Page 1

FORM NO. 3318-590 GB Rev A

MODEL NO. 03530—60001 & UP

MODEL NO. 03531—

®

To understand this product, and for safety and

optimum performance, read this manual before

starting the engine. Pay special attention to

SAFETY INSTRUCTIONS highlighted by this

symbol.

OPERATOR'S

60001 & UP

®

REELMASTER

5300-D

It means CAUTION, WARNING or DANGER—personal safety instruction. Failure to

comply with the instruction may result in personal injury.

MANUAL

©The TORO COMPANY—1995

Page 2

This operator's manual has instructions on safety, operation, and maintenance.

This manual emphasizes safety, mechanical and general product information. DANGER, WARNING and

CAUTION identify safety messages. Whenever the triangular safety alert symbol appears, understand the safety message that follows. “IMPORTANT” highlights special mechanical information and “NOTE” emphasizes

general product information worthy of special attention.

IDENTIFICATION AND ORDERING

MODEL AND SERIAL NUMBER

The model and serial number for the traction unit is on a plate that is mounted on the left front frame member.

The model and serial number for the cutting unit is on a plate that is mounted on the top front of the center cutting unit. Use model and serial number in all correspondence and when ordering parts.

To order replacement parts from an authorized TORO Distributor, supply the following information:

1. Model and serial numbers of the machine.

2. Part number, description and quantity of parts desired.

NOTE: Do not order by reference number if a parts catalog is being used; use the part number.

Table of Contents

Safety 3

Specifications 9

Before Operating 11

Controls 13

Operating 17

Maintenance 28

Page

2

Page 3

Safety

Training

1. Read the instructions carefully. Be familiar with

the controls and the proper use of the equipment.

2. Never allow children or people unfamiliar with

these instructions to use the lawn mower. Local

regulations may restrict the age of the operator.

3. Never mow while people, especially children, or

pets are nearby.

4. Keep in mind that the operator or user is respon-

sible for accidents or hazards occurring to other

people or their property.

5. Do not carry passengers.

6. All drivers should seek and obtain professional

and practical instruction. Such instruction should

emphasize:

• the need for care and concentration when

working with ride-on machines;

• control of a ride-on machine sliding on a

slope will not be regained by the application

of the brake. The main reasons for loss of

control are:

– insufficient wheel grip;

– being driven too fast;

• Store fuel in containers specifically

designed for this purpose.

• Refuel outdoors only and do not smoke

while refueling.

• Add fuel before starting the engine. Never

remove the cap of the fuel tank or add petrol

while the engine is running or when the

engine is hot.

• If petrol is spilled, do not attempt to start the

engine but move the machine away from the

are of spillage and avoid creating any source

of ignition until petrol vapors have dissipated.

• Replace all fuel tanks and container caps

securely.

4. Replace faulty silencers.

Operation

1. Do not operate the engine in a confined space

where dangerous carbon monoxide fumes can

collect.

2. Mow only in daylight or in good artificial light.

3. Before attempting to start the engine, disengage

all blade attachment clutches and shift into neutral.

– inadequate braking;

– the type of machine is unsuitable for its

task;

– lack of awareness of the effects of

ground conditions, especially slopes;

– incorrect hitching and load distribution.

Preparation

1. While mowing, always wear substantial footwear

and long trousers. Do not operate the equipment

when barefoot or wearing open sandals.

2. Thoroughly inspect the area where the equipment

is to be used and remove all objects which may

be thrown by the machine.

3. WARNING—Petrol is highly flammable.

4. Do not use on slopes of more than:

• Never mow side hills over 5°

• Never mow uphill over 10°

• Never mow downhill over 15°

5. Remember there is no such thing as a “safe”

slope. Travel on grass slopes requires particular

care. To guard against overturning:

• do not stop or start suddenly when going up

or downhill;

• engage the clutch slowly, and always keep

the machine in gear, especially when travailing downhill;

• machine speeds should be kept low on

slopes and during tight turns;

• stay alert for bumps and hollows and other

hidden hazards;

3

Page 4

Safety

• never mow across the face of the slope,

unless the lawn mower is designed for this

purpose.

6. Use care when pulling loads or using heavy

equipment.

• Use only approved drawbar hitch points.

• Limit loads to those you can safely control.

• Do not turn sharply. Use care when reversing.

• Use counterweight(s) or wheel weights

when suggested in the instruction handbook.

7. Watch out for traffic when crossing or near road-

ways.

8. Stop the blades rotating before crossing surfaces

other than grass.

9. When using any attachments, never direct dis-

charge of material toward bystanders nor allow

anyone near the machine while in operation .

10. Never operate the lawn mower with defective

guards, shields or without safety protective

devices in place.

11. Do not change the engine governor settings or

overspeed the engine. Operating the engine at

excessive speeds may increase the hazard of personal injury.

tor’s position.

• before clearing blockages;

• before checking, cleaning or working on

the lawnmower;

• after striking a foreign object. Inspect the

lawnmower for damage and make repairs

before restarting and operating the equipment.

15. Reduce the throttle setting during engine runout

and, if the engine is provided with a shutoff

valve, turn the fuel off at the conclusion of

mowing.

Maintenance and Storage

1. Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

2. Never store the equipment with petrol in the

tank inside a building where fumes may reach

an open flame or spark.

3. Allow the engine to cool before storing in any

enclosure.

4. To reduce the fire hazard, keep the engine,

silencer, battery compartment and petrol storage

area free of grass, leaves, or excessive grease.

5. Check the grass catcher frequently for wear or

deterioration.

12. Before leaving the operator’s position:

• disengage the power take-off and lower the

attachments;

• change into neutral and set the parking

brake;

• stop the engine and remove the key.

13. Disengage the drive to attachments when trans-

porting or not in use.

14. Stop the engine and disengage the drive to the

attachment

• before refueling;

• before removing the grass catcher;

• before making height adjustments unless

the adjustment can be made from the opera-

4

6. Replace worn or damaged parts for safety.

7. If the fuel tank has to be drained, this should be

done outdoors.

8. Be careful during adjustment of the machine to

prevent entrapment of the fingers between moving blades and fixed parts of the machine.

9. On multi-bladed machines, take care as rotating

one blade can cause other blades to rotate.

10. When the machine is to be parked, stored or left

unattended, lower the cutting means unless a

positive mechanical lock is used.

Page 5

Sound & Vibration Levels

Sound Levels

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 89.5 dB(A),

based on measurements of identical machines per

84/538/EEC.

This unit has a sound power level of 103.5

dB(A)/1pW, based on measurements of identical

machines per procedures outlined in Directive

79/113/EEC and amendments.

Vibration Levels

This unit has a vibration level of 2.5 m/s2at the posterior, based on measurements of identical machines

per ISO 2631 procedures.

Safety

This unit does not exceed a vibration level of 0.5

2

at the posterior based on measurements of iden-

m/s

tical machines per ISO 2631 procedures.

