Toro 03674, reelmaster 5010-H Operator's Manual

FormNo.3398-553RevA

Reelmaster

ModelNo.03674—SerialNo.316000001andUp

®

5010-HTractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3398-553*A

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsingolfcourses,parks,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbers

ofyourproductready .Themodelandserialnumbersare

onaplatemountedontheleftsideoftheframeunderthe

footrest.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

SafetyandInstructionalDecals.................................7

Setup...........................................................................11

1AdjustingtheTirePressure....................................11

2AdjustingtheControl-ArmPosition.......................12

3InstallingtheCuttingUnits....................................12

4MountingtheFinishingKits..................................14

5AdjustingtheTurf-CompensationSpring................16

6InstallingtheCEHoodLatch................................16

7UsingtheCutting-UnitKickstand...........................17

ProductOverview.........................................................18

Controls...............................................................18

Specications........................................................25

Attachments/Accessories........................................25

Operation....................................................................26

ThinkSafetyFirst...................................................26

CheckingtheEngine-OilLevel.................................27

AddingFuel...........................................................27

CheckingtheCoolingSystem...................................29

CheckingtheHydraulicFluid...................................29

CheckingtheReel-to-BedknifeContact.....................30

CheckingtheTorqueoftheWheelNuts.....................30

BreakingintheMachine..........................................30

BleedingtheFuelSystem.........................................30

StartingandStoppingtheEngine..............................31

SettingtheReelSpeed.............................................32

AdjustingtheLift-ArmCounterbalance.....................33

AdjustingtheLift-ArmTurnaroundPosition..............33

PushingorTowingtheMachine................................33

TransportingtheMachine........................................34

LoadingtheMachine..............................................35

JackingPoints........................................................35

TheDiagnosticLight..............................................36

CheckingtheInterlockSwitches...............................36

Hydraulic-ValveSolenoidFunctions.........................37

OperatingTips......................................................37

Maintenance.................................................................38

RecommendedMaintenanceSchedule(s)......................38

DailyMaintenanceChecklist....................................39

ServiceIntervalChart.............................................40

Lubrication...............................................................40

GreasingtheBearingsandBushings..........................40

EngineMaintenance..................................................42

ServicingtheAirCleaner.........................................42

ServicingtheEngineOilandFilter............................42

FuelSystemMaintenance...........................................43

DrainingtheFuelTank...........................................43

CheckingtheFuelLinesandConnections..................43

ServicingtheWaterSeparator...................................44

ServicingtheFuel-PickupTube................................44

BleedingAirfromtheFuelInjectors..........................44

ElectricalSystemMaintenance....................................45

ServicingtheBattery...............................................45

ReplacingtheFuses................................................45

DriveSystemMaintenance.........................................47

AdjustingtheTractionDriveforNeutral....................47

AdjustingtheRearWheelToe-in..............................47

CoolingSystemMaintenance......................................48

RemovingDebrisfromtheCoolingSystem................48

BrakeMaintenance....................................................49

AdjustingtheParkingBrakes....................................49

AdjustingtheParking-BrakeLatch............................49

BeltMaintenance......................................................50

TensioningtheAlternatorBelt.................................50

HydraulicSystemMaintenance....................................50

ChangingtheHydraulicFluid...................................50

ReplacingtheHydraulicFilter..................................51

CheckingtheHydraulicLinesandHoses....................51

TestingthePressureintheHydraulicSystem...............52

CuttingUnitSystemMaintenance.................................53

BacklappingtheCuttingUnits..................................53

Storage........................................................................54

PreparingtheTractionUnit.....................................54

PreparingtheEngine..............................................54

3

Safety

ThismachineisdesignedinaccordancewithENISO

5395:2013andANSIB71.4-2012specicationsineffectat

timeofproduction.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasizetheneedforcareandconcentrationwhen

workingwithride-onmachines.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Whilemowing,alwayswearsubstantial,slip-resistant

footwear,longtrousers,safetyglasses,andearprotection.

Tielonghairback.Donotwearjewelry.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthattheoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,useextreme

careinhandlingfuel.Fuelisextremelyammableandthe

vaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainerratherthanfroma

fuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelock-opendevice.

•Iffuelisspilledonyourclothing,changeyourclothing

immediately.

•Neveroverllthefueltank.Replacethefuelcapand

tightenitsecurely.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

blade-attachmentclutches,shiftintoneutral,andengage

theparkingbrake.

•Usecounterweight(s)orwheelweightswhensuggestedin

theOperator'sManual.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besure

thatallinterlocksareattached,adjustedproperly ,and

functioningproperly.

4

•Donotchangetheenginegovernorsettingsorover-speed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition,dothefollowing:

–Stoponlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Changeintoneutralandsettheparkingbrake.

–Stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachmentfor

thefollowing:

–Beforerefuelling

–Beforeremovingthegrasscatcher/catchers

–Beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition

–Beforeclearingblockages

–Beforechecking,cleaningorworkingonthemower

–Afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforestartingandoperatingthe

equipment

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthecylinders/reelsif

youarenotmowing.

•Donotoperatethemowerifyouaretired,ill,orunder

theinuenceofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

RolloverProtectionSystem(ROPS)

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.DonotweartheseatbeltwhentheROPSis

foldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,dropoffs,

orwater.

•Checkcarefullyforoverheadclearances(i.e.,branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

SlopeSafety

•Slowdownthemachineanduseextracareonhillsides.

Travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthestabilityofthemachine.

•Avoidstarting,stopping,orturningthemachineona

slope.Ifthetireslosetraction,disengagetheblade(s)and

proceedslowlystraightdowntheslope.

•Donotturnthemachinesharply .Usecarewhenreversing

themachine.

•Whenoperatingthemachineonaslope,alwayskeepall

cuttingunitslowered.

•Avoidturningthemachineonslopes.Ifyoumustturn,

turnslowlyandgraduallydownhill,ifpossible.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthemachine.

Followtherecommendationsforusingthemachineona

slopeinthisOperator’ sManual.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethatthe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartment,andfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifyoumustdrainthefueltank,dothisoutdoors.

•Becarefulwhileadjustingthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

5

•Onmulti-cylinder/multi-reelmachines,takecareas

rotating1cylinder/reelcancauseothercylinders/reels

torotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.Wait

forallmovementtostopbeforeadjusting,cleaning,or

repairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspills.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Connect

positiverstandnegativelast.

