Page 1

FormNo.3368-464RevB

5,8and11-Blade27-inchand

8-Blade32-inchDPACuttingUnit

Reelmaster

ModelNo.03180—SerialNo.311000001andUp

ModelNo.03181—SerialNo.311000001andUp

ModelNo.03182—SerialNo.311000001andUp

ModelNo.03183—SerialNo.311000001andUp

®

3100-DSeriesTractionUnit

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Introduction

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Thisreel-bladelawnmowerismountedtoaride-on

machineandisintendedtobeusedbyprofessional,hired

operatorsincommercialapplications.Itisprimarily

designedforcuttinggrassonwell-maintainedlawnsin

parks,golfcourses,sportselds,andoncommercial

grounds.Itisnotdesignedforcuttingbrush,mowing

grassandothergrowthalongsidehighways,orfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.

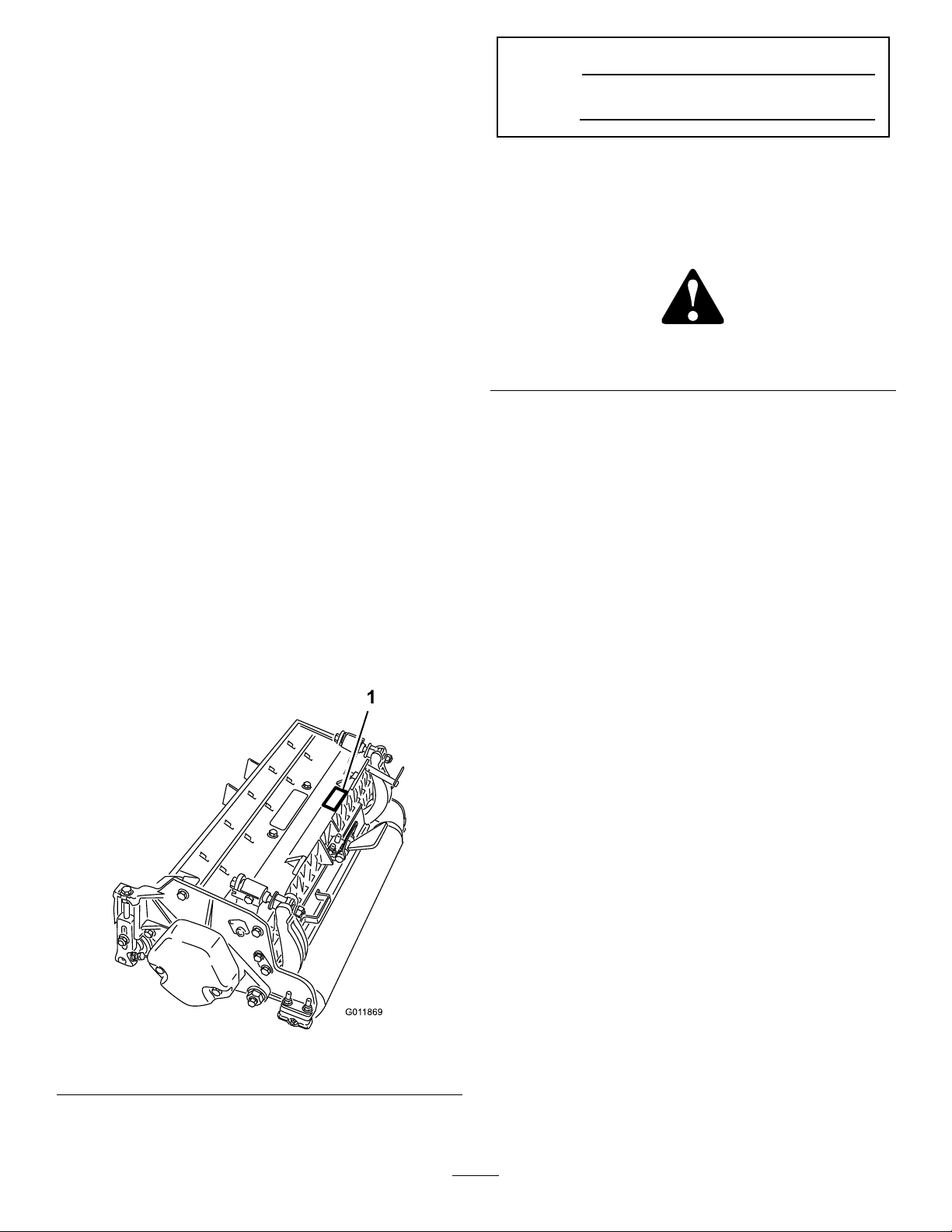

Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Locationofthemodelandserialnumbers

Contents

Introduction.................................................................2

Safety...........................................................................3

SafetyandInstructionalDecals.............................3

Setup............................................................................4

1Inspection.........................................................4

2CuttingUnitKickstand......................................4

3AdjustingtheRearShield...................................5

4MounttheCounterWeights...............................5

5InstallingtheTipperRollerKit

(Optional)........................................................6

6InstallingtheFixedPlateKit(Optional)..............6

ProductOverview........................................................8

Specications.......................................................8

CuttingUnitAccessoriesandKits(seeparts

catalogforpartnumbers)..................................8

Operation.....................................................................9

Adjustments.........................................................9

HeightofCutChartTerms.................................10

HeightofCutChart............................................11

ServicingBedknife.............................................13

Maintenance...............................................................15

Lubrication.........................................................15

AdjustingtheReelBearings................................15

ServicingtheBedbar...........................................16

ServicingtheRoller............................................17

©2011—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

Hazardcontrolandaccidentpreventionare

dependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedinthe

operation,transport,maintenance,andstorageof

themachine.Improperuseormaintenanceofthe

machinecanresultininjuryordeath.Toreduce

thepotentialforinjuryordeath,complywiththe

followingsafetyinstructions.

•Read,understand,andfollowallinstructionsinthe

tractionunitandcuttingunitoperatorsmanual’s

beforeoperatingthecuttingunit.

