Page 1

Operations & Maintenance Manual

For Commercial Use Only

TORNADO INDUSTRIES, LLC

3101 WICHITA COURT

FORT WORTH, TX 76140

PHONE: 800-VACUUMS

FAX: 817-551-0719

WWW.TORNADOVAC.COM

BD 17/6 17” AUTOMATIC SCRUBBER

Form No. L9617M

AB 02/17 ©Tornado Industries, LLC. All rights reserved

MODEL NO: 99617

1

Page 2

Long Term Buyer Protection Limited Warranty

Tornado Industries, LLC. (Tornado) warrants to the end/user customer that the Tornado product(s) will

be free from defects in material and workmanship for the duration(s) described below. This limited

warranty DOES NOT cover machines and/or components subject to normal wear and tear, damage

that occurs in shipping, failures resulting from modication, accident, unsuitable operating environment, misuse, abuse, neglect, or improper maintenance by you. For full details, contact your Authorized Tornado Distributor, Service Center, or the Tornado Technical Service Department. Tornado

sales and service representatives are not authorized to waive or alter the terms of this warranty, or to

increase the obligations of Tornado under the warranty.

10 Years*

Plastic water tanks and Rotationally-molded bodies

2 Years*

Parts on all Tornado cleaning equipment

1 Year*

Labor on all Tornado cleaning equipment

1 Year*

Warranty on batteries, one year prorated

All battery warranties are handled directly by the battery manufacturer, on a one year prorated basis

Terms subject to change without notice

1. Except all Windshears™ Blowers, Storm, TV2SS, Side and Downdraft, Insulation Blowers, CV 30,

CV 38, CK14/1 PRO, CK 14/2 PRO, SWM 31/9, CK LW13/1, CK LW 13/1 ROAM, CV 38/48 Dual,

PV6, PV10, PV6 ROAM, Wall Mount Vacuum and all chargers are warranted for 1 (one) year for both

parts and labor.

2. All non-wear item parts purchased after warranty expiration are warranted for 90 days.

3. Warranty starts from the date of sale to the consumer or, at Tornado’s discretion, 6 months after

the dealer purchased the unit from Tornado, whichever comes rst.

4. The EB 30 is warranted for a period of 90 days for both parts and labor.

5. The warranty on engines used on propane powered equipment is limited to motor manufacturer’s

warranty.

6. Ride-on Scrubbers are warranted for 24 months, parts, 6 months labor or 1,000 hours, whichever

occurs rst.

Note: Tornado, The Latest Dirt, Floorkeeper,

Carpetkeeper, Carpetrinser, Carpetrinser/Dryer,

Headmaster, Taskforce, PAC-VAC, T-Lite, Glazer,

Windshear, Max-Vac and Trot-Mop are trademarks

of Tornado Industries

Website: www.tornadovac.com

Phone 1-800-VACUUMS

Fax 817-551-0719

Address 3101 Wichita Court

Fort Worth, TX 76140

1-800-VACUUMS 90 Years of Cleaning Innovation A Tacony Company

Form F2662.©2017. All rights reserved

Page 3

NOTES

3

Page 4

NTRODUCTORY COMMENT

I

Thank you for selecting our machine.

This oor cleaning machine is used for

the commercial cleaning of most types

of hard oors. During forward movement, the combined action of the brush

and the detergent solution remove the

dirt which, is recovered through the rear

squeegee assembly, giving a perfectly

dry surface.

The machine must be used only for this

purpose. It gives the best performance

if it is used correctly and maintained in

good condition. Read this instruction

booklet carefully prior to using this ma-

chine and whenever difculties arise in

the course of the machine’s use. Contact our service department for all advice

and servicing as may prove necessary.

GENERAL RULES OF SAFETY

The rules below must be followed carefully in order to avoid injury to the operator and damage to the machine.

- Read the labels on the machine carefully. Do not cover them for any reason

and replace them immediately if damaged.

- The machine must be used only by authorized staff that have been instructed

on its correct and proper use.

- When operating the unit, pay attention

to other people and especially to children.

- Do not allow the machine to be used

as a toy.

- The machine is not to be used by per-

sons, with reduced physical, sensorial

or mental capabilities, or with lack of

experience and/or knowledge.

- The outlet for the charger must be

equipped with a standard electrical

ground system.

- Do not allow the cord to become damaged.

- Do not mix different detergents.,

- Storage temperature: between 32°F

(0°C) and 131°F (+55°C).

- Operating temperature: between 32°F

(0°C) and 104°F (+40°C).

- The humidity should not exceed 95%.

- Do not use the machine in explosive

atmosphere.

- Do not use the machine as a means of

transport.

- Do not use the machine onstairs.

- Do not use acid solutions which could

damage the machine.

- To avoid damage to the oor, do not

allow the brush to rotate while the

machine is in one place.The machine

muust be moving while the brush is

rotating.

- Do not use the machine on surfaces

covered with inammable liquids or

dusts (for example hydrocarbons, ashes

or soot).

- In case of re, use a powder based re

extinguisher. Do not use water.

- Do not strike structures where there is

a danger of falling objects.

- Do not use the machine on areas having a higher gradient than the one stated

on the number plate.

- Place appropriate signs in and around

the cleaning area.

- If the machine does not work properly,

check by conducting simple mainte-

nance procedures. Otherwise, ask for

technical advice from an authorized

service center.

- Where parts are required, ask for

ORIGINAL spare parts from the distributor and/or from an authorized dealer.

- Use only ORIGINAL brushes indicated

in the paragraph “RECOMMENDED

BRUSHES".

- For any cleaning and/or maintenance

operation remove the power from the

machine.

- Do not take off the protections which

require the use of tools for their removal.

- Do not wash the machine with direct

water jets or with high water pressure

nor with corrosive material.

- Every 200 working hours have a ma-

chine check by an authorized service

technician.

- Before using the machine, check that

all panels and coverings are in their

position as indicated in this use and

maintenance manual.

- Restore all electrical connections after

any maintenance operation.

- Provide for the scrapping of the mate-

rial of normal wear (brushes, squeegee

blades etc.) following strictly the respec-

tive rules.

- When your machine has stopped

functioning, provide for the appropri-

ate waste disposal of its materials,

especially oils, batteries and electronic

components, and considering that the

machine itself has been, where possible,

constructed using recyclable materials.

SYMBOLOGY

Symbol 0/1 indicating the ON/

OFF switch and its signal lamp.

Symbol denoting the solution

valve. Indicates the switch and

the signal lamp of the solenoid valve.

Symbol denoting the brush.

Indicates the switch and the signal lamp

of the brush motor.

Symbol denoting the suction

motor. Indicates the switch and the

signal lamp of the suction motor.

Symbol denoting the charge

level of the batteries.

Symbol that indicates the posi-

tion of the drain plug of the solution tank.

This symbol indicates

that the tanks are to be emptied before

rotating the machine.

Indication of the maximum tem-

perature of the solution detergent.

Symbol that indicates the ow

adjuster of the detergent solution.

Symbol denoting the crossed

bin. Indicates that at the end of its activity, the machine has to be disposed

conforming to the laws in force.

Symbol denoting the open book.

Indicates that the operator has to read

the manual before the use of the machine.

4

Page 5

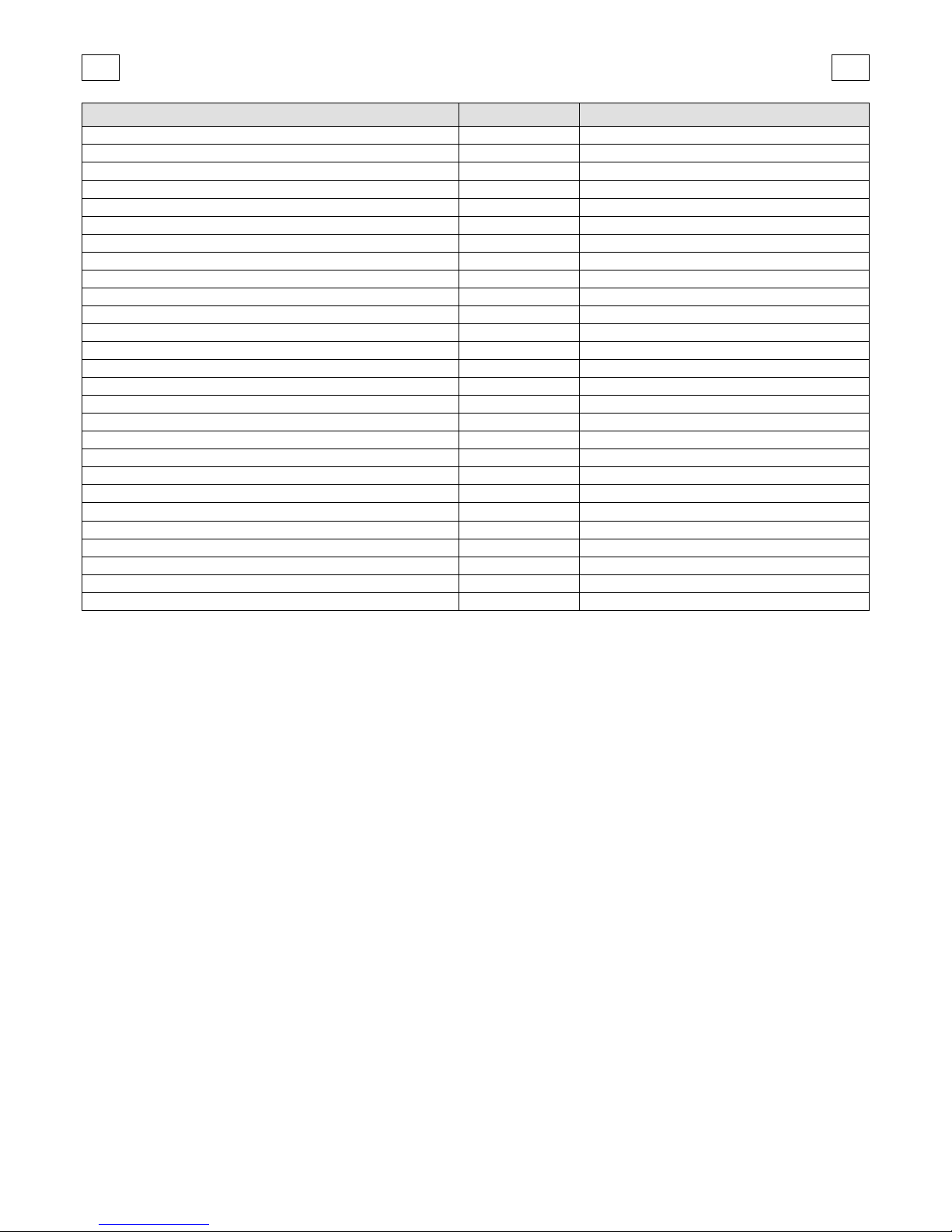

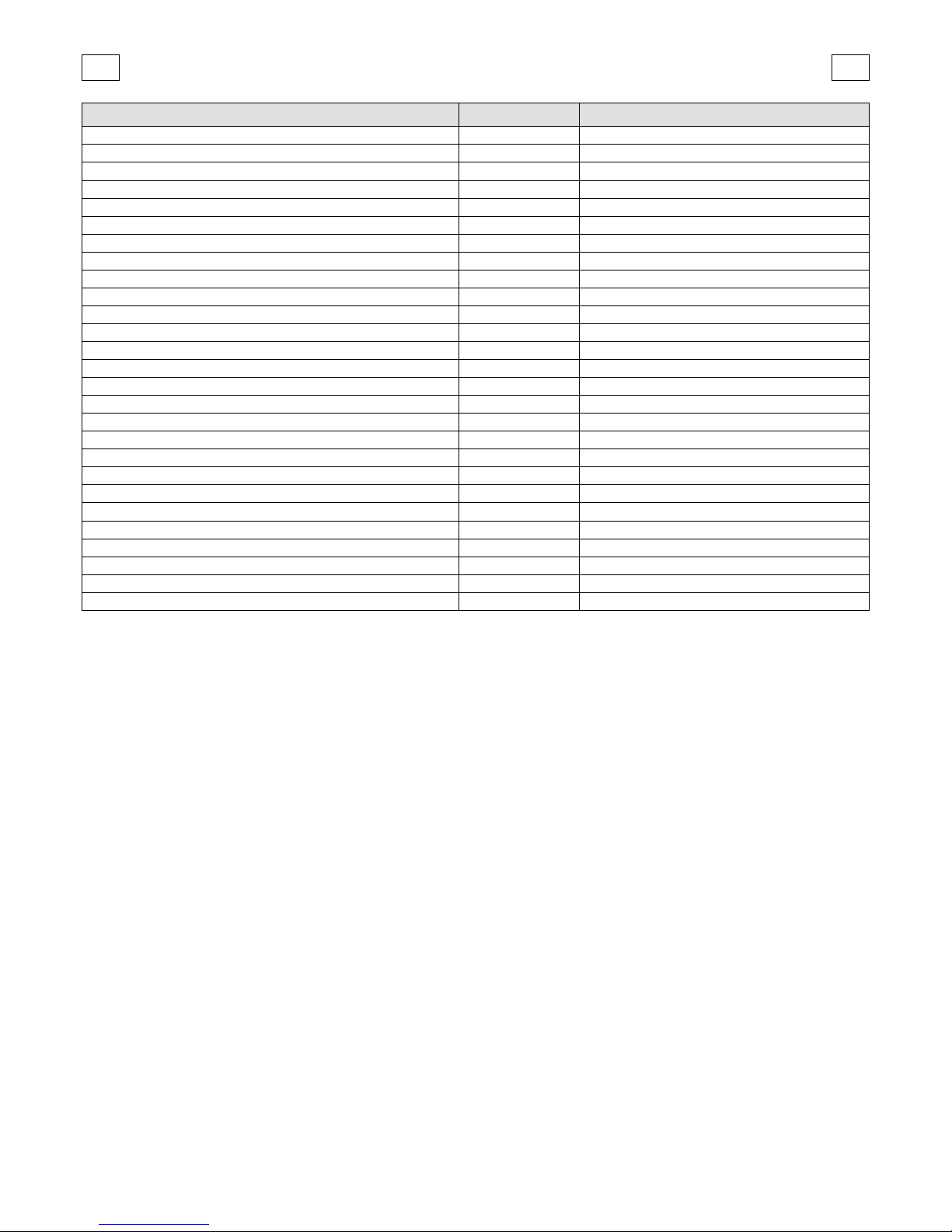

SUMMARY

INTRODUCTORY COMMENT 4

GENERAL RULES OF SAFETY 4

SYMBOLOGY 4

TECHNICAL DESCRIPTION 6

LEGEND INSTRUMENT BOARD AND CONTROLS 7

LEGEND MACHINE 7

BEFORE USE 8

HANDLING OF THE PACKED MACHINE 8

UNPACKING OF THE MACHINE 8

MOVEMENTS OF THE HANDLE BAR 8

BATTERY CONNECTIONS 8

BATTERY CHARGING 8

BATTERIES DISPOSAL 8

RECOVERY TANK 9

SOLUTION TANK 9

FLOOR CLEANING 9

STARTING OF THE MACHINE 9

COMPLETE SQUEEGEE ROTATION 9

DRYING GOING BACKWARDS 9

SQUEEGEE LIFTING 10

HANDLE BAR ADJUSTMENT 10

OVERFLOW DEVICE 10

STOPPING THE MACHINE AFTER CLEANING OPERATION 10

DAILY MAINTENANCE 11

RECOVERY TANK CLEANING 11

EMPTYING AND CLEANING OF THE SOLUTION TANK AND FILTER 11

SUCTION FILTER CLEANING 11

VERTICAL POSITIONING OF THE MACHINE 11

BRUSH CLEANING 11

BRUSH REMOVAL/INSTALLATION 11

SQUEEGEE CLEANING 12

ORDINARY MAINTENANCE 12

REAR SQUEEGEE RUBBER REPLACEMENT 12

FRONT SQUEEGEE RUBBER REPLACEMENT 12

TROUBLESHOOTING GUIDE 12

THE SUCTION MOTOR DOES NOT WORK 12

THE BRUSH MOTOR DOES NOT WORK 13

INSUFFICIENT WATER ON THE BRUSH 13

THE MACHINE DOES NOT CLEAN PROPERLY 13

THE SQUEEGEE DOES NOT DRY PERFECTLY 13

EXCESSIVE FOAM PRODUCTION 13

LED (2), (3) AND (4) BECOME RED 13

PROGRAMMED MAINTENANCE 14

RECOMMENDED BRUSHES 14

5

Page 6

TECHNICAL DESCRIPTION

Cleaning width mm/in. 430/17

Squeegee width /in.mm 510/20

Battery voltage V 24

Battery capacity Ah 5 34

Power rating W/A 670/28

Working capacity, up to sqm/h/sqft/hr 1505/16,200

Brush diameter mm/in. 430/17

Brush rpm rpm 155

Brush pressure kg/lbs. 35/77

Suction vacuum mbar/in. water lift 83/33

Type of drive semi autom.

