Page 1

Form No. 3354–709 Rev B

Verticutter

Reelmaster 5210/5410 Series Cutting Unit with

5in Reel

Model No. 03664—Serial No. 260000001 and Up

Operator’s Manual

English (EN)

Page 2

Contents

Introduction

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 3. . . . . . . . . . . . . . . .

Setup 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Transport Rollers 4. . . . . . . . . . . . . . . . . . . .

Inspection 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Blade Depth 5. . . . . . . . . . . . . . . . . .

Adjust the Rear Grass Shield 5. . . . . . . . . . . . . . . .

Adjusting the Roller Scrapers 5. . . . . . . . . . . . . . . .

Adjusting the Transport Rollers 6. . . . . . . . . . . . . .

Mount Verticutter Reel 6. . . . . . . . . . . . . . . . . . . . .

Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Training Period 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Tips 7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Reel Bearings 8. . . . . . . . . . . . . . . . .

Removing the Verticutter Blades from the Shaft 9.

Install Verticutter Blades 9. . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 12. .

Page

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. The model and serial

numbers are located on the side plate.

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

W 2006 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Page 3

Safety

Safe Operating Practices

• Read, understand, and follow all instructions in the

traction unit operator’s manual before operating the

verticutters.

• Read, understand, and follow all instructions in this

operator’s manual before operating verticutters.

• Never allow children to operate the verticutters. Do not

allow adults to operate traction unit or verticutters

without proper instruction. Only trained operators who

have read this manual should operate the verticutters.

• Never operate the verticutters when under the influence

of drugs or alcohol.

• Keep all shields and safety devices in place. If a shield,

safety device or decal is illegible or damaged, repair or

replace it before operation is commenced. Also tighten

any loose nuts, bolts, and screws to ensure the

verticutters are in safe operating condition.

• Always wear substantial shoes. Do not operate

verticutters while wearing sandals, tennis shoes,

sneakers or shorts. Also, do not wear loose fitting

clothing which could get caught in moving parts.

Always wear long pants and substantial shoes. Wearing

safety glasses, safety shoes and a helmet is advisable

and required by some local ordinances and insurance

regulations.

• Remove all debris or other objects that might be picked

up and thrown by the verticutter reel blades. Keep all

bystanders away from the working area.

• If the verticutter blades strike a solid object or the unit

vibrates abnormally, stop and shut the engine off. Check

the verticutters for damaged parts. Repair any damage

before restarting and operating the verticutters.

• Lower the verticutters to the ground and remove key

from ignition switch whenever machine is left

unattended.

• Be sure verticutters are in safe operating condition by

keeping nuts, bolts and screws tight.

• Remove key from ignition switch to prevent accidental

starting of the engine when servicing, adjusting or

storing the machine.

• Perform only those maintenance instructions described

in this manual. If major repairs are ever needed or

assistance is desired, contact an Authorized Toro

Distributor.

• To ensure optimum performance and safety, always

purchase genuine Toro replacement parts and

accessories to keep the Toro all TORO. Never use

“will-fit” replacement parts and accessories made by

other manufacturers. Look for the Toro logo to assure

genuineness. Using unapproved replacement parts and

accessories could void the warranty of The Toro

Company.