•Neverallowchildrentooperatethetractionunitor

cuttingunits.Donotallowadultstooperatetraction

unitorcuttingunitswithoutproperinstruction.

Onlytrainedoperatorswhohavereadthismanual

shouldoperatethetractionunitorcuttingunits.

•Neveroperatethecuttingunitswhenunderthe

inuenceofdrugsoralcohol.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydeviceordecalisillegibleordamaged,

repairorreplaceitbeforeoperationiscommenced.

Alsotightenanyloosenuts,bolts,andscrewsto

ensurecuttingunitisinsafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperate

cuttingunitswhilewearingsandals,tennisshoes,

sneakersorshorts.Also,donotwearloosetting

clothingwhichcouldgetcaughtinmovingparts.

Alwayswearlongpantsandsubstantialshoes.

Wearingsafetyglasses,safetyshoesandahelmetis

advisableandrequiredbysomelocalordinancesand

insuranceregulations.

•Removealldebrisorotherobjectsthatmightbe

pickedupandthrownbythecuttingunitreelblades.

Keepallbystandersawayfromtheworkingarea.

•Ifthecuttingbladesstrikeasolidobjectortheunit

vibratesabnormally,stopandshuttheengineoff.

Checkcuttingunitfordamagedparts.Repairany

damagebeforerestartingandoperatingthecutting

unit.

•Lowerthecuttingunitstothegroundandremove

keyfromignitionswitchwhenevermachineisleft

unattended.

•Besurecuttingunitsareinsafeoperatingcondition

bykeepingnuts,boltsandscrewstight.

•Removekeyfromignitionswitchtoprevent

accidentalstartingoftheenginewhenservicing,

adjustingorstoringthemachine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedToroDistributor.

•Toensureoptimumperformanceandsafety,always

purchasegenuineTororeplacementpartsand

accessoriestokeeptheT oroallToro.Neveruse

"will-t"replacementpartsandaccessories

madebyothermanufacturers.Lookforthe

Torologotoassuregenuineness.Usingunapproved

replacementpartsandaccessoriescouldvoidthe

warrantyofTheToroCompany.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-6688

1.Warning—readthe

instructionsbefore

servicingorperforming

maintenance.

2.Cuttinghazardofhandor

foot—stoptheengineand

waitformovingpartsto

stop.

3

Page 4

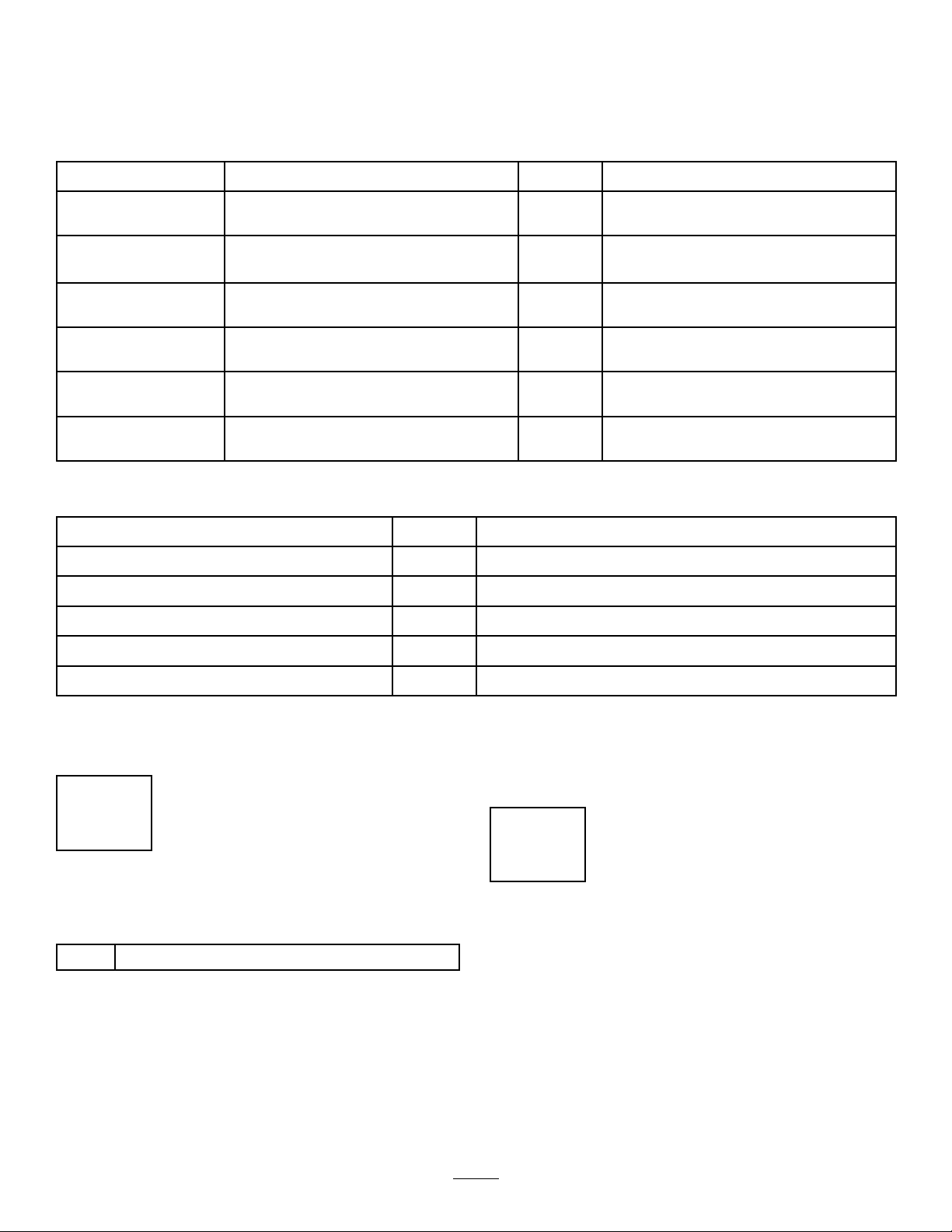

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

Cuttingunit

Nopartsrequired

Nopartsrequired

Nopartsrequired

Tipperrollerkit(notincluded)

Fixedplatekit(notincluded)

MediaandAdditionalParts

Description

Partscatalog1

Operator’sManual

CerticateofCompliance

Qty.

