Page 1

FormNo.3391-854RevA

Reelmaster

®

5410-Gor5510-G

TractionUnit

ModelNo.03608—SerialNo.315000001andUp

ModelNo.03609—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3391-854*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsingolfcourses,parks,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Figure1

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Themodelandserialnumbersareona

platemountedontheleftsideoftheframeunderthefoot

rest.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SafetyandInstructionalDecals.................................7

Setup...........................................................................10

1AdjustingtheTirePressure....................................10

2AdjustingtheStepHeight.....................................10

3AdjustingtheControlArmPosition........................11

4InstallingtheCuttingUnits....................................11

5AdjustingtheTurfCompensationSpring.................14

6UsingtheCuttingUnitKickstand...........................15

ProductOverview.........................................................16

Controls...............................................................16

Specications........................................................22

Attachments/Accessories........................................22

Operation....................................................................22

CheckingtheEngine-OilLevel.................................22

CheckingtheCoolingSystem...................................23

AddingFuel...........................................................23

CheckingtheHydraulicFluid...................................24

CheckingtheReeltoBedknifeContact......................26

CheckingtheTorqueoftheWheelNuts.....................26

StartingandStoppingtheEngine..............................26

SettingtheReelSpeed.............................................26

AdjustingtheLiftArmCounterbalance.....................26

AdjustingtheLiftArmTurnAroundPosition.............27

PushingorTowingtheMachine................................27

LocatingtheJackingPoints......................................28

LocatingtheTieDowns..........................................28

UnderstandingtheDiagnosticLight..........................28

CheckingtheInterlockSwitches...............................29

HydraulicValveSolenoidFunctions..........................29

OperatingTips......................................................30

Maintenance.................................................................31

RecommendedMaintenanceSchedule(s)......................31

DailyMaintenanceChecklist....................................32

ServiceIntervalChart.............................................33

Lubrication...............................................................33

GreasingtheBearingsandBushings..........................33

EngineMaintenance..................................................35

ServicingtheAirCleaner.........................................35

ServicingtheEngineOilandFilter............................35

ReplacingtheSparkPlugs........................................36

FuelSystemMaintenance...........................................37

ReplacingtheFuelFilter..........................................37

CheckingtheFuelLinesandConnections..................37

FuelPick-upTubeScreen........................................37

ElectricalSystemMaintenance....................................38

ServicingtheBattery...............................................38

CheckingtheFuses.................................................38

DriveSystemMaintenance.........................................39

AdjustingtheTractionDriveforNeutral....................39

AdjustingtheRearWheelToe-in..............................39

CoolingSystemMaintenance......................................40

RemovingDebrisfromtheCoolingSystem................40

BrakeMaintenance....................................................41

AdjustingtheServiceBrakes....................................41

AdjustingtheParkingBrake....................................41

BeltMaintenance......................................................42

TensioningtheAlternatorBelt.................................42

HydraulicSystemMaintenance....................................42

ChangingtheHydraulicFluid...................................42

ReplacingtheHydraulicFilters.................................43

CheckingtheHydraulicLinesandHoses....................43

UsingtheHydraulicSystemTestPorts.......................44

CuttingUnitSystemMaintenance.................................45

BacklappingtheCuttingUnits..................................45

Storage........................................................................46

PreparingtheTractionUnit.....................................46

PreparingtheEngine..............................................46

3

Page 4

Safety

Improperusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

SafeOperatingPractices

Training

•Readtheoperator'smanualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

people,orproperty.

Preparation

•Whilemowing,alwayswearsubstantial,slip-resistant

footwear,longtrousers,hardhat,safetyglasses,andear

protection.Longhair,looseclothing,orjewelrymayget

tangledinmovingparts.Donotoperatetheequipment

whenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Checkthattheoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.T oguardagainst

overturning:

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Machinespeedsshouldbekeptlowonslopesand

duringtightturns.

4

Page 5

–Stayalertforhumpsandhollowsandotherhidden

hazards.

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheoperator'smanual.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsorover-speed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–Stoponlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Changeintoneutralandsettheparkingbrake.

–Stoptheengineandremovethekey.

•Disengagethedrivestotheattachment(s)when

transportingthemachineornotusingthemachine.

•Stoptheengineanddisengagethedrivestothe

attachment:

–beforerefuelling;

–beforeremovingthegrasscatcher/catchers;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

–beforeclearingblockages;

–beforechecking,cleaningorworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperatingthe

equipment.

•Reducetheenginespeedsettingduringenginerun-out

and,iftheengineisprovidedwithashut-offvalve,turn

thefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcylinders/reelsifnot

mowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentandfuelstorage

areafreeofgrass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-cylinder/multi-reelmachines,takecareas

rotatingonecylinder/reelcancauseothercylinders/reels

torotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekeyfromignition.Wait

forallmovementtostopbeforeadjusting,cleaning,or

repairingthemachine.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.Clean

upanyoilorfuelspillage.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

terminallast.Connectthepositiveterminalrstandthe

negativeterminallast.

•Usecarewhencheckingthecylinders/reels.Weargloves

andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopen,well-ventilatedarea,away

fromsparksandames.Unplugthechargerbefore

connectingittoordisconnectingitfromthebattery.

Wearprotectiveclothinganduseinsulatedtools.

5

Page 6

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandard.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

•Usingthemachinedemandsattention.Topreventloss

ofcontrol:

–Donotdriveclosetosandtraps,ditches,creeks,or

otherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donotresume

mowinguntiltheareaiscleared.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Seekimmediatemedicalattentionifuidis

injectedintoskin.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Toensuresafetyandaccuracy,haveanAuthorizedToro

Distributorcheckthemaximumenginespeedwitha

tachometer.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrolof

themachine.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,silencer/mufer,orexhaust

pipewhiletheengineisrunningorsoonafterithas

stoppedbecausetheseareascouldbehotenoughtocause

burns.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

6

Page 7

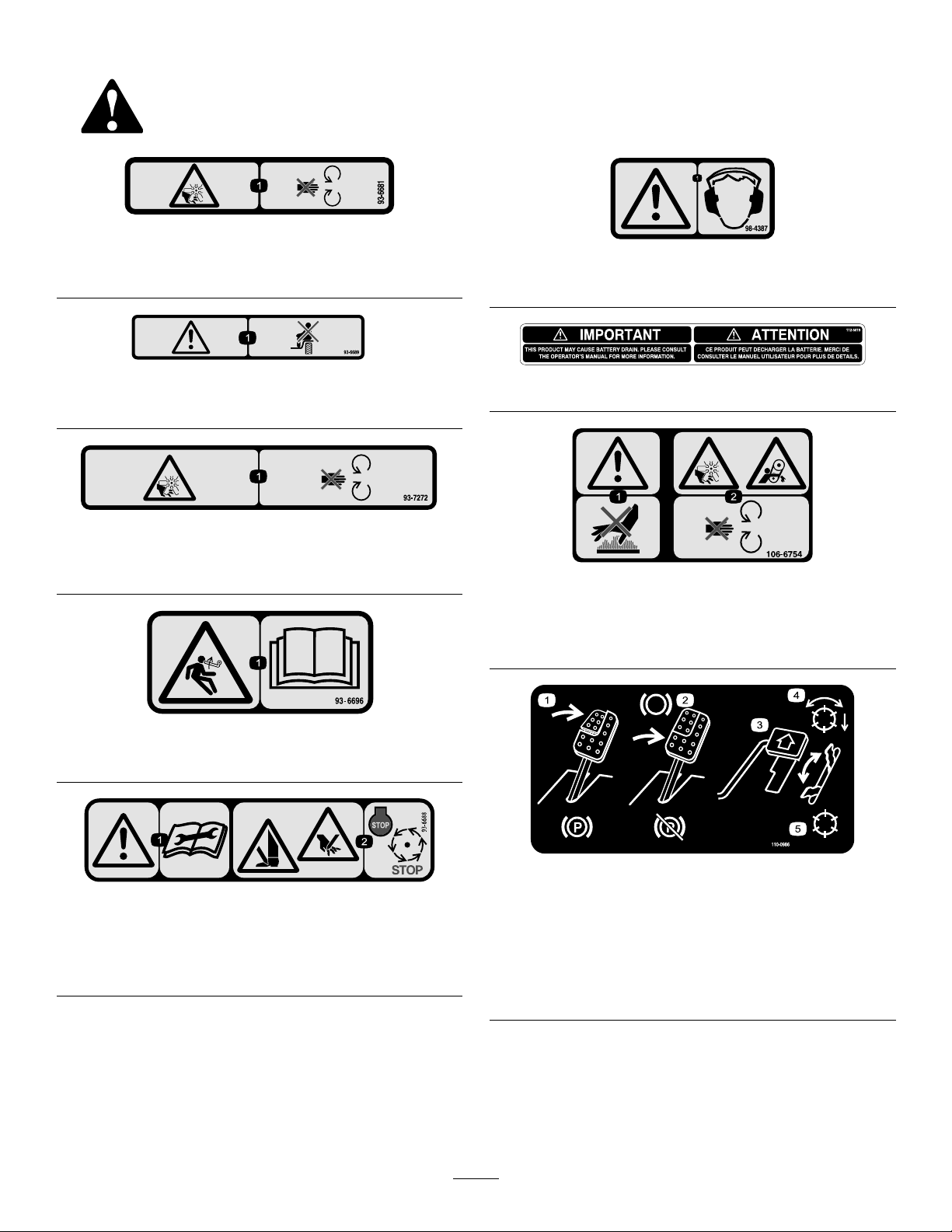

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

98-4387

1.Warning—wearhearingprotection.

93–6689

1.Danger—noriders.

93-7272

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

93–6696

1.Storedenergyhazard—readtheOperator'sManual.

112-5019

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

93-6688

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

110-0986

1.Pressthebrakepedalandparkingbrakepedaltosetthe

parkingbrake.

2.Pressthebrakepedaltoapplythebrake.

3.Pressthetractionpedaltomovethemachineforward.