5

Page 6

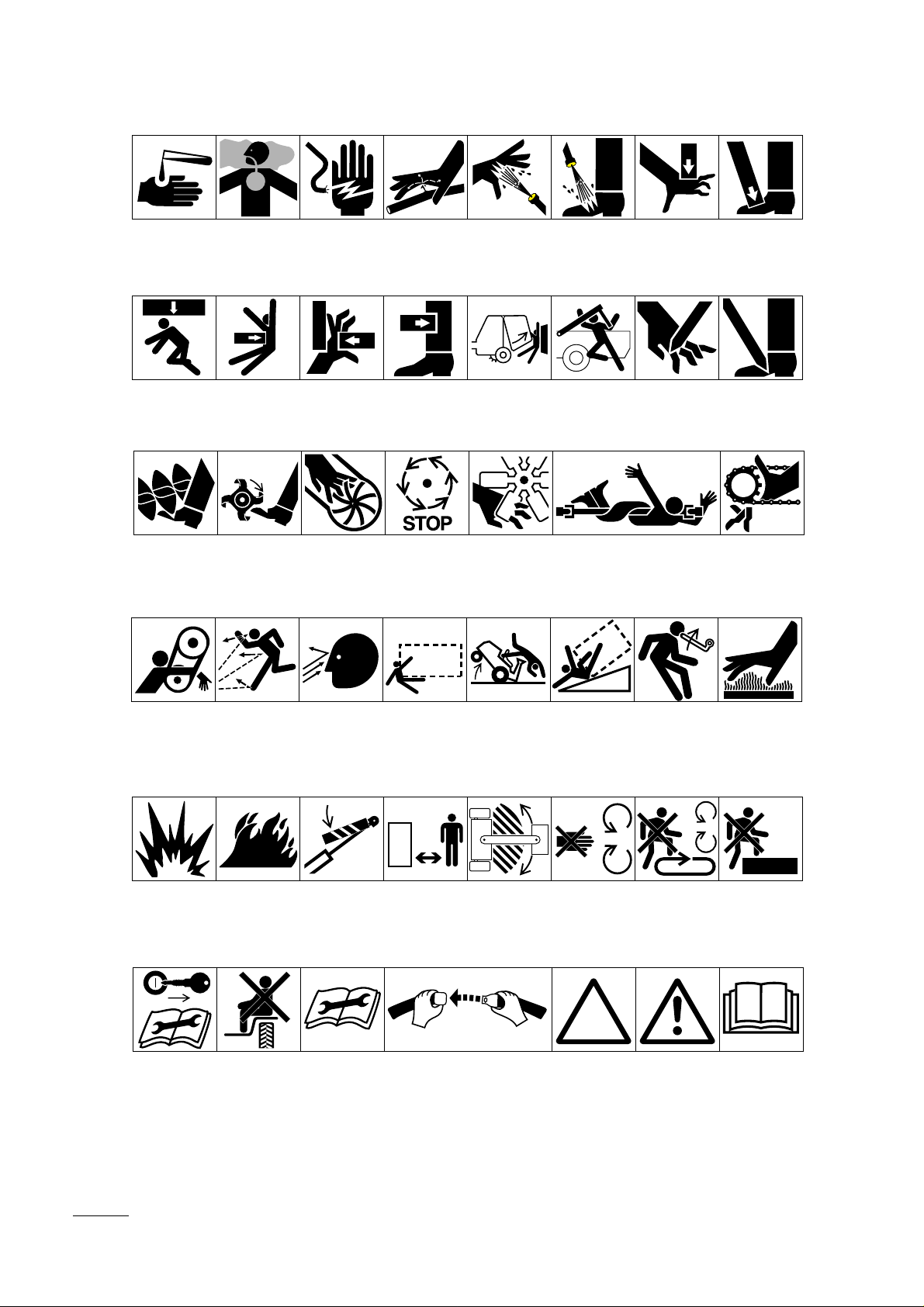

Symbol Glossary

Caustic liquids,

chemical burns to

fingers or hand

Crushing of

whole body,

applied from

above

Cutting or

entanglement of

foot, rotating auger

Poisonous

fumes or toxic

gases, asphyxiation

Crushing of

torso, force

applied from side

Severing of

foot, rotating

knives

Electrical shock,

electrocution

Crushing of fingers

or hand/, force

applied from side

Severing of

fingers or hand,

impeller blade

High pressure

fluid, injection

into body

force applied

from side

Wait until all

machine

components have

completely stopped

before touching them

High pressure

spray, erosion of

flesh

Crushing of

whole body

Severing of

fingers or hand,

engine fan

High pressure

spray, erosion of

flesh

Crushing of

head, torso and

arms

Whole body entanglement,

implement input drive line

Crushing of

fingers

or hand,

force

applied from

above

Cutting of

fingers or hand

Crushing of

toes or foot, force

applied from above

Cutting of footCrushing of leg,

Fingers or

hand entangle-

ment, chain drive

Hand & arm

entanglement,

belt drive

Explosion Fire or open

Shut off engine

& remove key before

performing mainten-

ance or repair work

Thrown or fly-

ing objects, whole

body exposure

flame

Riding on this

machine is allowed

only on a passen-

ger seat & only if the

driver’s view is not

hindered

Thrown or

flying objects,

face exposure

Secure lifting

cylinder with locking

device before getting

in hazardous area

Consult

technical manual

for proper service

procedures

Runover/back-

over, (relevant

machine to appear

in dashed box)

Stay a safe

distance from

the machine

Fasten seat belts Safety alert

Machine tipping,

riding mower

Stay clear of

articulation area

while engine is

running

Machine rollover,

ROPS (relevant

machine to appear

in dashed box)

