Toro 03634, 03635, reelmaster 5210 series, reelmaster 5410 series, reelmaster 5010-h series Operator's Manual

Page 1

FormNo.3392-633RevA

8and11-BladeDPACuttingUnit

with5inReel

Reelmaster

®

5010-H/5210/5410Series

TractionUnit

ModelNo.03634—SerialNo.315000001andUp

ModelNo.03635—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3392-633*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheDeclarationofIncorporation(DOI)

atthebackofthispublication.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Thisreel-bladelawnmowerismountedtoaride-onmachine

andisintendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedforcutting

grassonwell-maintainedlawnsinparks,golfcourses,sports

elds,andoncommercialgrounds.Itisnotdesignedfor

cuttingbrush,mowinggrassandothergrowthalongside

highways,orforagriculturaluses.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

SafetyandInstructionalDecals.................................3

Setup............................................................................4

1InspectingtheCuttingUnit....................................4

2CuttingUnitKickstand..........................................4

3AdjustingtheRearShield.......................................4

4InstallingtheLooseParts.......................................5

ProductOverview..........................................................7

Specications.........................................................7

CuttingUnitAccessoriesandKits(seeparts

catalogforpartnumbers)......................................7

Operation.....................................................................8

MakingAdjustments................................................8

Height-of-CutChartTerms.....................................10

Height-of-CutChart...............................................11

ServicingtheBedknife............................................15

Maintenance.................................................................16

Lubrication............................................................16

ServicingtheBedbar...............................................16

ServicingtheRoller.................................................18

1.Locationofthemodelandserialnumbers

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.Toreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitoperatorsmanualbeforeoperatingthe

cuttingunit.

•Read,understand,andfollowallinstructionsinthis

Operator’sManualbeforeoperatingthecuttingunit.

•Neverallowchildrentooperatethetractionunitor

cuttingunits.Donotallowadultstooperatetractionunit

orcuttingunitswithoutproperinstruction.Onlytrained

operatorswhohavereadthismanualshouldoperatethe

cuttingunits.

•Neveroperatethecuttingunitswhenundertheinuence

ofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,

safetydeviceordecalisillegibleordamaged,repairor

replaceitbeforeoperationiscommenced.Alsotighten

anyloosenuts,bolts,andscrewstoensurecuttingunitis

insafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperatecutting

unitswhilewearingsandals,tennisshoes,sneakersor

shorts.Also,donotwearloosettingclothingwhich

couldgetcaughtinmovingparts.Alwayswearlongpants

andsubstantialshoes.Wearingsafetyglasses,safetyshoes

andahelmetisadvisableandrequiredbysomelocal

ordinancesandinsuranceregulations.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbythecuttingunitreelblades.Keepall

bystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

cuttingunitfordamagedparts.Repairanydamagebefore

restartingandoperatingthecuttingunit.

•Lowerthecuttingunitstothegroundandremovekey

fromignitionswitchwhenevermachineisleftunattended.

•Besurecuttingunitsareinsafeoperatingconditionby

keepingnuts,boltsandscrewstight.

•Removekeyfromignitionswitchtopreventaccidental

startingoftheenginewhenservicing,adjustingorstoring

themachine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedT oroDistributor.

•Toensureoptimumperformanceandsafety ,always

purchasegenuineTororeplacementpartsandaccessories.

Donotuse"will-t"replacementpartsand

accessoriesmadebyothermanufacturers.Lookfor

theT orologotoassuregenuineness.Usingunapproved

replacementpartsandaccessoriescouldvoidthewarranty

ofTheToroCompany.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93–6688

1.Warning—readthe

Operator’sManualbefore

performingmaintenance.

2.Cuttinghazardofhandor

foot—stoptheengineand

waitforallmovingpartsto

stop.

3

Page 4

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Cuttingunit

Nopartsrequired

Nopartsrequired

Straightgreasetting

O-ring

MediaandAdditionalParts

Description

PartsCatalog

Operator'sManual

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

InspectingtheCuttingUnit

Qty.

Qty.

1Inspectthecuttingunit.

–

–

1

1

1

1

Reviewthematerialandsaveinanappropriateplace:

Usethekickstandwhentippingthe

cuttingunit.

Adjusttherearshield.

Installthelooseparts.