4.Reelenabledmode

5.Transportmode

7

Page 8

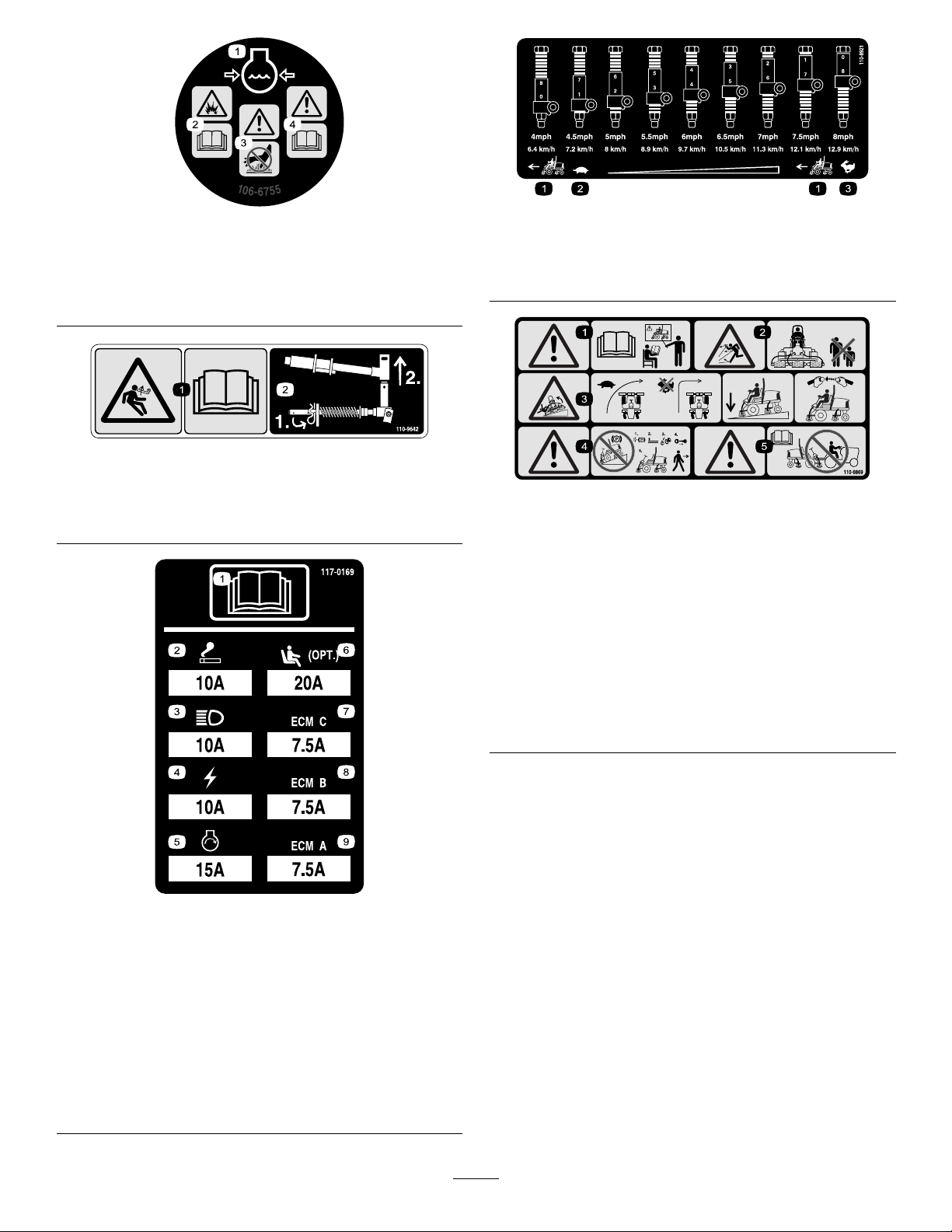

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

106-6755

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

110-9642

110-8921

1.Tractionunitspeed

2.Slow

3.Fast

1.Storedenergyhazard—readtheOperator'sManual.

2.Movethecotterpintotheholeclosesttotherodbracket

andthenremovetheliftarmandpivotyoke.

117–0169

110-8869

1.Warning—readtheOperator'sManual,donotoperatethis

machineunlessyouaretrained.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Tippinghazard—slowmachinebeforeturning,donotturn

athighspeeds;lowerthecuttingunitwhendrivingdown

slopes;usearolloverprotectionsystemandweartheseat

belt.AlwayswearaseatbeltwhenaROPSisinplace.

4.Warning—donotparkthemachineonslopes;engagethe

parkingbrake,lowerthecuttingdecks,stoptheengineand

removetheignitionkeybeforeleavingthemachine.

5.Warning—readtheOperator'sManual,donottowthe

machine.

1.ReadtheOperator'sManual.

2.Powerpoint—10amp

3.Headlights—10amp

4.Power—10amp

5.Enginestart—15amp

6.Optionalairrideseatsuspension—20amp

7.EnginecomputermanagementC—7.5amp

8.EnginecomputermanagementB—7.5amp

9.EnginecomputermanagementA—7.5amp

8

Page 9

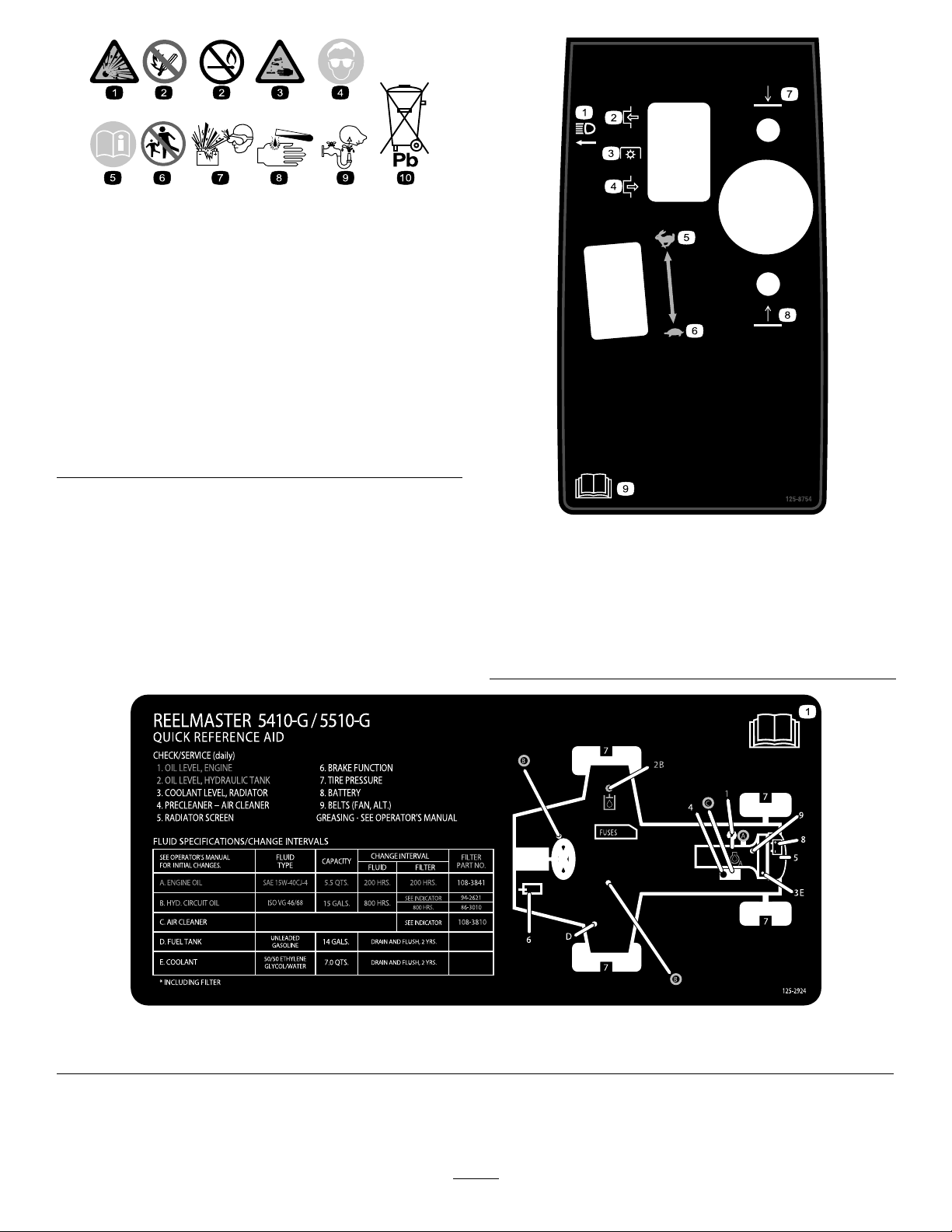

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

125–8754

1.Headlights

2.Engage7.Lowerthecuttingunits

3.Powertake-off(PTO)

4.Disengage

5.Fast

6.Slow

8.Raisethecuttingunits

9.ReadtheOperator’s

Manual.

1.ReadtheOperator’sManual.

125–2924

9

Page 10

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Nopartsrequired

Nopartsrequired

Fronthoseguide(right-hand)

Fronthoseguide(left-hand)

Nopartsrequired

Cuttingunitkickstand

MediaandAdditionalParts

Description

Operator'sManual

Engineoperator’smanual1

PartsCatalog

Qty.

Qty.

–

–

–

1

1

–

1

1

1

Readthemanualsbeforeoperatingthemachineanduse

themtoreferenceinformationaboutthemachine.

UsethePartsCatalogtoreferencepartnumbers.

Adjustthetirepressure.

Adjustthestepheight.

Adjustthecontrolarmposition.

Installthecuttingunits.

Adjusttheturfcompensationspring.

InstalltheCuttingUnitKickstand.

Use

Use

Operatortrainingmaterial

CuttingPerformancePaper

Shim

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

AdjustingtheTirePressure

NoPartsRequired

Procedure

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Correctairpressurein

thefrontandreartiresis83to103kPa(12to15psi).

1

1

1

Reviewthetrainingmaterialbeforeoperatingthemachine.

Usethepaperforadjustingthecuttingunitbedknifeto

reelcontact.

Usetheshimforadjustingthecuttingunitbedknifetoreel

contact.

2

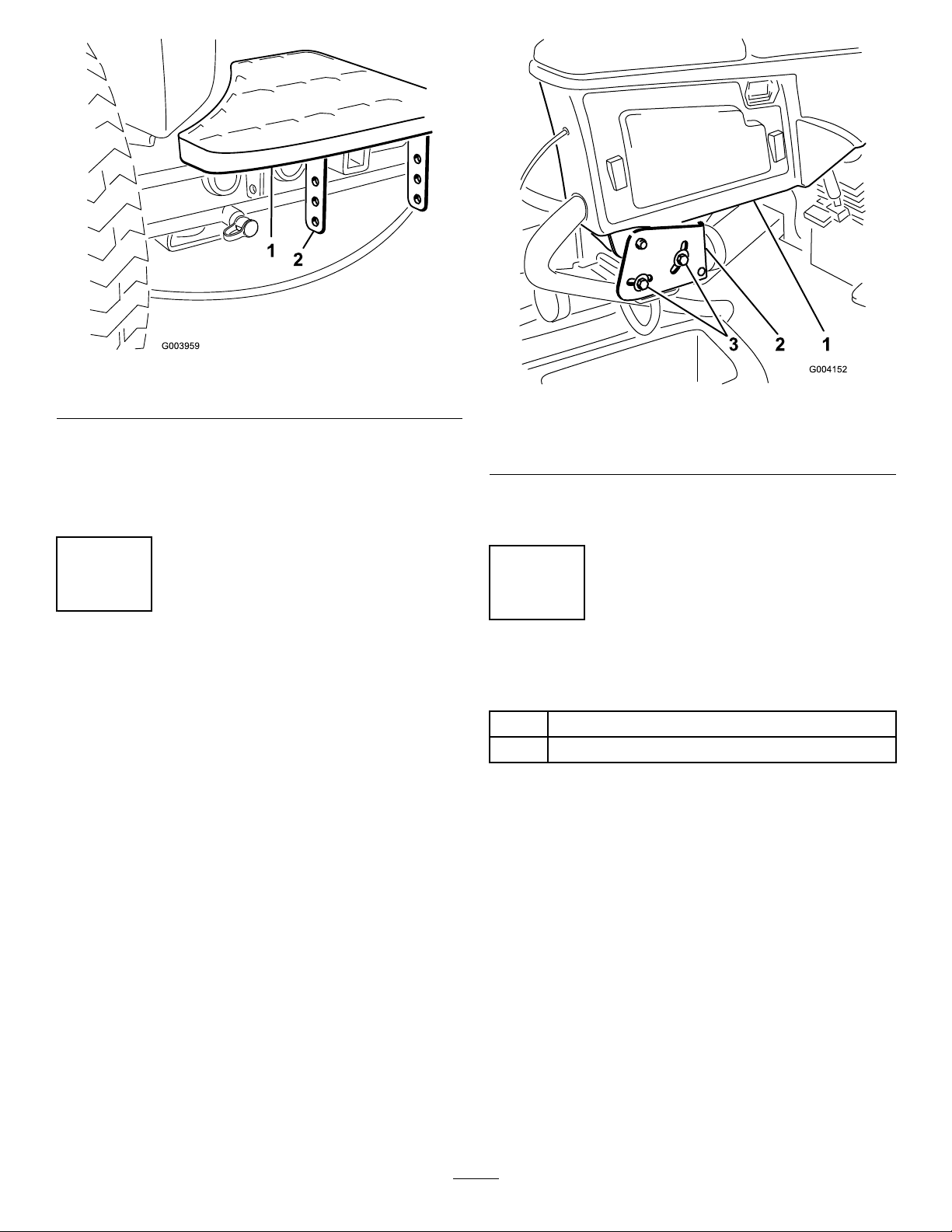

AdjustingtheStepHeight

NoPartsRequired

Procedure

Theheightofthestepscanbeadjustedfortheoperators

comfort.

