Page 1

FormNo.3363-312RevC

Reelmaster

ModelNo.03170—SerialNo.310000001andUp

ModelNo.03171—SerialNo.310000001andUp

ModelNo.03172

ModelNo.03173

®

3100-DTractionUnit

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ModelNo.

Introduction

ThisproductcomplieswithallrelevantEuropean

directives,fordetailspleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Thismachineisaride-on,reel-bladelawnmower

intendedtobeusedbyprofessional,hiredoperatorsin

commercialapplications.Itisprimarilydesignedfor

cuttinggrassonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.Itis

notdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Figure1

1.Modelandserialnumberlocation

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................6

SoundPowerLevel...............................................8

SoundPressureLevel...........................................8

VibrationLevel....................................................8

SafetyandInstructionalDecals.............................8

Setup.........................................................................13

1InstallingtheWheels........................................14

2InstallingtheSteeringWheel............................14

3Activating,Charging,andConnectingthe

Battery...........................................................15

4CheckingtheAngleIndicator...........................16

5InstallingtheHoodLatch(CEOnly)................16

6InstallingtheExhaustGuard(CE

Only)..............................................................17

7InstallingtheRollBar.......................................18

8InstallingtheFrontLiftArms...........................18

9InstallingtheCarrierFramestotheCutting

Units..............................................................19

10MountingtheCuttingUnits............................21

11MountingtheCuttingUnitDrive

Motors...........................................................21

12AdjustingtheLiftArms.................................22

ProductOverview......................................................24

Controls.............................................................24

Specications.....................................................26

Attachments/Accessories...................................26

Operation...................................................................27

CheckingtheEngineOilLevel............................27

FillingtheFuelTank...........................................27

CheckingtheCoolingSystem..............................28

CheckingtheHydraulicSystem...........................29

CheckingtheTirePressure.................................30

CheckingtheReel-to-BedknifeContact...............30

TorquingtheWheelNuts....................................30

StartingandStoppingtheEngine........................30

BleedingtheFuelSystem....................................30

CheckingtheInterlockSystem............................31

TowingtheTractionUnit....................................31

StandardControlModule(SCM)........................32

OperatingTips...................................................34

Maintenance...............................................................39

RecommendedMaintenanceSchedule(s)................39

DailyMaintenanceChecklist...............................40

ServiceIntervalChart.........................................41

PremaintenanceProcedures....................................41

RemovingtheHood...........................................41

Lubrication.............................................................42

GreasingtheBearingsAndBushings...................42

SealedBearings...................................................44

EngineMaintenance...............................................45

ServicingtheAirCleaner....................................45

ChangingtheEngineOilandFilter.....................45

FuelSystemMaintenance.......................................46

ServicingtheFuelTank......................................46

InspectingtheFuelLinesand

Connections...................................................46

DrainingtheWaterSeparator..............................46

ChangingtheFuelFilterCanister........................47

BleedingAirfromtheInjectors...........................47

ElectricalSystemMaintenance................................48

CaringfortheBattery.........................................48

StoringtheBattery..............................................48

Fuses..................................................................48

DriveSystemMaintenance.....................................49

AdjustingtheTractionDriveforNeutral.............49

CoolingSystemMaintenance..................................49

CleaningtheEngineCoolingSystem...................49

BrakeMaintenance.................................................50

AdjustingtheParkingBrake................................50

BeltMaintenance....................................................51

ServicingtheEngineBelts..................................51

ControlsSystemMaintenance.................................52

AdjustingtheThrottle........................................52

HydraulicSystemMaintenance...............................52

ChangingtheHydraulicFluid.............................52

ChangingtheHydraulicFilter.............................53

CheckingtheHydraulicLinesandHoses.............54

MiscellaneousMaintenance....................................54

BacklappingtheCuttingSystem..........................54

Storage.......................................................................55

PreparationforSeasonalStorage.........................55

Schematics.................................................................57

3

Page 4

Safety

ThismachinemeetsorexceedsCENstandardEN

836:1997(whenappropriatedecalsapplied),and

ANSIB71.4-2004specicationsineffectatthetime

ofproductionwhenequippedwithrequiredweights

aslistedintheweightchart.

◊Inadequatebraking

◊Thetypeofmachineisunsuitableforthetask

◊Lackofawarenessoftheeffectofground

conditions,especiallyslopes

◊Incorrecthitchingandloaddistribution

Improperuseormaintenancebytheoperator

orownercanresultininjury.T oreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandard

EN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•ReadtheOperator’ sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,

andtheproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthelanguage

ofthismanual,itistheowner’sresponsibilityto

explainthismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstruction

shouldemphasizethefollowing:

–Theneedforcareandconcentrationwhen

workingwithride-onmachines

–Controlofaride-onmachineslidingonaslope

willnotberegainedbytheapplicationofthe

brake.Themainreasonsforlossofcontrolare

asfollows:

◊Insufcientwheelgrip

◊Beingdriventoofast

Preparation

•Whilemowing,alwayswearsubstantialfootwear,

longtrousers,hardhat,safetyglasses,andhearing

protection.Longhair,looseclothing,orjewelrymay

gettangledinmovingparts.Donotoperatethe

equipmentwhenbarefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipment

istobeusedandremoveallobjectswhichmaybe

thrownbythemachine.

•Warning—Fuelishighlyammable.Takethe

followingprecautions:

–Storefuelincontainersspecicallydesignedfor

thispurpose.

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

–Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuelwhile

theengineisrunningorwhentheengineishot.

–Iffuelisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthe

areaofspillageandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

–Replaceallfueltankandcontainercapssecurely.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Checkthatoperator’spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageall

bladeattachmentclutches,shiftintoneutral,and

engagetheparkingbrake.Onlystarttheenginefrom

4

Page 5

theoperator’ sposition.NeverremovetheROPSand

alwaysweartheseatbeltsduringoperation.

•Rememberthereisnosuchthingasasafeslope.

Travelongrassslopesrequiresparticularcare.Do

thefollowingtoguardagainstoverturning:

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Keepmachinespeedslowonslopesandduring

tightturns.

–Stayalertforhumpsandhollowsandother

hiddenhazards.

–Nevermowacrossthefaceoftheslope,unless

themowerisdesignedforthispurpose.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossing

surfacesotherthangrass.

•Whenusinganyattachments,neverdirectdischarge

ofmaterialtowardbystandersnorallowanyonenear

themachinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatingtheengineat

excessivespeedmayincreasethehazardofpersonal

injury.

•Dothefollowingbeforeleavingtheoperator’s

position:

–Stoponlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Changeintoneutralandsettheparkingbrake.

–Stoptheengineandremovethekey.

•Disengagethedrivetoattachments,stopthe

engine,andremovetheignitionkeyinthefollowing

conditions:

–Beforerefueling

–Beforeremovingthegrasscatcher(s)

–Beforemakingheightadjustments,unlessthe

adjustmentcanbemadefromtheoperator’s

position.

–Beforeclearingblockages

–Beforechecking,cleaning,orworkingonthe

mower

–Afterstrikingaforeignobjectorifanabnormal

vibrationoccurs(checkimmediately).Inspect

themowerfordamageandmakerepairsbefore

restartingandoperatingtheequipment.

•Disengagethedrivetoattachmentswhen

transportingorwhenthemachineisnotinuse.

•Reducethethrottlesettingbeforestoppingthe

engineand,iftheengineisprovidedwithafuel

shut-offvalve,turnthefueloffattheconclusionof

mowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcylinders/reels

ifnotmowing.

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,do

notoperatethemachine;seekshelter.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Theoperatorshallturnonashingwarninglights,

ifprovided,whenevertravelingonapublicroad,

exceptwheresuchuseisprohibitedbylaw .

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetank

insideabuildingwherefumesmayreachanopen

ameorspark.

•Allowtheenginetocoolbeforestoringinany

enclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentfuelstorage

area,cuttingunitsanddrivesfreeofgrass,leaves,or

excessivegrease.Cleanupoilorfuelspillage.

•Keepallpartsingoodworkingconditionandall

hardwareandhydraulicttingstightened.Replace

wornordamagedpartsanddecalsforsafety .

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachineto

prevententrapmentofthengersbetweenmoving

bladesandxedpartsofthemachine.

5

Page 6

•Onmulti-cylinder/multi-reelmachines,takecare

asrotatingonecylinder/reelcancauseother

cylinders/reelstorotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekey.Waitforall

movementtostopbeforeadjusting,cleaningor

repairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.

Cleanupoilorfuelspillage.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearames.

•Parkthemachineonlevelground.

•Neverallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Usecarewhencheckingthecylinders/reels.Wear

glovesandusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

ToroMowerSafety

Thefollowinglistcontainssafetyinformationspecic

toToroproductsorothersafetyinformationthatyou

mustknowthatisnotincludedintheCEN,ISO,or

ANSIstandards.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintended

usecouldprovedangeroustouserandbystanders.

Preparation

Besuretoestablishyourownspecialproceduresand

workrulesforunusualoperatingconditions(e.g.,

slopestoosteepforoperation).Surveythecomplete

mowingsitetodeterminewhichhillscanbesafely

operatedon.Whenperformingthissitesurvey,always

usecommonsenseandtakeintoconsiderationtheturf

conditionandtherolloverrisk.Todeterminewhichhills

orslopesmaybesafelyoperatedon,usetheinclinometer

providedwitheachmachine.T operformasitesurvey,

followtheprocedureoutlinedintheOperationsection

ofthethismanual.Themaximumsidehillangleis

detailedontheslopedecalafxedneartheangle

indicator.

Training

Theoperatormustbeskilledandtrainedinhowtodrive

onhillsides.Failuretousecautiononslopesorhills

maycausethevehicletotiporroll,possiblyresulting

inpersonalinjuryordeath.

Operation

•Knowhowtostopthemachineandenginequickly .

•Donotoperatethemachinewhilewearingtennis

shoesorsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Keephands,feet,andclothingawayfrommoving

partsandthemowerdischargearea.

•Fillthefueltankuntillevelis1/2inch(12mm)

belowthebottomofthellerneck.Donotoverll.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Whenstartingtheengine,engagetheparkingbrake,

putthetractionpedalinneutral,anddisengage

thebladedrive.Aftertheenginestarts,releasethe

parkingbrakeandkeepyourfootoffofthetraction

pedal.Themachinemustnotmove.Ifmovement

isevident,refertotheMaintenancesectionofthis

manualtoadjustthetractiondrive.

•Useextremecautionwhenoperatingclosetosand

traps,ditches,creeks,steephillsides,orotherhazards.

•Reducespeedwhenmakingsharpturns.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.Do

notrunengineindoorsorinanenclosedarea.

•Donotturnonhills.

•Iftheenginestallsorlosesheadwayandcannotmake

ittothetopofaslope,donotturnthemachine

around.Alwaysbackslowly,straightdowntheslope.

6

Page 7

•Donotoperateonasidehillthatistoosteep.A

rollovermayoccurbeforelosingtraction.

•Model03171-Theslopeangleatwhichthemachine

willtipisdependentonmanyfactors.Amongthese

aremowingconditionssuchaswetorundulating

terrain,speed(especiallyinturns),positionofthe

cuttingunits(withtheSidewinder),tirepressure,

andoperatorexperience.Atsidehillanglesof15

degreesorless,theriskofarolloverislow .Asthe

slopeangleincreasestoarecommendedmaximum

limitof20degrees,theriskofarolloverincreasesto

amoderatelevel.Donotexceeda20degreeside

hillslopeanglebecausetheriskofarolloverand

seriousinjuryordeathisveryhigh.

•Model03170-Theslopeangleatwhichthemachine

willtipisdependentonmanyfactors.Amongthese

aremowingconditionssuchaswetorundulating

terrain,speed(especiallyinturns),positionofthe

cuttingunits,tirepressure,andoperatorexperience.

Atsidehillanglesof20degreesorless,theriskof

arolloverislow .Astheslopeangleincreasestoa

recommendedmaximumlimitof25degrees,therisk

ofarolloverincreasestoamoderatelevel.Donot

exceeda25degreesidehillslopeanglebecause

theriskofarolloverandseriousinjuryordeath

isveryhigh.

