Page 1

FormNo.3397-860RevB

22-inch8-Bladeor11-BladeDPA

CuttingUnitwith5inReel

Reelmaster

ModelNo.03621—SerialNo.315000001andUp

ModelNo.03623—SerialNo.315000001andUp

®

5010SeriesTractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3397-860*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheDeclarationofIncorporation(DOI)

atthebackofthispublication.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

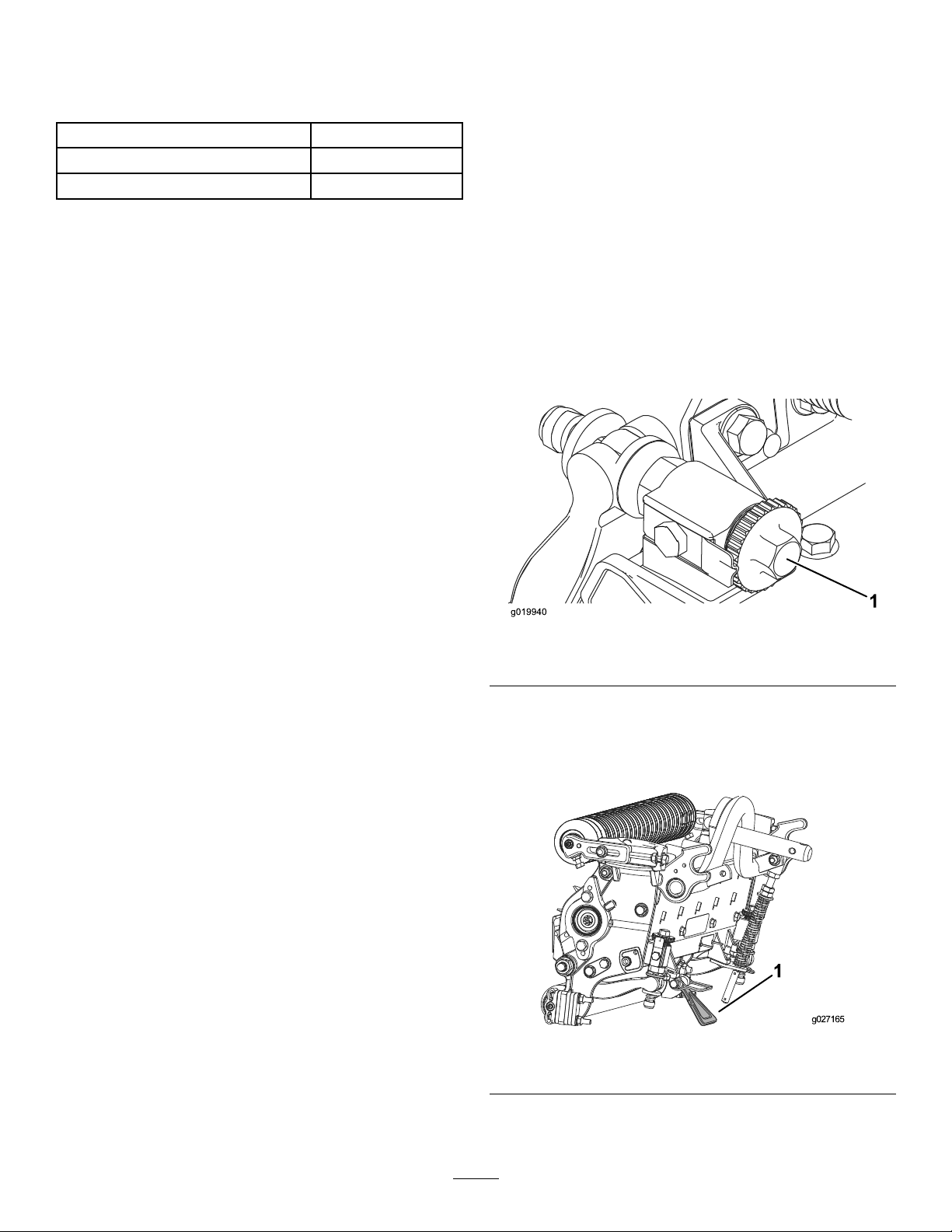

Figure2

1.Safety-alertsymbol

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................3

SafetyandInstructionalDecals.................................3

Setup............................................................................4

1InspectingtheCuttingUnit....................................4

2UsingtheCutting-UnitKickstand...........................4

3AdjustingtheRearShield.......................................5

4InstallingtheLooseParts.......................................5

ProductOverview..........................................................7

Specications.........................................................7

Attachments/Accessories.........................................7

Operation.....................................................................7

MakingAdjustments................................................7

Height-of-CutChartTerms......................................9

Height-of-CutChart...............................................10

Maintenance.................................................................14

LubricatingtheMachine..........................................14

Relief-GrindingtheReel..........................................14

ServicingtheBedknife............................................15

ServicingtheBedbar...............................................16

ServicingtheHDDualPointAdjusters

(DPA)...............................................................17

ServicingtheRoller.................................................19

1.Locationofthemodelandserialnumbers

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013andANSIB71.4-2012.

Improperuseormaintenanceofthisequipmentcan

resultininjuryordeath.T oreducethepotentialfor

injuryordeath,complywiththefollowingsafety

instructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitOperator’sManualbeforeoperatingthecutting

unit.

•Read,understand,andfollowallinstructionsinthis

Operator’sManualbeforeoperatingthecuttingunit.

•Neverallowchildrenoruntrainedpersonneltooperate

orservicethemachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Neveroperatethecuttingunitswhensick,tired,orunder

theinuenceofdrugsoralcohol.

•Keepallshieldsandsafetydevicesinplace.Ifashield,a

safetydevice,oradecalisillegibleordamaged,repairor

replaceitbeforeresumingoperation.Also,tightenany

loosenuts,bolts,andscrewstoensurethatthecutting

unitisinsafeoperatingcondition.

•Removealldebrisorotherobjectsthatmightbepicked

upandthrownbythereelbladesofthecuttingunit.Keep

allbystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.Check

thecuttingunitfordamagedparts.Repairanydamage

beforestartingandoperatingthecuttingunit.

•Lowerthecuttingunitstothegroundandremovethekey

fromtheignitionswitchwheneveryouleavethemachine

unattended.

•Besurethatthecuttingunitsareinsafeoperating

conditionbykeepingnuts,bolts,andscrewstight.

•Removethekeyfromtheswitchtopreventaccidental

startingoftheenginewhenservicing,adjusting,orstoring

themachine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Ifmajorrepairsareeverneededorassistance

isdesired,contactanAuthorizedT oroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

•Wearappropriateclothing,includingsafetyglasses,

slip-resistant,substantialfootprotection,andhearing

protection.Tiebacklonghairanddonotwearjewelry.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93–6688

1.Warning—readthe

Operator’sManualbefore

performingmaintenance.

2.Cuttinghazardofhandor

foot—stoptheengineand

waitforallmovingpartsto

stop.

3

Page 4

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Cuttingunit

Nopartsrequired

Nopartsrequired

Straightgreasetting

O-ring

Screws

MediaandAdditionalParts

Description

PartsCatalog

Operator'sManual

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Qty.

Qty.

1Inspectthecuttingunit.

–

–

1

1

2

1

1

Reviewthesematerialsandsavethemforfuturereference.

Usethekickstandwhentippingthe

cuttingunit.

Adjusttherearshield.

Installthelooseparts.

Use

Use

2

1

InspectingtheCuttingUnit

Partsneededforthisprocedure:

1

Cuttingunit

Procedure

Afteryouremovethecuttingunitfromthebox,inspectthe

following:

1.Checkeachendofthereelforgrease.

Note:Greaseshouldbevisiblyevidentinthereel

bearingsandinternalsplinesofthereelshaft.

2.Ensurethatallnutsandboltsaresecurelytightened.

3.Makesurethatthecarrier-framesuspensionoperates

freelyanddoesnotbindwhenyoumoveitbackand

forth.

