Page 1

Operations & Maintenance Manual

For Commercial Use Only

TORNADO INDUSTRIES, LLC

3101 WICHITA COURT

FORT WORTH, TX 76140

(800)-822-8867 FAX

(817)-551-6507

WWW.TORNADOVAC.COM

MINI-MARATHON 425

MODEL NO: 98150

Form No. L9724BA 05/12 ©Tornado Industries, LLC. All rights reserved

1

Page 2

10 Years

Plastic water tanks and Rotationally-molded bodies 1)2)4)

2 Years

Parts on all Tornado cleaning equipment 1) 3) 4)

1 Year

Labor on all Tornado cleaning equipment

1 Year

Warranty on batteries and chargers, one year prorated.

All battery warranties are handled by the battery manufacturer, on a one year prorated basis

Long-Term Buyer Protection Limited Warranty

Note: Tornado, The Latest Dirt, Floorkeeper, Carpetkeeper, Carpetrinser,

Carpetrinser/Dryer, Headmaster, Taskforce, PAC-VAC, T-Lite, Glazer,

Windshear, Max-Vac,and Trot-Mop are trademarks of Tornado Industries

Form F2662.© 2011. All rights reserved

*Effective January 1

st

, 2012. Terms subject to change without notice.

1. Except all Windshear™ Blower-Dryers, Side and Downdraft, Insulation Blowers, CV 30, CV 38, CW 50, CW 100, CK14/1, CK LW 13/1,

CV 38/48 Dual, PV6, PV10, all Push Sweepers, Dry Canister Vacuums, and all chargers are warranted for 1 (one) year for both parts

and labor.

2. All-non wear item parts purchased after warranty expiration are warranted for 90 days.

3. Warranty starts from the date of sale to the consumer or, at Tornado’s discretion, 6 months after the dealer

purchased the unit from Tornado, whichever comes first.

4. The EB 30 is warranted for a period of 90 days for both parts and labor

5. The warranty on engines used on propane po

wered equipment is limited to motor manufacturer’s warranty.

6. Ride on scrubbers are warranted for 24 months parts, 6 months labor or 1,000 hours, whichever occurs first.

Tornado Industries, Inc. (Tornado) warrants to the end user customer that the Tornado products will be free

from defects in material and workmanship for the duration(s) described below. is limited warranty DOES

NOT cover machines and/or components subject to normal wear and tear, damage that occurs in shipping,

failures resulting from modication, accident, unsuitable operating environment, misuse, abuse, neglect or improper maintenance by you. For full details, contact your Authorized Tornado Distributor, Service Center, or the

Tornado Technical Service Department. Tornado sales and service representatives are not authorized to waive or

alter the terms of this warranty, or to increase the obligations of Tornado under the warranty

Website: www.tornadovac.com

Phone 1.800.VACUUMS

Fax: (817)-551-6507

Address: 3101 WICHITA COURT

2

FORT WORTH, TX 76140

Page 3

NOTES

3

Page 4

This manual is furnished with each new model. It

provides necessary operation and maintenance

instructions.

MACHINE DATA

Model No.___________________

Read this manual completely and understand the

machine before operating or servicing.

TABLE OF CONTENTS:

Safety Precautions 4

Grounding Instructions 5

Safety Labels 6

Machine Components 7

Machine Setup 8

Machine Operation 9

Pre-Operation 9

Cleaning Carpets 10

While Operating 10

Cleaning with Accessory Tools 10

Draining Recovery Tank 11

Draining Solution Tank 11

Filter Maintenance 11

Daily Maintenance 12

Serial No.___________________

Install Date__________________

SAFETY PRECAUTIONS

This machine is intended for commercial use. It

is designed to clean carpet and upholstery in an

indoor environment and is not constructed for

any other use. Use only recommended cleaning

solutions and accessory tools.

The following safety alert symbols are used

throughout their manual as indicated in their

description.

WARNING: To warn of hazards or unsafe

practices which could result in server personal

injury or death.

WARNING: Hazardous Voltage. Shock or

electrocution can result. Always unplug machine

before servicing.

WARNING: Flammable materials can cause

an explosion or re. Do not use ammable

materials in tank(s).

