Page 1

FORM NO. 3318-232 GB Rev B

®

MODEL NO. 03422TE—70001 & UP

MODEL NO. 03427TE—70001 & UP

®

REELMASTER

Traction Unit

2300-D/2600-D

OPERATOR’S

MANUAL

© The T oro Company—1997

Page 2

This operator's manual has instructions on safety, operation, and maintenance.

This manual emphasizes safety, mechanical and general product information. DANGER, WARNING and CAUTION

identify safety messages. Whenever the triangular safety alert symbol appears, understand the safety message that

follows. “IMPORTANT” highlights special mechanical information and “NOTE” emphasizes general product information worthy of special attention.

IDENTIFICATION AND ORDERING

MODEL AND SERIAL NUMBER

The model and serial number for the traction unit is on a plate that is mounted on the left front frame member. The

model and serial number for the cutting unit is on a plate that is mounted on the top front of the center cutting unit.

Use model and serial number in all correspondence and when ordering parts.

To order replacement parts from an authorized TORO Distributor, supply the following information:

1. Model and serial numbers of the machine.

2. Part number, description and quantity of parts desired.

NOTE: Do not order by reference number if a parts catalog is being used; use the part number.

Table of Contents

Safety 3

Specifications 9

Before Operating 10

Controls 13

First-Time Operation 16

Operating 20

Maintenance 23

Page

2

Page 3

Safety

Training

1. Read the instructions carefully. Be familiar with

the controls and the proper use of the equipment.

2. Never allow children or people unfamiliar with

these instructions to use the lawn mower. Local

regulations may restrict the age of the operator.

3. Never mow while people, especially children, or

pets are nearby.

4. Keep in mind that the operator or user is responsi-

ble for accidents or hazards occurring to other

people or their property.

5. Do not carry passengers.

6. All drivers should seek and obtain professional

and practical instruction. Such instruction should

emphasize:

• the need for care and concentration when

working with ride-on machines;

• control of a ride-on machine sliding on a

slope will not be regained by the application

of the brake. The main reasons for loss of

control are:

– insufficient wheel grip;

– being driven too fast;

– inadequate braking;

3. WARNING—Petrol is highly flammable.

• Store fuel in containers specifically designed

for this purpose.

• Refuel outdoors only and do not smoke

while refueling.

• Add fuel before starting the engine. Never

remove the cap of the fuel tank or add petrol

while the engine is running or when the

engine is hot.

• If petrol is spilled, do not attempt to start the

engine but move the machine away from the

are of spillage and avoid creating any source

of ignition until petrol vapors have dissipated.

• Replace all fuel tanks and container caps

securely.

4. Replace faulty silencers.

Operation

1. Do not operate the engine in a confined space

where dangerous carbon monoxide fumes can collect.

2. Mow only in daylight or in good artificial light.

3. Before attempting to start the engine, disengage

all blade attachment clutches and shift into neutral.

– the type of machine is unsuitable for its

task;

– lack of awareness of the effects of

ground conditions, especially slopes;

– incorrect hitching and load distribution.

Preparation

1. While mowing, always wear substantial footwear

and long trousers. Do not operate the equipment

when barefoot or wearing open sandals.

2. Thoroughly inspect the area where the equipment

is to be used and remove all objects which may

be thrown by the machine.

4. Do not use on slopes of more than:

• Never mow side hills over 5°

• Never mow uphill over 10°

• Never mow downhill over 15°

5. Remember there is no such thing as a “safe”

slope. Travel on grass slopes requires particular

care. To guard against overturning:

• do not stop or start suddenly when going up

or downhill;

• engage the clutch slowly, and always keep

the machine in gear, especially when travailing downhill;

3

Page 4

Safety

• machine speeds should be kept low on

slopes and during tight turns;

• stay alert for bumps and hollows and other

hidden hazards;

• never mow across the face of the slope,

unless the lawn mower is designed for this

purpose.

6. Use care when pulling loads or using heavy

equipment.

• Use only approved drawbar hitch points.

• Limit loads to those you can safely control.

• Do not turn sharply. Use care when reversing.

• Use counterweight(s) or wheel weights

when suggested in the instruction handbook.

7. Watch out for traffic when crossing or near road-

ways.

• before refueling;

• before removing the grass catcher;

• before making height adjustments unless the

adjustment can be made from the operator’s

position.

• before clearing blockages;

• before checking, cleaning or working on the

lawnmower;

• after striking a foreign object. Inspect the

lawnmower for damage and make repairs

before restarting and operating the equipment.

15. Reduce the throttle setting during engine runout

and, if the engine is provided with a shutoff

valve, turn the fuel off at the conclusion of mowing.

Maintenance and Storage

8. Stop the blades rotating before crossing surfaces

other than grass.

9. When using any attachments, never direct dis-

charge of material toward bystanders nor allow

anyone near the machine while in operation .

10. Never operate the lawn mower with defective

guards, shields or without safety protective

devices in place.

11. Do not change the engine governor settings or

overspeed the engine. Operating the engine at

excessive speeds may increase the hazard of personal injury.

12. Before leaving the operator’s position:

• disengage the power take-off and lower the

attachments;

• change into neutral and set the parking

brake;

• stop the engine and remove the key.

13. Disengage the drive to attachments when trans-

porting or not in use.

14. Stop the engine and disengage the drive to the

attachment

1. Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

2. Never store the equipment with petrol in the tank

inside a building where fumes may reach an open

flame or spark.

3. Allow the engine to cool before storing in any

enclosure.

4. To reduce the fire hazard, keep the engine,

silencer, battery compartment and petrol storage

area free of grass, leaves, or excessive grease.

5. Check the grass catcher frequently for wear or

deterioration.

6. Replace worn or damaged parts for safety.

7. If the fuel tank has to be drained, this should be

done outdoors.

8. Be careful during adjustment of the machine to

prevent entrapment of the fingers between moving blades and fixed parts of the machine.

9. On multi-bladed machines, take care as rotating

one blade can cause other blades to rotate.

4

Page 5

10. When the machine is to be parked, stored or left

unattended, lower the cutting means unless a positive mechanical lock is used.

Sound & Vibration Levels

Sound Levels

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 84 dB(A), based

on measurements of identical machines per

84/538/EEC.

This unit has a sound power level of 98 dB(A)/1pW,

based on measurements of identical machines per procedures outlined in Directive 79/113/EEC and amendments.

Vibration Levels

Safety

This unit has a vibration level of 5.0 m/s2at the posterior, based on measurements of identical machines per

ISO 5349 procedures.

This unit does not exceed a vibration level of 0.5 m/s

at the posterior based on measurements of identical

machines per ISO 5349 procedures.