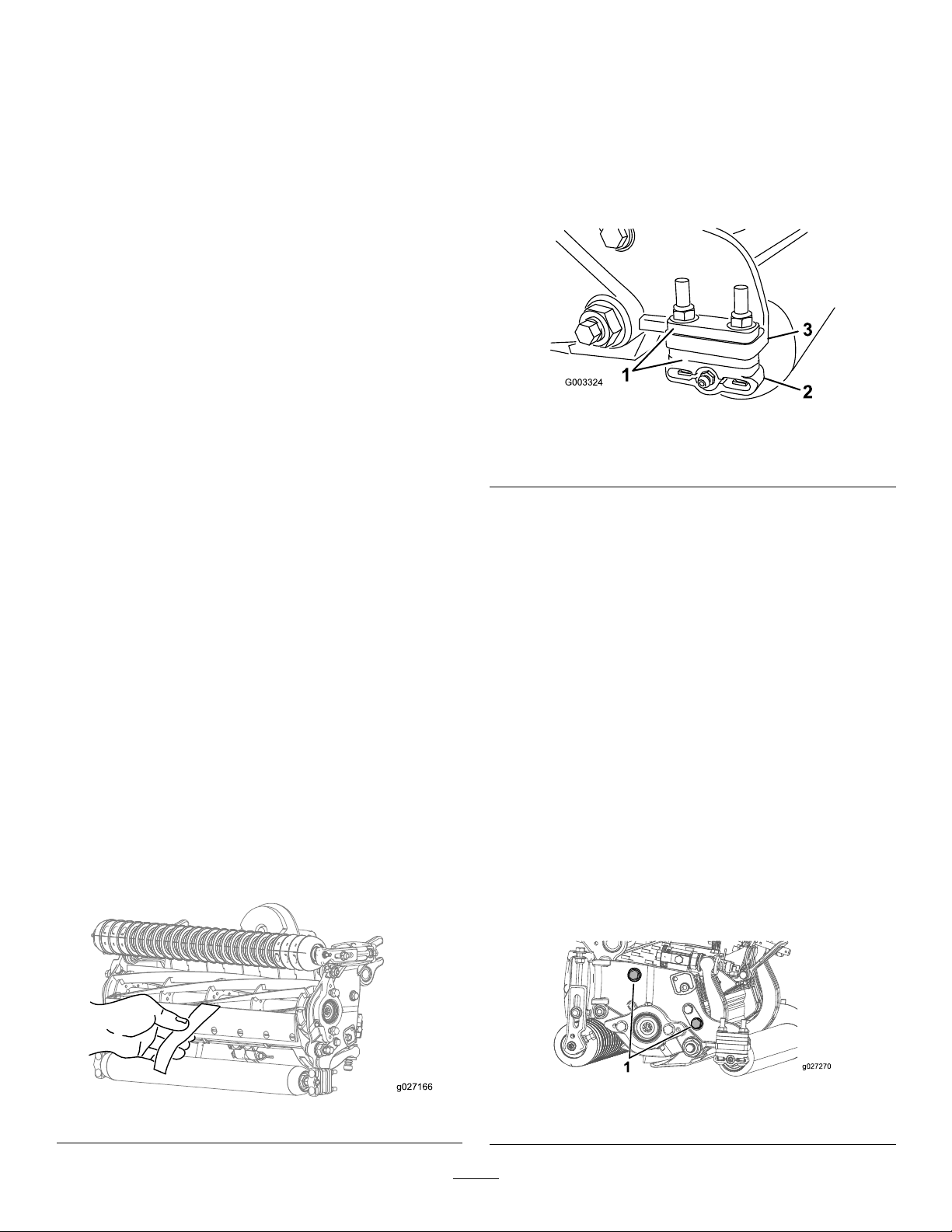

UsingtheCutting-Unit Kickstand

NoPartsRequired

Procedure

Wheneverthecuttingunithastobetippedtoexposethe

bedknifeorthereel,propuptherearofthecuttingunitwith

thekickstand(suppliedwiththetractionunit)tomakesure

thatthenutsonthebackendofthebedbar-adjustingscrews

arenotrestingontheworksurface(Figure3).

4

Page 5

Figure3

4

InstallingtheLooseParts

Partsneededforthisprocedure:

1

Straightgreasetting

1

O-ring

2

Screws

1.Cutting-unitkickstand

3

AdjustingtheRearShield

NoPartsRequired

Procedure

Undermostconditions,bestdispersionisattainedwhenthe

rearshieldisclosed(frontdischarge).Whenconditionsare

heavyorwet,youcanopentherearshield.

Toopentherearshield(Figure4),loosenthecapscrew

securingtheshieldtotheleftsideplate,rotatetheshieldto

theopenposition,andtightenthecapscrew.

Procedure

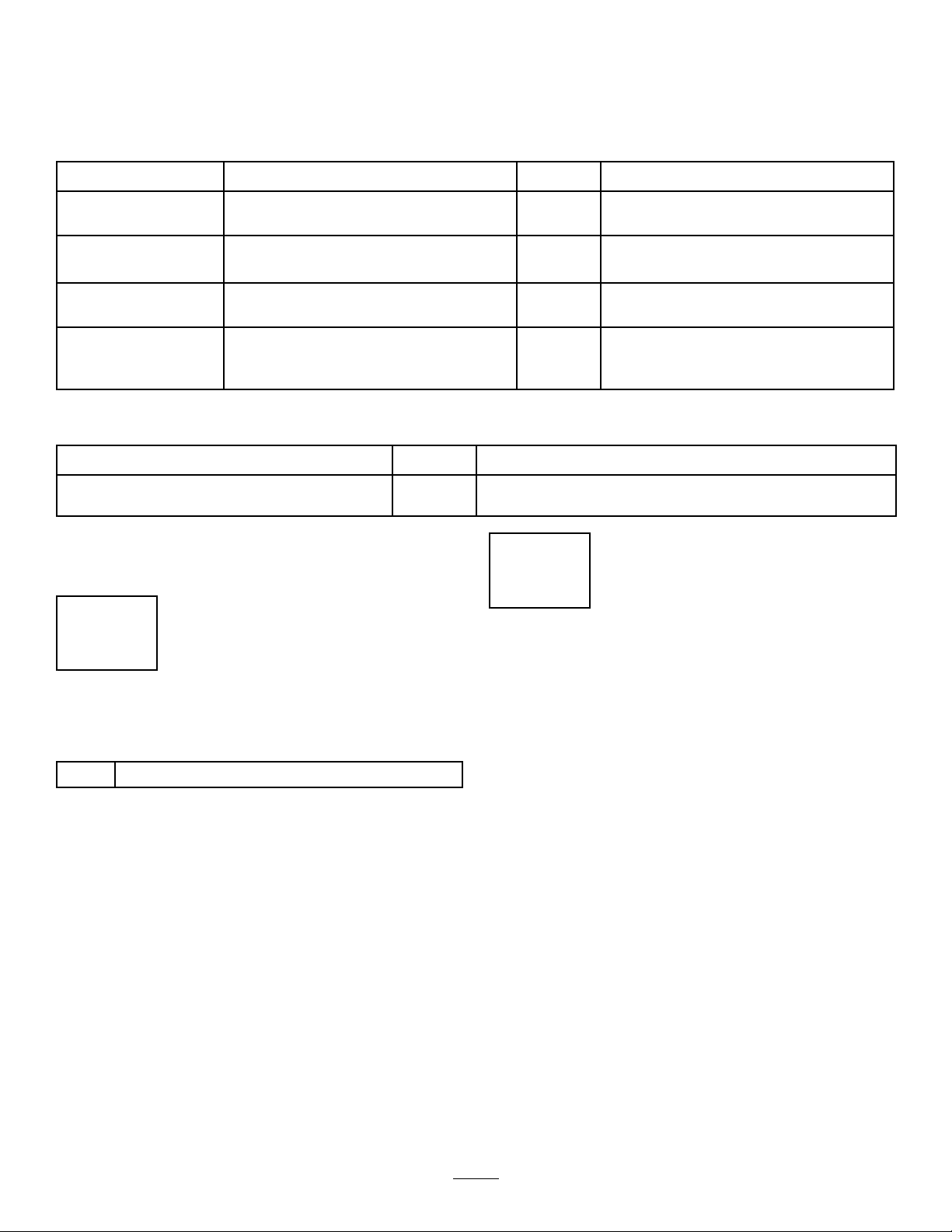

Installthegreasettingonthereel-motorsideofthecutting

unit.UseFigure5todeterminethepositionofthereel

motors.

Figure5

1.Cuttingunit15.Cuttingunit5

2.Cuttingunit2

3.Cuttingunit3

4.Cuttingunit4

1.Removeanddiscardthesetscrewonthereel-motor

sideplate(Figure6).