Weekly Maintenance 13

Monthly Maintenance 13

Quarterly Maintenance 13

Storing Machine 13

Troubleshooting 14

WARNING: Flammable materials or reactive

metals can cause an explosion or re. Do not pick

up any of these items or materials.

4

Page 5

All operators must read, understand, and practice

the following safety precautions.

• Report machine damage or faulty

operation immediately

FOR SAFETY:

1. Do not operate machine :

• Unless trained and authorized

• Unless operator manual is read and

understood

• In ammable or explosive area.

• Unless cord is properly grounded

• With damaged cord or plug

• If not in proper operating condition

• In outdoor area

• In standing water

• With the use of an extension cord

2. Before operating Machine

• Follow mixing and handling instructions

on chemical containers.

1. Before leaving or servicing machine.

• Turn off machine

• Unplug cord from wall outlet.

2. When servicing machine

• Unplug cord from wall outlet

• Avoid moving parts.

• Do not wear loose jackets, shirts or

sleeves.

• Use manufacture supplied approved

replacement parts.

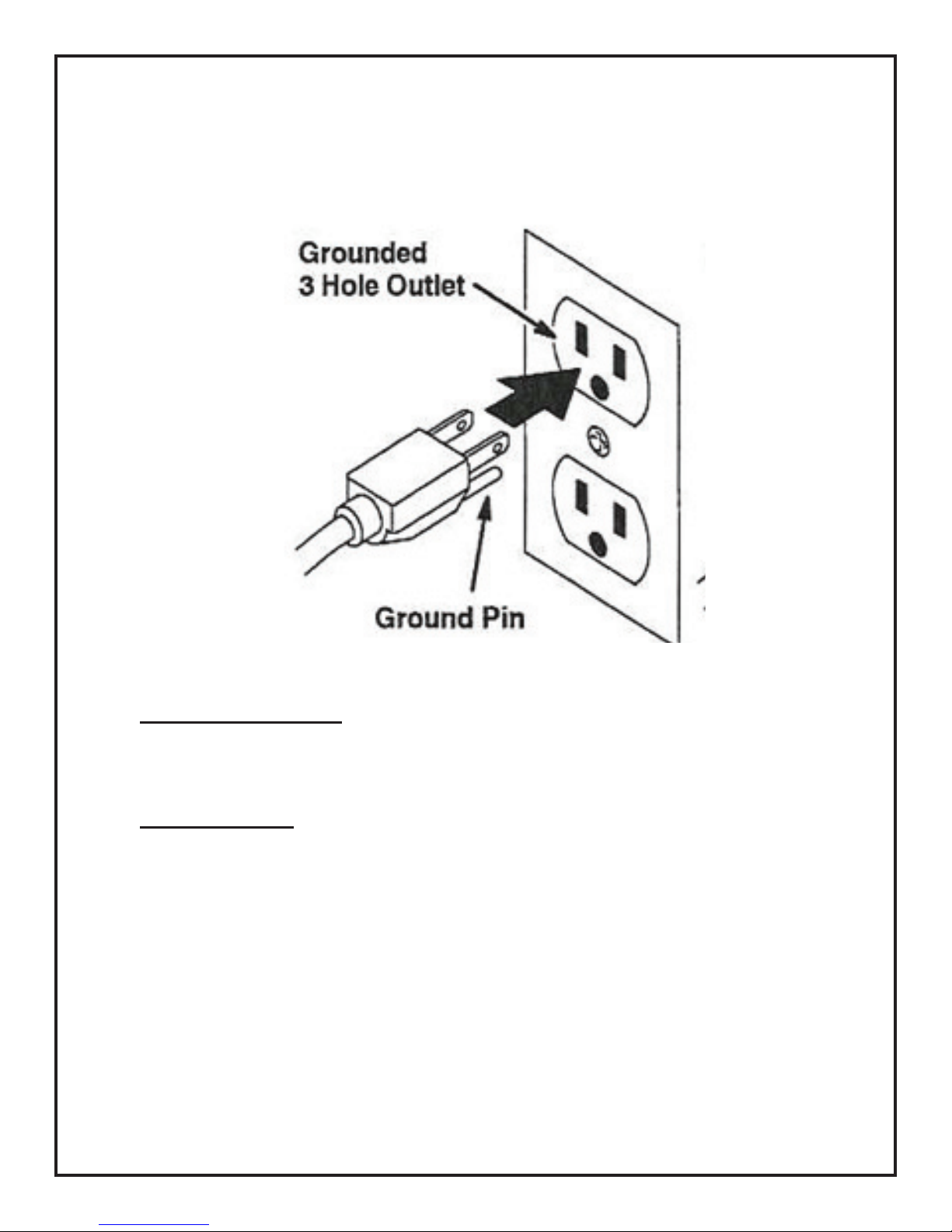

GROUNDING INSTRUCTIONS:

