Page 1

CAUTION – READ THESE INSTRUCTIONS BEFORE USING THIS MACHINE

TORNADO INDUSTRIES, LLC

333 CHARLES COURT

WEST CHICAGO, IL 60185

(630)-818-1300 FAX (630)-818-1301

WWW.TORNADOVAC.COM

Operations & Maintenance Manual

For Commercial Use Only

BD 26/27 RIDE ON SCRUBBER

MODEL NO: 99770

Form No. L3456A

©Tornado INDUSTRIES, LLC. All rights reserved

Page 2

SUMMARY 1

LEGEND PANEL OF CONTROLS 4

LEGEND MACHINE 4

TECHNICAL DESCRIPTION 5

INTRODUCTION 6

GENERAL RULES OF SECURITY 6

SYMBOLS 6

BEFORE USE 7

Handling packed machine 7

Unpacking the machine 7

Access to the battery compartment 7

Battery installation 7

Battery charger 7

BatterY charging 8

Batteries disposal 8

Connecting the batteries' connector and switching on the machine 8

Battery charge level indicator 8

Setting the battery check card 8

Hour meter 9

Squeegee assembly 9

Squeegee adjustment 9

Splash guard assembly 9

assembling the brushes 10

FLOOR CLEANING 10

Recovery tank 10

Detergent solution tank 10

STARTING THE MACHINE 10

Forward and backward movement 11

Horn 11

Working brake 11

Emergency brake 11

Automatic squeegee lifting when going backwards 11

Working in automatic mode 11

Working in manual mode 12

Working adjustments 12

Flow adjustment of the detergent solution 12

Brush pressure adjustment 12

Electric protection 13

Overflow device 13

STOPPING THE MACHINE AFTER CLEANING 13

DAILY MAINTENANCE 13

Emptying and cleaning the recovery tank 13

Cleaning the vacuum filter 14

Cleaning the brushes 14

Cisassembling the brushes 14

Cleaning the squeegee 14

WEEKLY MAINTENANCE 14

Rear squeegee rubber check 14

Squeegee hose cleaning 14

Cleaning the solution tank and the outer filter 14

TWO-MONTHLY MAINTENANCE 15

Front squeegee rubber check 15

SIX-MONTHLY MAINTENANCE 15

Splash guard rubber check 15

Cleaning the inner filter OF THE solution tank 15

CheckING the brakes 15

TROUBLESHOOTING GUIDE 15

The VACUUM motor does not work 15

The brush motor does not work 15

The traction motor does not work 15

The water does not come down onto the brushes or is insufficient 16

The machine does not clean properly 16

The squeegee does not dry suffiently 16

Excessive foam production 16

PROGRAMMED MAINTENANCE 17

RECOMMENDED BRUSHES 17

3

Page 3

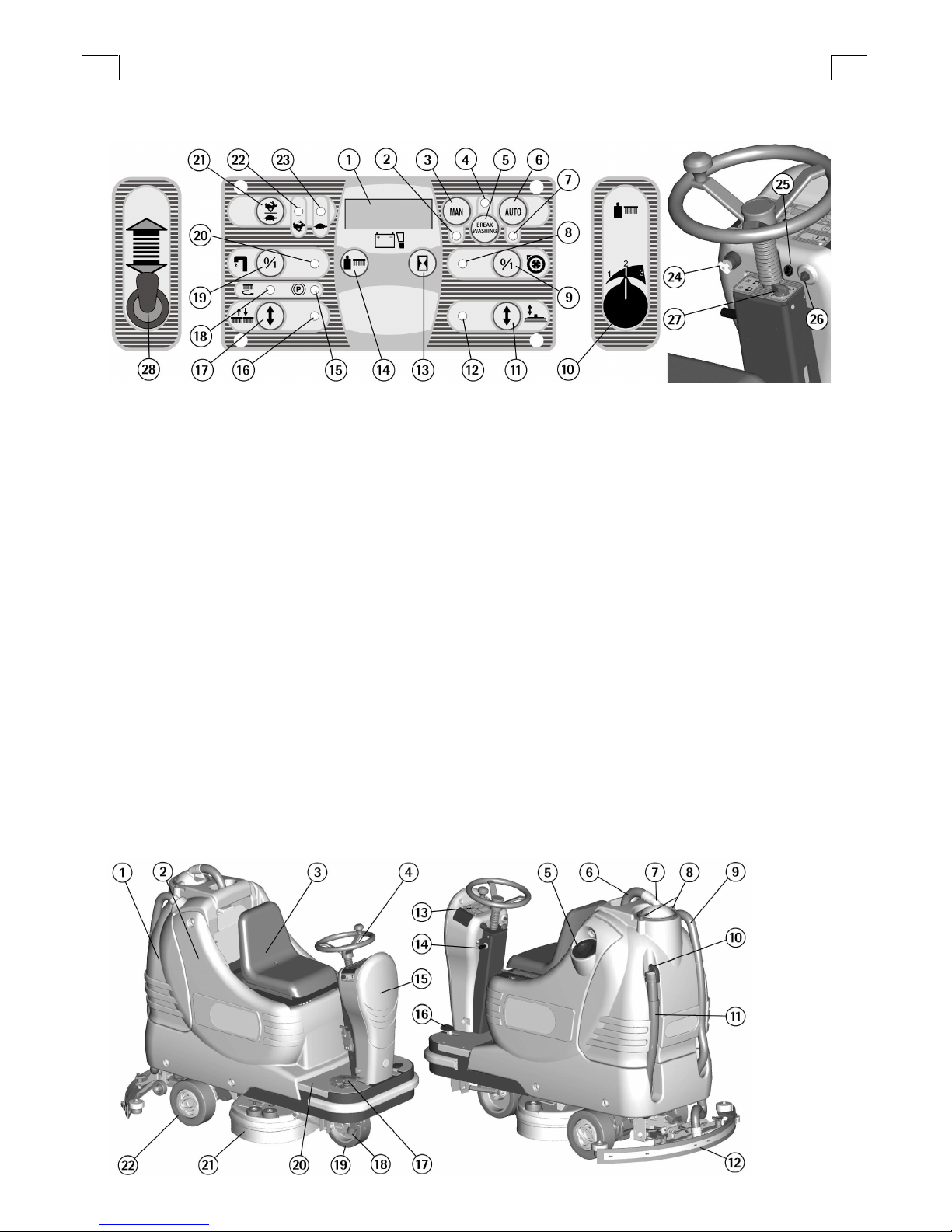

LEGEND PANEL OF CONTROLS

1. Display

2. Signal Lamp Manual Mode On

3. Push Button For Manual Mode

4. Signal Lamp Mode Break Washing On

5. Push Button For Break Washing Mode

6. Push Button For Automatic Mode

7. Signal Lamp Automatic Mode On

8. Signal Lamp Vacuum Motor On

9. Switch For Vacuum Motor

10. Adjustment Knob For Brush Pressure

11. Push Button To Raise/Lower Squeegee

12. Signal Lamp Squeegee Raise/Lower

13. Push Button Visualization Hour Meter (Display)

14. Push Button Visualization Brushes Pressure Set (Display)

LEGEND MACHINE

1. Recovery Tank

2. Solution Tank

3. Seat

4. Steering Wheel

5. Screw Cap For Solution Tank

6. Vacuum Hose

7. Vacuum Cover

8. Blocking Levers Vacuum Cover

9. Squeegee Hose

10. Recovery Tank Drain Hose Plug

11. Recovery Tank Drain Hose

15. Signal Lamp For Parking Brake On

16. Signal Lamp Brushes Raise/Lower

17. Push Button Raise/Lower Brushes

18. Signal Lamp Starting Brushes Rotation

19. Switch Water Opening (Solenoid Valve)

20. Signal Lamp Water Open (Solenoid Valve)

21. Push Button For Speed Selection

22. Signal Lamp Fast Speed

23. Signal Lamp Slow Speed

24. Key Switch

25. Switch For Front Light (Optional)

26. Push Button For Horn

27. Knob For Solution Valve

28. Direction Of Drive Selector

12. Squeegee Assembly

13. Panel Controls

14. Lever Block/Release Parking Brake

15. Cover Electrical Layout

16. Brake Pedal

17. Accelerator Pedal

18. Outer Filter Detergent Solution

19. Drive Wheel

20. Bottom Plate

21. Brushes Base Group

22. Traction Wheels

4

Page 4

TECHNICAL DESCRIPTION

U/M

BD26/27

Cleaning width in 26

Squeegee width in 38.5

Working capacity, up to sqm/h 35,521

Brush diameter in 2 x 13.5

Brush speed rpm 190

Brush pressure lb 133

Brush motor W 650 (27 A)

Traction motor W 500 (25 A)

Vacuum motor W 580 (24 A)

Suction vacuum Water lift 64”

Type of drive Auto

Movement speed Mph 0 to 3.1

Maximum gradient % 10

Solution tank capacity Gallon 26.4

Recovery tank capacity Gallon 27.7

Machine length In 62

Machine height In 52

