Toro 02000 GROUNDS PRO 2000, 02001 GROUNDS PRO 2000, 02002 GROUNDS PRO 2000 Operator's Manual

Page 1

FORM NO. 3321-155 GB Rev A

© The TORO Company 1998

To understand this product, and for safety and

optimum performance, read this manual

before starting operation. Pay special attention

to SAFETY INSTRUCTIONS highlighted by

this symbol.

MODEL 02000—80001 AND UP

MODEL 02001—80001 AND UP

MODEL 02002—80001 AND UP

®

GROUNDS PRO

OPERATOR'S

MANUAL

™

2000

Page 2

2

FOREWORD

This operator's manual has instructions on safety, proper set-up and operation, adjustments and maintenance.

Therefore, anyone involved with the product, including the operator, should read and understand this manual. This

manual emphasizes safety, mechanical and general product information. DANGER, WARNING and CAUTION

identify safety messages. Whenever the triangular safety alert symbol appears, understand the safety message that

follows. For complete safety instructions, read pages 3–5. IMPORTANT highlights special mechanical information

and NOTE emphasizes general product information worthy of special attention.

Whenever you have questions or need service, contact your local authorized Toro Distributor. In addition to having

a complete line of accessories and professional turf care service technicians, the distributor has a complete line of

genuine TORO replacement parts to keep your machine operating properly. Keep your TORO all TORO. Buy

genuine TORO parts and accessories.

SAFETY INSTRUCTIONS 3–5

SYMBOL GLOSSARY 6–8

SPECIFICATIONS 9–10

BEFORE OPERATING 11

CONTROLS 14

OPERATION 16

MAINTENANCE 20

Training

1. Read the instructions carefully. Be familiar with

the controls and the proper use of the equipment.

2. Never allow children or people unfamiliar with

these instructions to use the lawn mower. Local

regulations may restrict the age of the operator.

3. Never mow while people, especially children, or

pets are nearby.

4. Keep in mind that the operator or user is

responsible for accidents or hazards occurring to

other people or their property.

5. Do not carry passengers.

6. All drivers should seek and obtain professional and

practical instruction. Such instruction should

emphasize:

• the need for care and concentration when

working with ride-on machines;

• control of a ride-on machine sliding on a slope

will not be regained by the application of the

brake. The main reasons for loss of control are:

– insufficient wheel grip;

– being driven too fast;

TABLE OF CONTENTS

Page 3

– inadequate braking;

– the type of machine is unsuitable for its

task;

– lack of awareness of the effects of ground

conditions, especially slopes;

– ##incorrect hitching and load distribution.

Preparation

1. While mowing, always wear substantial footwear

and long trousers. Do not operate the equipment

when barefoot or wearing open sandals.

2. Thoroughly inspect the area where the equipment is

to be used and remove all objects which may be

thrown by the machine.

3. WARNING—Petrol is highly flammable.

• Store fuel in containers specifically designed

for this purpose.

• Refuel outdoors only and do not smoke while

refueling.

• Add fuel before starting the engine. Never

remove the cap of the fuel tank or add petrol

while the engine is running or when the engine

is hot.

• If petrol is spilled, do not attempt to start the

engine but move the machine away from the

are of spillage and avoid creating any source of

ignition until petrol vapors have dissipated.

• Replace all fuel tanks and container caps

securely.

4. Replace faulty silencers.

Operation

1. Do not operate the engine in a confined space where

dangerous carbon monoxide fumes can collect.

2. Mow only in daylight or in good artificial light.

3. Before attempting to start the engine, disengage all

blade attachment clutches and shift into neutral.

4. Do not use on slopes of more than:

• Never mow side hills over 5°

• Never mow uphill over 10°

• Never mow downhill over 15°

5. Remember there is no such thing as a “safe” slope.

Travel on grass slopes requires particular care. To

guard against overturning:

• do not stop or start suddenly when going up or

downhill;

• engage the clutch slowly, and always keep the

machine in gear, especially when travailing

downhill;

• machine speeds should be kept low on slopes

and during tight turns;

• stay alert for bumps and hollows and other

hidden hazards;

• never mow across the face of the slope, unless

the lawn mower is designed for this purpose.

6. Use care when pulling loads or using heavy

equipment.

• Use only approved drawbar hitch points.

• Limit loads to those you can safely control.

• Do not turn sharply. Use care when reversing.

• Use counterweight(s) or wheel weights when

suggested in the instruction handbook.

7. Watch out for traffic when crossing or near

roadways.

8. Stop the blades rotating before crossing surfaces

other than grass.

9. When using any attachments, never direct discharge

of material toward bystanders nor allow anyone

near the machine while in operation .

10. Never operate the lawn mower with defective

guards, shields or without safety protective devices

in place.

11. Do not change the engine governor settings or

overspeed the engine. Operating the engine at

3

Safety Instructions

Page 4

excessive speeds may increase the hazard of

personal injury.

12. Before leaving the operator’s position:

• disengage the power take-off and lower the

attachments;

• change into neutral and set the parking brake;

• stop the engine and remove the key.

13. Disengage the drive to attachments when

transporting or not in use.

14. Stop the engine and disengage the drive to the

attachment

• before refueling;

• before removing the grass catcher;

• before making height adjustments unless the

adjustment can be made from the operator’s

position.

• before clearing blockages;

• before checking, cleaning or working on the

lawn mower;

• after striking a foreign object. Inspect the lawn

mower for damage and make repairs before

restarting and operating the equipment.

15. Reduce the throttle setting during engine runout

and, if the engine is provided with a shutoff valve,

turn the fuel off at the conclusion of mowing.

Maintenance and Storage

1. Keep all nuts, bolts and screws tight to be sure the

equipment is in safe working condition.

2. Never store the equipment with petrol in the tank

inside a building where fumes may reach an open

flame or spark.

3. Allow the engine to cool before storing in any

enclosure.

4. To reduce the fire hazard, keep the engine, silencer,

battery compartment and petrol storage area free of

grass, leaves, or excessive grease.

5. Check the grass catcher frequently for wear or

deterioration.

6. Replace worn or damaged parts for safety.

7. If the fuel tank has to be drained, this should be

done outdoors.

8. Be careful during adjustment of the machine to

prevent entrapment of the fingers between moving

blades and fixed parts of the machine.

9. On multi-bladed machines, take care as rotating one

blade can cause other blades to rotate.

10. When the machine is to be parked, stored or left

unattended, lower the cutting means unless a

positive mechanical lock is used.

