Page 1

FormNo.3417-925RevB

Reelmaster

®

5410-Dor5510-D

TractionUnit

ModelNo.03606—SerialNo.401334001andUp

ModelNo.03607—SerialNo.401334001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3417-925*B

Page 2

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheseparate

productspecicDeclarationofConformity(DOC)

sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

trainingmayresultininjury.Formoreinformation

onsafeoperatingpractices,includingsafetytips

andtrainingmaterials,gotowww.Toro.com.

YoumaycontactT orodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersareonaplatemountedonthe

leftsideoftheframeunderthefootrest.Writethe

numbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Theenclosedengineowner’smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

Introduction

Thismachineisaride-on,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Itisprimarilydesigned

forcuttinggrassonwell-maintainedlawnsingolf

courses,parks,sportselds,andoncommercial

grounds.Itisnotdesignedforcuttingbrush,mowing

grassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

g000502

Figure1

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Tomaximizesafety,performance,

andproperoperationofthismachine,youmust

carefullyreadandfullyunderstandthecontents

ofthisOperator’sManual.Failuretofollow

theseoperatinginstructionsortoreceiveproper

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

GeneralSafety...................................................4

EngineEmissionCertication.............................4

SafetyandInstructionalDecals..........................5

Setup........................................................................9

1AdjustingtheTirePressure............................10

2AdjustingtheControl-ArmPosition.................10

3InstallingtheCuttingUnits...............................11

4AdjustingtheTurf-Compensation

Spring...........................................................14

5UsingtheCutting-UnitKickstand....................15

6ReplacingtheWarningDecalforCE

Compliance...................................................15

ProductOverview...................................................16

Controls...........................................................16

Specications..................................................23

Attachments/Accessories.................................23

Operation................................................................24

BeforeOperationSafety...................................24

FillingtheFuelTank..........................................24

CheckingtheEngine-OilLevel..........................25

CheckingtheCoolingSystem...........................26

CheckingtheHydraulicFluid............................26

CheckingtheReel-to-BedknifeContact............27

CheckingtheT orqueoftheWheel

Nuts..............................................................27

BurnishingtheBrakes.......................................27

DuringOperationSafety...................................28

StartingandShuttingofftheEngine..................29

CuttingGrasswiththeMachine........................29

DieselParticulateFilterRegeneration...............30

AdjustingtheLift-ArmCounterbalance.............42

AdjustingtheLift-ArmTurnaround

Position.........................................................42

PushingorT owingtheMachine........................43

HaulingtheMachine.........................................43

JackingPoints..................................................44

UnderstandingtheDiagnosticLight..................44

CheckingtheInterlockSwitches.......................45

AfterOperationSafety......................................46

HaulingtheMachine.........................................46

Hydraulic-ValveSolenoidFunctions.................46

OperatingTips.................................................46

Maintenance...........................................................47

RecommendedMaintenanceSchedule(s)...........47

DailyMaintenanceChecklist.............................48

ServiceIntervalChart.......................................49

Pre-MaintenanceProcedures..............................49

Pre-MaintenanceSafety...................................49

Lubrication..........................................................49

GreasingtheBearingsandBushings................49

EngineMaintenance...........................................51

EngineSafety...................................................51

ServicingtheAirCleaner..................................51

ServicingtheEngineOil....................................53

ServicingtheDiesel-OxidationCatalyst

(DOC)andtheSootFilter..............................54

FuelSystemMaintenance...................................55

ServicingtheWaterSeparator.........................55

ServicingtheEngineFuelFilter........................55

CheckingtheFuelLinesand

Connections..................................................56

FuelPick-upTubeScreen.................................56

ElectricalSystemMaintenance...........................56

ElectricalSystemSafety...................................56

ServicingtheBattery.........................................56

CheckingtheFuses..........................................57

DriveSystemMaintenance..................................58

AdjustingtheTractionDriveforNeutral.............58

AdjustingtheRearWheelToe-in.......................59

CoolingSystemMaintenance..............................59

CoolingSystemSafety.....................................59

RemovingDebrisfromtheCooling

System..........................................................59

BrakeMaintenance.............................................60

AdjustingtheParkingBrakes............................60

AdjustingtheParking-BrakeLatch....................61

BeltMaintenance................................................61

ServicingtheAlternatorBelt.............................61

HydraulicSystemMaintenance...........................62

HydraulicSystemSafety...................................62

ChangingtheHydraulicFluid............................62

ReplacingtheHydraulicFilters.........................63

CheckingtheHydraulicLinesand

Hoses............................................................63

Hydraulic-SystemT estPorts.............................64

CuttingUnitSystemMaintenance........................65

CuttingUnitSafety............................................65

BacklappingtheCuttingUnits...........................65

Storage...................................................................66

PreparingtheTractionUnit...............................66

PreparingtheEngine........................................66

3

Page 4

Safety

Thismachinehasbeendesignedtomeetorexceed

ENISO5395:2013(whenappropriatedecalsare

applied)andANSIB71.4-2017.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistraction;otherwise,injuryorproperty

damagemayoccur.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthisOperator’sManual.

EngineEmission

Certication

TheengineinthismachineisEP ATier4Finaland

stage3bcompliant.

4

Page 5

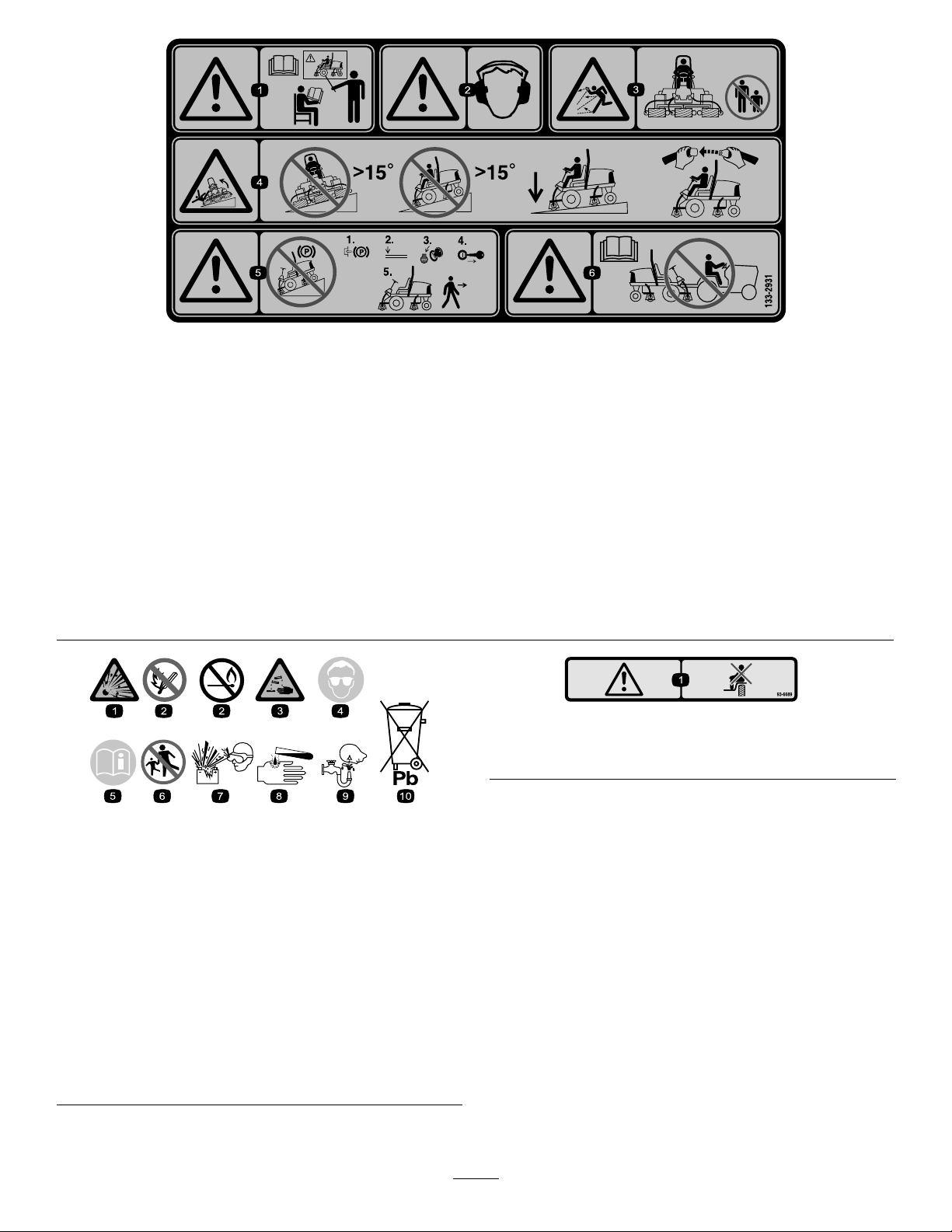

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

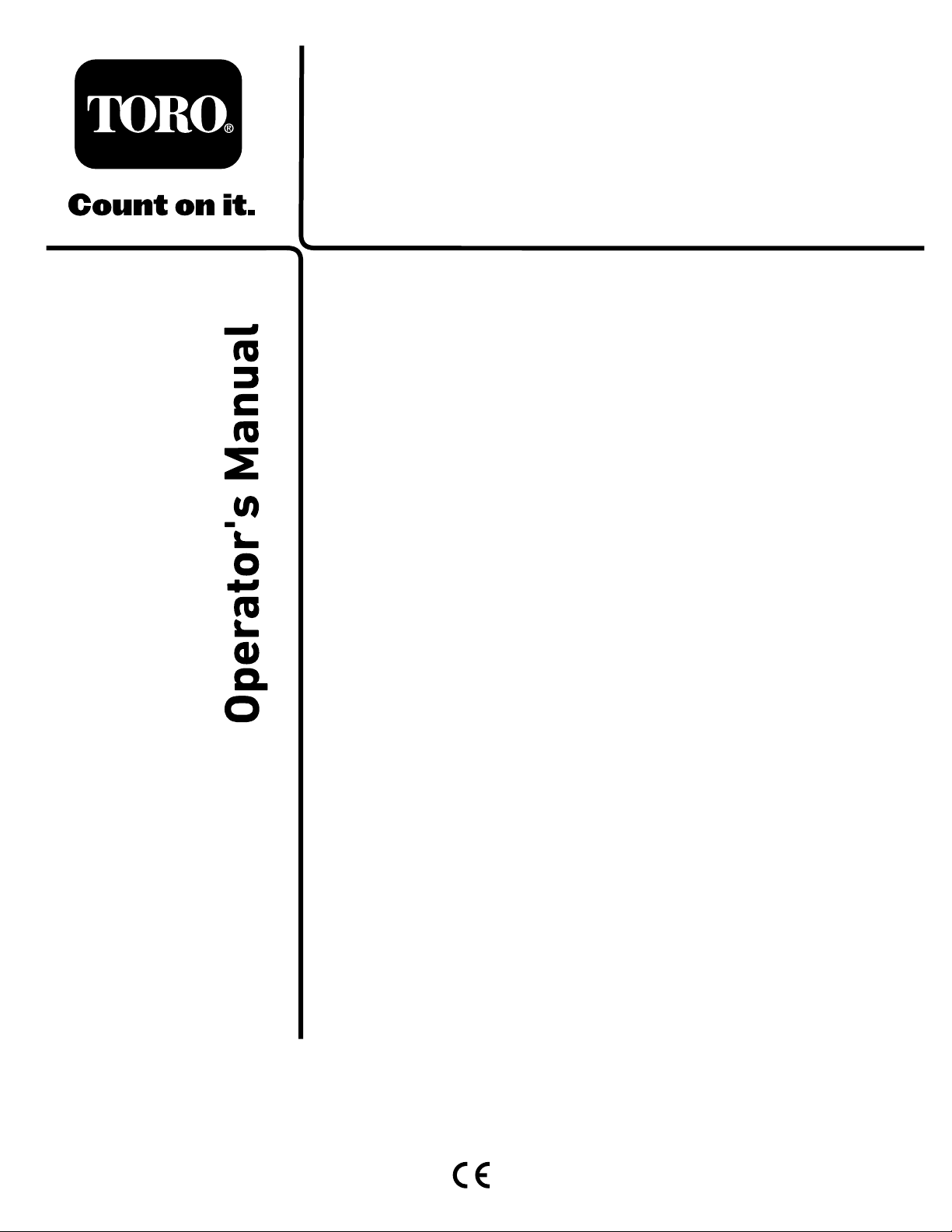

93-7272

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts.

decal93-7272

decal106-6755

106-6755

93–6696

1.Storedenergyhazard—readtheOperator'sManual.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

decal93-6696

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

decal110-9642

110-9642

1.Storedenergyhazard—readtheOperator'sManual.

2.Movethecotterpintotheholeclosesttotherodbracket

decal106-6754

andthenremovetheliftarmandpivotyoke.

110-0986

1.Pressthebrakepedalandparkingbrakepedaltosetthe

parkingbrake.

2.Pressthebrakepedaltoapplythebrake.

3.Pressthetractionpedaltomovethemachineforward.

4.Reelenabledmode

5.Transportmode

decal110-0986

5

Page 6

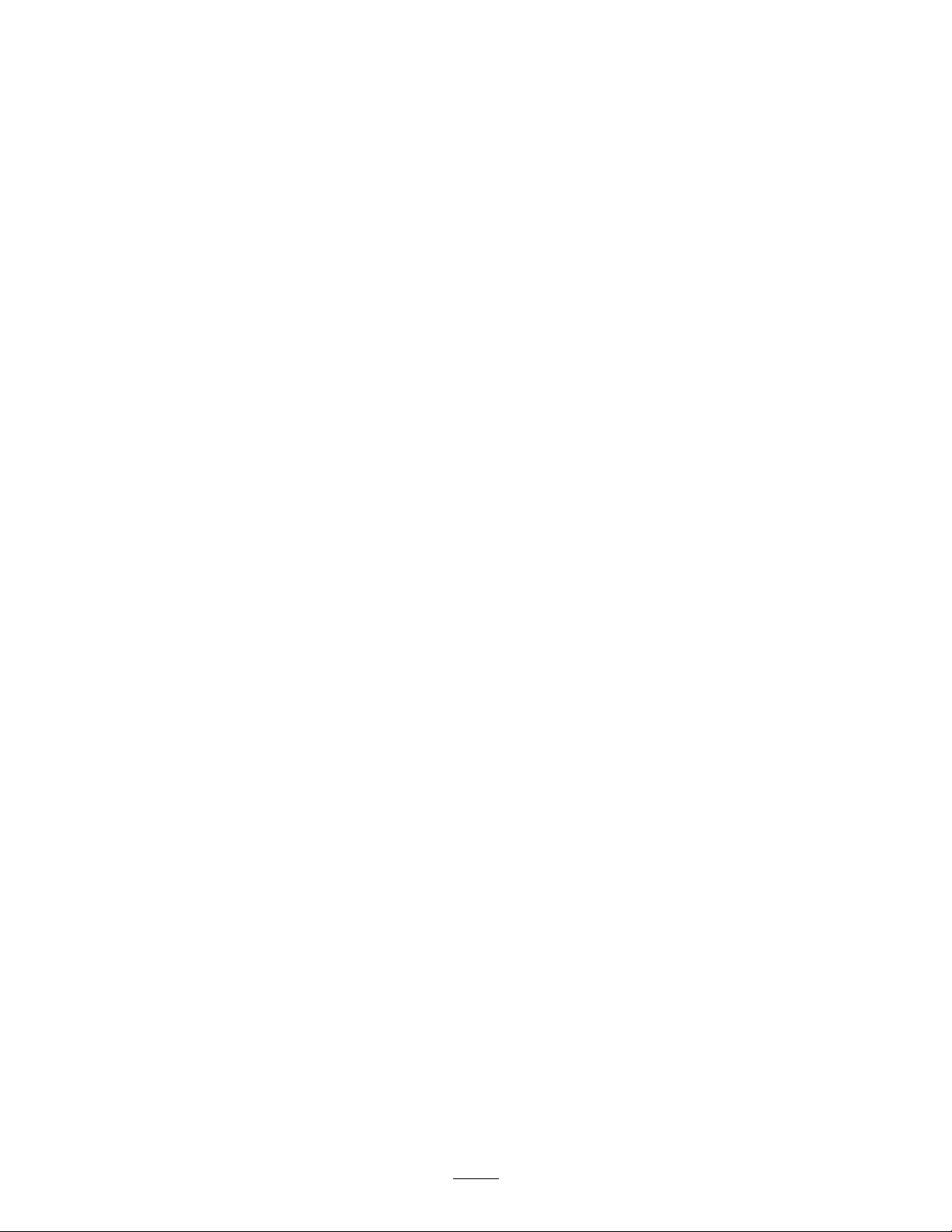

117-0169

1.ReadtheOperator'sManual.