Machine width (without squeegee) in 28

Weight of the machine (empty and without

batteries )

lb 573

Battery compartment in 16 x 20 x 15

Sound pressure level (in conformity with EN

60704-1)

dB (A) <70

Class III

Protection level IPX 3

Voltage V 24

5

Page 5

ow the brush pressure set

INTRODUCTION

Thank you for choosing our machine.

This floor cleaning machine is used

for industrial and commercial cleaning

and is able to clean any type of floor.

While moving forward, the combined

action of the brushes and the

detergent solution removes the dirt

which is picked up through the rear

vacuum assembly, leaving a dry

surface.

This machine must only be used for

the manufacturer’s approved

application. It gives the best

performance if it is used correctly and

maintained properly. We therefore ask

you to read this instruction manual

carefully. Please contact our service

department for advice and when

service is required.

GENERAL RULES OF SECURITY

The rules below must be followed

carefully in order to avoid injury and

damage to the machine.

- Read the labels carefully on the

machine. Do not cover them for any

reason and replace them immediately

if damaged.

- This machine must be used only by

authorized staff that has been

properly trained.

- Keep children and unauthorised

persons away from the machine when

in use.

- In case of danger act immediately

upon the emergency brake.

- When the machine is parked,

remove the key and put the parking

brake on.

- Do not mix different detergents, to

avoid harmful odours.

- Storage temperature: between –13º

and 131 º F (-25° and +55°C).

- Operating temperature: between 32º

and 104º F (0° and 40°C).

- The humidity should be between 30

and 95%.

- Do not use the machine in an

explosive atmosphere.

- Do not use the machine as a means

of transport.

- Do not use acid solutions in such

concentrations that could damage the

machine and/or the persons.

- Do not use the machine on surfaces

covered with inflammable liquids or

dusts (for example hydrocarbons,

ashes or soot).

- In case of fire, use a powder fire-

- Do not strike shelving or scaffoldings,

where there is danger of falling

objects.

- Adapt the machine speed to the

working conditions: particularly, slow

down before narrow curves have to

be faced.

- Do not use the machine on areas

having a higher gradient than the one

stated on the plate number.

- The machine carries out

simultaneous operations of washing

and drying. Different operations must

be carried out in restricted areas

prohibited to non-authorized

personnel. Signal the areas of wet

floors with suitable signs.

- If the machine does not work

properly, check by conducting simple

maintenance procedures. Otherwise,

ask for technical advice from an

authorized service center.

- When parts are required, ask for

ORIGINAL spare parts from a

distributor or an authorized dealer.

- Use only ORIGINAL brushes.

- For cleaning and/or maintenance

operations turn off the power supply

from the machine.

- Do not take off the protections which

require the use of tools to be removed.

- Do not wash the machine with direct

water jets or with high water pressure

nor with corrosive material.

- Every 200 working hours have the

machine checked by an authorized

service agent.

- In order to avoid scales on the

solution tank filter, do not fill the

machine with cleaning solution many

hours before use.

- Before using the machine, check

that all panels and coverings are in

position as indicated in this manual.

- Restore all electrical connections

after any maintenance operation.

- Provide for the scrapping of the

material of normal wear following

strictly the respective rules.

- When the machine can no longer be

used, provide for the appropriate

waste disposal of its materials,

especially oils, batteries and

electronic components.

SYMBOLS

Indicates the solution valve

lever

Indicates the solution valve

that adjusts the flow of

solution detergent.

Indicates the maximum

temperature of the solution

detergent.

Indicates the machine is in

manual mode.

Indicates the machine is in

automatic mode.

Indicates the machine is in

break washing mode.

Indicates the switch of the

brush motor.

Indicates the push button to

sh

on the display.

Indicates the button to

adjust the brush pressure.