2

5

Page 6

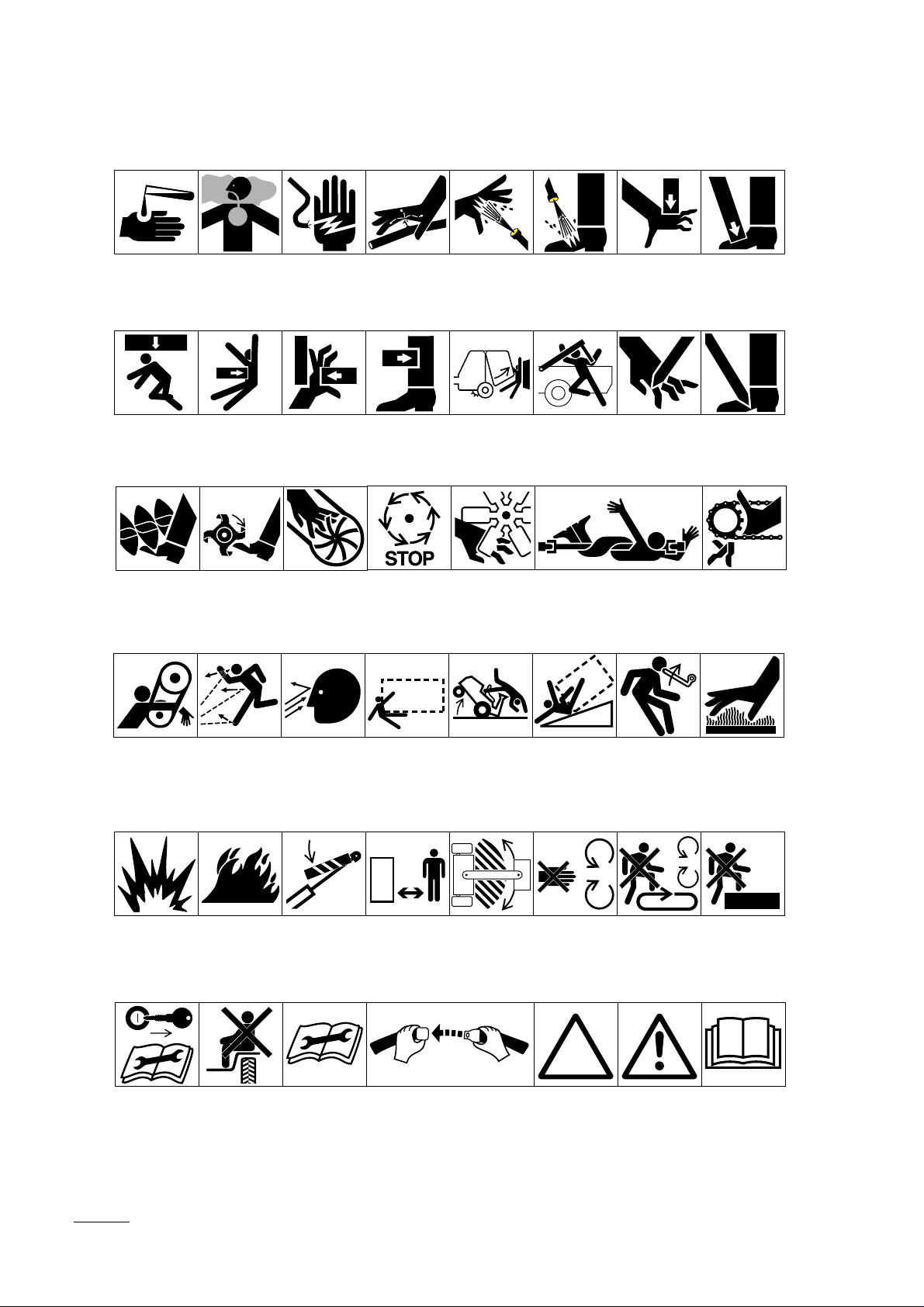

Symbol Glossary

Caustic liquids,

chemical burns to

fingers or hand

Crushing of

whole body,

applied from

above

Cutting or

entanglement of

foot, rotating auger

Poisonous

fumes or toxic

gases, asphyxiation

Crushing of

torso, force

applied from side

Severing of

foot, rotating

knives

Electrical shock,

electrocution

Crushing of fingers

or hand/, force

applied from side

Severing of

fingers or hand,

impeller blade

High pressure

fluid, injection

into body

force applied

from side

Wait until all

machine

components have

completely stopped

before touching them

High pressure

spray, erosion of

flesh

Crushing of

whole body

Severing of

fingers or hand,

engine fan

High pressure

spray, erosion of

flesh

Crushing of

head, torso and

arms

Whole body entanglement,

implement input drive line

Crushing of

fingers

or hand,

force

applied from

above

Cutting of

fingers or hand

Crushing of

toes or foot, force

applied from above

Cutting of footCrushing of leg,

Fingers or

hand entangle-

ment, chain drive

Hand & arm

entanglement,

belt drive

Explosion Fire or open

Shut off engine

& remove key before

performing mainten-

ance or repair work

Thrown or fly-

ing objects, whole

body exposure

flame

Riding on this

machine is allowed

only on a passen-

ger seat & only if the

driver’s view is not

hindered

Thrown or

flying objects,

face exposure

Secure lifting

cylinder with locking

device before getting

in hazardous area

Consult

technical manual

for proper service

procedures

Runover/back-

over, (relevant

machine to appear

in dashed box)

Stay a safe

distance from

the machine

Fasten seat belts Safety alert

Machine tipping,

riding mower

Stay clear of

articulation area

while engine is

running

Machine rollover,

ROPS (relevant

machine to appear

in dashed box)