•Usecarewhencheckingthecylinders/reels.Weargloves

andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotoperatetheengineinaconnedspace

wheredangerouscarbonmonoxideandother

exhaustgassescancollect.

•Knowhowtostoptheenginequickly.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Raisethecuttingunitswhendrivingfrom1workarea

toanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinornear

themowingarea,stopmowing.Donotresumemowing

untiltheareaiscleared.

MaintenanceandStorage

•Makesurethatallhydraulic-lineconnectorsaretightand

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifuidis

injectedintoskin.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,relieveallpressureinthesystemby

stoppingtheengineandloweringthecuttingunitsand

attachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Toensuresafetyandaccuracy,haveyourToroDistributor

checkthemaximumenginespeedwithatachometer.

Maximumgovernedenginespeedshouldbe3300rpm.

6

•Formajorrepairs,warrantywork,updatestosystems,or

assistance,contactyourToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof100dBA,

whichincludesanUncertaintyValue(K)of1dBA.

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasily

visibletotheoperatorandarelocatednear

anyareaofpotentialdanger.Replaceany

decalthatisdamagedorlost.

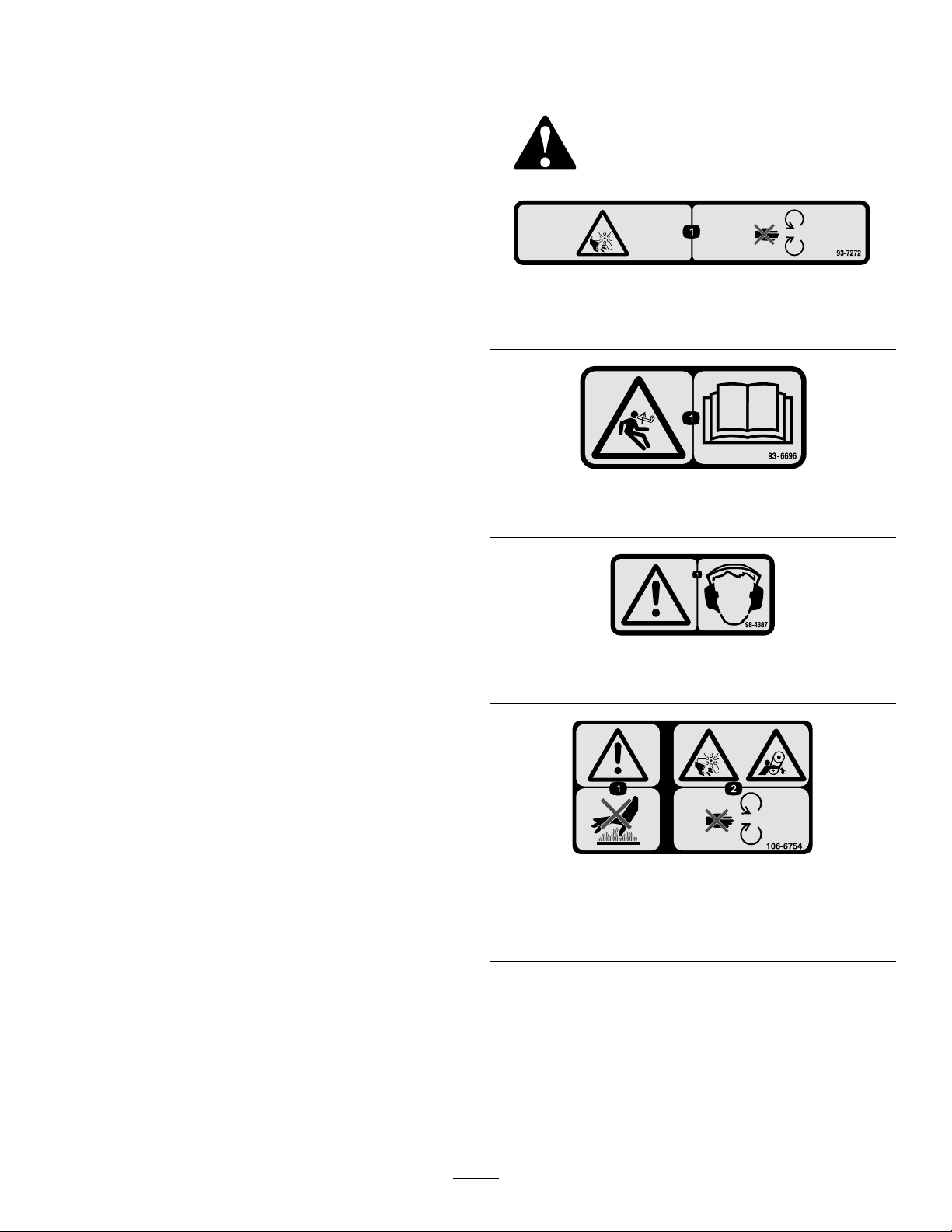

93-7272

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’searof81

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=0.4m/s

Measuredvibrationlevelforlefthand=0.4m/s

UncertaintyValue(K)=0.2m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBody

2

2

2

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

93–6696

1.Storedenergyhazard—readtheOperator'sManual.

98-4387

1.Warning—wearhearingprotection.

