®

Installation and Service Manual

1102/ TTX Swing Door Operator

TORMAX 1201 Swing Door Operator

Warning -

TORMAX USA Inc.

12859 Wetmore Road

San Antonio,TX 78247

210-494-3551

210-494-5930 (FAX)

888-685-3707

www.tormaxusa.com

info@tormaxusa.com

To reduce the risk of injury of persons - Use this operator only with swing doors.

Issue Date: 05/04/2018

P/N : US801918

Version: FW_3.11

TABLE OF CONTENTS

SECTION

Table of Contents

Important Information

Safety Warnings, Installation & Service, Glazing

Intended Installation Environment, Door Operation, ANSI/ BHMA

Operator Applications, Country Code, User mode with FCP

1. Modes of Door Operation

2. Components Overview

3. Applications

4. On-Board Programming Configuration Tool - Description

5. System Values for Application

Installation

6. Applications: Outswing 8-10 lbs. Spring Force Installation/ Commissioning

Outswing 18-20 lbs. Spring Force Installation/ Commissioning

Inswing 0” Reveal Installation/ Commissioning

Inswing 0”-6” Reveal Installation/ Commissioning

Double Egress Application Installation

Pair/ Double Egress Application Wiring

Pair/ Double Egress Application Commissioning

7. Adjustments:

1102/ 1201 Open Door Stop, 1201 Spring Tension

Frequently Used

8. Slim Line Header

Header Preparation

Application Illustrations

9. Programming with the FCP - Overview, Example

10. Commissioning with FCP

Commissioning, Adjustments

On-Board Codes 3, 6, 7 Descriptions/ BDM LED Display

11. Programming & Trouble Shooting Tables

12 Control Connection Diagram

13. Wiring Diagrams

Single Applications

Pair / Double Egress Applications

14. Technical Specifications:

Shaft Removal

T1253 Cable Plan

T1633 1201 Technical Information

T1634 1102 Technical Information

Electrical Requirements for Installation

T1753 Double Door Application

T1637 Basic Door Module (BDM) MCU42-BDM-A

T1638 Exterior Door Module (EDM) MCU42-EDM-A

T1640 Multi-Door Module (MDM) MCU42-MDM-A /B

T1639 Power Door Module (PDM) MCU42-PDM-A

T1691 Programming Interface Module (PIM) MCU42-PIM-A

T1757 Functional Control Panel (FCP) MCU32USIN-7-A

PAGE

2

3

4

5

6

7

8

9

10

11 - 12

13 - 14

15 - 16

17 - 18

19

20

21

22

23

24

25

26 - 28

29 - 30

31

32 - 36

37

38 - 42

43 - 47

48

49

50

51

52

53 - 54

55 - 56

57 - 58

59 - 60

61 - 62

63

64 - 65

2

Important Information

SAFETY/ WARNINGS SYMBOLS

NOTE indicates important information specific to the process or steps

!

being performed.

ELECTRICAL VOLTAGE indicates that electrical voltage is present

and that caution should be taken to prevent injury or property damage.

CAUTION indicates failure to follow instructions may result in personal

injury and/ or property damage.

OPTIONAL COMPONENTS indicates components that are not installed

in all systems.

WARNING - Failure to observe the information in this manual may result in

personal Injury or damage to equipment. To reduce the risk of

injury of persons use this operator only with pedestrian swing

doors.

Save these instructions for future reference.

Installation and Service

Any and all TORMAX equipment must be installed, serviced and inspected by an AAADM

Certified technician, to meet the current ANSI A156.10 and/ or ANSI A156.19 standard

and any local or state building codes.

The person responsible for the daily operation and maintenance of the system is referred to as

“End-User”.

It is the technicians responsibility:

1. Review the functions of the equipment with the end-user. Failure to do so, may lead to

the improper use, could cause injury to persons and/ or damage to the equipment.

2. Familiarize the end-user with the Daily Safety Check Decal and how to perform the

walk test procedures.

3. Illustrate to the end-user how to place the door out of service (turn off power or place

in P mode or OFF mode of operation), if the equipment does not perform as described

in the Daily Safety Check Decal.

4. Recommend to the end-user to have their equipment inspected annually by an

AAADM certified technician.

Glazing

The glazing material of all doors shall comply with the requirements of ANSI Z97.1, American

National Standard Performance Specifications and Methods of Test for Safety Glazing Material

Used in Buildings.

3

Important Information

Intended Installation Environment

The 1102/ TTX and the 1201 are non-handed swing door operators that can be used on

interior or exterior doors.

The operator is mounted above the door on the inside of the building. Any other use, or any

use exceeding this aim, is deemed as not used in accordance with its intended purpose.

The manufacturer will not be liable for damages resulting from such applications or warranty the

product. Arbitrary changes to the system will exempt the manufacturer from any liability for

damage resulting from this.

The 1102/ TTX is designed as a Low Energy operator to comply with ANSI A156.19

standard.

The 1201 can be utilized as a Low Energy operator and comply with ANSI A156.19

standard, or setup to operate as a Power Operated Pedestrian Door and comply with

ANSI A156.10 standard.

Upon completion of the installation the technician should perform an AAADM inspection to

ensure that the door complies to the appropriate standard ANSI a156.19 or ANSI A156.10

in which it is setup to operate within.

Door Operation

The 1102/ 1201 mode of operation is control by a 3-position switch (standard) or a (FCP)

Functional Control Panel (optional). The primary mode of operations are:

Off - The door remains in the closed position with lock engaged, but can

be opened by the Key Switch activating input.

Automatic - Two-way traffic, typical setting for normal operation. Allows the interior &

exterior sensors, Key switch and safety devices (if applicable) to operate

the door.

Hold Open - The door goes to the open position and remains there until the switch is taken

out of this position.

Upon a power loss the operation of the 1102/ 1201 operating system will function according to

specifications:

Immediate spring closing.

The operator functions as a manual door closure.

Lock function will operate to specification (fail secure/ fail safe).

Continued operation , if equipped with a battery backup.

ANSI/ BHMA A156.10, A156.19 standards - Knowing Act Switch

Doors activated by a manual switch must have the switch installed in a location

from which the operation of the door can be observed by the person operating

the switch. Refer to the latest revision of ANSI/ BHMA A156.10 or A156.19 for

location of Knowing Act switch and time delays.

4

Important Information

Operator Applications

The 1102/ 1201 are Surface Applied (SA) operators and are power open and spring close.

Basic configuration adjustments will be made with an on-board programming button.

The operator has 2 standard applications:

Outswing - The operator pushes the door open.

Inswing - The operator pulls the door open.

Within each standard application there are important points to know and consider during

the installation process.

Outswing: 8-10 lbs. of manual opening force (Low Energy ANSI A156.19) or Knowing

Act Door Activation (Power Operated Pedestrian Door ANSI A156.10)

18-20 lbs. of manual opening force ( Power Operated Pedestrian Door

ANSI A156.10)

InSwing: 0” reveal, non-handed arm

0“ - 6” reveal, handed arm

Country Code

The Country code is available in firmware V3.02 and above. The country code provides preset

values to aid the technician in installing the door to comply with ANSI Standard A156.19.

This does not eliminate the need for an AAADM inspection to be performed for compliance.

Additional adjustments may need to be made upon inspection.

“U” User mode on FCP

The User mode has two options:

UR - Ability to read specific programming parameters without changing the parameter.

UP - Ability to change programming parameters within a limited range.

Refer to programming table for specifics.

Recommend using “P” programming mode to have full range of adjustments on all parameters.

!

5

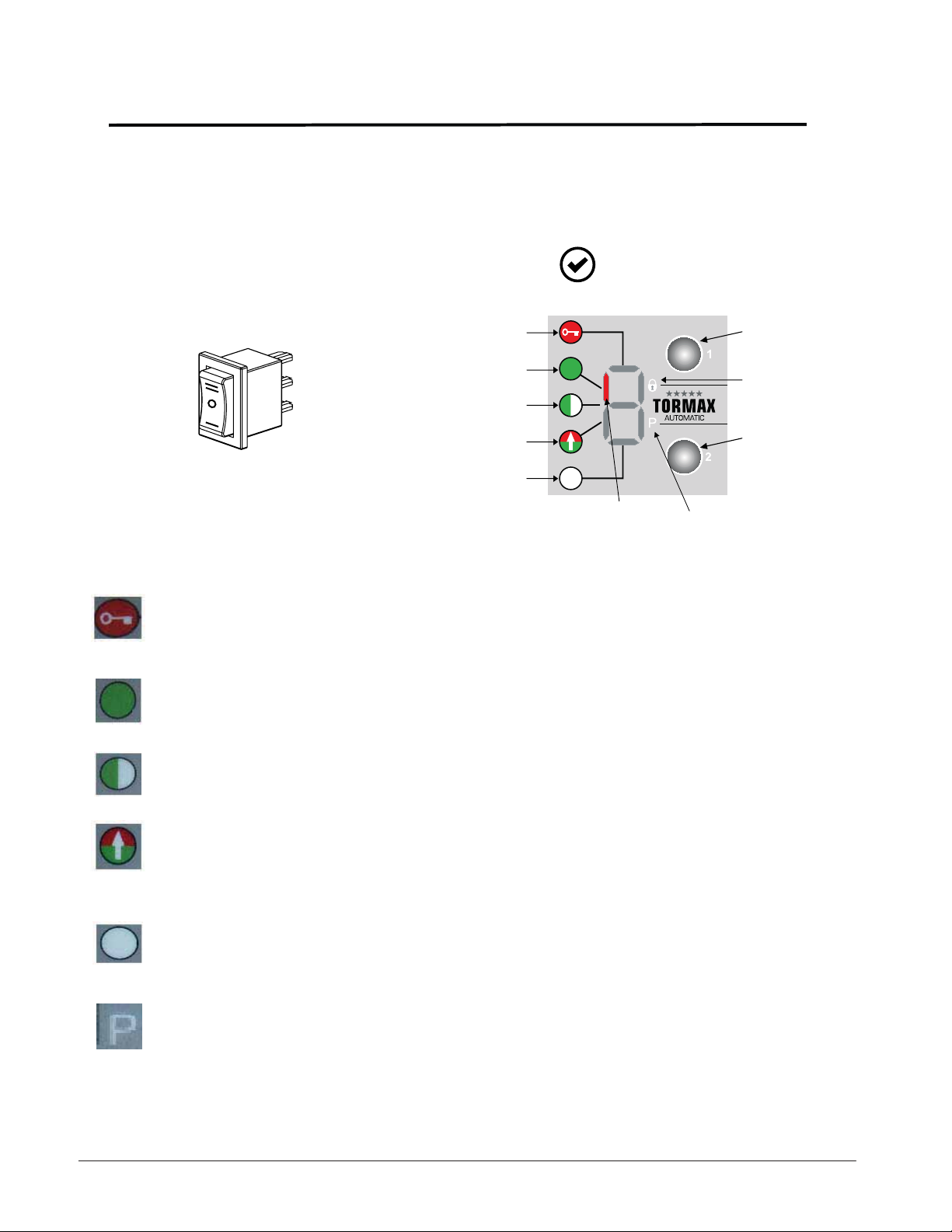

Modes of Door Operation

Modes of operation can be selected with either the standard 3-position switch or the

optional 6 position Functional Control Panel (FCP).

The technician will review the appropriate mode switch with the end-user.

HOLD OPEN

AUTO

OFF

1. OFF - The interior and exterior activators are inhibited after the door reached

the fully closed position, if an electric lock is present it will be activated. Door

will cycle open, if a signal is sent to the key switch input.

2. AUTOMATIC - Typical setting for normal 2-way traffic operation with interior

and exterior activators, key switch input and safety devices operating the door.

Standard:

1102/ 1201

#1) OFF Mode

#2) AUTOMATIC Mode

#3) REDUCED OPEN Mode

#4) EXIT Mode

#5) HOLD OPEN Mode

Optional:

1102/ 1201

www.tormaxusa.com

LED indicates current

operating mode

KEY 1

Electric door

lock LED indicator

KEY 2

#6) (P) MANUAL Mode

3. REDUCED OPERATING - Allows the door to open with a reduced opening

width. Activators and safety devices operate the same as automatic mode.

4. EXIT - (1-way traffic) Allows interior activator and key switch inputs to operate

the door. The exterior activator input is inhibited from opening the door while

the door is closed. When the door is opened/ closing the exterior activator

becomes operational and will re-open a closing door.

5. HOLD OPEN - Hold and maintains the door in the open position.

6. (P) MANUAL OPERATION - Allows the door to be used manually without the

use of sensors. Push and pull motion applied to the door to open and close

the door.

