Toro 03200 Reelmaster 3100-D, 03201 Reelmaster 3100-D, 03200, 03220, 03221 Operator's Manual

...Page 1

Reelmaster 3100–D

Traction Unit

Model No. 03200—240000001 and Up

Model No. 03201—240000001 and Up

Model No. 03220

Model No. 03221

Form No. 3350–555

Operator’s Manual

English (EN, GB)

Page 2

Warning

CALIFORNIA

Proposition 65 Warning

Diesel engine exhaust and some of its constituents

are known to the State of California to cause

cancer, birth defects, and other reproductive harm.

Important The engine in this product is not equipped

with a spark arrester muffler. It is a violation of California

Public Resource Code Section 4442 to use or operate this

engine on any forest-covered, brush-covered, or

grass-covered land as defined in CPRC 4126. Other states

or federal areas may have similar laws.

Contents

Page

Introduction 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Toro Riding Mower Safety 5. . . . . . . . . . . . . . . . . . .

Sound Pressure Level 7. . . . . . . . . . . . . . . . . . . . . . .

Sound Power Level 7. . . . . . . . . . . . . . . . . . . . . . . .

Vibration Level 7. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 7. . . . . . . . . . . . . . . . .

Specifications 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 11. . . . . . . . . . . . . . . . . . . . .

Optional Equipment 11. . . . . . . . . . . . . . . . . . . . . . . .

Setup 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts Chart 12. . . . . . . . . . . . . . . . . . . . . . . . . .

Install Wheels 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Steering Wheel 13. . . . . . . . . . . . . . . . . . . . . .

Activate, Charge and Connect Battery 13. . . . . . . . .

Install Seat 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Angle Indicator 15. . . . . . . . . . . . . . . . . . . . . .

Install Hood Latch

(European Compliance) 15. . . . . . . . . . . . . . . . . . .

Install Exhaust Guard

(European Compliance) 16. . . . . . . . . . . . . . . . . . .

Install ROPS 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Front Lift Arms 16. . . . . . . . . . . . . . . . . . . . . .

Mount Carrier Frames To Cutting Units 17. . . . . . . .

Mount Cutting Units 18. . . . . . . . . . . . . . . . . . . . . . .

Mount Cutting Unit Drive Motors 19. . . . . . . . . . . . .

Adjust Lift Arms 19. . . . . . . . . . . . . . . . . . . . . . . . . .

Before Operating 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Crankcase Oil 21. . . . . . . . . . . . . . . . . . . . . . .

Page

Fill Fuel Tank 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Cooling System 22. . . . . . . . . . . . . . . . . . . . . .

Check Hydraulic System Fluid 22. . . . . . . . . . . . . . .

Check Tire Pressure 23. . . . . . . . . . . . . . . . . . . . . . . .

Check Reel To Bedknife Contact 24. . . . . . . . . . . . . .

Check Torque Of Wheel Nuts 24. . . . . . . . . . . . . . . .

Controls 24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting/Stopping Engine 26. . . . . . . . . . . . . . . . . . . .

Bleeding Fuel System 27. . . . . . . . . . . . . . . . . . . . . .

Check Operation Of Interlock Switches 27. . . . . . . .

Towing Traction Unit 27. . . . . . . . . . . . . . . . . . . . . . .

Operating Characteristics 28. . . . . . . . . . . . . . . . . . . .

Mowing Techniques 29. . . . . . . . . . . . . . . . . . . . . . . .

After Mowing 29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting Clip Rate (Reel Speed) 30. . . . . . . . . . . . . .

Standard Control Module (SCM) 31. . . . . . . . . . . . . .

Lubrication 33. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 36. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 36. . . . . . . . .

Daily Maintenance Checklist 37. . . . . . . . . . . . . . . . .

Service Interval Chart 38. . . . . . . . . . . . . . . . . . . . . .

Hood Removal 38. . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Air Cleaner Maintenance 39. . . . . . . . . . . . .

Servicing Air Cleaner 39. . . . . . . . . . . . . . . . . . . . . . .

Engine Oil and Filter 39. . . . . . . . . . . . . . . . . . . . . . .

Fuel System 40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bleeding Air From Injectors 41. . . . . . . . . . . . . . . . .

Cleaning Engine Cooling System 41. . . . . . . . . . . . .

Servicing Engine Belts 42. . . . . . . . . . . . . . . . . . . . . .

Adjusting Throttle 42. . . . . . . . . . . . . . . . . . . . . . . . .

Changing Hydraulic Fluid 43. . . . . . . . . . . . . . . . . . .

Replacing Hydraulic Filter 43. . . . . . . . . . . . . . . . . . .

Checking Hydraulic Lines And Hoses 43. . . . . . . . . .

Adjusting Traction Drive For Neutral 44. . . . . . . . . .

Adjusting Parking Brake 44. . . . . . . . . . . . . . . . . . . .

Battery Care 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery Storage 45. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuses 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backlapping 45. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Schematic 47. . . . . . . . . . . . . . . . . . . . . . . .

Hydraulic Schematic 48. . . . . . . . . . . . . . . . . . . . . . .

Storage 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Traction Unit 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine 49. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 52. . .

2003 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Page 3

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready.The two numbers are

stamped into a plate that is riveted to the frame of mower.

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

CAUTION, WARNING, or DANGER—“personal

safety instruction.” Failure to comply with the

instruction may result in personal injury or death.

Safe Operating Practices

The following instructions are from the CEN standard EN

836:1997, ISO standard 5395:1990, and ANSI B71.4-1999.

Training

• Read the operator’s manual and other training material

carefully. Be familiar with the controls, safety signs,

and the proper use of the equipment.

• Never allow children or people unfamiliar with these

instructions to use or service the mower. Local

regulations may restrict the age of the operator.

• Never mow while people, especially children, or pets

are nearby.

• Keep in mind that the operator or user is responsible for

accidents or hazards occurring to other people or their

property.

• Do not carry passengers.

• All drivers and mechanics should seek and obtain

professional and practical instruction. The owner is

responsible for training the users. Such instruction

should emphasize:

– the need for care and concentration when working

with ride-on machines;

– The main reasons for loss of control on a slope are:

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Safety

This machine meets or exceeds CEN standard EN

836:1997, ISO standard 5395:1990, and ANSI

B71.4-1999 specifications in effect at the time of

production when rear tires are filled with calcium

chloride and two rear wheel weight kits (Part No.

11–0440) are installed.

Improper use or maintenance by the operator or owner

can result in injury. To reduce the potential for injury,

comply with these safety instructions and always pay

attention to the safety alert

symbol, which means

• insufficient wheel grip;

• being driven too fast;

• inadequate braking;

• the type of machine is unsuitable for its task;

• lack of awareness of the effect of ground

conditions, especially slopes;

• incorrect hitching and load distribution.

• The owner/user can prevent and is responsible for

accidents or injuries occurring to himself or herself,

other people, or property.

Preparation

• While mowing, always wear substantial footwear, long

trousers, hard hat, safety glasses, and ear protection.

Long hair, loose clothing, or jewelry may get tangled in

moving parts. Do not operate the equipment when

barefoot or wearing open sandals.

3

Page 4

• Thoroughly inspect the area where the equipment is to

be used and remove all objects which may be thrown by

the machine.

• Warning—Fuel is highly flammable. Take the

following precautions:

– Store fuel in containers specifically designed for this

purpose.

– Refuel outdoors only and do not smoke while

refuelling.

– Add fuel before starting the engine. Never remove

the cap of the fuel tank or add fuel while the engine

is running or when the engine is hot.

– If fuel is spilled, do not attempt to start the engine

but move the machine away from the area of

spillage and avoid creating any source of ignition

until fuel vapors have dissipated.

– Replace all fuel tanks and container caps securely.

• Replace faulty silencers/mufflers.

• Evaluate the terrain to determine what accessories and

attachments are needed to properly and safely perform

the job. Only use accessories and attachments approved

by the manufacturer.

• Check that operator’s presence controls, safety switches

and shields are attached and functioning properly. Do

not operate unless they are functioning properly.

• Watch out for traffic when crossing or near roadways.

• Stop the blades rotating before crossing surfaces other

than grass.

• When using any attachments, never direct discharge of

material toward bystanders nor allow anyone near the

machine while in operation.

• Never operate the machine with damaged guards,

shields, or without safety protective devices in place. Be

sure all interlocks are attached, adjusted properly, and

functioning properly.

• Do not change the engine governor settings or

overspeed the engine. Operating the engine at excessive

speed may increase the hazard of personal injury.

• Before leaving the operator’s position:

– stop on level ground;

– disengage the power take-off and lower the

attachments;

– change into neutral and set the parking brake;

– stop the engine and remove the key.

• Disengage drive to attachments when transporting or

not in use.

• Stop the engine and disengage drive to attachment

– before refuelling;

Operation

• Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

• Mow only in daylight or in good artificial light.

• Before attempting to start the engine, disengage all

blade attachment clutches, shift into neutral, and engage

the parking brake.

• Do not use on slopes of more than 25°.

• Remember there is no such thing as a safe slope. Travel

on grass slopes requires particular care. To guard

against overturning:

– do not stop or start suddenly when going up or

downhill;

– machine speeds should be kept low on slopes and

during tight turns;

– stay alert for humps and hollows and other hidden

hazards;

– never mow across the face of the slope, unless the

mower is designed for this purpose.

• Stay alert for holes in the terrain and other hidden

hazards.

– before removing the grass catcher/catchers;

– before making height adjustment unless adjustment

can be made from the operator’s position.

– before clearing blockages;

– before checking, cleaning or working on the mower;

– after striking a foreign object or if an abnormal

vibration occurs. Inspect the mower for damage and

make repairs before restarting and operating the

equipment.

• Reduce the throttle setting during engine run-out and, if

the engine is provided with a shut-off valve, turn the

fuel off at the conclusion of mowing.

• Keep hands and feet away from the cutting units.

• Look behind and down before backing up to be sure of

a clear path.

• Slow down and use caution when making turns and

crossing roads and sidewalks. Stop cylinders/reels if not

mowing.

• Do not operate the mower under the influence of

alcohol or drugs

• Use care when loading or unloading the machine into a

trailer or truck

4

Page 5

• Use care when approaching blind corners, shrubs, trees,

or other objects that may obscure vision.

Maintenance and Storage

• Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

• Never store the equipment with fuel in the tank inside a

building where fumes may reach an open flame or

spark.

• Allow the engine to cool before storing in any

enclosure.

• To reduce the fire hazard, keep the engine,

silencer/muffler, battery compartment and fuel storage

area free of grass, leaves, or excessive grease.

• Check the grass catcher frequently for wear or

deterioration.

• Keep all parts in good working condition and all

hardware and hydraulic fittings tightened. Replace all

worn or damaged parts and decals.

• If the fuel tank has to be drained, do this outdoors.

• Be careful during adjustment of the machine to prevent

entrapment of the fingers between moving blades and

fixed parts of the machine.

• On multi-cylinder/multi-reel machines, take care as

rotating one cylinder/reel can cause other

cylinders/reels to rotate.

• Disengage drives, lower the cutting units, set parking

brake, stop engine and remove key and disconnect spark

plug wire. Wait for all movement to stop before

adjusting, cleaning or repairing.

• Clean grass and debris from cutting units, drives,

silencers/mufflers, and engine to help prevent fires.

Clean up oil or fuel spillage.

• Use jack stands to support components when required.

• Carefully release pressure from components with stored

energy.

• Disconnect battery and remove spark plug wire before

making any repairs. Disconnect the negative terminal

first and the positive last. Reconnect positive first and

negative last.

• Use care when checking the cylinders/reels. Wear

gloves and use caution when servicing them.

• Keep hands and feet away from moving parts. If

possible, do not make adjustments with the engine

running.

• Charge batteries in an open well ventilated area, away

from spark and flames. Unplug charger before

connecting or disconnecting from battery. Wear

protective clothing and use insulated tools.

Toro Riding Mower Safety

The following list contains safety information specific to

Toro products or other safety information that you must

know that is not included in the CEN, ISO, or ANSI

standard.

This product is capable of amputating hands and feet and

throwing objects. Always follow all safety instructions to

avoid serious injury or death.

Use of this product for purposes other than its intended use

could prove dangerous to user and bystanders.

Warning

Engine exhaust contains carbon monoxide, which

is an odorless, deadly poison that can kill you.

Do not run engine indoors or in an enclosed area.