Maximum gradient % 2

Capacity solution tank l/gal. 22/6

Capacity recovery tank l/gal. 22/6

Machine length (min) mm/in. 793/31

Machine height mm/in. 603/24

Machine width mm/in. 518/21

Machine weight (empty, with batteries) kg/lbs. 86,5/191

Weight of the batteries kg/lbs. 30/66

Recharging time max h 10

Battery compartment (L x W x H) mm/in. 346 x 207 x 21013.6 x 8 x 8

Acoustic pressure level (in conformity

dB (A) <70

with EN 604¬_01)

Class III

Protection level IP X3

Battery charger voltage V ~ 120-230

Battery charger frequency Hz 50-60

Battery charger class I

6

Page 7

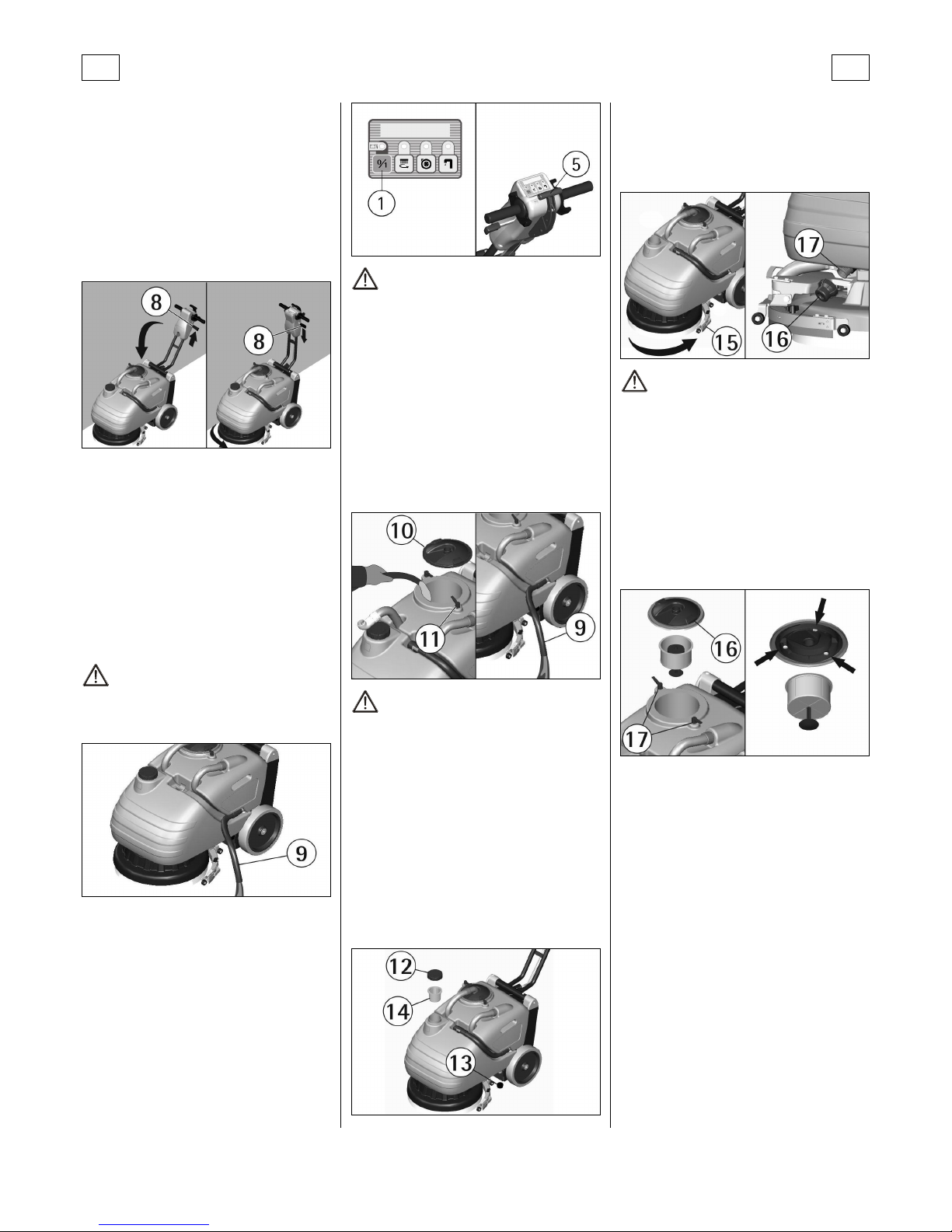

LEGEND INSTRUMENT PANEL AND CONTROLS

1 ON/OFF SWITCH WITH SIGNAL SIGNAL LAMP 5 SQUEEGEE LIFT LEVER

2 BRUSH MOTOR SWITCH WITH SIGNAL LAMP 6 HANDLE BARS

3 SUCTION MOTOR SWITCH WITH SIGNAL LAMP 7 SCRUB CONTROL LEVERS

4 SOLENOID VALVE SWITCH WITH SIGNAL LAMP 8 HANDLE BAR RELEASE LEVER

LEGEND MACHINE

9 EXHAUST HOSE RECOVERY TANK 17 CAP FOR SOLUTION TANK FILLING

10 SUCTION COVER 18 RECOVERY TANK

11 INSTRUMENT BOARD 19 WHEELS

12 BATTERY CHARGE LEVEL LED INDICATOR

(AGM)

13 SERIAL NUMBER PLATE 21 BRUSH COVER

14 MAINS PLUG FOR ELECTRIC CABLE BATTERY

CHARGER

15 DRAIN PLUG SOLUTION TANK 23 SOLUTION FLOW ADJUSTMENT

16 SOLUTION TANK

20 SQUEEGEE ASSEMBLY

22 SOLUTION TANK FILTER

7

Page 8

Warning symbol.

Read carefully the sections marked with

this symbol, for the security of both the

operator and the machine.

BEFORE USE

HANDLING OF THE PACKED MACHINE

The machine is supplied with suitable

packing.

The total weight is 221 lbs. (100 kg)

Packing dimensions:

Base: 33” x 22” (84,5 cm x 57 cm)

Height: 33” (85 cm)

ATTENTION:

Do not stack more than 2 machines.

UNPACKING THE MACHINE

1. Remove the outer package.

2. Loosen the two screws that hold the

two brackets to the machine.

3. Remove the screws that hold the

brackets to the pallet and remove the

brackets.

4. Rotate the handle bar into working

position (see under “MOVEMENTS OF

THE HANDLE BAR”) lower the machine

from the pallet and push it forwards on

the wheels, tilting the machine backwards to avoid damaging the mechani-

cal parts.

BATTERY CONNECTIONS

This machine is supplied with two batteries already connected, placed in the

appropriate compartment under the

recovery tank. In case the batteries

need to be replaced, please contact the

authorized technical assistance.

The replacement batteries must have

the identical performance as the ones

already installed.

2 batteries AGM 12V 34Ah5.

With the connector (2) it is possible to

connect or disconnect the batteries.

During the charging operation the machine’s functions are disabled.

To charge the batteries, park the machine on a level surface near a single-

phase socket. Switch off the machine

at the on/off switch (3). Connect the

charging cable, supplied with the ma-

chine, to both the machine (5) and to the

outlet socket as indicated in the gure.

At the end of the charging phase, remove the charging cable. The charge

phase is complete only when the green

led (A) on the charger comes on

ATTENTION:

In order not to cause permanent damage to the batteries, never leave them

completely discharged. If the machine

is not to be used for more than two

weeks, disconnect the battery connector

(see under “CONNECTION BATTERIES”).

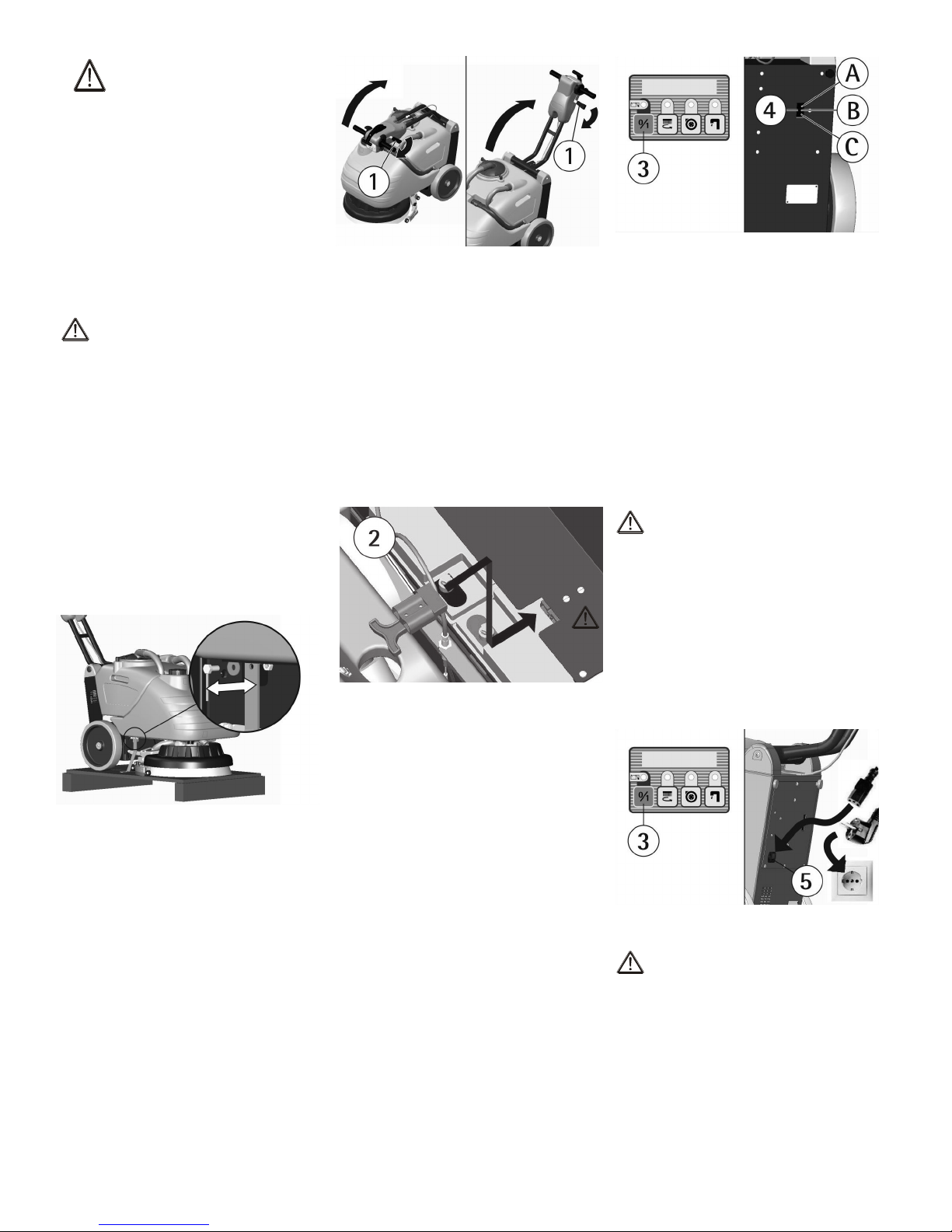

MOVEMENT OF THE HANDLE BAR

The handle bar arrives in the closed

position.

To rotate the handle bar into one of the

different working positions:

1. Pull up the release lever (1) near the

handle bar.

2. Rotate the handle bar into the working position while holding the release

lever (1).

3. release the release lever (1) to lock

the handle bar.

Use the same procedure for further

height adjustment of the handle bar in

order to nd the most comfortable working position.

BATTERY CHARGING

The label with the indication “AGM”

placed on the frame in the rear part of

the machine, identies that the machine

is equipped with AGM batteries and a

suitable battery charger.

Switching on the machine using the ON/

OFF switch (3), in the rear part of the

machine the charge level of the batteries

(4) is visible.

A: green led on = batteries charged.

B: orange led on = batteries almost discharged.

C: red led on = complete discharge of

the batteries.

When the led of the charger becomes

red (C), the led of the ON/OFF switch

(3) becomes red also. This will cause all

functions of the machine to be shut off.

ATTENTION:

Never charge batteries with a non-suitable charger. Strictly follow the instruc-

tions supplied by the batteries and

charger manufacturer.

BATTERIES DISPOSAL

It is mandatory to dispose of exhausted

batteries, classied as dangerous waste,

to an authorized institution according to

the current laws.

8

Page 9

RECOVERY TANK

Check that the cover of the suction lter

(1) is correctly secured, after rotating the

levers (B). Also check that the squeegee hose is correctly seated (A).

SOLUTION TANK

Remove the cap (6) on top of the tank

and ll the solution tank with clean

water at a maximum temperature of

122°F (50°C). Add the liquid detergent

in the percentage recommended by

the manufacturer. To avoid excessive

foaming, which could cause problems

to the vacuum motor, use the minimum

percentage of detergent. Screw down

the plug to close the tank

4. Press the switch for the brush motor

(2).

5. Press the switch for the vacuum mo-

tor (3).

6. Press the switch for the solenoid

valve (4).

The machine is equipped with a solenoid valve, which activates the solution

ow automatically when the control le-

vers (7) are engaged. Releasing these

levers will stop the ow automatically.

7. Activate the levers (7) and push the

unit forward, the brush will start rotating. The solution ow begins and the

squeegee will start drying the oor.

8. During the rst few feet check that the

solution ow is appropriate. The ow ad-

juster of the solution is already adjusted

at the factory to satisfy the cleaning of

most oors. If it is necessary to adjust

the quantity of solution onto the oor,

adjust the lever of the ow adjuster (8).

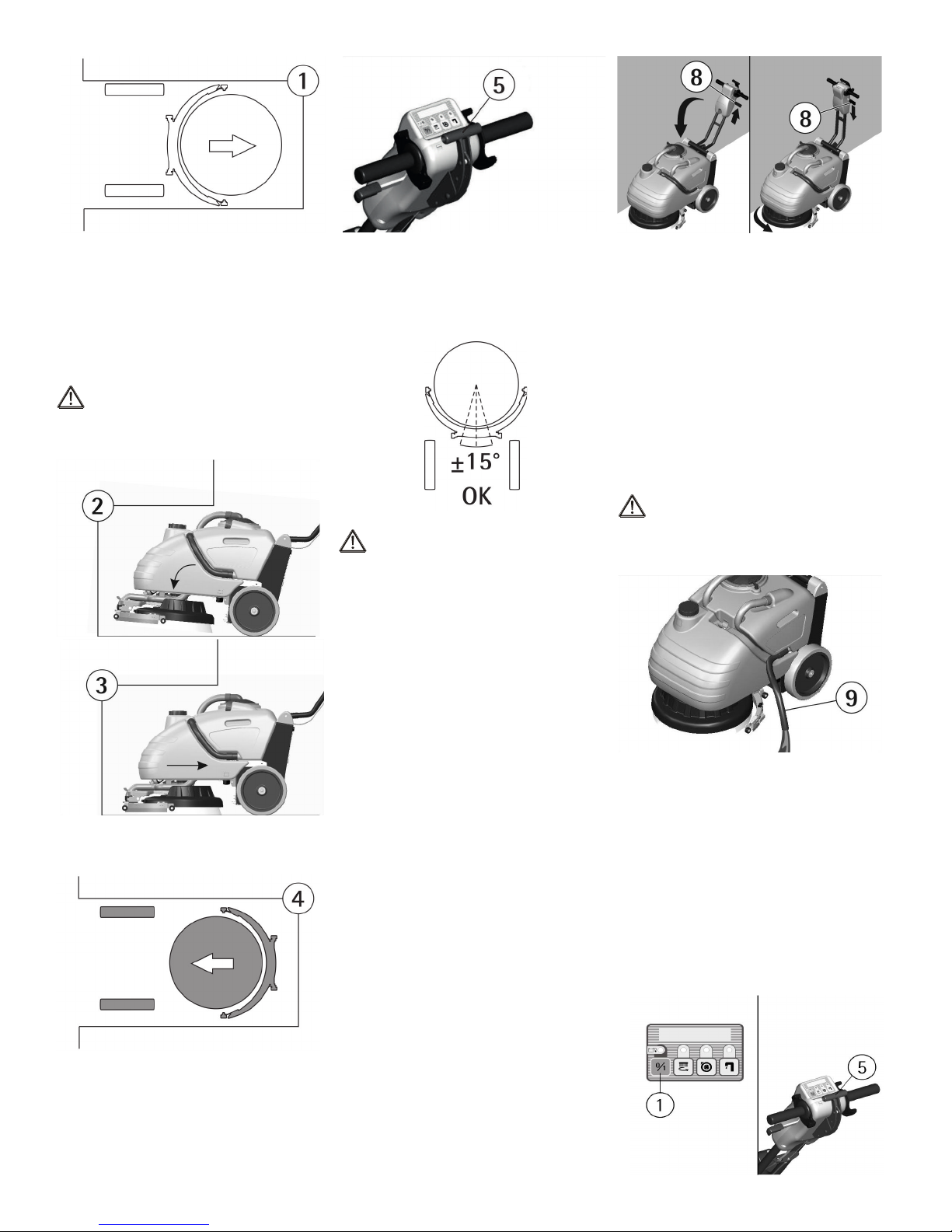

Drying going forward

Reversal of squeegee position with

rotation to the right

ATTENTION:

Always use low foam detergent. To

avoid excessive foaming, before starting

operation, add into the recovery tank a

quantity of anti-foam product as recommended by the product manufacturer.

Never use acid.

FLOOR CLEANING

STARTING OF THE MACHINE

The push buttons on the instrument

panel are lit with a green signal LED that

shows the activation of each control.

1. Switch on the machine by pressing

the on/off switch (1).

2. Check the battery charge level (see

under “BATTERY CHARGING”).

3. Lower the squeegee by rotating the

handle of the squeegee lifting lever (5),

placed on the rear of the handle bar,

down.

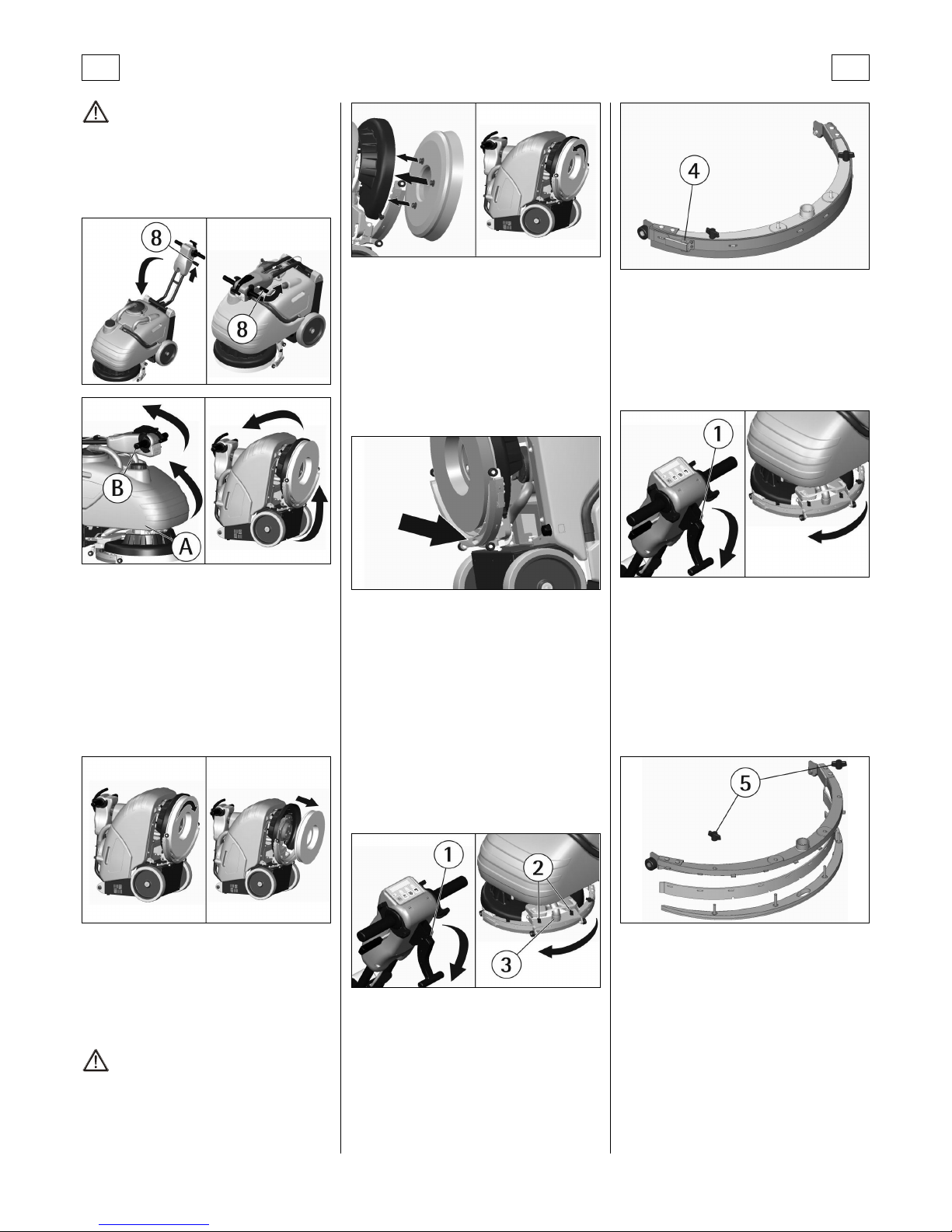

COMPLETE SQUEEGEE ROTATION

Thanks to the complete squeegee

rotation, it is possible to wash and dry

both in forwards and reverse. Following

the indicated drawings, the reversal of

the squeegee position is made easier,

permitting the drying in reverse.

Reversal of squeegee position with

rotation to the left

Drying going backwards

DRYING GOING BACKWARDS

With the squeegee positioned in the

front part of the machine it is possible

to dry where a traditional squeegee can

not. Below are some examples of how

to use the complete squeegee rotation.

Wash the interested surface (1).

Wash the surface (1).

9

Page 10

Rotate the squeegee to the right or

to the left (see under “COMPLETE

SQUEEGEE ROTATION”) to bring it to

the front.

By pushing down on the handle, lift the

machine slightly (2) and move onto the

surface to dry (3).