•Forsteeringcontrol,lowerthecuttingunitswhen

goingdownslopes.

•Avoidsuddenstopsandstarts.

•Usethereversepedalforbraking.

•Watchfortrafcwhennearorcrossingroads.

Alwaysyieldtheright-of-way.

•Raisethecuttingunitswhendrivingfromonework

areatoanother.

•Donottouchtheengine,mufer,exhaustpipe,or

hydraulictankwhiletheengineisrunningorsoon

afterithasstoppedbecausetheseareascouldbehot

enoughtocauseburns.

•Thismachineisnotdesignedorequippedfor

on-roaduseandisaslow-movingvehicle.Ifyou

mustcrossortravelonapublicroad,youshould

beawareofandcomplywithlocalregulations,such

asrequiredlights,slowmovingvehiclesigns,and

reectors.

•Thegrassbasketsmustbeinplaceduringoperation

ofthecylinders/reelsorthatchersformaximum

safety.Shuttheengineoffbeforeemptyingthe

baskets.

•Whenapersonorpetappearsunexpectedlyinor

nearthemowingarea,stopmowing.Careless

operation,combinedwithterrainangles,ricochets,

orimproperlypositionedguardscanleadtothrown

objectinjuries.Donotresumemowinguntilthe

areaiscleared.

MaintenanceandStorage

•Beforeservicingormakingadjustments,stopthe

engineandremovetheignitionkey.

•Ensurethattheentiremachineisproperlymaintained

andingoodoperatingcondition.Frequentlycheck

allnuts,bolts,screws,andhydraulicttings.

•Makesureallhydrauliclineconnectorsaretightand

allhydraulichosesandlinesareingoodcondition

beforeapplyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthydraulicuidunderhigh

pressure.Usepaperorcardboard,notyourhands,

tosearchforleaks.Hydraulicuidescapingunder

pressurecanhavesufcientforcetopenetratethe

skinandcauseseriousinjury.Ifuidisinjectedinto

theskinitmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

organgrenemayresult.

•Checkallfuellinesfortightnessandwearona

regularbasis.Tightenorrepairthemasneeded.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,allpressureinthesystemmust

berelievedbystoppingtheengineandloweringthe

cuttingunitstotheground.

•Iftheenginemustberunningtoperforma

maintenanceadjustment,keephands,feet,clothing,

andanypartsofthebodyawayfromthecutting

units,attachments,andanymovingparts.Keep

everyoneaway.

•Donotoverspeedtheenginebychanginggovernor

settings.T oensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximum

enginespeedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoil

oraddingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceis

desired,contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineTororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty.

7

Page 8

SoundPowerLevel

99-3444

VibrationLevel

Thisunithasaguaranteedsoundpowerlevelof96dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’ s

earof82dBA,whichincludesanUncertaintyValue(K)

of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

Hand-Arm

Measuredvibrationlevelforrighthand=.41m/s

Measuredvibrationlevelforlefthand=.52m/s

UncertaintyValue(K)=0.5m/s

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

WholeBody

Measuredvibrationlevel=.49m/s

UncertaintyValue(K)=0.5m/s

2

2

Measuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

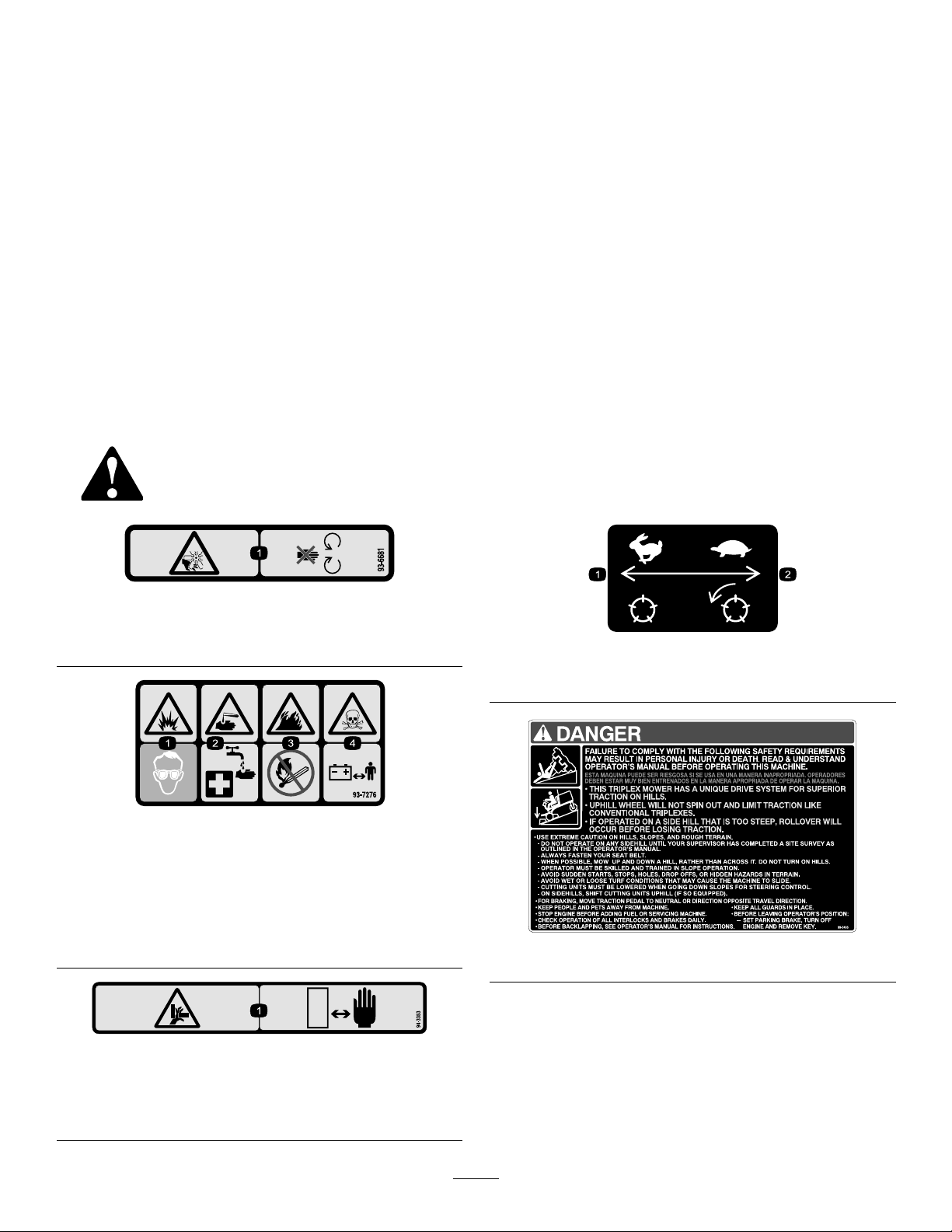

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

93-7276

1.Explosionhazard—weareyeprotection.

2.Causticliquid/chemicalburnhazard—toperformrstaid,

ushwithwater.

3.Firehazard—nore,openames,orsmoking.

4.Poisonhazard—keepchildrenasafedistancefromthe

battery.

99-3444

1.Reelspeed—fast

2.Reelspeed—slow

99-3496

94-3353

Model03207only

1.Crushinghazardofhand—keepyourhandsasafedistance

away.

8

Page 9

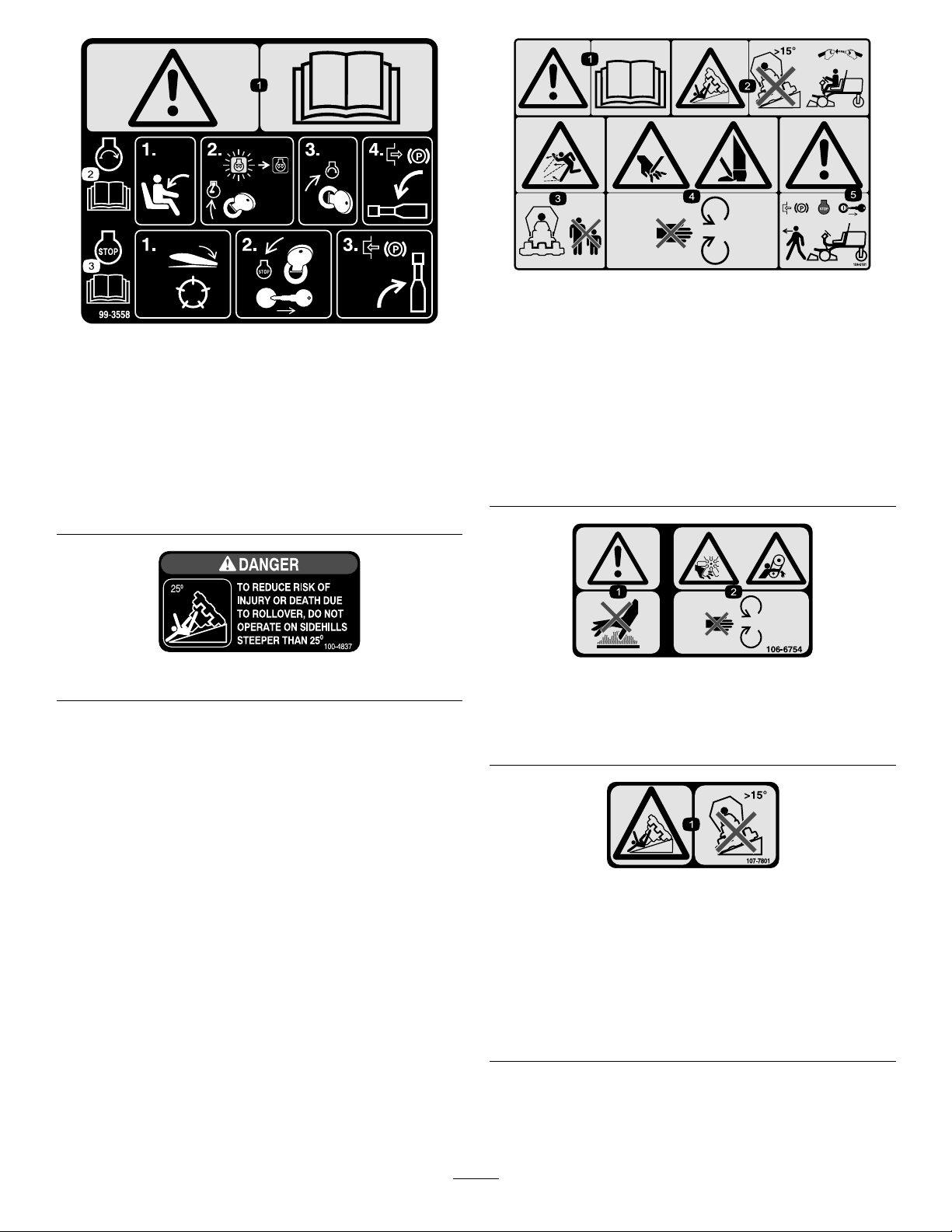

104-5181

CEonly

99-3558

CEonly

1.Warning—readtheOperator’sManual.

2.Tostarttheengine,sitontheseatandrotatetheignition

keytoOn/Preheatuntiltheglowplugindicatorlightgoes

out.Rotatethekeytostartanddisengagetheparking

brake.ReadtheOperator’sManualforfurtherinstructions.

3.Tostoptheengine,disengagethecuttingunits,rotatethe

ignitionkeytoOff,andremovethekey .Engagetheparking

brake.ReadtheOperator’sManualforfurtherinstructions.

100-4837

1.Warning—readtheOperator’sManual.

2.Tippinghazard—donotdriveonslopesgreaterthan15

degreesand,iftherollbarisinstalled,weartheseatbelt.

3.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

4.Cuttinghazardofhandorfoot—stayawayfrommoving

parts.

5.Warning—locktheparkingbrake,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

107-7801(CEonly)

Thissafetydecalincludesaslopewarningrequired

onthemachineforcompliancetotheEuropeanLawn

MowerSafetyStandardEN836:1997.Theconservative

maximumslopeanglesindicatedforoperationof

thismachineareprescribedbyandrequiredbythis

standard.

1.Tippinghazard—donotdriveonslopesgreaterthan15

degrees.