Stored energy

hazard, kickback

or upward motion

Do not open

or remove safety

shields while

engine is

running

triangle

Do not step on

loading platform if

PTO is connected to tractor

& engine is running

outline safety

alert symbol

Hot surfaces,

burns to fingers

or hands

Do not step

Read operator’s

manual

6

Page 7

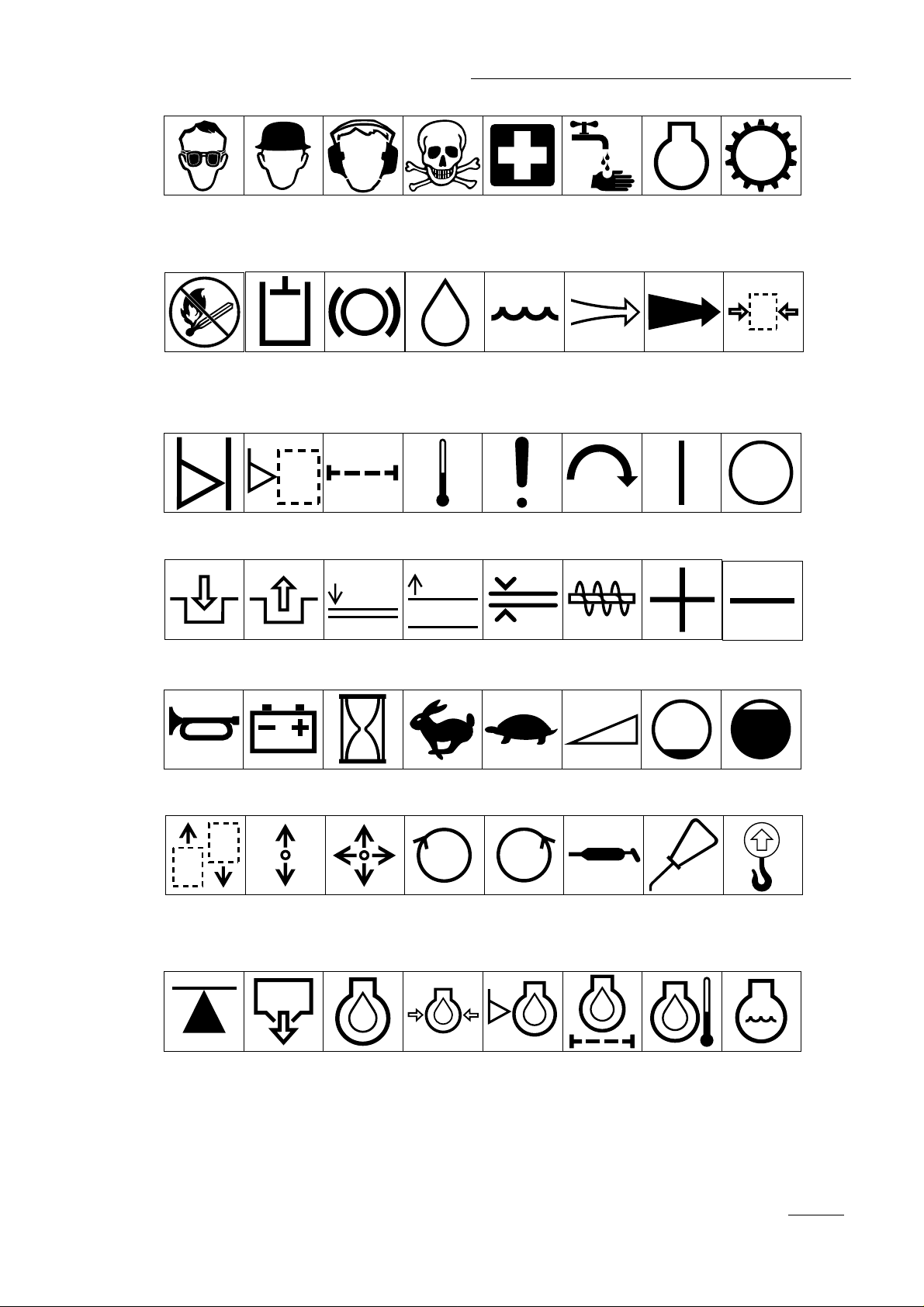

Safety

Eye protection

must be worn

Fire, open light

& smoking

prohibited

Level

indicator

Engage Disengage

Head protection

must be worn

Hydraulic

system

Liquid level Filter Temperature Failure/

Hearing

protection must

be worn

Brake system

Attachment

lower

Caution, toxic

risk

First aid

Oil Coolant (water) Intake air Exhaust gas Pressure

Malfunction

Attachment

raise

Spacing distance Snow thrower,

Flush with water Engine Transmission

Start switch/

mechanism

collector auger

On/start Off/stop

Plus/increase/

positive polarity

Minus/decrease/

negative polarity

Horn Battery charging

Machine travel

direction,

forward/rearward

Jack or

support point

condition

Control lever

operating

direction, dual

direction

Draining/

emptying

Hourmeter/elapsed

operating hours

Control lever

operating

direction, multiple

direction

Engine lubricating oil

Fast Slow Continuous

Clockwise

rotation

Engine lubricating

oil pressure

Counter-clockwise rotation

Engine lubricating

oil level

variable, linear

Grease

lubrication

point

Engine lubricating

oil filter

Volume empty Volume full

Oil lubrication

point

Engine

lubricating oil

temperature

Lift point

Engine coolant

7

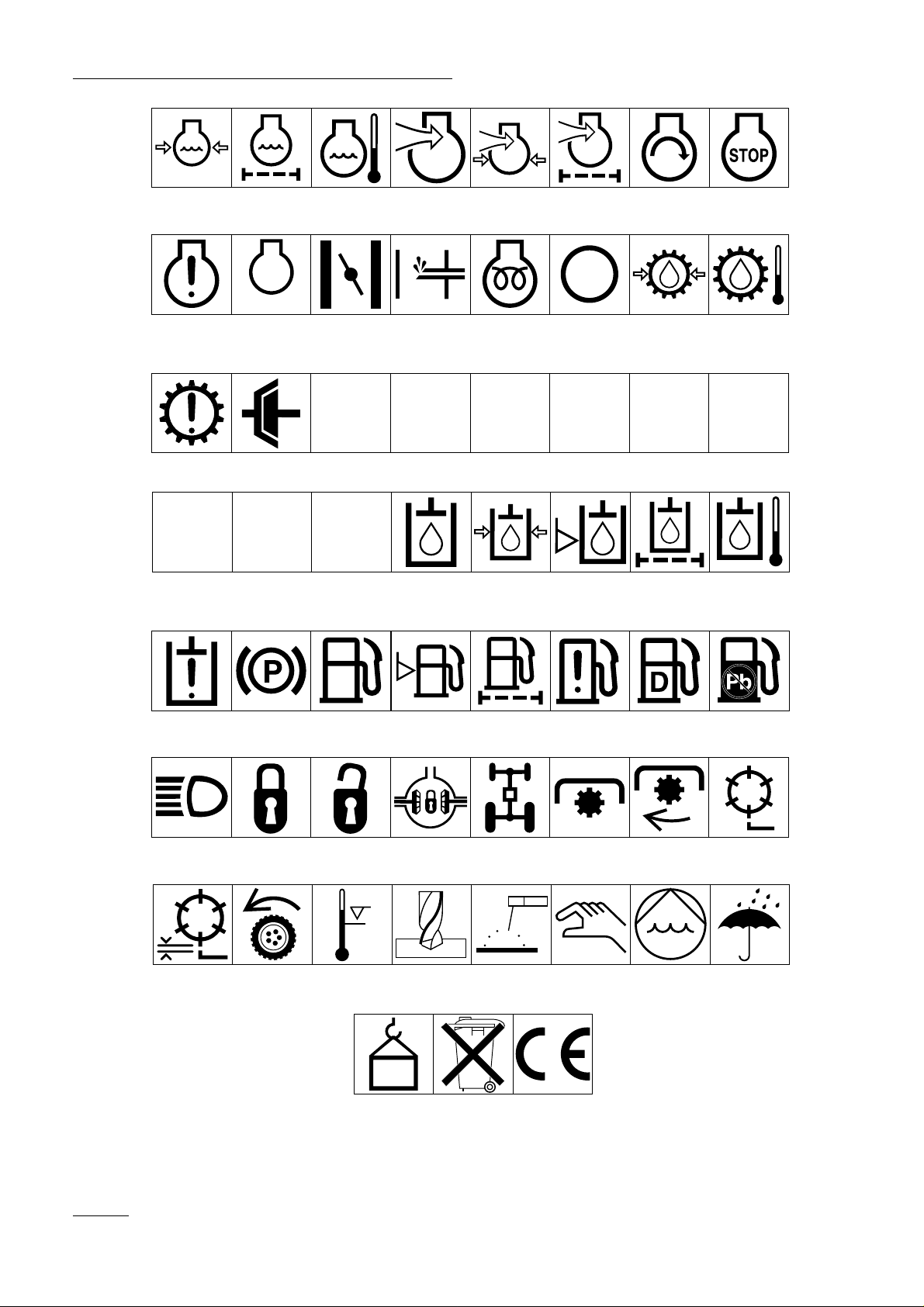

Page 8

Safety

Engine coolant

pressure

Engine coolant f

ilter

n/min

Engine failure/

malfunction

Transmission

failure/malfunction

Engine rotational

speed/frequency

Clutch Neutral High Low Forward Reverse Park

231

First gear Second gear

Engine

lubricating oil

pressure

Choke Primer (start aid) Electrical preheat

Engine intake/

combustion air

Engine intake/

combustion air

pressure

(low temperature

start aid)

Engine intake/

air filter

Transmission oil Transmission oil

Engine start Engine stop

pressure

Transmission oil

temperature

NHLFRP

Third gear (other #'s

may be used until

the maximum # of forward gears is reached.)

Hydraulic oil Hydraulic oil

Hydraulic oil

pressure

Hydraulic oil level Hydraulic oil filter

temperature

Hydraulic oil

failure/malfunction

Headlights Lock Unlock Differential lock 4-Wheel drive Power Take-Off Power Take-Off,

Reel cutting

element, height

adjustment

Parking brake Fuel Fuel level Fuel filter Fuel system

Traction Above working

temperature range

Drilling Manual metal arc

0430 weight Do not dispose

welding

in the garbage

failure/malfunction

Manual 0356 Water pump

CE logo

Diesel fuel Unleaded fuel

rotational speed

Reel cutting

element

0626 Keep dry

8

Page 9

Specifications

Engine: Mitsubishi three-cylinder, liquid-cooled

diesel. 20.9 kW (28 hp) @ governed maximum rpm

of 3200; 1,318 cc (80.4 cu. in.) displacement

Heavy-duty, 3-stage, remote-mounted air cleaner.

High water temperature shutdown switch.

Cooling System: Radiator capacity is 7.1 l (7.5 qt.)

of 50/50 mixture of ethylene glycol anti-freeze.

Remote mounted .9 l (1 qt.) expansion tank. A twospeed fan drive controls air flow.

Fuel System: Fuel tank capacity is 37.9 l (10 gal.)

of #2 diesel fuel. 12-volt, electric fuel pump with

replaceable fuel filter. Equipped with a fuel

filter/water separator to capture water in the fuel.

Traction System: Foot pedal controls forward/

reverse ground speed. Ground speed: 0–16.1 kmh

(0–10 m.p.h.) forward and 0–6.4 kmh (0-4 mph)

reverse. Hydrostatic transmission mounted directly

on a 20.9:1 ratio front axle. Axle/reservoir capacity

is 4.7 l (5 qts). Replaceable filter mounted directly

on transmission housing. Model 03531 only:

Mechanical rear axle is coupled to the front axle by a

drive shaft and overrunning clutch.

Electrical System: Automotive type electrical system. 12-volt, maintenance free battery with 530 cold

cranking Amps @ –18°C (0° F) and 85 minute

reserve capacity @ 29° C (85° F). 40-amp alternator

with I.C. regulator/rectifier. Seat switch, reel and

traction interlock switches. An electronic controller

monitors and controls safety and operational functions.

Controls: Foot-operated traction and brake pedals.

Hand-operated throttle, traction speed control lever,

parking brake lock, ignition switch with automatic

preheat cycle, single joy stick control for cutting unit

on/off and lift/lower. Cutting unit backlap switch and

reel speed controls located under the operator seat.

Gauges: Hour meter, speedometer, fuel gauge, temperature gauge. 4 warning lamps: oil pressure, water

temperature, amps and glow plug.

General Specifications (approx.):

Width-of-Cut : 241 cm (95 in.)

Overall Width:

Transport 220 cm (87 in.)

Outside of tires 208 cm (82 in.)

Cutting Unit Drive System: Hydraulic reel motors

feature quick disconnects to ease removal/installation on cutting units. Hydraulic fluid reservoir

capacity is 32.2 l (8.5 gal.). System protected by a

filter assembly with service indicator.

Seat: Deluxe high-back seat with adjustable fore

and aft travel, weight and height. Tool box at the left

side of the seat.

Steering System: Power steering with dedicated

power source.

Tires: Two rear tires: 19 x 8.50-8, tubeless, 4-ply rating. Two front tires: 26 x 12.00-12 tubeless, 4-ply

rating. Recommended tire pressure for the front and

rear tires is 69–103 kPa (10–15 psi).

Brakes: Individual drum-type wheel brakes on the

front traction wheels. Brakes controlled by individual pedals operated by the left foot. Hydrostatic

braking through traction drive.

Overall Length:

Without grass baskets: 263 cm (103.5 in.)

With grass baskets: 294 cm (116 in.)

Height:

With Rollover protector: 214 cm (84.5 in.)

Without 142 cm (56 in.)

Recommended Height-of-Cut:

5-Blade Cutting Unit: 1–1.9cm (1/2–3/4 in.)

8-Blade Cutting Unit: 0.4–1.6 cm (1/4–5/8 in.)

Weight: Model 03502 821 kg (2,200 lbs.)*

Model 03504 952 kg (2,550 lbs.)*

Model 03530 868 kg (2,325 lbs.)*

Model 03531 998 kg (2,675 lbs.)*

*With 8-Blade Cutting Units, baskets & full

fluid levels

Optional Equipment

5-Blade Cutting Unit, Model No. 03505

8-Blade Cutting Unit, Model No. 03508

9

Page 10

Specifications

Grass Basket Kit, Model No. 03513

Rear Weight Kit, Part No. 75-6690

Rear Roller Scraper Kit, Model No. 03512

Front Roller Scraper Kit, Model No. 83-5400

High Height-of-Cut Kit, Model No. 83-5300

Scraper/Comb Kit, Model No. 03518

Armrest Kit, Model No. 30707

Front Scraper, HHOC Kit P/N 82-6920

Thatcher Unit, Model No. 03516

Precleaner Bowl Extension Tube, Part No. 43-3810

(Clamp, Part No. 20-4840 required to install extension tube)

4-Wheel Drive Kit, Model No. 03517 (For use with

models 03502, 03530 only)

10

Page 11

Before Operating

CHECK THE ENGINE OIL

1. Park the machine on a level surface. Open the

hood.

2. Remove the dipstick, wipe it clean, then reinstall

it. Remove it again and check the oil level on

the dipstick; The oil level should be up to the

FULL mark.

➀

of the radiator daily, more often if conditions are

extremely dusty and dirty.

The cooling system is filled with a 50/50 solution of

water and permanent ethylene glycol anti-freeze.

Check the level of coolant in the expansion tank each

day before starting the engine. Cooling system

capacity is 9.6 l.

1. Check the level of coolant in the expansion tank.

It should be between the marks on the side of

the tank.

CAUTION

If the engine has been running, pressurized hot

coolant can escape when the radiator cap is

removed and cause burns.

Figure 1

1. Dipstick

3. If the oil is below the FULL mark, remove the

fill cap and add SAE 10W-30 CD classification

oil until the level reaches the FULL mark on the

dipstick. DO NOT OVERFILL. Crankcase

capacity is 3.8 l with filter.

➀

Figure 2

1. Oil Fill Cap

4. Install the oil fill cap and close the hood.

➀

Figure 3

1. Expansion Tank

2. If coolant level is low, remove the expansion

tank cap and replenish the system. DO NOT

OVERFILL.

3. Install the expansion tank cap.

FILL THE FUEL TANK

1. Remove the fuel tank cap.

CHECK THE COOLING SYSTEM

Clean debris from the screen, oil cooler and the front

2. Fill the tank to about 2.5 cm (one inch) below

the top of the tank, not the filler neck, with No.

