Page 1

FormNo.3394-200RevA

TM54905-GangorTM7490

7-GangTrailedMower

ModelNo.02700—SerialNo.315000001andUp

ModelNo.02701—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3394-200*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

Introduction

Thismachineisatrailed,reel-bladelawnmowerintended

tobeusedbyprofessional,hiredoperatorsincommercial

applications.Itisprimarilydesignedforcuttinggrass

onparks,sportselds,caravanparks,cemeteries,and

commercialgrounds.Itisnotdesignedforcuttingbrushor

foragriculturaluse.

Readthetractoroperator’smanualformoreinformationon

usingthetractorandattachingequipmenttothetractor.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactT orodirectlyforproductsafetyand

operationtrainingmaterials,accessoryinformation,help

ndingadealer,ortoregisteryourproductatToro

CommercialProductsServiceDepartmentSpellbrook,

Bishop’sStortford,CM234BU,England,+44(0)1279603019;

Email:uk.service@toro.com.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Themodelandserialnumbersareunder

thefrontcover.Writethenumbersinthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure1),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Contents

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................5

Setup............................................................................9

1InstallingtheCuttingUnits.....................................9

2InstallingtheLights..............................................14

3CheckingtheMinimumPTOLength......................15

4CheckingtheMaximumPTOLength......................17

ProductOverview.........................................................19

Controls...............................................................19

Back-LapControls..............................................19

Specications........................................................20

Attachments/Accessories........................................20

Operation....................................................................21

CheckingtheTirePressure......................................21

CheckingtheHydraulicFluid...................................21

CheckingthePump-GearboxOil..............................21

PreparingtheTractor..............................................21

ConnectingtheMowertoaTractor...........................22

DisconnectingtheMowerfromaTractor...................24

PreparingtheMowerforTransport...........................24

OperatingtheMower..............................................24

OperatingTips......................................................25

Maintenance.................................................................26

RecommendedMaintenanceSchedule(s)......................26

DailyMaintenanceChecklist....................................26

Lubrication...............................................................27

GreasingtheBearings,Bushings,andPivots...............27

LubricatingtheBrakeLink.......................................28

LubricatingthePTOShaft.......................................28

LubricatingtheCuttingUnits...................................28

BrakeMaintenance....................................................28

InspectingtheBrakes..............................................28

AdjustingtheBrakes...............................................29

ReplacingtheBrakeCables......................................29

HydraulicSystemMaintenance....................................30

ServicingtheHydraulicSystem.................................30

ChangingtheHydraulic-FluidReturnFilter................30

Cutting-UnitSystemMaintenance................................31

BackLappingtheCuttingUnits................................31

GrindingtheCuttingUnits......................................32

Storage........................................................................32

Troubleshooting...........................................................33

Figure1

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUK

AllRightsReserved

Page 3

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

Training

•ReadtheOperator'sManualandothertrainingmaterial

carefully.Befamiliarwiththecontrols,safetysigns,and

theproperuseoftheequipment.

•Iftheoperatorormechaniccannotreadorunderstand

theinformation,itistheowner’sresponsibilitytoexplain

ittothem.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstouseorservicethemower.Local

regulationsmayrestricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleand

damagetotheirproperty.

•Donotcarrypassengers.

•Alldriversandmechanicsshouldseekandobtain

professionalandpracticalinstruction.Theowneris

responsiblefortrainingtheusers.Suchinstructionshould

emphasize:

–Theneedforcareandconcentrationwhenworking

withtrailedmowers

–Controlofthetrailedmowerslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊insufcientwheelgrip,especiallyonwetgrass

◊beingdriventoofast

◊inadequatebraking

◊thetypeofmachineisunsuitableforitstask

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes

◊incorrecthitchingandloaddistribution

Preparation

•Whilemowing,alwayswearsubstantial,slip-resistant

footwear,longtrousers,hardhat,andsafetyglasses.Long

hair,looseclothing,orjewelrymaygettangledinmoving

parts.Donotoperatetheequipmentwhenbarefootor

wearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladebolts,andcutterassemblyarenotwornor

damaged.Replacewornordamagedbladesandboltsin

setstopreservebalance.

•Onmulti-bladedmachines,takecareasrotating1blade

cancauseotherbladestorotate.

•Checkthatthesafetyswitchesandshieldsareattached

andfunctioningproperly.Donotoperateunlesstheyare

functioningproperly.

Operation

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostartthetractorengine,setthe

parkingbrake,disengagethecutting-unitdrivesystem

andensurethattheforward/reversespeedcontrolsare

intheNEUTRALposition.

•Donotuseonaslopeofmorethan15degreeswhen

inuseor10degreeswiththecuttingunitsraised.Care

shouldbetakenwhenusingthemoweronanyslope

wheregroundconditionsaresuchthattheremaybearisk

ofthemowerrollingover.

Theslopeanglemaybereducedifthestabilityangleof

thetowingtractorislessthanthatofthemower.

•Rememberthatthereisnosuchthingasasafeslope.

Travelingongrassslopesrequiresparticularcare.To

guardagainstoverturning:

–Donotstoporstartsuddenlywhengoingupor

downhill.

–Machinespeedsshouldbekeptlowonslopesand

duringtightturns.

–Stayalertforhumpsandhollowsandotherhidden

hazards.

–Donotturnsharply.Usecarewhenreversing.

•Donotoperateneardrop-offs,ditches,steepbanks,or

water.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguards,

shields,orwithoutsafetyprotectivedevicesadjustedand

functioningproperly.

•Beforeleavingtheoperator'sposition:

–Stoponlevelground.

–Disengagethedrivetothecuttingunits.

–Liftthecuttingunitstothetransportpositionand

securelylockthesafetylatches,orlowerthecutting

unitstotheground.

3

Page 4

–Ensurethatthetransmissionisinneutralandengage

theparkingbrake.

–Stoptheengineandremovethekey.

•Whenmovingthemowerbetweenworksites,itis

importanttoensurethatthecuttingunitscannotbe

inadvertentlyloweredandstarted:

–disengagethedrivetothecuttingunits;

–raisethecuttingunitstothetransportposition;

–engagethetransportlatchesandthesafetylocking

rings.

•Stopthetractorengineanddisengagethedrivetothe

cuttingunits:

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

–beforeclearingblockages;

–beforechecking,cleaning,orworkingonthemower;

–afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthemowerfordamage

andmakerepairsbeforestartingandoperatingthe

equipment.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthecylinders/cutting

unitsifnotmowing.

•Donotoperatethemowerwhenyouareill,tired,or

undertheinuenceofalcoholordrugs.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Usecarewhenloadingorunloadingthemachineintoor

outofatraileroratruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Knowhowtostopthetractorenginequickly.

•Raiseandlatchthecuttingunitswhendrivingfromone

workareatoanother.

•Whenapersonorpetappearsunexpectedlyinornearthe

mowingarea,stopmowing.Carelessoperation,combined

withterrainangles,ricochets,orimproperlypositioned

guardscanleadtothrown-objectinjuries.Donotresume

mowinguntiltheareaiscleared.

•Becarefulduringadjustmentofthemachinetoprevent

entrapmentofthengersbetweenmovingbladesand

xedpartsofthemachine.

•Onmulti-bladedmachines,takecare,asrotating1blade

cancauseotherbladestorotate.

•Disengagedrives,lowerthecuttingunits,settheparking

brake,stoptheengine,andremovekeyfromthetractor

ignition.W aitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Usecarewhencheckingthecuttingunits.Weargloves

andusecautionwhenservicingthem.

•Makesurethatallhydraulic-lineconnectorsaretightand

allhydraulichosesandlinesareingoodconditionbefore

applyingpressuretothesystem.

•Keepyourbodyandhandsawayfrompin-holeleaksor

nozzlesthatejecthydraulicuidunderhighpressure.

Usepaperorcardboard,notyourhands,tosearchfor

leaks.Hydraulicuidescapingunderpressurecanhave

sufcientforcetopenetratetheskinandcauseserious

injury.Ifuidisinjectedintotheskinitmustbesurgically

removedwithinafewhoursbyadoctorfamiliarwiththis

formofinjury;otherwise,gangrenemayresult.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththetractorenginerunning.

•Beforedisconnectingorperforminganyworkonthe

hydraulicsystem,allpressureinthesystemmustbe

relievedbystoppingtheengineandloweringthecutting

unitstotheground.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keephands,feet,clothing,andanypartsof

thebodyawayfromthecuttingunits,attachments,and

anymovingparts.Keepeveryoneaway.

•Ifmajorrepairsareeverneededorifassistanceisdesired,

contactanAuthorizedToroDistributor.

•Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementparts

andaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

MaintenanceandStorage

•Keepallnuts,bolts,andscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Keepallpartsingoodworkingconditionandallhardware

andhydraulicttingstightened.Replaceallwornor

damagedpartsanddecalswithToroauthorizedparts.

4

Page 5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

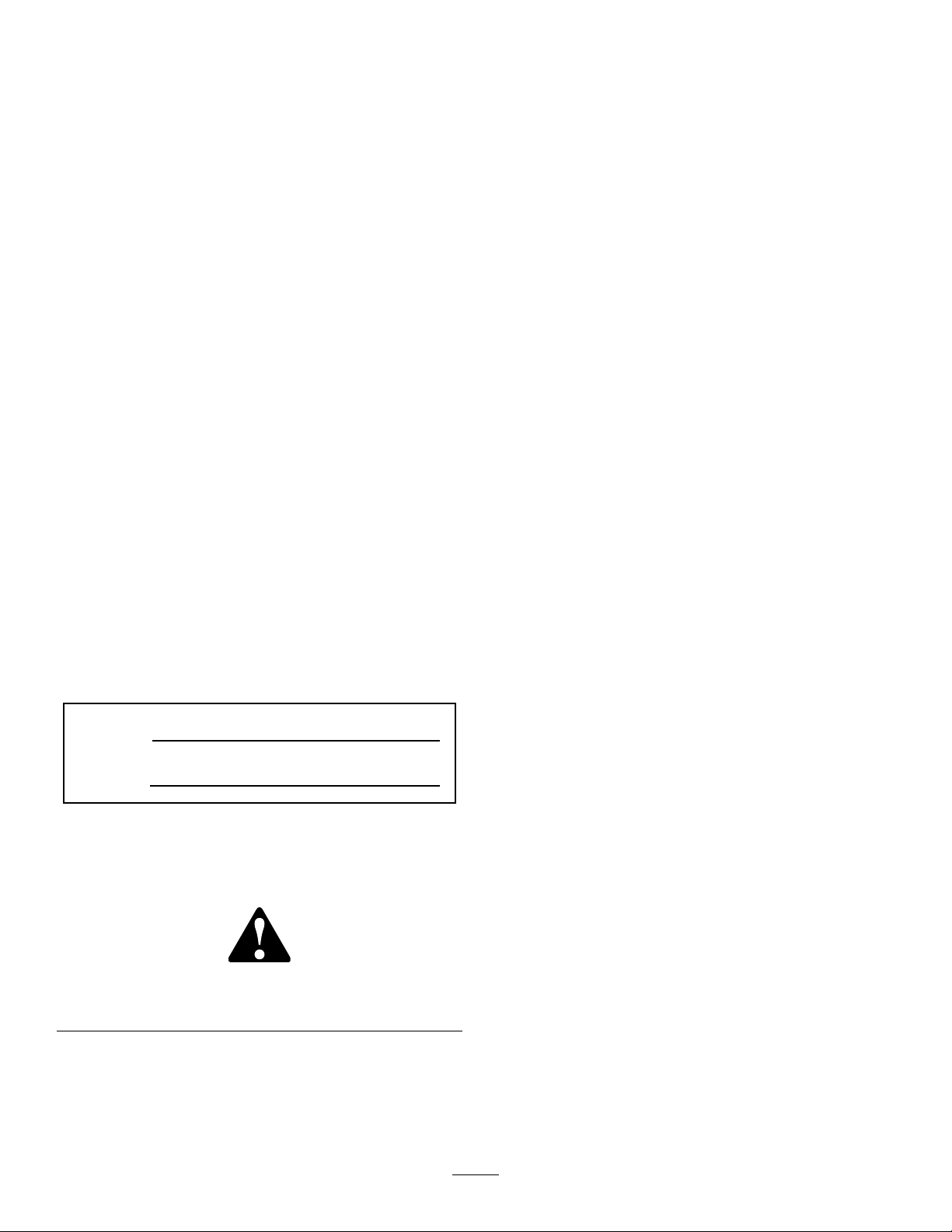

767811

214053

1.On-cutadjustment

749804

1.Crushing/fallinghazard—keepbystandersawayfromthe

machine.

