Page 1

FormNo.3363-235RevB

Reelmaster

ModelNo.03431—SerialNo.310000001andUp

®

2000TractionUnit

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Warning

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure1

1.Safetyalertsymbol

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

Introduction

Thismachineisaride-on,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedfor

cuttinggrassonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.Itis

notdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Themodel

andserialnumbersarestampedintoaplatethatis

rivetedtotheframeofthemachine.Writethenumbers

inthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure1),whichsignalsahazardthatmaycauseserious

©2010—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroRidingMowerSafety....................................6

SoundPowerLevel...............................................7

SoundPressureLevel...........................................7

VibrationLevel....................................................7

SafetyandInstructionalDecals.............................7

Setup..........................................................................12

1InstallingtheRearWheel.................................13

2AdjustingtheRearCarrierFrame

Height............................................................13

3MountingtheCarrierFramestotheCutting

Units..............................................................14

4InstallingtheFrontLiftArms...........................14

5MountingtheCuttingUnitDrive

Motors...........................................................15

6MountingtheCuttingUnits.............................16

7InstallingtheCounterbalanceSprings...............16

8AddingRearBallast..........................................19

9ActivatingandChargingtheBattery..................20

10InstallingCECompliantDecals......................20

11Breaking-inaNewMachine............................21

ProductOverview......................................................21

Controls.............................................................21

Specications.....................................................23

Attachments/Accessories...................................23

Operation...................................................................24

CheckingtheEngineOilLevel............................24

AddingFuel.......................................................25

CheckingtheCoolingSystem..............................26

CheckingtheHydraulicFluid..............................27

CheckingtheTirePressure.................................28

CheckingtheReeltoBedknifeContact................28

ChecktheTorqueoftheWheelNuts...................28

BleedingtheFuelSystem....................................28

StartingandStoppingtheEngine........................29

CheckingtheOperationoftheInterlock

Switches.........................................................30

TowingtheTractionUnit....................................30

OperatingCharacteristics...................................30

SettingtheReelSpeed.........................................31

TrainingPeriod...................................................32

BeforeMowing..................................................32

TransportOperation..........................................32

InspectionandClean-UpAfterMowing..............32

StandardControlModule(SCM)........................32

Maintenance...............................................................35

RecommendedMaintenanceSchedule(s)................35

DailyMaintenanceChecklist...............................36

ServiceIntervalChart.........................................37

PremaintenanceProcedures....................................37

RemovingtheHood...........................................38

Lubrication.............................................................38

GreasingtheBearingsandBushings....................38

EngineMaintenance...............................................40

ServicingtheAirCleaner....................................40

ChangingtheEngineOilandFilter.....................40

FuelSystemMaintenance.......................................41

CheckingtheFuelLinesandConnections...........41

DrainingW aterfromtheWaterSeparator............41

ReplacingtheFuelFilterCanister........................42

BleedingAirfromtheFuelInjectors...................42

ElectricalSystemMaintenance................................43

ServicingtheBattery...........................................43

Fuses..................................................................43

DriveSystemMaintenance.....................................44

AdjustingtheTractionDriveforNeutral.............44

AdjustingtheNeutralSwitch..............................45

CoolingSystemMaintenance..................................45

RemovingDebrisfromtheCooling

System............................................................45

BrakeMaintenance.................................................46

AdjustingtheParkingBrake................................46

BeltMaintenance....................................................47

TensioningtheAlternatorBelt............................47

TensioningtheHydraulicPumpBelt...................47

ControlsSystemMaintenance.................................48

AdjustingtheTractionPedal...............................48

AdjustingtheTractionPedalDamper..................48

HydraulicSystemMaintenance...............................49

ChangingtheHydraulicFluid.............................49

HydraulicSystemTestPorts...............................50

CuttingUnitSystemMaintenance...........................50

BacklappingtheCuttingUnits............................50

Storage.......................................................................51

PreparingtheTractionUnit................................51

StoringtheBattery..............................................51

PreparingtheEngine..........................................51

Schematics.................................................................53

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004specicationsineffectattimeof

production,whenequippedwithrearweight.Refer

tothesectioninthismanualonInstallingRear

Weight.

Improperuseormaintenancebytheoperator

orownercanresultininjury.Toreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•Readtheoperator’smanualandothertraining

materialcarefully .Befamiliarwiththecontrols,

safetysigns,andtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasizethefollowing:

–Theneedforcareandconcentrationwhen

workingwithride-onmachines

–Controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare

asfollows:

◊Insufcientwheelgrip

◊Beingdriventoofast

◊Inadequatebraking

◊Thetypeofmachineisunsuitableforitstask

◊Lackofawarenessoftheeffectofground

conditions,especiallyslopes

◊Incorrecthitchingandloaddistribution

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeople,orproperty.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andear

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely .

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthattheoperator’spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.To

guardagainstoverturning:

4

Page 5

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Machinespeedsshouldbekeptlowonslopes

andduringtightturns.

–Stayalertforhumpsandhollowsandother

hiddenhazards.

–Donotturnsharply.Usecarewhenreversing.

–Usecounterweight(s)orwheelweightswhen

suggestedintheoperator’smanual.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingsor

over-speedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Beforeleavingtheoperator’ sposition:

–Stoponlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Changeintoneutralandsettheparkingbrake.

–Stoptheengineandremovethekey.

•Disengagedrivetoattachmentswhentransporting

ornotinuse.

•Stoptheengineanddisengagethedrivetothe

attachment:

–Beforerefuelling

–Beforeremovingthegrasscatcher/catchers

–Beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator’s

position

–Beforeclearingblockages

–Beforechecking,cleaningorworkingonthe

mower

–Afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforerestartingandoperating

theequipment.

•Reducethethrottlesettingduringenginerun-out.If

theengineisprovidedwithafuelshut-offvalve,turn

thefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcylinders/reels

ifnotmowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartment,andfuel

storageareafreeofgrass,leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replaceall

wornordamagedpartsanddecals.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

•Onmulti-cylinder/multi-reelmachines,takecare

asrotatingonecylinder/reelcancauseother

cylinders/reelstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengine,andremovekeyfromignition.

Waitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.

Cleanupoilorfuelspillage.

5

Page 6

•Usejackstandstosupportcomponentswhen

required.

•Usingthemachinedemandsattention.T oprevent

lossofcontrol:

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingthecylinders/reels.Wear

glovesandusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO ,or

ANSIstandards.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

–Donotdriveclosetosandtraps,ditches,creeks,

orotherhazards.

–Reducespeedwhenmakingsharpturns.Avoid

suddenstopsandstarts.

–Whennearorcrossingroads,alwaysyieldthe

right-of-way.

–Applytheservicebrakeswhengoingdownhillto

keepforwardspeedslowandtomaintaincontrol

ofthemachine.

•Raisethecuttingunitswhendrivingfromonework

areatoanother.

•Donottouchtheengine,silencer/mufer,or

exhaustpipewhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Iftheenginestallsorlosesheadwayandcannotmake

ittothetopofaslope,donotturnthemachine

around.Alwaysbackslowly ,straightdowntheslope.

•Whenapersonorpetappearsunexpectedlyin

ornearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

Engineexhaustcontainscarbonmonoxide,

whichisanodorless,deadlypoisonthatcan

killyou.

Donotrunengineindoorsorinanenclosed

area.

•Knowhowtostoptheenginequickly.

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Handlefuelcarefully.Wipeupanyspills.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Beforestartingtheengine,sitontheseat.

MaintenanceandStorage

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunder

highpressure.Usepaperorcardboard,notyour

hands,tosearchforleaks.Hydraulicuidescaping

underpressurecanhavesufcientforcetopenetrate

theskinandcauseseriousinjury.Seekimmediate

medicalattentionifuidisinjectedintoskin.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitsandattachmentstotheground.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.Keep

everyoneaway.

6

Page 7

•Toensuresafetyandaccuracy,haveanAuthorized

ToroDistributorcheckthemaximumenginespeed

withatachometer.Maximumgovernedenginespeed

shouldbe3200RPM.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•UseonlyToro-approvedattachmentsand

replacementparts.Thewarrantymaybevoidedif

usedwithunapprovedattachments.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=1.54m/s

Measuredvibrationlevelforlefthand=1.04m/s

2

2

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof100

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’s

earof87dBA,whichincludesanUncertaintyValue(K)

of1dBA.

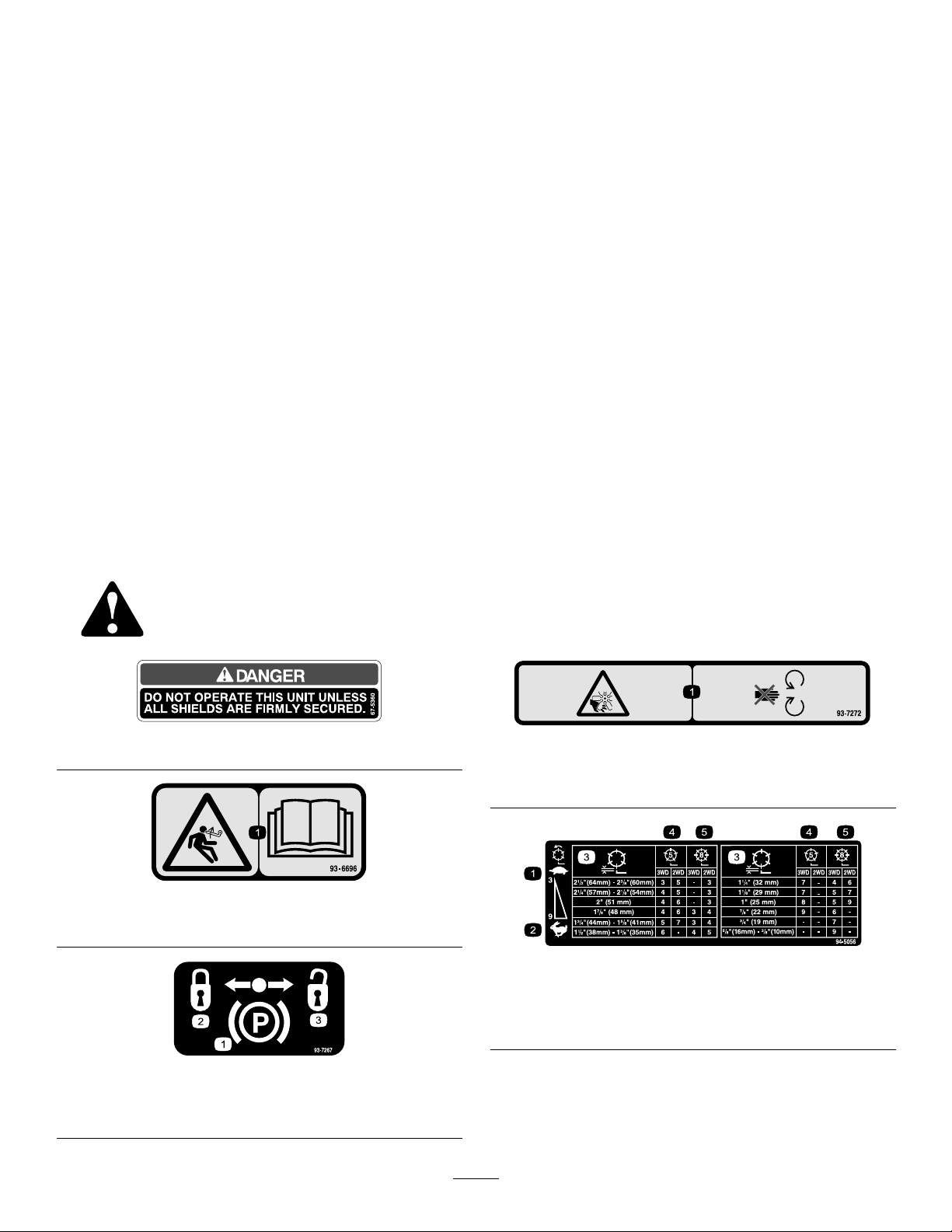

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

UncertaintyValue(K)=0.5m/s

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

WholeBody

Measuredvibrationlevel=6.22m/s

UncertaintyValue(K)=0.4m/s

2

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

67-5360

93-6696

1.Storedenergyhazard—readtheOperator’sManual.