• Be sure to establish your own special procedures and

work rules for unusual operating conditions (e.g. slopes

to steep for machine operation. Survey complete

mowing site to determine which hills can be safely

operated on. When performing this site survey always

use common sense and take into consideration the turf

condition and the rollover risk. To determine which

hills or slopes may be safely operated on use the

inclinometer provided with each machine. To perform a

site survey, lay a 4’ two by four on the slope surface and

measure the angle of the slope. The 2 by 4 will average

the slope but will not take into consideration dips or

holes. THE MAXIMUM SIDE HILL ANGLE

SHOULD NOT BE GREATER THAN 25

DEGREES.

• The Reelmaster 3100 is equipped with an angle

indicator, mounted on the steering tube, which indicates

the side hill angle the machine is operating on and

identifies the recommended maximum limit of 25

degrees. Stay alert for holes in terrain and other hidden

hazards which can cause a sudden change in side hill

angle.

• Use extreme caution when operating close to sand traps,

ditches, creeks, steep hillsides or other hazards. Reduce

speed when making sharp turns. Do not turn on hills.

Avoid sudden stops and starts. Use reverse pedal for

braking. Cutting units must be lowered when going

down slopes for steering control.

• Know how to stop the engine quickly.

• Do not operate the machine while wearing tennis shoes

or sneakers.

• Wearing safety shoes and long pants is advisable and

required by some local ordinances and insurance

regulations.

• Handle fuel carefully. Wipe up any spills.

5

Page 6

• Check the safety interlock switches daily for proper

operation. If a switch should fail, replace the switch

before operating the machine. After every two years,

replace all four interlock switches in the safety system,

whether they are working properly or not.

• Before starting the engine, sit on the seat.

• Using the machine demands attention. To prevent loss

of control:

– Do not drive close to sand traps, ditches, creeks, or

other hazards.

– Reduce speed when making sharp turns. Avoid

sudden stops and starts.

– When near or crossing roads, always yield the

right-of-way.

– Apply the service brakes when going downhill to

keep forward speed slow and to maintain control of

the machine.

• The grass baskets must be in place during operation of

the cylinders/reels or thatchers for maximum safety.

Shut the engine off before emptying the baskets.

• Raise the cutting units when driving from one work

area to another.

• Check all fuel lines for tightness and wear on a regular

basis. Tighten or repair them as needed.

• If the engine must be running to perform a maintenance

adjustment, keep hands, feet, clothing, and any parts of

the body away from the cutting units, attachments, and

any moving parts, especially the screen at the side of the

engine. Keep everyone away.

• To ensure safety and accuracy, have an Authorized Toro

Distributor check the maximum engine speed with a

tachometer. Maximum governed engine speed should be

2650 RPM.

• If major repairs are ever needed or if assistance is

desired, contact an Authorized Toro Distributor.

• Use only Toro-approved attachments and replacement

parts. The warranty may be voided if used with

unapproved attachments.

• Do not touch the engine, silencer/muffler, or exhaust

pipe while the engine is running or soon after it has

stopped because these areas could be hot enough to

cause burns.

• If the engine stalls or loses headway and cannot make it

to the top of a slope, do not turn the machine around.

Always back slowly, straight down the slope.

• When a person or pet appears unexpectedly in or near

the mowing area, stop mowing. Careless operation,

combined with terrain angles, ricochets, or improperly

positioned guards can lead to thrown object injuries. Do

not resume mowing until the area is cleared.

Maintenance and Storage

• Make sure all hydraulic line connectors are tight and all

hydraulic hoses and lines are in good condition before

applying pressure to the system.

• Keep your body and hands away from pin hole leaks or

nozzles that eject hydraulic fluid under high pressure.

Use paper or cardboard, not your hands, to search for

leaks. Hydraulic fluid escaping under pressure can have

sufficient force to penetrate the skin and cause serious

injury. Seek immediate medical attention if fluid is

injected into skin.

• Before disconnecting or performing any work on the

hydraulic system, all pressure in the system must be

relieved by stopping the engine and lowering the cutting

units and attachments to the ground.

6

Page 7

Sound Pressure Level

Vibration Level

This unit has an equivalent continuous A–weighted sound

pressure level at the operator ear of 83 dBA, based on

measurements of identical machines per Directive

98/37/EC and amendments.

Sound Power Level

This unit has a guaranteed sound power level of:

105 dBA/1 pW, based on measurements of identical

machines per Directive 2000/14/EC and amendments.

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

This unit does not exceed a vibration level of 2.5 m/s at

the hands based on measurements of identical machines per

ISO 5349 procedures.

This unit does not exceed a vibration level of .5 m/s at the

posterior based on measurements of identical machines per

ISO 2631 procedures.

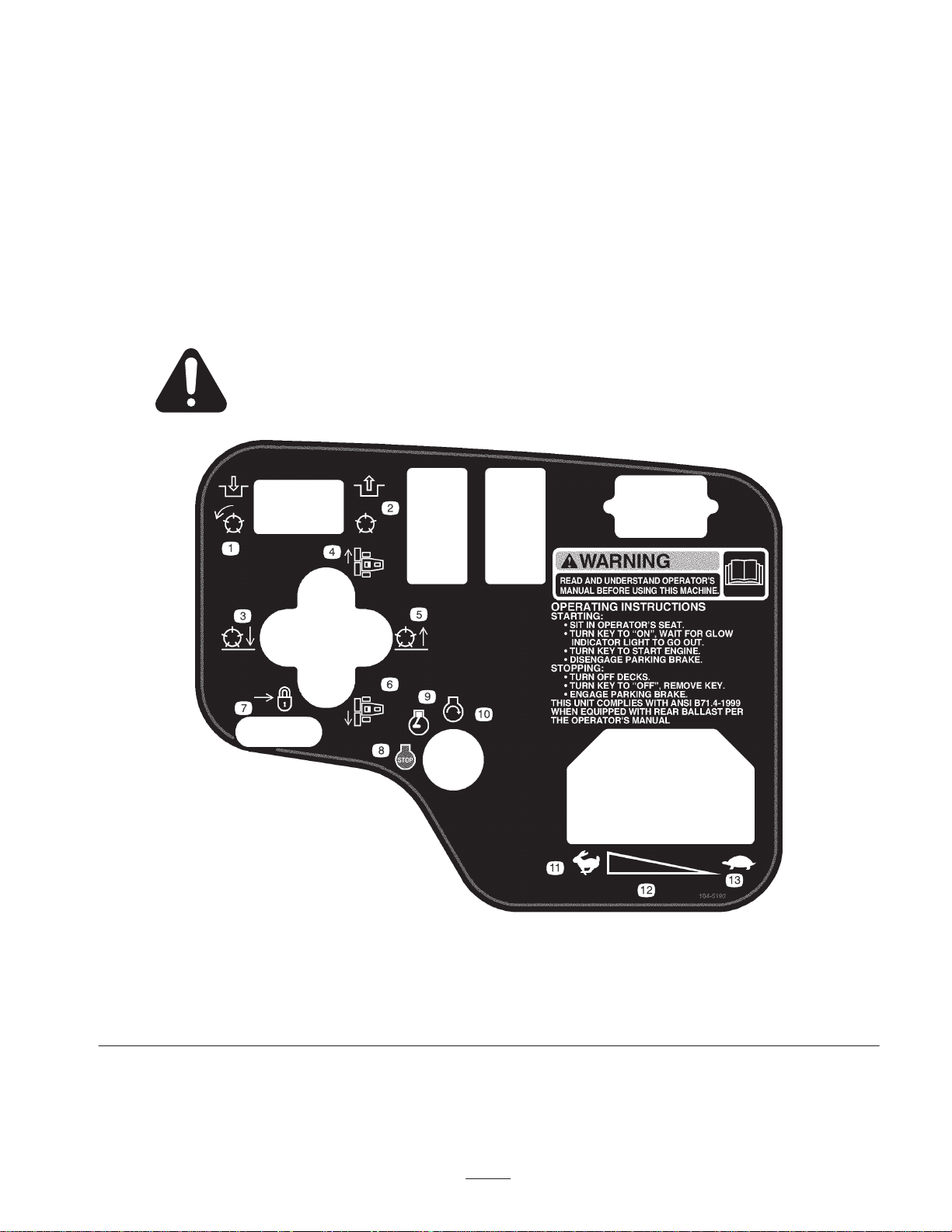

1. Engage the reels.

2. Disengage the reels.

3. Lower the reels.

4. Move the cutting units to the

right.

104–5192 for Model 03200

5. Raise the reels.

6. Move the cutting units to the

left.

7. Move rear ward to lock the

lift lever.

8. Engine—stop

9. Engine—run

10. Engine=start

7

11. Fast

12. Continuous variable setting

13. Slow

Page 8

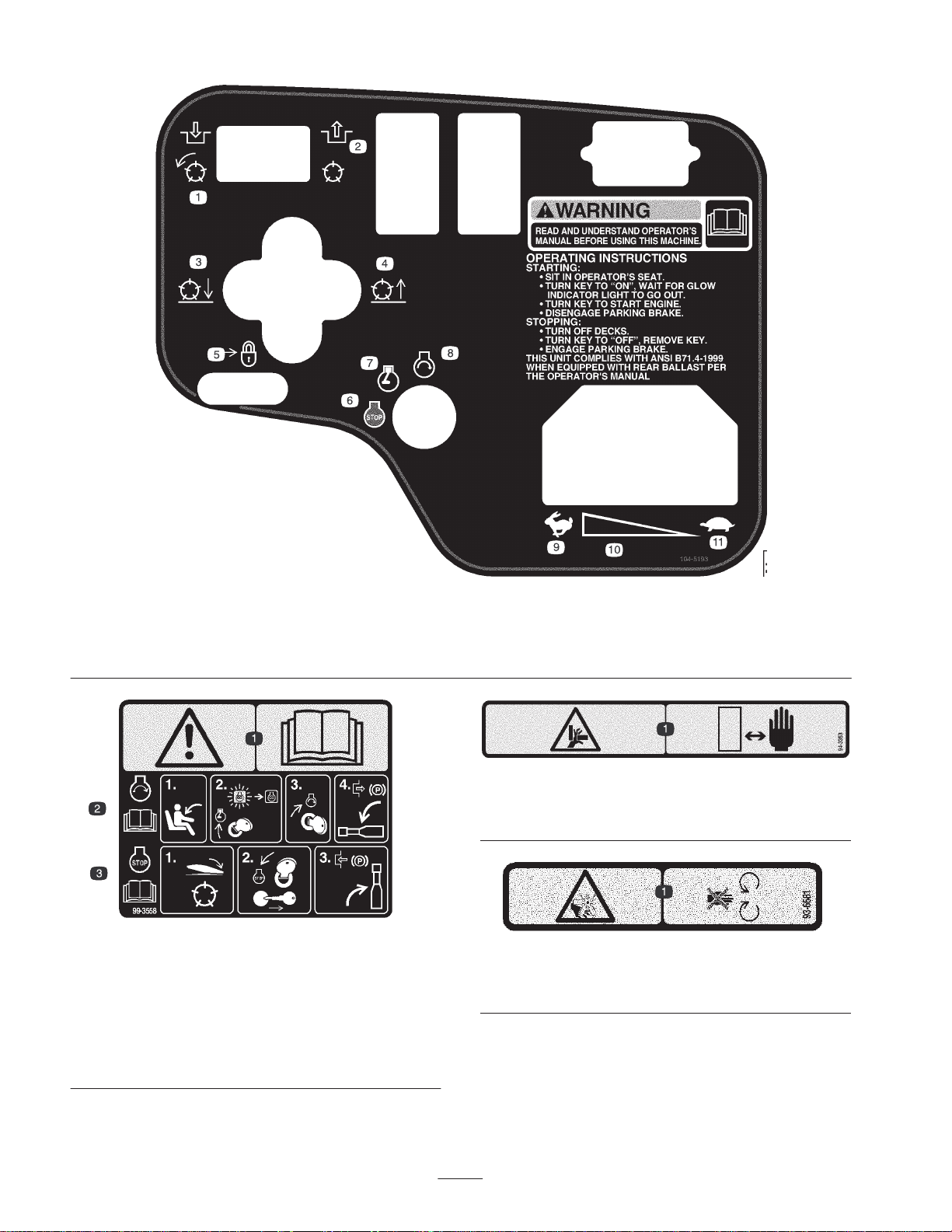

1. Engage the reels.

2. Disengage the reels.

3. Lower the reels.

104-5193 for Model 03201

4. Raise the reels.

5. Move rear ward to lock the

lift lever.

