Page 1

12

Greg Janey

Marketing Manager, Reelmaster Products

The Toro Company

Aftercut appearance, Part One: The science behind the art...

As most of you can attest, the one

thing you can always count on

changing is the environment — and

turf conditions along with it. At some

point in every turf manager’s career,

they will encounter turf and/or soil

variations that alter the aftercut ap-

pearance of their reel mowers.

After reviewing some of the latest

TurfNet Forum discussions regarding

aftercut appearance (ACA) on fairways,

we at Toro felt it appropriate to shed

some light on how the reel interacts

with the turf and how changes in turf

conditions can alter that interaction, as

well as share a few adjustment tips to

compensate for changing conditions.

Rather than provide a step-by-step

diagnosis tool, we want to help you bet-

ter understand how variations across

the season affect ACA, and in turn help

you better achieve the ACA you desire.

Our recommendations result from thou-

sands of hours of field testing and years

of research and development that cul-

minated with our Reelmaster 5010

series.

Every golf course (and even individ-

ual fairways) has its own unique condi-

tions that often require special atten-

tion. These variations can include differ-

ences in turf and soil composition, culti-

vars, seasonal growing periods, geo-

graphic location, water, fertilizer, and

even individual micro-environments

within a single fairway.

As a manufacturer, we design reel

mowers to perform optimally across a

broad range of mowing conditions. We

also provide a series of targeted adjust-

ments to compensate for turf variability

when conditions fall outside the range

of ‘normal’.

TurfNet Monthly, May 2008

Toro machines are shipped with

factory settings intended for the best

performance under the widest range of

conditions. They may, however, need to

be adjusted seasonally as dictated by

changes in specific turf conditions.

The following guidance is intended

to highlight ACA issues which can sur-

face during seasonal/environmental

changes, and provide directional adjust-

ments to compensate for them.

Changes in turf “spring rate”

causing bobbing...

Varying levels of turf unevenness cause

fairway cutting units to hop vertically as

they traverse the contours in the fair-

way. Firm turf and heavier cutting unit

weight help stabilize the reels to mini-

mize bobbing and the resulting uneven

cut.

There is, however, a window in early

spring when the turf comes out of dor-

mancy, the soil is very soft, and the

“spring rate” of the turf approaches the

level needed to create bobbing of the

cutting unit.

distance the turf deflects under the

weight of the cutting unit. The softer a

turf is — the lower the spring rate — the

longer it takes for the cutting unit to re-

stabilize and stop bouncing.

This turf condition is not isolated to

the beginning of the growth season —

but that is when it most often appears.

To understand this further, think of

a typical spring suspension on a car as

it rides over a bump. If the suspension is

stiff like a sports car (a high spring

rate), the tire (or in our case, the roller)

will traverse through the bump and

quickly stabilize back to following the

contours of the road.

Spring rate

determines the

On the other end of the spectrum, if

the suspension is softer (lower spring

rate) like a Cadillac, the tire will traverse

through the bump, absorb some of the

energy, and continue to bob or sway

vertically long after the initial impact.

This is how the cutting unit can become

“excited” to the point where bobbing

occurs and continues across a fairway.

Soft turf with a low spring rate does not re-

stabilize cutting units as quickly as firm

turf does, so bobbing is more likely.

To offset this variation in turf, Toro

engineered a turf compensation spring

to optimize front-to-rear weight bias of

the cutting unit. This adjustment gives

you the ability to aggressively follow un-

dulations of a fairway during normal

mowing conditions, and if needed, shift

more of the cutting unit weight to the

rear roller to reduce any bobbing that

may occur during the growing season.

Under soft conditions, the turf compensation

springs may need to be adjusted to shift

more c/u weight to the rear roller.

©2008, Turnstile Publishing Company All Rights Reserved

Page 2

Aftercut appearance (Continued from pg 12)

Wet Conditions...

Wet or spongy conditions create many

challenges for reel mowers. Cutting

units are designed to achieve a specific

mow height in relation to the bottom of

the rollers. Notice that I did not simply

say, “to achieve a specific height of cut.”

This is because the actual “effective”

height of cut (HOC) is influenced by how

far the rollers sink or engage into the

turf canopy.