2 diesel fuel. Then install the cap.

11

Page 12

Before Operating

DANGER

Because diesel fuel is flammable, use caution when

storing or handling it. Do not smoke while filling

the fuel tank. Do not fill the fuel tank while the

engine is running, hot, or when the machine is in an

enclosed area. Always fill the fuel tank outside and

wipe up any spilled diesel fuel before starting the

engine. Store the fuel in a clean, safety-approved

container and keep the cap in place. Use Diesel fuel

for the engine only; not for any other purpose.

groove mark. DO NOT OVERFILL by more

than .6 cm (1/4 inch) above the groove.

➀

Figure 5

1. Transmission Dipstick Cap

➀

Figure 4

1. Fuel Tank Cap

CHECK THE TRANSMISSION

FLUID

The front axle housing acts as the reservoir for the

system. The transmission and axle housing are

shipped from the factory with 4.7 l (5 quarts) of

Mobil 424 engine oil. However, check the level of

transmission oil before first starting the engine and

daily thereafter.

1. Position the machine on a level surface, lower

the cutting units and stop the engine.

2. Remove the access panel behind the foot rest.

3. Unscrew the dipstick cap from the transmission

filler neck and wipe it with a clean cloth. Screw

the dipstick into the filler neck. Remove the

dipstick and check the oil level. If the level is

not within 1.2 cm (1/2 inch) from the groove in

the dipstick, add enough oil to raise it to the

4. Screw the dipstick filler cap finger-tight onto

the filler neck. It is not necessary to tighten the

cap with a wrench.

CHECK THE HYDRA ULIC FLUID

The hydraulic system driving the reels is designed to

operate on anti-wear hydraulic fluid. The machine’s

reservoir is filled at the factory with 32.2 l (8.5 gallons) of Mobil 424 hydraulic fluid. Check the level

of hydraulic fluid before the first starting the engine

and daily thereafter.

Group 1 Hydraulic Oil (Recommended for ambient temperatures consistently below 38° C (100°

F):

ISO type 46/68 anti-wear hydraulic fluid

Mobil Mobil Fluid 424

Amoco Amoco 1000

International Harvester Hy-Tran

Texaco TDH

Shell Donax TD

Union Oil Hydraulic/Tractor Fluid

Chevron Tractor Hydraulic Fluid

BP Oil BP HYD TF

Boron Oil Eldoran UTH

Exxon Torque Fluid

Conoco Power-Tran 3

Kendall Hyken 052

12

Page 13

Before Operating

Phillips HG Fluid

Note: Oils within this group are interchange-

able.

Group 2 Hydraulic Oil—Recommended for ambient temperatures consistently above 21° C (70°

F):

ISO type 68 anti-wear hydraulic fluid

Mobil DTE 26 or DTE 16

Shell Tellus 68

Amoco Rykon Oil 68

Arco Duro AW S-315

Boron Industron 53

BP Oil Energol HLP68

Castrol Hyspin AWS68

Chevron Chevron EP68

Citgo Citgo A/W68

Conoco Super Hydraulic Oil 31

Exxon Nuto H68

Gulf 68AW

Pennzoil AW Hyd Oil 68

Phillips Magnus A315

Standard Industron 53

Texaco Rando HD68

Union Unax AW 315

Note: Oils within this group are inter-

changeable.

IMPORTANT: Two groups of hydraulic oil are

specified to allow optimal operation of the

machine in a wide range of temperatures encountered. The group 1 oils are a multi-viscosity

hydraulic oil that allow operation at lower temperatures without the increased viscosity associated with straight viscosity oils.

increased engine laboring while cold, sluggish or

non-operating valve spools while cold and increased

filter back pressure due to the higher oil viscosity.

Select the set of conditions (either ambient temperatures above 21° C (70° F) or below 38° C (100° F),

and use that type of oil throughout the year, rather

than changing oil types several times per year.

Group 3 Hydraulic Fluid (Biodegradable):

ISO VG 32/46 anti-wear hydraulic fluid

Mobile EAL 224L

Note: This biodegradable hydraulic fluid in this

group is not compatible with the fluids in

group 1 or 2.

Note: When changing from one type of hydraulic

oil to the other, remove all the old oil from

the system, because some brands of one type

are not completely compatible with some

brands of the other type of hydraulic oil. If

you always use Mobil products, the two

types of oil are compatible and interchangeable.

IMPORTANT: Use only the types of hydraulic

oils specified. Other fluids could cause system

damage.

Note: A red dye additive for the hydraulic system

oil is available in 20 ml bottles. One bottle

is sufficient for 15–22 l of hydraulic oil.

Order Part No. 44-2500 from your

Authorized Toro Distributor

1. Position the machine on a level surface, lower

the cutting units and stop the engine.

The Mobil DTE 26 type oils are straight viscosity

oils which remain slightly more viscous at higher

temperatures than the multi-viscosity oils.

Using the Mobil 424-type oils in the higher ambient

temperatures may result in decreased efficiency in

some hydraulic components compared to using the

Mobil DTE 26 type oils.

Using the Mobil DTE 26 type oils in the lower ambient temperatures may result in harder starting,

2. Clean the area around the filler neck and cap of

the hydraulic tank. Remove the cap from the

filler neck.

13

Page 14

Before Operating

➀

➁

➀

Figure 6

1. Hydraulic Tank Cap

3. Remove the dipstick from the filler neck and

wipe it with a clean cloth. Insert it into the filler

neck; then remove it and check the fluid level.

It should be within 6 mm (1/4 inch) of the mark

on the dipstick.

4. If the level is low, add fluid to raise the level to

the full mark.

5. Install the dipstick and cap onto the filler neck.

CHECK REAR AXLE LUBRICANT (Model 03531 only)

The rear axle has three separate reservoirs which use

SAE 80W-90 weight gear lube. Although the axle is

shipped with lubricant from the factory, check the

level before operating the machine.

Figure 7.

1. Check Plugs (2) 2. Mounting Bolts

➀

Figure 8.

1. Check/Fill Plug

CHECK REEL-TO-BEDKNIFE

CONTACT

1. Position the machine on a level surface.

2. Remove a check plug from each end of axle and

make sure the lubricant is up to bottom of the

hole. If the level is low, remove a mounting

bolt above each end plug and add enough lubricant to bring the level up to the bottom of the

hole

(Fig. 7).

3. Remove the plug in the center of the axle and

check the level. If the level is low, add enough

lubricant to bring it up to the bottom of the hole

(Fig. 5).

14

Each day before operating, check the reel-to-bedknife contact, regardless of whether the quality of cut

has been acceptable. There must be light contact

across the full length of the reel and bedknife.

CHECK WHEEL NUT TORQ UE

WARNING

Tighten the wheel nuts to 45-55 lbs after 1–4 hours

of operation and again after 10 hours of operation

and every 250 hours thereafter. Failure to maintain

correct torque could result in failure or loss of a

wheel, which may result in personal injury.

Page 15

Controls

Seat (Fig. 9)—The seat adjusting lever allows 10 cm

(4 inches) fore and aft adjustment. The seat adjusting knob adjusts the seat for operators’ weight. To

adjust the seat fore and aft, pull lever on the left side

of the seat assembly outward. After moving the seat

to the desired location, release the lever to lock the

seat into position. To adjust for the operator’s

weight, turn spring tension knob—clockwise to

increase tension, counterclockwise to decrease

spring tension.

➁

➀

Figure 9

1. Seat adjusting level 2. Seat adjusting knob

Engine Oil Pressure Warning Light (Fig. 11)—

Indicates dangerously low engine oil pressure.

➂

➁

➀

Figure 10

1. Traction pedal

2. Traction speed limiter

3. Reel control light

Engine Coolant Temperature Warning Light (Fig.

11)—The light illuminates and the engine shuts

down if the coolant reaches a dangerously high temperature.

Glow Plug Indicator Light (Fig. 11)—When lit,

indicates glow plugs are on.

Traction Pedal (Fig. 10)—Controls forward and

reverse operation. Depress the top of the pedal to

move forward and bottom to move backward.

Ground speed depends on how far the pedal is

depressed. For no load, maximum ground speed, fully

depress the pedal while throttle is in FAST. To stop,

reduce foot pressure on traction pedal and allow it to

return to center position.

Traction Speed Limiter (Fig.10)—Preset this lever

to limit the amount the traction pedal can be

depressed in the forward direction to maintain a constant mowing speed.

Lower Mow / Raise Control Lever (Fig. 11)—The

lever raises and lowers the cutting units and also

starts and stops the reels.

Speedometer (Fig. 11)—Indicates ground speed at

which the machine is traveling.

Fuel Gauge (Fig. 11)—Shows the amount of fuel in

the tank.

3

1

2

10

8

11

Figure 11

1. Lower Mow/Raise Control Lever

2. Speedometer

3. Fuel Gauge

4. Engine Coolant Temperature Gauge

5. Engine Oil Pressure Warning Light

6. Engine Coolant Temperature Warning Light.

7. Glow Plug Indicator Light

8. Charge Indicator

9. Key Switch

10. Throttle Control

11. Enable/Disable Switch

5

6

4

7

9

15

Page 16

Controls

Charge Indicator (Fig. 11)—Illuminates when system charging circuit malfunctions.

Key Switch (Fig. 11)—Three positions: OFF,

ON/Preheat and START.

Throttle Control (Fig. 11)—Move the control forward to increase engine speed, rearward to decrease

speed.

Enable/Disable Switch (Fig. 11)—Used in conjunction with lower mow / raise the control lever to operate reels.