Measuredvibrationlevel=0.23m/s

UncertaintyValue(K)=0.11m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

2

2

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

7

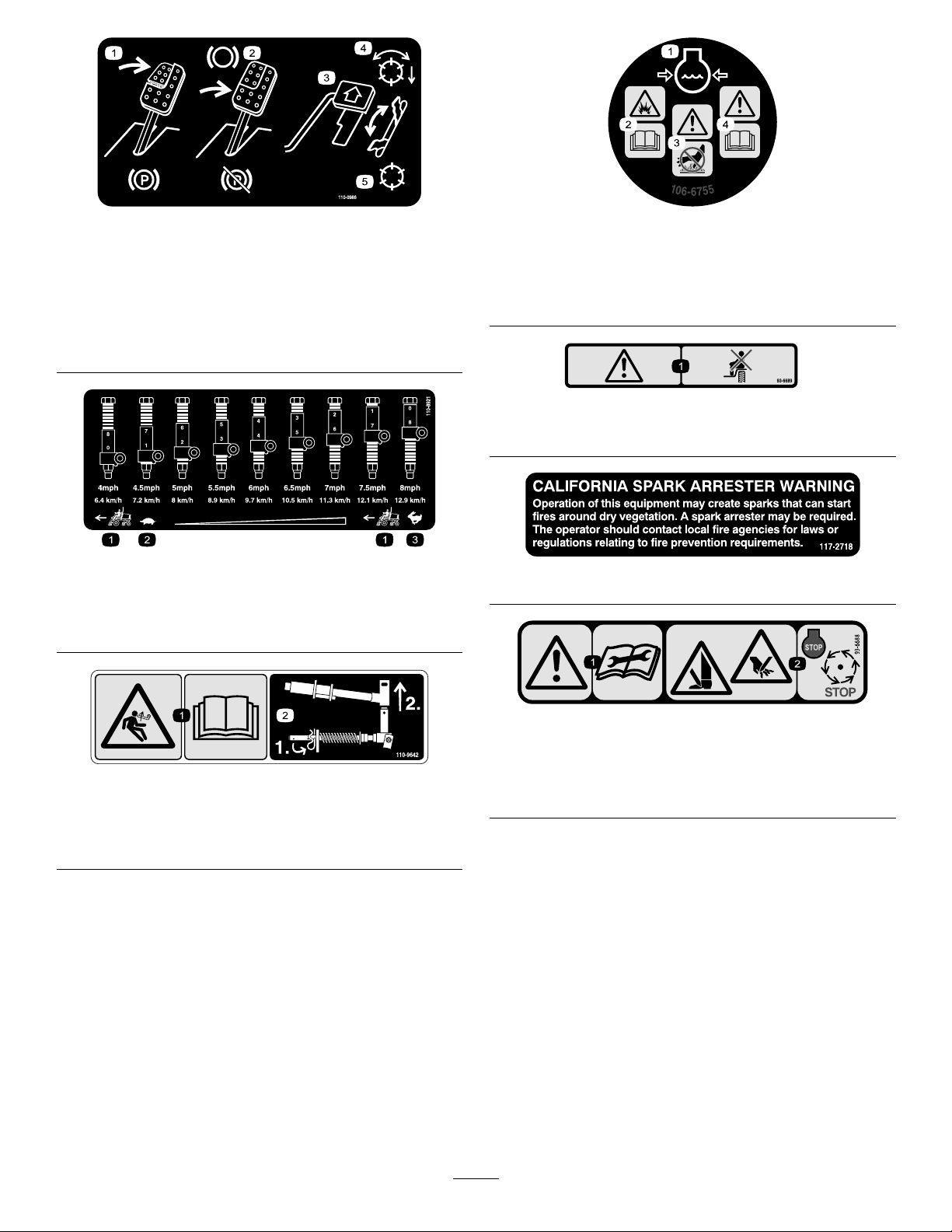

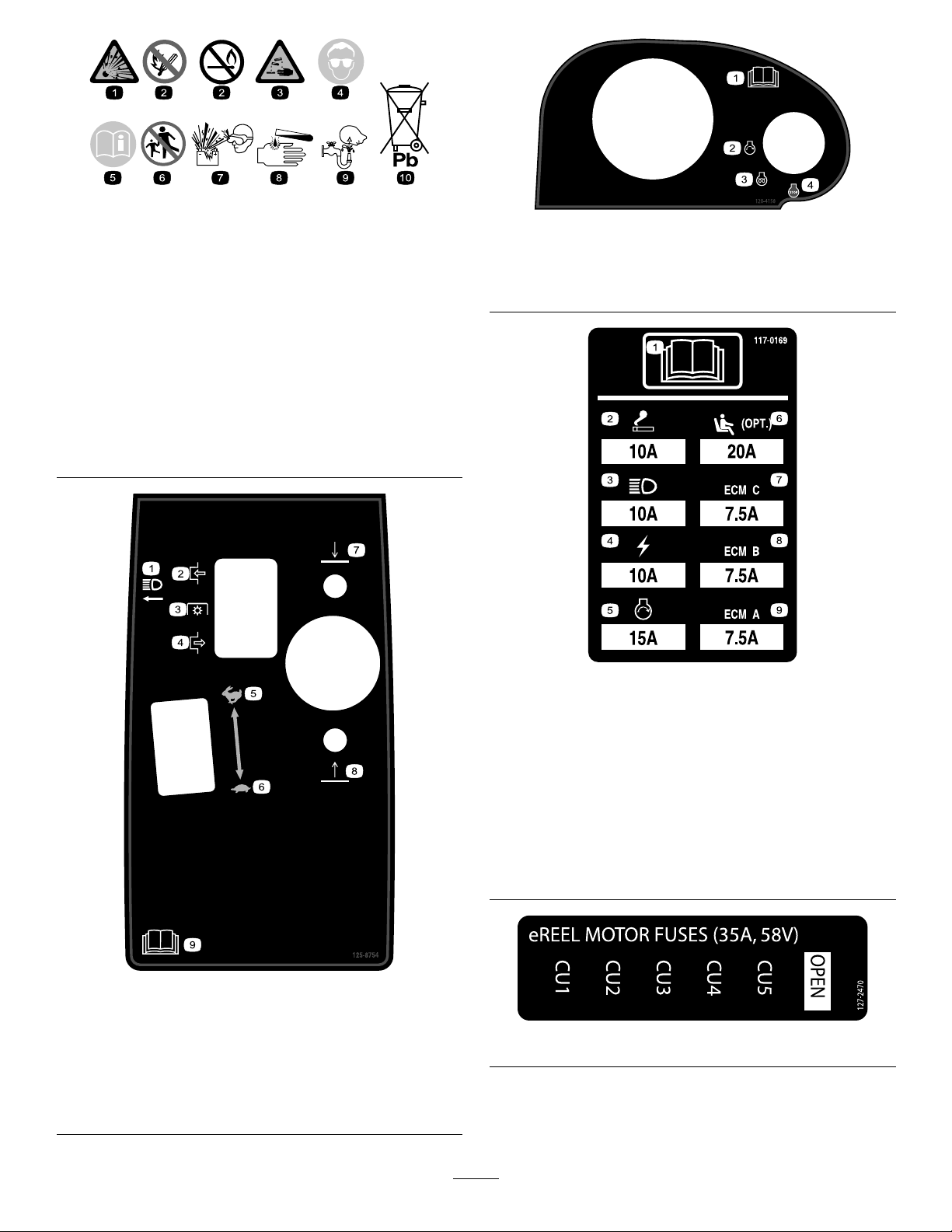

110-0986

106-6755

1.Pressthebrakepedalandparkingbrakepedaltosetthe

parkingbrake.