6.Reelmotor

7.Weight

1.Rearshield

Figure4

2.Capscrew

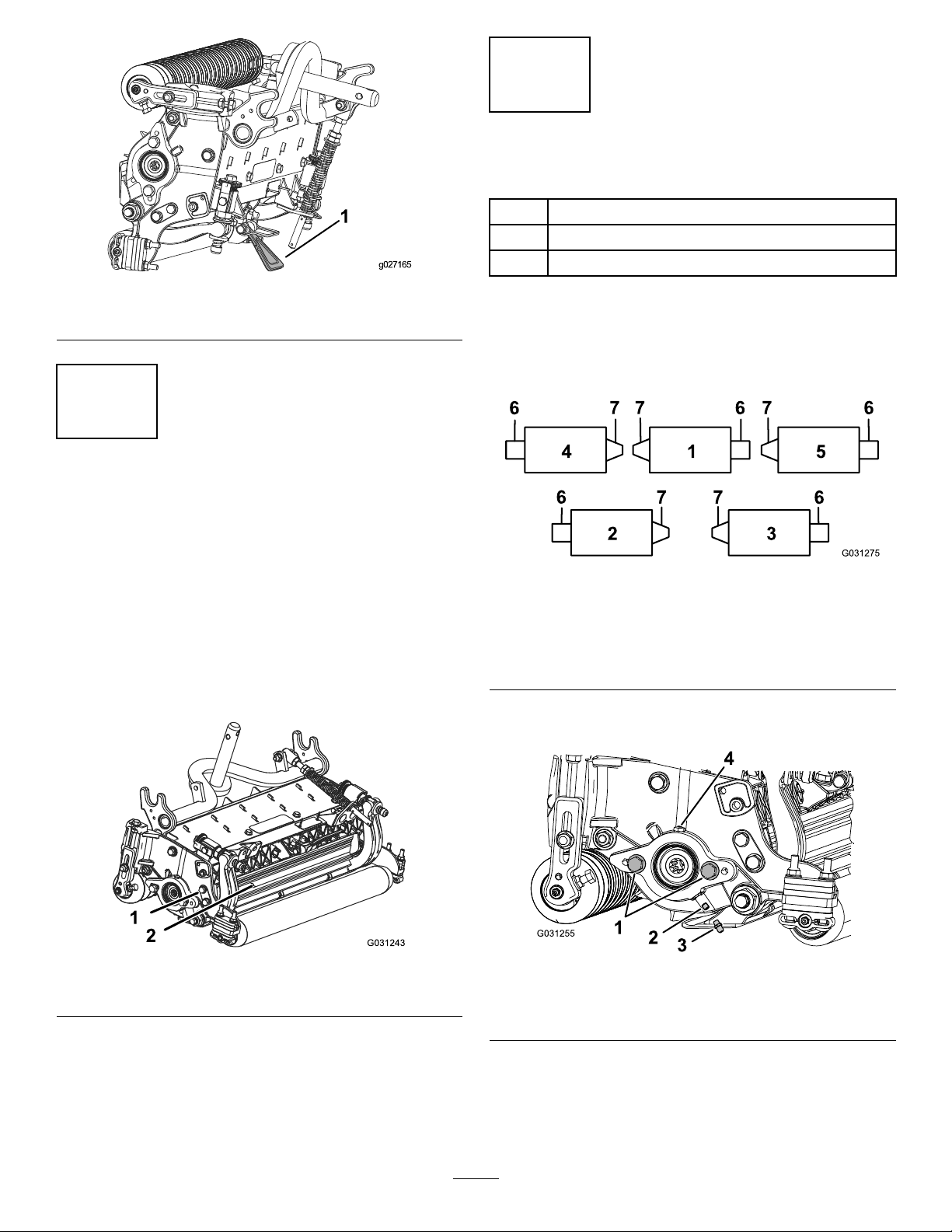

Figure6

1.Bolt(2)3.Greasetting

2.Setscrew4.Greasevent

2.Installthestraightgreasetting(Figure6).

3.Iftherearenoboltsonthereel-motorsideplate,install

them(Figure6).

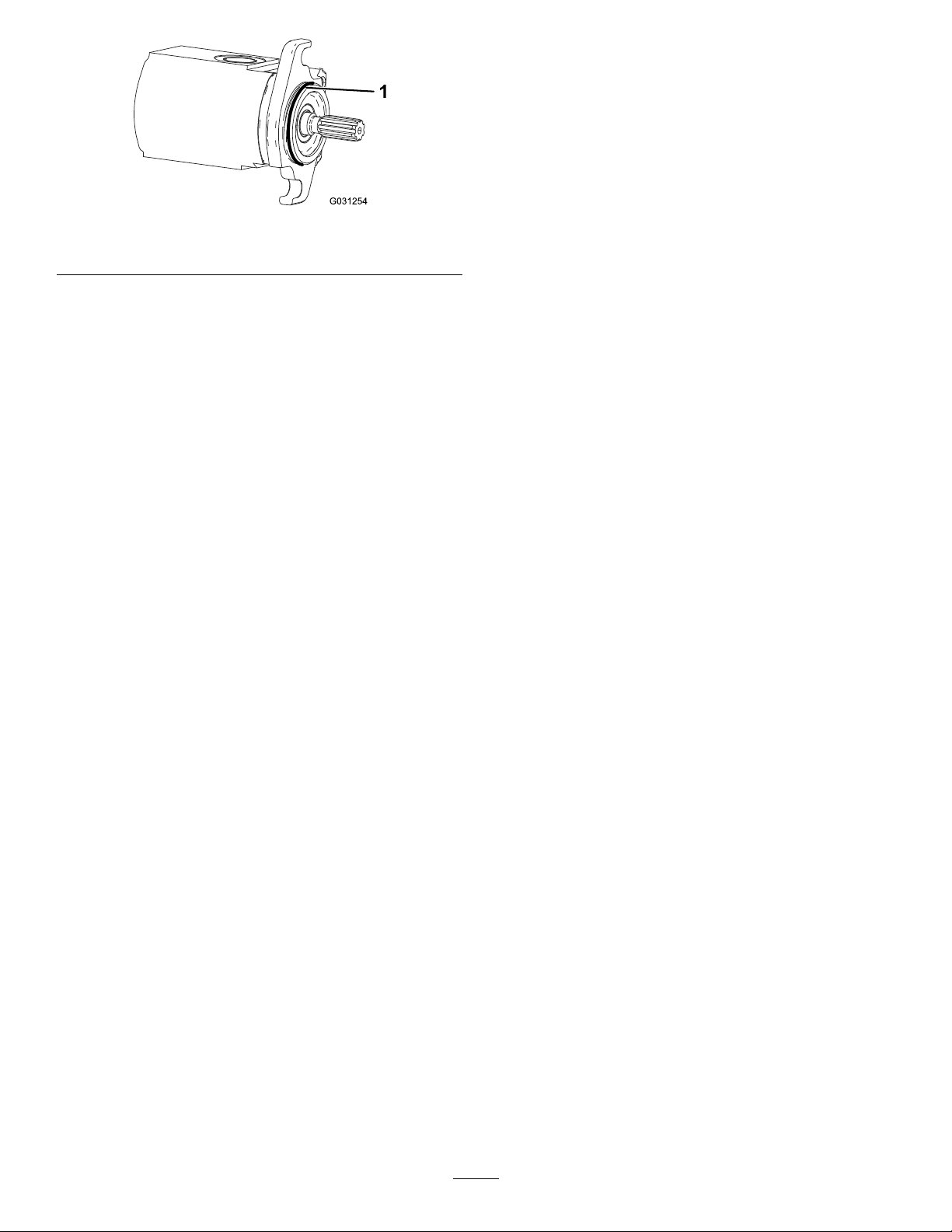

4.InstalltheO-ringonthereelmotor(Figure7).

5

Page 6

Figure7

1.O-ring

5.Installthereelmotor.

6.Greasethesideplateuntilexcessgreasecomesoutthe

greasevent(Figure6).

6

Page 7

ProductOverview

Specications

ModelNumberNetWeight

03621

03623

Attachments/Accessories

AselectionofToro-approvedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories

TobestprotectyourinvestmentandmaintainoptimalperformanceofyourToroequipment,countonTorogenuineparts.

Whenitcomestoreliability,Torodeliversreplacementpartsdesignedtotheexactengineeringspecicationofourequipment.

Forpeaceofmind,insistonT orogenuineparts.

51kg(1 12lb)

52kg(1 16lb)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

MakingAdjustments

AdjustingtheBedknifetotheReel

Usethisproceduretosetthebedknifetothereelandtocheck

theconditionofthereelandbedknifeandtheirinteraction.

Aftercompletingthisprocedure,alwaystestthecutting

unitperformanceunderyoureldconditions.Youmay

needtomakefurtheradjustmentstoobtainoptimalcutting

performance.