6

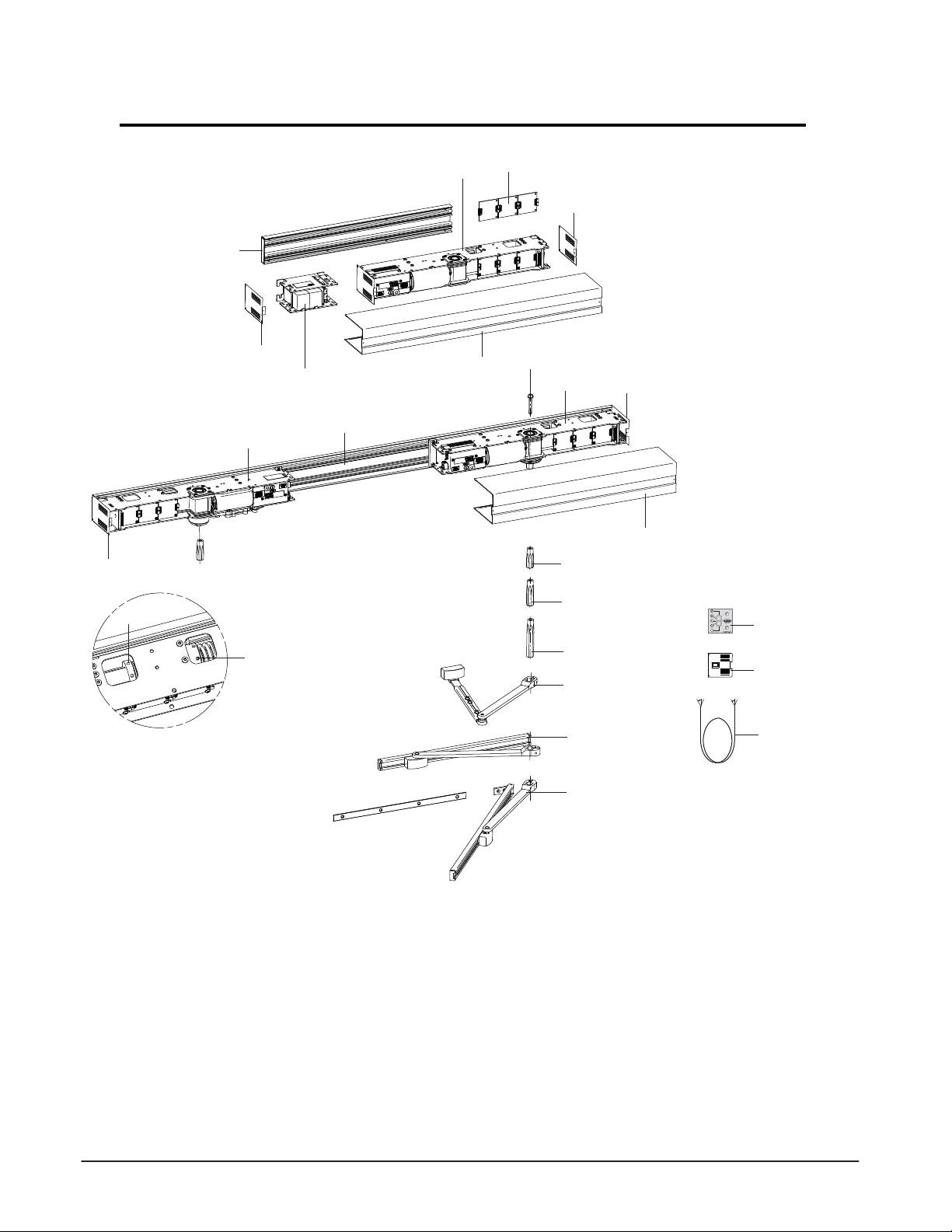

Components Overview

Single Door

15

1

13

Double Door

13

3

14

1

13

11

14

2

4

12

19

1

5

6

7

8

13

12

16

OPEN

AUTO

OFF

17

1 Primary drive TORMAX 1102/1201

2 Secondary drive TORMAX 1102/1201

3 Adjustment of spring force TORMAX 1201 only

4 Adjustment of internal open end stop

5 Shaft 2.48 in. (63 mm)

6 Shaft 3.22 in. (82 mm)

7 Shaft 4.84 in. (123 mm)

8 Out-Swing (Push) Arm 11.41/ 13.77 in. (290/350 mm)

9 In-Swing (Sliding Pull) Arm 13.77/ 19.68 in. (350/500 mm)

10 In-Swing (Slide/ Pull) Arm w/Panic 19.68 in. (350 mm)

(not available at this time)