9

Page 10

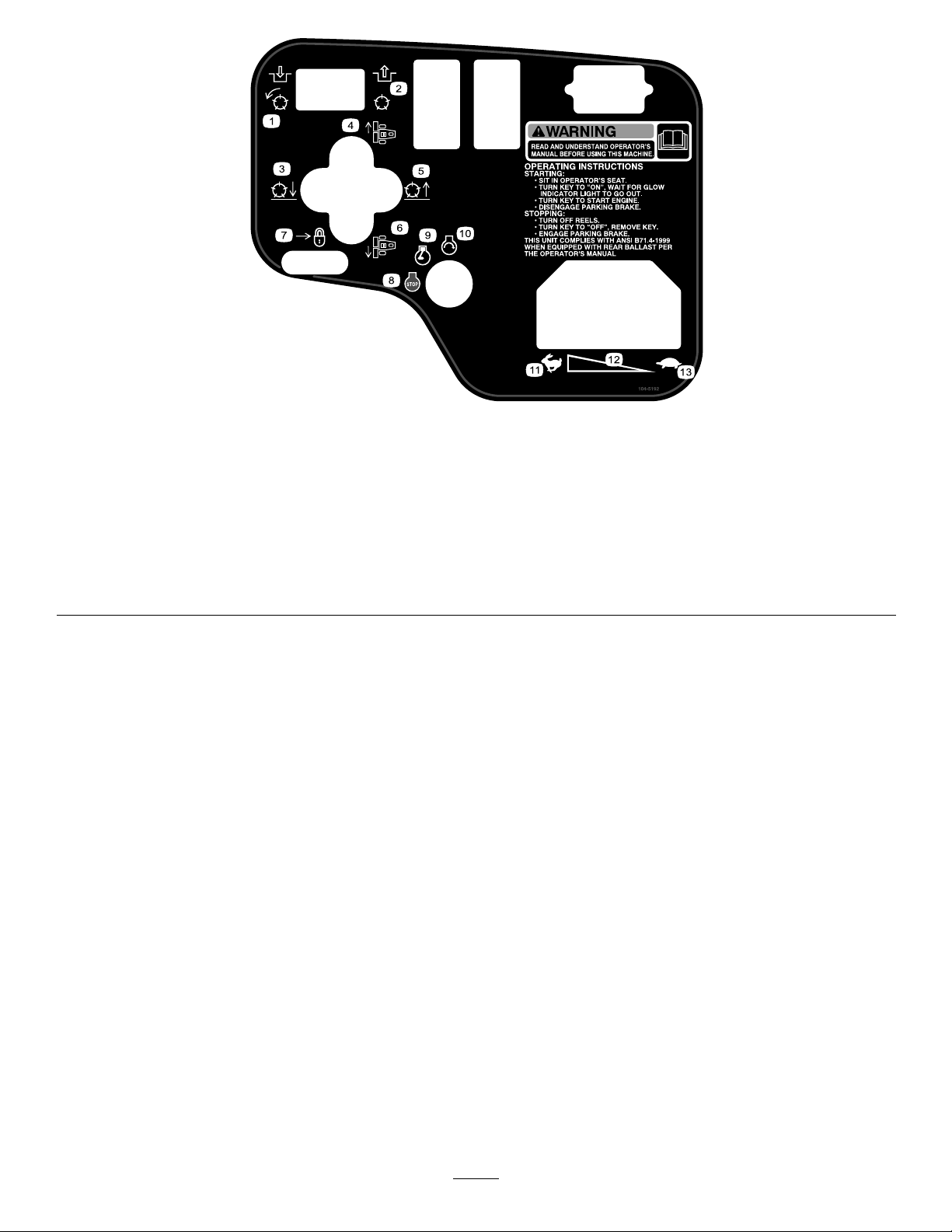

104-5192

Model03207only

1.Engagethepowertakeoff

(PTO).

2.Disengagethepowertake

off(PTO).

3.Lowerthecuttingunits.7.Moverearwardtolockthe

4.Movethecuttingunitsto

theright.

5.Raisethecuttingunits.9.Engine—run

6.Movethecuttingunitsto

theleft.

liftlever.

8.Engine—stop

13.Slow

10.Engine—start

11.Fast

12.Continuousvariablesetting

10

Page 11

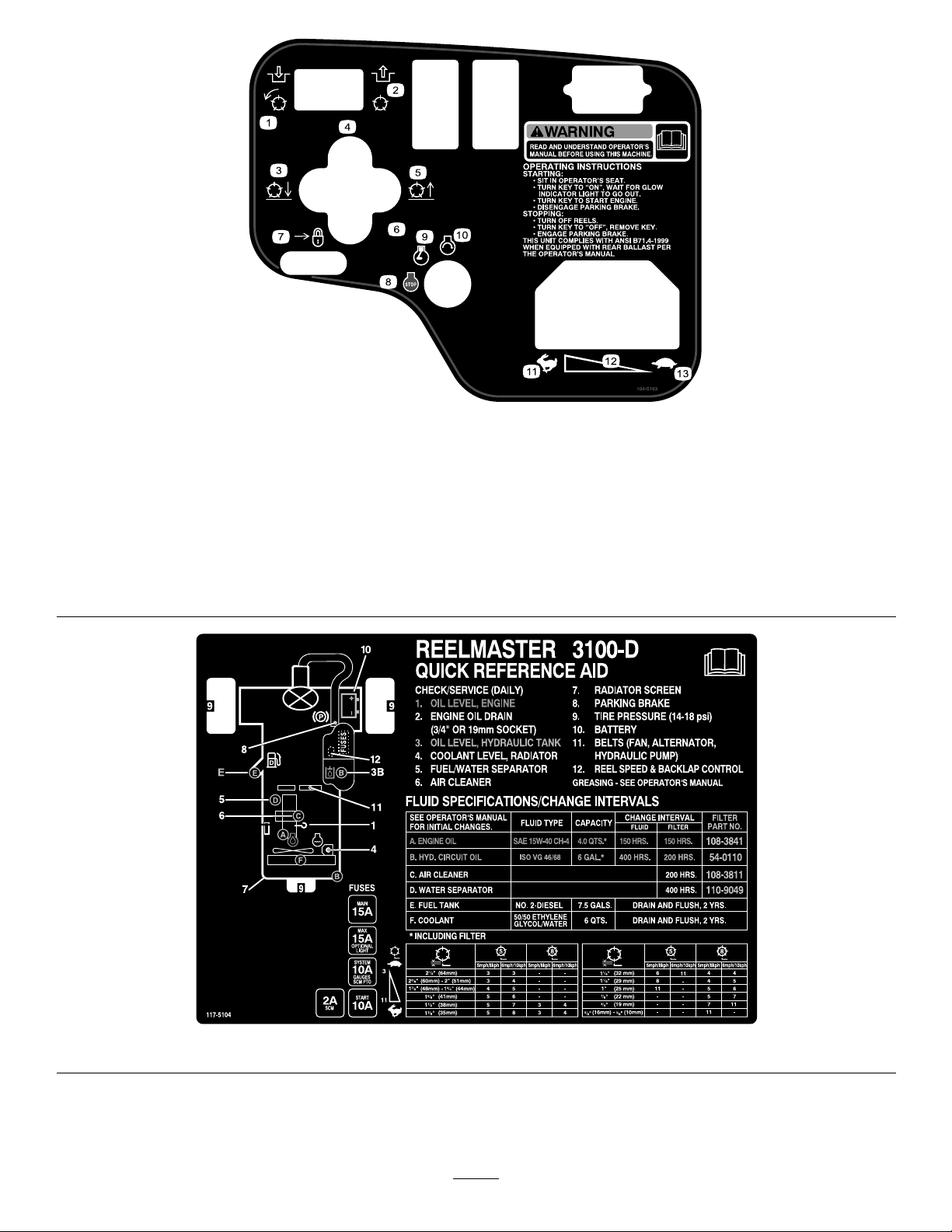

104-5193

Model03206only

1.Engagethepowertakeoff

(PTO).

2.Disengagethepowertake

off(PTO).

3.Lowerthecuttingunits.7.Moverearwardtolockthe

4.Movethecuttingunitsto

theright.

5.Raisethecuttingunits.9.Engine—run

6.Movethecuttingunitsto

theleft.

liftlever.

8.Engine—stop

13.Slow

10.Engine—start

11.Fast

12.Continuousvariablesetting

117-5104

11

Page 12

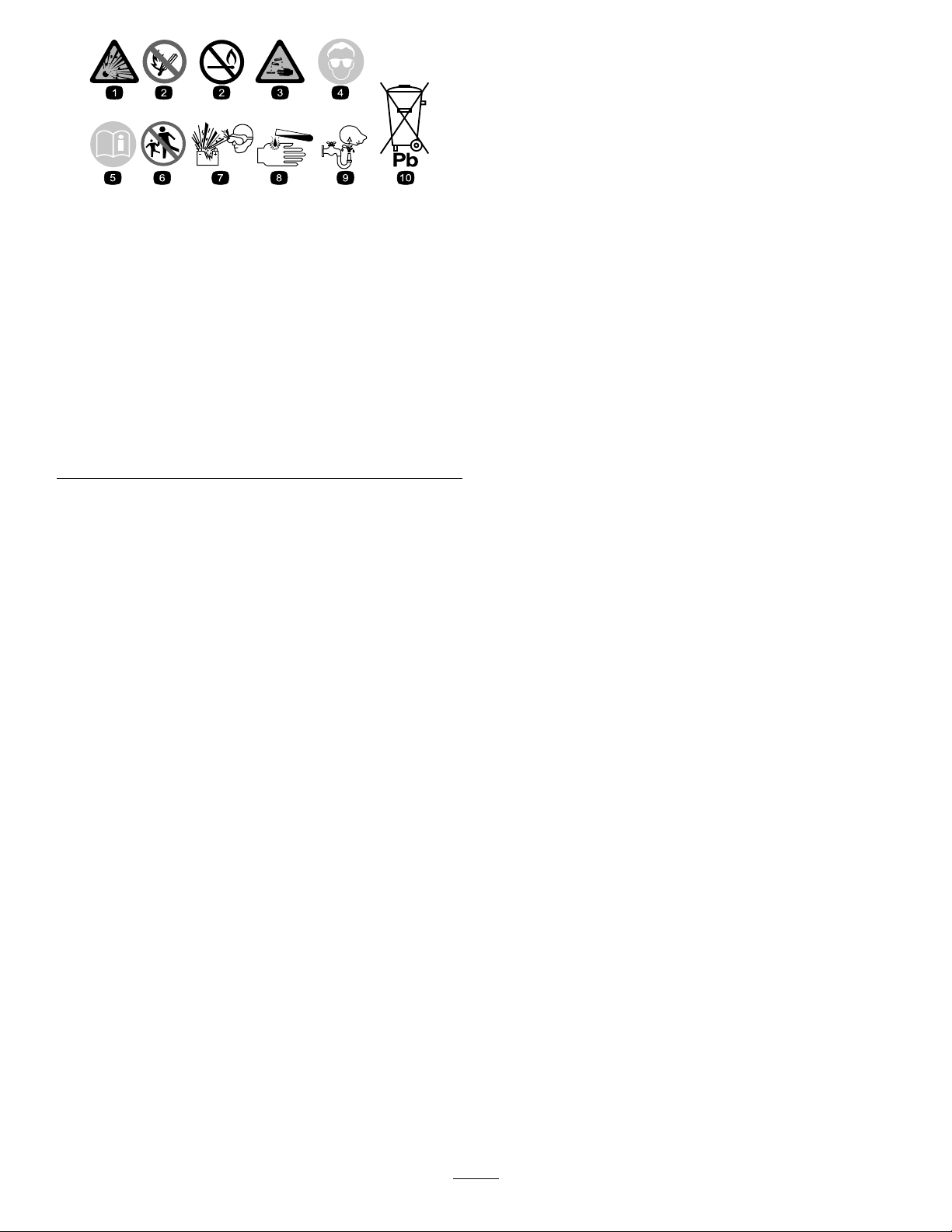

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

12

Page 13

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Frontwheelassemblies2

Rearwheelassembly1

Steeringwheel

Steeringwheelcap

Largewasher1

Jamnut1

Screw

Electrolyte

Inclinometer1

Lockbracket1

Rivet2

Washer1

Screw,1/4x2inches

Locknut,1/4inch

Exhaustguard1

Self-tappingscrew

Rollbarassembly1

Flangeheadbolts4

Locknuts4

Hoseclamp1

Liftarms

Pivotrod2

Bolt(5/16x7/8inch)

Nopartsrequired

Qty.