The amount of engagement is de-

pendent on many factors, including cut-

ting unit total weight on the turf, sus-

pension system down-pressure, front-to-

rear roller weight bias, roller type

(smooth, grooved), canopy thickness,

amount of clippings, and even the

amount of grass/turf removed.

Under wet turf

conditions, reel-to-reel

setup consistency

across the machine

becomes more

critical...

The effective vs bench-set HOC

variation becomes more apparent when

the turf is soft, as it will allow the cutting

unit to sink or engage further into the

canopy, resulting in a lower effective

HOC when compared to the same fair-

way when it is dry or firm.

Under wet turf conditions, reel-to-

reel setup consistency across the ma-

chine becomes more critical to ensure

a uniform ACA. Issues that may occur if

reels are not set up consistently include

scalping, marking, step-cut and excess

clippings, among many others. To com-

pensate, most reel mowers have vari-

ous roller options, adjustable counter

balance springs, and most importantly

HOC adjustment to allow you to achieve

the same effective HOC in a variety of

conditions.

When selecting a cutting unit con-

figuration, one must understand that

each cutting unit design or configura-

tion will have a different effective HOC

due to the differences in ground pres-

sure at the roller, the cutting unit sus-

Wet or high-growth conditions may require special adjustment to ensure a uniform

aftercut appearance across the full swath of the machine.

pension, the aggressiveness of cut, etc.

This means that the same HOC for one

type of reel mower will not necessarily

give the same result on another.

To ensure your mower provides the

desired ACA in wet conditions, it is most

important to ensure all adjustments

and attachments are set the same. If

needed, it may help to switch to full roll-

ers, add rear roller brushes, or in-

crease the HOC setting.

High growth conditions...

(cutting unit overlap)

In times of high growth rates (like in the

spring, after fertilizer applications, or

even from extended periods between

mowing), the thicker canopy and in-

creased amount of leaf blade removal

create a unique mowing surface which

may alter ACA from reel to reel.

13

As the cutting unit rides over the

turf, the canopy acts as a support,

pushing up on the rollers and bedknife

with varying force depending on the

amount of turf or canopy thickness be-

low it. This is also part of the reason

why you observe a difference between

bench set and effective HOC.