2.Powerpoint(10A)

3.Headlights(10A)

4.Power(10A)

5.Enginestart(15A)

6.Optionalairrideseatsuspension(10A)

7.EnginecomputermanagementC(10A)

8.EnginecomputermanagementB(10A)

9.EnginecomputermanagementA(10A)

decal110-8921

110-8921

1.Tractionunitspeed

2.Slow

3.Fast

r:\decal117-0169

decal117-2718

117–2718

133-2930

1.Warning—readtheOperator'sManual;donotoperatethis

machineunlessyouaretrained.

2.Warning—wearhearingprotection.5.Warning—donotparkonslopes;locktheparkingbrake,shut

3.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine.

4.Tippinghazard—slowthemachinebeforeturning;donotturn

athighspeeds;driveonlyonslopeswiththecuttingunits

lowered;alwayswearaseatbelt.

offtheengineandremovetheignitionkeybeforeleavingthe

machine.

6.Warning—readtheOperator'sManual;donottowthe

machine.

6

decal133-2930

Page 7

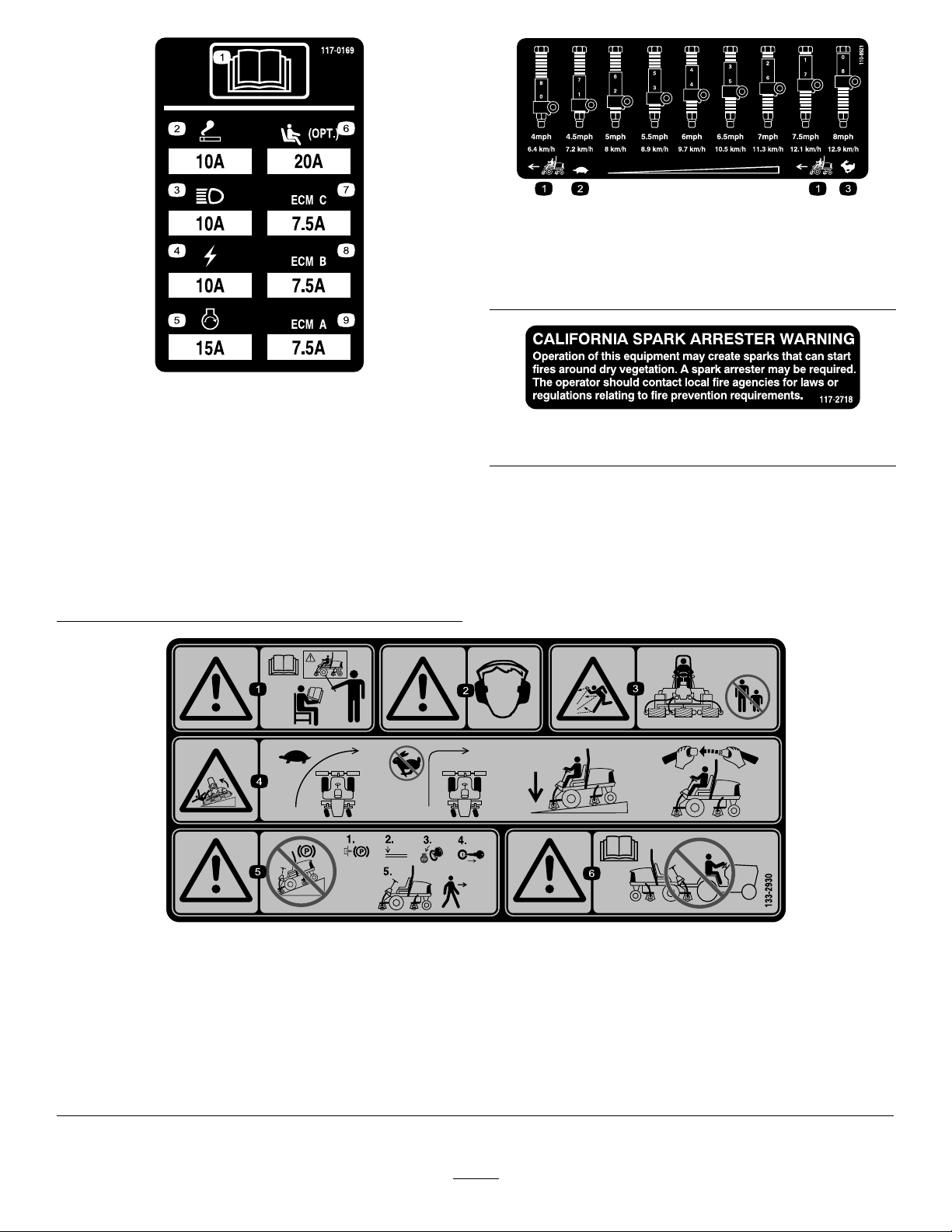

133-2931

(AfxoverPartNo.133-2930)

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal133-2931

1.Warning—readtheOperator'sManual;donotoperatethis

machineunlessyouaretrained.

4.Tippinghazard—donotdriveacrossordownslopesgreater

than15degrees;onlydriveonslopeswiththecuttingunits

lowered;alwayswearaseatbelt

2.Warning—wearhearingprotection.5.Warning—donotparkonslopes;engagetheparkingbrake,

shutofftheengine,andremovetheignitionkeybeforeleaving

themachine.

3.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine

6.Warning—readtheOperator'sManual;donottowthe

machine.

93–6689

1.Danger—noriders.

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

decal93-6689

7

Page 8

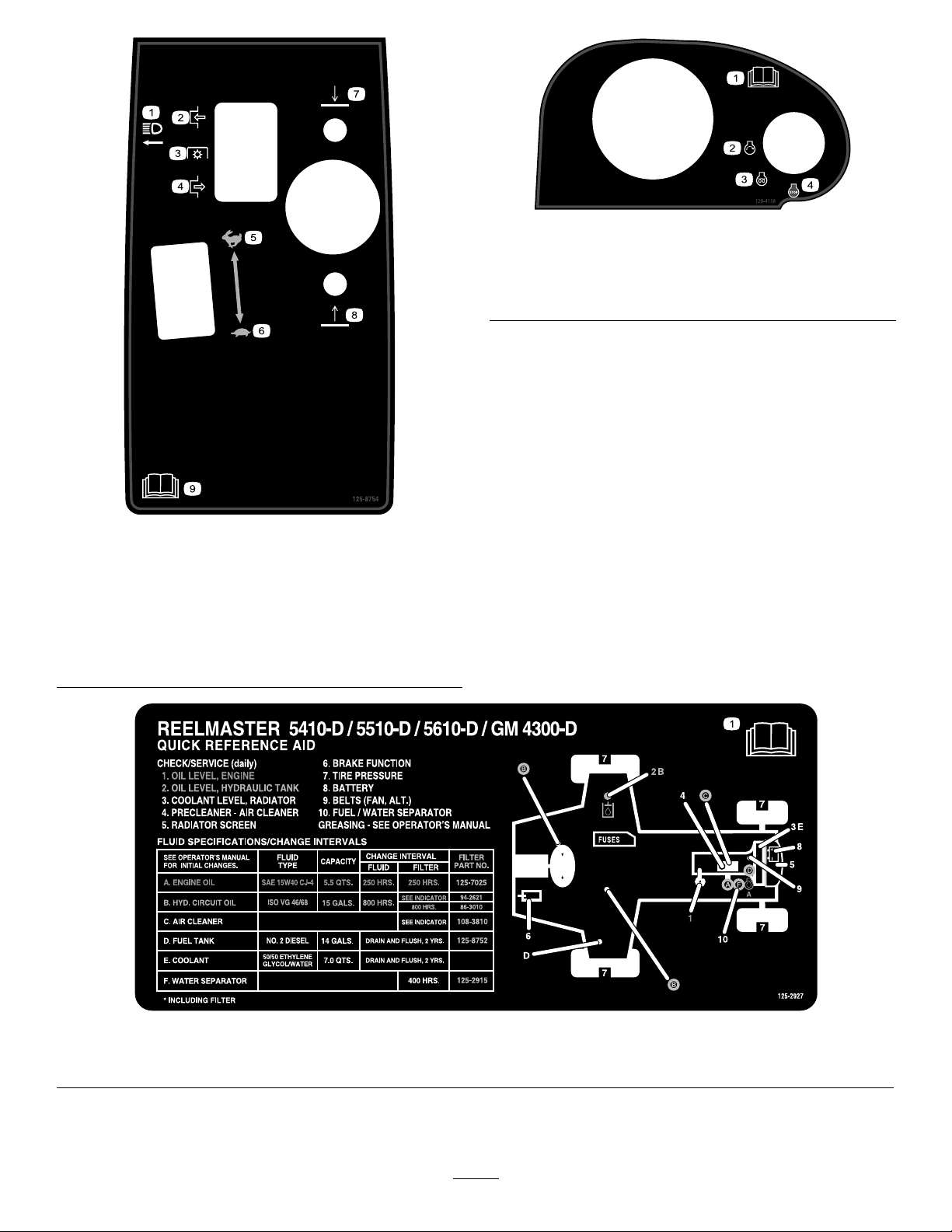

decal120-4158

120–4158

125–8754

1.Headlights

2.Engage7.Lowerthecuttingunits

3.Powertake-off(PTO)

4.Disengage

5.Fast

6.Slow

8.Raisethecuttingunits

9.ReadtheOperator’s

Manual.

1.ReadtheOperator’s

3.Engine—preheat

Manual.

2.Engine—start4.Engine—stop

decal125-8754

1.ReadtheOperator’sManualformaintenanceinformation.

decal125-2927

125–2927

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Nopartsrequired

Nopartsrequired

Right,fronthoseguide

Left,fronthoseguide

Nopartsrequired

Cutting-unitkickstand

Warningdecal1

MediaandAdditionalParts

Description

Operator'sManual

Engineowner’smanual1

Cuttingperformancepaper

Qty.

Qty.

–

–

1

1

–

1Installthecutting-unitkickstand.

1

1

ReadtheOperator'sManualbeforeoperatingthemachine.

Readthemanualbeforeoperatingtheengine.

Adjustthecutting-unitbedknifetoreel.

Adjustthetirepressure.

Adjustthecontrol-armposition.

Installthecuttingunits.

Adjusttheturf-compensationspring.

ReplacethedecalforCEcompliance.

Use

Use

Shim

1

Adjustthecutting-unitbedknifetoreel.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

9

Page 10

1

2

AdjustingtheTirePressure

NoPartsRequired

Procedure

Thetiresareover-inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.

Correctairpressureinthefrontandreartiresis83

to103kPa(12to15psi).

Important:Maintainevenpressureinalltiresto

ensurethatthereisuniformcontactwiththeturf.

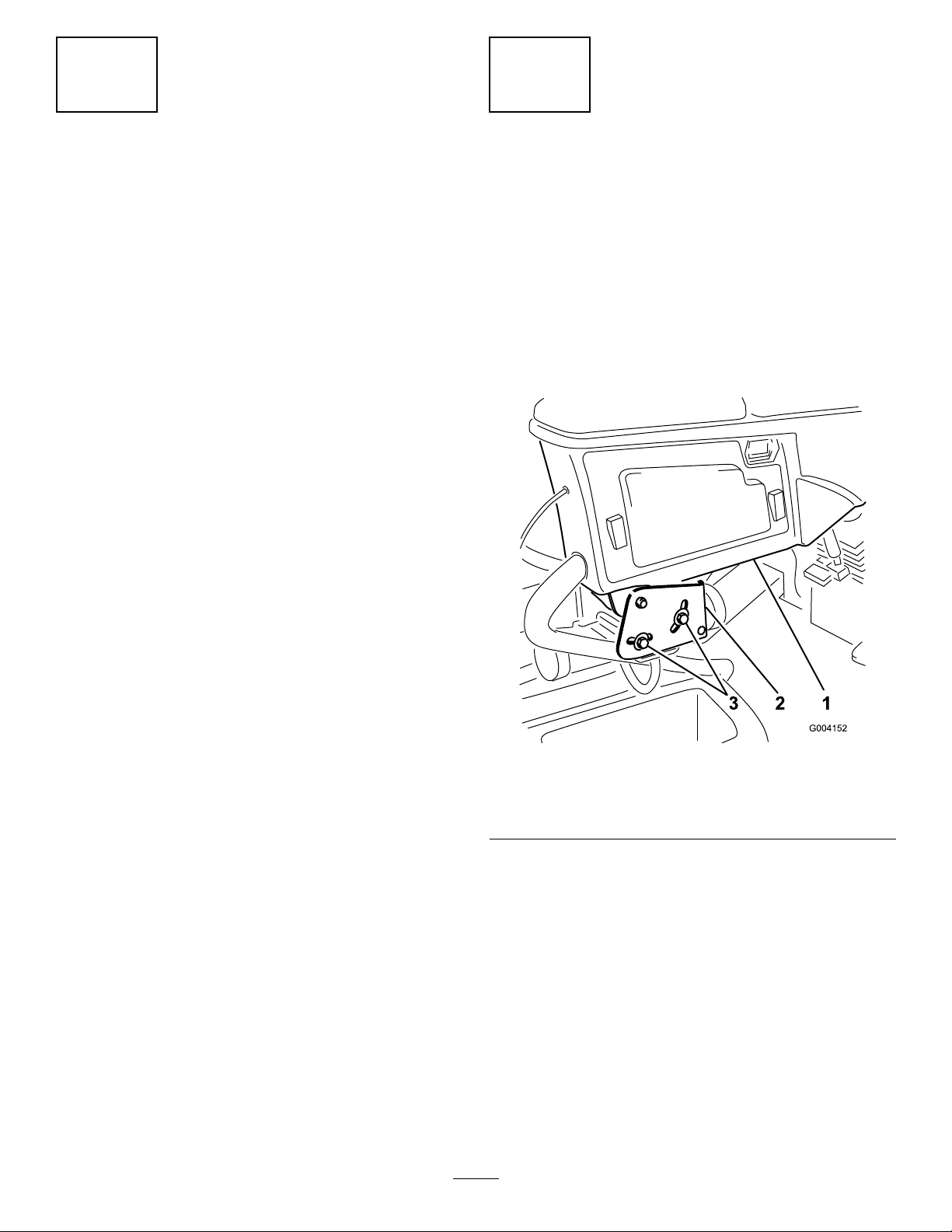

AdjustingtheControl-Arm Position

NoPartsRequired

Procedure

Thecontrol-armpositioncanbeadjustedforyour

comfort.

1.Loosenthe2boltssecuringthecontrolarmto

theretainingbracket(Figure2).

Figure2

1.Controlarm

2.Retainingbrackets

2.Rotatethecontrolarmtothedesiredposition

andtightenthe2bolts.

