Page 1

HoverPro550Machine

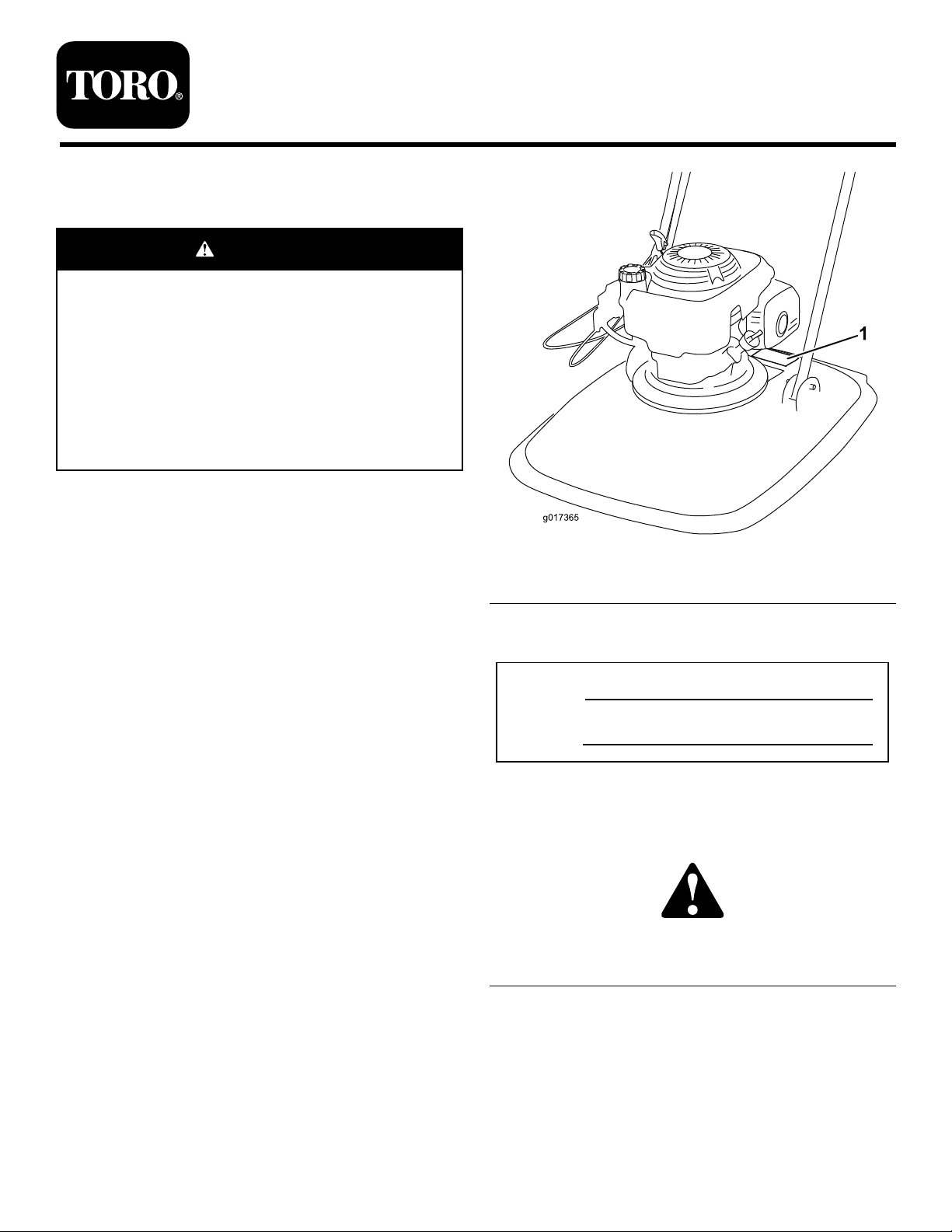

g017365

1

ModelNo.02611—SerialNo.315000001andUp

Introduction

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

FormNo.3392-576RevA

Operator'sManual

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.Keepforfuturereference.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.

Figure1

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthespace

below:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbytheengine

manufacturerinaccordancewithSAEJ1349.Ascongured

OriginalInstructions(EN)

PrintedintheUK

AllRightsReserved

*3392-576*A

Page 2

tomeetsafety,emission,andoperatingrequirements,the

actualenginehorsepoweronthisclassmachinewillbe

signicantlylower.