93-7267

1.Parkingbrake3.Unlocked

2.Locked

93-7272

1.Cutting/dismembermenthazard;fan—stayawayfrom

movingparts.

94-5056

1.Reelspeed—slow4.5Bladecuttingunit

2.Reelspeed—fast

3.Reelheight

5.8Bladecuttingunit

7

Page 8

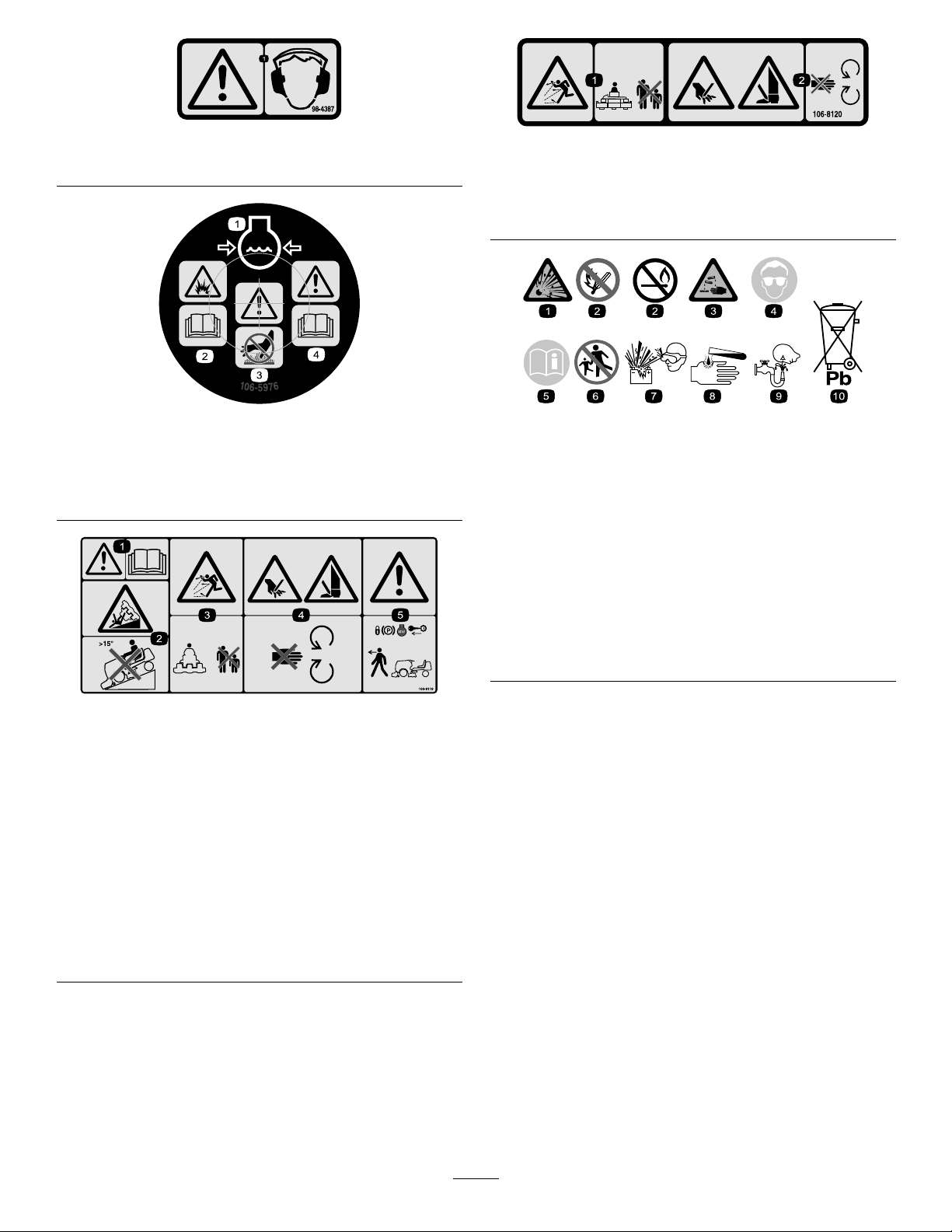

1.Warning—wearhearingprotection.

98-4387

106-8120

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cuttinghazardofhandandfoot—stayawayfrommoving

parts.

106-5976

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator’sManual.

3.Warning—donottouch

thehotsurface.

4.Warning—readthe

Operator’sManual.

106-8119

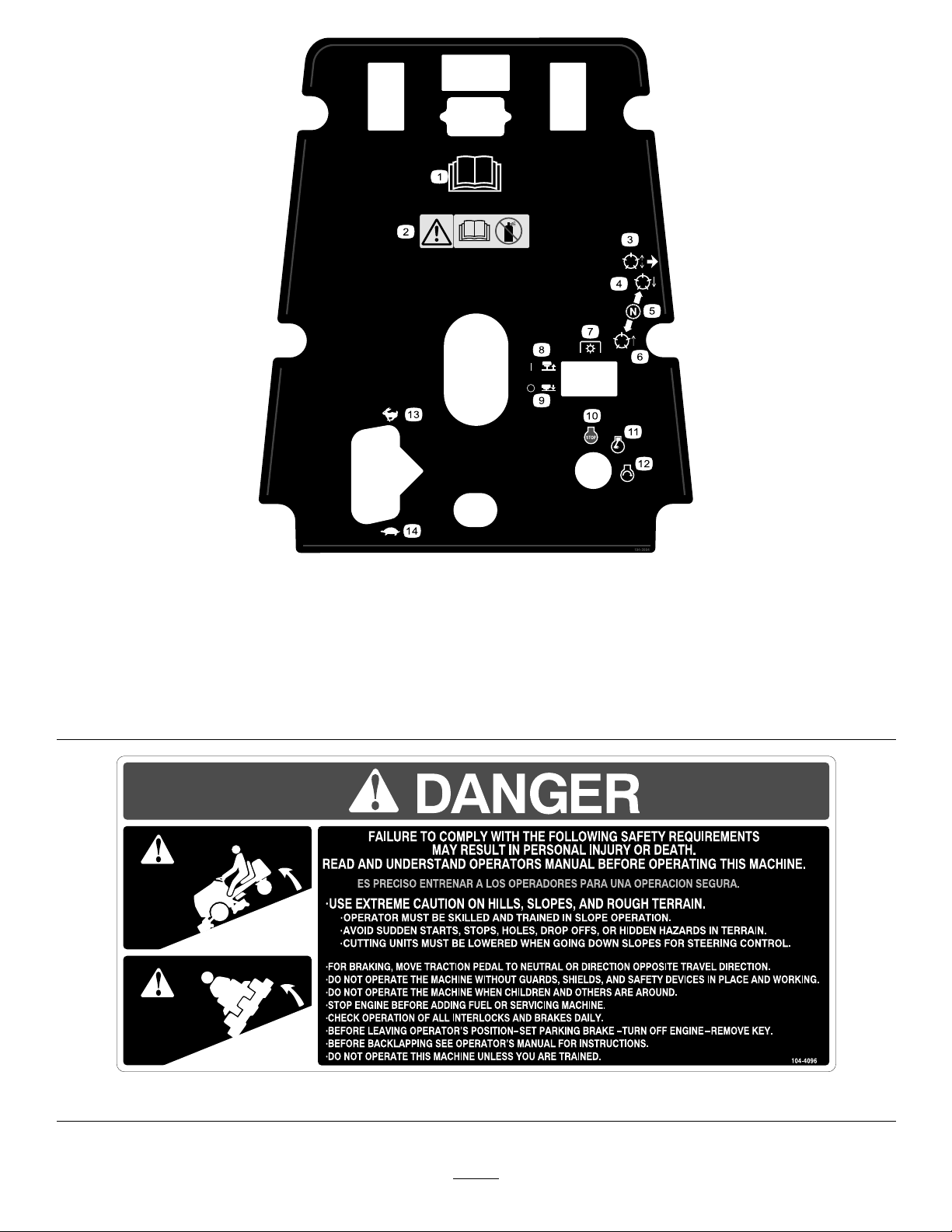

(Afxoverdecalpartno.104–4096forCE)

*Thissafetydecalincludesaslopewarningrequiredonthemachineforcompliance

totheEuropeanLawnMowerSafetyStandardEN836:1997.Theconservative

maximumslopeanglesindicatedforoperationofthismachineareprescribedby

andrequiredbythisstandard.

1.Warning—readtheOperator’sManual.

2.Tippinghazard—donotdrivethemachineonaslope

greaterthan15degrees.

3.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

4.Cuttinghazardofhandandfoot—stayawayfrommoving

parts,keepallguardsandshieldsinplace.

5.Warning—locktheparkingbrake,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

8

Page 9

104-3991

9

Page 10

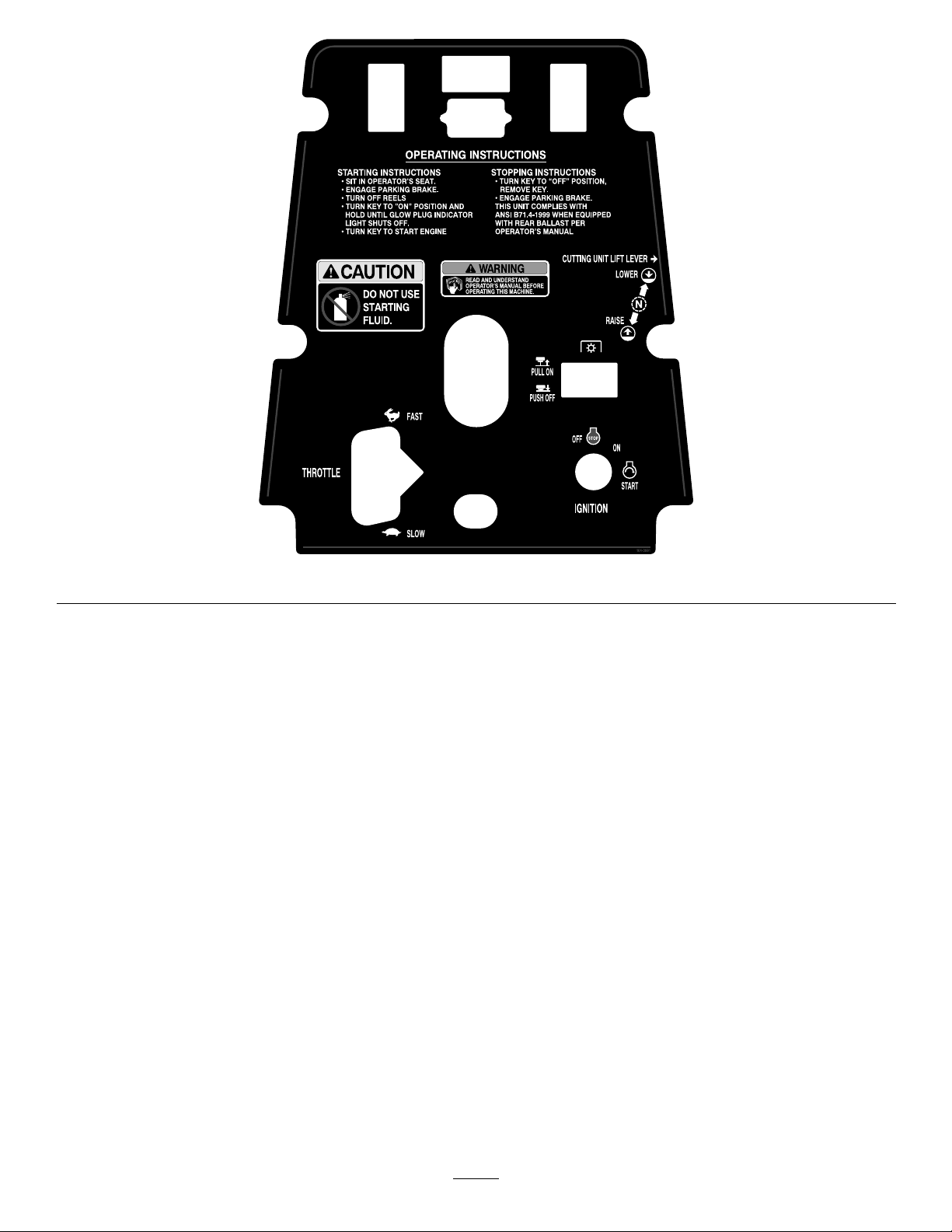

(Afxoverdecalpartno.104–3991forCE)

1.ReadtheOperator’s

Manual.