Safety Instructions

4

Page 5

Safety Instructions

5

Page 6

6

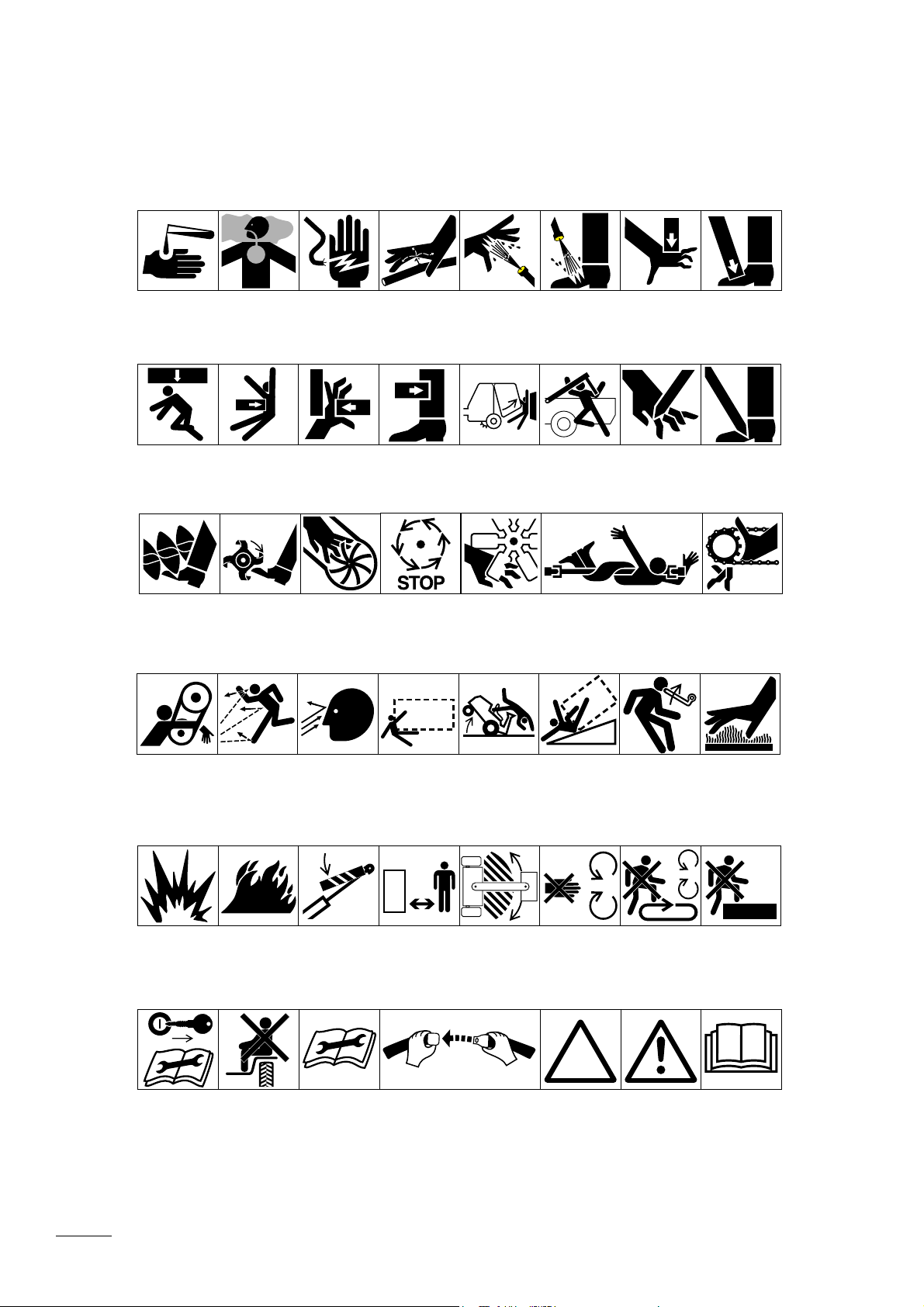

Symbol Glossary

Caustic liquids,

chemical burns to

fingers or hand

Crushing of

whole body,

applied from

above

Cutting or

entanglement of

foot, rotating auger

Poisonous

fumes or toxic

gases, asphyxiation

Crushing of

torso, force

applied from side

Severing of

foot, rotating

knives

Electrical shock,

electrocution

Crushing of fingers

or hand/, force

applied from side

Severing of

fingers or hand,

impeller blade

High pressure

fluid, injection

into body

force applied

from side

Wait until all

machine

components have

completely stopped

before touching them

High pressure

spray, erosion of

flesh

Crushing of

whole body

Severing of

fingers or hand,

engine fan

High pressure

spray, erosion of

flesh

Crushing of

head, torso and

arms

Whole body entanglement,

implement input drive line

Crushing of

fingers

or hand,

force

applied from

above

Cutting of

fingers or hand

Crushing of

toes or foot, force

applied from above

Cutting of footCrushing of leg,

Fingers or

hand entanglement, chain drive

Hand & arm

entanglement,

belt drive

Explosion Fire or open

Shut off engine

& remove key before

performing maintenance or repair work

Thrown or flying objects, whole

body exposure

flame

Riding on this

machine is allowed

only on a passenger seat & only if the

driver’s view is not

hindered

Thrown or

flying objects,

face exposure

Secure lifting

cylinder with locking

device before getting

in hazardous area

Consult

technical manual

for proper service

procedures

Runover/backover, (relevant

machine to appear

in dashed box)

Stay a safe

distance from

the machine

Fasten seat belts Safety alert

Machine tipping,

riding mower

Stay clear of

articulation area

while engine is

running

Machine rollover,

ROPS (relevant

machine to appear

in dashed box)

