FormNo.3380-145RevA

Reelmaster

ModelNo.03170—SerialNo.314000001andUp

ModelNo.03171—SerialNo.314000001andUp

®

3100-DTractionUnit

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3380-145*A

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

yourproductready.

Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisaride-on,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrasson

well-maintainedlawnsinparks,golfcourses,sportselds,

andoncommercialgrounds.Itisnotdesignedforcutting

brush,mowinggrassandothergrowthalongsidehighways,

orforagriculturaluses.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................6

SoundPowerLevel..................................................7

SoundPressureLevel...............................................7

VibrationLevel......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................12

1InstallingtheWheels............................................13

2InstallingtheSteeringWheel..................................13

3Activating,Charging,andConnectingthe

Battery..............................................................14

4CheckingtheAngleIndicator.................................15

5InstallingtheHoodLatch(CEOnly).......................15

6InstallingtheExhaustGuard(CEOnly)..................16

7InstallingtheRollBar...........................................17

8InstallingtheFrontLiftArms................................17

9InstallingtheCarrierFramestotheCutting

Units.................................................................18

10MountingtheCuttingUnits.................................20

11MountingtheCuttingUnitDriveMotors...............20

12AdjustingtheLiftArms......................................21

ProductOverview.........................................................23

Controls...............................................................23

Specications........................................................25

Attachments/Accessories........................................25

Operation....................................................................25

CheckingtheEngineOilLevel.................................25

FillingtheFuelTank...............................................26

CheckingtheCoolingSystem...................................26

CheckingtheHydraulicSystem................................27

CheckingtheTirePressure......................................28

CheckingtheReel-to-BedknifeContact.....................28

TorquingtheWheelNuts........................................28

StartingandStoppingtheEngine..............................28

BleedingtheFuelSystem.........................................29

CheckingtheInterlockSystem.................................29

TowingtheTractionUnit.........................................30

StandardControlModule(SCM)..............................30

OperatingTips......................................................32

Maintenance.................................................................36

RecommendedMaintenanceSchedule(s)......................36

DailyMaintenanceChecklist....................................37

ServiceIntervalChart.............................................38

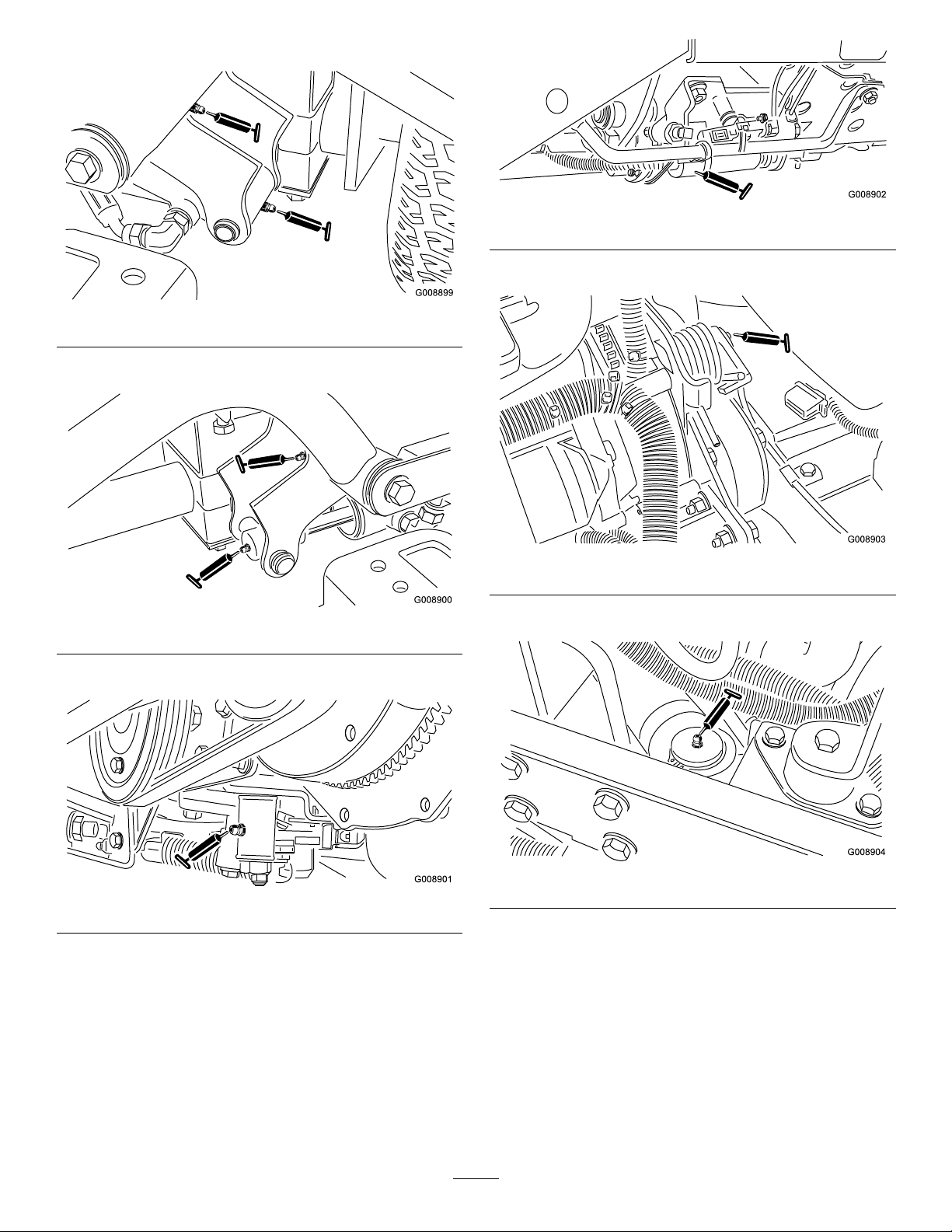

PremaintenanceProcedures........................................38

RemovingtheHood...............................................38

Lubrication...............................................................39

GreasingtheBearingsAndBushings.........................39

SealedBearings......................................................41

EngineMaintenance..................................................42

ServicingtheAirCleaner.........................................42

ChangingtheEngineOilandFilter...........................42

FuelSystemMaintenance...........................................43

ServicingtheFuelTank...........................................43

InspectingtheFuelLinesandConnections.................43

DrainingtheWaterSeparator...................................43

ChangingtheFuelFilterCanister..............................44

BleedingAirfromtheInjectors................................44

ElectricalSystemMaintenance....................................45

CaringfortheBattery..............................................45

StoringtheBattery..................................................45

Fuses....................................................................45

DriveSystemMaintenance.........................................46

AdjustingtheTractionDriveforNeutral....................46

CoolingSystemMaintenance......................................46

CleaningtheEngineCoolingSystem.........................46

BrakeMaintenance....................................................47

AdjustingtheParkingBrake.....................................47

BeltMaintenance......................................................47

ServicingtheEngineBelts.......................................47

ControlsSystemMaintenance.....................................48

AdjustingtheThrottle.............................................48

HydraulicSystemMaintenance....................................49

ChangingtheHydraulicFluid...................................49

ChangingtheHydraulicFilter...................................49

CheckingtheHydraulicLinesandHoses....................50

MiscellaneousMaintenance.........................................50

BacklappingtheCuttingSystem................................50

Storage........................................................................51

PreparationforSeasonalStorage..............................51

3

Safety

ThismachinemeetsorexceedsCENstandardEN

836:1997(whenappropriatedecalsapplied),and

ANSIB71.4-2004specicationsineffectatthetimeof

productionwhenequippedwithrequiredweightsas

listedintheweightchart.

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructionsand

alwayspayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Preparation

•Whilemowing,alwayswearsubstantialfootwear,long

trousers,hardhat,safetyglasses,andhearingprotection.

Longhair,looseclothing,orjewelrymaygettangled

inmovingparts.Donotoperatetheequipmentwhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Replacefaultysilencers/mufers.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromtheCEN

standardEN836:1997,ISOstandard5395:1990,andANSI

B71.4-2004.

Training

•ReadtheOperator’sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadthelanguage

ofthismanual,itistheowner’sresponsibilitytoexplain

thismaterialtothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasizethefollowing:

–Theneedforcareandconcentrationwhenworking

withride-onmachines

–Controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolareasfollows:

◊Insufcientwheelgrip

◊Beingdriventoofast

◊Inadequatebraking

◊Thetypeofmachineisunsuitableforthetask

◊Lackofawarenessoftheeffectofground

conditions,especiallyslopes

◊Incorrecthitchingandloaddistribution

•Checkthatoperator’spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Operation

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

4

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutches,shiftintoneutral,andengagethe

parkingbrake.Onlystarttheenginefromtheoperator’s

position.NeverremovetheROPSandalwayswearthe

seatbeltsduringoperation.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Dothefollowing

toguardagainstoverturning:

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Keepmachinespeedslowonslopesandduringtight

turns.

–Stayalertforhumpsandhollowsandotherhidden

hazards.

–Nevermowacrossthefaceoftheslope,unlessthe

mowerisdesignedforthispurpose.

•Stayalertforholesintheterrainandotherhiddenhazards.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesfromrotatingbeforecrossingsurfaces

otherthangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,shields,

orwithoutsafetyprotectivedevicesinplace.Besureall

interlocksareattached,adjustedproperly ,andfunctioning

properly.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedmay

increasethehazardofpersonalinjury.

•Dothefollowingbeforeleavingtheoperator’ sposition:

–Stoponlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Changeintoneutralandsettheparkingbrake.

–Stoptheengineandremovethekey.

•Disengagethedrivetoattachments,stoptheengine,and

removetheignitionkeyinthefollowingconditions:

–Beforerefueling

–Beforeremovingthegrasscatcher(s)

–Beforemakingheightadjustments,unlessthe

adjustmentcanbemadefromtheoperator’sposition.

–Beforeclearingblockages

–Beforechecking,cleaning,orworkingonthemower

–Afterstrikingaforeignobjectorifanabnormal

vibrationoccurs(checkimmediately).Inspectthe

mowerfordamageandmakerepairsbeforerestarting

andoperatingtheequipment.

•Disengagethedrivetoattachmentswhentransportingor

whenthemachineisnotinuse.

•Reducethethrottlesettingbeforestoppingtheengine

and,iftheengineisprovidedwithafuelshut-offvalve,

turnthefueloffattheconclusionofmowing.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopcylinders/reelsifnot

mowing.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Theoperatorshallturnonashingwarninglights,if

provided,whenevertravelingonapublicroad,except

wheresuchuseisprohibitedbylaw .

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumesmayreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,

silencer/mufer,batterycompartmentfuelstoragearea,

cuttingunitsanddrivesfreeofgrass,leaves,orexcessive

grease.Cleanupoilorfuelspillage.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replacewornor

damagedpartsanddecalsforsafety.

•Ifthefueltankhastobedrained,dothisoutdoors.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-cylinder/multi-reelmachines,takecareas

rotatingonecylinder/reelcancauseothercylinders/reels

torotate.

•Disengagedrives,lowerthecuttingunits,setparking

brake,stopengineandremovekey .Waitforallmovement

tostopbeforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

silencers/mufers,andenginetohelppreventres.Clean

upoilorfuelspillage.

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearames.

•Parkthemachineonlevelground.

5

•Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectbatterybeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.Reconnect

positiverstandnegativelast.

•Usecarewhencheckingthecylinders/reels.Weargloves

andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugchargerbeforeconnecting

ordisconnectingfrombattery.W earprotectiveclothing

anduseinsulatedtools.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCEN,ISO,orANSIstandards.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Useofthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustouserandbystanders.

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.Do

notrunengineindoorsorinanenclosedarea.

Preparation

Besuretoestablishyourownspecialproceduresandwork

rulesforunusualoperatingconditions(e.g.,slopestoosteep

foroperation).Surveythecompletemowingsiteto

determinewhichhillscanbesafelyoperatedon.When

performingthissitesurvey,alwaysusecommonsenseand

takeintoconsiderationtheturfconditionandtherolloverrisk.

Todeterminewhichhillsorslopesmaybesafelyoperated

on,usetheinclinometerprovidedwitheachmachine.To

performasitesurvey,followtheprocedureoutlinedinthe

Operationsectionofthethismanual.Themaximumside

hillangleisdetailedontheslopedecalafxednearthe

angleindicator.

Training

Theoperatormustbeskilledandtrainedinhowtodriveon

hillsides.Failuretousecautiononslopesorhillsmaycause

thevehicletotiporroll,possiblyresultinginpersonalinjury

ordeath.

Operation

•Knowhowtostopthemachineandenginequickly.

•Donotoperatethemachinewhilewearingtennisshoes

orsneakers.

•Wearingsafetyshoesandlongpantsisadvisableand

requiredbysomelocalordinancesandinsurance

regulations.

•Keephands,feet,andclothingawayfrommovingparts

andthemowerdischargearea.

•Fillthefueltankuntillevelis12mm(1/2inch)belowthe

bottomofthellerneck.Donotoverll.