2.Warning—readthe

Operator’sManual,do

notusestartinguid.

3.Raiseandlowerthereels.

4.Lowerthereels.8.Pullon12.Engine—start

5.Neutral

6.Raisethereels.10.Engine—stop

7.Powertake-off(PTO)

104-3994

9.Pushoff

11.Engine—run

13.Fast

14.Slow

104-4096

10

Page 11

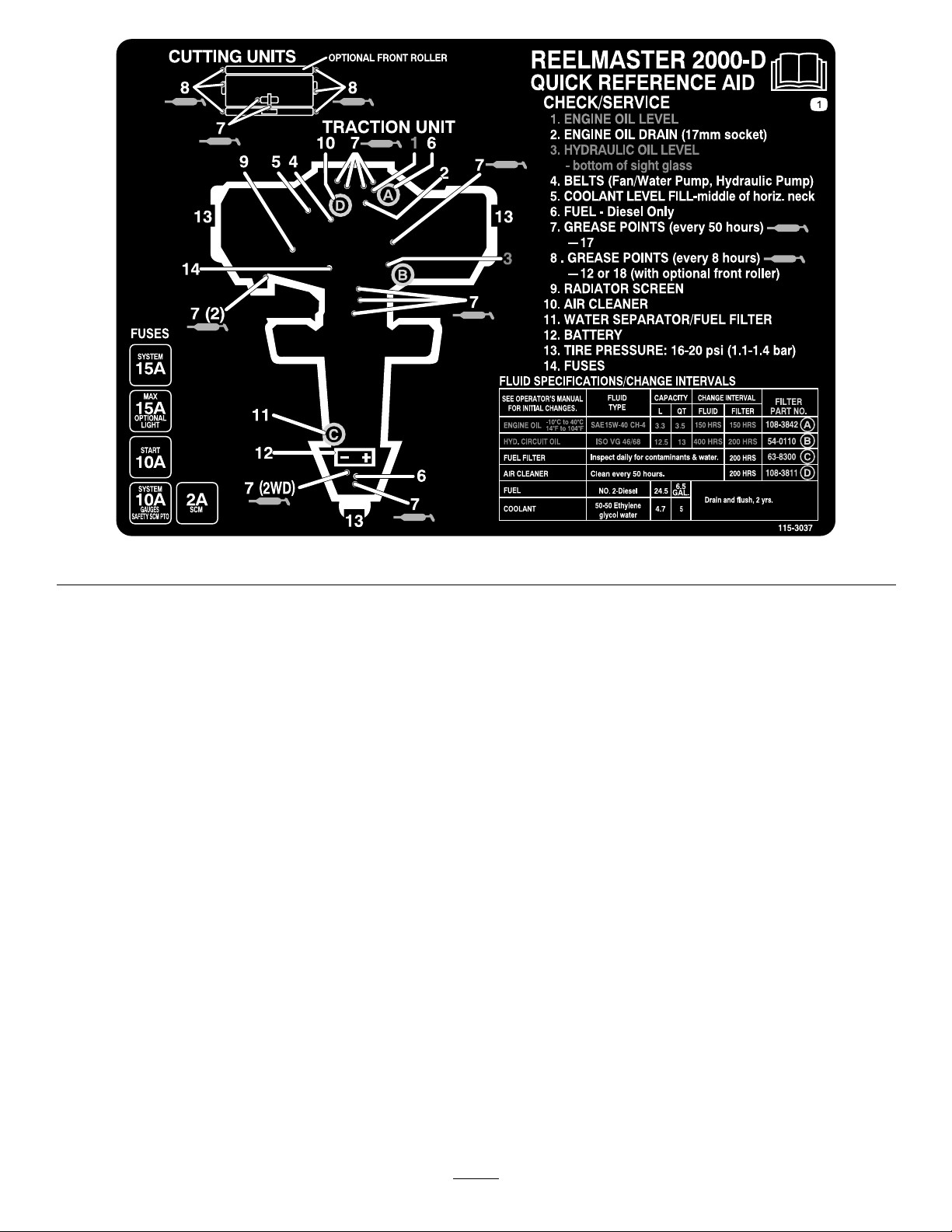

115–3037

11

Page 12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

Wheelassembly1

Lugnut4

Rearcarrierframe

Washer6

Bolt(3/8x2-1/4inches)

Locknut(3/8inch)

Liftarm

Pivotrod2

Bolt(5/16x7/8inch)

Lockwasher2

Liftchain

Clevispin

Cotterpin

Nopartsrequired

Trustwasher3

Flatwasher3

Flange-headbolt3

Spring

Vinylsleeve1

Springshackle

Clevispin

Cotterpin

Shackle(32inchcuttingunitonly)

Springanchor(32inchcuttingunitonly)

Bolt(1/4x3/4inch)(32inchcuttingunit

only)

Locknut(32inchcuttingunitonly)

Rearweightkit(s)

Varies

Qty.

Use

Installtherearwheel.

1

3

3

2

2

2

4

4

–

3

3

6

6

2

2

4

4

Adjusttherearcarrierframeheight.

Mountthecarrierframestothecutting

units.

Installthefrontliftarms(suppliedinthe

LiftArmKit).

Mountthecuttingunitdrivemotors

(suppliedintheLiftArmKit).

Mountthecuttingunits.

Installthecounterbalancesprings

(suppliedintheliftarmkit).

Addrearballast(orderfromyourT oro

Distributor).

9

10

11

Nopartsrequired

Decal104–39941

Decal106–81191

Nopartsrequired

MediaandAdditionalParts

Description

Key2

Hydraulicreserviorplug1

Qty.

–

–

Startthemachine

Pluggingthehydraulicreservoirduringalterchange.

12

ActivateandChargetheBattery

InstallCECompliantDecals(CEOnly)

Break-inanewmachine

Use

Page 13

Operator’sManual

G009850

1

2

3

G009851

1

3

3

2

4

EngineOperator’sManual

Operatortrainingmaterial

Description

Qty.

1

1

1

Readbeforeoperatingthemachine.

Viewbeforeoperatingthemachine.

Use

PartsCatalog

Certicateofcompliance

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

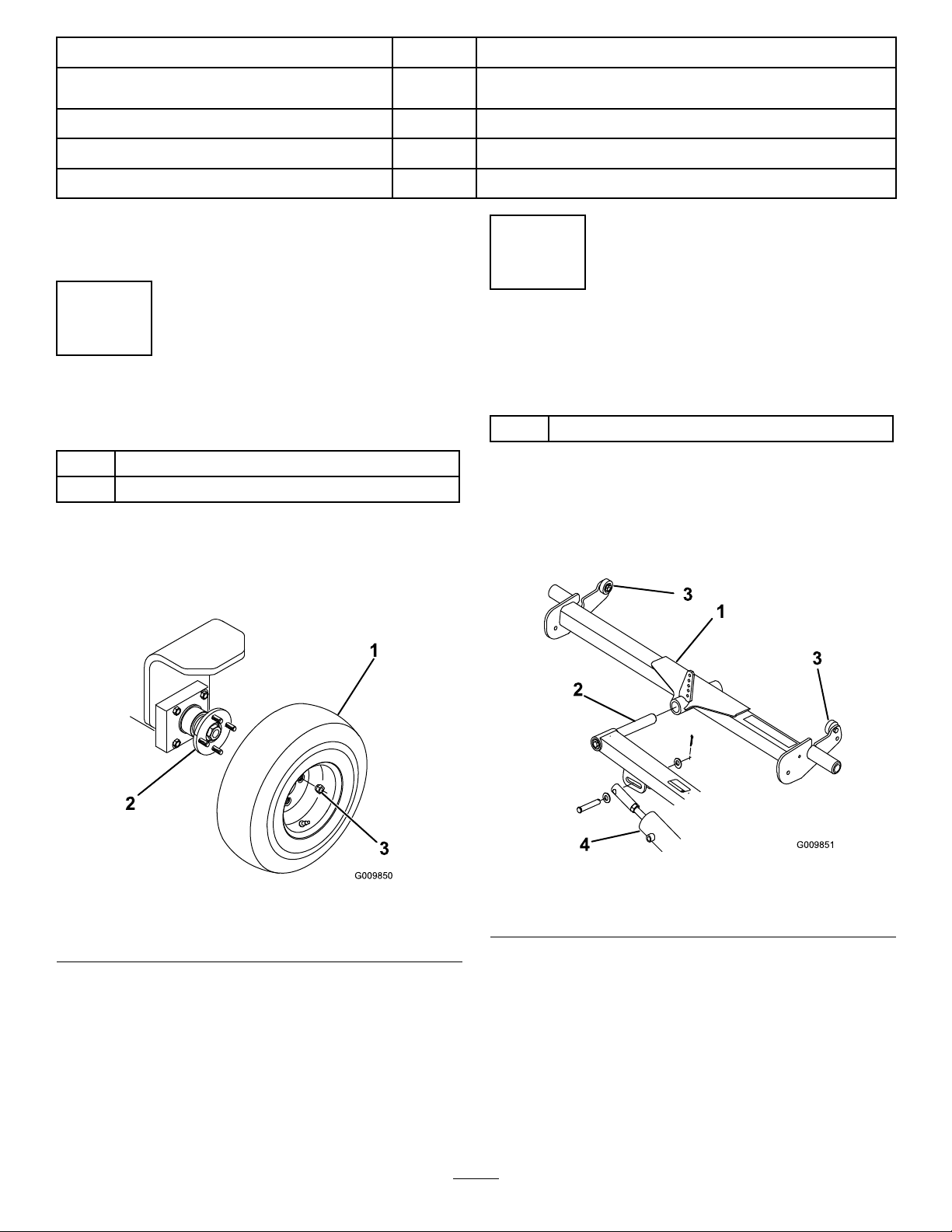

InstallingtheRearWheel

Partsneededforthisprocedure:

1Wheelassembly

4Lugnut

Procedure

1.Mountthewheelassemblyontotherearwheelhub

(Figure2).

1Viewandorderparts.