Contents

Introduction..................................................................1

Safety...........................................................................2

GeneralOperation..................................................2

SlopeOperation......................................................2

Children.................................................................3

Service...................................................................3

Hauling..................................................................4

SafetyandInstructionalDecals.................................5

Setup............................................................................6

1AssemblingtheHandle..........................................6

2InstallingtheFootstop...........................................6

3FillingtheEnginewithOil......................................7

ProductOverview..........................................................8

Operation.....................................................................8

FillingtheFuelTank................................................8

CheckingtheEngine-OilLevel..................................9

AdjustingtheCuttingHeight....................................10

StartingtheEngine.................................................11

AdjustingtheChoke...............................................12

StoppingtheEngine...............................................12

OperatingTips......................................................13

Maintenance.................................................................14

RecommendedMaintenanceSchedule(s)......................14

PreparingforMaintenance.......................................15

ReplacingtheAirCleaner........................................15

ChangingtheEngineOil.........................................15

ServicingtheSparkPlug..........................................16

ReplacingtheBlade................................................16

CleaningtheMachine..............................................17

Storage........................................................................17

PreparingtheMachineforStorage............................17

Troubleshooting...........................................................18

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013andANSIB71.4–2012.

Thiscuttingmachinecanamputatehandsandfeetand

throwobjects.Failuretoobservethefollowingsafety

instructionscouldresultinseriousinjuryordeath.

GeneralOperation

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtothemselves,other

people,orproperty.

•Donotputhandsorfeetnearorunderthemachine.

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Cleartheareaofobjectssuchasrocks,wire,toys,etc.,

whichcouldbethrownbytheblade.Staybehindthe

handlewhentheengineisrunning.

•Besuretheareaisclearofbystandersbeforeoperating.

Stopmachineifanyoneentersthearea.

•Wearappropriateclothingincludinghardhat,safety

glasses,andhearingprotection.Longhair,looseclothing,

orjewelrymaygettangledinmovingparts.

•Donotpullmachinebackwardunlessabsolutely

necessary.Alwayslookdownandbehindbeforeand

whilemovingbackward.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Materialmayricochetbacktowardtheoperator.Donot

operateovergravelsurfaces.

•Checkthattheoperator’spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

•Neverleavearunningmachineunattended.

•Stoptheengineandwaituntilthebladecomestoa

completestop,andremovethesparkplugwirebefore

cleaningoruncloggingthemachine.

•Operatemachineonlyindaylightorgoodarticiallight.

•Donotoperatemachinewhileundertheinuenceof

alcoholordrugs.

•Neveroperatemachineinwetgrass.Alwaysbesureof

yourfooting;walk;neverrun.

•Neverraisethedeckwiththeenginerunning.

•Ifthemachineshouldstarttovibrateabnormally,stop

theengineandcheckforthecauseimmediately.Vibration

isgenerallyawarningoftrouble.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•ReadtheOperator’sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglishitis

theownersresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andthesafetysigns.

SlopeOperation

Slopesareamajorfactorrelatedtoslipandfallaccidents,

whichcanresultinsevereinjury.Operationonallslopes

requireextracaution.Ifyoufeeluneasyonaslope,donot

mowit.

2

Page 3

•Mowacrossthefaceofslopes;neverupanddown.

Exerciseextremecautionwhenchangingdirectionon

slopes.

•Watchforholes,ruts,bumps,rocks,orotherhidden

objects.Uneventerraincouldcauseaslipandfall

accident.Tallgrasscanhideobstacles.

•Donotmowonwetgrassorexcessivelysteepslopes.

Poorfootingcouldcauseaslipandfallaccident.

•Donotmowneardrop-offs,ditches,orembankments.

Youcouldloseyourfootingorbalance.

•Whenusingthemachine,alwayskeepbothhandsonthe

handlebar.

•Whencuttingsteepslopesfromthetopoftheslopeand

alongerreachisneeded,nevertiethemachinetoarope,

usetheextendedhandlebarkitoption.

Children

Tragicaccidentscanoccuriftheoperatorisnotalerttothe

presenceofchildren.Childrenareoftenattractedtothe

machineandthemowingactivity .Neverassumethatchildren

willremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunderthe

watchfulcareofaresponsibleadultotherthanthe

operator.

•Bealertandturnmachineoffifachildentersthearea.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayblockyourviewofachild.

Service

SafeHandlingofGasoline

Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedgasolinecontainer.

•Neverremovegascaporaddfuelwiththeengine

running.Allowenginetocoolbeforerefueling.

•Neverrefuelordrainthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removegas-poweredequipmentfromthetruckortrailer

andrefuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentwithaportablecontainer,rather

thanfromagasolinedispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacegascapandtighten

securely.

WARNING

Exhaustcontainscarbonmonoxide,anodorless,

deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

GeneralService

•Neveroperatemachineinaclosedarea.

•Keepallnutsandboltstighttobesuretheequipmentis

insafeworkingcondition.

•Nevertamperwithsafetydevices.Checktheirproper

operationregularly.

•Keepmachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillageandremoveany

fuel-soakeddebris.Allowmachinetocoolbeforestoring

inanenclosedspace.