A/R

Use

Installthewheels.

1

1

Installthesteeringwheel.

1

Activate,charge,andconnectthe

battery.

Checktheangleindicator.

InstalltheHoodLatch(CE).

1

1

4

2

2

–

InstalltheExhaustGuard(CE).

Installtherollbar .

Installthefrontliftarms.(Partssupplied

intheLiftArmKit.)

Installthecarrierframestothecutting

units.

10

11

12

Nopartsrequired

Nopartsrequired

Nopartsrequired

13

–

–

–

Mountthecuttingunits.

Mountthecuttingunitdrivemotors.

Adjusttheliftarms.

Page 14

MediaandAdditionalParts

Description

Decal,CE

Ignitionkey2

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

Pre-deliverychecklist1

Certicateofcompliance

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

InstallingtheWheels

Partsneededforthisprocedure:

2Frontwheelassemblies

1Rearwheelassembly

Qty.

6

1

1

1Usetolookupandorderparts.

1

1

AfxtothemachineovercorrespondingEnglishdecals

forEuropeancompliance.

Starttheengine.

Readbeforeoperatingthemachine.

Viewbeforeoperatingthemachine.

Checktoensurethatthemachinehasbeenproperlyset

up.

EnsureCEcompliance.

2

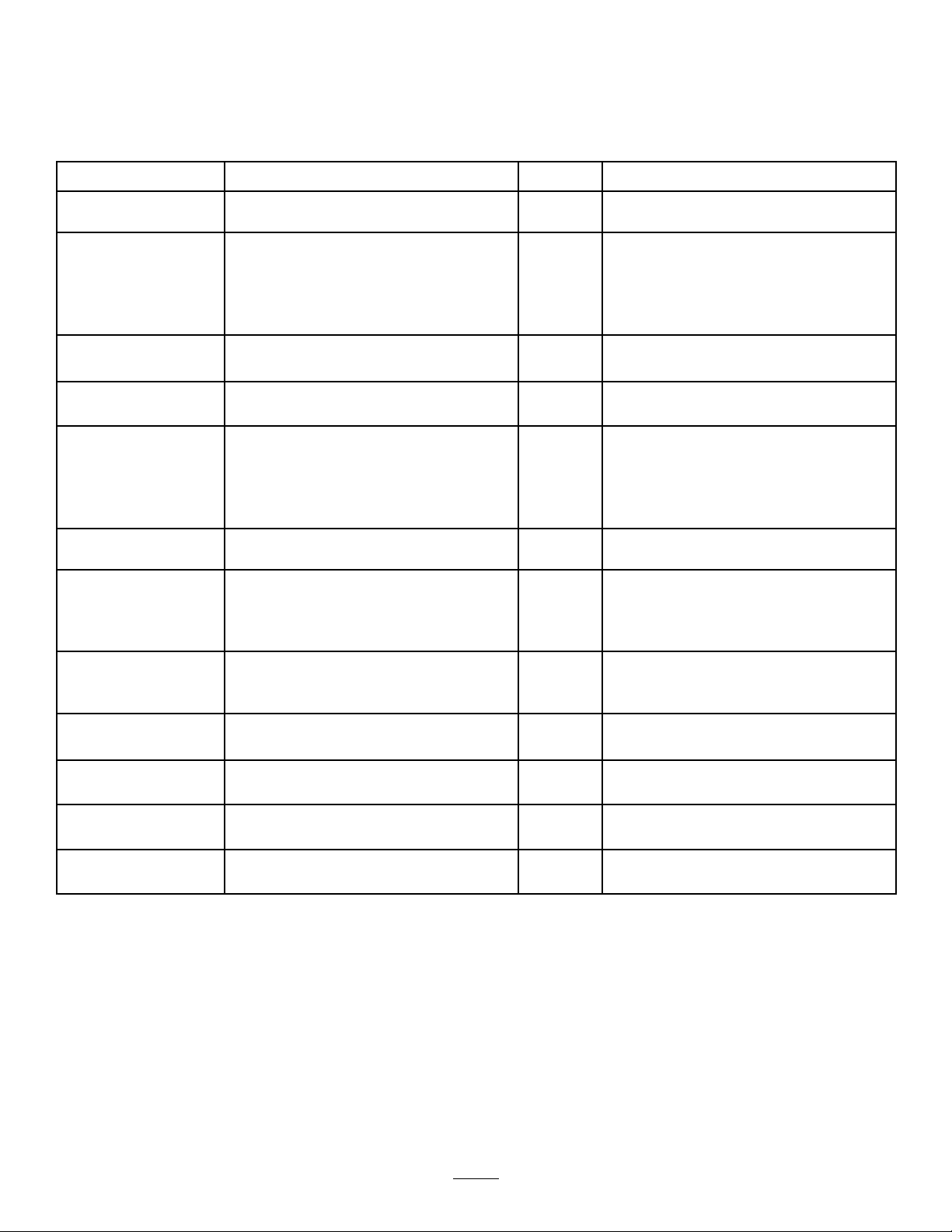

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

1

Steeringwheelcap

1Largewasher

1Jamnut

1

Screw

Use

Procedure

1.Mountawheelassemblyontoeachwheelhub(valve

stemoutward).

Important:Thereartirehasanarrowerrim

thanthefronttires.

2.Installlugnutsandtorqueto45to65ft-lb(61to

88N-m).

Procedure

1.Slidethesteeringwheelontothesteeringshaft

Figure3).

(

Figure3

1.Steeringwheel

2.Washer

2.Slidethewasherontothesteeringshaft(Figure3).

3.Jamnut

4.Cap

14

Page 15

3.Securethesteeringwheeltotheshaftwithajam

nutandtightenitto20to26ft-lb(27to35N-m)

(Figure3).

4.Installthecaptothesteeringwheelandsecureit

withascrew(

Figure3).

3

Activating,Charging,and

ConnectingtheBattery

Partsneededforthisprocedure:

Electrolyte

A/R

Procedure

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

Note:Ifthebatteryisnotlledwithelectrolyteor

activated,bulkelectrolytewith1.260specicgravity

mustbepurchasedfromalocalbatterysupplyoutlet

andaddedtothebattery.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyes,orclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

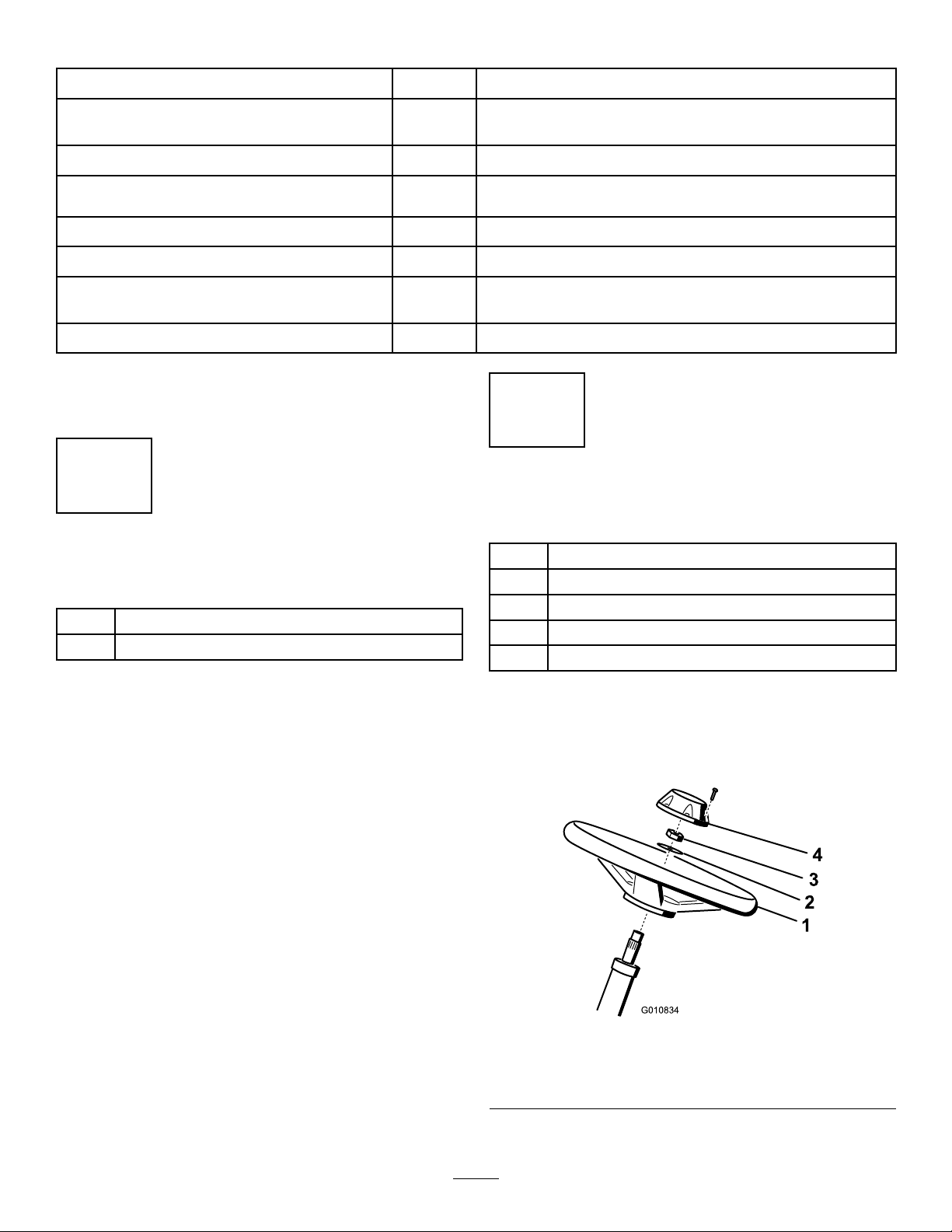

Figure4

1.Batterycover

4.Removethellercapsfromthebatteryandslowly

lleachcelluntilelectrolyteisjustabovetheplates.

5.Installthellercapsandconnecta3to4ampbattery

chargertothebatteryposts.Chargethebatteryata

rateof3to4ampsfor4to8hours.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

•Keepsparksandamesawayfrombattery.

•Neversmokenearthebattery.

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

7.Removethellercaps.Slowlyaddelectrolyteto

eachcelluntilthelevelisuptothellring.Install

thellercaps.

Important:Donotoverllthebattery.

Electrolytewilloverowontootherpartsofthe

machineandseverecorrosionanddeterioration

willresult.

8.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothe

negative(–)terminalofthebatteryandsecurethem

withboltsandnuts(

positive(+)terminalisallofthewayontothepost

andthecableispositionedsnugtothebattery.The

cablemustnotcontactthebatterycover.

Figure5).Makesurethatthe

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Purchasebulkelectrolytewith1.260specicgravity

fromalocalbatterysupplyoutlet.

2.Openthehood.

3.Removethebatterycover(Figure4).