Important:Donotovertightenthebedknifetothereel

oryouwilldamageit.

•Afterbacklappingthecuttingunitorgrindingthereel,you

mayneedtomowwiththecuttingunitforafewminutes

andthenperformthisproceduretoadjustthebedknifeto

thereelasthereelandbedknifeadjusttoeachother.

•Youmayneedadditionaladjustmentsiftheturfis

extremelydenseoryourcuttingheightisverylow .

Youwillneedthefollowingtoolstocompletethisprocedure:

•Shim(0.002inch)—ToroPartNo.125-5611

•Cuttingperformancepaper—ToroPartNo.125-5610

Figure8

1.Bedbar-adjustingscrew

2.Tipthemowertoexposethebedknifeandreel.

Important:Makesurethatthenutsontheback

endofthebedbaradjustingscrewsarenotresting

ontheworksurface(Figure9).

1.Positionthecuttingunitonaat,levelworksurface.

Turnthebedbar-adjustingscrewscounterclockwiseto

ensurethatthebedbardoesnotcontactthereel(Figure

8).

Figure9

1.Cutting-unitkickstand

3.Rotatethereelsothatabladecrossesthebedknife

approximately25mm(1inch)infromtheendofthe

7

Page 8

bedknifeontherightsideofthecuttingunit.Putting

g027270

anidentifyingmarkonthisbladewillmakesubsequent

adjustmentseasier.Insertthe0.05mm(0.002inch)

shimbetweenthemarkedreelbladeandthebedknife

atthepointwherethebladecrossesthebedknife.

4.Turntherightbedbaradjusterclockwiseuntilyoufeel

lightpressure(i.e.,drag)ontheshim,thenbackoffthe

bedbaradjuster2clicksandremovetheshim.(Since

adjusting1sideofthecuttingunitaffectstheother

side,the2clicksprovidetheclearancethatyouneed

forwhenyouadjusttheotherside.)

Note:Ifthereisalargegap,drawbothsidescloserby

alternatelytighteningtherightandleftsides.

5.Slowlyrotatethereelsothatthesamebladethatyou

checkedontherightsideiscrossingthebedknife

approximately25mm(1inch)infromtheendofthe

bedknifeontheleftsideofthecuttingunit.

Note:Ifthereisexcessivereeldrag,eitherbacklap

orgrindthecuttingunittoachievethesharpedges

neededforprecisioncutting.

AdjustingtheRearRoller

1.Adjusttherearrollerbrackets(Figure11)tothedesired

height-of-cutrangebypositioningtherequiredamount

ofspacersbelowtheside-platemountingange(Figure

11)pertheHOCChart.

6.Turntheleftbedbaradjusterclockwiseuntilyoucan

slidetheshimthroughthereeltobedknifegapwith

lightdrag.

7.Returntotherightsideandadjustasnecessarytoget

lightdragontheshimbetweenthesamebladeand

bedknife.

8.Repeatsteps6and7untilyoucanslidetheshim

throughbothgapswithslightdrag,but1clickinon

bothsidespreventstheshimfrompassingthroughon

bothsides.Thebedknifeisnowparalleltothereel.

Note:Y oushouldnotneedtoperformthisprocedure

fordailyadjustments,butaftergrindingordisassembly.

9.Fromthisposition(i.e.,1clickinandashimnot

passingthrough)turnthebedbaradjustersclockwise2

clickseach.

Note:Eachclickturnedmovesthebedknife0.018

(0.0007inch).Donotovertightentheadjusting

screws.

10.Testthecuttingperformancebyinsertingalongstripof

cuttingperformancepaper(ToroPartNo.125-5610)

betweenthereelandthebedknife,perpendiculartothe

bedknife(Figure10).Slowlyrotatethereelforward;it

shouldcutthepaper.

Figure11

1.Spacer3.Side-platemountingange

2.Rollerbracket

2.Raisetherearofthecuttingunitandplaceablock

underthebedknife.

3.Removethe2nutssecuringeachrollerbracketand

spacertoeachside-platemountingange.

4.Lowertherollerandthescrewsfromtheside-plate

mountingangesandspacers.

5.Placespacersontoscrewsonrollerbrackets.

6.Securetherollerbracketandspacerstotheunderside

oftheside-platemountingangeswiththenuts

previouslyremoved.

7.Verifythatthebedknife-to-reelcontactiscorrect.Tip

themowertoexposethefrontandrearrollersandthe

bedknife.

Note:Thepositionoftherearrollertothereel

iscontrolledbythemachiningtolerancesofthe

assembledcomponentsandparallelingisnotrequired.

Alimitedamountofadjustmentispossiblebysetting

thecuttingunitonasurfaceplateandlooseningthe

side-platemountingbolts(Figure12).Adjustand

tightenthebolts.Torquetheboltsto37to45N∙m

(27to33ft-lb).

Figure10

Figure12

1.Side-platemountingbolts

8

Page 9

Height-of-CutChartTerms

Height-of-CutSetting(HOC)

Thiscorrespondstothedesiredheightofcut.

Bench-SetHeightofCut

Thisistheheightatwhichthetopedgeofthebedknifeisset

aboveaatlevelsurfacethatcontactsthebottomofboththe

frontandrearrollers.

RearSpacers

Thenumberofrearspacersdeterminestheaggressiveness

ofcutforthecuttingunit.Foragivenheightofcut,adding

spacersbelowtheside-platemountingangeincreasesthe

aggressivenessofthecuttingunit.Allcuttingunitsona

givenmachinemustbesettothesameaggressivenessofcut

(numberofrearspacers,ToroPartNo.119-0626);otherwise,

theafter-cutappearancecouldbenegativelyaffected(Figure

13).

ChainLinks

EffectiveHeightofCut

Thisistheactualheightthegrasshasbeencut.Foragiven

bench-setheightofcut,theactualheightofcutwillvary

dependingonthetypeofgrass,timeofyear,turf,andsoil

conditions.Thecutting-unitsetup(aggressivenessofcut,

rollers,bedknives,attachmentsinstalled,turf-compensation

settings,etc.)willalsoaffecttheeffectiveheightofcut.Check

theeffectiveheightofcutusingtheTurfEvaluator(Model

04399)regularlytodeterminethedesiredbench-setheight

ofcut.

AggressivenessofCut

Cuttingunitaggressivenessofcuthasasignicantimpact

ontheperformanceofthecuttingunit.Aggressivenessof

cutreferstotheangleofthebedkniferelativetotheground

(Figure13).

Thebestcuttingunitsetupisdependentonyourturf

conditionsanddesiredresults.Experiencewiththecutting

unitonyourturfwilldeterminethebestsettingtouse.You

canadjusttheaggressivenessofcutthroughoutthecutting

seasontoallowforvariousturfconditions.

Ingeneral,lesstonormalaggressivesettingsaremore

appropriateforwarm-seasongrasses(Bermuda,paspalum,

zoysia)whilecool-seasongrasses(bent,bluegrass,rye)may

requirenormaltomoreaggressivesetups.Moreaggressive

setupscutmoregrassoffbyallowingthespinningreeltopull

moregrassupintothebedknife.

Thelocationatwhichthelift-armchainisattacheddetermines

thepitchangleoftherearroller(Figure14).

Figure14

1.Liftchain

2.U-Bracket

3.Bottomhole

Groomer

Thesearetherecommendedheightofcutsettingswhena

groomerkitisinstalledonthecuttingunit.