2.Pressthebrakepedaltoapplythebrake.

3.Pressthetractionpedaltomovethemachineforward.

4.Reelenabledmode

5.Transportmode

110-8921

1.Tractionunitspeed

2.Slow

3.Fast

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

1.Warning—donotcarrypassengers.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

93-6689

117–2718

110-9642

1.Storedenergyhazard—readtheOperator'sManual.

2.Movethecotterpintotheholeclosesttotherodbracket

andthenremovetheliftarmandpivotyoke.

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

93-6688

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

8

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

1.ReadtheOperator’s

Manual.

2.Engine—start4.Engine—stop

120–4158

3.Engine—preheat

125–8754

1.Headlights

2.Engage7.Lowerthecuttingunits

3.Powertake-off(PTO)

4.Disengage

5.Fast

6.Slow

8.Raisethecuttingunits

9.ReadtheOperator’s

Manual.

117–0169

1.ReadtheOperator'sManual.

2.Powerpoint—10A

3.Headlights—10A

4.Power—10A

5.Enginestart—15A

6.Optionalairrideseatsuspension—10A

7.EnginecomputermanagementC—10A

8.EnginecomputermanagementB—10A

9.EnginecomputermanagementA—10A

127-2470

9

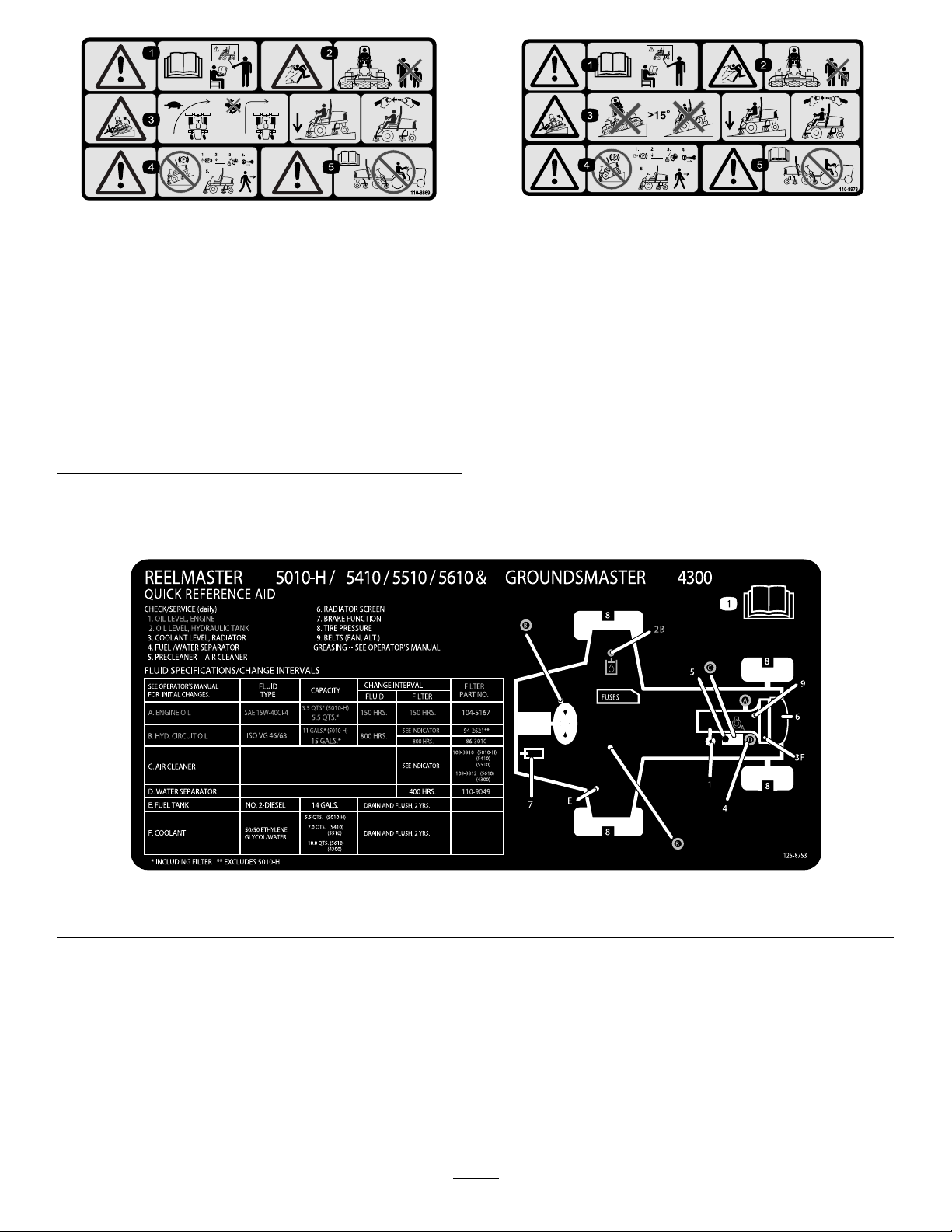

110-8869

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Tippinghazard—slowmachinebeforeturning,donotturn

athighspeeds;lowerthecuttingunitwhendrivingdown

slopes;usearolloverprotectionsystemandweartheseat

belt.AlwayswearaseatbeltwhenaROPSisinplace.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingdecks,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Warning—readtheOperator'sManual,donottowthe

machine.

110-8973

(AfxoverPartNumber1 10–8869forCE*)

*Thissafetydecalincludesaslopewarningrequiredonthemachineforcompliance

totheEuropeanLawnMowerSafetyStandardENISO5395:2013.Theconservative

maximumslopeanglesindicatedforoperationofthismachineareprescribedby

andrequiredbythisstandard.

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Tippinghazard—donotoperateonslopesgreaterthan15°;

lowerthecuttingdeckswhenoperatingonslopes;wear

thesafetybelt.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingdecks,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Warning—readtheOperator'sManualbeforetowingthe

machine.

1.ReadtheOperator'sManualformoremaintenanceinformation.