1.Removethe2boltsandnutssecuringthestepbrackets

tothetractionunitframe(Figure2).

Important:Maintainevenpressureinalltirestoensure

uniformcontactwiththeturf.

10

Page 11

Figure2

1.Step2.Stepbrackets

2.Raiseorlowerthesteptothedesiredheightand

re-securethebracketstotheframewiththe2bolts

andnuts.

3.Repeattheprocedureontheotherstep.

3

AdjustingtheControlArm Position

NoPartsRequired

Procedure

Thecontrolarmpositioncanbeadjustedfortheoperator’s

comfort.

1.Loosenthe2boltssecuringthecontrolarmtothe

retainingbracket(Figure3).

Figure3

1.Controlarm3.Bolts(2)

2.Retainingbrackets

2.Rotatethecontrolarmtothedesiredpositionand

tightenthe2bolts.

4

InstallingtheCuttingUnits

Partsneededforthisprocedure:

1

Fronthoseguide(right-hand)

1

Fronthoseguide(left-hand)

Procedure

1.Removethereelmotorsfromtheshippingbrackets.

2.Removetheshippingbracketsanddiscard.

3.Removethecuttingunitsfromthecartons.Assemble

andadjustthemasdescribedinthecuttingunit

Operator'sManual.

4.Makesurethecounterweight(Figure4)isinstalledto

theproperendofthecuttingunitasdescribedinthe

cuttingunitOperator'sManual.

11

Page 12

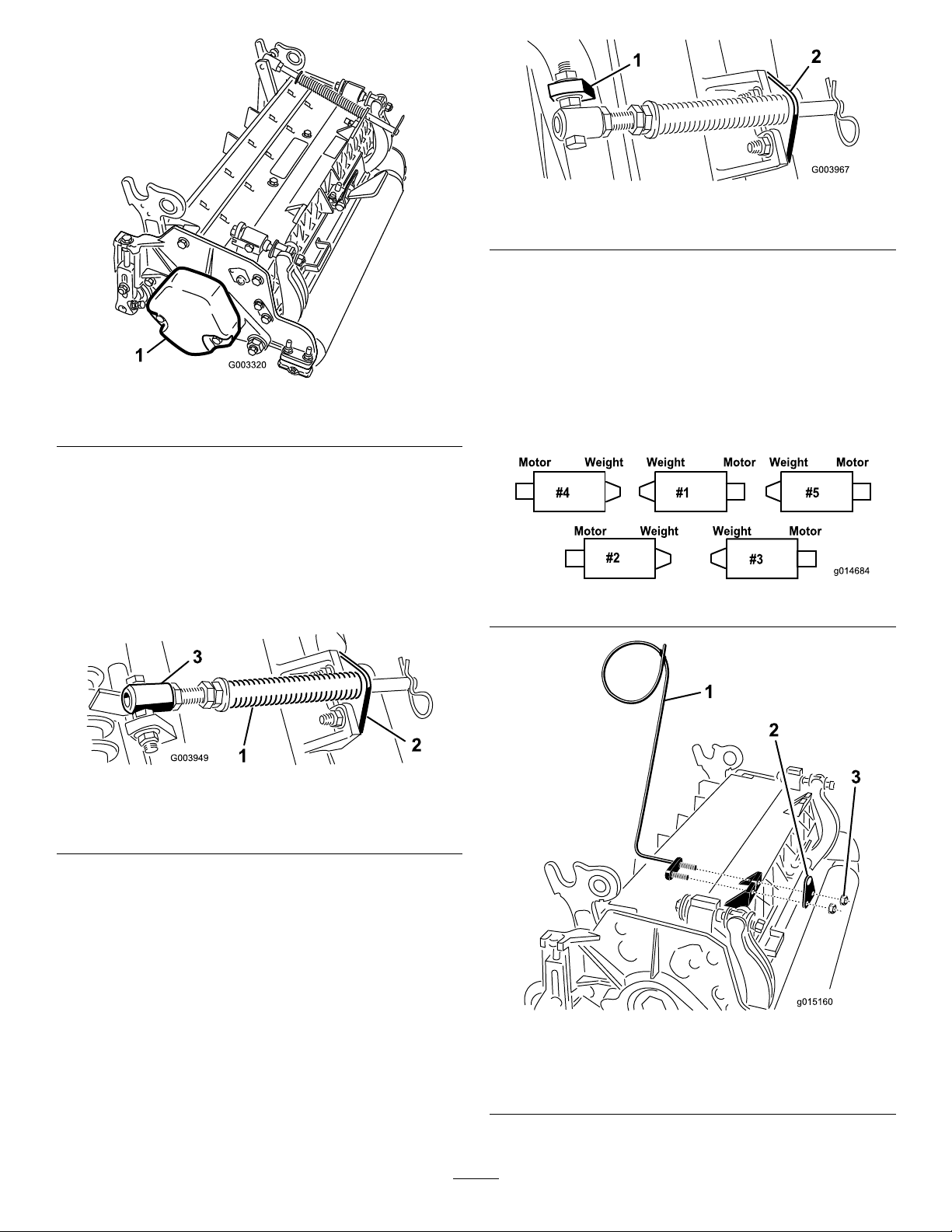

Figure6

Figure4

1.Counterweight

5.Allthecuttingunitsareshippedwiththeturf

compensationspringmountedtotherightsideofthe

cuttingunit.Theturfcompensationspringmustbe

mountedtothesamesideofthecuttingunitasthe

reeldrivemotor.Repositiontheturfcompensation

asfollows:

A.Removethe2carriageboltsandnutssecuringthe

rodbrackettothecuttingunittabs(Figure5).

1.Oppositecarrierframetab

2.Rodbracket

D.Mounttherodbrackettothecuttingunittabs

withthecarriageboltsandnuts(Figure6).

Important:Onthe#4(leftfront)and#5

(rightfront)cuttingunits(Figure7),use

therodbracketmountingnutstoinstallthe

hoseguidestothefrontofthecuttingunit

tabs(Figure8).Thehoseguidesshouldlean

towardthecentercuttingunit(Figure8and

Figure9).

Figure7

Figure5

1.Turfcompensationspring3.Springtube

2.Rodbracket

B.Removetheangenutsecuringthespringtube

bolttothecarrierframetab(Figure5)Remove

theassembly.

C.Mountthespringtubebolttotheoppositetabon

thecarrierframeandsecurewiththeangenut.

Theboltheadistobepositionedtotheouterside

ofthetabasshowninFigure6.

1.Hoseguide(#4cuttingunit

shown)

2.Rodbracket

12

Figure8

3.Nuts

Page 13

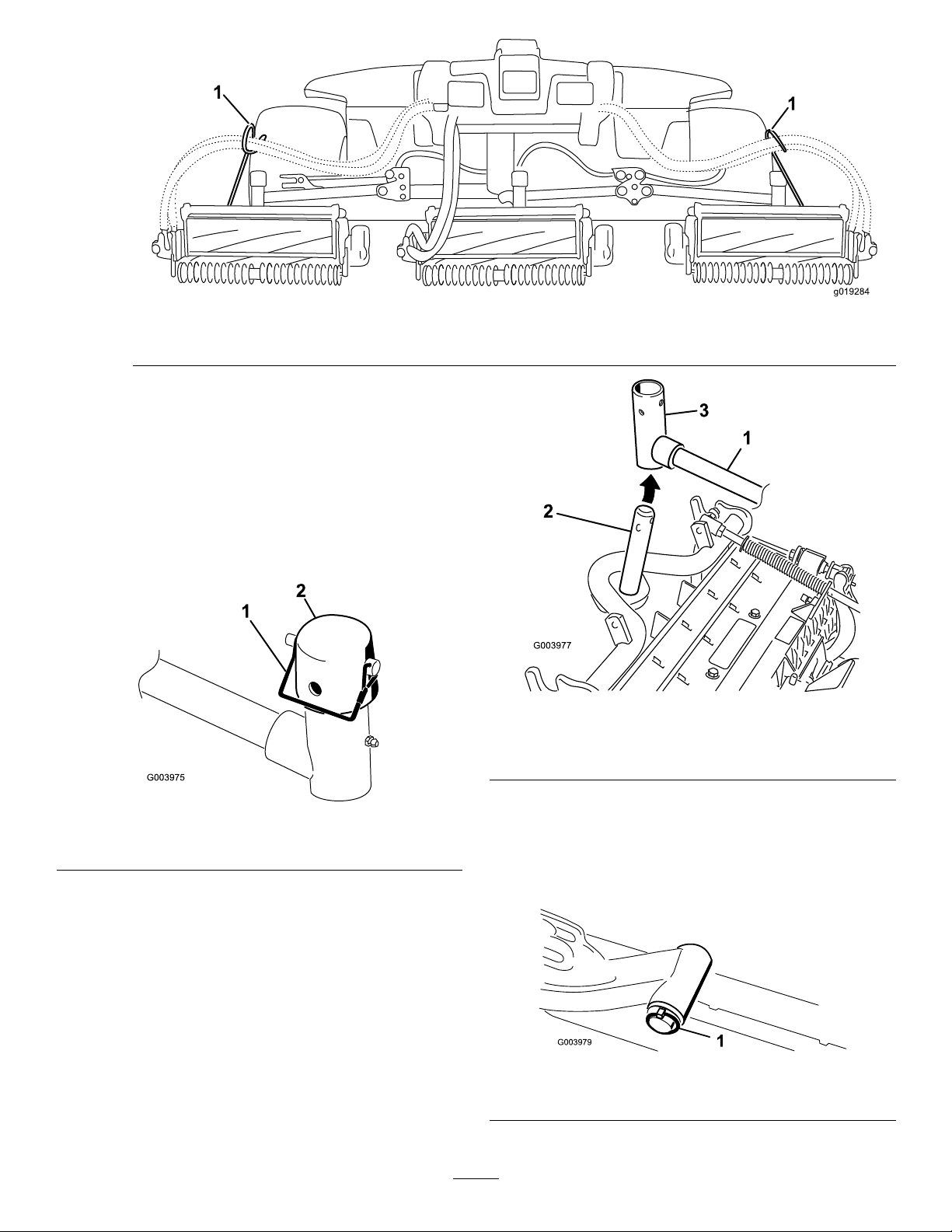

g019284

1

1

1.Hoseguides(eachmustleantowardthecentercuttingunit)

Note:Wheninstallingorremovingthecutting

units,makesurethehairpincotterisinstalledin

thespringrodholenexttotherodbracket.When

notinstallingorremovingthecuttingunits,the

hairpincottermustbeinstalledintheholeinthe

endoftherod.