Use

Use

2

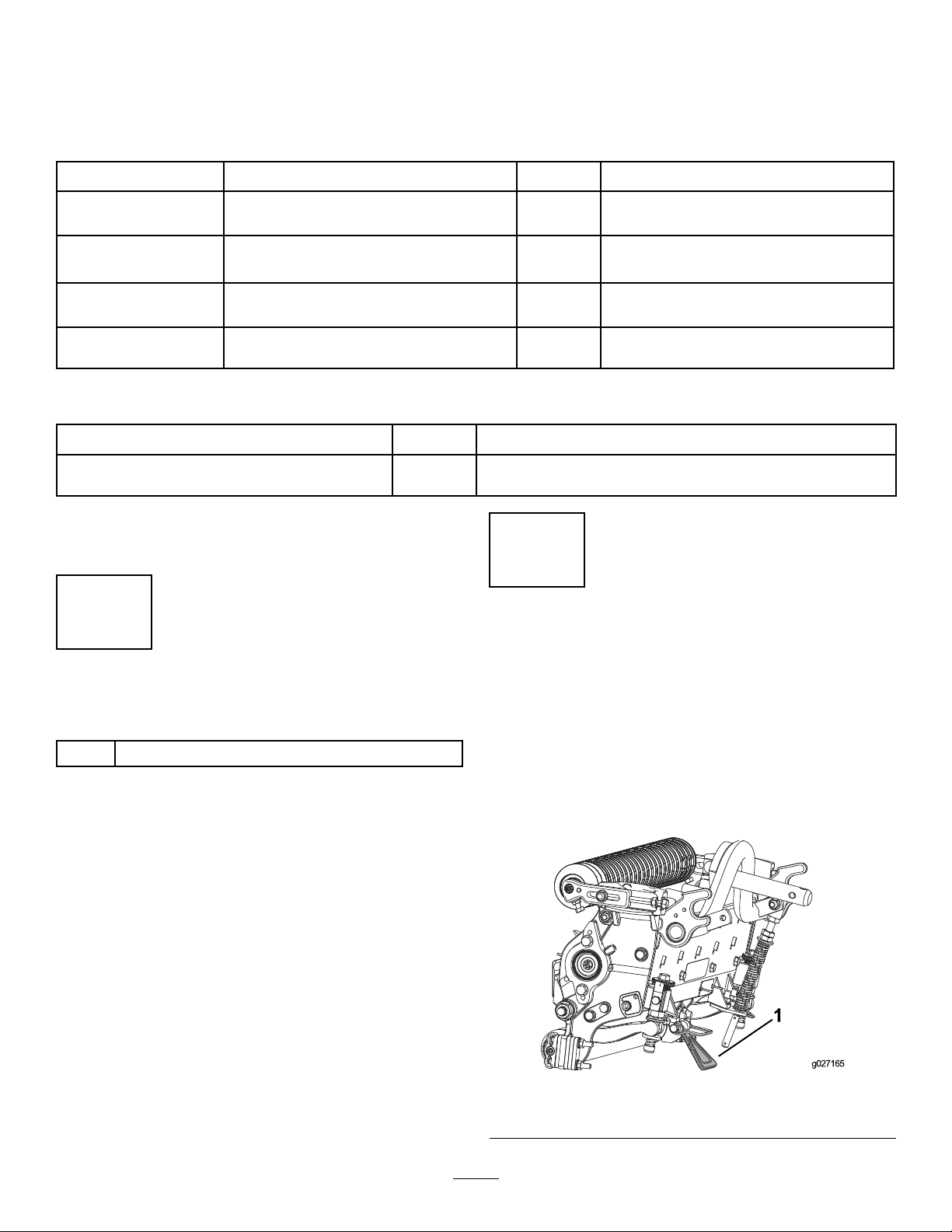

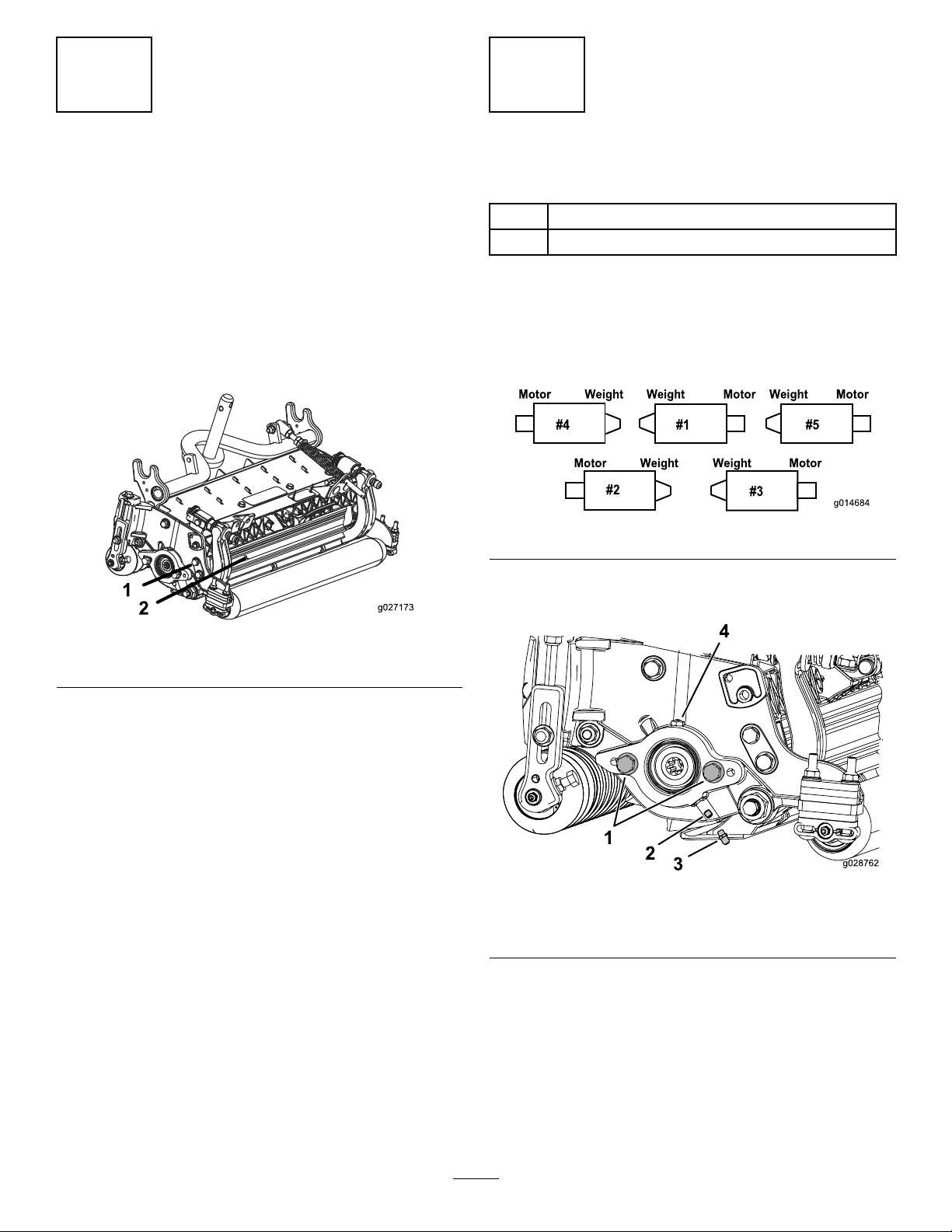

CuttingUnitKickstand

NoPartsRequired

Partsneededforthisprocedure:

1

Cuttingunit

Procedure

Afterthecuttingunitisremovedfromthebox,inspectthe

following:

1.Checkeachendofthereelforgrease.