1.Normalpositionofrotary

valvecontrolsforforward

cuttingunitrotation.

2.T oengage

backlap—rotatethelock

leverCWtoposition1;

rotatetherotaryvalve

CCWtoposition2;release

thelockleverCCWto

position3.

111-3901

1.Transmissionoil—readtheOperator'sManualformore

information.

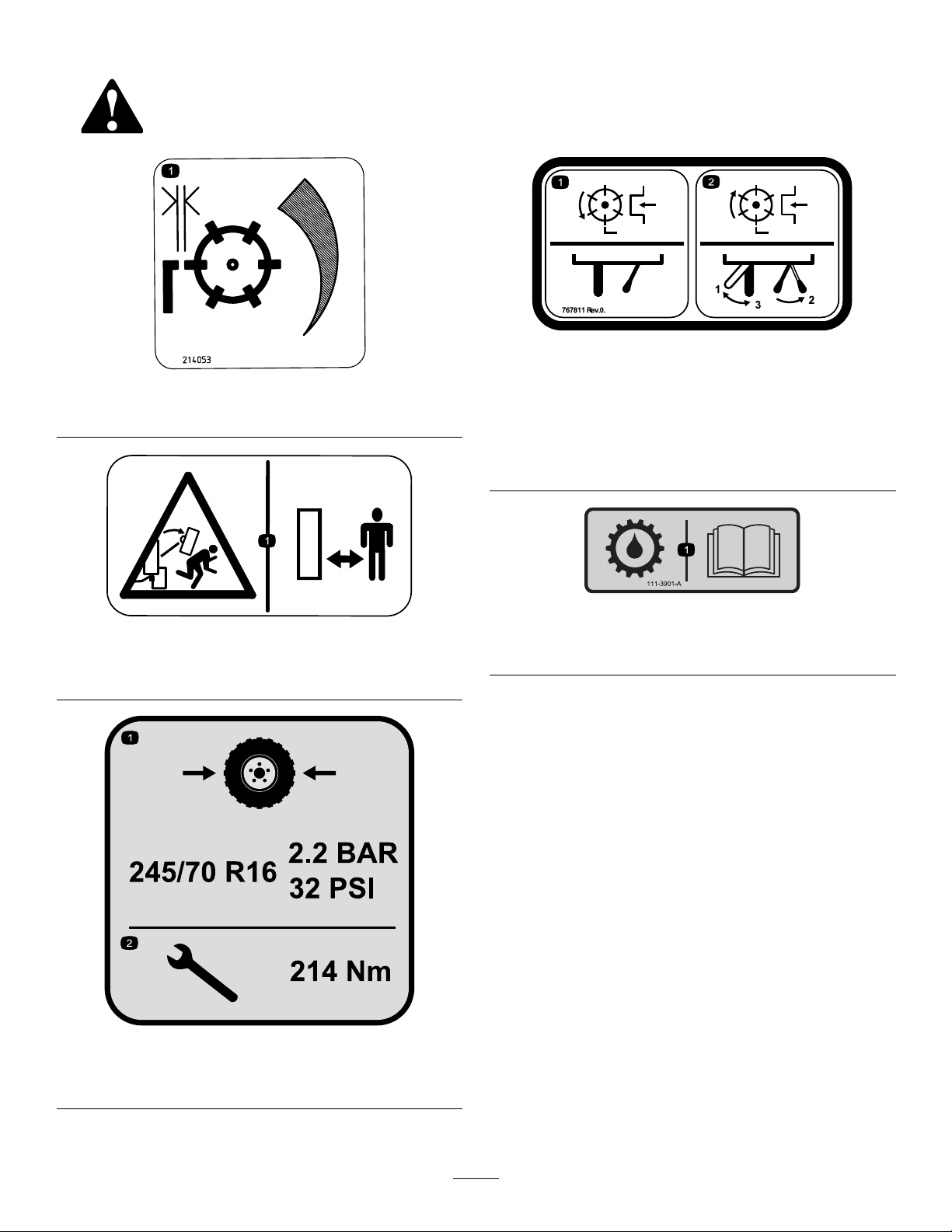

1.Tirepressure—2.2bar(32

psi)

767810

2.T orquethenuts—214N-m

5

Page 6

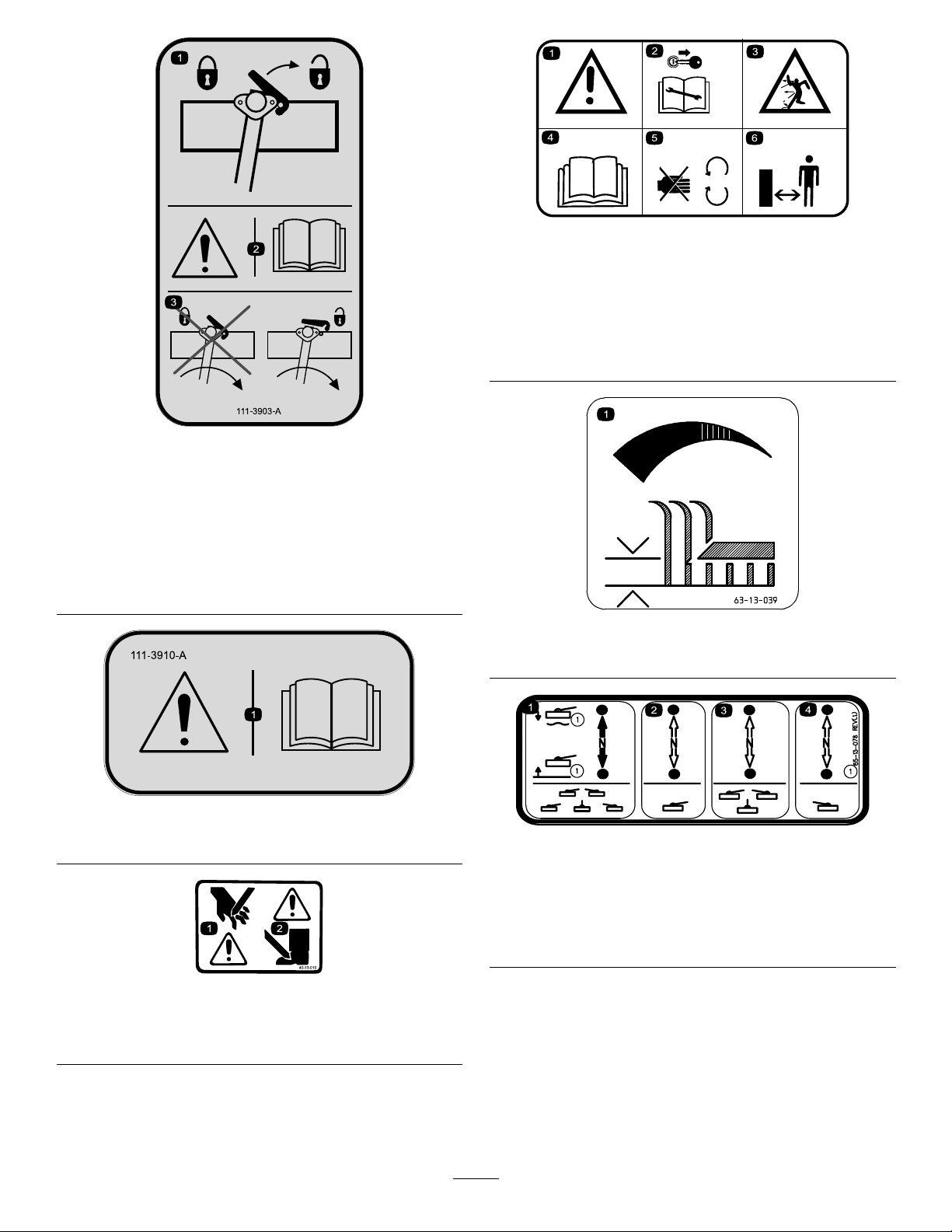

61–13–019

Model02701Only

1.Movethelevertotheleft

tolock—movetheleverto

therighttounlock.

2.Warning—readthe

Operator'sManual.

111-3903

3.Donotlowertheliftarm

whenthecuttingunitis

latchedinposition—unlock

thelatchbeforelowering

thecuttingunit.

1.Warning

2.Removethekeyfromthe

ignitionbeforeperforming

maintenance.

3.Thrownobjecthazard6.Keepbystandersaway

4.ReadtheOperator’s

Manual.

5.Keepawayfrommoving

parts.

frommachine.

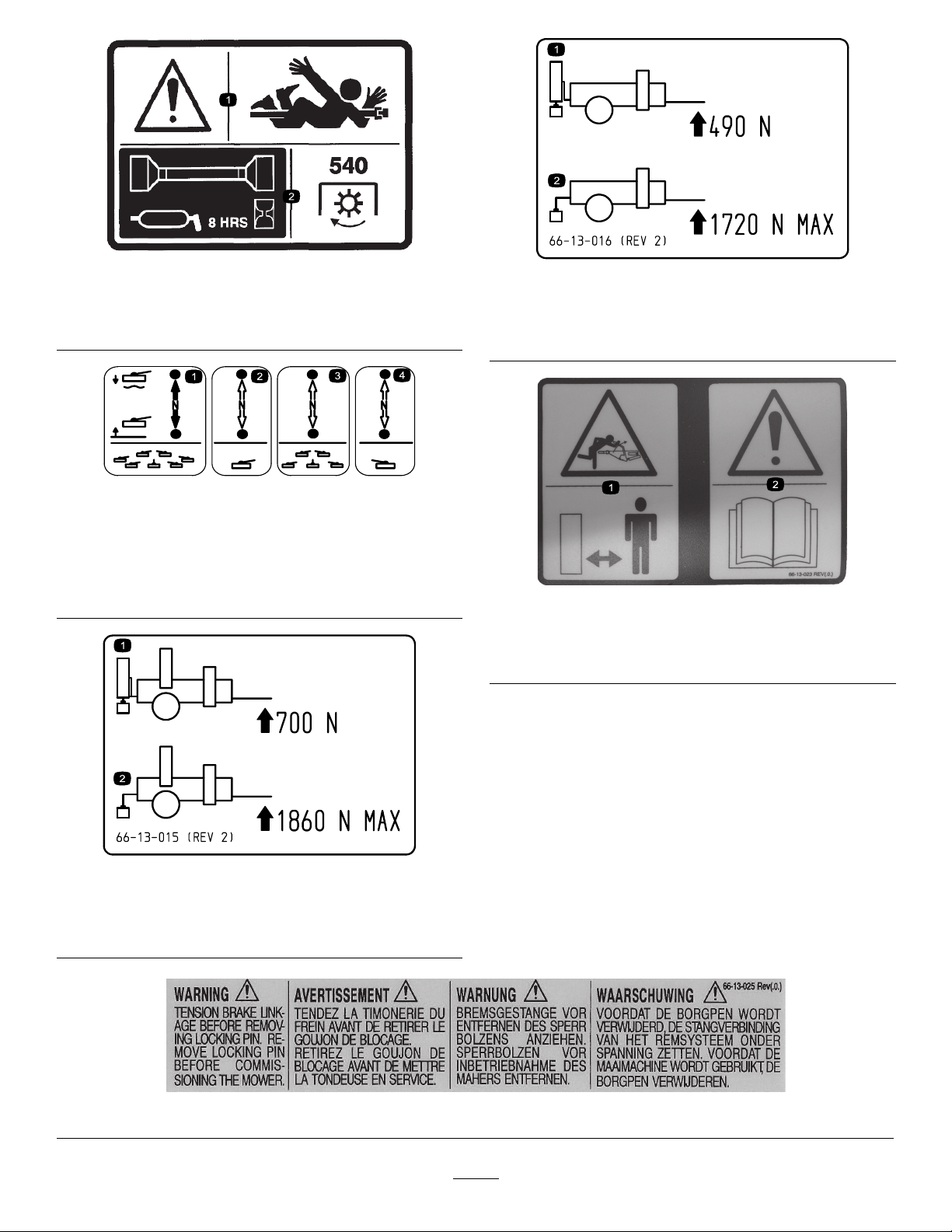

63-13-039

1.Height-of-cutadjustment

111-3910

1.Warning—readtheOperator'sManual.