6.Loweralltheliftarmscompletely.

7.Removethesnapperpinandthecapfromtheliftarm

pivotyoke(Figure10).

Figure9

Figure11

1.Liftarm3.Liftarmpivotyoke

2.Carrierframeshaft

Figure10

1.Snapperpin2.Cap

8.Forthefrontcuttingunits,slideacuttingunitunder

theliftarmwhileinsertingthecarrierframeshaftup

intotheliftarmpivotyoke(Figure11).

9.Usethefollowingprocedureontherearcuttingunits

whentheheightofcutisabove19.5mm(3/4inch).

A.Removethelynchpinandwashersecuringthelift

armpivotshafttotheliftarmandslidethelift

armpivotshaftoutoftheliftarm(Figure12).

Figure12

1.Liftarmpivotshaftlynchpinandwasher

13

Page 14

B.Inserttheliftarmyokeontothecarrierframe

shaft(Figure11).

C.Inserttheliftarmshaftintotheliftarmandsecure

itwiththewasherandlynchpin(Figure12).

10.Insertthecapoverthecarrierframeshaftandliftarm

yoke.

11.Securethecapandthecarrierframeshafttothelift

armyokewiththesnapperpin.Usetheslotifasteering

cuttingunitisdesiredorusetheholeifthecuttingunit

istobelockedinposition(Figure10).

12.Securetheliftarmchaintothechainbracketwiththe

snapperpin(Figure13).Usethenumberofchainlinks

describedinthecuttingunitOperator'sManual.

Figure14

1.Reeldrivemotor2.Mountingbolts

Figure13

1.Liftarmchain3.Snapperpin

2.Chainbracket

13.Onthe#4(leftfront)and#5(rightfront)cutting

units,insertthereelmotorhosesintotherespective

hoseguide.

14.Coatthesplineshaftofthereelmotorwithclean

grease.

15.OilthereelmotorO-ringandinstallitontothemotor

ange.

16.Installthemotorbyrotatingitclockwisesothatthe

motorangesclearthebolts(Figure14).Rotatethe

motorcounterclockwiseuntiltheangesencirclethe

boltsthentightenthebolts.

Important:Makesurethereelmotorhosesare

nottwisted,kinkedorintheriskofbeingpinched.

5

AdjustingtheTurf CompensationSpring

NoPartsRequired

Procedure

Theturfcompensationspring(Figure15)transfersweight

fromthefronttotherearroller.Thishelpstoreduceawave

patternintheturf,alsoknownasmarcellingorbobbing.

Important:Makespringadjustmentswiththecutting

unitmountedtothetractionunit,pointingstraight

ahead,andloweredtotheshopoor.

1.Makesurethatthehairpincotterisinstalledintherear

holeinthespringrod(Figure15).

14

Page 15

Figure15

1.Turfcompensationspring3.Springrod

2.Hairpincotter4.Hexnuts

Figure16

2.Tightenthehexnutsonthefrontendofthespring

roduntilthecompressedlengthofthespringis12.7

cm(5inches)onReelmaster5410,5inchcuttingunits

or15.9cm(6.25inches)onReelmaster5510,7inch

cuttingunits(Figure15).

Note:Whenoperatingonroughterraindecrease

thespringlengthby12.7mm(1/2inch);thisslightly

decreasesgroundfollowing.

6

UsingtheCuttingUnit Kickstand

Partsneededforthisprocedure:

1

Cuttingunitkickstand

Procedure

Wheneverthecuttingunithastobetippedtoexposethe

bedknife/reel,propuptherearofthecuttingunitwiththe

kickstandtomakesurethenutsonthebackendofthe

bedbaradjustingscrewsarenotrestingontheworksurface

(Figure16).

1.Cuttingunitkickstand

Securethekickstandtothechainbracketwiththesnapper

pin(Figure17).

Figure17

1.Chainbracket3.Cuttingunitkickstand

2.Snapperpin

15

Page 16

ProductOverview

Figure18

howfaryoupressthepedal.Fornoload,maximumground

speed,fullypressthepedalwhiletheenginespeedsetting

isintheFastposition.

Tostop,reducefootpressureonthetractionpedalandallow

ittoreturntothecenterposition.

1.Enginehood

2.Operator'sseat

3.Controlarm

4.Steeringwheel

5.Seatadjustingcontrols

6.Frontcuttingunits

7.Rearcuttingunits

Controls

SeatAdjustingControls

Theseatadjustinglever(Figure19)allowsyoutoadjustthe

seatforeandaft.Theweightadjustingknobadjuststheseat

fortheoperator'sweight.Theweightgaugeindicateswhen

theseatisadjustedtotheweightoftheoperator.Theheight

adjustingknobadjuststheseatfortheoperator'sheight.

Figure20

1.Tractionpedal4.Brakepedal

2.Mowspeedlimiter5.Parkingbrake

3.Spacers

6.Tiltsteeringpedal

MowSpeedLimiter

Whenthemowspeedlimiter(Figure20)isippedupit

controlsthemowspeedandallowsthecuttingunitstobe

engaged.Eachspaceradjuststhemowingspeedby0.8km/h

(1/2mph).Themorespacersyouhaveonthetopofthe

bolt,theslowerthemachinegoes.Fortransport,ipbackthe

mowspeedlimitertohavemaximumtransportspeed.

BrakePedal

Pressthebrakepedal(Figure20)tostopthemachine.

ParkingBrake

Figure19

1.Weightgauge3.Heightadjustingknob

2.Weightadjustingknob

4.Adjustinglever(foreand

aft)

TractionPedal

Thetractionpedal(Figure20)controlstheforwardand

reverseoperation.Pressthetopofthepedaltomoveforward

andthebottomtomoverearward.Groundspeeddependson

Toengagetheparkingbrake,(Figure20)pushdownonthe

brakepedalandpressthetopforwardtolatchit.Torelease

theparkingbrake,pressthebrakepedaluntiltheparking

brakelatchretracts.

TiltSteeringPedal

Totiltthesteeringwheeltowardsyou,pressthefootpedal

(Figure20)down,andpullthesteeringtowertowardyouto

themostcomfortablepositionandthenreleasethepedal.

EngineSpeedSwitch

Theenginespeedswitch(Figure21)has2modestochange

theenginespeed.Bymomentarilytappingtheswitch,youcan

16

Page 17

increaseordecreasetheenginespeedin100-rpmincrements.

1

2

3

4

5

6

G021208

1

g021209

Byholdingtheswitchdown,theenginespeedautomatically

movestoHighorLowidle,dependingonwhichendofthe

switchyoupress.

Figure21

1.Lowermow/raisecontrol

lever

2.Keyswitch5.Enginespeedswitch

3.InfoCenter

4.Enable/disableswitch

6.Headlightswitch

Enable/DisableSwitch

Usetheenable/disableswitch(Figure21)inconjunctionwith

thelowermow/raisecontrollevertooperatethecutterheads.

InfoCenter

TheInfoCenterLCDdisplayshowsinformationaboutyour

machinesuchastheoperatingstatus,variousdiagnosticsand

otherinformationaboutthemachine(Figure21).

KeySwitch

Thekeyswitch(Figure21)has3positions:Off,On/Run,

andStart.

LowerMow/RaiseControlLever

Figure22

1.Backlaplevers

HydraulicFilterRestrictionIndicator

Withtheenginerunningatnormaloperatingtemperature,

viewtheindicator(Figure23),itshouldbeintheGreenzone.

WhentheindicatorisintheRedzone,changethehydraulic

lters.

Thislever(Figure21)raisesandlowersthecuttingunitsand

alsostartsandstopsthecutterheadswhenthecutterheads

areenabledinthemowmode.Thecutterheadscannotbe

loweredwhenthemow/transportleverisinthetransport

position.

1.Hydrauliclterrestrictionindicator

Figure23

PowerPoint

HeadlightSwitch

Pivottheswitchdownwardtoturnontheheadlights(Figure

21).

Thepowerpointisa12voltpowersupplyforelectronic

devices(Figure24).

BacklapLevers

Usethebacklapleversinconjunctionwiththelower

mow/raisecontrolleverforbacklappingthereels(Figure22).

17

Page 18

1

g020650

2

3

4

TORO

InfoCenterIconDescription

Figure24

1.Powerpoint

UsingtheInfoCenterLCDDisplay

TheInfoCenterLCDdisplayshowsinformationaboutyour

machinesuchastheoperatingstatus,variousdiagnostics

andotherinformationaboutthemachine(Figure25)There

isasplashscreenandmaininformationscreenofthe

InfoCenter.Youcanswitchbetweenthesplashscreenand

maininformationscreen,atanytime,bypressinganyof

theInfoCenterbuttonsandthenselectingtheappropriate

directionalarrow .

SERVICEDUE

Indicateswhenscheduledservice

shouldbeperformed

Enginerpm/status—indicatesthe

enginespeed

Hourmeter

Infoicon

Fast

Slow

Fuellevel

Stationaryregenerationrequired

Glowplugsareactive

Raisecuttingunits

Lowercuttingunits

Operatormustsitinseat

ParkingBrakeIndicator—indicates

whentheparkingbrakeisOn

IdentiestherangeasHigh

(Transport)

Neutral

IdentiestherangeasLow(Mow)

Figure25

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•LeftButton,MenuAccess/BackButton—pressthis

buttontoaccesstheInfoCentermenus.Youcanuseitto

CoolantTemperature-indicatesthe

enginecoolanttemperatureineither

°Cor°F

Temperature(hot)

PTOisengaged

backoutofanymenuyouarecurrentlyusing.

•MiddleButton—usethisbuttontoscrolldownmenus.

•RightButton—usethisbuttontoopenamenuwherea

rightarrowindicatesadditionalcontent.

Note:Thepurposeofeachbuttonmaychangedepending

onwhatisrequiredatthetime.Eachbuttonwillbelabeled

Deniedornotallowed

EngineStart

Stoporshutdown

withanicondisplayingitscurrentfunction.

18

Page 19

InfoCenterIconDescription(cont'd.)