1Inspectthecuttingunit

–

–

–

1Installtheoptionaltipperrollerkit

1

Qty.

Usetoreferencepartnumbers

1Reviewthemanualandsaveinanappropriateplace

1

CEcompliance

Usethekickstandwhentippingthe

cuttingunit

Adjusttherearshield

Mountthecounterweights

InstalltheOptionalFixedPlateKit

Use

Use

O-ring

Screws

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

Inspection

Partsneededforthisprocedure:

1

Cuttingunit

Procedure

Afterthecuttingunitisremovedfromthebox,inspect

thefollowing:

1.Checkeachendofthereelforgrease.Greaseshould

bevisiblyevidentinthereelbearingsandinternal

splinesofthereelshaft.

1Usewhenmountingreelmotortocuttingunit

2Usetomountreelmotortocuttingunit

2.Ensurethatallnutsandboltsaresecurelytightened.

3.Makesurethecarrierframesuspensionoperates

freelyanddoesnotbindwhenmovedbackandforth.

2

CuttingUnitKickstand

NoPartsRequired

Procedure

Wheneverthecuttingunithastobetippedtoexposethe

bedknife/reel,propuptherearofthecuttingunitwith

thekickstand(suppliedwiththetractionunit)tomake

surethenutsonthebackendofthebedbaradjusting

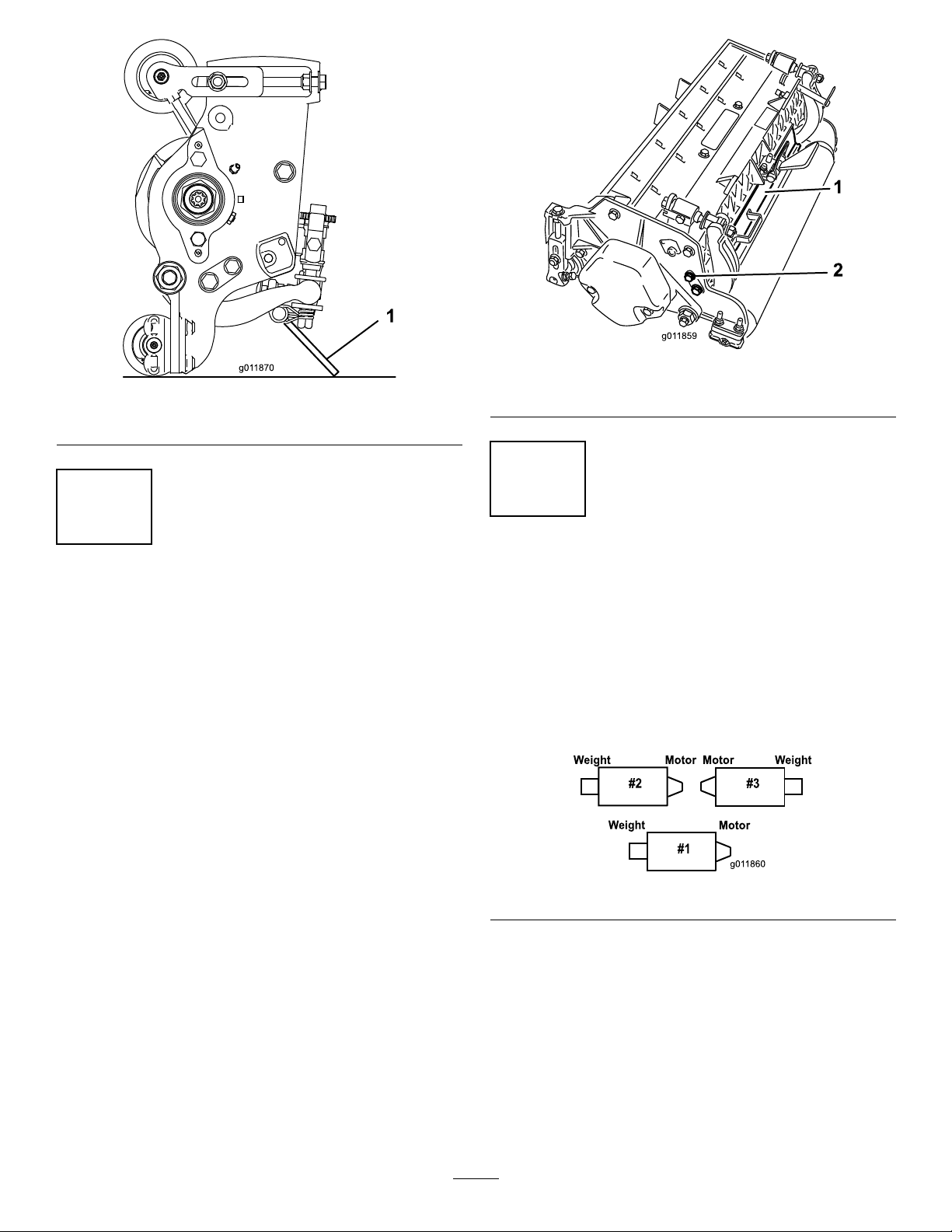

screwsarenotrestingontheworksurface(

Figure3).

4

Page 5

1.Cuttingunitkickstand

Figure3

1.Rearshield

Figure4

2.Capscrew

4

3

AdjustingtheRearShield

NoPartsRequired

Procedure

Undermostconditions,bestdispersionisattained

whentherearshieldisclosed(frontdischarge).When

conditionsareheavyorwet,rearshieldmaybeopened.

Toopentherearshield(Figure4),loosenthecapscrew

securingtheshieldtotheleftsideplate,rotatetheshield

totheopenpositionandtightenthecapscrew .