10

g004152

3.Bolt

Page 11

3

InstallingtheCuttingUnits

Partsneededforthisprocedure:

1

Right,fronthoseguide

1

Left,fronthoseguide

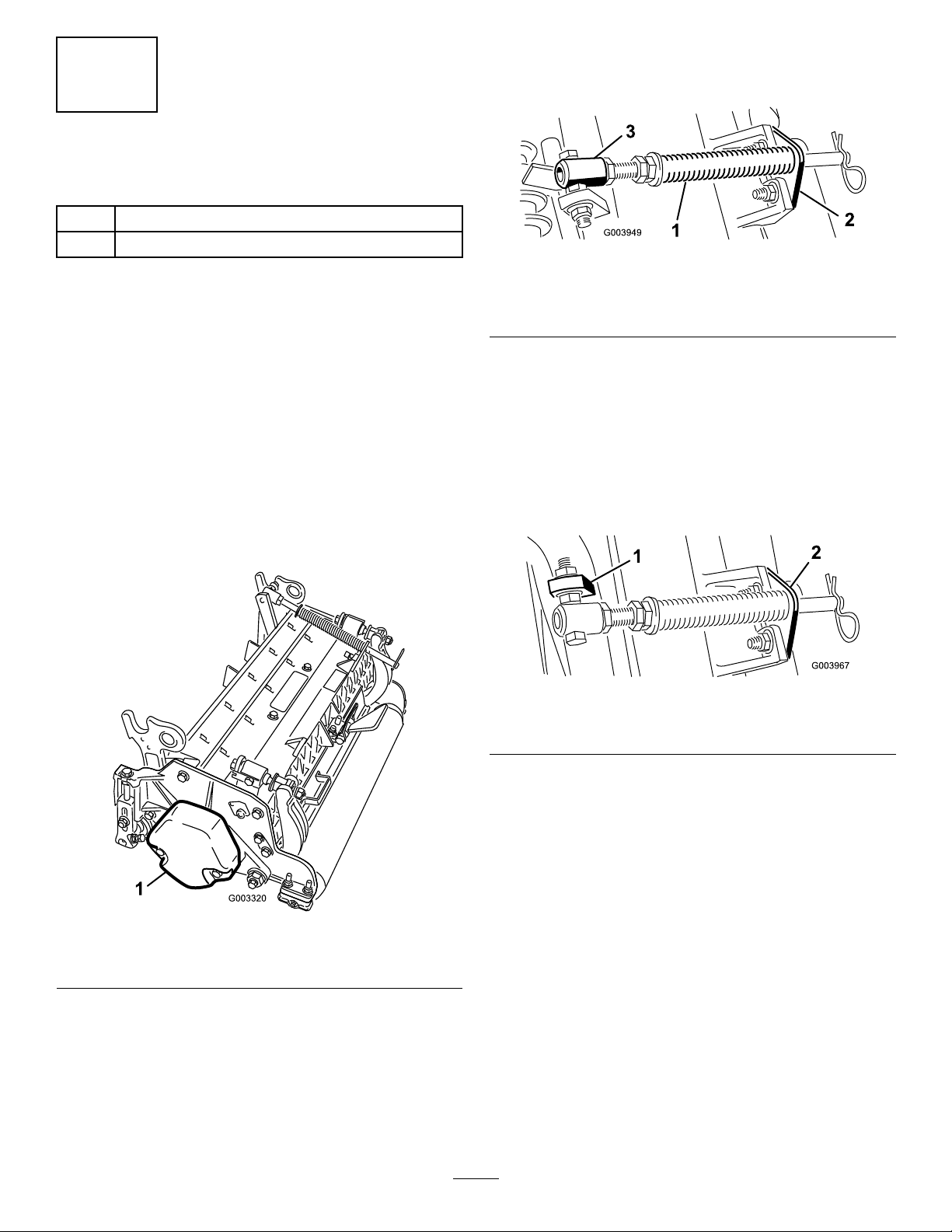

A.Removethe2carriageboltsandnuts

securingtherodbrackettothecutting-unit

tabs(Figure4).

g003949

Figure4

Procedure

1.Removethereelmotorsfromtheshipping

brackets.

Note:Discardtheshippingbrackets.

2.Removethecuttingunitsfromthecartons.

3.Assembleandadjustthecuttingunitsas

describedintheOperator'sManualforthe

cuttingunits.

4.Makesurethatthecounterweight(Figure3)is

installedtotheproperendofeachcuttingunit

asdescribedintheOperator'sManualforthe

cuttingunits.

1.Turf-compensationspring3.Springtube

2.Rodbracket

B.Removetheangenutsecuringthe

spring-tubebolttothecarrier-frametab

(Figure4).Removetheassembly.

C.Mountthespring-tubebolttotheopposite

tabonthecarrierframeandsecurewiththe

angenut.

Note:Positiontheboltheadtotheouter

sideofthetabasshowninFigure5.

Figure5

1.Oppositecarrier-frametab

2.Rodbracket

g003967

Figure3

1.Counterweight

5.Mounttheturf-compensationspringtothesame

sideofthecuttingunitasthereel-drivemotor.

Repositiontheturf-compensationspringas

follows:

Note:Allcuttingunitsareshippedwiththe

turf-compensationspringmountedtotheright

sideofthecuttingunit.

D.Mounttherodbrackettothecutting-unit

tabswiththecarriageboltsandnuts(Figure

5).

Important:Oncuttingunit4(leftfront)

andcuttingunit5(rightfront),usethe

rod-bracket-mountingnutstoinstall

g003320

thehoseguidestothefrontofthe

cutting-unittabs(Figure6andFigure7).

Thehoseguidesshouldleantowardthe

centercuttingunit(Figure7andFigure

8).

Note:Wheninstallingorremovingthe

cuttingunits,makesurethatthehairpin

cotterisinstalledinthespring-rodholenext

totherodbracket.Whennotinstallingor

removingthecuttingunits,thehairpincotter

mustbeinstalledintheholeintheendof

therod.

11

Page 12

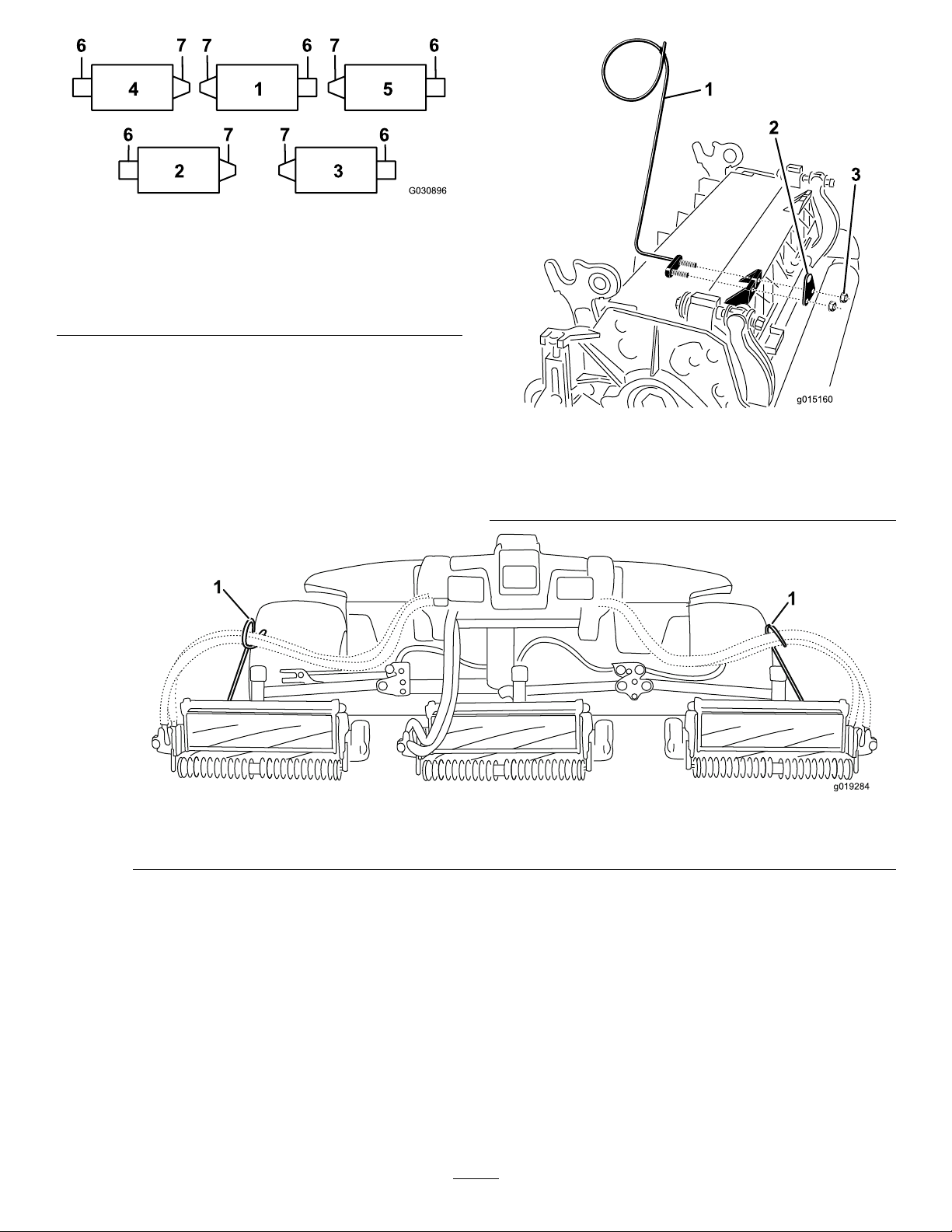

Figure6

1.Cuttingunit15.Cuttingunit5

2.Cuttingunit2

3.Cuttingunit3

4.Cuttingunit4

6.Reelmotor

7.Weight

g030896

g015160

Figure7

1.Hoseguidesmustleantowardthecentercuttingunit.

6.Lowerallliftarmscompletely .

1.Hoseguide(cuttingunit4

shown)

2.Rodbracket

Figure8

3.Nut

g019284

7.Removethesnapperpinandthecapfromthe

lift-arm-pivotyoke(Figure9).

12

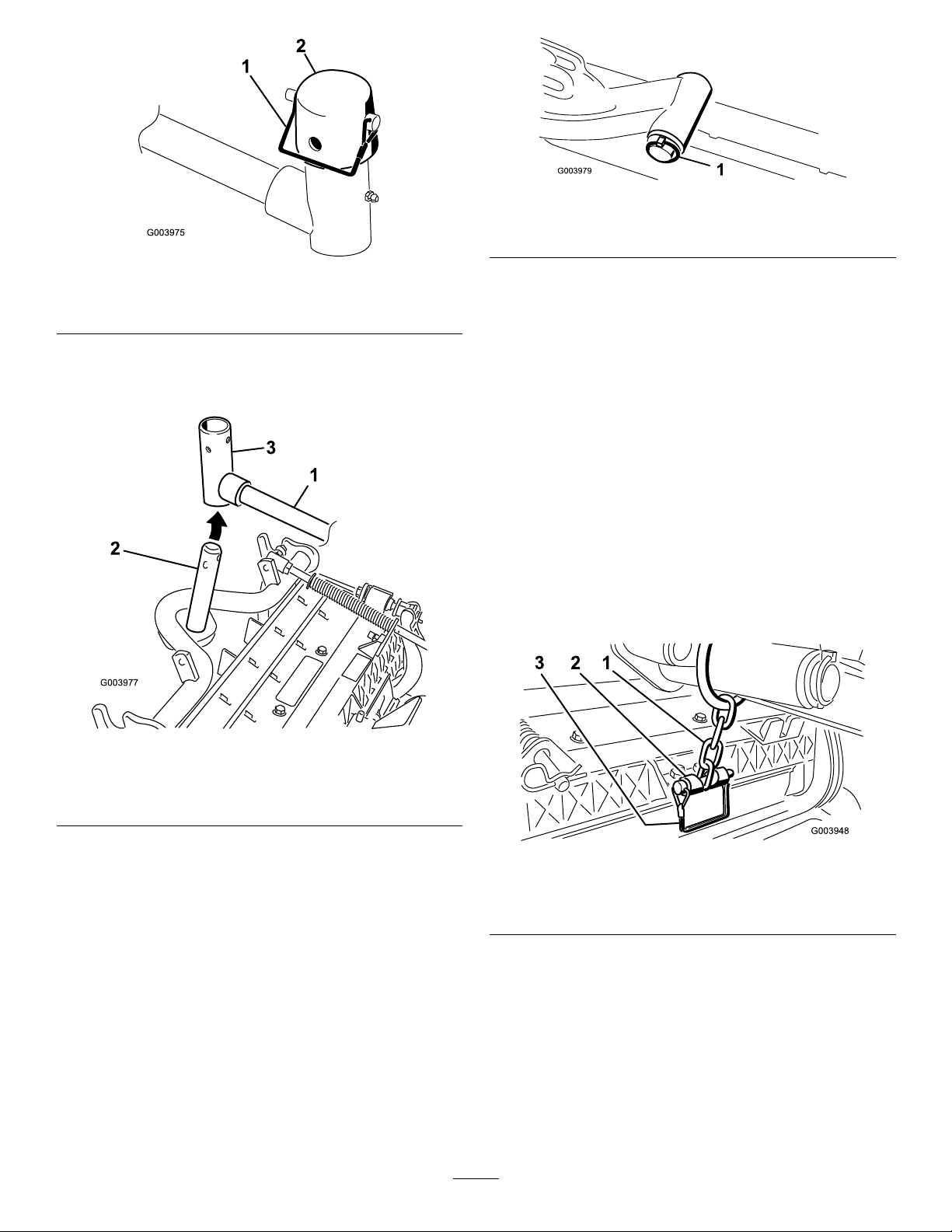

Page 13

Figure9

1.Snapperpin2.Cap

8.Forthefrontcuttingunits,slideacuttingunit

undertheliftarmwhileinsertingthecarrier-frame

shaftupintothelift-arm-pivotyoke(Figure10).

g003979

Figure11

1.Lynchpinandwasher

g003975

B.Insertthelift-armyokeontothecarrier-frame

shaft(Figure10).

C.Insertthelift-armshaftintotheliftarmand

secureitwiththewasherandlynchpin

(Figure1 1).

10.Insertthecapoverthecarrier-frameshaftand

lift-armyoke.

11.Securethecapandthecarrier-frameshaftto

thelift-armyokewiththesnapperpin(Figure9).

Note:Usetheslotifasteeringcuttingunitis

desiredorusetheholeifthecuttingunitistobe

lockedinposition

12.Securethelift-armchaintothechainbracket

withthesnapperpin(Figure12).

Note:Usethenumberofchainlinksdescribed

intheOperator'sManualforthecuttingunit.

Figure10

1.Liftarm3.Lift-arm-pivotyoke

2.Carrier-frameshaft

9.Usethefollowingprocedureontherearcutting

unitswhentheheightofcutisabove19mm

(3/4inch).

A.Removethelynchpinandwashersecuring

thelift-arm-pivotshafttotheliftarmand

slidethelift-arm-pivotshaftoutofthelift

arm(Figure11).

g003977

g003948

Figure12

1.Lift-armchain

2.Chainbracket

3.Pin

13.Oncuttingunit4(leftfront)andcuttingunit5

(rightfront),insertthereel-motorhosesintothe

respectivehoseguide.

14.Coatthesplineshaftofthereelmotorwithclean

grease.

15.Oilthereel-motorO-ringandinstallitontothe

motorange.

16.Installthemotorbyrotatingitclockwisesothat

themotorangesclearthebolts(Figure13).

13

Page 14

Note:Rotatethemotorcounterclockwiseuntil

theangesencircletheboltsandthentighten

thebolts.

Important:Makesurethatthereel-motor

hosesarenottwisted,kinked,oratriskof

beingpinched.

4

Adjustingthe Turf-CompensationSpring

NoPartsRequired

Procedure

Theturf-compensationspringtransfersweightfrom

thefronttotherearroller(Figure14).Thishelps

toreduceawavepatternintheturf,alsoknownas

marcellingorbobbing.

Important:Makespringadjustmentswiththe

cuttingunitmountedtothetractionunit,pointing

straightaheadandloweredtotheground.

1.Makesurethatthehairpincotterisinstalledin

therearholeinthespringrod(Figure14).