•Nevermakeanyadjustmentsorrepairswiththeengine

running.Disconnectthesparkplugwireandground

againstenginetopreventunintendedstarting.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Ifgasolineisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillageand

avoidcreatinganysourceofignitionuntilthegasoline

vaporhasdissipated.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethattheblade,

boltsandspacersarenotwornordamaged.Replacea

wornordamagedblade.

•Stopthebladeifthemachinehastobetiltedfor

transportationwhencrossingsurfacesotherthangrass,

andwhentransportingthemachinetoandfromthearea

tobemowed.

•Neverpickuporcarryamachinewhiletheengineis

running.

•Stoptheengineanddisconnectthesparkplugwire,make

surethatallmovingpartshavecometoacompletestop:

–Beforeclearingblockages.

–Beforechecking,cleaning,orworkingonthemachine.

–Afterstrikingaforeignobject.Inspectthemachine

fordamageandmakerepairsbeforerestartingand

operatingthemachine.

3

Page 4

–Ifthemachinestartstovibrateabnormally.

–Wheneveryouleavethemachine.

–Beforerefueling.

•Ensuretheengineandthefueltankareemptyoffuel

beforerotatingthemachinebeyonda45degreeangle.

•Usecarewhencheckingtheblades.Wrapthebladeor

weargloves,andusecautionwhenservicingthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Shutoffthefuelwhilestoringortransportingthe

machine.Donotfuelnearopenames,anddonotdrain

fuelindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,thisshouldbedone

outdoors.Thedrainedfuelshouldbestoredinacontainer

specicallydesignedforfuelstorageoritshouldbe

disposedofcarefully.

•StarttheenginecarefullyaccordingtotheOperator’ s

Manualandwithfeetawayfromthecuttingelements.

•Alwayswearearprotection.

•Whentiltingthemachinetostarttheengine,donottilt

itmorethanabsolutelynecessaryandliftonlythepart

whichisawayfromtheoperator.

•Examinethemachineregularlyandreplacewornor

damagedpartsforsafety.UseonlyTorogenuinespare

parts.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingthemachineintoa

traileroratruck.

•Tiethemachinedownsecurelyusingstraps,chains,

cables,orropes.Boththefrontandtherearstrapsshould

bedirecteddownandoutwardfromthemachine.