Stored energy

hazard, kickback

or upward motion

Do not open

or remove safety

shields while

engine is

running

triangle

Do not step on

loading platform if

PTO is connected to tractor

& engine is running

outline safety

alert symbol

Hot surfaces,

burns to fingers

or hands

Do not step

Read operator’s

manual

6

Page 7

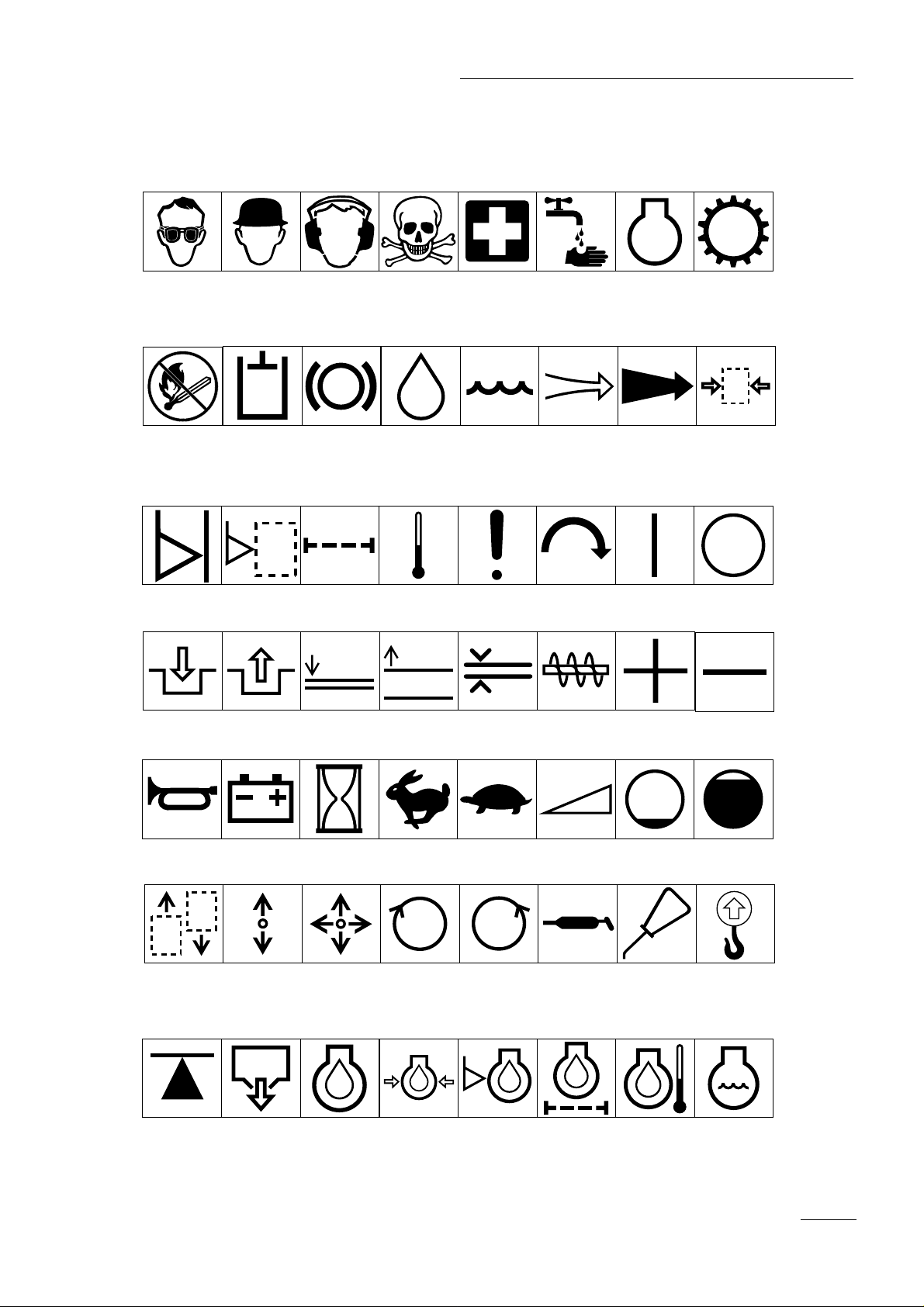

Safety

Eye protection

must be worn

Fire, open light

& smoking

prohibited

Level

indicator

Engage Disengage

Head protection

must be worn

Hydraulic

system

Liquid level Filter Temperature Failure/

Hearing

protection must

be worn

Brake system

Attachment

lower

Caution, toxic

risk

First aid

Oil Coolant (water) Intake air Exhaust gas Pressure

Malfunction

Attachment

raise

Spacing distance Snow thrower,

Flush with water Engine Transmission

Start switch/

mechanism

collector auger

On/start Off/stop

Plus/increase/

positive polarity

Minus/decrease/

negative polarity

Horn Battery charging

Machine travel

direction,

forward/rearward

Jack or

support point

condition

Control lever

operating

direction, dual

direction

Draining/

emptying

Hourmeter/elapsed

operating hours

Control lever

operating

direction, multiple

direction

Engine lubricating oil

Fast Slow Continuous

Clockwise

rotation

Engine lubricating

oil pressure

Counter-clockwise rotation

Engine lubricating

oil level

variable, linear

Grease

lubrication

point

Engine lubricating

oil filter

Volume empty Volume full

Oil lubrication

point

Engine

lubricating oil

temperature

Lift point

Engine coolant

7

Page 8

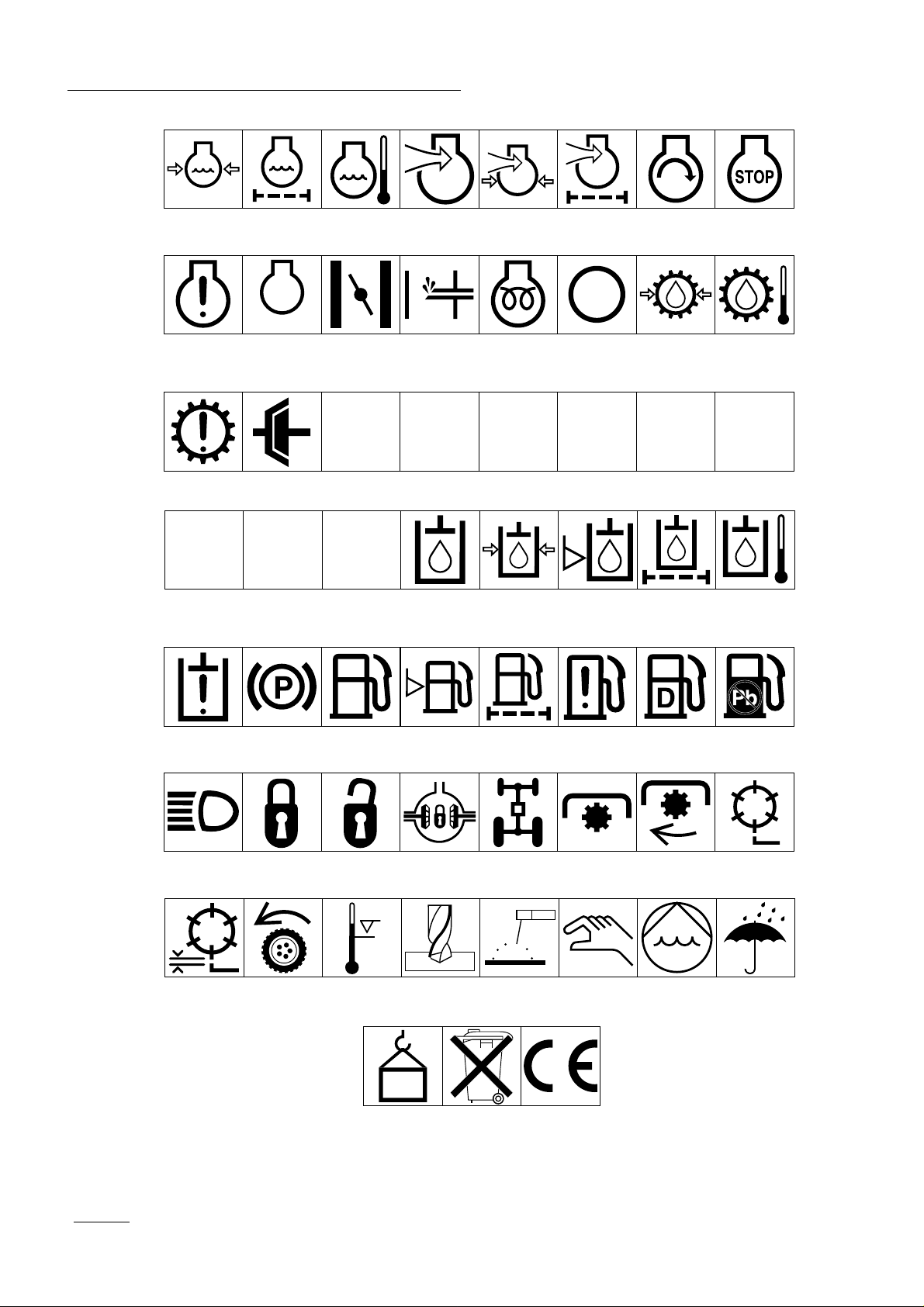

Safety

Engine coolant

pressure

Engine coolant f

ilter

n/min

Engine failure/

malfunction

Transmission

failure/malfunction

Engine rotational

speed/frequency

Clutch Neutral High Low Forward Reverse Park

231

First gear Second gear

Engine

lubricating oil

pressure

Choke Primer (start aid) Electrical preheat

Engine intake/

combustion air

Engine intake/

combustion air

pressure

(low temperature

start aid)

Engine intake/

air filter

Transmission oil Transmission oil

Engine start Engine stop

pressure

Transmission oil

temperature

NHLFRP

Third gear (other #'s

may be used until

the maximum # of forward gears is reached.)