•Checkthesafetyinterlockswitchesdailyforproper

operation.Ifaswitchshouldfail,replacetheswitch

beforeoperatingthemachine.

•Whenstartingtheengine,engagetheparkingbrake,put

thetractionpedalinneutral,anddisengagetheblade

drive.Aftertheenginestarts,releasetheparkingbrake

andkeepyourfootoffofthetractionpedal.Themachine

mustnotmove.Ifmovementisevident,refertothe

Maintenancesectionofthismanualtoadjustthetraction

drive.

•Useextremecautionwhenoperatingclosetosandtraps,

ditches,creeks,steephillsides,orotherhazards.

•Reducespeedwhenmakingsharpturns.

•Donotturnonhills.

•Iftheenginestallsorlosesheadwayandcannotmakeit

tothetopofaslope,donotturnthemachinearound.

Alwaysbackslowly,straightdowntheslope.

•Donotoperateonasidehillthatistoosteep.Arollover

mayoccurbeforelosingtraction.

•Model03171-Theslopeangleatwhichthemachine

willtipisdependentonmanyfactors.Amongtheseare

mowingconditionssuchaswetorundulatingterrain,

speed(especiallyinturns),positionofthecutting

units(withtheSidewinder),tirepressure,andoperator

experience.Atsidehillanglesof15degreesorless,the

riskofarolloverislow.Astheslopeangleincreasestoa

recommendedmaximumlimitof20degrees,theriskofa

rolloverincreasestoamoderatelevel.Donotexceeda

20degreesidehillslopeanglebecausetheriskofa

rolloverandseriousinjuryordeathisveryhigh.

•Model03170-Theslopeangleatwhichthemachine

willtipisdependentonmanyfactors.Amongtheseare

mowingconditionssuchaswetorundulatingterrain,

speed(especiallyinturns),positionofthecuttingunits,

tirepressure,andoperatorexperience.Atsidehillangles

of20degreesorless,theriskofarolloverislow .As

theslopeangleincreasestoarecommendedmaximum

6

limitof25degrees,theriskofarolloverincreasestoa

moderatelevel.Donotexceeda25degreesidehill

slopeanglebecausetheriskofarolloverandserious

injuryordeathisveryhigh.

•Forsteeringcontrol,lowerthecuttingunitswhengoing

downslopes.

relievedbystoppingtheengineandloweringthecutting

unitstotheground.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Avoidsuddenstopsandstarts.

•Usethereversepedalforbraking.

•Watchfortrafcwhennearorcrossingroads.Always

yieldtheright-of-way.

•Raisethecuttingunitswhendrivingfromoneworkarea

toanother.

•Donottouchtheengine,mufer,exhaustpipe,or

hydraulictankwhiletheengineisrunningorsoonafter

ithasstoppedbecausetheseareascouldbehotenough

tocauseburns.

•Thismachineisnotdesignedorequippedforon-roaduse

andisaslow-movingvehicle.Ifyoumustcrossortravel

onapublicroad,youshouldbeawareofandcomplywith

localregulations,suchasrequiredlights,slowmoving

vehiclesigns,andreectors.

•Thegrassbasketsmustbeinplaceduringoperationof

thecylinders/reelsorthatchersformaximumsafety.Shut

theengineoffbeforeemptyingthebaskets.

•Whenapersonorpetappearsunexpectedlyinornear

themowingarea,stopmowing.Carelessoperation,

combinedwithterrainangles,ricochets,orimproperly

positionedguardscanleadtothrownobjectinjuries.Do

notresumemowinguntiltheareaiscleared.

MaintenanceandStorage

•Beforeservicingormakingadjustments,stoptheengine

andremovetheignitionkey.

•Donotoverspeedtheenginebychanginggovernor

settings.Toensuresafetyandaccuracy,havean

AuthorizedToroDistributorcheckthemaximumengine

speedwithatachometer.

•Theenginemustbeshutoffbeforecheckingtheoilor

addingoiltothecrankcase.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

SoundPowerLevel

Thisunithasaguaranteedsoundpowerlevelof96dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’ searof82

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

•Ensurethattheentiremachineisproperlymaintained

andingoodoperatingcondition.Frequentlycheckall

nuts,bolts,screws,andhydraulicttings.

•Makesureallhydrauliclineconnectorsaretightandall

hydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Ifuidisinjectedintotheskinitmustbesurgically

removedwithinafewhoursbyadoctorfamiliarwiththis

formofinjuryorgangrenemayresult.

•Checkallfuellinesfortightnessandwearonaregular

basis.Tightenorrepairthemasneeded.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=.41m/s

Measuredvibrationlevelforlefthand=.52m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=.49m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

7

2

2

2

2

2

SafetyandInstructionalDecals

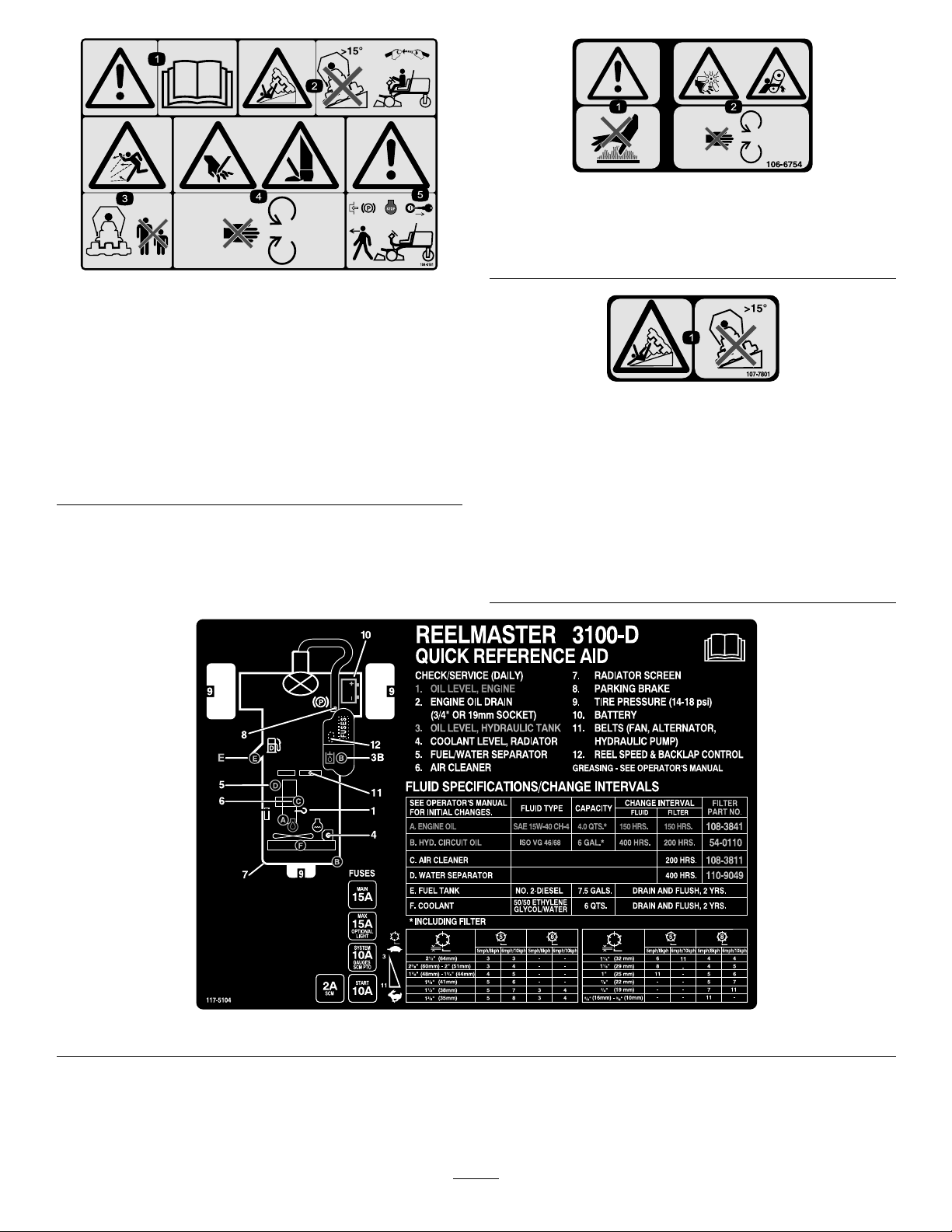

99-3444

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

93-7276

1.Explosionhazard—weareyeprotection.

2.Causticliquid/chemicalburnhazard—toperformrstaid,

ushwithwater.

3.Firehazard—nore,openames,orsmoking.

4.Poisonhazard—keepchildrenasafedistancefromthe

battery.

99-3496

94-3353

Model03207only

1.Crushinghazardofhand—keepyourhandsasafedistance

away.

99-3444

1.Reelspeed—fast

2.Reelspeed—slow

99-3558

CEonly

1.Warning—readtheOperator’sManual.

2.Tostarttheengine,sitontheseatandrotatetheignition

keytoOn/Preheatuntiltheglowplugindicatorlightgoes

out.Rotatethekeytostartanddisengagetheparking

brake.ReadtheOperator’sManualforfurtherinstructions.

3.Tostoptheengine,disengagethecuttingunits,rotatethe

ignitionkeytoOff,andremovethekey.Engagetheparking

brake.ReadtheOperator’sManualforfurtherinstructions.

100-4837

8

104-5181

CEonly

1.Warning—readtheOperator’sManual.

2.Tippinghazard—donotdriveonslopesgreaterthan15

degreesand,iftherollbarisinstalled,weartheseatbelt.

3.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

4.Cuttinghazardofhandorfoot—stayawayfrommoving

parts.

5.Warning—locktheparkingbrake,stoptheengine,and

removetheignitionkeybeforeleavingthemachine.

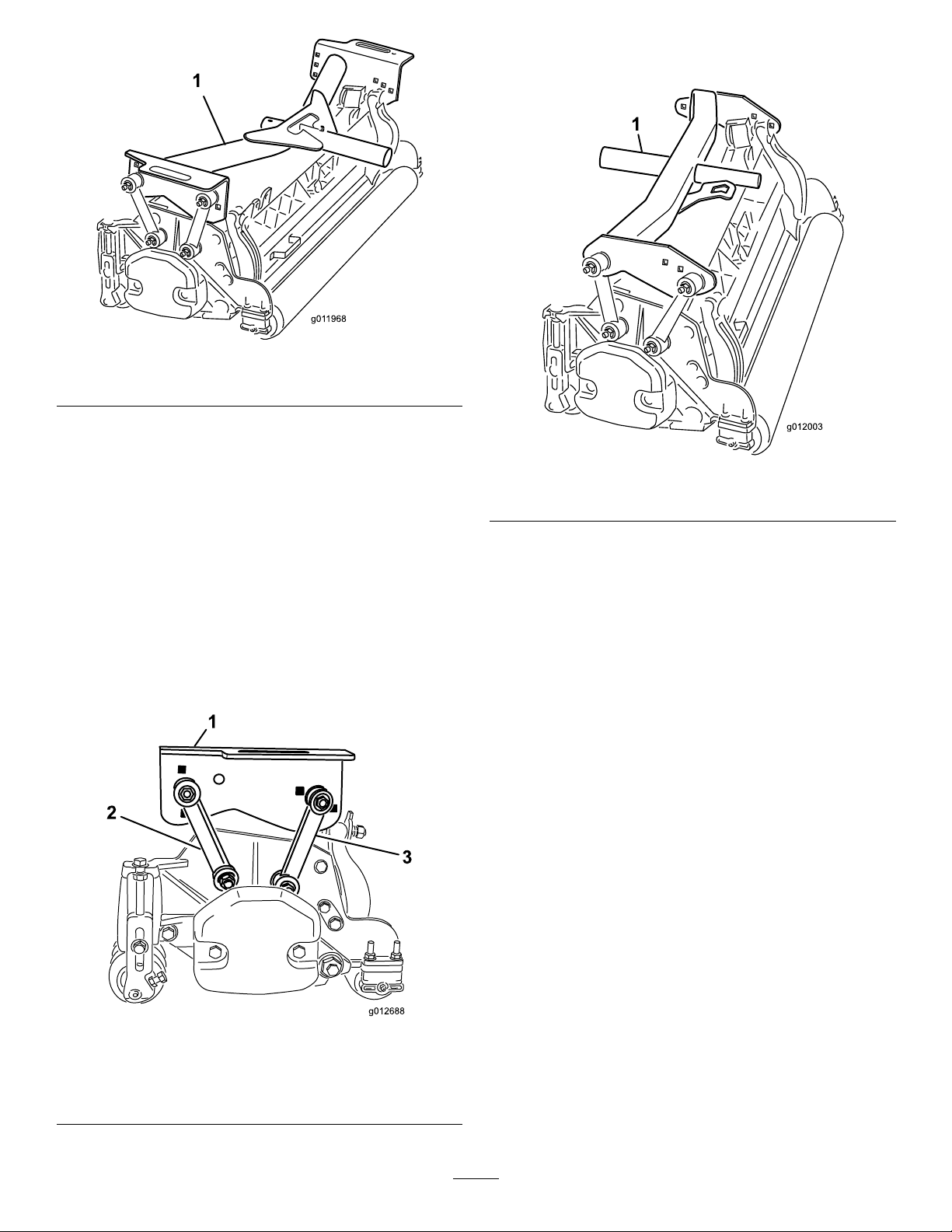

106-6754

1.Warning—donottouchthehotsurface.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt—stayawayfrommovingparts.