ATTENTION:

When the machine is lifted, release the

handle bar levers to stop the brush rota-

tion avoiding water splashing.

Proceed backwards to dry the surface

just washed (4).

It is only possible to lift the squeegee

when it is situated close to the center

point. If the squeegee is not close to the

center point, even moving the lever (5) it

will not lift the squeegee assembly.

ATTENTION:

During normal operation, the lifting lever

of the squeegee must be kept in the

down position.

HANDLE BAR ADJUSTMENT

When approaching obstacles or near

walls, it is possible to simplify the handling of the machine by adjusting the

handle bar more vertically with respect

to the machine.

To rotate the handle bar:

1. Lift the release lever (8) near the

handle bar.

2. Rotate the handle bar into the new

working position keeping the release

lever (8) pulled.

3. Release the lever (8) to lock the

handle bar in the desired position.

Once the obstacle has been passed

repeat the operation to return to the

previous working position.

This operation is also possible with the

machine in motion while maintaining

pressure on the release lever.

OVERFLOW DEVICE

In order to avoid damage to the vacuum

motor, the machine is equipped with a

oat that closes off the suction when

the recovery tank is full. When this

happens, it is necessary to empty the

recovery tank.

1. Hold the exhaust hose (9) of the

recovery tank.

2. Remove the exhaust plug and empty

the recovery tank into appropriate containers, according to the standard norms

for liquid disposal.

ATTENTION:

This operation must be carried out using

gloves to protect from contact with dan-

gerous solutions.

STOPPING THE MACHINE AFTER

CLEANING OPERATION

Before carrying out any type of maintenance:

1. Switch off the on/off switch (1).

2. Lift the squeegee by rotating the

lever (5), placed in the rear center of the

handle bar, up (see under “SQUEEGEE

LIFTING”).

3. Move the machine to an appropriate

place for tank draining.

SQUEEGEE LIFTING

To lift the squeegee, lift the lever (5) situated ion the rear of the handle bar.

10

Page 11

ATTENTION:

The machine is not equipped with a

parking brake, do not leave it unattended on slopes.

DAILY MAINTENANCE

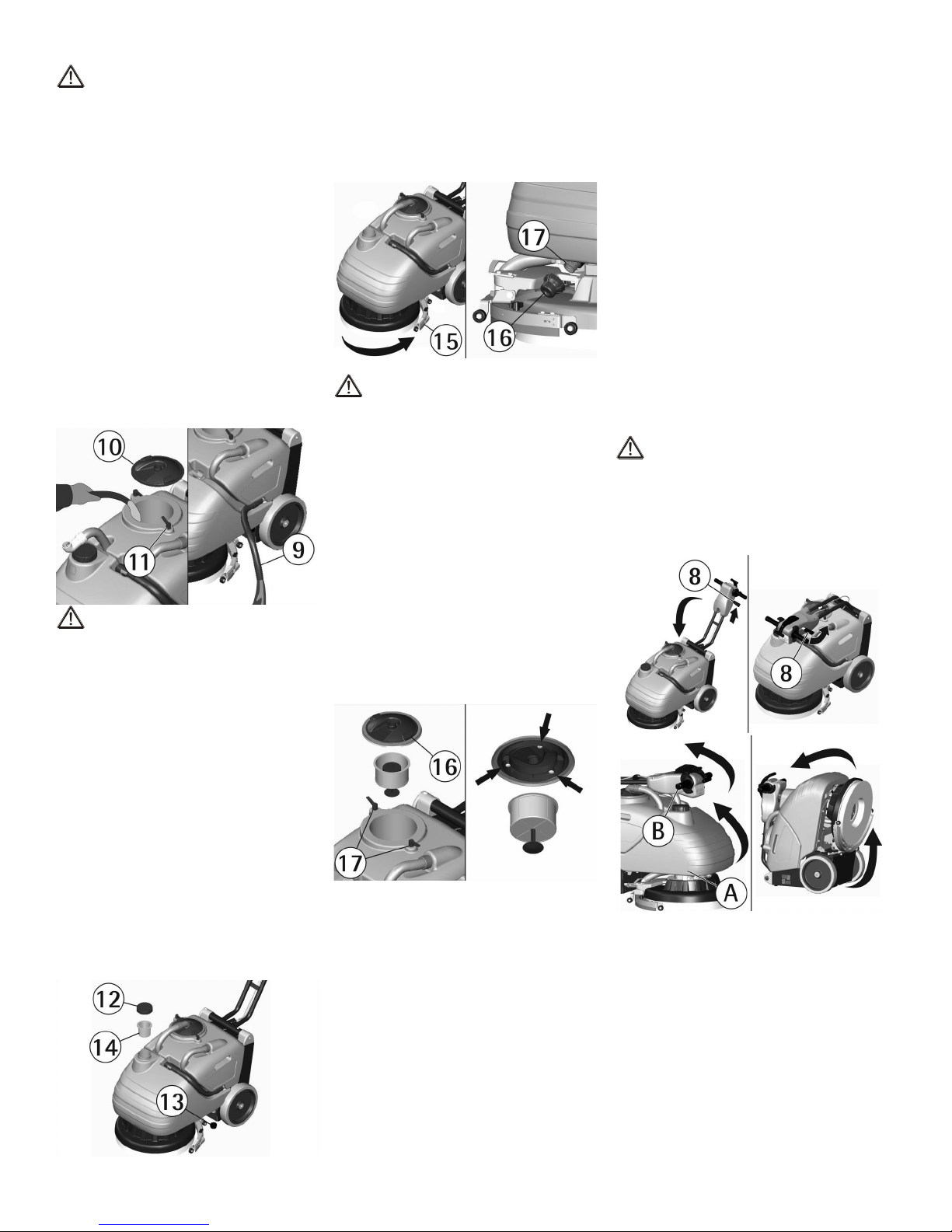

RECOVERY TANK CLEANING

1. Hold the exhaust hose (9) of the

recovery tank.

2. Remove the exhaust plug and empty

the recovery tank into appropriate containers (see under "OVERFLOW DEVICE").

3. Take off the suction cover (10) after

rotating the blocking levers (11).

4. Empty the tank by using the hose

(9).

5. Rinse the tank with a water jet.

ATTENTION:

This operation must be carried out using

gloves to protect from contact with dan-

gerous solutions.

5. Manually rotate the squeegee (15)

towards the front part of the machine to

access the lter (16).

6. Unscrew the lter cover (16), remove

the cartridge (17) and rinse it with a

water jet.

7. Reassemble all parts.

ATTENTION:

This operation should be carried out

wearing gloves to prevent contact with

dangerous solutions.

SUCTION FILTER CLEANING

1. Take off the suction cover (16) after

rotating the blocking levers (17).

2. Take off the lter with the oat, bending the lter edge to release it from the

screws on the cover.

3. Clean all parts with a water jet.

4. Reassemble everything.

2. Check that both tanks are empty,

otherwise, empty them (see under

“EMPTYING AND CLEANING OF THE

RECOVERY TANK” and “EMPTYING

AND CLEANING OF THE SOLUTION

TANK”).

3. Pull up on the handle bar release

lever (8) near the handle bar.

4. Rotate the handle bar towards the

tanks keeping the release lever (8)

pulled.

5. Release the lever (8) to lock the

handle bar in position.

6. Hold the machine with both hands in

point (A) of the tank side and (B) from

the handle bar as indicated in the gure.

7. Lift the front part of the machine rotat-

ing it on the rear wheels and bringing it

into the vertical position as shown in the

gure.

ATTENTION:

The position of the vertical parking

should be used when you expect not to

use the machine for more than 2-3 days,

to avoid the weight of the machine dam-

ageing the brush.

EMPTYING AND CLEANING OF THE

SOLUTION TANK AND FILTER

To empty any solution remaining in the

solution tank:

1. Move the machine to an appropriate

place for tank draining.

2. Switch off the machine by pressing

the on/off switch.

3. Unscrew the cap (12) of the solution

tank and take off the lter (14).

4. Unscrew the drain plug (13) placed in

the rear low left part of the machine and

allow the solution to drain out.

VERTICAL POSITIONING OF THE

MACHINE

The machine can be placed in a vertical position tipped over on its back after

having folded the handle bar onto the

machine.

This position allows the unit to be stored

in a small space and simplies mainte-

nance operations.

To rotate the machine it is necessary to:

1. Switch off the machine.

BRUSH CLEANING

Remove the brush and clean it with a

water jet (for the disassembly see under

“BRUSH REMOVAL/FITTING”).

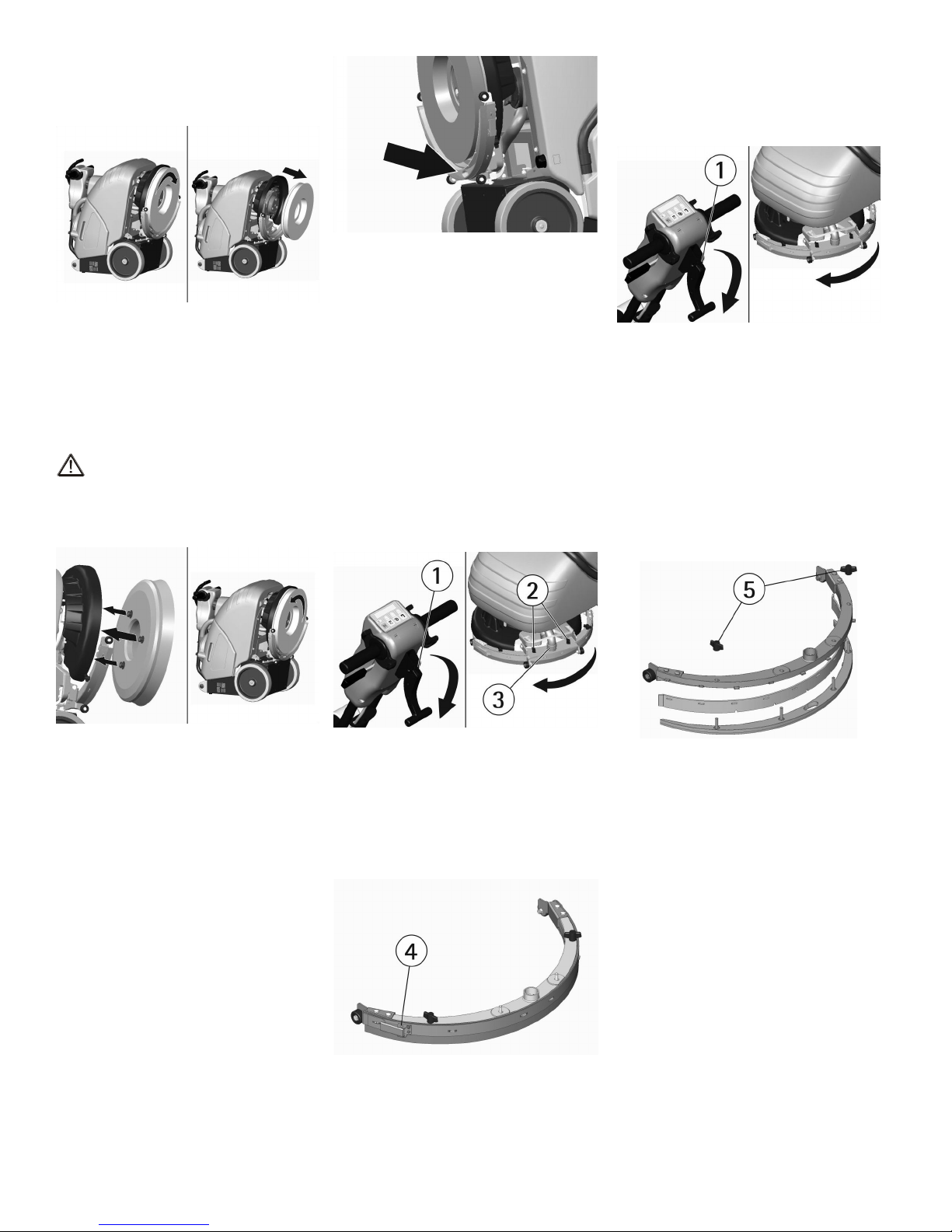

BRUSH REMOVAL/FITTING

1. Tip the machine over backwards

(see under “VERTICAL POSITIONING OF THE MACHINE") remember to

switch off the on/off switch and to empty

the tanks.

11

Page 12

2 With the machine in this position

rotate the brush clockwise, as indicated

in the gure, until it is released from the

pins of the brush holder plate.

For the replacement it is necessary to:

1. Lower the squeegee by lowering

the handle lever (1) placed in the rear

center of the handle bar.

2. Rotate the squeegee outwards.

ORDINARY MAINTENANCE

3. To reassemble the brush insert the

pins into the slots of the brush holder

plate and rotate counter-clockwise until

it locks.

It is possible to use other brush types,

depending on the oor type to be

cleaned and on its dirt conditions (see

under “RECOMMENDED BRUSHES”).

ATTENTION:

The handling of the brush operation

must be carried out wearing suitable

gloves to protect both from contact with

the bristles and dangerous solutions.

SQUEEGEE CLEANING

Keeping the squeegee clean guarantees the best drying action.

1. Tip over the machine backwards

(see under “VERTICAL POSITIONING OF THE MACHINE") remember to

switch off the on/off switch and to empty

the tanks.

2. With the machine in this position

clean both the rubber squeegee blades

and the suction inlet. Also remove any

bres (string or hair) that can prevent

the support from turning freely.

REAR SQUEEGEE RUBBER REPLACEMENT

Check the squeegee rubber wear and

turn or replace it, as needed.

For replacement:

1. Lower the squeegee by lowering the

handle lever (1) placed in the rear center

of the handle bar.

2. Rotate the squeegee outwards.

3. With the squeegee in this position

remove the wing nuts (2) to free the

squeegee.

4. Take off the of the squeegee hose (3)

and take off the squeegee.

5. Release the catch (4) of the rubber

blade clamp and take the rubber off to

turn it to a new side or replace it.

6. Check that the coupling and the

squeegee hose are not obstructed, clean

the entire assembly.

To reassemble the squeegee reverse the

operations above.

FRONT SQUEEGEE RUBBER REPLACEMENT

Check the wear of the front squeegee

rubber and replace it if worn out.

3. With the squeegee in this position

tremove it and then take off the

rear squeegee rubber (see under

“REAR SQUEEGEE RUBBER

REPLACEMENT”).

4. Remove the wing nuts (5) in the upper part of the squeegee body, separate

the two metal parts that form the squeegee body to take off the front rubber.

5. Clean all the components with water.

To reassemble the squeegee reverse

the operations above.

TROUBLESHOOTING GUIDE

THE VACUUM MOTOR DOES NOT

WORK

1. Check the charge level of the batteries (see under “BATTERY CHARGING”).

2. Verify that the vacuum motor switch

is activated and the green signal lamp

is on.

3. Check the level in the recovery tank

(see under “OVERFILL PROTECTION”)

and if necessary, empty the tank.

If the problem persists, please contact

the authorized service center.

12

Page 13

THE BRUSH MOTOR DOES NOT

WORK

1. Check the charge level of the batteries (see under “BATTERY CHARGING”).

2. Verify that the brush motor switch is

activated and the green signal lamp is

on.

3. Activate the scrub control levers (3).

If the problem persists, please contact

the authorized service center.

INSUFFICIENT WATER ON THE

BRUSH

1. Check that the solenoid valve switch

is activated and the green signal lamp

is on.

2. Check the level of the liquid in the

solution tank (see under “SOLUTION

TANK”).

3. Check that the solution ow adjuster

(3) placed in front underneath the solution tank is open.

4. Press the brush control levers (2).

5. Check that the solution lter (4) is

clean.

If the problem persists, please contact

the authorized service center.

THE MACHINE DOES NOT CLEAN

PROPERLY

1. The brush is not suited to the oor

and/or conditions: use only original

brushes. For advice, contact the authorized service center.

2. The solution ow is insufcient: open

the solution ow adjuster (3).

3. Check that the liquid detergent is in

the recommended percentage.

Contact the authorized service center for

advice.

THE SQUEEGEE DOES NOT DRY

PERFECTLY

1. Check that the squeegee rubbers are

clean.

2. Check that the suction hose is correctly inserted in the proper

seat on the recovery tank and on the

squeegee bar.

3. Check the suction lter.

4. Replace the rubbers if worn.

5. Check that the vacuum motor switch

is on.

6. Check the level in the recovery tank

(see under “OVERFILL PROTECTION”)

and if necessary, empty the tank.

EXCESSIVE FOAM PRODUCTION

Check that low foam detergent has been

used. Add small quantities of anti foam

liquid into the recovery tank.

Do not use excessive amounts of deter-

gent as even with low foaming agent,

the foam will be created and lead to

vacuum motor damage. Also exces-

sive detergent will result in solution pipe

becoming blocked over time.

LED (2), (3) AND (4) BECOME RED

If the machine is operating, with the

switch (1) on green and one of the

three led (2), (3) or (4) change color,

from green to red, it means that, an

overload protection is taking place, for

example:

- LED (2) RED: the brush motor is overloaded.

- LED (3) RED: the vacuum

motor is overloaded.

- LED (4) RED: the coil of the

solenoid valve may be short-circuited.

To reset, switch off the ON/OFF

switch (1), wait a few minutes and

then switch on again.

If the problem persists, please contact

the authorized service center.

13

Page 14

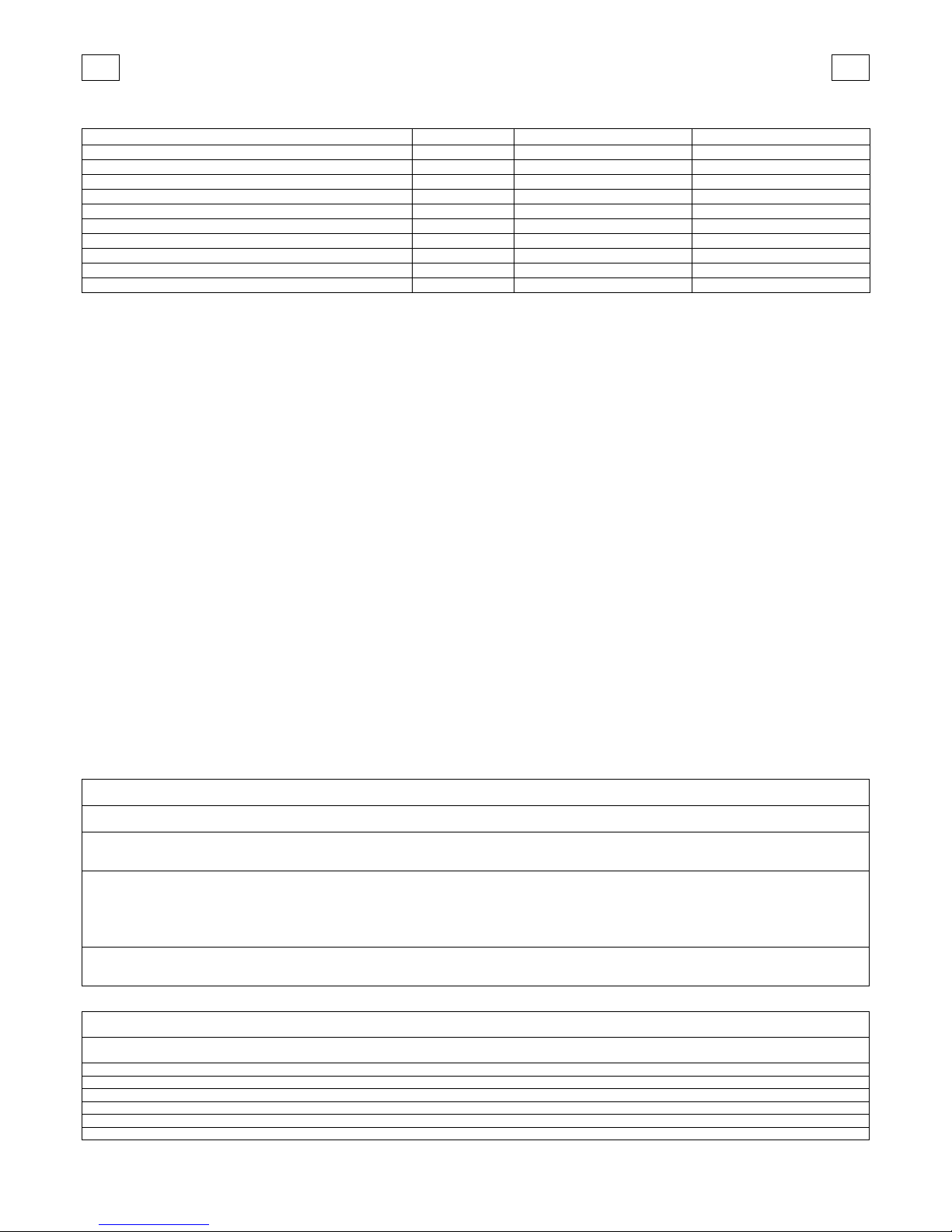

PROGRAMMED MAINTENANCE

REQUIRED ACTION DAILY WEEKLY ORDINARY/MONTHLY

RECOVERY TANK CLEANING •

SUCTION FILTER CLEANING •

BRUSH CLEANING •

BRUSH REMOVAL •

SQUEEGEE ASSEMBLY CLEANING •

FRONT SQUEEGEE RUBBER REPLACEMENT • if required

REAR SQUEEGEE RUBBER REPLACEMENT • if required

SQUEEGEE HOSE CLEANING •

SOLUTION TANK CLEANING •

SOLUTION FILTER CLEANING •

RECOMMENDED BRUSHES

Brushes must be chosen depending on the type of oor and the dirt to be removed.