40-13–010

1.Cuttinghazardofhand

2.Cuttinghazardoffoot

1.Raise/lowerallthecutting

units.

2.Raise/lowertheleftcutting

unit.

6

65-13-078

Model02700

3.Raise/lowerthecenter

cuttingunits.

4.Raise/lowertheright

cuttingunit.

Page 7

65–13–079

1.Warning—entanglement

hazard

2.LubricatethePTOshaft

every8hours—PTO540

rpm

1.Minimumdrawbar

load—490N

66-13-016

Model02700

2.Maximumdrawbar

load—1720Nmax

66–13–013

Model02701

1.Raise/lowerallthecutting

units.

2.Raise/lowertheleftcutting

unit.

1.Minimumdrawbar

load—700N

3.Raise/lowerthecenter

cuttingunits.

4.Raise/lowertheright

cuttingunit.

1.Hazard—spring-loaded

parkingbrake;keep

bystandersaway.

66–13–023

2.Warning—readthe

Operator’sManual.

66-13-015

Model02701

2.Maximumdrawbar

load—1860Nmax

66–13–025

7

Page 8

70-13-072

1.Jackingpoint

70-13-077

1.Warning—stoptheengineandremovetheignitionkey

beforereleasingoroperatingsafetylatches.

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Cuttingunit(soldseparately)

Lightboard1

Light-boardbracket2

Bolt(M8x80)

Washer(M8)

Locknut(M8)

Light-boardsecuringplate2

Bolt(M10x40)

Washer(M10)

Locknut(M10)

Nopartsrequired

Nopartsrequired

1

InstallingtheCuttingUnits

Qty.

–

4

8

4

4

8

4

–

–

Installthecuttingunits.

Installthelights.

ChecktheminimumPTOlength

(maximumcompressedcondition).

CheckthemaximumPTOlength.

Use

WARNING

Thecuttingunitisheavyandcancausepersonal

injury.

Usesuitableliftingequipmentwhenremovingthe

cuttingunitfromthecartonandduringinstallation.

Model02700(TM5490)Only

Partsneededforthisprocedure:

–

Cuttingunit(soldseparately)

InstallingtheCuttingUnits

Model02700(TM5490)Only

CAUTION

Somecomponentsonthecuttingunitaresharpand

cancutyou.

Takecaretoavoidthesharpedgesofthecutting

cylinderandthebottombladewhenliftingor

workingonthecuttingunit.

1.Startthetractorengine,hitchupthemower,and

connectthePTOshaft.

2.Operatethecontrollevertoliftthesuspensionarms

tothefullyraisedpositiontoreducepressureonthe

arms;refertoControlLevers(page19).

3.Unlockthecutting-unitsuspensionarmsbymoving

theredtransportlatchestothereleasedpositionand

carefullylowerthearmstotheoor;refertoTransport

Latches(page19).

4.Unpackthe5cuttingunits.

5.Layoutthecuttingunitsaroundthemachineinthe

correctpositionsasshowninFigure2.

9

Page 10

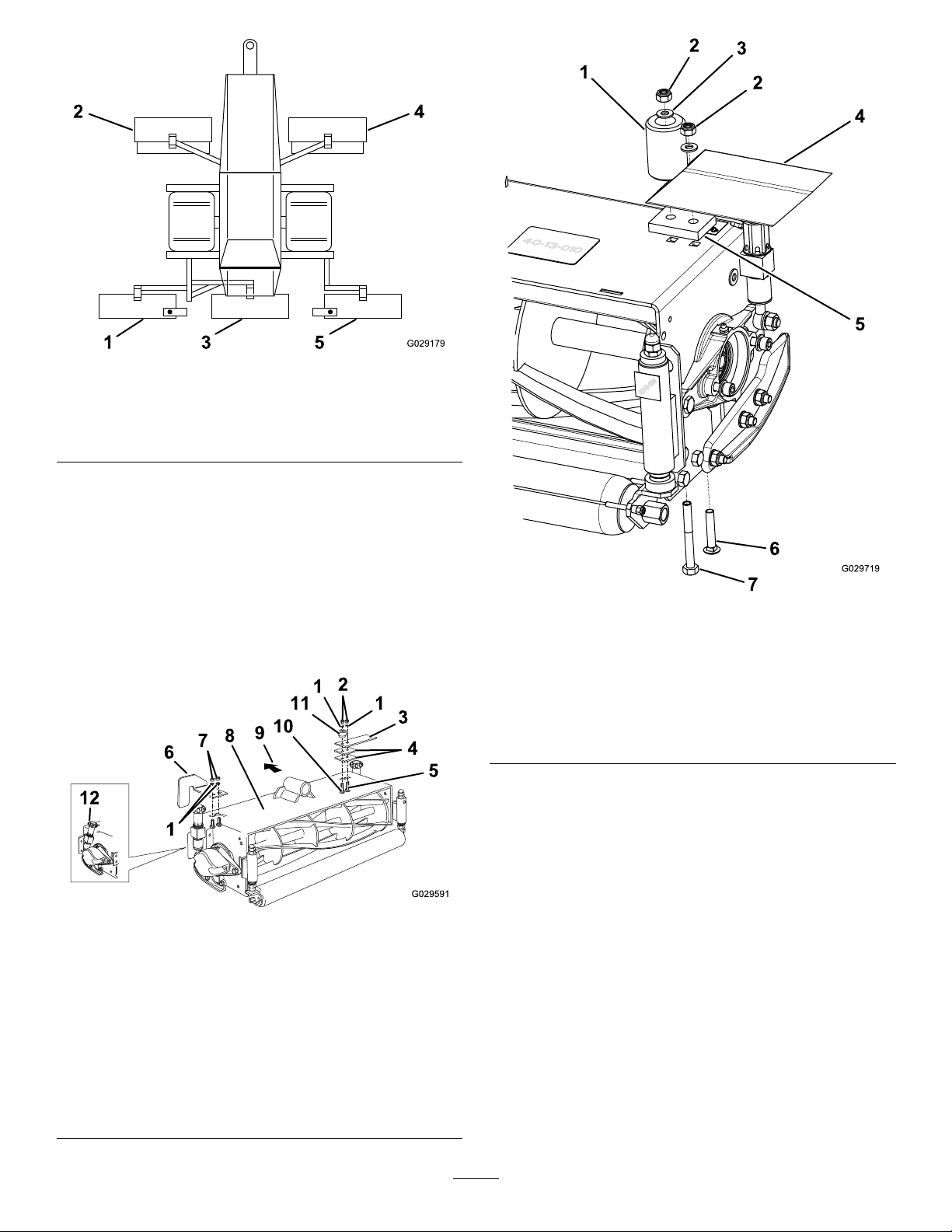

Figure2

1.Cuttingunit14.Cuttingunit4

2.Cuttingunit25.Cuttingunit5

3.Cuttingunit3

6.For254mm(10inch)cuttingunits,tthebumpstop,

2roller-boxplates,andtherollerplatetocuttingunits1

and5(hydraulic-motorend)using1carriagebolt(M10

x55mm),1hex-headbolt(M10x90mm),2locknuts

(M10),and2washers(M10);refertoFigure3.

For200mm(8inch)cuttingunits,tthebumpstop,

1roller-boxplate,andtherollerboxtocuttingunits1

and5(hydraulic-motorend)using1carriagebolt(M10

x55mm),1hex-headbolt(M10x90mm),2locknuts

(M10),and2washers(M10);refertoFigure4.

Figure4

200mm(8inch)cuttingunitonly

1.Bumpstop5.Roller-boxplate

2.Locknut(M10)6.Carriagebolt(M10x55

mm)

3.Washer(M10)7.Bolt(M10x90mm)

4.Rollerbox

7.Modifycuttingunits4and5fromleft-handto

right-handcongurationasfollows:

Figure3

Cuttingunits1and5only

1.Washer(M10)7.Locknut(M5)

2.Locknut(M10)8.Cutting-unitassembly

3.Plate9.Forward

4.Roller-boxplate

5.Carriagebolt(M10x55

mm)

6.Rightdeectorplate

10.Bolt(M10x90mm)

11.Bumpstop

12.Handwheelinangled-back

position

A.Removeanddiscardtheprotectivecover.

B.Removethesnapring.

C.Removethecounterweighttogetherwiththe

O-ringandtittothenon-driveend.

D.Tightenthesocket-headcapscrewsto80N-m

(59ft-lb).

10

Page 11

Figure5

Cuttingunits2and4only

1.Carriagebolt(M10x25

mm)

2.Washer(M10)9.Rightdeectorbracket

3.Locknut(M10)10.Carriagebolt(M10x55

4.Screw(M5x16mm)11.Leftdeectorbracket

5.Reardelfector12.Cutting-unitassembly

6.Deectorspacer

7.Washer(3/16inch)

8.Locknut(M5)

mm)

13.Forward

Important:Fitthesnapringtothedriveend.

8.Modifythecylinder-adjustmenthandwheelassemblies

oncuttingunit3totheangled-backpositionasfollows

(Figure6):

A.Removethenuts,bolts,andwashersfromthe

forwardholes.

B.Removethenuts,bolts,andwasherswhichattach

thehandwheelassembliestothecutting-unit

frame.

C.Removetheringboltclampnuts,washers,and

springwashers,andremovethehandwheel

assemblies.

Figure6

1.Handwheelangledtorear

9.Secureeachcuttingunittothemowerinthecorrect

positionusingthepivotpin,2locknuts(M24),2

washers(M24),2nutcaps,apinretainer,2Belleville

washers(whereapplicable),asetscrew(M12x30mm),

andaspringwasher(Figure7).

Note:Cuttingunits2and4mountinfrontoftheir

respectivesuspensionarms.

D.Adjustthehandwheelassembliestoprovidethe

correctfasteningcentersandinstalltheminthe

alternativepositions.

E.Installallfastenersandtightenthemsecurely.

Figure7

254-mmcuttingunit

1.Nutcap

2.Locknut(M24)7.Cutting-unitassembly

3.Screw(M12x30mm)

4.Springwasher(M12)

5.Suppliedwiththecutting

unit

11

6.Washer(M24)

8.Forward

9.Bellevillewashers

10.Pinretainer

Page 12

InstallingtheCuttingUnits

Model02701(TM7490)Only

CAUTION

Somecomponentsonthecuttingunitaresharpand

cancutyou.

Takecaretoavoidthesharpedgesofthecutting

cylinderandthebottombladewhenliftingor

workingonthecuttingunit.

WARNING

Thecuttingunitisheavyandcancausepersonal

injury.

Usesuitableliftingequipmentwhenremovingthe

cuttingunitfromthecartonandduringinstallation.