Do not open

or remove safety

shields while

engine is

running

triangle

Stored energy

hazard, kickback

or upward motion

Do not step on

loading platform if

PTO is connected to tractor

& engine is running

outline safety

alert symbol

Hot surfaces,

burns to fingers

or hands

Do not step

Read operator’s

manual

Page 7

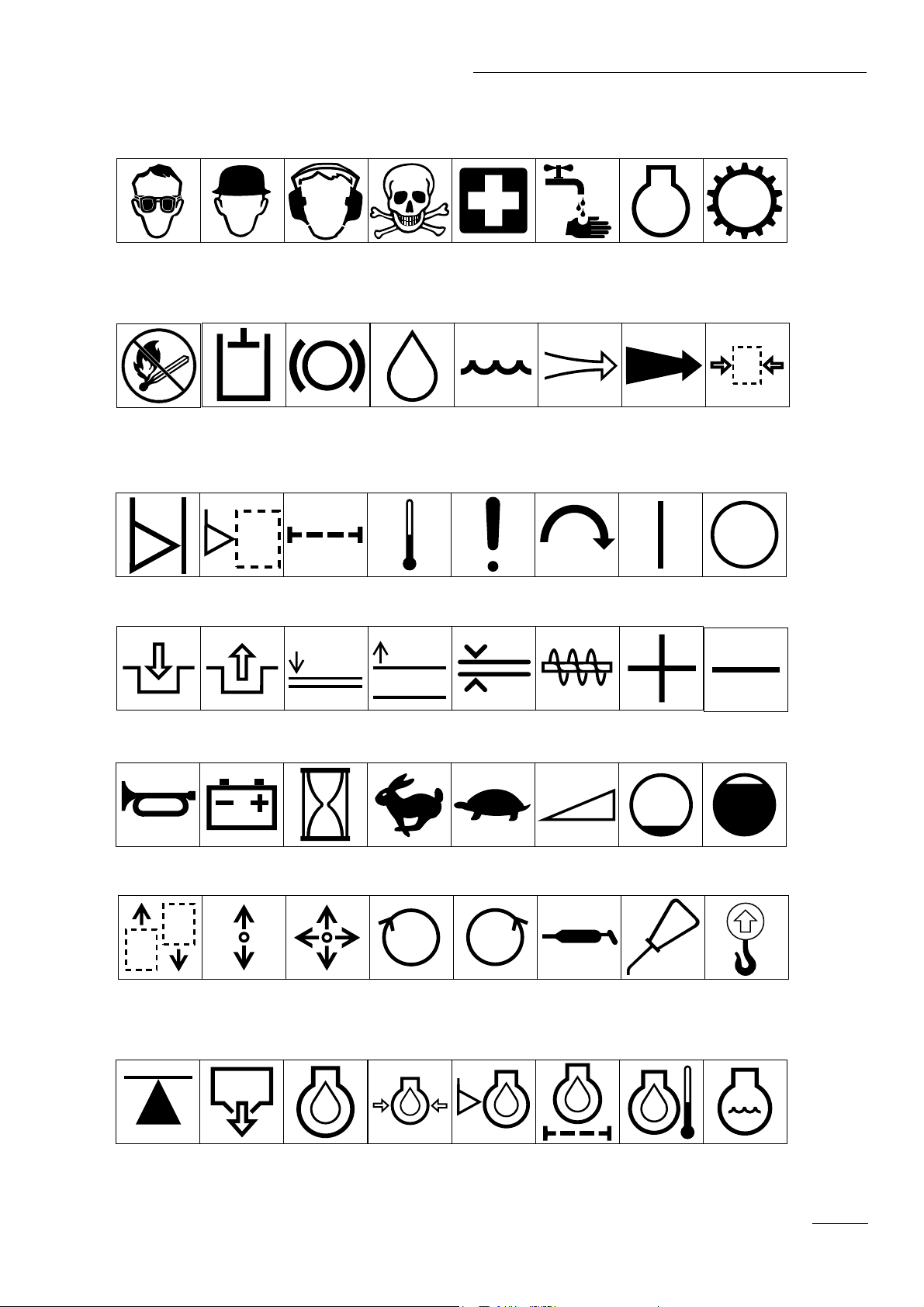

Safety Instructions

7

Eye protection

must be worn

Fire, open light

& smoking

prohibited

Level

indicator

Head protection

must be worn

Hydraulic

system

Liquid level Filter Temperature Failure/

Hearing

protection must

be worn

Brake system

Caution, toxic

risk

Oil Coolant (water) Intake air Exhaust gas Pressure

First aid

Malfunction

Flush with water Engine Transmission

Start switch/

mechanism

On/start Off/stop

Engage Disengage

Horn Battery charging

Machine travel

direction,

forward/rearward

Jack or

support point

condition

Control lever

operating

direction, dual

direction

Draining/

emptying

Attachment

lower

Hourmeter/elapsed

operating hours

Control lever

operating

direction, multiple

direction

Engine lubricating oil

Attachment

raise

Fast Slow Continuous

Clockwise

rotation

Engine lubricating

oil pressure

Spacing distance Snow thrower,

Counter-clockwise rotation

Engine lubricating

oil level

collector auger

variable, linear

Grease

lubrication

point

Engine lubricating

oil filter

Plus/increase/

positive polarity

Volume empty Volume full

Oil lubrication

point

Engine

lubricating oil

temperature

Minus/decrease/

negative polarity

Lift point

Engine coolant

Page 8

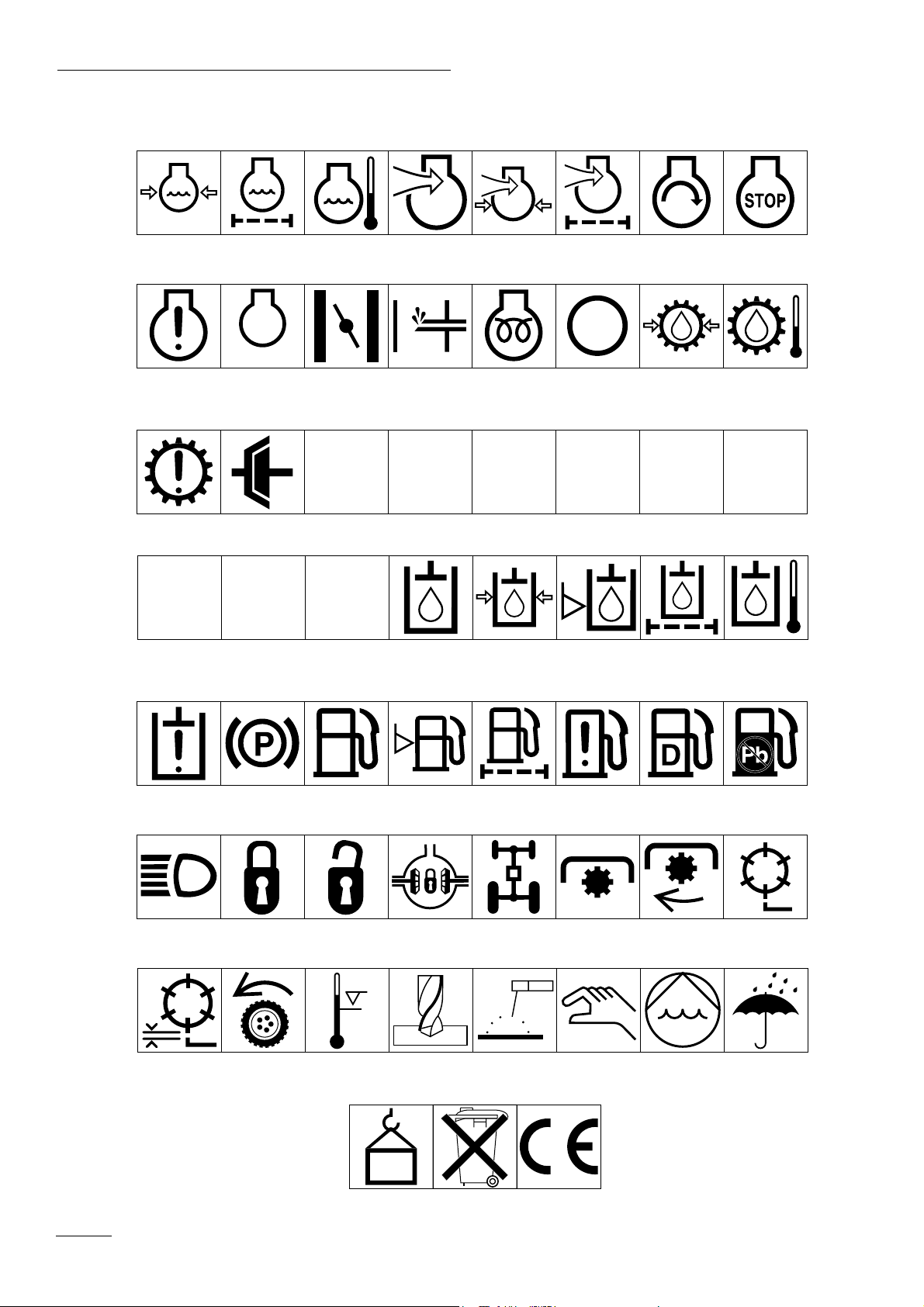

Safety Instructions

8

Symbol Glossary, continued

Engine coolant

pressure

Engine coolant f

ilter

n/min

Engine failure/

malfunction

Transmission

failure/malfunction

Engine rotational

speed/frequency

Clutch Neutral High Low Forward Reverse Park

231

First gear Second gear

Engine

lubricating oil

pressure

Choke Primer (start aid) Electrical preheat

Engine intake/

combustion air

Engine intake/

combustion air

pressure

(low t em perature

start aid)

Engine intake/

air filter

Transmission oil Transmission oil

Engine start Engine stop

pressure

Transmission oil

temperature

NHLFRP

Third gear (other #'s

may be used until

the maximum # of forward gears is reached.)

Hydraulic oil Hydraulic oil

Hydraulic oil

pressure

Hydraulic oil level Hydraulic oil filter

temperature

Hydraulic oil

failure/malfunction

Headlights Lock Unlock Differential lock 4-Wheel drive Power Take-Off Power Take-Off,

Reel cutting

element, height

adjustment

Parking brake Fuel Fuel level Fuel filter Fuel system

Traction Above working

temperature range

Drilling Manual metal arc

0430 weight Do not dispose

welding

in the garbage

failure/malfunction

Manual 0356 Water pump

CE logo

Diesel fuel Unleaded fuel

rotational speed

Reel cutting

element

0626 Keep dry

Page 9

Engine: Briggs & Stratton Vanguard, twin-cylinder, 4-

cycle, air-cooled, 11.9 kW @ 3600 rpm, 588 cc

displacement, governed speed of 3200 rpm. Mechanical

fuel pump, large-capacity dual element air cleaner. 2.5 l

oil capacity.

Fuel Capacity: 20 liter.

Traction Drive: Eaton model 11 hydrostatic transmission

integrally coupled to a Peerless model 1310 axle. Travel

speed range is 0–13.5 Km/h (0–8.5 mph) forward and

4.8 Km/h reverse (0–3 mph).

Controls: Foot-operated traction pedal. Hand-operated

throttle, choke, ignition switch, PTO switch, lift lever,

parking brake and seat adjustment.

Cutting Drive: Constant-tension belt drive system with

electric clutch utilizing a poly-V belt from the engine to

the jackshaft and BX section V-belt drive from the

jackshaft to each cutting unit.

Tires and Wheels: Two 23 x 8.5-12 front-drive turf tires

with 4-ply construction. Rear tires for the four-wheel

configuration, 16 x 6.5-6 turf tires with 4-ply

construction. Rear tire for the three-wheel configuration,

18 x 6.5-8 with 4-ply construction. 83–124 kPa inflation

pressure for all tires.

Electrical Features: 12-volt, 255 cold cranking amps at

180 C, 50-amp reserve capacity at 270 C. Battery, 16amp alternator, seat, traction, PTO and parking brake

interlock switches; electrical leads provided for optional

light and hour meter installations.

Steering: Pinion and gear sector with solid control link

to the rear steer assembly, 2.5 turns lock to lock.

Brakes: Service braking accomplished through

hydrostatic transmission. Parking brake controls

secondary shaft internal to the axle assembly and is

actuated by a control lever.

Main Frame: All-steel welded construction utilizing

tubular and formed sheet metal sections

Seat: Standard cushion seat and optional deluxe

suspension seat with arm rest and weight adjustment.

The seat is adjustable fore and aft. Arm rest kit also

available.

Lift System: Category “0” A-Frame mounting system

connected to the tractor via parallel linkage. One doubleacting 60 mm bore, 140-mm stroke hydraulic cylinder

receiving oil from hydrostatic transmission charge pump

via the control valve with float position. Maximum

operating pressure is 6895 kPa. When the traction unit is

equipped with cutting units, all three units are raised and

lowered via the single control lever. The lift system

works with the electric clutch to engage and disengage

the cutting units.