• Make sure all safety devices are in place

and operate properly

3. When using machine

• Do not run over cord

• Do not pull machine by plug or cord

• Do not pull cord around sharp edges or

corners

• Do not unplug by pulling on cord

• Do not stretch cord

• Do not handle plug with wet hands

• Keep cord away from heated surfaces

Machine must be grounded. If it should

malfunction or breakdown, grounding

provides a path of least resistance for

electrical shock. This machine is equipped

with a cord having an equipment grounding

conductor and grounding plug. The plug

must be plugged into an appropriate outlet

that is properly installed in accordance

with all local code as ordinances. Do not

remove ground pin; if missing. Replace plug

before use.

SAFETY LABELS:

The safety labels appear on the machine

in the locations indicated. Replace labels if

they become damaged or illegible.

5

Page 6

WARNING LABEL-Located on cover. Label warns operator of safe practices of

equipment.

FOR SAFETY LABEL-located on rear panel.

FOR SAFETY Read manual before operating machine.

FLAMMABLE MATERIALS/SPILLS LABEL- located near solution tank ll port and on

recovery tank lid.

WARNING: Flammable materials can cause an explosion or re. Do not use ammable materials

in tank(s). Flammable materials or reactive metals can cause explosion or re. Do not pick up these

types of products.

6

Page 7

MACHINE COMPONENTS

1. Main Power ON/OFF Switch

2. Pump Reset Button

3. Brush Reset Button

4. Solution Switch

5. Folding Handles

6. Recovery Tank Cover

7. Recovery Tank

8. Solution Tank

9. Accessory Tool Solution Hose

Coupler

10. Accessory Tool Vacuum Hose Port

11. Pick-Up Head

12. Folding Handle Lock Knob

13. Solution Tank Drain Hose

14. Power Cord Holder

1

2

3

Figure 1

4

5

6

13

14

12

7

8

9

10

11

Figure 3Figure 2

7

Page 8

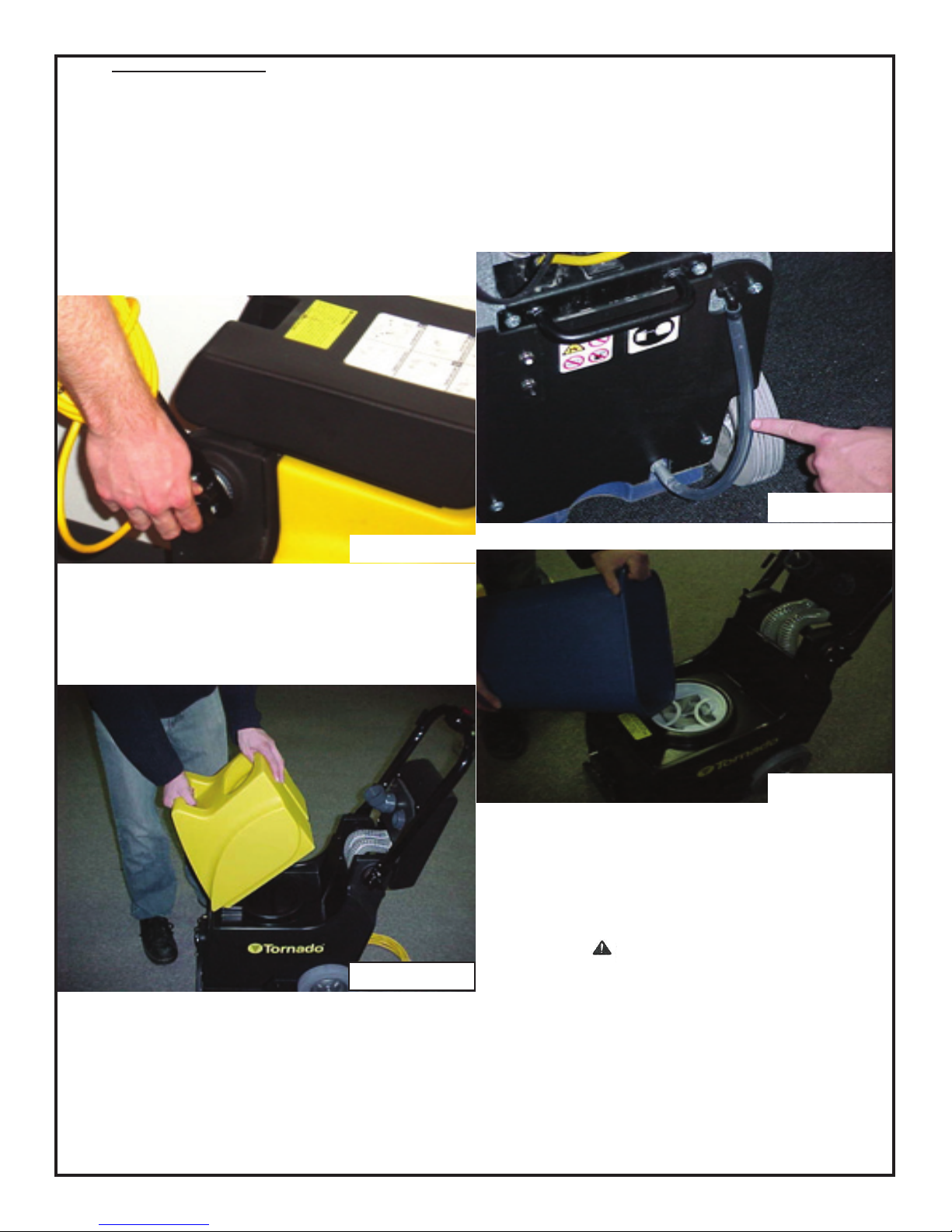

MACHINE SETUP

1. Carefully check carton for signs of

damage. Report damage at once to

carrier. The machine is shipped fully

assembled and is ready for use.

2. Adjust handle from transport position.

To adjust, loosen handle knobs, lift

handle to desired operating height,