107-7801

(CEonly)

*Thissafetydecalincludesaslopewarningrequiredonthemachinefor

compliancetotheEuropeanLawnMowerSafetyStandardEN836:1997.The

conservativemaximumslopeanglesindicatedforoperationofthismachineare

prescribedbyandrequiredbythisstandard.

1.Tippinghazard—donotdriveonslopesgreaterthan15

degrees.

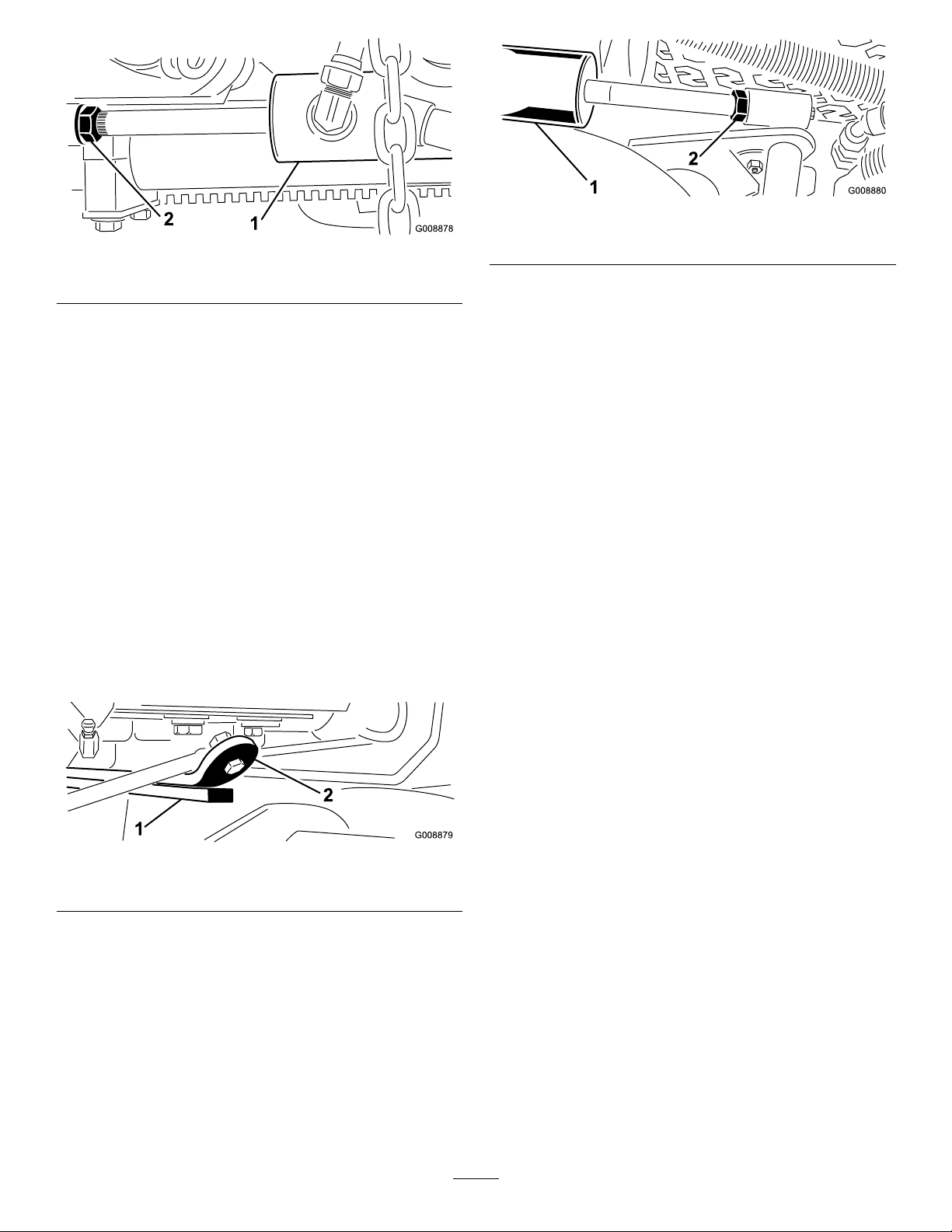

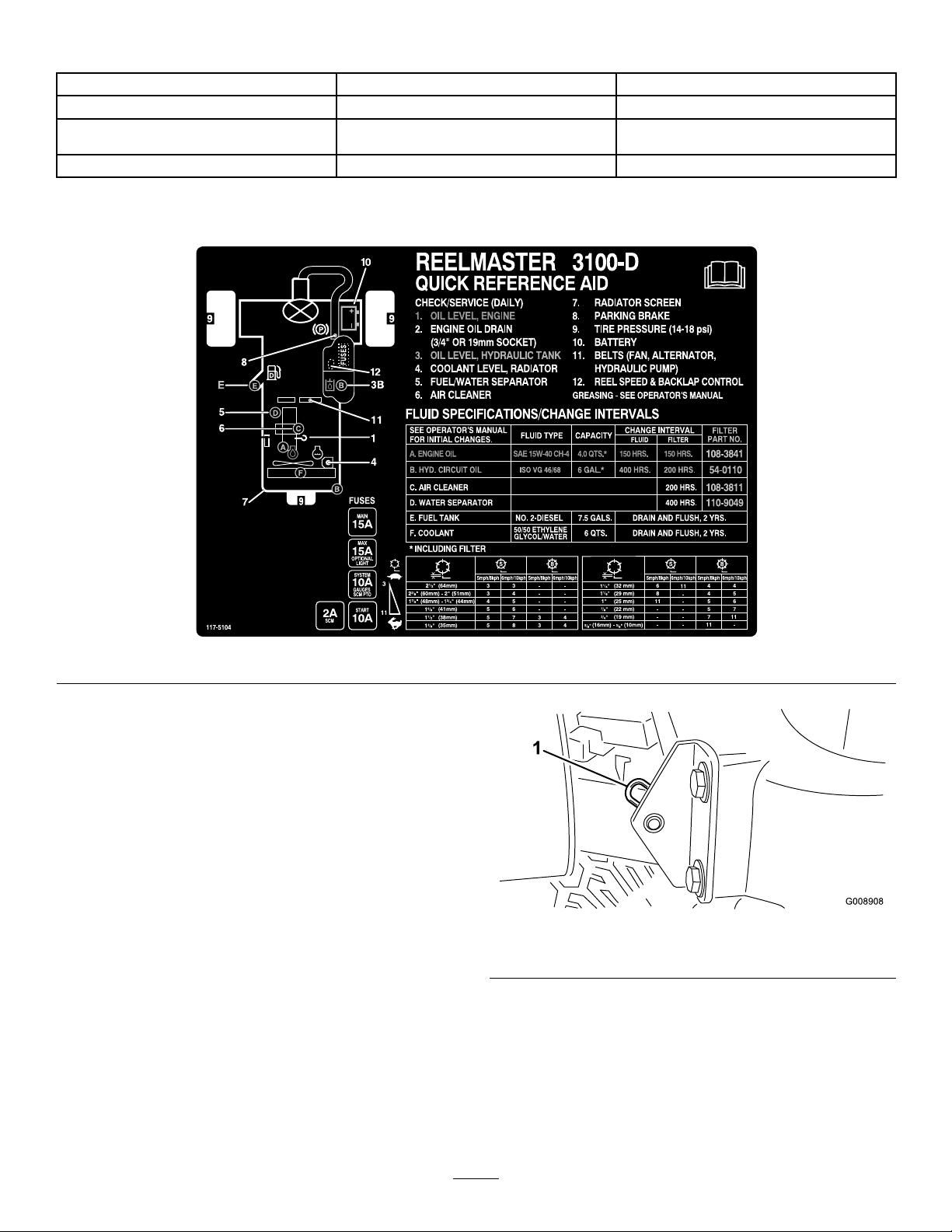

117-5104

9

104-5192

Model03207only

1.Engagethepowertakeoff

(PTO).

2.Disengagethepowertake

off(PTO).

3.Lowerthecuttingunits.7.Moverearwardtolockthe

4.Movethecuttingunitsto

theright.

5.Raisethecuttingunits.9.Engine—run

6.Movethecuttingunitsto

theleft.

liftlever .

8.Engine—stop

13.Slow

10.Engine—start

11.Fast

12.Continuousvariablesetting

10

104-5193

Model03206only

1.Engagethepowertakeoff

(PTO).

2.Disengagethepowertake

off(PTO).

3.Lowerthecuttingunits.7.Moverearwardtolockthe

4.Movethecuttingunitsto

theright.

5.Raisethecuttingunits.9.Engine—run

6.Movethecuttingunitsto

theleft.

liftlever .

8.Engine—stop

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

13.Slow

10.Engine—start

11.Fast

12.Continuousvariablesetting

11

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Frontwheelassemblies2

Rearwheelassembly1

Steeringwheel

Steeringwheelcap

Largewasher1

Jamnut1

Screw

Electrolyte

Inclinometer1

Lockbracket1

Rivet2

Washer1

Screw,1/4x2inches

Locknut,1/4inch

Exhaustguard1

Self-tappingscrew

Rollbarassembly1

Flangeheadbolts4

Locknuts4

Hoseclamp1

Liftarms

Pivotrod2

Bolt(5/16x7/8inch)

Nopartsrequired

Qty.

A/R

Use

Installthewheels.

1

1

Installthesteeringwheel.

1

Activate,charge,andconnectthe

battery.

Checktheangleindicator.

InstalltheHoodLatch(CE).

1

1

4

2

2

–

InstalltheExhaustGuard(CE).

Installtherollbar.

Installthefrontliftarms.(Partssupplied

intheLiftArmKit.)

Installthecarrierframestothecutting

units.

10

11

12

Nopartsrequired

Nopartsrequired

Nopartsrequired

12

–

–

–

Mountthecuttingunits.

Mountthecuttingunitdrivemotors.

Adjusttheliftarms.

MediaandAdditionalParts

Description

Decal,CE

Ignitionkey2

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

Pre-deliverychecklist1

Certicateofcompliance

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

1

InstallingtheWheels

Partsneededforthisprocedure:

2Frontwheelassemblies

1Rearwheelassembly

Qty.

6

1

1

1Usetolookupandorderparts.

1

1

AfxtothemachineovercorrespondingEnglishdecals

forEuropeancompliance.

Starttheengine.

Readbeforeoperatingthemachine.

Viewbeforeoperatingthemachine.

Checktoensurethatthemachinehasbeenproperlyset

up.

EnsureCEcompliance.

2

InstallingtheSteeringWheel

Partsneededforthisprocedure:

1

Steeringwheel

1

Steeringwheelcap

1Largewasher

1Jamnut

1

Screw

Use

Procedure

1.Mountawheelassemblyontoeachwheelhub(valve

stemoutward).

Important:Thereartirehasanarrowerrimthan

thefronttires.

2.Installlugnutsandtorqueto61to88N-m(45to65

ft-lb).

Procedure

1.Slidethesteeringwheelontothesteeringshaft(Figure

3).

Figure3

1.Steeringwheel

2.Washer

2.Slidethewasherontothesteeringshaft(Figure3).

3.Jamnut

4.Cap

13

3.Securethesteeringwheeltotheshaftwithajamnut

andtightenitto27to35N-m(20to26ft-lb)(Figure3).

4.Installthecaptothesteeringwheelandsecureitwitha

screw(Figure3).

3

Activating,Charging,and ConnectingtheBattery

Partsneededforthisprocedure:

A/R

Procedure

Note:Ifthebatteryisnotlledwithelectrolyteoractivated,

bulkelectrolytewith1.260specicgravitymustbepurchased

fromalocalbatterysupplyoutletandaddedtothebattery.

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

•Fillthebatterywherecleanwaterisalways

1.Purchasebulkelectrolytewith1.260specicgravity

2.Openthehood.

3.Removethebatterycover(

Electrolyte

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

DANGER

skin,eyes,orclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

availableforushingtheskin.

fromalocalbatterysupplyoutlet.

Figure4).

Figure4

1.Batterycover

4.Removethellercapsfromthebatteryandslowlyll

eachcelluntilelectrolyteisjustabovetheplates.

5.Installthellercapsandconnecta3to4ampbattery

chargertothebatteryposts.Chargethebatteryata

rateof3to4ampsfor4to8hours.

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

•Keepsparksandamesawayfrombattery.

•Neversmokenearthebattery.

6.Whenthebatteryischarged,disconnectthecharger

fromtheelectricaloutletandbatteryposts.

7.Removethellercaps.Slowlyaddelectrolytetoeach

celluntilthelevelisuptothellring.Installtheller

caps.