Overall Dimensions and Weight:

Wheel Tread Width 105.3 cm

Width across Front Tires 132 cm

Wheel Base 138.5 cm

Overall Length w/ Cutting Units Installed 229 cm

Overall Height 119 cm

Tractor Weight 50.4 kg

Weight with 5-Blade Fixed Cutting Units 440 kg

Weight with 8-Blade Floating Cutting Units 696 kg

Overall Width w/Fixed-Head Units 195 cm

Overall Width w/Floating Head Units 203 cm

Transport Width w/Fixed Head Units 140 cm

Transport Width w/Floating Head Units 200 cm

Optional Equipment:

Fixed Head Kit Model No. 02100

Floating Head Kit Model No. 02101

3-Wheel Axle Model No. 02200

4-Wheel Axle Model No. 02201

Full Roller Kit* Model No. 03440

Sectional Roller Kit* Model No. 03445

Wiehle Roller Kit* Model No. 03450

Skid Kit* Model No. 03446

Anti-Scalp Kit* Model No. 03447

Grass Basket Kit Model No. 02302

Power Take-off Kit Model No. 02301

Standard Seat Kit Model No. 30769

Deluxe Seat Kit Model No. 30772

Arm Rest Kit Model No. 30707

Roller Scraper Kit* Part No. 60-9560

Comb Kit* Part No. 67-9400

Rear Weight Part No. 24-5790

9

Specifications

Page 10

Rear Weight (2) Part No. 24-5780

Gauge Bar Kit Part No. 13-8199

Backlap Kit Part No. 84-5510

Tire Chains Part No. 82531

*3 per kit

SpeciÞcations

10

Page 11

11

CHECK THE ENGINE OIL (Fig. 1)

The engine is shipped with 1.7 1 of oil. However, check

the oil level before and after you first start the engine.

1. Position the machine on a level surface.

2. Unscrew the dipstick and wipe it with a clean cloth.

Screw the dipstick into the tube and make sure it is

seated fully. Unscrew the dipstick and check the oil

level. If it is low, remove the filler cap and add oil.

Use any high-quality detergent oil having the

American Petroleum Institute—API—”service

classification” SE, SF or SG. Recommended

viscosity (weight) is SAE 30. Refer to the Engine

Operator’s Manual for additional information.

Figure 1

1. Dipstick

2. Filler cap

3. Pour the oil into opening in the valve cover until the

oil level is up to the ”FULL’” mark on the dipstick.

Add the oil slowly and check the level often during

this process. DO NOT OVERFILL.

IMPORTANT Check the oil level every 8

operating hours or daily. Initially, change the oil

after the first 8 hours of operation; thereafter,

under normal conditions, change the oil every 50

hours and filter every 100 hours. However,

change it more often when operating the engine

in extremely dusty or dirty conditions.

5. Install the filler cap and the dipstick.

FILL THE FUEL TANK

THE TORO COMPANY STRONGLY RECOMMENDS

THE USE OF CLEAN, FRESH UNLEADED

REGULAR GASOLINE IN TORO GASOLINE

POWERED PRODUCTS. UNLEADED GASOLINE

BURNS CLEANER, EXTENDS ENGINE LIFE, AND

PROMOTES GOOD STARTING BY REDUCING THE

BUILD-UP OF COMBUSTION CHAMBER

DEPOSITS. LEADED GASOLINE CAN BE USED IF

UNLEADED IS NOT AVAILABLE.

NOTE: NEVER USE METHANOL, GASOLINE

CONTAINING METHANOL, GASOHOL

CONTAINING MORE THAN 10% ETHANOL,

GASOLINE ADDITIVES, PREMIUM GASOLINE, OR

WHITE GAS BECAUSE ENGINE FUEL SYSTEM

DAMAGE COULD RESULT.

Before Operating

Because gasoline is flammable, caution must be

used when storing or handling it. Do not fill the

fuel tank while the engine is running, hot or when

the machine is in an enclosed area. Vapors may

build up and be ignited by a spark or flame source

many feet away. DO NOT SMOKE while filling

the fuel tank to prevent the possibility of an

explosion. Always fill the fuel tank outside and

wipe up any spilled gasoline before starting the

engine. Use a funnel or spout to prevent spilling

gasoline before starting the engine and fill the

tank to about 3 cm from the top of the tank, not

the filler neck. Store gasoline in a clean safetyapproved container and keep the cap in place on

the container. Keep gasoline in a cool, wellventilated place; never in an enclosed area such as

a hot storage shed. To assure volatility, do not buy

more than a 30-day supply of gasoline. Gasoline

is a fuel for internal combustion engines;

therefore, do not use it for any other purpose.

Since many children like the smell of gas, keep it

out of their reach because the fumes are explosive

and dangerous to inhale.

DANGER

1

2

Page 12

Before Operating

12

Figure 2

1. Fuel tank cap

Fill the gasoline tank to the bottom of the filler

neck. DO NO OVERFILL. Install the cap.

CHECK THE HYDRAULIC SYSTEM

FLUID

The hydraulic system is designed to operate on SAE

10W-30 engine oil or, as a substitute, SAE 10W-40

engine oil. The reservoir is filled at the factory with 4.7 l

of 10W-30 engine oil. Check the oil level before first

starting the engine and daily thereafter.

1. Position the machine on a level surface and stop the

engine.

2. Remove the access panel to expose the hydraulic

system dipstick filler cap.

Figure 3

1. Access panel

3. Remove the dipstick cap from the filler neck and

wipe it with a clean cloth. Insert the dipstick cap

onto the filler neck; then remove it and check the oil

level.

Figure 4

1. Dipstick filler cap

4. If the level is not within 3 cm from the FULL mark

on the dipstick, add SAE 10W-30 engine oil to raise

the level to the FULL mark. Do not overfill.

5. Install the dipstick filler cap onto the filler neck.

6. Run the engine for one minute, recheck the oil level

and add more if needed.

CHECK TIRE PRESSURE

Correct air pressure in front and rear tires is 84–124 kPa.

LUBRICATE BEARINGS AND

BUSHINGS

The traction unit and cutting unit’s grease fittings must

be lubricated with No. 2 General Purpose Lithium Base

Grease.

CHECK REEL-TO-BEDKNIFE

CONTACT

Each day before operating, check reel-to-bedknife

contact.. There must be light contact across the full

length of the reel and bedknife. Refer to Adjusting the

Bedknife Parallel to the Reel.

1

1

1

Page 13

Before Operating

13

Figure 5

1. Bedknife adjusting knob

Page 14

Traction Pedal (Fig. 6)—The traction pedal: 1) makes

the machine move forward, 2) moves it backward and 3)

stops the machine. Using the heel and toe of your right

foot, depress the top of the pedal to move forward and

the bottom of the pedal to move backward or to assist in

stopping when moving forward. Also, allow the pedal to

move or move it to the neutral position to stop the

machine. Do not rest the heel of your foot on reverse

when going forward (Fig. 7).

Figure 6

1. Traction pedal

2. Parking brake

Figure 7

1. Forward

2. Reverse

Parking Brake (Fig. 6)—Whenever the engine is shut

off, the parking brake must be engaged to prevent

accidental movement of the machine. To engage the

parking brake, pull back on the lever. After releasing the

parking brake, move the mower slightly in reverse to

release the brakes before moving forward.

Throttle (Fig. 8)—The throttle is used to operate the

engine at various speeds. Moving the throttle upward

increases engine speed; downward decreases engine

speed. The throttle also controls the speed of the reel

blades and, with the traction pedal, controls the

machine’s ground speed.

Choke (Fig. 8)—To start a cold engine, close the choke

by moving the choke control upward to ON. After the

engine starts, regulate the choke to keep the engine

running smoothly. As soon as possible, open the choke

by pulling it downward to the OFF position. Awarm

engine requires little or no choking when starting.

Lift Lever (Fig. 8)—The lift lever has four positions:

LOWER, RAISE, NEUTRAL and FLOAT. To lower the

cutting units to the ground, move the lift lever forward.

To raise the cutting units, pull the lift lever rearward to

the RAISE position.

PTO Switch (Fig. 8)—The switch has two positions:

ENGAGE and DISENGAGE. Push the switch lever

forward to engage the cutting units. Pull the switch level

rearward to disengage the cutting units.

Figure 8

1. Throttle control

2. Choke control

3. PTO switch

4. Cutting unit lift lever

Ignition Switch (Fig. 9)—The ignition switch, used to

start and stop the engine, has three positions: OFF, RUN

and START. Turn the key clockwise—START

position—to engage the starter. Release the key when the

engine starts. The key will move automatically to ON.

To shut off the engine, turn the key counterclockwise to

OFF.

14

Controls

2

1

1

2

3

4

1

2

Page 15

Figure 9

1. Ignition switch

Seat Adjustments

Fore and Aft Adjustment—Move the lever on the side

of the seat outward, slide the seat to the desired position

and release the lever to lock the seat into position.

Deluxe Seat Adjustments (Fig. 10)

Fore and Aft Adjustment—Pull the handle on the left

side of the seat assembly outward. Release the handle to

lock the seat position.

Operator Weight Adjustment—Turn the knob

clockwise to increase tension, counterclockwise to

decrease tension.

Figure 10

1. Fore and aft lever

2. Weight adjustment lever

Cutting Unit Lock-up Lever (Fig. 11)—Locks the rear

cutting unit in the raised position.

Figure 11

1. Cutting unit lock-up lever

Fuel Valve (Fig. 12)—Close the fuel valve (located

under the fuel tank) when storing the machine.

Figure 12

1. Fuel valve

Controls

15

1

1

1

Page 16

STARTING AND STOPPING THE

ENGINE

1. Be sure the parking brake is set and the PTO switch

is in the DISENGAGED position.

2. Remove your foot from the traction pedal and make

sure the pedal is in the neutral position.

3. Move the choke lever to ON when starting a cold

engine—and the throttle lever to the half-throttle

position.

4. Insert the key into the ignition switch and turn it

clockwise to start the engine. Release the key when

the engine starts. Regulate the choke to keep the

engine running smoothly.

IMPORTANT, To prevent overheating the

starter motor, do not engage the starter longer

than 10 seconds. After 10 seconds of continuous

cranking, wait 60 seconds before engaging the

starter again.

5. When starting the engine for the first time, or after

overhauling the engine, operate the machine in

forward and reverse for one to two minutes. Also

operate the lift lever and PTO switch to be sure all

parts operate correctly.

Turn the steering wheel to the left and right to

check steering response. Then shut off the engine

and check for oil leaks, loose parts and any other

noticeable malfunctions.

6. To stop the engine, move the throttle downward to

the IDLE position, move the PTO switch to OFF

and turn the ignition key to OFF. Remove the key

from the switch to prevent accidental starting.

7. Set the parking brake.

8. Close the fuel valve before storing the machine.

OPERATING THE POWER TAKE

OFF (PTO)

The power take off (PTO) switch engages and

disengages power to the electric clutch.

Engaging the PTO

1. Release the parking brake.

2. Release pressure on the traction pedal to stop

movement.

3. To engage, lift the cover and move the PTO switch

forward to the “ON” position.

Disengaging the PTO

Closing the cover moves the PTO switch to the “OFF”

(disengaged) position.

DRIVING FORWARD OR

BACKWARD

Place the throttle control in the 3/4 position for best

performance.

Forward

1. To go forward, place your foot on the traction pedal.

2. Release the parking brake.

3. Slowly press on the upper pad of the traction

control to move forward.

Backward

1. To go backward, place your foot on the traction

pedal.

2. Release the parking brake.

16

Operation

Shut off the engine and wait for all moving parts

to stop before checking for oil leaks, loose parts

and other malfunctions.

CAUTION

Page 17

3. Slowly press on the lower pad of the traction pedal

to move rearward.

CHECK OPERATION OF

INTERLOCK SWITCHES

1. With the operator off the seat, the traction pedal in

neutral and the PTO switch in the disengage

position, the engine should start. If either the

traction pedal is depressed or the PTO switch is

engaged, the engine should stop. Correct the

problem if the system is not operating properly.

2. With the operator in the seat, the parking brake

engaged and the engine running, depress the

traction pedal either forward or reverse. The engine

should stop. Correct the problem if the system is not

operating properly.

3. With the operator in the seat, the parking brake

engaged and engine running, lower the cutting units

to the ground. Engage the PTO switch, the electric

clutch on the engine should engage. Raise the

cutting units, the PTO switch should disengage.

Correct the problem if the system is not operating

properly.

IMPLEMENT LIFT LEVER

Raising Attachments

Pull the implement lift lever rearward to raise an

attachment to the desired height.

Lowering Attachments

Push the implement lift lever forward to lower the

attachment.

NOTE: Hold the lift lever in the down position for 1–2

seconds after the attachment is down to allow the

attachment to float with changes in ground contour.

PUSHING OR TOWING THE

MACHINE

In an emergency, the traction unit can be pushed or

towed for a very short distance. TORO does not

recommend this as standard procedure.

IMPORTANT: Do not push or tow the traction unit

faster than 3 to 5 kmh because the transmission may

be damaged. If the traction unit must be moved a

considerable distance, transport it on a truck or

trailer.

1. To push or tow forward, the traction pedal must be

fully depressed forward.

2. To push or tow in reverse, the traction pedal must

be fully depressed in reverse.

TRAINING PERIOD

Before mowing with the Grounds Pro 2000, The TORO

Company suggests you find a clear area and practice

starting and stopping, raising and lowering the cutting

units, turning, etc. This training period will be beneficial

in gaining confidence in the performance of the Grounds

Pro 2000.

BEFORE MOWING

Inspect the area for debris and clear the area. Determine

the direction in which the area was last mowed. (Always

mow in an alternate pattern from the previous mowing,

so that the grass blades will be less apt to lay down and

therefore be difficult to gather between the reel blades

and bedknife.)

OPERATING CHARACTERISTICS

Practice operating the Grounds Pro 2000 and become

thoroughly familiar with it. Because of its hydrostatic

transmission, its characteristics differ from many turf

Operation

17

Do not disconnect the safety switches because they are

for the operator’s protection. Check switch operation

daily to be sure the system is operating correctly. If a

switch is not operating correctly, replace it before

operating the machine. Replace the switches every two

years to be sure of maximum safety.

CAUTION

Page 18

maintenance machines. Issues to consider when

operating are the traction drive, engine speed and the

load on the cutting units. Regulate the traction pedal to

keep engine rpm high and somewhat constant while

mowing to maintain adequate power for the traction and

cutting units.

Follow operating guidelines presented in this manual and

know how to operate the machine safely on all types of

terrain. Use the slope gauge, page 34, to determine slope

angles of questionable areas. Hills (or slopes) over 15

degrees should be traversed or mowed up and down, not

side to side and hills over 20 degrees should generally be

avoided unless special safeguards, skills and conditions

exist.

Always plan well ahead to avoid the need for sudden

stops, starts or turns. To stop, use the reverse pedal for

braking. Before stopping the engine, disengage all

controls, move the throttle to IDLE, and set the parking

brake.

CAUTION: This product may exceed noise levels of 85

dB(A) at the operator position. Ear protectors are

recommended for prolonged exposure to reduce the

potential of permanent hearing damage.

TRANSPORT OPERATION

Be sure the lift arms are fully raised and the transport

bracket is installed and secured with the retainer (Fig.

13). Also, lock the rear cutting unit in the raised position

(Fig. 14).

While operating on slopes and uneven terrain, always

reduce speed and use extreme caution before turning to

reduce risk of tipping or losing control. Watch carefully

and avoid holes in the terrain, sudden drop-offs and other

hazards. To prevent costly damage and down time,

familiarize yourself with the width of the Grounds Pro

2000. Do not attempt to pass between immovable objects

placed close together.

Figure 13

1. Transport bracket

Figure 14

1. Rear cutting unit lock-up lover

INSPECTION AND CLEAN-UP

AFTER MOWING

After mowing, thoroughly wash the machine with a

garden hose—without a nozzle—so excessive water

pressure will not cause contamination and damage seals

and bearings.

Note: Do not spray water directly onto a hot engine or

hot bearings.

Make sure the cooling fins and the area around the

engine air intake are kept free of dirt or grass clippings.

After cleaning, inspect the machine for possible

hydraulic fluid leaks, damage or wear to hydraulic and

mechanical components. Check the cutting units for

Operation

18

1

Page 19

sharpness and correct reel-to-bedknife adjustment.

CUTTING UNIT

CHARACTERISTICS

The single-knob bedknife adjustment system simplifies

the procedure for delivering optimum mowing

performance. The precise adjustment possible gives the

control to provide a continual self-sharpening action—

thus maintaining sharp cutting edges, good quality of

cut, and greatly reduced need for routine backlapping.

Also, the rear roller positioning system permits optimum

bedknife attitude and location for varying heights of cut

and turf conditions.

DAILY CUTTING UNIT

ADJUSTMENTS

Before each day’s mowing, or as needed, check each

cutting unit to verify correct bedknife-to-reel contact. Do

this even though quality of cut is acceptable.

1. Shut off the engine and lower the cutting units onto

a hard surface.

2. Slowly turn the reel in the reverse direction,

listening for reel-to-bedknife contact. If no contact

is evident, turn the bedknife adjusting knob

clockwise, one click at a time, until you feel or hear

light contact.

3. If you feel excessive contact, turn the bedknife

adjusting knob counterclockwise, one click at a

time, until no contact is evident. Then turn the knob

one click at a time clockwise, until light contact is

felt and heard.

IMPORTANT: Light contact is preferred at all

times, otherwise bedknife and reel edges will not

self-sharpen. If excessive contact is maintained,

bedknife and reel wear will accelerate. Uneven

wear can result, adversely affecting quality of

cut.

Note: As the reel blades run against the bedknife, a

slight burr will appear on the front cutting edge

surface over the full length of the bedknife.

Occasionally running a file across the front edge to

remove this burr will improve cutting.

After extended running, a ridge will eventually develop

at both ends of the bedknife. These must be rounded off

or filed flush with the cutting edge of bedknife to assure

smooth operation.

19

Operation

Page 20

20

Maintenance Procedure Maintenance Interval & Service

✝Initial break in at 8 hours

‡Initial break in at 50 hours

De-carbon the combustion chamber

Torque head bolts and adjust valves

Service the spark plugs

Change hydraulic fluid

‡Check engine RPM (idle and full throttle)

Maintenance Schedule

Replace moving hoses

Replace safety switches

Fuel tank—drain and flush

Replace the fuel filter

Hydraulic tank—drain and flush

Replace the hydraulic filter

Adjust the clutch

Change the hydraulic fluid filter

Service the air filter cartridge

✝ Change the engine oil filter

✝ Torque the wheel lug nuts

Replace the fuel filter

✝ Change the engine oil

Service the air filter pre cleaner

✝ Check alternator fan belt tension

Check battery fluid /connections

Lubricate grease fittings

Every

400

hours

Every

800

hours

Every

200

hours

Every

100

hours

Every

50

hours

Every

25

hours

Recommendations

Items are recommended every 2000 hours

or 2 years, whichever occurs first.

Daily Maintenance Checklist

✓ Safety Interlock Operation

✓ Brake Operation

✓ Engine Oil & Fuel Level

✓ Air Filter Pre-cleaner

✓ Unusual Engine Noises

✓ Unusual Operating Noises

✓ Hydraulic System Oil Level

✓ Hydraulic Hoses for Damage

✓ Fluid Leaks

✓ Tire Pressure

✓ Instrument Operations

✓ Reel-to-Bedknife Adjustment

✓ Height-of-Cut Adjustment

✓ Cutting Unit Belt Adjustment

Maintenance

Page 21

LUBRICATION

GREASING BEARINGS AND BUSHINGS

The traction unit and cutting unit’s grease fittings must

be lubricated regularly with No. 2 General Purpose

Lithium Base Grease. If the machine is operated under

normal conditions, lubricate bearings and bushings after

every 25 hours of operation. Bearings and bushings must

be lubricated daily when operating conditions are

extremely dusty and dirty. Dusty and dirty operating

conditions could cause dirt to get into the bearings and

bushings, resulting in accelerated wear. Lubricate grease

fittings immediately after every washing, regardless of

the interval listed.

The traction unit bearings and bushings, and the cutting

unit lubrication points that must be lubricated are shown

in the photos and illustrations.

Figure 15

Figure 16

Figure 17

Figure 18

Figure 19

Figure 20

21

Maintenance

Page 22

Figure 21

Figure 22

Figure 23

Figure 24

Figure 25

Figure 26

Maintenance

22

Page 23

Maintenance

23

CHANGING THE ENGINE OIL AND

FILTER (Fig. 26–28)

Change the oil and filter initially after the first 8 hours of

operation; thereafter change the oil every 50 hours and

filter every 100 hours.

Note: Change the oil and filter every 25 hours when

operating under heavy load or high ambient

temperatures.

1. Remove the drain plug and oil fill cap and let oil

flow into drain pan. When the oil stops, install the

drain plug.

Figure 27

1. Drain plug

2. Remove the oil filter. Apply a light coat of clean oil

to the new filter gasket.

Figure 28

1. Oil filter

3. Screw the filter on by hand until the gasket contacts

the filter adapter, then tighten

1

⁄2 to 3⁄4 turn further.

DO NOT OVER-TIGHTEN.

4. Add oil to the crankcase; refer to CHECK THE

ENGINE OIL.

5. Start the engine and check for leaks around the

filter.

6. Dispose of the oil properly.

SERVICING THE AIR CLEANER

(Fig. 29–30)

Service the foam pre-cleaner after every 50 operating

hours and the air cleaner cartridge after every 100

operating hours. Clean more often cleaning when

operating in dusty or dirty conditions.

1. Release the locking clips and remove the air cleaner

cover. Clean the cover thoroughly.

Figure 29

1. Air cleaner cover

Before servicing or making adjustments to the

machine, stop the engine and remove the key from the

switch.

CAUTION

1

1

1

Page 24

Maintenance

24

2. Remove the wing nut securing the elements to the

air cleaner body.

3. If the foam element is dirty, remove it from the

paper element. Clean thoroughly.

Figure 30

1. Foam element

2. Paper element

A. WASH the foam element in a solution of liquid

soap and warm water. Squeeze to remove dirt,

but do not twist because foam may tear.

B. DRY by wrapping in a clean cloth. Squeeze the

cloth and foam element to dry.

C. SATURATE the element with clean engine oil.

Squeeze element to remove excess oil and to

distribute the oil thoroughly. An oil damp

element is desirable.

4. When servicing the foam element, check condition

of the paper element. Clean by gently tapping it on

a flat surface or replace as required.

5. Install foam element, paper element and air cleaner

cover.

IMPORTANT: Do not operate the engine without air

the cleaner element because extreme engine wear and

damage will likely result.

ADJUSTING THE THROTTLE

CONTROL (Fig. 31)

Proper throttle operation depends upon proper

adjustment of the throttle control. Before adjusting the

carburetor, assure the throttle control is operating

properly.

1. Loosen cable clamp screw securing the cable to the

engine.

2. Move the remote throttle control lever forward to

FAST position.

3. Pull firmly on the throttle cable until back of swivel

contacts stop.

Figure 31

1. Throttle cable

2. Choke cable

4. Tighten cable clamp screw and check the engine

RPM setting.

High Idle: 3200 + 50 –100

Low Idle: 1400 ± 50

The engine must be running during adjustment of

the carburetor and speed control. To guard against

possible personal injury, shift into neutral, and

engage the parking brake. Keep hands, feet, face,

and other parts of the body away from the cutter

blades, and any rotating engine parts.

WARNING

1

1

2

2

Page 25

Maintenance

25

ADJUSTING THE CHOKE

CONTROL (Fig. 31)

1. Loosen the cable clamp screw securing the cable to

the engine.

2. Move the remote choke control lever forward to the

CLOSED position.

3. Pull firmly on the choke cable until the choke is

completely closed, then tighten the cable clamp

screw.

ADJUSTING CARBURETOR AND

SPEED CONTROL (Fig. 32)

IMPORTANT: Before the carburetor and speed

control are adjusted, the throttle and choke controls

must be correctly adjusted.

1. Start the engine and let it run at half throttle for five

minutes.

2. Move the throttle control to SLOW. Hold the

governor lever so the throttle lever is in the idle

position (against the idle stop screw) and adjust the

idle stop screw to 1400 ± 50 rpm by turning the

screw in or out. Check speed with a tachometer.

3. Turn the idle mixture screw slowly clockwise (lean

mixture) until engine speed just starts to decrease.

Note the needle’s position.

Now turn the idle mixture screw slowly

counterclockwise (rich mixture) until engine speed

just starts to increase. Note the needle’s position

Set the screw midway between the rich and lean

settings.

4. After the idle mixture has been adjusted, hold the

governor lever so the throttle lever is in the idle

position (against the idle stop screw) and readjust

the idle stop screw to bring speed to 1200± 50 rpm.

5. With the governor control lever in the governed idle

position (no tension on the high-speed spring) bend

the idle spring anchor tang to attain a governed idle

speed of 1400± 50 rpm.

.

Shown with Air Cleaner Removed

Figure 32

1. Governed idle spring anchor tang

2. High-speed spring anchor tang

6. Move the throttle control to FAST. Bend the high-

speed spring anchor tang to attain a high speed of

3200 + 50 –100 rpm.

REPLACING SPARK PLUGS

(Fig. 33)

Replace spark plugs after every 800 operating hours.

Recommended air gap is 7.5 mm (0.030”).

Correct spark plug to use is a Champion RC 12YC.

Note: Spark plugs usually last a long time; however,

plugs should be removed and checked whenever the

engine malfunctions,

1. Clean the area around spark plugs so foreign matter

cannot fall into the cylinder when a spark plug is

removed.

2. Pull spark plug wires off spark plugs and remove

the plugs from the cylinder head.

3. Check the condition of the side and center

electrodes and the center electrode insulator to

assure there is no damage.

IMPORTANT: A cracked, fouled, dirty or

otherwise malfunctioning spark plug must be

replaced. Do not sand blast, scrape, or clean

electrodes by using a wire brush because grit

may eventually release from the plug and fall

Page 26

Maintenance

26

into the cylinder. The result is usually a damaged

engine.

4. Set the air gap between the center and side of the

electrodes at 0.030”. Install a correctly gapped

spark plug with gasket seal and tighten the plug to

200 in-lb. If a torque wrench is not used, tighten the

plug firmly.

Figure 33

CHECKING THE PARKING BRAKE

1. Park the machine on a level surface, disengage the

PTO switch, set the parking brake and turn the

ignition key to “OFF” to stop the engine. Remove

the key.

2. The drive wheels must lock when the brake is

applied. Adjustment is required if the wheels turn

and do not lock; refer to Adjusting the Brake.

3. Release the brake; wheels should turn freely.

4. If both conditions are met, no adjustment is

required.

IMPORTANT: With the parking brake released, the

drive wheels must turn freely. If brake action and

free wheel rotation cannot be achieved, contact your

service dealer immediately.

ADJUSTING THE PARKING

BRAKE (Fig. 34)

If drive wheels do not turn when the brake lever is in the

OFF position, or the brake does not hold when the lever

is in the ON position, an adjustment is required.

1. Move the brake lever to the ON position.

2. Measure the distance between the disc brake

actuating arm and the stop pin on the axle bracket

assembly. Distance should be less than 6 mm.

3. If the distance is greater than 6 mm, tighten the

locknut to decrease distance.

4. With the brake lever OFF, check the clearance

between the brake pads and the disc with a feeler

gauge. Correct clearance is approximately 2.5 mm

(.010 in.).

5. The actuating arm should be no more than 10 mm

away from STOP with the brake lever in the OFF

position.

Figure 34

1. Brake actuating arm

2. Stop pin

3. Locknut

4. Disc pad

5. Disc

6. Check the brake operation again; refer to Checking

the Brake.

7. Check adjustment. Drive wheels should turn freely

when the brake lever is in the OFF position.

REPLACING THE FUEL FILTER

(Fig. 35)

Replace the fuel filter after every 100 operating hours or

yearly, whichever occurs first.

Note: Never install a dirty filter if it is removed from the

fuel line.

Page 27

Maintenance

27

1. Disengage the PTO switch, set the parking brake

and turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Close the fuel valve.

3. Loosen hose clamps and slide them up the hose,

away from the filter.

Figure 35

1. Fuel filter

2. Fuel line

3. Hose clamp

4. Remove the filter from the fuel lines.

5. Install a new filter, if the filter has an arrow, install

it with the arrow pointing toward the carburetor.

6. Move the hose clamps close to the filter and tighten.

7. Open the fuel shut off valve.

ADJUSTING TOE- IN & STEERING

STOPS (Fig. 36)

(4-Wheel Axle Only)

1. Make sure both tie rods are adjusted to the same

length.

2. Measure toe-in distance (at axle height) at front and

rear of steering tires. Front measurement must be

2–4 mm less than the rear measurement.

3. Loosen the jam nuts and rotate the tie rod to adjust

the front of the tires in or out.

Figure 36

1. Tie rod

2. Steering stop

4. Loosen the jam nuts and adjust the left and right

steering stops to allow 6-mm clearance for steering

arm in a full left and full right turn. Tighten jam

nuts.

ADJUSTING THE TRANSMISSION

FOR NEUTRAL (Fig. 37)

With the machine on a level surface and the parking

brake disengaged, the machine must not creep when the

traction pedal is released. If it does creep, an adjustment

is required.

1. Park the machine on a level surface, lower the

cutting unit and shut off the engine. Disengage the

PTO switch and engage the parking brake.

2. Jack up the front of the machine until the tires are

off the shop floor. Support the machine with jack

stands to prevent it from falling accidentally.

3. Loosen the lock nut on the adjustment cam.

4. Start the engine and turn the adjusting cam in either

direction until the wheels stop rotating.

The engine must be running so final adjustment of

the traction adjustment cam can be performed. To

guard against possible personal injury, keep hands,

feet, face and other parts of the body away from

the muff muffler other hot parts of the engine, and

other rotating parts.

WARNING

2

1

Page 28

5. Stop the engine and tighten the lock nut to secure

adjustment.

6. Start the engine and check adjustment. Repeat

adjustment if necessary.

7. Stop the engine. Remove the jack stands and lower

the machine to the shop floor. Test drive the

machine to be sure it does not creep.

Figure 37

1. Adjustment cam

2. Locknut

ADJUSTING THE ELECTRIC

CLUTCH (Fig. 38)

The clutch is adjusted to ensure proper engagement and

braking action.

1. Disengage the PTO switch, set the parking brake,

and turn the ignition key to “OFF” to stop the

engine. Remove the key.

2. Adjust the clutch by tightening or loosening the

lock nuts on the flange studs.

3. Check adjustment by inserting a feeler gauge

through the slots next to the studs.

4. The correct disengaged clearance between the

clutch plates is 0.23-0.30 mm. It will be necessary

to check this clearance at each of the three slots to

ensure the plates are parallel to each other.

Figure 38

1. Clutch

2. Locknut

3. Adjustment slot

CHANGING HYDRAULIC SYSTEM

OIL (Fig. 39–40)

The hydraulic system oil must be changed after every

400 hours of operation or yearly, whichever comes first.

The reservoir has a capacity of 4.7 l.

1. Park the machine on a level surface, lower the

cutting units, engage the parking brake, and shut off

the engine.

2. Clean the area around the hydraulic oil filter and

remove the filter from the filter housing.

3. Disconnect the tube and hose assembly from the

reservoir and allow the oil to flow into a drain pan.

Figure 39

1. Hydraulic filter

Maintenance

28

2

1

1

1

2

3

Page 29

Figure 40

1. Reservoir

2. Hose assembly

Note: To drain the oil remaining in the system,

disconnect the spark plug wires and crank the

engine for 15 seconds. This will pump the

remaining oil out of the system. Do not crank the

engine for more than 15 seconds.

4. Install the new hydraulic filter to the filter housing.

5. Install the tube assembly and hose assembly to the

reservoir.

6. Fill the reservoir to the proper level; refer to Check

Hydraulic System Fluid.

7. Place all controls in the neutral or disengaged

position and start the engine. Run the engine at the

lowest possible RPM to purge air from the system.

8. Run the engine until the lift cylinder extends and

retracts and forward and reverse wheel motion is

achieved.

9. Stop the engine and check the oil level; add oil if

necessary.

10. Check all connections for leaks.

CHANGING THE HYDRAULIC OIL

FILTER (Fig. 40)

The hydraulic oil filter must be serviced at regular

intervals. The intervals are: initially, after the first 8

hours of operation, and thereafter every 200 hours of

operation or yearly, whichever comes first. Use a

genuine TORO oil filter for replacement.

1. Remove the hydraulic oil filter from the mounting

head.

2. Apply a film of oil on the gasket. Install the filter by

hand until the gasket contacts the mounting head;

then tighten the filter an additional 3/4 turn.

3. Start the engine and check for oil leaks. Allow the

engine to run for about two minutes to purge air

from the system. Then shut off the engine.

4. Check the level of oil; refer to Check the Hydraulic

System Fluid.

CHANGING FRONT AXLE OIL

(Fig. 41)

After every 400 hours of operation, change the oil in the

front axle.

1. Drive the machine for five minutes before changing

oil to warm the axle oil. Warm oil flows more freely

and carries more contaminants than cold oil.

2. Clean the area around the drain plug and place a

drain pan below the drain plug on axle.

Figure 41

1. Drain plug

2. Fill plug

Remove the drain plug and allow the oil to flow into

drain pan. After the oil is drained, reinstall drain plug.

Remove the fill plug and fill to plug level with ISO

150/220 (SAE EP-90) oil (approximately 44 oz.).

Maintenance

29

1

2

1

2

Page 30

ADJUSTING THE CUTTING UNIT

BELTS (Fig. 42)

Make sure cutting unit belts are properly tensioned to

assure correct operation and prevent unnecessary wear.

Check all belts often.

1. The cutting unit drive belts should have a maximum

deflection of 12 mm with a 3.7 kg load applied.

2. Loosen the jam nut on the front end of the belt

tension rod. Turn the rod to lengthen or shorten the

rod to the desired length. Then tighten the jam nut.

Figure 42

1. Belt tension rod

BATTERY CARE

1. Battery electrolyte level must be maintained and the

top of the battery kept clean. If the Grounds Pro

2000 is stored in a location where temperatures are

extremely high, the battery will run down more

rapidly than if is stored in a cooler location.

2. Check the electrolyte level every 25 operating hours

or, if the machine is in storage, every 30 days.

3. Maintain cell level with distilled or demineralized

water. Do not fill cells above the bottom of the split

ring inside each cell.

4. Keep the top of the battery clean by washing it

periodically with a brush dipped in ammonia or

bicarbonate of soda solution. Flush the top surface

with water after cleaning. Do not remove the fill

caps while cleaning.

5. Battery cables must be tight on terminals to provide

good electrical contact.

6. If corrosion occurs at terminals, disconnect the

cables—negative (–) cable first—and scrape the

clamps and terminals separately. Reconnect the

cables—positive cable first—and coat the terminals

with petroleum jelly.

WIRE HARNESS SERVICE

Prevent corrosion of wiring terminals by applying Grafo

11 2X (Skin-over) grease, Toro Part No. 505-47, to the

inside of all harness connectors whenever the harness is

replaced.

Whenever working with the electrical system, always

disconnect the battery cables, negative (–) cable first to

prevent possible wiring damage from electrical shorts.

Before welding on the machine, disconnect ground cable

from the battery to prevent damage to the electrical

system.

Maintenance

30

1

Since the gasses from the battery and the gasoline

fumes are explosive, keep open flames and

electrical sparks away from the area; do not

smoke.

CAUTION

Page 31

BACKLAPPING THE CUTTING

UNITS

The cutting units may be backlapped on the machine.

Backlap Kit, Part no. 84-5510 is available from your

Authorized TORO Distributor.

Backlap according to procedures in the Toro Sharpening

Reel and Rotary Mowers Manual Form No. 80-300 PT.

SETTING HEIGHT OF CUT AND

LEVELING THE REAR ROLLER

(Floating Cutting Units)

Note: For best results, perform adjustments on the

cutting units when they are removed from traction unit.

1. Position the cutting unit on a flat level table or

board.

2. Slightly loosen the nut securing each roller bracket

to the angle bracket.

3. Adjust the support capscrew to achieve 25 mm ±2

mm dimension between the height-of-cut support

and the front roller bracket (2 places).

4. Adjust the support capscrew to achieve 16 mm +2

mm dimension between the height-of-cut support

and the rear roller bracket (2 places).

5. Remove the hairpin cotters securing the rear height-

of-cut pins and install them in the 1/2" setting as

shown on the height-of-cut plate.

Figure 43

1. Roller bracket

2. Angle bracket

3. Height-of-cut pin

4. Support capscrew

5. Locknuts

6. Remove the hairpin cotters securing the front

height-of-cut pins and install them in the 6 mm

setting as shown on height-of-cut plate to allow

clearance between the roller and table.

7. Position a 2 cm or thicker bar under the reel blades

and against the front face of the bedknife. Make

sure the bar covers the full length of the reel blades.

8. Check that the rear roller is level by inserting a

piece of paper under each end of the roller.

9. Level the roller by adjusting the appropriate support

capscrew on the rear roller supports until the roller

is parallel and the entire length of the roller touches

the table.

10. When the roller is level, adjust both rollers to the

desired height-of-cut pins. Tighten the nuts securing

the roller brackets.

11. Verify that the rollers are level and the bedknife is

parallel to the surface.

(Fixed Cutting Units)

Note: For best results, perform adjustments to the

cutting units when they are mounted on the traction unit.

1. Position the cutting unit on flat level surface or

Maintenance

31

Be careful when lapping the reel because contact

with the reel or other moving parts can result in

personal injury.

CAUTION

Under no circumstances use a short-handled

paintbrush. APart #29-9100 handle assembly

complete—or individual parts—are available from

your local Authorized TORO Distributor.

DANGER

4

1

2

5

16 mm

3

2.5 cm

Page 32

board.

2. Slightly loosen the nuts securing the roller brackets

to the angle brackets.

3. Adjust the support capscrews to achieve16 mm+ 2

mm dimension between the height-of-cut support

and roller bracket (2 places).

4. Remove the hairpin cotters securing the height-of-

cut pins and install them in the hole at the desired

setting shown on the height-of-cut plate

Figure 44

1. Roller bracket

2. Angle bracket

3. Height-of-cut pin

4. Support capscrew

5. Skid

5. Use a gauge block with a thickness equal to the

desired height of cut and position it against the front

edge of the bedknife at one end. Turn the support

capscrew to adjust the height of the bedknife equal

to the gauge block.

6. Repeat the procedure at the other end; then recheck

the original end.

7. Tighten the nuts securing the roller brackets.

8. Height of cut may be changed by re-positioning the

height-of-cut pins to the desired setting.

9. Adjust the skids 1/8" to 1/4" higher than the height-

of-cut setting.

ADJUSTING THE BEDKNIFE

PARALLEL TO THE REEL

(Fig. 45-46)

(Floating or Fixed Cutting Units)

1. Make sure the reel contact is removed by turning

the bedknife adjustment knob counterclockwise

(Fig. 45). Tip the cutting unit to gain access to the

reel and bedknife (Fig. 46).

Figure 45

1. Bedknife adjusting screw

2. On either end of the reel, insert a long strip of dry

newspaper between the reel and bedknife. While

slowly rotating the reel into the bedknife, turn the

bedknife adjusting knob clockwise, one click at a

time until the paper is pinched lightly, which results

in a slight drag when the paper is pulled.

3. Check for light contact at the other end of reel using

paper. If light contact is not evident, proceed to next

step.

4. Loosen the (2) carriage bolts on the bedbar adjuster

(Fig. 46).

5. Adjust the nuts to move the bedbar adjuster up or

down until the paper is pinched along the entire

bedknife surface, when the bedknife adjustment

knob is adjusted to no more than two clicks beyond

first contact of the reel bedknife.

6. Tighten the nuts and carriage bolts and verify

adjustment.

Maintenance

32

1

Page 33

Figure 46

Figure 47

1. Bedbar adjuster

2. Carriage bolts

3. Adjustment nuts

VERIFYING HEIGHT-OF-CUT

SETTING (Fig. 48)

(Floating Cutting Unit)

1. On a gauge bar, set the head of the screw to the

desired height of cut. This measurement is from the

bar face to the underside of the screw head. Agauge

bar (Toro Part No. 13-8199) may be obtained from

your local TORO Distributor.

Figure 48

1. Gauge bar

2. Front roller support screw

2. Slightly loosen the nut securing each front roller

bracket to the angle bracket.

3. Place the bar across the front and rear rollers and

adjust the front roller support screws until the

underside of the screw head engages the bedknife

cutting edge. Do this on both ends of the reel.

4. Tighten the nuts securing the roller brackets.

IDENTIFICA TION AND ORDERING

MODEL AND SERIAL NUMBER

The mower has two identification numbers: a model

number and a serial number. The two numbers are

stamped into a plate that is riveted to the frame. In any

correspondence concerning the mower, supply the model

and serial numbers to assure that correct information and

replacement parts are obtained.

Note: Do not order by reference number if a parts

catalog is being used; use the part number.

To order replacement parts from an Authorized TORO

Service Dealer, supply the following information:

1. Model and serial numbers of the mower.

2. Part number, description and quantity of part(s)

desired.

Maintenance

33

Page 34

Maintenance

34

Fold along line

Align this edge with a vertical surface

(Tree, building, fence post, pole, etc.

Example:

Compare slope

with folded edge.

This is a 20° Slope

This is a 15° Slope

15° and 20° Slope Chart

Page 35

Page 36

Loading...

Loading...