1

CEcertication

2

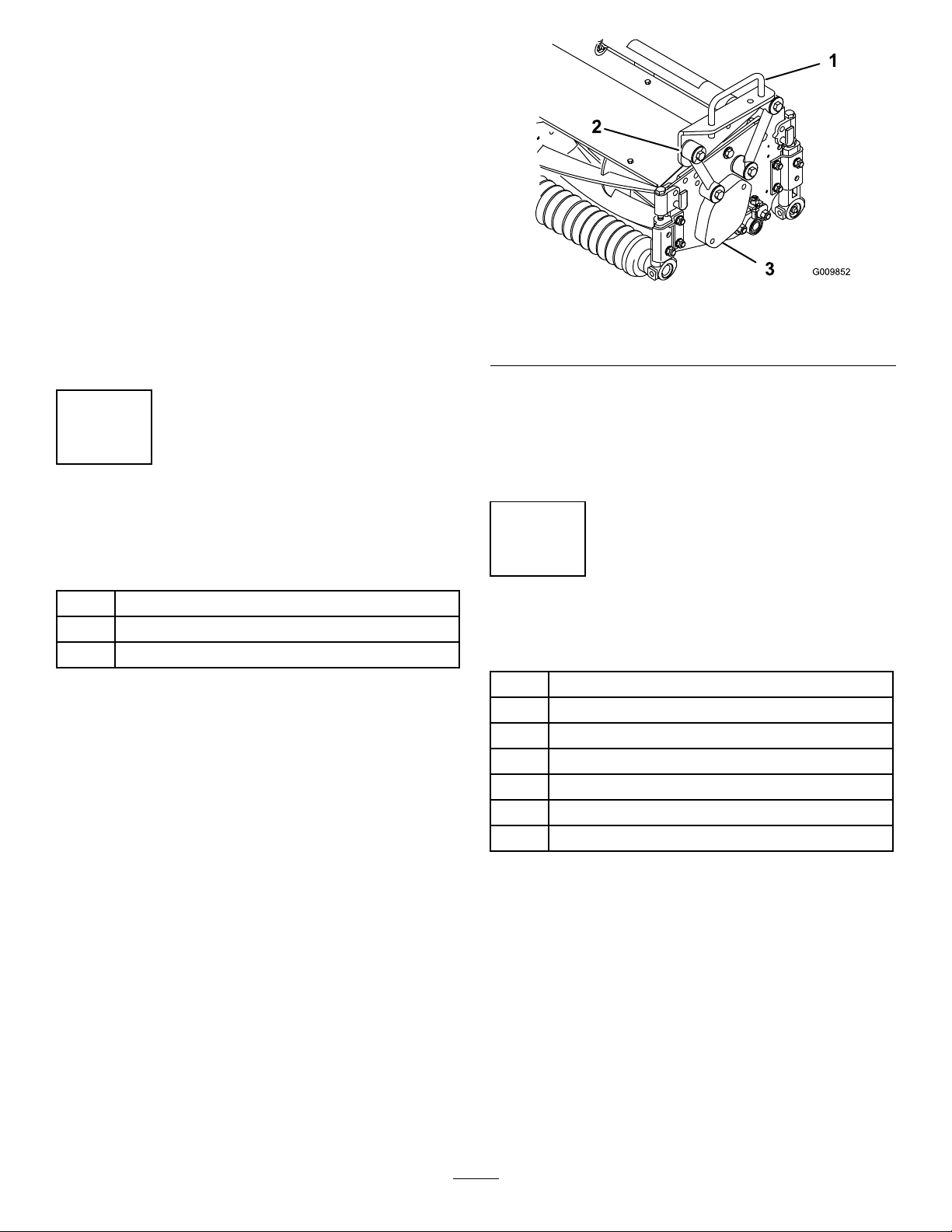

AdjustingtheRearCarrier

FrameHeight

Partsneededforthisprocedure:

1

Procedure

1.Slidetherearcarrierframeontotherearliftarm

pivotrod(Figure3).Donotinstallthecarrierframe

tothecuttingunitatthistime.

Rearcarrierframe

Figure3

Figure2

1.Wheelassembly3.Lugnut

2.Rearwheelhub

2.Installthelugnuts(Figure2)andtightenthemto45

to65ft-lb(3to5N-m).

1.Rearcarrierframe

2.Pivotrod

2.Raisetheliftarmsandcarrierframefully.

3.Pressdownononeendofthecarrierframeuntilthe

upstopontheoppositeendcontactstheunderside

ofthefootstep(Figure3).

Thedistancebetweentheupstopandtheunderside

ofthefootstep,ontheendpresseddown,shouldbe

approximately1/4inch(6mm).

13

3.Upstop

4.Liftcylinder

Page 14

•Ifthedistanceiscorrect,removethecarrier

G009852

1

3

2

frameandproceedwiththesetupinstructions.

•Ifthedistanceisnot1/4inch(6mm),adjustthe

liftcylinderasfollows:

A.Removetheclevispinsecuringtherodend

oftheliftcylindertotheliftarm(Figure3).

B.Loosenthehexnutsecuringtheclevistothe

cylinderrod.

C.Rotatetheclevisendinoroutuntilyou

attain1/4inch(6mm)clearance.Checkthe

adjustmentandrepeatsteps2through3as

required.

D.Tightenthehexnutandconnectthecylinder

rodendtotheliftarm(Figure3).

3

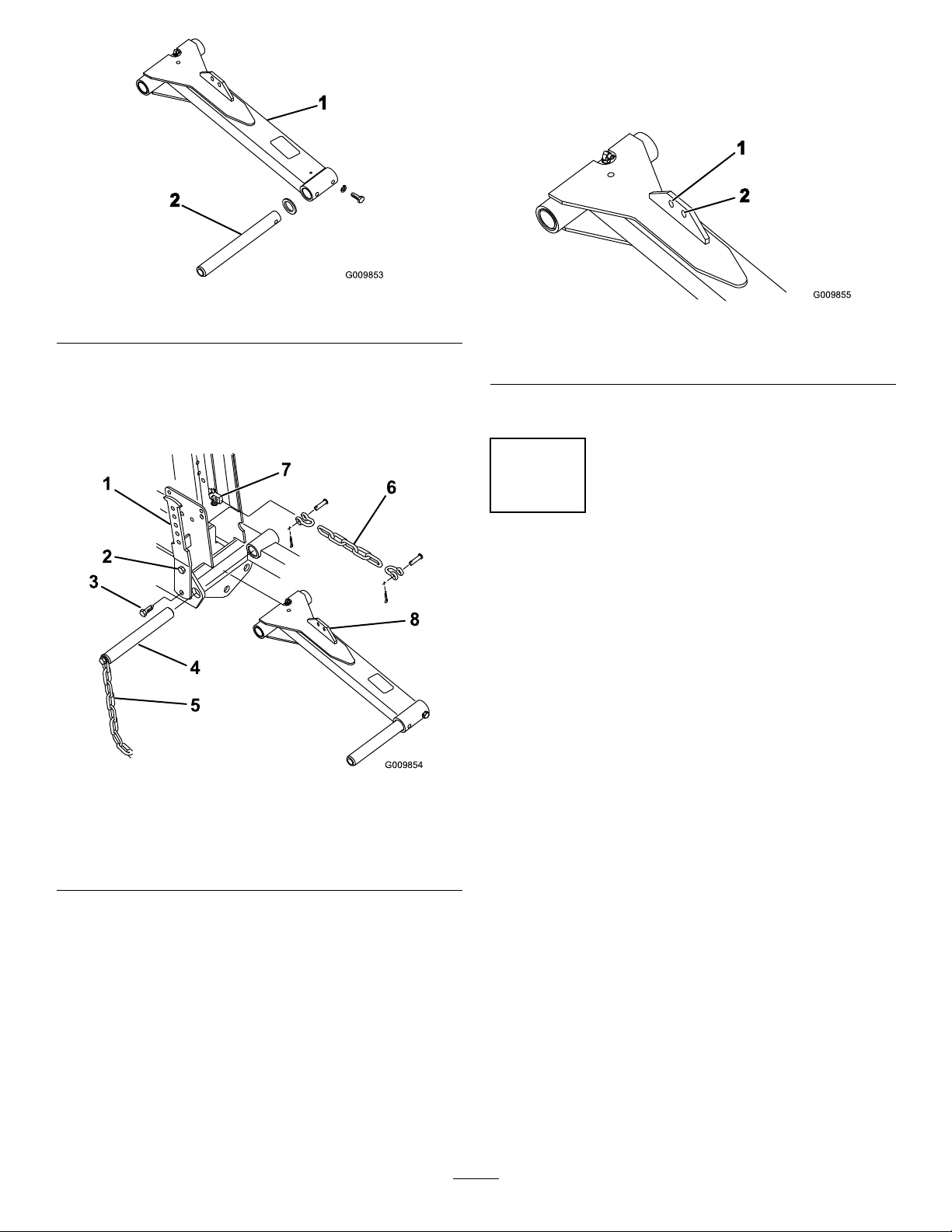

MountingtheCarrierFrames

Figure4

1.Carrierframe

2.Mountinglink

3.Secureeachmountinglinktothecarrierframewith

abolt(3/8x2-1/4inches),2washers,andalocknut,

asshowninFigure4.Positionawasheroneach

sideofthelinkwhenmounting.Torqueto31ft-lb

(42N-m).

3.Bearinghousingcover

totheCuttingUnits

Partsneededforthisprocedure:

6Washer

3

Bolt(3/8x2-1/4inches)

3

Locknut(3/8inch)

Procedure

1.Removethecuttingunitsfromthecartons.Adjust

thempertheCuttingUnitOperator’ sManual.

2.Positionacarrierframeontoeachcuttingunit,

aligningthemountingholeswiththemountinglinks

(Figure4).

4

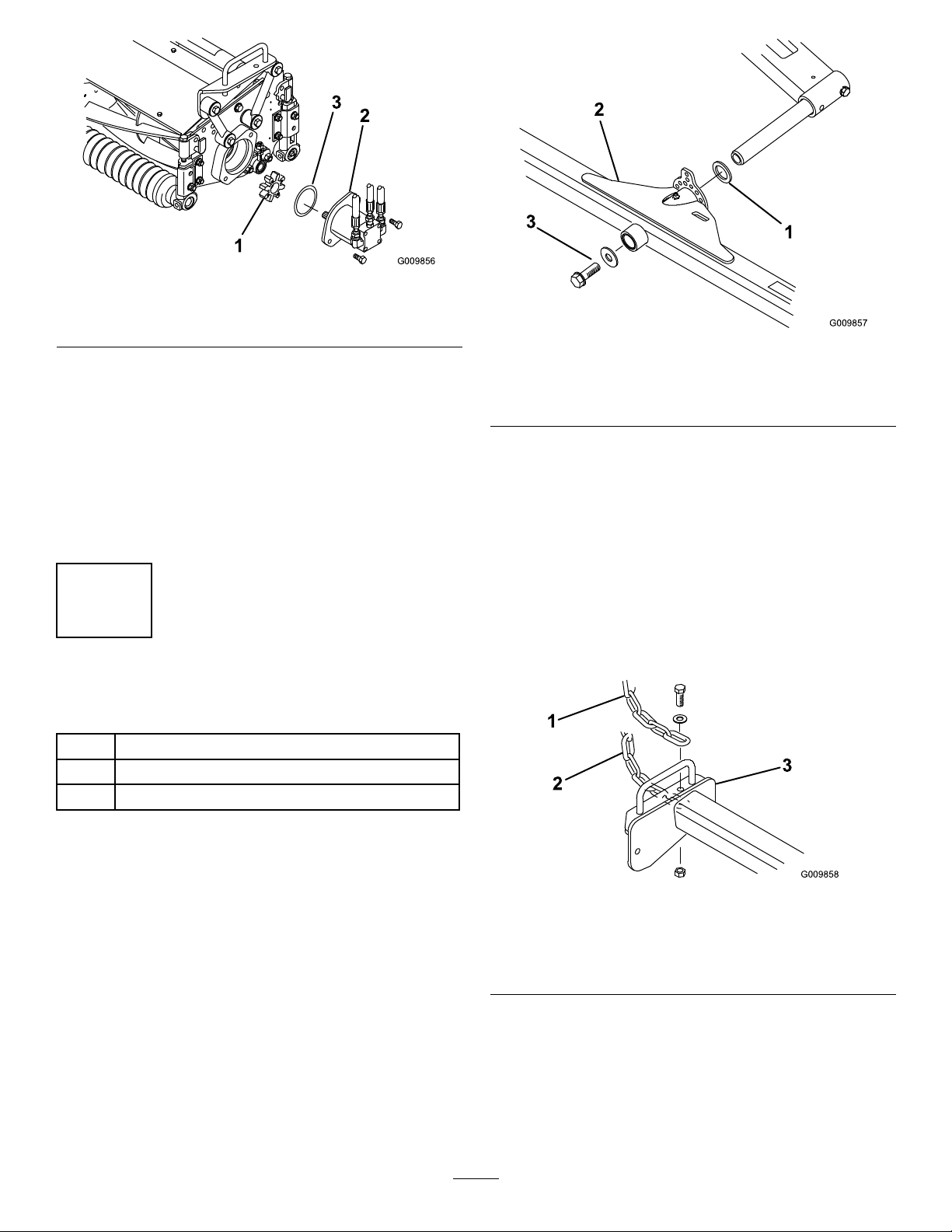

InstallingtheFrontLiftArms

Partsneededforthisprocedure:

2

Liftarm

2Pivotrod

2

Bolt(5/16x7/8inch)

2Lockwasher

2

Liftchain

4

Clevispin

4

Cotterpin

Procedure

1.Insertapivotrodintotheleftliftarmandalignthe

mountingholes(Figure5).