4

Page 5

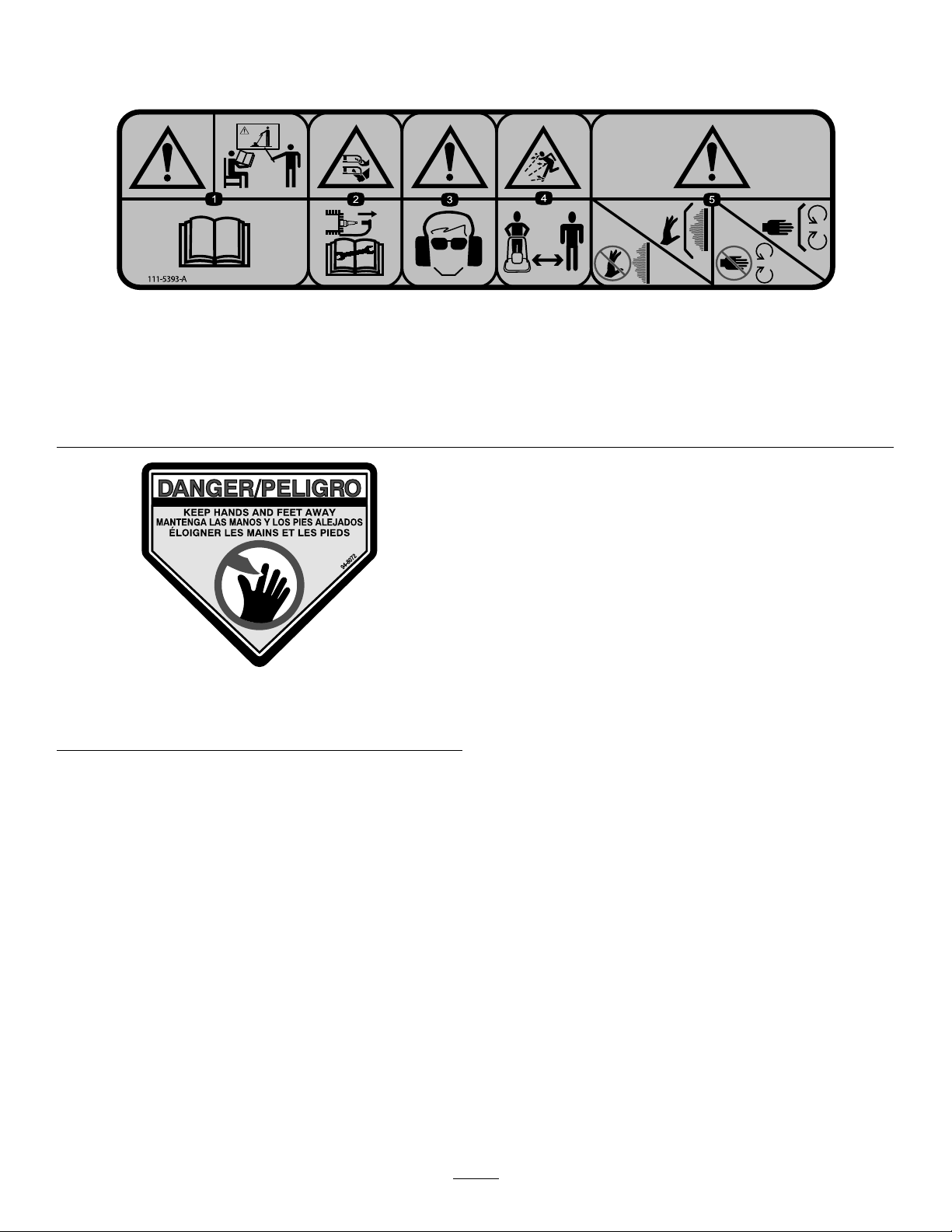

SafetyandInstructionalDecals

Important:Safetyandinstructiondecalsarelocatednearareasofpotentialdanger.Replacedamageddecals.

111-5393

1.Warning—Receivetrainingontheproduct;readthe

Operator’sManual.

2.Cutting/dismembermenthazardofhandorfoot,mowerblade;

disconnectthewirefromthesparkplugbeforeworkingonthe

machine;nevertmetalcuttingparts.

3.Warning—weareyeandhearingprotection.

94-8072

1.Warning—cutting/dismembermenthazardofhandorfoot,

cuttingmechanism.

4.Thrownobjecthazard;keepbystandersawayfromthe

machine.

5.Warning—donottouchhotsurfaces;keepguardsinplace;

Stayawayfrommovingparts;keepguardsinplace.