Indicates the squeegee

lever

Indicates the switch of the

vacuum motor

Indicates the battery charge

level.

Indicates the hour meter.

Indicates the switch for

driving speed.

extinguisher.

Do not use water.

6

Page 6

Indicates the direction of

operation:

forwards/backwards.

Indicates the brake. Light

indicates the brake is on.

Indicates the parking brake.

Indicates the operator has

to read the manual before

using the machine.

Warning symbol.

Read carefully the sections

marked with this symbol.

BEFORE USE

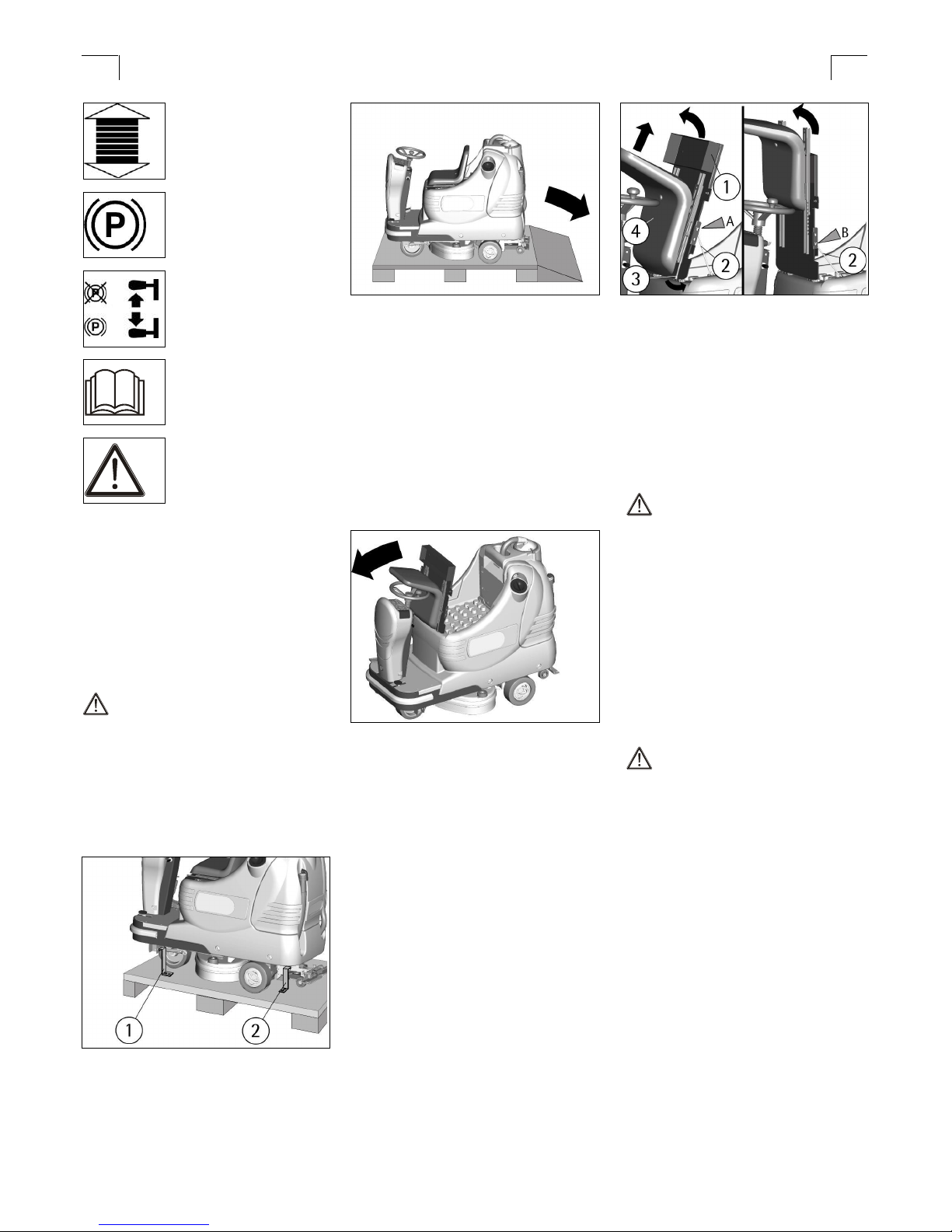

HANDLING PACKED MACHINE

The machine is supplied with suitable

packing for fork lift handling.

Total weight: 290kg.

Packing dimensions:

Base: 178 cm x 93 cm

Height: 138 cm

ATTENTION:

Do not place more than two

packages on top of each other.

UNPACKING THE MACHINE

1. Remove the external packing.

2. Unscrew the brackets (1and 2) that

secure the machine to the pallet.

4. Keep the pallet and the brackets for

future transport.

ACCESS TO THE BATTERY

COMPARTMENT

1. Ensure the machine is on a flat

surface.

2. Rotate the seat platform forward

and hook the bar.

When the operation is finished close

the battery compartment and

reposition the seat platform.

To install a battery into the

compartment, it is necessary to:

1. Rotate the seat platform forward

and hook the bar (2) into position A.

2. Remove the holder (1) by

unscrewing the two wing nuts under

the platform.

3. Pull the releasing lever of the seat

outwards (3) sliding the seat (4) up to

the highest position.

4. Rotate the platform further in order

to hook the bar (2) into position B.

This position will allow batteries to be

handled using suitable lifting

equipment.

BATTERY INSTALLATION

The machine is equipped batteries

connected in series for a total of 24

Volts, placed in its appropriate

compartment under the seat platform

and must be handled using suitable

lifting equipment (due to weight,

considering the type of batteries, and

coupling system).

ATTENTION:

The machine and the battery check

card indicates the use of traditional

lead batteries.

CHECK THE SETTING OF THE

CHECK CARD on the indicator (see

under paragraph "BATTERY

CHARGE LEVEL INDICATOR").

If using GEL batteries it is necessary

to MODIFY THE SETTING of the

electronic check card (see under

paragraph SETTING THE BATTERY

CHECK CARD”).

ATTENTION:

Strictly follow

manufacturer/distributor indications

for the maintenance and recharging of

batteries. All installation and

maintenance operations must be

carried out by authorized staff, using

suitable protection accessories.

To install the batteries it is necessary

to reach the battery compartment as

indicated under paragraph “ACCESS

TO THE BATTERY COMPARTMENT”.

1. Place the batteries in the

compartment.