9

10

11 Battery unit

18

12 Header cover

13 Side plate

14 Mounting profile

15 Upgrade modules MDM, PDM, EDM

16 Functional Control Panel (FCP) User interface (Option)

17 On/Off/Hold Open mode of operation switch (Standard)

18 Sync Cable for pairs

19 Shaft retaining bolt

7

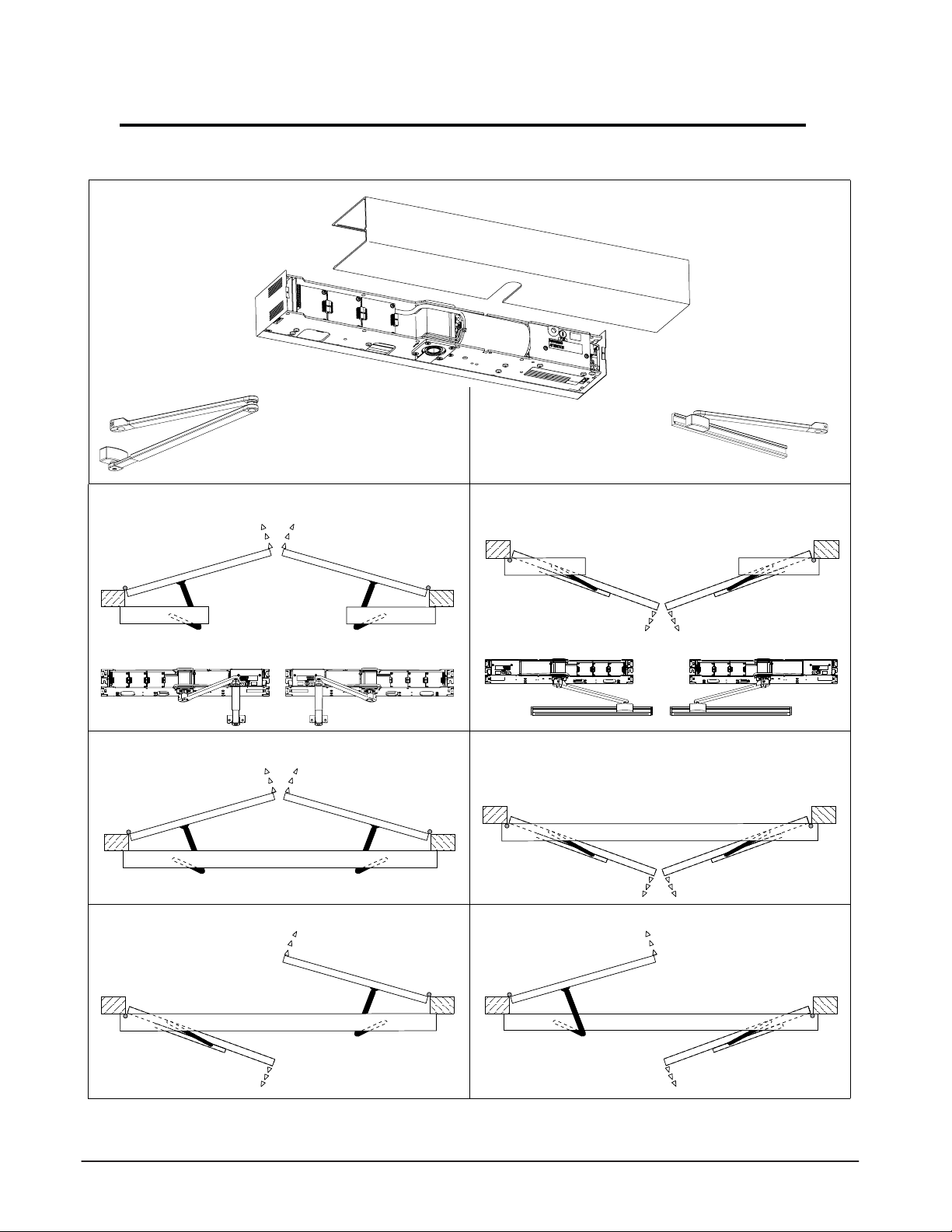

APPLICATIONS

Standard (Out-Swing) Push Arm Singles

Operator Non-handed

LH

Standard (Out-Swing) Push Arm Pair

Operator Non-handed

LH

Standard Double Egress Pair - RH

Operator Non-handed

RH

RH

Standard (In-swing) Pull Slide Arm Singles

Operator Non-handed

RH

Standard (In-Swing) Pull Slide Arm Pair

Operator Non-handed

Standard Double Egress Pair - LH

Operator Non-handed

LH

LHRH

RH

RH

LH

LH

8

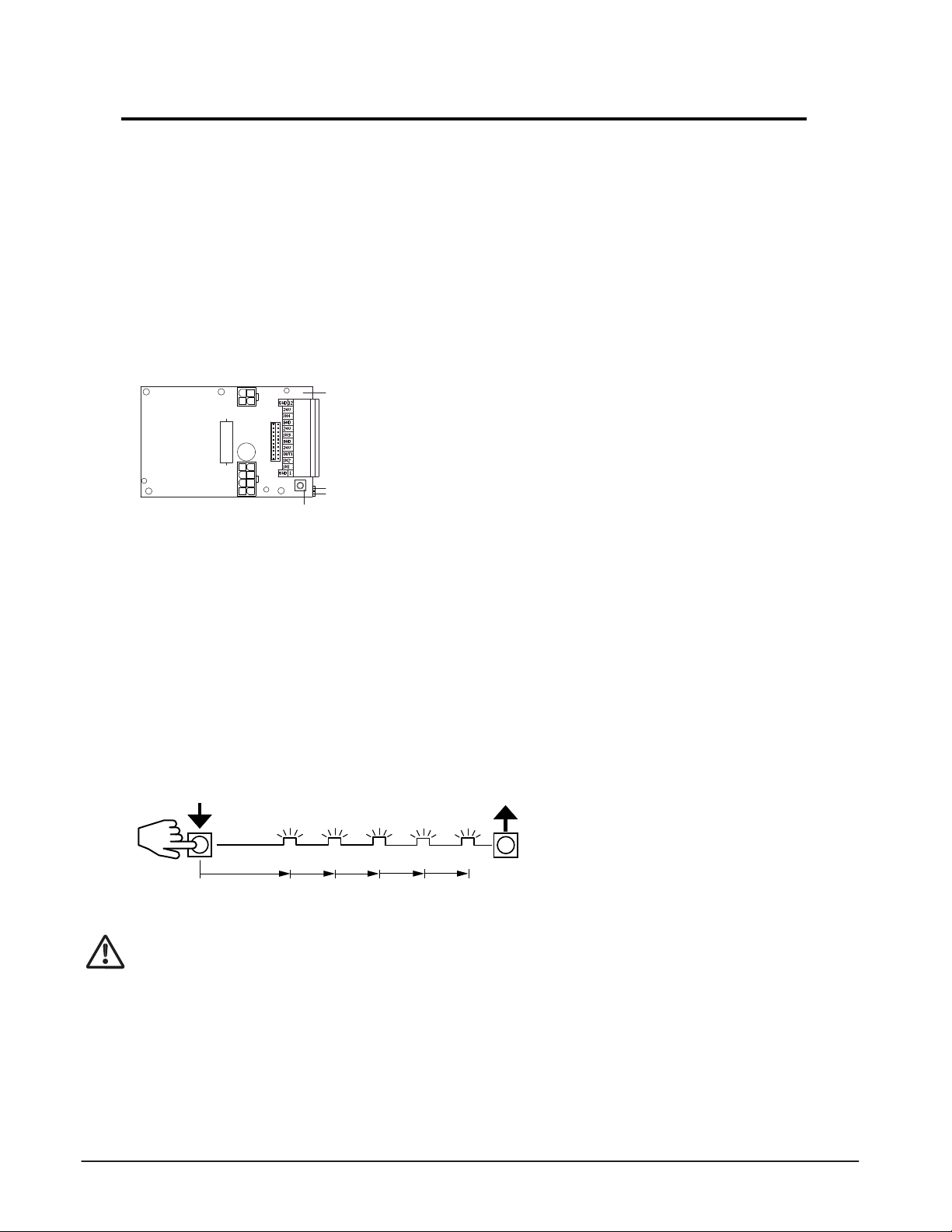

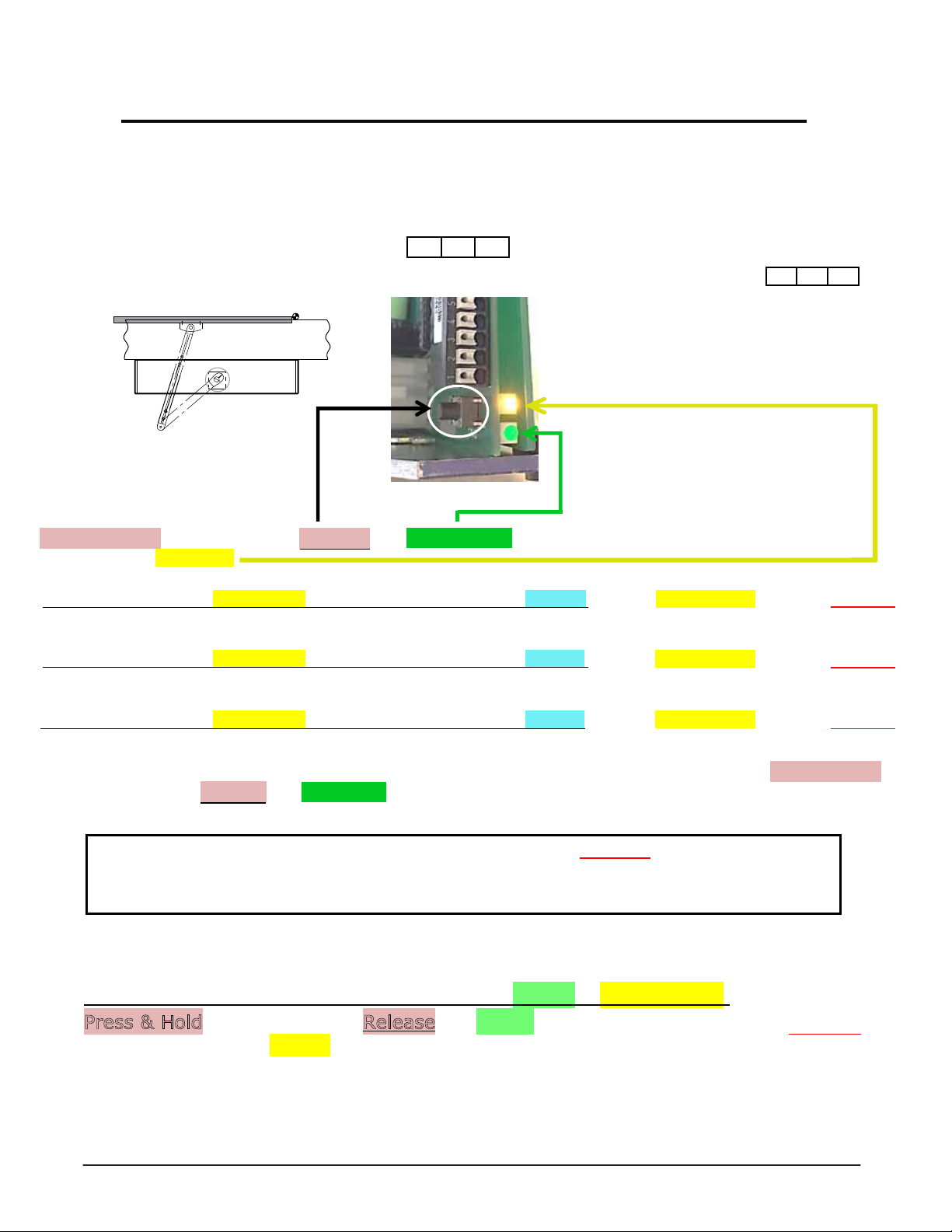

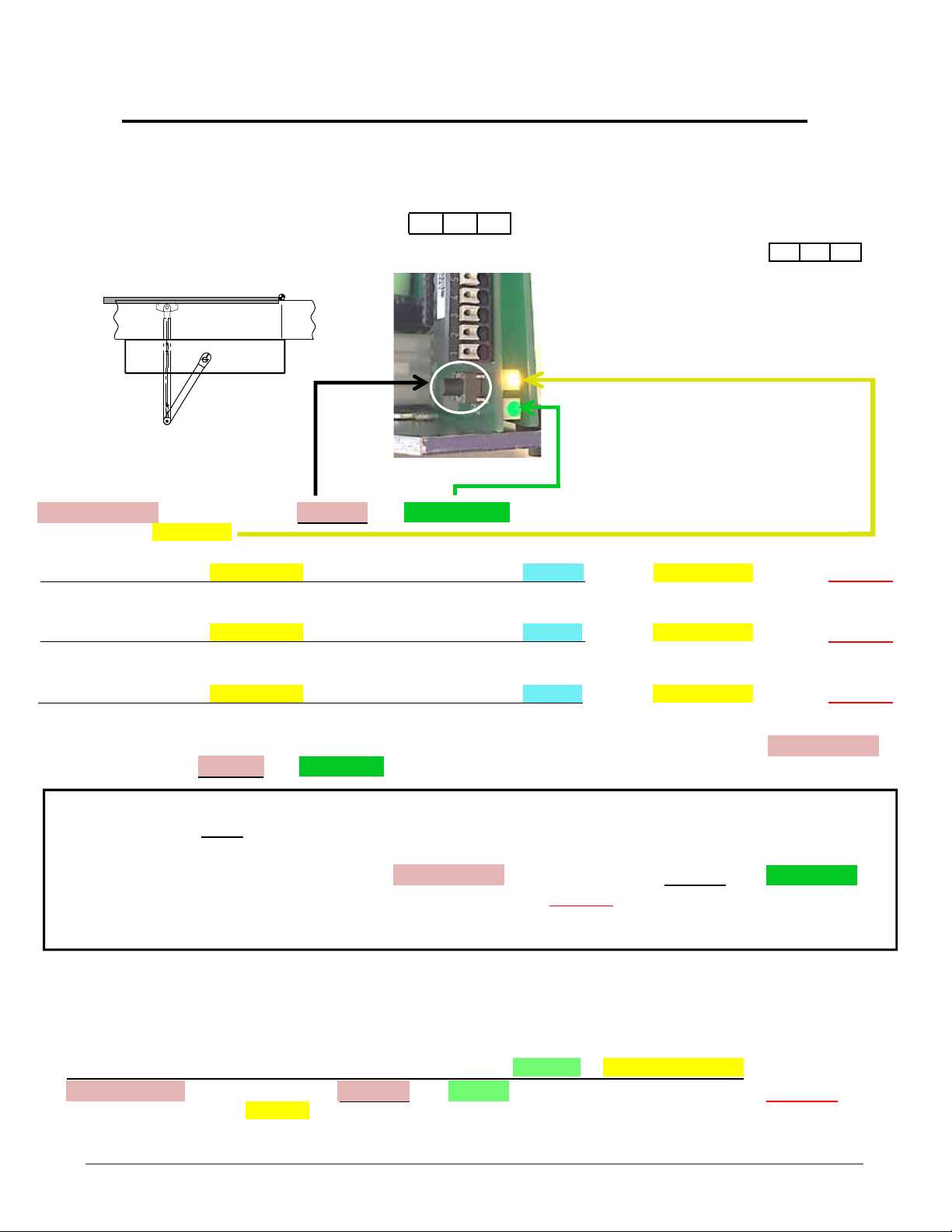

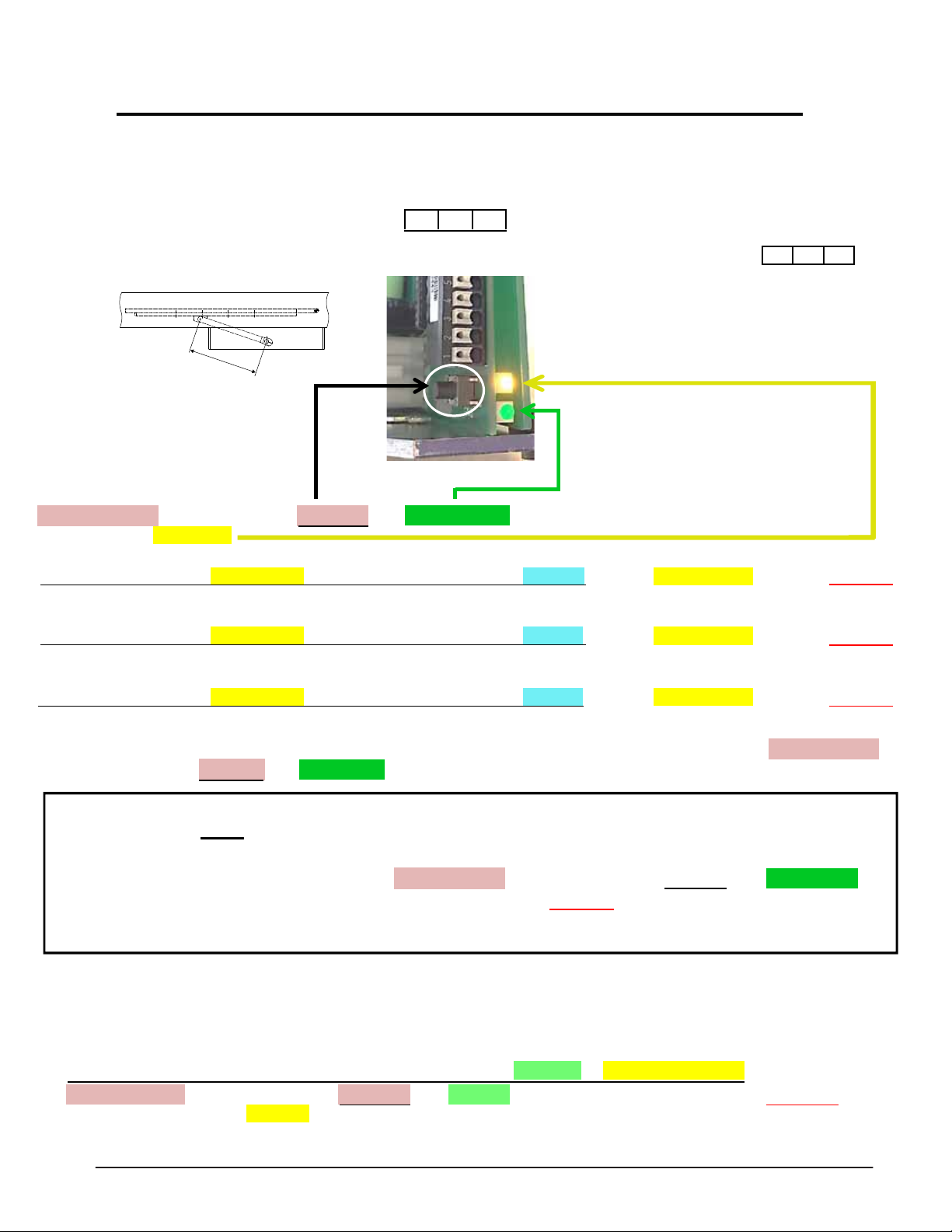

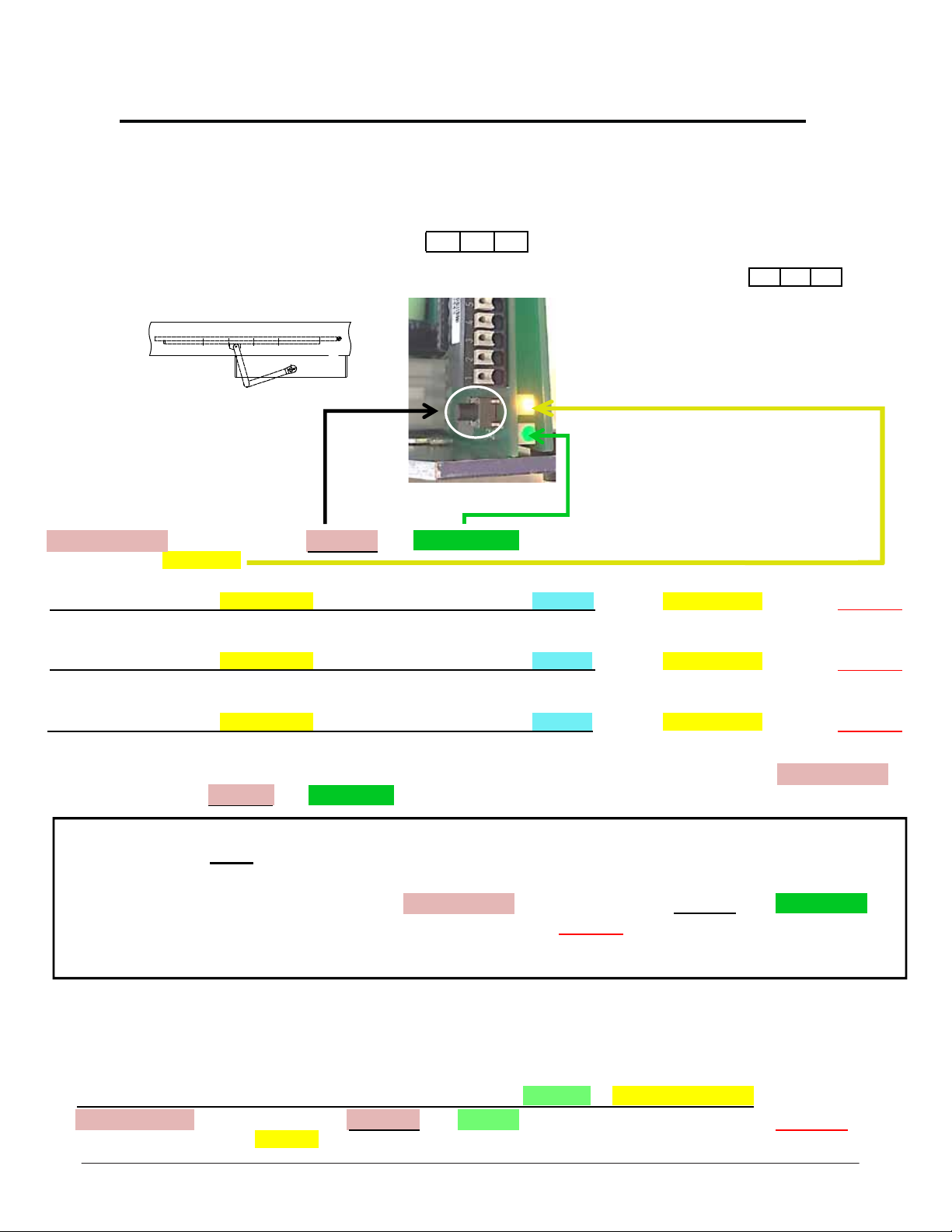

On-Board Programming Configuration Tool - Description

Overview

The On-board programming tool allows the installer to commission the operator without the

use of the FCP. If additional changes are needed i.e. time delay, push-n-go the FCP will be

required.

The on-board programming tool utilizes the programming button, green & yellow LEDs and

an audible tone device to aid the installer during the commissioning process. During the

commissioning process, the LED’s flashing sequence and audible tone will continually repeat

until a selection is made, then the audible tone and flashing sequence changes for the next

parameter selection.

On-board Configuration Tool Familiarization

M

1

A

T1652_1

Programming functions can be launched by means of the programming button.

The GREEN LED supports parameter selection Release the button at the right point in time.

4

3

2

The YELLOW LED indicates the parameter by a series of flashes Press the button at the right point in time.

Programming Procedure – General

• Keep the programming button depressed. The GREEN LED starts to FLASH at one second intervals

for a short time. The number of flashes corresponds to the programming code as in the programming

table.

• Release the programming button after the required number of GREEN FLASHES.

Example: Code 5 “Factory Reset” (see below for codes)

Press Programming button

GREEN LED

3 s 1. 2. 3.

1 Base door module BDM

2 Programming Button

3 LED GREEN: status display (control system ready for operation)

or configuration display.

4 LED YELLOW: error display or configuration display

Release Programming button

This ends the programming step.

5.

4.

Programming Codes

In order to ensure the safety of the system, please follow the details of the programming steps in

the following pages.