1.Startthetractorengine,hitchupthemower,and

connectthePTOshaft.

2.Operatethecontrollevertoliftthesuspensionarms

tothefullyraisedpositiontoreducepressureonthe

arms;refertoControlLevers(page19).

3.Unlockthecutting-unitsuspensionarmsbymoving

theredtransportlatchestothereleasedpositionand

carefullylowerthearmstotheoor;refertoTransport

Latches(page19).

4.Unpackthe7cuttingunits.

5.Layoutthecuttingunitsaroundthemachineinthe

correctpositionsasshowninFigure8.

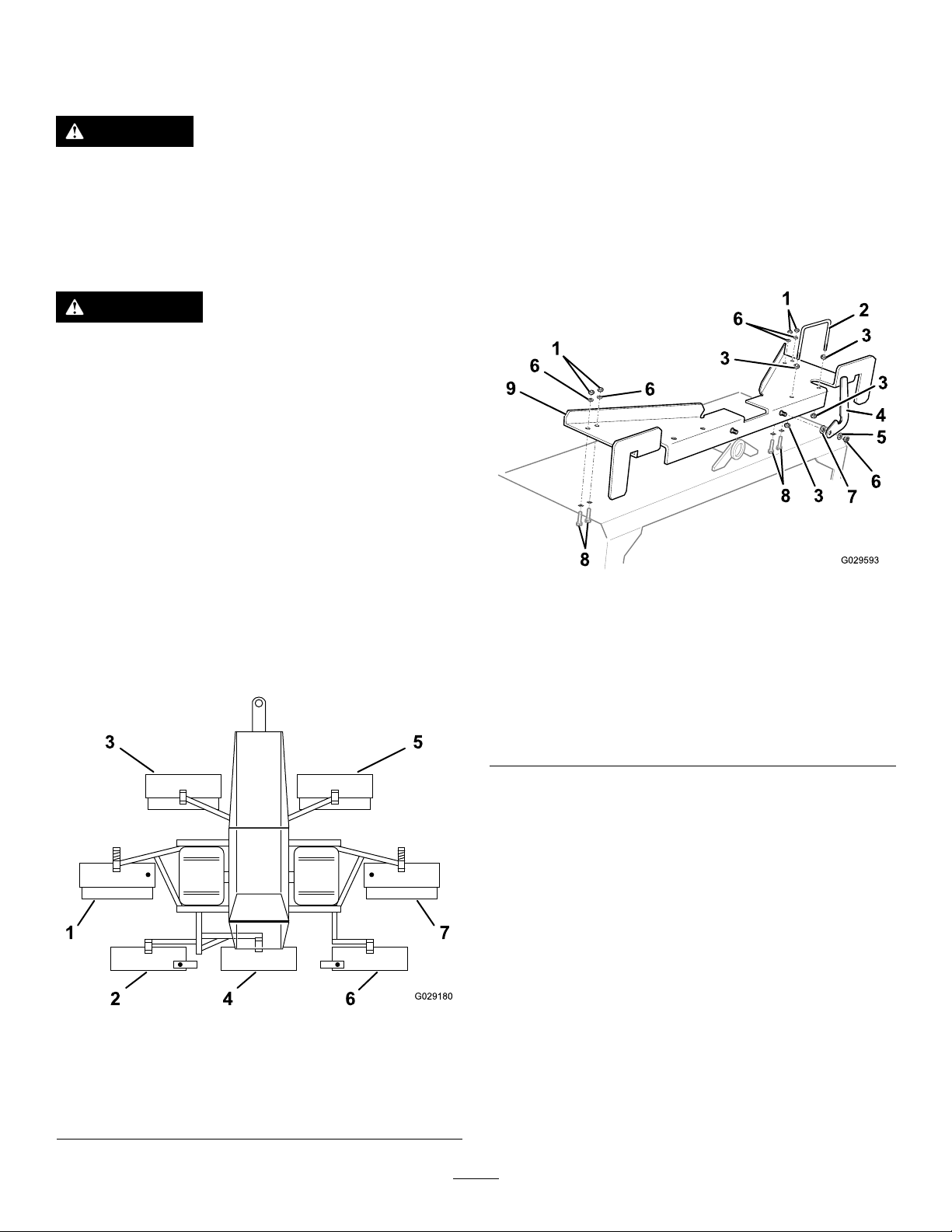

6.Assemblethewing-armlatchplatesforcuttingunits1

and7asfollows(Figure9):

A.Fitthewasher(M16),thelatch,thespringwasher

(M12),andthelocknut(M12)totheshouldered

pinonthelatchplate.

B.Tightenthenutsothatthelatchisstiffbutcan

movefromsidetoside.

C.Assemblethehoseguideand4nuts(M10)tothe

latchplate.

D.Preparetheotherassemblyintheoppositehand

conguration.

Figure9

Cuttingunits1and7only

1.Locknut(M10)6.Locknut(M12)

2.Hoseguide

3.Nut(M10)8.Carriagebolt(M10x25

4.Latch9.Latchplate

5.Springwasher(M12)

7.Washer(M16)

mm)

Figure8

1.Cuttingunit15.Cuttingunit5

2.Cuttingunit26.Cuttingunit6

3.Cuttingunit37.Cuttingunit7

4.Cuttingunit4

7.For254mm(10inch)cuttingunits,tthebumpstop,

2roller-boxplates,andtherollerplatetocuttingunits2

and6(hydraulic-motorend)using1carriagebolt(M10

x55mm),1hex-headbolt(M10x90mm),2locknuts

(M10),and2washers(M10);refertoFigure10.

For200mm(8inch)cuttingunits,tthebumpstop,

1roller-boxplate,andtherollerboxtocuttingunits2

and6(hydraulic-motorend)using1carriagebolt(M10

x55mm),1hex-headbolt(M10x90mm),2locknuts

(M10),and2washers(M10);refertoFigure11.

12

Page 13

Figure10

Cuttingunits2and6only

1.Washer(M10)7.Locknut(M5)

2.Locknut(M10)8.Cutting-unitassembly

3.Plate9.Forward

4.Roller-boxplate

5.Carriagebolt(M10x55

mm)

6.Rightdeectorplate

10.Bolt(M10x90mm)

11.Bumpstop

12.Handwheelinangled-back

position

Figure11

200mm(8inch)cuttingunitonly

1.Bumpstop5.Rollerboxplate

2.Locknut(M10)6.Carriagebolt(M10x55

mm)

3.Washer(M10)7.Bolt(M10x90mm)

4.Rollerbox

8.Installthewing-armlatch-plateassemblies(step6)to

therespectivecuttingunits,andsecureeachassembly

with4carriagebolts(M10x25),4washers(M10),and

4locknuts(M10).

9.Modifycuttingunits5,6,and7fromleft-handto

right-handcongurationasfollows:

A.Removeanddiscardtheprotectivecover.

B.Removethesnapring.

C.Removethecounterweighttogetherwiththe

O-ringandtittothenon-driveend.

D.Tightenthesocket-headcapscrewstoatorqueof

80N-m(59ft-lb).

E.Fitthesnapringtothedriveend.

Note:Refertothecuttingunitoperator’ smanualfor

moreinformation.

13

Page 14

10.Modifythecylinder-adjustmenthandwheelassemblies

oncuttingunit4totheangled-backpositionasfollows;

refertoFigure6:

Note:Thehosesforcuttingunits1and7must

passthroughthehoseguideontherespective

wing-armlatch-plateassembly.

A.Removethenuts,bolts,andwashersfromthe

forwardhole.

B.Removethenuts,bolts,andwasherswhichattach

thehandwheelassembliestothecutting-unit

frame.

C.Removetheringboltclampnuts,washers,

andspringwashersandremovethehandwheel

assemblies.

D.Adjustthehandwheelassembliestoprovidethe

correctfasteningcentersandinstalltheminthe

alternativepositions.

E.Installallfastenersandtightenthemsecurely.

11.Secureeachcuttingunittothemowerinthecorrect

positionusingthepivotpin,2locknuts(M24),2

washers(M24),2nutcaps,apinretainer,2Belleville

washers(whereapplicable),asetscrew(M12x30mm),

andaspringwasher(Figure12).

Note:Cuttingunits3and5mountinfrontoftheir

respectivesuspensionarms

D.Alignandmeshthemotor-shaftsplinewiththe

couplingonthecuttingcylinder.Ensurethatthe

motorisfullylocatedintothebearinghousing.If

necessary,gentlytapthemotorintopositionwith

asoftmallet,untilitissecureagainstthebearing

housing.

E.Securethemotorinpositionusingthefasteners

previouslyremovedandtorqueto80N-m(59

ft-lb).

F.RepeatstepsAtoEfortheremainingcutting

units.

13.Fitthedeectorstocuttingunits1,3,5,and7using

thedeectorbracketsandspacers,andsecurethem

withthefastenersasshowninFigure13.

Figure12

1.Nutcap

2.Locknut(M24)7.Cutting-unitassembly

3.Screw(M12x30mm)

4.Springwasher(M12)

5.Suppliedwiththecutting

unit

6.Washer(M24)

8.Forward

9.Bellevillewashers

10.Pinretainer

12.Assemblethehydraulic-motorassembliestothecutting

unitsasfollows:

A.Removethesocketcapscrews,springwashers,

plainwashers,andtheprotectivecover.

B.Removethehosetiesecuringthehydraulic-motor

assemblytothemachine.

C.Unfoldthehosesandensurethattheyareneatly

routedwhileofferingthemotoruptothecutting

unit.

Figure13

Cuttingunits1,3,5,and7only

1.Carriagebolt(M10x25

mm)

2.Washer(M10)9.Rightdeectorbracket

3.Locknut(M10)10.Carriagebolt(M10x55

4.Screw(M5x16mm)11.Leftdeectorbracket

5.Reardelfector12.Cutting-unitassembly

6.Deectorspacer

7.Washer(3/16inch)

8.Locknut(M5)

mm)

13.Forward

14.Immediatelyfollowinginstallation,llallbearing

housingsfullofgreaseviathegreasettings.

Note:Thisrequiresasignicantquantityofa

good-quality,medium-gradegrease.

14

Page 15

2

InstallingtheLights

Partsneededforthisprocedure:

1Lightboard

2Light-boardbracket

4

Bolt(M8x80)

8

Washer(M8)

4

Locknut(M8)

2Light-boardsecuringplate

4

Bolt(M10x40)

8

Washer(M10)

4

Locknut(M10)

Procedure

1.Assemblethelight-boardbracketstotherearofthe

machine,using4bolts(M8x80),8washers(M8),and

4locknuts(M8),aswellasthe2fastenersholdingthe

divertervalvesforthetworearcornercuttingunits

(cuttingunits1and5forModel02700;cuttingunits2

and6forModel02701)tosecurethelowerpartofthe

bracketasshown(Figure14).

WARNING

Amalfunctioningdivertervalvecouldlead

toanaccidentandcausepersonalinjuryor

propertydamage.

Ensurethatthecamfollowerisincontact

withthecamandthatthedivertervalveaction

isinfullworkingorderafterassemblingthe

diverter-valvefasteners.

Figure14

1.Rightlight-boardbracket

2.Lightingboard

3.Washer(M10)8.Locknut(M8)

4.Bolt(M10x60mm)9.Bolt(M8x80mm)

5.Lightingboardsecuring

plate

6.Leftlight-boardbracket

7.Washer(M8)

10.Nut(M10)

Figure15

1.Divertervalve3.Armcam

2.Camfollower

2.Fitthelightboardtothebracketsandsecureitusing

2light-boardsecuringplates,4bolts(M10x40),8

washers(M10),and4locknuts(M10);refertoFigure

14.

3

CheckingtheMinimumPTO Length

NoPartsRequired

Procedure

Eachtractorcanbedifferent.ChecktheminimumPTO

lengtheverytimethatyouconnectthemowertoadifferent

tractor.