Symbolsareoften

combinedtoform

sentences.Some

examplesareshown

below

Engine

Keyswitch

Indicateswhenthecuttingunitsare

beinglowered

Indicateswhenthecuttingunitsare

beingraised

PINpasscode

CANbus

InfoCenter

Badorfailed

Bulb

OutputofTECcontrollerorcontrol

wireinharness

Switch

Operatormustreleaseswitch

Operatorshouldchangetoindicated

state

Operatorshouldputmachinein

neutral

Enginestartdenied

Engineshutdown

Enginecoolanttoohot

Sitdownorsetparkingbrake

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthemenuaccess

buttonwhileatthemainscreen.Thisbringsyoutothemain

menu.Refertothefollowingtablesforasynopsisofthe

optionsavailablefromthemenus:

MainMenu

MenuItemDescription

FaultsTheFaultsmenucontains

ServiceTheServicemenucontains

DiagnosticsTheDiagnosticsmenu

SettingsTheSettingsmenuallows

AboutTheAboutmenuliststhe

Service

MenuItemDescription

Hours

Counts

Diagnostics

MenuItemDescription

CuttingUnitsIndicatestheinputs,qualiers

Hi/LowRangeIndicatestheinputs,qualiers

PTOIndicatestheinputs,qualiers

alistoftherecentmachine

faults.RefertotheService

ManualoryourAuthorized

ToroDistributorformore

informationontheFaults

menuandtheinformation

containedthere.

informationonthemachine

suchashoursofusecounters

andothersimilarnumbers.

displaysthestateofeach

machineswitch,sensorand

controloutput.Y oucanuse

thistotroubleshootcertain

issuesasitquicklytellsyou

whichmachinecontrolsareon

andwhichareoff.

youtocustomizeandmodify

congurationvariablesonthe

InfoCenterdisplay.

modelnumber,serialnumber,

andsoftwareversionofyour

machine.

Liststhetotalnumberofhours

thatthemachine,engineand

PTOhavebeenon,aswell

asthenumberofhoursthe

machinehasbeentransported

andservicedue.

Listsnumerouscountsthe

machinehasexperienced.

andoutputsforraisingand

loweringthecuttingunits.

andoutputsfordrivingin

transportmode.

andoutputsforenablingthe

PTOcircuit.

19

Page 20

EngineRun

Backlap

Settings

MenuItemDescription

Units

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

FrontBacklapReelSpeedControlsthespeedofthefront

RearBacklapReelSpeedControlsthespeedoftherear

ProtectedMenusAllowsthe

AutoIdle

BladeCountControlsthenumberofblades

MowSpeedControlsthegroundspeedfor

Heightofcut(HOC)Controlstheheightofcut

FReelRPMDisplaysthecalculatedreel

RReelRPMDisplaysthecalculatedreel

Indicatestheinputs,qualiers

andoutputsforstartingthe

engine.

Indicatestheinputs,qualiers

andoutputsforoperatingthe

backlapfunction.

Controlstheunitsusedonthe

InfoCenter.Themenuchoices

areEnglishorMetric

Controlsthelanguageused

ontheInfoCenter*.

LCDdisplay.

LCDdisplay.

reelsinbacklapmode.

reelsinbacklapmode.

superintendant/mechanic

toaccessprotectedmenusby

inputtingapasscode.

Controlstheamountoftime

allowedbeforereturningthe

enginetolowidlewhenthe

machineisstationary.

onthereelforreelspeed.

determiningthereelspeed.

(HOC)fordeterminingthereel

speed.

speedforthefrontreels.The

reelscanalsobemanually

adjusted.

speedfortherearreels.The

reelscanalsobemanually

adjusted.

*Only"operator-faced"textistranslated.Faults,Service,

andDiagnosticsscreensare"service-faced".Titlesareinthe

selectedlanguage,butmenuitemsareinEnglish.

About

MenuItemDescription

Model

SNListstheserialnumberofthe

Liststhemodelnumberofthe

machine.

machine.

MachineControllerRevisionListsthesoftwarerevisionof

InfoCenterRevisionListsthesoftwarerevisionof

CANBus

themastercontroller .

theInfoCenter.

Liststhemachine

communicationbusstatus.

ProtectedMenus

Thereare7operatingcongurationsettingsthatareadjustable

withintheSettingsMenuoftheInfoCenter:autoidletime

delay,BladeCount,MowSpeed,HeightofCut(HOC),F

ReelRPMandRReelRPM.Thesesettingscanbelocked

byusingtheProtectedMenu.

Note:Atthetimeofdelivery,theinitialpasswordcodeis

programmedbyyourdistributor.

AccessingtheProtectedMenuSettings

ToaccesstheProtectedMenuSettings

•FromtheMainMenu,scrolldowntotheSettingsMenu

andpresstherightbutton.

•IntheSettingsMenu,scrolldowntotheProtectedMenu

andpresstherightbutton.

•Toenterthepasscode,usethecenterbuttontosetthe

rstdigitthenpresstherightbuttontomoveontothe

nextdigit.

•Usethecenterbuttontosettheseconddigitthenpress

therightbuttontomoveontothenextdigit.

•Usethecenterbuttontosetthethirddigitthenpressthe

rightbuttontomoveontothenextdigit.

•Usethecenterbuttontosetthefourthdigitthenpress

therightbutton.

•Pressthemiddlebuttontoenterthecode.

•Ifthecodehasbeenacceptedandtheprotectedmenu

hasbeen“Unlocked”,“PIN”isdisplayedintheupper

rightcornerofthedisplayscreen.

TheabilitytoviewandchangethesettingsintheProtected

Menucanbechanged.OncetheProtectedMenuhasbeen

accessed,scrolldowntoProtectSettings.Usingtheright

button,changingProtectSettingstoOFFallowstheabilityto

viewandchangethesettingsintheProtectedMenuwithout

enteringthepasscode.ChangingProtectSettingstoON

hidestheprotectedoptionsandrequiresenteringapasscode

tochangethesettingintheProtectedMenu.Afterthepass

codehasbeenset,thekeyswitchmustbeturnedoffandback

ontoenableandsavethisfeature.

Note:Ifthepasscodehasbeenforgottenormisplaced,

pleasecontactyourdistributorforassistance.

SettingtheAutoIdle

•IntheSettingsMenu,scrolldowntoAutoIdle.

•Presstherightbuttontochangetheautoidletime

betweenOFF,8S,10S,15S,20S,and30S.

20

Page 21

SettingtheBladeCount

•IntheSettingsMenu,scrolldowntoBladeCount.

•Presstherightbuttontochangethebladecountbetween

5,8,or11bladereels.

SettingtheMowSpeed

•IntheSettingsMenu,scrolldowntoMowSpeed.

•Presstherightbuttontoselectmowspeed.

•Usethecenterandrightbuttontoselecttheappropriate

mowspeedsetonthemechanicalmowspeedlimiteron

thetractionpedal.

•Presstheleftbuttontoexitmowspeedandsavethe

setting.

SettingtheHeightofCut(HOC)

•IntheSettingsMenu,scrolldowntoHOC.

•PresstherightbuttontoselectHOC.

•Usethecenterandrightbuttontoselecttheappropriate

HOCsetting.(Iftheexactsettingisnotdisplayed,select

thenearestHOCsettingfromthelistdisplayed).

•PresstheleftbuttontoexitHOCandsavethesetting.

SettingtheFrontandRearReelSpeeds

Althoughthefrontandrearreelspeedsarecalculatedby

inputtingthenumberofblades,mowspeedandHOCinto

theInfoCenter,thesettingcanbemanuallychangedto

accommodatefordifferentmowingconditions.

•TochangetheReelSpeedSettings,scrolldowntotheF

ReelRPM,RReelRPMorboth.

•Presstherightbuttontochangethereelspeedvalue.As

thespeedsettingischanged,thedisplaycontinuesto

showthecalculatedreelspeedbasedonbladecount,

mowspeedandHOCwhichwaspreviouslyentered,but

thenewvalueisalsodisplayed.

21

Page 22

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

SpecicationReelMaster®5410-GReelMaster®5510-G

Transportwidth

Widthofcut254cm(100inches)254cm(100inches)

Length

Height

Weight

(withuidsand8bladecuttingunitsinstalled)

EngineKubota49hp

Fueltankcapacity

228cm(90inches)233cm(92inches)

282cm(111inches)282cm(111inches)

160cm(63inches)160cm(63inches)

1,247kg(2,750lb)1,335kg(2,943lb)

WG1605EFI

53liters(14USgallons)53liters(14USgallons)

Kubota49hp

WG1605EFI

Transportspeed

Mowingspeed

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

0–16km/h(0–10mph)0–16km/h(0–10mph)

0–13km/h(0–8mph)0–13km/h(0–8mph)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyintheignitionswitch,someone

couldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Lowerthecuttingunitstotheground,setthe

parkingbrakeandremovethekeyfromtheignition

switchbeforeservicingormakingadjustmentsto

themachine.

CheckingtheEngine-OilLevel

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Crankcasecapacity:approximately6liters(6.3USqt)with

thelter

Useanyhigh-qualityengineoilthatmeetstheAPI

classicationlevelofSLorhigher.

Changethetypeofengineoilaccordingtotheambient

temperature.

ToroPremiumEngineoilisavailablefromyourdistributorin

either15W -40or10W-30viscosity .

22

Page 23

Above25degreesC(77

g02121 1

2

1

g021214

1

degreesF)

0degreesCto25degreesC

(32degreesFto77degrees

F)

0degreesCto–20degreesC

(32degreesFto–4degrees

F)

SAE30orSAE10W-30

SAE15W-40

SAE20orSAE10W-30

SAE10WorSAE10W-30

1.Parkthemachineonalevelsurface,stoptheengine,

settheparkingbrake,andremovethekeyfromthe

ignitionswitch.

2.Openthehood.

3.Removethedipstick,wipeitclean,andinstallit(Figure

26).

4.Removedipstickandcheckoillevelondipstick.The

oillevelshouldbeuptotheFullmark.

5.IftheoillevelisbelowtheFullmark,removethell

cap(Figure26)andaddoiluntilthelevelreachesthe

Fullmarkondipstick.Donotoverllthecrankcase.

6.Afteraddingoil,waitmorethan5minutesandcheck

theoillevelagain.Ittakessometimefortheoilto

draindowntothepan.

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolantifreeze.Checkthelevelof

thecoolantintheexpansiontankatthebeginningofeachday

beforestartingtheengine.Thecapacityofthecoolingsystem

is6.6liters(7.0USqt).

CAUTION

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhentheengine

isrunning.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

1.Checkthelevelofcoolantintheexpansiontank

(Figure27).

Thecoolantlevelshouldbebetweenthemarksonthe

sideofthetank.

Figure26

1.Dipstick

2.Oil-llcap

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultof

overllingorunder-llingthecrankcase.

7.Installtheoil-llcapandclosethehood.

CheckingtheCoolingSystem

Cleandebrisoffofthescreen,oilcooler,andfrontofthe

radiatordailyandmoreoftenifconditionsareextremely

dustyanddirty.RefertoRemovingDebrisfromtheCooling

System(page40).

Figure27

1.Expansiontank

2.Ifthecoolantlevelislow,removetheexpansion-tank

capandreplenishthesystem.Donotoverllthe

expansiontank.

3.Installtheexpansion-tankcap.