15

Page 16

WARNING

Incorrectbatterycableroutingcoulddamage

thetractorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

4

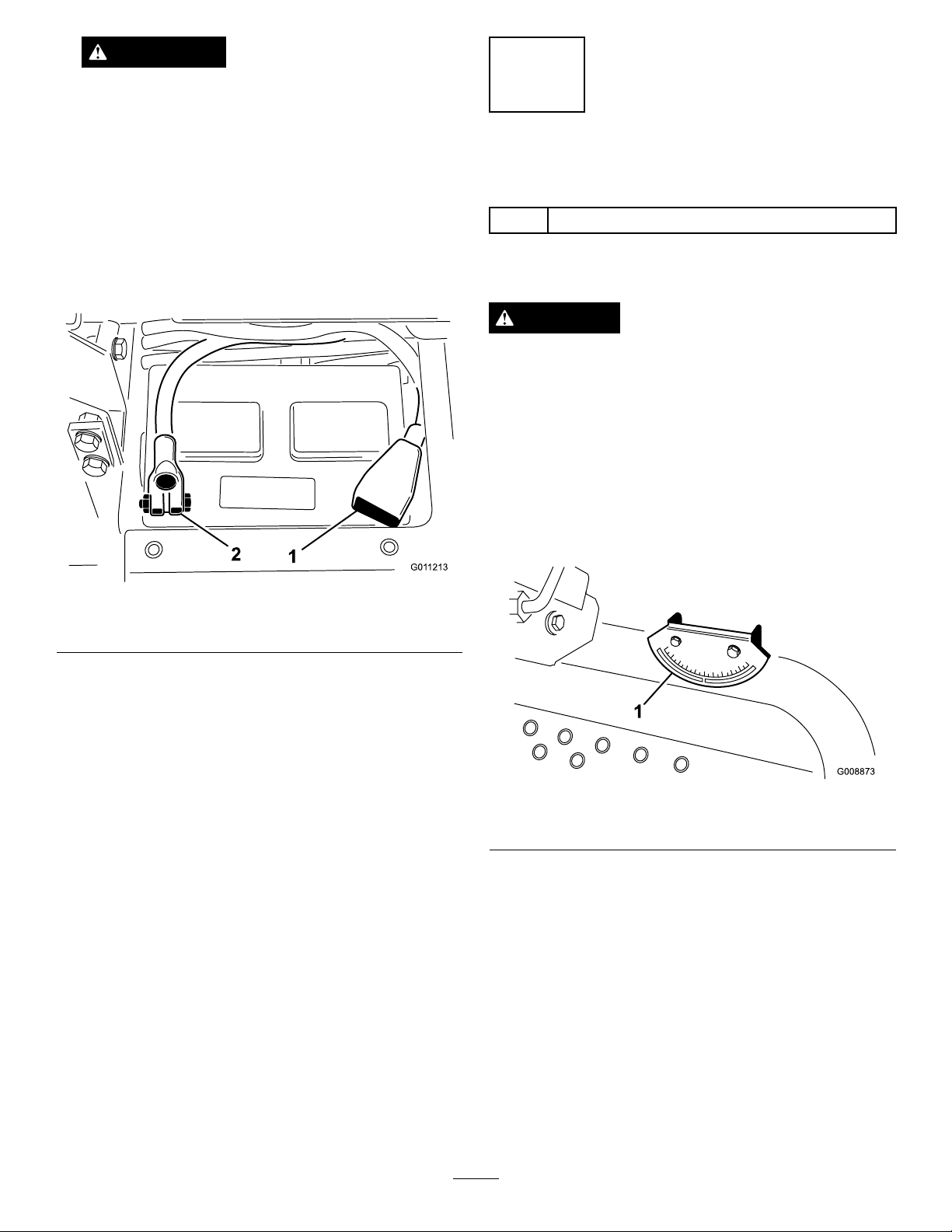

CheckingtheAngleIndicator

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

Figure5

1.Positive(+)batterycable2.Negative(–)batterycable

Partsneededforthisprocedure:

1Inclinometer

Procedure

DANGER

Toreduceriskofinjuryordeathduetorollover,do

notoperatethemachineonsidehillssteeperthan

25º.

1.Parkthemachineonaat,levelsurface.

2.Verifythatthemachineislevelbyplacingahand

heldinclinometer(suppliedwiththemachine)on

theframecrossrail,bythefueltank(

inclinometershouldreadzerodegreeswhenviewed

fromtheoperator’sposition.

Figure6).The

Important:Ifthebatteryiseverremoved,make

surethatthebatteryclampboltsareinstalled

withtheboltheadspositionedonthebottom

sideandthenutsonthetopside.Iftheclamp

boltsarereversed,theymayinterferewiththe

hydraulictubeswhenshiftingthecuttingunits.

9.CoatbothbatteryconnectionswithGrafo112X

(skinover)grease,ToroPartNo.505-47,petroleum

jelly,orlightgreasetopreventcorrosion.

10.Slidetherubberbootoverthepositiveterminalto

preventapossibleshortfromoccurring.

11.Installthebatterycover.

Figure6

1.Angleindicator

3.Iftheinclinometerdoesnotreadzerodegrees,

movethemachinetoalocationwhereazerodegree

readingisobtained.Theangleindicator,mountedon

themachine,shouldnowreadzerodegreesaswell.

4.Iftheangleindicatordoesnotreadzerodegrees,

loosenthetwoscrewsandnutssecuringtheangle

indicatortothemountingbracket,adjustthe

indicatortoobtainazerodegreereading,andtighten

thebolts.

16

Page 17

5

G012628

1

2

G012629

1

2

G012630

1

G012631

1

2

3

InstallingtheHoodLatch(CE

Only)

Partsneededforthisprocedure:

1Lockbracket

2Rivet

1Washer

1

Screw,1/4x2inches

1

Locknut,1/4inch

Procedure

1.Unhookthehoodlatchfromthehoodlatchbracket.

2.Removethe(2)rivetssecuringthehoodlatchbracket

tothehood(Figure7).Removethehoodlatch

bracketfromthehood.

Figure8

1.CElockbracket

2.Boltandnutassembly

4.Alignthewasherswiththeholesontheinsideofthe

hood.

5.Rivetthebracketsandthewasherstothehood

(Figure8).

6.Hookthelatchontothehoodlatchbracket

Figure9).

(

Figure9

1.Hoodlatch

Figure7

1.Hoodlatchbracket2.Rivets

7.Screwtheboltintotheotherarmofhoodlock

brackettolockthelatchinposition(Figure10).

Tightenboltsecurelybutdonottightennut.

3.Whilealigningthemountingholes,positiontheCE

lockbracketandthehoodlatchbracketontothe

hood.Thelockbracketmustbeagainstthehood

(Figure8).Donotremoveboltandnutassembly

fromthelockbracketarm.

1.Bolt

2.Nut

Figure10

3.Armofhoodlockbracket

17

Page 18

6

7

InstallingtheExhaustGuard

(CEOnly)

Partsneededforthisprocedure:

1Exhaustguard

4

Self-tappingscrew

Procedure

1.Positiontheexhaustguardaroundthemuferwhile

aligningthemountingholeswiththeholesinthe

frame(

Figure11).

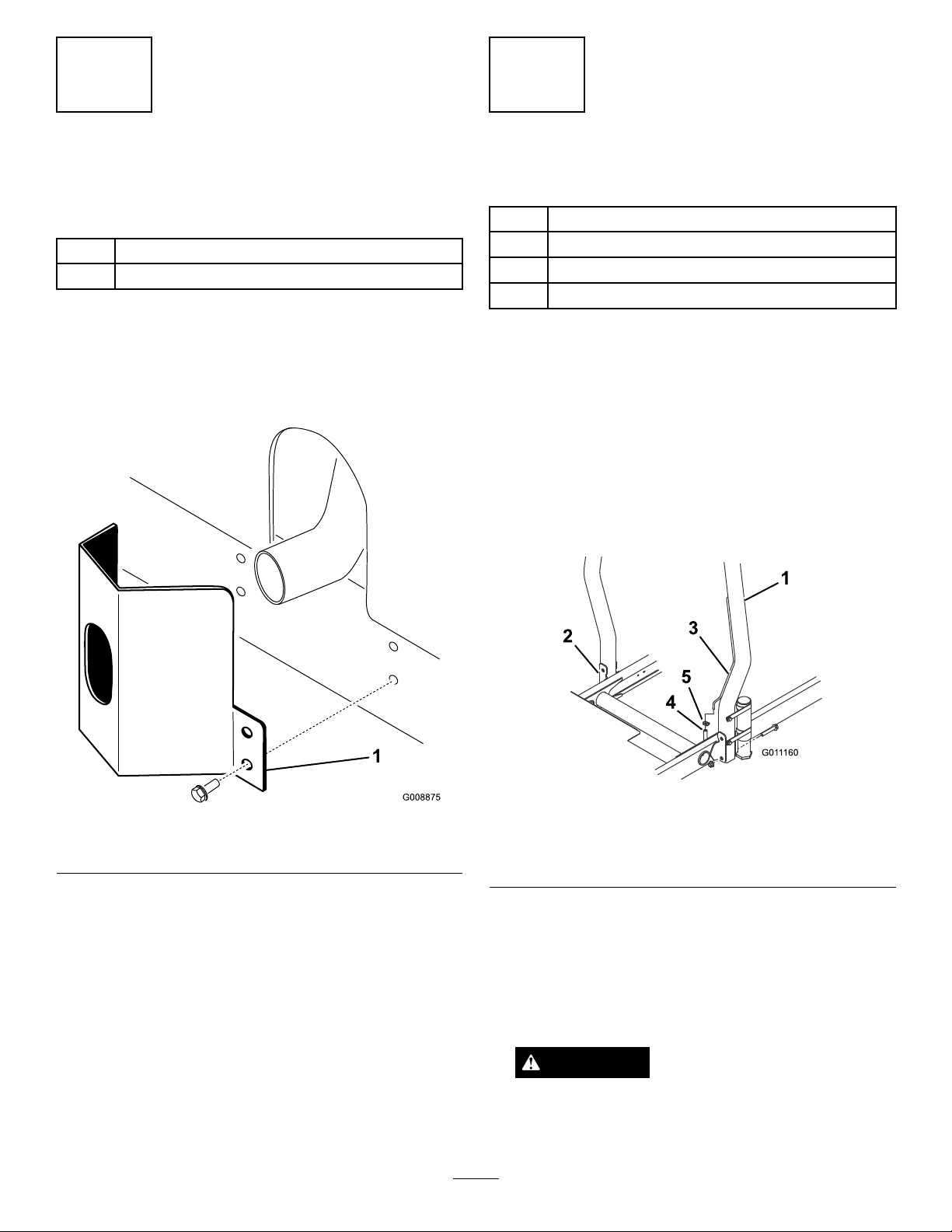

InstallingtheRollBar

Partsneededforthisprocedure:

1Rollbarassembly

4Flangeheadbolts

4Locknuts

1Hoseclamp

Procedure

Important:Neverweldormodifyarollover

protectionsystem(ROPS).Replaceadamaged

ROPS,donotrepairorrevise.Anyalterationofa

ROPSmustbeapprovedbythemanufacturer.

1.Lowertherollbarontothetractionunitmounting

brackets,aligningthemountingholes.Ensurethat

theventtubeontherollbarisontheleftsideof

themachine(

Figure12).

Figure11

1.Exhaustguard

2.Securetheexhaustguardtotheframewith4

self-tappingscrews(

Figure11).

Figure12

1.ROPS

2.Mountingbracket5.Hoseclamp

3.Venttube

2.Secureeachsideoftherollbartothemounting

bracketswith2angeheadboltsandlocknuts

(

Figure12).Torquethefastenersto60ft-lb(81

N-m).

3.Securethefuellineventhosetotheventtubeonthe

rollbarwiththehoseclamp.

4.Fuellineventtubehose

CAUTION

Youmustconnectthefuellineventhosetothe

venttubepriortostartingtheengineorfuelwill

owfromthehose.

18

Page 19

8

InstallingtheFrontLiftArms

Partsneededforthisprocedure:

2

Liftarms

2Pivotrod

2

Bolt(5/16x7/8inch)

Procedure

1.Removethe2boltsthatsecuretheliftarmpivot

shaftlinktotheliftarmpivotshafts,andremoveand

retainthepivotshaftlinkandbolts(

Figure13).

4.Inserttheliftarmsontotheliftarmpivotshafts

(Figure15),andsecureeachwithaliftarmpivot

shaftlinkandboltspreviouslyremoved.

Note:Torquetheboltsto70ft-lb(95N-m).

Figure15

1.Liftarm,right4.Liftcylinder

2.Retainingring

3.Liftarm,left

5.Spacers(2)

6.Mountingpin

Figure13

1.Liftarm,pivotshaftlink2.Liftarmpivotshaft

2.Insertapivotrodintoeachliftarmandalignthe

mountingholes(Figure14).

Figure14

1.Liftarm

2.Pivotrod

5.Removetherearretainingringssecuringthe

mountingpinstoeachendoftheliftcylinder.