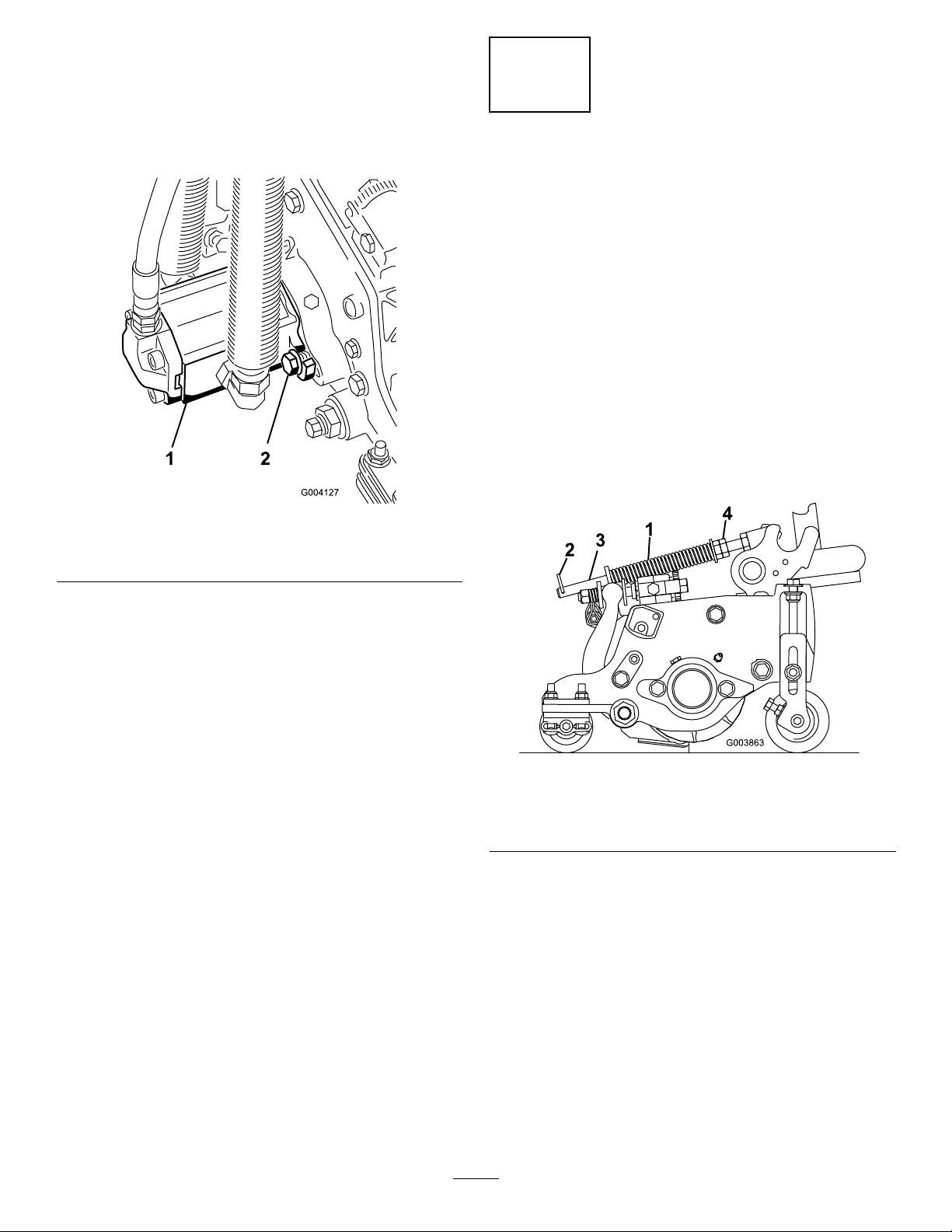

Figure13

1.Reel-drivemotor2.Mountingbolts

g004127

g003863

Figure14

1.Turf-compensationspring3.Springrod

2.Hairpincotter4.Hexnuts

2.Tightenthehexnutsonthefrontendofthe

springroduntilthecompressedlengthofthe

springis12.7cm(5inches)for5-inchcutting

unitsor15.9cm(6.25inches)for7-inchcutting

units(Figure14).

Note:Whenoperatingonroughterrain,

decreasethespringlengthby12.7mm(1/2

inch).Thisslightlydecreasestheground

following.

14

Page 15

5

UsingtheCutting-Unit Kickstand

Partsneededforthisprocedure:

1

Cutting-unitkickstand

Procedure

Wheneveryouneedtotipthecuttingunittoexpose

thebedknife/reel,propuptherearofthecuttingunit

withthekickstandtomakesurethatthenutsonthe

backendofthebedbar-adjustingscrewsarenot

restingontheworksurface(Figure15).

g004144

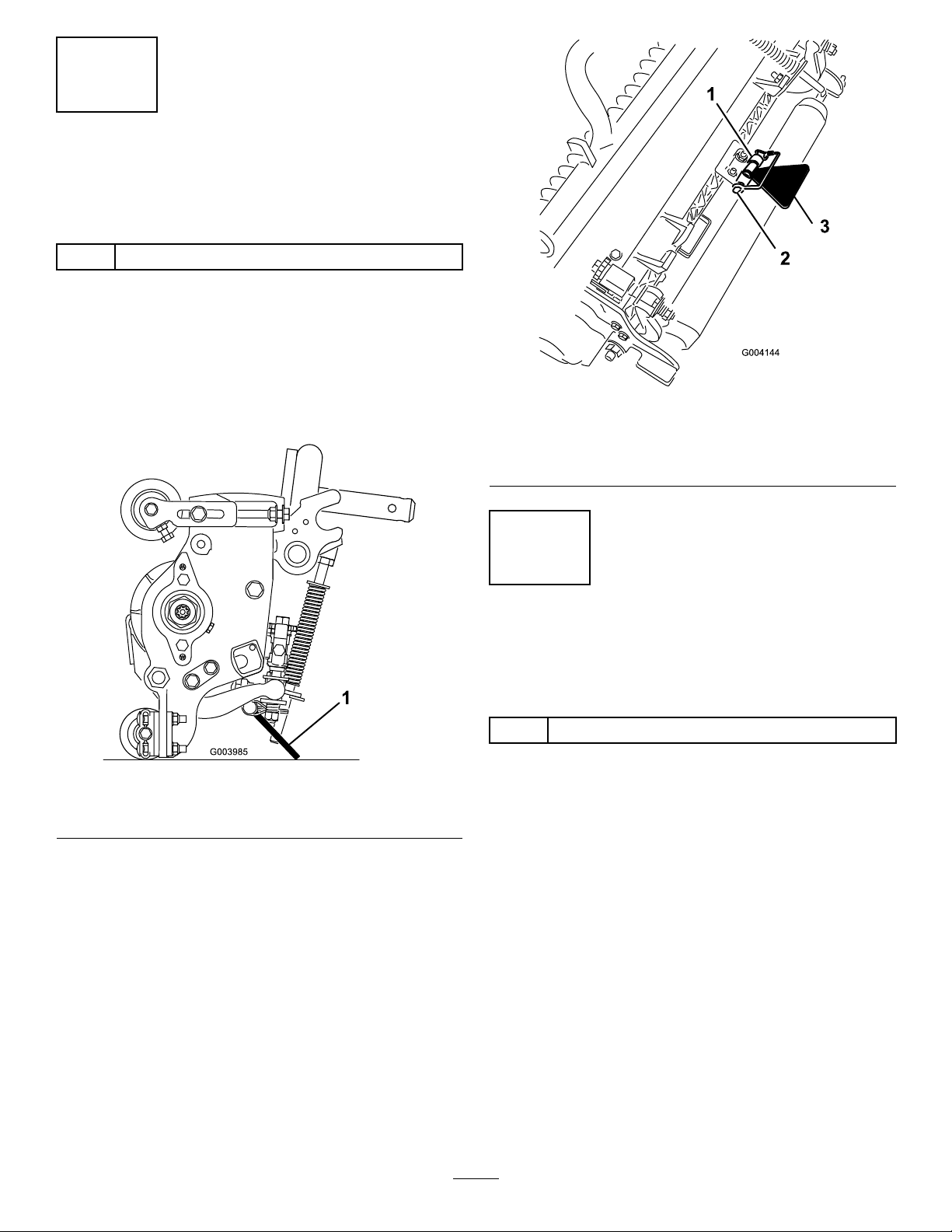

Figure16

1.Chainbracket3.Cutting-unitkickstand

2.Snapperpin

Figure15

1.Cutting-unitkickstand

Securethekickstandtothechainbracketwiththe

snapperpin(Figure16).

6

ReplacingtheWarning DecalforCECompliance

Partsneededforthisprocedure:

1Warningdecal

g003985

Procedure

OnmachinesrequiringCECompliance,afxtheCE

warningdecal(PartNo.133-2931)overthestandard

warningdecal(PartNo.133-2930).

15

Page 16

ProductOverview

g216864

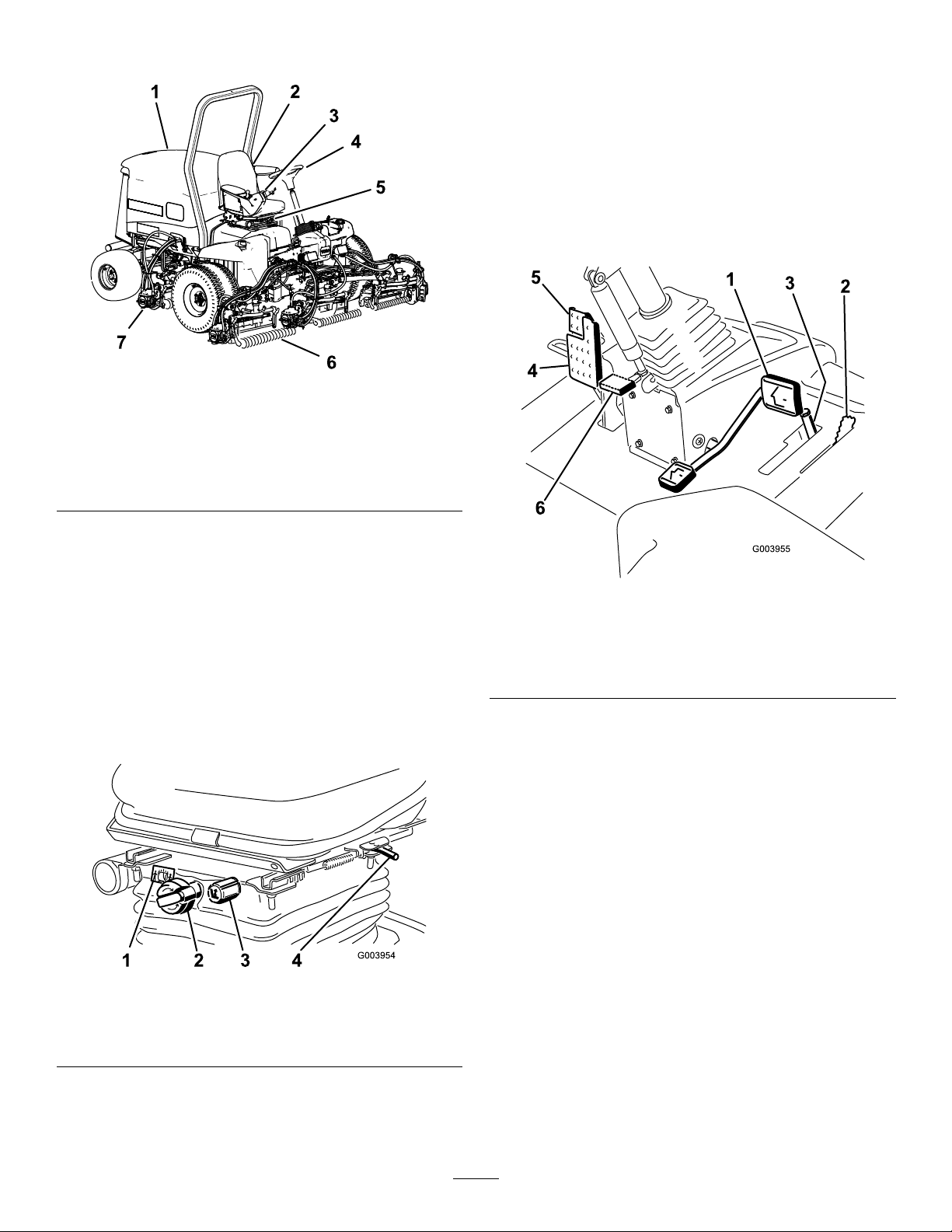

Figure17

TractionPedal

Thetractionpedalcontrolstheforwardandreverse

operation(Figure19).Pressthetopofthepedal

tomoveforwardandthebottomtomoverearward.

Groundspeeddependsonhowfaryoupressthe

pedal.Fornoload,maximumgroundspeed,setthe

enginespeedtotheFASTpositionandfullypressthe

pedal.

Tostop,reducefootpressureonthetractionpedal

andallowittoreturntothecenterposition.

1.Enginehood

2.Seat

3.Controlarm

4.Steeringwheel

5.Seatadjustments

6.Frontcuttingunits

7.Rearcuttingunits

Controls

Seat-AdjustingKnobs

Theseat-adjustingleverallowsyoutoadjust

theseatforwardandrearward(Figure18).The

weight-adjustingknobadjuststheseatforyourweight.

Theweightgaugeindicateswhentheseatisadjusted

toyourweight.Theheight-adjustingknobadjuststhe

seatforyourheight.

Figure19

1.Tractionpedal4.Brakepedal

2.Mow-speedlimiter5.Parkingbrake

3.Spacers

6.Tilt-steeringpedal

Mow-SpeedLimiter

Whenthemow-speedlimiterisippedup,itcontrols

themowspeedandallowsthecuttingunitstobe

engaged(Figure19).Eachspaceradjuststhe

mowingspeedby0.8km/h(0.5mph).Themore

spacersyouhaveonthetopofthebolt,theslowerthe

mowingspeed.Totransportthemachine,ipbackthe

mow-speedlimiterforthemaximumtransportspeed.

g003955

Figure18

1.Weightgauge3.Height-adjustingknob

2.Weight-adjustingknob4.Adjustinglever

BrakePedal

g003954

Pressthebrakepedaltostopthemachine(Figure19).

ParkingBrake

Toengagetheparkingbrake,pushdownonthebrake

pedalandpressthetopforwardtolatch(Figure19).

Toreleasetheparkingbrake,pressthebrakepedal

untiltheparking-brakelatchretracts.

16

Page 17

Tilt-SteeringPedal

LowerMow/RaiseControlLever

Totiltthesteeringwheeltowardyou,pressthefoot

pedaldown,pullthesteeringtowertowardyouto

themostcomfortableposition,andreleasethepedal

(Figure19).

Engine-SpeedSwitch

Theengine-speedswitchhas2modestochangethe

enginespeed(Figure20).Bymomentarilytappingthe

switch,youcanchangetheenginespeedin100rpm

increments.Ifyouholdtheswitchdown,theengine

automaticallymovestoHighorLowidle,depending

onwhichendoftheswitchyoupress.

Thisleverraisesandlowersthecuttingunitsandalso

startsandstopsthecuttingunitswhenthecutting

unitsareenabledintheMOWmode(Figure20).You

cannotlowerthecuttingunitswhenthemow/transport

leverisintheTRANSPORTposition.

HeadlightSwitch

Pivottheswitchdownwardtoturnontheheadlights

(Figure20).