Hydraulic oil Hydraulic oil

Hydraulic oil

pressure

Hydraulic oil level Hydraulic oil filter

temperature

Hydraulic oil

failure/malfunction

Headlights Lock Unlock Differential lock 4-Wheel drive Power Take-Off Power Take-Off,

Reel cutting

element, height

adjustment

Parking brake Fuel Fuel level Fuel filter Fuel system

Traction Above working

temperature range

Drilling Manual metal arc

0430 weight Do not dispose

welding

in the garbage

failure/malfunction

Manual 0356 Water pump

CE logo

Diesel fuel Unleaded fuel

rotational speed

Reel cutting

element

0626 Keep dry

8

Page 9

Specifications

Engine: Perkins, 4-cycle, 3-cylinder, liquid-cooled,

vertical overhead valve, diesel engine with centrifugal

water pump. 13.4 kW governed to a maximum speed

of 3200 rpm. 676 cc displacement. Forced lubrication

gear pump. Mechanical centrifugal governor.

Mechanical fuel transfer pump. Fuel filter/water separator with replaceable filter element. 12-volt (0.7 kW)

starter. Heavy-duty remote mounted air cleaner. Spinon oil

filter.

Radiator: Side-mounted radiator. Cooling system

capacity is 4.7 liters.

Electrical: 12-volt Group 55, 450 cold-cranking amps

at –18°, 75-minute reserve capacity at 27°C. 14-amp

alternator with regulator/rectifier. Seat switch, PTO

and traction interlock switches. Indicator light when

cutting units are running.

Fuel Capacity: 24.6 liters

Traction Drive: Three high-torque hydraulic wheel

motors. 3-wheel drive; two-position selector valve

located below the seat, push for 3-wheel drive and pull

for 2-wheel drive. Oil cooler and shuttle valve provide

positive closed-loop cooling.

Hydraulic Oil Capacity/Filter: Remote mounted, 8.7

liter oil reservoir. 25-micron remote-mounted spin-on

the filter.

Ground Speed: Infinitely variable speed selection in

forward and reverse

Mowing speed: 0–8 km/h

Transport speed: 0–13 km/h

Reverse speed: 0–3 km/h

Tires/Wheels: Two front traction tires, 20 x 10-8,

tubeless, 4-ply rating. Rear steering tire and tube: 20 x

8-8, 2-ply rating. Demountable front rims.

Recommended tire pressure 97–138 kPa front tires and

55–69 kPa rear tire.

teristics of the hydrostat. Parking or emergency brake

is actuated by a ratchet hand lever on the operator’s

left-hand side.

Controls: Foot-operated traction pedal and traction

pedal stop. Hand-operated throttle, ignition switch,

reel engagement switch, cold start button reel unit lift

lever, parking brake and seat adjustment, 2-position

selector valve for 2- or 3-wheel drive selection.

Gauges and Protective Systems: Hour meter, temperature gauge, 4-light warning cluster gauge: oil pressure, water temperature amps and glow plug. High

water temperature shutdown. Electric traction pump

declutching switch for cold start. Engine preheat

incorporated into the ignition switch.

Seat: Adjustable to operator weight, fore and aft, with

removable fold-up armrests.

Cutting Unit Lift: Hydraulic lift with an automatic

reel shut off.

Overall Dimensions:

Wheel tread width: 138

cm

Wheel base: 140

cm

Width: 194

cm

Length: 249

cm

Height: 112

cm

Weight: 562 kg with 5-blade cutting

unit

569 kg with 8-blade cutting

unit

Frame: The frame consists of formed steel, welded

steel and steel tubing components. Tricycle vehicle

with 3-wheel traction drive and rear wheel steering.

Steering: Pinion and sector gear with solid drag link

to rear steer wheel arm.

Brakes: Service braking through the dynamic charac-

9

Page 10

Before Operating

CAUTION

Before servicing or making adjustments to the

machine, stop the engine and remove the key

from the switch.

IMPORTANT Check the oil level every 5 operating

hours or daily. Change the oil after every 50 hours

of operation.

Fill The Fuel T ank

Check The Crankcase Oil

(Fig 1 & 2)

The engine is shipped with oil in the crankcase; however, you must check the oil level before and after you

first start the engine.

1. Position the machine on a level surface.

2. Remove the dipstick and wipe it with a clean

cloth. Push the dipstick down into the dipstick

tube and make sure it is seated fully. Pull out the

dipstick and check the oil level.

3. If the oil level is low, remove the oil fill cap (Fig

2) and gradually add small quantities of oil,

checking the level frequently, until the level

reaches the FULL mark on the dipstick.

4. The engine uses any high-quality 10W30 deter-

gent oil having the American Petroleum

Institute—API—service classification CD.

The engine runs on No. 2 diesel fuel. Fuel tank

capacity is 24.6 liters.

DANGER

Because diesel fuel is flammable, use caution when

storing or handling lt.

• Do not smoke while filling the fuel tank.

• Do not fill the fuel tank while the engine is

running, hot, or when the machine is in an

enclosed area.

• Always fill the fuel tank outside and wipe up

any spilled diesel fuel before starting the

engine.

• Store fuel in a clean, safety-approved container

and keep the cap in place. Use diesel fuel for

the engine only; not for any other purpose.

1. Clean the area around the fuel tank cap.

1. Dipstick

1. Oil fill cap

Figure 1

Figure 2

2. Remove the fuel tank cap.

Figure 3

1. Fuel tank cap

3. Fill the tank to about 2.5 cm below the top of the

tank (bottom of the filler neck). DO NOT

OVERFILL. Then install the cap.

10

Page 11

Before Operating

4. To prevent a fire hazard, wipe up any fuel that

may have spilled.

Check the Cooling System

Clean debris off the radiator screen, radiator and oil

cooler daily (Fig. 4), or hourly if conditions are

extremely dusty and dirt.

The cooling system is filled with a 50/50 solution of

water and permanent ethylene glycol anti-freeze.

Check the level of coolant at the beginning of each

day before you start the engine. Capacity of the cooling system is 5.0 liters.

WARNING

If the engine has been running, pressurized hot

coolant can escape when the radiator cap is

removed and cause burns.

1. Carefully remove the cap from the radiator.

2. Check the level of coolant in the radiator. The

radiator should be filled to the top of the filler

neck.

3. If the coolant level is low, replenish the system.

DO NOT OVERFILL.

4. Install the radiator cap.

Check The Hydraulic System Fluid

The hydraulic system is designed to operate on antiwear hydraulic fluid. The machine’s system is filled at

the factory with approximately 12.5 liters of fluid.

However, check the level of hydraulic fluid before you

first start the engine and daily thereafter.