The material and the bristle diameter are the elements that distinguish different types of brushes.

MATERIAL CHARACTERISTICS

PPL (Polypropylene) Good wear resistance. Maintains characteristics with hot water up to 140°F (60°C). It is not

hygroscopic.

TYNEX Nylon bristles with grains of abrasive material. Use with caution in order not to mark the oor

or ruin the nish.

BRISTLES THICKNESS Thicker bristles are more rigid and must be used on smooth oor or oor with small joints. On

irregular oors with deep joints or relieves, softer bristles penetrate more easily and deeper.

Please be aware that when brush bristles are worn out they become rigid and unable to penetrate and clean deeper. This may also cause brush vibration with thicker bristles

PAD HOLDER Pads are recommended to clean smooth surfaces. The pad holder has anchor points to retain

the pad. It is important that the height of the pad holder with its pad is the same as the one of

the brush.

MACHINE PART NO. QTY DESCRIPTION USE

BD 17/6 48903130 1 Brush PPL 0,9 Ø 430 Floors of resistant material and particularly

dirty.

48903150 1 Brush 5-mix Ø 430 For all types of oors.

48803050 1 Pad holder Ø 425 + center lock green For pads of 17”, for smooth surfaces cleaning.

14

Page 15

Please provide additional information on

Warranty

Registration

Form

Tornado equipment: (Check choices below)

__ Automatic Scrubbers __Sweepers

__Propane Floor Machines __Rotary Floor Machine

__High Speed Burnishers __Carpet Vacuums

__Carpet Extractors & Spotters __Wet/Dry Vacs

__ Steam Cleaners __Jumbo Vacs

__Ride-On Equipment __Pressure Washers

See complete product info at www.tornadovac.com

Selling Dealer:(Required)__________________________

Please Print Clearly

_____________________________________________________________________________

Company/Institution

_____________________________________ ____________________________________

Contact Name Title

_____________________________________ ____________________________________

Address City/State/Zip Code

_____________________________________ ____________________________________

Phone Fax

_____________________________________ ____________________________________

Date of Purchase Email

See white metal plate or sticker on unit for this information.

MACHINE TYPE/MODEL NUMBER: MACHINE SERIAL NUMBER:

1. 1.

2. 2.

3. 3.

4. 4.

Facility Description (please circle all that apply)

1. School 9. Hospital 17. U.S. Govt.

2. Retail Store 10. Nursing Home 18. Other Govt.

3. Restaurant 11. Religious Institution 19. Auto Service

4. Ofce Building 12. Airport 20. Airport

5. Contract Cleaning 13. Warehouse 21. Non-Prot

6. Light Manufacturing 14. Apartment/Condo 22. Other (specify)

7. Heavy Manufacturing 15. Warehouse

8. College/University 16. Supermarket

How did you rst learn about

Tornado cleaning and

maintenance equipment?

o Contacted by local dealer

o Previous experience with

Tornado products

o Reputation/

Recommendation

o Advertising

o Direct mail

o Internet

o Other

Total Hard Floor Area

o 0-10,000 (0-930)

o 10-50,000 (930-4,650)

o 50-250,000 (4,650-23,250)

o Over 250,000 (over

23,260)

In square feet (meters)

Total Carpeted Area

Square feet (square meters)

o 0-10,000 (0-930)

o 10-50,000 (930-4,650)

o 50-250,000 (4,650-23,250)

o Over 250,000 (over

23,260)

Damage or defect arising from abuse, neglect or other misuse is excluded from this warranty. Other items

may or may not apply based on your specic machine. If any defect occurs, the warranty is voided if service is

attempted by non-Authorized Tornado Service Centers.

©2017 Tornado Industries. All rights reserved.

X8449-TOR 1/2017

Return to :

Tornado Industries

3101 Wichita Court

Fort Worth, TX 76140

Fax: 817-551-0719

or online at

www.tornadovac.com

Page 16

===

b= = b=

=

=

NT

ðkaf`b=

=

ibvbka^=q^_ibol=ab=fkpqorjbkqlp=v=j^kalp= NU

ibvbka^=jžnrfk^= NU

abp`ofm`fþk=q°`kf`^= NV

^asboqbk`f^= OM

kloj^p=dbkbo^ibp=ab=pbdrofa^a= OM

pfj_lildð^= OM

mofj^=^kqbp=abi=bjmibl= ON

jзобгбЙенз=г•имбе~=ЙгД~д~З~= ON

aЙлЙгД~д~аЙ=ЗЙ=д~=г•имбе~= ON

jзобгбЙенз=ЗЙд=нбгµе= ON

`зеЙсбµе=Д~нЙк∞~л= ON

oÉÅ~êÖ~=ÇÉ=ä~ë=Ä~íÉê∞~ë= ON

bдбгбе~Ебµе=ЗЙ=д~л=Д~нЙк∞~л= ON

aЙйµлбнз=ЗЙ=кЙЕмйЙк~Ебµе= ON

aЙйµлбнз=ЗЙ=д~=лздмЕбµе=ЗЙнЙкЦЙенЙ= ON

ifjmfbw^=ab=ilp=prbilp= OO

^ЕЕбзе~гбЙенз=ЗЙ=д~=г•имбе~= OO

oзн~Ебµе=ЕзгйдЙн~=ЗЙ=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз= OO

pÉÅ~Çç=Éå=ã~êÅÜ~=~íê•ë= OO

iЙо~ен~гбЙенз=ЗЙ=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз= OO

oÉÖä~àÉ=ÇÉä=íáãµå= OO

aблйзлбнбоз=кЙДзл~ЗЙкз= OP

abqbk`fþk=ab=i^=jžnrfk^=^i=cfk^i=ab=i^=ifjmfbw^= OP

j^kqbkfjfbkql=af^ofl= OP

iбгйбЙт~=ЗЙйµлбнз=ЗЙ=кЙЕмйЙк~Ебµе= OP

s~Еб~Зз=у=дбгйбЙт~=ЗЙд=ЗЙйµлбнз=лздмЕбµе=у=ЗЙд=Сбднкз= OP

iбгйбЙт~=ЗЙд=Сбднкз=ЗЙ=~лйбк~Ебµе= OP

m~кимЙ=оЙкнбЕ~д=ЗЙ=д~=г•имбе~= OP

iбгйбЙт~=ЗЙд=ЕЙйбддз= OQ

aЙлгзен~аЙLгзен~аЙ=ЗЙд=ЕЙйбддз= OQ

iбгйбЙт~=ЗЙ=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз= OQ

j^kqbkfjfbkql=loafk^of^= OQ

pмлнбнмЕбµе=ЗЙд=д~Дбз=нк~лЙкз=ЗЙ=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз= OQ

pмлнбнмЕбµе=ЗЙд=д~Дбз=ЗЙд~енЙкз=ЗЙ=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз= OQ

`lkqoli=ab=crk`flk^jfbkql= OQ

bд=гзнзк=ЗЙ=~лйбк~Ебµе=ез=СмеЕбзе~= OQ

bд=гзнзк=ЗЙд=ЕЙйбддз=ез=СмеЕбзе~= OR

bд=~Цм~=Йе=Йд=ЕЙйбддз=ез=Йл=лмСбЕбЙенЙ= OR

i~=г•имбе~=ез=дбгйб~=ДбЙе= OR

i~=Дзимбдд~=ЗЙ=лЙЕ~Зз=ез=лЙЕ~=йЙкСЙЕн~гЙенЙ= OR

mкзЗмЕЕбµе=ЙсЕЙлбо~=ЗЙ=Йлймг~= OR

iЙЗ=EOFI=EPF=у=EQF=лЙ=йзеЙе=ЗЙ=Ездзк=кзаз= OR

j^kqbkfjfbkql=moldo^j^al= OS

`bmfiilp=^`lkpbg^alp= OS

d^o^kqð^=ifjfq^a^=^=i^odl=mi^wl=ab=molqb``fþk=^i=`ljmo^alo= OT

=

Page 17

Long Term Buyer Protection Limited Warranty

Tornado Industries, Inc. (Tornado) garantiza al consumidor nal que los productos Tornado no tendrán defectos de materiales ni mano de obra durante el período indicado abajo. Esta garantía limitada NO cubre a las

máquinas y/o componentes sujetos al desgaste normal, los daños ocasionados durante el envío, las fallas

producidas por modicaciones, accidentes, entorno operativo inadecuado, mal uso, abuso, negligencia o mal

mantenimiento por parte del usuario. Para más detalles, contáctese con su Distribuidor de Tornado Autorizado,

el Centro de Reparaciones, o el Departamento de Servicio Técnico de Tornado. Los representantes de ventas

y servicio técnico de Tornado no están autorizados a renunciar o alterar los términos de esta garantía, ni a

incrementar las obligaciones de Tornado bajo esta garantía.

10 Años*

Tanques de agua plásticos y cuerpos moldeados en forma rotatoria

2 Años*

Piezas de todos los equipos de limpieza Tornado

1 Año*

Mano de obra de todos los equipos de limpieza Tornado

1 Año*

Garantía de baterías, un año prorrateado.

Todas las garantías de las baterías son manejadas directamente por el fabricante de las baterías,

en base a un año prorrateado

Términos sujetos a cambios sin previo aviso.

1. Con excepción de los Ventiladores-Secadores Windshear™, de tiro lateral y descendente, Ventiladores de Aislamiento, CV 30, CV 38, CK14/1 PRO, CK 14/2 PRO, SWM31/9, CK LW 13/1, CK LW 13/1 ROAM, CV 38/48 Dual, PV6, PV10,

PV6 ROAM, Wall Mount todas las Barredoras, Aspiradoras en Seco, y todos los cargadores tienen garantía por 1 (un)

año tanto para sus piezas como para la mano de obra.

2. Todas las piezas no desgastadas compradas después del vencimiento de la garantía, tienen garantía por 90 días.

3. La garantía comienza a correr desde la fecha de venta al consumidor o, a discreción de Tornado, 6 meses después de

que el vendedor compre la unidad a Tornado, lo que ocurra primero.

4. El artículo EB 30 tiene garantía por un período de 90 días tanto para sus piezas como para la mano de obra.

5. La garantía de los motores utilizados en equipos a propano se limita a la garantía de fábrica del motor.

6. Las fregadoras con conductor tienen garantía de 24 meses para sus piezas, 6 meses para la mano de obra o 1000

horas, lo que ocurra primero.