6. Engine—stop

7. Engine—run

8. Engine=start

9. Fast

10. Continuous variable setting

11. Slow

94-3353 for Model 03201 only

1. Crushing hazard of hand—keep your hands a safe distance

away.

99-3558 for CE

1. Warning—read the

2. To start the engine, sit on the operator’s seat,, turn the key to

Run and wait for the engine preheat light to turn off, turn the

key to Start, and disengage the parking brake by moving the

lever down; read the

3. To stop the engine, press the switch to disengage the reels,

turn the key to Stop and remove it, engage the parking brake

by pulling the lever up; read the

Operator’s Manual.

Operators Manual.

Operators Manual.

93-6681

1. Cutting/dismemberment hazard, fan—stay away from moving

parts.

8

Page 9

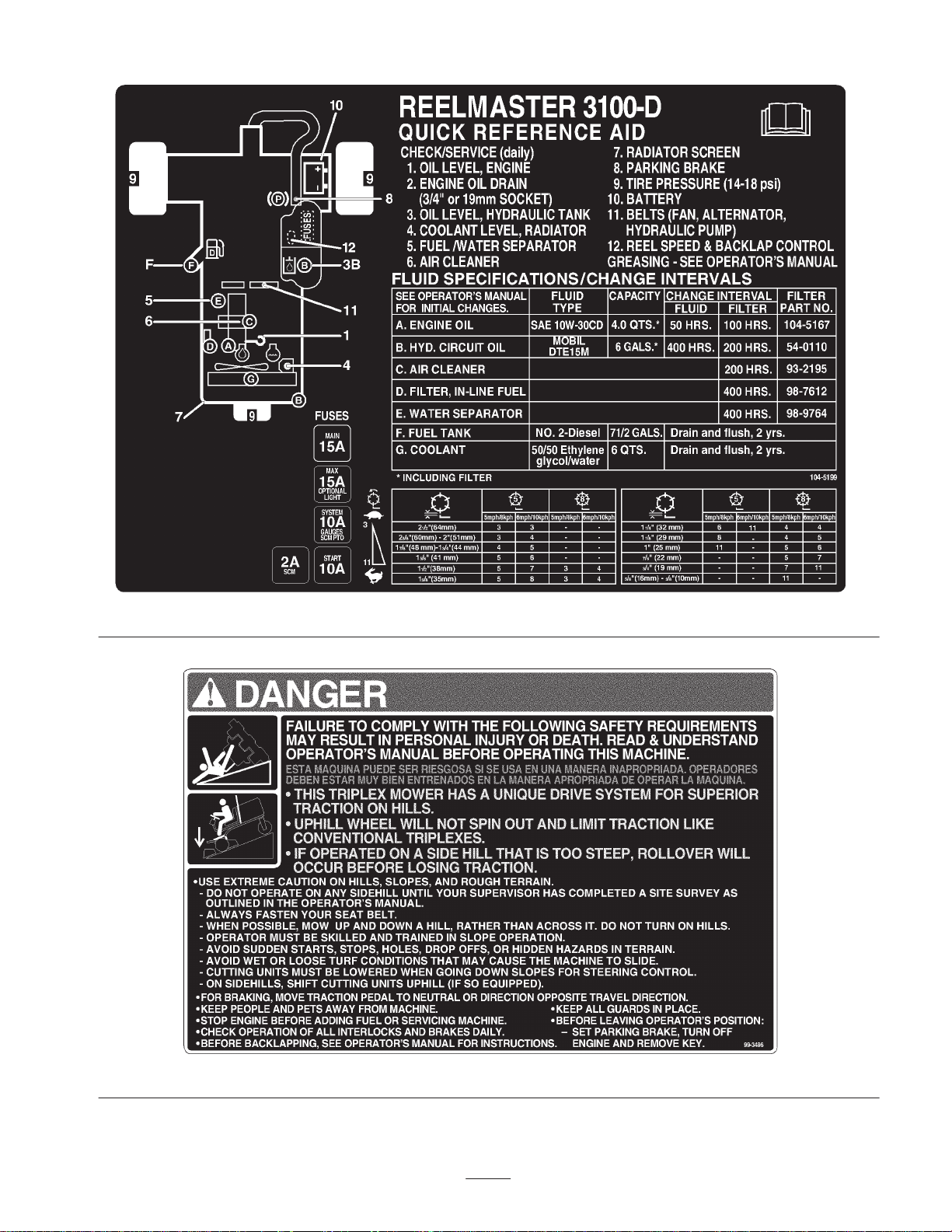

104-5199

99-3496

9

Page 10

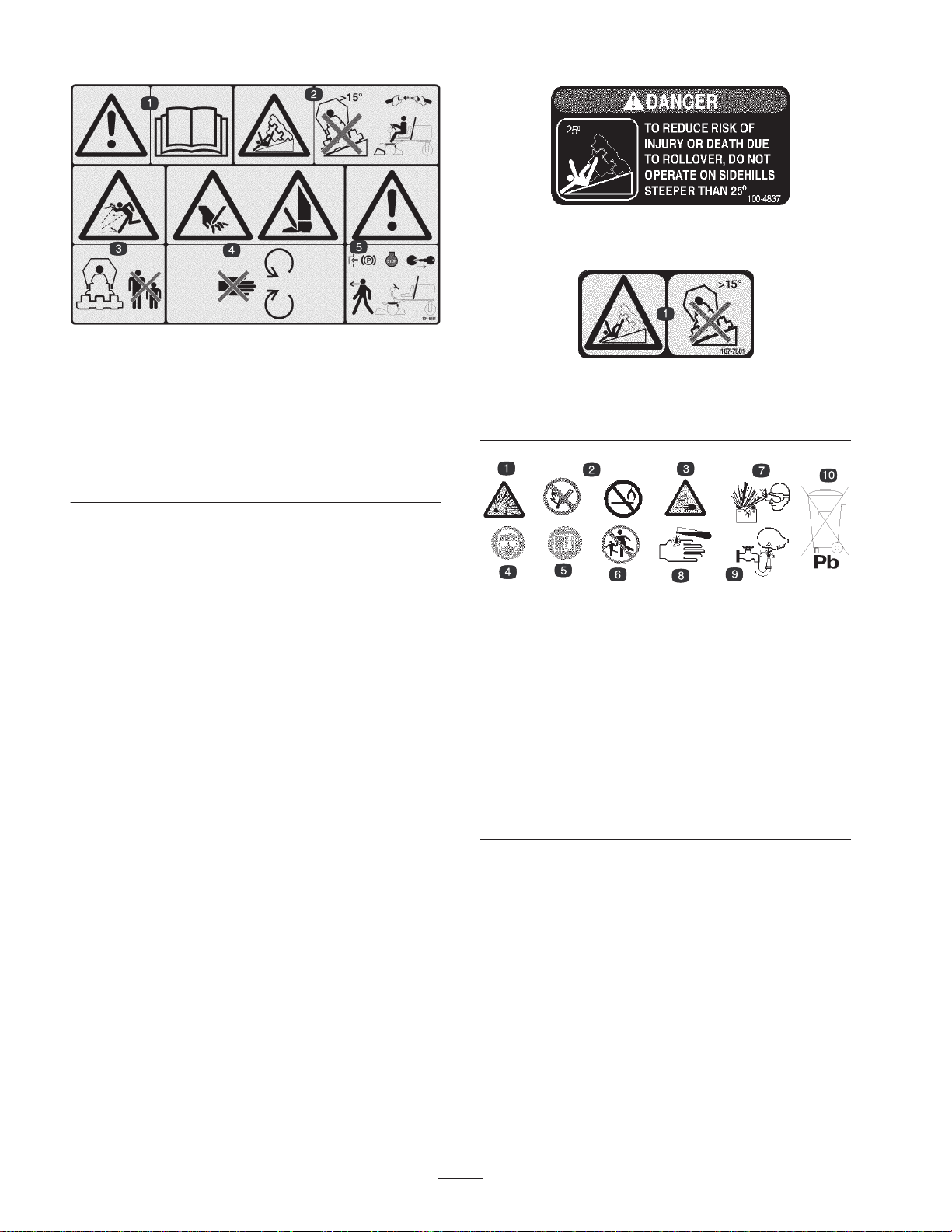

104-5181 for CE

1. Warning—read the

2. Tipping hazard—do not drive on slopes greater than 15

degrees and always wear the seat belt with ROPS.

3. Thrown object hazard—keep bystanders a safe distance from

the machine.

4. Cutting hazard of hand or foot—stay away from moving parts.

5. Warning—lock the parking brake, stop the engine, and remove

the ignition key before leaving the machine.

Operator’s Manual.

100-4837

107-7801 for CE

1. Tipping hazard—do not drive on slopes greater than 15

degrees.

Battery Symbols

Some or all of these symbols are on your battery.

1. Explosion hazard

2. No fire, open flames, or

smoking.

3. Caustic liquid/chemical

burn hazard

4. Wear eye protection

5. Read the

Manual.

6. Keep bystanders a safe

distance from the battery.

Operator’s

7. Wear eye protection;

explosive gases can

cause blindness and

other injuries

8. Battery acid can cause

blindness or severe

burns.

9. Flush eyes immediately

with water and get

medical help fast.

10. Contains lead; do not

discard.

10

Page 11

Specifications

Note: Specifications and design subject to change without notice.

General Specifications

Kubota three cylinder, 4 cycle liquid cooled diesel engine. 21.5 hp @ 2500 rpm

Engine

Governed to 2650 rpm. 68.5 cu. in. (1124 cc) displacement. Heavy duty, 2-stage,

remote mounted air cleaner. High water temperature shutdown switch.

Cooling System

Electrical

Fuel Capacity 7.5 gallons.

Traction Drive

Hydraulic System Remote mounted, 3.5 gallon oil reservoir. 10 micron remote mounted spin on filter.

Ground Speed

Tires/Wheels

Frame

Steering Power steering.

Brakes

Radiator capacity is approximately 6 qts. of 50/50 mixture of ethylene glycol

anti–freeze. Remote mounted 1 qt. expansion tank.

12 volt Group 55, 450 cold cranking amps at 0F (–18C), 75 minute reserve

capacity at 80F (27C). 40 amp alternator with regulator/rectifier. Seat switch,

PTO, parking brake and traction interlock switches.

High torque hydraulic wheel motors. 3–wheel drive. Oil cooler and shuttle valve

provide positive closed–loop cooling.

Infinitely variable speed selection in forward and reverse

Mowing speed: 0–6 mph (adjustable)

Transport speed: 0–9 mph

Reverse speed: 0–3.5 mph

Front tires are 20 x 12–10 tubeless tires and rear tires are 20 x 10–10 tubeless. All

have 4–ply rating with demountable rims. Recommended tire pressure: 14–18 psi

front and rear tires.

Tricycle vehicle with 3–wheel traction drive and rear wheel steering. Frame consists

of formed steel, welded steel and steel tubing components.

Service braking accomplished through dynamic characteristics of Hydrostat.

Parking or emergency brake is actuated by ratchet hand lever on the operator’s

right hand side.

Foot operated forward and reverse traction pedals and Mow/Transport slide. Hand

Controls

Gauges & Protective

Systems

Seat Optional standard or deluxe seats.

Cutting Unit Lift Hydraulic lift with automatic reel shut off.

operated throttle, ignition switch, reel engagement switch, reel unit lift and shift

lever, parking brake and seat adjustment. Shift lever only on Model 03201.

Hour meter. 4 light warning cluster gauge: oil pressure, water temperature, amps,

glow plug and side hill angle indicator.

Optional Equipment

Standard Seat Model No. 03224

11

Page 12

Setup

Note: Determine the left and right sides of the machine from the normal operating position.

Loose Parts Chart

Note: Use this chart as a checklist to ensure all parts necessary for assembly have been shipped. If any of these parts are

missing, total setup cannot be completed.

Description

Wheel assembly 3 Mount to wheel hubs

Steering wheel

Jam nut

Cover

Screw

Hood lock bracket

Screw 1/4–20 x 1–1/2” lg.

Flat washer 1/4–20

Lock nut 1/4–20

Exhaust guard

Self tapping screw

Hose clamp 1 Secure vent hose to vent tube of ROPS

Lift arms

Pivot rod

Capscrews 5/16–18 x 7/8” lg.