Group 1—Hydraulic Fluid (Recommended for

ambient temperatures consistently below 37° C.)

1. Radiator screen

2. Radiator

3. Oil cooler

Figure 4

ISO-type 46/68 anti-wear hydraulic fluid

Mobil Mobil Fluid 424

Shell Donax TD

Amoco Amoco 1000

Conoco Power Tran 3

International Harvester Hy-Tran

Texaco TDH

Exxon Torque Fluid

Kendall Hyken 052

BP Oil BP HYD TF

Boron Oil Eldoran UTH

Phillips HG Fluid

Union Oil Hydraulic/Tractor

Fluid

Chevron Tractor Hydraulic

Fluid

Note: All are interchangeable.Group 2—Hydraulic

Fluid (Biodegradable):

ISO VG 32/46 anti-wear hydraulic fluid

1. Radiator cap

Mobil EAL 224 H

IMPORTANT: Due to the nature of biodegradable

fluids, it is critical that the fluid be changed at the

recommended intervals or severe hydraulic component damage may occur.

Figure 5

Note: The fluid in Group 2 is not compatible with the

11

Page 12

Before Operating

fluids in Group 1.

IMPORTANT: These hydraulic fluids are specified

to allow optimal operation of the machine in a wide

range of temperatures. The group 1 fluids are

multi-viscosity hydraulic fluids that allow operation

at lower temperatures without the increased viscosity associated with straight viscosity fluids.

Note: When changing from one type of hydraulic fluid

to the other, be certain you remove all the old fluid

from the system because some brands of one type are

not completely compatible with some brands of the

other type of hydraulic fluid.

IMPORTANT:Use only the types of hydraulic fluids specified. Other fluids could cause system damage.

Note: A red dye additive for the hydraulic system oil

is available in 20 ml bottles. One bottle is sufficient

for 15–23 liters of hydraulic oil. Order Part No. 442500 from your authorized Toro distributor.

1. Position the machine on a level surface.

IMPORTANT To prevent system contamination, clean the top of the hydraulic oil containers before puncturing. Make sure the pour

spout and funnel are clean.

4. Install the reservoir cap. Wipe up any oil that

may have spilled.

Inspect the Fuel Filter

Inspect the fuel filter bowl daily for water or other

contaminants. If water or other contaminants are present, they must be removed before operation.

1. Close the fuel shut-off above the filter.

2. Unscrew the nut securing the bowl to the filter

head. Remove water or other contaminants from

the bowl.

3. Inspect the fuel filter and replace it if it is dirty.

4. Install the bowl to the filter head. Make sure to

position the O-ring correctly between the bowl

mounting nut and the filter head.

2. Make sure the machine has been operated so the

oil is warm. Check the oil level oil by looking in

the sight gauge. If the oil level is at the center of

the gauge, it is sufficient.

3. If the oil level is not at the center of the gauge,

remove the cap from the hydraulic oil reservoir

and slowly fill the reservoir with Mobil 424 or

equivalent hydraulic oil until the level reaches the

center of the sight gauge. DO NOT OVERFILL.

1. Fuel filter

Figure 7

5. Open the fuel shut-off above the filter to re-fill

with fuel. Close the bleed screw.

6. Open the bleed screw on the filter mounting,

allowing the bowl to re-fill with fuel. Close the

bleed screw.

1. Hydraulic reservoir cap

2. Sight Gauge

12

Figure 6

Page 13

DANGER

Because diesel fuel is flammable, use caution

when storing or handling lt.

• Do not smoke while filling the fuel tank.

• Do not fill the fuel tank while the engine

is running, hot, or when the machine is in

an enclosed area.

• Always fill the fuel tank outside and wipe

up any spilled diesel fuel before starting

the engine.

• Store fuel in a clean, safety-approved container and keep the cap in place. Use

diesel fuel for the engine only; not for any

other purpose.

Before Operating

Check Tire Pressure

The tires are over-inflated for shipping. Therefore,

release some of the air to reduce the pressure. Correct

air pressure in the front tires is 83–110 kPa and the

rear tire is 55–68 kPa.

IMPORTANT: Maintain even pressure in all tires

to assure a good quality of cut and proper machine

performance. DO NOT UNDERINFLATE.

Check Reel-to-Bedknife Contact.

Each day before operating, check the reel-to-bedknife

contact, regardless of whether quality of cut had previously been acceptable. There much be light contact

across the full length of the reel and bedknife.

Check The Torque of the Wheel

Nuts

WARNING

Torque the wheel nuts to 61–88 Nm after 1–4

hours of operation and again after 10 hours of

operation and every 200 hours thereafter.

Failure to maintain proper torque could result in

failure or loss of the wheel and may result in

personal injury.

13

Page 14

Contr ols

Traction and Stopping Pedal (Fig. 8, 9, & 10)—The

traction pedal has three functions: one, to make the

machine move forward; two, to move it backward; and

three, to stop it. Using the heel and toe of your right

foot, depress the top of the pedal to move forward and

bottom of the pedal to move backward or to assist in

stopping when moving forward. Also, move the pedal

to the neutral position to stop the machine. For your

comfort, do not rest the heel of your foot on reverse

when operating forward.

Figure 9

Throttle (Figure 11)—Moving the throttle upward

increases engine speed; downward decreases engine

speed.

1. Traction pedal

Figure 8

2. Speed selector

3. Pedal stop

Speed Selector (Fig. 8)—The cam lever at the side of

the traction pedal can be rotated to maintain the

desired speed.

The reverse pedal stop (under the pedal) is set at the

factory to provide 4.8 kmh (3 mph) maximum speed in

reverse.

Ignition Switch—The ignition switch, which is used

to start, stop and preheat the engine, has four positions: OFF, ON, START and GLOW PLUGS (PREHEAT).

To start the engine, turn the key counterclockwise—

GLOW PLUG position—and hold it there for 20 to 30

seconds, then, turn the key clockwise to the START

position to engage the starter motor. Release the key

when the engine starts. The key will move automatically to ON. To shut off the engine, turn the key counterclockwise to OFF. Remove the key from the switch

and install the switch cover to prevent accidental starting.

Cutting Unit Lift Lever (Figures 11)—The lift lever

has three positions: LOWER, RAISE, and NEUTRAL.

To lower the cutting units to the ground, move the lift

lever forward.

When lowering the cutting units, make sure the

hydraulic cylinder is completely retracted before

releasing the lift lever. The cutting units won’t operate

unless the cylinder is retracted.

To raise the cutting units, pull the lift lever rearward to

the RAISE position.

Cutting Unit Drive Switch (Figures 11) —The switch

has two positions: ENGAGE and DISENGAGE. An

amber light on the dash indicates when the reels are

turning. Pull the switch lever out to move from disengage to engage.

Hour Meter (Figures 11)—Indicates the total hours of

machine operation. The hour meter starts whenever

the key switch is turned to “ON.”

Temperature Gauge (Fig. 10)—Registers coolant

temperature in the system.

Oil Pressure Light (Fig. 10)—Glows if the engine oil

pressure drops below a safe level.

WaterTemperature Light (Figure 10)—This light

glows and the engine automatically shuts-down if the

14

Page 15

engine coolant temperature gets too high.