Code 1: Commissioning (enter system values, preloads, performs learn)

Code 2: (Consult factory)

Code 3: Detecting/mask out safety features

Code 4: Spring pre-tension parameter (only applicable for TORMAX 1201)

Code 5: Factory reset (Reset all values, excluding operator type)

Code 6: Repeat commissioning (without entering system values, door preloads, performs learn)

Code 7: Preset value 1 = Low Energy (preset values for multiple parameters)

9

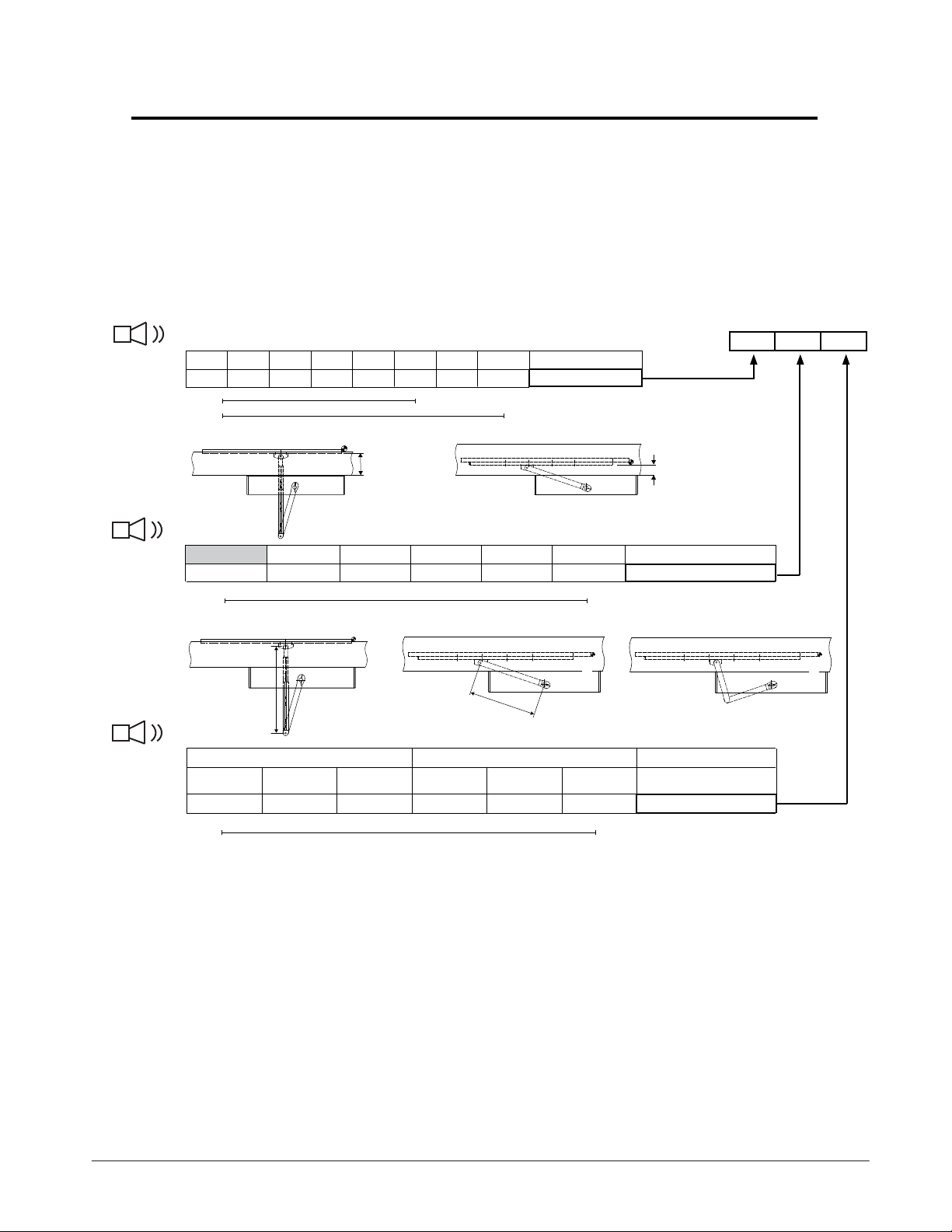

System Values for the Application

System Values

After installing the operator determine the 3 system values. Measure the dimensions

shown in the illustrations below, select each system value listed below the measurement.

Write these numbers down as they are referenced during commissioning.

Audible Tone

Number of Flashes

Audible Tone

Number of Flashes

Audible Tone

Number of Flashes

1

Door width

28” 32” 36” 40” 44” 48”

1 2 3 4 5 6 7 8

1102

1201

2

Reveal

0 - 2” 2 - 4” 4 - 6” 6- 8.5” 8.5 - 10.5” 10.5 - 12.5” Distance A

Yellow LED

Yellow LED

A

*52” *56” Door width

Value 1

Green LED

1 2 3 4 5 6 Value 2

C

3

Drive Arm

Outswing Inswing

11-3/8”

Custom 13-3/4”

A

A

Custom

B

1 2 3 4 5 6 Value 3

Yellow LED

A

Green LEDYellow LED

Lever length C

Green LED

System Values

B

10

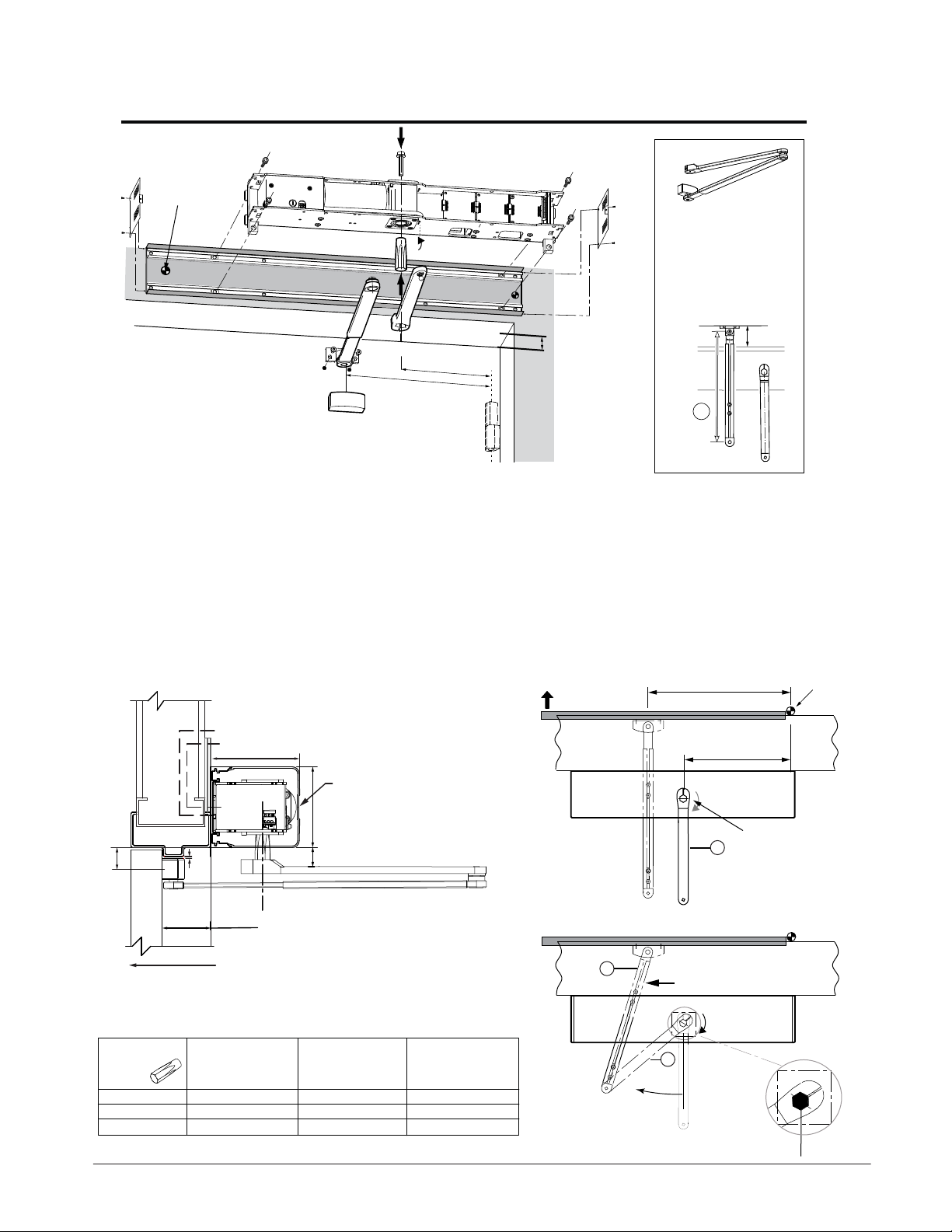

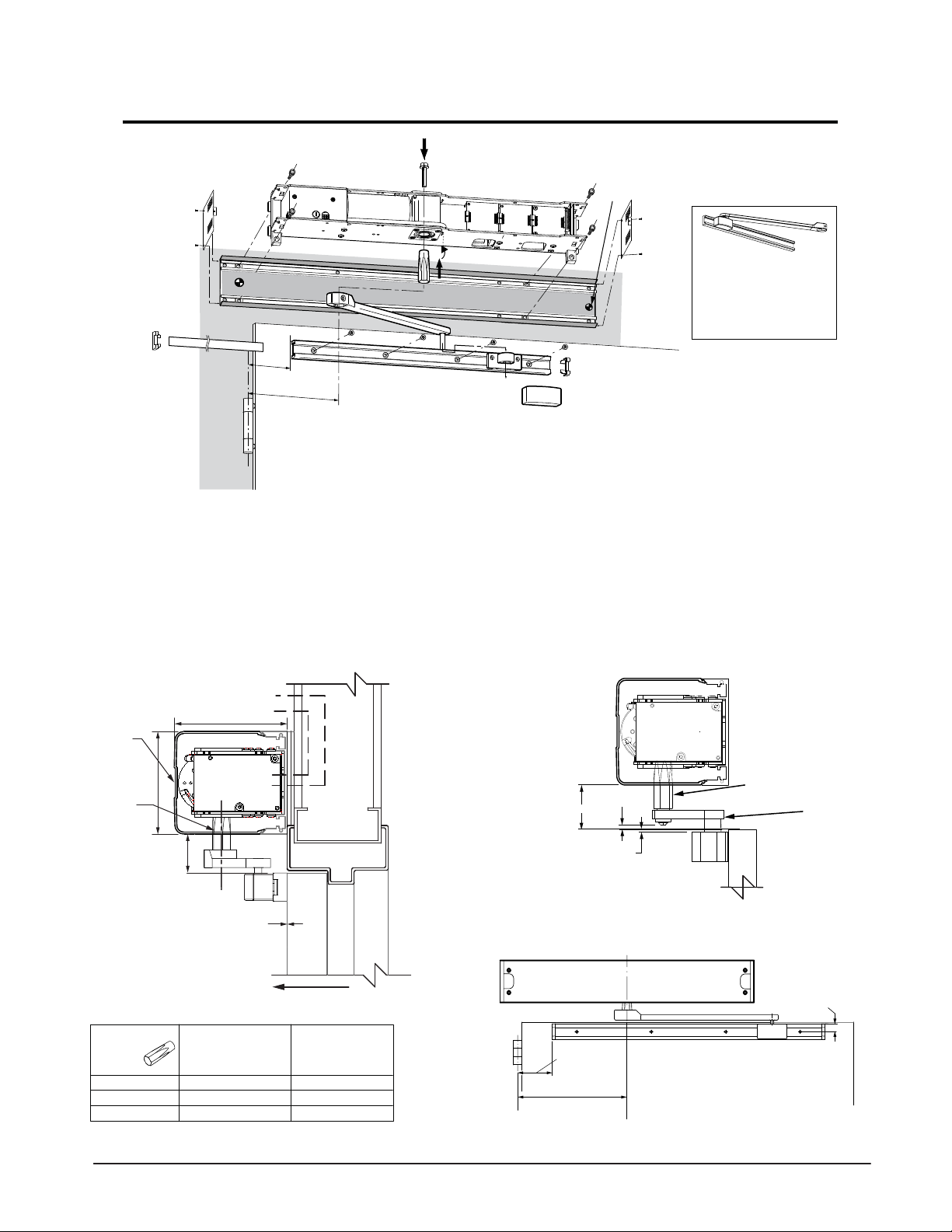

Outswing - Low Energy 8 - 10 lbs Spring Holding Force

Preferred

Primary

Power

1 Push Arm P/N: 408368

0 - 4-

11.41 in. (290 mm)

2 Push Arm P/N: 408369

4-

13.77 in. (350 mm)

3/16” Reveal

1/8” - 9-7/8” Reveal

12-

3/16

” [310]

14-

1/4

” [362]

1) Determine the handing of the operator according to

the door. Note that arrow on operator indicates

opening direction of rotation.

2) Locate & mark output shaft location 12-3/16” from

CL of hinge onto door frame

3) Align header at the bottom of the door frame as shown

below.

4) Secure header to the wall with appropriate hardware.

5) For Stainless Steel Arm refer to illustration on page 13

for mounting dimensions.

Standard Aluminum Arm

Electrical

Controls

5" [127]

TORMAX

1102, 1201

OPERATOR

C

L

Access Cover

4 - 9/16" [116]

Mounting Height

Header

backplate

Reveal Dim.

1,2

CL

Hinge

6) Locate and mount door arm attachment bracket to the

door at Y dimension for shaft used and 14-1/4” from CL of

hinge as shown below.

7) Insert shaft/ drive arm (6) into the operator perpendicular to the

door as shown below. Tighten shaft bolt to 25 ft/ lbs.

8) Manually rotate drive arm (8) as shown below 40°-45°, check

connection point of the two arms to determine how much of the

door portion arm (7) may need to be shortened and/ or cut

off to connect the two arms.

9) Proceed to page 12 to perform commissioning.

CL

14-1/4” [362]

12-3/16” [310]

Header

Hinge

Wall

Y

SWING

DOOR

1/8"

[3]

SWING DIRECTION

Reveal distance is

from the face of the

to the rear of the

Operator 0” - 9-7/8”

X

(0 - 251)

X: Clearance required (distance bottom of header to top of arm)

Y: Distance between bottom of header back plate and centerline

of door mounting shoe

Part No.

141032 (STD)

141106 (D.E.)

141205

Shaft Length

3-

7/32” (82mm)

15/16” (100mm)

34-

27/32” (123mm)

X

1/16” (27mm)

11-25/32” (45mm)

2-

11/16” (68mm)

Y

12-5/32” (55mm)

3-

For extended reveals contact TORMAX

7/16” (36mm)

1/16” (78mm)

7

Rotate Drive Arm

(8) 40° - 45°

NOTE: The door portion arm may need to

be shortened and/ or cut off to

connect the two arms.

Tighten shaft bolt

6

on top of operator

to 25 ft/lbs.

8

11

Outswing - Low Energy 8 - 10 lbs Commissioning

Requirements

1. Shaft should be secured into drive unit during mechanical installation.

2. Refer to page 22 to adjust open door stop.

3. Determine system values for your application based on the illustrations on page 10.

Commissioning

Commissioning Example: (3) = 36” door width, (1) = 0-2” reveal, (1) = Standard outswing Arm 11 3/8.

Press & Hold Programming Button, Release after 1 Green LED Flash. The operator will make 1 beep and immediately

begin to flash the Yellow LED.

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 1X, then after 3 yellow flashes, Press & Release

Programming Button

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 2X, then after 1 yellow flashes, Press & Release

Programming Button

PAUSE

PAUSE

PAUSE

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 3X, then after 1 yellow flashes, Press & Release

Programming Button

MADE AN ERROR DON’T WORRY: To start over Disconnect Power for 10 seconds, Reconnect Power, then Press & Hold

Programming Button and Release after 5 Green LED Flashes.

3 1 1

The operator will open 20 degrees stop and beep 2x. Press & Release programming button.