Now, let’s address the fact that all

cutting units have a certain amount of

overlap between them to minimize un-

cut turf when turning or mowing on side

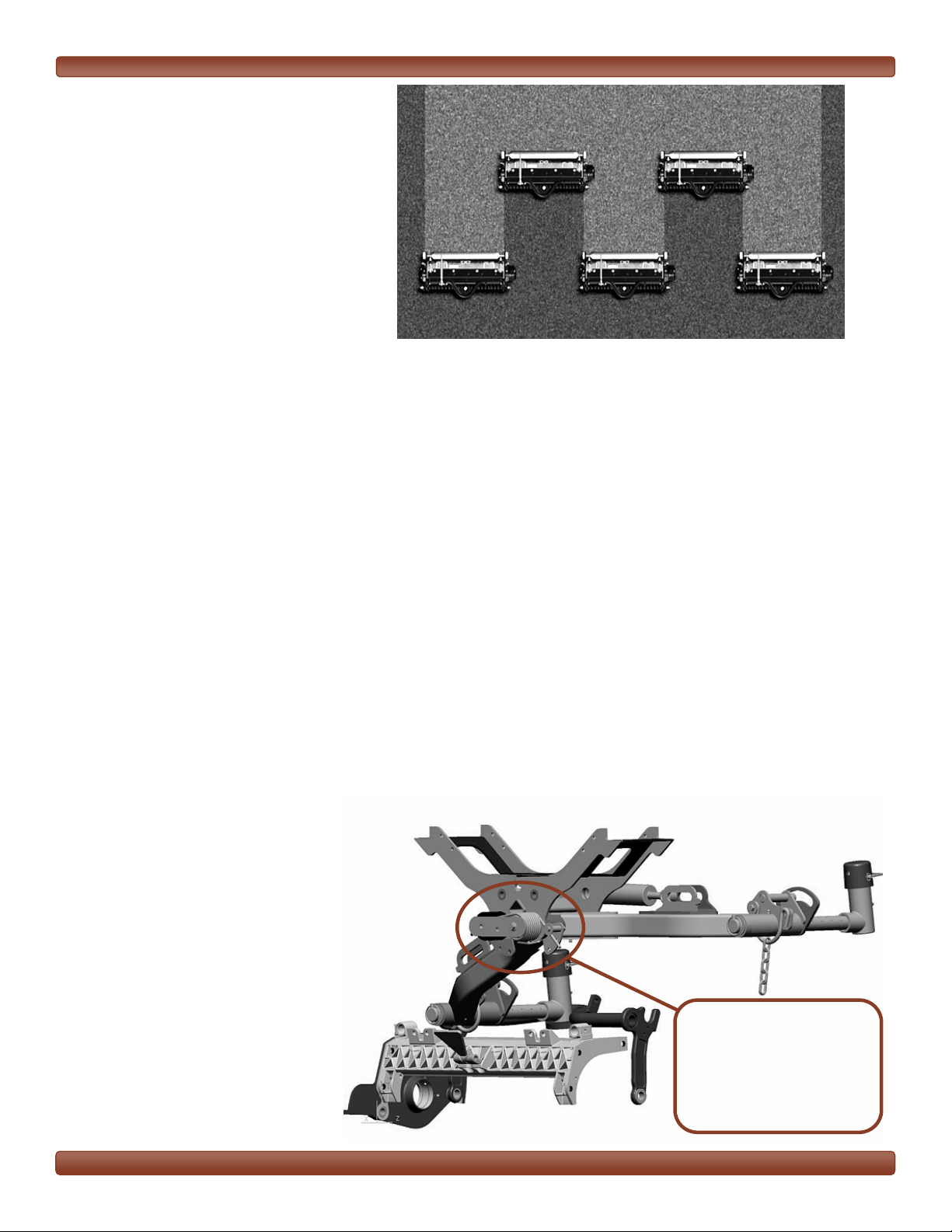

hills. The Reelmaster 5010 series with

22” DPA cutting units, for instance, was

designed with 2½ ” of overlap on each

side of the cutting unit. This means the

front three reels are exposed to a full

22” of thick, uncut turf canopy, while the

rear two only see 17” of full turf canopy

(and 5” of pre-cut turf). This is over 20%

less full canopy pushing up on the roll-

ers and bedknife, which in high growth

(Continued on next page)

Because rear cutting units are

cutting (and being supported by)

over 20% less turf than the front

cutting units, a counter balance

spring has been designed to

relieve some of the weight off the

rear cutting units — so they don’t

engage as far into the turf canopy.

(Continued on page 14)

©2008, Turnstile Publishing Company All Rights Reserved

TurfNet Monthly, May 2008

Page 3

14

Aftercut appearance (Continued from pae13)

or even soft wet conditions can result in

a lower effective HOC on the rear units

— which, in turn, can create a step-cut

look across the mowing path.

To compensate for this, Toro has

designed in a simple counter-balance

spring that can be set to relieve some

of the weight off the rear two cutting

units, thus reducing the difference be-

tween front and rear cutting units for a

more uniform HOC and resulting ACA.

Double roll or double cut marks?

Run two passes side by side in the same direction, one pass with

the reels on and the other with the reels off. If the strips go away on

the pass where the reels were not spinning, then it is a

the strip is the same between the two, it is generally a

A second technique is to examine individual strips from both sides of the

mowing pass (behind and in-front). If the color appears lighter from both

directions, it generally indicates a double cut mark. Roller options like front

shoulder rollers or a decreased bedknife attitude should be considered. If

the color shifts from light to dark when viewed in different directions, it

generally indicates a double roller mark and roller options should be

considered with different end designs (example: shorter rear rollers).

double cut

double roll

TIP!

mark. If

mark.

Each of four settings on the

counterbalance springs increases or

decreases counter-balance on the cutting

unit by 5 lb. The springs can be positioned

on the back side of the spring actuator to

remove all counter balance (4th position).

Other ACA variations which can

result from cutting unit overlap include

double roll

double roll

double roll double roll

Each has its own unique visual appear-

ance and typically shows up as small (2”

or less) strip between each cutting unit.

To compensate for these, Toro devel-

oped shorter rear rollers (standard on

5” dia. cutting units) to eliminate the

double roller marks most often seen in

cool season grasses.

cutting unit showing the full width rear

roller (installed) with the now-standard

marks and

A top view of the Toro 5” DPA fairway

shorter rear roller behind it.

double cut

double cut

double cut double cut

marks.