2. Connect the terminals. Pay

attention to the polarities and avoid

contact with other parts that could

3. Move the machine backwards, as

indicated in the figure, avoiding heavy

contact to any mechanical parts.

short circuit.

BATTERY CHARGER

Be sure that the battery charger is

suitable for the batteries installed

(lead/acid or GEL or equivalent).

7

Page 7

BATTERY CHARGING

1. Plug the battery connector (3) of

the battery charger into the battery

connector (1).

2. Proceed with charging.

1. Disconnect the connector of the

battery charger from the battery

connector (1).

2. Reconnect the battery connector to

the machine connector (2).

3. The battery charge level indicator is

digital and remains fixed on the

display. The battery charge level

starts from 100, which indicates 100%

of the total charge and decreases in

10’s to 10. When the charge level

reaches 20%, the display starts

blinking.

ATTENTION:

Never charge a GEL battery with a

non suitable charger. Strictly follow

BATTERY CHARGE LEVEL

INDICATOR

To start any function of the machine, it

is necessary to rotate the key

clockwise (24). Rotating it counter

clockwise will switch the machine off.

the instructions supplied by the

battery and charger manufacturer.

In order not to cause permanent

damage to the battery, avoid

complete discharge. Charge the

battery within a few minutes after the

battery discharge signal starts blinking.

NOTE: Never leave the battery

completely discharged even when the

machine is not in use. In case of

traditional batteries, please check the

electrolyte level every 20 charging

cycles and top them up with distilled

water. Never leave the batteries

discharged for more than two weeks.

When the machine is switched on,

information will be displayed in the

following order (1):

1. the version (for example A003) of

software installed on the machine.

ATTENTION:

After a few seconds when the four

lines start blinking, all the functions

stop automatically. With the remaining

charge it is possible to finish the

drying operation before proceeding to

charge.

ATTENTION:

When charging the battery it is

important to follow all instructions

given by the manufacturer or

distributor. Installation and

maintenance operations must be

carried out by qualified staff. Danger

of gas exhalations and emission of

corrosive liquids. Fire danger: do not

approach with free flames.

BATTERIES DISPOSAL

It is mandatory to hand over

exhausted batteries, classified as

dangerous waste, to an authorized

institution according to the current

laws.

CONNECTING THE BATTERIES

CONNECTOR AND SWITCHING ON

THE MACHINE

Once the battery has been charged:

2. the setting of the battery check card

which can be:

GE 24 (check card set for GEL

batteries).

or

Pb 24 (check card set for lead

batteries).

SETTING THE BATTERY CHECK

CARD

The machine, if not specified

otherwise, is supplied with the battery

check card set for lead batteries. To

modify this setting, it is necessary to:

1. Switch the machine off then back

on.

2. Immediately after having switched

the machine back on, when the

writing Pb24 appears on the display

(1), press simultaneously the buttons

(3) and (6) until the writing begins to

flash.

3. When the writing begins to flash,

release the buttons and press the

button again once (6).

8

Page 8

4. The writing GE24 appears flashing.

5. When the writing stops flashing, the

setting is modified.

Both wheels must be adjusted to the

same height.

To change the setting from gel

batteries to lead batteries, repeat the

procedure pressing button (3) instead

of button (6).

SQUEEGEE ADJUSTMENT

In order to achieve good drying

HOUR METER

The machine is equipped with an hour

meter located on the same display (1)

as the battery charge level indicator.

Hold the button (13), the first data

indicates the working hours and after

a few seconds the working minutes

are shown.

results, the rear rubber of the

squeegee must be bent equally in

length. To adjust, it is necessary to

put the machine in operation and

therefore the vacuum motor has to be

switched on and the brushes have to

function together with the detergent

solution.

ATTENTION:

Every type of floor requires a

specific adjustment. For example,

concrete floors (where the friction

results will be high) need little

pressure, while smooth floors

(ceramics) need higher pressure.

If the cleaning operations are made

always on the same type of floor, the

adjustment can change only in

function of the rubber wear.

SPLASH GUARD ASSEMBLY

The two splash guards have to be

assembled onto the brushes base

group as indicated in the following

figures. Insert the metal strips inside

SQUEEGEE ASSEMBLY

1. Keep the squeegee support (1)

slightly lifted from the floor.

2. Insert the threaded parts of the two

bolts (4) sliding them inside the two

slots on the support placed on the

upper part of the squeegee (2).

3. Put the washers (3) into position,

there are two for each bolt, so that

they are assembled one under and

the other over each of the two slots

present on the support.

4. Secure the squeegee by rotating

the two levers (4) clockwise.

5. Insert the squeegee hose (5) into

its coupling, follow the picture for

positioning.

The lower part of the rubber is overly

bent

Take off the pressure by rotating the

wing nut (6) counterclockwise.

The lower part of the rubber is not

bent enough

Increase the pressure rotating the

wing nut (6) clockwise. Check that the

wheels that adjust the height are not

resting on the floor, in this case adjust

them as indicated in paragraph

"Height adjustment".

The bend is not equal

Adjust the squeegee inclination

rotating the wing nut counterclockwise

(7) to increase the bend in the central

part, or clockwise to increase the

the slots present on the rubber. Place

the round hole at the extremity of the

strip onto the screw (1) place in the

front part of the brushes base group.

Secure the strips through the nut

blocking it.

Secure the coupling lever (2) in the

rear part of the brushes base group to

the ring placed at the extremity of the

metal strip still free. Repeat as above

for both splash guard rubbers.

The splash guard must slightly touch

the floor when the brushes are

assembled.

To remove the splash guard follow the

above instructions in reverse.

bend on the outer part.

Height adjustment

Once the pressure and inclination of

the squeegee have been adjusted, it

is necessary to fix this optimum

condition ensuring the wheels only

slightly touch the floor. Rotate

counterclockwise the bolts (8) to lower

the wheels or clockwise to raise them.

9

Page 9

inclination of the bristles causes

excessive motor overload or

troublesome vibrations.

ASSEMBLING THE BRUSHES

To assemble the brushes it is

necessary that the brushes base is in

the lifted position. If it is not lifted,

proceed as follows:

Without the operator seated, turn the

key switch clockwise, the display

comes on and after 3 seconds all

working groups switch off

automatically and are lifted from the

floor.

Switch off the machine turning the key

counterclockwise.

ATTENTION:

Carrying out brush operations with

the electric supply on may cause

injury.