Important:Donotoverllthebattery.Electrolyte

willoverowontootherpartsofthemachineand

severecorrosionanddeteriorationwillresult.

8.Installthepositivecable(red)tothepositive(+)

terminalandthenegativecable(black)tothenegative

(–)terminalofthebatteryandsecurethemwithbolts

andnuts(Figure5).Makesurethatthepositive(+)

terminalisallofthewayontothepostandthecable

ispositionedsnugtothebattery.Thecablemustnot

contactthebatterycover.

WARNING

Incorrectbatterycableroutingcoulddamage

thetractorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

14

Figure5

1.Positive(+)batterycable2.Negative(–)batterycable

Important:Ifthebatteryiseverremoved,make

surethatthebatteryclampboltsareinstalledwith

theboltheadspositionedonthebottomsideand

thenutsonthetopside.Iftheclampboltsare

reversed,theymayinterferewiththehydraulic

tubeswhenshiftingthecuttingunits.

9.CoatbothbatteryconnectionswithGrafo112X(skin

over)grease,T oroPartNo.505-47,petroleumjelly,or

lightgreasetopreventcorrosion.

10.Slidetherubberbootoverthepositiveterminalto

preventapossibleshortfromoccurring.

11.Installthebatterycover.

4

CheckingtheAngleIndicator

Partsneededforthisprocedure:

1Inclinometer

Figure6

1.Angleindicator

3.Iftheinclinometerdoesnotreadzerodegrees,move

themachinetoalocationwhereazerodegreereading

isobtained.Theangleindicator,mountedonthe

machine,shouldnowreadzerodegreesaswell.

4.Iftheangleindicatordoesnotreadzerodegrees,

loosenthetwoscrewsandnutssecuringtheangle

indicatortothemountingbracket,adjusttheindicator

toobtainazerodegreereading,andtightenthebolts.

5

InstallingtheHoodLatch(CE Only)

Partsneededforthisprocedure:

1Lockbracket

2Rivet

1Washer

1

Screw,1/4x2inches

1

Locknut,1/4inch

Procedure

DANGER

Toreduceriskofinjuryordeathduetorollover,do

notoperatethemachineonsidehillssteeperthan

25º.

1.Parkthemachineonaat,levelsurface.

2.Verifythatthemachineislevelbyplacingahandheld

inclinometer(suppliedwiththemachine)ontheframe

crossrail,bythefueltank(Figure6).Theinclinometer

shouldreadzerodegreeswhenviewedfromthe

operator’sposition.

Procedure

1.Unhookthehoodlatchfromthehoodlatchbracket.

2.Removethe(2)rivetssecuringthehoodlatchbracket

tothehood(

fromthehood.

15

Figure7).Removethehoodlatchbracket

G012628

1

2

G012629

1

2

G012630

1

Figure9

G012631

1

2

3

Figure7

1.Hoodlatchbracket2.Rivets

3.Whilealigningthemountingholes,positiontheCE

lockbracketandthehoodlatchbracketontothehood.

Thelockbracketmustbeagainstthehood(Figure8).

Donotremoveboltandnutassemblyfromthelock

bracketarm.

Figure8

1.Hoodlatch

7.Screwtheboltintotheotherarmofhoodlockbracket

tolockthelatchinposition(Figure10).Tightenbolt

securelybutdonottightennut.

Figure10

1.Bolt

2.Nut

3.Armofhoodlockbracket

1.CElockbracket

2.Boltandnutassembly

6

4.Alignthewasherswiththeholesontheinsideofthe

hood.

5.Rivetthebracketsandthewasherstothehood(Figure

8).

6.Hookthelatchontothehoodlatchbracket(Figure9).

InstallingtheExhaustGuard (CEOnly)

Partsneededforthisprocedure:

1Exhaustguard

4

Self-tappingscrew

Procedure

1.Positiontheexhaustguardaroundthemuferwhile

aligningthemountingholeswiththeholesintheframe

(

Figure11).

16

Figure12

Figure11

1.Exhaustguard

2.Securetheexhaustguardtotheframewith4

self-tappingscrews(Figure11).

7

InstallingtheRollBar

Partsneededforthisprocedure:

1Rollbarassembly

4Flangeheadbolts

4Locknuts

1Hoseclamp

Procedure

1.ROPS

2.Mountingbracket5.Hoseclamp

3.Venttube

2.Secureeachsideoftherollbartothemounting

bracketswith2angeheadboltsandlocknuts(Figure

12).T orquethefastenersto81N-m(60ft-lb).

3.Securethefuellineventhosetotheventtubeonthe

rollbarwiththehoseclamp.

4.Fuellineventtubehose

CAUTION

Youmustconnectthefuellineventhosetothe

venttubepriortostartingtheengineorfuel

willowfromthehose.

8

InstallingtheFrontLiftArms

Partsneededforthisprocedure:

2

Liftarms

2Pivotrod

2

Bolt(5/16x7/8inch)

Important:Neverweldormodifyarolloverprotection

system(ROPS).ReplaceadamagedROPS,donotrepair

orrevise.AnyalterationofaROPSmustbeapproved

bythemanufacturer.

1.Lowertherollbarontothetractionunitmounting

brackets,aligningthemountingholes.Ensurethat

theventtubeontherollbarisontheleftsideofthe

machine(

Figure12).

Procedure

1.Removethe2boltsthatsecuretheliftarmpivotshaft

linktotheliftarmpivotshafts,andremoveandretain

thepivotshaftlinkandbolts(

17

Figure13).

Figure13

Figure15

1.Liftarm,pivotshaftlink2.Liftarmpivotshaft

2.Insertapivotrodintoeachliftarmandalignthe

mountingholes(Figure14).

Figure14

1.Liftarm

3.Securethepivotrodstotheliftarmswith2bolts(5/16

x7/8inch).

4.Inserttheliftarmsontotheliftarmpivotshafts(

15

),andsecureeachwithaliftarmpivotshaftlinkand

boltspreviouslyremoved.

2.Pivotrod

1.Liftarm,right4.Liftcylinder

2.Retainingring

3.Liftarm,left

5.Removetherearretainingringssecuringthemounting

pinstoeachendoftheliftcylinder.

6.Securetherightendoftheliftcylindertotherightlift

armwithapinand2spacers(Figure15).Secureitwith

aretainingring.

7.Securetheleftendoftheliftcylindertotheleftliftarm

withapin.Secureitwitharetainingring.

5.Spacers(2)

6.Mountingpin

9

InstallingtheCarrierFrames totheCuttingUnits

Figure

NoPartsRequired

Note:Torquetheboltsto95N-m(70ft-lb).

Procedure

1.Removethecuttingunitsfromthecartons.Adjust

themasdescribedintheCuttingUnitOperator’sManual.

2.Positionafrontcarrierframe(Figure16)ontoeach

frontcuttingunit.

18

Figure16

1.Frontcarrierframe

3.Securethemountinglinkstothefrontcarrierframes

asfollows:

•Securethefrontmountinglinkstothemiddle

carrierframeholeswithabolt(3/8x2-1/4inch),

2atwashers,andalocknut,asshowninFigure

17.Positionawasheroneachsideofthelinkwhen

mounting.Torquethefastenersto42N-m(31

ft-lb).

•Securetherearmountinglinkstothemiddlecarrier

frameholeswithabolt(3/8x2-1/4inch),2at

washers,andalocknut,asshowninFigure17.

Positionawasheroneachsideofthelinkwhen

mounting.Torquethefastenersto42N-m(31

ft-lb).

4.Positiontherearcarrierframe(Figure18)ontotherear

cuttingunit.

Figure18

1.Rearcarrierframe

5.Securethemountinglinkstotherearcarrierframeas

follows:

•Securethefrontmountinglinkstothecarrierframe

holeswithabolt(3/8x2-1/4inch),2atwashers,

andalocknut,asshownin

Figure19.Positiona

washeroneachsideofthelinkwhenmounting.

Torquethefastenersto31ft-lb(42N-m).

•Securetherearmountinglinkstotherearcarrier

frameholeswithabolt(3/8x2-1/4inch),2at

washers,andalocknut,asshowninFigure19.

Positionawasheroneachsideofthelinkwhen

mounting.Torquethefastenersto31ft-lb(42

N-m).

1.Frontcarrierframe

2.Frontmountinglink

3.Rearmountinglink

Figure17

19

Figure19

unithosesareroutedasshowin(Figure21).

Raisethecuttingunitsandshiftthemtotheleft

(Model03170).Therearcuttingunithosesmust

notcontacttractioncablebracket.Repositionthe

ttingsand/orhoses,ifnecessary.

1.Rearcarrierframe

2.Frontmountinglink

3.Rearmountinglink

10

MountingtheCuttingUnits

NoPartsRequired

Procedure

1.Slideathrustwasherontoeachfrontliftarmpivotrod.

2.Slidethecuttingunitcarrierframeontothepivotrod

andsecureitwithalynchpin(

Note:Onrearcuttingunit,positionthethrustwasher

betweentherearofthecarrierframeandthelynchpin.

Figure20).

Figure21

4.Routeatipperchainupthroughtheslotontheendof

eachcarrierframe.Securethetipperchaintothetop

ofthecarrierframewithabolt,awasher,andalocknut

(Figure22).

Figure22

1.Tipperchain

Figure20

1.Thrustwasher3.Lynchpin

2.Carrierframe

3.Greasealltheliftarmandcarrierframepivotpoints.

Important:Ensurethatthehosesarefreeof

twistsorsharpbendsandthattherearcutting

11

MountingtheCuttingUnit DriveMotors

NoPartsRequired

Procedure

1.Positionthecuttingunitsinfrontoftheliftarmpivot

rods.

2.Removetheweightando-ring(Figure23)fromthe

insideendoftherighthandcuttingunit.

20

Figure23

12

AdjustingtheLiftArms

NoPartsRequired

Procedure

1.Starttheengine,raisetheliftarms,andchecktoensure

thattheclearancebetweeneachliftarmandtheoor

platebracketis5to8mm(0.18to0.32inches)(Figure

25).

1.O-ring

2.Weight

3.Removetheplugfromthebearinghousingonthe

outsideendoftherighthandcuttingunitandinstall

theweightsandgasket.

4.Removetheshippingplugfromthebearinghousings

ontheremainingcuttingunits.

5.InserttheO-ring(suppliedwiththecuttingunit)on

theangeofthedrivemotor(Figure24).

3.Mountingbolts

Figure25

Cuttingunitsremovedforclarity

1.Liftarm3.Clearance

2.Floorplatebracket

Note:Iftheclearanceisnotinthisrange,adjustthe

cylinderasfollows:

A.Backoffthestopboltsandadjustthecylinderto

attaintheclearance(Figure26).

Figure24

1.O-ring

6.Mountthemotortothedriveendofthecuttingunit,

andsecureitwithtwocapscrewsprovidedwithcutting

unit(Figure24).

2.Reelmotor

Figure26

1.Stopbolt3.Clearance

2.Liftarm

B.Backoffthejamnutonthecylinder(Figure27).

21

Figure29

Figure27

1.Frontcylinder2.Jamnut

C.Removethepinfromtherodendandrotatethe

clevis.

D.Installthepinandchecktheclearance.

E.RepeatstepsAthroughDifnecessary.

F.Tightentheclevisjamnut.

Note:Iftherearliftarmclunksduringtransport,

reducetheclearance.

2.Checktoensurethattheclearancebetweeneachlift

armandstopboltis0.13to1.02mm(0.005to0.040

inches)(Figure26).

Note:Iftheclearanceisnotinthisrange,adjustthe

stopboltstoattainclearance.

3.Starttheengine,raisetheliftarms,andchecktoensure

thattheclearancebetweenthewearstraponthetopof

therearcuttingunitwearbarandthebumperstrapis

0.51to2.54mm(0.02to0.10inches)(Figure28).

1.Rearcylinder2.Adjustingnut

B.Graspthecylinderrodclosetothenutwitha

pliersandragandrotatetherod.

C.Raisethecuttingunitsandchecktheclearance.

D.RepeatstepsAthroughCifnecessary.

E.Tightentheclevisjamnut.

Important:Lackofclearanceatthefrontstopsorthe

rearwearbarcoulddamagetheliftarms.

Figure28

1.Wearbar2.Bumperstrap

Iftheclearanceisnotinthisrange,adjusttherear

cylinderasfollows:

A.Lowerthecuttingunitsandbackoffthejamnut

onthecylinder(Figure29).