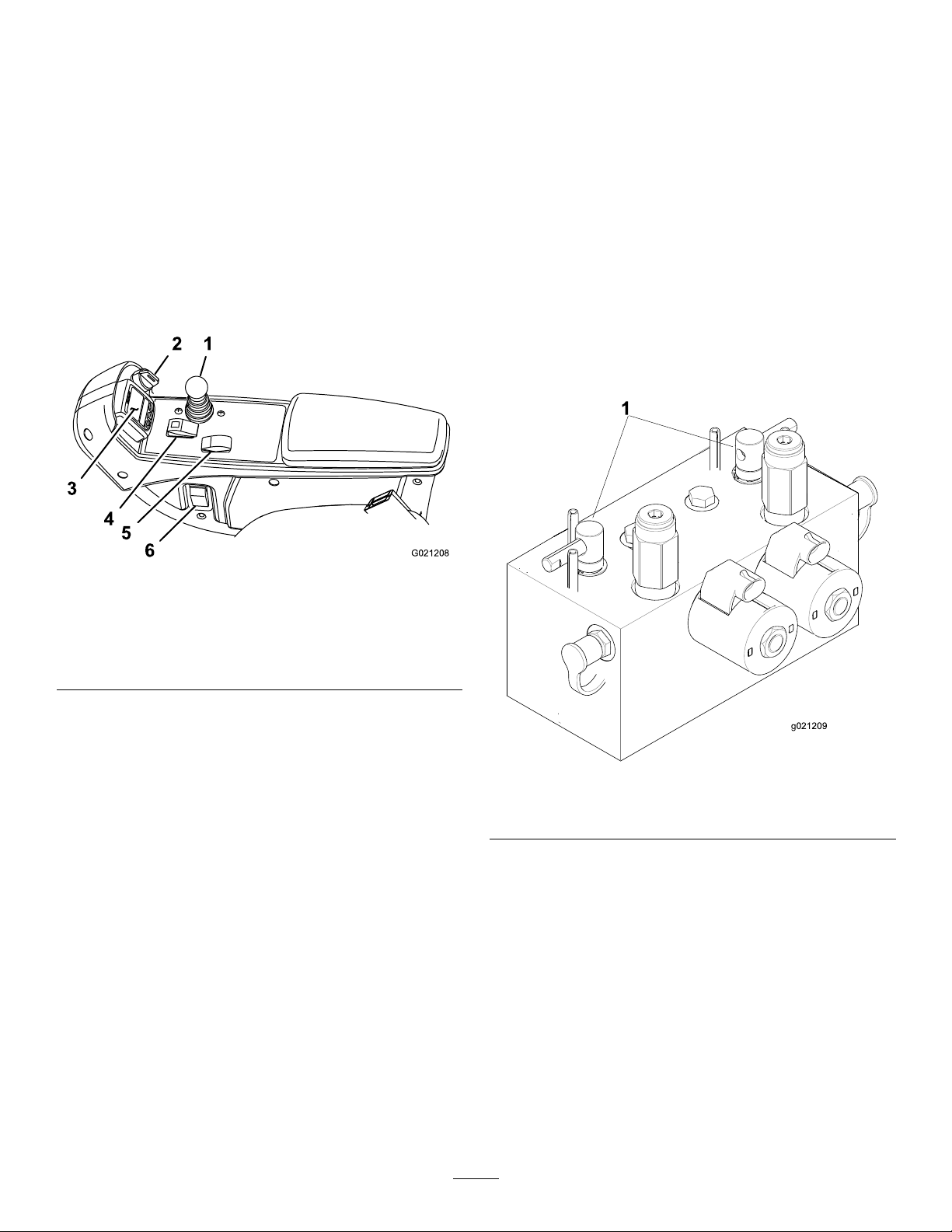

BacklapLevers

Usethebacklapleversinconjunctionwiththelower

mow/raisecontrolleverforbacklappingthereels

(Figure21).

Figure20

1.Lowermow/raisecontrol

lever

2.Keyswitch5.Engine-speedswitch

3.InfoCenter

4.Enable/disableswitch

6.Headlightswitch

Enable/DisableSwitch

Usetheenable/disableswitchinconjunctionwiththe

lowermow/raisecontrollevertooperatethecutting

units(Figure20).

InfoCenter

TheInfoCenterLCDdisplayshowsinformationabout

yourmachine,suchastheoperatingstatus,various

diagnostics,andotherinformationaboutthemachine

(Figure20).

KeySwitch

g021208

g021209

Figure21

1.Backlaplevers

Thekeyswitchhas3positions:OFF,ON/RUN,and

START(Figure20).

17

Page 18

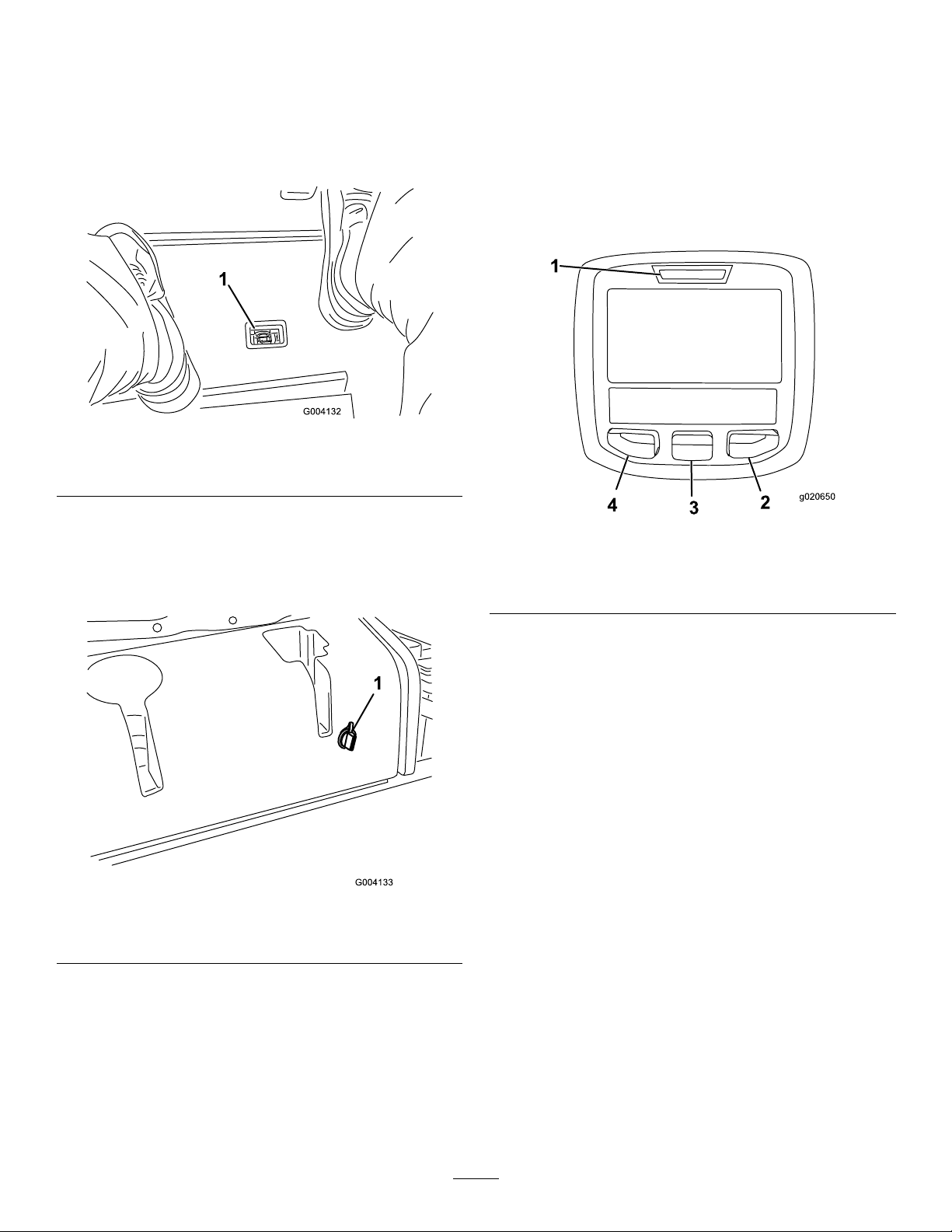

Hydraulic-Filter-Restriction

UsingtheInfoCenterLCDDisplay

Indicator

Withtheenginerunningatnormaloperating

temperature,ensurethattheindicatorisinthegreen

zone(Figure22).Whentheindicatorisinthered

zone,changethehydrauliclters.

Figure22

1.Hydraulic-lter-restrictionindicator

PowerPoint

Thepowerpointisa12Vpowersupplyforelectronic

devices(Figure23).

TheInfoCenterLCDdisplayshowsinformationabout

yourmachine,suchastheoperatingstatus,various

diagnostics,andotherinformationaboutthemachine

(Figure24).Thereisasplashscreenandmain

informationscreenoftheInfoCenter.Youcanswitch

betweenthesplashscreenandmaininformation

screen,atanytime,bypressinganyoftheInfoCenter

buttonsandthenselectingtheappropriatedirectional

arrow.

g004132

g020650

Figure24

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

1.Powerpoint

•LeftButton,MenuAccess/BackButton—Press

thisbuttontoaccesstheInfoCentermenus.

Youcanuseittobackoutofanymenuyouare

currentlyusing.

•MiddleButton—Pressthisbuttontoscrolldown

menus.

•RightButton—Pressthisbuttontoopenamenu

wherearightarrowindicatesadditionalcontent.

Note:Thepurposeofeachbuttonmaychange

dependingonwhatisrequiredatthetime.Each

buttonislabeledwithanicondisplayingitscurrent

function.

g004133

Figure23

18

Page 19

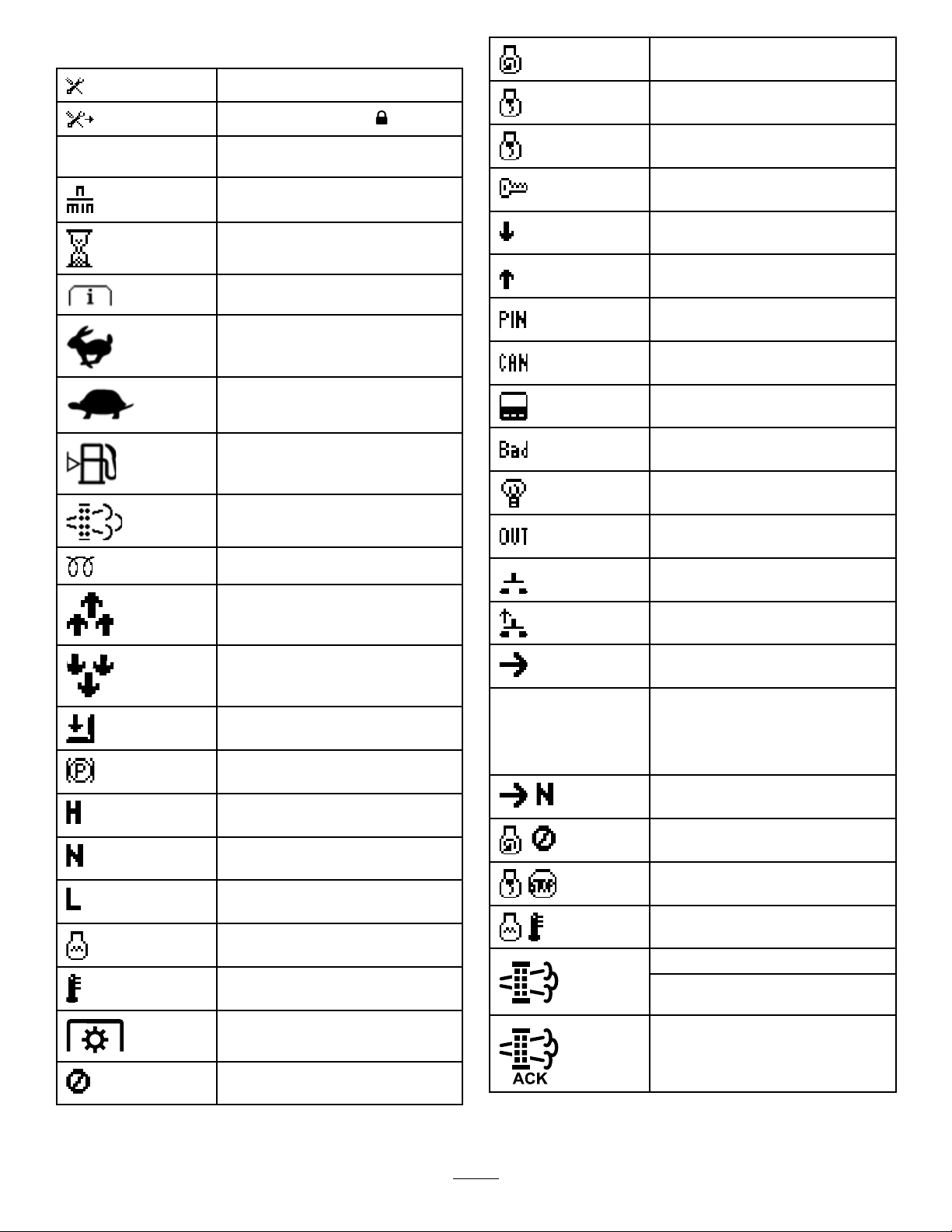

InfoCenterIconDescription

Starttheengine.

SERVICEDUE

Hoursremaininguntilservice

Resettheservicehours

Indicateswhenscheduledservice

shouldbeperformed

Enginerpm/status—indicatesthe

enginespeed(rpm)

Hourmeter

Infoicon

Fast

Slow

Fuellevel

Stationaryregenerationisrequired.

Theglowplugsareactive.

Raisethecuttingunits.

Shutofftheengine.

Engine

Keyswitch

Thecuttingunitsarelowering.

Thecuttingunitsareraising.

PINcode

CANbus

InfoCenter

Badorfailed

Bulb

OutputofTECcontrollerorcontrol

wireinharness

Switch

Releasetheswitch.

Lowerthecuttingunits.

Sitintheseat.

ParkingbrakeisOn.

Therangeishigh(transport).

Neutral

Therangeislow(mow).

Engine-coolanttemperature(°Cor

°F)

Temperature(hot)

ThePTOisengaged.

Notallowed

Changetotheindicatedstate.

Symbolsareoften

combinedtoform

sentences.Some

examplesareshown

below

PutthemachineintoNeutral.

Enginestartisdenied.

Engineshutdown

Enginecoolantistoohot.

Reset-standbyregenerationrequest

Parkedorrecoveryregeneration

request

Aparkedorrecoveryregenerationis

processing.

19

Page 20

Highexhausttemperature

DPFash-accumulation

notication—RefertoDPFAsh

Accumulation(page31)fordetails.

Sitdownorengagetheparkingbrake

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthe

menuaccessbuttonwhileatthemainscreen.This

bringsyoutothemainmenu.Refertothefollowing

tablesforasynopsisoftheoptionsavailablefrom

themenus:

MainMenu

MenuItemDescription

Faults

ServiceContainsinformationonthe

Diagnostics

Settings

AboutListsthemodelnumber,serial

Service

MenuItemDescription

Hours

Counts

DPFRegeneration

Containsalistoftherecent

machinefaults.Refertothe

ServiceManualorcontactyour

authorizedTorodistributorfor

moreinformationontheFaults

menuandtheinformation

containedthere.

machinesuchashoursof

usecountersandothersimilar

numbers.

Displaysthestateofeach

machineswitch,sensorand

controloutput.Y oucanuse

thistotroubleshootcertain

issuesasitquicklytellsyou

whichmachinecontrolsareon

andwhichareoff.

Allowsyoutocustomizeand

modifycongurationvariables

ontheInfoCenterdisplay.

number,andsoftwareversion

ofyourmachine.

Liststhetotalnumberofhours

thatthemachine,engineand

PTOhavebeenon,aswell

asthenumberofhoursthe

machinehasbeentransported

andservicedue.

Listsnumerouscountsthe

machinehasexperienced.

Thedieselparticulatelter

regenerationoptionandDPF

submenus

InhibitRegenUsetocontrolreset

ParkedRegenUsetoinitiateaparked

LastRegenListsthenumberhourssince

RecoverRegenUsetoinitiatearecovery

Diagnostics

MenuItemDescription

CuttingUnitsIndicatestheinputs,qualiers

Hi/LowRangeIndicatestheinputs,qualiers

PTOIndicatestheinputs,qualiers

EngineRun

Backlap

Settings

MenuItemDescription

Units

Language

LCDBacklightControlsthebrightnessofthe

LCDContrastControlsthecontrastofthe

FrontBacklapReelSpeedControlsthespeedofthefront

RearBacklapReelSpeedControlsthespeedoftherear

ProtectedMenusAllowsapersonauthorized

AutoIdle

BladeCount

MowSpeed

regeneration

regeneration

thelastreset,parked,or

recoveryregeneration

regeneration

andoutputsforraisingand

loweringthecuttingunits.

andoutputsfordrivingin

transportmode.

andoutputsforenablingthe

PTOcircuit.

Indicatestheinputs,qualiers

andoutputsforstartingthe

engine.

Indicatestheinputs,qualiers

andoutputsforoperatingthe

backlapfunction.

Controlstheunitsusedonthe

InfoCenter.Themenuchoices

areEnglishorMetric

Controlsthelanguageused

ontheInfoCenter*.

LCDdisplay.