1.Rearspacers

2.Side-platemountingange

Figure13

3.Aggressivenessofcut

9

Page 10

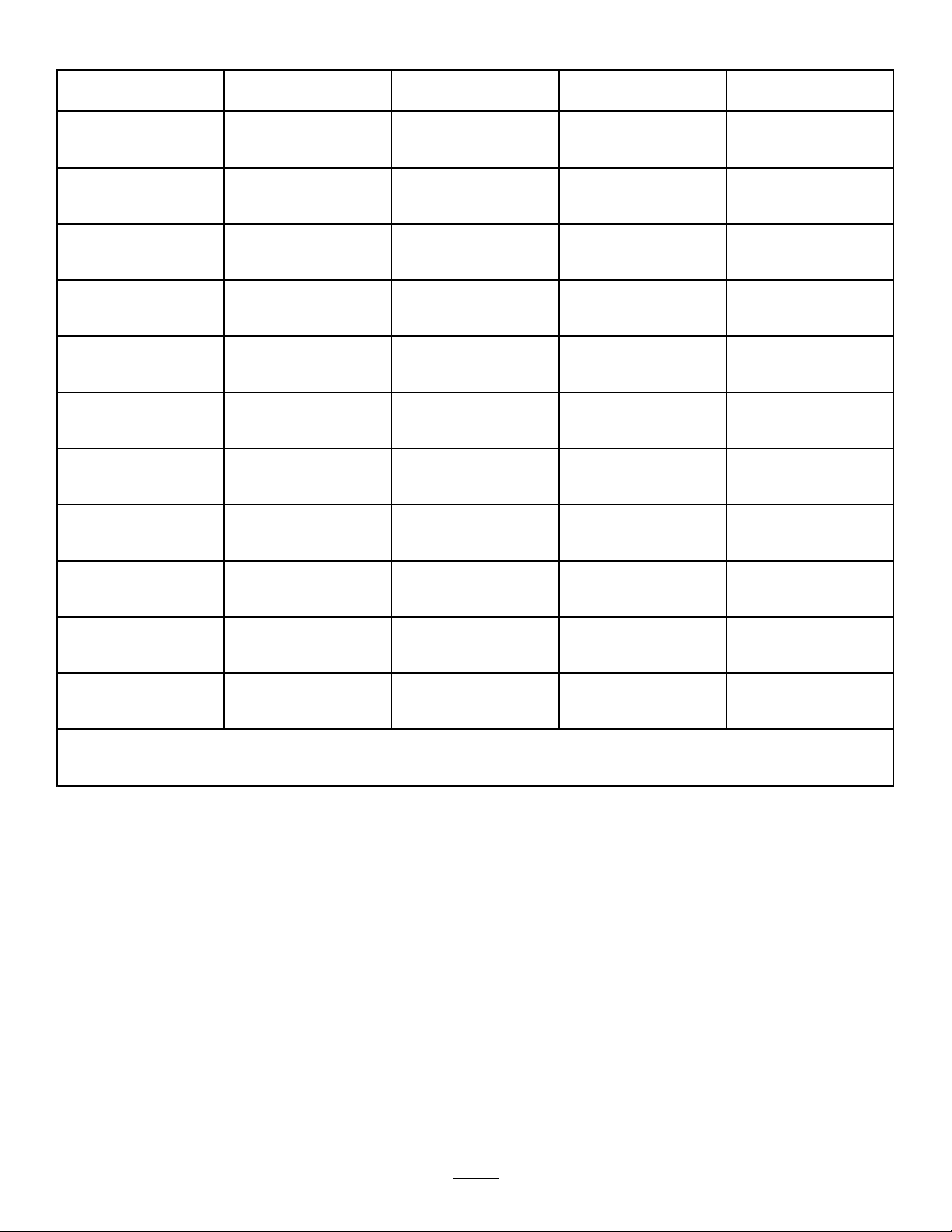

Height-of-CutChart

HOCSettingAggressivenessofCutNo.ofRearSpacersNo.ofChainLinksWithGroomerkits

0.64cm(0.250inches)

0.95cm(0.375inches)

1.27cm(0.500inches)

1.56cm(0.625inches)

1.91cm(0.750inches)

2.22cm(0.875inches)

2.54cm(1.000inch)

2.86cm(1.125inches)*

3.18cm(1.250inches)*

3.49cm(1.375inches)*

3.81cm(1.500inches)*

+IndicatestheU-bracket,onliftarm,ispositionedinthebottomhole(Figure14).

*HighHOCKit(Part110-9600)mustbeinstalled.ThefrontHOCbracketmustbepositionedinthetopside-platehole.

**YindicatesthatthiscombinationofHOCandspacerscanbeusedwithgroomers.

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

0

0

1

0

1

2

0

1

2

1

2

3

2

3

4

2

3

4

3

4

5

4

5

6

4

5

6

4

5

6

5

6

7

3+

3+

3

4

3

3

4

3+

3

4

3

3

3+

3

3

4

3

3

3+

3

3

4

3

3

4

3

3

4

3

3

3+

3

3

installed**

Y

Y

-

Y

Y

-

Y

Y

Y

Y

Y

-

Y

Y

-

Y

Y

-

Y

Y

-

-

-

-

-

-

-

-

-

-

-

-

-

Note:Changing1chainlinkchangestherearrollerpitchanglemovementby7.0degrees.

Note:ChangingtheU-bracket,ontheliftarm,tothebottomholeadds3.5degreestotherearrollerpitchangle.

10

Page 11

AdjustingtheHeightofCut

Note:Forheightsofcutgreaterthan2.54cm(1inch)install

theHighHeight-of-CutKit.

1.Loosenthelocknutssecuringtheheight-of-cutbrackets

tothecutting-unitsideplates(Figure15).

Figure15

1.Adjustingscrew

2.Locknut

3.Height-of-cutbracket

Figure17

Important:Whensetproperly,therearandfront

rollerswillcontactthegaugebarandthescrew

willbesnugagainstthebedknife.Thisensures

thattheheightofcutisidenticalatbothendsof

thebedknife.

5.Tightenthenutstosecuretheadjustment.Donot

overtightenthenuts—justenoughtoremoveanyplay

fromthewasher.

2.Loosenthenutonthegaugebar(Figure16)andset

theadjustingscrewtothedesiredheightofcut.The

distancebetweenthebottomofthescrewheadandthe

faceofthebaristheheightofcut.

Figure16

1.Gaugebar4.Holesusedforsettingthe

2.Height-adjustingscrew5.Holenotused

3.Nut

heightofgroom(HOG)

3.Hookthescrewheadonthecuttingedgeofthe

bedknifeandresttherearendofthebarontherear

roller(Figure17).

4.Rotatetheadjustingscrewuntilthefrontrollercontacts

thegaugebar(Figure17).Adjustbothendsofroller

untiltheentirerollerisparalleltothebedknife.

11

Page 12

Usethefollowingcharttodeterminewhichbedknifeis

bestsuitedforthedesiredheightofcut.

Bedknife/HeightofCutChart

Bedknife

LowHOC(Optional)

EdgeMax®LowHOC

(Model03623)

ExtendedLowHOC

(Optional)

ExtendedEdgeMax®Low

HOC(Optional)

EdgeMax®(Model03621)

Standard(Optional)

HeavyDuty(Optional)

PartNo.

110-40845.6mm

127-71325.6mm

120-16405.6mm

119-42805.6mm

108-90956.9mm

108-90966.9mm

110-40749.3mm

*Warm-seasongrassesmayrequiretheLowHOC

bedknifefor12.7mm(0.500inch)andbelow.

BedknifeLipHeightHeightofCut

(0.220inch)

(0.220inch)

(0.220inch)

(0.220inch)

(0.270inch)

(0.270inch)

(0.370inch)

6.4to12.7mm

(0.250to0.500inch)

6.4to12.7mm

(0.250to0.500inch)

6.4to12.7mm

(0.250to0.500inch)

6.4to12.7mm

(0.250to0.500inch)

9.5to38.1mm

(0.375to1.50inches)*

9.5to38.1mm

(0.375to1.50inches)*

12.7to38.1mm

(0.500to1.50inches)

Figure18

1.Bedknifelipheight

AdjustingtheTurf-Compensation

Settings

Theturf-compensationspringtransferstheweightfromthe

fronttotherearroller.Thishelpstoreduceawavepatternin

theturf,alsoknownasmarcellingorbobbing.

Important:Makespringadjustmentswiththecutting

unitmountedtothetractionunit,pointingstraight

aheadandloweredtotheshopoor.

1.Makesurethatthehairpincotterisinstalledintherear

holeinthespringrod(Figure19).

Figure19

1.Turf-compensationspring3.Springrod

2.Hairpincotter4.Hexnuts

2.Tightenthehexnutsonthefrontendofthespringrod

untilthecompressedlengthofthespringis12.7cm(5

inches);refertoFigure19.

Note:Whenoperatingonroughterraindecreasethe

springlengthby1.3cm(1/2inch).Groundfollowing

willbeslightlydecreased.

Note:Youwillneedtoresettheturfcompensation

settingiftheHOCsettingortheaggressiveness-of-cut

settingischanged.

12

Page 13

CheckingandAdjustingtheCutting

Unit

Thedualknobbedknife-to-reeladjustmentsystem

incorporatedinthiscuttingunitsimpliestheadjustment

procedureneededtodeliveroptimummowingperformance.

Thepreciseadjustmentpossiblewiththedualknob/bedbar

designgivesthenecessarycontroltoprovideacontinual

self-sharpeningaction-thusmaintainingsharpcuttingedges,

ensuringgoodqualityofcut,andgreatlyreducingtheneed

forroutinebacklapping.