With the base of the brushes in the

lifted position, insert the brushes into

their plate seat underneath the

brushes base turning them until the

three metal buttons are properly

seated in their slots; rotate the

brushes to push the button towards

the coupling spring until they are

locked.

The figure shows the rotating direction

for brushes coupling.

For a longer life of the brushes we

suggest to daily alternate their

position. Whenever brushes do

become deformed we suggest to

reassemble them in the same position,

in order to avoid that the different

ATTENTION:

Use only brushes supplied with the

machine or ones indicated in the

paragraph “RECOMMENDED

BRUSHES”. The use of other brushes

can affect the cleaning result.

FLOOR CLEANING

RECOVERY TANK

Check that the cover of the vacuum

filter (1) is correctly secured, after

rotating the levers (2) and that the

vacuum motor hose (3) is correctly

connected to it.

Verify also that the squeegee hose

couplings (4/5) are correctly inserted

into their seats and that the drain

hose plug (6) placed in the rear part of

the machine is closed securely.

DETERGENT SOLUTION TANK

The solution tank capacity is indicated

in the technical data.

Open the screw cap placed in the left

part of the machine and fill the

solution tank with clean water at a

maximum temperature of 122º F

(50°C). Add the liquid detergent in

the percentage and conditions

recommended by the manufacturer.

To avoid excessive foaming, which

could cause problems to the vacuum

motor, use a minimum amount of

detergent. Screw down the cap to

close the tank.

ATTENTION:

Always use a low foaming detergent.

To avoid foaming, before starting the

machine, use a small amount of antifoaming product in the recovery tank.

Never use pure acid.

STARTING THE MACHINE

A safety device ensures that if the

operator is not seated correctly in the

seating position the machine does not

move.

To switch on the machine:

1. Sit on the seat.

2. Turn the key switch (24) clockwise

to switch on the machine.

Automatically, the machine gets ready

in manual (MAN) mode and in forward

movement with the quick speed

(signal lamp 22).

3. Check the charge level of the

batteries on the display (1).

4. Pressing the push button (5) the

functioning of BREAK WASHING is

chosen and the transfer operations of

the machine are carried out (see

under paragraph “FORWARD AND

BACKWARD MOVEMENT"). When

the signal lamp (4) is on the machine

is in BREAK WASHING mode.

5. Pressing the push button (6) the

automatic (AUTO) function is chosen,

when pressing the push button (3),

the function of the machine becomes

manual (MAN).

A. When the signal lamp (7) is on, the

machine is functioning in automatic

(AUTO) mode and the machine

activates and deactivates all the

working functions in an automatic

mode (see under paragraph

“WORKING IN AUTOMATIC MODE”).

B. When the signal lamp (2) is on, the

machine is functioning in manual

(MAN) mode and it is then possible to

choose:

I. to transport the machine without

activating or deactivating the working

functions.

10

Page 10

II. to separately activate only the

controls relative to the washing

function with the brushes (see under

paragraph “WORKING IN MANUAL

MODE”).

III. to separately activate only the

controls relative to the drying

that the fast drive is selected, while

signal lamp (23) indicates that the

slow drive is selected.

9. When moving in reverse, an

intermittent warning device is

activated.

function with the squeegee (see

under paragraph “WORKING IN

MANUAL MODE”).

ATTENTION:

In manual mode every function of

the machine has to be activated or

deactivated manually.

AUTOMATIC SQUEEGEE LIFTING

FORWARD AND BACKWARD

MOVEMENT

It is always recommended to move

and transport the machine in (BREAK

WASHING) mode

To activate the movement of the

machine proceed as follows:

1. Sit on the seat.

2. Turn the key switch (24) clockwise

to switch on the machine.

3. Check the charge level of the

batteries on the display (1).

4. Pressing the push button (5) the

functioning of BREAK WASHING is

chosen to carry out the transfer of the

machine. In fact, in this mode the

washing functions of the machine are

not working and only the traction

system functions. When the signal

lamp (4) is on, then the machine is in

BREAK WASHING mode.

5. Check through the signal lamp (15)

that the parking brake is not on and

release it if required (see under

paragraph EMERGENCY-PARKING

BRAKE”).

6. Positioning the selector (28)

forward, the forward drive is chosen,

while positioning it back, the rear drive

is selected.

7. Press the accelerator pedal placed

on the right of the platform to start the

machine.

8. Adjust the speed in forward drive

by pressing the push button (21) to

choose the slow one (maximum 3,6

km/h) or the fast one (maximum 5

km/h). The signal lamp (22) indicates

HORN

The machine is equipped with a horn

which is activated by pressing the

push button (1).

WORKING BRAKE

To stop the machine during normal

working conditions, it is sufficient to

release the accelerator pedal,

because the machine has an

electronic brake system. To restart,

press the accelerator pedal again.

EMERGENCY BRAKE

In case of an emergency, press the

brake pedal (1) placed on the lefthand side of the platform

To activate the parking brake press

the brake pedal (1) and

simultaneously move the lever

downward (2) situated on the left side

of the steering column.

On the instrument board the signal

lamp (15) comes on which signals

that the parking brake is on.

To release the parking brake press

the brake pedal (1).

WHEN GOING BACKWARDS

When reverse movement is selected

the squeegee is automatically raised

to the upper position. It will then lower

again once the forward movement

has been selected.

This happens both in automatic and in

manual mode in order to protect the

squeegee.

WORKING IN AUTOMATIC MODE

The automatic mode of operation is

useful to simplify the operator’s work.

1. Activate the machine (see under

paragraph “STARTING THE

MACHINE”).

2. Pressing the push button (6) the

automatic (AUTO) mode function is

selected. When the signal lamp (7) is

on, then the machine is functioning in

automatic (AUTO) mode.

3. Check that the knob of the solution

valve (27) is in the position of

optimum flow, depending on the type

of floor and the type of dirt (see under

the paragraph “FLOW ADJUSTMENT

OF THE DETERGENT SOLUTION”).

4. Position the selector (28) forward to

choose the forward drive.

5. Adjust the movement speed in

forward with the push button (21) (see

under paragraph "FORWARD AND

BACKWARD MOVEMENT").

6. By pressing the accelerator

pedal, the machine begins to move

forward and in automatic mode

pressing the accelerator pedal

activates all the working functions.