Thrust washers

Lynch pin

Qty. Use

1

1

1

1

1

1

1

1

1

4

2

2

2

2

2

Mount to steering shaft

Mount to hood for European Compliance

Mount to machine for European Compliance

Install pivot rods to lift arms

(supplied with Lift Arm Kit)

Mount cutting units to lift arms

(supplied with Lift Arm Kit)

Key 2

Inclinometer 1 Use for site survey before operating machine

EEC Decal

EEC Certificate

Operator’s manual 2 Read before operating the machine.

Engine operator’s manual 1 Read before operating the machine.

Parts catalog 1

Operator video 1 View before operating the machine

Pre–delivery check list 1

Registration cards 2 Fill out and return to Toro.

Note: Specifications and design subject to change without notice.

4

Affix to machine for European Compliance

2

12

Page 13

Install Wheels

1. Mount a wheel assembly onto each wheel hub (valve

stem outward).

Important Rear tire has a narrower rim than front tires.

2. Install lug nuts and torque to 45–65 ft–Ib.

Install Steering Wheel

1. Slide steering wheel onto steering shaft.

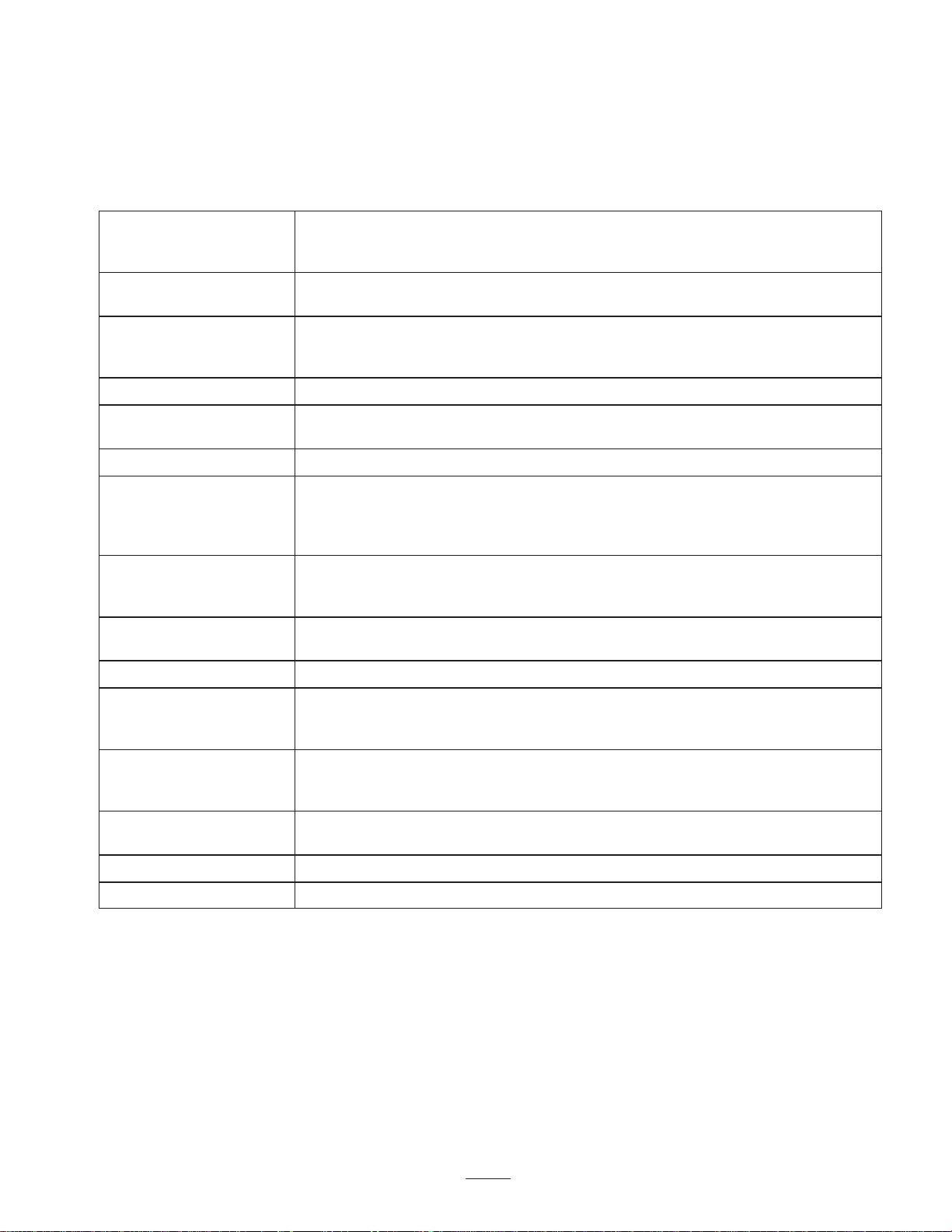

3

2

1

Figure 1

1. Steering wheel

2. Jam nut

3. Cap

3. If Battery is not filled with electrolyte or activated, bulk

electrolyte with 1.260 specific gravity must be

purchased from a local battery supply outlet and added

to battery.

4. Remove filler caps from battery and slowly fill each

cell until electrolyte is just above the plates.

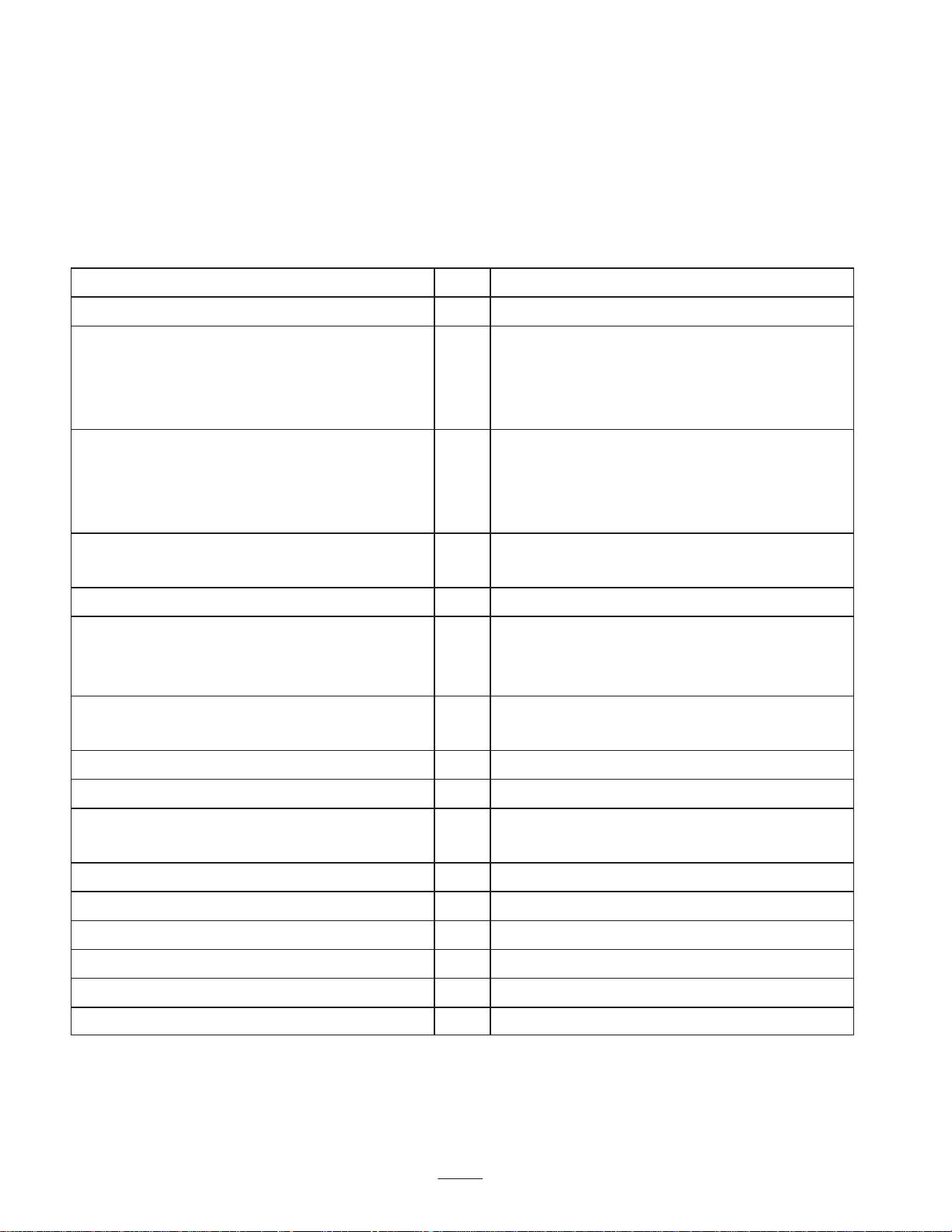

1

Figure 2

1. Battery cover

5. Replace filler caps and connect a 3 to 4 amp battery

charger to the battery posts. Charge the battery at a rate

of 3 to 4 amperes for 4 to 8 hours.

Caution

2. Secure steering wheel to shaft with jam nut and tighten

it to 25 ft-lb.

3. Install cap to steering wheel with screw.

Activate, Charge and Connect

Battery

Warning

CALIFORNIA

Proposition 65 Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

1. Open hood.

2. Remove battery cover.

Wear safety goggles and rubber gloves when

working with electrolyte. Charge the battery in a

well ventilated place so gasses produced while

charging can dissipate. Since the gases are

explosive, keep open flames and electrical spark

away from the battery; do not smoke. Nausea may

result if the gases are inhaled. Unplug charger

from electrical outlet before connecting to or

disconnecting charger leads from battery posts.

6. When battery is charged, disconnect charger from

electrical outlet and battery posts.

7. Remove filler caps. Slowly add electrolyte to each cell

until level is up to fill ring. Install filler caps.

Important Do not overfill battery. Electrolyte will

overflow onto other parts of the machine and severe

corrosion and deterioration will result.

8. Install the positive cable (red) to the positive (+)

terminal and the negative cable (black) to the negative

(—) terminal of the battery and secure with capscrews

and nuts. Make sure positive (+) terminal is all the way

onto post and cable is positioned snug to battery. Cable

13

Page 14

must not contact battery cover. Slide the rubber boot

over the positive terminal to prevent possible short–out

from occurring.

Warning

• Connecting cables to the wrong post could

damage the electrical system and result in

personal injury.

2

1. Positive (+) battery cable 2. Negative (–) battery cable

1

Figure 3

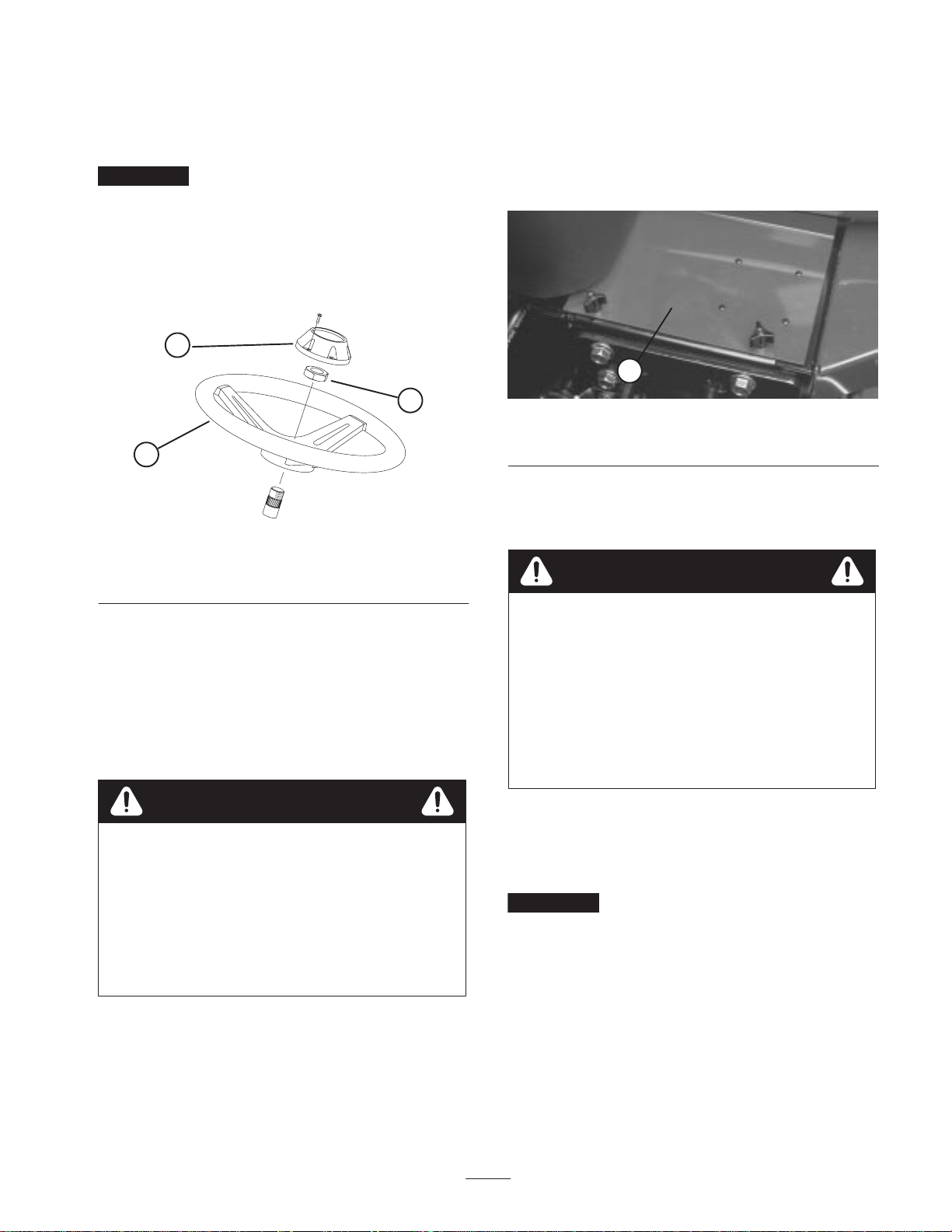

1

Figure 4

1. Seat mounting strap (2)

3. Install seat belt to holes on each side of seat with (2)

bolts and lockwashers (standard seat) or (2) bolts and

locknuts (deluxe seat). All mounting fasteners supplied

with seat kit loose parts.