Note:Greaseshouldbevisiblyevidentintheinternal

splinesofthereelshaft.

2.Ensurethatallnutsandboltsaresecurelytightened.

3.Makesurethatthecarrierframesuspensionoperates

freelyanddoesnotbindwhenmovedbackandforth.

Procedure

Wheneverthecuttingunithastobetippedtoexposethe

bedknife/reel,propuptherearofthecuttingunitwiththe

kickstand(suppliedwiththetractionunit)tomakesurethat

thenutsonthebackendofthebedbaradjustingscrewsare

notrestingontheworksurface(Figure3).

Figure3

1.Cuttingunitkickstand

4

Page 5

3

4

AdjustingtheRearShield

NoPartsRequired

Procedure

Undermostconditions,bestdispersionisattainedwhenthe

rearshieldisclosed(frontdischarge).Whenconditionsare

heavyorwet,rearshieldmaybeopened.

Toopentherearshield(Figure4),loosenthecapscrew

securingtheshieldtotheleftsideplate,rotatetheshieldto

theopenpositionandtightenthecapscrew.

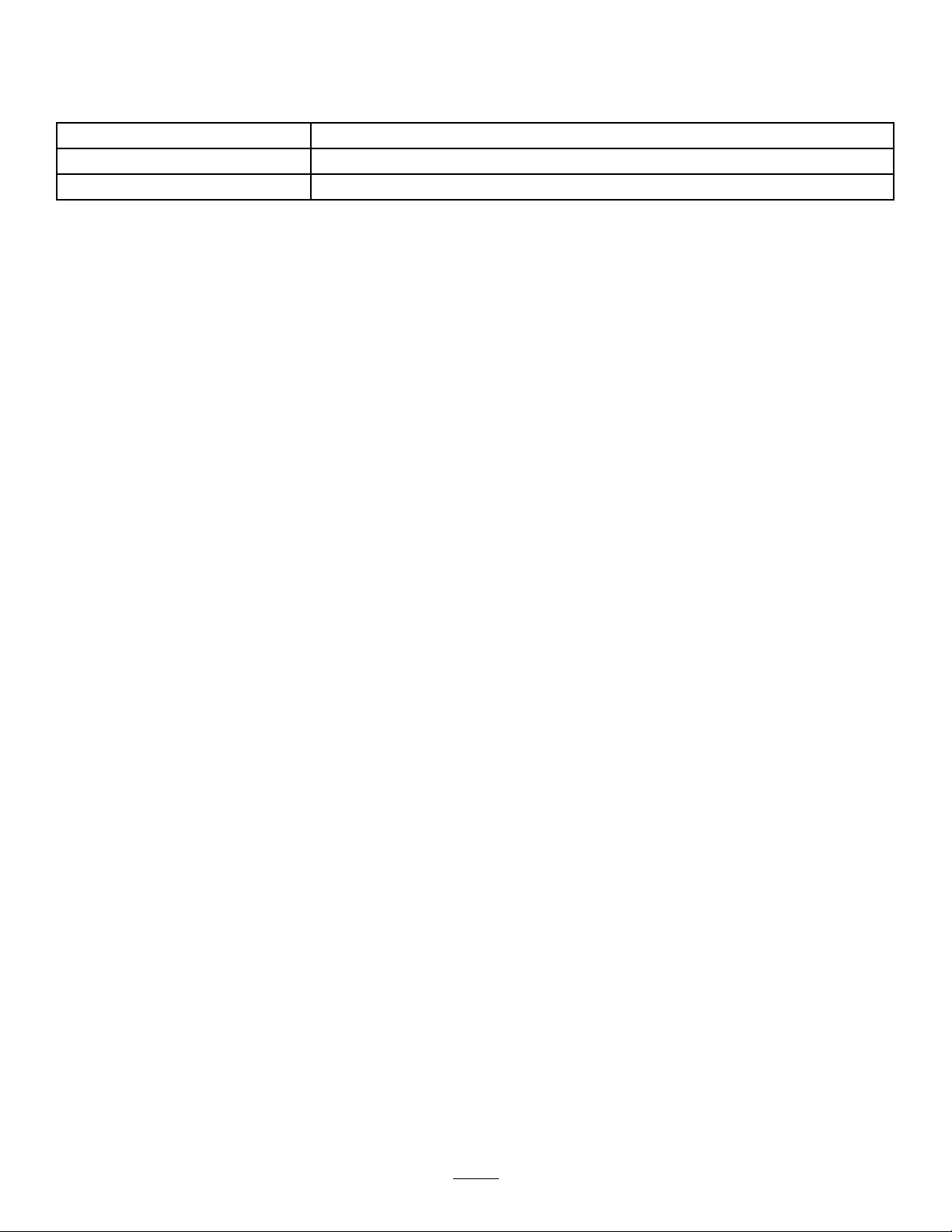

InstallingtheLooseParts

Partsneededforthisprocedure:

1

Straightgreasetting

1

O-ring

Procedure

Thegreasettingsmustbeinstalledonthereelmotorsideof

thecuttingunit.Usethefollowingdiagramtodeterminethe

positionofthereelmotors.

Figure5

1.Removeanddiscardthesetscrewonthereel-motor

side-plate(Figure6).

1.Capscrew

Figure4

2.Rearshield

Figure6

1.Capscrew(2)3.Greasetting

2.Setscrew4.Greasevent

2.Installthestraightgreasetting(Figure6).

3.Iftherearenocapscrewsonthereel-motorside-plate,

installthem(Figure6).

4.InstalltheO-ringonthereelmotor(Figure7).

5

Page 6

Figure7

1.O-ring

5.Installthereelmotor,andgreasethesideplateuntil

excessgreasepoursoutofthegreasevent(Figure6).