AddingFuel

•Fueltankcapacity:53liters(14USgallons)

•RecommendedFuel:

–Forbestresults,useonlyclean,fresh(lessthan30

daysold),unleadedgasolinewithanoctaneratingof

87orhigher((R+M)/2ratingmethod).

–Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)by

volumeisacceptable.EthanolandMTBEarenotthe

same.Gasolinewith15%ethanol(E15)byvolume

isnotapprovedforuse.Neverusegasolinethat

containsmorethan10%ethanolbyvolume,

23

Page 24

suchasE15(contains15%ethanol),E20(contains

1

G021210

20%ethanol),orE85(containsupto85%ethanol).

Usingunapprovedgasolinemaycauseperformance

problemsand/orenginedamagewhichmaynotbe

coveredunderwarranty.

–Donotusegasolinecontainingmethanol.

–Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizeris

used.

–Donotaddoiltogasoline.

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafueldispensernozzle.

•Ifafueldispensernozzlemustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleanareaaroundfueltankcap.

3.Removethecapfromthefueltank(Figure28).

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Figure28

1.Fueltankcap

4.Addunleadedregulargasolinetothefueltankuntilthe

levelis25mm(1inch)belowthebottomoftheller

neck.

Thisspaceinthetankallowsgasolinetoexpand.Do

notllthefueltankcompletelyfull.

5.Installthefueltankcapsecurely.Wipeupanygasoline

thatmayhavespilled.

CheckingtheHydraulicFluid

Thereservoirislledatthefactorywithapproximately30

liters(8USgallons)ofhigh-qualityhydraulicuid.Thebest

timetocheckthehydraulicoiliswhentheuidiscold.The

24

Page 25

machineshouldbeinitstransportconguration.Iftheoil

levelisbelowthe‘add’markonthedipstick,addoiltobring

theoilleveltothemiddleoftheacceptablerange.Donot

overllthereservoir.Iftheoillevelisbetweenthe‘full’and

the‘add’marks,nooiladditionisrequired.

Therecommendedreplacementuidis:

ToroPremiumAllSeasonHydraulicFluid

(availablein19liter(5gallon)containersor208liter(55

gallon)drums—seethepartsdocumentationoryourToro

distributorforpartnumbers)

Alternativeuids:IftheTorouidisnotavailable,other

conventional,petroleum-baseduidsmaybeused,provided

thattheymeetallofthefollowingmaterialpropertiesand

industryspecications.Checkwithyouroilsuppliertosee

whethertheoilmeetsthesespecications.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

HighViscosityIndex/LowPourPointAntiwearHydraulic

Fluid,ISOVG46Multigrade

MaterialProperties:

Viscosity,ASTMD445cSt@40°C(104°F)

Viscosityindex,ASTM

D2270

Pourpoint,ASTMD97-36.7°Cto-45°C(-34°Fto

FZG,failstage

Watercontent(newuid)500ppm(maximum)

IndustrySpecications:

VickersI-286-S,VickersM-2950-S,DenisonHF-0,

Vickers35VQ25(EatonATS373-C)

44to48

cSt@100°C(212°F)

7.9to9.1

140orhigher(high

viscosityindexindicatesa

multiweightuid)

-49°F)

11orbetter

Theproperhydraulicuidsmustbespeciedfor

mobilemachinery(asopposedtoindustrialplantusage),

multiweight-type,withZnDTPorZDDPanti-wearadditive

package(notanashless-typeuid).

Important:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein20ml(2/3oz)

bottles.Onebottleissufcientfor15to22liters(4to6

USgallons)ofhydraulicoil.Orderpart44-2500from

yourAuthorizedT oroDistributor.

Synthetic,BiodegradableHydraulicFluid

(availablein19liter(5gallon)containersor208liter(55

gallon)drums—seethepartsdocumentationoryourToro

distributorforpartnumbers)

Thishigh-quality,synthetic,biodegradableuidhasbeen

testedandfoundcompatibleforthisToromodel.Other

brandsofsyntheticuidmayhavesealcompatibilityproblems

andTorocannotassumeresponsibilityforunauthorized

substitutions.

Note:Thissyntheticuidisnotcompatiblewiththe

ToroBiodegradableFluidpreviouslysold.SeeyourToro

Distributorformoreinformation.

Alternativeuids:

•MobilEALEnvirosynH46(US)

•MobilEALHydraulicOil46(international)

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,andstoptheengine.

2.Cleantheareaaroundthellerneckandthecapof

thehydraulictank(Figure29).Removethecapfrom

thellerneck.

25

Page 26

1

g021215

Figure29

StartingandStoppingthe Engine

StartingtheEngine

1.Sitontheseat,keepyourfootoffofthetractionpedal

sothatitisinNeutral,engagetheparkingbrake,setthe

enginespeedswitchtotheMidpositionandensurethat

theEnable/DisableswitchisintheDisableposition.

2.Removeyourfootfromthetractionpedalandmake

surethepedalisintheNeutralposition.

3.Insertandrotatetheignitionkeyclockwiseuntilthe

enginestarts.

1.Hydraulic-tankcap

3.Removethedipstickfromthellerneckandwipeit

withacleanrag.Insertthedipstickintothellerneck,

thenremoveitandchecktheleveloftheuid.The

uidlevelshouldbewithin6.3mm(1/4inch)ofthe

markonthedipstick.Donotoverllthetank.

4.Ifthelevelislow ,addtheappropriateuidtoraisethe

leveltothefullmark.

5.Installthedipstickandthecapontothellerneck.

CheckingtheReeltoBedknife Contact

Eachdaybeforeoperating,checkreeltobedknifecontact,

regardlessifthequalityofcuthadpreviouslybeenacceptable.

Theremustbelightcontactacrossthefulllengthofthereel

andthebedknife(refertoAdjustingtheReeltoBedknifein

thecuttingunitOperator'sManual).

CheckingtheTorqueofthe WheelNuts

StoppingtheEngine

1.MoveallcontrolstoNeutral,settheparkingbrake,

movetheenginespeedswitchtothelowidleposition

andallowtheenginetoreachlowidlespeed.

2.TurnthekeytotheOffpositionandremoveitfrom

theswitch.

SettingtheReelSpeed

Toachieveaconsistent,highqualityofcutandauniform

aftercutappearance,itisimportantthatyousetthereelspeed

tothepropersetting.Adjustthereelspeedasfollows:

1.IntheInfoCenter,enterthebladecount,mowspeed

andHOCtocalculatetheproperreelspeed.

2.Iffurtheradjustmentsarerequired,scrolldownonthe

InfoCentertotheFReelRPM,RReelRPM,orboth.

3.Presstherightbuttontochangethereelspeedvalue.

Asthespeedsettingischanged,thedisplaycontinues

toshowthecalculatedreelspeedbasedonblade

count,mowspeed,andHOC,butthenewvalueis

alsodisplayed.

Note:Thereelspeedmayneedtobeincreasedor

decreasedtocompensateforvaryingturfconditions.

Torquethewheelnutsto94to122N-m(70to90ft-lb)

after1to4hoursofoperationandagainafter10hoursof

operation.T orquethemevery250hoursthereafter.

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

Maintainpropertorqueofthewheelnuts.

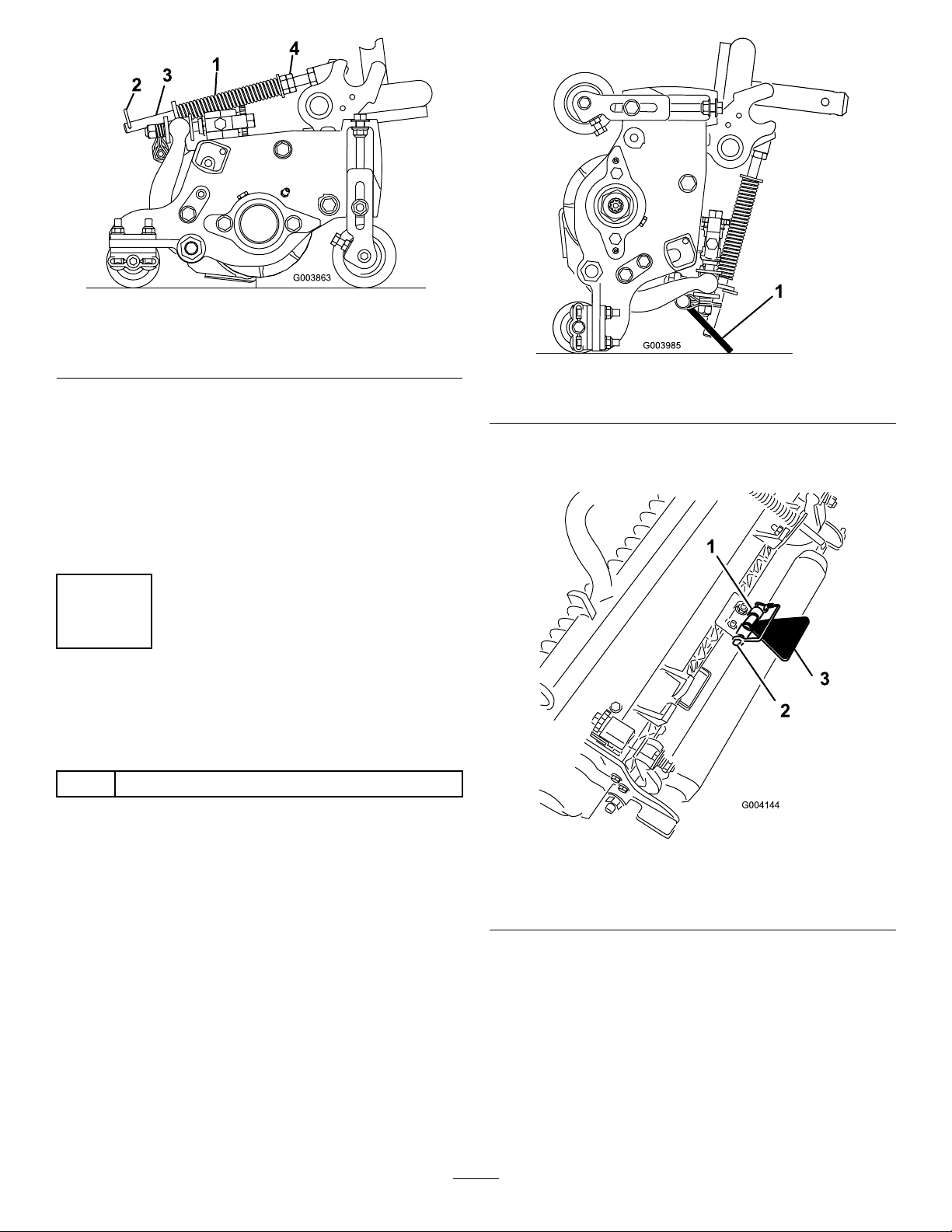

AdjustingtheLiftArm Counterbalance

Youcanadjustthecounterbalanceontherearcuttingunit

liftarmstocompensatefordifferentturfconditionsandto

maintainauniformheightofcutintheroughconditionsor

inareasofthatchbuildup.

Youcanadjusteachcounterbalancespringto1of4settings.

Eachincrementincreasesordecreasescounterbalanceonthe

cuttingunitby2.3kg(5lb).Thespringscanbepositioned

onthebacksideoftherstspringactuatortoremoveall

counterbalance(fourthposition).