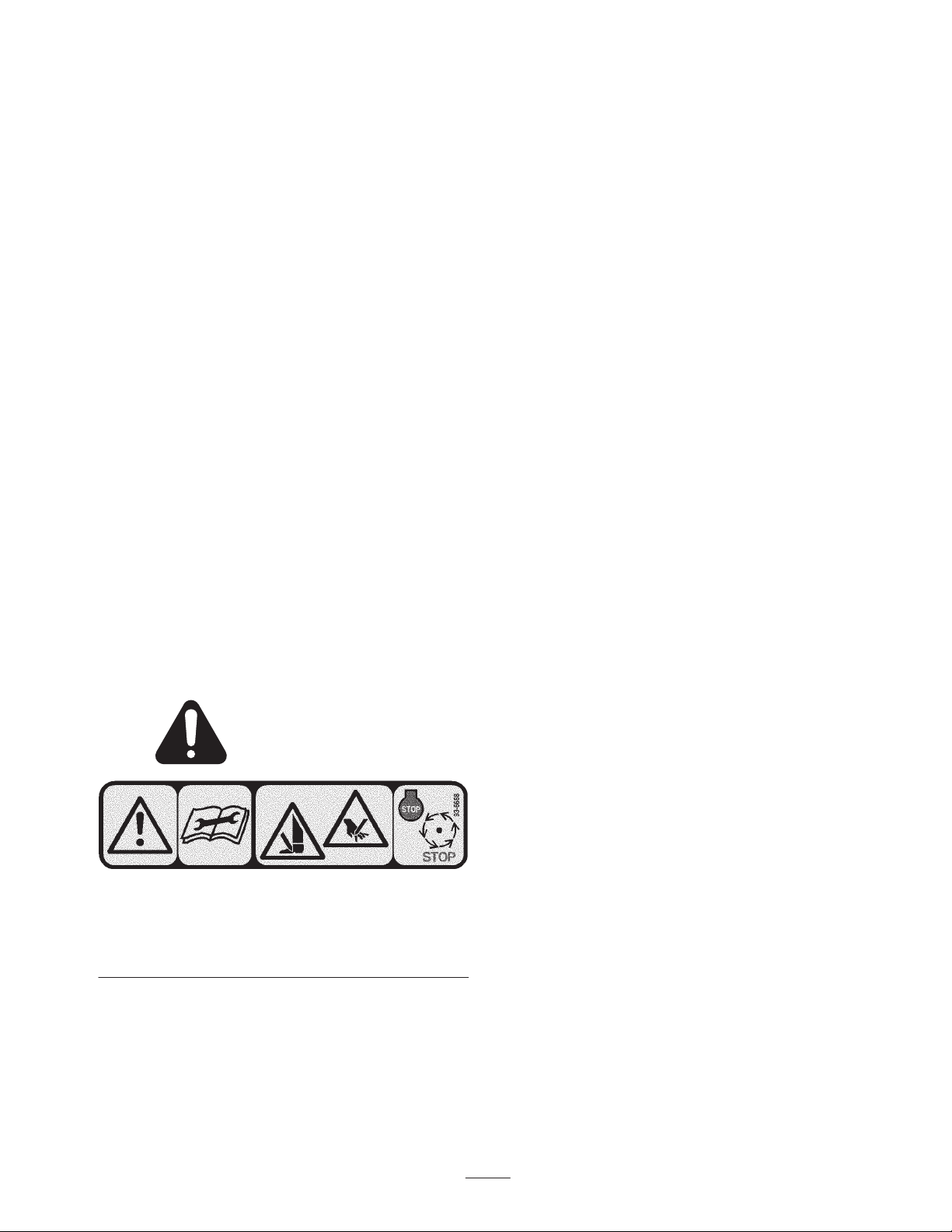

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

93-6688

1. Warning—read the

instructions before

servicing or performing

maintenance

2. Cutting hazard of hand or

foot—stop the engine and

wait for moving parts to

stop.

3

Page 4

Setup

Loose Parts

Note: Use this chart as a checklist to ensure that all parts have been received. Without these parts, total setup cannot be

completed.

Description

Transport roller assembly 2

Cotter pin 2 Use to secure transport rollers

O–ring 1 For use with reel motor bearing housing

Operator’s manual 1 Read before operating.