An optional front shoulder roller is

designed to reduce double cut marks

(most often seen in warm season

grass) by increasing the rolling action of

the cutting unit in the overlap areas.

High growth conditions

(clipping dispersion)...

Excessive clippings during high growth

conditions can have a significant affect

on ACA due to their ability to alter the

way sunlight reflects off the canopy and

affect the HOC between reels..

When clippings are thrown for-

ward, they thicken the canopy and re-

duce the ability of the to engage into

the turf, thereby altering the effective

HOC. This issue is magnified by the helix

design of the reels because the front

reels tend to throw additional clippings

into the path of the rear cutting units —

causing them to rise up, resulting in a

higher effective HOC and creating an

opposite

Toro has designed a clipping deflec-

tion system to compensate for this con-

dition, but you may also need to con-

sider the rear throw configuration to

improve mowing capacity and reduce

clumping in high growth conditions.

Rear roller brushes have shown dra-

matic improvements in clipping disper-

sion and ensure a smooth, level roller,

which ultimately increases consistency

from reel to reel.

step cut appearance.

High thatch conditions...

Thatch buildup is another turf condition

that affects the interaction of the reel

with the canopy and the resulting ACA

of the turf. Because thatch creates a

spongy surface and a denser canopy,

the cutting unit may exhibit similar ten-

dencies to wet or high growth condi-

tions.

The most critical issue created by

thatch buildup is related to how the

denser canopy reduces the amount of

sunlight and nutrients exposed to the

base of the canopy. This ultimately re-

duces the amount and depth of green

leaf tissue on the leaf blades, which

magnifies any inconsistencies between

cutting units, especially from an effec-

tive HOC standpoint.

In high thatch

conditions, the greento-white color gradient

from tip to crown is

smaller than normal...

To understand this further, we

need to take into account the fact that

the leaf blade has a color gradient from

tip to crown, green to white/tan re-

spectively. Because of this, aftercut ap-

pearance and mowing uniformity is

highly dependent on uniformity in effec-

tive HOC. This is especially in high

thatch conditions where the color gradi-

ent is smaller than normal, or when

taking off more than 1/3 of the leaf

blade.

To compensate for this potential

turf condition, Toro has engineered an

integrated blade and brush style

groomer. This optional attachment

combines the cutting action of a blade

(Continued on page 15)

TurfNet Monthly, May 2008

©2008, Turnstile Publishing Company All Rights Reserved

Page 4

15

Aftercut appearance (Continued from pg 14)

with the lifting action of a brush to re-

duce thatch, encourage lateral growth,

and reduce grain, resulting in a firmer,

healthier fairway, and a cleaner cut.

Other maintenance options effec-

tive in reducing thatch and grain include

verti-cutting, mowing in alternating di-

rections, aeration, topdressing, etc. But

like all changes in turf maintenance

practices, removing thatch or grain will

involve patience due to the retraining

process of the turf.

Hot or dry conditions...

When turf enters into the peak season

for heat and dryness, it is fairly common

for the leaf blade to dry out or retain

less moisture resulting in a less lush

canopy. This reduction in canopy mois-

ture has a direct impact on the cutting

unit as the moisture in the clippings

acts as a lubricant for the reel as is

makes contact with the bedknife.

When this moisture in the leaf

blade is reduced, cutting units have a

tendency to experience increased heat

and friction across the reel and bed-

knife surface. It is a good rule of thumb

to run not as tight of contact between

the reel and bedknife during these sea-

sonal conditions. Similarly, during high

turf stress conditions, it is generally a

good rule of thumb to back off on the

HOC to relieve stress on the turf.

In conclusion, maintaining fairways

requires a high level of knowledge and

skill to understand the potential turf

variations across such a large area. The

more you can understand about how

your mower interacts with the natural

variations of the turf, the better

equipped you will be to deliver the qual-

ity experience your golfers expect. The

adjustments highlighted above are only

guidelines. They work well in most condi-

tions, but additional adjustments may

be necessary to meet specific require-

ments or circumstances.

Coming next month:

“Aftercut Appearance Part 2:

Demystifying Step Cut

Appearance” ———— where we will

explore the most common

types of step cut, review

diagnostic tips, and provide

directional recommendations

to optimize the aftercut

appearance of your fairways.

©2008, Turnstile Publishing Company All Rights Reserved

TurfNet Monthly, May 2008

Loading...

Loading...