The operator will slowly close and beep 2x, next it will slowly fully open and beep 2x, then close

(beep 1x) followed by 5 beeps, and will cycle fully open & close at normal speed.

Enter Country Code 7 1: (Read Enre Step BEFORE aempng to enter Country Code)

PERFORM

THIS STEP WHILE LOOKING AT BOTH GREEN & YELLOW LEDS.

Press & Hold programming buon, Release aer 7 Green flashes then immediately Press & Release

programming buon aer 1 Yellow flash.

Programming is complete - for further programming enhancements refer to page 23 or Programming Tables

12

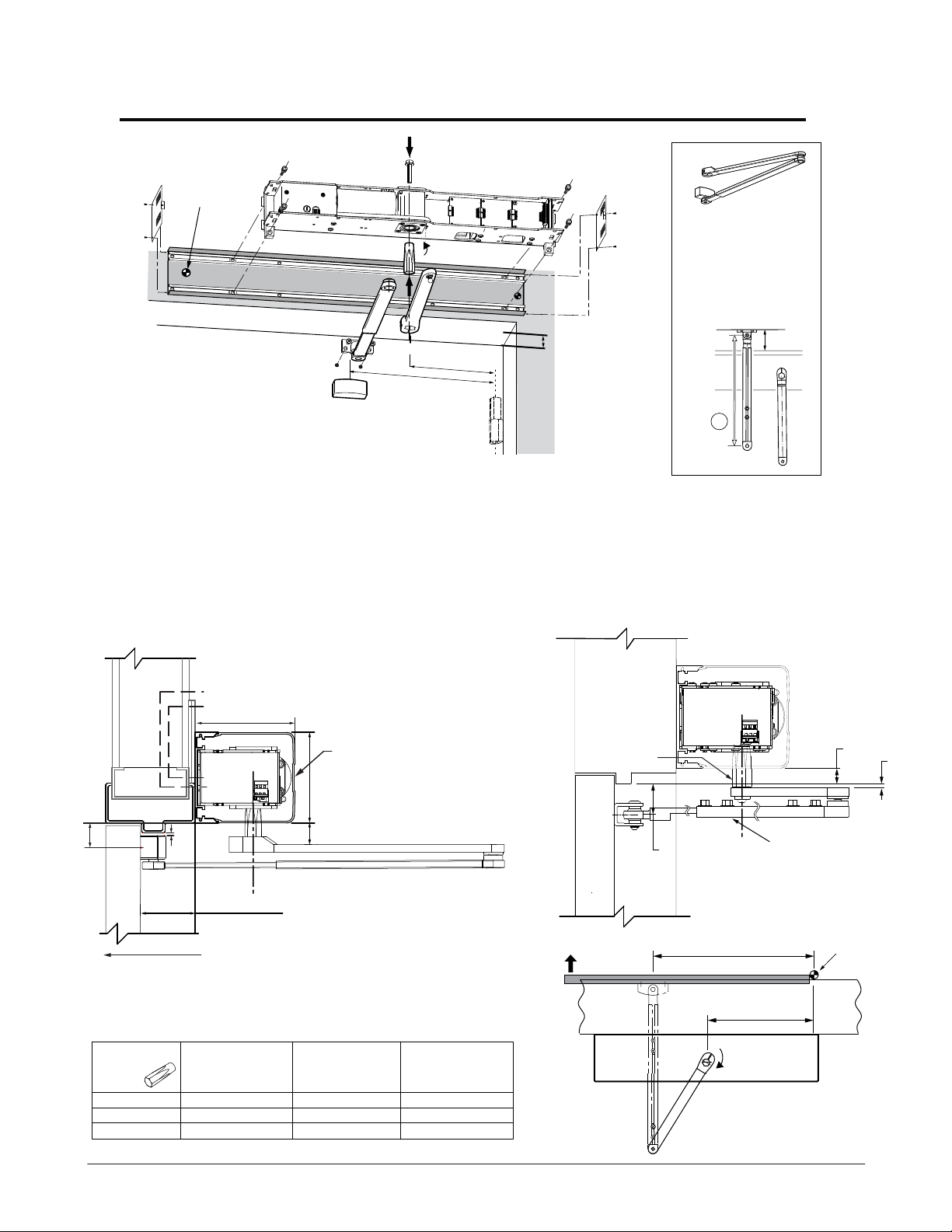

Outswing Full Pedestrian 18 - 20 lbs Spring Holding Force

Preferred

Primary

Power

1 Push Arm P/N: 408368

0 - 4-

11.41 in. (290 mm)

2 Push Arm P/N: 408369

4-

13.77 in. (350 mm)

3/16” Reveal

1/8” - 9-7/8” Reveal

16-

1) Determine the handing of the operator according to

the door. Note that arrow on operator indicates

opening direction of rotation.

2) Locate & mark output shaft location 12-3/16” from

CL of hinge onto door frame

3) Align header at the bottom of the door frame and CL

of the shaft location as shown below.

4) Secure header to the wall with appropriate hardware.

Standard Aluminum Arm

Electrical

Controls

5" [127]

TORMAX

1102, 1201

OPERATOR

C

L

Access Cover

4 - 9/16" [116]

1/8

12-

” [410]

3/16

” [310]

Mounting Height

Header

backplate

Reveal Dim.

1,2

CL

Hinge

5) Locate and mount door arm attachment bracket to the

door at Y dimension for shaft used and 16-1/8” from CL of

hinge as shown below.

6) Insert shaft/ drive arm into the operator, leave shaft bolt loose

until appropriate step during commissioning procedure.

7) Proceed to page 14 to perform commissioning.

Stainless Steel Arm

TORMAX

1102, 1201

C

L

OPERATOR

S.S. Shaft

PT# US801966

11/16" [17]

3/16" [5]

Y

1/8"

SWING

DOOR

SWING DIRECTION

[3]

Reveal distance is

from the face of the

to the rear of the

Operator 0” - 9-7/8”

(0 - 251)

X

X: Clearance required (distance bottom of header to top of arm)

Y: Distance between bottom of header back plate and centerline of door

mounting shoe

Part No.

141032 (STD)

141106 (D.E.)

141205

Shaft Length

3-

7/32” (82mm)

15/16” (100mm)

34-

27/32” (123mm)

X

1/16” (27mm)

11-

25/32” (45mm)

2-

11/16” (68mm)

Y

7/16” (36mm)

12-

5/32” (55mm)

3-

1/16” (78mm)

For extended reveals contact TORMAX

SWING

DOOR

1-3/8" [35]

16-1/8” [410]

12-3/16” [310]

S.S. 0 - 4-3/16” Reveal

Outswing Arm PT# US801983

CL

Hinge

Wall

Header

13

Outswing Full Pedestrian 18 - 20 lbs Commissioning

Requirements

1. Shaft should be loose in the drive unit. Drive arm connected to door and shaft.

2. Determine system values for your application based on the illustrations on page 10.

Commissioning

Commissioning Example: (3) = 36” door width, (1) = 0-2” reveal, (1) = Standard outswing Arm 11 3/8.

Press & Hold Programming Button, Release after 1 Green LED Flash. The operator will make 1 beep and immediately

begin to flash the Yellow LED.

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 1X, then after 3 yellow flashes, Press & Release

Programming Button

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 2X, then after 1 yellow flashes, Press & Release

Programming Button

PAUSE

PAUSE

PAUSE

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 3X, then after 1 yellow flashes, Press & Release

Programming Button

MADE AN ERROR DON’T WORRY: To start over Disconnect Power for 10 seconds, Reconnect Power, then Press & Hold

Programming Button and Release after 5 Green LED Flashes.

3 1 1

The operator will open 20 degrees stop and beep 2x. Attach Door Arm to Shaft and Door, place the Door in the

Closed Position, and

adjust open door stop to desired position, refer to page 22 for adjusting internal Open Door Stop.

RECONNECT POWER (operator beeps 1x), then Press & Hold programming button & Release after 6 Green LED

Flashes. The operator will open 20 degrees stop and beep 2x.

slowly close and beep 2x, next slowly fully open & beep 2x, then close (beep 1x) followed by 5 beeps, and will cycle

fully open & close at normal speed.

NOW Tighten the shaft to the operator at 25 ft-lbs. REMOVE POWER from Operator and

Press & Release programming button. Operator will

Commissioning is complete for High Energy Applications. For Low Energy application complete the last step below

Program the country code into the controller. For additional programming refer to page 23 or Programming Tables.

Enter Country Code 7 1: (Read Entire Step BEFORE attempting to enter Country Code)

PERFORM THIS STEP WHILE LOOKING AT BOTH GREEN & YELLOW LEDS.

Press & Hold

programming button after 1 Yellow flash.

programming button, Release after 7 Green flashes then immediately Press & Release

14

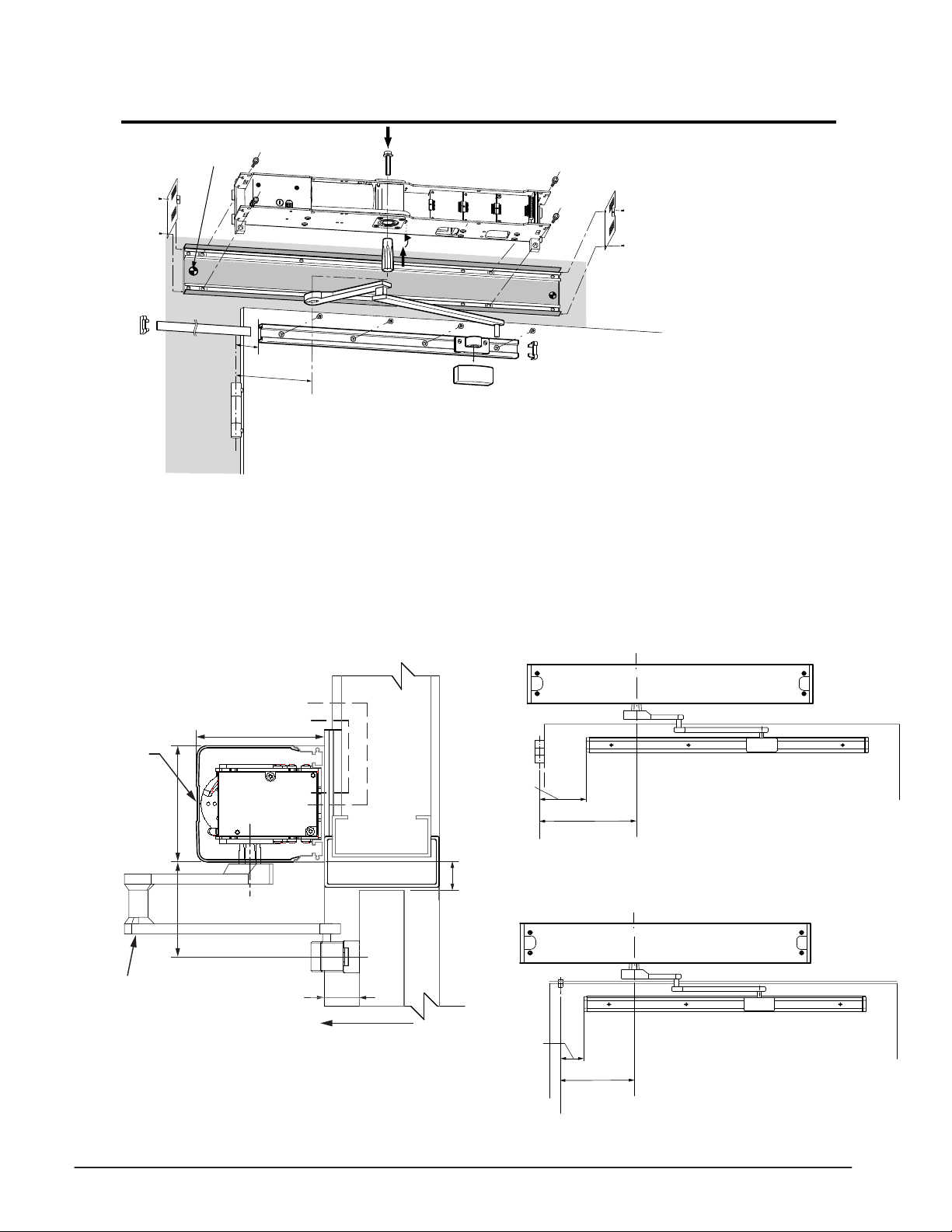

Inswing (Pull) Arm 0” Reveal Installation

Preferred

Primary

Power

4”[102mm]

12-

3/16

”

[310mm]

1) Determine the handing of the operator according to

the door. Note that arrow on operator indicates

opening direction of rotation.

2) Locate & mark output shaft location 12-3/16” from

CL of hinge onto door frame as

3) Determine header mounting height = X. See below.

4) Bolt header to the wall with appropriate hardware.

Standard Aluminum Arm

Electrical

C

L

Controls

TORMAX

1102, 1201

OPERATOR

ACCESS

COVER

4 9/16" [116]

Standard

Shaft 141032

3-7/32” (82mm)

5" [127]

X

Standard Inswing Arm

0” Reveal, P/N 407456

13.77 in. (350 mm

1) )

5) Locate and mount door arm slide track onto the door at

4” from C/L of pivot, mounting holes 5/8” from top of the

door as shown below.

6) Insert shaft/ drive arm into the operator, leave shaft bolt

loose until appropriate step during commissioning

procedure.

7) Proceed to page 16 to perform commissioning.

Stainless Steel Arm

TORMAX

1102, 1201

OPERATOR

S.S. Shaft

PT# US801966

3/16” [5]

1-7/8” [48]

1/8” [3]

Top of

the Door

S.S. 0” Reveal

Inswing Arm

PT# US801996

SWING

0” Reveal

Door Arm

407456

X: Mounting height (distance bottom of header to top of door)

Part No.

141032 (STD)

141205

141020

Shaft Length

3-

7/32” [82mm]

27/32” [123mm]

42-

5/8” [67mm]

DOOR

SWING DIRECTION

X

3/4”” (44mm]

13-

3/8” [86mm]

1-

5/32” [29mm]

For extended reveals contact TORMAX

C/L

Pivot

Header

4”

[102]

12-3/16” [310]

Butt Hingle or Offset Pivot

5/8” [16]

C/L

Shaft

15

Inswing (Pull) Arm 0” Reveal Commissioning

Requirements

1. Shaft should be loose in the drive unit. Drive arm connected to slide track and shaft.

2. Determine system values for your application based on the illustrations on page 10.

Commissioning

Commissioning Example: (3) = 36” door width, (1) = 0-2” reveal, (1) = Standard inswing Arm 11 3/8.