Priortomowingeachday,orasrequired,checkeachcutting

unittoverifyproperbedknife-to-reelcontact.Performthis

procedureevenifthequalityofcutisacceptable.

1.Slowlyrotatethereelinareversedirection,listening

forreel-to-bedknifecontact.

Note:Overtime,youwillneedtogrindthechamfer

(Figure21),asitisonlydesignedtolast40%ofthe

bedknifelife.

Figure21

Note:Theadjustmentknobshavedetents

correspondingto0.018mm(0.0007inch)bedknife

movementforeachindexedposition.Referto

AdjustingtheBedknifetotheReel(page7).

2.Testthecuttingperformancebyinsertingalongstrip

ofcuttingperformancepaper(ToroPart125-5610)

betweenthereelandthebedknife,perpendiculartothe

bedknife(Figure20).Slowlyrotatethereelforward;it

shouldcutthepaper.

Figure20

Note:Ifexcessivecontact/reeldragisevident,either

backlap,refacethefrontofthebedknife,orgrindthe

cuttingunittoachievethesharpedgesneededfor

precisioncutting;refertotheToroManualforSharpening

ReelandRotaryMowers,FormNo.09168SL.

1.Lead-inchamferonright

endofbedknife

2.6mm(0.25inch)

3.1.5mm(0.060inch)

Note:Donotmakethelead-inchamfertoolargeas

itmaycauseturftufting.

Important:Lightcontactispreferredatalltimes.

Ifyoudonotmaintainlightcontact,thebedknife

andreeledgeswillnotsufcientlyself-sharpen

andwilldullafteraperiodofoperation.Ifyou

maintainexcessivecontact,thebedknifeandreel

willwearquicker,wearunevenly,andthequality

ofcutmaybeadverselyaffected.

Note:Afterextendedrunning,aridgewilleventually

developatbothendsofthebedknife.Roundoffor

lethesenotchesushwiththecuttingedgeofthe

bedknifetoensuresmoothoperation.

13

Page 14

Maintenance

LubricatingtheMachine

Regularlylubricatethe6greasettingsofeachcuttingunit

(Figure22)withNo.2lithiumgrease.

Thereare2lubricationpointsonthefrontroller,2onthe

rearroller,and2forthereelbearing.

Note:Lubricatingthecuttingunitsimmediatelyafter

washinghelpspurgewateroutofthebearingsand

increasesbearinglife.

1.Wipeeachgreasettingwithacleanrag.

2.Applygreaseuntilcleangreasecomesoutoftheroller

sealsandthebearingreliefvalve.

3.Wipeanyexcessgreaseaway .

Figure22

Greasettinglocationsonleftside

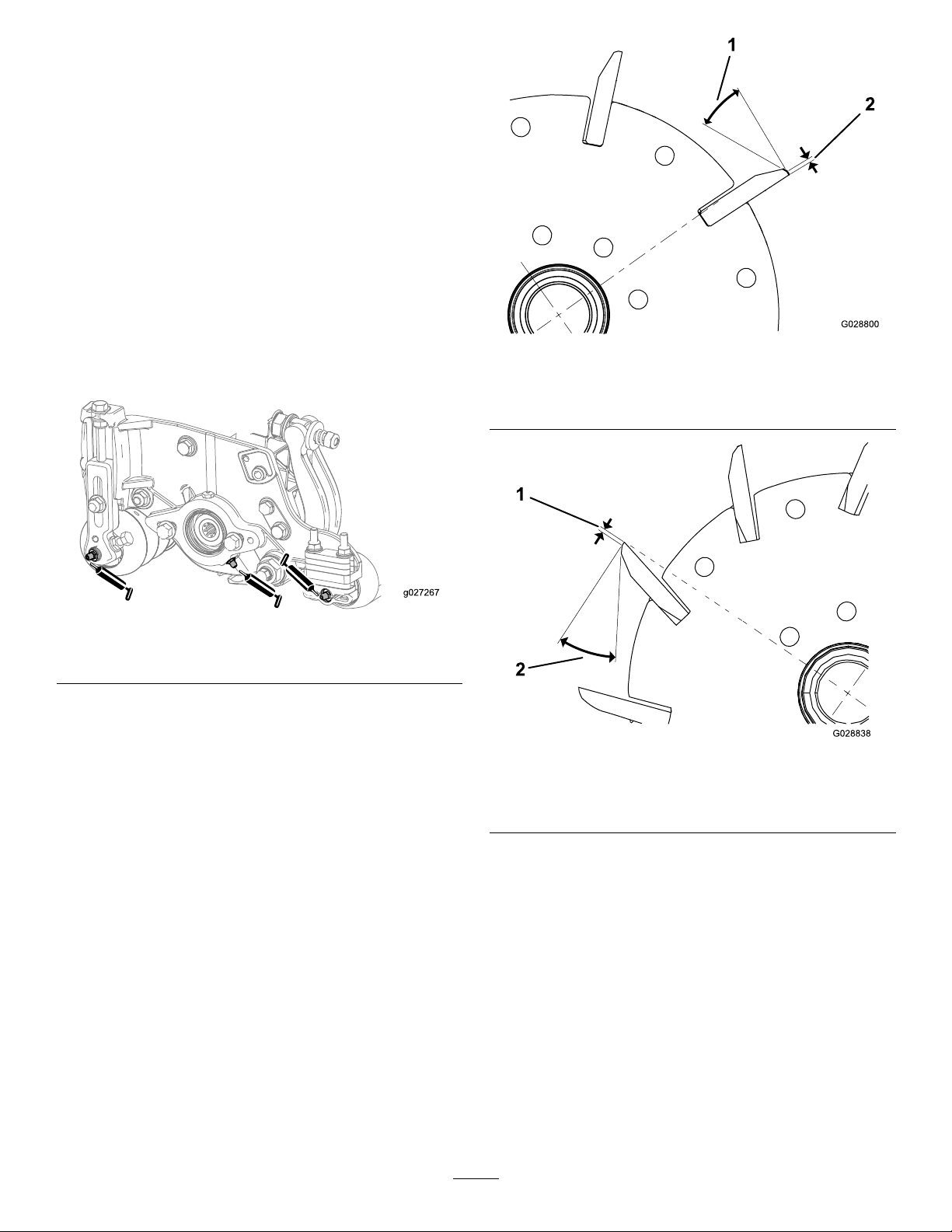

Relief-GrindingtheReel

Thereelhasalandwidthof1.3to1.5mm(0.050to0.060

inch)anda30-degreereliefgrind.

Whenthelandwidthgetslargerthan3mm(0.120inch)wide,

dothefollowing:

1.Applya30degreereliefgrindonallreelbladesuntil

thelandwidthis1.3mm(0.050inch)wide(Figure23

andFigure24).

Figure23

Model036321

1.30degrees

Model03623

1.1.3mm(0.050inch)

2.Spingrindthereeltoachieve<0.025mm(0.001inch)

reelrun-out.

Note:Thiscausesthelandwidthtogrowslightly.

2.1.3mm(0.050inch)

Figure24

2.30degrees

Note:Toextendthelongevityofthesharpnessoftheedge

ofthereelandthebedknife—aftergrindingthereeland/or

thebedknife—checkthereel-to-bedknifecontactagainafter

cutting2fairways,asanyburrswillberemoved,whichmay

createimproperreel-to-bedknifeclearanceandthusaccelerate

wear.