MounttheCounterWeights

NoPartsRequired

Procedure

Allcuttingunitsareshippedwiththecounterweight

mountedtotheleftendofthecuttingunit.Usethe

followingdiagramtodeterminethepositionofthe

counterweightsandreelmotors.

Figure5

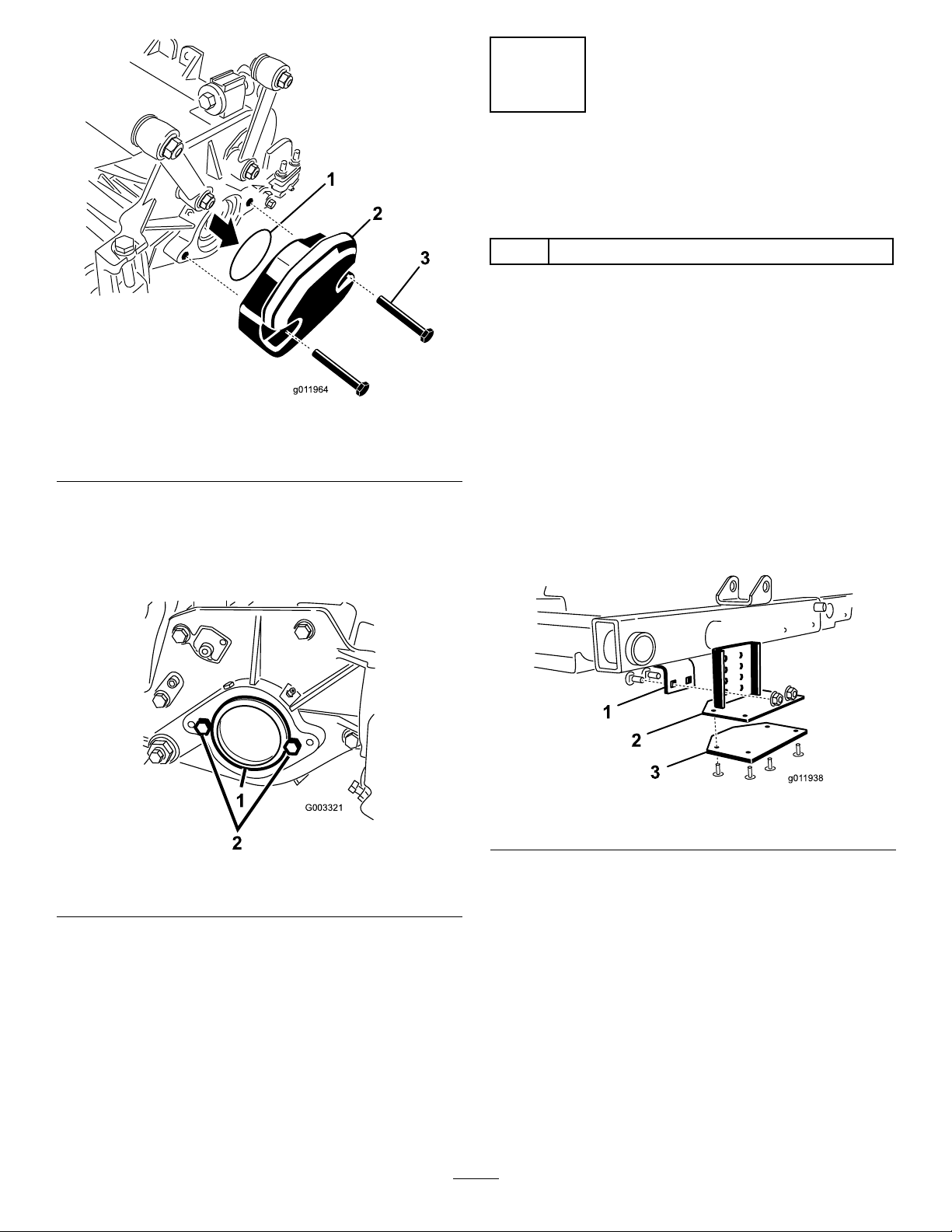

1.Onthe#3cuttingunit,removethe2capscrews

securingthecounterweighttotheleftendofthe

cuttingunit.Removethecounterweight(Figure6).

5

Page 6

Figure6

G003321

1

2

1.O-ring

2.Counterweight

2.Onrightendofcuttingunit,removetheplasticplug

fromthebearinghousing(Figure7).

3.Removethe2capscrewsfromtherightsideplate

(Figure7).

3.Mountingbolts

5

InstallingtheTipperRollerKit

(Optional)

Partsneededforthisprocedure:

1

Tipperrollerkit(notincluded)

Procedure

Whencuttinginhigherheightsofcut,itisrecommended

thattheTipperRollerKitbeinstalled.

1.Raisethecuttingunitsallthewayup.

2.Locatetheframebracketabovethecentercutting

unit(Figure8).

3.Whilepressingdownonthefrontrollerofthecenter

cuttingunit,determinewhichholesonthetipper

bracketalignwiththeframebracketholestoattain

thesamerollercontactwhenthetipperbracketis

installed(

Figure8).

Figure7

1.Plasticplug

4.Installthecounterweighttotherightendofthe

cuttingunitwiththe2screwspreviouslyremoved.

5.Looselyinstallthe2reelmotormountingcapscrews

totheleftsideplateofthecuttingunit(Figure7).

2.Capscrew(2)

Figure8

1.Framebracket2.Tipperbracket

4.Lowerthecuttingunitsandmountthetipperbracket

totheframewiththe(2)carriageboltsandnuts

suppliedwiththekit(Figure8).

6

Page 7

6

InstallingtheFixedPlateKit

(Optional)

Partsneededforthisprocedure:

1

Fixedplatekit(notincluded)

Procedure

1.Removethenutsandwasherssecuringtheliftlinks

tothecuttingunitsideplateandcarrierframe

(Figure10).