LCDdisplay.

reelsinbacklapmode.

reelsinbacklapmode.

byyourcompanywiththe

PINcodetoaccessprotected

menus.

Controlstheamountoftime

allowedbeforereturningthe

enginetolowidlewhenthe

machineisstationary.

Controlsthenumberofblades

onthereelforreelspeed.

Controlsthegroundspeedfor

determiningthereelspeed.

20

Page 21

Heightofcut(HOC)

FReelRPM

RReelRPM

Controlstheheightofcut

(HOC)fordeterminingthereel

speed.

Displaysthecalculatedreel

speedpositionforthefront

reels.Thereelscanalsobe

manuallyadjusted.

Displaysthecalculatedreel

speedpositionfortherear

reels.Thereelscanalsobe

manuallyadjusted.

*Onlyoperator-facedtextistranslated.Faults,

Service,andDiagnosticsscreensareservice-faced.

Titlesappearintheselectedlanguage,butmenu

itemsareinEnglish.

ProtectedunderProtectedMenus—accessibleonly

byenteringPIN

AccessingProtectedMenus

Note:ThefactorydefaultPINcodeforyoumachine

iseither0000or1234.

IfyouchangedthePINcodeandforgotthecode,

contactyourauthorizedT orodistributorforassistance.

1.FromtheMAINMENU,usethecenterbuttonto

scrolldowntotheSETTINGSMENUandpressthe

rightbutton(Figure25).

About

MenuItemDescription

Model

SNListstheserialnumberofthe

Machine-ControllerRevisionListsthesoftwarerevisionof

InfoCenterRevisionListsthesoftwarerevisionof

CANBus

Liststhemodelnumberofthe

machine.

machine.

themastercontroller .

theInfoCenter.

Liststhemachine

communicationbusstatus.

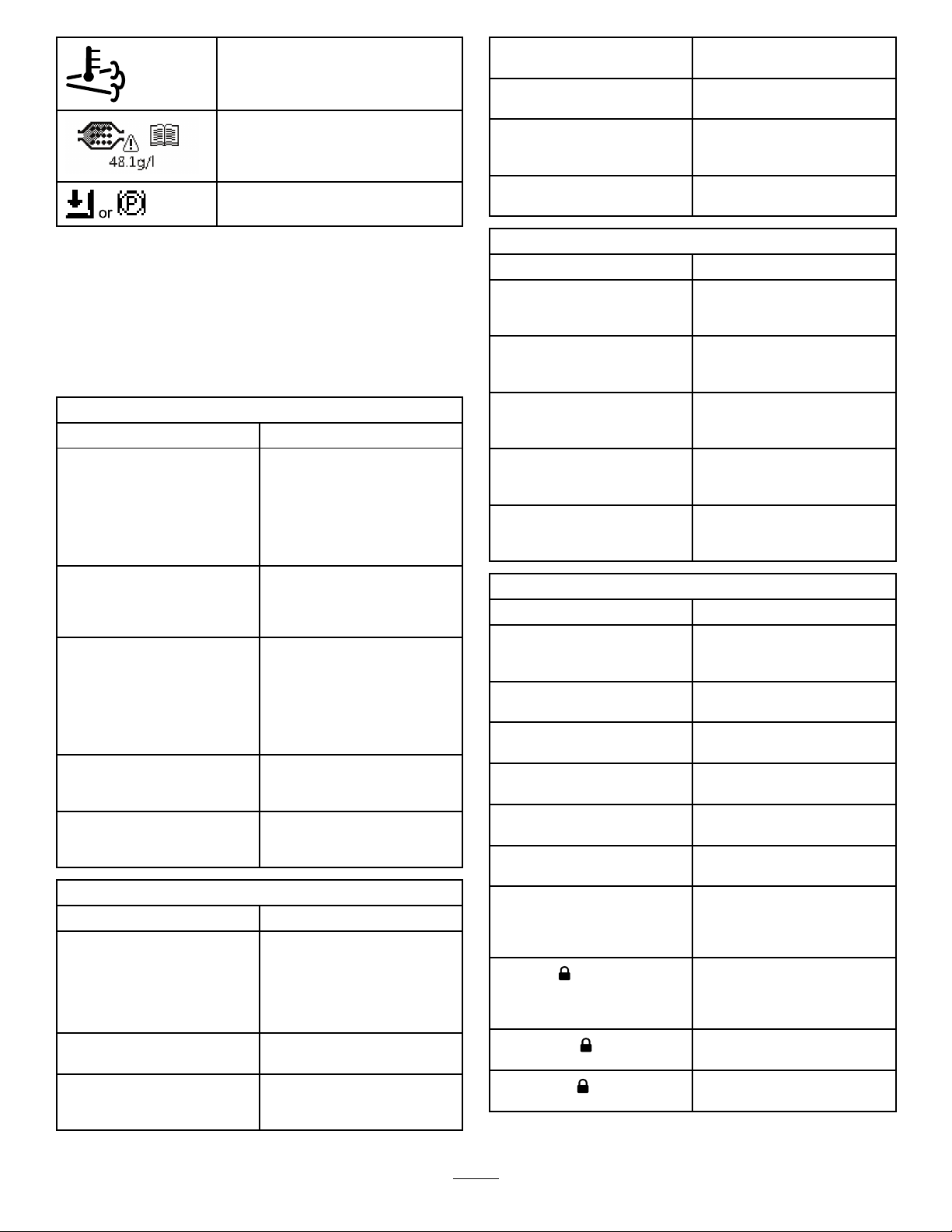

ProtectedMenus

Thereare8operatingcongurationsettingsthatare

adjustablewithintheSettingsMenuoftheInfoCenter:

autoidletimedelay ,BladeCount,MowSpeed,Height

ofCut(HOC),FReelRPM,andRReelRPM.These

settingscanbelockedbyusingtheProtectedMenu.

Note:Atthetimeofdelivery ,theinitialpassword

codeisprogrammedbyyourdistributor.

g028523

Figure25

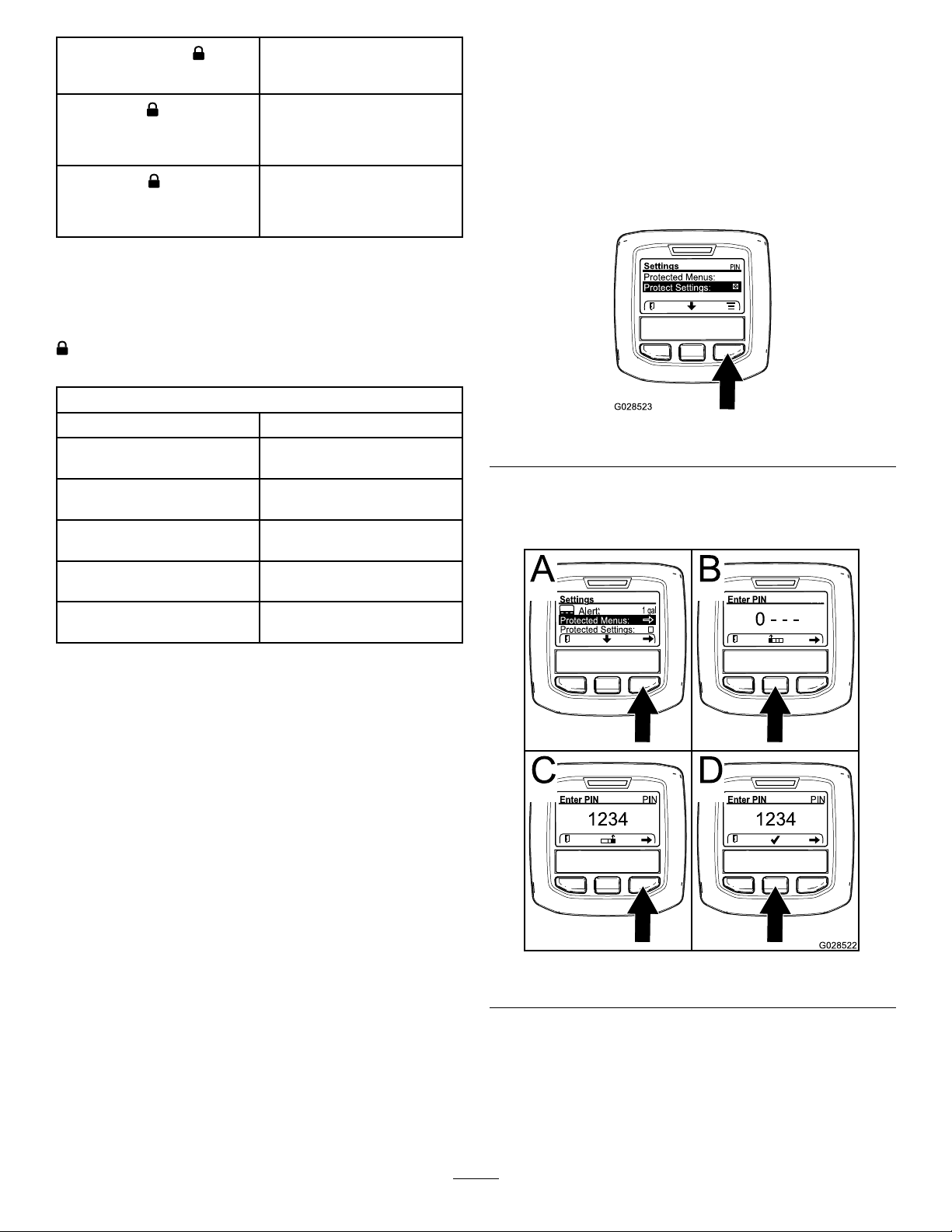

2.IntheSETTINGSMENU,usethecenterbuttonto

scrolldowntothePROTECTEDMENUandpress

therightbutton(Figure26A).

Figure26

3.ToenterthePINcode,pressthecenterbutton

untilthecorrectrstdigitappears,thenpress

therightbuttontomoveontothenextdigit

(Figure26BandFigure26C).Repeatthisstep

untilthelastdigitisenteredandpresstheright

buttononcemore.

21

g028522

Page 22

4.PressthemiddlebuttontoenterthePINcode

(Figure26D).

WaituntiltheredindicatorlightoftheInfoCenter

illuminates.

Note:IftheInfoCenteracceptsthePINcode

andtheprotectedmenuisunlocked,theword

“PIN”displaysintheupperrightcornerofthe

screen.

Note:RotatethekeyswitchtotheOFFpositionand

thentotheONpositionlockstheprotectedmenu.

Youhavetheabilitytoviewandchangethesettingsin

theProtectedMenu.OnceyouaccesstheProtected

Menu,scrolldowntoProtectSettingsoption.Usethe

rightbuttontochangethesetting.SettingtheProtect

SettingstoOFFallowsyoutoviewandchangethe

settingsintheProtectedMenuwithoutenteringthe

PINcode.SettingtheProtectSettingstoONhidesthe

protectedoptionsandrequiresyoutoenterthePIN

codetochangethesettingintheProtectedMenu.

AfteryousetthePINcode,rotatethekeyswitchOFF

andbacktotheONpositiontoenableandsavethis

feature.

SettingtheMowSpeed

1.IntheSettingsMenu,scrolldowntoMowSpeed.

2.Presstherightbuttontoselectmowspeed.

3.Usethecenterandrightbuttontoselectthe

appropriatemowspeedsetonthemechanical

mow-speedlimiteronthetractionpedal.

4.Presstheleftbuttontoexitmowspeedandsave

thesetting.

SettingtheHeightofCut(HOC)

1.IntheSettingsMenu,scrolldowntoHOC.

2.PresstherightbuttontoselectHOC.

3.Usethecenterandrightbuttontoselectthe

appropriateHOCsetting.(Iftheexactsettingis

notdisplayed,selectthenearestHOCsetting

fromthelistdisplayed).

4.PresstheleftbuttontoexitHOCandsavethe

setting.

SettingtheFrontandRearReel

ViewingandChangingthe

ProtectedMenuSettings

1.IntheProtectedMenu,scrolldowntoProtect

Settings.

2.Toviewandchangethesettingswithoutentering

apasscode,usetherightbuttontochangethe

ProtectSettingstoOFF.

3.Toviewandchangethesettingswitha

passcode,usetheleftbuttontochangethe

ProtectSettingstoON,setthepasscode,and

turnthekeyintheignitionswitchtotheOFF

positionandthentotheONposition.

SettingtheAutoIdle

1.IntheSettingsMenu,scrolldowntoAutoIdle.

2.Presstherightbuttontochangetheautoidle

timebetweenOFF,8S,10S,15S,20S,and30S.

SettingtheBladeCount

Speeds

Althoughthefrontandrearreelspeedsarecalculated

byinputtingthenumberofblades,mowspeedand

HOCintotheInfoCenter,thesettingcanbemanually

changedtoaccommodatefordifferentmowing

conditions.

1.TochangetheReelSpeedSettings,scrolldown

totheFReelRPM,RReelRPM,orboth.

2.Presstherightbuttontochangethereelspeed

value.Asyouchangethespeedsetting,the

displaycontinuestoshowthecalculatedreel

speedbasedonbladecount,mowspeedand

HOC,whichwaspreviouslyentered,butthe

newvalueisalsodisplayed.

1.IntheSettingsMenu,scrolldowntoBlade

Count.

2.Presstherightbuttontochangethebladecount

between5,8,or11bladereels.

22

Page 23

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

SpecicationReelMaster®5410-DReelMaster®5510-D

Transportwidth

Widthofcut254cm(100inches)254cm(100inches)

Length

Height

Weight

(withuidsand8bladecuttingunitsinstalled)

Engine

Fuel-tankcapacity

Transportspeed

Mowingspeed

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.T oro.comfora

listofallapprovedattachmentsandaccessories.

228cm(90inches)233cm(92inches)

282cm(111inches)282cm(1 11inches)

160cm(63inches)160cm(63inches)

1,335kg(2,943lb)1,420kg(3,131lb)

Yanmar

36hp

53L(14USgallons)53L(14USgallons)

0to16km/h(0to10mph)0to16km/h(0to10mph)

0to13km/h(0to8mph)0to13km/h(0to8mph)

Yanmar

36hp

TobestprotectyourinvestmentandmaintainoptimalperformanceofyourToroequipment,countonT oro

genuineparts.Whenitcomestoreliability,Torodeliversreplacementpartsdesignedtotheexactengineering

specicationofourequipment.Forpeaceofmind,insistonTorogenuineparts.

23

Page 24

Operation

FillingtheFuelTank

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainthefuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

FuelTankCapacity

53L(14USgallons)

FuelSpecication

Important:Useonlyultra-lowsulphurdiesel

fuel.Fuelwithhigherratesofsulfurdegrades

thedieseloxidationcatalyst(DOC),whichcauses

operationalproblemsandshortenstheservicelife

ofenginecomponents.

Failuretoobservethefollowingcautionsmay

damagetheengine.

•Neverusekeroseneorgasolineinsteadofdiesel

fuel.

•Nevermixkeroseneorusedengineoilwiththe

dieselfuel.

•Neverkeepfuelincontainerswithzincplatingon

theinside.

•Donotusefueladditives.

PetroleumDiesel

Cetanerating:45orhigher

Sulfurcontent:Ultra-lowsulfur(<15ppm)

FuelTable

Dieselfuelspecication

ASTMD975

No.1-DS15

No.2-DS15

EN590EuropeanUnion

ISO8217DMX

JISK2204GradeNo.2

KSM-2610

•Useonlyclean,freshdieselfuelorbiodieselfuels.

•Purchasefuelinquantitiesthatcanbeusedwithin

180daystoensurefuelfreshness.

Usesummer-gradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwinter-grade

fuel(No.1-DorNo.1-D/2-Dblend)belowthat

temperature.

Note:Useofwinter-gradefuelatlowertemperatures

provideslowerashpointandcoldowcharacteristics

whicheasesstartingandreducesfuellterplugging.

Usingsummer-gradefuelabove-7°C(20°F)

contributestowardlongerfuelpumplifeandincreased

powercomparedtowinter-gradefuel.

Location

USA

International

Japan

Korea

24

Page 25

Biodiesel

Thismachinecanalsouseabiodieselblendedfuelof

uptoB20(20%biodiesel,80%petroleumdiesel).