1

2

3

Important If battery is ever removed, make sure

battery clamp bolts are reinstalled with bolt heads

positioned on bottom side and nuts on top side. If clamp

bolts are reversed, they may interfere with hard lines when

shifting cutting units.

9. Coat both battery connections with Grafo 112X (skin

over) grease, Toro Part No. 505–47, petroleum jelly or

light grease to prevent corrosion and slide rubber boot

over positive terminal.

10.Install battery cover.

Install Seat

The Reelmaster 3100 is shipped without the seat assembly.

Deluxe Seat Kit, Model 03225 or Standard Seat Kit, Model

03224, must be installed as follows:

1. Remove capscrews securing seat mounting straps to

traction unit frame (Fig. 4).

2. Secure seat mounting straps to seat adjusters with (4)

flange nuts (standard seat) or (4) capscrews, flat

washers and flange nuts (deluxe seat). Mounting

fasteners supplied with seat kit loose parts.

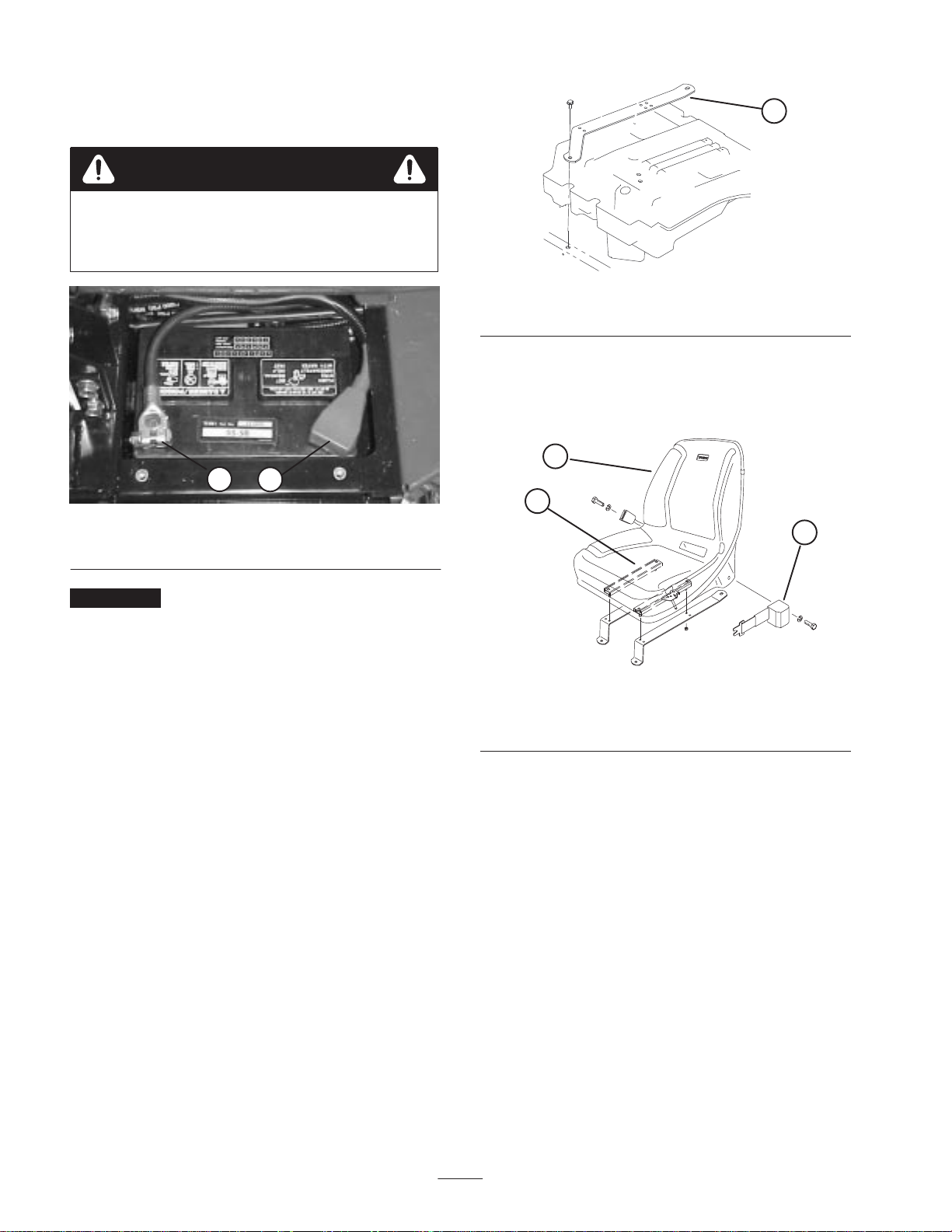

Figure 5

1. Standard seat

2. Seat adjusters

4. Position seat and seat straps on frame aligning

mounting holes.

5. Route seat switch wire under right hand seat strap and

connect to appropriate seat switch connector on harness.

6. On deluxe seat only, route unused seat switch connector

back under seat strap and secure both wires to rear most

hole in seat strap (Fig. 6) with a cable tie (cable tie

supplied with seat kit).

3. Seat belt

14

Page 15

1

Figure 6

1. Seat switch wire 2. Cable tie

7. On standard seat only, slide seat all the way forward,

pull wire to the right so unused connector is positioned

as shown in figure 7 and secure seat switch wire to rear

most hole in seat strap with a cable tie (cable tie

supplied with seat kit).

2

1

Figure 8

1. Angle indicator

3. If inclinometer does not read zero degrees, move the

machine to a location where a zero degree reading is

obtained. The angle indicator, mounted on machine,

should now read zero degrees as well.

4. If angle indicator does not read zero degrees, loosen the

two screws and nuts securing angle indicator to

mounting bracket, adjust indicator to obtain a zero

degree reading and tighten capscrews.

1

Figure 7

1. Seat switch wire 2. Cable tie

8. Mount seat straps to frame with fasteners previously

removed.

9. Slide seat completely forward and backward to ensure

proper operation and that seat switch wires and

connectors are not pinched or do not contact any

moving parts.

2

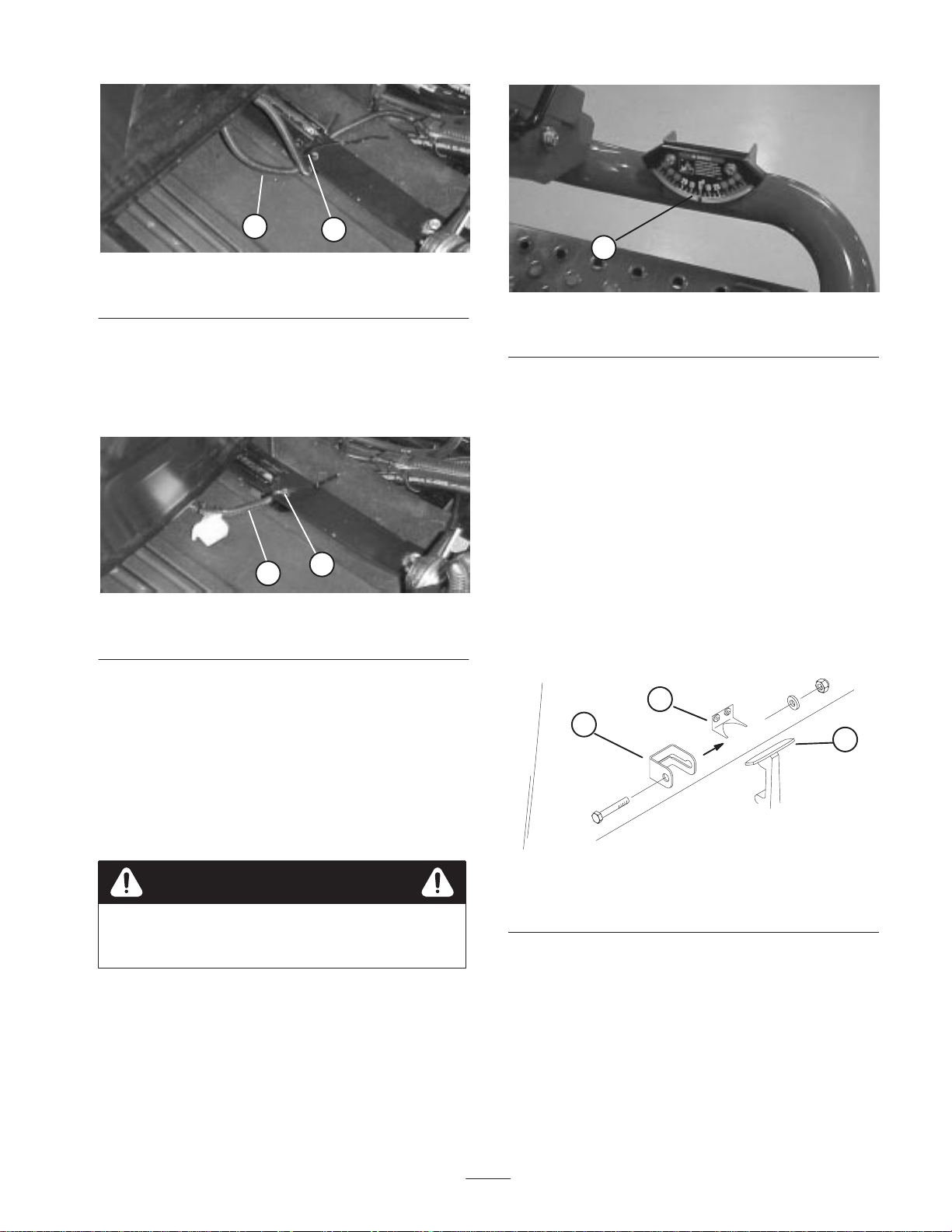

Check Angle Indicator

Danger

To reduce risk of injury or death due to rollover do

not operate on side hills steeper than 25.

1. Park machine on a flat, level surface.

2. Verify that the machine is level by placing a hand held

inclinometer (supplied with machine) on the frame

cross rail, by the tool box. The inclinometer should read

zero degrees, when viewed from the operator’s position.

Install Hood Latch

(European Compliance)

1. Unhook hood latch from bracket.

2. Slide hood lock bracket onto latch.

2

3

Figure 9

1. Hood latch

2. Hood latch bracket

3. Re–hook latch onto bracket.

4. Insert 1/4–20 x 1–1/2” lg. capscrew thru hood lock

bracket and secure with a capscrew, flat washer and

locknut.

3. Hood lock bracket

1

15

Page 16

Install Exhaust Guard

(European Compliance)

1

1. Position exhaust guard around muffler while aligning

mounting holes with holes in frame.