Figure9

1.Nuts2.Washers

2.Usingthenumber2holes,insertaxedplateonto

theboltsandsecurewiththenutsremoved.The

number1holesaretobepositionedtowardthe

front.Donotreusethewashers.

Figure10

1.Nuts2.Fixedplate

3.Loosenthelocknutssecuringtheheight-of-cut

bracketstothecuttingunitsideplates(Figure11).

Figure11

1.Height-of-cutbracket

2.Locknut

4.Removetheheight-of-cutbracketsandtheroller

fromthecuttingunit.

5.Repeattheprocedureontheremainingcuttingunits.

3.Adjustingscrew

Note:Number1isalessaggressivesettingand

number3isamoreaggressivesetting.

7

Page 8

ProductOverview

Specications

Weight

27inch5Blade–148lb.(67kg)27inch8Blade–153lb.(69kg)

27inch11Blade–158lb.(72kg)32inch8Blade–167lb.(76kg)

CuttingUnitAccessoriesandKits(see

partscatalogforpartnumbers)

Note:Allaccessoriesandkitsare1percuttingunit

unlessotherwisespecied.

GrassBasketKit:Aseriesofclippingcollectionbaskets

attachedtothecuttingunitstocollectgrassclippings.

TipperRollerKit:Anadjustablebracketinstalledon

thetractionunitframe,whichwhenthecuttingunitsare

raised,thecentercuttingunitfrontrollercontactsthe

bracketandcausestherearrollertoriseforincreased

groundclearance.Recommendedforhigherheightsof

cut.

RearRollerBrushKit:Ahighspeed,highcontact

brushthatkeepstherearrollerfreeofgrassanddebris,

whichmaintainsaconsistentheightofcutandprevents

clumping.Thisleadstoabetterafter-cutappearance.

Comb/ScraperKit:Axedcombinstalledbehindthe

frontrollerwhichhelpsreducegrainandspongyturfby

standingupthegrassbeforecutting.Ascraperforthe

frontWiehlerollerisincludedinthekit.

FixedPlateKit:Boltingonxedplatesoverthe

suspensionmountinglinksremovesthepitchmovement

ofthecuttingunit.Recommendedforuseonlevel

surfacesandforhigherheightsofcut(greaterthan1.50

inches[38mm]).Becausethefrontrollerisremoved

whenusingthexedplates,thequalityofcut(efciency

ofcut)isincreased.

ShoulderRoller:Helpsreduceover-lapmarksfor

warmseasongrasses(Bermuda,Zoysia,Paspalum).

CollarKit(6neededperroller):Helpsreduceover

lapmarksforwarmseasongrasses(Bermuda,Zoysia,

Paspalum).Thiskitisinstalledontheouterthree

groovesoftheexistingWiehleroller,butisnotas

aggressiveastheShoulderroller.

ShortRearRoller:Helpsreducedoublerollermarks

forcoolseasongrasses(Bent,Bluegrass,Rye).

FullFrontRoller:Helpsproducemorepronounced

striping(repeatedcuttinginthesamedirection/path),

however,effectiveheightofcutisraisedandqualityof

cutisreduced.

Scrapers(Wiehle,Shoulder,Rearroller,FullFront

Roller):Fixedscrapersforalloptionalrollersare

availableforreducinggrassbuilduponrollerswhich

canaffectheightofcutsettings.

RollerRebuildKit:Includesallthebearings,bearing

nuts,innersealsandoutersealsrequiredtorebuilda

roller.

RollerRebuildToolKit:Includesallthetoolsandthe

installationinstructionsrequiredtorebuildarollerwith

therollerrebuildkit.

8

Page 9

Operation

G003323G003323

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Adjustments

AdjustingtheBedknifetotheReel

Bedknifetoreeladjustmentisaccomplishedby

looseningortighteningbedbaradjustingscrews,located

ontopofmower.

1.Positionmachineonaat,levelworksurface.Make

surereelcontactisremovedbyturningbedbar

adjustingscrewscounterclockwise(

Figure12

1.Bedbaradjustingscrew

Figure12).

2.Tiltmoweronback,ontothecuttingunitkickstand,

toexposebedknifeandreel.

Important:Makesurenutsonbackendof

bedbaradjustingscrewsarenotrestingonthe

worksurface(

Figure12).

Figure13

4.Checkforlightcontactatotherendofreelusing

paperandadjustasrequired.

5.Afteradjustmentisaccomplished,checktoseeif

reelcanpinchpaperwheninsertedfromthefront

andcutpaperwheninsertedatarightangletothe

bedknife(Figure13).Itshouldbepossibletocut

paperwithminimumcontactbetweenthebedknife

andthereelblades.Ifexcessivecontact/reeldrag

isevidentitwillbeeithernecessarytobacklapor

regrindthecuttingunittoachievethesharpedges

neededforprecisioncutting(RefertotheToro

manualforSharpeningReelandRotaryMowers,

FormNo.80-300PT).

AdjustingtheRearRoller

1.Adjusttherearrollerbrackets(Figure14)tothe

desiredheightofcutrangebypositioningthe

requiredamountofspacersbelowthesideplate

mountingange(Figure14)pertheHOCChart.

3.Atoneendofreel,insertastripofnewspaper

betweenreelandbedknife(Figure13).Whileslowly

rotatingreelforward,turnbedbaradjustingscrew

Figure12)clockwise(onsameendofreel,one

(

clickatatime,untilpaperispinchedlightly,when

insertedfromthefront,paralleltothebedknife.A

slightdragwillbenotedasthepaperispulled.

Note:Eachtimeadjustingscrewisrotatedone

clickclockwise,bedknifemoves.0009in(.023mm).

closertoreel.Donotovertightentheadjusting

screws.

Figure14

1.Spacer3.Sideplatemountingange

2.Rollerbracket

2.Raiserearofcuttingunitandplaceablockunder

bedknife.

3.Remove(2)nutssecuringeachrollerbracketand

spacertoeachsideplatemountingange.

4.Lowerrollerandscrewsfromsideplatemounting

angesandspacers.

5.Placespacersontoscrewsonrollerbrackets.