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,engagetheparking

brakes,andremovethekeyfromtheignitionswitch.

26

Page 27

2.Insertatubeorsimilarobjectontothelongspringend

g019276

1

2

andpivotitaroundthespringactuatortothedesired

position(Figure30).

CAUTION

Thespringsareundertension.

Usecautionwhenadjustingthem.

Figure31

1.Switch2.Liftarmsensingdevice

Figure30

1.Spring2.Springactuator

3.Repeattheprocedureontheotherspring.

AdjustingtheLiftArmTurn AroundPosition

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,stoptheengine,engagetheparking

brakes,andremovethekeyfromignitionswitch.

2.Theliftarmswitchislocatedunderneaththehydraulic

tankbehindthefrontrightliftarm(Figure31).

3.Loosentheswitchmountingscrews(Figure31)and

movetheswitchdowntoincreasetheliftarmturn

aroundheightormovetheswitchuptodecreasethelift

armturnaroundheight.Tightenthemountingscrews.

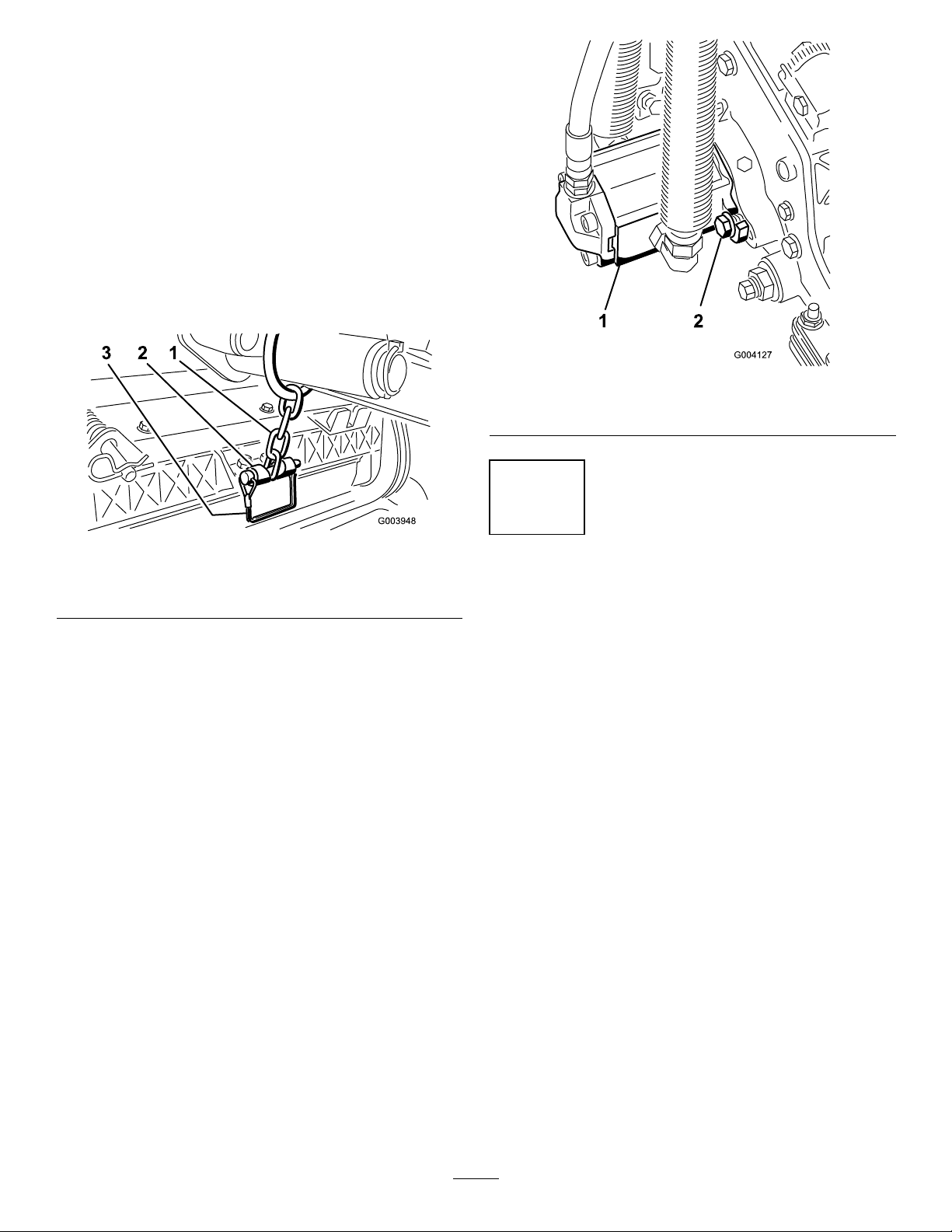

PushingorTowingthe Machine

Inanemergency,themachinecanbemovedbyactuatingthe

bypassvalveinthevariabledisplacementhydraulicpumpand

pushingortowingthemachine.

Important:Donotpushortowthemachinefasterthan

3to4.8km/h(2to3mph)becauseinternaltransmission

damagemayoccur.Thebypassvalvemustbeopen

wheneverthemachineispushedortowed.

1.Thebypassvalveislocatedontheleftsideofthe

hydrostat(Figure32).Rotatethebolt1-1/2turnsto

openandallowoiltobypassinternally.Becauseuid

isbypassed,themachinecanbemovedslowlywithout

damagingthetransmission.

Figure32

1.Bypassvalve

2.Closethebypassvalvebeforestartingtheengine.

However,donotexceed7to11N-m(5to8ft-lb)

torquetoclosethevalve.

27

Page 28

Important:Runningtheenginewiththebypass

valveopencausesthetransmissiontooverheat.

LocatingtheJackingPoints

Note:Usejackstandstosupportthemachinewhenrequired.

•Front—rectangularpad,undertheaxletube,insideeach

fronttire(Figure33)

Figure34

1.Fronttiedown

•Rear—eachsideofthemachineontherearframe(Figure

35).

Figure33

1.Frontjackingpoint

•Rear—rectangularaxletubeontherearaxle

LocatingtheTieDowns

•Front—theholeintherectangularpad,undertheaxle

tube,insideeachfronttire(Figure34).

Figure35

1.Reartiedown

UnderstandingtheDiagnostic Light

Themachineisequippedwithadiagnosticlightwhich

indicatesifthemachinedetectsamalfunction.Thediagnostic

lightislocatedontheInfoCenter,abovethedisplayscreen

(Figure36).Whenthemachineisfunctioningproperly

andthekeyswitchismovedtotheOn/Runposition,the

diagnosticlightturnsonbrieytoindicatethatthelight

isworkingproperly.Whenamachineadvisorymessageis

displayed,thelightilluminateswhenthemessageispresent.

28

Page 29

Whenafaultmessageisdisplayed,thelightblinksuntilthe

g021272

TORO

faultisresolved

5.Ifaswitchisclosedandtheappropriateindicatordoes

notchange,checkallwiringandconnectionstothe

switchand/orchecktheswitcheswithanohmmeter.

Replaceanydefectiveswitchesandrepairanydefective

wiring.

Note:TheInfoCenterdisplayalsohastheabilitytodetect

whichoutputsolenoidsorrelaysareturnedon.Thisisa

quickwaytodetermineifamachinemalfunctioniselectrical

orhydraulic.

VerifyingOutputFunction

1.Parkthemachineonalevelsurface,lowerthecutting

units,stoptheengine,andengagetheparkingbrake.

Figure36

1.Diagnosticlight

CheckingtheInterlock Switches

Thepurposeoftheinterlockswitchesistopreventthe

enginefromcrankingorstartingunlessthetractionpedalis

intheNeutralposition,theEnable/Disableswitchisinthe

Disableposition,andtheLowerMow/Raisecontrolisinthe

Neutralposition.Inaddition,theengineshouldstopwhen

thetractionpedalispressedwithoperatoroffoftheseatorif

theparkingbrakeisleftengaged.

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

VerifyingtheInterlockSwitchFunction

1.Parkthemachineonalevelsurface,lowerthecutting

units,stoptheengine,andengagetheparkingbrake.

2.TurnthekeyswitchtotheOnposition,butdonot

startthemachine.

2.TurnthekeyswitchtotheOnposition,butdonot

startthemachine.

3.Locatetheappropriateoutputfunctioninthe

diagnosticsmenuontheInfoCenter.

4.Sitontheseatandattempttooperatethedesired

functionofthemachine.Theappropriateoutputs

shouldchangestatetoindicatethattheECMisturning

onthatfunction.

Note:Ifthecorrectoutputsdonotilluminate,verifythatthe

requiredinputswitchesareinthenecessarypositionstoallow

thatfunctiontooccur.Verifycorrectswitchfunction.

Iftheoutputdisplaysareonasspecied,butthemachine

doesnotfunctionproperly,thisindicatesanon-electrical

problem.Repairasnecessary.

HydraulicValveSolenoid Functions

Usethelistbelowtoidentifyanddescribethedifferent

functionsofthesolenoidsinthehydraulicmanifold.Each

solenoidmustbeenergizedtoallowfunctiontooccur.

Solenoid

SP2

SP1

SVRVLift/lowercuttingunits

SV1Lift/lowerfrontcuttingunits

SV3Lift/lowerrearcuttingunits

SV2

Frontreelcircuit

Rearreelcircuit

Raiseanycuttingunits

Function

3.Locatetheappropriateswitchfunctioninthe

diagnosticsmenuontheInfoCenter.

4.Individually,changeeachoftheswitchesfromopento

closed(i.e.,sitonseat,engagetractionpedal,etc.),and

notethattheappropriatestateoftheswitchchanges.

Repeatthisforallswitchesthatyoucanchangeby

hand.

29

Page 30

OperatingTips

BecomingFamiliarwiththeMachine

Beforemowinggrass,practiceoperatingthemachineinan

openarea.Startandstoptheengine.Operateinforwardand

reverse.Lowerandraisethecuttingunitsandengageand

disengagethereels.Whenyoufeelfamiliarwiththemachine,

practiceoperatingupanddownslopesatdifferentspeeds.

UnderstandingtheWarningSystem

Ifawarninglightcomesonduringoperation,stopthe

machineimmediatelyandcorrecttheproblembefore

continuingoperation.Seriousdamagecouldoccurifyou

operatethemachinewithamalfunction.

MowingGrass

Starttheengineandmovetheenginespeedswitchtothe

Fastposition.MovetheEnable/DisableswitchtotheEnable

positionandusetheLowerMow/Raiselevertocontrolthe

cuttingunits(thefrontcuttingunitsaretimedtolowerbefore

therearcuttingunits).Tomoveforwardandcutgrass,press

thetractionpedalforward.

Note:Allowtheenginetoidlefor5minutesbeforeshutting

itoffafterafullloadoperation.Failuretodosomayleadto

turbo-chargertrouble.

DrivingtheMachineinTransportMode

MovetheEnable/DisableswitchtotheDisablepositionand

raisethecuttingunitstothetransportposition.Movethe

Mow/Transportlevertothetransportposition.Becareful

whendrivingbetweenobjectssothatyoudonotaccidentally

damagethemachineorthecuttingunits.Useextracarewhen

operatingthemachineonslopes.Driveslowlyandavoid

sharpturnsonslopestopreventroll-overs.Lowerthecutting

unitswhengoingdownhillforsteeringcontrol.