Controls

1. Starter switch & cover

Figure 10

2. Throttle

3. Cutting unit lift lever

4. Cutting unit drive switch

S. Hour meter

6. Water temperature gauge

7. Oil pressure light

8. Amp gauge

9. Glow plug indicator

10. High water temperature shut-down light

11. Reel operating light

12. Cold-start button

1. Deck engagement control Pull out—Two-wheel drive

Figure 11

Push in—Three-wheel drive

Reel Speed Control (Fig. 12)—For the desired reel

speed, turn the reel speed control knob to the appropriate setting for height-of-cut setting and mower

speed. Refer to Selecting the Clip Rate section of this

manual.

Backlap Control (Fig. 12)—Turn the knob clockwise

0for backlapping and counterclockwise for mowing

Amp Light (Fig. 10)—The amp light should be off

when the engine is running. If it is on, the charging

system should be checked and repaired as necessary.

Glow Plug Indicator (Fig. 10)—This indicator light

will glow when the glow plugs are operating.

Cold Start Button (Fig. 10)—When starting a cold

engine, press the cold start button to electrically declutch the traction pump. When the engine starts,

release the button.

Parking Brake— Whenever the engine is shut off,

the parking brake must be engaged to prevent accidental movement of the machine. To engage the parking

brake, pull back on the lever.

Drive Engagement Control (Fig 11)—Located on the

lower left side of the operator. Pull the knob out for

2-wheel drive; push the knob in for 3-wheel drive.

1. Reel speed control

Fig. 12

2. Backlap control

Seat Adjustments (Fig. 13)

Fore and Aft Adjustment—Move the lever on the side

of the seat outward, slide the seat to the desired position and release the lever to lock the seat into position.

Deluxe Seat Adjustments (Fig. 13)

Weight Adjustment—Push the lever up or down to

adjust to the operator’s weight. Lever up—light operator, lever in middle position—medium weight operator or lever down for heavy operator.

Inclining Backrest—Turn the handle to adjust the

backrest angle. (Deluxe Seat only).

15

Page 16

Controls

1. Fore and aft lever

Figure 13

2. Weight adjustment lever

3. Inclining backrest

Fuel Shut-off Valves, (Fig. 14 & 15)—Close the fuel

shutoff valves under the fuel tank and on the fuel filter

when storing the machine.

1. Fuel shut off (on the fuel filter)

Figure 15

1. Fuel shut off (under the fuel tank)

Figure 14

16

Page 17

Operating Instructions

Starting/Stopping The Engine

IMPORTANT: The fuel system may have to be

bled if any of the following situations have

occurred:

• Initial start up of a new engine.

• The engine has ceased running due to lack of

fuel.

• Maintenance has been done on fuel system

components; i.e., the filter replaced, etc.

Refer to Bleeding The fuel System

1. Be sure the parking brake is set and the reel drive

switch is in DISENGAGE.

2. Remove your foot from the traction pedal and

make sure the pedal is in the neutral position.

3. Move the throttle lever to the full throttle position.

be sure all parts operate correctly.

Turn the steering wheel to the left and right to

check steering response. Then shut the engine off

and check for oil leaks, loose parts and any other

noticeable malfunctions.

CAUTION

Shut off the engine and wit for all moving

parts to stop before checking for oil leaks,

loose parts and other malfunctions.

7. To stop the engine, move the throttle control

downward to IDLE, move the reel drive switch to

DISENGAGE and turn the ignition key to OFF.

Remove the key from the switch and install the

switch cover to prevent accidental starting.

8. Close the fuel shut-off valves before storing the

machine.

Bleeding The Fuel System

4. Remove the cover from the ignition switch.

Insert the key and turn it counterclockwise to the

GLOW PLUG position—and hold it there for

approximately 20 to 30 seconds. Then, turn the

key clockwise to START to engage the starter

motor. Release the key when the engine starts.

The key will move automatically to ON.

IMPORTANT To prevent overheating the

starter motor, do not engage the starter longer

than 10 seconds. After 10 seconds of continuous cranking, wait 60 seconds before engaging

the starter motor again.

5. For cold-weather starting, press the cold-start but-

ton to declutch the electric traction pump. When

the engine starts, release the button.

6. When starting the engine for the first time, or

after an engine overhaul, operate the machine in

forward and reverse for one to two minutes. Also

operate the lift lever and the reel drive switch to

1. Park the machine on a level surface. Make sure

the fuel tank is at least half full.

DANGER

Because diesel fuel is flammable, use caution

when storing or handling lt.

• Do not smoke while filling the fuel tank.

• Do not fill the fuel tank while the engine

is running, hot, or when the machine is in

an enclosed area.

• Always fill the fuel tank outside and wipe

up any spilled diesel fuel before starting

the engine.

• Store fuel in a clean, safety-approved container and keep the cap in place. Use

diesel fuel for the engine only; not for any

other purpose.

2. Unlatch and raise the hood.

17

Page 18

Operating

3. Open the fuel shut-off valve under the fuel tank

and on the fuel filter.

4. Open the (2) bleed screws on the side of the fuel

filter mounting head, allowing the bowl to re-fill

with fuel. Close bleed screws when the bowl is

filled.

1. Fuel shutoff

Figure 16

2. Bleed screws (2)

3. Bowl

5. On the left side of the engine (below the alterna-

tor) find the transfer pump inlet screw. Note the

angle of the fitting on the transfer pump inlet and

loosen the screw (left screw only).

6. When a steady stream of fuel flows out of the

transfer pump screw, tighten the screw, retaining

the angle of fitting before it was loosened.

7. Loosen the injection pump inlet screw on the

right side of the engine.

8. Pump the priming lever until a steady stream of

fuel flows out of the injection pump inlet screw,

then tighten the screw.

1. Transfer pump screw

Figure 17

2. Injection pump Inlet screw location

3. Injection pump inlet screw

4. Priming lever

5. Note fitting angle

Check The Interlock Switch

Operation

CAUTION

Do not disconnect the safety switches because they

are for the operator’s protection. Check the safety

switch operation dally to be sure the system operates

correctly. If a switch is not operating correctly,

replace it before operating the machine. Replace the

switches every two years to be sure of maximum

safety.

1. Be sure the parking brake is set and all bystanders

are away from the area of operation. Keep your

hands and feet away from the cutting units.

18

2. With the operator off the seat, the backlap knob

turned counterclockwise, the traction pedal in

neutral and the reel switch switch in the OFF

position, the engine should start. If either the

traction pedal is depressed or the reel switch is

turned ON with the operator off the seat, the

engine should stop. Correct the problem if the

safety switches are not operating correctly.

3. With the engine running, the operator off the seat

and the backlap knob turned clockwise, the

engine should not stop when the reel switch is

turned ON. Correct the problem if the safety

Page 19

Operating

switches are not operating correctly.

4. With the operator on the seat, the engine running,

and the reel switch in the ON position, the dash

indicator light should be glowing and the reel

motors turning when the lift cylinder is fully

retracted. As the lift cylinder is extended, the

light should go out and the reel motors should

stop turning. Correct the problem if the system is

not operating correctly.

5. With the operator on the sea, the engine must not

start with either reel switch engaged or the traction control engaged. Correct the problem if the

system is not operating correctly.