9

Page 10

6.Re-securerollerbracketandspacerstounderside

ofsideplatemountingangeswithnutspreviously

removed.

regularlytodeterminethedesiredbenchsetheightof

cut.

7.Verifythatbedknifetoreelcontactiscorrect.Tip

mowertoexposefrontandrearrollersandbedknife.

Note:Thepositionoftherearrollertothe

reeliscontrolledbythemachiningtolerances

oftheassembledcomponentsandparallelingis

notrequired.Alimitedamountofadjustmentis

possiblebysettingthecuttingunitonasurface

plateandlooseningthesideplatemountingcap

screws(

Figure15).Adjustandretightencapscrews.

Torquethecapscrewsto27-33ft-lb(37-45N-m).

AggressivenessofCut

CuttingunitAggressivenessofCuthasasignicant

impactontheperformanceofthecuttingunit.

AggressivenessofCutreferstotheangleofthe

bedkniferelativetotheground(

Thebestcuttingunitsetupisdependentonyour

turfconditionsanddesiredresults.Experiencewith

thecuttingunitonyourturfwilldeterminethebest

settingtouse.Aggressivenessofcutmaybeadjusted

throughoutthecuttingseasontoallowforvariousturf

conditions.

Ingeneral,lesstonormalaggressivesettingsare

moreappropriateforwarmseasongrasses(Bermuda,

Paspalum,Zoysia)whilecoolseasongrasses(Bent,

Bluegrass,Rye)mayrequirenormaltomoreaggressive

setups.Moreaggressivesetupscutmoregrassoffby

allowingthespinningreeltopullmoregrassupinto

thebedknife.

Figure16).

Figure15

1.Sideplatemountingcapscrews

HeightofCutChartTerms

HeightofCutSetting(HOC)

ThedesiredHeightofCut.

BenchSetHeightofCut

Theheightatwhichthetopedgeofthebedknifeisset

aboveaatlevelsurfacethatcontactsthebottomof

boththefrontandrearroller.

EffectiveHeightofCut

Thisistheactualheightthegrasshasbeencut.For

agivenbenchsetheightofcut,theactualheightof

cutwillvarydependingonthetypeofgrass,timeof

year,turfandsoilconditions.Thecuttingunitsetup

(aggressivenessofcut,rollers,bedknives,attachments

installed,turfcompensationsettings,etc.)willalso

affecttheeffectiveheightofcut.Checktheeffective

heightofcutusingtheTurfEvaluator,Model04399

Figure16

1.Rearspacers

2.Sideplatemountingange

3.Aggressivenessofcut

RearSpacers

Thenumberofrearspacersdeterminesthe

aggressivenessofcutforthecuttingunit.Foragiven

heightofcut,addingspacers,belowthesideplate

mountingange,increasestheaggressivenessofthe

cuttingunit.Allcuttingunitsonagivenmachinemust

besettothesameaggressivenessofcut(Numberof

rearspacers,partno.119–0626),otherwisetheafter-cut

appearancecouldbenegativelyaffected(

Figure16).

10

Page 11

HeightofCutChart

HOCSetting

0.250"(6mm)

0.375"(9mm)

0.500"(13mm)

0.625"(16mm)

0.750"(19mm)

0.875"(22mm)

1.000"(25mm)

1.125"(29mm)

1.250"(32mm)

1.375"(35mm)

1.500"(38mm)

1.625"(41mm)

1.750"(44mm)

1.875"(48mm)

2.000"(51mm)

2.125"(54mm)*

2.250"(57mm)*

2.375"(60mm)*

2.500"(64mm)*

Aggressiveness

ofCut

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

Less

Normal

More

No.ofRear

Spacers

0

0

1

0

1

2

0

1

2

1

2

3

2

3

4

2

3

4

3

4

5

4

5

6

4

5

6

4

5

6

5

6

7

6

7

8

6

7

8

7

8

9

7

8

9

8

9

10

8

9

10

9

10

11

*FixedPlateKits(PartNo.119–0646–03)arerecommended

for2.00to2.5inch(51to64mm)heightsofcut.

AdjustingtheHeightofCut

1.Loosenlocknutssecuringheight-of-cutbracketsto

cuttingunitsideplates(Figure17).

1.Height-of-cutbracket

2.Locknut

2.Loosennutongaugebar(Figure18)andset

adjustingscrewtodesiredheight-of-cut.Distance

betweenbottomofscrewheadandfaceofbaris

height-of-cut.

1.Gaugebar

2.Heightadjustingscrew

3.Hookthescrewheadoncuttingedgeofbedknife

andrestrearendofbaronrearroller(Figure19).

4.Rotatetheadjustingscrewuntilthefrontroller

contactsthegaugebar(Figure19).Adjustbothends

Less

Normal

More

Figure17

3.Adjustingscrew

Figure18

3.Nut

9

10

11

ofrolleruntilentirerollerisparalleltothebedknife.

11

Page 12

Figure19

Important:Whensetproperly,therearand

frontrollerswillcontactthegaugebarandthe

screwwillbesnugagainstthebedknife.This

ensuresthattheheight-of-cutisidenticalat

bothendsofthebedknife.

5.Tightennutstosecureadjustment.Donot

overtightennut.Tightenenoughtoremoveplay

fromwasher.

Figure20

1.BedknifeLipHeight*

6.Toadjusttheheightofcutwhenxedplatekitsare

installedonthecuttingunits,proceedasfollows:

•Removetheheightofcutbracketsandfront

rollerasdescribedinProcedure6intheSet-Up

section.

•Installthecuttingunitontothetractionunit

asdescribedintheTractionUnitOperator’s

Manual.

•Lowerthecuttingunittotheoorandmeasure

thedistancefromtheoortothetopofthe

bedknife,asshownin

Figure21

Usethefollowingcharttodeterminewhich

bedknifeisbestsuitedforthedesiredheightofcut.

Bedknife/HeightofCutChart

Bedknife

LowHOC

(Optional)

EdgeMax®

(Optional)

Standard

(Production)

HeavyDuty

(Optional)

PartNo.