A

Press & Hold Programming Button, Release after 1 Green LED Flash. The operator will make 1 beep and immediately

begin to flash the Yellow LED.

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 1X, then after 3 yellow flashes, Press & Release

Programming Button

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 2X, then after 1 yellow flashes, Press & Release

Programming Button

PAUSE

PAUSE

PAUSE

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 3X, then after 4 yellow flashes, Press & Release

Programming Button

MADE AN ERROR DON’T WORRY: To start over Disconnect Power for 10 seconds, Reconnect Power, then Press & Hold

Programming Button and Release after 5 Green LED Flashes.

3 1 4

The operator will open 20 degrees stop and beep 2x. Attach Door Arm to Slide Track and Shaft, place the Door in the

Closed Position, and

adjust open door stop to desired position, refer to page 22 for adjusting internal Open Door Stop.

RECONNECT POWER (operator beeps 1x), then Press & Hold programming button & Release after 6 Green LED

Flashes. The operator will open 20 degrees stop and beep 2x.

slowly close and beep 2x, next slowly fully open & beep 2x, then close (beep 1x) followed by 5 beeps, and will cycle

fully open & close at normal speed.

NOW Tighten the shaft to the operator at 25 ft-lbs. REMOVE POWER from Operator and

Press & Release programming button. Operator will

Commissioning is complete for High Energy Applications. For Low Energy application complete the last step below

Program the country code into the controller. For additional programming refer to page 23 or Programming Tables.

Enter Country Code 7 1: (Read Entire Step BEFORE attempting to enter Country Code)

PERFORM THIS STEP WHILE LOOKING AT BOTH GREEN & YELLOW LEDS.

Press & Hold

programming button after 1 Yellow flash.

programming button, Release after 7 Green flashes then immediately Press & Release

16

Inswing (Pull) Arm 0 - 6” Reveal Installation

Primary

Power

See details below

1) Determine the handing of the operator according

to the door. Note that arrow on operator indicates

opening direction of rotation.

2) Locate & mark output shaft location as shown

below from CL of hinge or pivot onto door frame.

3) Mark header mounting height of 1 1/8” from the top

of the door as shown below.

4) Secure header to the wall with appropriate hardware.

Electrical

Controls

5" [127]

Access

Cover

TORMAX

4 9/16" [116]

3 3/4” [95]

1102, 1201

OPERATOR

C

L

SWING

DOOR

5) Locate and mount door arm slide track onto the door at 3 3/4”

from bottom of the header and at the dimensions listed below

for the application.

6) Insert shaft/ drive arm into the operator, leave shaft bolt loose

until appropriate step during commissioning procedure.

7) Proceed to page 18 to perform commissioning.

Butt Hinge

Header

2-1/4”

[57]

10-5/8” [270]

C/L

Pivot

1 1/8" [28]

C/L

Shaft

Center Pivot

0 - 6”” Reveal Door Arm

141133 R.H.Shown

141134 L.H.Not Shown

REVEAL DISTANCE

FROM THE FACE OF

THE DOOR TO THE

REAR OF OPERATOR

0"-6" (0-152)

SWING DIRECTION

1-1/4”

[32]

9-7/16”[240]

C/L

Pivot

Header

C/L

Shaft

17

Inswing (Pull) Arm 0 - 6” Reveal Commissioning

Requirements

1. Shaft should be loose in the drive unit. Drive arm connected to door and shaft.

2. Determine system values for your application based on the illustrations on page 10.

Commissioning

Commissioning Example: (3) = 36” door width, (1) = 2-4” reveal, (1) = Extended inswing Arm B.

B

Press & Hold Programming Button, Release after 1 Green LED Flash. The operator will make 1 beep and immediately

begin to flash the Yellow LED.

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 1X, then after 3 yellow flashes, Press & Release

Programming Button

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 2X, then after 2 yellow flashes, Press & Release

Programming Button

PAUSE

PAUSE

PAUSE

WHILE LOOKING AT THE YELLOW LED, WAIT FOR THE OPERATOR TO BEEP 3X, then after 6 yellow flashes, Press & Release

Programming Button

MADE AN ERROR DON’T WORRY: To start over Disconnect Power for 10 seconds, Reconnect Power, then Press & Hold

Programming Button and Release after 5 Green LED Flashes.

3 2 6

The operator will open 20 degrees stop and beep 2x. Attach Door Arm to Slide Track and Shaft, place the Door in the

Closed Position, and

adjust open door stop to desired position, refer to page 22 for adjusting internal Open Door Stop.

RECONNECT POWER (operator beeps 1x), then Press & Hold programming button & Release after 6 Green LED

Flashes. The operator will open 20 degrees stop and beep 2x.

slowly close and beep 2x, next slowly fully open & beep 2x, then close (beep 1x) followed by 5 beeps, and will cycle

fully open & close at normal speed.

NOW Tighten the shaft to the operator at 25 ft-lbs. REMOVE POWER from Operator and

Press & Release programming button. Operator will

Commissioning is complete for High Energy Applications. For Low Energy application complete the last step below

Program the country code into the controller. For additional programming refer to page 23 or Programming Tables.

Enter Country Code 7 1: (Read Entire Step BEFORE attempting to enter Country Code)

PERFORM THIS STEP WHILE LOOKING AT BOTH GREEN & YELLOW LEDS.

Press & Hold

programming button after 1 Yellow flash.

programming button, Release after 7 Green flashes then immediately Press & Release

18

Double Egress Application Installation

”8/50

10 5/8” [270]

”4/12

Butt Hung & Offset Pivot

C/L of

Pivot

1) Determine the handing of the operators according to

the door. Note that arrow on operator indicates

opening direction of rotation.

2) Locate & mark output shaft locations as shown above,

for both operators.

3) Determine header mounting height. If both operators are

in a single header then mount the operators at 1-1/8”

from top of the door as shown below for In-Swing operator.

0 - 6”” Reveal Door Arm

141133 R.H.Shown

141134 L.H.Not Shown

Shaft 141032

16 1/8” [410]

12 3/16” [310]

4) Secure header to the wall with appropriate hardware.

5) Locate and mount door arm and slide track onto the

doors at dimensions listed above.

6) Insert shaft/ drive arms into the operators, leave shaft

bolts loose until appropriate step during commisioning

procedure.

7) Proceed to page 20 to check or connect sync cable and

additional wiring.

In-Swing Operator

Electrical

Controls

TORMAX

1102, 1201

OPERATOR

C

C

L

L

Access

Cover

4 9/16" [116]

Standard

3 7/32” (82)

5" [127]

1 1/8" [29]

Electrical

Controls

Out-Swing Operator

5" [127]

TORMAX

1102, 1201

OPERATOR

SWING

DOOR

SWING DIRECTION

3 9/16" [90]

C

L

REVEAL DISTANCE FROM THE

FACE OF THE DOOR TO THE

REAR OF OPERATOR

0"-9 7/8" (0-251)

4 9/16" [116]

1 1/8" [29]

Access

Cover

Standard D.E. Shaft 141106

3 15/16” (100mm)

3 3/4” [95]

REVEAL DISTANCE

FROM THE FACE OF

THE DOOR TO THE

REAR OF OPERATOR

0"-6" (0-152)

SWING

DOOR

SWING DIRECTION

19

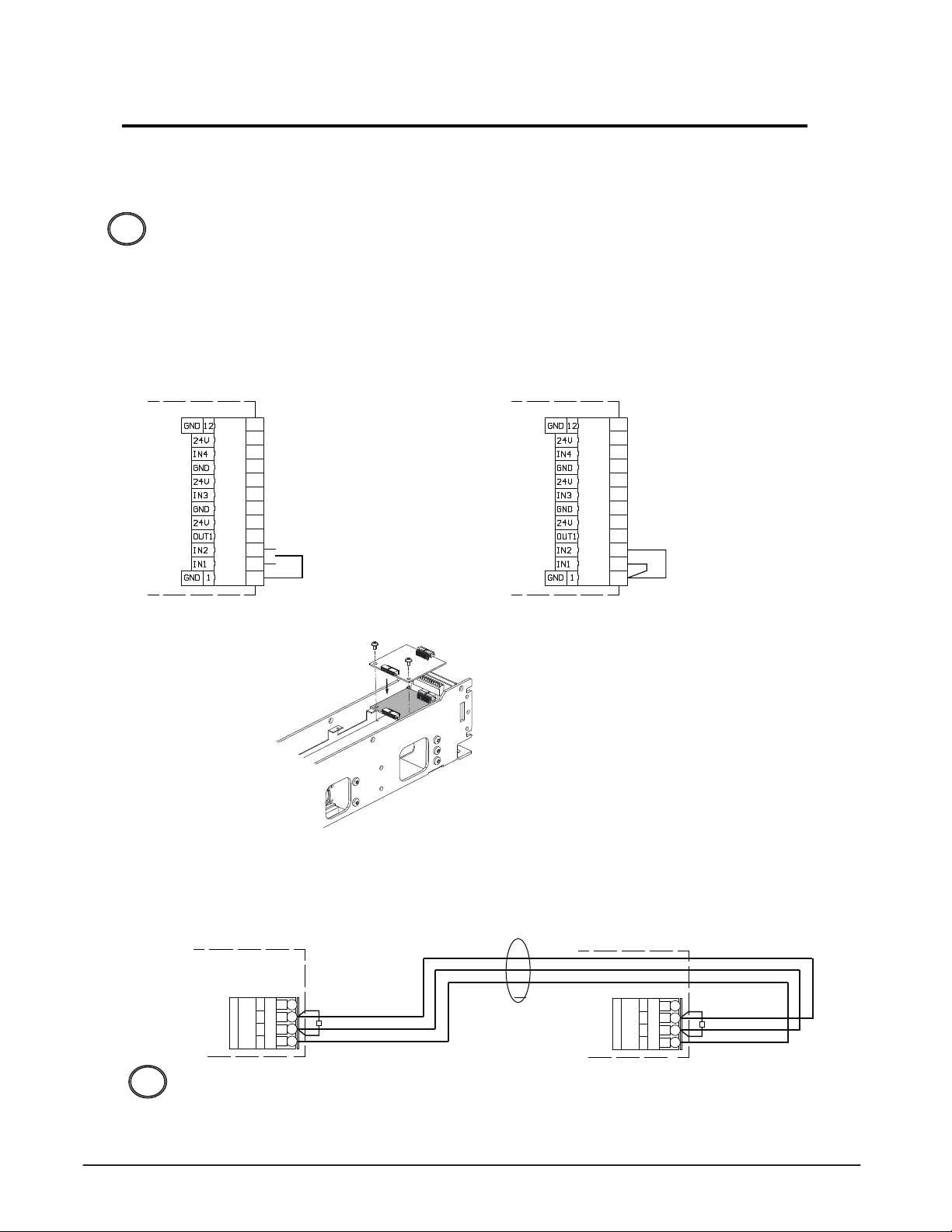

Pair & Double Egress Application Wiring

1. Determine which operator will be the primary drive as this will have the 3-position

switch connection.

The FCP is an option in place of the 3-position and will be connected to the primary

drive with appropriate module, Exterior Door module EDM or Programming Interface

!

module PIM.

2. Check and/ or install jumpers between GND pin 1 - IN1 pin 2 and GND pin 1 - IN2 Pin 3

in place of the 3-position switch on the secondary drive as shown below.

Primary Drive Secondary Drive

Base Door Module BDM Base Door Module BDM

A

12

11

10

9

8

7

6

5

4

OPEN

3

2

1

3-pos.-switchOFF

A

12

11

10

9

8

7

6

5

4

3

2

1

Double door configuration

Recognition as

secondary drive

3. Install Multi Door Module MDM-B into each operator.

T1638_4

4. Connect Sync cable (US801886) to both drives Multi Door Module MDM - B as shown below.

Wiring of Sync Cable

Primary Drive

Multi Door Module MDM-B

A

4

24V

H

3

GND

2

L

1

120 Ω

Red

Green

Black

SYNC

CABLE

Secondary Drive

Multi Door Module MDM-B

A

4

24V

H

3

GND

2

L

1

120 Ω

Red

Green

Black

Do not apply primary power to the drive units until the appropriate step.

!

Proceed to page 21.

20

Pair & Double Egress Application Commissioning

Requirements for Both Operator

1. An MDM module Installed in both operators along with optional modules (PIM, EDM, PDM)

prior to start-up. Refer to Technical Specifications section.

2. Refer to application’s commissioning page to determine shaft condition. (loose or secured)

3. Determine system values based on the illustrations on page 10.

Primary

Secondary

Commissioning

1. Connect primary power 120vAC to Primary operator first, then the Secondary

operator this will configure the operators (Primary/ Secondary).

10AT

L1

L1

N

N

2. Commissioning sequence - Perform Commissioning of Primary operator first,

then perform Commissioning of Secondary operator.

3. Refer to the applications Commissioning page:

115 V~

50/60 Hz

Outswing 8-10 lbs. Spring Holding force (Low Energy) Refer to page 11 for securing the Shaft & Arm position,

Page 12 for commissioning

Outswing 14- 15 lbs. Spring Holding Force (Full Power) - Page14

Inswing 0” Reveal - Page 16

Inswing 0-6” Reveal - Page 18

4. Adjustments:

A

B

Double egress/ simultanious pairs - Turn OFF delayed activation of secondary operator =

Code 830

Frequently used adjustments are listed on page 23

21

Adjustments - Door Stop/ 1201 Spring Tension

Adjusting Internal Open Door Stop

Determine opening angle required for application adjust internal stop accordingly.

–

–

+

+

!

An external door stop may be needed depending on application (abuse, excessive wind...).

!

Mechanical Spring Tension Adjustment (Optional ) - 1201 ONLY

max. 170 °

Adjust spring tension to close the door in adverse applications with no primary power applied.

!

–

+

1. Adjust spring tension on the operator, note Code for the adjustment made.

Example 20mm = Code 5.

0 5 10 15 20 25 30 35 40 Tension length in mm

Number of Flashes

1 * 2 3 4 5 6 7 8 9 Code

2. Programming spring tension adjustment with On-Board Button:

(Read Entire Step BEFORE attempting to enter Country Code)

PERFORM THIS STEP WHILE LOOKING AT BOTH GREEN & YELLOW LEDS.