15

Page 16

Important:RemovethePTOshaftbeforepositioning

thetractorandperformingthisprocedure.

DANGER

Operatingamachineonaslopesteeperthanthat

speciedbythemachinemanufacturercouldresult

inpossibleinjuryordeath.

•Followtheslopelimitsspeciedbythetractor

manufacturer.

•Donotusethemoweronslopesgreaterthan

15degreeswiththecuttingunitslowered,or

greaterthan10degreeswiththecuttingunits

raised.

Reducetheslopeangleasrequiredifthestability

angleofthetowingtractorislessthanthatof

themower.

1.Withthetractorcoupledtothemachineinastraight

lineandparkedinapositiontogivetheshortest

PTO-shaftlength(Figure16),applythehandbrakeof

thetractor,turntheignitionswitchtotheOFFposition,

andapplythemowerparkingbrake.

Figure16

1.LocationofPTOshaft(removed)

Figure17

1.PTOshaftatshortest

workinglength

2.40mm(1-9/16inches)

3.Cuttheguardhere.

5.Removetheshaftsfromthemachineandthetractor.

Note:Cutonlytheplasticguardateachcuttingline,

takingcarenottomarktheshaftinside.

Note:Retainthecut-offsectionsoftheguard.

6.Usingacut-offsectionoftheguardasatemplate,mark

acuttinglinefromtheendofeachshaft(Figure18).

Note:Thisensuresthatyouremovethesameamount

ofshaftandguard.

2.Separatethe2halvesofthePTOshaft.

3.Assemblethehalfwiththewideanglejointtothe

tractorandtheotherhalftothemower.

4.Alignthe2halvessidebysideandtransferamarkfrom

thebackoftheguardendoftheotherhalf.Fromthis

mark,measureback40mm(1-9/16inches)andmarka

cuttinglineonbothhalves.

Figure18

1.Cut-offsectionofguard3.PTOshaft

2.EndofPTOshaftaligned

withendofguardsection

7.Cuteachshaftatthemark,usingasuitablecutting

device,suchasahacksaworanabrasivecuttingwheel.

16

Page 17

CAUTION

Youcouldbeinjuredifyoudonotwearthe

appropriatepersonalprotectiveequipment

whilecuttingtheshafts.

Weareyeprotection,earprotection,andwork

gloves.

4

CheckingtheMaximumPTO Length

8.Removeanyburrsandroughedgesfromtheinside

andoutsideofeachshaft.

Important:Burrsandroughedgeswilldamage

theRilsancoatingontheshaftsandshortenthe

workinglifeoftheshaft.

9.Drilla25mm(1inch)holeontheinnerguardtube

through1wallonly,andremoveallburrs(Figure19).

Note:Thisisforfuturegreasingoftheshaft.

Figure19

1.25mm(1inch)hole

10.Greasethe2shaftsandassemblethemtogether.

Note:Ensurethatthehalvesslidesmoothlyand

uninterrupted.

11.InstallthePTOshafttothemachineandthetractor.

Important:DonotmodifythePTOshaftinany

otherway .

NoPartsRequired

Procedure

Eachtractorcanbedifferent.CheckthemaximumPTO

lengtheverytimethatyouconnectthemowertoadifferent

tractor.

Connectthemowertoatractor;refertoConnectingthe

MowertoaTractor(page22).

1.RemovethePTOshaft.

2.Positionthetractor/mowercombinationwiththe

tractorturningsharplyonasteepdownwardslopeand

themoweronlevelground(Figure20).

DANGER

Operatingamachineonaslopesteeperthan

thatspeciedbythemachinemanufacturer

couldresultinpossibleinjuryordeath.

•Followtheslopelimitsspeciedbythe

tractormanufacturer.

•Donotusethemoweronslopesgreater

than15degreeswiththecuttingunits

lowered,orgreaterthan10degreeswith

thecuttingunitsraised.

Reducetheslopeangleasrequiredifthe

stabilityangleofthetowingtractorisless

thanthatofthemower.

Figure20

1.PTOshaft

17

Page 18

3.Setthetractorparkingbrake,stoptheengine,remove

theignitionkey,applythemowerhandbrake,andchock

thereartractorwheels.

4.AssemblethePTOshaft,ensuringthatthelarge

wide-anglejointisconnectedtothetractorPTO(as

shownonthePTOguard).

Important:Ensurethatthereleaseclipsarefully

engaged.Inthisposition,theoverlapofthe2

shaftsmustbeatleast1/3ofthelengthofeach

half-shaft(Figure21).Iftheshaftextensiondoes

notachievethisminimumoverlap,thenserious

damagewillresult.

Thetelescopicshaftshouldoperatewithasmuch

engagementaspossibleundernormalworking

conditionsforoptimumworkinglife.Ifitisless

thantheminimum,contactyourAuthorizedToro

Distributor.

Figure21

1.1/32.2/3

18

Page 19

ProductOverview

Controls

Thestandardcontrolsincludedwiththemachinearelevers.

Ifyourmachinehastheoptionalelectricliftkit,refertothe

kitinstructionsforinformationaboutthosecontrols.

ControlLevers

Thecontrollevers(Figure22)raiseandlowerthecutting

units.Theshortleverontheleftraisesandlowersallthe

cuttingunitstogether.Thelongleftleverraisesandlowers

onlytheleft-mostcuttingunit.Thelongcenterleverraises

andlowersthecentercuttingunits.Thelongrightleverraises

andlowersonlytheright-mostcuttingunit.

Back-LapControls

Figure23

1.Locklever2.Back-laplever

LockLever

Rotatethelocklever(Figure23)clockwiseallowtheback-lap

levertomove.Rotateitcounterclockwisetolocktheback-lap

leverintoposition.

1.Allcuttingunits

2.Leftcuttingunit

Back-LapLever

Rotatetheback-laplever(Figure23)counterclockwisetostart

backlappingthecuttingunits.

TransportLatches

Thetransportlatches(Figure24,Figure25,andFigure26)

automaticallysecurethecuttingunitsintopositionwhenyou

raisetheliftarms.Usethesafetylocktopreventthelatch

frombouncingupandreleasingthearm.

Note:Ifasafetylockisintheengagedpositionwhilethe

cuttingunitsareintheloweredposition,itpreventsthe

transportlatchfromlatchingautomaticallywhenyouraisethe

liftarms.Thereisnosafetylockonthewing-headlatches

(Model02701only).

Figure22

3.Centercuttingunits

4.Rightcuttingunit

Figure24

1.Transport

latch—automaticlatching

position

19

2.Safetylock—ippedup

Page 20

Specications

Model02700Model02701

Overallworking

width

Mowingwidth

Transportwidth

Overalllength360.0cm(141.7

Figure25

Transportheight

1.Safetylock—engaged

Approximate

workingweight

Drawbarweight

(transport)

PTOGearbox

368.0cm(144.9

inches)

350.0cm(137.8

inches)

212.0cm(83.5

inches)

inches)

161.0cm(63.4

inches)

1385kg(3053lb)1680kg(3703lb)

50kg(110.2lb)55kg(121.3lb)

497.0cm(195.7

inches)

478.0cm(188.2

inches)

237.0cm(93.3

inches)

360.0cm(141.7

inches)

160.0cm(63.0

inches)

Input

Output

Capacity1.0L(1.06USqt)

540rpm,1-3/8inch6-spline

PTOshaft,counterclockwise

rotation(lookingonendof

shaft)

1862rpmatpumpcoupling

Figure26

1.Wing-headlatch(Model02701only)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhanceandexpandits

capabilities.ContactyourAuthorizedServiceDealerorDistributor.

TobestprotectyourinvestmentandmaintainoptimalperformanceofyourToroequipment,countonTorogenuineparts.

Whenitcomestoreliability,Torodeliversreplacementpartsdesignedtotheexactengineeringspecicationofourequipment.

Forpeaceofmind,insistonT orogenuineparts.

20

Page 21

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Tirepressure:221kPa(32psi)

CheckingtheHydraulicFluid

ServiceInterval:Beforeeachuseordaily

Tankcapacity:133L(35.1USgallons)

Totalsystemcapacity:142L(37.5USgallons)

Ambienttemperaturerange

0°to30°C(32°to86°F)ISOviscositygrade46

hydraulicuid

15°to40°C(59°to104°F)ISOviscositygrade68

hydraulicuid

CheckingthePump-Gearbox Oil

Capacity:1.0L(1.06USqt)

EP90gearoil

1.Checkthattheoilisuptotheleveloftheuppermark

onthedipstick(Figure27).

2.Topupwiththecorrectgradeofoilasnecessary

throughthedipstickhole.

Important:Donotoverllthegearbox.

1.Removethellercapontopofthehydraulictank.

2.Checkthelevelofthehydraulicuid.Ifitisnotatthe

upperblacklineontheuid-levelsightgaugelocatedat

thefrontofthetankunderthepumpcover,llittothe

correctlevelwiththecorrectgradeofhydraulicuid.

3.Installthellercapandwipecleananyspillage.

Figure27

1.Fillerplug/breather3.Drainplug(underside)

2.Dipstick

PreparingtheTractor

TheTM5490andTM7490trailedgangmowersaredesigned

forusewithstandardagriculturalorindustrialtractors

havingaminimumpowerof45bhp(TM5490)and70bhp

(TM7490).Theymustalsobeequippedwitharinghitch

(pintlehook)anda540rpmrearPTO .

TheTM5490andTM7490gangmowershaveafully

independenthydraulicsystemwhichispoweredfromthe

tractorrearPTO.Thesystemislivewhenyouengagethe

tractorrearPTO.Y oucanraiseorlowerthecuttingunitsvia

aremotecontrolsitedadjacenttotheoperator.

21

Page 22

DANGER

ModifyingasafetycaboraROPScanweakenit

andincreasethechancesofseriousinjuryordeath

intheeventofacrash.

Donotattachthemountingbracketstotheframe

orstructureofasafetycaboraROPS.

Dothisprocedureafterattachingthemowertothetractor

forthersttime.

Aquick-releasemountingbracketissuppliedwiththe

machineformountingthecontrolleverstothetractor,in

aconvenientpositionfortheoperator.Whenchoosinga

positionleaveadequateslackintheBowdencablestoallow

forarticulationofthetractorandmowerwhenturningor

negotiatingbrowsofhills,etc.Seriousdamagecouldresult

iftheBowdencablesbecomestretchedorpinchedinwork.

ChecktheroutingoftheBowdencablesandensurethatthey

arefreeofpinchpointsandhaveadequateslack.

Thetractorshouldbeequippedwithturf-patterntiresto

minimizedamagetoneturfareas.Consultyourtractor

operator’smanualortractordealerforfulldetailsof

recommendedtireequipment.Payparticularattentionto

thetractortirepressuresasthishasaconsiderableeffecton

steering,traction,andassociatedturfdamage.

ConnectingtheMowertoa Tractor

Important:Beforeusingthemower,ensurethatthe

PTOshaftistheappropriatelength;refertoSetup(page

9).

ConnectingtheHitches

1.Reversethetractortoapproximatelythecorrect

positioninrelationtothemowertoestablishthe

mowerdrawbarposition.

Figure28

1.T opsetofholesonmower

2.Middlesetofholeson

mower

3.Bottomsetofholeson

mower

4.Upperholesindrawbar

5.Lowerholesindrawbar

DrawbarMountingLocations

Upperholesin

drawbar

Topsetofholeson

mower

Middlesetofholes

onmower

Bottomsetofholes

onmower

546to570mm

(21.50to22.44

inches)

496to520mm

(19.53to20.47

inches)

0to470mm(0to

18.50inches)

4.Assemblethedrawbartothemowerintherequired

positionandtightenthe4fastenersto200N-m(148

ft-lb).