5

Page 6

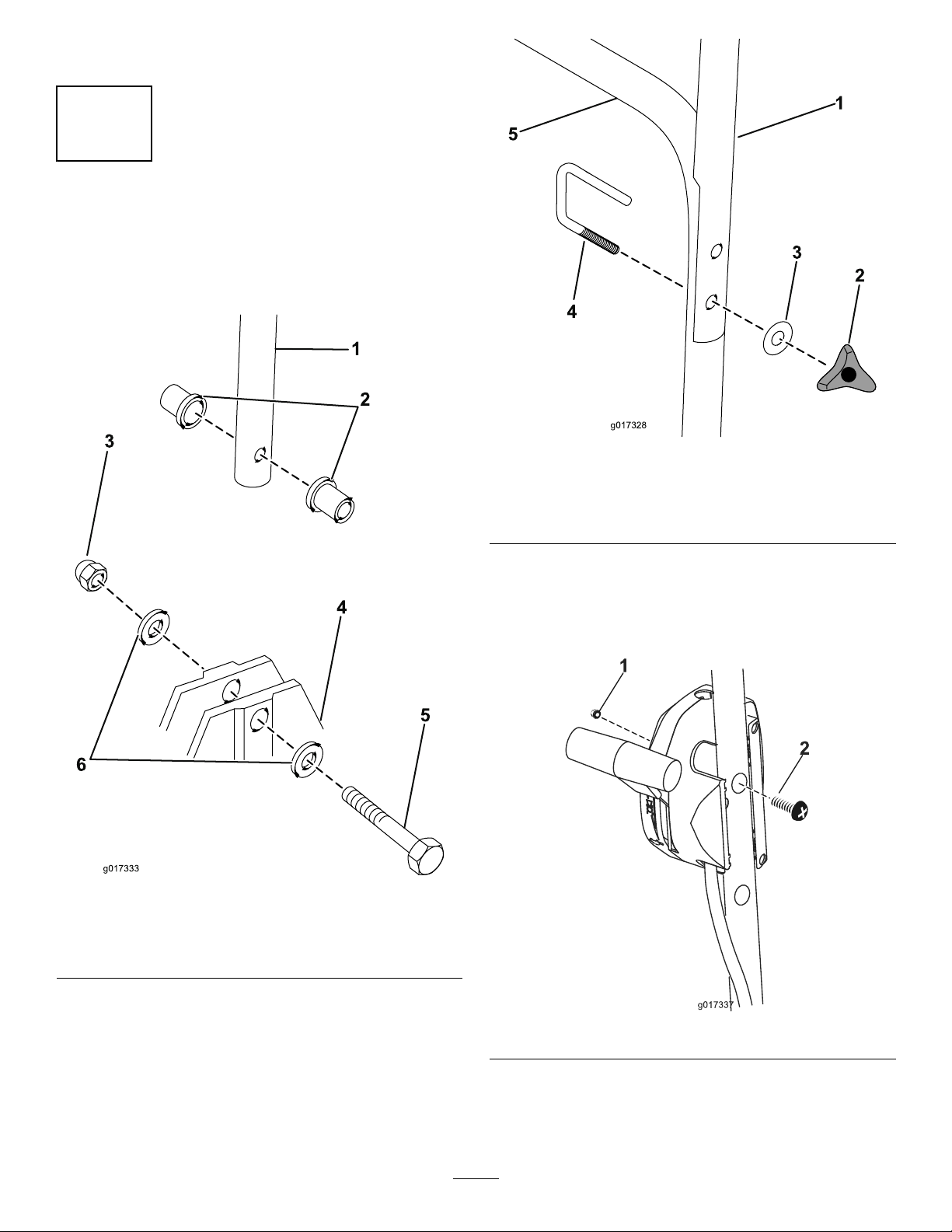

Setup

g017333

1

2

3

4

5

6

g017328

1

2

3

4

5

1

AssemblingtheHandle

NoPartsRequired

Procedure

1.Slide2bushesintotheframe.

Figure4

1.Upperhandle4.Ubolt

2.Handwheel5.Lowerhandle

3.Washer

5.FittheUboltthroughtheupperandlowerhandleand

secureitwithawasherandahandwheel.

6.Attachthethrottleassemblytotheoutsideofthe

handlebarandsecureitwithanutandapanscrew.

Figure3

1.Lowerhandle4.Frame

2.Bushes5.Bolt

3.Nut6.Washers

2.Placethelowerhandlebetweenthebushesandsecure

itwith1handlebarbolt,2washers,and1nut.

Note:Placethelowerhandlebetweenthebusheswith

thekickstopassemblyontherighthandside.

3.Repeatfortheoppositeside.

4.Aligntheholesontheupperhandlewiththelower

handle.

Figure5

6

Page 7

2

1

2

3

g017332

g017338

InstallingtheFootstop

NoPartsRequired

Procedure

Securethefootstoptotheboltontherightsideofthelower

handleusinganutand2washers(Figure6).

Note:Installthefootstopusingthelowerholeinthe

footstopasshowninFigure6.

Max.ll:0.59L(20oz),type:SAE30orSAE10W-30

detergentoilwithanAPIserviceclassicationofSF,SG,SH,

SJ,SL,orhigher.

1.Movethemachinetoalevelsurface.

2.Removethedipstick(Figure7).

Figure7

Figure6

1.Footstop4.Bolt

2.Nut5.Lowerhandle

3.Washer

1.Theoillevelisatits

maximum.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

3.Slowlypouroilintotheoilllhole,wait3minutes,

andchecktheoillevelonthedipstickbywipingthe

dipstickcleanandtheninserting,butnotscrewingin,

theoilllcapintothehole(Figure8).

3.Theoillevelistoo

low—addoiltothe

crankcase.

Figure8

3

FillingtheEnginewithOil

NoPartsRequired

Procedure

Important:Yourmachinedoesnotcomewithoilin

theengine.Beforestartingtheengine,lltheengine

withoil.

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrect

asshowninFigure7.Ifyouoverlltheenginewith

oil,removetheexcessoilasdirectedinChangingthe

EngineOil(page15).

4.Installthedipstickandhandtightenitsecurely.

Important:

operating hour s

toChangingtheEngineOil(page15).

7

Change the engine oil after the r st 5

;changeityearlythereafter.Refer

Page 8

ProductOverview

g017341

1

2

3

4

5

6

7

8

9

1

2

3

7

8

9

g017335

4

5

6

Operation

FillingtheFuelTank

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

directlyonthegroundbeforelling,notina

vehicleoronanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

RecommendedFuel:

Figure9

1.Fuelcap6.Handlebarsecuringknob

2.Enginestart7.Exhaustguard

3.Throttlecontrol8.Enginecover

4.Enginestophandle9.Dipstick

5.Handlebar

Figure10

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

85%ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamagewhichmay

notbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

6.Fuelcap

9.Carburetor

1.Sparkplug

2.Exhaustguard7.Fingerguard

3.Exhaust8.Aircleaner

4.Dipstick

5.Startergrip

8

Page 9

g017340

Figure11

1

2

3

g017332

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Removethedipstickandwipeitwithacleancloth.

3.Insert,butdonotscrewin,thedipstickintotheoil

llhole.

4.Removethedipstickandcheckit.

5.Todeterminetheproperoillevelonthedipstick,refer

toFigure12).

Figure12

1.Theoillevelisatits

maximum.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

3.Theoillevelistoo

low—addoiltothe

crankcase.

6.Iftheoillevelislow,slowlypouroilintotheoilll

hole,wait3minutes,andchecktheoillevelonthe

dipstickbywipingthedipstickcleanandtheninserting,

butnotscrewingin,theoilllcapintothehole.