14

Page 15

ServicingtheBedknife

2

3

g027268

1

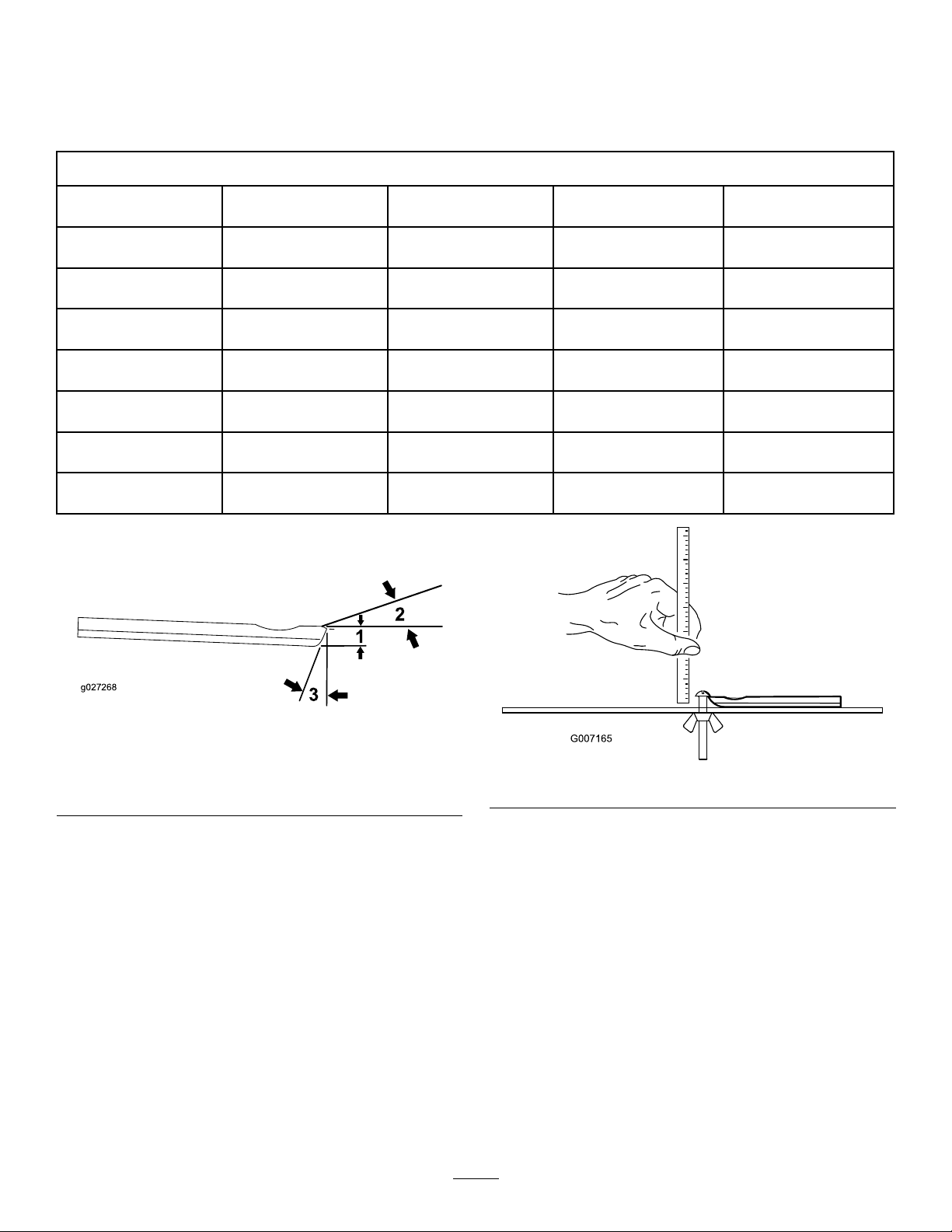

Thebedknifeservicelimitsarelistedinthefollowingchart.

Important:Operatingthecuttingunitwiththebedknifebelowtheservicelimitmayresultinpoorafter-cut

appearanceandreducethestructuralintegrityofthebedknifeforimpacts.

BedknifeServiceLimitChart

Bedknife

LowHOC(Optional)

EdgeMax®LowHOC

(Model03623)

ExtendedLowHOC

(Optional)

ExtendedEdgeMax®

LowHOC(Optional)

EdgeMax®(Model

03621)

Standard(Optional)

HeavyDuty(Optional)

PartNo.

110-40845.6mm

127-71325.6mm

120-16405.6mm

119-42805.6mm

108-90956.9mm

108-90966.9mm

110-40749.3mm

RecommendedT opandFrontBedknifeGrindAngles

(Figure25)

BedknifeLipHeight*ServiceLimit*GrindAngles

(0.220inch)

(0.220inch)

(0.220inch)

(0.220inch)

(0.270inch)

(0.270inch)

(0.370inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

4.8mm

(0.190inch)

Top/FrontAngles

10/5Degrees

10/5Degrees

10/10Degrees

10/10Degrees

10/5Degrees

10/5Degrees

10/5Degrees

Figure25

1.Bedknifeservicelimit*

2.Topgrindangle

3.Frontgrindangle

Note:Allbedknifeservicelimitmeasurementsreferencethe

bottomofthebedknife(Figure26)

Figure26

CheckingtheTopGrindAngle

Theanglethatyouusetogrindyourbedknivesisvery

important.

Usetheangleindicator(ToroPartNo.131-6828)andthe

angle-indicatormount(ToroPartNo.131-6829)tocheck

theanglethatyourgrinderproducesandthencorrectfor

anygrinderinaccuracy .

1.Placetheangleindicatoronthebottomsideofthe

bedknifeasshowninFigure27.

15

Page 16

Figure27

ServicingtheBedbar

RemovingtheBedbar

1.Turnthebedbar-adjustingscrewscounterclockwiseto

backthebedknifeawayfromthereel(Figure29).

1.Bedknife(vertical)

2.Angleindicator

2.PresstheAltZerobuttonontheangleindicator.

3.Placetheangle-indicatormountontheedgeofthe

bedknifesothattheedgeofthemagnetismatedwith

theedgeofthebedknife(Figure28).

Note:Thedigitaldisplayshouldbevisiblefromthe

samesideduringthisstepasitwasinstep1.

Figure29

1.Bedbar-adjustingscrew3.Bedbar

2.Spring-tensionnut

4.Washer

2.Backoutthespring-tensionnutuntilthewasherisno

longertensionedagainstthebedbar(Figure29).

3.Oneachsideofthemachine,loosenthelocknut

securingthebedbarbolt(Figure30).

Figure28

1.Angle-indicatormount

2.Edgeofthemagnetmated

withtheedgeofthe

bedknife

3.Bedknife

4.Angleindicator

4.Placetheangleindicatoronthemountasshownin

Figure28.

Note:Thisistheanglethatyourgrinderproduces,

andshouldbewithin2degreesoftherecommended

topgrindangle.

Figure30

1.Bedbarbolt2.Locknut

4.Removeeachbedbarbolt,allowingthebedbartobe

pulleddownwardandremovedfromthemachinebolt

(Figure30).

Note:Accountfor2nylonwashersand1stamped

steelwasheroneachendofthebedbar(Figure31).

Figure31

1.Bedbarbolt

2.Nut4.Nylonwasher

3.Steelwasher

16

Page 17

AssemblingtheBedbar

1.Installthebedbar,positioningthemountingears

betweenthewasherandthebedbaradjuster.

2.Securethebedbartoeachsideplatewiththebedbar

bolts(nutsonbolts)andthe6washers.

Note:Positionanylonwasherontheeachsideof

theside-plateboss.Placeasteelwasheroutsideofthe

outernylonwashers(Figure31).

3.Torquethebedbarboltsto27to36N∙m(240to320

in-lb).

4.Tightenthelocknutsequallyoneachsideuntiltheouter

steelwasherscannotberotatedbyhand.Thenloosen

thelocknutsuntiltheoutersteelwashersjustrotateby

hand,yetthereisnobedbarendplay(Figure32).

Note:Overtighteningthelocknutscandeecttheside

platesandthebedbar,whichcanaffectreel-to-bedknife

contact.

Note:Thewashersontheinsidemayhaveagap.

Note:Donotovertightenthenuts,asdamagetothe

springmayoccur.

Threadthebedbar-adjusterscrewintotheadjuster

shaft.

7.Looselyinstallthehardenedwasher,spring,andspring

tensionnutontotheadjusterscrew .

8.Installthebedbar,positioningthemountingears

betweenthewasherandthebedbaradjuster.

9.Securethebedbartoeachsideplatewiththebedbar

bolts(nutsonbolts)and6washersasfollows:

A.Positionanylonwasheroneachsideofthe

side-plateboss.

B.Placeasteelwasheroutsideeachofthenylon

washers(Figure33).

C.Torquethebedbarboltsto37to45N∙m(27to

33ft-lb).

D.Tightenthelocknutsuntiltheoutsidesteelwasher

stopsrotatingandendplayisremoved,butdonot

overtightenordeectthesideplates.

Note:Thewashersontheinsidemayhaveagap

(Figure31).

10.Tightenthenutoneachbedbaradjusterassembly

untilthecompressionspringisfullycompressed,then

loosenthenut1/2turn(Figure32).