Sulfurcontent:Ultra-lowsulfur(<15ppm)

Biodieselfuelspecication:ASTMD6751or

EN14214

Blendedfuelspecication:ASTMD975,EN590,

orJISK2204

Important:Thepetroleumdieselportionmust

beultra-lowsulfur.

Observethefollowingprecautions:

•Biodieselblendsmaydamagepaintedsurfaces.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatime

afterconvertingtobiodieselblends.

•ContactyourauthorizedT orodistributorifyouwish

formoreinformationonbiodiesel.

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;referto

CheckingtheEngine-OilLevel(page53).

AddingFuel

1.Parkthemachineonalevelsurface,lowerthe

cuttingunits,shutofftheengine,andremove

thekey .

2.Usingacleanrag,cleanareaaroundfuel-tank

cap.

3.Removethecapfromthefueltank(Figure27).

Figure27

1.Fuel-tankcap

4.Fillthetankuntilthelevelis6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.

g021210

5.Installthefuel-tankcaptightlyafterllingthe

tank.

Note:Ifpossible,llthefueltankaftereachuse.

Thisminimizespossiblebuildupofcondensation

insidethefueltank.

25

Page 26

CheckingtheCooling

CheckingtheHydraulic

System

ServiceInterval:Beforeeachuseordaily

Cleandebrisoffthescreen,oilcooler,andfrontof

theradiatordailyandmoreoftenifconditionsare

extremelydustyanddirty .RefertoRemovingDebris

fromtheCoolingSystem(page59).

Thecoolingsystemislledwitha50/50solution

ofwaterandpermanentethyleneglycolantifreeze.

Checkthelevelofcoolantintheexpansiontankatthe

beginningofeachdaybeforestartingtheengine.The

capacityofthecoolingsystemis6.6L(7.0USqt).

CAUTION

Iftheenginehasbeenrunning,the

pressurized,hotcoolantcanescapeand

causeburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

1.Checkthelevelofcoolantintheexpansiontank

(Figure28).

Thecoolantlevelshouldbebetweenthemarks

onthesideofthetank.

Fluid

ServiceInterval:Beforeeachuseordaily

Themachinesreservoirislledatthefactorywith

approximately30L(8USgallons)ofhigh-quality

hydraulicuid.Checkthelevelofthehydraulicuid

beforetheengineisrststartedanddailythereafter.

Therecommendedreplacementuidisasfollows:

ToroPremiumAllSeasonHydraulicFluid(Availablein

19L(5USgallon)pailsor208L(55USgallon)drums.

SeethePartsCatalogoryourauthorizedTorodistributor

forpartnumbers.)

Alternateuids:IftheT orouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Do

notusesyntheticuid.Consultwithyourlubricant

distributortoidentifyasatisfactoryproduct.

Note:T orodoesnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souse

onlyproductsfromreputablemanufacturerswho

standbehindtheirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to50

ViscosityIndexASTMD2270

PourPoint,ASTMD97-36.6°C(-34°F)to9.4°C

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S(Quality

Level),DenisonHF-0

Important:TheISOVG46Multigradeuid

hasbeenfoundtoofferoptimalperformance

inawide-rangeoftemperatureconditions.

Foroperationinconsistentlyhighambient

temperatures,18°C(65°F)to49°C(120°F),

ISOVG68hydraulicuidmayofferimproved

performance.

cSt@100°C7.9to8.5

140to160

(-49°F)

Figure28

1.Expansiontank

2.Ifthecoolantlevelislow,removethe

expansion-tankcapandreplenishthesystem.

Donotoverll.

3.Installtheexpansion-tankcap.

PremiumBiodegradableHydraulicFluid-Mobil

EALEnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

g021866

syntheticbiodegradableuidapprovedbyToro.

Thisuidiscompatiblewiththeelastomersused

inTorohydraulicsystemsandissuitablefora

wide-rangeoftemperatureconditions.Thisuidis

compatiblewithconventionalmineraloils,butfor

maximumbiodegradabilityandperformance,the

hydraulicsystemshouldbethoroughlyushed

ofconventionaluid.Theoilisavailablein19L

(5USgallon)containersor208L(55USgallon)

drumsfromyourMobildistributor.

Important:Manyhydraulicuidsarealmost

colorless,makingitdifculttospotleaks.A

26

Page 27

reddyeadditiveforthehydraulicsystemoil

isavailablein20ml(2/3oz)bottles.1bottle

issufcientfor15to22L(4to6gallons)of

hydraulicoil.OrderPartNumber44-2500from

yourauthorizedT orodistributor.Thisreddyeis

notrecommendedforusewithbiodegradable

uids.Usefoodcoloring.

1.Positionthemachineonalevelsurface,lower

thecuttingunits,andshutofftheengine.

2.Cleantheareaaroundthellerneckandcapof

thehydraulictank(Figure29).Removethecap

fromthellerneck.

Figure29

1.Hydraulic-tankcap

CheckingtheTorqueofthe WheelNuts

ServiceInterval:Afterthersthour

Aftertherst10hours

Every250hours

Torquethewheelnutsto94to122N∙m(70to90ft-lb).

WARNING

Failuretomaintainpropertorqueofthewheel

nutscouldresultinpersonalinjury.

Maintainthepropertorqueonthewheelnuts.

BurnishingtheBrakes

Toensureoptimumperformanceoftheparking-brake

system,burnish(breakin)thebrakesbeforeuse.

Settheforwardtractionspeedto6.4km/h(4mph)

tomatchthereversetractionspeed(all8spacers

movedtothetopofthemow-speedcontrol).With

theengineathighidle,proceedforwardwiththe

mow-speed-controlstopengagedandridethebrake

g021215

for15seconds.Proceedbackwardatfullreverse

speedandridethebrakefor15seconds.Repeatthis

5times,waiting1minutebetweeneachforwardand

reversecycletoavoidoverheatingthebrakes;referto

AdjustingtheParkingBrakes(page60).

3.Removethedipstickfromthellerneckand

wipeitwithacleanrag.

4.Insertthedipstickintothellerneck;then

removeitandchecktheleveloftheuid.

Note:Theuidlevelshouldbewithin6.3mm

(1/4inch)ofthemarkonthedipstick.

Important:Donotoverll.

5.Ifthelevelislow,addappropriateuidtoraise

theleveltotheFULLmark.

6.Installthedipstickandcapontothellerneck.

Checkingthe Reel-to-BedknifeContact

ServiceInterval:Beforeeachuseordaily

Eachdaybeforeoperating,checkreel-to-bedknife

contact,regardlessifthequalityofcuthadpreviously

beenacceptable.Theremustbelightcontactacross

thefulllengthofthereelandthebedknife(refer

toAdjustingtheReeltoBedknifeintheOperator's

Manualforthecuttingunits).

27

Page 28

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;slip-resistant,substantialfootwear;

longpants;andhearingprotection.Tiebacklong

hairanddonotweardanglingjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifawheelgoesovertheedgeoriftheedge

givesway .

•Stopthecuttingunitswheneveryouarenot

mowing.

•Stopthemachineandinspectthecuttingunits

afterstrikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshut

offtheenginebeforeadjustingtheheightof

cut(unlessyoucanadjustitfromtheoperating

position).

•Neverrunanengineinanareawhereexhaust

gassesareenclosed.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

–Parkthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey .

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

•Useaccessories,attachments,andreplacement

partsapprovedbyTheT oro®Companyonly.

RolloverProtectionSystem (ROPS)Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairoralter

it.

MachineswithaFoldableRollBar

•Alwaysusetheseatbeltwiththerollbarinthe

raisedposition.

•TheROPSisanintegralsafetydevice.Keepa

foldingrollbarintheraisedandlockedposition,

andusetheseatbeltwhenoperatingthemachine

withtherollbarintheraisedposition.

•Lowerafoldingrollbartemporarilyonlywhen

necessary.Donotweartheseatbeltwhenthe

rollbarisfoldeddown.

•Beawarethatthereisnorolloverprotectionwhen

afoldedrollbarisinthedownposition.

•Checktheareathatyouwillbemowingandnever

folddownafoldingrollbarinareaswherethere

areslopes,drop-offs,orwater.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Y ouareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey .

28

Page 29

•Reviewtheslopeinstructionslistedbelowfor

operatingthemachineonslopesandreviewthe

conditionstodeterminewhetheryoucanoperate

themachineintheconditionsonthatdayandat

thatsite.Changesintheterraincanresultina

changeinslopeoperationforthemachine.

•Avoidstarting,stoppingorturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction.Maketurnsslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

•Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhiddenhazards.

Tallgrasscanhideobstructions.Uneventerrain

couldoverturnthemachine.

•Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.

•Useextremecautionwhenoperatingthemachine

neardropoffs,ditches,embankments,water

hazardsorotherhazards.Themachinecould

suddenlyrolloverifawheelgoesovertheedge

ortheedgecavesin.Establishasafetyarea

betweenthemachineandanyhazard.

•Identifyhazardsatthebaseoftheslope.

Iftherearehazards,mowtheslopewitha

pedestrian-controlledmachine.

•Ifpossible,keepthecuttingunit(s)loweredtothe

groundwhileoperatingonslopes.Raisingthe

cuttingunit(s)whileoperatingonslopescancause

themachinetobecomeunstable.

•Useextremecautionwithgrasscollectionsystems

orotherattachments.Thesecanchangethe

stabilityofthemachineandcausealossofcontrol.

StartingandShuttingoff theEngine

Important:Thefuelsystemautomaticallybleeds

itselfwhenanyofthefollowingsituationsoccur:

•Youarestartinganewmachineforthersttime.

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuel

systemcomponents.

totheMIDDLEposition,andensurethatthe

Enable/DisableswitchisintheDISABLEposition.

2.Removeyourfootfromthetractionpedaland

makesurethatthepedalisintheNEUTRAL

position.

3.TurntheignitionkeytotheRUNposition.

4.Whentheglowindicatordims,turntheignition

keytotheST ARTposition.Releasethekey

immediatelywhentheenginestartsandallowit

toreturntotheRUNposition.Allowtheengineto

warmup(withoutload),thenmovethethrottle

controltothedesiredposition.

ShuttingofftheEngine

1.MoveallcontrolstoNEUTRAL,engagethe

parkingbrake,movetheengine-speedswitch

tothelowidlepositionandallowtheengineto

reachlowidlespeed.

2.TurnthekeytotheOFFpositionandremoveit

fromtheswitch.

CuttingGrasswiththe Machine

Note:Cuttinggrassataratethatloadstheengine

promotesDPFregeneration.

1.Movethemachinetothejobsiteandalignthe

machineoutsidethecuttingareafortherst

cuttingpass.

2.EnsurethatthePTOswitchissettotheDISABLE

position.

3.Movetheleverforthemow-speedlimiter

forward.

4.Pressthethrottle-speedswitchtosettheengine

speedtoHIGHIDLE.

5.Usethejoysticktolowerthecuttingunitstothe

ground.

6.PressthePTOswitchtopreparecuttingunits

foroperation.

7.Usethejoysticktoraisethecuttingunitsoffthe

ground.

8.Beginmovingthemachinetowardthecutting

areaandlowerthecuttingunits.

Note:Cuttinggrassataratethatloadsthe

enginepromotesDPFregeneration.

StartingtheEngine

1.Sitontheseat,keepyourfootoffthetraction

pedalsothatitisinNEUTRAL,engagethe

parkingbrake,settheengine-speedswitch

9.Whenyoucompletethemowingpass,usethe

joysticktoliftthecuttingunits.

10.Performatear-shapedturntoquicklylineupfor

yournextpass.

29

Page 30

DieselParticulateFilter Regeneration

Thedieselparticulatelter(DPF)ispartoftheexhaust

system.Thediesel-oxidationcatalystoftheDPF

reducesharmfulgassesandthesootlterremoves

sootfromtheengineexhaust.

TheDPFregenerationprocessusesheatfromthe

engineexhausttoincineratethesootaccumulatedon

thesootlter,convertingthesoottoash,andclears

thechannelsofthesootltersothatlteredengine

exhaustowsouttheDPF .

Theenginecomputermonitorstheaccumulationof

sootbymeasuringthebackpressureintheDPF .If

thebackpressureistoohigh,sootisnotincinerating

inthesootlterthroughnormalengineoperation.T o

keeptheDPFclearofsoot,rememberthefollowing:

•Passiveregenerationoccurscontinuouslywhile

theengineisrunning—runtheengineatfull

enginespeedwhenpossibletopromoteDPF

regeneration.

Operateandmaintainyourmachinewiththefunction

oftheDPFinmind.Engineloadathighidle(full

throttle)enginespeedgenerallyproducesadequate

exhausttemperatureforDPFregeneration.

Important:Minimizetheamountoftimethatyou

idletheengineoroperatetheengineatlow-engine

speedtohelpreducetheaccumulationofsootin

thesootlter.

DPFSootAccumulation

•Overtime,thedieselparticulatelteraccumulates

sootinthesootlter.Thecomputerfortheengine

monitorsthesootlevelintheDPF .

•Whenenoughsootaccumulates,thecomputer

informsyouthatitistimetoregeneratetheDPF.

•DPFregenerationisaprocessthatheatstheDPF

toconvertthesoottoash.

•Inadditiontothewarningmessages,thecomputer

reducesthepowerproducedbytheengineat

differentsoot-accumulationlevels.

•IfthebackpressureintheDPFistoohighora

resetregenerationhasnotoccurredfor100hours,

theenginecomputersignalsyouthroughthe

InfoCenterwhenresetregenerationisrunning.

•Allowtheresetregenerationprocesstocomplete

beforeshuttingofftheengine.

EngineWarningMessages—SootAccumulation

IndicationLevel

Level1:Engine

Warning

Level2:Engine

Warning

FaultCode

g213866

Figure30

CheckEngine

SPN3719,FMI16

g213867

Figure31

CheckEngine

SPN3719,FMI0

EnginePowerRatingRecommendedAction

Thecomputerde-ratesthe

enginepowerto85%.

Thecomputerde-ratesthe

enginepowerto50%.

Performaparkedregeneration

assoonaspossible;refer

toParkedorRecovery

Regeneration(page37).

Performarecoveryregeneration

assoonaspossible;refer

toParkedorRecovery

Regeneration(page37).

30

Page 31

DPFAshAccumulation

•Thelighterashisdischargedthroughtheexhaust

system;theheavierashcollectsinthesootlter.

•Ashisaresidueoftheregenerationprocess.Over

time,thedieselparticulatelteraccumulatesash

thatdoesnotdischargewiththeengineexhaust.

•Thecomputerfortheenginecalculatestheamount

ofashaccumulatedintheDPF.

InfoCenterAdvisoryandEngineWarningMessages—AshAccumulation

•Whenenoughashaccumulates,theengine

computersendsinformationtotheInfoCenter

intheformofanenginefaulttoindicatethe

accumulationofashintheDPF.

•Thefaultmessagesindicatethatitistimeto

servicetheDPF.

•Inadditiontothewarnings,thecomputerreduces

thepowerproducedbytheengineatdifferent

ash-accumulationlevels.

Indication

Level1:

Engine

Warning

Level2:

Engine

Warning

Level3:

Engine

Warning

Level

FaultCode

g213863

EngineSpeed

Reduction

None

Figure32

EnginePowerRatingRecommendedAction

Thecomputer

de-ratestheengine

powerto85%.

ServicetheDPF;

refertoServicingthe

Diesel-OxidationCatalyst

(DOC)andtheSoot

Filter(page54)

CheckEngine

SPN3720,FMI16

ServicetheDPF;

refertoServicingthe

Diesel-OxidationCatalyst

(DOC)andtheSoot

Filter(page54)

g213863

Figure33

Thecomputer

None

de-ratestheengine

powerto50%.

CheckEngine

SPN3720,FMI16

ServicetheDPF;

refertoServicingthe

Diesel-OxidationCatalyst

(DOC)andtheSoot

Filter(page54)

g214715

Figure34

Enginespeedat

maximumtorque+

200rpm

Thecomputer

de-ratestheengine

powerto50%.