14

Page 15

G009853

1

2

Figure5

G009854

1

2

3

4

5

8

6

7

G009855

2

1

1.Liftarm

2.Pivotrod

2.Securethepivotrodtotheliftarmwithabolt(5/16

x7/8inch)andlockwasher.

3.Loosenthetopboltsecuringtheleftcounterbalance

armtotheframe(Figure6).

8.Securetheotherendoftheliftchaintothehole

intheliftarmmountingtabwithclevispinsand

cotterpins.Usetheappropriateholeintheliftarm

asdesignatedinFigure7.

Figure7

1.27inchcuttingunit(inner

hole)

2.32inchcuttingunit(outer

hole)

9.Repeattheprocedureontheright-handliftarm.

5

MountingtheCuttingUnit

DriveMotors

NoPartsRequired

Procedure

1.Positionthecuttingunitsinfrontofthepivotrods.

2.Removethebearinghousingcover(Figure4)from

theinsideendoftheright-handcuttingunit.Install

Figure6

1.Counterbalancearm

2.Topbolt

3.Bottombolt

4.Liftarmpivotpin8.Liftarmtab

5.Tipperchain

6.Liftchain

7.Cylinderpin

4.Removethebottomboltandnutsecuringtheleft

counterbalancearmtotheframe(Figure6).

5.Rotatethecounterbalancearmoutwardandremove

theliftarmpivotpinandtipperchain(Figure6).

6.Positiontheliftarmbetweentheframemembers,

alignthemountingholes,andinstallthepivot

pin(Figure6).Insertthepivotpinsothatthe

counterbalancearmtsintotheslotinthepin.Do

notsecurethecounterbalancearmatthistime.

7.Secureoneendoftheliftchaintotheliftcylinder

pinwithaclevispinandcotterpin.

15

thecoverandgasket(suppliedwiththecuttingunit)

ontheoutsideend.Locatethespidercoupling

(Figure8)shippedinthebearinghousing.

Page 16

G009856

1

2

3

Figure8

G009857

1

2

3

G009858

1

2

3

1.Spidercoupling3.O-ring

2.Reelmotor

3.InserttheO-ring(suppliedwiththecuttingunit)on

theangeofthedrivemotor(Figure8).

4.Mountthemotorandthespidercouplingtothe

driveendofthecuttingunitandsecurethemwith2

boltsprovidedwiththecuttingunit(Figure8).

5.Onthecenterandleft-handcuttingunits,remove

thebearinghousingcoverandinstallthegasket

(suppliedwiththecuttingunits).

6

MountingtheCuttingUnits

Partsneededforthisprocedure:

Figure9

1.Thrustwasher3.Flatwasherand

ange-headbolt

2.Carrierframe

2.Slidethecuttingunitcarrierframeontothepivot

rodandsecureitwithaatwasherandange-head

bolt(Figure9).

Note:Ontherearcuttingunit,positionthethrust

washerbetweentherearofthecarrierframeandthe

atwasher.

3.Secureatipperchaintothetopofeach27inch

cuttingunitcarrierframeandtothebottomofeach

32inchcuttingunitcarrierframewithabolt,washer,

andlocknut(Figure10).

3Trustwasher

3Flatwasher

3Flange-headbolt

Procedure

1.Slideathrustwasherontotheliftarmpivotrod

(Figure9).

1.Tipperchain(27inch

cuttingunits)

2.Tipperchain(32inch

cuttingunits)

4.Greaseallliftarmandcarrierframepivotpoints.

16

Figure10

3.Carrierframe

Page 17

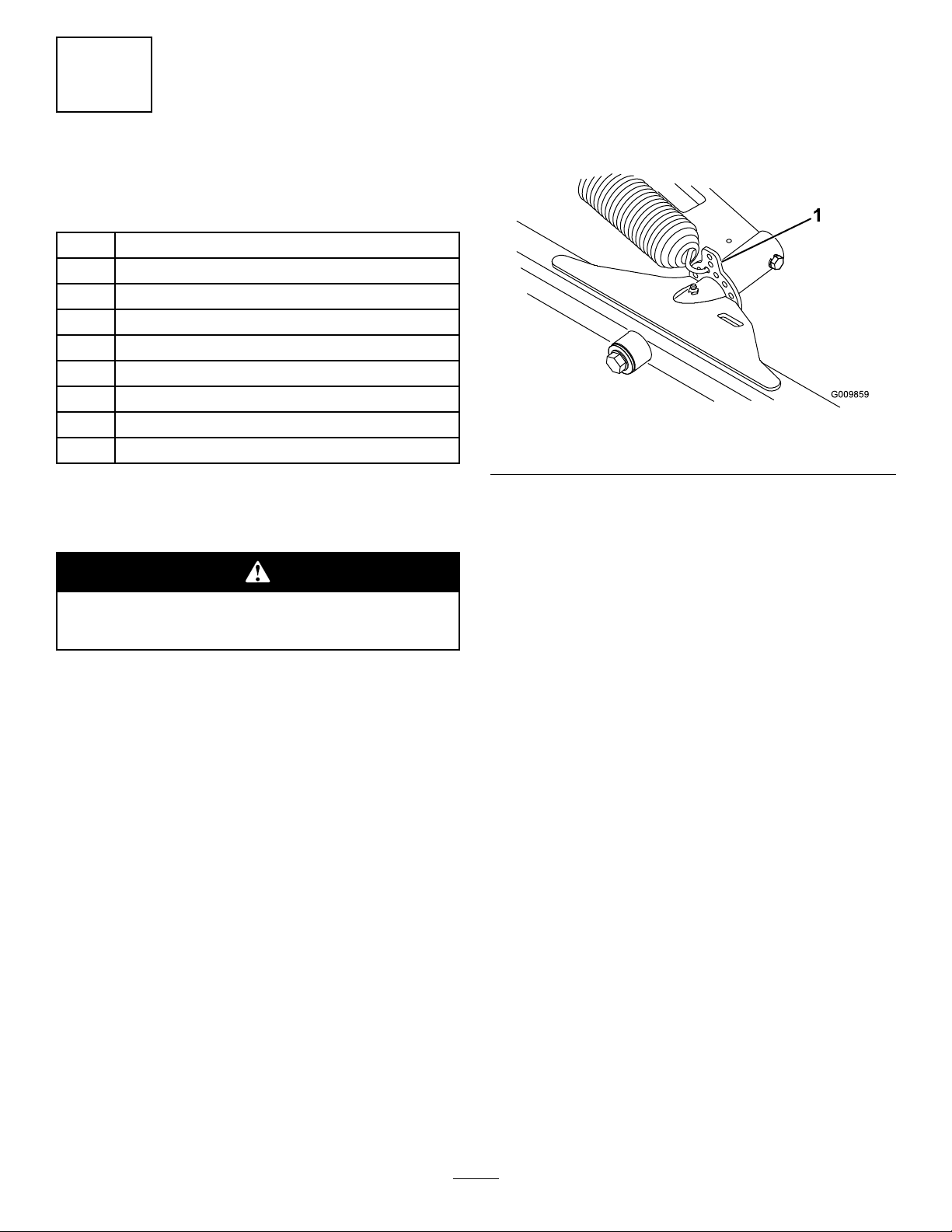

7

G009859

1

InstallingtheCounterbalance

Springs

Partsneededforthisprocedure:

3

Spring

1Vinylsleeve

3

Springshackle

6

Clevispin

6

Cotterpin

2

Shackle(32inchcuttingunitonly)

2

Springanchor(32inchcuttingunitonly)

4

Bolt(1/4x3/4inch)(32inchcuttingunitonly)

4

Locknut(32inchcuttingunitonly)

Note:Selectingthe#4holeposition(increasing

thespringtension)willreducetheweightonthe

inboardendofthecuttingunit,increasetheweight

ontheoutboardendofthecuttingunit,andincrease

traction.Selectingthe#2holepositionhasthe

oppositeaffect.

Figure11

1.Cuttingunitlifttab

PrecautionsandSettingsforthe

CounterbalanceSprings

Usecautionwhentensioningthespringsas

theyareunderheavyload.

Thecounterbalancespringshelpbalancethecutting

unitstoallowequalamountsofweight(downpressure)

tobedistributedtoeachendofthecuttingunit.The

springsalsotransferweightfromthecuttingunitstothe

tractionunit,thereforeincreasingtraction.

Thesettingsrecommendedinthefollowingprocedures

mayberequireminorchangestoachieveoptimum

performanceforyourturfconditions.Theweight,at

eachendofthecuttingunit,canbecheckedeasilywitha

springscale.

•Increasingthespringtensionreducestheweight

oninboardendofthecuttingunitandincreases

theweightontheoutboardend.

•Decreasingthespringtensionincreasestheweight

ontheinboardendofthecuttingunitandreduces

theweightonoutboardend.

2.Securetheotherendofthespringtotheappropriate

hole(seebelow)onthefrontandrearcounterbalance

arms(Figure12andFigure13)withthespring

shackle,clevispin,andcotterpin.

•5bladereels—fourthholefromthetop

•8bladereels—thirdholefromthetop

•Reelswithbaskets—tophole

Note:Ontherearcounterbalancespring,installthe

vinylcoveroverthespringbeforeinstalling.

Note:Increasingthespringtensionwillreduce

theweightontheinboardendofthecuttingunit,

increasetheweightontheoutboardendofthe

cuttingunit,andincreasetraction.Decreasingthe

springtensionhastheoppositeeffect.

InstallingtheCounterbalanceSprings

on27InchCuttingUnits

1.Hookthespringintothethirdholefromthetopon

theinboardsideofbothfrontcuttingunitlifttabs

andontherearcuttingunitlifttab(Figure11).

17

Page 18

Figure12

G009862

1

2

1.Counterbalancearm4.Springshackle

2.Topbolt

3.Bottombolt

5.Clevispinandcotterpin

InstallingtheCounterbalanceSprings

on32InchCuttingUnits

1.Mountaspringanchortotherearinboardsideof

eachfrontcuttingunitlifttabwith2bolts(1/4x3/4

inch)andlocknuts,asshowninFigure14.

Figure14

1.Cuttingunitlifttab2.Springanchor

2.Onthefrontcuttingunits,hookthespringintothe

secondholefromthebottom(#3position)inthe

springanchor(Figure14).

Figure13

1.Rearcounterbalance

spring

2.Vinylcover

3.Springshackle

3.Insertthebreakerbarintothesquareholeinthe

counterbalancearmandpivotthearmbacktoits

originalposition,aligningthemountingholes.

4.Securethebottomofthecounterbalancearmtothe

framewiththeboltandnutpreviouslyremoved.

Tightenthetopbolt(Figure12).

5.Totensionthecounterbalancesprings,proceedas

follows:

A.Removethecotterpinandclevispinsecuringthe

springshackletothecounterbalancearm.Do

notremovetheotherclevispin.

B.Movetheshackleupordownonthe

counterbalancearmuntilitisalignedwiththe

desiredholeonthearm.Installtheclevispin

andcotterpin.

Note:Selectingthe#4holeposition(increasing

thespringtension)willreducetheweightonthe

inboardendofthecuttingunit,increasetheweight

ontheoutboardendofthecuttingunit,andincrease

traction.Selectingthe#2holepositionhasthe

oppositeaffect.

3.Ontherearcuttingunit,hookthespringintothetop

holeontherearcuttingunitlifttab.

Note:Increasingthespringtensionwillreduce

theweightontheinboardendofthecuttingunit,

increasetheweightontheoutboardendofthe

cuttingunit,andincreasetraction.Decreasingthe

springtensionhastheoppositeaffect.

4.Securetheotherendofthespringtotheappropriate

hole(seebelow)onthefrontandrearcounterbalance

arms(Figure15andFigure16)withthespring

shacklewiththechain,clevis,clevispin,andcotter

pin.

•5bladereels—thirdholefromthetop

•8bladereels—secondholefromthetop

•Reelswithbaskets—tophole

Note:Onrearcounterbalancespring,installthe

vinylcoveroverthespringbeforeinstalling.