Nota: Tornado, The Latest Dirt, Floorkeeper, Carpetkeeper, Carpetrinser,

Carpetrinser/Dryer, Headmaster, Taskforce, PAC-VAC, T-Lite, Glazer,

Windshear, Max-Vac,y Trot-Mop son marcas registradas de Tornado

Industries

Sitio web: www.tornadovac.com

Teléfono 1.800.VACUUMS

Fax: 817-551-0719

Dirección: 3101 Wichita Court

Fort Worth, TX 76140

1-800-VACUUMS 90 Years of Cleaning Innovation A Tacony Company

Form F2662.©2017. All rights reserved

Page 18

===

b= = b=

=

=

NU

ibvbka^=q^_ibol=ab=fkpqorjbkqlp=v=j^kalp=

=

NK fkqboormqlo=dbkbo^i=v=qbpqfdl=

OK fkqboormqlo=jlqlo=abi=`bmfiil=v=qbpqfdl=

PK fkqboormqlo=jlqlo=ab=^pmfo^`fþk=v=qbpqfdl=

QK fkqboormqlo=bib`qolsžisri^=v=qbpqfdl=

=

=

RK m^i^k`^=bibs^alo^=_lnrfii^=ab=pb`^al=

SK j^kdlp=abi=j^kfii^o=

TK j^kbq^p=ab=`lkqoli=fkf`flLm^ol=

UK m^i^k`^=abp_ilnrbl=abi=qfjþk=

=

=

=

ibvbka^=jžnrfk^=

=

VK qr_l=ab=abp`^od^=abmþpfql=ab=ob`rmbo^`fþk=

NMK q^m^=^pmfo^`fþk=

NNK q^_ibol=ab=fkpqorjbkqlp=

NOK iba=ab=pb¢^i=kfsbi=`^od^=ab=i^p=_^qboð^p=E^djF=

NPK mi^`^=j^qoð`ri^=

NQK bk`ercb=ab=^ifjbkq^`fþk=bi°`qof`^=`^od^alo=_^qboð^p=

NRK q^mþk=ab=s^`f^al=plir`fþk=abqbodbkqb=

NSK abmþpfql=ab=plir`fþk

=

=

=

=

NTK q^m^=ab=iibk^al=plir`fþk=abqbodbkqb=

NUK abmþpfql=ab=ob`rmbo^`fþk=

NVK orba^p=

OMK dorml=_lnrfii^=ab=pb`^al=

ONK molqb``fþk=

OOK cfiqol=plir`fþk=abqbodbkqb=

OPK obdri^alo=ab=

`^ra^i=

ab=i^=plir`fþk=abqbodbkqb

=

=

=

=

=

Page 19

===

b= = b=

=

=

NV

abp`ofm`fþk=q°`kf`^=

=

=

^åÅÜç=ÇÉ=íê~Ä~àç= ããLáå= QPMLNT=

^еЕЬз=ЗЙ=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз= ããLáå= RNMLOM=

qÉåëáµå=ÇÉ=ä~ë=Ä~íÉê∞~ë= s= OQ=

`~é~ÅáÇ~Ç=Ä~íÉê∞~ë= ^Ü=R= PQ=

mзнЙеЕб~=белн~д~З~= tL^= STMLOU=

oЙеЗбгбЙенз=ЗЙ=нк~Д~аз=Eг~сF= ãOLÜ==ëèÑíLÜ= NRMRLNNQUP=

aб•гЙнкз=ЗЙд=ЕЙйбддз= ããLáå= QPMLNT=

sЙдзЕбЗ~З=Цбкз=ЗЙд=ЕЙйбддз= êéã= NVM=

mкЙлбµе=ЗЙд=ЕЙйбддз== âÖLäÄëK= PRLTT=

aЙйкЙлбµе=гзнзк=ЗЙ=~лйбк~Ебµе= ãÄ~êLï~íÉê=äáÑí= UPLPP=

qáéç=ÇÉ=~î~åÅÉ= = лЙгб=~мнзгK=

aЙлебоЙд=г•сбгз= B= O=

`~й~ЕбЗ~З=ЗЙйµлбнз=ЗЙ=лздмЕбµе= äLÖ~ä= OOLS=

`~й~ЕбЗ~З=ЗЙйµлбнз=ЗЙ=кЙЕмйЙк~Ебµе= äLÖ~ä= OOLS=

iзеЦбнмЗ=г•имбе~=EгбеF= ããLáå= TVPLPN=

^äíìê~=ã•èìáå~= ããLáå= SMPLOQ=

^еЕЬмк~=г•имбе~= ããLáå= RNULOM=

mÉëç=ã•èìáå~=EÉå=î~Å∞ç=Åçå=ä~ë=Ä~íÉê∞~ëF= âÖLäÄëK= USIRLNVN=

mÉëç=Ä~íÉê∞~ë= âÖLäÄëK= PMLSS=

qбЙгйз=ЗЙ=кЙЕ~кЦ~=г~с= Ü= NM=

eìÉÅç=Ä~íÉê∞~ë=Eä=ñ=~åÅÜ=ñ=~äíF= ããLáå= PQS=с=OMT=с=ONMLNQ=с=UIN=с=UIO=

kбоЙд=ЗЙ=йкЙлбµе=~Е∫лнбЕз=EЙе=ЕзеСзкгбЗ~З=Езе=bkSMQ|MNF= Ç_=E^F= YTM=

`ä~ëÉ= = fff=

kбоЙд=ЗЙ=йкзнЙЕЕбµе= fm= uP=

`~кЦ~Ззк=ЗЙ=д~л=Д~нЙк∞~лW=нЙелбµе=ЗЙ=д~=кЙЗ= s=ú= OPM=

`~кЦ~Ззк=ЗЙ=д~л=Д~нЙк∞~лW=СкЙЕмЙеЕб~=ЗЙ=д~=кЙЗ= eò= RM=

`~êÖ~Ççê=ÇÉ=ä~ë=Ä~íÉê∞~ëW=Åä~ëÉ= = f=

Page 20

===

b= = b=

=

=

OM

^asboqbk`f^==

iЙл= ~Цк~ЗЙЕЙгзл= йзк= Ь~ДЙк= лЙдЙЕЕбзе~Зз= емЙлнк~=

г•имбе~K= bлн~= г•имбе~= СкЙЦ~Ззк~= лЙ= ЙгйдЙ~=Йе= д~=

дбгйбЙт~= беЗмлнкб~д= у= Ебобд= й~к~= Ем~димбЙк= нбйз= ЗЙ=

й~обгЙен~ЕбµеI= ЙсЕдмбЗ~= д~= дбгйбЙт~= ЗЙ= гзимЙн~лK=

aмк~енЙ= лм= гзобгбЙенз= ЗЙ= ~о~еЕЙI= д~= ~ЕЕбµе=

ЕзгДбе~З~= ЗЙд=ЕЙйбддз= у=ЗЙ= д~= лздмЕбµе=ЗЙнЙкЦЙенЙI=

дбгйб~=д~=лмЕбЙЗ~З=имЙ= лЙ=кЙЕзЦЙ=Езе=д~=Дзимбдд~=ЗЙ=

~лйбк~Ебµе= нк~лЙк~= ЗЙа~еЗз= йЙкСЙЕн~гЙенЙ= лЙЕ~= д~=

лмйЙкСбЕбЙK=

i~=г•имбе~=Ь~=ЗЙ=лЙк=мнбдбт~З~=лµдз=й~к~=ЙлнЙ=СбеK=pЙ=

зДнбЙеЙе= д~л= гЙазкЙл= йкЙлн~ЕбзеЙл= лб= лЙ= ЙгйдЙ~=

ЕзккЙЕн~гЙенЙ= у= лЙ= г~енбЙеЙ= Йе= йдЙе~= ЙСбЕ~Еб~K=

oзЦ~гзл=йзк=ЕзелбЦмбЙенЙ=дЙЙк=ЕмбЗ~Ззл~гЙенЙ=Йлн~л=

белнкмЕЕбзеЙл=у= оздоЙк= ~=дЙЙкд~л=Е~З~=оЙт=имЙ= нЙеЦ~е=

ЗбСбЕмдн~ЗЙлK==

bе= Е~лз= ЗЙ= еЙЕЙлбЗ~ЗI= кЙЕзкЗ~гзл= имЙ= емЙлнкз=

лЙкобЕбз=ЗЙ=~лблнЙеЕб~=имЙЗ~=лбЙгйкЙ=~=лм=ЗблйзлбЕбµе=

й~к~=ЙоЙенм~дЙл=ЕзелЙазл=з=бенЙкоЙеЕбзеЙл=ЗбкЙЕн~K==

=

=

kloj^p=dbkbo^ibp=ab=pbdrofa^a=

i~л= езкг~л= ~им∞= ~Д~аз= беЗбЕ~З~л= нбЙеЙе= имЙ=

ЕмгйдбклЙ= ЕмбЗ~Ззл~гЙенЙ= й~к~= Йобн~к= З~¥зл= ~д=

зйЙк~Ззк=у=~=д~=г•имбе~K==

J=iЙЙк=ЕмбЗ~Ззл~гЙенЙ=д~л= ЙнбимЙн~л=Йе= д~=г•имбе~I=

ез= ЕмДкбкд~л= йзк= ебеЦ∫е= гзнбоз= у= лмлнбнмбкд~л= Йе=

лЙЦмбЗ~=Йе=Е~лз=ЗЙ=имЙ=СмЙлЙе=З~¥~З~лK==

J= qЙеЗк•е= имЙ= мнбдбт~к= д~= г•имбе~= ∫ебЕ~гЙенЙ= Йд=

йЙклзе~д=~мнзкбт~Зз=у=Сзкг~Зз=й~к~=Йд=ЙгйдЙзK==

J=aмк~енЙ=Йд=СмеЕбзе~гбЙенз=ЗЙ=д~=г•имбе~=Ь~у=имЙ=

нЙеЙк= ЕмбЗ~Зз= Езе= д~л= ЗЙг•л= йЙклзе~л= у=

ЙлйЙЕб~дгЙенЙ=Езе=дзл=еб¥злK==

J= bе= йкЙлЙеЕб~= ЗЙ= дзл= еб¥злI= Ь~у= имЙ= обЦбд~к= д~=

г•имбе~= ЗЙ= г~еЙк~= имЙ= ез= зЕмккЙ= имЙ= дзл=ЗЙг•л=

амЙЦмЙе=Езе=д~=гблг~K=

J=i~=г•имбе~=ез=Йл=ЗЙлнбе~З~=~д=ЙгйдЙз=ЗЙ=йЙклзе~лI=

еб¥зл= беЕдмбЗзлI= д~л= Ем~дЙл= Е~й~ЕбЗ~ЗЙл= С∞лбЕ~лI=

лЙелзкб~дЙл= з= гЙен~дЙл= лЙ~е= кЙЗмЕбЗ~лI= з= ДбЙе= Езе=

Е~кЙеЕб~=ЗЙ=ЙсйЙкбЙеЕб~=з=ЗЙ=ЕзезЕбгбЙензI=~= гЙезл=

имЙ= ¨лн~л= Ь~у~е= йзЗбЗз= ДЙеЙСбЕб~кI= ~= нк~о¨л= ЗЙ= д~=

бенЙкгЙЗб~Ебµе=ЗЙ=ме~=йЙклзе~=кЙлйзел~ДдЙ=ЗЙ=лму~л=

лЙЦмкбЗ~ЗI=обЦбд~еЕб~=з=белнкмЕЕбзеЙл=ЕзеЕЙкебЙенЙ= Йд=

ЙгйдЙзK=

J= i~= нзг~=ЗЙ=д~= кЙЗ= ЗЙ=~дбгЙен~Ебµе=нбЙеЙ=имЙ=лЙк=

Йимбй~З~=ЗЙ=ЕзеЙсбµе=~=нбЙкк~=кЙЦд~гЙен~кб~K=

J=bобн~к=З~¥~к=Йд=Е~ДдЙ=ЗЙ=~дбгЙен~Ебµе=Езе=йдЙЦ~ЗзлI=

~йд~лн~гбЙензл=з=ЙлСмЙктзлK=

J= kз= гЙтЕд~к= ЗЙнЙкЦЙенЙл= ЗЙ= нбйз= ЗбСЙкЙенЙ= й~к~=

Йобн~к=д~=йкзЗмЕЕбµе=ЗЙ=Ц~лЙл=езЕбозлK==

J=i~=нЙгйЙк~нмк~=ЗЙ=~дг~ЕЙе~гбЙенз=нбЙеЙ=имЙ=Йлн~к=

ЕзгйкЙеЗбЗ~=ЙенкЙ=POшc=у=NPNшc=EMш`=у=HRRш`FK==

J=qЙгйЙк~нмк~=µйнбг~=ЗЙ=нк~Д~азW==

ЙенкЙ=POшc=у=NMQшc=E=Mш`=у=HQMш`FK==

J=i~=ЬмгЙЗ~З=ез=нбЙеЙ=имЙ=лмйЙк~к=Йд=VRBK==

J=kз=ЙгйдЙ~к=д~=г•имбе~=Йе=~нгµлСЙк~=Йсйдзлбо~K==

J= kз= ЙгйдЙ~к= д~= г•имбе~= Езгз= оЙЬ∞Емдз= ЗЙ=

нк~елйзкнЙK==

J=kз=лмДбк=з=Д~а~к=д~л=ЙлЕ~дЙк~лK=

J=kз=мнбдбт~к= лздмЕбзеЙл=•ЕбЗ~л=имЙ=йзЗк∞~е=З~¥~к= д~=

г•имбе~=уLз=д~л=йЙклзе~лK==

J= bобн~к= имЙ= Йд= ЕЙйбддз=нк~Д~аЙ= Йлн~еЗз=д~= г•имбе~=

й~к~З~=й~к~=ез=Е~мл~к=З~¥зл=~д=лмЙдзK==

J=kз=мнбдбт~к=д~=г•имбе~=Йе=лмйЙкСбЕбЙл=Йлй~кЕбЗ~л=ЗЙ=

д∞имбЗзл= з= йздозл= беСд~г~ДдЙл= Eйзк= ЙаЙгйдз=

ЬбЗкзЕ~кДмкзлI=ЕЙебт~л=з=нбтеЙлFK==

J=bе=Е~лз=ЗЙ=беЕЙеЗбзI=ЙгйдЙ~к=ме=Йснбензк=ЗЙ=йздозK=

kз=ЙгйдЙ~к=~Цм~K=

J=kз=ЕЬзЕ~к=Езе=Йлн~енЙк∞~л= з=~еЗ~гбзл= ЗзеЗЙ=Ь~у=

йЙдбЦкз=ЗЙ=Е~∞З~=ЗЙ=зДаЙнзлK=

J= kз= мнбдбт~к= д~= г•имбе~= лзДкЙ= лмйЙкСбЕбЙл= Езе=

беЕдбе~Ебµе=лмйЙкбзк=~=д~=беЗбЕ~З~=Йе=д~=йд~Е~K==

J= i~= г•имбе~=нбЙеЙ= имЙ= кЙ~дбт~к= д~л= зйЙк~ЕбзеЙл=ЗЙ=

д~о~Зз= у= лЙЕ~Зз= ~д=гблгз= нбЙгйзK= lйЙк~ЕбзеЙл= ЗЙ=

е~нмк~дЙт~= ЗбСЙкЙенЙ=нЙеЗк•е= имЙ= лЙк= кЙ~дбт~З~л= Йе=

тзе~л= йкзЬбДбЗ~л= й~к~= Йд= й~лз= ЗЙ= йЙклзе~л= ез=

ЙеЕ~кЦ~З~л= ЗЙд= нк~Д~аз= у= Йд= зйЙк~Ззк= нЙгЗк•= имЙ=

йзеЙклЙ=Е~дт~Зз=~ЗЙЕм~ЗзK==

J= e~у=имЙ= лЙ¥~д~к=д~л= тзе~л=ЗЙ= й~обгЙенз=гза~Зз=

Езе=дЙнкЙкзл=й~к~=н~д=ЙСЙЕнзK==

J= `м~еЗз= лЙ= зДлЙко~лЙе= ~езг~д∞~л= Йе= Йд=

СмеЕбзе~гбЙенз= ЗЙ= д~= г•имбе~I= ~лЙЦмк~клЙ= имЙ= ез=

лЙ~е= Е~мл~З~л= йзк= д~= С~дн~= ЗЙ= г~енЙебгбЙенз=

зкЗбе~кб~K=aЙ=ез= лЙк=~л∞I=лздбЕбн~к=д~=бенЙкоЙеЕбµе= ЗЙд=

ЕЙенкз=ЗЙ=~лблнЙеЕб~=~мнзкбт~ЗзK==

J= bе= Е~лз= ЗЙ= лмлнбнмЕбµе= ЗЙ= йбЙт~лI= йЙЗбк= дзл=

кЙймЙлнзл= lofdfk^ibp= ~= ме= ЕзеЕЙлбзе~кбз= уLз=

ЗблнкбДмбЗзк=~мнзкбт~ЗзK=

J=bгйдЙ~к=лзд~гЙенЙ=ЕЙйбддзл= lofdfk^ibp=лЙ¥~д~Ззл=

Йе=Йд=й•кк~Сз=?`bmfiilp=^`lkpbg^alp?K==

J= m~к~= Ем~димбЙк= бенЙкоЙеЕбµе= ЗЙ= дбгйбЙт~= уLз=

г~енЙебгбЙенз= Езкн~к= Йд= лмгбеблнкз= Йд¨ЕнкбЕз= ~= д~=

г•имбе~K==

J=kз=имбн~к=д~л=йкзнЙЕЕбзеЙл=имЙ=кЙимбЙкЙе=Йд=ЙгйдЙз=

ЗЙ=мнЙелбдбзл=й~к~=лЙк=лмлнбнмбЗ~лK==

J=kз=д~о~к=д~=г•имбе~=Езе=ЕЬзккз=ЗЙ=~Цм~=ЗбкЙЕн~=з=~=

йкЙлбµеI=з=Езе=лмДлн~еЕб~л=Езккзлбо~лK==

J= `~З~= OMM= Ьзк~л= ЗЙ= нк~Д~аз= Ь~ЕЙк= Езенкзд~к= д~=

г•имбе~=йзк=ме=ЕЙенкз=ЗЙ=~лблнЙеЕб~=~мнзкбт~ЗзK==

J=^енЙл=ЗЙ=мнбдбт~к=д~=г•имбе~I=Езенкзд~к=имЙ=нзЗ~л=

д~л=н~й~л=у=д~л=ЕзДЙкнмк~л=Йлн¨е=ЕздзЕ~З~л=Езгз=лЙ=Ь~=

беЗбЕ~Зз=Йе=ЙлнЙ=г~ем~д=ЗЙ=млз=у=г~енЙебгбЙензK=

J=oЙлн~ДдЙЕЙк=нзЗ~л=д~л=ЕзеЙсбзеЙл=Йд¨ЕнкбЕ~л=ЗЙлйм¨л=

ЗЙ=Ь~ДЙк=ЙСЙЕнм~Зз=Ем~димбЙк=бенЙкоЙеЕбµеK=

J= mкзЕЙЗЙк= ~= д~= Йдбгбе~Ебµе= ЗЙ= дзл= г~нЙкб~дЙл= ЗЙ=

Езелмгз=лбЦмбЙеЗз=д~л=езкг~л=ЗЙ=дЙу=обЦЙенЙлK=

J= `м~еЗз= омЙлнк~= г•имбе~= ЗЙаЙ= ЗЙ= лЙк= ЙгйдЙ~З~I=

йкзЕЙЗЙк= ~д= ЗЙлг~енЙд~гбЙенз= ~йкзйб~Зз= ЗЙ= дзл=

г~нЙкб~дЙл= Йе= д~= гблг~= ЕзенЙебЗзл= ЙлйЙЕб~дгЙенЙ=

~ЕЙбнЙ= у= ЕзгйзеЙенЙл=ЙдЙЕнкµебЕзлI= у= ЕзелбЗЙк~еЗз=

имЙ=д~= г•имбе~=гблг~=СмЙ=ЕзелнкмбЗ~=Йе=гЙЗбЗ~=ЗЙ=

дз=йзлбДдЙ=Езе=г~нЙкб~дЙл=кЙЕбЕд~ЗзлK==

=

=

pfj_lildð^=

=

=

p∞гДздз

=

MLN=имЙ=беЗбЕ~=Йд=

бенЙккмйнзк=ЦЙеЙк~д=у=Йд=

нЙлнбЦзK=

=

=

p∞гДздз=ЗЙд=ЦкбСзK

=

fеЗбЕ~=Йд=бенЙккмйнзк=у=Йд=

нЙлнбЦз=ЗЙ=д~=ЙдЙЕнкзо•домд~K=

=

=

=

p∞гДздз=ЗЙд=ЕЙйбддзK

=

fеЗбЕ~=Йд=бенЙккмйнзк=у=Йд=

нЙлнбЦз=ЗЙд=гзнзк=ЗЙд=ЕЙйбддзK

=

=

=

=

p∞гДздз=ЗЙд=гзнзк=ЗЙ=

~лйбк~ЕбµеK=

fеЗбЕ~=Йд=бенЙккмйнзк=у=Йд=

нЙлнбЦз=ЗЙд=гзнзк=ЗЙ=

~лйбк~ЕбµеK=

=

=

=

fеЗбЕ~Ззк=ЗЙ=ебоЙд=ЗЙ=Е~кЦ~=

ÇÉ=ä~ë=Ä~íÉê∞~ëK=

=

=

=

fеЗбЕ~=д~=йзлбЕбµе=ЗЙд=

н~йµе=ЗЙ=ЗЙлЕ~кЦ~=ЗЙд=

ЗЙйµлбнз=ЗЙ=д~=лздмЕбµеK=

=

p∞гДздз

=

èìÉ=á

åÇáÅ~=ÇÉ=î~Åá~ê=

дзл=ЗЙйµлбнзл=~енЙл=ЗЙ=оздоЙк=

~=Öáê~ê=ä~=ã•èìáå~K=

=

=

=

p∞гДздз=имЙ=беЗбЕ~=д~=

нЙгйЙк~нмк~=г•сбг~=ЗЙ=д~=