125-8753

10

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

MediaandAdditionalParts

Description

Operator'sManual

Nopartsrequired

Nopartsrequired

Cuttingunits

Finishingkit1

Nopartsrequired

Hood-latchassembly1

Washer1

Cuttingunitkickstand

Qty.

1

ReadtheOperator'sManualbeforeoperatingthemachine.

Qty.

–

–

5

–

1Installthecutting-unitkickstand.

Adjustthetirepressure.

Adjustthecontrol-armposition.

Installthecuttingunits.

Mountthenishingkits(nishingkits

aresoldseparately).

Adjusttheturf-compensationspring.

InstalltheCEhoodlatch.

Use

Use

EngineOperator'sManual

PartsCatalog

DeclarationofConformity

OperatorTrainingMaterial

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

AdjustingtheTirePressure

NoPartsRequired

Procedure

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Correctairpressurein

thefrontandreartiresis83to103kPa(12to15psi).

1

1

1

1

Engineinformation

Usetoreferencepartnumbers

Declarationofconformity

Reviewbeforeoperatingthemachine

Important:Maintainevenpressureinalltirestoensure

uniformcontactwiththeturf.

11

2

1

G027133

3

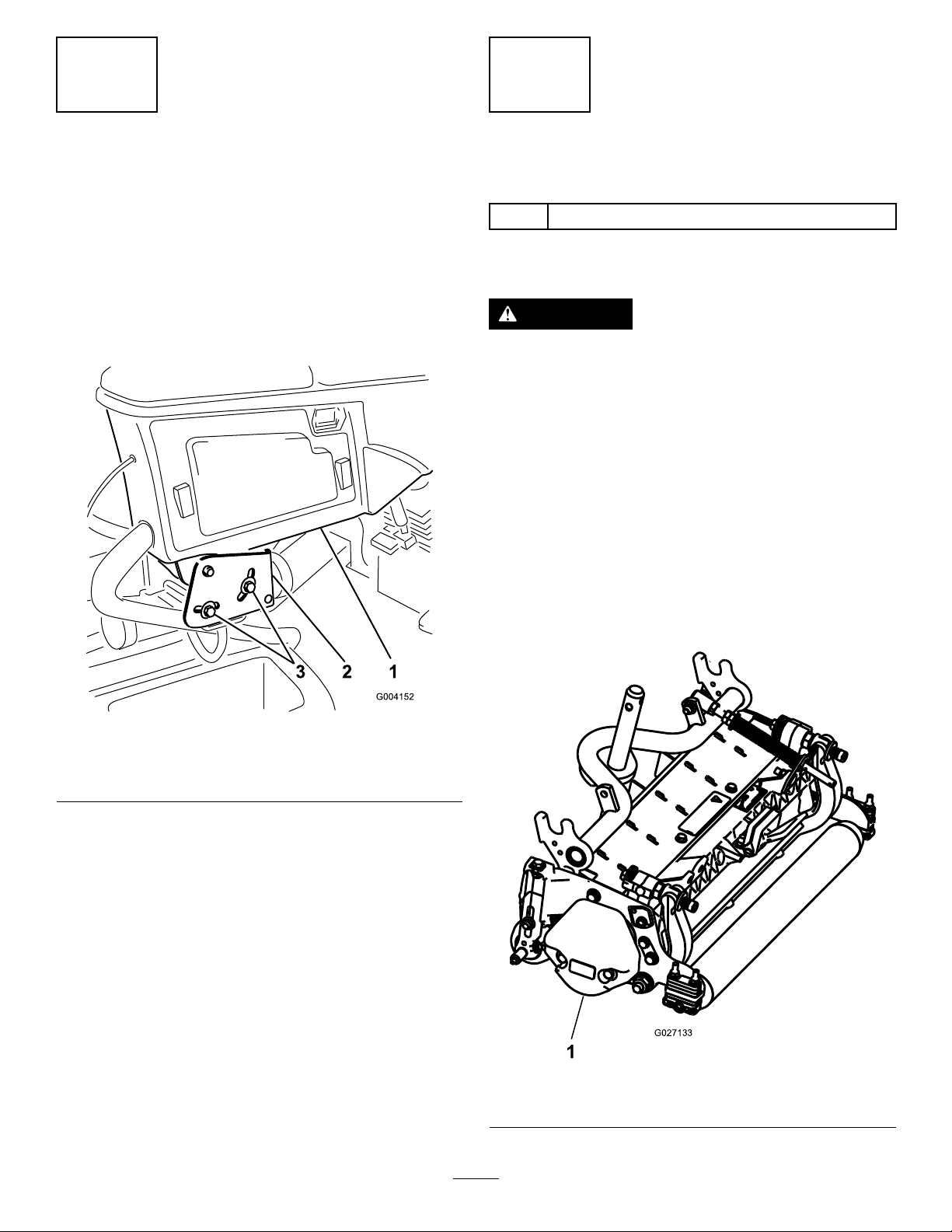

AdjustingtheControl-Arm Position

NoPartsRequired

Procedure

Thecontrol-armpositioncanbeadjustedforyourcomfort.

1.Loosenthe2boltssecuringthecontrolarmtothe

retainingbracket(Figure2).

InstallingtheCuttingUnits

Partsneededforthisprocedure:

5

Cuttingunits

Procedure

CAUTION

Ifyoudonotdisconnectthepowertothecutting

units,someonecouldaccidentallystartthecutting

unit,causingseriousinjurytohandsandfeet.

Alwaysseparatethepower-disconnectconnectors

beforeworkingonthecuttingunits(Figure26).

1.Disconnectthepower-disconnectconnector;referto

Cutting-Unit-PowerDisconnect(page20).

2.Removethecuttingunitsfromthecartons.Assemble

andadjustasdescribedinthecuttingunitOperator's

Manual.

Figure2

1.Controlarm3.Bolts(2)

2.Retainingbrackets

2.Rotatethecontrolarmtothedesiredpositionand

tightenthe2bolts.

3.Makesurethatthecounterweight(Figure3)isinstalled

totheproperendofthecuttingunitasdescribedinthe

counterweightkitInstallationInstructions.

Figure3

1.Counterweight

12

4.Mounttheturf-compensationspringtothesameside

ofthecuttingunitasthereel-drivemotor.Positionthe

turfcompensationasfollows:

Note:Allcuttingunitsareshippedwiththe

turf-compensationspringmountedtotherightside

ofthecuttingunit.