5.Lubricatethecontactpointsbetweenthemowerring

hitchandthetractorhitchwithgrease.

6.Connectthemowerringhitchtothetractorhitch.

Lowerholesin

drawbar

571to620mm

(22.48to24.41

inches)

521to545mm

(20.51to21.46

inches)

471to495mm

(18.54to19.49

inches)

2.Applythetractorparkingbrake,stoptheengine,and

removetheignitionkey.

3.Alignthemowertowhitchwiththetractorringhitch.

Ifnecessaryadjusttheheightoftheringhitchby

ttingthedrawbarintheappropriatemountingholes

inthemowerfrontplate;refertoDrawbarMounting

Locations(page22).

Figure29

1.Mowerfrontplate

2.Drawbar4.Tractorhitch

22

3.T owhitch

Page 23

7.Rotatethejockey-wheelhandleclockwisetoraisethe

jockeywheeltoapositionjustabovetheground.

Figure30

1.Handle

8.Unclampthejockey-wheelassembly,moveitupward

tothehighestposition,andclampitagaintosecure

itinthestorageposition.

9.Checkthatthemowerframeisstillhorizontallyaligned

withthegroundandadjustitifnecessary.

10.Assemblethebreakawaycablebetweenthehandbrake

leverandarigidlocationonthetractor.

Note:Ensurethatthebreakawaycablelocation

providesstraight-lineoperationintheeventofa

breakaway.

2.Clamplever

Figure31

1.Breakawaycable

11.Releasethehandbrakebycarefullymovingittothe

lowestposition.

12.AssemblethePTOshaft.

WARNING

AlwaysexaminetheconditionofthePTO

shaftandguardsbeforeuse.Neverusea

damagedPTOshaftassembly.

Important:EnsurethatthePTO-shaftrestis

foldeddowninthestoragepositionwhenthePTO

shaftisconnectedtothetractor.

13.GreasethePTOshaftbypartiallywithdrawingthe

telescopingshafttoexposethegreasenipplethrough

theouterguardapertureandlubricatingitwitha

good-qualitygrease.

14.Pushthetelescopingsectionbackintoposition.

15.Greasetheuniversaljoints.

16.Assemblethelargewideanglejointtothetractor(as

shownonthePTOguard)andtheotherendtothe

mower,ensuringthatthereleaseclipsarefullyengaged.

17.WhenthePTOiscorrectlyinstalled,attachthePTO

shaft-guardrestraintchains:connect1chaintothe

holeonthemowerPTOguardandconnecttheother

chaintoasuitablepositiononthetractor.

Important:Ifthetractorisequippedwitha3-point

linkage,checktherelationshipwiththemowerfor

potentialinterferencewhenmakingtightturnsorwhen

mowingundulatingground.Toeliminatepotential

damage,removethelowerlinkarmswhenusingthe

mower.

Note:Intheeventofthemoweruncouplingfrom

thetractorthebreakawaycableautomaticallyapplies

thebrakes.

WARNING

Usingadamagedbreakawaycablecould

resultinpersonalinjuryorpropertydamage.

Ensurethatthebreakawaycableisingood

workingcondition.

PositioningtheControlLevers

Unhookthecontrol-leverassemblyfromthemower

mountingbracketandattachittothetractormounting

bracket,ensuringthattheremotecablesareclearlyroutedand

freetoallowarticulationofthetractorrelativetothemower.

ConnectingtheLights

Connectthelightingplugofthemowertothelightsocketon

thetractor,andensurethatalllightsoperatecorrectlybefore

23

Page 24

usingthemower.Ensurethatthecableisneatlyrouted

alongsidethecontrolcables.

ConnectingtheBrakeHose

Note:Donotallowtheremote-controlboxtolieon

theground.

7.Disconnectthelighting-systemplugandcablefromthe

tractorsocketandstoreitonthemower.

Connectthebrakehosefromthefrontbulkheadofthe

mowertothetractorauxiliarybrakeconnector.Checkthat

thebrakingsystemoperatescorrectlybeforeusingthemower.

Ensurethatthehoseisneatlyroutedalongsidethecontrol

cableandthelightingcable.

DisconnectingtheMowerfrom aTractor

WARNING

Improperlydisconnectingthemowerfromatractor

couldresultinseriousinjuryorpropertydamage.

Beforeattemptingtodisconnectthemowerfrom

thetractoralwaysdothefollowing:

•Positionthetractorandthemoweronlevel

ground.

•Applythetractorparkingbrake,disengagethe

PTOdrive,stoptheengine,removetheignition

key,andsetthemowerhandbrake.

1.Carefullyraisethehandbrakelevertothehighest

positiontoengagethemowerbrakes.

2.Disconnectthebreakawaycablefromthetractor.

3.Supportthemoweronthejockeywheelasfollows

(Figure30):

8.Operatethetractortodisconnecttheringhitchfrom

themowertowhitch.

9.Disconnectthebrakehosefromtheauxiliarybrake

connectoronthetractor.

10.Connectthebrakehosetothettingmountedonthe

mowerbulkhead.

11.Movethetractorawayfromthemower.

Important:Checkthattherearenoobstructions

andthatallconnectionstothemowerare

disconnectedbeforedrivingthetractorawayfrom

themower.

PreparingtheMowerfor Transport

1.StartthetractorengineandengagethePTOdrive.

2.Operatetheoverridecontrollever(shortcontrollever)

toliftallcuttingunitstothefullyraisedtransport

position.

3.Stopthetractorengine,returntothemower,and

secureallcutting-unitsuspensionarmsandouter

cuttingunitsinthetransportpositionbylockingthe

transport-latchsafetylocks.

4.Applyathincoatingofgreasetoallexposed

hydraulic-cylinderrodsandtothefacesofthe

diverter-valveoperatingcams.

A.Releasetheclamplevertounclampthejockey

wheel.

B.Lowerthewheeltotheground,andclampthe

jockeyassemblyagain.

C.Turnthehandletocausethedrawbartoriseup

andoffthetractorhitch.

4.DisconnectthePTOshaftfromthetractorandstore

itonthePTO-shaftrest.

Note:NeverrestthePTOshaftontheground.

5.Disconnectthemanual-levercontrol:Removethe

control-leverassemblyfromthetractorandattachit

tothestoragepositiononthemowerwiththecables

neatlycoiledandprotectedfromdamage.

6.Ifthemowerisequippedwiththeoptionalelectriclift

kit,disconnectthepowercablefromthecigar-lighter

socketandthecontrolcablefromthein-cab

remote-controlunitasfollows:

Detachtheremote-controlboxfromitsmounting

bracketonthetractorandstowitonthemower.

OperatingtheMower

CheckingtheControls

Operatetheouterlongcontrolleversinturntoliftthe2wing

cuttingunits(cuttingunits1and5forModel02700,orcutting

units1and7forModel02701).Carryoutthisexercisewith

careandobservethemovementofthecuttingunitstoensure

thattheyarenotimpededbypoorroutingofthehydraulic

hoses.Itisnormaltoexperiencesomedelayintheresponse

ofthecontrolsforthersttimeasairispurgedfromthe

hydraulicsystem.Lowerthecuttingunitstotheground.

Operatethecenterlongcontrollevertoraisethecentral

cuttingunits(cuttingunits2,3,and4forModel02700,or

cuttingunits2,3,4,5,and6forModel02701),followingthe

sameprocedureoutlinedabove.

24

Page 25

CommissioningtheBrakingSystem

OperatingTips

WARNING

Ifyoutestthemachinewherethereareotherpeople

andvehicles,thereisariskofinjuryandproperty

damage.

Performthesetestsonaprivateroad,where

possible.

1.Inspectthebrakesystemandensurethatall

componentsareassembledandsecuredcorrectlyand

thatallcablesarecorrectlytensioned.Carefullyoperate

thehandbrakeupwards.Ensurebrakesareonwhen

theleverhasmoved70to80percentofitstravel.If

not,releasethehandbrake,adjustusingturnbuckleand

retry.

Note:Repeatthissequenceuntil70to80percenthas

beenachieved.

2.Applythehandbrakeagain.

3.Operatethetractorandattempttopullthemower

forwards.Checkthatthemowerbrakesoperate

satisfactorily.Operatethetractorandattempttopush

themowerinreverse.Checkthatthemowerbrakes

operatesatisfactorily.

•Therotationalspeedofthecuttingcylindersshould

alwaysbekeptashighaspossibleinordertomaintain

thehighestqualityofcut.Thisinturnrequiresthatthe

tractorenginespeedbekeptashighaspossiblewithout

exceedingaPTOspeedof540rpm.

•Excessiveforwardspeedcausesthequalityofcutto

deteriorate.Alwaysbalancethequalityofcutwiththe

workraterequiredandsettheforwardspeedaccordingly.

•Neverletthetractorenginelabor.Reducetheforward

speedorincreasetheheightofcut.Checkthatthecutting

cylindersarenotinheavycontactwiththeirbottom

blades.

•Regularlycheckthecylindertothebottomblade

adjustmenteveryfewhoursevenwhencutting

performanceappearstobesatisfactory.Heavycontact

orexcessiveclearancebetweenthecylindersandbottom

bladescausesrapidweartotakeplace.

•AlwaysdisengagethetractorPTOwhentravellingacross

areaswithnograss.Grasslubricatesthecuttingedges

whilemowing.Excessiveheatwillbuildupifyourunthe

cuttingcylinderswhennotmowing,andthiscausesrapid

weartotakeplace.Therefore,reducethecuttingcylinder

speedwhenmowinglightlygrassedareasorwhenthe

grassisdry.

Note:Ifcorrectoperationisnotachieved,checkthe

brakesystemlinkagesagain.Consultyourdealerif

assistanceisrequired.

4.Lowerthehandbrakelevertoitslowestpositionto

releasethebrakes.

5.Drivethetractor/mowercombinationinastraightline

at32km/h(20mph)andbrakegraduallyandrmly

withoutskidding.Checkthebrakingperformanceof

themower.

Note:Ifthebrakingeffectattheleftandrightwheels

isunequal,adjustthewheelbrakecables.Repeatthe

brakingtestuntilsatisfactoryperformanceisachieved.

6.Drivethetractor/mowercombinationatthemaximum

speedatwhichitistobeusedbutdonotexceed40

km/h(25mph);refertoSafeOperatingPractices(page

3).Applythebrakermlywithoutskidding.Before

comingtorest,increasethespeedbacktomaximum.

Note:Ensurethatthebrakingperformanceisgradual

andsympathetictothesystem(notsevere).Avoid

aggressive/violentbrakingduringthesetestsinorder

toallowthebrakepadstobed-incorrectly.

•Cuttingperformanceisbestwhencuttingagainstthelie

ofthegrass.Therefore,youshouldattempttoalternate

thedirectionofmowingbetweencuts.

•Donotleaveuncutstripsofgrassattheoverlappoints

betweentheadjacentcuttingunitsbyavoidingtightturns.

•Removetherearrollerscraperswhereconditionsallow ,

asbestgrassdischargeisachievedwithoutthem.Install

thescraperswhenconditionsaresuchthatmudandgrass

starttobuildupontherollers.

25

Page 26

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Toobtainanelectricalschematicorahydraulicschematicforyourmachine,visitwww.Toro.com.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Every50hours

Every250hours

Every500hours

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

MaintenanceProcedure

•Adjustthebrakes.

•Changethehydraulic-uidreturnlter.

•Checkthetirepressure.

•Checkthehydraulicuid.

•Checkthetirepressure.

•Greasethebearings,bushings,andpivots(greasethemimmediatelyafterevery

washingregardlessoftheintervallisted).

•LubricatethePTOshaft.

•Greasethebearings,bushings,andpivots(greasethemimmediatelyafterevery

washingregardlessoftheintervallisted).

•Lubricatethebrakelink.

•Inspectthebrakes.