Figure32

1.Spring-tensionnut2.Spring

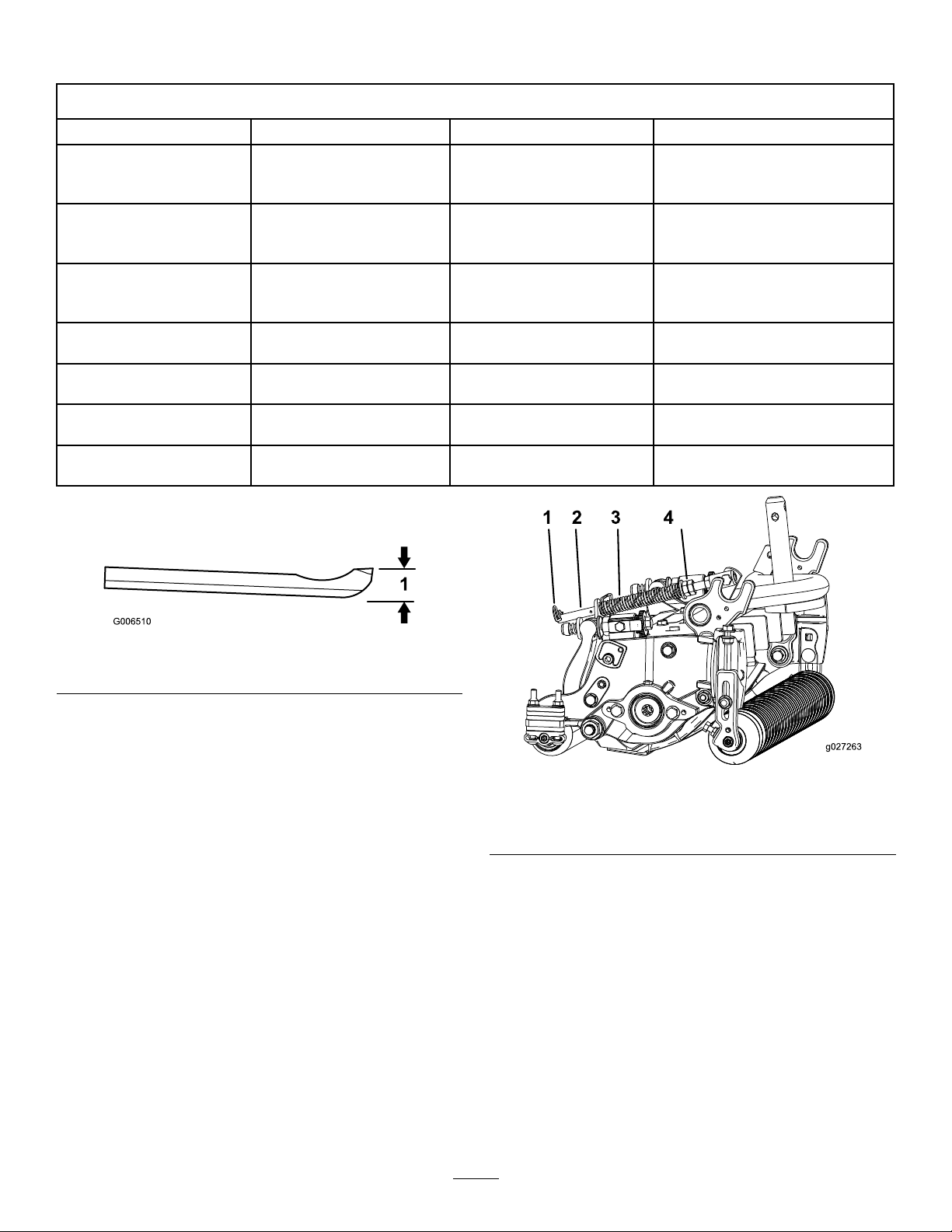

ServicingtheHDDualPoint Adjusters(DPA)

1.Removeallparts;refertoInstallationInstructionsforHD

DPAKitModel120-7230andtoFigure33.

2.Applyanti-seizecompoundtotheinsideofthebushing

areaonthecentercuttingunitframe(Figure33).

3.Alignthekeysontheangebushingstotheslotsinthe

frameandinstallthebushings(Figure33).

4.Installawavewasherontotheadjustershaftandslide

theadjustershaftintotheangebushingsintheframe

ofthecuttingunit(Figure33).

11.Repeattheprocedureontheotherendofthecutting

unit.

12.Adjustthebedknifetothereel.

5.Securetheadjustershaftwithaatwasheranda

locknut(Figure33).Torquethelocknutto20to27

N∙m(15to20ft-lb).

Note:Thebedbar-adjustershafthasleft-handthreads.

6.Applyanti-seizecompoundtothethreadsofthe

bedbar-adjusterscrewthattsintotheadjustershaft.

17

Page 18

1

2

3

4

5

6

7

8

9

10

11

G016355

Figure33

1.Shaftadjuster

2.Wavewasher5.Flatwasher8.Bedbar-adjusterscrew

3.Flangebushing6.Locknut9.Hardenedwasher

4.Applyanti-seizecompound

here.

7.Applyanti-seizecompound

here.

10.Compressionspring

11.Spring-tensionnut

18

Page 19

ServicingtheRoller

ARollerRebuildKit,PartNo.114-5430anda

RollerRebuildT oolKit,PartNo.115-0803(Figure

34)areavailableforservicingtheroller.TheRoller

RebuildKitincludesallthebearings,bearingnuts,

innerseals,andoutersealstorebuildaroller.

TheRollerRebuildToolKitincludesallthetoolsandthe

installationinstructionsrequiredtorebuildarollerwiththe

RollerRebuildKit.RefertoyourPartsCatalogorcontactyour

distributorforassistance.

Figure34

1.Rebuildkit(PartNo.114-5430)

2.Rebuildtoolkit(PartNo.1 15-0803)

3.Innerseal8.Washer

4.Bearing

5.Outerseal

6.Bearingnut

7.Inner-sealtool

9.Bearing/outer-sealtool

19

Page 20

Notes:

20

Page 21

Notes:

21

Page 22

DeclarationofIncorporation

TheT oroCompany,811 1LyndaleAve.South,Bloomington,MN,USAdeclaresthatthefollowingunit(s)

conform(s)tothedirectiveslisted,wheninstalledinaccordancewiththeaccompanyinginstructionsontocertain

ToromodelsasindicatedontherelevantDeclarationsofConformity.

ModelNo.

03621315000001andUp

03623315000001andUp

SerialNo.

ProductDescriptionInvoiceDescription

22-inch8-BladeDPA

CuttingUnitwith5inReel,

Reelmaster3555or5010

SeriesTractionUnit

22-inch11-BladeDPA

CuttingUnitwith5inReel,

Reelmaster3555or5010

SeriesTractionUnit

22IN5IN8-BLD(RR)DP A

CU(5010-H)

22IN5-IN11-BLD(FSR)

DPACU(5010-H)

GeneralDescription

Directive

Cuttingunit2006/42/EC

Cuttingunit2006/42/EC

RelevanttechnicaldocumentationhasbeencompiledasrequiredperPartBofAnnexVIIof2006/42/EC.

Wewillundertaketotransmit,inresponsetorequestsbynationalauthorities,relevantinformationonthispartly

completedmachinery.Themethodoftransmissionshallbeelectronictransmittal.

ThismachineryshallnotbeputintoserviceuntilincorporatedintoapprovedToromodelsasindicatedonthe

associatedDeclarationofConformityandinaccordancewithallinstructions,wherebyitcanbedeclaredin

conformitywithallrelevantDirectives.

Certied:EUTechnicalContact:

MarcVermeiren

ToroEuropeNV

B-2260Oevel-Westerloo

Belgium

DavidKlisTel.003214562960

Sr.EngineeringManager

811 1LyndaleAve.South

Bloomington,MN55420,USA

April25,2016

Fax003214581911

22

Page 23

InternationalDistributorList

Distributor:

AgrolancKft

AsianAmericanIndustrial(AAI)

B-RayCorporation

BrisaGoodsLLC

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

FatDragon

FemcoS.A.Guatemala

FIVEMANSNew-T echCo.,LtdChina

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260T oroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India00914424494387ValtechMorocco212537663636

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

Country:

Hungary3627539640

HongKong85224977804

Korea82325512076

Mexico12104952417

PuertoRico7877888383

NorthernIreland442890813121

China

Estonia3723846060

Japan81726325861Riversa

Turkey902163365993

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

5062391138

94112746100

442890813121ParklandProductsLtd.NewZealand6433493760

8861080841322

5024423277

86-10-63816136

30109350054

4635100000

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

Lely(U.K.)Limited

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

Country:

Japan81332522285

Argentina541 148219999

Russia749541 16120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

UnitedKingdom441480226800

France33130817700

India911292299901

PhoneNumber:

5712364079

420255704220

420255704220

34952837500

35722434131

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0269RevK

Page 24

TheT oroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser .

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevD

Loading...

Loading...