2. Secure exhaust guard to frame with (4) self tapping

screws.

1

Figure 10

1. Exhaust guard

3

2

5

4

2

Figure 11

1. ROPS

2. Mounting bracket

3. Vent tube

4. Fuel line vent tube hose

5. Hose clamp

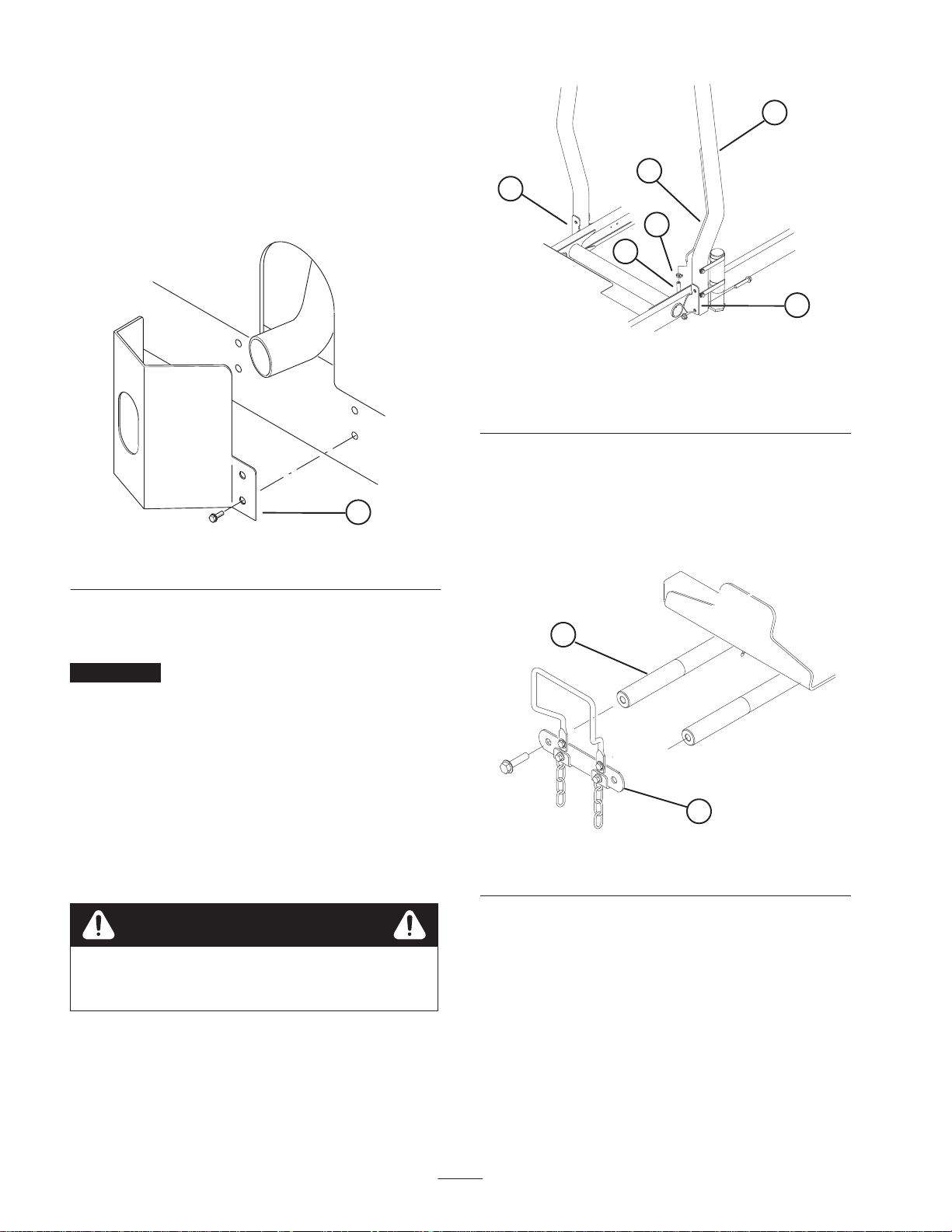

Install Front Lift Arms

1. Remove (2) capscrews securing lift arm pivot shaft link

to lift arm pivot shafts. Remove and retain pivot shaft

link and capscrews (Fig. 12).

Install ROPS

Important Never weld or modify ROPS. Replace a

damaged ROPS, do not repair or revise. Any alteration of

ROPS must be approved by manufacturer.

1. Lower ROPS frame onto traction unit mounting

brackets, aligning mounting holes. Vent tube, secured to

ROPS, must be positioned on left side of machine.

2. Secure each side of roll bar to mounting brackets with

(2) flange head capscrews and locknuts (Fig. 11).

Torque fasteners to 60 ft–lbs.

3. Secure fuel line vent hose to vent tube on ROPS with

hose clamp.

Caution

Fuel line vent hose must be connected to vent tube

prior to starting engine or fuel will flow from hose.

2

1

Figure 12

1. Lift arm pivot shaft link 2. Lift arm pivot shaft

2. Insert a pivot rod into each (R.H. & L.H.) lift arm and

align mounting holes (Fig. 13).

16

Page 17

1

2

Figure 13

1. Lift arm 2. Pivot rod

3. Secure pivot rods to lift arms with a 5/16 – 18 x 7/8” lg.

capscrew.

1

1. Lift cylinder

2. Hoses

2

3

Figure 15

3. Clearance here

4. Insert R.H. & L.H. lift arms onto lift arm pivot shafts.

Secure with lift arm pivot shaft link and capscrews

previously removed. Torque capscrews to 70 ft–lbs.

5. Remove rear retaining rings securing mounting pins to

each end of lift cylinder.

3

1

4

6

2

4

5

Figure 14

1. Lift arm (R.H.)

2. Lift arm (L.H.)

3. Retaining ring

4. Mounting pin

5. Lift cylinder

6. Spacer (2)

7. Secure left end of lift cylinder to left lift arm with pin.

Secure with retaining ring.

Note: With lift arms fully raised, hoses should be routed as

shown in figure 18 and clear lift arm by .04–.12”.

Mount Carrier Frames To

Cutting Units

1. Remove cutting units from cartons. Adjust per Cutting

Unit Operator’s Manual.

2. Position a front carrier frame (Fig. 16) onto each front

cutting unit. Align mounting holes with mounting links

as shown in figure 18.

1

6. Secure right end of lift cylinder to right lift arm with pin

and (2) spacers. Secure with retaining ring.

Figure 16

1. Front carrier frame

17

Page 18

3. Position rear carrier frame (Fig. 17) onto rear cutting

unit, aligning mounting holes with mounting links as

shown in figure 18.

Note: On rear cutting unit, thrust washer to be positioned

between rear of carrier frame and lynch pin.

1

Figure 17

1. Rear carrier frame

4. Secure each mounting link to carrier frame with a

3/8–16 x 2–1/4” lg capscrew, (2) flatwashers and a

locknut, as shown in figure 18. Position a washer on

each side of link when mounting. Torque to 31 ft–lb.

1

2

3

Figure 19

1. Thrust washer

2. Carrier frame

3. Lynch pin

3. Grease all lift arm and carrier frame pivot points.

Important Make sure hoses are free of twists or

sharp bends and rear cutting unit hoses are routed as

shown in Fig. 20. Raise cutting units and shift them to

the left (Model 03201 only). Rear cutting unit hoses

must not contact traction cable bracket. Re–position

fittings and / or hoses, if required.

1

2

3

FRONT

Figure 18

1. Carrier frame

2. Mounting link

3. Plug

Mount Cutting Units

1. Slide a thrust washer onto each front lift arm pivot rod.

2. Slide cutting unit carrier frame onto pivot rod and

secure with a lynch pin (Fig. 19).

Figure 20

4. Route a tipper chain up thru slot in end of each carrier

frame. Secure tipper chain to top of carrier frame with a

capscrew, washer and locknut (Fig. 21).

18

Page 19

1

Figure 21

1. Tipper chain

Mount Cutting Unit Drive

Motors

1. Spider coupling

2. Reel motor

1

Figure 23

3. O–ring

3

2

1. Position cutting units in front of lift arm pivot rods.

2. Remove weights and gasket (Fig. 22) from inside end of

right hand cutting unit. Remove plug from bearing

housing on outside end of right hand cutting unit and

install weights and gasket. Locate spider coupling

(Fig. 23) shipped in bearing housing.

1

2

Figure 22

1. Weights 2. Gasket

3. Remove shipping plug from bearing housings on

remaining cutting units (Fig. 18).

Adjust Lift Arms

1. Start engine, raise lift arms and check to make sure

clearance between each lift arm and floor plate bracket

is .18” – .32” (Fig. 24). If clearance is not in this range,

back off stop bolts (Fig. 26) and adjust cylinder to attain

clearance. To adjust cylinder, back off the jam nut on

the cylinder (Fig. 25), remove pin from rod end and

rotate clevis. Install pin and check clearance. Repeat

procedure if required. Tighten clevis jam nut.

2

3

1

Figure 24

1. Lift arm

2. Floor plate bracket

3. Clearance

4. Insert O–ring (supplied with cutting unit) on flange of

drive motor.

5. Mount the motor and the spider coupling to the drive

end of the cutting unit and secure with two capscrews

provided with cutting unit.

19

Page 20

2

1

2

1

Figure 25

1. Front cylinder 2. Jam nut

1

3

2

Figure 26

1. Stop bolt

2. Lift arm

3. Clearance

Note: If rear lift arm “clunks” during transport, clearance

can be reduced.

Figure 27

1. Wear bar 2. Bumper strap

1

2

Figure 28

1. Rear cylinder 2. Adjusting nut

Important Lack of clearance at front stops or rear

wear bar could damage lift arms.

2. Check to make sure clearance between each lift arm and

stop bolt is .005” – .040” (Fig. 26). If clearance is not in

this range, adjust stop bolts to attain clearance.

3. Start engine, raise lift arms and check to make sure

clearance between wear strap on top of rear cutting unit

wear bar and bumper strap is .020” – .100” (Fig. 27). If

clearance is not in this range, adjust rear cylinder to

attain clearance. To adjust cylinder, lower the cutting

units and back off the jam nut on the cylinder (Fig. 28).

Grasp cylinder rod close to the nut with a pliers and rag

and rotate the rod. Raise the cutting units and check

clearance. Repeat procedure if required. Tighten clevis

jam nut.

20

Page 21

Before Operating

Note: Determine the left and right sides of the machine

from the normal operating position.

Check Crankcase Oil

The engine is shipped with oil in the crankcase; however,

level of oil must be checked before and after the engine is

first started.

Important Check level of oil every 5 operating hours

or daily. Change oil after every 50 hours of operation.

Fill Fuel Tank

The engine runs on No. 2 diesel fuel.

Fuel tank capacity is approximately 7.5 gallons.

1. Clean area around fuel tank cap.

Crankcase capacity is approximately 4 qts. (2.8 l) with

filter.

1. Position machine on a level surface.

2. Remove dipstick and wipe it with a clean rag. Push

dipstick down into dipstick tube and make sure it is

seated fully. Pull dipstick out and check level of oil. If

oil level is low, add enough oil to raise level to FULL

mark on dipstick.

1

Figure 29

1. Dipstick

1

Figure 31

1. Fuel tank cap 2.

2. Remove fuel tank cap.

Danger

Under certain conditions, diesel fuel and fuel

vapors are highly flammable and explosive. A fire

or explosion from fuel can burn you and others

and can cause property damage.

1

Figure 30

1. Oil fill cap

3. If oil level is low, remove oil fill cap and gradually add

small quantities of oil, checking level frequently, until

level reaches FULL mark on dipstick.

4. The engine uses any high–quality 10W30 detergent oil

having the American Petroleum Institute – API –

“service classification” CD, CE, CF CF–4 or CG–4.

5. Install oil fill cap and close hood.

• Use a funnel and fill the fuel tank outdoors, in

an open area, when the engine is off and is cold.

Wipe up any fuel that spills.

• Do not fill the fuel tank completely full. Add fuel

to the fuel tank until the level is 1 in. (25 mm)

below the bottom of the filler neck. This empty

space in the tank allows the fuel to expand.

• Never smoke when handling fuel, and stay away

from an open flame or where fuel fumes may be

ignited by a spark.

• Store fuel in a clean, safety-approved container

and keep the cap in place.

3. Fill tank to bottom of filler neck. DO NOT

OVERFILL. Then install cap.

4. Wipe up any fuel that may have spilled to prevent a fire

hazard.