6

Page 7

ProductOverview

Specications

ModelNumberNetWeight

03634

03635

41kg(90lb)

42kg(93lb)

CuttingUnitAccessoriesandKits(see partscatalogforpartnumbers)

Note:Allaccessoriesandkitsare1percuttingunitunless

otherwisespecied.

BroomerKit:Multiplebrushstripswovenintothehelical

groomerbladesimprovetheeffectivenessofthegroomerkit.

Performanceofthegroomerisenhancedbyenablingafull

width"Brooming"effectofturfwhileopeningupthecanopy

forbettergrassclippingintegration.Thecombinationof

groomerandbroomersystemsoptimizethequalityofcutand

after-cutappearanceformoreconsistentplayingconditions.

CollarKit(6neededperroller):Reducesover-lapmarks

forwarmseasongrasses(Bermuda,Zoysia,Paspalum).This

kitisinstalledontheouter3groovesoftheexistingWiehle

roller,butisnotasaggressiveastheShoulderroller.

Comb/ScraperKit:Axedcombinstalledbehindthefront

rollerwhichhelpsreducegrainandspongyturfbystanding

upthegrassbeforecutting.AscraperforthefrontWiehle

rollerisincludedinthekit.

FullFrontRoller:Producesamorepronouncedstriping

(repeatedcuttinginthesamedirection/path).Effective

height-of-cutisraisedandthequalityofthecutisreduced.

GrassBasketKit:Aseriesofclippingcollectionbaskets

attachedtothefrontofthecuttingunitstocollectgrass

clippings.

GroomerKit:Rotatingbladesassembledbehindthefront

rollerwhichprovidethebestmethodforreducinggrainand

spongyturfbystandingupthegrassbeforecutting.The

groomeralsoknocksoffanydewfordecreasedstickiness

andclumping.Thiskitopensupthecanopyforbettergrass

clippingintegration,andliftsgrassforacleancrispcut.The

overalldesignimprovesthequalityofcutforhealthierturf

grasswhileimprovingtheaftercutappearance.

HighHOCKit:Newfrontrollerbracketsandadditional

spacersfortherearrollerallowsthecuttingunittoachieve

heightsofcutabove5mm(1.00inch).Thenewfrontroller

bracketsalsomovesthefrontrolleroutfarthertoimprove

after-cutappearanceattheseheightsofcut.

LongRearRoller:Helpsreduceover-lapmarksand

mismatchbetweencuttingunitsforwarmseasongrasses

(Bermuda,Zoysia,Paspalum).

RearLiftCylinderKit:Collarsassembledontherearcutting

unitliftarmcylinderstolimittheheightofthecuttingunits.

Thisincreasestheareaforthereargrassbaskets.

RearRollerBrushKit:Ahigh-speed,high-contactbrush

thatkeepstherearrollerfreeofgrassanddebris,which

maintainsaconsistentheightofcutandpreventsclumping.

Thisleadstoabetterafter-cutappearance.

RollerRebuildKit:Includesallthebearings,bearingnuts,

innerseals,andoutersealsrequiredtorebuildaroller.

RollerRebuildT oolKit:Includesallthetoolsand

installationinstructionsrequiredtorebuildarollerwiththe

rollerrebuildkit.

Scrapers(Wiehle,Shoulder,Rearroller,FullFront

Roller):Fixedscrapersforalloptionalrollersareavailable

forreducinggrassbuilduponrollerswhichcanaffect

height-of-cutsettings.

ShoulderRoller:Helpsreduceover-lapmarksforwarm

seasongrasses(Bermuda,Zoysia,Paspalum).

WeightKit:Includescounterweightsthatattachtothe

cuttingunitsandmaintainbalancewhenotheraccessories

arenotinuse.

7

Page 8

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

MakingAdjustments

AdjustingtheBedknifetotheReel

Usethisproceduretosetthebedknifetothereelandtocheck

theconditionofthereelandbedknifeandtheirinteraction.

Aftercompletingthisprocedure,alwaystestthecutting

unitperformanceunderyoureldconditions.Youmay

needtomakefurtheradjustmentstoobtainoptimalcutting

performance.

Important:Donotovertightenthebedknifetothereel

oryouwilldamageit.

•Afterbacklappingthecuttingunitorgrindingthereel,you

mayneedtomowwiththecuttingunitforafewminutes

andthenperformthisproceduretoadjustthebedknifeto

thereelasthereelandbedknifeadjusttoeachother.

•Youmayneedadditionaladjustmentsiftheturfis

extremelydenseoryourcuttingheightisverylow .

Youwillneedthefollowingtoolstocompletethisprocedure:

•Shim(0.002inch)

Figure9

1.Cuttingunitkickstand

4.Rotatethereelsothatabladecrossesthebedknife

approximately25mm(1inch)infromtheendofthe

bedknifeontherighthandsideofthecuttingunit.

Note:Putanidentifyingmarkonthisbladetomake

subsequentadjustmentseasier.

5.Insertthe0.05mm(0.002inch)shimbetweenthe

markedreelbladeandthebedknifeatthepointwhere

thebladecrossesthebedknife.

6.Turntherightbedbaradjusterclockwiseuntilyoufeel

lightpressure(i.e.drag)ontheshim,thenbackoffthe

bedbaradjustertwoclicksandremovetheshim.

•Cuttingperformancepaper

1.Positionthecuttingunitonaat,levelworksurface.

2.Turnthebedbaradjustingscrewscounterclockwiseto

ensurethatthebedbardoesnotcontactthereel(Figure

8).

Figure8

1.Bedbaradjustingscrew

3.Tipthemower,toexposethebedknifeandreel.

Important:Makesurethatthenutsontheback

endofthebedbaradjustingscrewsarenotresting

ontheworksurface(Figure9).

Note:Adjusting1sideofthecuttingunitaffectsthe

otherside,the2clickswillprovideclearanceforwhen

theothersideisadjusted.

Note:Ifstartingwithalargegap,bothsidesshould

initiallybedrawncloserbyalternatelytighteningthe

rightandlefthandsides.