Parts catalog 1

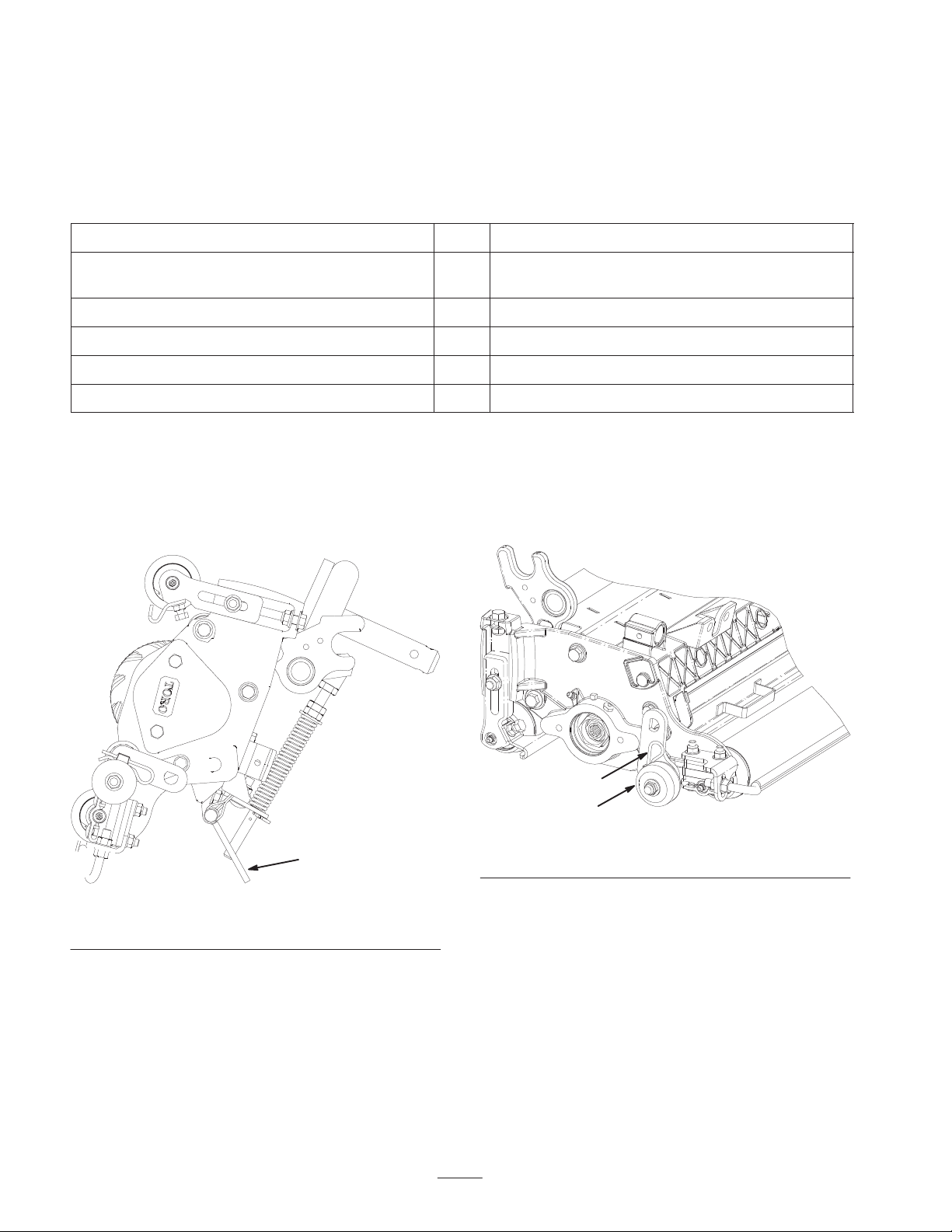

Note: Determine the left and right sides of the machine

from the normal operating position.

Whenever the cutting unit has to be tipped to expose the

verticutter blades, use the cutting unit kick stand (supplied

with traction unit) (Fig. 1).

Qty. Use

Use when the verticutters are lowered to the shop

floor

Install Transport Rollers

Secure a transport roller bracket to each sideplate pin with a

cotter pin (Fig. 2). The roller should be positined to the rear

of the vertricutter.

1. Cutting unit kick stand

Figure 1

2

1

Figure 2

1

1. Transport roller assembly 2. Cotter pin

Inspection

After the cutting unit is unboxed, inspect the following:

1. Check each end of the reel for grease. Grease should be

visibly evident in the reel bearings and internal splines

of the reel shaft.

2. Ensure that all nuts and bolts are securely tightened.

3. Make sure the carrier frame suspension operates freely

and does not bind when moved back and forth.

4

Page 5

Adjusting the Blade Depth

Note: The maximum recommended setting is 1/8 in.

(3 mm) deep blade penetration.

1. Place the verticutter reel on a level surface.

2. Place 2 gauge bars, which have the desired depth of

blade penetration below the ground, under the front and

rear rollers of the verticutter reel (on each end of the

reel) (Fig. 3).

Note: The verticutter blades must not touch the gauge bars.

3. Turn the adjusting bolt on each height-of-cut bracket

(Fig. 3) so that the reel blades come in contact with the

level surface on both ends.