A.Removethe2carriageboltsandnutssecuringthe

rodbrackettothecutting-unittabs(Figure4).

Figure4

1.Turf-compensationspring3.Springtube

2.Rodbracket

B.Removetheangenutsecuringthespringtube

bolttothecarrier-frametab(Figure4)Remove

theassembly.

Figure6

1.Snapperpin2.Cap

7.Forthefrontcuttingunits,slideacuttingunitunder

theliftarmwhileinsertingthecarrier-frameshaftup

intothelift-arm-pivotyoke(Figure7).

C.Mountthespring-tubebolttotheoppositetabon

thecarrierframeandsecurewiththeangenut.

Note:Positiontotheboltheadtotheouterside

ofthetabasshowninFigure5.

Figure5

1.Oppositecarrier-frametab

2.Rodbracket

D.Mounttherodbrackettothecutting-unittabs

withthecarriageboltsandnuts(Figure5).

Note:Wheninstallingorremovingthecutting

units,makesurethatthehairpincotterisinstalled

inthespringrodholenexttotherodbracket.

Otherwise,installthehairpincotterintheholein

theendoftherod.

Figure7

1.Liftarm3.Lift-arm-pivotyoke

2.Carrier-frameshaft

8.Usethefollowingprocedureontherearcuttingunits

whentheheightofcutisabove19mm(3/4inch).

A.Removethelynchpinandwashersecuringthe

lift-arm-pivotshafttotheliftarmandslidethe

lift-arm-pivotshaftoutoftheliftarm(Figure8).

5.Lowerallliftarmscompletely.

6.Removethesnapperpinandthecapfromtheliftarm

pivotyoke(Figure6).

Figure8

1.Lynchpinandwasher

13

B.Insertthelift-armyokeontothecarrier-frame

12

g027140

shaft(Figure7).

C.Insertthelift-armshaftintotheliftarmand

secureitwiththewasherandlynchpin(Figure8).

9.Insertthecapoverthecarrier-frameshaftandlift-arm

yoke.

10.Securethecapandthecarrier-frameshafttothe

lift-armyokewiththesnapperpin(Figure6).

Note:Usetheslotifasteeringcuttingunitisdesired

orusetheholeifthecuttingunitistobelockedin

position.

11.Securethelift-armchaintothechainbracketwiththe

snapperpin(Figure9).

Note:Usethenumberofchainlinksdescribedinthe

cuttingunitOperator'sManual.

Figure9

1.Lift-armchain

2.Chainbracket

12.Coatthesplineshaftofthereelmotorwithclean

grease.

13.OilthereelmotorO-ringandinstallitontothemotor

ange.

14.Installthemotorbyrotatingitclockwisesothatthe

motorangesclearthebolts(Figure10).

Note:Rotatethemotorcounterclockwiseuntilthe

angesencircletheboltsandthentightenthebolts.

Important:Makesurethatthereel-motorhoseis

nottwisted,kinkedorintheriskofbeingpinched.

3.Pin

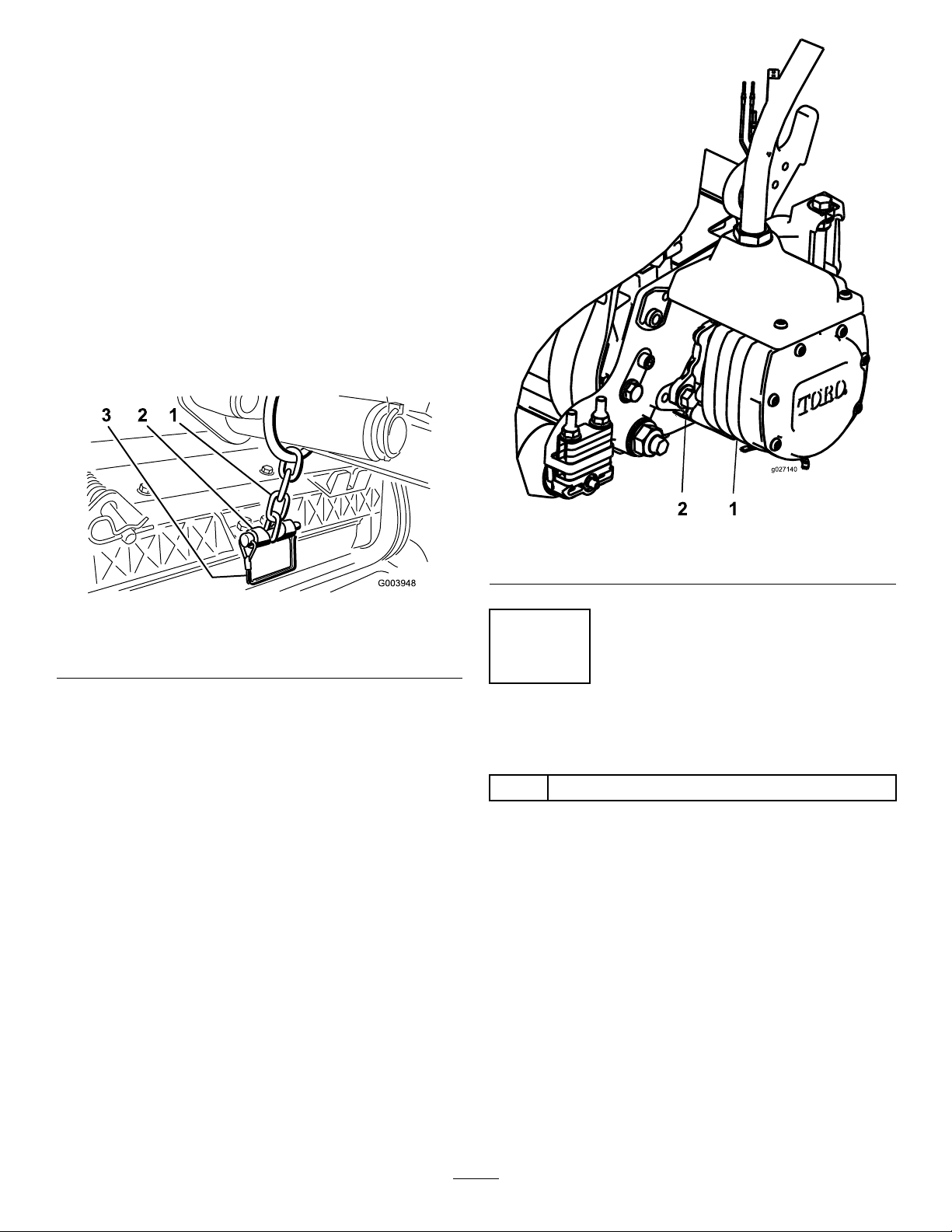

Figure10

1.Reel-drivemotor

2.Mountingbolt(2)

4

MountingtheFinishingKits

Partsneededforthisprocedure:

1Finishingkit

Procedure

Important:Toensurethatthehoseroutingis

appropriateandthehosesarenottwisted,mount

themotorstothecuttingunitsbeforemountingthe

nishingkits.