Note:Max.ll:0.59l(20oz.)SAE10W -30detergent

oilwithanAPIserviceclassicationofSF,SG,SH,

SJ,SL,orhigher.

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrectas

showninFigure12.Ifyouoverlltheenginewith

oil,removetheexcessoilasdirectedinChangingthe

EngineOil(page15).

7.Installthedipstickandhandtightenitsecurely.

Important:

operating hour s

toChangingtheEngineOil(page15).

Change the engine oil after the r st 5

;changeityearlythereafter.Refer

9

Page 10

AdjustingtheCuttingHeight

WARNING

Adjustingthecuttingheightmaybringyouinto

contactwiththeblade,causingseriousinjury.

•Stoptheengineandwaitforallmovingparts

tostop.

•Weargloveswhilehandlingtheblade.

CAUTION

Iftheenginehasbeenrunning,themuferwillbe

hotandcanseverelyburnyou.Keepawayfromthe

hotmufer.

Adjustthecuttingheightasdesired.

1.Turnthefuelswitchtotheoffposition.

2.Disconnectthewirefromthesparkplug.

3.Tiltthemachineonitsleftside.

4.Wearingprotectivegloves,removethebladebolt

andspacers.

5.Repositionthespacerstothedesiredheight,reinstall

thebladeretainerandspacers(Figure13,),andtighten

theboltto25N-m(18ft-lbs).

Figure13

1.Cutterbar

2.Spacers

3.Bladeretainer

Note:Thelargespacermustbepositioneddirectly

belowtheimpelleratalltimes.

4.Bolt

5.Largespacer

10

Page 11

StartingtheEngine

OFF

ON

g017346

g017334

1

2

g017329

1.Placethethrottlecontroltothechokeposition,ensure

thatthefuelswitchisinthe‘On’position.

Figure14

2.Holdtheenginestophandleagainstthehandle.

Figure15

1.Handle2.Enginestophandle

Figure16

4.Pulltherecoilstarthandle.

Note:Ifthemachinedoesnotstartafterseveralattempts,

contactanAuthorizedServiceDealer.

3.Placeyourfootonthedeckandtiltthemachine

towardsyou(Figure16).

11

Page 12

AdjustingtheChoke

g017367

1

2

g017366

StoppingtheEngine

Usethethrottleassemblytoadjustthechoke(Figure17).

ServiceInterval:Beforeeachuseordaily

Tostoptheengine,releasethebladecontrolbar(Figure18).

Important:Whenyoureleasetheenginestophandle,

boththeengineandbladeshouldstopwithin3seconds.

Iftheydonotstopproperly,stopusingyourmachine

immediatelyandcontactanAuthorizedServiceDealer.

Figure18

Figure17

1.Chokeon2.Chokeoff

12

Page 13

OperatingTips

GeneralMowingTips

•Cleartheareaofsticks,stones,wire,branches,andother

debristhatthebladecouldhit.

•Avoidstrikingsolidobjectswiththeblade.Never

deliberatelymowoveranyobject.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelystoptheengine,disconnectthewirefrom

thesparkplug,andexaminethemachinefordamage.

•Forbestperformance,installanewbladebeforethe

cuttingseasonbegins.

•ReplacethebladewhennecessarywithaToro

replacementblade.

CuttingGrass

•Cutonlyaboutathirdofthegrassbladeatatime.Donot

cutbelowthe32mm(1.25inch)settingunlessthegrass

issparseoritislatefallwhengrassgrowthbeginstoslow

down.RefertoAdjustingtheCuttingHeight.

•Mowinggrassover15cm(6inches)inlengthisnot

recommended.Ifthegrassistoolong,themachinemay

plugandcausetheenginetostall.

•Mowonlydrygrassorleaves.W etgrassandleavestend

toclumpontheyardandcancausethemachinetoplug

ortheenginetostall.

WARNING

Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.Mowonlyindry

conditions.

•Alternatethemowingdirection.Thishelpsdispersethe

clippingsoverthelawnforevenfertilization.

•Ifthenishedlawnappearanceisunsatisfactory,tryone

ormoreofthefollowing:

–Replacethebladeorhavethebladesharpened.

–Walkataslowerpacewhilemowing.

–Raisethecuttingheightonyourmachine.

–Cutthegrassmorefrequently.

–Overlapcuttingswathsinsteadofcuttingafullswath

witheachpass.

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthelawnshows

throughthecutleafcover.Y oumayneedtomakemore

thanonepassovertheleaves.

•Slowdownyourmowingspeedifthemachinedoesnot

cuttheleavesnelyenough.

13

Page 14

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every100hours

Beforestorage

Yearly

MaintenanceProcedure

•Changetheengineoil.

•Checktheengine-oillevel.