6.Securetherightendoftheliftcylindertotheright

liftarmwithapinand2spacers((

Secureitwitharetainingring.

7.Securetheleftendoftheliftcylindertotheleftlift

armwithapin.Secureitwitharetainingring.

Figure15),).

9

InstallingtheCarrierFrames

totheCuttingUnits

NoPartsRequired

Procedure

1.Removethecuttingunitsfromthecartons.Adjust

themasdescribedintheCuttingUnitOperator’ s

Manual.

2.Positionafrontcarrierframe(Figure16)ontoeach

frontcuttingunit.

3.Securethepivotrodstotheliftarmswith2bolts

(5/16x7/8inch).

19

Page 20

Figure16

1.Frontcarrierframe

3.Securethemountinglinkstothefrontcarrierframes

asfollows:

•Securethefrontmountinglinkstothemiddle

carrierframeholeswithabolt(3/8x2-1/4

inch),2atwashers,andalocknut,asshownin

Figure17.Positionawasheroneachsideofthe

linkwhenmounting.Torquethefastenersto31

ft-lb(42N-m).

•Securetherearmountinglinkstothemiddle

carrierframeholeswithabolt(3/8x2-1/4

inch),2atwashers,andalocknut,asshownin

Figure17.Positionawasheroneachsideofthe

linkwhenmounting.Torquethefastenersto31

ft-lb(42N-m).

4.Positiontherearcarrierframe(Figure18)ontothe

rearcuttingunit.

Figure18

1.Rearcarrierframe

5.Securethemountinglinkstotherearcarrierframe

asfollows:

•Securethefrontmountinglinkstothecarrier

frameholeswithabolt(3/8x2-1/4inch),2at

washers,andalocknut,asshownin

Figure19.

Positionawasheroneachsideofthelinkwhen

mounting.Torquethefastenersto31ft-lb(42

N-m).

•Securetherearmountinglinkstotherearcarrier

frameholeswithabolt(3/8x2-1/4inch),2at

washers,andalocknut,asshownin

Figure19.

Positionawasheroneachsideofthelinkwhen

mounting.Torquethefastenersto31ft-lb(42

N-m).

1.Frontcarrierframe

2.Frontmountinglink

3.Rearmountinglink

Figure17

20

Page 21

Figure19

3.Greasealltheliftarmandcarrierframepivotpoints.

Important:Ensurethatthehosesarefreeof

twistsorsharpbendsandthattherearcutting

unithosesareroutedasshowin(

Raisethecuttingunitsandshiftthemtotheleft

(Model03170).Therearcuttingunithosesmust

notcontacttractioncablebracket.Reposition

thettingsand/orhoses,ifnecessary.

Figure21).

1.Rearcarrierframe

2.Frontmountinglink

3.Rearmountinglink

10

MountingtheCuttingUnits

NoPartsRequired

Procedure

1.Slideathrustwasherontoeachfrontliftarmpivot

rod.

2.Slidethecuttingunitcarrierframeontothepivotrod

andsecureitwithalynchpin(

Note:Onrearcuttingunit,positionthethrust

washerbetweentherearofthecarrierframeand

thelynchpin.

Figure20).

Figure21

4.Routeatipperchainupthroughtheslotontheend

ofeachcarrierframe.Securethetipperchaintothe

topofthecarrierframewithabolt,awasher,anda

locknut(

Figure22).

Figure20

1.Thrustwasher3.Lynchpin

2.Carrierframe

Figure22

1.Tipperchain

21

Page 22

11

MountingtheCuttingUnit

DriveMotors

NoPartsRequired

Procedure

1.Positionthecuttingunitsinfrontoftheliftarm

pivotrods.

2.RemovetheweightandO-ring(

insideendoftherighthandcuttingunit.

Figure23

1.O-ring

2.Weight

3.Mountingbolts

Figure23)fromthe

Figure24

1.O-ring

6.Mountthemotortothedriveendofthecutting

unit,andsecureitwithtwocapscrewsprovidedwith

cuttingunit(Figure24).

2.Reelmotor

12

AdjustingtheLiftArms

NoPartsRequired

Procedure

1.Starttheengine,raisetheliftarms,andcheckto

ensurethattheclearancebetweeneachliftarmand

theoorplatebracketis0.18to0.32inches(5to

8mm)(Figure25).

3.Removetheplugfromthebearinghousingonthe

outsideendoftherighthandcuttingunitandinstall

theweightsandgasket.

4.Removetheshippingplugfromthebearinghousings

ontheremainingcuttingunits.

5.InserttheO-ring(suppliedwiththecuttingunit)on

theangeofthedrivemotor(

Figure24).

Figure25

Cuttingunitsremovedforclarity

1.Liftarm3.Clearance

2.Floorplatebracket

22

Page 23

Note:Iftheclearanceisnotinthisrange,adjustthe

cylinderasfollows:

A.Backoffthestopboltsandadjustthecylinderto

attaintheclearance(Figure26).

Figure26

1.Stopbolt3.Clearance

2.Liftarm

B.Backoffthejamnutonthecylinder(Figure27).

bumperstrapis0.02to0.10inches(0.51to2.54

mm)(

Figure28).

Figure28

1.Wearbar2.Bumperstrap

Iftheclearanceisnotinthisrange,adjusttherear

cylinderasfollows:

A.Lowerthecuttingunitsandbackoffthejamnut

onthecylinder(Figure29).

Figure27

1.Frontcylinder2.Jamnut

C.Removethepinfromtherodendandrotatethe

clevis.

D.Installthepinandchecktheclearance.

E.RepeatstepsAthroughDifnecessary.

F.Tightentheclevisjamnut.

Note:Iftherearliftarmclunksduringtransport,

reducetheclearance.

2.Checktoensurethattheclearancebetweeneachlift

armandstopboltis0.005to0.040inches(0.13to

1.02mm)(

Figure26).

Note:Iftheclearanceisnotinthisrange,adjustthe

stopboltstoattainclearance.

Figure29

1.Rearcylinder2.Adjustingnut

B.Graspthecylinderrodclosetothenutwitha

pliersandragandrotatetherod.

C.Raisethecuttingunitsandchecktheclearance.

D.RepeatstepsAthroughCifnecessary.

E.Tightentheclevisjamnut.

Important:Lackofclearanceatthefrontstopsor

therearwearbarcoulddamagetheliftarms.

3.Starttheengine,raisetheliftarms,andcheckto

ensurethattheclearancebetweenthewearstrap

onthetopoftherearcuttingunitwearbarandthe

23

Page 24

ProductOverview

TiltSteeringLever

Pullthetiltsteeringlever(Figure30)backtoadjustthe

Controls

steeringwheeltothedesiredposition,thenpushthe

leverforwardtotighten.

IndicatorSlot

Theslotintheoperatorplatform(Figure30)indicates

whenthecuttingunitsareinthecenterposition.

AngleIndicator

Theangleindicator(Figure30)indicatesthesidehill

angleofthemachineindegrees.

IgnitionSwitch

Figure30

1.Forwardtractionpedal4.Tiltsteeringlever

2.Reversetractionpedal5.Indicatorslot

3.Mow/transportslide

6.Angleindicator

TractionPedals

Pressthetractionforwardpedal(Figure30)tomove

forward.Presstractionreversepedal(Figure30)to

movebackwardortoassistinstoppingwhenmoving

forward.Also,allowthepedaltomoveormoveittothe

neutralpositiontostopthemachine.

Mow/TransportSlide

Usingyourheel,movethemow/transportslide

(Figure30)tothelefttotransportandtotherightto

mow .Thecuttingunitswillonlyoperateinthemow

position.

Important:Themowspeedissetatthefactoryto

6mph(9.7km/h).Itcanbeincreasedordecreased

byadjustingthespeedstopscrew(

Figure31).

Theignitionswitch(Figure32),whichisusedtostart,

stop,andpreheattheengine,hasthreepositions:

Off,On/Preheat,andStart.Rotatethekeytothe

On/Preheatpositionuntiltheglowplugindicatorlight

goesout(approximately7seconds);thenrotatethe

keytotheStartpositiontoengagethestartermotor.

Releasethekeywhentheenginestarts.Thekeywill

moveautomaticallytotheOn/Runposition.Toshutthe

engineoff,rotatethekeytotheOffpositionandremove

thekeyfromtheswitchtopreventaccidentalstarting.

Figure32

1.Throttle

2.Hourmeter

3.Temperaturelight9.Ignitionswitch

4.Oilpressurelight

5.Glowplugindicatorlight1 1.Liftleverlock

6.Alternatorlight

7.Cuttingunitdriveswitch

8.Cuttingunitshiftlever

10.Parkingbrake

1.Speedstopscrew

Figure31

Throttle

Movethethrottle(Figure32)forwardtoincreasethe

enginespeedandrearwardtodecreasetheenginespeed.

24

Page 25

CuttingUnitDriveSwitch

GlowPlugIndicator

Thecuttingunitdriveswitch(Figure32)hastwo

positions:EngageandDisengage.Therockerswitch

operatesasolenoidvalveonthevalvebanktodrivethe

cuttingunits.

HourMeter

Thehourmeter(Figure32)indicatesthetotalhoursof

machineoperation.Thehourmeterstartstofunction

wheneverthekeyswitchisOn.

CuttingUnitShiftLever

Tolowerthecuttingunitstotheground,movethe

cuttingunitshiftlever(Figure32)forward.Thecutting

unitswillnotdropunlesstheengineisrunning,and

theywillnotoperateintheraisedposition.Toraisethe

cuttingunits,pulltheshiftleverrearwardtotheRaise

position.

Movethelevertotherightorlefttomovethecutting

unitsinthesamedirection.Thisshouldonlybedone

whenthecuttingunitsareraisedoriftheyareonthe

groundandthemachineismoving(Model03170only).

Theglowplugindicatorlight(Figure32)willglowwhen

theglowplugsareoperating.

ParkingBrake

Whenevertheengineisshutoff,engagetheparking

brake(Figure32)topreventaccidentalmovementofthe

machine.Toengagetheparkingbrake,pulluponthe

lever.Theenginewillstopifyoupressthetractionpedal

withtheparkingbrakeengaged.

LiftLeverLock

Movetheliftleverlock(Figure32)rearwardtoprevent

thecuttingunitsfromdropping.

ReelSpeedControl

Thereelspeedcontrolislocatedundertheconsole

cover(

(reelspeed),rotatethereelspeedcontrolknobtothe

appropriateheight-of-cutsettingandmowerspeed.

RefertoSelectingtheClipRate.

Figure33).Toobtainthedesiredcliprate

Note:Theleverdoesnothavetobeheldintheforward

positionwhilethecuttingunitsarelowered.

DANGER

Shiftingthecuttingunitsdownhilldecreases

machinestability .Thiscouldcausearollover,

whichmayresultinpersonalinjuryordeath.

Shiftthecuttingunitsuphillwhileonasidehill.

EngineCoolantTemperatureWarning

Light

Thetemperaturewarninglight(Figure32)glowsifthe

enginecoolanttemperatureishigh.Ifthetractionunitis

notstoppedandthecoolanttemperaturerisesanother

10°F,theenginewillkill.

OilPressureWarningLight

Theoilpressurewarninglight(Figure32)glowsifthe

engineoilpressuredropsbelowasafelevel.

AlternatorLight

Thealternatorlight(Figure32)shouldbeoffwhenthe

engineisrunning.Ifitison,thechargingsystemshould

becheckedandrepairedasnecessary.

Figure33

1.Reelspeedcontrol2.Backlapcontrol

BacklapControl

Thebacklapcontrolislocatedundertheconsolecover

(Figure33).RotatetheknobtoRforbacklappingandto

Fformowing.Donotchangetheknobpositionwhile

thereelsarerotating.

25

Page 26

FuelGauge

Thefuelgauge(Figure34)registerstheamountoffuel

inthetank.