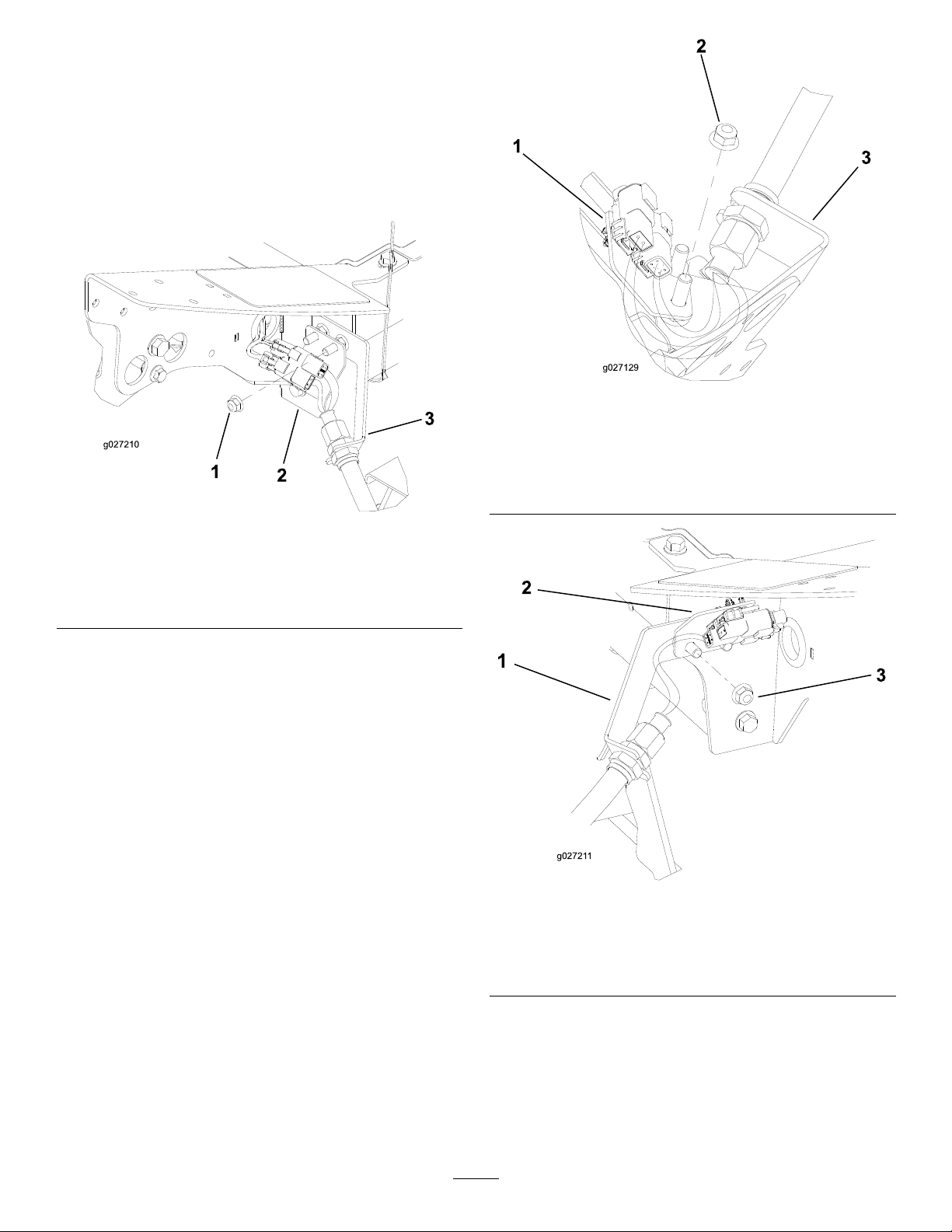

1.Onthefrontleftcorneroftheframe(#4cuttingunit

location),removetheextraangeheadnutonthebolt

securingthebulkheadbrackettothemachine(Figure

11).

2.Loosenthenutsonthenishingkithosetting,insert

thehoseintotheslotonthebulkheadbracketand

tightenthenuts.

Note:Whentighteningthenuts,useabackupwrench

topreventthehosefromtwistingorkinking.

14

3.Inserttheconnectorplateontothebulkhead-mounting

2

3

g027210

1

2

3

g027129

g02721 1

3

2

boltswiththeconnectorspositionedasshownin

Figure11.

4.Securetheconnectorplateto1ofthemountingbolts

withtheangenutpreviouslyremoved.

5.Locatethewireharnessonthemachineandplug

thewireconnectorsintothewireconnectorsofthe

nishingkit.

Figure12

#1CuttingUnitLocation,CenterFront

(Asviewedfromunderthemachine)

1.Extraange-headnut

2.Connectorplate

6.Repeattheprocedureontheremaining4bulkhead

Figure11

#4CuttingUnitLocation,LeftFront

3.Bulkheadbracket

locationsasshowninFigure12throughFigure15.

Important:Theconnectorplatesarepositioned

differentlyattheremaininglocationssothehose

canberoutedthroughthebulkheadbracketandto

thecuttingunitwithoutgettingtwistedorkinked.