18

Page 19

Figure15

1.Counterbalancearm4.Springshackle

2.Topbolt

3.Bottombolt

5.Clevispinandcotterpin

6.Chain,clevis,andclevis

B.Movetheshackleupordownonthe

counterbalancearmuntilitisalignedwiththe

desiredholeonthearm.Installtheclevispin

andcotterpin.

8

AddingRearBallast

Partsneededforthisprocedure:

pin

Varies

Procedure

ThisunitcomplieswithANSlB71.4–2004Standardsand

allapplicableEuropeanrequirementswhenequipped

withrearballast.Usethefollowingcharttodetermine

theweightorcombinationsofweightsneeded.

Rearweightkit(s)

Figure16

1.Rearcounterbalance

spring

2.Vinylcover

3.Springshackle

5.Securetheotherendofthespringtothesecondhole

fromthetopwiththespringshacklewiththechain,

clevis,clevispin,andcotterpin(Figure15).

6.Ontherearcounterbalancearms,installthevinyl

coveroverthespringbeforehookingtheotherend

ofthespringintothespringshackleinthesecond

holefromthetop(Figure16).

7.Insertthebreakerbarintothesquareholeinthe

counterbalancearmandpivotthearmbacktoits

originalposition,aligningthemountingholes.

8.Securethebottomofthecounterbalancearmtothe

framewiththeboltandnutpreviouslyremoved.

Tightenthetopbolt(Figure15).

CuttingUnitConguration

Standardmachinewith27inch

cuttingunits

Standardmachinewith27inch

cuttingunits&baskets

Standardmachinewiththree

wheeldrivekit&27inch

cuttingunits

Standardmachinewiththree

wheeldrivekit,27inchcutting

units&baskets

Standardmachinewith32inch

cuttingunits

Standardmachinewith32inch

cuttingunits&threewheel

drivekit

WeightKitsRequired

(1)83-9370

(2)83-9390

(1)83-9370(3)83-9390

(2)94-3698

(1)83-9390

(1)83–9370

(2)83-9390(2)94-3698

(1)83–9370

(3)83-9390(2)94-3698

(1)83–9370

(1)83-9370(2)83-9390

(1)94–3698

Note:Allcongurationsrequirecalciumchlorideinthe

reartire.Thetireshouldbelledtoapproximately75%

capacity(levelwiththevalveatthetop)(60lb(27kg)

uidor74lb(33.5kg)tireanduid).

Important:Ifapunctureoccursinatirewith

calciumchloride,removetheunitfromtheturfarea

asquicklyaspossible.T opreventpossibledamage

totheturf,immediatelysoaktheaffectedareawith

water.

9.Totensionthecounterbalancespringsproceedas

follows:

A.Removethecotterpinandclevispinsecuringthe

springshackletothecounterbalancearm.Do

notremovetheotherclevispin.

EitherType1(77%)orType2(94%)commercial

calciumchlorideakemaybeused.

Plainwaterfreezessolidat32°F(0°C).The3-1/2lb.

(1.6kg)calciumchlorideto1gallon(3.8l)ofwater

19

Page 20

solutionisslushfreeto-12°F(-24°C)andwillfreeze

solidat-52°F(-46°C).The5lb.(2.3kg)pergallon(liter)

solutionisslushfreeto-50°F(-45°C)andwillfreeze

solidat-62°F(-52°C).

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

9

ActivatingandChargingthe

Battery

NoPartsRequired

Procedure

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Ifthebatteryisnotlledwithelectrolyteoractivated,

bulkelectrolytewith1.260specicgravitymustbe

purchasedfromalocalbatterysupplyoutletandadded

tothebattery.

1.Removethellercapsfromthebatteryandslowlyll

eachcelluntiltheelectrolyteisjustabovetheplates.

3.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

4.Removethellercaps.Slowlyaddelectrolyteto

eachcelluntilthelevelisuptothellring.Install

thellercaps.

Important:Donotoverllthebattery.

Electrolytewilloverowontootherpartsofthe

machineandseverecorrosionanddeterioration

willresult.

5.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothe

negative(-)terminalofthebatteryandsecurethem

withboltsandnuts.Slidetherubberbootoverthe

positiveterminaltopreventapossibleshortfrom

occurring.

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Always

batterycablebeforedisconnectingthe

positive(red)cable.

disconnect

thenegative(black)

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

2.Replacethellercapswiththeventspointingto

therear(towardthefueltank)andconnecta3to4

ampbatterychargertothebatteryposts.Chargethe

batteryatarateof3to4amperesfor4to8hours.

•Always

cablebeforeconnectingthenegative(black)

cable.

20

connect

thepositive(red)battery

Page 21

ProductOverview

10

InstallingCECompliantDecals

Partsneededforthisprocedure:

1Decal104–3994

1Decal106–81 19

Procedure

IfyouaresettingupthisunitforuseintheEuropean

Union(CE),installtheCEcompliantdecalsovertheir

UScounterpartsasfollows:

Note:RefertoSafetyandInstructionalDecalsfor

illustrationsofthesedecals.

1.Installdecal104-3994overdecal104-3991.

2.Installdecal106-8119overdecal104-4096.

Controls

TractionandStoppingPedal

Thetractionpedal(Figure17)hasthreefunctions:to

makethemachinemoveforward,tomoveitbackward,

andtostopthemachine.Usingtheheelandtoeofthe

rightfoot,pressthetopofthepedaltomoveforward

andthebottomofthepedaltomovebackwardorto

assistinstoppingwhenmovingforward(Figure18).

Also,allowthepedaltomoveormoveittotheneutral

positiontostopthemachine.Donottherestheelof

yourfootonreversewhenoperatingforward.

11

Breaking-inaNewMachine

NoPartsRequired

Procedure

Whentheengineisstartedforthersttime,orafter

overhaulingtheengine,operatethemachineinforward

andreverseforonetotwominutes.Alsooperatethelift

leverandreeldriveswitchtobesureofproperoperation

ofallparts.

Turnthesteeringwheeltotheleftandrighttocheck

thesteeringresponse.Thenshuttheengineoffand

checkforoilleaks,looseparts,andanyothernoticeable

malfunctions.

Shuttheengineoffandwaitforallmoving

partstostopbeforecheckingforoilleaks,loose

parts,andothermalfunctions.

Figure17

1.Tractionpedal3.Pedalstop

2.Speedselector

Figure18

SpeedSelector

Thespeedselectorisacamleveratthesideofthe

tractionpedal(Figure17)thatcanberotatedtomaintain

desiredspeed.Thereversepedalstop(underthepedal)

21

Page 22

(Figure17)issetatthefactorytoprovide3MPH

maximumspeedinreverse.

StarterSwitch

CuttingUnitLiftLeverLock

Thecuttingunitliftleverlock(Figure19)lockscutting

unitsintheraisedpositionfortransporting.

Thestarterswitch(Figure19),usedtostart,stop,and

preheattheengine,hasthreepositions:Off,On,and

Start.RotatethekeyclockwisetotheOnpositionand

holdituntiltheglowpluglightgoesout.Thenrotate

thekeyclockwisetotheStartpositiontoengagethe

startermotor.Releasethekeywhentheenginestarts.

ThekeywillmoveautomaticallytotheOnposition.To

shuttheengineoff,rotatethekeycounterclockwiseto

theOffposition.Removethekeyfromtheswitchto

preventaccidentalstarting.

CuttingUnitDriveSwitch

Theswitch(Figure19)hastwopositions:Engageand

Disengage.Thepush-pullswitchoperatesasolenoid

valveonthevalvebank,todrivethecuttingunits.

HourMeter

Thehourmeter(Figure20)indicatesthetotalhoursof

machineoperation.Thehourmeterstartstofunction

wheneverthekeyswitchisrotatedtotheOnposition.

Figure19

1.Starterswitch4.Cuttingunitliftlever

2.Throttle

3.Cuttingunitdriveswitch

5.Cuttingunitliftleverlock

Throttle

Movingthethrottle(Figure19)upwardincreasesthe

enginespeedanddownwarddecreasestheenginespeed.

CuttingUnitLiftLever

Theliftlever(Figure19)hasthreepositions:Lower,

Raise,andNeutral.Tolowerthecuttingunitstothe

ground,movetheliftleverforward.Whenloweringthe

cuttingunits,makesurethatthefronthydrauliccylinder

iscompletelyretractedbeforereleasingtheliftlever.

Thecuttingunitswillnotoperateunlessthecylinderis

retracted.Toraisethecuttingunits,pulltheliftlever

rearwardtotheRaiseposition.

Figure20

1.Oilpressurelight4.Glowplugindicatorlight

2.Alternatorlight5.Hourmeter

3.Highwatertemperature

shut-downlight

6.Reeloperatinglight

OilPressureLight

Theoilpressurelight(Figure20)glowsiftheengineoil

pressuredropsbelowasafelevel.

WaterTemperatureLight

Thewatertemperaturelight(Figure20)glowsand

theengineautomaticallyshutsdownwhentheengine

coolanttemperaturegetstoohigh.

AlternatorLight

Thealternatorlight(Figure20)shouldbeoffwhen

theengineisrunning.Ifitison,checkandrepairthe

chargingsystemasnecessary.

22

Page 23

GlowPlugIndicator

G009878

1

2

Theindicatorlight(Figure20)willglowwhenglow

plugsareoperating.

ReelEngageIndicator

Thereelengageindicatorlight(Figure20)willglow

whenreelsareloweredtocuttingposition.

ParkingBrake

Whenevertheengineisshutoff,engagetheparking

braketopreventaccidentalmovementofthemachine.

Toengagetheparkingbrake,pullbackonthelever.

ReelSpeedControl

Toobtainthedesiredcliprate(reelspeed),rotatethe

reelspeedcontrolknob(Figure21)totheappropriate

settingfortheheight-of-cutsettingandmowerspeed.

RefertoSettingtheReelSpeed.

Figure21

1.Reelspeedcontrol2.Backlapcontrol

BacklapControl

Rotatetheknob(Figure21)toRforbacklappingandto

Fformowing.Donotchangetheknobpositionwhen

thereelsarerotating.

Figure22

1.Fuelshut-off(underthefueltank)

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Transportwidthwith27inch

cuttingunits

Transportwidthwith32inch

cuttingunits

Widthofcut76-1/2inches(194cm)

Length

Heightwithouttheseat

NetWeight(withoutcutting

units)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

72inches(183cm)

85inches(216cm)

96inches(244cm)

44inches(112cm)

1,250lbs.(567kg)

SeatAdjustment

Movetheleveronthesideoftheseatoutward,slidethe

seatforwardorrearwardtothedesiredposition,and

releasethelevertolocktheseatintoposition.

FuelShut-OffValve

Closethefuelshut-offvalve,underthefueltank

(Figure22),whenstoringthemachine.

23

Page 24

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Ifyouleavethekeyintheignitionswitch,

someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Lowerthecuttingunitstotheground,setthe

parkingbrake,andremovethekeyfromthe

ignitionswitchbeforeservicingormaking

adjustmentstothemachine.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityisapproximately3.5qt.(3.3l)with

thelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher

•Preferredoil:SAE15W-40(above0°F/-18°C)

Figure23

1.Dipstick

3.Removethedipstickandchecktheoillevelonthe

dipstick.

TheoillevelshouldbeuptotheFullmark.

4.IftheoillevelisbelowtheFullmark,removethe

llcap(Figure24)andaddoiluntilthelevelreaches

theFullmarkonthedipstick.Donotoverll.

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultof

overllingorunderllingtheengineoil.

•Alternateoil:SAE10W-30or5W -30(all

temperatures)

ToroPremiumEngineoilisavailablefromyour

distributorineither15W-40or10W -30viscosity .

1.Parkthemachineonalevelsurface,stoptheengine,

settheparkingbrake,andremovethekeyfromthe

ignitionswitch.

2.Removethedipstick,wipeitclean,andinstallit,

ensuringthatitisfullyseated(Figure23).

Figure24

1.Oilllcap

Important:Whenaddingengineoilorlling

oil,theremustbeclearancebetweentheoilll

deviceandtheoilllholeinthevalvecoveras

showninFigure25.Thisclearanceisnecessary

topermitventingwhenlling,whichprevents

oilfromoverrunningintothebreather.