30

Page 31

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•T orquethewheellugnutsto94to122N-m(70to90ft-lb).

•Checktheconditionandtensionofthealternatorbelt.

•T orquethewheellugnutsto94to122N-m(70to90ft-lb).

•Changetheengineoilandlter.

•Checktheenginespeed(idleandfullspeed).

•Checktheengine-oillevel.

•Checkthecoolingsystem.

•Checkthehydraulic-uidlevel.

•Checkthereeltobedknifecontact.

•Checktheoperationoftheinterlockswitches.

•Removedebrisfromthescreenandradiator/oilcooler(morefrequentlyindirty

operatingconditions).

•Checkthehydrauliclinesandhosesforleaks,kinkedlines,loosemountingsupports,

wear,loosettings,weatherdeterioration,andchemicaldeterioration.

•Greasethebearingsandbushings(greasethemimmediatelyaftereverywashing

regardlessoftheintervallisted).

•Checktheconditionofandcleanthebattery .

•Checkthebatterycableconnections.

•Inspectthecoolingsystemhoses.

•Checktheconditionandtensionofthealternatorbelt.

Every200hours

Every250hours

Every400hours

Every800hours

Every2,000hours

Every2years

•Changetheengineoilandlter.

•Drainmoisturefromthehydraulic-uidtank.

•Checkthereelbearingpreload.

•T orquethewheellugnutsto94to122N-m(70to90ft-lb).

•Servicetheaircleaner(serviceitearlieriftheaircleanerindicatorshowsred).

Serviceitmorefrequentlyinextremelydirtyordustyconditions.

•Replacethefuellter.

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Checktheenginespeed(idleandfullspeed).

•Checktherearwheeltoe-in.

•Changethehydraulicuid.

•Changethehydrauliclters(sooneriftheserviceintervalindicatorisintheRed

zone).

•Packtherearwheelbearings.

•Adjusttheenginevalves(refertotheengineoperator'smanual).

•Replacethesparkplugs.

•Flushandreplacethecoolingsystemuid.

•Drainandushthehydraulictank.

•Replaceallmovinghoses.

31

Page 32

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

MaintenanceCheckItem

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checktheengineoilandfuellevel.

Checktheairlterrestrictionindicator.

Checktheradiatorandscreenfordebris.

Checkunusualenginenoises.

Checkunusualoperatingnoises.

Checkthehydraulicsystemoillevel.

Checkthehydrauliclterindicator.

Checkhydraulichosesfordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheinstrumentoperation.

Checkthereel-to-bedknifeadjustment.

Checktheheight-of-cutadjustment.

Checkallgreasettingsforlubrication.

Touch-updamagedpaint.

1.Checkwiththeenginerunningandtheoilatoperatingtemperature

1

2

Fortheweekof:

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

2

3

4

5

6

7

8

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

Note:Toobtainanelectricalschematicorahydraulicschematicforyourmachine,visitwww.Toro.com.

Information

32

Page 33

ServiceIntervalChart

g021216

Figure37

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

GreasingtheBearingsand Bushings

Ifyouoperatethemachineundernormalconditions,lubricate

allgreasettingsforthebearingsandbushingsafterevery50

hoursofoperationwith#2general-purpose,lithium-base

grease.Lubricatethebearingsandbushingsimmediately

aftereverywashing,regardlessoftheintervallisted.

Thegreasettinglocationsandquantitiesareasfollows:

•Pumpdriveshaft(3)(Figure38)

•Cuttingunitliftarmcylinders(2each)(Figure39)

Figure39

•Liftarmpivots(1each)(Figure39)

Figure38

33

Page 34

•Cuttingunitcarrierframeandpivot(2each)(Figure40)

G011615

•Axlesteeringpivot(1)(Figure43)

Figure43

Figure40

•Liftarmpivotshaft(1each)(Figure41)

Figure41

•Rearaxletierod(2)(Figure42)

•Steeringcylinderballjoints(2)(Figure44)

Figure44

•Brakepedal(1)(Figure45)

Figure42

Figure45

34

Page 35

EngineMaintenance

g021217

3

1

2

3

2

1

g021218

g021212

ServicingtheAirCleaner

Checktheair-cleanerbodyfordamagewhichcouldcausean

airleak.Replaceifdamaged.Checkthewholeintakesystem

forleaks,damageorloosehoseclamps.

Servicetheair-cleanerlteronlywhentheserviceindicator

(Figure46)requiresit.Changingtheairlterbeforeitis

necessaryonlyincreasesthechanceofdirtenteringtheengine

whenthelterisremoved.

Important:Besurethatthecoverisseatedcorrectly

andsealswiththeair-cleanerbody.

1.Releasethelatchessecuringtheair-cleanercovertothe

aircleanerbody(Figure46).

Figure46

1.Air-cleanercover3.Air-cleanerservice

indicator

2.Air-cleanercoverlatch

Figure47

1.Air-cleanercover

2.Air-cleanerlter

3.Air-cleanerindicator

4.Cleanthedirtejectionportlocatedintheremovable

cover.Removetherubberoutletvalvefromthecover,

cleanthecavityandreplacetheoutletvalve.

5.Installthecoverorientingtherubberoutletvalveina

downwardposition—betweenapproximately5:00to

7:00whenviewedfromtheend.

6.Securethelatches.

ServicingtheEngineOiland Filter

Changetheengineoilandlterinitiallyaftertherst50hours

ofoperationandevery200hoursthereafter.

1.Removethedrainplug(Figure48)andlettheoilow

intoadrainpan.

2.Removethecoverfromtheaircleanerbody.Before

removingthelter,uselowpressureair(40psi,clean

anddry)tohelpremovelargeaccumulationsofdebris

packedbetweenoutsideofthelterandthecanister.

Avoidusinghigh-pressureairwhichcouldforce

dirtthroughthelterintotheintaketract.

Thiscleaningprocesspreventsdebrisfrommigrating

intotheintakewhenthelterisremoved.

3.Removeandreplacethelter(Figure47).

Cleaningoftheusedelementisnotrecommendeddue

tothepossibilityofdamagetotheltermedia.Inspect

thenewlterforshippingdamage,checkingthesealing

endofthelterandthebody .Donotuseadamaged

element.Insertthenewlterbyapplyingpressureto

theouterrimoftheelementtoseatitinthecanister.

Donotapplypressuretotheexiblecenterofthe

lter.

Figure48

1.Oildrainplug

2.Whentheoilstops,installthedrainplug.

3.Removetheoillter(Figure49).

35

Page 36

g021213

1

Figure49

1.Oillter

4.Applyalightcoatofcleanoiltothenewltergasket.

5.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thencontinuetighteningby

handuntilitistight.

Important:Donotover-tightenthelter.

6.Addoiltothecrankcase;refertoCheckingthe

Engine-OilLevel(page22).

7.Runtheengineforawhileandcheckforleaks.Add

oilasrequired.

Figure50

1.Airgap

5.Installthecorrectlygappedsparkplugwithgasketseal,

andtightentheplugto25to30N-m(18to21.6ft-lb).

Ifatorquewrenchisnotused,tightentheplugrmly.

ReplacingtheSparkPlugs

Replacethesparkplugsafterevery2000operatinghours.

Therecommendedairgapis0.76mm(0.030inch).

ThecorrectsparkplugtouseisaNGKIFR6F8DN.

Note:Thesparkplugusuallylastsalongtime;however,the

plugshouldberemovedandcheckedwhenevertheengine

malfunctions.

1.Cleantheareaaroundthesparkplugssothatforeign

mattercannotfallintothecylinderwhenthespark

plugisremoved.

2.Pullthesparkplugwiresoffofthesparkplugsand

removetheplugsfromthecylinderhead.

3.Checktheconditionofthesideelectrode,center

electrode,andcenterelectrodeinsulatortoensurethat

thereisnodamage.

Important:Replaceacracked,fouled,dirty,or

otherwisemalfunctioningsparkplug.Donotsand

blast,scrape,orcleanelectrodesbyusingawire

brushbecausegritmayeventuallyreleasefromthe

plug,fallintothecylinder,anddamagetheengine.

4.Settheairgapbetweenthecenterandsideofthe

electrodesat0.76mm(0.03inch)(Figure50).

36

Page 37

FuelSystem

G021237

1

1

2

1

3

g021236

Maintenance

ReplacingtheFuelFilter

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

1.Fuelpump

2.Hoseclamp

Figure52

3.Fuelline/fuellter

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Removethe(5)screwssecuringthefuelpumpcoverto

thefueltankandremovethecover(Figure51).

4.Removethefuelpumpcapfromthetopofthefuel

tank(Figure52).

5.Removethefuelpumpassemblyandfuellterfrom

thetank(Figure52).

6.Removetheclampsecuringthefuellterhosetothe

fuelpumptting.Removethehosefromthetting

(Figure52).

7.Insertthenewhoseclampontothenewfuellterhose.

8.Insertthehoseontothefuelpumpandsecurethe

clamp

9.Inserttheassemblyintothefueltankandtightenthe

capto20to22N-m(175to200in-lb).

10.Connectthewiresandsecurethehosewiththehose

clamp.

CheckingtheFuelLinesand

Figure51

1.Covermountingscrews

2.Fueltank

2.Unplugthewireharnessconnectorsfromthefuel

pump(Figure52).

3.Loosenthehoseclampanddisconnectthefuelline

fromthefuelpumpcap(Figure52).

3.Fuelpumpcover

Connections

Checkthefuellinesandconnectionsevery400hoursor

yearly,whichevercomesrst.Inspectthemfordeterioration,

damage,orlooseconnections.

FuelPick-upTubeScreen

Thefuelpick-uptube,locatedinsidethefueltank,isequipped

withascreentohelppreventdebrisfromenteringthefuel

system.Removethefuelpick-uptubeandcleanscreenas

required.

37

Page 38

ElectricalSystem

1

g021219

CheckingtheFuses

Maintenance

Important:Beforeweldingonthemachine,disconnect

bothcablesfromthebattery,bothwiringharnessplugs

fromtheelectroniccontrolmodule,andtheterminal

connectorfromthealternatortopreventdamagetothe

electricalsystem.

ServicingtheBattery

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

DANGER

Thereare8fusesintheelectricalsystem.Thefuseblock

(Figure53)islocatedbehindthecontrolarmaccesspanel.

Figure53

1.Fuseblock

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfromit.

Checkthebatteryconditionweeklyorafterevery50hours

ofoperation.Keeptheterminalsandtheentirebatterycase

cleanbecauseadirtybatterydischargesslowly.Tocleanthe

battery,washtheentirecasewithasolutionofbakingsoda

andwater.Rinseitwithclearwater.

Figure54

38

Page 39

DriveSystem

Maintenance

AdjustingtheTractionDrive

5.Tightenthelocknuttosecuretheadjustment.

6.Stoptheengine.Removethejackstandsandlowerthe

machinetotheshopoor.

7.Testdrivethemachinetomakesureitdoesnotcreep.

forNeutral