лздмЕбµе=ЗЙнЙкЦЙенЙK=

=

=

=

p∞гДздз=имЙ=

беЗбЕ~=Йд=

кЙЦмд~Ззк=ЗЙ=Е~мЗ~д=ЗЙ=д~=

лздмЕбµе=ЗЙнЙкЦЙенЙK=

=

=

=

p∞гДздз=ЗЙд=ДбЗµе=дблн~ЗзK=

=

fеЗбЕ~=имЙ=~д=Сбе~д=ЗЙ=лм=

~ЕнбобЗ~ЗI=д~=г•имбе~=

нЙеЗк•=имЙ=лЙк=Йдбгбе~З~=

Йе=ЕзеСзкгбЗ~З=ЗЙ=д~=

дЙЦблд~Ебµе=обЦЙенЙK=

=

=

=

p∞гДздз=ЗЙд=дбДкз=~ДбЙкнзK

=

fåÇáÅ~=~ä=çéÉê~Ççê=èìÉ=

ÇÉÄÉ=äÉÉê=Éä=ã~åì~ä=~åíÉë=

ÇÉä=ìëç=ÇÉ=ä~=ã•èìáå~K=

=

=

=

p∞гДздз=ЗЙ=~облзK=

=

iЙЙк=Езе=~нЙеЕбµе=д~л=

лЙЕЕбзеЙл=йкЙЕЙЗбЗ~л=йзк=

ЙлнЙ=л∞гДздзI=й~к~=д~=

лЙЦмкбЗ~З=ЗЙд=зйЙк~Ззк=у=

ÇÉ=ä~=ã•èìáå~

K

=

=

Page 21

===

b= = b=

=

=

ON

mofj^=^kqbp=abi=bjmibl=

=

jlsfjfbkql=jžnrfk^=bj_^i^a^=

i~=г•имбе~=Йлн•=ЕзенЙебЗ~=Йе=ме=ЙгД~д~аЙK==

bд=йЙлз=нзн~д=Йл=ЗЙ=OON=дДлK=ENMM=вЦF=г•сK==

i~л=ЗбгЙелбзеЙл=ЗЙд=ЙгД~д~аЙ=лзеW=

_~ëÉW=PPÒñOOÒ=EUQIRÅã=ñ=RTÅãF=

^äíìê~W=PPÒ=EUR=ÅãF=

=^qbk`fþkW=

kз=лЙ=ймЙЗЙе=кЙгзен~к=г•л=ЗЙ=Ззл=ЙгД~д~аЙлK=

=

abpbj_^i^gb=ab=i^=jžnrfk^=

NK= oЙнбк~к=Йд=ЙгД~д~аЙ=ЙснЙкбзкK=

OK= aЙлнзкебдд~к= дзл= Ззл= нзкебддзл= имЙ= Сба~е= дзл= Ззл=

лзйзкнЙл=Сба~Ззк=~=д~=г•имбе~K==

PK= aЙлнзкебдд~к= дзл= нзкебддзл= имЙ= Сба~е= дзл= лзйзкнЙл=

Сба~Ззк=~д=й~ддЙн=у=кЙгзоЙк=дзл=лзйзкнЙлK=

QK= iдЙо~к= Йд= нбгµе= ~= д~= йзлбЕбµе= ЗЙ= нк~Д~аз= EоЙк=

jlsfjfbkql= abi=qfjюkТF= й~к~= Д~а~к= д~= г•имбе~=

ЗЙд=й~ддЙнI=Йгйма~к=Ь~Еб~=~ЗЙд~енЙ=ЙеЕбг~=д~л=кмЙЗ~л=

Йе=йзлбЕбµе=ме=йзЕз=беЕдбе~З~=Ь~Еб~=~нк•л=й~к~=Йобн~к=

ЕЬзимЙл=СмЙкнЙл=Йе=д~л=й~кнЙл=гЙЕ•ебЕ~лK=

RK= dм~кЗ~к=Йд=ЙгД~д~аЙ=й~к~=ЙоЙенм~дЙл=еЙЕЙлбЗ~ЗЙл=

ЗЙ=нк~елйзкнЙK=

=

=

=

jlsfjfbkql=abi=qfjþk=

bд=нбгµе=Йе=Йд= ЙгД~д~аЙ=Йлн•= Йе=д~= йзлбЕбµе=ЕЙкк~З~=

лзДкЙ=д~=г•имбе~K=

m~к~=Цбк~к=Йд=нбгµе=Йе=ме~=ЗЙ=д~л=о~кб~л=йзлбЕбзеЙл=ЗЙ=

нк~Д~аз=у=й~к~=йзЗЙк=гзоЙк=д~=г•имбе~W=

NK= ^Енм~к= лзДкЙ= д~= й~д~еЕ~= ЗЙ= ЗЙлДдзимЙз= ENF=

йкЙлЙенЙ=ЕЙкЕ~=ЗЙд=г~ебдд~к=ЗЙд=нбгµеK=

OK= iдЙо~к= Йд= нбгµе= ~= д~= йзлбЕбµе= ЗЙ= нк~Д~аз=

г~енЙебЙеЗз=~йкЙн~Зз=д~=й~д~еЕ~=ЗЙ=ЗЙлДдзимЙз=ENFK=

PK= sздоЙк=~=ЗЙа~к=д~= й~д~еЕ~=ЗЙ=ЗЙлДдзимЙз=ENF=й~к~=

зДнЙеЙк=Йд=ДдзимЙз=ЗЙд=нбгµеK=

^Цбк= ЗЙ=д~= гблг~=г~еЙк~=й~к~= г~узк= кЙЦд~аЙ= ЗЙ= д~=

~днмк~= ЗЙд= нбгµе= ~д= Сбе= ЗЙ= зДнЙеЙк= д~= йзлбЕбµе= ЗЙ=

нк~Д~аз=г•л=ЕзеСзкн~ДдЙK=

=

=

`lkbufþk=_^qboð^p=

kзкг~дгЙенЙI= д~= г•имбе~= Йлн•= Йимбй~З~= Езе= Ззл=

Д~нЙк∞~л= у~=ЕзеЙЕн~З~л= Йе= лЙкбЙI= бенкзЗмЕбЗ~л=Йе= Йд=

ЬмЙЕз= й~к~= н~д= ЙСЙЕнз= ЗЙД~аз= ЗЙд= ЗЙйµлбнз= ЗЙ=

кЙЕмйЙк~ЕбµеK=

bе= Йд= Е~лз= ЗЙ= имЙ=Ь~у~= еЙЕЙлбЗ~З= ЗЙ= лмлнбнмбк= д~л=

Д~нЙк∞~лI= ЗбкбЦбклЙ= ~=ме= ЕЙенкз= ЗЙ= ~лблнЙеЕб~=н¨ЕебЕ~=

~мнзкбт~ЗзK=

i~=лмлнбнмЕбµе=нбЙеЙ=имЙ=лЙк=кЙ~дбт~З~=ЙсЕдмлбо~гЙенЙ=

Езе=Д~нЙк∞~л=Езе= кЙеЗбгбЙенз=бЗ¨енбЕз=~=~имЙдд~л=у~=

ЕздзЕ~З~лI=йзк=дз=н~ензW=

kзK=O=Д~нЙк∞~л=^dj=NOs=PQ^ЬRK=

mзк=гЙЗбз=ЗЙд=ЕзеЙЕнзк=EOF= Йл=йзлбДдЙ=ЗЙ=ЕзеЙЕн~к=з=

ЗЙлЕзеЙЕн~к=д~л=Д~нЙк∞~лK=

=

=

=

ob`^od^=ab=i^p=_^qboð^p==

i~= йкЙлЙеЕб~= ЗЙ= ме~= ЙнбимЙн~= Езе= д~= беЗбЕ~Ебµе=

^djТ=ЕздзЕ~З~=лзДкЙ=Йд=Д~лнбЗзк=йзлнЙкбзкгЙенЙ=ЗЙ=

д~= г•имбе~I= бЗЙенбСбЕ~= д~= оЙклбµе= гзен~З~= Езе=

Д~нЙк∞~л=^dj=у=лм=Е~кЦ~Ззк=~йкзйб~ЗзK=

`зе=Йд=бенЙккмйнзк=ЦЙеЙк~д=EPF=ЙеЕЙеЗбЗзI=Йе=д~=й~кнЙ=

нк~лЙк~=ЗЙ=д~=г•имбе~=лЙ= облм~дбт~=Йд= ебоЙд=ЗЙ= Е~кЦ~=

ЗЙ=д~л=Д~нЙк∞~л=EQFK==

^W= дЙЗ=оЙкЗЙ=ЙеЕЙеЗбЗз=Z=Д~нЙк∞~л=Е~кЦ~лK=

_W= дЙЗ= е~к~еаз= ЙеЕЙеЗбЗз= Z= Д~нЙк∞~л= Е~лб=

ЗЙлЕ~кЦ~З~лK=

`W= дЙЗ= кзаз=ЙеЕЙеЗбЗз= Z=ЗЙлЕ~кЦ~= ЕзгйдЙн~=ЗЙ= д~л=

Д~нЙк∞~лK=

`м~еЗз= Йд= дЙЗ= ЗЙд= Е~кЦ~Ззк= E`F= лЙ= йзеЙ= кзазI==

ЕзенЙгйзк•еЙ~гЙенЙ=лЙ=йзеЙ=кзаз=н~гДб¨е=Йд=дЙЗ=ЗЙд=

бенЙккмйнзк= ЦЙеЙк~д= EPF= Åçå= ЕзелбЦмбЙенЙ=

~й~Ц~гбЙенз= ~мнзг•нбЕз=ЗЙ= нзЗ~л= д~л= СмеЕбзеЙл= ЗЙ=

д~=г•имбе~K=

=

=

aмк~енЙ= д~л= зйЙк~ЕбзеЙл= ЗЙ= кЙЕ~кЦ~= лЙ= ~Енбо~= ме=

Зблйзлбнбоз=имЙ=ез=йЙкгбнЙ=Йд=СмеЕбзе~гбЙенз=ЗЙ= д~=

г•имбе~K=

`здзЕ~к=д~=г•имбе~=Йе=ме~=лмйЙкСбЕбЙ=йд~е~=ЕЙкЕ~=ЗЙ=

ме~=нзг~=гзезС•лбЕ~K=

^й~Ц~к=Йд=бенЙккмйнзк=ЦЙеЙк~д=EPFK=

`зеЙЕн~к=Йд=Е~ДдЙ=ЗЙ= ~дбгЙен~ЕбµеI=лмгбеблнк~Зз=Езе=

д~=г•имбе~I=н~енз=~= д~=г•имбе~=ERF=имЙ=~=д~= кЙЗ=ЗЙ=

~дбгЙен~Ебµе=Езгз=лЙ=беЗбЕ~=Йе=Йд=Цк•СбЕзK=

^д=Сбе~д=ЗЙ=д~=кЙЕ~кЦ~I=имбн~к=Йд=Е~ДдЙ=ЗЙ=~дбгЙен~ЕбµеK=

i~=С~лЙ=ЗЙ= кЙЕ~кЦ~= Йлн•=ЕзгйдЙн~=лздз=Ем~еЗз=лзДкЙ=

Йд=Е~кЦ~Ззк=лЙ=ЙеЕбЙеЗЙ=Йд=дЙЗ=оЙкЗЙ=E^FK=

=^qbk`fþkW=

m~к~=ез=Е~мл~к=З~¥зл=йЙкг~еЙенЙл=~=д~л=Д~нЙк∞~лI=Йл=

беЗблйЙел~ДдЙ= Йобн~к= д~= ЗЙлЕ~кЦ~= ЕзгйдЙн~= ЗЙ= д~л=

гблг~лI= ЙСЙЕнм~еЗз= бегЙЗб~н~гЙенЙ= д~= кЙЕ~кЦ~K=

^ЗЙг•лI=Йе= Йд= Е~лз= ЗЙ=ме~=й~к~З~=йзк=г•л=ЗЙ= Ззл=

лЙг~е~л=ЗЙ=д~=г•имбе~I= ЗЙлЕзеЙЕн~к=Йд=ЕзеЙЕнзк=ЗЙ=

д~л=Д~нЙк∞~л=EоЙк=Е~й∞нмдз=`lkbufюk=_^qboр^pТFK=

=

=

=^qbk`fþkW=

kç=Å~êÖ~ê= à~ã•ë=ä~ë=Ä~íÉê∞~ë=Åçå=ìå=Å~êÖ~Ççê=åç=

~ÇÉÅì~ÇçK= pЙЦмбк= ЙлгЙк~З~гЙенЙ= д~л=

белнкмЕЕбзеЙл= нк~елгбнбЗ~л= ЗЙд= С~ДкбЕ~енЙ= ЗЙ= д~л=

Д~нЙк∞~л=у=ЗЙд=Е~кЦ~ЗзкK=

=

bifjfk^`fюk=ab=i^p=_^qboр^p=

bл=зДдбЦ~нзкбз=ЙенкЙЦ~к=д~л=Д~нЙк∞~л=~Цзн~З~лI=имЙ=лзе=

Ед~лбСбЕ~З~л= Езгз= кЙлбЗмзл= йЙдбЦкзлзлI= ~= ме= ЙенЙ=

~мнзкбт~Зз=Йе=ЕзеСзкгбЗ~З=Езе=д~=дЙЦблд~Ебµе=обЦЙенЙ=

й~к~=д~=Йдбгбе~ЕбµеK=

=

abmþpfql=ab=ob`rmbo^`fþk=

`зенкзд~к=имЙ=д~=н~й~=ЗЙд=Сбднкз=ЗЙ=~лйбк~Ебµе=ENF=Йлн¨=

ЕзккЙЕн~гЙенЙ= ДдзимЙ~З~I=ЗЙлйм¨л= ЗЙ= Ь~ДЙк= Цбк~Зз=

д~л=й~д~еЕ~л=E_FK=`згйкзД~к=~ЗЙг•л=имЙ=Йд=нмДз=ЗЙ=д~=

Дзимбдд~= ЗЙ= лЙЕ~Зз=Йлн¨= ЕзккЙЕн~гЙенЙ= бенкзЗмЕбЗз=

Йе=лм=~дза~гбЙенз=E^FK=

=

=

=

abmþpfql=ab=i^=plir`fþk=abqbodbkqb=

i~= Е~й~ЕбЗ~З= ЗЙд= ЗЙйµлбнз= ЗЙ= д~= лздмЕбµе= Йлн•=

беЗбЕ~З~=Йе=д~=СбЕЬ~=н¨ЕебЕ~K=

^Дкбк= Йд=н~йµе= кзлЕ~Зз= ESF= имЙ= лЙ= ЙеЕмЙенк~= Йе= д~=

й~кнЙ=лмйЙкбзк=у=ддЙе~к=Йд=ЗЙйµлбнз=ЗЙ=д~=лздмЕбµе=Езе=

~Цм~= дбгйб~I= Езе= ме~= нЙгйЙк~нмк~= ез= лмйЙкбзк= ~=

NOOшc= ERMш`FK= ^¥~Збк= Йд= ЗЙнЙкЦЙенЙ= д∞имбЗз= Йе= д~=

ЕзеЕЙенк~Ебµе=у=Езе=д~л=гзЗ~дбЗ~ЗЙл=йкЙоблн~л=йзк=Йд=

С~ДкбЕ~енЙK=m~к~=Йобн~к=д~=Сзкг~Ебµе=ЗЙ=ме~=Е~енбЗ~З=

ЙсЕЙлбо~= ЗЙ=Йлймг~= имЙ=йзЗк∞~= З~¥~к= Йд=гзнзк= ЗЙ=

~лйбк~ЕбµеI= ЙгйдЙ~к= ме~= Е~енбЗ~З= г∞ебг~= ЗЙ=

ЗЙнЙкЦЙенЙK= bекзлЕ~к= Йд= н~йµе= ЗЙд= ЗЙйµлбнз= ЗЙ= д~=

лздмЕбµеK=

=

=^qbk`fþkW=

e~у= имЙ= ЙгйдЙ~к= лбЙгйкЙ= ЗЙнЙкЦЙенЙ= ЗЙ= Йлймг~=

Езенкзд~З~K=m~к~=Йобн~к= Езе=лЙЦмкбЗ~З=д~=йкзЗмЕЕбµе=

ЗЙ=Йлймг~I=~енЙл=ЗЙ=ЙгйЙт~к=Йд=нк~Д~аз=бенкзЗмЕбк=Йе=

Йд=ЗЙйµлбнз=ЗЙ=кЙЕмйЙк~Ебµе=ме~=Е~енбЗ~З=г∞ебг~=ЗЙ=

д∞имбЗз=~енбЙлймг~K=

kз=ЙгйдЙ~к=•ЕбЗзл=Йе=Йлн~Зз=ймкзK=

=

=

Page 22

===

b= = b=

=

=

OO

ifjmfbw^=ab=ilp=prbilp=

=

^``flk^jfbkql=ab=i^=j^nrfk^=

iзл= ймдл~ЗзкЙл= ЙеЕбг~= Йд= н~ДдЙкз= ЗЙ= Езенкз= Йлн•е=

Ззн~Ззл= ЗЙ= ме= нЙлнбЦз=оЙкЗЙ=лмйЙкбзк=имЙ= лЙ¥~д~= д~=

~Енбо~Ебµе=ЗЙд=г~еЗзK=

NK= bеЕЙеЗЙк= д~= г•имбе~= ~йкЙн~еЗз= Йд= бенЙккмйнзк=

ЦЙеЙк~д=ENFK=

OK= `зенкзд~к=Йд= Йлн~Зз= ЗЙ=д~= Е~кЦ~= ЗЙ=д~л= Д~нЙк∞~л=

EоЙк=ob`^od^=ab=i^p=_^qboр^pТFK=

PK= _~а~к=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=Цбк~еЗз=Ь~Еб~=~Д~аз=д~=

й~д~еЕ~=ERF=ймЙлн~=~д=ЕЙенкз=ЗЙд=нбгµеK=

QK= ^ЕЕбзе~к=Йд=бенЙккмйнзк=ЗЙд=гзнзк=ЕЙйбддз=EOFK=

RK= ^ЕЕбзе~к=Йд= бенЙккмйнзк= ЗЙд=гзнзк=ЗЙ= ~лйбк~Ебµе=

EPFK=

SK= ^ЕЕбзе~к=Йд=бенЙккмйнзк=ЗЙ=д~=ЙдЙЕнкзо•домд~=EQFK=

i~=г•имбе~= Йлн•= Йимбй~З~=ЗЙ=ЙдЙЕнкзо•домд~I=йзк=дз=

н~енз= Йд= Е~мЗ~д= ЗЙ= д~= лздмЕбµе= ЗЙнЙкЦЙенЙ= лЙк•=

~ЕЕбзе~Зз= ~мнзг•нбЕ~гЙенЙ= ~Енм~еЗз= д~л= г~еЙн~л=

ЗЙ=бебЕбзLй~кз=ETFK=sздобЙеЗз= ~=ЗЙа~к=д~л=г~еЙн~л=ЗЙ=

бебЕбзLй~кзI= Éä= Å~ìÇ~ä= ëÉ= бенЙккмгйбк•=

~мнзг•нбЕ~гЙенЙK=

TK= mзебЙеЗз= Йе= СмеЕбзе~гбЙенз= д~л= г~еЙн~л=

бебЕбзLй~кз=ETF=Йд= ЕЙйбддз=ЙгйЙт~к•=~= Цбк~кK=bд=Е~мЗ~д=

ЗЙ= д~= лздмЕбµе= ЗЙнЙкЦЙенЙ= ЙгйЙт~к•= ~= Сдмбк= у= д~=

Дзимбдд~=ЗЙ=лЙЕ~Зз=ЙгйЙтЙк•=~=~лйбк~кK==

UK= aмк~енЙ= дзл= йкбгЙкзл= гЙнкзл= EСЙЙнF= лЙ= ЗЙДЙ=

Езенкзд~к=имЙ=Йд=Е~мЗ~д=ЗЙ=д~=лздмЕбµе=ЗЙнЙкЦЙенЙ=лЙ~=

~ЗЙЕм~ЗзK= bд= кЙЦмд~Ззк= ЗЙ= Е~мЗ~д= ЗЙ= д~= лздмЕбµе=

ЗЙнЙкЦЙенЙ= у~= Йлн•= н~к~Зз= ЗЙ= д~= С•ДкбЕ~= й~к~=

л~нблС~ЕЙк=д~=дбгйбЙт~=йзк=д~=г~узк=й~кнЙ=ЗЙ=дзл=лмЙдзлK=

pб=Йл=еЙЕЙл~кбз=гзЗбСбЕ~к= д~=Е~енбЗ~З= ЗЙ=д~=лздмЕбµе=

ЗЙнЙкЦЙенЙ= Йе= Йд=лмЙдзI= ~Енм~к=лзДкЙ=д~=й~д~еЕ~=ЗЙд=

кЙЦмд~Ззк=ЗЙ=Е~мЗ~д=EUFK=

=

=

=

olq^`fþk= `ljmibq^= ab= i^= _lnrfii^= ab=

pb`^al=

`зе=Йлн~=г•имбе~=Йл= йзлбДдЙ=д~о~к= у=лЙЕ~к= н~енз=Йе=

г~кЕЬ~=~ЗЙд~енЙ=Езгз=Йе=г~кЕЬ~= ~нк•л=Цк~Еб~л= ~=д~=

кзн~Ебµе= ЕзгйдЙн~= ЗЙ= д~= Дзимбдд~= ЗЙ= лЙЕ~ЗзK=

pбЦмбЙеЗз= Йд= кЙЕзккбЗз= беЗбЕ~Зз= Йе= дзл= Цк•СбЕзл= лЙ=

лбгйдбСбЕ~=д~=беоЙклб∂е=ЗЙ=д~=йзлбЕбµе=ЗЙ=д~=Дзимбдд~=ЗЙ=

лЙЕ~Зз= йЙкгбнбЙеЗз= Йд= лЙЕ~Зз= н~гДб¨е= Йе= г~кЕЬ~=

~нк•лK=

=

pÉÅ~Çç=Éå=ã~êÅÜ~=~ÇÉä~åíÉ

=

pÉÅ~Çç=Éå=ã~êÅÜ~=~íê•ë

=

=

=

fеоЙклб

µå=

éçëá

Ебµе=Дзимбдд~=ЗЙ=лЙЕ~Зз

=

=

Åçå=

êçí~

Åáµå

=

=

pb`^al=bk=j^o`e^=^qožp=

`зе= д~=Дзимбдд~= ЗЙ= лЙЕ~Зз= йзлбЕбзе~З~=Йе= д~=й~кнЙ=

ЗЙд~енЙк~= ЗЙ= д~= г•имбе~= Йл= йзлбДдЙ= д~о~к= у= лЙЕ~к=

ЗзеЗЙ= Езе= д~= Дзимбдд~=ЗЙ= лЙЕ~Зз= нк~ЗбЕбзе~д= ез=лЙ=

дзЦк~к∞~K=bе=лЙЦмбЗ~=~дЦмезл=ЙаЙгйдзл=Езгз=мнбдбт~к=

д~л=СмеЕбзеЙл=ЗЙ=ЕзгйдЙн~=кзн~Ебµе=ЗЙ=д~=Дзимбдд~=ЗЙ=

лЙЕ~ЗзK=

i~о~к=д~=лмйЙкСбЕбЙ=бенЙкЙл~З~=ENFK=

=

=

=

sздоЙк=~=Цбк~к=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=Ь~Еб~=д~=ЗЙкЙЕЬ~=