tighten handle knobs to lock handle

(gure 4).

Figure 4

4. Using a clean bucket or hose, ll solution

tank with 4 gallons (15 L) of hot water, 140°F

(60°C) maximum. Observe solution tank hose at

rear of machine when lling (gure 6). The hose

indicates the amount of water in solution tank. Do

not use recovery tank to ll machine. Use a clean

bucket. (Figure 7).

Figure 6

3. Lift recovery tank cover and remove

recovery tank. Make sure the oat shut-

off screen and solution tank strainer are in

place before use (gure 5).

Figure 5

Figure 7

ATTENTION: Do not use recovery

tank to ll solution tank. Residual dirt

or debris could cause damage to the

solution pump.

WARNING: Flammable materials

can cause an explosion or re. Do not

use ammable materials in tank(s). Add

a recommended cleaning uid.

5. Replace recovery tank and close

cover after lling.

6. Plug power cord in a grounded

wall outlet. (Figure 8).

8

Page 9

FOR SAFETY: Do not operate machine unless cord is

properly grounded.

FOR SAFETY: Do not operate machine with an extension

cord

Figure 8

MACHINE OPERATION

FOR SAFETY: Do not operate machine unless operator manual is read and understood.

PRE-OPERATION:

1. Vacuum carpet to remove debris.

2. Perform MACHINE SETUP procedures.

3. Inspect power cord for damage.

9

Page 10

CLEANING CARPETS

1. Turn main power switch on (gure 9).

Figure 9

2. To begin cleaning carpets push solution

switch and slowly pull machine backwards

(gure 10).

WARNING: Flammable materials or

reactive metals can cause explosion or re.

Do not pick up these types of products.

1. Work away from the outlet and power cord

to prevent cord damage.

2. Periodically check for excessive foam build

up in recovery tank. Use Defoamer foam

control solution to prevent vacuum motor

damage.

ATTENTION: Excessive foam buildup will not

activate the oat shut off.

3. If brush stops, the circuit breaker may have

been tripped. Unplug the power cord and

check brush for obstruction. Push brush

reset button to resume (gure 11).

Figure 10

3. Release solution switch near the end of the

path and continue to pull machine to pick up

solution.