7.Slowlyrotatethereelsothatthesamebladethatyou

checkedontherightsideiscrossingthebedknife

approximately25mm(1inch)infromtheendofthe

bedknifeonthelefthandsideofthecuttingunit.

8.Turntheleftbedbaradjusterclockwiseuntiltheshim

canbeslidthroughthereeltobedknifegapwithlight

drag.

9.Returntotherightsideandadjustasnecessarytoget

lightdragontheshimbetweenthesamebladeand

bedknife.

10.Repeatsteps8and9untiltheshimcanbeslidthrough

bothgapswithslightdrag,butoneclickinonboth

sidespreventstheshimfrompassingthroughonboth

sides.

Note:Thebedknifeisnowparalleltothereel.

Note:Thisprocedureshouldnotbeneededondaily

adjustments,butshouldbedoneaftergrindingor

disassembly.

8

Page 9

11.Fromthisposition(i.e.1clickinandshimnotpassing

through)turnthebedbaradjustersclockwise2clicks

each.

6.Securetherollerbracketandspacerstotheunderside

ofthesideplatemountingangeswiththenuts

previouslyremoved.

Note:Eachclickturnedmovesthebedknife0.018

mm(0.0007inches).Donotovertightenthe

adjustingscrews.

12.Testthecuttingperformancebyinsertingalongstrip

ofT orocuttingperformancepaperbetweenreeland

bedknife,perpendiculartothebedknife(Figure10).

Slowlyrotatethereelforward;itshouldcutthepaper.

Figure10

Note:Shouldexcessivereeldragbeevident,itwillbe

eithernecessarytobacklaporregrindthecuttingunit

toachievethesharpedgesneededforprecisioncutting.

7.Verifythatbedknife-to-reelcontactiscorrect.Tipthe

mowertoexposethefrontandrearrollersandthe

bedknife.

Note:Thepositionoftherearrollertothereel

iscontrolledbythemachiningtolerancesofthe

assembledcomponentsandparallelingisnotrequired.

Alimitedamountofadjustmentispossiblebysetting

thecuttingunitonasurfaceplateandlooseningthe

sideplatemountingcapscrews(Figure12).

Figure12

1.Sideplatemountingcapscrews

8.Adjustandtightencapscrewsandtorquethecap

screwsto37-45N-m(27-33ft-lb).

AdjustingtheRearRoller

1.Adjusttherearrollerbrackets(Figure11)tothedesired

heightofcutrangebypositioningtherequiredamount

ofspacersbelowthesideplatemountingange(Figure

11)pertheHOCChart.

Figure11

1.Spacer3.Sideplatemountingange

2.Rollerbracket

2.Raisetherearofthecuttingunitandplaceablock

underthebedknife.

3.Removethe2nutssecuringeachrollerbracketandthe

spacertoeachsideplatemountingange.

4.Lowertherollerandthescrewsfromsideplate

mountingangesandspacers.

5.Placethespacersontothescrewsonrollerbrackets.

9

Page 10

Height-of-CutChartTerms

Height-of-CutSetting(HOC)

Thedesiredheight-of-cut.

BenchSetHeight-of-Cut

Thebenchsetheight-of-cutistheheightatwhichthetop

edgeofthebedknifeissetaboveaatlevelsurfacethat

contactsthebottomofboththefrontandrearroller.

EffectiveHeight-of-Cut

Thisistheactualheightthatthegrasshasbeencut.Fora

givenbenchsetheight-of-cut,theactualheight-of-cutwill

varydependingonthetypeofgrass,timeofyear,turf,and

soilconditions.Thecuttingunitsetup(aggressivenessofcut,

rollers,bedknives,attachmentsinstalled,turfcompensation

settings,etc.)willalsoaffecttheeffectiveheightofcut.Check

theeffectiveheight-of-cutusingtheTurfEvaluator(model

04399)regularlytodeterminethedesiredbenchsetheight

ofcut.

RearSpacers

Thenumberofrearspacersdeterminestheaggressiveness

ofcutforthecuttingunit.Foragivenheightofcut,adding

spacers,belowthesideplatemountingange,increasesthe

aggressivenessofthecuttingunit.Allcuttingunitsona

givenmachinemustbesettothesameaggressivenessofcut

(Numberofrearspacers,partno.106-3925),otherwisethe

after-cutappearancecouldbenegativelyaffected(Figure13).

ChainLinks

Thelocationatwhichtheliftarmchainisattacheddetermines

therearrollerpitchangle(Figure14).

AggressivenessofCut

Aggressivenessofcuthasasignicantimpactonthe

performanceofthecuttingunit.AggressivenessofCutrefers

totheangleofthebedkniferelativetotheground(Figure13).

Thebestcuttingunitsetupisdependentonyourturf

conditionsanddesiredresults.Experiencewiththecutting

unitonyourturfwilldeterminethebestsettingtouse.

Aggressivenessofcutmaybeadjustedthroughoutthecutting

seasontoallowforvariousturfconditions.

Ingeneral,lesstonormalaggressivesettingsaremore

appropriateforwarmseasongrasses(Bermuda,paspalum,

zoysia)whilecoolseasongrasses(bent,bluegrass,rye)may

requirenormaltomoreaggressivesetups.Moreaggressive

setupscutmoregrassoffbyallowingthespinningreeltopull

moregrassupintothebedknife.

Figure14

1.Liftchain

2.U-backet

3.Bottomhole

Groomer

Thesearetherecommendedheight-of-cutsettingswhena

groomerkitisinstalledonthecuttingunit.

1.Rearspacers

2.Sideplatemountingange

Figure13

3.Aggressivenessofcut

10

Page 11

Height-of-CutChart

HOCSettingAggressivenessofCutNo.ofRearSpacersNo.ofChainLinksWithGroomerkits

0.64cm(0.250inches)

0.95cm(0.375inches)

1.27cm(0.500inches)

1.56cm(0.625inches)

1.91cm(0.750inches)

2.22cm(0.875inches)

2.54cm(1.000inch)

2.86cm(1.125inches)*

3.18cm(1.250inches)*

3.49cm(1.375inches)*

3.81cm(1.500inches)*

+IndicatestheU-bracket,onliftarm,ispositionedinthebottomhole(Figure14).