2

2

1

Figure 3

1. Gauge bar (1/8”) 2. Adjusting bolt

Note: As the verticutter blades wear, the diameter of the

reel will decrease and the depth setting will change.

Check height setting periodically to insure desired

setting is achieved.

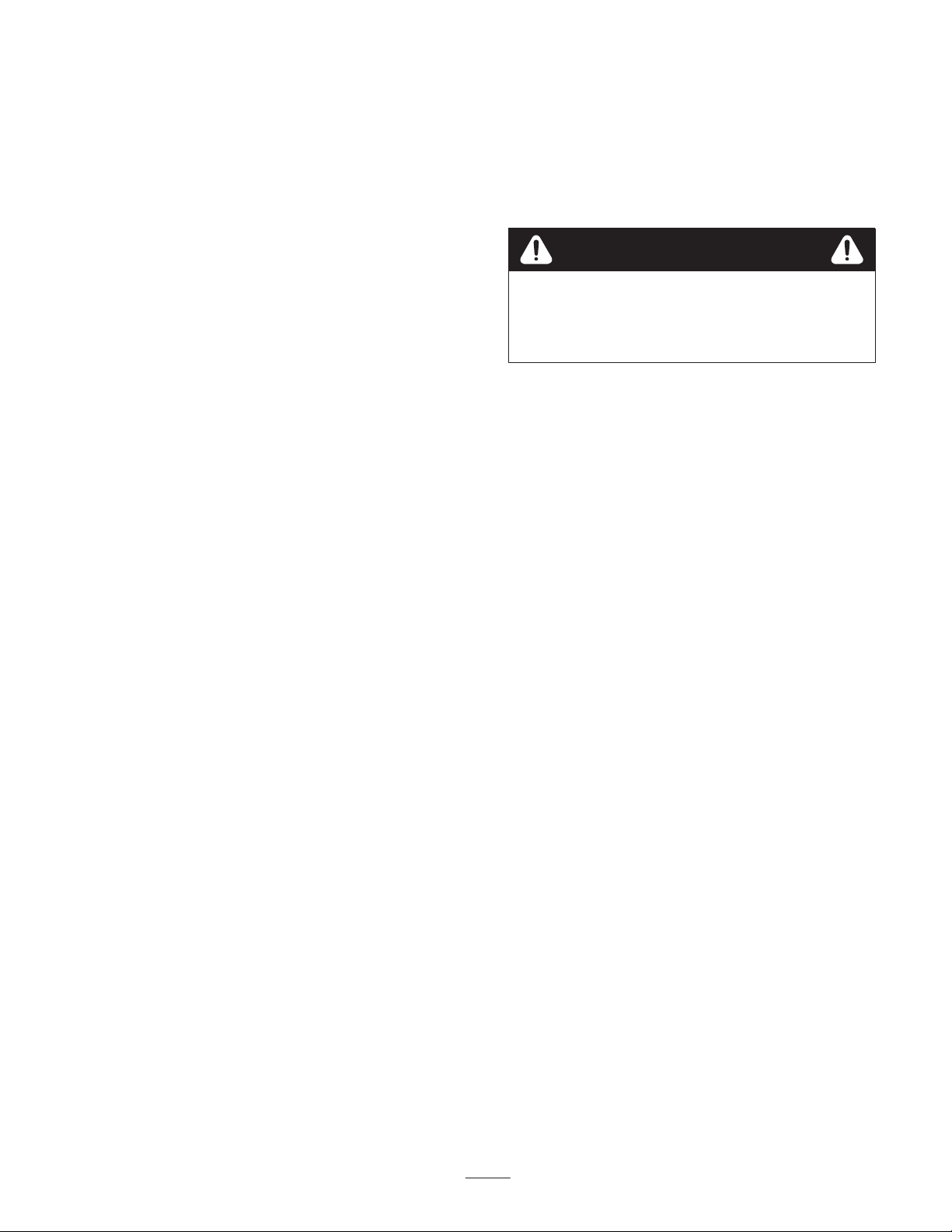

Adjust the Rear Grass Shield

1

2

Figure 4

1. Rear grass shield 2. Pivot capscrew

Caution

Do not open rear shield so it is higher than level to

ground

Thrown debris could cause personal injury

Adjusting the Roller Scrapers

1. Loosen flange nuts securing roller scrapers (Fig. 5).

2. Move scraper rods in or out to attain 0.0 to 0.03 in.

(.0 to .75mm) clearance between the scraper and roller.