22

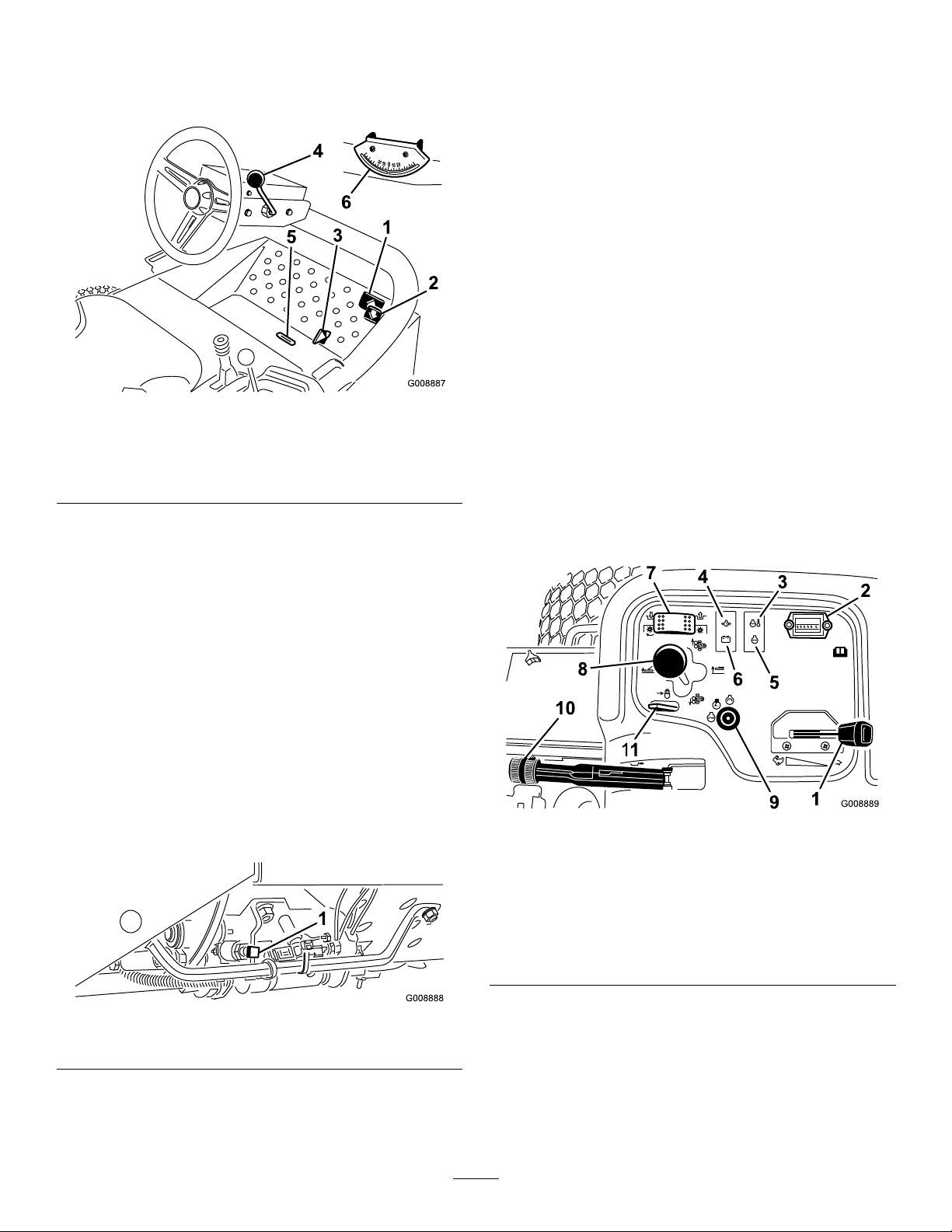

ProductOverview

Controls

TiltSteeringLever

Pullthetiltsteeringlever(Figure30)backtoadjustthe

steeringwheeltothedesiredposition,thenpushthelever

forwardtotighten.

IndicatorSlot

Theslotintheoperatorplatform(Figure30)indicateswhen

thecuttingunitsareinthecenterposition.

AngleIndicator

Theangleindicator(Figure30)indicatesthesidehillangleof

themachineindegrees.

IgnitionSwitch

Figure30

1.Forwardtractionpedal4.Tiltsteeringlever

2.Reversetractionpedal5.Indicatorslot

3.Mow/transportslide

6.Angleindicator

TractionPedals

Pressthetractionforwardpedal(Figure30)tomoveforward.

Presstractionreversepedal(

toassistinstoppingwhenmovingforward.Also,allowthe

pedaltomoveormoveittotheneutralpositiontostopthe

machine.

Figure30)tomovebackwardor

Mow/TransportSlide

Usingyourheel,movethemow/transportslide(Figure30)

tothelefttotransportandtotherighttomow.Thecutting

unitswillonlyoperateinthemowposition.

Important:Themowspeedissetatthefactoryto9.7

km/h(6mph).Itcanbeincreasedordecreasedby

adjustingthespeedstopscrew(

Figure31).

Theignitionswitch(Figure32),whichisusedtostart,stop,

andpreheattheengine,hasthreepositions:Off,On/Preheat,

andStart.RotatethekeytotheOn/Preheatpositionuntilthe

glowplugindicatorlightgoesout(approximately7seconds);

thenrotatethekeytotheStartpositiontoengagethestarter

motor.Releasethekeywhentheenginestarts.Thekeywill

moveautomaticallytotheOn/Runposition.T oshutthe

engineoff,rotatethekeytotheOffpositionandremovethe

keyfromtheswitchtopreventaccidentalstarting.

Figure32

1.Throttle

2.Hourmeter

3.Temperaturelight9.Ignitionswitch

4.Oilpressurelight

5.Glowplugindicatorlight1 1.Liftleverlock

6.Alternatorlight

7.Cuttingunitdriveswitch

8.Cuttingunitshiftlever

10.Parkingbrake

1.Speedstopscrew

Figure31

Throttle

Movethethrottle(Figure32)forwardtoincreasetheengine

speedandrearwardtodecreasetheenginespeed.

23

CuttingUnitDriveSwitch

ParkingBrake

Thecuttingunitdriveswitch(Figure32)hastwopositions:

EngageandDisengage.Therockerswitchoperatesasolenoid

valveonthevalvebanktodrivethecuttingunits.

HourMeter

Thehourmeter(Figure32)indicatesthetotalhoursof

machineoperation.Thehourmeterstartstofunction

wheneverthekeyswitchisOn.

CuttingUnitShiftLever

Tolowerthecuttingunitstotheground,movethecutting

unitshiftlever(Figure32)forward.Thecuttingunitswillnot

dropunlesstheengineisrunning,andtheywillnotoperatein

theraisedposition.Toraisethecuttingunits,pulltheshift

leverrearwardtotheRaiseposition.

Movethelevertotherightorlefttomovethecuttingunits

inthesamedirection.Thisshouldonlybedonewhenthe

cuttingunitsareraisedoriftheyareonthegroundandthe

machineismoving(Model03170only).

Note:Theleverdoesnothavetobeheldintheforward

positionwhilethecuttingunitsarelowered.

Whenevertheengineisshutoff,engagetheparkingbrake

(Figure32)topreventaccidentalmovementofthemachine.

Toengagetheparkingbrake,pulluponthelever.Theengine

willstopifyoupressthetractionpedalwiththeparkingbrake

engaged.

LiftLeverLock

Movetheliftleverlock(Figure32)rearwardtopreventthe

cuttingunitsfromdropping.

ReelSpeedControl

Thereelspeedcontrolislocatedundertheconsolecover

(Figure33).Toobtainthedesiredcliprate(reelspeed),rotate

thereelspeedcontrolknobtotheappropriateheight-of-cut

settingandmowerspeed.RefertoSelectingtheClipRate.

DANGER

Shiftingthecuttingunitsdownhilldecreases

machinestability.Thiscouldcausearollover,

whichmayresultinpersonalinjuryordeath.

Shiftthecuttingunitsuphillwhileonasidehill.

EngineCoolantTemperatureWarning

Light

Thetemperaturewarninglight(Figure32)glowsiftheengine

coolanttemperatureishigh.Ifthetractionunitisnotstopped

andthecoolanttemperaturerisesanother10°F,theengine

willkill.

OilPressureWarningLight

Theoilpressurewarninglight(Figure32)glowsiftheengine

oilpressuredropsbelowasafelevel.

AlternatorLight

Thealternatorlight(Figure32)shouldbeoffwhentheengine

isrunning.Ifitison,thechargingsystemshouldbechecked

andrepairedasnecessary.

Figure33

1.Reelspeedcontrol2.Backlapcontrol

BacklapControl

Thebacklapcontrolislocatedundertheconsolecover

(Figure33).RotatetheknobtoRforbacklappingandtoF

formowing.Donotchangetheknobpositionwhilethe

reelsarerotating.

FuelGauge

Thefuelgauge(Figure34)registerstheamountoffuelin

thetank.

GlowPlugIndicator

Theglowplugindicatorlight(Figure32)willglowwhenthe

glowplugsareoperating.

24

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Theengineisshippedwithoilinthecrankcase;however,the

oillevelmustbecheckedbeforeandaftertheengineisrst

started.

Crankcasecapacityisapproximately2.8liters(4quarts)with

thelter.

Figure34

1.Foreandaftlever

2.Fuelgauge

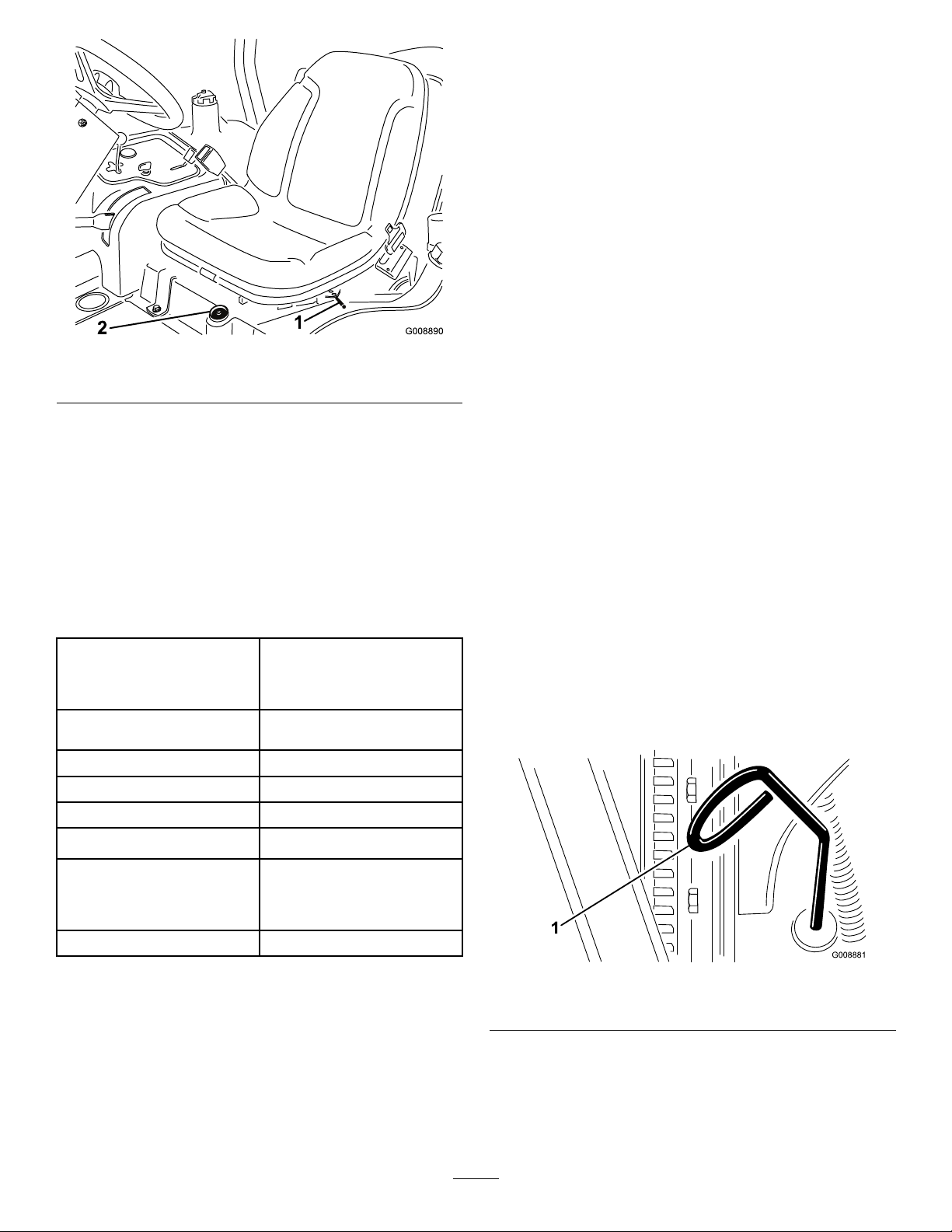

ForeandAftSeatAdjustments

Movethelever(Figure34)onthesideoftheseatoutward,

slidetheseattothedesiredposition,andreleasethelever

tolocktheseatintoposition.