4. Tip machine back on the wheels and push

machine forward to begin next path.

WHILE OPERATING

1. Overlap each path by 2 inches (50mm).

Figure 11

CLEANING WITH ACCESSORY TOOLS

1. Connect accessory tool hoses to solution

hose couplet and vacuum hose port located

the front of the unit (gure 12).

Figure 12

10

Page 11

2. Turn main power switch on (gure 9).

3. Operate accessory tools as normal (gure

13).

NOTE: When cleaning upholstery, always check

cleaning instruction attached to the furniture by

manufacturer.

Figure 13

4. After cleaning, relieve water pressure from

tool before disconnecting hose. Push the

switch on the hand tool after turning main

power switch off.

NOTE: Make sure to rinse out recovery tank

after each use. Do not use this tank to ll

machine with cleaning solution.

SOLUTION TANK

1. Pull solution tank drain hose off of hose

barb at rear of machine and empty

remaining solution (gure 15).

Figure 15

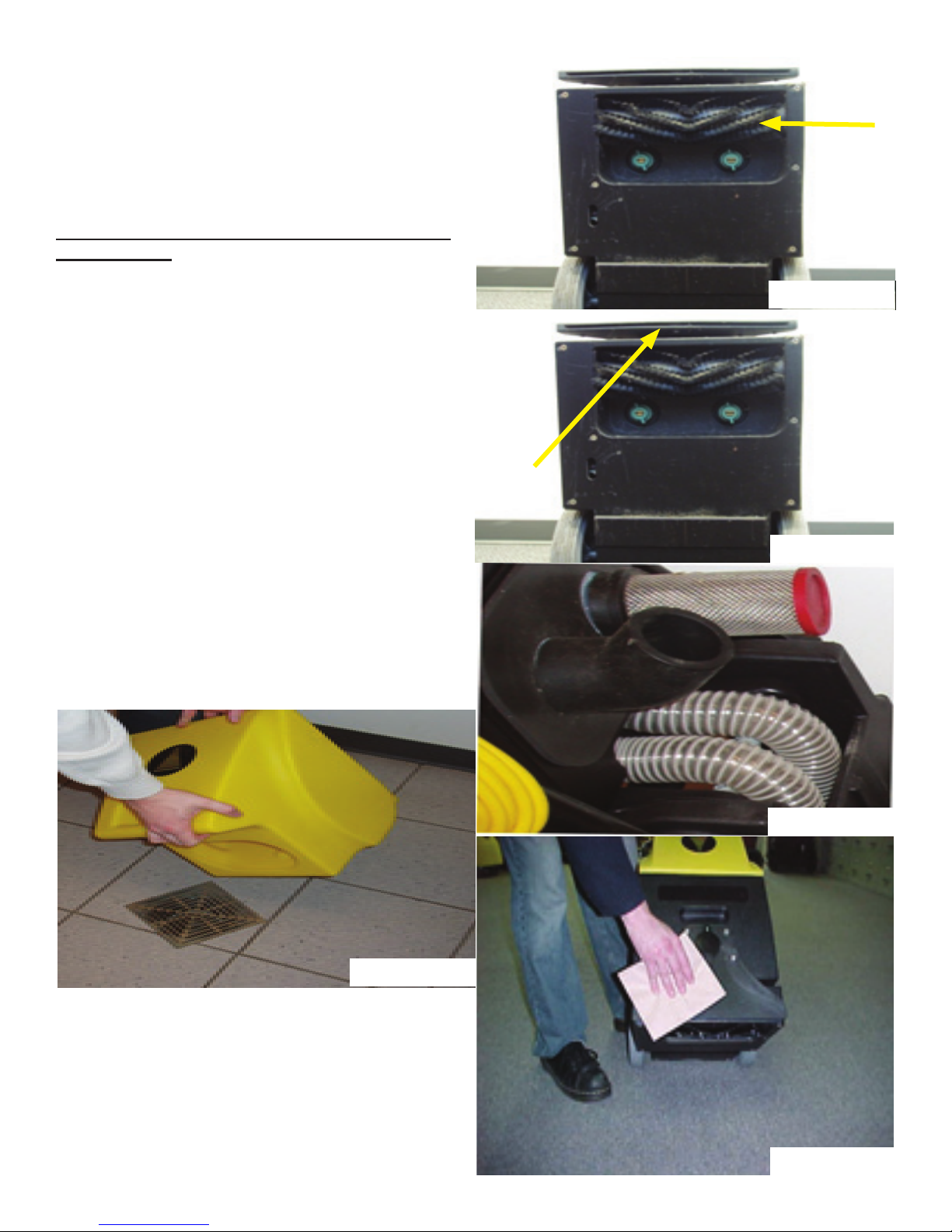

FILTER MAINTENANCE

To clean the external lter, remove the recovery

tank and locate the lter, grasp the inner handle

and pull out the lter. Rinse the lter bag inside

and out. You can then replace the lter by

snapping the lter back into place gure 16).

DRAINING TANKS

FOR SAFETY: When servicing machine, unplug

cord from wall outlet.

RECOVERY TANK

1. Turn machine off and unplug power cord.

2. Lift recovery tank cover, remove recovery

tank, and empty (gure 14).

Figure 14

Figure 16

To clean the internal lter, remove the back

cover by removing the 4 screws, locate the lter

next to the vacuum motor and unscrew the cap.

Remove the lter screen from the cap and rinse it

thoroughly. Once nished, reassemble the screen

and cap and replace the back cover (gure 17).

Figure 17

11

Page 12

To keep the machine in food working condition,

simply follow the daily, weekly, and monthly

maintenance procedures.

FOR SAFETY: When servicing machine, unplug

cord from wall outlet

DAILY MAINTENANCE (EVERY 4 HOURS OF

OPERATION)

1. Empty and rinse out recovery tank

thoroughly (gure 18).

2. Drain remaining solution from solution tank.

3. Clean solution tank ll port strainer.

4. Remove any entangled carpet ber and

debris from brush (gure 19).

5. Remover any debris lodged in pick up head