•Replaceallbrakecables.

•Servicethehydraulicsystem.

•Changethehydraulic-uidreturnlter.

Fortheweekof:

MaintenanceCheckItem

Checkthesafetyinterlockoperation.

Checkthebrakeoperation.

Checkunusualoperatingnoises.

Checkthehydraulic-systemoillevel.

Checkhydraulichosesfordamage.

Checkforuidleaks.

Checkthetirepressure.

Checktheoperationofthecontrols.

Checkthecylinder-to-bedknifeadjustment.

Checktheheight-of-cutadjustment.

Checkallgreasettingsforlubrication.

Touchupdamagedpaint.

1.Checktheglowplugandinjectornozzlesifhardstarting,excesssmoke,orroughrunningisnoted.

2.Immediatelyaftereverywashing,regardlessoftheintervallisted

2

Mon.Tues.Wed.Thurs.Fri.

Sat.Sun.

26

Page 27

NotationforAreasofConcern

Inspectionperformedby:

ItemDate

1

2

3

4

5

Information

Lubrication

GreasingtheBearings, Bushings,andPivots

ServiceInterval:Beforeeachuseordaily

Every50hours

Lubricateallgreasettingsforthebearingsandbushingswith

general-purpose,lithium-basedgrease.Lubricatebearings

andbushingsimmediatelyaftereverywashing,regardlessof

theintervallisted.

Replaceanydamagedgreasettings.

Greaseallcutting-unit-greasepointsandinjectsufcient

greasesuchthatyoucanseecleangreaseescapingfromthe

rollerendcaps.Thisprovidesvisibleevidencethattheroller

sealshavebeenpurgedofgrass,ensuringmaximumworking

life.

Thegrease-ttinglocationsandquantitiesareasfollows:

Note:Ifyourmachineisequippedwiththeoverrundrawbar,

thedrawbarmayrequirelubricationaswell.

Figure32

Model02700

1.–Greasedaily3.–Greaseevery50hours(weekly)

2.

–Greasedaily(iftted)

27

Page 28

Figure33

Model02701

1.–Greasedaily3.–Greaseevery50hours(weekly)

2.

–Greasedaily(iftted)

LubricatingtheBrakeLink

ServiceInterval:Every250hours

Lubricatethebrakelinkwithoilandensurethatitoperates

freely.

LubricatingthePTOShaft

ServiceInterval:Beforeeachuseordaily

Exposethegreasettingontheshaftthroughtheouterguard

aperture,andinjectgreaseintothetting.

Lubricatetheuniversaljoints.

LubricatingtheCuttingUnits

RefertothecuttingunitOperator’sManualforadditional

informationaboutlubricatingthecuttingunits.

BrakeMaintenance

InspectingtheBrakes

ServiceInterval:Every250hours

Figure34

1.Brakeshoe

Removethewheelhubsandinspectthebrakeshoes(Figure

34).Replacetheshoesiftheliningthicknessislessthan1.5

28

2.Spring

Page 29

mm(0.059inch).UsegenuineT ororeplacementparts.Do

notrelinethebrakeshoes.

•Checkthatthebrakewedgesoperatethebrakeshoes

correctly.Wedgeswhicharewornexcessivelydonot

applythebrakesfully;replacethem.

•Ensurethatthebrakecablesoperatefreelyandthatthere

arenosignsoffrayingorotherdamage.Alwaysreplace

damagedcables.

•Ensurethatallbrakelinkagesareingoodcondition,

operatefreely ,andaresecuredcorrectly.Lubricateall

pivotpointswithoil.

Checkthebrakecylinderandtheassociatedhydraulichoses

forleaks.Alwaysreplaceanyleakingcomponents.

AdjustingtheBrakes

ServiceInterval:Aftertherst50hours

1.Raisethemachinesothatthewheelsareofftheground.

WARNING

ReplacingtheBrakeCables

ServiceInterval:Every500hours

ContactyourAuthorizedToroDistributor.

Mechanicalorhydraulicjacksmayfailto

supportthemachineandcauseseriousinjury.

Usejackstandswhensupportingthemachine.

2.Rotatetheleftwheelinthedirectionofforwardtravel.

3.Turnthebrakeadjuster(Figure35)untilthewheelis

nolongerabletorotate.

Note:Thisputspreloadonthebrakes.

Figure35

1.Brakeadjuster2.Backplate

4.Turnthebrakeadjusterbackinhalf-turn

increments—tappingtheadjusteraftereach

increment—untilyoucanrotatethewheelbyhand

againstslightresistance.

5.Repeattheprocedurefortheotherwheel.

6.Carefullylowerthemachinetotheground.

29

Page 30

HydraulicSystem

Maintenance

ChangingtheHydraulic-Fluid ReturnFilter

ServiceInterval:Aftertherst50hours

ServicingtheHydraulic System

ServiceInterval:Every500hours

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.

•Makesurethatallhydraulicuidhosesand

linesareingoodconditionandallhydraulic

connectionsandttingsaretightbefore

applyingpressuretothehydraulicsystem.

•Keepyourbodyandhandsawayfrompin-hole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

Every500hours

1.Removethetopofthereturn-lterassembly.

Figure36

1.Filtercanister(Part65-06-483)

2.Withdrawthelter-elementcanisteranddiscardit.

3.Installanewltercanister(Part65-06-483)andinstall

thescrewtop.

Important:EnsurethattheO-ringsealis

correctlypositioned.

•Getimmediatemedicalhelpifuidisinjected

intoskin.

1.Lowerthecuttingunitstothegroundanddrainthe

hydraulicuidbyremovingthehydraulic-tankdrain

plug.

2.Removetheoil-tank-llerangetoaccessthestrainer

insidethetank.

3.Unscrewandremovethestrainer.

4.Cleanthestrainerinparafn(kerosene).

Note:Replacethestrainerifitisdamaged.

5.Installthestrainer.

Replacethereturn-lineoil-lterelement;refertoChanging

theHydraulic-FluidReturnFilter(page30).

30

Page 31

Cutting-UnitSystem

G014445

Maintenance

BackLappingtheCutting Units

Thisprocessisforrestoringthesharpcuttingedgestothe

cylindersandthebottomblades,whichareessentialfor

good-qualitygrasscutting.

Thisprocessremovesonlyasmallamountofmetaltorestore

thecuttingedges.Ifthebladeedgesareseverelywornor

damaged,removethecomponentpartsandhavethem

groundagain.

1.Lowerthecuttingunitstotheground.

2.Ensurethatthetractorengineisoffandthatthe

parkingbrakeisset.

3.Adjustthecuttingcylinderstothebottombladesto

obtaineetingcontact.

4.Applyamedium-grade,detergent-basedcarborundum

pastetothecuttingedgesofthecylinderswitha

long-handledbrush.

80-gradecarborundumpaste

WeightPartnumber

0.45kg(1lb)

11.25kg(25lb)

5.Sitontheoperatorseat,startthetractorengine,and

settheenginespeedatidle.

63-07-088

63-07-086

Figure37

WARNING

Ifyoutouchthecuttingunitswhentheengine

isrunning,youcouldbeseriouslyinjured.

•Ensurethattheareasurroundingthe

cuttingunitsisclearofpeople.

•Keephandsandfeetclearofthecutting

cylindersduringtheperiodwhenthe

tractorengineisrunning.

6.Settherotaryvalveattherearofthemachineto

REVERSE;refertoFigure38.

31

Page 32

Storage

•Parkthemoweronlevelground.

•Performroutinechecks.

•Releasethemowerbrakes—operatethemowerhandbrake

downwardtothelowestpositiontoreleasethemower

brakes.

Figure38

1.Normalpositionofrotary

valvecontrolsforforward

cutting-unitrotation

7.OperatethetractorPTOswitch/levertotheOFF

position(Figure38)andswitchoffthetractorengine

whenthegrindingactionhasstopped.

8.Thoroughlycleanthebladeedgesandadjustthecutting

cylinderstothebottomblades.

9.Checkthatathinpieceofpapercanbecutcleanlyat

allpointsalongthecuttingedgeswhilerotatingthe

cylindersbyhand.

10.Iffurtherbacklappingisnecessary,repeatsteps3

through9.

11.Thoroughlyremoveandwashoffalltracesofthe

carborundumpastefromthecylindersandthebottom

blades.

2.T ostarttheback-lapping

procedure,rotatethe

lockleverclockwiseto

position1;rotatetherotary

valvecounterclockwiseto

position2;releasethelock

levercounterclockwiseto

position3.

•Adjustthecuttingcylinderssuchthattheyareclearofthe

bottomblades.

•Preventtiredistortion—supportthemowerchassison

blockssuchthatthetiresareclearofthegroundto

preventtiredistortion.

•Preventcorrosion—treatbaremetalsurfacesincluding

thecuttingedgesofthecuttingcylinders,bottomblades,

andexposedhydraulic-cylinderrodswithgrease,oil,ora

proprietarycorrosioninhibitor.

12.Movethecontrollevertotheoriginalpositionfor

normaloperation.

Note:Theback-lapcontrollockshouldspringback,

lockingthecontrolleverinposition.

GrindingtheCuttingUnits

HaveyourToroAuthorizedDistributorcarryoutagrinding

operationtocorrectthecylinderspiraledgesand/or

bottom-bladeedgeswhentheyhavebecomeexcessively

roundedordistorted.Ifthebottombladesarenearingthe

endoftheirwearlife,havethemreplaced.Havethenew

bladesgroundontheirholderspriortoinstallingthem.Grind

boththecylindersandthebottombladesatthesametime.

Theonlyexceptiontothisruleiswhenanewcylinderistted,

inwhichcaseitisonlynecessarytogrindthebottomblade.

Allsuchgrindingoperationsshouldbecarriedoutbyyour

authorizeddealerordistributoronaquality,well-maintained

cylinder/bottom-bladegrindingmachine.

32

Page 33

Troubleshooting

Problem

Thereareareasofuncutgrassatthe

overlapbetweencuttingcylinders.

Therearefull-widthridgelinesinthecut

acrossthedirectionoftravel.

Thereareridgelinesinthecutgrass,

acrossthedirectionoftravel,overthe

cuttingwidthof1cylinder.

Thereisastepinthecutgrassheight

atthepointofoverlapbetweencutting

cylinders.

PossibleCauseCorrectiveAction

1.Y ouareturningtootightly.1.Increasetheturningradius

2.Themachineslidessidewayswhen

travellingacrossthefaceofaslope.

3.Thereisnogroundcontacton1end

ofthecutterbecauseofpoorlyrouted

hosesorwronglypositionedhydraulic

adaptors.

4.Thereisnogroundcontacton1end

ofthecutterbecauseapivotpinis

seizing.

5.Thereisnogroundcontacton1end

ofthecutterbecauseofgrassbuildup

underthecutterhead.

1.Theforwardspeedistoohigh.1.Reduceforwardspeed.

2.Thecylinderspeedistooslow.2.Increasethetractorenginespeed.

3.Theheightofcutistoolow.3.Raisetheheightofcut.

1.Acylinderisrunningslow.

1.Thereisaninconsistentheightofcut

settingon1cylinder.

2.Theraise/lowerpositioncontrolisnot

intheoatposition.

3.Thereisnogroundcontacton1end

ofthecutterbecauseofpoorlyrouted

hosesorwronglypositionedhydraulic

adaptors.

4.Thereisnogroundcontacton1end

ofthecutterbecauseofpivotpins

seizing.

5.Thereisnogroundcontacton1end

ofthecutterbecauseofgrassbuildup

underthecutterhead

2.Mowup/downtheslope.

3.Correctthehoseroutingortheposition

ofthehydraulicadaptors.

4.Releaseandgreasethepivotpoints.

5.Clearthegrassbuildup.

1.Checkthecylinderspeed;consultyour

authorizeddistributor.

1.Checkandadjusttheheightofcut

setting.