*HighHOCKit(PartNo.110-9600)mustbeinstalled.FrontHOCbracketmustbepositionedinthetopsideplatehole.

**YindicatesthatthiscombinationofHOCandspacerscanbeusedwithgroomers.

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

0

0

1

0

1

2

0

1

2

1

2

3

2

3

4

2

3

4

3

4

5

4

5

6

4

5

6

4

5

6

5

6

7

3+

3+

3

4

3

3

4

3+

3

4

3

3

3+

3

3

4

3

3

3+

3

3

4

3

3

4

3

3

4

3

3

3+

3

3

installed**

Y

Y

-

Y

Y

-

Y

Y

Y

Y

Y

-

Y

Y

-

Y

Y

-

Y

Y

-

-

-

-

-

-

-

-

-

-

-

-

-

Note:Changing1chainlinkchangestherearrollerpitchanglemovementby7.0degrees.

Note:ChangingtheU-bracketontheliftarmtothebottomholeadds3.5degreestotherearrollerpitchangle.

11

Page 12

AdjustingtheHeight-of-Cut

Note:Forheightsofcutgreaterthan2.54cm(1.000inch)

theHighHeight-of-CutKitmustbeinstalled.

1.Loosenlocknutssecuringheight-of-cutbracketsto

cuttingunitsideplates(Figure15).

Figure15

1.Adjustingscrew

2.Locknut

2.Loosennutongaugebar(Figure16)andsetadjusting

screwtodesiredheight-of-cut.

3.Height-of-cutbracket

Figure17

Important:Whensetproperly,therearandfront

rollerswillcontactthegaugebarandthescrew

willbesnugagainstthebedknife.Thisensures

thattheheight-of-cutisidenticalatbothendsof

thebedknife.

6.Tightennutstosecureadjustment.

Note:Donotovertightennut.Tightenenoughto

removeplayfromwasher.

Usethefollowingcharttodeterminewhichbedknifeis

bestsuitedforthedesiredheightofcut.

Figure16

1.Gaugebar4.Holesusedforsetting

GroomerHOG

2.Heightadjustingscrew5.Holenotused

3.Nut

3.Measurethedistancebetweenthebottomofthescrew

headandthefaceofthebartogettheheight-of-cut.

4.Hookthescrewheadoncuttingedgeofbedknifeand

restrearendofbaronrearroller(Figure17).

5.Rotatetheadjustingscrewuntilthefrontrollercontacts

thegaugebar(Figure17).Adjustbothendsofroller

untilentirerollerisparalleltothebedknife.

Bedknife/HeightofCutChart

BedknifeBedknifeLip

EdgeMax®Low

HOC(03635)

LowHOC

(Optional)

Extended

EdgeMax®Low

HOC(Optional)

ExtendedLow

HOC(Optional)

EdgeMax®

(03634)

Standard

(Optional)

HeavyDuty

(Optional)

*WarmseasongrassesmayrequiretheLowHOC

bedknifefor12.7mm(0.500inches)andbelow.

(0.220inch)

(0.220inch)

(0.220inch)

(0.220inch)

(0.270inch)

(0.270inch)

(0.370inch)

Height

5.6mm

(0.250-0.500inch)

5.6mm

(0.250-0.500inch)

5.6mm

(0.250-0.500inch)

5.6mm

(0.250-0.500inch)

6.9mm

(0.375-1.50inch)*

6.9mm

(0.375-1.50inch)*

9.3mm

(0.500-1.50inch)

HeightofCut

6.4-12.7mm

6.4-12.7mm

6.4-12.7mm

6.4-12.7mm

9.5-38.1mm

9.5-38.1mm

12.7-38.1mm

12

Page 13

Figure18

1.BedknifeLipHeight

AdjustingtheTurfCompensation

Settings

Theturfcompensationspringtransferstheweightfromthe

fronttotherearroller.(Thishelpstoreduceawavepattern

intheturf,alsoknownasmarcellingorbobbing.)

Important:Makespringadjustmentswiththecutting

unitmountedtothetractionunit,pointingstraight

aheadandloweredtotheshopoor.

1.Makesurethatthehairpincotterisinstalledintherear

holeinthespringrod(Figure19).

Thepreciseadjustmentpossiblewiththedualknob/bedbar

designgivesthenecessarycontroltoprovideacontinual

self-sharpeningaction-thusmaintainingsharpcuttingedges,

ensuringgoodquality-of-cut,andgreatlyreducingtheneed

forroutinebacklapping.

Priortomowingeachday ,orasrequired,eachcuttingunit

mustbecheckedtoverifyproperbedknife-to-reelcontact.

Thismustbeperformedeventhoughqualityofcutis

acceptable.

1.Lowerthecuttingunitsontoahardsurface,shutoff

theengine,andremovetheignitionkey.

2.Slowlyrotatethereelinareversedirection,listening

forreel-to-bedknifecontact.

Ifnocontactisevident,turnthebedknifeadjustingknobs

clockwise,oneclickatatime,untillightcontactisfeltand

heard.

Thereelmustcutonesheetofpaper,wheninsertedataright

angletothebedknife,atbothendsandatthecenterofthe

reel;refertostep12andFigure10in(page)

Theadjustmentknobshavedetentescorrespondingto0.022

mm(0.0009inch)bedknifemovementforeachindexed

position.

Figure19

1.Turfcompensationspring3.Springrod

2.Hairpincotter4.Hexnuts

2.Tightenthehexnutsonthefrontendofthespringrod

untilthecompressedlengthofthespringis15.9cm

(6.25inches)(Figure19).

Note:Whenoperatingthemachineonroughterrain,

decreasethespringlengthby12.7mm(1/2inch).