(gure 20).

6. Remove oat shut-off screen form recovery

tank cover and clean (gure 21).

7. Wipe off power cord and check for damage,

replace if necessary. Coil cord neatly after

use

Clean machine with All Purpose cleaner and damp

cloth (gure 22).

Figure 19

Figure 18

Figure 20

Figure 18

Figure 17

Figure 21

Figure 22

12

Page 13

WEEKLY MAINTENANCE (EVERY 20 HOURS

OF OPERATION)

1. Inspect vacuum hoses for holes and loose

cuffs.

2. Inspect spray pattern for plugging. If

plugged, remove spray tips by twisting

spray tip body counter-clockwise and clean

orices (gure 23).

3. Inspect cord and cord grip for damage.

Replace immediately if damaged.

2. Lubricate wheels with water resistant oil.

3. Inspect machine for water leaks and loose

hardware.

QUATERLY MAINTENANCE (EVERY 250

HOURS OF OPERATION)

1. Check vacuum motor for carbon brush

wear. Replace brushes if worn to a length

of 38/” (10mm) or less

STORING MACHINE

1. Before storing machine, be certain to rinse

and drain tanks of all water

2. Store machine in a dry area in the upright

position

3. Open recovery tank cover to promote air

circulation.

Figure 23

MONTHLY MAINTENANCE EVERY 80 HOURS

OF OPERATION)

1. Flush solution system with recommended

liquid neutralizer to dissolve normal

chemical build up.

• Pour 2 gallons (7.5L) of hot water 140°F

(60°C) into solution tank. Add a liquid

neutralizer according to mixing instructions

on bottle.

FOR SAFETY: When using machine,

following mixing and handling instructions

on chemical containers.

• Position brush over oor drain and operate

machine for one minute.

• Connect hand tool solution hose to machine

and also over a oor drain operate tool for

one minute.

ATTENTION: Do not expose to rain. Store

indoors.

ATTENTION: Do not store in freezing

temperatures of 32°F (0°C) or below.

• Shut off machine and allow remaining

solution to break down chemical buildup

overnight.

• Next day, spray out remaining solution and

ush system with 3 gallons (11L) of clean

water.

13

Page 14

Machine does not

operate.

Faulty switches or wiring.

Faulty power cord.

Building circuit breaker

tripped

PROBLEM CAUSE SOLUTION

Brush motor does not

operate.

Brush motor circuit

breaker tripped.

Switch not pushed.

Loose or broken brush

belt.