120–1641

(27inch)

120–1642

(32inch)

112-8910

(27inch)

112–8956

(32inch)

114–9388

(27inch)

114–9389

(32inch)

114–9390

(27inch)

114–9391

(32inch)

Bedknife

LipHeight

*

.220inch

(5.6mm)

.270inch

(6.9mm)

.270inch

(6.9mm)

.370inch

(9.3mm)

HeightofCut

.250-.500inch

(6.4–12.7mm)

.375-2.50inches*

(9.5–63.5mm)

.375-2.50inches*

(9.5–63.5mm)

.500-2.50inches

(12.7-63.5mm)

*WarmseasongrassesmayrequiretheLowHOC

bedknifefor.500inches(12.7mm)andbelow.

Figure21

1.Fixedplate

2.Uppermountingholes

3.Rearheightofcutspacers

4.Heightofcut

•Toattainthedesiredheightofcut,adjustthe

rearrollerbracketstothedesiredheightofcut

rangebypositioningtherequiredamountof

spacersbelowthesideplatemountingange

pertheHOCChart.RefertoAdjustingtheRear

Roller.

Note:Toachievealessaggressivecut,mount

thecuttingunitlinksinthenumber1position

ormountthelinkstothenumber3positionfor

amoreaggressivecut.

12

Page 13

CuttingUnitCharacteristics

Thedualknobbedknife-to-reeladjustmentsystem

incorporatedinthiscuttingunitsimpliesthe

adjustmentprocedureneededtodeliveroptimum

mowingperformance.Thepreciseadjustment

possiblewiththedualknob/bedbardesigngivesthe

necessarycontroltoprovideacontinualself-sharpening

action-thusmaintainingsharpcuttingedges,ensuring

goodquality-of-cut,andgreatlyreducingtheneedfor

routinebacklapping.

DailyAdjustmentsofCuttingUnit

Note:Overtime,thechamfer(

Figure22)willneed

toberegroundasitisonlydesignedtolast40%

ofthebedknifelife.

Priortomowingeachday,orasrequired,eachcutting

unitmustbecheckedtoverifyproperbedknife-to-reel

contact.Thismustbeperformedeventhough

qualityofcutisacceptable.

1.Lowerthecuttingunitsontoahardsurface,shutoff

theengine,andremovetheignitionkey.

2.Slowlyrotatethereelinareversedirection,

listeningforreel-to-bedknifecontact.Ifnocontact

isevident,turnthebedknifeadjustingknobs

clockwise,oneclickatatime,untillightcontactis

feltandheard.

Note:Thereelmustcutonesheetofpaper,when

insertedatarightangletothebedknife,atboth

endsandthecenterofthereel.

Note:Theadjustmentknobshavedetents

correspondingto0.0009inch(0.023mm)bedknife

movementforeachindexedposition.

3.Ifexcessivecontactisneededtocutpaper,

backlappingorgrindingisrequired.

Important:Lightcontactispreferredatall

times.Iflightcontactisnotmaintained,

thebedknife/reeledgeswillnotsufciently

self-sharpenanddullcuttingedgeswillresult

afteraperiodofoperation.Ifexcessivecontact

ismaintained,bedknife/reelwearwillbe

accelerated,unevenwearcanresult,andquality

ofcutmaybeadverselyaffected.

Note:Asthereelbladescontinuetorunagainst

thebedknife,aslightburrwillappearonthefront

cuttingedgesurfacealongthefulllengthofthe

bedknife.Ifaleisoccasionallyrunacrossthe

frontedgetoremovethisburr,improvedcutting

canbeobtained.

Afterextendedrunning,aridgewilleventually

developatbothendsofthebedknife.Thesenotches

mustberoundedofforledushwiththecutting

edgeofthebedknifetoensuresmoothoperation.

Figure22

1.Lead-inchamferonright

endofbedknife

2..060inch(1.5mm)

3..340inch(8.6mm)

Note:Donotmakelead-inchamfertoolargeas

itmaycauseturftufting.

ServicingBedknife

Thebedknifeservicelimitsarelistedinthefollowing

charts.

Important:Operatingthecuttingunitwiththe

bedknifebelowthe“servicelimit”mayresultin

poorafter-cutappearanceandreducethestructural

integrityofthebedknifeforimpacts.

BedknifeServiceLimitChart

Bedknife

LowHOC

(Optional)

EdgeMax®

(Optional)

Standard

(Production)

HeavyDuty

(Optional)

Note:Therecommendedtopandfrontbedknifegrind

angleis3to7degrees(Figure23).

PartNo.

120–1641

(27inch)

120–1642

(32inch)

112-8910

(27inch)

112–8956

(32inch)

114–9388

(27inch)

114–9389

(32inch)

114–9390

(27inch)

114–9391

(32inch)

BedknifeLip

Height*

.220inch

(5.6mm)

.270inch

(6.9mm)

.270inch

(6.9mm)

.370inch

(9.3mm)

Service

Limit*

.190inch

(4.8mm)

.190inch

(4.8mm)

.190inch

(4.8mm)

.190inch

(4.8mm)

13

Page 14

Figure23

1.BedknifeServiceLimit*

Note:Allbedknifeservicelimitmeasurements

referencethebottomofthebedknife(Figure24)

Figure24

14

Page 15

Maintenance

G003331

Lubrication

Eachcuttingunithas(6)greasettings(Figure25)that

mustbelubricatedregularlywithNo.2GeneralPurpose

LithiumBaseGrease.

Thelubricationpointsarefrontroller(2),rearroller(2)

andreelbearing(2).

Figure26

1.Bedknifeadjustingknob

Note:Lubricatingcuttingunitsimmediatelyafter

washinghelpspurgewateroutofbearingsand

increasesbearinglife.

1.Wipeeachgreasettingwithacleanrag.

2.Applygreaseuntilcleangreaseisseencomingoutof

rollersealsandbearingreliefvalve.