Figure34

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

1.Foreandaftlever

2.Fuelgauge

ForeandAftSeatAdjustments

Movethelever(Figure34)onthesideoftheseat

outward,slidetheseattothedesiredposition,and

releasethelevertolocktheseatintoposition.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

TransportWidth

Widthofcut72"(183cm)or85"(216cm)

Length

Height

Netweight*1860lbs.(844kg)

Fueltankcapacity

GroundspeedMow:0-6mph(0-10km/h);

*Withcuttingunitsanduids

80"(203cm)in72"

(183cm)widthofcut

92"(234cm)in85"(216

cm)widthofcut

widthofcut

93"(248cm)

71"(180cm)withROPS

7.5gallons(28liters).

Transport:0-9mph(0-14

km/h).Reverse:0-4mph.(0-6

km/h).

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

26

Page 27

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;

however,theoillevelmustbecheckedbeforeandafter

theengineisrststarted.

Crankcasecapacityisapproximately4qt.(2.8l)with

thelter.

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4or

higher.

•Preferredoil:SAE15W-40(above0ºF(-17ºC))

3.Pushthedipstickdownintothedipsticktubeand

ensurethatitisseatedfully,thenpullthedipstick

outandchecktheoillevel.

4.Iftheoillevelislow ,removetheoilllcap

Figure36)andgraduallyaddsmallquantitiesofoil,

(

checkingthelevelfrequently ,untilthelevelreaches

theFullmarkonthedipstick.

Figure36

1.Oilllcap

•Alternateoil:SAE10W -30or5W -30(all

temperatures)

Note:ToroPremiumEngineoilisavailablefroma

distributorineither15W-40or10W-30viscosity.See

thepartscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Ifithasalreadybeenrun,allowtheoiltodrain

backdowntothesumpforatleast10minutesbefore

checking.Iftheoillevelisatorbelowthe“add”mark

onthedipstick,addoiltobringtheoilleveltothe“full”

mark.Donotoverll.Iftheoillevelisbetweenthe

“full”and“add”marks,youdonotneedtoaddoil.

1.Positionthemachineonalevelsurface.

2.Removethedipstick(

acleanrag.

Figure35)andwipeitwith

5.Installtheoilllcapandclosethehood.

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultof

overllingorunderllingtheengineoil.

FillingtheFuelTank

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to1/2

inch(6to13mm)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuelfumes

maybeignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

Figure35

1.Dipstick

27

andkeepthecapinplace.

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Page 28

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatcanbeusedwithin180daysto

ensurefuelfreshness.

Thefueltankcapacityisapproximately7.5gallons(28

liters).

3.Fillthetanktothebottomofthellerneck.Do

notoverll.

4.Installthecap.

5.Wipeupanyfuelthatmayhavespilled.

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Usingwinter

gradefuelatlowertemperaturesprovidesalowerash

pointandcoldowcharacteristicswhichwillease

startingandreducepluggingofthefuellter.

Useofsummergradefuelabove20°F(-7°C)will

contributetowardlongerfuelpumplifeandincreased

powercomparedtowintergradefuel.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Cleandebrisoffoftheradiatorandtheoilcoolerdaily

Figure38).Cleantheradiatorhourlyifconditionsare

(

extremelydustyanddirty;refertoCleaningtheEngine

CoolingSystem.

Figure38

1.Accesspanel

2.Radiator

3.Oilcooler

•Monitorseals,hoses,gasketsincontactwithfuelas

theymaybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactadistributorformoreinformationon

biodieselblendedfuel.

1.Cleantheareaaroundthefueltankcap(

Figure37

1.Fueltankcap

Figure37).

2.Removethefueltankcap.

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethyleneglycolanti-freeze.Check

thecoolantlevelatthebeginningofeachdaybefore

startingtheengine.

Thecapacityofthecoolingsystemisapproximately

6qt(5.7l).

CAUTION

Iftheenginehasbeenrunning,thepressurized,

hotcoolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhentheengine

isrunning.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

1.Checkthecoolantlevelintheexpansiontank

(Figure39).

28

Page 29

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein2/3oz.(20ml)

bottles.Onebottleissufcientfor4-6U.S.gallons

(15-221)ofhydraulicoil.Orderpartno.44-2500from

anauthorizedTorodistributor.

BiodegradableHydraulicFluid—Mobil224H

Figure39

1.Expansiontank

Note:Withacoldengine,thecoolantlevelshould

beapproximatelymidwaybetweenthemarksonthe

sideofthetank.

2.Ifthecoolantlevelislow ,removetheexpansion

tankcapandreplenishthesystem.Donotoverll.

3.Installtheexpansiontankcap.

CheckingtheHydraulic

System

ServiceInterval:Beforeeachuseordaily—Checkthe

hydraulicuidlevel.

Thehydraulicuidtankislledatthefactorywith

approximately3.5U .S.gallons(13.2l)ofhigh-quality

hydraulicuid.Checkthelevelofthehydraulic

uidbeforetheengineisrststartedanddaily

thereafter.Therecommendedreplacementuid

isT oroPremiumAllSeasonHydraulicFluid

(Availablein5-gallonpailsor55-gallondrums.See

partscatalogorT orodistributorforpartnumbers.)

ToroBiodegradableHydraulicFluid(Availablein5gallon

pailsor55gallondrums.SeepartscatalogoraT oro

distributorforpartnumbers.)

Alternateuid:MobilEAL224H

Thisisvegetable-oilbasedbiodegradableoiltestedand

approvedbyToroforthismodel.Thisuidisnot

asresistanttohightemperaturesasstandarduid,so

installanoilcoolerifrequiredbytheoperatormanual

andfollowrecommendeduidchangeintervalswith

thisuid.Contaminationbymineral–basedhydraulic

uidswillchangethebiodegradabilityandtoxicityof

thisoil.Whenchangingfromstandarduidtothe

biodegradabletype,becertaintofollowtheapproved

ushingprocedure.ContactalocalToroDistributor

fordetails.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,andstoptheengine.

2.Cleantheareaaroundthellerneckandcapofthe

hydraulicuidtank(

Figure40)andremovethecap.

Alternateuids:IftheTorouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Toro

doesnotrecommendusingsyntheticuid.Consultwith

alubricantdistributortoidentifyasatisfactoryproduct.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehind

theirrecommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

cSt@100°C7.9to8.5

140to160

Figure40

1.Hydraulicuidtankcap

3.Removethedipstickfromthellerneckandwipe

itwithacleanrag.Insertthedipstickintotheller

neck;thenremoveitandchecktheuidlevel.The

uidlevelshouldbewithin1/4inch(6mm)ofthe

markonthedipstick.

29

Page 30

4.Ifthelevelislow ,addtheappropriateuidtoraise

theleveltothefullmark.

5.Installthedipstickandcapontothellerneck.

•Theenginehasceasedrunningduetolackof

fuel.

•Maintenancehasbeenperformeduponthefuel

systemcomponents;e.g.,lterreplaced,etc.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,

releasesomeoftheairtoreducethepressure.The

properairpressureinthetiresis14to18psi(97to

124kPa).

Note:Maintaintherecommendedpressureinalltires

toensureagoodqualityofcutandpropermachine

performance.

DANGER

Lowtirepressuredecreasesmachinesidehill

stability.Thiscouldcausearollover,whichmay

resultinpersonalinjuryordeath.

Donotunder-inatethetires.

CheckingtheReel-to-Bedknife

Contact

ServiceInterval:Beforeeachuseordaily

Checkthereel-to-bedknifecontactevenifthequalityof

cuthadbeenacceptablepreviously .Theremustbelight

contactacrossthefulllengthofthereelandbedknife;

refertoAdjustingReeltoBedknifeintheCuttingUnit

Operator’sManual.

TorquingtheWheelNuts

StartingtheEngine

1.Ensurethattheparkingbrakeissetandthereel

driveswitchisintheDisengageposition.

2.Removeyourfootfromthetractionpedaland

ensurethatthepedalisintheneutralposition.

3.Movethethrottlelevertothe1/2throttleposition.

4.Insertthekeyintotheswitchandrotateittothe

On/Preheatpositionuntiltheglowplugindicator

lightgoesout(approximately7seconds);thenrotate

thekeytotheStartpositiontoengagethestarter

motor.Releasethekeywhentheenginestarts.

Note:Thekeywillmoveautomaticallytothe

On/Runposition.

Important:Topreventoverheatingofthe

startermotor,donotengagethestarterlonger

than15seconds.After10secondsofcontinuous

cranking,wait60secondsbeforeengagingthe

startermotoragain.

5.Whentheengineisstartedforthersttimeorafter

anoverhauloftheengine,operatethemachinein

forwardandreverseforonetotwominutes.Also

operatetheliftleverandcuttingunitdriveswitchto

ensureproperoperationofallparts.

Note:Turnthesteeringwheeltotheleftandright

tocheckthesteeringresponse,thenshuttheengine

offandcheckforoilleaks,looseparts,andany

othernoticeablemalfunctions.

ServiceInterval:Afterthersthour

Aftertherst10hours

Every200hours

Torquethewheelnutsto45to65ft-lb(61to88N-m).

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

StartingandStoppingthe

Engine

Youmayneedtobleedthefuelsystemifanyof

thefollowingsituationshaveoccurred(referto

BleedingtheFuelSystem):

•Itistheinitialstartupofanewengine.

CAUTION

Stoptheengineandwaitforallmovingpartsto

stopbeforecheckingforoilleaks,looseparts,

andothermalfunctions.

StoppingtheEngine

MovethethrottlecontroltotheIdleposition,movethe

reeldriveswitchtoDisengage,androtatethestarter

keytoOff.

Note:Removethekeyfromtheswitchtoprevent

accidentalstarting.

BleedingtheFuelSystem

1.Parkthemachineonalevelsurface,andensurethat

thefueltankisatleasthalffull.

2.Unlatchandraisethehood.

30

Page 31

DANGER

CheckingtheInterlockSystem

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyspilledfuel.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

3.Opentheairbleedscrewonthefuelinjectionpump

(Figure41).

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

1.Ensurethatallbystandersareawayfromtheareaof

operation,andkeephandsandfeetawayfromthe

cuttingunits.

2.Whilesittingontheseat,theenginemustnotstart

witheitherthecuttingunitswitchengagedorthe

tractionpedalengaged.Correcttheproblemifitis

notoperatingproperly .

3.Whilesittingontheseat,putthetractionpedalin

neutral,disengagetheparkingbrake,andsetthe

cuttingunitswitchintheOffposition.Theengine

shouldstart.Risefromtheseatandslowlypress

thetractionpedal,andtheengineshouldstopin

onetothreeseconds.Correcttheproblemifitis

notoperatingproperly .

Figure41

1.Fuelinjectionpumpbleedscrew

4.TurnthekeyintheignitionswitchtotheOn

position.Theelectricfuelpumpwillbegin

operation,therebyforcingairoutaroundtheair

bleedscrew .

Note:LeavethekeyintheOnpositionuntilasolid

streamoffuelowsoutaroundthescrew .

5.TightenthescrewandturnthekeytoOff.

Note:Normallytheengineshouldstartafterfollowing

thebleedingproceduresabove.However,iftheengine

doesnotstart,airmaybetrappedbetweentheinjection

pumpandtheinjectors;refertoBleedingAirfromthe

Injectors.

Note:Themachineisequippedwithaninterlock

switchontheparkingbrake.Theenginewillstopif

thetractionpedalispressedwiththeparkingbrake

engaged.

TowingtheTractionUnit

Incaseofanemergency,themachinecanbetowedfor

ashortdistance;however,Torodoesnotrecommend

thisasastandardprocedure.

Important:Donottowthemachinefasterthan2

to3mph(3to4km/h)becauseitmaydamage

thedrivesystem.Ifthemachinemustbemoveda

considerabledistance,transportitonatruckor

trailer.

1.Locatethebypassvalveonthepump(Figure42)

androtateit90°.

31

Page 32

Figure42

1.Bypassvalve

2.Beforestartingtheengine,closethebypassvalveby

rotatingit90°(1/4turn).Donotstarttheengine

whilethevalveisopen.

ThedecalontheSCMonlyincludessymbols.Three

LEDoutputsymbolsareshownintheoutputbox.All

otherLEDsareinputs.Thechartbelowidentiesthe

symbols.

Figure43

StandardControlModule

(SCM)

TheStandardControlModuleisapottedelectronic

deviceproducedinaone-size-ts-allconguration.The

moduleusessolidstateandmechanicalcomponents

tomonitorandcontrolstandardelectricalfeatures

requiredforsafeproductoperation.