Faulty switch or wiring.

Faulty brush motor.

Solution pump does not

operate.

Solution pump circuit

breaker tripped.

Switch not pushed.

Faulty switch or wiring.

Faulty solution pump

motor.

Vacuum motor does not

operate

Loose or broken wiring.

Faulty main power

switch.

Defective vacuum motor.

Worn carbon brushes.

Poor solution pick-up. Defective recovery tank

cover gasket.

Clogged oat shut-off

screen.

Accessory tool vacuum

hose port cover is loose

or missing.

Loose vacuum hose

cuffs.

Pulling machine too fast.

Uneven or no spray. Plugged spray tips.

Improper spray tip size or

spray angle.

Clogged solenoid valve.

Worn spray tips.

Solution tank low or

empty.

Faulty solution pump.

Pump needs priming.

Contact Tornado.

Contact Tornado.

Reset breaker.

Let motor cool and reset

brush motor breaker

button at rear of machine,

Push solution switch.

Contact Tornado

.

Contact Tornado.

Contact Tornado.

Let pump cool and reset

pump breaker button at

rear of machine.

Push solution switch.

Contact Tornado.

Contact Tornado.

Contact Tornado.

Contact Tornado.

Contact Tornado.

Contact Tornado.

Replace gasket.

Open recovery tank

cover and clean lint off

screen.

Check vacuum hose port

cover.

Secure connections

under cover.

Slow down cleaning

process.

Clean or replace tips.

Replace with proper tips

.

Contact Tornado.

Replace spray tips.

Rell solution tank.

Contact Tornado.

Prime pump by pressing

solution hose coupler

tip located at front of

machine.

14

Page 15

Warranty

Registration

Form

Please provide additional information on

Tornado equiptment: (Check choices below)

__ Automatic Scrubbers __Sweepers

__Propane Floor Machines __Rotary Floor Machine

__High Speed Burnishers __Carpet Vacuums

__Carpet Extractors & Spotters __Wet/Dry Vacs

__ Steam Cleaners __Jumbo Vacs

__Ride-On Equiptment __Pressure Washers

See complete product info at www.tornadovac@.com

Please Print Cleary

Selling Dealer:(Required)__________________________

__________________________________________________________________________

Company/Institution

_____________________________________ _______________________________

Contact Name Title

_____________________________________ _______________________________

Address City/State/Zip Code

_____________________________________ _______________________________

Phone Fax

_____________________________________ _______________________________

Date of Purchase Ema

See white metal plate or sticker on unit for his information.

MACHINE TYPE/MODEL NUMBER: MACHINE SERIAL NUMBER:

1. 1.

2. 2.

3. 3.

4. 4.

Facility Description (please circle all that apply)

1. School 9. Hospital 17. U.S. Govt.

2. Retail Store 10. Nursing Home 18. Other Govt.

3. Restaurant 11. Religious Institution 19. Auto Service

4. Ofce Building 12. Airport 20. Airport

5. Contract Cleaning 13. Warehouse 21. Non-Prot

6. Light Manufacturing 14. Apartment/Condo 22. Other (specify)

7. Heavy Manufacturing 15. Warehouse

8. College/University 16. Supermarket

How did you rst lean about

Tornado cleaning and

maintenance equipment?

o Contacted by local dealer

o Previous experience with

Tornado products

o Reputation/Recommendation

o Advertising

o Direct mail

o Internet

o Other

Damage or defect arising from abuse, neglect or other misuse is excluded from this warranty. Other

items may or may not apply based on your specic machine. If any defect occurs, the warranty is voided

if service is attempted by non-Authorized Tornado Service Centers.

©2012 Tornado Industries. All rights reserved.

X8449-TOR 3/2012

In square feet (meters)

Total Hard Floor Area

o 0-10,000 (0-930)

o 10-50,000 (930-4,650)

o 50-250,000 (4,650-23,250)

o Over 250,000 (over

23,260)

15

Total Carpeted Area

Square feet (square meters)

o 0-10,000 (0-930)

o 10-50,000 (930-4,650)

o 50-250,000 (4,650-23,250)

o Over 250,000 (over

23,260)

Return to:

Tornado Industries 3101

WICHITA COURT

FORT WORTH, TX 76140

Fax: (817)-551-6507

Loading...

Loading...