Towing the Traction Unit

In case of emergency, the Reelmaster 2300-D can be

towed for a short distance. However, Toro does not

recommend this as a standard procedure.

IMPORTANT Do not tow the machine faster than

3–4.8 kmh because the drive system may be damaged. If the machine must be moved a considerable distance, transport it on a truck or trailer.

nance machines. Points to consider when operating

are the traction drive, engine speed and the load on the

cutting units. Regulate the traction pedal to keep the

engine rpm high and somewhat constant while mowing to maintain adequate power for the traction and

cutting units. Adjust the speed selector to maintain

constant ground speed and quality of cut. However,

when on hilly terrain, do not use the speed selector.

Follow the operating guidelines in this manual and

know how to operate the machine safely on all types

of terrain. Never traverse or mow up and down on

slopes over 20 degrees, nor traverse or mow side hills

in excess of 15 degrees. Always plan well ahead to

avoid the need for sudden stops, starts or turns. To

stop, use the reverse pedal for braking. Before stopping the engine, disengage all controls, move the

throttle to IDLE, and set the parking brake.

Selecting Clip Rate (Reel Speed)

To achieve a consistent, high-quality cut and a uniform after-cut appearance, the reel speed must be

matched to the height of cut.

1. Turn the by-pass valve on pump 90°.

Figure 18

1. Hose plug

2. Before starting the engine, close the by-pass

valve securely by rotating it 90°. Do not start the

engine when the valve is open.

Operating Characteristics

Practice operating the Reelmaster and become thoroughly familiar with it. Because of its hydrostatic

transmission and choices of either two or three wheel

drive, its characteristics differ from many turf mainte-

1. Reel speed control

Figure 19

Adjust the clip rate (reel speed) as follows:

1. Verify the height-of-cut setting on the cutting

units. Using the column of the chart listing either

5- or 8-blade reels, find the height-of-cut listing

nearest the actual height-of-cut setting. Look

across the chart to find the number corresponding

to that height of cut.

2. Turn the reel speed control knob to the number

setting you found in step 1.

3. Operate the machine for several days, then exam-

19

Page 20

Operating

ine the cut to ensure you are satisfied with the quality of cut. The reel speed knob may be set one

position of either side of the position on the chart to

account for differences in grass condition, grass

length removed, and your personal preferences.

Training Period

Before mowing with the Reelmaster, The Toro Company

suggests you find a clear area and practice starting and

stopping, raising and lowering the cutting units, turning,

etc. This training period will help the operator gain confidence in the performance of the Reelmaster.

Before Mowing

Inspect the area for debris and clear it if necessary.

Determine the direction best to mow on the previous

mowing direction. Always mow in an alternate pattern

from the previous mowing, so that the grass blades will

be less apt to lay down and therefore be difficult to gather between the reel blades and bedknife.

Transport Operation

Be sure the cutting units are in the fully up position,

move the traction pedal stop from under the pedal to

allow full traction pedal travel and place the throttle

control FAST. While operating on slopes and uneven

terrain, always reduce speed and use extreme caution

before turning to reduce risk of tipping or losing control.

Watch carefully for, and avoid, holes in the terrain, sudden drop-off s and other hidden hazards. To prevent

costly damage and downtime, familiarize yourself with

the width of the Reelmaster. Do not attempt to pass

between immovable objects placed close together.

Inspection And Clean-Up After

Mowing

After mowing, thoroughly wash the machine with a garden hose—without a nozzle so excessive water pressure

will not cause contamination and damage to seals and

bearings.

Height of Cut (cm)

6.4

6.0

5.7

5.4

5.1

4.8

4.5

4.1

3.8

3.5

3.2

2.9

2.5

2.2

1.9

1.6

1.3

1.0

5-Blade Reel

Reel Speeds Reel Speeds

3-Wheel Drive

5–8 kmh

3

3

4

4

4

4

5

5

6

6

7

7

8

9

Selecting Reel Speed

2-Wheel Drive

10–11 kmh

5

5

5

5

6

6

7

7

8-Blade Reel

3-Wheel Drive

5–8 kmh

3

3

3

4

4

4

5

5

6

7

9

9

9

2-Wheel Drive

10–11 kmh

3

3

3

3

3

4

4

4

5

5

6

7

9

20

Page 21

Make sure the radiator screen, radiator and the oil

cooler(diesel models) and cooling fins and area around

the engine cooling air intake (gasoline models) are

kept free of dirt or grass clippings. After cleaning, it

is recommended

– the machine be inspected for possible hydraulic

fluid leaks, damage or wear to the hydraulic and

mechanical components

– the cutting units be checked for sharpness and cor-

rect reel-to-bedknife adjustment.

Operating

21

Page 22

Maintenance

Minimum Recommended Maintenance Intervals

Inspect the air filter, dust

cap and burp valve

Lube all grease fittings

✝Change engine oil

✝Check engine belt tension

✝Change the engine oil filter

✝Check the traction belt’s tension

Service the air filter

Replace the fuel filter

✝Replace the hydraulic filter

✝Torque the wheel lug nuts

Replace hydraulic fluid

Check battery level and connections

Inspect the traction linkage movement

✝✝Torque the head bolts and adjust the valves

✝✝Check the engine RPM (idle and full throttle)

✝Initial break in at 10 hours

✝✝Initial break in at 50 hours

Every 50

hours

Every 100

hours

Every

200 hours

Every

400 hours

Replace moving hoses

Replace safety switches

Flush cooling the cooling system and replace hoses

Replace the thermostat

Drain and flush the fuel tank

Drain and flush the hydraulic tank

Annual Recommendations:

Items are recommended every 1000 hours or

two years, whichever occurs first.

22

Page 23

Quick Reference Aid

1. Engine oil level

2. Engine oil drain (17mm socket)

3. Hydraulic oil level—Center of sight glass

4. Belts (Fan/water pump, hydraulic pump)

5. Coolant level fill

6. Fuel—Diesel only

7. Grease points

8. Radiator screen

9. Air cleaner

10. Water separator/fuel filter

11. Battery

12. Tire pressure:

(.8–1.1 bar) front

(.6–.7 bar) rear

13. Fuses

GREASING BEARINGS AND BUSHINGS

(Fig. 20–26)

The traction unit and cutting unit’s grease fittings must

be lubricated regularly with No. 2 General Purpose

Lithium Base Grease. If the machine is operated under

normal conditions, lubricate bearings and bushings after

every 50 hours of operation. Bearings and bushings

must be lubricated daily when operating conditions are

extremely dusty and dirty. Dusty and dirty operating

conditions could cause dirt to get into the bearings and

bushings, resulting in accelerated wear.

Engine oil

Hyd. circuit oil

Fuel filter

Air cleaner

Fuel

Coolant

Fluid

Type

SAE

10W30 CD

Mobil 424 12.5 l 400 hours 200 hours 54-0110

No. 2

Diesel

50/50

Ethylene gly-

col water

Capacity

3.0 l 50 hours 100 hours 85-4930

Clean every 50 hours 200 hours 93-2195

24.5 l

4.7 l

Change

Fluid

Change

Filter

200 hours

Drain and flush, 2 years

Filter

Part No.