Reel Control Light (Fig. 11)—When lit, indicates

the machine is being operated in a way in which the

automatic reel speed control cannot obtain the

desired clip.

Backlap Switch (Fig. 12)—Used with lower mow /

➀

Figure 13

1. Height- of-Cut Selector Knob

2. Hour Meter

ing and to aid in sidehill traction. A Locking pin

connects the pedals for parking brake operation and

transport.

Parking Brake Latch (Fig. 14)—A knob on the left

side of the console actuates the parking brake lock.

To engage the parking brake, connect the pedals with

the locking pin, push down on both pedals and pull

the parking brake latch out. To release the parking

brake, depress both pedals until the parking brake

latch retracts.

Figure 12

1. Backlap Switch

raise

control

lever for backlapping operation.

Height-of-Cut Selector Knob (Fig. 13)—Turning

the knob to the appropriate setting informs the electronic controller at what height of cut the machine is

being operated so desired clip may be obtained.

Hour Meter (Fig. 13)—Shows the total hours the

machine has been operated.

Brake Pedals (Fig. 14)—Two foot pedals operate

individual wheel brakes for turning assistance, park-

➁

➀

➂

Figure 14

1. Brake Pedals

2. Parking Brake Latch

3. Locking Pin

16

Page 17

Operation

CAUTION

Before servicing or making adjustments to the

machine, stop the engine and remove the key from

the switch.

STARTING AND ST OPPING

IMPORTANT: The fuel system must be bled if

any of the following situations have occurred.

A. Initial start up of a new machine.

B. The engine has ceased running due to lack of

fuel.

C. Maintenance has been performed upon fuel sys-

tem components; i.e., filter replaced, separator

serviced, etc.

Refer to Bleeding The Fuel System

1. Sit on the seat, keeping your foot off the trac-

tion pedal. Assure the parking brake is engaged,

the traction pedal is in NEUTRAL, the throttle

is in the SLOW position and the ENABLE /

DISABLE switch is in the DISABLE position.

BLEEDING THE FUEL SYSTEM

1. Raise the hood over the engine.

2. Loosen the air bleed screw on top of the fuel fil-

ter/water separator (Fig. 15)

Figure 15

1. Air Bleed Screw

3. Turn the key in the ignition switch to ON. The

electric fuel pump will begin operation, forcing

air out around the air bleed screw. Leave the

key in the ON position until a solid stream of

fuel flows out around the screw. Tighten the

screw and turn the key to OFF.

2. Turn the ignition switch to the ON/Preheat posi-

tion. An automatic timer will control preheat

for 6 seconds. After preheat, turn the key to

START. CRANK THE ENGINE FOR NO

LONGER THAN 15 SECONDS. Release the

key when the engine starts. If additional preheat

is required, turn the key to OFF then to the

ON/Preheat position. Repeat the process as

needed.

3. Run the engine at idle speed or partial throttle

until the engine warms up.

4. To stop, move all controls to NEUTRAL and

set the parking brake. Return the throttle to the

idle position, turn the key to OFF and remove it

from switch.

4. Open the air bleed screw on the fuel injection

pump with a 12 mm wrench.

➀

Figure 16

1. Fuel injection Pump Bleed Screw

17

Page 18

Operating Instructions

5. Turn the key in the ignition switch to ON. The

electric fuel pump will begin operation, forcing

air out around the air bleed screw on the fuel

injection pump. Leave the key in the ON position until a solid stream of fuel flows out around

the screw. Tighten the screw and turn the key to

OFF.

Note: Normally the engine should start after the

above bleeding procedures. However, if the

engine does not start, air may be trapped

between the injection pump and the injectors; refer to Bleeding Air From The

Injectors.

A UTOMA TIC CLIP CONTR OL

The 5300-D is equipped with an electronic controller

which is programmed for automatic clip control.

The machine will automatically adjust the reel speed

to attain the desired clip as the traction speed

changes. For the controller to know what clip is

desired, the operator must input the number of blades

on the reels and the height of cut setting of the

machine.

SELECTING CLIP RATE

(REEL SPEED)

To achieve a consistent, high quality of cut, and a

uniform after-cut appearance, it is important that the

reel speed be matched to the height of cut. The

machine controller is programmed to automatically

control the reel speed to give the correct clip, even as

the traction speed changes. To control the reel speed

as desired, the controller must know the height of cut

of the machine, and whether the machine is equipped

with 5- or 8-blade reels.

Adjust the height-of-cut selector knob as follows:

1. Set the 5 / 8 blade switch to the setting indicat-

ing the type of cutting units mounted on the

machine.

2. Verify the height-of-cut settings on the cutting

units. Using the column of the chart listing

either 5- or 8-blade reels, look down the chart to

find the height-of-cut listing nearest the actual

height-of-cut setting. Look across the chart to

find the letter corresponding to that height of

cut.

The range of possible reel speeds is a minimum of

about 600 RPM and a maximum of about 1,800

RPM. As long as the desired clip requires a reel

speed within this range, the machine will maintain

the desired clip. If the traction speed is too slow or

too fast to allow the desired clip, the Reel Control

light (on the front control panel) will illuminate,

indicating that the desired clip is not being maintained. For example, if the traction speed is zero, the

reels will still run at the minimum speed of about

600 RPM, which will result in a clip smaller than

desired and cause the Reel Control light to illuminate. The ranges of traction speed that will result in

the desired clip are as follows for several of the possible heights of cut:

No. of Blades

per C.U.

8 6 mm (0.25 in.) 1.9 kmh (1.2 mph) 6.4 kmh (4.0 mph)

8 12 mm (0.50 in.) 4.0 kmh (2.5 mph) 12.9 kmh (8.0 mph)

5 12 mm (0.50 in.) 2.7 kmh (1.7 mph) 8 kmh (5.0 mph)

5 2 cm (0.88 in.) 4.3 kmh (2.7 mph) 13.4 kmh (8.3 mph)

Height of Cut Minimum Traction

3. Turn the height-of-cut selector knob to the letter

setting determined in step 2.

4. Operate the machine for several days until the

grass being cut is “conditioned” to being

mowed with this machine. Then examine the

cut to ensure satisfaction with the quality of cut.

The height-of-cut knob may be set one position

on either side of the position shown on the chart

to account for differences in grass condition,

grass length removed, and the personal preference of the superintendent.

Full Speed—There may be times when it is desirable for the reels to run at full speed, regardless of

the traction speed of the machine. Examples of this

are vertical cutting or heavy scalping. In such cases,

Maximum Traction

Speed

Speed

18

Page 19

Operating Instructions

the height-of-cut selector knob may be set to position

"A", which will direct the machine controller to run

the reels at full speed at all times. Also, set the

height-of-cut selector knob to position "A" when

troubleshooting the electrical system.

Figure 17

1. Height -of- cut selector knob

REEL CONTROL LIGHT

The reel control light on the front control panel is

used to tell the operator that the machine controller is

able to achieve the desired clip. If the machine is

operated at a traction speed which is too low or too

high, the machine controller may not be able to set

the reel speed at the required value to achieve the

desired clip. If this occurs, the reel control light will

illuminate.

If the reel control light illuminates, it means one of

the following things:

1. The machine is being operated at a traction

speed too slow to allow desired clip.

2. The machine is being operated at a traction

speed too fast to allow desired clip. To correct

the situation, change the traction speed until the

light goes out.

8-Blade Cutting Unit 5-Blade Cutting Unit

Height of Cut Knob

Position

A Full Speed A Full Speed

B 6.4 mm B 12.7 mm

C 7.6 mm C 14.0 mm

D 8.9 mm D 15.2 mm

E 10.2 mm E 16.5 mm

F 11.4 mm F 17.8 mm

G 12.7 mm G 19.0 mm

H 14.0 mm H 20.3 mm

I 15.2 mm I 21.6 mm

J 16.5 mm J 22.9 mm

K 17.8 mm

L

M

N

O

P

CLIP RATE (REEL SPEED) SELECTIONS CHART

Height of Cut Height of Cut Knob

Position

K

19.0 mm

20.3 mm

21.6 mm

22.9 mm

24.1 mm

L

M

N

O

P

Height of Cut

24.0 mm

25.4 mm

27.0 mm

30.0 mm

33.0 mm

36.0 mm

FULL SPEED—Cutting units always set to full speed in this position.

19

Page 20

Operating Instructions

3. A foreign object, such as a stick, piece of turf,

etc., is stuck in the reel, restricting rotation.

If changing the traction speed does not cause the

light to go out, and the reel control light remains illuminated regardless of traction speed, then a service

issue is required. In this case contact your local

authorized Toro Distributor

ADJUSTING LIFT ARM DO WN

PRESSURE

The down pressure spring on each cutting unit lift

arm can be adjusted to compensate for different turf

conditions. Increased down pressure will help keep

the cutting units on the ground when mowing at

higher speeds and helps maintain a uniform heightof-cut in rough conditions or in areas of thatch buildup.

Each down pressure spring may be adjusted to one of

four settings. Each increment increases or decreases

down pressure on cutting unit by 3 kg (8 lbs.).

1. Position the machine on a level surface, lower

the cutting units, stop the engine, engage the

parking brakes and remove the key from the

ignition switch.

Place an open end wrench on the hex shaft of

the spring bracket.

4. Remove the capscrew and locknut securing

retaining bracket while rotating hex shaft to

relieve spring tension.

5. Move the spring bracket to the desired location

and install the capscrew and locknut, while

turning the hex shaft to relieve spring tension.

TOWING THE TRACTION UNIT

If it becomes necessary to tow the machine, tow it

forward only and at a speed no greater than 16 kmh

(10 mph).

Note: If you exceed these towing limits, severe

damage to the hydrostatic transmission may

occur.