Press & Hold

programming button after # Yellow flashes for code value .

programming button, Release after 4 Green flashes then immediately Press & Release

3. Changing the spring tension will require a commissioning process to be performed with

On-Board button Code 6 Green flashes or entering Code 021 with FCP.

22

Adjustments - Frequently Used

Adjustments

Country Code configures the operator for Low Energy application for more details refer to

page 31. To set the Country code 7 with On-Board Button follow the instructions below:

Enter Country Code 7 1: (Read Entire Step BEFORE attempting to enter Country Code)

PERFORM THIS STEP WHILE LOOKING AT BOTH GREEN & YELLOW LEDS.

Press & Hold

programming button after 1 Yellow flash.

programming button, Release after 7 Green flashes then immediately Press & Release

Additional adjustments may be made after commissioning which require a PIM

Program Interface module and an FCP. If the door requires or is equipped with an EDM

Exterior Door Module then a PIM in not needed.

Listed below are the most common adjustments. For a complete list of adjustments refer to

the Programming Charts.

*Hold open time = Code 10?

*Push-N-Go OFF = Code 860

*Close Check Force OFF = Code 320

**Power Close for Lock Release ON = Code 581

**Delay Time to Open = Code 591

Power Pulse when Opening = Code 43? Over come wind stack pressure or lock

*Double egress/ simultanious pairs = Code 830

Turn OFF delayed activation of secondary operator for pair applications.

Detecting/ mask out safety functions details on page 31:

On-Board Button = Code 3

FCP = Code 023

Repeat commissioning without system values details on page 31.

On-Board Button = Code 6

Power Assist in AUTO ON = Code 862

Power Assist Hold open Time = Code 150

* Adjustments have been changed by entering Country code 7.

** Adjustment 591 needs to be made in conjunction with 581.

Testing

Test the door in accordance with ANSI A156.19 Power Assist and Low Energy Power

Operated Doors or ANSI A156.10 Power Operated Pedestrian Doors standards before

putting the door into service and handing it over to the End-User.

23

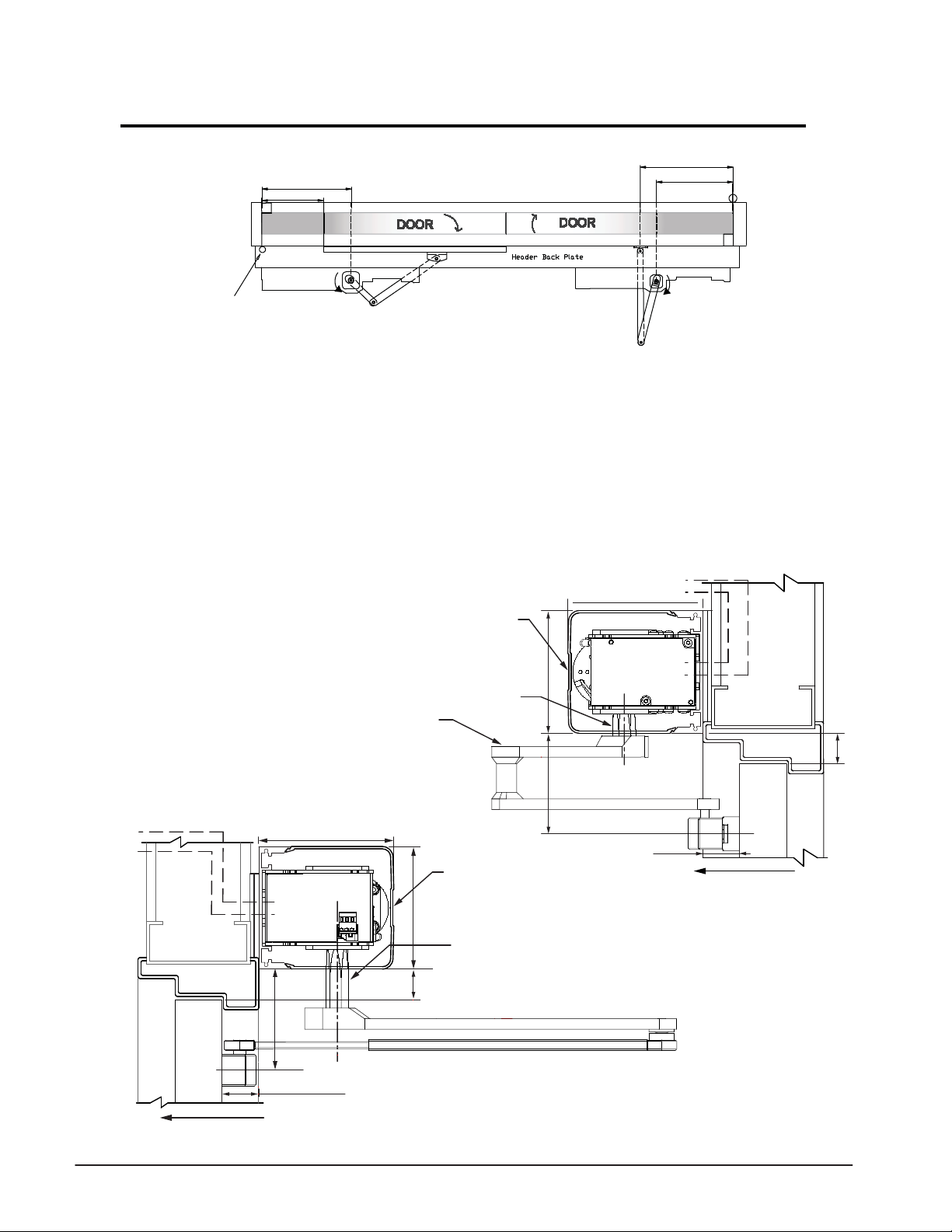

Slim Line - Header Preparation

12-9/32" - Butt Hinges, Inswing (0-6" Reveal)

14-5/8" - C.P. W/1" F.G. (3-3/4") 2-1/8"

13-5/8" - C.P. W/O F.G. (2-3/4") 1-13/16"

16-3/8" - C.P. W/O F.G. (2-3/4") 3-7/8"

14-3/8" - 3/4" Offset Pivots 1-7/8"

17-3/8" - C.P. W/1" F.G. (3-3/4") 4-7/8"

3-3/8"

"C"

RH Outswing Shown.

11/16"

Tormax USA, Inc.

DRAWING IS THE SOLE PROPERTY OF

TORMAX USA. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF TORMAX USA

IS PROHIBITED.

1102-1201 Header Fabrication Sheet

Drawing Number \ Revision

Slim Line Swing Door

Header Preparation

Mario Higuera 5/11/2016

THE INFORMATION CONTAINED IN THIS

PROPRIETARY AND CONFIDENTIAL

Description:

1102 / 1201

Door Width + 3-1/2" - 5/8" = Header Width

"8/1-1segniH ttuB - "8/5-31

"B""A"

1-3/16"

1-3/16"

C

L

Output

9/16"

See Chart

"A"

RH Out

LH In

12-3/16"

C

L

Pivot

Cut to Length in Field

As Supplied

or

23-5/8"

A

REVISIONS

"B"

3/8"

11/16"

HM6102/72/4eussI tsriF

DEVORPPAETADNOITPIRCSED.VER

3-5/16"

:etaD:yB nwarD

SHEET 1 OF 2

1-5/8"

24

Slim Line - Application Illustrations

[32]

Pivot

C/L

9-7/16”

[240]

Shaft

C/L

Commissioning and

programming page 18.

Tormax USA, Inc.

Commissioning and

programming page 12.

1-1/4”

Operator Header

Door

3

arm to shorten the length.

May require cutting the

Pivot

C/L

10-5/8” [270]

Shaft

C/L

Center Pivot

Hinge

[57]

CL

Operator Header

2-1/4”

Door

14-1/4” [362]

Wall

1

Butt Hinge

Operator Header

Hinge

CL

12-3/16” [310]

2

Operator Header

4-11/16"

8 - 10 lbs. Spring Holding Force

14-1/4” [362]

programming page 14.

Wall

mounting hole

C/L Bottom

C = 2-5/8"

1-1/2"

Inswing 0” - 6” Reveal

Hinge

CL

bolt loose in the operator.

Leave shaft mounting

12-3/16” [310]

Operator Header

Commissioning and

Pivot

C/L

12-3/16” [310]

4”

[102]

Shaft

C/L

Commissioning and

programming page 16.

5/8” [16]

Door

14 - 15 lbs. Spring Holding Force

16-1/8” [410]

Wall

Butt Hingle or Offset Pivot

Operator Header

2"

1-3/16"

C = 7/8"

mounting hole

C/L Bottom

Outswing

Inswing 0” Reveal

1-5/8”"

mounting hole

C = 2-5/8"

C/L Bottom

Operating manual for commissioning

and programming instructions for

specific applications listed.

DRAWING IS THE SOLE PROPERTY OF

TORMAX USA. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF TORMAX USA

IS PROHIBITED.

1102-1201 Header Fabrication Sheet

Drawing Number \ Revision

Mario Higuera 5/11/2016

Applications

aD:yB nwarD

t

:e

SHEET 2 OF 2

Reference 1102/ 1201 Installation and

THE INFORMATION CONTAINED IN THIS

PROPRIETARY AND CONFIDENTIAL

Description:

Slim Line Swing Door

1102 / 1201

Application Wiring page 20, commissioning and

programming page 21.

2-1/4”

[57]

Pivot

C/L

10-5/8” [270]

Shaft

C/L

Arm

Shaft

Pivot

Portion

Door

C/L

12-3/16” [310]

C/L

C/L

16-1/8” [409]

Inswing 0 - 6” Reveal - Butt Hinge

Header

Door

Outswing 14 - 15 lbs. Spring Holding Force

Header

Inswing

mounting hole

C/L Bottom

4-11/16"

C = 2-5/8"

1-1/2"

Double Egress Pair

C= 2-5/8”

1-3/4"

ER

V

FA

tsri

sI

RCSED.

REVISIONS

PPAETADNOITPI

HM6102/72/4eus

DEVOR

25

Programming with the FCP - Overview

Programming with the Functional Control Panel (FCP) refer to T1757 in Technical Specification

section requires at least one of the following modules to be installed PIM shown below refer

!

to T1691 or EDM T1638.

Symbols for

Operating Modes

OFF

AUTOMATIC

REDUCED OPEN

EXIT

OPEN

www.tormaxusa.com

Key (1) increase value

of code (0....9)

OR

selects operating mode

Electric lock

output indicator

Mode P

Manual Operation

Key

OR

selects operating mode

The Functional Control Panel (FCP) has 2 function levels:

Level 1 - End user

- Select operating modes

- Display three-digit fault codes.

- Access protected eliminates

unauthorized programming.

Level 2 - AAADM Certified Technician

- “U” = User readable parameter - allows

technician to read specific parameters.

See programming chart for parameters.

- Access protection, access code (111)

- Programming door system to comply

with the current ANSI A156.10 or

ANSI A156.19 standard.

- Displays currently set parameter.

- 10 min time out after the last programming

entry is made. The technician will be required

PIM

MODULE

to enter the access code (111) to make

further adjustments.

T1691_1

26

Programming with the FCP - Overview

Button 1 - Changes the number or letter by increments of one (0,1,2,3 - 9,a,b,c,...back to 0)

!

Button 2 - Confirms/ enter displayed number or letter into the control.

1) Start Access Code

Indication of operating mode

Press button 1 and 2

simultaneously a “U”

appears, continue to

press until a “C”

appears.

2) Entering Access Code 111

Letter U is shown (= User)

Letter C is shown (= Code)

Release both buttons

Immediately Press

button 2 a “0” will

display.

“0” appears

Press button 1

to display 1

Then

Press button 2

to comfirm/ enter

1st number

Letter P is shown ( = programming)

Press button 2

before P goes

out you will be

able to enter a

parameter.

3) Start Programming Level

Indication of operating mode

Press button 1 and 2

simultaneously a “U”

appears, continue to

press until a “P”

appears.

“0” re-appears

Press button 1 to

display 1

Then

Press button 2

to comfirm/ enter

2nd number

Release both

buttons immediately

Press button 2

a number will

display.

“0” re-appears

Press button 1 to

display 1

Then

Press button 2

to comfirm/ enter

3rd number

4) Entering Parameter

Code 103

any # appears

Press button 1

to display “1”

Then

Press button 2

to comfirm/ enter

1st number

any # appears

Press button 1

to display “0”

Then

Press button 2

to comfirm/ enter

2nd number

If a number is entered incorrectly, stop and let the process time out. (no change made)

!

any flashing # or letter appears

Press button 1 to

display “3”

Then

Press button 2

to comfirm/ enter

3rd number

“P” appears process complete

27

Programming with the FCP

Example 1: Enter access code 111

Display on FCP

Press both buttons simultaneously a U

continue to press both buttons and a C

*Press button 2 and 0

Press button 1 to display 1

Press button 1 1

Press button 1 1

P

will display

will display, release both buttons

will display

Press button 2 to confirm/ enter

Will display

0

Press button 2 to confirm/ enter

Will display

0

Press button 2 to confirm/ enter

Will display,operator is ready to be programmed

Example 2: Enter code 103 to adjust the Hold Open time for 2 sec

Display on FCP

Press both buttons simultaneously a U

continue to press both buttons and a P

Press button 2 and ? a number will be displayed,

Press button 1 to display 1

Press button 1 to display 0

a slow flashing ?

Press button 1 to display 3

will display, release both buttons,

Press button 2 to confirm/ enter,

? A number will be displayed,

Press button 2 to confirm/ enter,

number or letter is displayed,

Press button 2 to confirm/ enter

3

Will rapidly flash for 1 sec

P Will display for 10 sec then operating mode will display.

Hold Open time for Automatic 1 is now set for 2 sec

Within 10 minutes you can enter the programming mode by pressing both keys

!

simultaneously and P will display. If no further adjustments are made after

10 minutes the FCP will time out and require access code re-entry. Repeat example 1.

After confirming/ entering the 2nd number of the code, the 3rd flashing value (number or letter)

!

of the code is the parameter setting. If the value is confirmed the FCP will rapidly flash

for 1 sec then display “P” again.

Quickly pressing and releasing both buttons simultaneously the FCP will return to

!

displaying the mode of operation.

28

Commissioning with FCP

Requirements:

1. Programming with the Functional Control Panel (FCP) requires at least one of the

following modules to be installed PIM refer to T1691 or EDM T1638. If optional modules

(MDM, PDM) are required install prior to start-up.