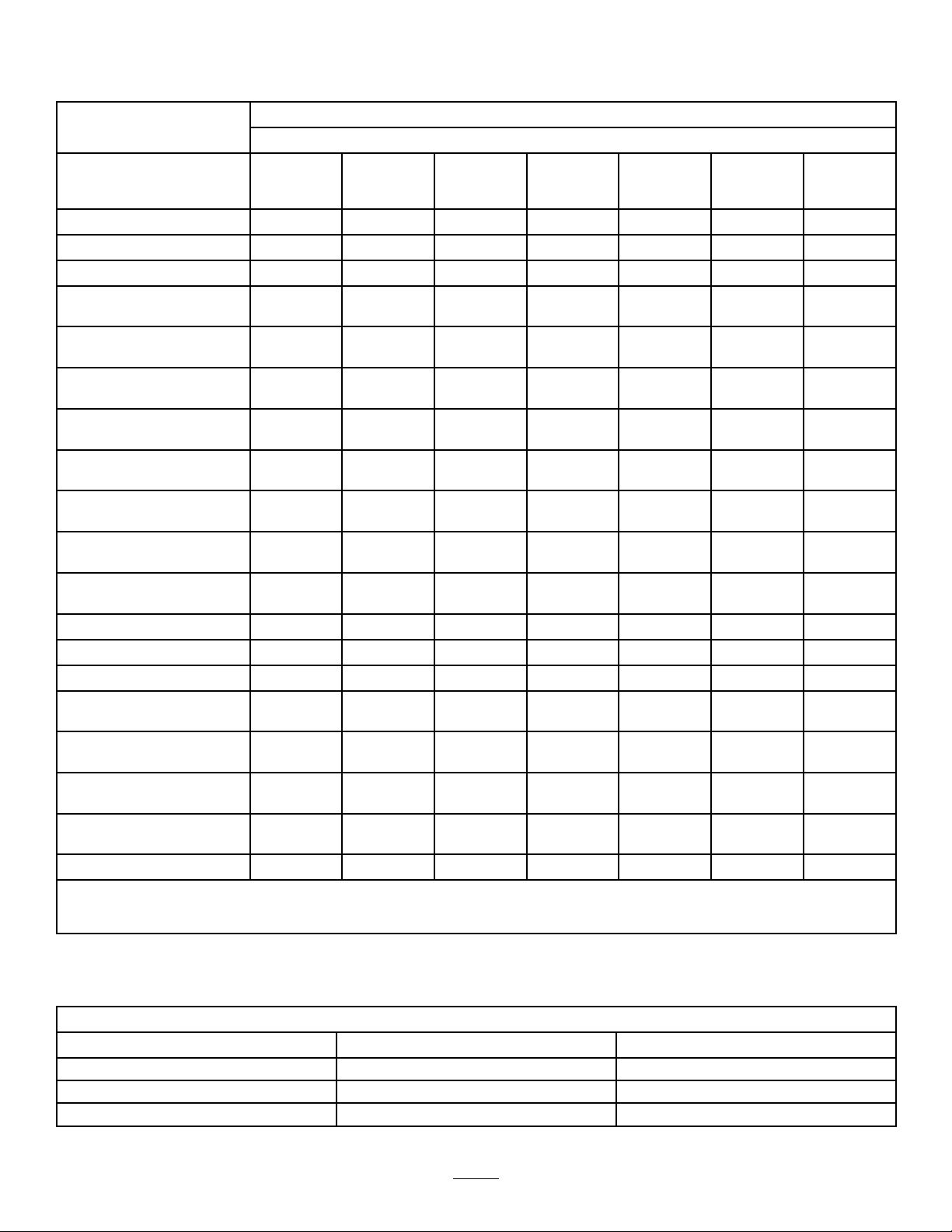

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

TransportWidth

Widthofcut183cm(72inches)or216cm

Length

Height

Netweight*844kg(1860lbs)

Fueltankcapacity

203cm(80inches)in183

cm(72inches)widthofcut

234cm(92inches)in216cm

(85inches)widthofcut

(85inches)widthofcut

248cm(93inch)

180cm(71inches)withROPS

28liters(7.5gallons).

Usehigh-qualityengineoilthatmeetsthefollowing

specications:

•APIClassicationLevelRequired:CH-4,CI-4orhigher.

•Preferredoil:SAE15W-40(above0ºF(-17ºC))

•Alternateoil:SAE10W-30or5W-30(alltemperatures)

Note:ToroPremiumEngineoilisavailablefroma

distributorineither15W-40or10W-30viscosity.Seethe

partscatalogforpartnumbers.

Note:Thebesttimetochecktheengineoiliswhenthe

engineiscoolbeforeithasbeenstartedfortheday.Ifit

hasalreadybeenrun,allowtheoiltodrainbackdownto

thesumpforatleast10minutesbeforechecking.Iftheoil

levelisatorbelowthe“add”markonthedipstick,addoilto

bringtheoilleveltothe“full”mark.Donotoverll.Ifthe

oillevelisbetweenthe“full”and“add”marks,youdonot

needtoaddoil.

1.Positionthemachineonalevelsurface.

2.Removethedipstick(Figure35)andwipeitwitha

cleanrag.

GroundspeedMow:0-10km/h(0-6mph);

Transport:0-14km/h(0-9

mph).Reverse:0-6km/h(0-4

mph)

*Withcuttingunitsanduids

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Figure35

1.Dipstick

3.Pushthedipstickdownintothedipsticktubeand

ensurethatitisseatedfully,thenpullthedipstickout

andchecktheoillevel.

4.Iftheoillevelislow ,removetheoilllcap(Figure36)

andgraduallyaddsmallquantitiesofoil,checkingthe

25

levelfrequently,untilthelevelreachestheFullmark

onthedipstick.

Figure36

1.Oilllcap

5.Installtheoilllcapandclosethehood.

Important:Besuretokeeptheengineoillevel

betweentheupperandlowerlimitsontheoil

gauge.Enginefailuremayoccurasaresultofover

llingorunderllingtheengineoil.

FillingtheFuelTank

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

fuelatlowertemperaturesprovidesalowerashpointand

coldowcharacteristicswhichwilleasestartingandreduce

pluggingofthefuellter.

Useofsummergradefuelabove-7°C(20°F)willcontribute

towardlongerfuelpumplifeandincreasedpowercompared

towintergradefuel.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblends.

•Contactadistributorformoreinformationonbiodiesel

blendedfuel.

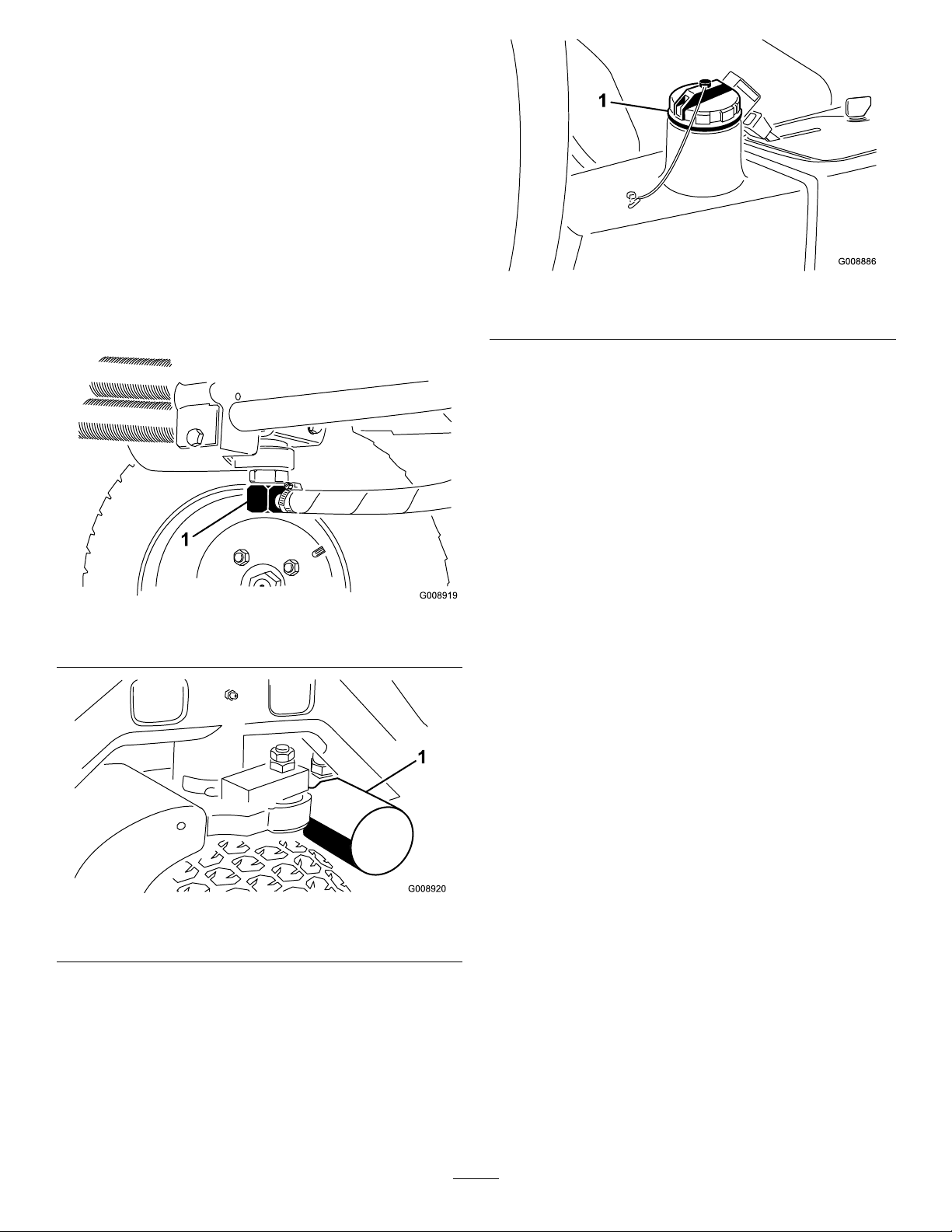

1.Cleantheareaaroundthefueltankcap(

Figure37).

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis6to13mm

(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Thefueltankcapacityisapproximately28liters(7.5gallons).

Usesummergradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Usingwintergrade

Figure37

1.Fueltankcap

2.Removethefueltankcap.

3.Fillthetanktothebottomofthellerneck.Donot

overll.

4.Installthecap.

5.Wipeupanyfuelthatmayhavespilled.

CheckingtheCoolingSystem

ServiceInterval:Beforeeachuseordaily

Cleandebrisoffoftheradiatorandtheoilcoolerdaily(Figure

38).Cleantheradiatorhourlyifconditionsareextremely

dustyanddirty;refertoCleaningtheEngineCoolingSystem.

26

Figure38

1.Accesspanel

2.Radiator

3.Oilcooler

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolanti-freeze.Checkthecoolant

levelatthebeginningofeachdaybeforestartingtheengine.

Thecapacityofthecoolingsystemisapproximately5.7liters

(6quarts).

2.Ifthecoolantlevelislow,removetheexpansiontank

capandreplenishthesystem.Donotoverll.

3.Installtheexpansiontankcap.

CheckingtheHydraulic System

ServiceInterval:Beforeeachuseordaily—Checkthe

hydraulicuidlevel.

Thehydraulicuidtankislledatthefactorywith

approximately13.2liters(3.5U.S.gallons)ofhigh-quality

hydraulicuid.Checkthelevelofthehydraulicuid

beforetheengineisrststartedanddailythereafter.

TherecommendedreplacementuidisT oroPremium

AllSeasonHydraulicFluid(Availablein5-gallonpailsor

55-gallondrums.SeepartscatalogorTorodistributorfor

partnumbers.)

Alternateuids:IftheT orouidisnotavailable,other

uidsmaybeusedprovidedtheymeetallthefollowing

materialpropertiesandindustryspecications.Torodoesnot

recommendusingsyntheticuid.Consultwithalubricant

distributortoidentifyasatisfactoryproduct.

CAUTION

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcauseburns.

•Donotopentheradiatorcapwhentheengine

isrunning.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

1.Checkthecoolantlevelintheexpansiontank(Figure

).

39

Figure39

1.Expansiontank

Note:Withacoldengine,thecoolantlevelshouldbe

approximatelymidwaybetweenthemarksontheside

ofthetank.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendation.

HighViscosityIndex/LowPourPointAnti-wearHydraulic

Fluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTM

D2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:

VickersI-286-S(QualityLevel),VickersM-2950-S

(QualityLevel),DenisonHF-0

cSt@100°C7.9to8.5

140to160

Important:TheISOVG46Multigradeuidhasbeen

foundtoofferoptimalperformanceinawiderangeof

temperatureconditions.Foroperationinconsistently

highambienttemperatures,65°F(18°C)to120°F

(49°C),ISOVG68hydraulicuidmayofferimproved

performance.

PremiumBiodegradableHydraulicFluid-MobilEAL

EnviroSyn46H

Important:MobilEALEnviroSyn46Histheonly

syntheticbiodegradableuidapprovedbyT oro.This

uidiscompatiblewiththeelastomersusedinToro

hydraulicsystemsandissuitableforawide-range

oftemperatureconditions.Thisuidiscompatible

withconventionalmineraloils,butformaximum

biodegradabilityandperformancethehydraulicsystem

shouldbethoroughlyushedofconventionaluid.The

oilisavailablein19liters(5gallon)containersor55

gallondrumsfromyourMobilDistributor.