1.Connectorplate

2.Extraange-headnut

#5CuttingUnitLocation,RightFront

1.Bulkheadbracket

2.Connectorplate

3.Bulkheadbracket

Figure13

3.Extraange-headnut

15

Figure14

g027209

2

1

3

#3CuttingUnitLocation,RightRear

1.Extraange-headnut3.Connectorplate

2.Bulkheadbracket

5

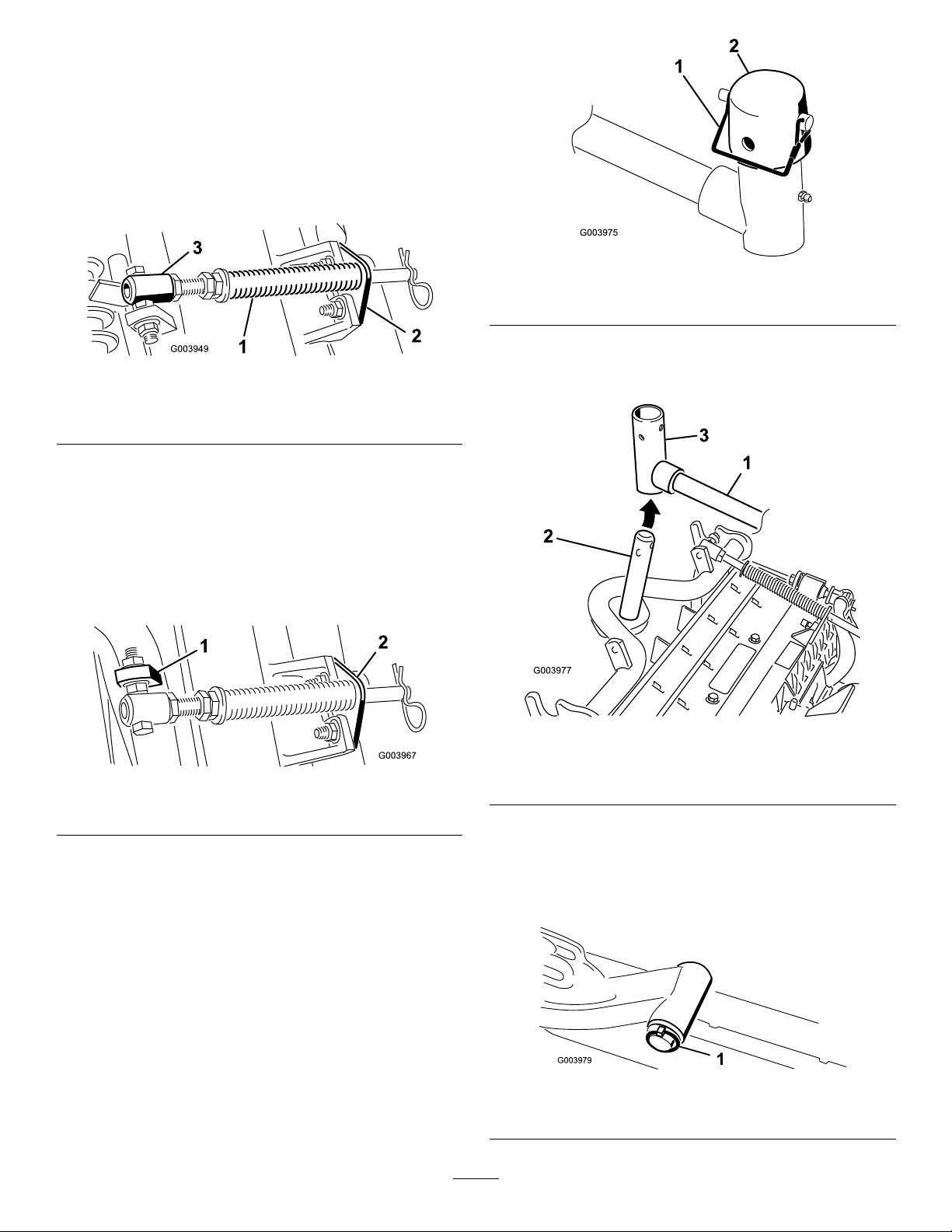

Adjustingthe Turf-CompensationSpring

NoPartsRequired

Procedure

Theturf-compensationspring(Figure16)transferstheweight

fromthefronttotherearroller.Thishelpstoreduceawave

patternintheturf,alsoknownasmarcellingorbobbing.

Important:Makespringadjustmentswiththecutting

unitmountedtothetractionunit,pointingstraight

aheadandloweredtotheground.

1.Makesurethatthehairpincotterisinstalledintherear

holeinthespringrod(Figure16).

#2CuttingUnitLocation,LeftRear

1.Bulkheadbracket

2.Extraange-headnut

Figure15

3.Connectorplate

Figure16

1.Turf-compensationspring3.Springrod

2.Hairpincotter4.Hexnuts

2.Tightenthehexnutsonthefrontendofthespringrod

untilthecompressedlengthofthespringis12.7cm(5

inches)for5-inchcuttingunitsor15.9cm(6.25inches)

for7-inchcuttingunits(Figure16).

Note:Whenoperatingonroughterraindecrease

thespringlengthby12.7mm(1/2inch).Ground

followingwillbeslightlydecreased.

16

g027072

4.Outsidethehood,insertthehookendofthelatch

throughtheholeinthehood.Makesurethatthe

6

rubbersealingwasherremainsontheoutsideofthe

hood.

InstallingtheCEHoodLatch

Partsneededforthisprocedure:

1Hood-latchassembly

1Washer

Procedure

1.Unlatchandraisethehood.

2.Removetherubbergrommetfromtheholeintheleft

sideofthehood(Figure17).

5.Insidethehood,insertthemetalwasherontothelatch

andsecurewiththenut.Makesurethatthelatch

engagestheframecatchwhenitislocked.Usethe

enclosedhood-latchkeytooperatethehoodlatch.

7

UsingtheCutting-Unit Kickstand

Partsneededforthisprocedure:

1

Cuttingunitkickstand

Procedure

Wheneverthecuttingunithastobetippedtoexposethe

bedknife/reel,propuptherearofthecuttingunitwiththe

kickstandtomakesurethatthenutsonthebackendofthe

bedbar-adjustingscrewsarenotrestingontheworksurface

(Figure19).

Figure17

1.Rubbergrommet

3.Removethenutfromthehood-latchassembly(Figure

18).

Figure18

1.Hoodlatch3.Rubberwasher

2.Nut4.Metalwasher

Figure19

1.Cutting-unitkickstand

Securethekickstandtothechainbracketwiththesnapper

pin(Figure20).

17

Loading...

Loading...