•Ensurethattheenginestopswithin3secondsafterreleasingthebladecontrolbar.

•Cleangrassclippingsanddirtfromtheentiremachine.

•Cleangrassclippingsanddirtfromtheentiremachine.

•Checkthesparkplugandreplaceitifnecessary.

•Emptythefueltankbeforerepairsasdirectedandbeforeannualstorage.

•Cleanthecoolingsystem;removegrassclippings,debris,ordirtfromtheengine

aircoolingnsandstarter.Cleanthesystemmorefrequentlyindirtyorhigh-chaff

conditions.

•Replacetheairlter;replaceitmorefrequentlyindustyoperatingconditions.

•Changetheengineoil.

•Replacethebladeorhaveitsharpened(morefrequentlyiftheedgedullsquickly).

14

Page 15

PreparingforMaintenance

g017342

1

2

3

g017339

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthesparkplugwirefromthesparkplug

(Figure19)beforeperforminganymaintenance

procedure.

Figure20

Figure19

1.Sparkplugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthesparkplugwiretothesparkplug.

WARNING

Tippingthemachinemaycausethefuelto

leak.Gasolineisammable,explosiveand

cancausepersonalinjury.

Runtheenginedryorremovethegasoline

withahandpump;neversiphon.

1.Cover

2.Latchtabs

2.Openthecover.

3.Removethelter(Figure20).

4.Inspectthelter,andreplaceitifitisdamagedor

excessivelydirty.

5.Inspectthepaperairlter.

A.Ifthelterisdamagedoriswetwithoilorfuel,

replaceit.

B.Ifthelterisdirty,tapitonahardsurfaceseveral

timesorblowcompressedairlessthan207kPa

(30psi)throughthesideofthelterthatfaces

theengine.

Note:Donotbrushthedirtoffthelter;

brushingforcesdirtintothebers.

6.Removedirtfromtheaircleanerbodyandcoverusing

amoistrag.Donotwipedirtintotheairduct.

7.Insertthelterintotheaircleaner.

8.Installthecover.

3.Filter

ChangingtheEngineOil

Important:Alwaystipthemachineontoitsside

withthedipstickdown.

ReplacingtheAirCleaner

ServiceInterval:Yearly

1.Pressdownonthelatchtabsontopoftheaircleaner

cover(Figure20).

ServiceInterval:Aftertherst5hours

Yearly

1.Ensurethatthefueltankcontainslittleornofuelso

thatfueldoesnotleakoutwhenyoutipthemachine

ontoitsside.

2.Runtheengineafewminutesbeforechangingtheoil

towarmit.

Note:Warmoilowsbetterandcarriesmore

contaminants.

3.Disconnectthewirefromthesparkplug.Referto

PreparingforMaintenance.

4.Removethedipstick.

5.Tipthemachineontoitsside,withthedipstickdown,

todraintheusedoiloutthroughtheoillltube.

15

Page 16

6.Returnthemachinetotheoperatingposition.

1

2

3

g017332

7.Slowlypouroilintotheoilllhole,wait3minutes,

andchecktheoillevelonthedipstickbywipingthe

dipstickcleanandtheninserting,butnotscrewingin,

theoilllcapintothehole.

Note:Max.ll:0.59l(20oz.),type:SAE30orSAE

10W-30detergentoilwithanAPIserviceclassication

ofSF,SG,SH,SJ,SL,orhigher.

Note:Filltheenginecrankcasewithoiluntilthe

dipstickindicatesthattheengineoilleveliscorrectas

shownin(Figure21).Ifyouoverlltheenginewithoil,

removetheexcessoilasdirectedinstep5.

Figure21

1.Theoillevelisatits

maximum.

2.Theoillevelistoo

high—removeoilfrom

thecrankcase.

3.Theoillevelistoo

low—addoiltothe

crankcase.

Figure22

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto20N-m(15ft-lb).

8.Connectthewiretothesparkplug.

ReplacingtheBlade

ServiceInterval:Yearly

Important:

blades pr oper l y

areuncomfortableperformingthisprocedure,contact

anAuthorizedServiceDealer.

Examinethebladeswheneveryourunoutofgasoline.If

thebladeisdamagedorcracked,replaceitimmediately.If

thebladesedgesaredullornicked,havethemsharpenedor

replaced.

WARNING

Y ou will need a torque wr ench to install the

.Ifyoudonothaveatorquewrenchor

8.Installthedipstickandhandtightenitsecurely.

9.Disposeoftheusedoilproperlyatalocalrecycling

center.

ServicingtheSparkPlug

ServiceInterval:Every100hours

Checkthesparkplugafterevery100operatinghours.Usean

ChampionRN9YCsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodesbecause

gritenteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.76mm(0.030inch)(Figure

22).

Thebladeissharp;contactingthebladecanresult

inseriouspersonalinjury.