Perkins

130366040

The traction unit bearings and bushings that must be

lubricated are:

Steering column (Fig. 20), steering gears (2) (Under

skirt below steering sector), steering shaft (2) (Fig. 21),

lift arms (3) (Fig. 22), rear lift cylinder pivot (Fig.24),

traction pedal pivot (Fig 25).

Also, apply grease to slots in cylinder support (Fig. 26).

Figure 20

23

Page 24

Maintenance

Figure 21

Figure 24

Figure 22

Figure 23

Figure 25

Figure 26

24

Page 25

CAUTION

Before servicing or making adjustments to the

machine, stop the engine and remove the key

from the switch.

Hood Removal

The hood may be easily removed to ease maintenance

in the engine area.

1. Unlatch and raise the hood.

2. Remove the cotter pin securing the hood pivot to

the mounting brackets.

3. Slide the hood to the right side, lift the other side

and pull the hood out of the brackets.

Maintenance

Figure 28

1. Dust Cup & Baffle

2. Filter Element

3. Air Cleaner Body

4. Reverse the procedure to install the hood.

Figure 27

1. Cotter pin

Servicing The Air Cleaner

Service the air cleaner filter every 400 hours, or more

frequently in extremely dusty or dirty conditions, by

washing or using compressed air.

1. Release the latches that secure the air cleaner

cover to the air cleaner body. Separate the cover

from the body. Clean inside the air cleaner cover.

2. Gently slide the filter out of the air cleaner body

to reduce the amount of dust dislodged. Avoid

knocking the filter against the air cleaner’s body.

3. Inspect the filter and discard it if it is damaged.

Do not was or reuse a damaged filter.

Washing Method

1. Prepare a solution of filter cleaner and water and

soak the filter element about 15 minutes.

2. After soaking the filter for 15 minutes, rinse it

with clear water.

3. Dry the filter element using warm, flowing air no

hotter than 71° C, or allow the element to air dry.

Do not use compressed air or a light bulb to dry

the filter element because they may damage it.

Compressed Air Method

1. Blow compressed air from inside to the the out-

side of the dry filter element. Do not exceed 689

kPa (100 psi) to prevent damage to the filter.

2. Keep the air hose nozzle at least 3 cm from the

pleated paper, and move the nozzle up and down

while rotating the filter element.

3. Inspect for holes and tears by looking through the

filter toward a bright light.

25

Page 26

Maintenance

Installing A New Air Filter

1. Inspect the new filter for shipping damage.

Check the sealing end of the filter. Do not install

a damaged filter.

2. Insert the new filter into the air cleaner body.

Make sure the filter is sealed properly by applying pressure to the outer rim of the filter when

installing. Do not press on the flexible center of

the filter.

3. Install the cover and secure the latches. Make

sure the cover is positioned with the TOP side up.

Changing The Engine Oil And

Filter

Change the oil and the oil filter initially after the first

20 hours of operation, thereafter change the oil every

50 hours and the oil filter every 100 hours.

1. Reservoir plug

Figure 29

2. Reservoir outlet

This will retain most of the fluid in the reservoir

when the filter is removed.

3. Clean the area around the hydraulic oil filter.

Remove the filter from the bottom of the filter

housing and allow the oil to flow into a drain pan.

Use a bottom type filter wrench.

1. Locate the engine the oil drain plug on the bottom

of the oil pan.. Remove the drain plug and let the

oil flow into the drain pan. When the oil stops,

install the drain plug.

2. Locate the engine filter on the front of the engine.

Remove the oil filter. Apply a light coat of clean

oil to the new filter seal before screwing it on.

DO NOT OVER-TIGHTEN.

3. Add oil to the crankcase.

Changing the Hydraulic System

Fluid And Filter

The hydraulic system filter must be changed after the

first five hours of operation, and after that, every 250

hours of operation or yearly, whichever comes first.

Use a genuine Toro oil filter for replacement. The

hydraulic fluid must be changed every 500 hours of

operation or yearly, whichever comes first.

1. Park the machine on a level surface, lower the

cutting units, set the parking brake and turn the

engine off.

2. If only the filter is to be changed, remove the

reservoir cap and insert the reservoir plug (Fig.

30), to the block outlet.

1. Hydraulic oil filter

Figure 30

4. Apply a film of oil on the filter gasket. Install the

filter by hand until gasket contacts mounting

head; then tighten the filter an additional threefourths of a turn.

5. Fill the reservoir to the correct level.

6. Place all controls in the neutral or disengaged

position and start the engine. Run the engine at

the lowest possible rpm to purge the system of

air.

7. Run the engine until the lift cylinder extends and

retracts and forward and reverse wheel motion is

achieved.

8. Stop the engine and check the oil level in the

26

Page 27

Maintenance

reservoir; add oil if necessary.

9. Check all connections for leaks.

Backlapping

DANGER

TO AVOID PERSONAL INJURY OR DEATH:

• Never place your hands or feet in the reel area

while the engine is running.

• While backlapping, reels may stall and then

restart.

• Do not attempt to restart reels by hand or foot.

• Do not adjust reels while the engine is running.

• If the reel stalls, stop the engine before trying

to clear the reel.

1. Position the machine on a clean, level surface,

lower the cutting units, stop the engine, engage

parking brake and remove key from ignition

switch.

panel

6. Apply lapping compound with long handled

brush supplied with machine.

CAUTION

Be careful when lapping the reel because contact with the reel or other moving parts can

result in personal injury.

7. To make an adjustment to the cutting units while

backlapping, turn reels OFF by pushing in on

knob on instrument panel and turning engine

OFF. After adjustments have been completed,

repeat steps 4-6.

8. When backlap operation is completed, rotate

backlap knob clockwise to MOW position, set

reel speed controls to desired mowing setting and

wash ail lapping compound off cutting units.

NOTE: Additional instructions and procedures

on Backlapping are available in the TORO

Sharpening Reel & Rotary Mowers Manual Form

No. 80-300PT.

2. Unlatch and raise the hood to expose controls.

3. Turn backlap knob, on valve block, clockwise to

backlap position. Turn the reel speed knob to

position 1.

Figure 31

1. Reel speed knob

2. Backlap knob

4. Make initial reel to bedknife adjustments appro-

priate for backlapping on all cutting units Start

engine and set engine to low idle speed.

NOTE: For a better cutting edge, run a file

across the front face of the bedknife when the

lapping operation is completed. This will remove

any burrs or rough edges that may have built up

on the cutting edge.

MODEL AND SERIAL NUMBER

The mower has two identification numbers: a model

number and a serial number. The two numbers are

stamped into a plate that is riveted to the frame at the

rear of the mower. In any correspondence concerning

the mower, supply the model and serial numbers to

assure that correct information and replacement parts

are obtained.

NOTE: Do not order by reference number if a parts

catalog is being used; use the part number.

To order replacement parts from an Authorized TORO

Service Dealer, supply the following information:

1. Model and serial numbers of the mower.

5. Engage reels by pulling out knob on instrument

2. Part number, description and quantity of part(s)

desired.

27

Page 28

15° and 20° Slope Chart

Align this edge with a vertical surface such as a tree, building, pole, etc.

Example: Compare

the slop with the

folded edge.

This is a 15° Slope

This is a 20°Slope

Fold along the appropriate line

28

Page 29

Loading...

Loading...