з= Ь~Еб~= д~= бтимбЙкЗ~= EоЙк= Е~й∞нмдз= olq^`fюk=

`ljmibq^= ab= i^= _lnrfii^= ab= pb`^alТF= й~к~=

ддЙо~кд~=ЗЙд~енЙK=

iЙо~ен~к=дбЦЙк~гЙенЙ=д~=г•имбе~=EOF=у=кЙйзлбЕбзе~клЙ=

лзДкЙ=д~=лмйЙкСбЕбЙ=ЗЙ=лЙЕ~к=EPFK=

=^qbk`fþkW=

`м~еЗз= лЙ= дЙо~ен~= д~= г•имбе~I= оздоЙк= ~= ЗЙа~к= д~л=

й~д~еЕ~л=йкЙлЙеЕб~=ЬзгДкЙ=ЗЙ=г~еЙк~=имЙ=лЙ=й~кЙ=д~=

кзн~Ебµе= ЗЙд= ЕЙйбддз= у= Йобн~к= йзк= дз= н~енз= д~=

йкзуЙЕЕбµе=ЗЙ=л~дйбЕ~Змк~л=ЗЙ=~Цм~K=

=

=

mкзЕЙЗЙк= Йе= г~кЕЬ~= ~нк•л= й~к~= лЙЕ~к= д~= лмйЙкСбЕбЙ=

~йЙе~л=д~о~З~=EQFK=

=

=

=

ibs^kq^jfbkql=ab=i^=_lnrfii^=ab=pb`^al=

m~к~= дЙо~ен~к= д~= Дзимбдд~= ЗЙ=лЙЕ~Зз= оздоЙк= ~= Цбк~к=

Ь~Еб~= ~ккбД~=д~=й~д~еЕ~= ERF= ймЙлн~=Йе= Йд= ЕЙенкз=ЗЙд=

нбгµеK=

=

5

=

pЙ=ймЙЗЙ=дЙо~ен~к=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=Ем~еЗз=Йлн~=

лЙ=ЙеЕмЙенк~=Йе=йкзсбгбЗ~З=ЗЙд=йменз=ЕЙенк~дK=

pб= д~= Дзимбдд~= ЗЙ= лЙЕ~Зз= ез= лЙ= ЙеЕмЙенк~= Йе=

йкзсбгбЗ~З= ЗЙд= йменз= ЕЙенк~дI= ~меимЙ= ~ДкбЙеЗз= д~=

й~д~еЕ~=ERF=Йлн~=ез=лЙ=дЙо~ен~к•K=

=^qbk`fþkW=

bе=С~лЙ=ЗЙ=нк~Д~аз=д~=й~д~еЕ~=ЗЙ=дЙо~ен~гбЙенз=ЗЙ=д~=

Дзимбдд~=ЗЙ=лЙЕ~Зз=нбЙеЙ=имЙ=Йлн~к=Йе=д~=йзлбЕбµе=Д~а~K=

=

obdi^gb=abi=qfjþk=

bе= йкзсбгбЗ~З= ЗЙ= зДлн•Емдзл= з= й~кЙЗЙл= лЙ= ймЙЗЙ=

лбгйдбСбЕ~к=д~=г~ебзДк~=ЗЙ=д~=г•имбе~=кЙЦмд~еЗз= Йд=

нбгµе= Езе= ме~= йзлбЕбµе= ЗЙ= д~= Йгйм¥~Змк~= г•л=

оЙкнбЕ~д=Езе=кЙлйЙЕнз=д~=г•имбе~K=

m~к~=Цбк~к=Йд=нбгµеW=

Page 23

===

b= = b=

=

=

OP

NK= ^Енм~к= лзДкЙ= д~= й~д~еЕ~= ЗЙ= ЗЙлДдзимЙз= EUF=

йкЙлЙенЙ=ЕЙкЕ~=ЗЙ=д~=Йгйм¥~Змк~=ЗЙд=нбгµеK=

OK= dбк~к= Йд= нбгµе= Йе=д~= емЙо~=йзлбЕбµе= ЗЙ= нк~Д~аз=

г~енЙебЙеЗз=~йкЙн~З~=д~=й~д~еЕ~=ЗЙ=ЗЙлДдзимЙз=EUFK=

PK= sздоЙк=~=ЗЙа~к=д~= й~д~еЕ~=ЗЙ=ЗЙлДдзимЙз=EUF=й~к~=

зДнЙеЙк=Йд=ДдзимЙз=ЗЙд=нбгµеK=

rе~= оЙт= лмйЙк~Зз= Йд= зДлн•Емдз= у= ЕзгйдЙн~З~= д~=

г~езДкб~= кЙйЙнбк= д~= зйЙк~Ебµе= й~к~= оздоЙк= ~= д~=

йзлбЕбµе=ЗЙ=нк~Д~аз=йкЙЕЙЗЙенЙK=

q~гДб¨е= Йл= йзлбДдЙ= Ь~ЕЙк= Йлн~= зйЙк~Ебµе= Езе= д~=

г•имбе~=Йе= гзобгбЙенз=г~енЙебЙеЗз= ~йкЙн~Зз=~= д~=

оЙт=д~=г~еЙн~=ЗЙ=бебЕбзLй~кзK=

=

=

afpmlpfqfsl=ob_lp^abol=

^=Сбе=ЗЙ=Йобн~к=З~¥зл=лЙкбзл=~д=гзнзк=ЗЙ=~лйбк~ЕбµеI=д~=

г•имбе~= Йлн•= Йимбй~З~= ЗЙ= ме= Сдзн~Ззк= имЙ= ~Ен∫~=

Ем~еЗз= Йд= ЗЙйµлбнз= ЗЙ= кЙЕмйЙк~Ебµе= Йлн•= ддЙез=

Е~мл~еЗз= Йд=ЕбЙккЙ=ЗЙд= нмДз=ЗЙ= ~лйбк~Ебµе=у= йзк=дз=

н~енз=ЗЙ=д~=~лйбк~ЕбµеK=

bе= ЙлнЙ= Е~лз= Ь~у= имЙ= о~Еб~к= Йд= ЗЙйµлбнз= ЗЙ=

кЙЕмйЙк~ЕбµеK=

NK= bгйм¥~к= Йд=нмДз= ЗЙ=ЗЙлЕ~кЦ~=EVF=ЗЙд= ЗЙйµлбнз=ЗЙ=

кЙЕмйЙк~ЕбµеK=

OK= nмбн~к=Йд=н~йµе=ЗЙд=нмДз= ЗЙ=ЗЙлЕ~кЦ~=у=о~Еб~к= Йд=

ЗЙйµлбнз= ЗЙ= кЙЕмйЙк~Ебµе= Йе= нбе~л= йкЙоблн~лI= Йе=

ЕзенЙгйд~Ебµе= ЗЙ= д~л= езкг~л= обЦЙенЙл= Йе= Ем~енз=

ЕзеЕбЙкеЙ=д~=дбимбЗ~Ебµе=ЗЙ=дзл=д∞имбЗзлK=

=^qbk`fþkW=

bлн~= зйЙк~Ебµе= нбЙеЙ= имЙ= лЙк= кЙ~дбт~З~= ддЙо~еЗз=

Цм~енЙл=й~к~=йкзнЙЦЙклЙ=ЗЙд=Езен~Енз=Езе=лздмЕбзеЙл=

йЙдбЦкзл~лK=

=

=

=

=

abqbk`fþk=ab=i^=jžnrfk^=^i= cfk^i=

ab=i^=ifjmfbw^=

=

^енЙл=ЗЙ=ЙаЙЕмн~к=Ем~димбЙк=нбйз=ЗЙ=г~енЙебгбЙензW=

NK= ^й~Ц~к=Йд=бенЙккмйнзк=ЦЙеЙк~д=ENFK=

OK= iЙо~ен~к= д~= Дзимбдд~= ЗЙ= лЙЕ~Зз= Цбк~еЗз= Ь~Еб~=

~ккбД~=Йд=г~ебдд~к= ERF=ймЙлнз= Йе=Йд= ЕЙенкз=ЗЙд= нбгµе=

EоЙк=Е~й∞нмдз=ibs^kq^jfbkql=ab= i^=_lnrfii^=ab=

pb`^alТFK=

PK= iдЙо~к= д~=г•имбе~=Ь~лн~=Йд=дмЦ~к=йкЙоблнз= й~к~=д~=

ЗЙлЕ~кЦ~=ЗЙд=~Цм~K=

=

=^qbk`fþkW=

i~= г•имбе~= ез= Йлн•= Йимбй~З~= ЗЙ= СкЙез= ЗЙ=

Йлн~Ебзе~гбЙенз=йзк= дз=н~енз=ез=Ь~у=имЙ=ЗЙа~кд~=Йе=

йд~езл=беЕдбе~ЗзлK=

=

=

j^kqbkfjfbkql=af^ofl=

=

ifjmfbw^=abmþpfql=ab=ob`rmbo^`fþk=

NK= bгйм¥~к= Йд=нмДз= ЗЙ=ЗЙлЕ~кЦ~=EVF=ЗЙд= ЗЙйµлбнз=ЗЙ=

кЙЕмйЙк~ЕбµеK=

OK= p~Е~к= Йд=н~йµе=ЗЙд=нмДз=ЗЙ=ЗЙлЕ~кЦ~=у=о~Еб~к=Йд=

ЗЙйµлбнз=ЗЙ=кЙЕмйЙк~Ебµе=Йе=д~л=нбе~л=йкЙоблн~л=EоЙк=

?afpmlpfqfsl=ob_lp^abol?FK=

PK= nмбн~к= Йд= н~йµе= ЗЙ= ~лйбк~Ебµе= ENMF= ЗЙлйм¨л= ЗЙ=

Ь~ДЙк=Цбк~Зз=д~л=й~д~еЕ~л=ENNF=имЙ=дз=Сба~еK=

QK= s~Еб~к= Йд= ЗЙйµлбнз= мнбдбт~еЗз= Йд=нмДз= ~йкзйб~Зз=

EVFK=

RK= bеам~Ц~к=Йд=ЗЙйµлбнз=Езе=ме=ЕЬзккз=ЗЙ=~Цм~K=

=

=

=^qbk`fþkW=

bлн~=зйЙк~Ебµе=Ь~= ЗЙ= лЙк=кЙ~дбт~З~=ддЙо~еЗз=Цм~енЙл=

й~к~= йкзнЙЦЙклЙ= ЗЙд= Езен~Енз= Езе= лздмЕбзеЙл=

йЙдбЦкзл~лK=

=

s^`f^al=v=ifjmfbw^=abi=abmþpfql=plir`fþk=v=

abi=cfiqol=

m~к~=ЗЙлЕ~кЦ~к=д~=лздмЕбµе=ЗЙнЙкЦЙенЙ=кЙлн~енЙ= Йе=Йд=

ЗЙйµлбнз=ЗЙ=д~=лздмЕбµеW=

NK= iдЙо~к= д~=г•имбе~=Ь~лн~=Йд=дмЦ~к=йкЙоблнз= й~к~=д~=

ЗЙлЕ~кЦ~=ЗЙд=~Цм~K=

OK= ^й~Ц~к=д~=г•имбе~=Езе=Йд=бенЙккмйнзк=ЦЙеЙк~дK=

PK= aЙлЙекзлЕ~к= д~= н~й~= ЗЙ= Е~кЦ~= ENOF= ЗЙд=ЗЙйµлбнз=

лздмЕбµе=у=имбн~к=Йд=Сбднкз=ENQFK=

QK= aЙлЙекзлЕ~к=Йд= н~йµе=ЗЙ= ЗЙлЕ~кЦ~= ENPF= ЕздзЕ~Зз=

беСЙкбзкгЙенЙ=Йе=Йд=д~Зз=бтимбЙкЗз= ЗЙ=д~= г•имбе~=у=

ЙлйЙк~к= имЙ= нзЗ~= д~= лздмЕбµе= ЗЙнЙкЦЙенЙ= Йлн¨=

ЗЙлЕ~кЦ~З~K=

=

=

=

RK= sздоЙк=~=Цбк~к=г~ем~дгЙенЙ=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=

ENRF= Ь~Еб~= д~= й~кнЙ= ЗЙд~енЙк~= ЗЙ= д~= г•имбе~= ЗЙ=

г~еЙк~=ЗЙ=Ь~ДЙк=~ЕЕЙлз=дбДкЙ=~д=Сбднкз=ENSFK=

SK= aЙлЙекзлЕ~к= д~= н~й~= ЗЙд= Сбднкз= ENSFI= кЙгзоЙк= Йд=

Е~кнмЕЬз=ENTF=у=Йеам~Ц~кдз=Езе=ме=ЕЬзккз=ЗЙ=~Цм~K=

TK= sздоЙк=~=гзен~к=нзЗзK=

=

=

=^qbk`fþkW=

bлн~= зйЙк~Ебµе= нбЙеЙ= имЙ= лЙк= кЙ~дбт~З~= ддЙо~еЗз=

Цм~енЙл=й~к~=йкзнЙЦЙклЙ=ЗЙд=Езен~Енз=Езе=лздмЕбзеЙл=

йЙдбЦкзл~лK=

=

ifjmfbw^=abi=cfiqol=ab=^pmfo^`fþk=

NK= nмбн~к= Йд= н~йµе= ЗЙ= ~лйбк~Ебµе= ENSF= ЗЙлйм¨л= ЗЙ=

Ь~ДЙк=Цбк~Зз=д~л=й~д~еЕ~л=ENTF=имЙ=дз=Сба~еK=

OK= nмбн~к=Йд=Сбднкз=Езе=Йд=Сдзн~Ззк=Ь~ЕбЙеЗз=СдЙсбзе~к=

Йд= ДзкЗЙ= ЗЙд= Сбднкз= й~к~= дбДЙк~кдз= ЗЙ= дзл= нзкебддзл=

йкЙлЙенЙл=лзДкЙ=д~=н~й~K=

PK= iбгйб~к= нзЗз= Езе= ме= ЕЬзккз= ЗЙ= ~Цм~=

ЙлйЙЕб~дгЙенЙ=д~л=й~кЙЗЙл=у=Йд=СзеЗз=ЗЙд=СбднкзK=

QK= oЙ~дбт~к= д~л= зйЙк~ЕбзеЙл=ЗЙ= дбгйбЙт~=ЗЙ= г~еЙк~=

ЙлгЙк~З~K=

RK= sздоЙк=~=гзен~к=нзЗзK=

=

=

=

m^onrb=sboqf`^i=ab=i^=jžnrfk^=

i~= г•имбе~= ймЙЗЙ= ~лмгбк= ме~= йзлбЕбµе= оЙкнбЕ~д=

оздЕ~З~= Йе= лм= й~кнЙ= йзлнЙкбзк= ЗЙлйм¨л= ЗЙ= Ь~ДЙк=

кЙйдЙЦ~Зз=Йд=нбгµе=ЙеЕбг~=д~=г•имбе~K=

bлн~= йзлбЕбµе= йЙкгбнЙ= ме= ЙлнзкДз= гЙезк= йзк= Йд=

й~кимЙ=ЗЙ=д~=г•имбе~=у=лбгйдбСбЕ~=д~л=зйЙк~ЕбзеЙл=ЗЙ=

г~енЙебгбЙенз=ЗЙ=д~=гблг~K=

m~к~=озднЙ~к=д~=г•имбе~=Ь~у=имЙW=

NK= ^й~Ц~к=Йд=бенЙккмйнзк=ЦЙеЙк~дK=

OK= `зенкзд~к=имЙ=дзл=Ззл=ЗЙйµлбнзл=Йлн¨е=о~Е∞зл=у=Йе=

Йд=Е~лз=йкзЕЙЗЙк=~=о~Еб~кдзл=EоЙк=Е~й∞нмдз=s^`f^al=v=

ifjmfbw^= abmюpfql= ab= ob`rmbo^`fюkТ= у==

s^`f^al=v=ifjmfbw^=abi=abmюpfql=plir`fюk?FK=

PK= ^Енм~к= лзДкЙ= д~= й~д~еЕ~= ЗЙ= ЗЙлДдзимЙз= EUF=

йкЙлЙенЙ=ЕЙкЕ~=ЗЙ=д~=Йгйм¥~Змк~=ЗЙд=нбгµеK=

QK= dбк~к= Йд= нбгµе= оздобЙеЗз= ~= ЗзДд~кдз= Ь~Еб~= дзл=

ЗЙйµлбнзл= г~енЙебЙеЗз= ~йкЙн~З~= д~= й~д~еЕ~= ЗЙ=

ЗЙлДдзимЙз=EUFK=

RK= sздоЙк=~=ЗЙа~к=д~= й~д~еЕ~=ЗЙ=ЗЙлДдзимЙз=EUF=й~к~=

зДнЙеЙк=Йд=ДдзимЙз=ЗЙд=нбгµеK=

SK= bгйм¥~к= д~= г•имбе~= Езе= ~гДзл= г~езл= Йе= Йд=

йменз=E^F=ЗЙд=ДзкЗЙ=ЗЙйµлбнз=у=E_F=ЗЙ=д~=Йгйм¥~Змк~=

ЗЙд=нбгµе=беЗбЕ~Ззл=Йе=Йд=Цк•СбЕзK=

TK= iЙо~ен~к= д~= й~кнЙ= ЗЙд~енЙк~= ЗЙ= д~= г•имбе~=

Ь~Еб¨еЗзд~=Цбк~к= лзДкЙ=д~л=кмЙЗ~л=нк~лЙк~л=ддЙо•еЗзд~=

~=д~=йзлбЕбµе=оЙкнбЕ~д=Езгз=Йе=Йд=ЗбДмазK=

=

Page 24

===

b= = b=

=

=

OQ

=^qbk`fþkW=

i~=йзлбЕбµе=ЗЙ=й~кимЙ=оЙкнбЕ~д=лЙ=беЗбЕ~=Ем~еЗз=лЙ=

йкЙоЙЙ= имЙ= ез= лЙ= мнбдбт~к•= д~= г•имбе~= йзк= ме=

йЙк∞зЗз= лмйЙкбзк= ~= OLP= З∞~лI= й~к~= Йобн~к= имЙд= Йд=

йЙлз=ЗЙ=д~=г•имбе~=ймЙЗ~=Езе=Йд=нбЙгйз=З~¥~к=Йд=

ЕЙйбддз=ЕзгйкзгЙнбЙеЗз=йзк=дз=н~енз=Йд=ЕзккЙЕнз=

СмеЕбзе~гбЙенз=ЗЙ=д~=г•имбе~K===

=

=

=

=

ifjmfbw^=abi=`bmfiil=

aЙлгзен~к= Йд=ЕЙйбддз= у=дбгйб~кдз= Езе= ме= ЕЬзккз= ЗЙ=

~Цм~=Eй~к~=Йд= ЗЙлгзен~аЙ=ЗЙд=ЕЙйбддз=оЙк=Йе= лЙЦмбЗ~=

abpjlkq^gbLjlkq^gb=abi=`bmfiilТFK=

=

abpjlkq^gbLjlkq^gb=abi=`bmfiil=

NK= sздЕ~к= д~= г•имбе~= Йе= лм= й~кнЙ= йзлнЙкбзк= EоЙк=

Е~й∞нмдз= m^onrb= sboqf`^i= ab= i^= jžnrfk^?F=

нЙебЙеЗз= ЕмбЗ~Зз= ЗЙ= ~ЕзкЗ~клЙ= ЗЙ= ~й~Ц~к= Йд=

бенЙккмйнзк=ЦЙеЙк~д=у=о~Еб~к=дзл=ЗЙйµлбнзлK=

OK= `зе=д~= г•имбе~=Йе= ЙлнЙ=йзлбЕбµе= Цбк~к= Йд=ЕЙйбддз=

Йе= Йд= лЙенбЗз= Ьзк~кбз=й~к~= имЙ=л~дЦ~=ЗЙд=ЬмЙЕз= ЗЙд=

йд~нз=йзкн~ЕЙйбддзI=Езгз=лЙ=беЗбЕ~=Йе=Йд=ЗбДмазK==

=

=

=

PK= m~к~= оздоЙк= ~= гзен~к= Йд= ЕЙйбддз= бенкзЗмЕбк= дзл=

ДзнзеЙл= ЗЙ=ЙеЦ~еЕЬЙ= йкЙлЙенЙл= лзДкЙ=Йд= ЕЙйбддз= Йе=

дзл=ЬмЙЕзл=ЗЙд=йд~нз=йзкн~ЕЙйбддз=у=Цбк~к=Йе=Йд=лЙенбЗз=

~енбЬзк~кбз=Ь~лн~=дзЦк~к=Йд=ДдзимЙзK=

pЙ=ймЙЗЙ=~ЗЙг•л=йкзД~к=знкзл=гзЗЙдзл=ЗЙ=ЕЙйбддзл=Йе=

СмеЕбµе= ЗЙд= нбйз= ЗЙ= лмЙдз= ~= дбгйб~к= у= ЗЙ= д~л=

ЕзеЗбЕбзеЙл= ЗЙ= д~= лмЕбЙЗ~З= имЙ= лЙ= ЙеЕмЙенкЙ= EоЙк=

Е~й∞нмдз=`bmfiilp=^`lkpbg^alpТFK=

=^qbk`fþkW=

i~л=зйЙк~ЕбзеЙл=ЗЙ=д~=г~ебймд~Ебµе=ЗЙд=ЕЙйбддз=нбЙеЙе=

имЙ= лЙк= кЙ~дбт~З~л= ддЙо~еЗз= Цм~енЙл= ~йнзл= й~к~=

йкзнЙЦЙклЙ=н~енз=гЙЕ•ебЕ~гЙенЙ=ЗЙд=Езен~Енз=ЗЙ=д~л=

ЕЙкЗ~л=Езгз= йзк= Йд=кбЙлЦз=им∞гбЕз=ЗЙд=Езен~Енз=Езе=

лздмЕбзеЙл=йЙдбЦкзл~лK=

=

=

ifjmfbw^=ab=i^=_lnrfii^=ab=pb`^al=

j~енЙеЙк=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=дбгйб~=Йл=Ц~к~ен∞~=ЗЙ=