21

Page 22

Check Cooling System

4. Install expansion tank cap.

Clean debris off radiator and oil cooler daily (Fig. 32),

hourly if conditions are extremely dusty and dirty; refer to

Cleaning Radiator.

1. The cooling system is filled with a 50/50 solution of

water and permanent ethylene glycol anti–freeze. Check

level of coolant at beginning of each day before starting

the engine. Capacity of cooling system is approximately

6 quarts.

Caution

• If engine has been running, pressurized hot

coolant can escape when radiator cap is

removed and cause burns.

2

3

Check Hydraulic System Fluid

The hydraulic system driving the reels is designed to

operate on anti–wear hydraulic fluid. The machines

reservoir is filled at the factory with approximately 3.5

gallons of high quality hydraulic fluid. Check level of

hydraulic fluid before engine is first started and daily

thereafter. Appropriate hydraulic fluids are listed below.

The following list is not assumed to be all–inclusive.

Hydraulic fluids produced by other manufacturers may be

used if they can cross reference to find an equivalent to the

products listed. Toro will not assume responsibility for

damage caused by improper substitutions, so use only

products from reputable manufacturers who will stand

behind their recommendation.

Important Use only types of hydraulic fluids

specified. Other fluids could cause system damage.

Group 1 Hydraulic Fluid (Moderate climate– average

duty)

Note: The fluids within this group are interchangeable.

ISO VG 46/68 multi-viscosity anti-wear

hydraulic fluid

1

Figure 32

1. Access panel

2. Radiator

2. Check level of coolant in expansion tank. With a cold

engine, coolant level should be midway (approx)

between the marks on side of tank.

1

Figure 33

1. Expansion tank

3. Oil cooler

Mobil DTE 15M

Amoco Rykon Premium ISO 46

Castrol AWH 46

Conoco Hydroclear AW MV46

Gulf Harmony HVI 46 AW

Kendall Hyken Golden MV SAE 5W-20

Pennzbell AWX MV46

Phillips Magnus A KV 5W-20

Shell Tellus T 46

Sunoco Sun Hyd. Oil 2105

Texaco Rando HDZ 46

Universal Tractor Hydraulic Fluid

Mobil Mobil Fluid 424

Amoco 1000 Fluid

Chevron Tractor Hydraulic Fluid

Conoco Power-Tran 3

Exxon Torque Fluid

Pennzoil Hydra–Tranz

Shell Donax TD

Texaco TDH

3. If coolant level is low, remove expansion tank cap and

replenish the system. DO NOT OVERFILL.

22

Page 23

Group 2 Hydraulic Fluid (Hot Climate– Heavy Duty)

Note: The fluids within this group are interchangeable.

ISO VG 68 anti-wear hydraulic fluid

Note: A red dye additive for the hydraulic system fluid is

available in 2/3 oz. bottles. One bottle is sufficient for 4–6

gal. of hydraulic fluid. Order Part No. 44–2500 from your

Authorized Toro Distributor.

Mobil DTE 26

Amoco Rykon AW No. 68

Castrol AWS 68

Chevron Hydraulic Oil AW ISO 68

Conoco Hydroclear AW 68

Exxon Nuto H 68

Gulf Harmony 68AW

Kendall Four Seasons AW 68

Marathon ISO 68

Pennzbell AW Hydraulic Oil 68

Phillips Magnus A ISO 68

Shell Tellus 68

76 Lubricants AW 68

Sunoco SunVis 868

Texaco Rando HD 68

Important Group 1 fluids are recommended for use at

typical ambient temperatures of 32F (0C) to 105F

(41C). The ISO Type 46/68 fluid has been found to offer

optimal performance in a wide range of temperature

conditions for the average user. The Universal Tractor

Fluids offer similar performance for those who prefer them,

with perhaps some slight loss of efficiency at high ambient

temperatures compared to the Type 46/68 fluids.

Group 2 fluids are recommended for heavy-duty use in hot

climates where ambient temperatures range from about

70F (20C) to 120F (49C). Use at lower ambient

temperatures may result in hard starting, increased engine

laboring while cold, sluggish or non-operating spool valves

while cold and high filter back-pressure due to the higher

viscosity of these fluids.

Note: When changing from one type of hydraulic fluid to

another, be certain to remove all the old fluid from the

system, as some fluids are incompatible with others.

1

Figure 34

1. Hydraulic tank cap

1. Position machine on a level surface, lower the cutting

units and stop the engine.

2. Clean area around filler neck and cap of hydraulic tank.

Remove cap from filler neck.

3. Remove dipstick from filler neck and wipe it with a

clean rag. Insert dipstick into filler neck; then remove it

and check level of fluid. Fluid level should be within

1/4 inch of mark on dipstick.

4. If level is low, add appropriate fluid to raise level to full

mark.

5. Install dipstick and cap onto filler neck.

Check Tire Pressure

The tires are over–inflated for shipping. Therefore, release

some of the air to reduce the pressure. Correct air pressure

in tires is 14 –18 psi.

Important Maintain recommended pressure in all tires

to assure a good quality–of–cut and proper machine

performance.

Group 3 Hydraulic Fluid (Biodegradable)

ISO VG 32/46 anti-wear hydraulic fluid

Mobil EAL 224H

Note: This biodegradable hydraulic fluid is not compatible

with the fluids in Group 1 and 2.

Note: When changing from standard fluid to the

biodegradable type, be certain to follow approved flushing

procedures as published by Mobil. Contact your local Toro

Distributor for details.

Important Use only types of hydraulic fluids

specified. Other fluids could cause system damage.

Danger

Low tire pressure decreases the machine’s sidehill

stability. Do not under inflate tires. This could

cause a rollover, which may result in personal

injury or death.

23

Page 24

Check Reel To Bedknife

Contact

Each day before operating, check reel to bedknife contact,

regardless if quality of cut had previously been acceptable.

There must be light contact across the full length of the reel

and bedknife (refer to Adjusting Reel to Bedknife in

Cutting Unit Operator’s Manual).

Mow/Transport Slide

Using your heel, move slide to the left to transport and to

the right to mow. The cutting units will only operate in

the mow position.

Note: Mow speed is set at the factory to 6 mph. It can be

increased or decreased by adjusting the speed stop screw

(Fig. 36)

Check Torque Of Wheel Nuts

Warning

Torque wheel nuts to 45-65 ft–lb after 1-4 hours of

operation and again after 10 hours of operation

and every 200 hours thereafter. Failure to maintain

proper torque could result in failure or loss of

wheel and may result in personal injury.

Controls

Note: Determine the left and right sides of the machine

from the normal operating position.

Traction Pedals

Depress traction forward pedal to move forward. Depress

traction reverse pedal to move backward or to assist in

stopping when moving forward. Also, allow pedal to move

or move it to neutral position to stop machine.

4

Tilt Steering Lever

Pull lever back to loosen to tilt the steering wheel to desired

position. Then push lever forward to tighten.

Angle Indicator

Indicates sidehill angle of the machine in degrees.

Indicator Slot

The slot in the operator’s platform indicates when the

cutting units are in the center position.

1

Figure 36

1. Speed stop screw

1. Forward traction pedal

2. Reverse traction pedal

3. Mow/transport pedal

5

Figure 35

4. Tilt steering wheel

5. Indicator slot

6. Angle indicator

Starter Switch

6

3

1

2

The starter switch, used to start, stop and preheat the

engine, has three positions: OFF, ON/PREHEAT and

START. Rotate key to ON/PREHEAT position until glow

plug indicator light goes out (approximately 7 seconds),

then rotate key to START position to engage starter motor.

Release key when engine starts. The key will move

automatically to the ON/RUN position. To shut engine off,

rotate key to OFF position. Remove key from switch to

prevent accidental starting.

Throttle

Moving throttle forward increases engine speed, rearward

decreases engine speed.

24

Page 25

Cutting Unit Shift Lever

Hour Meter

To lower cutting units to the ground, move lift lever

forward. Cutting units will not drop unless engine is

running and will not operate in raised position. To raise

cutting units, pull lift lever rearward to the RAISE position.

Model 03201 only– Move lever to the right or left to move

cutting units in same direction. This should only be done

when cutting units are raised or if they’re on the ground

and the machine is moving.

Danger

The machine is most stable on a side hill when the

cutting units are shifted uphill. Shifting cutting

units downhill decreases machine stability. This

could cause a rollover, which may result in

personal injury or death.

Note: Lever does not have to be held in forward position

while cutting units are lowered.

Cutting Unit Drive Switch

The switch has two positions: ENGAGE and

DlSENGAGE. Rocker switch operates a solenoid valve, on

valve bank, to drive cutting units.

7

8

4

6

3

5

2

1

Indicates the total hours of machine operation. The Hour

Meter starts to function whenever the key switch is ON.

Engine Coolant Temperature Warning

Light

Light glows if engine coolant temperature is high. If

traction unit is not stopped and coolant temperature rises

another 10 F., the engine will kill.

Oil Pressure Warning Light

Light glows if engine oil pressure drops below a safe level.

Alternator Light

The amp light should be off when engine is running. If it is

on, the charging system should be checked and repaired as

necessary.

Glow Plug Indicator

Indicator light will glow when glow plugs are operating.

Parking Brake

Whenever the engine is shut off, the parking brake must be

engaged to prevent accidental movement of the machine.

To engage the parking brake, pull up on lever. Engine will

stop if traction pedal is depressed with parking brake

engaged.

Lift Lever Lock

10

11

1. Throttle

2. Hour meter

3. Temperature light

4. Oil pressure light

5. Glow plug indicator

6. Alternator light

Figure 37

7. Cutting unit drive switch

8. Cutting unit shift lever

9. Ignition switch

10. Parking brake

11. Lift lever lock

Move lever rearward to prevent cutting units from

9

dropping.

Reel Speed Control

(Located under console cover) – To obtain the desired clip

rate (reel speed), rotate reel speed control knob to

appropriate setting for height–of–cut setting and mower

speed. Refer to Selecting Clip Rate section of Manual.

Backlap Control

(Located under console cover) – Rotate knob clockwise for

backlapping and counterclockwise for mowing. Do not

change knob position when reels are rotating.

25

Page 26

2

Figure 38

1. Reel speed control 2. Backlap control

1

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Starting/Stopping Engine

Important The fuel system may have to be bled if

any of the following situations have occurred:

• Initial start up of a new engine.

• Engine has ceased running due to lack of fuel.

• Maintenance has been performed upon fuel

system components; i.e. filter replaced, etc.

Fuel Gauge

Registers amount of fuel in tank.

Seat Adjustments

Fore and Aft Adjustment — Move lever on side of seat

outward, slide seat to desired position and release lever to

lock seat into position.

Deluxe Seat Adjustments

Weight Adjustment — Push lever up or down to adjust to

operator’s weight. Lever up — light operator, lever in

middle position — medium weight operator or lever down

for heavy operator.

Inclining Backrest — Turn handle to adjust angle of

backrest.

• Refer to Bleeding Fuel System

1. Be sure parking brake is set and Reel Drive switch is in

DISENGAGE position.

2. Remove foot from traction pedal and make sure pedal is

in neutral position.

3. Move throttle lever to 1/2 throttle position.

4. Insert key into switch and rotate it to ON/PREHEAT

position until glow plug indicator light goes out

(approximately 7 seconds), then rotate key to START

position to engage starter motor. Release key when

engine starts. The key will move automatically to the

ON/RUN position.

Important To prevent overheating of the starter

motor, do not engage starter longer than 15 seconds.

After 10 seconds of continuous cranking, wait 60

seconds before engaging starter motor again.

5. When engine is started for the first time, or after

overhaul of the engine, operate the machine in forward

and reverse for one to two minutes. Also operate the lift

lever and reel drive switch to be sure of proper

operation of all parts.

Turn steering wheel to the left and right to check steering

response. Then shut engine off and check for oil leaks,

loose parts and any other noticeable malfunctions.

2

Figure 39

1. Fore and aft lever 2. Fuel gauge

Caution

• Shut engine off and wait for all moving parts to

stop before checking for oil leaks, loose parts or

1

26

other malfunctions.

6. To stop engine, move throttle control to IDLE position,

move reel drive switch to DISENGAGE and rotate

starter key to OFF. Remove key from switch to prevent

accidental starting.

Page 27

Bleeding Fuel System

1. Park the machine on a level surface. Make sure fuel

tank is at least half full.

2. Unlatch and raise hood.

3. Open the air bleed screw on the fuel injection pump

(Fig. 40).