27

Important:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemoilisavailablein20ml(2/3

oz.)bottles.Onebottleissufcientfor15-22liters(4-6

gallons)ofhydraulicoil.Orderpartno.44-2500from

yourauthorizedT orodistributor.

1.Positionthemachineonalevelsurface,lowerthe

cuttingunits,andstoptheengine.

2.Cleantheareaaroundthellerneckandcapofthe

hydraulicuidtank(Figure40)andremovethecap.

CheckingtheReel-to-Bedknife Contact

ServiceInterval:Beforeeachuseordaily

Checkthereel-to-bedknifecontactevenifthequalityof

cuthadbeenacceptablepreviously.Theremustbelight

contactacrossthefulllengthofthereelandbedknife;refer

toAdjustingReeltoBedknifeintheCuttingUnitOperator’ s

Manual.

TorquingtheWheelNuts

ServiceInterval:Afterthersthour

Aftertherst10hours

Every200hours

Torquethewheelnutsto61to88N-m(45to65ft-lb).

WARNING

Failuretomaintainpropertorqueofthewheelnuts

couldresultinpersonalinjury.

Figure40

1.Hydraulicuidtankcap

3.Removethedipstickfromthellerneckandwipeit

withacleanrag.Insertthedipstickintothellerneck;

thenremoveitandchecktheuidlevel.Theuidlevel

shouldbewithin6mm(1/4inch)ofthemarkonthe

dipstick.

4.Ifthelevelislow ,addtheappropriateuidtoraisethe

leveltothefullmark.

5.Installthedipstickandcapontothellerneck.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Thetiresareover-inatedforshipping.Therefore,release

someoftheairtoreducethepressure.Theproperair

pressureinthetiresis97to124kPa(14to18psi).

Note:Maintaintherecommendedpressureinalltiresto

ensureagoodqualityofcutandpropermachineperformance.

StartingandStoppingthe Engine

Youmayneedtobleedthefuelsystemifanyofthe

followingsituationshaveoccurred(refertoBleeding

theFuelSystem):

•Itistheinitialstartupofanewengine.

•Theenginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponthefuel

systemcomponents;e.g.,lterreplaced,etc.

StartingtheEngine

1.Ensurethattheparkingbrakeissetandthereeldrive

switchisintheDisengageposition.

2.Removeyourfootfromthetractionpedalandensure

thatthepedalisintheneutralposition.

3.Movethethrottlelevertothe1/2throttleposition.

4.Insertthekeyintotheswitchandrotateittothe

On/Preheatpositionuntiltheglowplugindicatorlight

goesout(approximately7seconds);thenrotatethe

keytotheStartpositiontoengagethestartermotor.

Releasethekeywhentheenginestarts.

DANGER

Lowtirepressuredecreasesmachinesidehill

stability.Thiscouldcausearollover,whichmay

resultinpersonalinjuryordeath.

Donotunder-inatethetires.

Note:ThekeywillmoveautomaticallytotheOn/Run

position.

Important:Topreventoverheatingofthestarter

motor,donotengagethestarterlongerthan15

seconds.After10secondsofcontinuouscranking,

wait60secondsbeforeengagingthestartermotor

again.

5.Whentheengineisstartedforthersttimeorafteran

overhauloftheengine,operatethemachineinforward

28

andreverseforonetotwominutes.Alsooperatethe

liftleverandcuttingunitdriveswitchtoensureproper

operationofallparts.

Note:Turnthesteeringwheeltotheleftandright

tocheckthesteeringresponse,thenshuttheengine

offandcheckforoilleaks,looseparts,andanyother

noticeablemalfunctions.

CAUTION

Stoptheengineandwaitforallmovingparts

tostopbeforecheckingforoilleaks,loose

parts,andothermalfunctions.

StoppingtheEngine

MovethethrottlecontroltotheIdleposition,movethereel

driveswitchtoDisengage,androtatethestarterkeytoOff.

Note:Removethekeyfromtheswitchtopreventaccidental

starting.

BleedingtheFuelSystem

1.Parkthemachineonalevelsurface,andensurethatthe

fueltankisatleasthalffull.

2.Unlatchandraisethehood.

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyspilledfuel.

•Donotllthefueltankcompletelyfull.

Addfueltothefueltankuntilthelevelis

6to13mm(1/4to1/2inch)belowthe

bottomofthellerneck.Thisemptyspace

inthetankallowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

3.Opentheairbleedscrewonthefuelinjectionpump

(Figure41).

Figure41

1.Fuelinjectionpumpbleedscrew

4.TurnthekeyintheignitionswitchtotheOnposition.

Theelectricfuelpumpwillbeginoperation,thereby

forcingairoutaroundtheairbleedscrew .

Note:LeavethekeyintheOnpositionuntilasolid

streamoffuelowsoutaroundthescrew .

5.TightenthescrewandturnthekeytoOff.

Note:Normallytheengineshouldstartafterfollowingthe

bleedingproceduresabove.However,iftheenginedoesnot

start,airmaybetrappedbetweentheinjectionpumpandthe

injectors;refertoBleedingAirfromtheInjectors.

CheckingtheInterlockSystem

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifthesafetyinterlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

1.Ensurethatallbystandersareawayfromtheareaof

operation,andkeephandsandfeetawayfromthe

cuttingunits.

2.Whilesittingontheseat,theenginemustnotstart

witheitherthecuttingunitswitchengagedorthe

tractionpedalengaged.Correcttheproblemifitisnot

operatingproperly.

3.Whilesittingontheseat,putthetractionpedalin

neutral,disengagetheparkingbrake,andsetthecutting

unitswitchintheOffposition.Theengineshouldstart.

Risefromtheseatandslowlypressthetractionpedal,

andtheengineshouldstopinonetothreeseconds.

Correcttheproblemifitisnotoperatingproperly.

29

Note:Themachineisequippedwithaninterlockswitchon

theparkingbrake.Theenginewillstopifthetractionpedalis

pressedwiththeparkingbrakeengaged.

TowingtheTractionUnit

Incaseofanemergency ,themachinecanbetowedfora

shortdistance;however,Torodoesnotrecommendthisas

astandardprocedure.

Important:Donottowthemachinefasterthan3to

4km/h(2to3mph)becauseitmaydamagethedrive

system.Ifthemachinemustbemovedaconsiderable

distance,transportitonatruckortrailer.

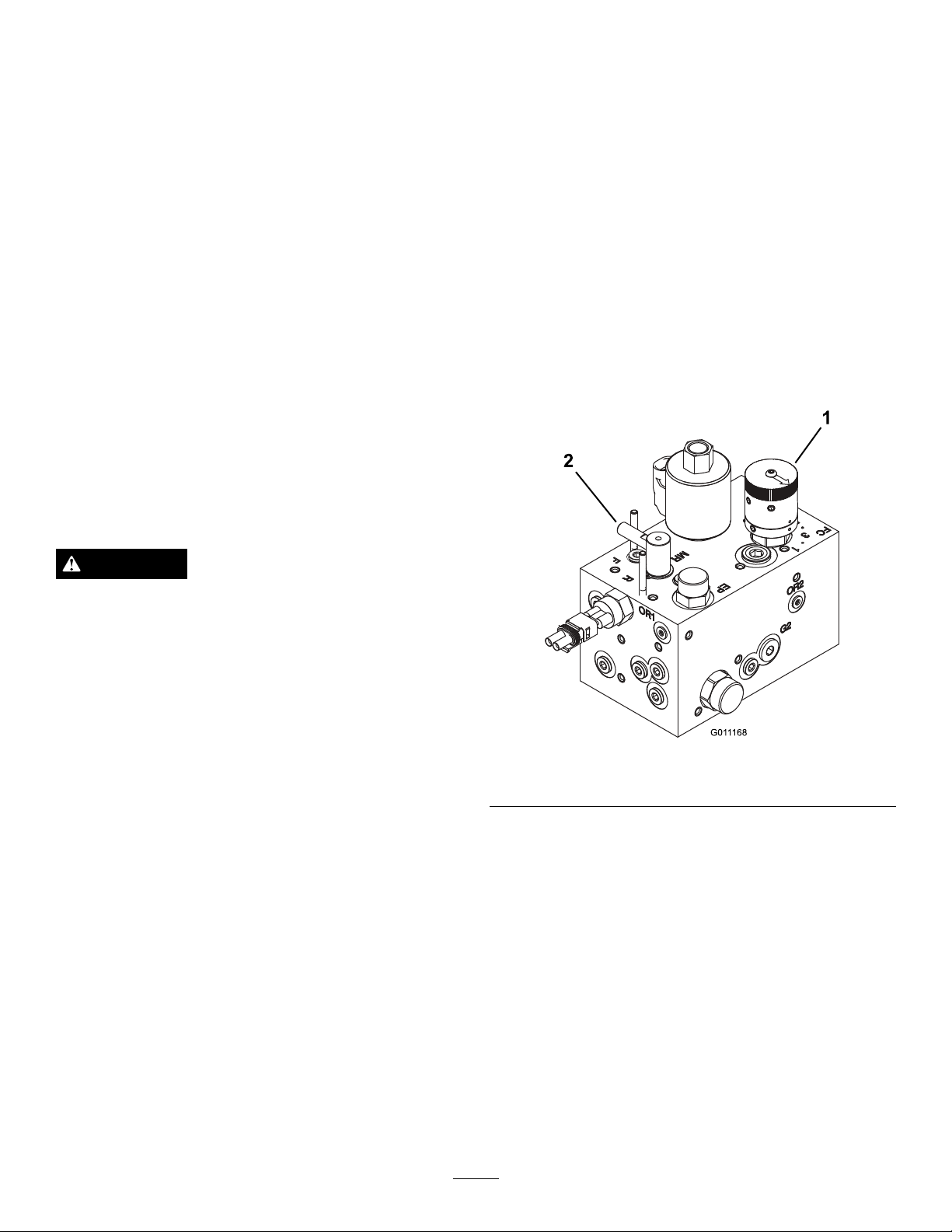

1.Locatethebypassvalveonthepump(Figure42)and

rotateit90°.

START.OutputLEDsmonitorrelayconditionindicatingthe

presenceofvoltageatoneofthreespecicoutputterminals.

Outputcircuitsdonotdetermineoutputdeviceintegrity,so

electricaltroubleshootingincludesoutputLEDinspection

andconventionaldeviceandwireharnessintegritytesting.

Measurethedisconnectedcomponentimpedance,the

impedancethroughwireharness(disconnectatSCM),orby

temporarily”testenergizing”thespeciccomponent.

TheSCMdoesnotconnecttoanexternalcomputerorhand

helddevice,cannotbere-programmed,anddoesnotrecord

intermittentfaulttroubleshootingdata.

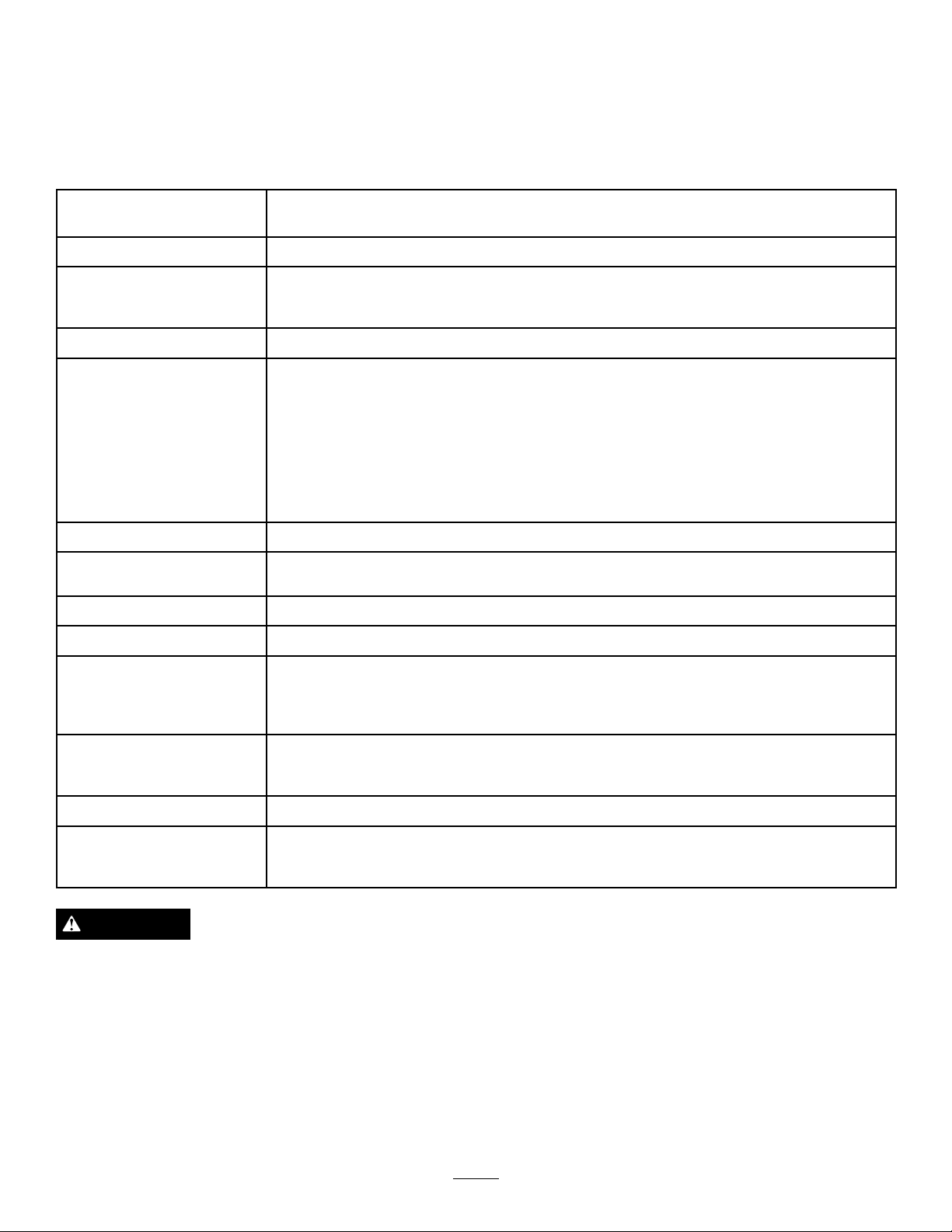

ThedecalontheSCMonlyincludessymbols.ThreeLED

outputsymbolsareshownintheoutputbox.AllotherLEDs

areinputs.Thechartbelowidentiesthesymbols.