To tow a disabled machine:

1. Loosen and remove the capscrews securing the

drive shaft to the engine. Loosen the capscrews

clamping the drive shaft to transmission

(Fig. 19). Remove the drive shaft.

2. Remove the floor plate in front of the seat and

open the hood to gain access to all (5) springs.

CAUTION

Springs are under tension, use caution when

adjusting.

➁

Figure 18

1. Spring Bracket Hex Shaft

2. Retaining Bracket

➀

➀

Figure 19

1. Drive shaft

3.

Important: If the drive shaft is not removed

before towing, the transmission input shaft

will not be able to rotate, not the allowing

transmission to maintain its internal lubrication. Severe damage to the transmission may

occur.

2. Attach a suitable chain, strap or cable to the

20

Page 21

center of the front frame member (Fig. 20).

➀

Figure 20

1. Center of Front Frame Member

Note: Lock both brake pedals together before

towing.

3. Attach the other end of the towing device to a

vehicle that is capable of towing the machine

safely at speeds below 16 kmh (10 mph).

4. An operator must be on the machine to steer it

and keep the traction pedal fully depressed in

the forward position while towing.

Operating Instructions

Figure 21

1. Electron~ Controller Light

When the controller diagnostic light blinks, one of

the following problems has been detected by the controller:

1. One of the outputs has been shorted.

2. One of the outputs is open circuited.

Using the diagnostic display, determine which output

is malfunctioning; refer to Checking Interlock

Switches.

If the diagnostic light is not illuminated when the

key switch is in the ON position, this indicates that

the electronic controller is not operating. Possible

causes are:

5. When towing is completed, reinstall the drive

shaft as shown in Figure 19. (The splines are

designed to allow assembly only when the two

halves of the shaft are properly oriented.)

DIA GNOSTIC LIGHT (Fig. 21)

The RM 5300-D is equipped with a diagnostic light

which indicates if the electronic controller is functioning correctly. The green diagnostic light is located under the control panel, next to the fuse block.

When the electronic controller is functioning correctly and the key switch is moved to the ON position,

the controller diagnostic light will be illuminated.

The light will blink if the controller detects a malfunction in the electrical system. The light will stop

blinking and automatically reset when the key switch

is turned to the OFF position.

1. Loopback is not connected.

2. The light is burned out.

3. Fuses are blown.

4. Not functioning correctly.

Check electrical connections, input fuses and the

diagnostic light bulb to determine malfunction. Make

sure the loopback connector is secured to the wire

harness connector.

DIA GNOSTIC A CE DISPLAY

The RM 5300-D is equipped with an electronic controller that controls most machine functions. The

controller determines what function is required for

various input switches (i.e., seat switch, key switch,

etc.) and turns on the outputs to actuate solenoids or

relays for the requested machine function.

For the electronic controller to control the machine

as desired, each of the input switches, output solenoids and relays must be connected and functioning

21

Page 22

Operating Instructions

properly.

The Diagnostic ACE display is a tool to help the

user verify correct electrical functions of the

machine.

CHECKING INTERLOCK

SWITCHES

CAUTION

THE INTERLOCK SWITCHES ARE FOR THE

PROTECTION OF THE OPERATOR AND

BYSTANDERS, AND TO ENSURE CORRECT

OPERATION OF THE MA-CHINE, SO DO NOT

BYPASS OR DISCONNECT THEM. CHECK

OPERATION OF THE SWITCHES DAILY TO

ASSURE INTERLOCK SYSTEM IS OPERATING. IF A SWITCH IS DEFECTIVE, REPLACE

IT BEFORE OPERATING. THE CONTROLLER

HAS THE ABILITY TO DETECT BY-PASSED

SWITCHES AND MAY PREVENT THE OPERATION OF THE MACHINE IF SWITCHES ARE

BYPASSED. DO NOT RELY ENTIRELY ON

SAFETY SWITCHES—USE COMMON SENSE!

The purpose of the interlock switches are to prevent

the engine from cranking or starting unless the traction pedal is in NEUTRAL, the Enable / Disable

switch is in DISABLE and the Lower Mow / Raise

control is in the neutral position. In addition, the

engine will stop when the traction pedal is depressed

with operator off the seat.

To verify interlock switch function:

Figure 22

1. Wire Harness and Connectors

3. Connect the Diagnostic ACE display connector

to the harness connector. Make sure correct

overlay decal is positioned on Diagnostic ACE

display.

4. Turn the key switch to the ON position, but do

not start the machine.

Figure 23

1. Diagnostic ACE

Note: The red text on the overlay decal refers

to input switches and the green text refers to

outputs.

1. Park machine on a level surface, lower the cut-

ting units, stop the engine and engage the parking brake.

2. Open control panel cover. Locate wire harness

and connectors near controller. Carefully

unplug loop back connector from harness connector.

22

5. The "inputs displayed" LED, on lower right

column of the Diagnostic ACE, should be illuminated. If "outputs displayed" LED is illuminated, press the toggle button, on Diagnostic

ACE, to change LED to "inputs displayed".

6. The Diagnostic ACE will illuminate the LED

associated with each of the inputs when that

input switch is closed.

Individually, change each of the switches from

open to closed (i.e., sit on the seat, engage the

traction pedal, etc.), and note that the appropri-

Page 23

Operating Instructions

ate LED on Diagnostic ACE will blink on and

off when corresponding switch is closed. Repeat

on each switch that it is possible to be changed

by hand.

7. If the switch is closed and the appropriate LED

does not turn on, check all wiring and connections to the switch and/or check the switches

with an ohm meter. Replace any defective

switches and repair any defective wiring.

The Diagnostic ACE also has the ability to detect

which output solenoids or relays are on. This is a

quick way to determine if a machine malfunction is

electrical or hydraulic.

To verify output function:

1. Park the machine on a level surface, lower the

cutting units, stop the engine and engage the

parking brake.

2. Open the control panel cover. Locate the wire

harness and connectors near controller.

Carefully unplug the loopback connector from

the harness connector. Set the height-of-cut

selector knob to position "A".

3. Connect the Diagnostic ACE connector to the

harness connector. Make sure the correct overlay decal is positioned on the Diagnostic ACE.

4. Turn the key switch to the ON position, but do

not start the machine.

Note: The red text on the overlay decal refers to

input switches and the green text refers to outputs.

5. The "outputs displayed" LED, on the lower-

right column of the Diagnostic ACE, should be

illuminated. If the "inputs displayed" LED is

illuminated, press the toggle button, on the

Diagnostic ACE to change the LED to "outputs

displayed".

Note: It may be necessary to toggle between

"inputs displayed" and "outputs displayed" several times to do the following

step. To toggle back and forth, press the

toggle button once. This may be done as

often as required. DO NOT HOLD THE

BUTTON.

6. Sit on the seat and attempt to operate the desired

function of the machine. The appropriate output

LED's should illuminate to indicate that the

ECU is turning on that function.

Note: If any output LED is blinking, this indi-

cates an electrical problem with that

OUTPUT. Repair / replace defective

electrical parts immediately. To reset a

blinking LED, turn the key switch

"OFF", then back "ON".

If no output LED's are blinking, but the correct output LED's do not illuminate, verify that the required

input switches are in the necessary positions to allow

that function to occur. Verify correct switch function.

If the output LED's are on as specified, but the

machine does not function properly, this indicates a

non-electrical problem. Repair as necessary.

Note: Due to electrical system constraints, the output

LED's for "START", "PREHEAT" and

"ETR/ALT" may not blink even though an electrical problem may exist for those functions. If

the machine problem appears to be with one of

these functions, be certain to check the electrical

circuit with a volt / ohm meter to verify that no

electrical problem exists to these functions.

If each output switch is in the correct position and

functioning correctly, but the output LED's are not

correctly illuminated, this indicates an ECU problem.

If this occurs, contact your Toro Distributor for assistance.

IMPORTANT: The Diagnostic ACE display must

not be left connected to the machine. It is not

designed to withstand the environment of the

machine's every day use. When done using

Diagnostic ACE, disconnect it from the machine

and reconnect loopback connector to harness connector. Machine will not operate without loopback connector installed on harness. Store

Diagnostic ACE in dry, secure location in shop,

not on machine.

23

Page 24

Operating Instructions

LEAK DETECTOR OPERATION

The TurfDefender is an electronic hydraulic fluid

leak detection device that fits inside the hydraulic

tank of your machine. It is a pressure-based system

that requires a sealed hydraulic tank to function

properly. Very small changes to the oil level in the

sealed tank result in a large movement of the leak

detector's internal float. The TurfDefender's internal

microprocessor analyzes the float movement and

determines if there is a leak in the system.

• Turn the ignition key to the "ON" position to

start the system. (The system will reset itself

whenever the ignition key is moved to the

"OFF" position. Wait 5 seconds, then move the

key to "ON" position to restart the system.)

• When the machine is started, the alarm will give

one short beep to indicate that everything is

operating properly. If the alarm makes no noise

at all, it should be checked by a mechanic.

• If the alarm gives four short beeps it means a

system problem has been detected and it should

be checked by a mechanic. The 4-beep pattern

will continue for approximately 1then stop, unless the ignition key is moved to

the "OFF" position.

Note: The low or high oil level 4-beep signal

may occur if machine is started on a

slope. Move the machine to a level surface, move the ignition key to the "OFF"

position, wait 5 seconds, then move the

key to the "ON" position to restart the

system.

• If the alarm gives a loud continuous beep while

mowing and shuts off the cutting units, it means

that a leak has been detected. On the traction

unit, the red light on the steering console will

also blink, indicating the ECU has shut off the

cutting units.