•Disconnectthewirefromthesparkplug .

•Weargloveswhenservicingtheblade.

1.Disconnectthesparkplugwirefromthesparkplug.

RefertoPreparingforMaintenance.

2.Tipthemachineontoitsside,withtheairlterup.

3.Useablockofwoodtoholdthebladesteady.

4.Removetheblade(turnthebladebolt

counterclockwise),savingallthemounting

hardware.

5.Installthenewblade(turnthebladeboltclockwise)

andallmountinghardware.

Important:Positionthecurvedendsoftheblade

topointtowardthemachinehousing.

6.Useatorquewrenchtotightenthebladeboltto

25N-m(18ft-lb).

16

Page 17

Important:Abolttorquedto25N-m(18ft-lb)is

verytight.Whileholdingthebladewithablock

ofwood,putyourweightbehindtheratchetor

wrenchandtightentheboltsecurely.Thisboltis

verydifculttoovertighten.

Storage

Storethemachineinacool,clean,dryplace.

PreparingtheMachinefor

CleaningtheMachine

ServiceInterval:Beforeeachuseordaily

Aftereachuse

WARNING

Themachinemaydislodgematerialfromunderthe

machinehousing.

•Weareyeprotection.

•Stayintheoperatingposition(behindthe

handle).

•Donotallowbystandersinthearea.

1.Tipthemachineonitsside.

2.Useabrushorcompressedairtoremovegrassand

debrisfromtheexhaustguard,thetopcowl,andthe

surroundingdeckareas.

Storage

WARNING

Gasolinevaporscanexplode.

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosurenear

anopename.

•Allowtheenginetocoolbeforestoringit.

1.Onthelastrefuelingoftheyear,addfuelstabilizerto

thefuelasdirectedbytheenginemanufacturer.

2.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

3.Primetheengineandstartitagain.

4.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

5.Disconnectthewirefromthesparkplug.

6.Removethesparkplug,add30ml(1oz.)ofoilthrough

thesparkplughole,andpullthestarterropeslowly

severaltimestodistributeoilthroughoutthecylinder

topreventcylindercorrosionduringtheoff-season.

7.Installthesparkplugandtightenitwithatorque

wrenchto20N-m(15ft-lb).

8.Tightenallnuts,bolts,andscrews.

17

Page 18

Troubleshooting

Problem

Theenginedoesnotstart

Theenginestartshardorlosespower

PossibleCauseCorrectiveAction

1.Thewireisnotconnectedtothespark

plug.

2.Thefuelcapventholeisplugged.2.Cleanthefuelcapventholeorreplace

3.Thesparkplugispitted,fouled,orthe

gapisincorrect.

4.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

1.Thefuelcapventholeisplugged.1.Cleanthefuelcapventholeorreplace

2.Theairlterelementisdirtyandis

restrictingtheairow.

3.Theundersideofthemachinehousing

containsclippingsanddebris.

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

5.Theengineoillevelistoolow,toohigh,

orexcessivelydirty .

6.Thefueltankcontainsstalefuel.6.Drainandllthefueltankwithfresh

1.Connectthewiretothesparkplug.

thefuelcap.

3.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

4.Drainand/orllthefueltankwith

freshgasoline.Iftheproblempersists,

contactanAuthorizedServiceDealer.

thefuelcap.

2.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

3.Cleanunderthemachinehousing.

4.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

5.Checktheengineoil.Changetheoilif

itisdirty;addordraintheoiltoadjust

theoilleveltotheFullmarkonthe

dipstick.

gasoline.

Theenginerunsrough

Themachineorenginevibrates

excessively

Thereisanunevencuttingpattern

1.Thewireisnotconnectedtothespark

plug.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

3.Theairlterelementisdirtyandis

restrictingtheairow.

1.Theundersideofthemachinehousing

containsclippingsanddebris.

2.Theenginemountingboltsareloose.2.Tightentheenginemountingbolts.

3.Theblademountingboltloose.3.Tightentheblademountingbolt.

4.Thebladeisbentorisoutofbalance.4.Balancetheblade.Ifthebladeisbent,

1.Youaremowinginthesamepattern

repeatedly.

2.Theundersideofthemachinehousing

containsclippingsanddebris.

3.Thebladeisdull.

1.Connectthewiretothesparkplug.

2.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

3.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

1.Cleanunderthemachinehousing.

replaceit.

1.Changethemowingpattern.

2.Cleanunderthemachinehousing.

3.Sharpenandbalancetheblade.

18

Page 19

Notes:

19

Page 20

ToroGeneralCommercialProductWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany ,pursuant

toanagreementbetweenthem,jointlywarrantyourToroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser .

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroW arrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-T oro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner .

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofToro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.Toromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedT oroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroW arrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheT oroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EPA)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty .RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.

374-0253RevC

Loading...

Loading...