Figure42

1.Bypassvalve

2.Beforestartingtheengine,closethebypassvalveby

rotatingit90°(1/4turn).Donotstarttheenginewhile

thevalveisopen.

StandardControlModule (SCM)

TheStandardControlModuleisapottedelectronicdevice

producedinaone-size-ts-allconguration.Themodule

usessolidstateandmechanicalcomponentstomonitorand

controlstandardelectricalfeaturesrequiredforsafeproduct

operation.

Themodulemonitorsinputsincludingneutral,parkingbrake,

PTO,start,backlap,andhightemperature.Themodule

energizesoutputsincludingPTO,Starter,andETR(energize

torun)solenoid.

Themoduleisdividedintoinputsandoutputs.Inputsand

outputsareidentiedbygreenLEDindicatorsmountedon

theprintedcircuitboard.

Thestartcircuitinputisenergizedby12VDC.Allother

inputsareenergizedwhenthecircuitisclosedtoground.

EachinputhasaLEDthatisilluminatedwhenthespecic

circuitisenergized.UsetheinputLEDsforswitchandinput

circuittroubleshooting.

Figure43

HerearethelogicaltroubleshootingstepsfortheSCMdevice.

1.Determinetheoutputfaultyouaretryingtoresolve

(PTO,START,orETR).

2.MovethekeyswitchtotheOnpositionandensure

thattheredpowerLEDisilluminated.

3.MovealltheinputswitchestoensurethatallLEDs

changestate.

4.Positiontheinputdevicesattheappropriatepositionto

achievetheappropriateoutput.Usethefollowinglogic

charttodeterminetheappropriateinputcondition.

5.IfthespecicoutputLEDisilluminatedwithoutthe

appropriateoutputfunction,checktheoutputharness,

connections,andcomponent.Repairasneeded.

6.IfthespecicoutputLEDisnotilluminated,check

bothfuses.

7.IfthespecicoutputLEDisnotilluminatedandthe

inputsareintheappropriatecondition,installanew

SCManddetermineifthefaultdisappears.

Eachrow(across)inthelogicchartbelowidentiesinputand

outputrequirementsforeachspecicproductfunction.The

productfunctionsarelistedintheleftcolumn.Thesymbols

identifythespeciccircuitconditionincluding:energizedto

voltage,closedtoground,andopentoground.

Outputcircuitsareenergizedbyanappropriatesetofinput

conditions.ThethreeoutputsincludePTO,ETR,and

30

INPUTSOUTPUTS

FunctionPower

Start

Run(Off

Unit)

Run(On

Unit)

Mow

Backlap

HiTemp

ON

——

——

—

—

——

—

In

Neutral

StartON

OO

OO

Brake

ON

+

OOOOOOO

OO

O

OO

—

———

PTOONInSeat

O

—

•(–)Indicatesacircuitclosedtoground—LEDON.

•(O)Indicatesacircuitopentogroundorde-energized

—LEDOFF.

•(+)Indicatesanenergizedcircuit(clutchcoil,solenoid,or

startinput)—LEDON.

•ABlankindicatesacircuitthatisnotinvolvedwiththe

logic.

Totroubleshoot,turnonthekeywithoutstartingtheengine.

Identifythespecicfunctionthatdoesnotworkandwork

acrossthelogicchart.Inspecttheconditionofeachinput

LED’stoensurethatitmatchesthelogicchart.

—

—

OO

HiTempBacklap

OO

OOO

OOO

—

—

Start

++

O

OOO

ETR

+

+

++

++

PTO

O

O

O

IftheinputLEDsarecorrect,checktheoutputLED .Ifthe

outputLEDisilluminatedbutthedeviceisnotenergized,

measuretheavailablevoltageattheoutputdevice,the

continuityofthedisconnecteddevice,andthepotential

voltageonthegroundcircuit(oatingground).Repairswill

varydependingonyourndings.

31

OperatingTips

GeneralTipsforModel03171

DANGER

Themowerhasauniquetractionsystemthatwill

allowthemachinetomoveforwardonsidehills,

eveniftheuphillwheelshouldcomeoffofthe

ground.Ifthisshouldhappen,theoperatororany

bystanderscouldbeseriouslyinjuredorkilledina

rollover.

Theslopeangleatwhichthemachinewilltipis

dependentonmanyfactors.Amongtheseare

mowingconditionssuchaswetorundulatingturf,

speed(especiallyinturns),positionofthecutting

units(withSidewinder),tirepressure,andoperator

experience.

Atsidehillanglesof15degreesorless,theriskof

arolloverislow.Astheslopeangleincreasestoa

recommendedmaximumlimitof25degrees,the

riskofarolloverincreasestoamoderatelevel.

not ex ceed a 20 deg r ee side hill slope ang le because

the risk of a r ollo v er and serious injur y or death is

v er y high.

Todeterminewhichhillsorslopesyoumaysafely

operateon,youmustconductasitesurveyof

themowingarea.Whenperformingthissite

survey,alwaysusecommonsenseandtakeinto

considerationtheturfconditionandtherollover

risk.T odeterminewhichhillsorslopesmaybe

safelyoperatedon,usetheinclinometerprovided

witheachmachine.Toperformasitesurvey,laya

1.25mplank(4ft2x4)ontheslopesurfaceand

measuretheangleoftheslope.The1.25mplank

(4ft2x4)willaveragetheslopebutwillnottake

intoconsiderationdipsorholeswhichcancausea

suddenchangeinsidehillangle.

T he maximum

side hill ang le should not be g r eater than 20 deg r ees.

Additionally,themachineisequippedwithan

angleindicatormountedonthesteeringtube.This

indicatesthesidehillanglethemachineisonand

identiestherecommendedmaximumlimitof25

degrees.

Al w ays w ear y our seat belt.

•Practiceoperatingthemachineandbecomethoroughly

familiarwithit.

•Starttheengineandrunitathalfidleuntilitwarmsup.

Pushthethrottleleverallthewayforward,liftthecutting

units,disengagetheparkingbrake,presstheforward

tractionpedal,andcarefullydrivetoanopenarea.

Do

•Practicemovingforwardandreverse,andstartingand

stoppingthemachine.Tostop,takeyourfootoffofthe

tractionpedalandletitreturntoneutralorpressdown

onthereversepedaltostop.Goingdownahill,youmay

needtousethereversepedaltostop.

•Whendrivingonslopes,driveslowlytomaintainsteering

controlandavoidturnstopreventrollovers.Insidehill

situationsyoushouldshiftthesidewindercuttingunits

totheuphillsidetogiveyoumorestability.Conversely,

shiftingthecuttingunitstothedownhillsidewillgive

youlessstability.Thisshouldalwaysbedonebefore

goingonasidehill.

•Whenpossible,mowupanddownhillsratherthanacross

them.Havethecuttingunitsloweredwhengoingdowna

hilltomaintainsteeringcontrol.Donotattempttoturn

onahill.

•Practicedrivingaroundobstacleswiththecuttingunits

upanddown.Becarefulwhendrivingbetweennarrow

objectssothatyoudonotdamagethemachineorcutting

units.

•OntheSidewinderunit,getafeelforthereachofthe

cuttingunitssothatyoudonothangthemupordamage

theminanyway.

•Donotshifttheunitsfromsidetoside,unlessthecutting

unitsaredownandthemachineismoving,orthecutting

unitsareupinthetransportposition.Shiftingthecutting

unitswhentheyaredownandthemachineisnotmoving

maydamagetheturf.

•Alwaysdriveslowlyinroughareas.

•Ifapersonappearsinorneartheoperatingarea,stop

themachine,anddonotstartitagainuntiltheareais

cleared.Themachineisdesignedforoneperson.Never

letanyoneelserideonthemachinewithyou.Thisis

extremelydangerousandcouldresultinseriousinjury.

•Accidentscanhappentoanyone.Themostcommon

causesareexcessivespeed,suddenturns,terrain(not

knowingwhichslopesandhillscanbemowedsafely),not

stoppingtheenginebeforeleavingtheoperator’sseat,

anddrugsthatimpairyouralertness.Coldcapsulesor

prescriptiondrugsmaycausedrowsiness,ascanalcohol

andotherdrugs.Stayalertandstaysafe.Failuretodoso

couldresultinseriousinjury.

•TheSidewinderoffersuptoamaximumof33cm(13

inches)ofoverhang,allowingyoutotrimclosertothe

edgeofsandtrapsandotherobstacles,whileatthesame

timekeepingthetractortiresasfarawayfromtheedge

oftrapsorwaterhazardsaspossible.

•Ifanobstacleisintheway,shiftthecuttingunitstoeasily

mowaroundit.

•Whentransportingthemachinefromoneworkareato

another,raisethecuttingunitstothefullyupposition,

movethemow/transportslidetothelefttotransport,

andplacethethrottleintheFastposition.

32

GeneralTipsforModel03170

DANGER

Themowerhasauniquetractionsystemthatwill

allowthemachinetomoveforwardonsidehills,

eveniftheuphillwheelshouldcomeoffofthe

ground.Ifthisshouldhappen,theoperatororany

bystanderscouldbeseriouslyinjuredorkilledina

rollover.

Theslopeangleatwhichthemachinewilltipis

dependentonmanyfactors.Amongtheseare

mowingconditionssuchaswetorundulatingturf,

speed(especiallyinturns),positionofthecutting

units,tirepressure,andoperatorexperience.

Atsidehillanglesof20degreesorless,theriskof

arolloverislow.Astheslopeangleincreasestoa

recommendedmaximumlimitof25degrees,the

riskofarolloverincreasestoamoderatelevel.

not ex ceed a 25 deg r ee side hill slope ang le because

the risk of a r ollo v er and serious injur y or death is

v er y high.

Todeterminewhichhillsorslopesyoumaysafely

operateon,youmustconductasitesurveyof

themowingarea.Whenperformingthissite

survey,alwaysusecommonsenseandtakeinto

considerationtheturfconditionandtherollover

risk.T odeterminewhichhillsorslopesmaybe

safelyoperatedon,usetheinclinometerprovided

witheachmachine.Toperformasitesurvey,laya

1.25mplank(4ft2x4)ontheslopesurfaceand

measuretheangleoftheslope.The1.25mplank

(4ft2x4)willaveragetheslopebutwillnottake

intoconsiderationdipsorholeswhichcancausea

suddenchangeinsidehillangle.

T he maximum

side hill ang le should not be g r eater than 25 deg r ees.

Additionally,themachineisequippedwithan

angleindicatormountedonthesteeringtube.This

indicatesthesidehillanglethemachineisonand

identiestherecommendedmaximumlimitof25

degrees.

Al w ays w ear y our seat belt.

•Practiceoperatingthemachineandbecomethoroughly

familiarwithit.

•Starttheengineandrunitathalfidleuntilitwarmsup.

Pushthethrottleleverallthewayforward,liftthecutting

units,disengagetheparkingbrake,presstheforward

tractionpedal,andcarefullydrivetoanopenarea.

•Practicemovingforwardandreverse,andstartingand

stoppingthemachine.Tostop,takeyourfootoffofthe

tractionpedalandletitreturntoneutralorpressdown

Do

onthereversepedaltostop.Goingdownahill,youmay

needtousethereversepedaltostop.

•Whendrivingonslopes,driveslowlytomaintainsteering

controlandavoidturnstopreventrollovers.Insidehill

situationsyoushouldshiftthesidewindercuttingunits

totheuphillsidetogiveyoumorestability.Conversely,

shiftingthecuttingunitstothedownhillsidewillgive

youlessstability.Thisshouldalwaysbedonebefore

goingonasidehill.