Themodulemonitorsinputsincludingneutral,parking

brake,PTO ,start,backlap,andhightemperature.The

moduleenergizesoutputsincludingPTO ,Starter,and

ETR(energizetorun)solenoid.

Themoduleisdividedintoinputsandoutputs.Inputs

andoutputsareidentiedbygreenLEDindicators

mountedontheprintedcircuitboard.

Thestartcircuitinputisenergizedby12VDC.All

otherinputsareenergizedwhenthecircuitisclosedto

ground.EachinputhasaLEDthatisilluminatedwhen

thespeciccircuitisenergized.UsetheinputLEDsfor

switchandinputcircuittroubleshooting.

Outputcircuitsareenergizedbyanappropriatesetof

inputconditions.ThethreeoutputsincludePTO,ETR,

andSTART.OutputLEDsmonitorrelaycondition

indicatingthepresenceofvoltageatoneofthree

specicoutputterminals.

Outputcircuitsdonotdetermineoutputdevice

integrity,soelectricaltroubleshootingincludesoutput

LEDinspectionandconventionaldeviceandwire

harnessintegritytesting.Measurethedisconnected

componentimpedance,theimpedancethroughwire

harness(disconnectatSCM),orbytemporarily”test

energizing”thespeciccomponent.

HerearethelogicaltroubleshootingstepsfortheSCM

device.

1.Determinetheoutputfaultyouaretryingtoresolve

(PTO,START,orETR).

2.MovethekeyswitchtotheOnpositionandensure

thattheredpowerLEDisilluminated.

3.MovealltheinputswitchestoensurethatallLEDs

changestate.

4.Positiontheinputdevicesattheappropriate

positiontoachievetheappropriateoutput.Usethe

followinglogiccharttodeterminetheappropriate

inputcondition.

5.IfthespecicoutputLEDisilluminatedwithout

theappropriateoutputfunction,checktheoutput

harness,connections,andcomponent.Repairas

needed.

6.IfthespecicoutputLEDisnotilluminated,check

bothfuses.

7.IfthespecicoutputLEDisnotilluminatedand

theinputsareintheappropriatecondition,installa

newSCManddetermineifthefaultdisappears.

Eachrow(across)inthelogicchartbelowidenties

inputandoutputrequirementsforeachspecicproduct

function.Theproductfunctionsarelistedintheleft

column.Thesymbolsidentifythespeciccircuit

conditionincluding:energizedtovoltage,closedto

ground,andopentoground.

TheSCMdoesnotconnecttoanexternalcomputeror

handhelddevice,cannotbere-programmed,anddoes

notrecordintermittentfaulttroubleshootingdata.

32

Page 33

INPUTSOUTPUTS

FunctionPower

Start

Run(Off

Unit)

Run(On

Unit)

Mow

Backlap

HiT emp

ON

——

——

—

—

——

—

In

Neutral

OO

OO

StartON

Brake

ON

+

OOOOOOO

OO

O

OO

—

———

PTOONInSeat

—

•(–)Indicatesacircuitclosedtoground—LEDON.

•(O)Indicatesacircuitopentogroundor

de-energized—LEDOFF .

•(+)Indicatesanenergizedcircuit(clutchcoil,

solenoid,orstartinput)—LEDON.

•ABlankindicatesacircuitthatisnotinvolvedwith

thelogic.

Totroubleshoot,turnonthekeywithoutstartingthe

engine.Identifythespecicfunctionthatdoesnot

workandworkacrossthelogicchart.Inspectthe

conditionofeachinputLED’stoensurethatitmatches

thelogicchart.

HiT empBacklap

—

O

—

OO

OO

OOO

OOO

—

—

Start

++

O

OOO

ETR

+

+

++

++

PTO

O

O

O

IftheinputLEDsarecorrect,checktheoutputLED.

IftheoutputLEDisilluminatedbutthedeviceisnot

energized,measuretheavailablevoltageattheoutput

device,thecontinuityofthedisconnecteddevice,and

thepotentialvoltageonthegroundcircuit(oating

ground).Repairswillvarydependingonyourndings.

33

Page 34

OperatingTips

theforwardtractionpedal,andcarefullydriveto

anopenarea.

GeneralTipsforModel03171

DANGER

Themowerhasauniquetractionsystemthatwill

allowthemachinetomoveforwardonsidehills,

eveniftheuphillwheelshouldcomeoffofthe

ground.Ifthisshouldhappen,theoperatororany

bystanderscouldbeseriouslyinjuredorkilledina

rollover.

Theslopeangleatwhichthemachinewilltipis

dependentonmanyfactors.Amongtheseare

mowingconditionssuchaswetorundulatingturf,

speed(especiallyinturns),positionofthecutting

units(withSidewinder),tirepressure,andoperator

experience.

Atsidehillanglesof15degreesorless,therisk

ofarolloverislow.Astheslopeangleincreases

toarecommendedmaximumlimitof25degrees,

theriskofarolloverincreasestoamoderatelevel.

Do not ex ceed a 20 deg r ee side hill slope ang le

because the risk of a r ollo v er and serious injur y or

death is v er y high.

Todeterminewhichhillsorslopesyoumaysafely

operateon,youmustconductasitesurveyof

themowingarea.Whenperformingthissite

survey,alwaysusecommonsenseandtakeinto

considerationtheturfconditionandtherollover

risk.T odeterminewhichhillsorslopesmaybe

safelyoperatedon,usetheinclinometerprovided

witheachmachine.Toperformasitesurvey,lay

a4ft2x4(1.25mplank)ontheslopesurface

andmeasuretheangleoftheslope.The2x

4willaveragetheslopebutwillnottakeinto

considerationdipsorholeswhichcancausea

suddenchangeinsidehillangle.

side hill ang le should not be g r eater than 20

deg r ees.

Additionally,themachineisequippedwithan

angleindicatormountedonthesteeringtube.This

indicatesthesidehillanglethemachineisonand

identiestherecommendedmaximumlimitof25

degrees.

Al w ays w ear y our seat belt.

•Practiceoperatingthemachineandbecome

thoroughlyfamiliarwithit.

•Starttheengineandrunitathalfidleuntilitwarms

up.Pushthethrottleleverallthewayforward,lift

thecuttingunits,disengagetheparkingbrake,press

T he maximum

•Practicemovingforwardandreverse,andstarting

andstoppingthemachine.Tostop,takeyourfoot

offofthetractionpedalandletitreturntoneutral

orpressdownonthereversepedaltostop.Going

downahill,youmayneedtousethereversepedal

tostop.

•Whendrivingonslopes,driveslowlytomaintain

steeringcontrolandavoidturnstopreventrollovers.

Insidehillsituationsyoushouldshiftthesidewinder

cuttingunitstotheuphillsidetogiveyoumore

stability.Conversely ,shiftingthecuttingunitsto

thedownhillsidewillgiveyoulessstability.This

shouldalwaysbedonebeforegoingonasidehill.

•Whenpossible,mowupanddownhillsratherthan

acrossthem.Havethecuttingunitsloweredwhen

goingdownahilltomaintainsteeringcontrol.Do

notattempttoturnonahill.

•Practicedrivingaroundobstacleswiththecutting

unitsupanddown.Becarefulwhendriving

betweennarrowobjectssothatyoudonotdamage

themachineorcuttingunits.

•OntheSidewinderunit,getafeelforthereachof

thecuttingunitssothatyoudonothangthemup

ordamagetheminanyway.

•Donotshifttheunitsfromsidetoside,unlessthe

cuttingunitsaredownandthemachineismoving,

orthecuttingunitsareupinthetransportposition.

Shiftingthecuttingunitswhentheyaredownand

themachineisnotmovingmaydamagetheturf.

•Alwaysdriveslowlyinroughareas.

•Ifapersonappearsinorneartheoperatingarea,

stopthemachine,anddonotstartitagainuntilthe

areaiscleared.Themachineisdesignedforone

person.Neverletanyoneelserideonthemachine

withyou.Thisisextremelydangerousandcould

resultinseriousinjury.

•Accidentscanhappentoanyone.Themost

commoncausesareexcessivespeed,suddenturns,

terrain(notknowingwhichslopesandhillscan

bemowedsafely),notstoppingtheenginebefore

leavingtheoperator’sseat,anddrugsthatimpair

youralertness.Coldcapsulesorprescriptiondrugs

maycausedrowsiness,ascanalcoholandother

drugs.Stayalertandstaysafe.Failuretodoso

couldresultinseriousinjury.

•TheSidewinderoffersuptoamaximumof13

inches(33cm)ofoverhang,allowingyoutotrim

closertotheedgeofsandtrapsandotherobstacles,

whileatthesametimekeepingthetractortiresas

34

Page 35

farawayfromtheedgeoftrapsorwaterhazards

aspossible.

•Ifanobstacleisintheway ,shiftthecuttingunits

toeasilymowaroundit.

•Whentransportingthemachinefromonework

areatoanother,raisethecuttingunitstothefully

upposition,movethemow/transportslidetothe

lefttotransport,andplacethethrottleintheFast

position.

GeneralTipsforModel03170

DANGER

Themowerhasauniquetractionsystemthatwill

allowthemachinetomoveforwardonsidehills,

eveniftheuphillwheelshouldcomeoffofthe

ground.Ifthisshouldhappen,theoperatororany

bystanderscouldbeseriouslyinjuredorkilledina

rollover.

Theslopeangleatwhichthemachinewilltipis

dependentonmanyfactors.Amongtheseare

mowingconditionssuchaswetorundulatingturf,

speed(especiallyinturns),positionofthecutting

units,tirepressure,andoperatorexperience.

Atsidehillanglesof20degreesorless,therisk

ofarolloverislow.Astheslopeangleincreases

toarecommendedmaximumlimitof25degrees,

theriskofarolloverincreasestoamoderatelevel.

Do not ex ceed a 25 deg r ee side hill slope ang le

because the risk of a r ollo v er and serious injur y or

death is v er y high.

Todeterminewhichhillsorslopesyoumaysafely

operateon,youmustconductasitesurveyof

themowingarea.Whenperformingthissite

survey,alwaysusecommonsenseandtakeinto

considerationtheturfconditionandtherollover

risk.T odeterminewhichhillsorslopesmaybe

safelyoperatedon,usetheinclinometerprovided

witheachmachine.Toperformasitesurvey,lay

a4ft2x4(1.25mplank)ontheslopesurface

andmeasuretheangleoftheslope.The2x

4willaveragetheslopebutwillnottakeinto

considerationdipsorholeswhichcancausea

suddenchangeinsidehillangle.

T he maximum

side hill ang le should not be g r eater than 25

deg r ees.

Additionally,themachineisequippedwithan

angleindicatormountedonthesteeringtube.This

indicatesthesidehillanglethemachineisonand

identiestherecommendedmaximumlimitof25

degrees.

Al w ays w ear y our seat belt.

•Practiceoperatingthemachineandbecome

thoroughlyfamiliarwithit.

•Starttheengineandrunitathalfidleuntilitwarms

up.Pushthethrottleleverallthewayforward,lift

thecuttingunits,disengagetheparkingbrake,press

theforwardtractionpedal,andcarefullydriveto

anopenarea.

35

Page 36

•Practicemovingforwardandreverse,andstarting

andstoppingthemachine.Tostop,takeyourfoot

offofthetractionpedalandletitreturntoneutral

orpressdownonthereversepedaltostop.Going

downahill,youmayneedtousethereversepedal

tostop.

•Whendrivingonslopes,driveslowlytomaintain

steeringcontrolandavoidturnstopreventrollovers.

Insidehillsituationsyoushouldshiftthesidewinder

cuttingunitstotheuphillsidetogiveyoumore

stability.Conversely ,shiftingthecuttingunitsto

thedownhillsidewillgiveyoulessstability.This

shouldalwaysbedonebeforegoingonasidehill.

•Whenpossible,mowupanddownhillsratherthan

acrossthem.Havethecuttingunitsloweredwhen

goingdownahilltomaintainsteeringcontrol.Do

notattempttoturnonahill.

•Practicedrivingaroundobstacleswiththecutting

unitsupanddown.Becarefulwhendriving