Note:Theturfcompensationsettingwillneedtobe

resetiftheHOCsettingortheaggressiveness-of-cut

settingischanged.

Ifexcessivecontact/reeldragisevidentitwillbeeither

necessarytobacklap,refacethefrontofthebedknife,or

regrindthecuttingunittoachievethesharpedgesneededfor

precisioncutting(RefertotheToroManualforSharpening

ReelandRotaryMowers).

Lightcontactispreferredatalltimes.Iflightcontactisnot

maintained,thebedknife/reeledgeswillnotsufciently

self-sharpenanddullcuttingedgeswillresultafteraperiodof

operation.Ifexcessivecontactismaintained,bedknife/reel

wearwillbeaccelerated,unevenwearcanresult,andquality

ofcutmaybeadverselyaffected.

Asthereelbladescontinuetorunagainstthebedknife,a

slightburrwillappearonthefrontcuttingedgesurfacealong

thefulllengthofthebedknife.Youcanremoveburrsand

improvecuttingbyoccasionallyrunningaleacrossthefront

edge.

Afterextendedrunning,aridgewilleventuallydevelopat

bothendsofthebedknife.Thesenotchesmustberounded

offorledushwiththecuttingedgeofthebedknifeto

ensuresmoothoperation.

Overtime,thechamfer(Figure20)willneedtobereground

asitisonlydesignedtolast40%ofthebedknifelife.

CheckingandAdjustingtheCutting

Unit

Thedualknobbedknife-to-reeladjustmentsystem

incorporatedinthiscuttingunitsimpliestheadjustment

procedureneededtodeliveroptimummowingperformance.

13

Page 14

Figure20

1.Lead-inchamferonrightendofbedknife

Donotmakelead-inchamfertoolargeasitmaycauseturf

tufting.

14

Page 15

ServicingtheBedknife

2

3

g027268

1

Thebedknifeservicelimitsarelistedinthefollowingcharts.

Important:Operatingthecuttingunitwiththebedknifebelowtheservicelimitmayresultinpoorafter-cut

appearanceandreducethestructuralintegrityofthebedknifeforimpacts.

BedknifeServiceLimitChart

Bedknife

EdgeMax®LowHOC

(model03635)

LowHOC(Optional)

ExtendedEdgeMax®

LowHOC(Optional)

ExtendedLowHOC

(Optional)

EdgeMax®

(model03634)

Standard(Optional)

HeavyDuty(Optional)

PartNo.

127–71325.6mm

110-40845.6mm

119–42805.6mm

120–16405.6mm

108-90956.9mm

108-90966.9mm

110-40749.3mm

RecommendedT opandFrontBedknifeGrindAngles

(Figure21)

BedknifeLipHeight*ServiceLimit*GrindAngles

(0.220inch)

(0.220inch)

(0.220inch)

(0.220inch)

(0.270inch)

(0.270inch)

(0.370inch)

6.4-12.7mm

(0.250-0.500inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

Top/FrontAngles

10/5Degrees

10/5Degrees

10/10Degrees

10/10Degrees

10/5Degrees

10/5Degrees

10/5Degrees

Figure21

1.Bedknifeservicelimit*

2.Topgrindangle

3.Frontgrindangle

Note:Allbedknifeservicelimitmeasurementsreferencethe

bottomofthebedknife(Figure22)

Figure22

15

Page 16

Maintenance

ServicingtheBedbar

Lubrication

Eachcuttingunithas5greasettings(Figure23)thatmustbe

lubricatedregularlywithNo.2general-purposelithium-base

grease.

Thereare2lubricationpointsonthefrontroller,rearroller,

and1atthereelmotorspline.

Note:Lubricatingcuttingunitsimmediatelyafter

washinghelpspurgewateroutofbearingsandincreases

bearinglife.

1.Wipeeachgreasettingwithacleanrag.

2.Applygreaseuntilcleangreaseisseencomingoutof

rollersealsandbearingreliefvalve.

3.Wipeexcessgreaseaway.

RemovingtheBedbar

1.Turnbedbaradjusterscrewscounterclockwisetoback

thebedknifeawayfromreel(Figure24).

Figure24

1.Bedbaradjustingscrew3.Washer

2.Bedbar

2.Backoutthespringtensionnut,untilthewasherisno

longertensionedagainstthebedbar(Figure24).

3.Oneachsideofthemachine,loosenthelocknut

securingthebedbarbolt(Figure25).

4.Springtensionnut

Figure23

Greasettinglocationsonthereelmotorside.

Figure25

1.Bedbarbolt2.Locknut

4.Removeeachbedbarboltallowingbedbartobepulled

downwardandremovedfrommachinebolt(Figure25).

Note:Accountfor2nylonand1stampedsteel

washersoneachendofbedbar(Figure26).

Figure26

1.Bedbarbolt

2.Nut4.Nylonwasher

3.Steelwasher

16

Page 17

AssemblingtheBedbar

1.Installthebedbar,positioningthemountingears

betweenthewasherandbedbaradjuster.

2.Securethebedbartoeachsideplatewiththebedbar

bolts(nutsonbolts)andthe6washers.

Note:Positionanylonwasheroneachsideoftheside

plateboss.Placeasteelwasheroutsideeachofthe

nylonwashers(Figure26).

3.Torquethebedbarboltsto37-45N-m(27–33ft-lbs).

Note:Tightenthelocknutsuntiltheoutsidesteel

washerstopsrotatingandtheendplayisremovedbut,

donotovertightenordeectthesideplates.Washers

ontheinsidemayhaveagap.

4.Tightenthespringtensionnutuntilthespringis

collapsed,thenbackoff1/2turn(Figure27).