2.Setthepositioncontroltotheoat

position.

3.Correctthehoseroutingandthe

positionofthehydraulicadaptors.

4.Releaseandgreasethepivotpoints.

5.Removethegrassbuildup.

Therearesomeuncutorpoorlycut

strandsofgrass.

Therearelinesofuncutorbadlycutgrass

inthedirectionoftravel.

1.Acuttingcylinderispartiallyoutof

contactwiththebottomblade.

2.Acuttingcylinderisinheavycontact

withthebottomblade.

3.Theheightofcutistoohigh.3.Lowertheheightofcut.

4.Thecuttingedgesofthecutting

cylinders/bottombladesarerounded.

1.Thereistramliningofthecutting

edgesduetoheavycontactcausedby

poorcutting-cylinder-to-bottom-blade

adjustment.

2.Thebottombladeisincontactwiththe

ground.

3.Thebottombladehasanose-down

attitude.

4.Thecutterheadsarebouncing.

5.Thereareworncylinder

bearings/bearinghousingpivots.

6.Thereareloosecomponentsinthe

cutterhead.

1.Adjustthecontactbetweenthecutting

cylinderandthebottomblade.

2.Adjustthecontactbetweenthecutting

cylinderandthebottomblade.

4.Backlaporgrindtheedges.

1.Backlaporgrindtheedges.

2.Raisetheheightofcut.

3.Adjustthecutterheadtopositionthe

bottombladeparalleltotheground.

4.Reducetheforwardspeedandreduce

theweighttransfer.

5.Replaceanywornparts.

6.Checkandtightencomponentsas

necessary.

33

Page 34

Problem

PossibleCauseCorrectiveAction

Thereisexcessivebottombladewear .

Thehydraulicsystemoverheats.

1.Theundulationsaretoosevereforthe

1.Useoatingcutterheads. Thereisscalpingoftheturf.

heightofcutsetting.

2.Theheightofcutistoolow.2.Raisetheheightofcut.

1.Thebottombladeisinheavycontact

1.Raisetheheightofcut.

withtheground.

2.Thecuttingedgesofthecutting

2.Backlaporgrindtheedges.

cylinderand/orbottombladeare

rounded.

3.Thecylinderisinheavycontactwith

thebottomblade.

4.Thereisadamagedcuttingcylinderor

3.Adjustthecontactbetweenthecutting

cylinderandthebottomblade.

4.Grindorreplacepartsasnecessary.

bottomblade.

5.Thereareexcessivelyabrasiveground

5.Raisetheheightofcut.

conditions.

1.Thecylindersaretightagainstthe

1.Adjustthesettings.

bottomblades.

2.Thereliefvalvesettingislow.2.Havethereliefvalvepressurechecked.

Consultyourauthorizeddistributor.

3.Thebrakesareapplied.3.Releasethebrakes.

4.Theuidlevelislow.

4.Fillthereservoirtothecorrectlevel.

5.Theworkrateistooexcessive.5.Reducetheworkratebyincreasing

theheightofcutand/ordecreasingthe

forwardspeed.

6.Thehydraulicuidisthewrong

viscosity.

6.Drainthehydraulicsystemandll

itwithuidofthecorrectgradeand

viscosity.

Thereisexcessivenoiseinthehydraulic

system.

Thecylindersrotateinthewrongdirection.

1.Apumpiswornordamaged.

1.Identifythenoisypumpandserviceit

orreplaceit.

2.Amotoriswornordamaged.

2.Identifythenoisymotorandserviceit

orreplaceit.

3.Thereisairleakingintothesystem.3.Tightenorreplacetheleakinghydraulic

ttings,particularlyinthesuctionlines.

4.Thesuctionstrainerisblockedor

4.Cleanorreplacethesuctionstrainer.

damaged.

5.Theuidviscosityisincreaseddueto

5.Allowthesystemtowarmup.

coldconditions.

6.Therelief-valvesettingislow.6.Havetherelief-valvepressure

checked.Consultyourauthorized

distributor.

7.Thehydraulic-uidlevelislow.

1.Theback-lapcontrolleverisnotlocked

intheNORMALOPERATIONposition.

2.Thehosesareconnectedwrongly.

7.Fillthereservoirtothecorrectlevel.

1.Locktheback-lapcontrolleverinthe

NORMALOPERATIONposition.

2.Checkthehydrauliccircuitandconnect

thehosescorrectly .

34

Page 35

Problem

PossibleCauseCorrectiveAction

Afteraninitialperiodofsatisfactory

operation,themachinelosespower .

Acylinderknockswhilerotating.

Onecylinderrotatesslowly.

1.Apumpormotorisworn.1.Replacepartsasnecessary.

2.Thehydraulic-uidlevelislow.2.Fillhydraulicuidtanktocorrectlevel

3.Theuidinthehydraulicsystemhas

thewrongviscosity .

3.Replacetheoilinthehydraulictank

withthecorrectviscosity-gradeoil;

refertotheSpecicationssection.

4.Thelterelementisblocked.4.Changethelterelement.

5.Thepressurereliefvalveis

malfunctioning.

5.Havethereliefvalvecleanedand

thepressurechecked.Consultyour

authorizeddistributor.

6.Thesystemisoverheating.

6.Checkthecylinder-to-bottom-blade

adjustment.Reducetheworkrate

(increasetheheightofcutorreduce

theforwardspeed).

7.Thereareleaksonthesuctionhose.

7.Checkandtightenthettings.Replace

thehoseifnecessary.

1.Thereisahighspotonthecylinderor

thebottombladeduetocontactwitha

foreignobject.

1.Removethehighspotwithastoneand

backlaptorestorethecuttingedges.

Severedamagewillrequiregrinding.

2.Thecylinderbearingsareworn.2.Replacethebearingsasnecessary.

1.Acuttingcylinderbearingisseized.1.Replacethebearingsasnecessary.

2.Amotorwithincorrectrotationwas

installed.

3.Themotorintegralcheckvalveis

jammedopen.

4.Thecuttingcylinderistightonthe

2.Checkthemotorandreplaceitif

necessary.

3.Havethecheckvalvecleanedand

checked.

4.Adjustthesetting.

bottomblade.

5.Themotorisworn.5.Replacethemotor.

Acuttingunitfailstoliftoutofwork.

Thecuttingunitsdonotfollowthecontours

oftheground.

1.Thereisalift-cylindersealfailure.

2.Thepressurereliefvalveisjammed

openorwronglyset.

1.Replacetheseals.

2.Havethereliefvalvepressurechecked.

Consultyourauthorizeddistributor.

3.Thereisamalfunctioningcontrolvalve.3.Overhaulthecontrolvalve.

4.Thereismechanicalblockage.4.Removetheblockage.

1.Thehoseroutingortheorientationof

thehydraulicttingsisincorrect.

1.Movethecuttingunitsthroughoutthe

extremesofmovementandobserve

anytightnessinthehoses.Correctly

routethehosesandorientatethe

ttingsasnecessary .

2.Thepivotpointsaretootight.2.Releaseandgreasethepivotpointas

necessary.

3.Themowerisbeingoperatedinthe

HOLDposition.

3.Movethepositioncontrolswitchtothe

DOWN/FLOATposition.

4.Theweighttransferissettoohigh.4.Reducetheweighttransfer.

35

Page 36

Problem

PossibleCauseCorrectiveAction

Thecuttingunitsfailtostartupwhen

loweredintowork.

ThePTOshaftisheavilyworn.

1.Theseatsensorswitchis

malfunctioning.

1.Checkthemechanicalandelectrical

operationoftheswitch.

2.Thehydraulic-uidlevelislow.2.Fillthehydraulic-uidreservoirtothe

correctlevel.

3.Adriveshaftissheared.3.Checkthemotorandcylinder

driveshaftsandreplacethemif

necessary.

4.Thepressurereliefvalveisjammed

openorwronglyset.

4.Havetherelief-valvepressure

checked.Consultyourauthorized

dealer.

5.Acuttingcylinderisjammed.

6.Acuttingcylinderistightonthebottom

5.Clearanyjamsasnecessary.

6.Adjustthesetting.

blade.

7.Acutting-unitcontrolvalveisinthe

OFFposition,causedbymalfunctioning

7.Overhaulthecontrolvalve.

controlvalve.

8.Acutting-unitcontrolvalveisintheOFF

position,causedbyanelectricalfault.

9.Thelift-armproximityswitchis

8.Havetheelectricalsystemcheckedfor

anelectricalfault.

9.Checkandadjusttheproximityswitch.

incorrectlyset.

1.Thereisalackoflubrication.1.GreasethePTOshaftevery8hours.

2.Thereisinsufcientoverlaptheinner

sectionandtheoutersectionofthe

2.CheckandadjustthePTOoperating

length.

shaft.

3.Thereisdamageduetocontactwith

thetractordrawbarpin.

3.Checkandadjusttheverticalalignment

ofthemowerdrawbar.

Thereisexcessivehandbraketravel

and/orpoorbrakingperformance.

1.Thebrakeshoesareworn.1.Adjustorreplacethebrakeshoesas

necessary.

2.Thereisslackinthebrakecables.2.Adjustthebrakecables.

3.Abrakecylinderisworn.3.Replacethecylinder.

Themowerpullsto1sidewhilebraking.1.Thecableadjustmentisunbalanced.1.Adjustthebrakecables.

36

Page 37

Notes:

37

Page 38

Notes:

38

Page 39

InternationalDistributorList

Distributor:

AgrolancKft

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

CyrilJohnston&Co.RepublicofIreland

EquiverMexico525553995444ParklandProductsLtd.NewZealand6433493760

FemcoS.A.Guatemala

ForGarderOU

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GolfinternationalTurizm

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IrrimacPortugal351212388260T oroEuropeNVBelgium3214562960

IrrigationProductsInt'lPvtLtd.India0091442449

JeanHeybroekb.v.Netherlands31306394611VictusEmakPoland48618238369

Country:

Hungary3627539640

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Estonia3723846060

Japan81726325861

Turkey902163365993Riversa

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479T-MarktLogisticsLtd.Hungary3626525500

Egypt2025194308ToroAustraliaAustralia61395807355

PhoneNumber:Distributor:

5062391138

94112746100

442890813121

5024423277

30109350054

862087651338

4635100000

4387

Country:

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

Mountelda.s.CzechRepublic

Mountelda.s.Slovakia

MunditolS.A.

NormaGarden

OslingerTurfEquipmentSA

OyHakoGroundandGarden

Ab

Perfetto

PratoverdeSRL.

Prochaska&Cie

RTCohen2004Ltd.

LelyTurfcare

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

ValtechMorocco21253766

Japan81332522285

Argentina54114821

Russia74954116120

Ecuador59342396970

Finland35898700733

Poland48618208416

Italy390499128

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France331308177

India911292299901

Phone

Number:

5712364079

420255704

220

420255704

220

9999

128

34952837500

00

35722434131

3636

EuropeanPrivacyNotice

TheInformationToroCollects

ToroWarrantyCompany(Toro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer.

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMATION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.ToromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany.Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw .

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalToroDealer.

374-0269RevH

Page 40

TheToroTotalCoverageGuarantee

ALimitedWarranty

ConditionsandProductsCovered

TheToro

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser .

*Productequippedwithanhourmeter.

®

Companyanditsafliate,T oroWarrantyCompany,pursuant

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

CommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator’sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

contamination,useofunapprovedcoolants,lubricants,additives,

fertilizers,water,orchemicals,etc.

•Normalnoise,vibration,wearandtear ,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

NoteRegardingDeepCycleBatteryWarranty:

Deepcyclebatterieshaveaspeciedtotalnumberofkilowatt-hoursthey

candeliverduringtheirlifetime.Operating,recharging,andmaintenance

techniquescanextendorreducetotalbatterylife.Asthebatteriesin