CheckEngine

SPN3251,FMI0

31

Page 32

TypesofDieselParticulateFilterRegeneration

Typesofdieselparticulatelterregenerationthatareperformedwhilethemachineisoperating:

TypeofRegenerationConditionsthatcauseDPFregenerationDPFdescriptionofoperation

Passive

Assist

Reset

Occursduringnormaloperationofthemachineat

high-enginespeedorhigh-engineload

Occursbecauseoflow-enginespeed,low-engine

load,orafterthecomputerdetectstheDPFis

becomingobstructedwithsoot

Occursevery100hours

Alsooccursafterassistregenerationonlyifthe

computerdetectsthatassistregenerationdidnot

sufcientlyreducethesootlevel

•TheInfoCenterdoesnotdisplayaniconindicating

passiveregeneration.

•Duringpassiveregeneration,theDPFprocesses

high-heatexhaustgasses,oxidizingharmful

emissions,andburningsoottoash.

RefertoPassiveDPFRegeneration(page34).

•TheInfoCenterdoesnotdisplayaniconindicating

assistregeneration.

•Duringassistregeneration,theenginecomputer

adjuststheenginesettingstoraisetheexhaust

temperature.

RefertoAssistDPFRegeneration(page35).

•Whenthehighexhaust-temperatureicon

isdisplayedintheInfoCenter,aregenerationisin

progress.

•Duringresetregeneration,theenginecomputer

adjuststheenginesettingstoraisetheexhaust

temperature.

RefertoResetRegeneration(page35).

Typesofdieselparticulatelterregenerationthatrequireyoutoparkthemachine:

TypeofRegenerationConditionsthatcauseDPFregenerationDPFdescriptionofoperation

Parked

Occursbecausethecomputerdetectsback

pressureintheDPFduetosootbuildup

Alsooccursbecausetheoperatorinitiatesaparked

regeneration

MayoccurbecauseyousettheInfoCentertoinhibit

resetregenerationandcontinuedoperatingthe

machine,addingmoresootwhentheDPFalready

needsaresetregeneration

Mayresultfromusingtheincorrectfuelorengineoil

•Whenthereset-standby/parkedorrecovery

regenerationiconorADVISORY#188

displaysintheInfoCenter,aregenerationis

requested.

•Performtheparkedregenerationassoonas

possibletoavoidneedingarecoveryregeneration.

•Aparkedregenerationrequires30to60minutes

tocomplete.

•Youmusthaveatleasta1/4tankoffuelinthe

tank.

•Youmustparkthemachinetoperformaparked

regeneration.

RefertoParkedorRecoveryRegeneration(page

37).

32

Page 33

Typesofdieselparticulatelterregenerationthatrequireyoutoparkthemachine:(cont'd.)

TypeofRegenerationConditionsthatcauseDPFregenerationDPFdescriptionofoperation

Recovery

Occursbecausetheoperatorignoredrequestsfor

aparkedregenerationandcontinuedoperatingthe

machine,addingmoresoottotheDPF

•Whenthereset-standby/parkedorrecovery

regenerationiconorADVISORY#190

displaysintheInfoCenter,arecoveryregeneration

isrequested.

•Arecoveryregenerationrequiresupto3hours

tocomplete.

•Youmusthaveatleasta1/2tankoffuelinthe

machine.

•Youmustparkthemachinetoperformarecovery

regeneration.

RefertoParkedorRecoveryRegeneration(page

37).

AccessingtheDPFRegeneration Menus

AccessingtheDPFRegenerationMenus

1.AccesstheServicemenu,pressthecenter

buttontoscrolldowntotheDPFREGENERATION

option(Figure35).

UsetheLASTREGENeldtodeterminehowmany

hoursyouhaveruntheenginesincethelastreset,

parked,orrecoveryregeneration.

g224693

Figure36

Figure35

2.PresstherightbuttontoselecttheDPF

Regenerationentry(Figure35).

TimeSinceLastRegeneration

AccesstheDPFRegenerationmenu,pressthecenter

buttontoscrolldowntotheLASTREGENeld(Figure

36).

g227667

TechnicianMenu

Important:Foroperatingconvenience,you

maydecidetoperformaparkedregeneration

beforethesootloadreaches100%,provided

theenginehasrunmorethan50hourssince

thelastsuccessfulreset,parked,orrecovery

regeneration.

Usethetechnicianmenutoviewthecurrentstateof

engineregenerationcontrolandviewthereported

sootlevel.

AccesstheDPFRegenerationmenu,pressthecenter

buttontoscrolldowntotheTECHNICIANoption,and

33

Page 34

presstherightbuttontoselecttheT echnicianentry

(Figure37).

DPFOperationT able(cont'd.)

Figure37

•UsetheDPFoperationtabletounderstandthe

currentstateofDPFoperation(Figure38).

State

ResetRegenTheenginecomputerisrunningareset

ParkedStby

ParkedRegenYouinitiatedaparkedregeneration

Recov.Stby

Recov.RegenY ouinitiatedarecoveryregeneration

g227348

•Viewthesootloadwhichismeasuredasthe

percentageofsootintheDPF(Figure39);referto

Description

regeneration.

Theenginecomputerisrequestingthat

yourunaparkedregeneration.

requestandtheenginecomputeris

processingtheregeneration.

Theenginecomputerisrequestingthat

yourunarecoveryregeneration.

requestandtheenginecomputeris

processingtheregeneration.

thesoot-loadtable.

Note:Thesootloadvaluevariesasthemachine

isoperatedandDPFregenerationoccurs.

.

DPFOperationTable

State

NormalTheDPFisinnormal-operating

AssistRegen

ResetStby

Figure38

Description

mode—passiveregeneration.

Theenginecomputerisperformingan

assistregeneration.

Theengine

computeristrying

torunareset

regeneration,but

1ofthefollowing

conditionsprevents

regeneration:

Theregeninhibit

settingissettoON.

Theexhaust

temperature

istoolowfor

regeneration.

g227359

Figure39

Soot-LoadTable

ImportantSootLoadValuesRegenerationState

0%to5%

78%Theenginecomputerperforms

g227360

100%

122%

Minimumsootloadrange

anassistregeneration.

Theenginecomputer

automaticallyrequestsa

parkedregeneration.

Theenginecomputer

automaticallyrequestsa

recoveryregeneration.

PassiveDPFRegeneration

•Passiveregenerationoccursaspartofnormal

engineoperation.

•Whileoperatingthemachine,runtheengineat

full-enginespeedandhighloadwhenpossibleto

promoteDPFregeneration.

34

Page 35

AssistDPFRegeneration

•Theenginecomputeradjustsenginesettingsto

raisetheexhausttemperature.

•Whileoperatingthemachine,runtheengineat

fullenginespeedandhighloadwhenpossibleto

promoteDPFregeneration.

ResetRegeneration

•TheicondisplaysintheInfoCenterwhilethereset

regenerationisprocessing.

•Wheneverpossible,donotshutofftheengineor

reduceenginespeedwhiletheresetregeneration

isprocessing.

Important:Wheneverpossible,allowthe

machinetocompletetheresetregeneration

processbeforeshuttingofftheengine.

CAUTION

Theexhausttemperatureishot(approximately

600°C(1,112°F)duringDPFregeneration.Hot

exhaustgascanharmyouorotherpeople.

•Neveroperatetheengineinanenclosed

area.

•Makesurethattherearenoammable

materialsaroundtheexhaustsystem.

•Nevertouchahotexhaustsystem

component.

•Neverstandnearoraroundtheexhaust

pipeofthemachine.

PeriodicResetRegeneration

IftheenginehasnotcompletedasuccessfulReset,

Parked,orRecoveryregenerationintheprevious100

hoursofengineoperation,theenginecomputerwill

attempttoperformaresetregeneration.

SettingtheInhibitRegen

ResetRegenerationOnly

Note:IfyousettheInfoCentertoinhibitregeneration,

theInfoCenterdisplaysADVISORY#185(Figure41)

every15minuteswhiletheenginerequestsareset

regeneration.

g224692

Figure41

Aresetregenerationproducestheelevatedengine

exhaust.Ifyouareoperatingthemachinearound

trees,brush,tallgrass,orothertemperature-sensitive

plantsormaterials,youcanusetheInhibitRegen

settingtopreventtheenginecomputerfrom

performingaresetregeneration.

Figure40

•Thehighexhaust-temperatureicondisplays

intheInfoCenter(Figure40).

•Theenginecomputeradjustsenginesettingsto

raisetheexhausttemperature.

Important:Thehighexhaust-temperature

iconindicatesthattheexhausttemperature

dischargedfromofyourmachinemaybe

hotterthanduringregularoperation.

•Whileoperatingthemachine,runtheengineat

fullenginespeedandhighloadwhenpossibleto

promoteDPFregeneration.

g224417

Important:Whenyoushutofftheengineand

startitagain,theinhibitregensettingdefaultsto

OFF.

1.AccesstheDPFRegenerationmenu,pressthe

centerbuttontoscrolldowntotheINHIBITREGEN

option,andpresstherightbuttontoselectthe

InhibitRegenentry(Figure42).

35

Page 36

Figure42

g227304

Figure44

g224394

2.Presstherightbuttontochangetheinhibit

regenerationsettingfromOntoOff(Figure42)

orfromOfftoOn(Figure43).

Figure43

AllowingaResetRegeneration

TheInfoCenterdisplaysthehighexhaust-temperature

icon

whentheresetregenerationisinprocess.

Note:IfINHIBITREGENissettoON,theInfoCenter

displaysADVISORY#185(Figure44).Pressbutton3

tosetinhibitregenerationsettingtoOFFandcontinue

withtheresetregeneration.

Note:Iftheengineexhausttemperatureistoolow,

theInfoCenterdisplaysADVISORY#186(Figure45)to

informyoutosettheenginetofullthrottle(highidle).

g224691

g224395

Figure45

Note:Whentheresetregenerationcompletes,the

highexhaust-temperature

InfoCenterscreen.

disappearsfromthe

36

Page 37

ParkedorRecoveryRegeneration

•Whentheenginecomputerrequestseithera

parkedregenerationorarecoveryregeneration,

theregenerationrequesticon(Figure46)displays

intheInfoCenter.

Figure46

•Themachinedoesnotautomaticallyperforma

parkedregenerationorarecoveryregeneration,

youmustruntheregenerationthroughthe

InfoCenter.

ParkedRegenerationMessages

regenerationrequired—powertakeoffdisabled

ADVISORY#189(Figure49).

g224398

Figure49

Important:Performaparkedregenerationto

restorethePTOfunction;refertoPreparingto

PerformaParkedorRecoveryRegeneration

(page38)andPerformingaParkedorRecovery

Regeneration(page38).

Note:TheHomescreendisplaysthePTO

disabledIcon(Figure50).

g224404

g224415

Figure50

Whenaparkedregenerationisrequestedbythe

enginecomputerthefollowingmessagesdisplayin

theInfoCenter:

•EnginewarningSPN3720,FMI16(Figure47)

Figure47

•ParkedregenerationrequiredADVISORY#188

(Figure48)

Note:Advisory#188displaysevery15minutes.

Figure48

RecoveryRegenerationMessages

Whenarecoveryregenerationisrequestedbythe

enginecomputer,thefollowingmessagesdisplayin

theInfoCenter:

•EnginewarningSPN3719,FMI0(Figure51)

g213863

g213867

Figure51

•Recoveryregenerationrequired—powertakeoff

disabledADVISORY#190(Figure52)

g224397

•Ifyoudonotperformaparkedregeneration

within2hours,theInfoCenterdisplaysparked

g224399

Figure52

37

Page 38

Important:Performarecoveryregeneration

torestorethePTOfunction;refertoPreparing

toPerformaParkedorRecoveryRegeneration

(page38)andPerformingaParkedorRecovery

Regeneration(page38).

Note:TheHomescreendisplaysthePTOdisabled

Icon;refertoFigure50inParkedRegeneration

Messages(page37).

DPFStatus-Limitation

•Iftheenginecomputerrequestsarecovery

regenerationorisprocessingarecovery

regenerationandyouscrolldowntothePARKED

REGENoption,parkedregenerationlocksandthe

lockicon(Figure53)appearsinthelowerright

corneroftheInfoCenter.

2.Movethemachineoutsidetoanareaawayfrom

combustiblematerials.

3.Parkthemachineonalevelsurface.

4.Ensurethatthetractioncontrolormotion-control

leversareintheNEUTRALposition.

5.Ifapplicable,shutoffthePTO,andlowerthe

cuttingunitsoraccessories.

6.Engagetheparkingbrake.

7.SetthethrottletothelowIDLEposition.

PerformingaParkedorRecovery

Regeneration

CAUTION

Theexhausttemperatureishot(approximately

600°C(1,112°F)duringDPFregeneration.Hot

exhaustgascanharmyouorotherpeople.

•Neveroperatetheengineinanenclosed

area.

Figure53

•Iftheenginecomputerhasnotrequesteda

recoveryregenerationandyouscrolldown

totheRECOVERYREGENoption,therecovery

regenerationlocksandthelockicon(Figure54)

appearsinthelowerrightcorneroftheInfoCenter.

Figure54

PreparingtoPerformaParkedorRecovery

Regeneration

•Makesurethattherearenoammable

g224625

materialsaroundtheexhaustsystem.

•Nevertouchahotexhaustsystem

component.

•Neverstandnearoraroundtheexhaust

pipeofthemachine.

Important:Thecomputerofthemachinecancels

DPFregenerationifyouincreasetheenginespeed

fromlowidleorreleasetheparkingbrake.

1.AccesstheDPFRegenerationmenu,press

thecenterbuttontoscrolldowntoeitherthe

PARKEDREGENST ARToptionortheRECOVERY

REGENSTARToption(Figure55),andpressthe

rightbuttontoselectthestarttheregeneration

(Figure55).

g224628

1.Ensurethatthemachinehasfuelinthetankfor

thetypeofregenerationyouareperforming:

•ParkedRegeneration:Ensurethatyou

have1/4tankoffuelbeforeperformingthe

parkedregeneration.

•RecoveryRegeneration:Ensurethatyou

have1/2tankoffuelbeforeperformingthe

recoveryregeneration.

38

Page 39

Figure55

3.AttheDPFchecklistscreen,verifythatthe

parkingbrakeisengagedandthattheengine

speedissettolowidle(Figure57).

g224402

g224407

g224629

2.AttheVERIFYFUELLEVELscreen,verifythatyou

have1/4tankoffuelifyouareperformingthe

parkedregenerationor1/2tankoffuelifyouare

performingtherecoveryregeneration,andpress

therightbuttontocontinue(Figure56).

g227679

Figure57

4.AttheINITIATEDPFREGENscreen,pressthe

rightbuttontocontinue(Figure58).

g224414

g224626

Figure56

g227678

g224630

Figure58

39

Page 40

5.TheInfoCenterdisplaystheINITIATINGDPF

REGENmessage(Figure59).

Figure59

6.TheInfoCenterdisplaysthetimetocomplete

message(Figure60).

CheckMessageandCorrectiveActionTable

(cont'd.)

g224411

CorrectiveAction:Startandruntheengine.

g227681

CorrectiveAction:Runtheenginetowarmthecoolant

temperatureto60°C(140°F).

Figure60

7.Theenginecomputercheckstheenginestate

andfaultinformation.TheInfoCentermay

displaythefollowingmessagesfoundinthe

tablethatfollows:

CheckMessageandCorrectiveActionTable

CorrectiveAction:Exittheregenerationmenuandrunthe

machineuntilthetimesincelastregenerationisgreaterthan

50hours;refertoTimeSinceLastRegeneration(page33).

g224406

g224416

CorrectiveAction:Changetheenginespeedtolowidle.

CorrectiveAction:Troubleshoottheenginecomputer

conditionandretryDPFregeneration.

8.TheInfoCenterdisplaysthehomescreenand

theregenerationacknowledgeicon(Figure61)

appearsinthelowerrightcornerofthescreen

astheregenerationprocesses.

g224403

Figure61

CorrectiveAction:Troubleshoottheenginefaultandretry

DPFregeneration.

Note:WhiletheDPFregeneration

runs,theInfoCenterdisplaysthehigh

exhaust-temperatureicon.

9.Whentheenginecomputercompletesa