3.Wipeexcessgreaseaway.

Figure25

1.Reliefvalve

2.Usingaragorthicklypaddedglove,holdontothe

reelbladeandtrytomovethereelassemblysideto

Figure27).

side(

Figure27

3.Ifendplayexists,proceededasfollows:

A.Loosenexternalsetscrewsecuringbearing

adjustingnuttobearinghousinglocatedonthe

leftsideofthecuttingunit(Figure28).

AdjustingtheReelBearings

Toensurelonglifeofthereelbearings,periodically

checkifreelendplayexists.Thereelbearingscanbe

checkedandadjustedasfollows:

1.Loosenreeltobedknifecontactbyturning

thebedknifeadjustingknobs(Figure26)

counterclockwiseuntilnocontactexists.

Figure28

B.Usinga1-3/8"socketwrench,slowlytightenthe

reelbearingadjustmentnutuntilnoendplayof

thereelexists.Ifadjustingnutdoesnoteliminate

reelendplay,replacereelbearings.

15

Page 16

Note:Reelbearingsdonotrequirepreload.

Overtighteningreelbearingadjusternutwill

damagereelbearings.

4.Retightensetscrewsecuringbearingadjustingnutto

bearinghousing.Torqueto12-15in-lb.

ServicingtheBedbar

RemovingtheBedbar

1.Turnbedbaradjusterscrews,counterclockwise,to

backbedknifeawayfromreel(Figure29).

Figure29

1.Bedbaradjustingscrew3.Bedbar

2.Springtensionnut

2.Backoutthespringtensionnut,untilthewasheris

nolongertensionedagainstthebedbar(Figure29).

3.Oneachsideofthemachine,loosenthelocknut

securingthebedbarbolt(Figure30).

4.Washer

Figure31

1.Bedbarbolt

2.Nut4.Nylonwasher

3.Steelwasher

AssemblingtheBedbar

1.Installbedbar,positioningmountingearsbetween

washerandbedbaradjuster.

2.Securebedbartoeachsideplatewithbedbarbolts

(nutsonbolts)and6washers.Anylonwasheristo

bepositionedoneachsideofsideplateboss.Place

asteelwasheroutsideeachofthenylonwashers

Figure31).T orquebedbarboltsto27-33(37-45

(

N-m).Tightenlocknutsuntiltheoutsidesteel

washerstopsrotatingandendplayisremovedbut

donotovertightenordeectsideplates.Washers

oninsidemayhaveagap.

Figure30

1.Bedbarbolt2.Locknut

4.Removeeachbedbarboltallowingbedbartobe

pulleddownwardandremovedfrommachinebolt

(Figure30).Accountfor2nylonand1stampedsteel

washersoneachendofbedbar(Figure31).

3.Tightenspringtensionnutuntilspringiscollapsed,

thenbackoff1/2turn(

Figure32).

Note:Donotovertightenasdamagetothespring

mayoccur.

Figure32

1.Springtensionnut2.Spring

16

Page 17

ServicingtheRoller

ARollerRebuildKit,PartNo.114–5430andaRoller

RebuildToolKit,PartNo.115–0803(Figure33)are

availableforservicingtheroller.TheRollerRebuildKit

includesallthebearings,bearingnuts,innersealsand

outersealstorebuildaroller.TheRollerRebuildTool

Kitincludesallthetoolsandtheinstallationinstructions

requiredtorebuildarollerwiththerollerrebuildkit.

Refertoyourpartscatalogorcontactyourdistributor

forassistance.

Figure33

1.Rebuildkit(PartNo.114–5430)

2.Rebuildtoolkit(PartNo.1 15–0803)

3.Innerseal8.Washer

4.Bearing

5.Outerseal

6.Bearingnut

7.Innersealtool

9.Bearing/outersealtool

17

Page 18

Notes:

18

Page 19

Notes:

19

Page 20

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheT oro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

®

Companyanditsafliate,T oroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenance

andadjustmentsstatedinyourOperator’sManual.Failuretoperform

requiredmaintenanceandadjustmentscanbegroundsfordisallowinga

warrantyclaim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-T ororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinan

abusive,negligentorrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobe

defective.Examplesofpartswhichareconsumed,orusedup,during

normalProductoperationinclude,butarenotlimitedto,brakes

padsandlinings,clutchlinings,blades,reels,bedknives,tines,

sparkplugs,castorwheels,tires,lters,belts,andcertainsprayer

componentssuchasdiaphragms,nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Itemsconsideredtobeoutside

inuenceinclude,butarenotlimitedto,weather,storagepractices,

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damageto

seatsduetowearorabrasion,wornpaintedsurfaces,scratched

decalsorwindows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowill

makethenaldecisionwhethertorepairanyexistingpartorassemblyor

replaceit.Toromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesinthis

productareconsumed,theamountofusefulworkbetweencharging

intervalswillslowlydecreaseuntilthebatteryiscompletelywornout.

Replacementofwornoutbatteries,duetonormalconsumption,isthe

responsibilityoftheproductowner.Batteryreplacementmayberequired

duringthenormalproductwarrantyperiodatowner’sexpense.

MaintenanceisatOwner’sExpense

Enginetune-up,lubricationcleaningandpolishing,replacementof

ItemsandConditionsNotCoveredlters,coolant,andcompleting

RecommendedMaintenancearesomeofthenormalservicesT oro

productsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.

Allimpliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.Somestatesdonotallowexclusions

ofincidentalorconsequentialdamages,orlimitationsonhowlongan

impliedwarrantylasts,sotheaboveexclusionsandlimitationsmaynot

applytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAir

ResourcesBoard(CARB).Thehourlimitationssetforthabovedonot

applytotheEmissionsControlSystemWarranty .RefertotheEngine

EmissionControlW arrantyStatementprintedinyourOperator’sManual

orcontainedintheenginemanufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirToroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor’sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.Ifallotherremediesfail,youmaycontactusatToroWarrantyCompany.

374-0253RevA

Loading...

Loading...