Automatically the squeegee goes

down, the brushes begin to turn, the

11

Page 11

solenoid valve opens to permit the

detergent solution to flow down onto

the brushes and the vacuum system

is activated to recover the dirty water

from the floor.

By positioning the selector (28)

backwards the reverse drive is

selected and by pressing the

accelerator pedal the reverse drive

starts, the squeegee lifts automatically

and will then return to lower itself

during the next forward movement.

If the accelerator pedal is released

for more than 3 seconds, all the

functions are automatically

switched off and both the brushes

stop and the squeegee is lifted.

Pressing the pedal again, the

machine starts to move and in

automatic mode all the working

functions are reactivated.

TO CARRY OUT THE WASHING

WITH ONLY THE BRUSHES:

1. Check that the knob of the solution

valve (27) is in the position of

optimum flow, depending on the type

of floor and the type of dirt (see under

the paragraph “FLOW ADJUSTMENT

OF THE DETERGENT SOLUTION”).

2. Press the push button (17) to lower

the brushes. Once lowered, the

brushes begin to turn. The signal

lamp (16) indicates that the brushes

base is lowering or lifting, while the

signal lamp (18) signals that the

brushes are turning.

3. Press the switch (19) to open the

solenoid valve and permit the

detergent solution to flow down onto

the brushes. The signal lamp (20) will

come on, to indicate that the solenoid

valve is open.

WORKING ADJUSTMENTS

In automatic mode as in manual mode,

during the first metres check:

1. That the squeegee adjustment

guarantees a perfect drying result

(see under paragraph “SQUEEGEE

ADJUSTMENT”).

2. That the adjustment of the

detergent solution flow is sufficient to

wet the floor evenly avoiding the

leakage of detergent from the splash

guards (see under paragraph “FLOW

ADJUSTMENT OF THE

DETERGENT SOLUTION”).

3. That the pressure of the brushes

permit an efficient washing action in

relation to the dirt and the speed (see

under paragraph “ADJUSTMENT OF

THE BRUSHES PRESSURE”).

FLOW ADJUSTMENT OF THE

DETERGENT SOLUTION

To adjust the detergent solution

quantity that flows down onto the

brushes it is necessary to adjust the

solution valve knob (27) placed on the

right of the steering column, rotate the

knob counterclockwise to increase the

flow and clockwise to reduce it up to

shutting off the flow of solution.

BRUSH PRESSURE ADJUSTMENT

Using the knob (10) it is possible to

adjust the brush pressure onto the

floor in three pre-set pressure levels.

The display (1) will indicate the

pressure in kg that has been

previously set by pressing the push

button (14).

Adjustment is possible in both

automatic and manual mode.

WORKING IN MANUAL MODE

The manual model is useful when, in

specific cases, it is necessary to carry

out only the washing with the brushes

or only the drying of the floor.

ATTENTION:

The washing and drying functions,

when they are not carried out

simultaneously, represent an

improper use of the machine (see

under paragraph “GENERAL

RULES OF SECURITY”). If they are

carried out separately, it is

necessary to prohibit un-authorized

personnel from the cleaning areas

and to signal areas of wet floors

with suitable signs.

1. Activate the machine (see under

paragraph “STARTING THE

MACHINE”).

2. Press the push button (3), manual

(MAN) mode is chosen. When the

signal lamp (2) is on, the machine is

functioning in manual (MAN) mode.

TO CARRY OUT THE FUNCTION OF

ONLY DRYING:

1. Press the raise/lower squeegee

button (11) to lower the squeegee.

The signal lamp (12) indicates that the

squeegee is lowering or lifting.

2. Press the vacuum motor switch (9)

to start the vacuum system. The

signal lamp (8) indicates that the

machine is drying.

Position the selector (28) forward to

choose the forward drive.

Adjust the movement speed in

forward with the push button (21) (see

under paragraph "FORWARD AND

BACKWARD MOVEMENT”).

Pressing the accelerator pedal, the

machine begins to proceed forward

and to work according to the set

functions.

ATTENTION:

In manual mode every function of

the machine has to be activated or

deactivated manually.

12

Page 12

ATTENTION:

In order not to overload the brush

motor, reduce the brush pressure

functions have to be re-established

manually.

going from smooth floors to rough

ones (ex. concrete).

STOPPING THE MACHINE AFTER

ELECTRIC PROTECTION

The machine is equipped with an

electronic system of protection for all

components that carry out functions of

power or control. This device blocks

the defective component and

indicates on the display (1) the

corresponding alarm from ”AL01” to

“AL20”.

ATTENTION:

To restore the functioning of the

component, turn the machine off and

back on using the key switch. If the

problem persists, please contact an

authorized technical person.

OVERFLOW DEVICE

To avoid serious damage to the

vacuum motor, the machine is

equipped with a mechanical float that

intervenes when the recovery tank is

full which closes the vacuum hose

and stops the vacuum.

CLEANING

IN AUTOMATIC OR MANUAL

WORKING MODE:

1. At the end of the washing cycle,

pressing the push button (5), the

function of BREAK WASHING is

chosen. When the signal lamp (4) is

on, then the machine is in BREAK

WASHING mode. In this way the

brushes lift automatically, the solenoid

valve shuts down and it is possible to

finish the drying operation.

2. When the accelerator pedal is

released for more than 3 seconds, the

squeegee raises itself and the

vacuum switches off automatically.

3. After three seconds, the accelerator

can be pressed again, if a machine's

transfer has to be made (the transfer

can be carried out also if the pedal is

never lifted, in this case the squeegee

gets lifted and the vacuum stops

automatically after 15 seconds).

4. Turn the switch key

counterclockwise to switch off the

machine.

5. Insert the parking brake (see under

paragraph “EMERGENCY-PARKING

BRAKE”).

ATTENTION:

The mode (BREAK WASHING)

is specific for the transfer at the end of

the cleaning operation.

DAILY MAINTENANCE

ATTENTION:

The following maintenance and

cleaning operations refer to those

components that are in contact

with liquids:

· Solution and recovery tanks

· Solution and recovery filters

· Squeegee including squeegees

and hoses

· Brushes

The following operations must be

carried out using gloves to protect

from dangerous solutions.

EMPTYING AND CLEANING THE

RECOVERY TANK

1. Hold the drain hose (1) placed in

the rear part of the machine after

having taken it off from its fixed

position.

2. Take the plug off (2) the drain hose

by pulling the lever (3) and empty the

recovery tank into appropriate

containers, in compliance with the

respective rules of liquid disposal

regulations.

