Aftertherst50hours—Change

theengineoilandlter.

Every150hours

1.Removethedrainplug(Figure53)andletthe

oilowintoadrainpan.

g027076

1.Dipstick

4.Removethedipstickandchecktheoillevelon

thedipstick.

Note:TheoillevelshouldbeuptotheFULL

mark.

40

Page 41

Figure53

1.Oil-drainplug

2.Whenalltheoilisdrained,installthedrainplug.

3.Removetheoillter(Figure54).

FuelSystem

Maintenance

DANGER

Undercertainconditions,fuelandfuelvapors

arehighlyammableandexplosive.Areor

explosionfromfuelcanburnyouandothers

andcancausepropertydamage.

•Fillthefueltankoutdoors,inanopenarea,

g003970

whentheengineisoffandiscold.Wipeup

anyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis25mm

(1inch)belowthetopofthetank,notthe

llerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

Figure54

1.Oillter

4.Applyalightcoatofcleanoiltothenewlter

seal.

5.Installthereplacementoilltertothelter

adapter.Turntheoillterclockwiseuntilthe

rubbergasketcontactsthelteradapter,then

tightenthelteranadditional1/2turn.

Important:Donotover-tightenthelter.

6.Addoiltothecrankcase;refertoCheckingthe

Engine-OilLevel(page40).

DrainingtheFuelTank

ServiceInterval:Every800hours

Beforestorage

Drainandcleanthefueltankifthefuelsystem

becomescontaminatedorifthemachineistobe

storedforanextendedperiod.Usecleanfueltoush

outthetank.

CheckingtheFuelLines

g003971

andConnections

ServiceInterval:Every400hours(Oryearly,

whichevercomesrst).

Inspectthefuellinesfordeterioration,damage,or

looseconnections.

ServicingtheWater

Separator

ServiceInterval:Beforeeachuseordaily—Drain

waterorothercontaminantsfrom

thewaterseparator.

Every400hours

1.Placeacleancontainerunderthefuellter.

2.Loosenthedrainplugonthebottomofthelter

canister.

41

Page 42

Figure55

1.Water-separator-ltercanister

3.Cleantheareawheretheltercanistermounts.

4.Removetheltercanisterandcleanthe

mountingsurface.

5.Lubricatethegasketontheltercanisterwith

cleanoil.

6.Installtheltercanisterbyhanduntilthegasket

contactsthemountingsurface,thenrotateitan

additional1/2turn.

BleedingAirfromtheFuel

Injectors

Note:Performthisprocedureonlyifthefuelsystem

hasbeenpurgedofairthroughnormalpriming

proceduresandtheenginedoesnotstart;referto

BleedingtheFuelSystem(page25).

1.LoosenthepipeconnectiontotheNo.1nozzle

andholderassembly(Figure56).

g007367

g027141

Figure56

7.Tightenthedrainplugonthebottomofthelter

canister.

ServicingtheFuel-Pickup

Tube

Thefuel-pickuptube,locatedinsidethefueltank,

comeswithascreentohelppreventdebrisfrom

enteringthefuelsystem.Removethefuel-pickuptube

andcleanthescreenasrequired.

1.Fuelinjectors

2.TurnthekeytotheONpositionandwatchthe

fuelowaroundtheconnector.Whenyou

observeasolidowoffuel,turnthekeytothe

OFFposition.

3.Tightenthepipeconnectorsecurely .

4.Repeatsteps1through3ontheremaining

nozzles.

42

Page 43

ElectricalSystem

ReplacingtheFuses

Maintenance

Important:Beforeweldingonthemachine,

disconnectallcablesfromthebattery,bothwire

harnessplugsfromtheelectroniccontrolmodule,

andtheterminalconnectorfromthealternatorto

preventdamagetotheelectricalsystem.

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe