Toro Reelmaster 5 Blade, Reelmaster 7 Blade, Reelmaster 11 Blade, 01007, 01005 Operator's Manual

...Page 1

Form No. 3312–270 Rev. H

Reelmaster 5, 7, & 11 Blade

Model No. 01005—Serial No. 40001 thru 70001 and Up

Model No. 01007—Serial No. 40001 thru 70001 and Up

Model No. 01011—Serial No. 40001 thru 70001 and Up

Operator ’s Manual

English (EN)

Page 2

Contents

Introduction

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 3. . . . . . . . . . . . . . . . . . . . .

Optional Equipment 4. . . . . . . . . . . . . . . . . . . . . . .

Setting Up Instructions 5. . . . . . . . . . . . . . . . . . . . . . . .

Remove Mower From Carton 5. . . . . . . . . . . . . . . .

Check Wheel Hubs And Install Wheels 5. . . . . . . .

Gear Case Oil 5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Critical Adjustments 6. . . . . . . . . . . . . . . . . . . . . . . . . .

Check Reel Bearings And Mower Fasteners 6. . . .

Parallel Bedknife To Reel 6. . . . . . . . . . . . . . . . . . .

Set Height Of Cut 7. . . . . . . . . . . . . . . . . . . . . . . . .

Reel Bearing Adjustment 7. . . . . . . . . . . . . . . . . . .

Operating Instructions 8. . . . . . . . . . . . . . . . . . . . . . . .

Adjust Bedknife To Reel For Light Contact 8. . . . .

Causes of Poor Quality of Cut 9. . . . . . . . . . . . . . .

Maintenance 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grinding 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lapping 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bedknife Replacement 11. . . . . . . . . . . . . . . . . . . . .

Reel, Roller and Wheel Bearing Adjustment 11. . . .

Mower Servicing Procedure Disassembly 12. . . . . .

Gear Case And Frame Assembly 16. . . . . . . . . . . . .

Roller Disassembly 17. . . . . . . . . . . . . . . . . . . . . . . .

Roller Assembly 17. . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro General Commercial Products Warranty 20. .

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. The two numbers are

stamped on a plate which is located on the cross tube.

Write the product model and serial numbers in the space

below:

Model No.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

1983, 2003 The The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses two other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

All Rights Reserved

Printed in the USA

2

Page 3

Specifications

General Specifications

Reel Drive

Reduction, Reel to

Wheels

Welded Reel

Bedknife & Bedbar

Bedknife to Reel

Adjustment

Wheels and Tires

Differential Disengaging over–running idler gear in gear train.

Width of Cut 30” (0.762 m)

Reel driven by wheels 75T ring gear to 10T pinion through 14T disengaging idler

gear.

7.5:1

Medium carbon steel, induction hardened blades are welded to seven steel spiders

which are mounted on a 1–1/2” (38 mm) diameter shaft. Tapered roller bearings

support reel shaft, and an adjusting nut compensates for bearing wear. Diameter of

11 blade reel is 7 inches (17.8 cm). 5 and 7 blade reels are 8” inches (20.3 cm).

Single edge high carbon steel knife attached to a fabricated steel bar; single screw

adjustment on adjustable rod ends.

Bedknife adjusts against reel, with positive adjustment control knob located at

center of bedbar. Adjustment knob contains detent with .001 inch (0.0254 mm)

movement of bedknife for each indexed position. Pivot point at top of bedbar is

greasable.

16” (0.406 m) diameter pneumatic wheels with tire and tube, studded tread,

stamped steel wheel and cast iron hubs; 16” (0.406 m) diameter semi pneumatic

tires with stamped steel wheels and cast iron hubs; 16” (0.4(06 m) diameter cast

iron wheels – one piece construction; 16” (0.406 m) diameter low profile

semi–pneumatic tires with stamped steel wheels and cast iron hubs; 18” (0.457 m)

semi–pneumatic tires with stamped steel wheels and cast iron hubs.

Height of Cut

Frequency of Clip

Chassis

Roller

11 Blade – .38 inches (9.5 mm) to 1.25 inches (32 mm) with 16” (0.406 m) dia.

wheel.

7 Blade – .75 inches (19 mm) to 1.75 inches (45 mm) with 16” (0.406 m) dia. wheel.

5 Blade – 1.25 inches (32 mm) to 2.25 inches (57 mm) with 16” (0.406 m) dia.

wheel

5 Blade – 2.00 inches (50 mm) to 3.00 inches (76 mm) with 18” (0.457 m) dia.

wheel

All adjustment are made in .040 inch increments.

11 Blade w/16” wheels – .58” clip (68 cuts per meter)

7 Blade w/16” wheels – .91” clip (43 cuts per meter)

5 Blade w/16’ wheels – 1.28” clip (31 cuts per meter)

5 Blade w/18” wheels – 1.51” clip (26 cuts per meter)

Ribbed cast iron gear cases with tubular cross members. Front cross member

provides easy attachment for the mower to the Reelmaster Universal and

Reelmaster Transport frames.

3–1/2” (88.9 mm) O.D. Iron pipe running on taper bearings double lip oil seal with

wear sleeves. Grease fittings provided.

3

Page 4

General Specifications (continued)

Width

41–1/2” (1.054 m) with iron wheels, 45” (1. 1 43 m) with semi–pneumatic tires.

Height

General Specifications

(approx.)

Note: Specifications and design subject to change without notice.

16” (0.406 m) or 18” (0.457 m) depending on tires.

Weight

11 Blade – 252 lbs. (114 kg)

7 Blade – 248 lbs. (112 kg)

5 Blade – 243 lbs. (110 kg)

All with 16” (0.406 m) semi–pneumatic tires (without draw bars).

Optional Equipment

16” (0.406 m) cast iron wheel Model No. 01336

16” (0.406 m) pneumatic tires Model No. 01323

16” (0.406 m) semi–pneumatic low

profile

18” (0.457 m) semi–pneumatic

tires

Roller Scraper Kit Part No. 47–4540

Grass Dispersion Shield Kit

(5 & 7 Blade)

Grass Dispersion Shield Kit

(11 Blade)

Adapter Kit Model No. 01050

Universal Frame Adapter Kit Part No. 47–2220

Model No. 01304

Model No. 01035

Part No. 51–0800

Part No. 47–5390

4

Page 5

Setting Up

Instructions

Remove Mower From Carton

1. Slit four corners of carton so sides lie flat.

2. Remove shipping caps from wheel hubs.

Note: Keep the shipping caps. They can be installed on

wheel hubs to prevent grinding dust from entering wheel

bearing whenever reel is ground.

4. Install drive wheels with capscrews and lockwashers

(Fig. 2). Do not try to install wheels over the shipping

caps.

Check Wheel Hubs And Install

Wheels

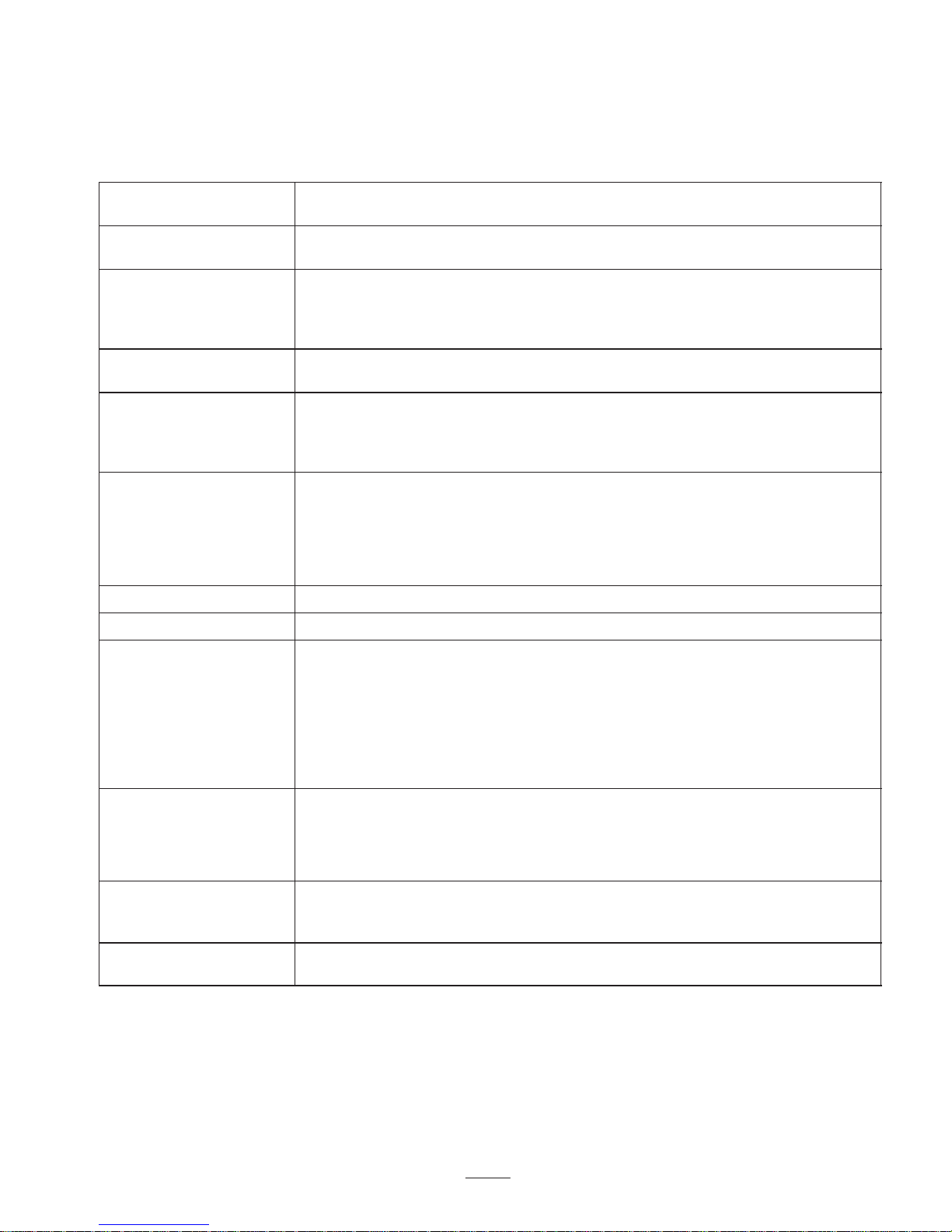

1. Rotate wheel hub (Fig. 1) to check bearing adjustment.

A slight drag must be felt when hub is rotated. If drag is

not evident, tighten wheel hub nut (Fig. 1) until slight

drag is felt when hub is rotated.

Figure 1

1. Wheel hub

2. Wheel hub nut

3. O–ring

Figure 2

Gear Case Oil

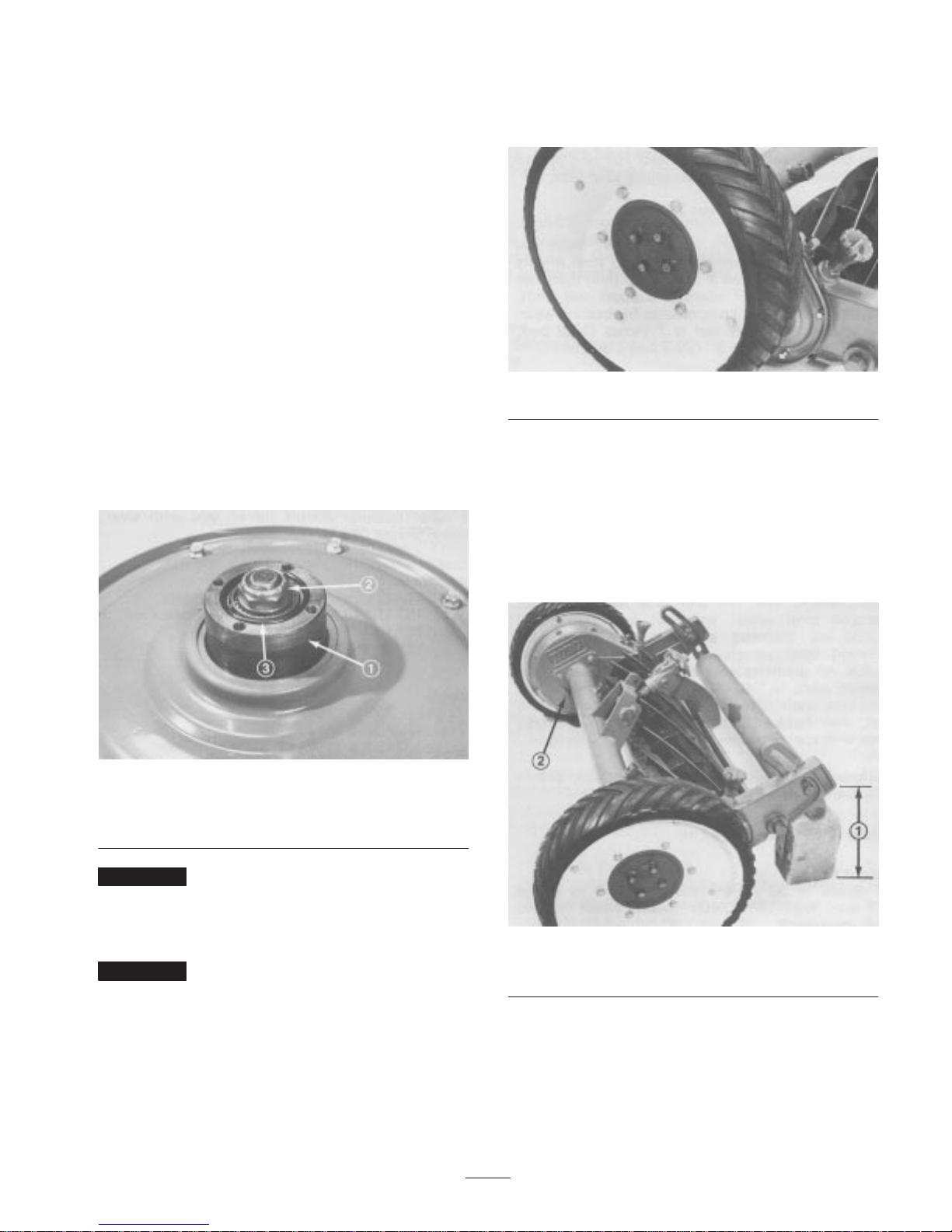

1. Position mower on a level surface.

2. Raise and block back of mower until there is

approximately 10–1/4 inches (0.260 m) between bottom

of gear case extending behind roller bracket and level

surface (Fig. 3).

Important Do not over–tighten wheel hub nut because

the bearing will wear rapidly.

2. Check O–ring to assure it is not damaged, and make

sure it is seated in inside diameter of wheel hub (Fig. 1).

Important An O–ring that is damaged or installed

incorrectly will allow oil to leak out of the gear case. If

enough oil leaks out, mechanical damage will likely result.

3. If pneumatic wheels are installed, set tire pressure at

35 psi (241.3 Kpa).

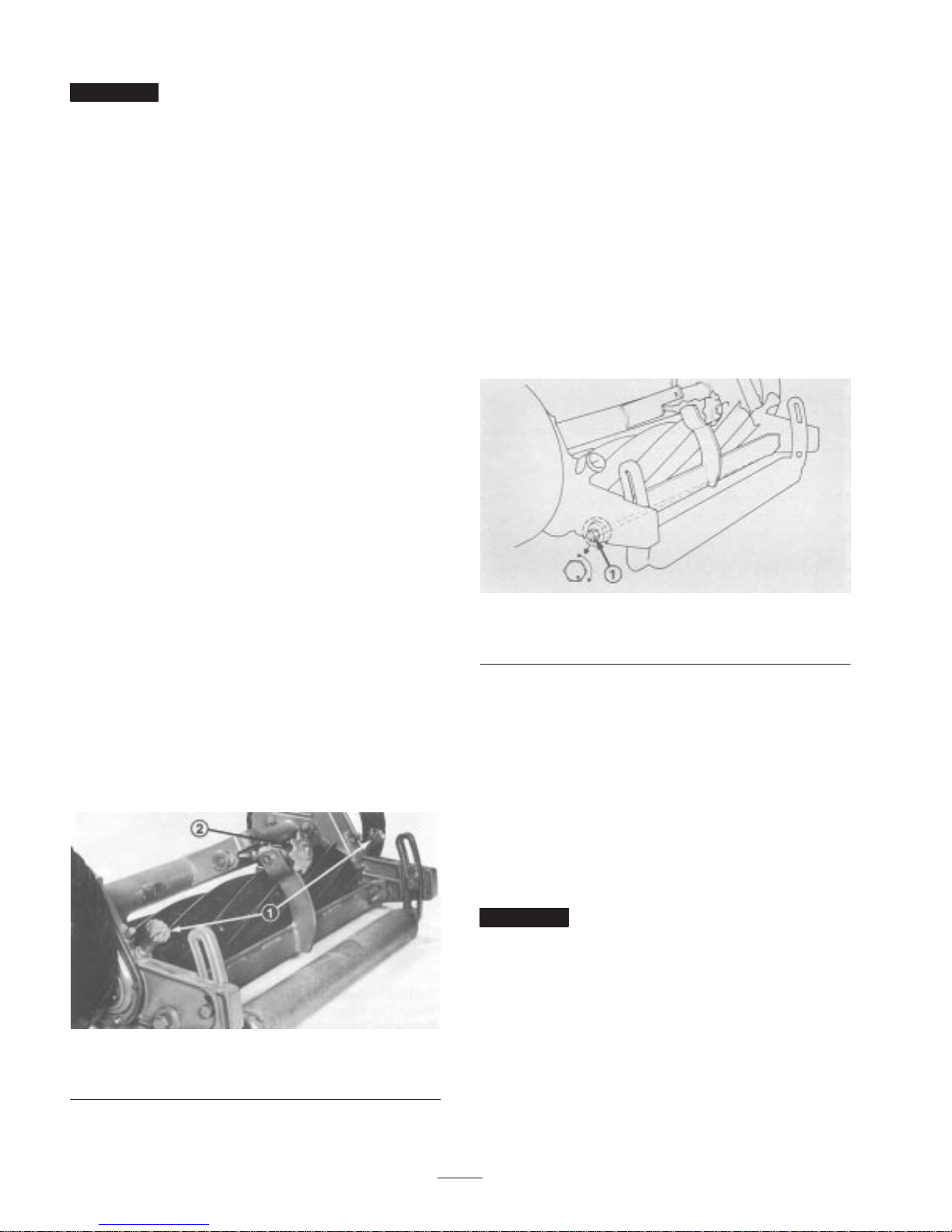

Figure 3

1. 10–1/4 inches 2. Filler plug

3. Remove filler plug from inside of each gear case

(Fig. 3). Check oil level in gear case: it should be level

with bottom of filler hole. If oil is level with bottom of

hole, reinstall filler plug.

5

Page 6

Important Check for oil leaks caused by a defective or

improperly installed O–ring or gasket, and loose side plate

bolts. Make all repairs before adding oil to gear cases.

4. If level of oil is low, fill gear case to point of

overflowing with SAE 80–90 gear lube and reinstall

filler plug. DO NOT OVERFILL.

Critical Adjustments

Check Reel Bearings And

Mower Fasteners

1. Rotate center adjusting knob until bedknife does not

contact reel. Try to spin the reel. If reel does not spin,

adjust reel bearings; refer to Reel Bearing Adjustment,

page 6. If reel spins freely, proceed to step 2.

2. Try to move reel back and forth. If reel can be moved,

reel bearings must be adjusted; refer to Reel Bearing

Adjustment, page 7.

3. Check and tighten all nuts, bolts, and screws to assure

all parts are secure.

4. Continue to check for light contact across full length of

bedknife using paper. If light contact is not evident,

bedknife is not parallel to reel.

5. Loosen nut on left bedbar pivot bolt enough to ease

turning of eccentric bolt.

6. Parallel bedknife to reel by rotating the left bed– bar

pivot bolt (Fig. 5). The left pivot bolt has an offset

thread which, when rotated, acts as a cam to raise or

lower the bedbar. On the left hand pivot bolt there is an

offset dot (Fig. 5) which denotes the thread of the bolt.

When the dot is in the up position (Fig. 5) the left end

of bedbar is raised. As bolt is turned clockwise and dot

is lowered, so is the left end of bedbar. Identification

dot is to be positioned within the rear (180) position

when adjusting.

Parallel Bedknife To Reel

1. Position mower on a level surface. Remove paint and

grease from bedknife and reel cutting edges.

2. Make sure throwout knobs (Fig. 4) are disengaged and

bedknife to reel contact is removed by turning bedknife

adjustment knob counterclockwise.

3. Insert a long strip of newspaper between reel blade and

bedknife. While rotating reel backward, turn bedknife

adjusting knob (Fig. 4) clockwise, one click at a time,

until paper is pinched lightly, which results in paper

being cut or a slight drag when paper is pulled.

Figure 5

1. Bedbar pivot bolt

7. Rotate left pivot bolt to raise or lower bedbar.

8. Insert a long strip of newspaper between reel blade and

bedknife. While rotating reel backward, turn bedknife

adjusting knob clockwise, one click at a time, until

paper is pinched lightly, which results in paper being

cut or a slight drag when paper is pulled.

9. When light contact is evident across full length of

bedknife, tighten pivot bolt nut, while holding bolt in

position and check to make sure pivot bolt did not

become misadjusted when tightened. Readjust as

required.

Important To make sure bedknife and reel are not

damaged while mowers are transported to or installed on

the towing frame, rotate bedknife adjusting knob

counterclockwise until bedknife does not touch the reel.

Figure 4

1. Throwout knobs 2. Bedknife adjusting knob

6

Page 7

Set Height Of Cut

Reel Bearing Adjustment

The height of cut is adjustable in approximately 3/32”

(2.38 mm) increments by raising or lowering rear roller.

1. Loosen capscrews securing adjusting nuts in roller

brackets (Fig. 6).

Figure 6

1. Bottom edge of adjusting

nut

2. Position roller adjusting nuts in desired notches and

tighten capscrews. Make sure same number of notches

show below adjusting nuts.

2. 11 blade mounting hole

3. 5 & 7 blade mounting hole

If end play is evident in reel or if mower has been

disassembled, an adjustment to the reel bearing may be

necessary.

1. Remove (4) four screws securing left wheel to wheel

hub and remove wheel. Place wheel under gear case for

support.

2. Raise and block back of mower until there is 7 to 8

inches (0.178 to 0.203 m) between bottom of gear case

extending behind roller bracket and level surface.

3. Remove (3) three capscrews securing inspection cover

to gear case cover.

4. In small increments, rotate the adjusting nut on reel

shaft, in clockwise direction to remove all end play

from the reel. Make sure to hold reel so it cannot rotate.

5. When end play is removed, rotate nut an additional 1/4

turn to preload the bearing.

6. Reinstall inspection cover and the wheel.

3. If a higher height of cut is desired, every notch moved

adds approximately 3/32 of an inch (2.38 mm) to the

cutting height.

Note: These are bench settings. The mower will cut at a

different height in turf because of grass conditions and the

weight of the mower.

4. To make a finer adjustment to cutting height or to adjust

roller, adjusting nut may be moved 1/2 notch or 3/64 of

an inch (1.19 mm) by using the following procedure:

A. Remove capscrew and adjusting nut securing roller

bracket to gear case. Do not move roller bracket.

B. Reposition capscrew and adjusting nut to upper hole

in gear case.

C. Slide roller bracket up or down 1/2 notch to position

adjusting nut into correct notch and tighten

capscrew.

7

Page 8

Operating

Instructions

5. Check the reel “carry over” by spinning reel backward

again. Reel should rotate one to two complete

revolutions. Less than one revolution indicates heavy

contact, which means the bedknife and reel must be

readjusted for light contact; refer to steps 1, 3 and 4.

Adjust Bedknife To Reel For

Light Contact

Important After mower is set up and installed on the

towing frame, the bedknife and reel must be adjusted for

light contact. Adjust bedknife to reel while mower is setting

on the grass to be cut because the force of turf against

underside of bedknife during actual operation must be

duplicated to ensure correct setting. To assure sharp cutting

edges, bedknife and reel must have light contact.

1. Stand behind the mower.

2. Disengage reel throwout knobs (Fig. 7). Carefully spin

reel backward to insure free movement.

3. While spinning reel backward, rotate bedknife adjusting

knob counterclockwise (Fig. 7) until bedknife does not

touch reel blades.

6. At the beginning of the cutting day, when reels are cold,

engage the reel throwout knobs (Fig. 7). Operate

mowers for 15 to 20 minutes so the bedknife and reel

reach normal operating temperature; then stop

operation. Next, disengage reel throwout knobs and spin

reel backward. A whispering sound, not clicking,

should be emitted, and this assures correct adjustment.

If a whispering sound is not heard, bedknife and reel

must be readjusted; refer to steps 3–5. By contrast,

when reels are warm from being used, use only steps

1–5 to maintain light contact between bedknife and reel.

Important Never adjust bedknife to reel for light

contact if mowers are cold because the increase in

temperature during operation could cause the metal to

expand and result in heavy contact. Heavy contact causes

uneven bedknife wear and poor quality of cut. However,

light contact between bedknife and reel, which is desirable,

minimizes wear and keeps cutting edges sharp. Adjust for

light contact every four hours or sooner, even though

quality of cut is acceptable. When mowers are operated in

sparse grass or temperature of air is high, the adjustment

for light contact must be checked even more frequently to

avoid heavy contact between the bedknife and reel. If

mowers are not operated for a short time, one hour after

any use, check for light contact after resuming operation for

15 to 20 minutes; refer to steps 1–6.

Figure 7

1. Throwout knobs 2. Bedknife adjusting knob

4. While spinning reel backward, rotate adjusting knob

clockwise (Fig. 7), one click at a time, until light

contact of bedknife and reel is noticed or a whispering

cutting sound is heard.

Note: Spring arm (clicker) may be adjusted for positive

detent by loosening capscrews securing spring arm to

adjustment arm retainer, adjust until a solid clicking sound

is achieved when adjusting knob is turned, and retightening

capscrews.

Mower Use

1. Mowing Speed – The mower is designed to cut grass

well at any ground speed between 1 and 6 mph (1.6 and

9.66 km/hr) but for most turf conditions, ground speeds

of 4–6 mph (6.4–9.66 km/hr) produce the best quality

of cut. Ground speed, however, must be reduced when

turning because excessive speed will cause outside

mowers to bounce and skip on the turf. Excessive heat,

caused by the reel spinning too fast, can also damage

the bedknife and reel. Since grass lubricates the

bedknife and reel during operation, slow down when

cutting sparse grass, extremely dry grass, or when

trimming. Any lack or significant reduction of

lubrication produces excessive heat build–up and

subsequently, heavy contact between bedknife and reel,

which results in uneven bedknife wear and poor quality

of cut. Therefore, reels must be disengaged and stopped

before mowers are transported across parking lots,

roads, or whenever lubrication is minimal.

2. Height–of–Cut – To determine the effective

height–of–cut, the length of the grass to be cut must be

checked. Height–of–cut should be set and turf mowed

frequently so no more than 1/3 of the leaf is cut off. If

8

Page 9

mower is equipped with pneumatic tires, pressure must

be maintained at 35 psi (241.3 kpa) (Fig. 8). Low tire

pressure can cause bedknife to dip into the grass and

scalp the turf. An uneven cut will likely result.

Figure 8

3. Operating Sound – A mower that is adjusted correctly

gives off a whispering sound when operated. If there are

buzzing, clicking, or metallic sounds, the mower has

probably been operated with heavy contact between

bedknife and reel. The reel or bedknife could also have

hit a foreign object. A noisy mower must be stopped,

repaired, and adjusted or severe damage will result.

Figure 9

Note: Rifling is the uneven or wavy condition that

develops on bedknife and reel when there is heavy contact

between these two parts (Fig. 10). Streaks of uncut grass

and an overall poor quality of cut are signs of rifling.

Grinding the bedknife and reel is the only way to repair a

rifled mower.

4. Mowing Pattern – To prevent grass from lying down

and improve appearance of turf, alternate mowing

directions if possible, each time an area is cut.

Causes of Poor Quality of Cut

1. Bedknife/Reel Contact (Fig. 9) – There must be light

contact between bedknife and reel to keep cutting edges

sharp and to produce an excellent quality of cut. By

contrast, mowers operated with– out light contact allow

abrasive materials and grass to pass between the

bedknife and reel. This eroding action rounds off the

bedknife and reel cutting edges, which results in a poor

quality of cut. If cutting edges become round, bedknife

and reel must be lapped. Excessive rounding off of

cutting edges may require that bedknife and reel be

ground and lapped. Never compensate for round cutting

edges by tightening bedknife adjusting knob until there

is heavy contact because the bedknife and reel will wear

unevenly and cause “rifling”.

Figure 10

2. Noise – A mower that has sharp cutting edges and is

adjusted with light contact will emit a desirable

whispering sound when reel is spinning. By contrast,

buzzing, clicking, or metallic sounds during operation

indicate that mower is probably being operated with

heavy contact between bedknife and reel. Heavy contact

causes uneven or wavy wear on the bedknife and reel

cutting edges. Grinding is required to repair a damaged

bedknife and reel. Although the bedknife and reel are

adjusted correctly for light contact, notches will

eventually develop at both ends of the bedknife. These

notches must be rounded off or filed flush with cutting

edge of bedknife to assure smooth operation.

3. Loose Reel Bearings – If reel bearings are suspected to

be loose, check them immediately or extensive damage

may result; refer to Reel Bearing Adjustment, page 7.

4. Hitting a Foreign Object – The bedknife and reel

cutting edges can be damaged if a foreign object is hit.

The damage, if it is not too severe, can be repaired in

the field. Start by filing down high spots on the

9

Page 10

bedknife and reel (Fig. 11). Use a ball peen hammer to

straighten any reel blades that may be bent. Since

bedknife usually springs away from the reel upon

impact, bedknife must be adjusted; refer to Parallel

Bedknife to Reel, page 6.

Figure 11

Maintenance

Lubrication

1. The gear cases have been fully lubricated at the factory.

Once each season, drain and clean the right and left gear

cases. When gear cases are clean, add SAE 140 gear

lube; refer to Gear Case Oil, page 5.

2. The mowers should be greased every 8 hours of

operation with Heavy Duty 2 wheel bearing grease, to

obtain maximum life. This grease can be used on all

greasing points (Fig. 12). When pressure is felt while

greasing the roller, bearing cavity between seals if full.

DO NOT CONTINUE TO GREASE BECAUSE

INNER BEARING SEAL MAY BE DAMAGED.

Figure 12

Important Do not use high pressure hose to clean areas

where there are seals or bearings because foreign matter

will likely be forced into the bearing. The result will be

rapid seal and bearing deterioration. Grease the mower

immediately after cleaning. Failure to do so may cause

damage to the bearings or other components.

Grinding

Note: For detailed sharpening information, order the Toro

Sharpening Reel and Rotary Mowers Manual, from the

Commercial Service Department.

New and old bedknives should be ground attached to the

bedbar; this ensures rigidity during grinding and insures a

true knife. Refer to figure 13 when grinding tHe knives and

obtain as near as possible the relief angles indicated. In

grinding, avoid a hard contact between knife and grinding

wheel. If hard contact occurs, excessive heat buildup will

take place, causing premature wearing of the grinding

wheel and reduced life of the knife.

10

Page 11

Figure 13

The land area and relief angle of reel blade are pointed out

in figure 14. The land area is that part of the reel blade that

actually comes in contact with the bedknife and cuts the

grass in a scissors action. The relief or back grind angle is

ground into reel blade to provide clearance or relief be–

hind contacting edges to reduce drag or friction.

Recommended relief angle is 15 degrees.

If the reel blade edges and bedknife edge are slightly

rounded and do not have severe nicks, lapping only with a

lapping compound may restore the edges and match.

Oftentimes a mower is deemed by users to need grinding

when reel bearing adjustment, bedknife adjustment and/or

lapping is all that is necessary.

Lapping

Mowers are set up as follows:

1. Remove the right hand wheel.

2. Place wheel under gear case for support.

3. Remove the reel pinion cover (Fig. 15).

Figure 14

Note: After a reel has run for an extended period of time

the blade contact point or land area will keep getting wider

and eventually will be full blade width. This is normal and

does not mean that the reel has to be reground to stay

effective. A cutting unit can cut effectively with full width

blades if the adjustment is checked frequently to maintain

sharp cutting edges.

After reel and bedknife have been ground, perform the

following adjustments:

1. Set Height–of–Cut, page 7.

2. Parallel Bedknife to Reel, page 6.

Note: As the reel blades continue to run against the

bedknife a slight burr will appear on the front cutting edge

surface the full length of the bedknife. If a file is

occasionally run across the front edge to remove this burr,

improved cutting can be obtained.

Figure 15

1. Reel pinion cover

4. Disengage the reel.

5. Connect the lapping machine coupler to the nut on the

end of the reel shaft.

When lapping, use a good grade of commercial lapping

compound. A medium grit should be for initial lapping and

a fine grit for finishing. A solution of one part liquid

detergent and two parts lapping compound is

recommended. The liquid detergent greatly eases washing

away the compound when finished. Water soluble oil may

also be used as a compound carrier.

Note: Lapping solution must be kept in free flowing

condition to get even distribution on bedknife and reel.

The lapping procedure is as follows:

1. Adjust bedknife to reel so light contact is evident.

2. Operate the lapping machine so the reel turns in a

reverse direction. Apply lapping solution continuously

and maintain light bedknife to reel contact.

3. Stop lapping machine periodically to check cutting

surfaces for sharpness. Continue lapping until sharp

cutting edges have been restored.

11

Page 12

Note: If the cutting edges are severely rounded, both

sharpening and lapping may be required.

4. Wash off all lapping solution. Using paper, check for

sharpness along entire length of each reel blade. If

paper cannot be cut cleanly along entire length of each

reel blade, continued lapping is necessary.

Bedknife Replacement

1. To replace the bedknife, remove the eleven (11) screws

holding the knife to the bed bar; replace the knife and

reinstall the screws. All screws should be lubricated

with oil and torqued to 250–300 in.–lb

(28.3 – 33.9 N.m). The screws should be tightened by

starting at center of the bedknife and alternating until all

screws are secured.

2. True the bedknife attached to the bedbar by grinding.

Refer to the TORO SHARPENING REEL and

ROTARY MOWERS MANUAL.

Mower Servicing Procedure

Disassembly

1. Remove four (4) capscrews securing wheel to wheel

hub. Remove wheel from hub.

2. Remove O–ring from inside of hub (Fig. 16).

3. After bedknife has been ground and is “true”, perform

the following adjustments:

Reel, Roller and Wheel Bearing

Adjustment

After the initial 30 operating hours, check the reel bearing,

roller bearing, and wheel bearing. Thereafter, check these

parts every 200–250 operating hours. If necessary, adjust

the reel bearing (See Reel Bearing Adjustment, page 7. If

necessary, adjust the roller bearing (See Roller Assembly,

page 17). If necessary, adjust the wheel bearing (See Check

Wheel Hubs, page 5.)

Figure 16

3. Remove wheel hub nut from axle shaft (Fig. 17).

Figure 17

1. Wheel hub nut

4. Place oil pan under gear case assembly. Loosen the ten

(10) capscrews securing cover to gear case (Fig. 18).

12

Page 13

Figure 18

1. Mounting capscrews

5. Separate cover from gear case and allow oil to drain.

Remove cover and discard gear case gasket (Fig. 19).

Figure 19

1. Gasket 2. Double lip seal

Figure 20

1. Drift pin punch

2. Bearing cups

3. Hub

8. Remove inner cone and O–ring from axle shaft

(Fig. 21).

6. Remove double lip seal (Fig. 19) from cover if worn or

damaged. The ring gear hub and gear assembly can be

removed from axle shaft as soon as gear case cover is

removed.

7. Use a drift pin punch to remove bearing cups from hub

(Fig. 20).

Note: Access is provided in the bore for drift pin punch.

Figure 21

1. O–ring 2. Bearing cones

9. To prevent the reel from turning, place a wooden block

between reel blades and axle shaft.

13

Page 14

Using a socket wrench, remove ratchet gear stud securing

ratchet gear (Fig. 22). Remove left–hand ratchet gear stud

by rotating it clockwise. Remove right–hand ratchet gear

stud by rotating it counterclockwise. Removal of the ratchet

gear stud will free ratchet gear (Fig. 22).

Figure 24

1. Splined shaft

Figure 22

1. Rachet gear stud

2. Rachet gear

3. Nut

4. Pinion gear

10.Remove needle bearing from ratchet gear using a sleeve

and arbor press (Fig. 23).

Figure 23

11. (Left end) Remove nut securing pinion gear to reel shaft

and slide gear off splined shaft (Fig. 24).

12.(Right end) Remove nut securing pinion gear to reel

shaft. Insert a pry bar in groove provided and pry off

pinion gear. Remove woodruff key from key way in reel

shaft (Fig. 25).

Figure 25

14

Page 15

13.Remove the lower compression spring. Disassemble the

ratchet ring from the ratchet gear ring by removing

three (3) locknuts and prying equally around the ratchet

ring (Fig. 26). Be extremely careful to prevent damage

to the mating surfaces.

Figure 26

1. Lower compression

spring

2. Locknuts

3. Rachet ring

14.For removal of the throwout handle (Fig. 27), O–ring

and finger, drive pin from throwout handle. Remove

throwout sleeve by turning counterclockwise.

Figure 27

1. Throwout handle

Note: When replacing O–ring, sleeve must be removed

(Fig. 28). Throwout sleeve need only be loosened for

removal of rachet ring gear.

Figure 28

1. O–ring 2. Sleeve

15.Lift out the upper compression spring. Remove rachet

gear ring from gear case.

16.Remove roller adjustment bolts and nuts from each side

of roller (Fig. 29).

15

Page 16

Figure 29

17.Loosen locknuts allowing removal of Allen head set

screws securing bedbar to bedbar retainer (Fig. 30).

Note: When reinstalling bedbar to bedbar retainer, center

bedbar retainer, tighten setscrews until seated and tighten

locknuts.

Figure 30

1. Locknuts 2. Allen head set screws

Figure 31

1. Bearing removal tool, part no. 49–8060

Note: Remove any rust from cross tube shaft to prevent

binding. Clean gear case with solvent. If studs have been

removed, apply Permatex No. 2 to threads.

22.Remove stub axle shaft from gear case by loosening

locknut and tapping with soft head mallet (Fig. 32).

18.Remove pivot bolts and nuts securing bedbar assembly

to gear cases (Fig. 29).

19.Remove three nuts securing each gear case to cross

tube. Using a soft head mallet, drive gear cases off cross

tube.

20.Bearing and gear case will now slide off left end of reel

shaft.

Note: To aid in the removal of reel bearings, a Bearing

Removal Tool, Part No. 49–8060, is available from your

Authorized Toro Distributor.

21.Remove bearing and gear case from right end of reel

shaft (Fig. 31).

Figure 32

1. Stub axle shaft

16

Page 17

Gear Case And Frame

Assembly

1. Apply Permatex #2 to serrations on drive tube studs and

press into gear case.

2. Apply Never Seez to threads and mount stub axles to

gear cases and secure with locknuts. Tighten locknuts to

40–55 ft. lb.

3. Press seal and bearing cup into right hand gear case.

Make sure plastic seal guard is installed over seal boss.

15.Place O–ring into groove on right hand throwout finger,

coat ring with heavy oil or grease, and slide through

sideplate, making sure that O–ring does not get

damaged. Install throwout sleeve over throwout finger

and tighten securely in gear case.

16.Slide throwout handle over finger and secure in place

with drive lock pin.

17.Position woodruff key in key slot in reel shaft and slide

on pinion gear.

18.Secure nut (left hand thread) on right hand reel shaft.

4. Slide gear case onto right hand end of reel shaft (key

slot end).

Note: Use caution not to damage seal in gear case when

inserting reel shaft.

5. Tap bearing cone onto reel shaft just far enough to

allow insertion of woodruff key and pinion gear.

Important Right hand bearing must be pressed onto

reel shaft by tightening pinion gear nut. DO NOT PRESS

ON OTHERWISE.

6. Install woodruff key, pinion gear, and nut and tighten

until gear bottoms out on reel shaft (left hand thread).

7. Remove nut, pinion gear and woodruff key before

continuing assembly.

8. Mount cross tube to right hand gear case and secure

finger tight with (3) lockwashers and nuts.

9. Press seal and bearing cup into left hand gear case.

Make sure plastic seal guard is installed over seal boss.

10.Slide gear case onto left hand end of reel shaft and gear

case studs into mounting holes in cross tube.

Note: Use caution not to damage seal in gear case when

inserting reel shaft.

11. Secure gear case to cross tube with (3) lockwashers and

nuts. Tighten nuts on both ends of cross tube to

80–90 ft.–lb.

12.Slide bearing cone onto left hand end of reel shaft and

into gear case.

13.Assemble the right hand ratchet gear ring over the shaft

and insert two (2) compression springs.

14.Assemble right hand ratchet ring over ratchet gear ring

and seat with a driver and hammer. Secure entire

assembly with (3) three stop nuts. Nuts should be drawn

up evenly and gradually to 14–22 ft. lb.

(19.04–29.8 N–m) to prevent breaking the ratchet ring.

Note: Ensure that assembly will ratchet. If assembly does

not ratchet, back nuts off slightly.

19.Assemble the ratchet gear and bearing assembly to right

hand, ratchet gear ring and secure with right hand

ratchet gear stud.

20.On the left side, assemble ratchet gear ring over the reel

shaft and insert (2) compression springs.

21.Assemble left hand ratchet ring over the ratchet gear

ring and seat with a driver and hammer. Secure entire

assembly with three (3) stop nuts. Nuts should be drawn

up evenly and gradually to 14–22 ft. lb.

(19.04–29.8 N.m) to prevent breakage of the ratchet

ring.

Note: Ensure that assembly will ratchet. If assembly does

not ratchet, back nuts off slightly.

22.Place O–ring into groove on left hand throwout finger,

coat ring with heavy oil or grease, and slide through

sideplate, making sure that O–ring does not get

damaged. Install throwout sleeve over throwout finger

and tighten securely in gear case.

23.Slide throwout handle over finger and secure in place

with a drive lock pin.

24.Aligning mark on pinion gear with mark on reel shaft

slide gear onto spline shaft.

25.Instal new nut (right hand thread) on left hand reel shaft

but do not tighten. When mower is completely

reassembled adjust reel bearing, refer to Adjusting Reel

Bearing, page 7.

26.Assemble the ratchet gear and bearing assembly to the

left hand reel ratchet gear ring and secure with the left

hand ratchet gear stud.

27.Mount bedbar to gear cases with shoulder bolts, rubber

spacers, plastic washers and locknuts. Use bottom

mounting hole in bedbar for 1 1 blade reels and top

mounting hole for 5 and 7 blade reels. When installing

left hand shoulder bolt (offset thread) thread the bolt in

until it touches rubber spacer, then back it out one

complete turn and tighten nut. Do not back out right

hand bolt. This will allow bedbar adjustment. Refer to

Parallel Bedknife to Reel, page 6.

28.Position roller bracket assembly in slots of gear case.

17

Page 18

29.Position right hand and left hand roller adjusting nuts

on roller bracket assemblies. Secure in place with

capscrews and lockwashers.

30.Press bearing cups in ring gear hub. Assemble bearing

cone to left side of stub shaft. Place large ring gear and

hub assembly over stub shaft and bearing cone.

31.Place another bearing over stub shaft and into ring gear

hub.

32.Position wheel hub nut on stub shaft and run down with

an open end wrench. Adjust bearing by tightening nut

until slight drag is felt when wheel bolt is rotated.

33.Press seal into gear case cover. Position gasket on gear

case. Lightly lubricate wheel hub seal in gear case

cover.

34.Position left hand gear case cover and secure with ten

(10) self tapping screws. Torque screws to approx. 125

in. lbs. (14.1 N–m) evenly and gradually.

35.Add approximately 15 ounces (0.44 1) of SAE 80–90

gear lubricant to gear. DO NOT OVERFILL.

5. Remove bearing cones from each end of roller.

6. Remove bearing cups with caution.

7. Remove inner seals by using a seal remover.

Roller Assembly

1. Lightly oil lips of inner seals. Install inner seals on each

end of roller, making sure that garter springs face

inboard.

2. Replace bearing cups and insert bearing cones into

roller.

36.Place O–ring into recess in wheel hub.

37.Secure the wheel to the wheel hub with four (4)

capscrews.

38.Repeat steps 30–37 on opposite side.

Roller Disassembly

As viewed from rear

Figure 33

1. Remove brackets and washers from each end of roller

and inspect bushings.

As viewed from rear

Figure 34

3. Lightly oil lips of outer seals. Install outer seals on each

end of roller, making sure that garter springs face

inboard.

4. Slide one (1) sleeve onto roller shaft against double jam

nuts.

5. Wrap threaded area of roller shaft with cellophane tape

to protect seals, and carefully slide shaft through

right–hand side of the roller. Slide roller shaft into roller

until it penetrates the inner most oil seal on the

right–hand side.

6. Pour approximately one (1) pint (16 ounces [0.0296 l)

of SAE 90 or 140 gear oil into the roller housing.

7. After oil has been added, carefully push roller shaft

through the entire roller assembly. Remove cellophane

tape.

8. Install sleeve on roller shaft and slide up against bearing

cone.

2. Remove elastic stop nut.

Note: After elastic stop nut has been removed, slide sleeve

off roller shaft. Point end of roller downward into a

container, at the same time pulling roller shaft out, allowing

lubricant to drain from roller.

3. If roller shaft is to be replaced, remove double jam nuts.

4. Remove remaining sleeve and seals from both ends of

roller.

9. Install elastic stop nut and secure by holding double jam

nuts. Tighten elastic stop nut (Fig. 35).

Note: Tighten elastic stop nut until all axial and radial

motion has been removed from the roller shaft and

bearings. Ensure that roller rotates freely on shaft.

10.Grease bearings with Heavy Duty 2 wheel bearing

grease.

11. Reinstall washers and install left and right–hand bracket

and bushing assemblies.

18

Page 19

Figure 35

Important After the mower has been completely

assembled, perform the following critical adjustments:

A. Check Reel Bearings and Mower Fasteners, page 6.

B. Set Height–of–Cut, page 7.

C. Parallel Bedknife to Reel, page 6.

When the adjustments have been completed, move the

mower to a turf area and adjust the bedknife to reel (See

Adjust Bedknife to Reel For Light Contact, page 8).

19

Page 20

20

Page 21

The Toro General Commercial Products Warranty

A Two-Year Limited Warranty

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an a g r eement between them, jointly warrant your 1996

or newer Toro Commercial Product (“Product”) purchased after

January 1, 1997, to be free from defects in materials or

workmanship for tw o years or 1500 operational hours*, whichever

occurs first. Where a warrantable condition exists, we will repair the

Product at no cost to you including diagnosis, labor, parts, and

transportation. This warranty begins on the date the Product is

delivered to the original retail purchaser.

* Product equipped with hour meter

Instructions for Obtaining Warranty Service

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from whom

you purchased the Product as soon as you believe a warrantable

condition exists.

If you need help locating a Commercial Products Distributor or

Authorized Dealer, or if you have questions regarding your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

952-888-8801 or 800-982-2740

E-mail: commercial.service@toro.com

Owner Responsibilities

As the Product owner, you are responsible for required maintenance and adjustments stated in your operator’s manual. Failure

to perform required maintenance and adjustments can be grounds

for disallowing a warranty claim.

Items and Conditions Not Covered

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship. This

express warranty does not cover the following:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapproved accessories

• Product failures which result from failure to perform required

maintenance and/or adjustments

• Product failures which result from operating the Product in an

abusive, negligent or reckless manner

• Parts subject to consumption through use unless found to be

defective. Examples of parts which are consumed, or used up,

during normal Product operation include, but are not limited to,

blades, reels, bedknives, tines, spark plugs, castor wheels,

tires, filters, belts, etc.

• Failures caused by outside influence. Items considered to be

outside influence include, but are not limited to, weather,

storage practices, contamination, use of unapproved coolants,

lubricants, additives, or chemicals, etc.

• Normal “wear and tear” items. Normal “wear and tear” includes,

but is not limited to, damage to seats due to wear or abrasion,

worn painted surfaces, scratched decals or windows, etc.

Parts

Parts scheduled for replacement as required maintenance are

warranted for the period of time up to the scheduled replacement

time for that part.

Parts replaced under this warranty become the property of Toro.

T oro will make the final decision whether to repair any existing part

or assembly or replace it. Toro may use factory remanufactured

parts rather than new parts for some warranty repairs.

General Conditions

Repair by an Authorized Toro Distributor or Dealer is your sole

remedy under this warranty.

Neither The Toro Company nor Toro Warranty Company is

liable for indirect, incidental or consequential damages in

connection with t h e use of the Toro Products covered by this

warranty, including any cost or expense of providing substitute equipment or service during reasonable periods of

malfunction or non-use pending completion of repairs under

this warranty. Except for the Emissions warranty referenced

below, if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for use are

limited to the duration of this express warranty.

Some states do not allow exclusions of incidental or consequential

damages, or limitations on how long an implied warranty lasts, so

the above exclusions and limitations may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Note regarding engine warranty: The Emissions Control System

on your Product may be covered by a separate warranty meeting

requirements established by the U.S. Environmental Protection

Agency (EPA) and/or the California Air Resources Board (CARB).

The hour limitations set forth above do not apply to the Emissions

Control System Warranty. Refer to the Engine Emission Control

Warranty Statement printed in your operator’s manual or contained in the engine manufacturer’s documentation for details.

Countries Other than the United States or Canada

Customers who have purchased Toro products exported from the United States or Canada should contact their Toro Distributor (Dealer)

to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with your Distributor’s service or

have difficulty obtaining guarantee information, contact the Toro importer. If all other remedies fail, you may contact us at Toro Warranty

Company.

Part No. 374-0031 Rev. –

Loading...

Loading...