1

⁄2minutes,

CHECKING LEAK DETECTOR

OPERATION

The operation of the TurfDefender should be

checked if any of the following conditions occur:

a. No beeps are heard when the ignition

switch is turned "ON".

b. Any time the machine gives a series of four

short beeps.

c. False alarms occur.

1. Park the machine on a level surface, stop the

engine and engage the parking brake.

2. Open the control panel cover. Locate the leak

detector harness loopback connector with the

hydraulic symbol tag. Carefully unplug the

loopback connector from the harness connector.

3. Connect the Diagnostic ACE display connector

to the correct harness loopback connector.

Install the TurfDefender overlay decal (supplied

with the leak detector kit) onto the Diagnostic

ACE (Fig. 24).

4. Turn the key switch to the ON position, but do

not start the machine.

Note: The red text on the overlay decal refers to

inputs and the green text refers to outputs.

5. The red "Inputs displayed" LED (Light Emitting

Diode), on lower right column of the Diagnostic

ACE, should be illuminated. If the green

"Outputs displayed" LED is illuminated, press

and release the toggle button on the Diagnostic

ACE, to change LED to "Inputs displayed". Do

not hold the button down (Fig. 24).

If the TurfDefender is functioning normally:

1. When the "Inputs displayed" LED is lit, the

actual Float position (1 or 2 LED's on left row)

and "Oil level OK" LED should be displayed

(Fig. 25).

2. Press the toggle button until the green "Outputs

displayed" LED is lit. "Valve ON", "data line"

and "self diagnostic"LED's should be lit steadily. "Alarm ON" LED may be displayed temporarily (about 5 seconds) (Fig. 26).

Note: If "data line" or "self diagnostic" LED's

are blinking, there is a problem in the

system.

If No beeps are heard:

24

Page 25

Operating Instructions

1. Check the alarm wires to make sure they are not

disconnected, broken or "+" and "–" are

reversed.

2. Toggle "outputs displayed" on Diagnostic ACE

display (Fig. 26).

• Alarm open circuit (LED blinking): Check

/ replace the TurfDefender alarm or wires.

• Alarm short circuit (LED blinking): Check

/ replace the TurfDefender alarm or wires.

If four beeps are heard:

The most common cause for a 4-beep signal is from

an improper oil level reading. Make sure the

machine is on a level surface when checking the oil

level. Since the oil level will vary with temperature,

it is best to check when cool.

1. When toggling "input", a LED should display

(Fig. 25) any of the following problems diagnosed by the TurfDefender:

• Self-diagnostic LED Blinking: Internal circuit failure in TurfDefender. Consult your

Authorized Toro Distributor for assistance.

• Data Line LED Blinking: Problem with

communications between the machine and

the leak detector; or problem with wires.

Consult your Authorized Toro Distributor

for assistance.

Note: If the machine must be operable with

leak detector disabled, unplug the leak

detector 4-pin connector from the 4-pin

connector of the main harness. Do not

unplug the leak detector alarm.

If false alarms occur:

1. The oil level may be low, causing air to be

drawn out of the system. Check the oil level.

2. Extremely hard left turns can cause oil to slosh

to the right, exposing the suction line and purging air out of system. Normal maneuvering

should not cause this condition.

• Oil level low: Position machine on a level

surface and fill to proper level.

• Oil level high: Position machine on a level

surface and remove excess oil until proper

level is attained.

• Oil too hot: Allow machine to cool and

clean any debris from oil cooler.

• Air leak in the system: Assure tank cap is

tight or check for leak in tank.

Note: Only large air leaks can be detected by

the hand-held Diagnostic ACE. A leakdown test is required to identify small air

leaks. Consult your Authorized Toro

Distributor for assistance.

2. When toggling "output" a LED should display

(Fig. 26) any of the following problems diagnosed by the TurfDefender:

• Valve open circuit (LED blinking): Check /

replace TurfDefender electric solenoid

valve or wires.

• Valve short circuit (LED blinking): Check /

replace TurfDefender electric solenoid

valve or wires.

3. An air leak in the system. Check to make sure

the cap is securely on the tank. Contact your

local authorized Toro Distributor for further

assistance with an air leak problem.

4. To check for a system problem, install the hand-

held Diagnostic ACE, toggle input/output and

check for any problems previously discussed.

Note: The system will reset itself whenever the

ignition key is turned to the "OFF" position. The hand-held Diagnostic ACE

must be connected and observed during

a false alarm. Once the ignition key is

turned to the "OFF" position, the

TurfDefender will reset itself.

5. Your Authorized Toro Distributor has equip-

ment to analyze system problems.

IMPORTANT: The Diagnostic ACE displays

must not be left connected to the machine. It

is not designed to withstand the environment

of the machine's everyday use. When you are

finished using the Diagnostic ACE, disconnect

it from the machine and reconnect the loopback connectors to the harness connectors.

The machine will not operate without the

loopback connectors installed on the harness.

25

Page 26

Operating Instructions

Diagnostic ACE Display Functions

1. Overlay decal (English shown)

2. “Inputs Displayed” LED (Red)

3. “Outputs Displayed” LED (Green)

4. Toggle button

Figure 24

Using “Inputs Displayed” (Red Text)

1. LED is lit if the oil level is too high

2. LED is lit if the oil level is too high

3. LED is lit if the oil level is too high

4. LED is lit if the oil level is too high

5. LED is lit if a system air leak has been detected.

6. One or two LED’s are lit displaying the relative

position of the Turfdefender’s internal float.

7. “Inputs Displayed” LED “ON” (Red)

Normal Operation:

a. “Oil Level OK” LED lit

b. 1 or 2 LEDs are lit on the left column

Figure 25

Using “Outputs Displayed” (Green Text)

Normal Operation:

a. “Valve ON” LED lit steadily

b. “Self-Diagnostic” LED lit steadily

c. “DATA LINE” LED lit steadily

d. “Alarm ON” LED lit temporarily

Problem Diagnosed:

The appropriate LED will blink to identify the

problem.

Figure 26

26

Page 27

Operating Instructions

Store the Diagnostic ACE in a dry, secure

location in the shop, not on the machine.

HYDRA ULIC VALVE SOLENOID

FUNCTIONS

Use the list below to identify and describe the different functions of the solenoids in the hydraulic manifold. Each solenoid must be energized for the function to occur.

Solenoid Function

VS1,S1 Front reel circuit

VS2,S2 Rear reel circuit

S3 Lift / lower front wing cutting units

S4 Lift / lower center cutting unit

S5 Lift / lower rear cutting unit

S6 Lower any cutting units

S7 Lift any cutting units

S8,S9 Backlap any cutting units

HEIGHT-OF-CUT SELECTION

POTENTIOMETER REPLACEMENT

The height-of-cut selection potentiometer is factory

calibrated. If the height-of-cut selection potentiometer should be replaced for any reason, the new potentiometer must be calibrated to assure correct clip . If

the potentiometer is not calibrated correctly, the clip

may be as much as 2 or 3 settings different from the

desired setting. This calibration must be done by

your Toro distributor.

some slope conditions, the uphill wheel slips and

loses traction. If this situation occurs, depress the

uphill turn pedal gradually and intermittently until

the uphill wheel stops slipping, thus, increasing traction on the downhill wheel.

Warning: When operating the machine, always

use the seat belt and roll-over protection system.

Warning System—If a warning light comes on dur-

ing operation, stop the machine immediately and correct the problem before continuing operation.

Serious damage could occur if the machine is operated with a malfunction.

Mowing—Start the engine and move the throttle to

FAST so the engine is running at maximum speed.

Move the ENABLE / DISABLE switch to ENABLE

and use the LOWER MOW / RAISE lever to control

the cutting units (front cutting units are timed to

lower before the rear cutting units). To move forward

and cut grass, press the traction pedal forward.

Maintain a speed which does not result in the Reel

Control LIght illuminating. Gradually increase or

decrease traction speed to ensure proper clip.

Transport—Move the ENABLE / DISABLE switch

to DISABLE and raise the cutting units to the transport position. Be careful when driving between

objects so you do not accidentally damage the

machine or cutting units. Use extra care when operating the machine on slopes. Drive slowly and avoid

sharp turns on slopes to prevent roll overs. The cutting units should be lowered when going downhill

for steering control.

OPERATING

CHARACTERISTICS

Familiarization—Before mowing grass, practice

operating the machine in an open area. Start and

stop the engine. Operate in forward and reverse.

Lower and raise the cutting units and engage and disengage the reels. When you feel familiar with the

machine, practice operating up and down slopes at

different speeds.

The brakes can be used to assist in turning the

machine. However, use them carefully, especially on

soft or wet grass conditions because the turf may be

torn accidentally. Individual turning brakes may also

be used to help maintain traction. For example, in

Selecting Clip Rate (Reel Speed)—The automatic

clip control programmed into the machine controller

requires that it be told at what height of cut the

machine is being operated and whether the machine

is equipped with 5- or 8-blade reels. Refer to

Selecting Clip Rate (Reel Speed).

When the machine is being operated in such a way

that it can control the reel speed to achieve the

desired clip, the reel control light will not light. If

the reel control light is illuminated, the traction

speed is too low or too high to allow the machine to

achieve the desired clip.

27

Page 28

Maintenance

CAUTION

Before servicing or making adjustments to the

machine, stop the engine and remove the key from

the switch.

GREASING BEARINGS AND

BUSHINGS

The machine has grease fittings that must be lubricated regularly with No. 2 General Purpose Lithium

Base Grease. If the machine is operated under normal conditions, lubricate all bearings and bushings

after every 50 hours of operation.