3. Take off the vacuum cover (4) after

rotating the blocking levers (5).

4. Take off the filter and the filter

protection (6).

5. Rinse the inside of the tank with a

water jet.

6. Reassemble all parts.

When this happens, empty the

recovery tank (see under paragraph

“RECOVERY TANK EMPTYING AND

CLEANING”).

To start the cleaning operation again:

A. to start working in automatic mode

(AUTO) press push button (6).

B. to start working in manual mode

(MAN) press push button (3). All

13

Page 13

3. Turn the rubber to a new side or

replace it.

To reassemble the squeegee repeat

inversely the operations mentioned

above, inserting the rubber on the

guides and blocking it with the rubber

holder blade.

CLEANING THE VACUUM FILTER

1. Take off the vacuum cover (4) after

rotating the blocking levers (5).

2. Take off the filter (8) and its filter

protection (6).

3. Clean all parts with a water jet and

especially the inside surfaces and the

filter bottom.

4. Carry out cleaning operations

carefully.

5. Reassemble all parts.

CLEANING THE BRUSHES

Disassemble the brushes and clean

them with a water jet (for dissembling

the brushes see under paragraph

“DISASSEMBLING THE BRUSHES”).

DISASSEMBLING THE BRUSHES

With the brushes base in the lifted

position (see under paragraph

"BRUSH ASSEMBLY"), rotate the

brushes in order to release the button

from the coupling spring until it

becomes free and wash them with a

water jet. The figure shows the

rotating direction to release the

brushes.

ATTENTION:

Disassembling the brushes with the

electric supply on may cause injury.

CLEANING THE SQUEEGEE

Keeping the squeegee clean

guarantees the best drying result.

To clean the squeegee it is necessary

to:

1. Take off the squeegee hose (5)

from the coupling.

2. Disassemble the squeegee (2) from

its support (1) by loosening the knobs

(4) counterclockwise and sliding the

threaded parts in the appropriate slots

up to their release.

3. Clean with care the internal part of

the squeegee inlet eliminating any dirt.

4. Clean with care the squeegee

rubbers.

5. Reassemble all parts paying

attention to put the washers (3) into

position, there are two for each knob,

so that they are assembled one under

and the other on each of the two slots

present on the support.

WEEKLY MAINTENANCE

REAR SQUEEGEE RUBBER

CHECK

Check the squeegee rubber wear and

eventually turn or replace it.

For the replacement it is necessary to:

1. Lift the squeegee (see under

paragraph “STOP OF THE MACHINE

AFTER CLEANING OPERATION”).

2. Release the hook (1) of the rubber

holder blade and take off the rubber.

SQUEEGEE HOSE CLEANING

Weekly or in case of insufficient

vacuum, it is necessary to check that

the squeegee hose is not blocked. To

clean it, proceed as follows:

1. Take off the hose (1) from the

squeegee coupling.

2. Wash the inside of the hose with a

water jet.

3. To reassemble the hose repeat in

reverse the above-mentioned

operations.

CLEANING THE SOLUTION TANK

AND THE OUTER FILTER

1. Bring the machine to an

appropriate area to drain the solution

tank.

2. Unscrew the solution tank cap (1).

3. Unscrew the cap of the exhaust

filter (2) and take off the filter. Be

careful not to lose the cap’s gasket.

4. Open the solution valve (see under

paragraph “FLOW ADJUSTMENT OF

THE DETERGENT SOLUTION”), so

that the detergent solution flows down

into appropriate containers.

5. Rinse the solution tank and filter

components with a water jet.

14

Page 14

6. Reassemble all parts.

NOTE: if required it is possible to

wash only the components of the

Pour some water into the tank to

clean it. Reassemble the fitting onto

the solution tank.

outer solution filter by closing the

solution valve adjustment (see under

paragraph “FLOW ADJUSTMENT OF

THE DETERGENT SOLUTION”), so

that the detergent solution remains in

the solution tank.

CHECKING THE BRAKES

Check the brake of both rear wheels.

Should the braking be insufficient,

please contact an authorized

technical assistance.

TWO-MONTHLY MAINTENANCE

FRONT SQUEEGEE RUBBER

CHECK

Check the wear of the squeegee

blade and replace when necessary.

For replacement:

1. Take off the squeegee (see under

paragraph “CLEANING THE

SQUEEGEE”).

2. Unscrew the wing nuts in the front

part of the squeegee.

3.Take off the squeegee holder blade.

4. Replace the front blade.

5. Reassemble all parts.

SIX-MONTHLY MAINTENANCE

SPLASH GUARD RUBBER CHECK

With the brushes assembled, the

splash guards must touch the floor

slightly. If they are worn, they have to

be replaced. Just release the springs

placed in the rear part of the brushes

base group from the slots placed at

the free extremities of the metal strips

to take off the rubbers and to reinsert

the new ones (see under paragraph

“SPLASH GUARD ASSEMBLY”).

CLEANING THE INNER FILTER OF

THE SOLUTION TANK

Empty the solution tank, remove the

fitting (1) of the water outlet by taking

off the two screws that fix it to the tank

in the rear part of the machine. Clean

the inside filtration part of the fitting.

TROUBLESHOOTING GUIDE

ATTENTION:

If when the key switch is positioned

clockwise when switching the

machine on and the display and other

functions are not activated, it is

necessary to check the batteries'

connection to the machine (see under

paragraph “CONNECTION

BATTERIES' CONNECTION AND

STARTING THE MACHINE”). If the

problem persists, please contact the

authorized technical assistance.

THE VACUUM MOTOR DOES NOT

WORK

1. Verify that the key switch is

positioned clockwise to switch on the

machine. If the alarm signals it is

necessary to switch the machine off

and on again to restore the

functionality.

2. Check the charge level of the

batteries on the display (1).

3. Verify that the drying function is

correctly activated. (see under

paragraph “STARTING THE

MACHINE”).

4. Check that the recovery tank is not

full.

5. If, both in mode (MAN) and

(AUTO),the signal lamp (8) is on

but the vacuum system does not

work, please contact the

authorized technical assistance.

THE BRUSH MOTOR DOES NOT

WORK

1. Verify that the key switch is

positioned clockwise to switch on the

machine. If the alarm signals it is

necessary to switch the machine off

and on again to restore the

functionality.

2. Check the charge level of the

batteries on the display (1).