Figure27

1.Springtensionnut2.Spring

17

Page 18

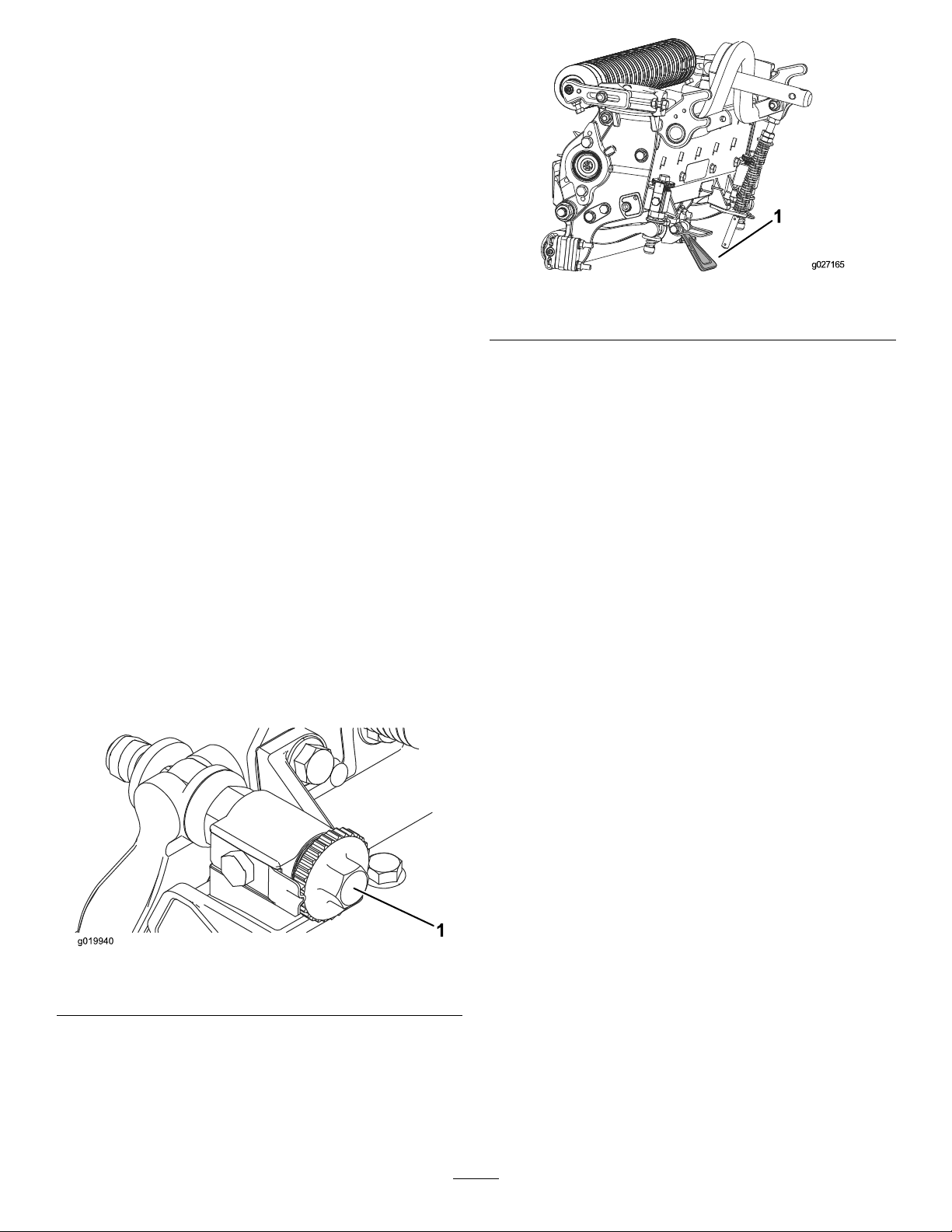

ServicingtheRoller

TherollerRebuildKitandtheRollerRebuildToolKit

(Figure28)areavailableforservicingtheroller.TheRoller

RebuildKitincludesallthebearings,bearingnuts,innerseals

andoutersealstorebuildaroller.TheRollerRebuildTool

Kitincludesallthetoolsandtheinstallationinstructions

requiredtorebuildarollerwiththerollerrebuildkit.Refer

toyourPart’sCatalogorcontactyourAuthorizedDistributor

forassistance.

Figure28

1.RollerRebuildKit(PartNo.1 14–5430)

2.RollerRebuildToolKit(PartNo.1 15–0803)

3.Innerseal8.Washer

4.Bearing

5.Outerseal

6.Bearingnut

7.Innersealtool

9.Bearing/outersealtool

18

Page 19

Notes:

19

Page 20

Notes:

20

Page 21

Notes:

21

Page 22

DeclarationofIncorporation

TheT oroCompany,81 11LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

03634315000001andUp

03695315000001andUp

SerialNo.

ProductDescriptionInvoiceDescription

8-BladeDPACuttingUnit

with5inReel,Reelmaster

5010-H/5210/5410Series

TractionUnit

11-BladeDP ACuttingUnit

with5inReel,Reelmaster

5010-H/5210/5410Series

TractionUnit

22IN5-IN8-BLDDPACU

[5010HYBRID]

22IN5-IN11-BLDDPACU

[5010HYBRID]

GeneralDescription

CuttingUnit2006/42/EC

CuttingUnit2006/42/EC

Directive

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

PeterT etteroo

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

May29,2012

Fax003214581911

22

Page 23

InternationalDistributorList

Distributor:

AgrolancKft

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260ToroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India0091442449

JeanHeybroekb.v.Netherlands3130639461 1VictusEmakPoland48618238369

Country:

Hungary3627539640

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Estonia3723846060

Japan81726325861

Turkey902163365993Riversa

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

5062391138

94112746100

442890813121

5024423277

30109350054

862087651338

4635100000

4387

Country:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGarden

Ab

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

ValtechMorocco21253766

Japan81332522285

Argentina54114821

Russia74954116120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France331308177

India911292299901

Phone

Number:

5712364079

420255704

220

420255704

220

9999

128

34952837500

00

35722434131

3636

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0269RevH

Page 24

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser .

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevC

Loading...

Loading...