24

Page 25

Figure25

1.Clearance

5.Installthedipstickandtheoilllcap.Closethe

hood.

6.Startandruntheengineatidlefor30seconds.Shut

theengineoff.Wait30secondsandchecktheoil

level.Ifneeded,addoiltoraisetheleveltotheFull

markonthedipstick.

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelwith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Fueltankcapacity:6.5gallons(24.6l)

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-Dor

No.1-D/2-Dblend)belowthattemperature.Useof

wintergradefuelatlowertemperaturesprovideslower

ashpointandcoldowcharacteristicswhichwillease

startingandreducefuellterplugging.

Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblended.

•Contactyourdistributorifyouwishformore

informationonbiodiesel.

25

Page 26

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuy

morethana30-daysupplyoffuel.

Note:Ifpossible,llthefueltankaftereachuse.This

willminimizepossiblebuildupofcondensationinside

thefueltank.

1.Parkthemachineonalevelsurface.

2.Usingacleanrag,cleantheareaaroundthefuel

tankcap.

3.Removethecapfromthefueltank(Figure26).

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitethefuelvapors.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Alwaysplacefuelcontainersontheground

awayfromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmay

insulatethecontainerandslowthelossof

anystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfromafuel

dispensernozzle.

Figure26

1.Fueltankcap

4.Fillthetanktoabout1inch(25mm)belowthe

topofthetank(bottomofthellerneck).Donot

overll.

5.Installthefueltankcaptightly.

6.Wipeupanyfuelthatmayhavespilledtopreventa

rehazard.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Cleandebrisoffofthescreen,oilcooler,andfront

oftheradiatordailyandmoreoftenifconditionsare

extremelydustyanddirty.RefertoRemovingDebris

fromtheCoolingSystem.

Thecoolingsystemislledwitha50/50solution

ofwaterandpermanentethyleneglycolantifreeze.

Checkthelevelofcoolantintheexpansiontankatthe

beginningofeachdaybeforestartingtheengine.The

capacityofthecoolingsystemis5.25quarts(5l).

•Ifafueldispensernozzlemustbeused,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

26

Page 27

3.Ifthecoolantlevelislow,replenishthesystem.Do

notoverll.

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhenthe

engineisrunning.

•Usearagwhenopeningtheradiatorcap,

andopenthecapslowlytoallowsteamto

escape.

1.Carefullyremovetheradiatorcap(Figure27).

Figure27

1.Radiatorcap

2.Checkthelevelofcoolantintheradiatorand

expansiontank(Figure28).

Theradiatorshouldbelledtothemiddleofthe

horizontalllerneck.Theexpansiontankshould

belledhalfwaybetweentheFullandLowmarks.

4.Installtheradiatorandexpansiontankcaps.

CheckingtheHydraulicFluid

ServiceInterval:Beforeeachuseordaily

Thehydraulicreservoirislledatthefactorywith

approximately3.3USgallons(12.5l)ofhighquality

hydraulicuid.Checkthelevelofthehydraulic

uidbeforetheengineisrststartedanddaily

thereafter.Therecommendedreplacementuidisas

follows:

ToroPremiumAllSeasonHydraulicFluid(Availablein

5gallonpailsor55gallondrums.Seethepartscatalogor

yourT orodistributorforpartnumbers.)

Alternateuids:IftheT orouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Toro

doesnotrecommendtheuseofsyntheticuid.Consult

withyourlubricantdistributortoidentifyasatisfactory

product.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehind

theirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

1.Expansiontank

Figure28

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemoilisavailablein2/3oz.(20

ml)bottles.Onebottleissufcientfor4-6gal(15-22

l)ofhydraulicoil.Orderpartno.44-2500fromyour

authorizedTorodistributor.

BiodegradableHydraulicFluid-Mobil224H

ToroBiodegradableHydraulicFluid(Availablein5

gallonpailsor55gallondrums.SeepartscatalogorT oro

distributorforpartnumbers.)

Alternateuid:MobilEAL224H

Note:Thisisvegetable-oilbasedbiodegradable

oiltestedandapprovedbyT oroforthismodel.

Thisuidisnotasresistanttohightemperaturesas

standarduid,sobesuretofollowtherecommended

uidchangeintervalswiththisuid.Contamination

27

Page 28

bymineral-basedhydraulicuidswillchangethe

biodegradabilityandtoxicityofthisoil.Whenchanging

fromstandarduidtothebiodegradabletype,be

certaintofollowtheapprovedushingprocedure.

ContactyourlocalToroDistributorfordetails.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,andstoptheengine.

Note:Thetiresareover-inatedforshipping.

Therefore,releasesomeoftheairtoreducethepressure

beforeusingthemachineforthersttime.

CheckingtheReeltoBedknife

Contact

2.Checktheuidlevelbyviewingitinthesightgauge

(Figure29).

Iftheuidiscold,thelevelshouldbeatthebottom

ofthegauge.Iftheuidishot,thelevelshouldbe

atthecenterofthegauge.

Figure29

1.Hydraulicreservoircap

3.Topreventsystemcontamination,cleanthetopof

thehydraulicuidcontainersbeforepuncturing.

Ensurethatthepourspoutandfunnelareclean.

Also,cleanaroundthehydraulicreservoircap.

2.Sightgauge

ServiceInterval:Beforeeachuseordaily

Eachdaybeforeoperating,checkreeltobedknife

contact,regardlessifthequalityofcuthadpreviously

beenacceptable.Theremustbelightcontactacross

thefulllengthofthereelandthebedknife(referto

AdjustingtheReeltoBedknifeinthecuttingunit

Operator’sManual).

ChecktheTorqueoftheWheel

Nuts

ServiceInterval:Afterthersthour

Aftertherst10hours

Every250hours

Torquethewheellugnutsto45to65ft-lb(61to88

N-m).

Failuretomaintainpropertorqueofthewheel

nutscouldresultinpersonalinjury.

4.Iftheuidlevelisnotatleastatthebottomofthe

gaugewhenitiscold,removethecapfromthe

hydraulicuidreservoir(Figure29)andslowlyll

thereservoirwithhighqualityhydraulicuiduntil

thelevelinitreachesthebottomofthesightgauge.

Donotoverll.

5.Installthereservoircap.Wipeupanyuidthatmay

havespilled.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Checktoensurethattheairpressureinthetiresis

16–20psi(110–138kPa).

Important:Maintaintherecommendedpressure

inalltirestoensureagoodquality-of-cut

andpropermachineperformance.

under -inate.

Do not

BleedingtheFuelSystem

Bleedthefuelsystembeforestartingtheengineifany

ofthefollowingsituationshaveoccurred:

•Initialstartupofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuelsystem

components;i.e.,lterreplaced,separatorserviced,

etc.

28

Page 29

Incertainconditions,fuelisextremely

G009880

1

2

3

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

Note:Normally,theengineshouldstartafterthe

abovebleedingproceduresarefollowed.However,if

theenginedoesnotstart,airmaybetrappedbetween

injectionpumpandinjectors;refertoBleedingAir

fromtheInjectors.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuel

thatspills.

•Neverllthefueltankinsideanenclosed

trailer.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuy

morethana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

1.Parkthemachineonalevelsurfaceandensurethat

thefueltankisatleasthalffull.

2.Openthehood.

3.Loosentheventplugontopoffuellter/water

separator(Figure30).

StartingandStoppingthe

Engine

Important:Youmustbleedthefuelsystembefore

startingtheengineifyouarestartingtheengine

forthersttime,theenginehasstoppeddueto

lackoffuel,oryouhaveperformedmaintenanceon

thefuelsystem;refertoBleedingtheFuelSystem.

StartingtheEngine

1.Sitontheseat,keepyourfootoffofthetraction

pedalsothatitisinNeutral,engagetheparking

brake,setthethrottletotheFastposition,and

ensurethatthereeldriveswitchisintheDisengage

position.

2.TurntheignitionswitchtotheOnpositionand

holdituntiltheglowpluglightgoesout,thenrotate

thekeyclockwisetotheStartpositiontoengage

thestartermotor.Releasethekeywhentheengine

starts.

Important:Topreventoverheatingofthe

startermotor,donotengagethestarterlonger

than10seconds.After10secondsofcontinuous

cranking,wait60secondsbeforeengagingthe

startermotoragain.

3.Runtheengineatlowidlespeeduntilitwarmsup.

StoppingtheEngine

1.MovethereeldriveswitchtotheDisengage

position,settheparkingbrake,andmovethe

throttletothelowidleposition.

Figure30

1.Fuellter/waterseparator

2.Ventplug

3.Drainvalve

4.TurnthekeyintheignitionswitchtotheOn

position.Theelectricfuelpumpwillbegin

operation,therebyforcingairoutaroundthevent

plug.LeavethekeyintheOnpositionuntilasolid

streamoffuelowsoutaroundtheplug.

5.TightentheplugandturnthekeytotheOff

position.

2.TurnthekeytotheOffpositionandremoveit

fromtheswitch.

3.Closethefuelshut-offvalvebeforestoringthe

machine.

29

Page 30

CheckingtheOperationofthe

TowingtheTractionUnit

InterlockSwitches

ServiceInterval:Beforeeachuseordaily

Ifthesafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

1.Ensurethattheparkingbrakeissetandall

bystandersareawayfromtheareaofoperation.

Keephandsandfeetawayfromthecuttingunits.

2.Withtheoperatoroffoftheseat,thebacklapknob

intheFposition,thetractionpedalinneutral,the

parkingbrakeengaged,andthereelswitchinthe

Offposition,theengineshouldstart.Ifeither

thetractionpedalispressedorthereelswitchis

turnedOn,withtheoperatoroffoftheseat,the

engineshouldstop.Correcttheproblemifitisnot

operatingproperly .

Incaseofanemergency,themachinecanbetowedfor

ashortdistance.However,wedonotrecommendthis

asastandardprocedure.

Important:Donottowthemachinefasterthan2

to3MPHbecausethedrivesystemmaybecome

damaged.Ifthemachinemustbemoveda

considerabledistance,transportitonatruckor

trailer.

1.Locatethebypassvalveonthepump(Figure31)

androtateit90°(thebypassvalvelevershouldbe

horizontalwhenitisopen).

Figure31

1.Bypassvalve

3.Withtheenginerunning,theoperatoroffofthe

seat,andthebacklapknobintheRposition,

theengineshouldnotstopwhenthereelswitch

isturnedOn.Correcttheproblemifitisnot

operatingproperly .

4.Withtheenginerunning,theoperatoroffofthe

seat,andthebacklapknobintheRposition,the

engineshouldstopifthetractionpedalisengaged.

Correcttheproblemifitisnotoperatingproperly.

5.Withtheoperatorontheseat,theenginerunning,

andthereelswitchintheOnposition,thedash

indicatorlightshouldbeglowingandthereelmotors

turningwhentheliftcylinderisfullyretracted.As

theliftcylinderisextended,thelightshouldgoout

andthereelmotorsshouldstopturning.Correct

theproblemifitisnotoperatingproperly.

6.Withtheoperatorontheseat,theenginemust

notstartwitheitherthereelswitchengagedorthe

tractioncontrolengaged.Correcttheproblemifit

isnotoperatingproperly.

2.Beforestartingtheengine,closethebypassvalve

byrotatingit90°(thebypassvalvelevershouldbe

verticalwhenclosed).Donotstarttheenginewhen

thevalveisopen.

OperatingCharacteristics

Thismachineproducessoundlevelsinexcess

of85dBAattheoperatorsearandcancause

hearinglossthroughextendedperiodsof

exposure.

Wearhearingprotectionwhenoperatingthis

machine.

Practiceoperatingthemachineandbecomethoroughly

familiarwithit.Becauseofitshydrostatictransmission,

itscharacteristicsdifferfrommanyturfmaintenance

machines.Pointstoconsiderwhenoperatingarethe

tractiondrive,enginespeed,andloadonthecutting

units.Regulatethetractionpedaltokeeptheengine

RPMhighandsomewhatconstantwhilemowingto

maintainadequatepowerforthetractionandcutting

30

Page 31

units.Adjustthespeedselectortomaintainconstant

G009915

G010094

1

2

groundspeedandqualityofcut.However,whenon

hillyterrain,donotusethespeedselector.