3. Verify that the function of washing

with the brushes has been correctly

selected (see under paragraph

“STARTING THE MACHINE”).

4.If, both in mode (MAN) and (AUTO),

the signal lamp (18) is on but the

brushes do not turn, please contact

an authorized technical centre.

THE TRACTION MOTOR DOES NOT

WORK

1. Sit on the seat.

2. Verify that the key switch is

positioned clockwise to switch on the

machine. If the alarm signals it is

necessary to switch the machine off

and on again to restore the

functionality.

3. Check the charge level of the

batteries on the display (1).

15

Page 15

4. Check that the parking brake signal

lamp (15) is not on and release it if

necessary (see under paragraph

“EMERGENCY-PARKING BRAKE”).

5. Press the accelerator pedal placed

on the right side to start the machine.

If the problem persists, please contact

the authorized technical assistance.

THE WATER DOES NOT COME

DOWN ONTO THE BRUSHES OR IS

INSUFFICIENT

1. Verify that the key switch is

positioned clockwise to switch on the

machine.

2. Check the charge level of the

batteries on the display (1).

3. Verify that the function of washing

with the brushes is correctly activated

(see under paragraph “STARTING

THE MACHINE”).

4. Check that the solution valve is

open (see under paragraph “FLOW

ADJUSTMENT OF THE

DETERGENT SOLUTION”).

5. If, both in (MAN) and (AUTO),

mode the signal lamp (20) is on but

the detergent solution does not come

down onto the brushes, it is

necessary to:

a. check the level of the liquid in

the tank.

b. check that the solution filter is

clean (see under paragraph

“CLEANING THE SOLUTION

TANK AND THE OUTER

FILTER”).

c. check that the inner filter of

the solution tank is clean (see

under paragraph “CLEANING

THE INNER FILTER OF THE

SOLUTION TANK”).

If the problem persists, please contact

the authorized technical assistance.

THE MACHINE DOES NOT CLEAN

PROPERLY

1. The brushes do not have the

suitable bristle dimension: contact an

authorized technical centre.

2. The brushes have worn out bristles.

Check the brush wear condition and

replace if necessary (the brushes

have to be replaced when the bristles

have reached a height of about ½”

15mm).

To replace the brushes, see

instructions under paragraph

“DISASSEMBLING THE BRUSHES”

and “ASSEMBLING THE BRUSHES”.

3. The detergent solution is

insufficient: open the solution valve

more (see under paragraph “FLOW

ADJUSTMENT OF THE

DETERGENT SOLUTION”).

4. Check that the liquid detergent is in

the recommended percentage.

5. Increase the brush base pressure

(see under paragraph " BRUSHES

PRESSURE ADJUSTMENT ").

Contact an authorized technical

centre for advice.

THE SQUEEGEE DOES NOT DRY

SUFFICIENTLY

1. Check that the vacuum function is

on and that the recovery tank is not

full.

2. Check that the squeegee blades

are clean (see under paragraph

“CLEANING THE SQUEEGEE”).

3. Check the adjustment of the height

and the inclination of the squeegee

(see under paragraph “SQUEEGEE

ADJUSTMENT”).

4. Check that the vacuum and the

squeegee hoses are correctly inserted

in their proper seats on the recovery

tank.

5. Clean the vacuum filter (see under

paragraph “CLEANING THE

VACUUM MOTOR”).

6. Clean the squeegee hose (see

under paragraph “SQUEEGEE HOSE

CLEANING”).

7. Replace the blades if worn out.

EXCESSIVE FOAM PRODUCTION

Check that low foam detergent has

been used. Add small quantities of

anti foam liquid into the recovery tank.

Please be aware that more foam is

produced the cleaner the floor. In this

case please dilute detergent solution.

16

Page 16

PROGRAMMED MAINTENANCE

IINTERVAL DAILY 20 HOURS * 200 HOURS *

RECOVERY TANK CLEANING

VACUUM FILTER CLEANING

·

·

SOLUTION TANK FILTER CLEANING

BRUSH CLEANING

BRUSH DISASSEMBLY AND CLEANING

SQUEEGEE CLEANING

·

·

·

FRONT SQUEEGEE BLADE REPLACEMENT

REAR SQUEEGEE BLADE REPLACEMENT

·

·

·

SPLASH GUARD RUBBER REPLACEMENT

CHECK SQUEEGEE ADJUSTMENT

SQUEEGEE HOSE CLEANING

SOLUTION TANK CLEANING

CHECK BATTERY ELECTROLYTE

·

·

·

·

CHECK THE BRAKE

CHECK THE TRACTION MOTOR

CHECK THE BRUSH MOTOR

CHECK THE VACUUM MOTOR

CHECK THE BRUSH BASE

·

SCREW TIGHTENING

1000 HOURS

*

·

·

·

·

·

·

* The hours refer to the ones indicated on the display (see under paragraph ”HOUR METER”).

RECOMMENDED BRUSHES

Brushes must be chosen depending on floor type and dirt to be removed.

The material and bristle diameter are the elements that distinguish different types of brushes.

MATERIAL CHARACTERISTICS

PPL (Polypropylene) Good wear resistance. Maintains characteristics with hot water up to 50°C. It is not hygroscopic.

NYLON Excellent wear resistance, even with hot water. It is hygroscopic.

TYNEX

BRISTLES

THICKNESS

PAD HOLDER

Nylon bristles with grains of abrasive material. Use with caution in order not to mark the floor or

ruin the polishing.

Thicker bristles are more rigid and must be used on smooth floor or floor with small joints. On

irregular floors with deep joints or relieves, it is recommended to use softer bristles which

penetrate more easily and deeper. Please be aware that when brush bristles are worn out and

therefore too small, they become rigid and unable to penetrate and clean deeper. This may also

happen with thicker bristles creating brush vibration.

It has anchor points which permit the blocking of the abrasive pad during work. The pad is

recommended to clean smooth floors.

MACHINE CODE QUANTITY DESCRIPTION USE

BD26/22 48903020 2 Brush PPL 0,6 Ø 345 Normal floors.

Smooth floors with small joints and

48903030 2 Brush PPL 0,9 Ø 345

persistent dirt.

48903040 2 Brush TYNEX Ø 345 Floors of resistant material and particularly

48803030 2

Pad holder Ø 330 + center lock

green

dirty.

For pads of 14”, for smooth surfaces

cleaning.

17

Loading...

Loading...