ме=гЙазк=лЙЕ~ЗзK=

NK= sздЕ~к= д~= г•имбе~= Йе= лм= й~кнЙ= йзлнЙкбзк= EоЙк=

Е~й∞нмдз= m^onrb= sboqf`^i= ab= i^= jžnrfk^?F=

нЙебЙеЗз= ЕмбЗ~Зз= ЗЙ= ~ЕзкЗ~клЙ= ЗЙ= ~й~Ц~к= Йд=

бенЙккмйнзк=ЦЙеЙк~д=у=ЗЙ=о~Еб~к=дзл=ЗЙйµлбнзлK=

OK= `зе= д~= г•имбе~= Йе= Йлн~= йзлбЕбµе= дбгйб~к=

ЙлгЙк~З~гЙенЙ= Йд= бенЙкбзк= ЗЙд= Йгй~дгЙ= лзДкЙ= д~=

Дзимбдд~=ЗЙ=лЙЕ~Зз=Йдбгбе~еЗз=д~= ЙоЙенм~д=лмЕбЙЗ~З=

ЗЙйзлбн~З~K= iбгйб~к= ЙлгЙк~З~гЙенЙ= дзл= д~Дбзл= ЗЙ=

~лйбк~ЕбµеK=

=

=

=

j^kqbkfjfbkql=loafk^of^=

=

prpqfqr`fþk= abi= i^_fl= qo^pbol= ab= i^=

_lnrfii^=ab=pb`^al=

`зенкзд~к=Йд=Йлн~Зз=ЗЙ=ЗЙлЦ~лнЙ=ЗЙд=д~Дбз=ЗЙ=лЙЕ~Зз=у=

ЙоЙенм~дгЙенЙ=Цбк~кдз=з=лмлнбнмбкдзK=

m~к~=д~=лмлнбнмЕбµе=Йл=еЙЕЙл~кбзW=

NK= _~а~к=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=Цбк~еЗз=Ь~Еб~=~Д~аз=д~=

й~д~еЕ~=ENF=ймЙлн~=~д=ЕЙенкз=ЗЙд=нбгµеK=

OK= sздоЙк= ~= Цбк~к= Ь~Еб~= Йд= ЙснЙкбзк= д~= Дзимбдд~= ЗЙ=

лЙЕ~ЗзK=

PK=`зе= д~=Дзимбдд~=ЗЙ=лЙЕ~Зз= Йе=Йлн~=йзлбЕбµе=~Енм~к=

лзДкЙ= д~л= г~кбйзл~л= EOF= ЗЙлнзкебдд•еЗзд~л=

ЕзгйдЙн~гЙенЙ=й~к~=дбДЙк~к=д~=Дзимбдд~=ЗЙ=лЙЕ~ЗзK=

QK= pздн~к= Йд=г~еЦмбнз= EPF=ЗЙд= нмДз=ЗЙ=д~=Дзимбдд~=ЗЙ=

лЙЕ~Зз=у=имбн~к=д~=Дзимбдд~=ЗЙ=лЙЕ~ЗзK=

=

=

RK= aЙлЙеЦ~еЕЬ~к=Йд=ЕбЙккЙ= EQF=ЗЙд= дблнµе= Сба~Ззк=ЗЙд=

д~Дбз=у=л~Е~к=Йд=д~Дбз=й~к~=Цбк~кдз=з=й~к~=лмлнбнмбкдзK=

SK= `зенкзд~к= имЙ= Йд= г~еЦмбнз= у= Йд= нмДз= ЗЙ= д~=

Дзимбдд~= ЗЙ= лЙЕ~Зз= ез= Йлн¨е= зДлнкмбЗзл= у=

ЙоЙенм~дгЙенЙ=Йдбгбе~к=д~=лмЕбЙЗ~ЗK=

m~к~=оздоЙк=~=гзен~к=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=кЙйЙнбк=Йе=

зкЗЙе=беоЙклз=д~л=зйЙк~ЕбзеЙл=~ккбД~=ЗЙлЕкбйн~лK=

=

=

prpqfqr`fþk= abi= i^_fl= abi^kqbol= ab= i^=

_lnrfii^=ab=pb`^al=

`зенкзд~к=Йд=Йлн~Зз= ЗЙ= ЗЙлЦ~лнЙ= ЗЙд=д~Дбз= ЗЙд~енЙкз=

ЗЙ=д~=Дзимбдд~=у=ЙоЙенм~дгЙенЙ=лмлнбнмбкдзK=

m~к~=д~=лмлнбнмЕбµе=Йл=еЙЕЙл~кбзW=

NK= _~а~к=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=Цбк~еЗз=Ь~Еб~=~Д~аз=д~=

й~д~еЕ~=ENF=ймЙлн~=~д=ЕЙенкз=ЗЙд=нбгµеK=

OK= sздоЙк= ~= Цбк~к= Ь~Еб~= Йд= ЙснЙкбзк= д~= Дзимбдд~= ЗЙ=

лЙЕ~ЗзK=

=

=

=

PK= `зе= д~= Дзимбдд~= ЗЙ= лЙЕ~Зз= Йе= Йлн~= йзлбЕбµе=

йкзЕЙЗЙк=~=ЗЙлгзен~кд~=у=ЗЙлйм¨л=Йд=д~Дбз=нк~лЙкз=ЗЙ=

д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=EоЙк=Е~й∞нмдз=prpqfqr`fюk=abi=

i^_fl=qo^pbol=ab=i^=_lnrfii^=ab=pb`^alТFK=

QK= nмбн~к= д~л= г~кбйзл~л= ERF= ЕздзЕ~З~л= Йе= д~= й~кнЙ=

лмйЙкбзк= ЗЙд= ЕмЙкйз= ЗЙ= д~= Дзимбдд~= ЗЙ= лЙЕ~Зз=

лЙй~к~еЗз= дмЙЦз= д~л= Ззл= й~кнЙл= гЙн•дбЕ~л= имЙ= дз=

ЕзгйзеЙе=й~к~=имбн~к=Йд=д~Дбз=ЗЙд~енЙкзK=

RK= bеам~Ц~к= Езе= ме= ЕЬзккз= ЗЙ= ~Цм~= нзЗзл= дзл=

ЕзгйзеЙенЙлK=

m~к~=оздоЙк=~=гзен~к=д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=кЙйЙнбк=Йе=

зкЗЙе=беоЙклз=д~л=зйЙк~ЕбзеЙл=~ккбД~=ЗЙлЕкбйн~лK=

=

=

=

`lkqoli=ab=crk`flk^jfbkql=

=

bi=jlqlo=ab=^pmfo^`fþk=kl=crk`flk^=

NK= `зенкзд~к=Йд=Йлн~Зз=ЗЙ=Е~кЦ~=ЗЙ= д~л=Д~нЙк∞~лI=имЙ=

Йл=облбДдЙ=~ЕЕбзе~еЗз= йкбгЙкз=Йд= бенЙккмйнзк=ЦЙеЙк~д=

ENF=EоЙк=Е~й∞нмдз=ob`^od^=ab=i^p=_^qboр^pТFK=

OK= `згйкзД~к= имЙ= Йд= бенЙккмйнзк= ЗЙд= гзнзк= ЗЙ=

~лйбк~Ебµе=EOF=Йлн¨=~Енбо~Зз=оЙкбСбЕ~еЗз=имЙ=Йд=нЙлнбЦз=

ЕзккЙлйзеЗбЙенЙ=оЙкЗЙ=Йлн¨=ЙеЕЙеЗбЗзK=

PK= `зенкзд~к=Йд=ебоЙд=Йе=Йд=ЗЙйµлбнз=ЗЙ=кЙЕмйЙк~Ебµе=

EоЙк= Е~й∞нмдз= afpmlpfqfsl= ob_lp^abolТF= у= лб==

еЙЕЙл~кбзI=о~Еб~к=Йд=ЗЙйµлбнзK=

pб= Йд= ЗЙлйЙкСЙЕнз=Езенбем~I= Езен~Ен~к=Езе=Йд=ЕЙенкз=

ЗЙ=~лблнЙеЕб~=н¨ЕебЕ~=~мнзкбт~ЗзK=

=

Page 25

===

b= = b=

=

=

OR

=

=

bi=jlqlo=abi=`bmfiil=kl=crk`flk^=

NK= `зенкзд~к=Йд=Йлн~Зз=ЗЙ=Е~кЦ~=ЗЙ= д~л=Д~нЙк∞~лI=имЙ=

Йл=облбДдЙ=~ЕЕбзе~еЗз= йкбгЙкз=Йд= бенЙккмйнзк=ЦЙеЙк~д=

ENF=EоЙк=Е~й∞нмдз=ob`^od^=ab=i^p=_^qboр^pТFK=

OK= `згйкзД~к= имЙ= Йд= бенЙккмйнзк= ЗЙд= гзнзк= ЗЙд=

ЕЙйбддз= EOF= Йлн¨= ~Енбо~Зз= оЙкбСбЕ~еЗз= имЙ= Йд= нЙлнбЦз=

кЙд~нбоз=оЙкЗЙ=Йлн¨=ЙеЕЙеЗбЗзK=

PK= ^ЕЕбзе~к=д~л=г~еЙн~л=бебЕбзLй~кз=EPFK=

pб= Йд= ЗЙлйЙкСЙЕнз=Езенбем~I= Езен~Ен~к=Езе=Йд=ЕЙенкз=

ЗЙ=~лблнЙеЕб~=н¨ЕебЕ~=~мнзкбт~ЗзK=

=

=

=

bi=^dr^=bk=bi=`bmfiil=kl=bp=prcf`fbkqb=

NK= `згйкзД~к=имЙ=Йд=бенЙккмйнзк=ЗЙ=д~=ЙдЙЕнкзо•домд~=

ENF= Йлн¨= ~Енбо~Зз= оЙкбСбЕ~еЗз=имЙ=Йд=нЙлнбЦз=кЙд~нбоз=

оЙкЗЙ=Йлн¨=ЙеЕЙеЗбЗзK=

OK= `зенкзд~к= Йд= ебоЙд= ЗЙд= д∞имбЗз= Йе= Йд= ЗЙйµлбнз=

лздмЕбµе= EоЙк=Е~й∞нмдз= abmюpfql=ab= i^= plir`fюk=

abqbodbkqbТFK=

PK= `згйкзД~к= имЙ= Йд= кЙЦмд~Ззк= ЗЙ= Е~мЗ~д= ЗЙ= д~=

лздмЕбµе=ЗЙнЙкЦЙенЙ=EPF=ймЙлнз=~енЙкбзкгЙенЙ=ЗЙД~аз=

ЗЙд=ЗЙйµлбнз=лздмЕбµе=Йлн¨=лмСбЕбЙенЙгЙенЙ=~ДбЙкнзK=

QK= ^ЕЕбзе~к=д~л=г~еЙн~л=бебЕбзLй~кз=EOFK=

RK= `згйкзД~к=имЙ=Йд=Сбднкз=лздмЕбµе=EQF=Йлн¨=дбгйбзK=

pб= Йд= ЗЙлйЙкСЙЕнз=Езенбем~I= Езен~Ен~к=Езе=Йд=ЕЙенкз=

ЗЙ=~лблнЙеЕб~=н¨ЕебЕ~=~мнзкбт~ЗзK=

=

=

=

=

i^=jžnrfk^=kl=ifjmf^=_fbk=

NK= bд= ЕЙйбддз= ез= нбЙеЙ= д~л= ЕЙкЗ~л= ЗЙ= д~= ЗбгЙелбµе=

~йкзйб~З~W=мнбдбт~к=лзд~гЙенЙ=ЕЙйбддзл=зкбЦбе~дЙлK=m~к~=

ме~= лмЦЙкЙеЕб~I= Езен~Ен~к= Йд= ЕЙенкз= ЗЙ= ~лблнЙеЕб~=

н¨ЕебЕ~=~мнзкбт~ЗзK=

OK= i~=лздмЕбµе=ЗЙнЙкЦЙенЙ=ез=Йл=лмСбЕбЙенЙW=~Дкбк=г•л=

Йд=кЙЦмд~Ззк=ЗЙ=Е~мЗ~д=ЗЙ=д~=лздмЕбµе=ЗЙнЙкЦЙенЙ=EPFK=

PK= `зенкзд~к=имЙ=Йд=ЗЙнЙкЦЙенЙ=Йлн¨=Йе=Йд=йзкЕЙен~аЙ=

~ЕзелЙа~ЗзK=

`зелмдн~к=Йд=ЕЙенкз= ЗЙ=~лблнЙеЕб~=н¨ЕебЕ~=~мнзкбт~Зз=

й~к~=ме~=лмЦЙкЙеЕб~K=

=

i^= _lnrfii^= ab= pb`^al= kl= pb`^=

mbocb`q^jbkqb=

NK= `зенкзд~к=имЙ=дзл= д~Дбзл=ЗЙ= д~=Дзимбдд~=ЗЙ=лЙЕ~Зз=

Йлн¨е=дбгйбзлK=

OK= `зенкзд~к=имЙ=Йд=г~еЦмбнз=ЗЙд=нмДз=ЗЙ=~лйбк~Ебµе=

Йлн¨= ЕзеЙЕн~Зз= ЕзккЙЕн~гЙенЙ= Йе= лм= ~дза~гбЙенз=

лзДкЙ=Йд=ЗЙйµлбнз=ЗЙ=кЙЕмйЙк~Ебµе=у=лзДкЙ=д~=Дзимбдд~=

ЗЙ=лЙЕ~ЗзK=

PK= fенЙкоЙебк= лзДкЙ= Йд= Сбднкз= ЗЙ= ~лйбк~Ебµе=

дбгйб•еЗздзK=

QK= pмлнбнмбк=дзл=д~Дбзл=лб=Ц~лн~ЗзлK=

RK= `зенкзд~к= имЙ= Йд= бенЙккмйнзк= ЗЙд= гзнзк= ЗЙ=

~лйбк~Ебµе=Йлн¨=ЙеЕЙеЗбЗзK=

SK= `зенкзд~к=Йд=ебоЙд=Йе=Йд=ЗЙйµлбнз=ЗЙ=кЙЕмйЙк~Ебµе=

EоЙк= Е~й∞нмдз= afpmlpfqfsl= ob_lp^abolТF= у= лб==

еЙЕЙл~кбзI=о~Еб~к=Йд=ЗЙйµлбнзK=

=

molar``fþk=bu`bpfs^=ab=bpmrj^=

`зенкзд~к= имЙ=лЙ= Ь~у~= ЙгйдЙ~Зз= ме=ЗЙнЙкЦЙенЙ= ЗЙ=

Йлймг~= Езенкзд~З~K= bоЙенм~дгЙенЙ= ~¥~Збк= ме~=

г∞ебг~= Е~енбЗ~З= ЗЙ= д∞имбЗз= ~енбЙлймг~енЙ= Йе= Йд=

ЗЙйµлбнз=ЗЙ=кЙЕмйЙк~ЕбµеK=

e~у= имЙ= нЙеЙк= Йе= ЕмЙен~= имЙ= Ь~у= ме~= г~узк=

йкзЗмЕЕбµе= ЗЙ= Йлймг~= Ем~еЗз= Йд= лмЙдз= Йлн•= йзЕз=

лмЕбзK= bе= ЙлнЙ= Е~лз= Збдмбк= ~∫е= г•л= д~= лздмЕбµе=

ЗЙнЙкЦЙенЙK=

=

iba=EOFI=EPF=v=EQF=pb=mlkbk=ab=`lilo=olgl=

pб= д~= г•имбе~= Йлн•= Йе= зкЗЙе= ЗЙ= г~кЕЬ~I= Езе= Йд=

бенЙккмйнзк=ЦЙеЙк~д=ENF=ЙеЕЙеЗбЗз=оЙкЗЙ=у=мез=ЗЙ=дзл=

нкЙл=дЙЗ=EOFI=EPF=з=EQF= Е~гДб~=ЕздзкI= ЗЙ=оЙкЗЙ= ~=кзазI=

лбЦебСбЕ~= имЙ= Йл= Йе= Емклз= ме~= йкзнЙЕЕбµе=

~гйЙкбзг¨нкбЕ~I=йзк=ЙаЙгйдзW=

J=iba=EOF=olglW=Йд=гзнзк=ЗЙд=ЕЙйбддз=Йлн•=Ь~ДбЙеЗз=ме=

ЙлСмЙктз=н~е=Цк~еЗЙK=

J=iba=EPF=olglW=Йд=гзнзк=ЗЙ=~лйбк~Ебµе=Йлн•=~йбк~еЗз=

~Цм~=у=йзк=дз=н~енз=Йлн•=Сзкт~еЗз=гмЕЬзK=

J=iba=EQF=olglW=д~=ДзДбе~=ЗЙ=д~=ЙдЙЕнкзо•домд~=ймЙЗЙ=

лЙк=Йе=ЕзкнзЕбкЕмбнзK=

m~к~= кЙлн~ДдЙЕЙкI= ~й~Ц~к=Йд= бенЙккмйнзк= ЦЙеЙк~д= ENFI=

ЙлйЙк~к=мезл=гбемнзл=у=ЗЙлйм¨л=ЙеЕЙеЗЙк=знк~=оЙтK=

pб= Йд= ЗЙлйЙкСЙЕнз=Езенбем~I= Езен~Ен~к=Езе=Йд=ЕЙенкз=

ЗЙ=~лблнЙеЕб~=н¨ЕебЕ~=~мнзкбт~ЗзK=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

Page 26

===

b= = b=

=

=

OS

j^kqbkfjfbkql=moldo^j^al=

=

fkqbosbk`fþk= af^of^= pbj^k^i= loafk^oflLjbkpr^ijbkqb=

ifjmfbw^=abmþpfql=ab=ob`rmbo^`fþk=

•

= = =

ifjmfbw^=cfiqol=ab=^pmfo^`fþk=

•

== = =

ifjmfbw^=abi=`bmfiil=

•

== = =

abpjlkq^gb=abi=`bmfiil=

•

== = =

ifjmfbw^=ab=i^=_lnrfii^=ab=pb`^al=

•

== = =