Followtheoperatingguidelinespresentedinthismanual

andknowhowtooperatethemachinesafelyonall

typesofterrain.Hills(orslopes)over15degreesshould

betraversedormowedupanddown,notsidetoside,

andhillsover20degreesshouldgenerallybeavoided

unlessspecialsafeguards,skills,andconditionsexist.

Alwaysplanwellaheadtoavoidtheneedforsudden

stops,starts,orturns.Tostop,usethereversepedal

forbraking.Beforestoppingtheengine,disengageall

controls,movethethrottletotheSlowposition,and

settheparkingbrake.

Figure33

1.Reelspeedcontrolknob2.Backlapknob

SettingtheReelSpeed

thecuttoensuresatisfactionwiththequality-of-cut.

Thereelspeedknobmaybesetonepositionon

eithersideofthepositionindicatedonthechart

toaccountfordifferencesingrasscondition,grass

lengthremoved,andpersonalpreferenceofthe

superintendent.

4.Operatethemachineforseveraldays,thenexamine

VariableReelSpeedSelectionChart—5BladeReel

Figure32

Toachieveaconsistent,highquality-of-cutanda

uniformaftercutappearance,itisimportantthatthe

reelspeedbematchedtotheheight-of-cut.Adjustthe

reelspeedcontrolsasfollows:

1.Verifytheheight-of-cutsettingonthecuttingunits.

HeightofCut(inches)

2-1/2(2.50)

2-3/8(2.38)

2-1/4(2.25)

2-1/8(2.13)

2(2.00)

3WD

Speeds

3–5MPH

3

3

4

4

46

2WD

Speeds

6–7MPH

5

5

5

5

Usingthecolumnofthechartlistingeither5or

8bladereels,ndtheheightofcutlistingnearest

theactualheight-of-cutsetting.Lookacrossthe

charttondthenumbercorrespondingtothat

height-of-cut.

2.EnsurethatthebacklapknobissetintheForward

(F)position(Figure33).

3.Turnthereelspeedcontrolknob(Figure33)tothe

numbersettingdeterminedinstep1.

*Thisheight-of-cutand/ormowingspeednotrecommended

for5bladereels.

1-7/8(1.88)

1-3/4(1.75)

1-5/8(1.63)

1-1/2(1.50)

1-3/8(1.38)

1-1/4(1.25)

1-1/8(1.13)

1(1.00)

7/8(.88)

3/4(.75)9*9*

5/8(.63)9*9*

1/2(.50)9*9*

3/8(.38)9*9*

46

57

57

6

6

7

7

8

9

9*

9*

9*

9*

9*

9*

31

Page 32

VariableReelSpeedSelectionChart—8BladeReel

HeightofCut(inches)

2-1/2(2.50)3*

2-3/8(2.38)3*

2-1/4(2.25)3*

2-1/8(2.13)3*

2(2.00)3*

1-7/8(1.88)

1-3/4(1.75)

1-5/8(1.63)

1-1/2(1.50)

1-3/8(1.38)

1-1/4(1.25)

1-1/8(1.13)

1(1.00)

7/8(.88)

3/4(.75)

5/8(.63)

1/2(.50)

3/8(.38)

*Thisheight-of-cutand/ormowingspeednotrecommended

for8bladereels.

3WD

Speeds

3–5MPH

34

34

34

4

4

46

57

5

6

7

9

9

9

6–7MPH

TrainingPeriod

Beforemowingwiththemachine,ndaclearareaand

practicestartingandstopping,raisingandlowering

cuttingunits,turning,etc.Thistrainingperiodwillbe

benecialtotheoperatoringainingcondenceinthe

performanceofthemachine.

anduseextremecautionbeforeturningtoreducethe

riskoftippingorlosingcontrol.W atchcarefullyfor

2WD

Speeds

3

3

3

3

3

andavoidholesintheterrain,suddendrop-offs,and

otherhiddenhazards.Topreventcostlydamageand

downtime,familiarizeyourselfwiththewidthofthe

machine.Donotattempttopassbetweenimmovable

objectsplacedclosetogether.

InspectionandClean-UpAfter

Mowing

Atthecompletionofthemowingoperation,thoroughly

washthemachinewithagardenhose—withouta

nozzle—sothatexcessivewaterpressurewillnotcause

5

5

contaminationanddamagetothesealsandbearings.

Makesurethattheradiatorscreen,radiator,andoil

coolerarekeptfreeofdirtorgrassclippings.After

cleaning,itisrecommendedthatthemachinebe

9

9*

9*

9*

9*

9*

inspectedforpossiblehydraulicuidleaks,damageor

weartothehydraulicandmechanicalcomponents,and

thecuttingunitscheckedforsharpnessandproperreel

tobedknifeadjustment.

StandardControlModule

(SCM)

TheStandardControlModuleisapottedelectronic

deviceproducedinaonesizetsallconguration.The

moduleusessolidstateandmechanicalcomponents

tomonitorandcontrolstandardelectricalfeatures

requiredforsafeproductoperation.

Themodulemonitorsinputsincludingneutral,parking

brake,PTO ,start,backlap,andhightemperature.The

moduleenergizesoutputsincludingPTO,Starter,and

ETR(energizetorun)solenoid.

BeforeMowing

Inspecttheareafordebrisandclearareaifnecessary.

Determinethebestdirectiontomowontheprevious

mowingdirection.Alwaysmowinanalternatepattern

fromthepreviousmowing,sothatthegrassbladeswill

belessapttolaydownandthereforebedifcultto

gatherbetweenthereelbladesandbedknife.

TransportOperation

Besurethatthecuttingunitsareinthefullyupposition,

movethetractionpedalstopfromunderthepedalto

allowfulltractionpedaltravel,andplacethethrottle

controlintheFASTposition.Whileoperatingon

slopesanduneventerrain,alwaysreduceyourspeed

Themoduleisdividedintoinputsandoutputs.Inputs

andoutputsareidentiedbygreenLEDindicators

mountedontheprintedcircuitboard.

Thestartcircuitinputisenergizedby12VDC.All

otherinputsareenergizedwhenthecircuitisclosedto

ground.EachinputhasaLEDthatisilluminatedwhen

thespeciccircuitisenergized.UsetheinputLED’ s

forswitchandinputcircuittroubleshooting.

Outputcircuitsareenergizedbyanappropriatesetof

inputconditions.ThethreeoutputsincludePTO,ETR,

andSTART.OutputLED’smonitorrelaycondition

indicatingthepresenceofvoltageatoneofthree

specicoutputterminals.

Outputcircuitsdonotdetermineoutputdevice

integritysoelectricaltroubleshootingincludesoutput

32

Page 33

LEDinspectionandconventionaldeviceandwire

harnessintegritytesting.Measuredisconnected

componentimpedance,impedancethroughwire

harness(disconnectatSCM),orbytemporarily”test

energizing”thespeciccomponent.

1.Input5.Inseat

2.Backlap

3.Hightempshutdown

4.Hightempwarning(Not

used)

6.PTOswitch10.PTO

7.Parkbrakeoff1 1.Start

8.Neutral12.ETR

TheSCMdoesnotconnecttoanexternalcomputeror

handhelddevice,cannotbere–programmed,anddoes

notrecordintermittentfaulttroubleshootingdata.

ThedecalontheSCMonlyincludessymbols.Three

LEDoutputsymbolsareshownintheoutputbox.

AllotherLED’ sareinputs.Figure34identiesthe

symbols.

Figure34

9.Output13.Start

14.Power

HerearethelogicaltroubleshootingstepsfortheSCM

device.

1.Determinetheoutputfaultyouaretryingtoresolve

(PTO,Start,orETR).

2.MoveignitionswitchtotheOnpositionandensure

theredpowerLEDisilluminated.

3.MoveallinputswitchestoensureallLED’ schange

state.

4.Positioninputdevicesatappropriatepositionto

achievetheappropriateoutput.Usethefollowing

logiccharttodeterminetheappropriateinput

condition.

•IfspecicoutputLEDisilluminatedwithout

appropriateoutputfunction,checkoutput

harness,connections,andcomponent.Repair

asrequired.

•IfspecicoutputLEDisnotilluminated,check

bothfuses.

•IfspecicoutputLEDisnotilluminatedand

inputsareinappropriatecondition,installnew

SCManddetermineiffaultdisappears.

conditionincluding:energizedtovoltage,closedto

ground,andopentoground.

Eachrow(across)inthelogicchartbelowidenties

inputandoutputrequirementsforeachspecic

productfunction.Productfunctionsarelistedin

theleftcolumn.Symbolsidentifyspeciccircuit

33

Page 34

Inputs

FunctionPower

Start

Run(offunit)

Run(onunit)

Mow

Backlap

Hi-Temp

On

––

––

–

–

––

–

InNeutral

StartOnBrakeOffPTOOnInSeat

+

OOOOOOO

OO

OO

OO

O

OO

–

–––

O

–

HiT empBacklap

–

–

OO

Note:-Indicatesacircuitclosedtoground.-LEDON

OIndicatesacircuitopentogroundorde-energized-LEDOFF

+Indicatesanenergizedcircuit(clutchcoil,solenoid,orstartinput)LEDON.

""ABlankindicatesacircuitthatisnotinvolvedwiththelogic.

Totroubleshoot,turnonthekeywithoutstarting

theengine.Identifythespecicfunctionthatdoes

notworkandworkacrossthelogicchart.Inspect

theconditionofeachinputLED’ stoensureit

matchesthelogicchart.

IftheinputLED’ sarecorrect,checktheoutput

LED.IftheoutputLEDisilluminatedbutthe

deviceisnotenergized,measureavailablevoltageat

theoutputdevice,continuityofthedisconnected

device,andpotentialvoltageonthegroundcircuit

(oatingground).Repairswillvarydependingon

yourndings.

OO

OOO

OOO

–

–

Outputs

Start

++

O

OOO

ETR

+

+

++

++

PTO

O

O

O

34

Page 35

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst5hours

Aftertherst8hours

Aftertherst10hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

MaintenanceProcedure

•T orquethewheellugnutsto45to65ft-lb(61to88N-m).

•Changethehydraulicoillter.

•Checktheconditionandtensionofthealternatorbelt.

•Checktheconditionandtensionofthehydraulicpumpbelt.

•T orquethewheellugnutsto45to65ft-lb(61to88N-m).

•Changetheengineoilandlter.

•ChecktheengineRPM(idleandfullthrottle).

•Checktheengineoillevel.

•Checkthecoolingsystem.

•Checkthehydraulicuidlevel.

•Checkthetirepressure.

•Checkthereeltobedknifecontact.

•Checktheoperationoftheinterlockswitches.

•Drainwaterfromthewaterseparator.

•Removedebrisfromthescreen,oilcoolers,andradiator.(Cleanmorefrequently

indirtyoperatingconditions.)

•Checktheelectrolytelevelandcleanthebattery.

•Checkthebatterycableconnections.

•Greasethebearingsandbushings.(Greaseimmediatelyaftereverywashing

regardlessoftheintervallisted.)

•Checktheconditionandtensionofthealternatorbelt.

Every100hours

Every150hours

Every200hours

Every250hours

Every400hours

Every1,000hours

•Checktheconditionandtensionofthehydraulicpumpbelt.

•Changetheengineoilandlter.

•Servicetheaircleaner.(Serviceitmorefrequentlyinextremelydirtyordusty

conditions.)

•Changethehydraulicoillter.

•T orquethewheellugnutsto45to65ft-lb(61to88N-m).

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacethefuelltercanister.

•Changethehydraulicuid.

•ChecktheengineRPM(idleandfullthrottle).

•Inspectthetractionlinkagemovement.

•Flushandreplacethecoolingsystemuidandhoses.

•Replaceallmovinghoses.

•Replacethethermostat.

•Drainandushthefueltank.

•Drainandushthehydraulictank.

35

Page 36

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Mon.Tues.Wed.Thurs.Fri.

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checktheengineoillevel.

Checkthecoolingsystemuidlevel.

Drainthewater/fuelseparator.