3. Ensure that the scraper rod is parallel to the roller and

the level surface.

4. Tighten flange nuts to lock adjustment.

Note: When operating in turf conditions where much

debris is encountered, or unusually heavy thatch, open

the rear discharge shield to help allow the debris to

discharge from the reel.

1. Loosen the capscrews on the pivot of the grass shield

(Fig. 4).

2. Rotate the grass shield to the desired setting and tighten

the capscrews (Fig. 4).

5

Page 6

4

2

3

1

Figure 5

1. Front roller scraper

2. Rear roller scraper

3. Transport roller

4. Cotter pin

Adjusting the Transport Rollers

Before the verticutters are lowered to the shop floor or

removed from the traction unit, lower the transport rollers

(Fig. 5) to protect the blades from hard surface contact.

Motor Weight

Weight Motor Weight Motor

#1#4 #5

Motor Weight

Weight Motor

#3#2

Figure 6

Note: Counterweights are shipped installed to the right end

of the verticutters. The capscrews on the left end are to be

used for securing the hydraulic motor.

Verticutter reels are mounted to traction unit the same way

cutting units are. Refer to Traction Unit Operator’s Manual

for mounting instructions.

Important When connecting the lift arm chain to the

veticutter, use the third link from the top instead of the

forth.

1. Remove the cotter pin securing the transport roller

bracket to the sideplate pin.

2. Position the transport roller as follows:

• Lower the roller bracket before the verticutter is

lowered to the shop floor.

• Raise the roller bracket after the verticutter is raised

to the operating position.

3. Secure the transport roller bracket to the sideplate pin

with the cotter pin.

4. Repeat the procedure on the opposite end of verticutter.

Mount Verticutter Reel

Important When lowering verticutter reels, care

must be taken to prevent damage to the reel blades due

to contact with a concrete floor or a paved surface.

Lower the transport rollers before lowering the

verticuttiers to a concrete floor or a paved surface.

The verticutters can be installed at any of the five locations

on the traction unit. Figure 6 shows the orientation of the

hydraulic drive motor for each of the locations. For any of

the locations requiring the motor to be mounted on the right

end of the verticutters, install a counterweight on the left

end of the verticutters. For the locations requiring the motor

to be mounted on the left end, install a counterweight on

the right end of the verticutters.

1

Figure 7

1. Lift arm chain third link

6

Page 7

Operation

3. Power requirements to operate the verticutter reels will

vary with turf and soil conditions. Travel speed may

need to be reduced in some conditions.

Training Period

Before operating the verticutter reels, evaluate the

performance of the reel at the desired setting. Operate in a

clear, unused area to determine if the desired results will be

achieved. Adjust as desired.

Operating Tips

1. Operate the traction unit at full throttle, full reel speed

(setting 11) and between 3–5 MPH (5–8 Km/h).

2. The maximum recommended setting is 1/8 in. (3 mm)

deep blade penetration.

4. When operating in turf conditions where much debris is

encountered, or unusually heavy thatch, open the front

and rear discharge shields to help allow the debris to

discharge from the reel.

Caution

Do not open rear shield so it is higher than level to

ground

Thrown debris could cause personal injury

7

Page 8

Maintenance

Note: Determine the left and right sides of the machine

from the normal operating position.

Lubrication

Each cutting unit has (7) grease fittings (Fig. 8) that must

be lubricated regularly with No. 2 General Purpose Lithium

Base Grease.

The lubrication points are front roller (2), rear roller (2),

reel bearing (2) and bedknife adjuster.

Important Lubricating cutting units immediately after

washing helps purge water out of bearings and increases

bearing life.

1. Wipe each grease fitting with a clean rag.

2. Apply grease until clean grease is seen coming out of

roller seals and bearing relief valve.

3. Wipe excess grease away.

1

Figure 9

1. Reel shaft

2. If end play exists, proceeded as follows:

A. Loosen external set screw securing bearing

adjusting nut to bearing housing located on the left

side of the cutting unit (Fig. 10).