Figure 29

Figure 27

Figure 28

Figure 30

Figure 31

28

Page 29

Maintenance

Figure 32

CHECK/SERVICE (DAILY)

1. Oil level, engine 7. Radiator screen

2. Oil level, transmission 8. Brake function

3. Oil level, hydraulic tank 9. Tire pressure

4. Coolant level, radiator 10. Battery

5. Fuel/Water separator 11. Belts (Fan, alt)

6. Precleaner—air cleaner

FLUID SPECIFICATIONS/ CHANGE INTERVALS

FLUID

TYPE

CAPACITY

CHANGE

FLUID

Figure 33

CHANGE

FILTER

FILTER

PART NO.

CAPACITY SAE 10W-30 3.7 l 50 hours 100 hours 67-4330

TRANSMISSION OIL

HYDRAULIC CIRCUIT OIL Mobil 424 32.2 . 800 hours

AIR CLEANER

FUEL PUMP 400 hours 43-2550

WATER SEPARATOR 400 hours 63-8300

FUEL TANK

COOLANT

*INCLUDING FILTER

Mobil 424 4.7 l* 800 hours 800 hours 75-1330

No. 2 Diesel 37.9 l

50/50 Ethylene

glycol/water

9.1 l

Where indicator

is in red zone

400 hours 27-7110

75-1310

29

Page 30

Maintenance

Minimum Recommended Maintenance Intervals

Maintenance Procedure Maintenance Interval & Service

Check battery fluid level

Check battery cable connectors

Lubricate all grease fittings

Change engine oil

Instpect air filter, dust cup and baffle

belt tension

‡Replace engine oil filter

Inspect cooling system hoses

Drain moisture—hydraulic tank

Drain moisture—Fuel tank

Check the reel bearing preload

✝Torque wheel lug nuts

Service the air filter

Replace the fuel pump filter

Replace the fuel/water separator filter

Inspect traction linkage movement

‡Torque head and adjust valves

‡Check engine rpm (idle and full throttle)

Every 50

hours

Every 100

hours

✝Check

fan and

alternator

Every

200 hours

Every

400 hours

Every

800 hours

Change hydraulic fluid

✝Change transmission fluid

✝Replace transmission filter

Check rear wheel toe-in

Rear axle service

–Pack rear axle bearings (2-wheel drive)

–Change rear axle lubricant (4-wheel drive)

✝Initial break in at 10 hours

‡Initial break in at 50 hours

Replace moving hoses

Replace safety switches

Flush the cooling system and replace fluid

Drain and flush the fuel tank

Drain and flush the hydraulic tank

Annual Recommendations:

Items are recommended every 1600 hours or

two years, whichever occurs first.

30

Page 31

Daily Maintenance Checklist

1. Safety interlock operation

2. Brake operation

3. Engine oil & fuel filter

4. Cooling system fluid level

5. Drain water/fuel separator

6. Air filter/precleaner condition

7. Radiator& screen for debris

8. Unusua lengine noises

9. Unusual operating noises

10. Transmission oil level

11. Transmission filter indicator

12. Hydraulic hoses for drainage

13. Fluid leaks

14. Tire pressure

15. Instrument operation

16 Reel-to-bedknife adjustment

17. Height-of-cut adjustment

18. Cutting units shear pin

18. Lubricate all grease fillings

19. Touch-up damaged paint

1

2

3

Maintenance

1= Check glow plug and injector nozzles, if hard starting,

excess smoke or rough running is noted.

2= Check with the engine running and the oil at operating

temperature.

3= Immediately after every washing, regardless of the interval

listed.

31

Page 32

Maintenance

➀

➀

Figure 34

1. Pre Cleaner Bowl

➁

➀

Figure 35

1. Dust Cup & Baffle 3. Air Cleaner Body

2. Filter Element

Figure 37

1. Engine Oil Filter

3

Figure 38

1. Fuel Filter/Water Separator

2. Drain plug

1. Engine Oil Drain Plug

32

Figure 36

Figure 39

1. Fuel pump 2. Cover

Page 33

➀

Maintenance

Figure 40

1. Fuel Injectors (3)

➀

Figure 41

1. Pull up screen and slide it out of the mounting tracts.

Clean it thoroughly with water or compressed air.

Figure 43

1. Alternator Belt

➀

➁

Figure 44

1. Cooling Fan Belt 2. Tensioner Lever

➁

➀

Figure 42

1. Oil Cooler 3. Transmission Oil Cooler

2. Radiator

➂

➀

Figure 45

1. Injection Pump Lever Arm

IMPORTANT: Use only hydraulic oils specified.

Other fluids could cause system damage.

33

Page 34

Maintenance

➀

WARNING

Keep your body and hands away from pin-hole leaks

or nozzles that eject high-pressure hydraulic fluid.

Use cardboard or paper to find hydraulic leaks.

Hydraulic fluid escaping under pressure can penetrate skin and cause injury. Fluid accidentally injected into the skin must be surgically removed within a

few hours by a doctor familiar with this form of

injury or gangrene may result.

Figure 46

1. Hydraulic Reservoir

REPLACING THE HYDRAULIC

FILTER

The hydraulic system filter head is equipped with a

service interval indicator. With the engine running,

view the indicator; it should be in the GREEN zone.

When the indicator is in the RED zone, the filter element should be changed. Use the Toro replacement

filter (Part No. 75-1310).

IMPORTANT: Use of any other filter may void

the warranty on some components.

CHECKING HYDRA ULIC LINES

AND HOSES

Daily, check hydraulic lines and hoses for leaks,

kinked lines, loose mounting supports, wear, loose

fittings, weather deterioration and chemical deterioration. Make all necessary repairs before operating.

ADJUSTING THE TRACTION

DRIVE FOR NEUTRAL

The machine must not creep when traction pedal is

released. If it does creep, an adjustment is required.

1. Park the machine on a level surface, shut the

engine off and lower the cutting units to the

floor. Depress only the right brake pedal and

engage the parking brake.

2. Jack up the left side of the machine until the

front tire is off the shop floor. Support the

machine with jack stands to prevent it from

falling accidentally.

3. Under the right side of the machine, loosen the

locknut on the traction adjustment cam.

34

➀

Figure 47

1. Traction Adjustment Cam

Page 35

WARNING

The engine must be running for the final adjustment of the traction cam. To guard against possible personal injury, keep hands, feet, face and other

parts of the body away from the muffler, other hot

parts or the engine, and other rotating parts.

Maintenance

4. After the desired lift rate is attained, tighten the

setscrew to lock adjustment.

Outside Front Cutting Units

1. Locate the valve on the left front lift cylinder

(under the foot rest).

4. Start the engine and rotate the cam hex in either

direction until the wheel ceases rotation.

5. Tighten the locknut securing adjustment.

6. Stop the engine and release the right brake.

Remove the jack stands and lower the machine

to the shop floor. Test drive the machine to

make sure it does not creep.

ADJUSTING THE CUTTING

UNIT LIFT RATE

The cutting unit lift circuit is equipped with (2)

adjustable valves used to ensure the center and rear

cuttings units do not raise too quickly and bang

against lift stops. Adjust the cutting units as follows:

Center Cutting Unit

1. Locate the valve behind the access panel above

the operator's platform.

2. Loosen the setscrew on the valve and rotate it

1

⁄2turn clockwise.

3. Verify the lift rate adjustment by raising and

lowering the cutting unit several times. Readjust

as required.

4. After the desired lift rate is attained, tighten the

setscrew to lock adjustment.

Rear Cutting Units

1. Raise the hood and locate the valve on the left

rear side of the machine.

➀

➀

Figure 48

1. Center cutting unit adjustment valve.

2. Loosen the setscrew on the valve and rotate the

valve approximately one turn clockwise.

3. Verify lift rate adjustment by raising and lower-

ing the cutting unit several times. Readjust as

required.

Figure 49

1. Rear cutting units adjustment valve.

2. Loosen the setscrew on the valve and rotate the

valve approximately one turn clockwise.

3. Verify the lift rate adjustment by raising and

lowering the cutting units several times.

Readjust as required.

4. After the desired lift rate is attained, tighten the

setscrew to lock adjustment.

CHECKING AND ADJUSTING

TRACTION LINKAGE

Due to normal wear in the control linkage and hydrostatic transmission, an increased amount of force

35

Page 36

Maintenance

may be required to return the transmissions to neutral. Periodically check the machine.

To Check Traction Linkage

1. On a large, flat open area, drive the machine at

full throttle and full traction speed.

2. Remove your foot from the traction pedal and

measure the distance required for the machine

to come to a stop.

3. If the distance required to stop is greater than

5.5 meters, (18 feet) an adjustment to the traction linkage is required. Go to the next step.

To Adjust Traction Linkage

1. Park the machine on a level surface, lower the

cutting units to the floor and shut the engine off.

2. Connect the brake pedals together with the lock-

ing pin, push both pedals down and pull the

parking brake latch out.

3. Loosen the outer hex nut securing the eye bolt

to the spring anchor plate.

4. Shorten the distance to decrease the time

required to stop the machine.

5. Rotate clockwise, until the distance between

inside of the eye bolt loop and inside of spring

anchor plate is shortened 3 mm (1/8"). Tighten

the hex nut.

6. Operate the machine and check stopping dis-

tance. Repeat procedure if required.

Figure 50

1. Spring Anchor Plate

2. Eye bolt

3. Inner locknut

4. Outer Locknut

Note: Shortening the distance between the inside

of the eye bolt loop and the inside of the

spring anchor plate increases the force on the

traction pedal. Do not over adjust.

CHANGING TRANSMISSION

FLUID

Change the transmission oil after every 800 hours of

operation, in normal conditions.

1. Position the machine on a level surface, lower

the cutting units, stop the engine, engage the

parking brakes and remove the key from the

ignition switch.

2. Clean the area around the suction line on the

bottom of the transmission. Place the drain pan

under the line.