Note: Normally, engine should start after above bleeding

procedures are followed. However, if engine does not start,

air may be trapped between injection pump and injectors;

refer to Bleeding Air From Injectors.

Check Operation Of Interlock

Switches

Caution

Figure 40

1. Fuel injection pump bleed

screw

Danger

Under certain conditions, diesel fuel and fuel

vapors are highly flammable and explosive. A fire

or explosion from fuel can burn you and others

and can cause property damage.

• Use a funnel and fill the fuel tank outdoors, in

an open area, when the engine is off and is cold.

Wipe up any fuel that spills.

• Do not fill the fuel tank completely full. Add fuel

to the fuel tank until the level is 1 in. (25 mm)

below the bottom of the filler neck. This empty

space in the tank allows the fuel to expand.

• Never smoke when handling fuel, and stay away

from an open flame or where fuel fumes may be

ignited by a spark.

• Store fuel in a clean, safety-approved container

and keep the cap in place.

1

If safety interlock switches are disconnected or

damaged the machine could operate unexpectedly

causing personal injury.

• Do not tamper with the interlock switches.

• Check the operation of the interlock switches

daily and replace any damaged switches before

operating the machine.

• Replace switches every two years regardless of

whether they are operating properly or not.

1. Make sure all bystanders are away from the area of

operation. Keep hands and feet away from cutting units.

2. With operator on seat, the engine must not start with

either reel switch engaged or traction pedal engaged.

Correct problem if not operating properly.

3. With operator on the seat, traction pedal in neutral,

parking brake off and reel switch in OFF position, the

engine should start. Lift off the seat and slowly depress

the traction pedal, the engine should stop in one to

three seconds. Correct problem if not operating

properly.

4. With operator on the seat, engine running, reel transport

slide in mow and reel switch in ON position, lower

cutting units. Reels should come on. Pull back on the

lift lever, the reels should stop when fully raised.

Correct problem if not operating properly.

Note: The machine is equipped with an interlock switch on

the parking brake. Engine will stop if traction pedal is

depressed with parking brake engaged.

Towing Traction Unit

4. Turn key in ignition switch to the ON position. Electric

fuel pump will begin operation, thereby forcing air out

around air bleed screw. Leave key in ON position until

solid stream of fuel flows out around screw. Tighten

screw and turn key to OFF.

In case of emergency, the Reelmaster can be towed for a

short distance. However, Toro does not recommend this as

a standard procedure.

27

Page 28

Important Do not tow the machine faster than 2–3 mph

because drive system may be damaged. If machine must be

moved a considerable distance, transport it on a truck or

trailer.

Operating Characteristics

Danger

1. Locate by–pass valve on pump and rotate it 90.

1

Figure 41

1. By–pass valve

2. Before starting engine, close by–pass valve by rotating

it 90. Do not start engine when valve is open.

The mower has a unique traction system that will

allow the machine to move forward on side hills,

even if the uphill wheel should come of the ground.

If this should happen, the operator or any

bystanders can be seriously injured or killed in a

rollover.

The slope angle at which the machine will tip is

dependent on many factors. Among these are

mowing conditions such as wet or undulating turf,

speed (especially in turns), position of the cutting

units (with Sidewinder) tire pressure and operator

experience.

At side hill angles of 20 degrees or less the risk of a

rollover is low. As the slope angle increases to a

Toro recommended maximum limit of 25 degrees

the risk of a rollover increases to a moderate level.

DO NOT EXCEED A 25 DEGREE SIDE HILL

SLOPE ANGLE BECAUSE THE RISK OF A

ROLLOVER AND SERIOUS INJURY OR

DEATH IS VERY HIGH.

To determine which hills or slopes may be safely

operated on, a site survey of the mowing area must

be done. When performing this site survey always

use common sense and take into consideration the

turf condition and the rollover risk. To determine

which hills or slopes may be safely operated on use

the inclinometer provided with each machine. To

perform a site survey, lay a 4’ two by four on the

slope surface and measure the angle of the slope.

The 2 by 4 will average the slope but will not take

into consideration dips or holes which can cause a

sudden change in sidehill angle. THE MAXIMUM

SIDE HILL ANGLE SHOULD NOT BE

GREATER THAN 25 DEGREES.

Additionally, the Reelmaster 3100–D is equipped

with an angle indicator mounted on the steering

tube. This indicates the sidehill angle the machine

is on and identifies the recommended maximum

limit of 25 degrees.

ALWAYS WEAR YOUR SEAT BELT.

Practice operating the Reelmaster and become thoroughly

familiar with it.

Start the engine and run it at half idle until it warms up.

Push the throttle lever all the way forward, lift the cutting

units, disengage the parking brake, press the forward

traction pedal and carefully drive off to an open area.

28

Page 29

Practice going both forward and in reverse, starting and

stopping the machine. To stop, take your foot off

traction pedal and let it return to neutral or press down on

the reverse pedal to stop. Going down a hill, you may need

to use the reverse pedal to stop.

When driving on slopes, drive slowly to maintain steering

control and avoid turns to prevent rollovers. In side hill

situations you should shift the sidewinder cutting units

to the up hill side to give you more stability. Conversely,

shifting the cutting units to the down hill side will give

you less stability. This should always be done before

going on a side hill.

When possible, mow up and down hills rather than across

them. Have the cutting units lowered when going down a

hill to maintain steering control. Do not attempt to turn on a

hill.

Practice driving around obstacles with the reels up and

down. Be careful when driving between narrow objects so

you don’t damage the machine or cutting units.

On the Sidewinder unit, get a feel for the reach of the

cutting units so you don’t hang them up or damage them in

any way.

Don’t shift the units from side to side, unless the cutting

units are down and the machine is moving, or the cutting

units are up in the transport position. Shifting the cutting

units when they are down and the machine is not moving

may cause turf damage.

The Reelmaster is a precision mowing machine, so always

drive slowly in rough areas.

If a person appears in or near the operating area, stop the

machine, and don’t start up again until the area is cleared.

The Reelmaster is a one–person machine. Never let anyone

else ride on the machine with you. This is extremely

dangerous and could result in serious injury.

Accidents can happen to anyone. The most common causes

are excessive speed, sudden turns, terrain (with the

Reelmaster 3100–D that’s knowing what slopes and hills

can be mowed safely), not stopping the engine before

leaving the operator’s seat, and drugs which impair your

alertness. Cold capsules or prescription drugs may cause

drowsiness, as can alcohol and other drugs. Stay alert and

stay safe. Failure to do so could result in serious injury.

the

When transporting the machine from one work area to

another, raise cutting units to the fully up position, move

Mow/Transport slide to the left to transport and place

throttle in FAST position. (The cutting units will not

operate in transport.)

Mowing Techniques

To begin cutting, engage the reels, then approach the

mowing area slowly. Once the front reels are over the

mowing area, lower the cutting units.

To achieve the professional straight line cut and striping

that is desirable for some applications, find a tree or other

object in the distance and drive straight toward it.

As soon as the front reels reach the edge of the mowing

area, lift the cutting units and perform a tear drop turn, to

quickly line you up for your next pass.

Mowing around bunkers ponds or other contours is easily

done with The Reelmaster 3100–D with Sidewinder. To use

the Sidewinder application, move the control lever left or

right, depending on your mowing application. The cutting

units can also be shifted to vary tire tracking.

The Reelmaster 3100–D cutting units can throw clippings

to the front or rear. Front throw should be used when

cutting off smaller amounts of grass; thus, leaving a better

after cut appearance. To throw clippings to the front, simply

close the rear shield on the cutting units.

Caution

• Shut engine off and wait for all moving parts to

stop before opening or closing cutting unit

shields

When cutting off larger amounts of grass, the shields shown

be positioned to just below horizontal. Do not open the

shields too far or excessive clippings can build up on the

frame, rear radiator screen and engine area.

The cutting units are also equipped with balance weights,

on the non–motor end, to give an even cut. Weights can be

added or removed if mismatch occurs on your turf.

The Sidewinder offers up to a maximum of 23 inches of

overhang, allowing you to trim closer to the edge of traps

and other obstacles, while at the same time keeping the

tractor tires as far away from the edge of traps or water

hazards as possible.

If an obstacle is in the way, shift the cutting units to easily

mow around it.

The use of protective equipment for eyes, ears, feet, and

head is recommended.

After Mowing

At the completion of mowing operation, thoroughly wash

the machine with a garden hose – without a nozzle – so

excessive water pressure will not cause contamination and

damage to seals and bearings. Make sure radiator and oil

cooler are kept free of dirt or grass clippings. After

cleaning, it is recommended the machine be inspected for

possible hydraulic fluid leaks, damage or wear to hydraulic

and mechanical components and the cutting units checked

for sharpness and proper reel to bedknife adjustment.

29

Page 30

IMPORTANT: After wash down, move the Sidewinder

mechanism (model 03201 only) from left to right several

times to remove water between bearing blocks and cross

tube.

Selecting Clip Rate

(Reel Speed)

To achieve a consistent, high quality of cut, and a uniform

after cut appearance, it is important that the reel speed be

matched to the height of cut.

Important If reel speed is too slow, clip marks may be

visible. If reel speed is too fast the cut may have a fuzzy

appearance.

Adjust the clip rate (reel speed) as follows:

1. Verify the height–of–cut setting on the cutting units.

Using the column of the chart, on page 30, listing either

5 or 8 blade reels, find the height of cut listing nearest

the actual height–of–cut setting. Look across the chart

to find the number corresponding to that height of cut.

Note: The higher the number, the higher the speed.

2. Turn the reel speed control knob to the number setting

determined in step 1.

1

5 BLADE REEL

REEL SPEED SELECTION CHART

5 MPH 6 MPHHEIGHT OF CUT

2–1/2 2.50 3 3

2–3/8 2.38 3 4

2–1/4 2.25 3 4

2–1/8 2.13 3 4

2 2.00 3 4

1–7/8 1.88 4 5

1–3/4 1.75 4 5

1–5/8 1.63 5 6

1–1/2 1.50 5 7

1–3/8 1.38 5 8

1–1/4 1.25 6 11

1–1/8 1.13 8 11*

1 1.00 11 11*

7/8 0.88 11* 11*

3/4 0.75 11* 11*

5/8 0.63 11* 11*

1/2 0.50 11* 11*

3/8 0.38 11* 11*

* This height–of–cut and/or mowing speed not recommended

for 5 blade reels.

8 BLADE REEL

REEL SPEED SELECTION CHART

Figure 42

1. Reel speed control

3. Operate the machine for several days, then examine the

cut to ensure satisfaction with the quality of cut. The

reel speed knob may be set one position on either side

of the position indicated on the chart to account for

differences in grass condition, grass length removed and

personal preference.

5 MPH 6 MPHHEIGHT OF CUT

2–1/2 2.50 3* 3*

2–3/8 2.38 3* 3*

2–1/4 2.25 3* 3*

2–1/8 2.13 3* 3*

2 2.00 3* 3*

1–7/8 1.88 3* 3*

1–3/4 1.75 3* 3*

1–5/8 1.63 3* 3*

1–1/2 1.50 3 4

1–3/8 1.38 3 4

1–1/4 1.25 4 4

1–1/8 1.13 4 5

1 1.00 5 6

7/8 0.88 5 7

3/4 0.75 7 11

5/8 0.63 11 11*

1/2 0.50 11 11*

3/8 0.38 11 11*

* This height–of–cut and/or mowing speed not recommended

for 8 blade reels.

Note: Positions 9 to 11 give the same reel speed.

30

Page 31

Standard Control Module

(SCM)

The Standard Control Module is a ”potted” electronic

device produced in a ”one size fits all” configuration. The

module uses solid state and mechanical components to

monitor and control standard electrical features required for

safe product operation.

The module monitors inputs including neutral, parking

brake, PTO, start, backlap, and high temperature. The

module energizes outputs including PTO, Starter, and ETR

(energize to run) solenoid.

The module is divided into inputs and outputs. Inputs and

outputs are identified by green LED indicators mounted on

the printed circuit board.

The start circuit input is energized by 12 VDC. All other

inputs are energized when the circuit is closed to ground.

Each input has a LED that is illuminated when the specific

circuit is energized. Use the input LED’s for switch and

input circuit troubleshooting.

Output circuits are energized by an appropriate set of input

conditions. The three outputs include PTO, ETR, and

START. Output LED’s monitor relay condition indicating

the presence of voltage at one of three specific output

terminals.

Output circuits do not determine output device integrity so