1

Figure 8

1. Relief valve

Adjusting the Reel Bearings

To insure long life of the reel bearings, periodically check if

reel end play exits. The reel bearings can be checked and

adjusted as follows:

1. Hold on to the reel shaft and try to move the reel

assembly side to side (Fig. 9).

1

1. Set screw 2. Bearing adjusting nut

B. Using a 1–3/8” socket wrench, slowly tighten the

reel bearing adjustment nut until no end play of the

reel exists. If adjusting nut does not eliminate reel

end play, replace reel bearings.

2

Figure 10

Note: Reel bearings do not require pre–load. Over

tightening reel bearing adjuster nut will

damage reel bearings.

3. Retighten set screw securing bearing adjusting nut to

bearing housing. Torque set screw to 12–15 in–lbs.

8

Page 9

Removing the Verticutter

Install Verticutter Blades

Blades from the Shaft

1. Secure the end of the verticutter shaft, which has only

one washer and nut, in a vise.

2. On other end of shaft, rotate nut counter–clockwise.

Remove nut.

Caution

The blades are extremely sharp and may have

burrs that will cut your hands.

Use caution when removing the blades from the

shaft.

3. Remove small spacer, washer, blades and large spacers.

Clean and lubricate hex shaft with a light coating of

grease to simplify assembly.

Important Do not invert verticutter reel blades. The

order of disassembly is extremely important. Do not

invert verticutter reel blades when disassembling or

reverse the order when assembling. Note the verticutter

blades index hole. The index hole is provided for

assembly in order to obtain the proper helix for the

verticutter reel.

1. First, assemble a reel blade (Fig. 11).

2. Next, assemble a large spacer.

3. Do not invert reel blades when reassembling on reel

shaft. If the blades are inverted, the blades that are in

use, (rounded) will be mixed with the sharp ends of the

blades which were not in use. This will cause

unsatisfactory performance in the verticutter reel unit.

Attention should always be taken when disassembling

verticutter blades from reel.

4. Install the next blade clockwise

hole (Fig. 12) is not aligned with the first blade hole by

one flat of the shaft. Continue to install spacers and

blades in this manner until the full complement of

blades have been installed. When properly assembled,

the blades will be staggered in such a manner to give a

helix appearance.

so the index reference

1. Shaft

2. Nut

3. Washer

This end in vise

6

5

4

3

Figure 11

4. Small spacer

5. Blade (16)

6. Large spacer (15)

1

1

Figure 12

1. Index reference hole

5. Install small spacer to shaft.

6. Apply Blue Loctite #242 to nut. Install nut onto shaft,

(machined side of nut toward spacer) and tighten to

80 –100 ft–lb.

2

9

Page 10

10

Page 11

Page 12

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly warrant your Toro

Commercial Product (“Product”) to be free from defects in

materials or workmanship for two years or 1500 operational

hours*, whichever occurs first. Where a warrantable condition

exists, we will repair the Product at no cost to you including

diagnosis, labor, parts, and transportation. This warranty begins

on the date the Product is delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists.

If you need help locating a Commercial Products Distributor or

Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: commercial.service@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your operator’s manual. Failure

to perform required maintenance and adjustments can be grounds

for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in an

abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up,

during normal Product operation include, but are not limited to,

blades, reels, bedknives, tines, spark plugs, castor wheels,

tires, filters, belts, and certain sprayer components such as

diaphragms, nozzles, and check valves, etc.

• Failures caused by outside influence. Items considered to be

outside influence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, or chemicals, etc.

• Normal “wear and tear” items. Normal “wear and tear” includes,

but is not limited to, damage to seats due to wear or abrasion,

worn painted surfaces, scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are

warranted for the period of time up to the scheduled replacement

time for that part.

Parts replaced under this warranty become the property of Toro.

Toro will make the final decision whether to repair any existing part

or assembly or replace it. Toro may use factory remanufactured

parts rather than new parts for some warranty repairs.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with the use of the Toro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note regarding engine warranty: The Emissions Control System

on your Product may be covered by a separate warranty meeting

requirements established by the U.S. Environmental Protection

Agency (EPA) and/or the California Air Resources Board (CARB).

The hour limitations set forth above do not apply to the Emissions

Control System Warranty. Refer to the Engine Emission Control

Warranty Statement printed in your operator’s manual or contained in the engine manufacturer’s documentation for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0031 Rev. C

Loading...

Loading...