2. The drive arm is connected to the door and the drive arm shaft has not been

tightened, exception outswing 8 - 10 lbs .

3. Pair of doors - the sync cable and additional wiring outlined on page 20 has been completed.

4. Connect safety sensors to door control, adjust in accordance to manufacturer’s specifications.

Start-up:

Double egress/ simultanious pairs applying power in the wrong sequence will

!

cause configuration problems.

1. Apply primary power to the operator, for pair of doors apply power

to the Primary operator first, then to the Secondary operator.

L1

2. Enter System Parameters - Refer to page 10 to determine values.

Complete sequence for Primary operator first.

Enter Code 06? Door width

Enter Code 07? Distance of drive arm

Enter Code 08? Sliding lever length

3. Arm Preload

Enter Code 021 operator will rotate 20 degrees, with the door arm connected to the door,

place the door in the closed position, tighten shaft retaining bolt to 25 ft.lbs.

Remove primary power plug from operator, door will close.

L1

10AT

L1

N

N

4. For pair applications - repeat process for secondary operator beginning at step 2.

10AT

L1

N

N

115 V~

50/60 Hz

115 V~

50/60 Hz

5. Adjusting Open door stop

Determine opening angle required for application adjust internal stop accordingly.

–

–

+

+

!

An external door stop may be needed depending on application (abuse, excessive wind ).

!

max. 170 °

Proceed to page 30

29

Commissioning with FCP

Commissioning

1. Apply primary power to the operator, for pair of doors apply power

to the Primary operator first, then to the Secondary operator.

2. Commissioning - Enter Code 021 Start commissioning, for pairs complete primary operator

sequence first.

3. Door will automatically open and hold open at 20 degrees.

4. Exit Preload - Enter Code 020 door closes.

5. Door will automatically begin opening until the open door stop is reached, door will

immediately close.(Checking door weight/ momentum)

6. Escalating 6 tones will occur before door begins opening. (Door mounted safety sensor

inhibiting)

7. For pair applications, repeat sequence for secondary operator, begin at step 2. Primary

operator will go to the open position until commissioning is completed.

Additional Adjustments

Additional adjustments may need to be made after commissioning. Listed below are the most

common adjustments. For additional adjustments refer to the Programming Charts.

*Hold open time = Code 10?

*Push-N-Go OFF = Code 860

*Close Check Force OFF = Code 320

**Power Close for Lock Release ON = Code 581

**Delay Time to Open = Code 591

Power Pulse when Opening = Code 43? Over come wind stack pressure

*Double egress/ simultanious pairs = Code 830

Turn OFF delayed activation of secondary operator for pair applications.

Detecting/ mask out safety functions details on page 31 = Code 023

Power Assist in AUTO ON = Code 862

Power Assist Hold open Time = Code 150

Repeat commissioning without system values details on page 31.

On-Board Button = Code 6

* Adjustments have been changed by entering Country code 7.

** Adjustment 591 needs to be made in conjunction with 581.

Testing

Test the door in accordance with ANSI A156.19 Power Assist and Low Energy Power Operated Doors or

ANSI A156.10 Power Operated Pedestrian Doors standards before putting the door into service and handing

it over to the End-User.

L1

2 Audible Tones

2 Audible Tones

6 Audible Tones This ends the programming step.

10AT

L1

N

N

115 V~

50/60 Hz

30

Code Descriptions/ BDM LED Displays

Country Code

The Country code is available in firmware V3.02 and above. The country code provides preset

values to aid the technician in installing the door to comply with ANSI Standard A156.19.

Country code can be set with On-board button Code 7/1 or FCP code 031. To remove the

country code adjustments perform a factory reset. Functions changed are listed below:

Hold Open Time=105 Opening Speed=203 Closing Speed=214

Closing Force=311 Close Check Force=320 Safety Function BDM IN4=602

Safety Function PDM IN4=651 Pair without Overlap=830 Push N Go OFF=860

Detecting safety features (optional)

If the safety sensors in the opening and/or closing direction were not detected correctly or

have been connected for the first time, they can be subsequently detected. Detect and save

safety features 1–2

Code 3 on-board configuration (FCP code = 023 )

Procedure according to Code 023 or OB Code 3 Conditions Result

Waiting time 5 seconds (rising motor signal tone).

The safety sensor connection type is detected.

The door opens and closes again.

After the door reaches the open position, the number

of testable safety sensors is indicated by the number of

times the green LED (0–2 times).

Sensors must be

correctly connected.

Do not enter the

detection area of the

moving safety sensors.

If the testing of the safety feature “open” is

success

ful, the door opens at full power.If the

testing of the safety feature “close” is

successful, the door closes at full power.

The safety feature “open” is automatically

suppressed if the door moves against a wall.

Repeat commissioning (without system values)

If the door arm or shaft position was changed or glass was installed in the door after

commissioning.

Code 6 on-board configuration

Procedure according to OB Code 6

Operator rotates 20°, beeps 2x, Press & Release the

OB button, operator will close slowly, automatically

opens slowly & fully open & beeps 2X, close (beep

1x) followed by 5 beeps. and will fully open & close

at normal speed.

Displays

Troubleshooting codes displays as E / H on the user interface. See the Troubleshooting Codes Chart in this manual

for their meaning.

LED displays on the base door module BDM

Yellow LED off OK

Yellow LED on Error (E). See the user interface or Skipper for the error display.

Green LED on Power supply and module OK

Green LED off No power supply or power supply overloaded.

Green LED flashes A programming step was started via the on-board programming button.

The Green LED flashes

after the open position is

reached

See the Trouble shooting chart in this manual.

The process is on going. Press the button briefly to stop the process.

0 × = No testable safety feature available. Door moves with low energy.

1 × = 1 testable safety feature available. Door move

2 × = 2 testable safety features available. Door moves with full energy.

Conditions

Door travel path unobstructed, no physical

contact with the door

during the learn cycles.

Minimal wind load.

Result

Door open & closed positions detected. Door

weight detected.

Safety functions detection according to Code 023,

OB Code 3.

s with low energy.

31

Programming Table

Code Function Note

01 1

UR Door operator type 1102

01 2 UR Door operator type 1201

02 0 End procedure "Spring preload"

02 1 Start commissioning

02 2 Start Teach-In

02 3 Detecting and storing of safety functions

02 4 Delete registration of unplugged modules MDM, PDM, EDM

03 1

Preset 1=Handicap Function (=OB code 7/1) (=P105,203,214,311,320,602,651,830,860,870)

04 0 UR Reset

04 1 Factory Reset

04 2

UR Display firmware version

04 3 UR Display number of cycles

04 4 UR Display number of operating hours

04 5 Delete fault protocol

05 0 Display registration module EDM

05 1 Display registration module PDM

05 2 Display registration module MDM

05 3 Display registration secondary door operator

05 4 Display voltage intermediate circuit 40VDC

05 5 Display voltage 24VDC supply

05 8 Display temperature transformer (calculated) (from FW V03.10)

05 9 Display temperature motor (calculated) (from FW V03.10)

06 1...8 Door width (=OB code 1/1)

0 * 1 2 3 4 5 6 7 8 code

0

28” 32” 36” 40” 44” 48” 52” 56” inches

07 1...6 Reveal (=OB code 1/2)

0 * 1 2 3 4

0 1-2” 2-4” 4-6” 6-8.5”

5

8.5-10.5”

6

10.5-12.5”

08 1...6 Drive Arm Length (=OB code 1/3)

2

3

0 * 1

11-3/8”

0

Custom 13-3/4”

4 5 6

Custom

13-3/4”

Custom

09 0...9 Spring tension (=OB code 4) ONLY APPLIES to 1201 Operator

1 * 2 3 4 5 6 7 8 9

5

0

10 15 20 25 30 35 40 mm

10 0...F UP Hold-open time for Auto Mode

0 1 * 2 3 4 5 6 7 8 9 A b C d E F code

0 1 2 3 4 5 6 7 8 9 10 15 20 40 60 >/> sec. (>/>=step control)

11 0...F UP Hold-open time of activator for Beds

0 1 2 3 4 5 6 7 8 * 9 A b C d E F code

0 1 2 3 4 5 6 7 8 9 10 15 20 40 60 >/> sec. (>/>=step control)

12 0...F UP Key Switch Hold-open time

0 1 2 3 * 4 5 6 7 8 9 A b C d E F code

0 1 2 3 4 5 6 7 8 9 10 15 20 40 60 >/> sec. (>/>=step control)

13 0...9 UP Delay time Mode of op. OFF

0 1 2 * 3 4 5 6 7 8 9 code

1 3 5 7.5 10 15 20 30 45 60 sec.

14 0...9 UP out3 EDM: Bell active time

0 1 2 * 3 4 5 6 7 8 9 code

0 0.5 1 2 3 4 5 6 8 10 sec.

15 0...9 Power Assist Hold- open time after opening

0 1 *

0

2

3 4 5 6 7 8 9 code

1

2 3 4 5 6 8 10 12.5 sec.

A

15

b

17.5

C d E

20

UP=(P) Program mode. UR=(R) Read parameter mode

40

60

Remains after factory reset

Remains after factory reset

Only possible after entering system parameters 06x, 07x, 08x

Safety functions on terminals in3+4 PDM" and in4 BDM

The modules will be registered automatically at power-up

Reverse with factory reset

Starts program with calibration run

All adjustments back to default values (see *)

Example: r06_00 = V06.00

Example: c10_302 = 10'302 cycles (max. 99?999?999)

Example: h4_002 = 4002 hours (max.99'999'999)

A0 =not registered, A1 =registered

A0 =not registered, A1 =registered

A0 =not registered, A1 =MDM-A registered, A2 =MDM-B registered

A0 =Single door, A1 =primary door, A2 =secundary door

Example: u22_8 = 22,8V

Example: u22_8 = 22,8V

Example: t39_5 = 39,5 degree C

Example: t39_5 = 39,5 degree C

code

inches

code

inches (Out-Swing Arm/ Push 1,2,3) (In-Swing Arm/ Pull 4,5,6)

Is also determined by the teach-in.

0 = Off

0 = Off

F

>/>

* = Default value

32

Programming Table

Code Function Note

20 0...9 UP Opening speed

8

130

120

120 130

9

9

Low Energy max 67N / F (+0 to -30%)

9

30

Low Energy max 67N / F (+0 to -30%)

Low energy max 67N / F (+0-30%) / S= only force of spring

Low energy max 67N / F (+0-30%) / S= only force of spring

% of the set spring force.

Force on door edge

0 = 5 degrees before the closed position

Stop = open against endstop (not if H17 is displayed)

Valid only from FW V02.10

Note the context of the parameters P22x, P32x, P42x

0 = off, 3 = maximum

0 1 2 3 4 5 6 * Code

10 25 40 55 70 85 100 %

7

110

21 0...9 UP Closing speed

0 1 2 3 4 5 6 * Code

10 25 40 55 70 85 100 %

7 8

110

22 0...9 Close check speed

0 * 1 2 3 4 5 6 7 8 code

2 5 8 11 14 17 20 23 26 N (no= no limit)

30 1...9 UP Motor force opening

1 2 3 4 5 6 * 7 8 9 code

40 55 67 80 95 120 150 175 no N (no= no limit)

31 0...9 UP Motor force closing

0 1 2 3 4 5 6 * 7 8 9 code

S 40 55 67 80 95 120 150 175 no N (no = no limit)

32 0...8 UP Motor force at close check

0 1 2 3 4 5 6 * 7 8 code

S 40 55 67 80 95 120 150 175 N (max)

33 0...6 Motor holding closed force (New commissioning required! >H14)

0 1 2 3 * 4 5 6 code

-90 -60 -30 0 +30 +60 +90 %

34 1...5 Power Assist closing force after opening

0 * 1 2 3 4 5 code

S 5 10 15 20 25 N (S=Spring force)

35 0...9 Reversing time obstacle opening

0 1 2 3 4 5 6 * 7 8 9 code

5 4.5 4 3.5 3 2.5 2 1.5 1 0.5 sec.

36 0...9 Reversing time obstacle closing

0 1 2 3 4 5 6 * 7 8 9 code

5 4.5 4 3.5 3 2.5 2 1.5 1 0.5 sec.

37 1...5 Power Assist opening resistance

0 1 2 3 * 4 code

5 10 15 20 25 N

38 0...6 UP Push-and-Go/ Power Assist start angle

0 1 2 3 * 4 5 6 code

1 2 3 5 8 12 16 degree

39 0...5 UP Push-and-Close start angle

0 1 2 3 4 5 * code

- 8 10 12 14 16 degree

40 0...9 Correction open position

0 1 2 3 4 * 5 6 7 8 9 code

95 97 98 99 100 101 102 103 105 Stop %

41 1...9 Advance angle for unlocking

1 2 3 4 5 6 7 * 8 9 code

1 1.5 2 2.5 3 3.5 4 4.5 5 degree

42 0...9 Angle for close & open check

0 * 1 2 3 4 5 6 7 8 9 code

0 1 1.5 2 2.5 3 3.5 4 4.5 5 degre

43 0 *...3 Power pulse when opening

UP=(P) Program mode. UR=(R) Read parameter mode

* = Default value

33

Programming Table

Code Function Note

50 0 No switch off safety sensors

50 1 Switch off safety sensors in: P

50 2 * Switch off safety sensors in: P, OFF if door closed >60s, OPEN >60s

51 0 No switch off activator sensors

51 1 Switch off sensor in: P

51 2 * Switch off sensor in: P, OFF if door closed, OPEN

51 3 Switch off sensor in: P, OFF and EXIT if door closed, OPEN

52 0 No switch off of LED on User Interface USIN-7

52 1 * Switch off LEDs on user interface USIN-7 1 min. after use

55 0 Locks in operating mode OFF

55 1 Locks in operating mode OFF, EXIT

55 2 Locks in operating mode OFF, AUTO, EXIT

55 3 * Locks in operating mode OFF, AUTO, EXIT, P

56 0 * out2 EDM: Without holding magnet function

56 1 out2 EDM: Holding magnet active in closed position

56 2 out2 EDM: Holding magnet active in open position

57 0 * out1B EDM: Electric strike: current-free locked - fail secure

57 1 out1B EDM: Electric strike/ Maglock: current-free unlocked - fail safe

57 2 out1B EDM: No lock

57 3 out1B EDM: Motorised lock

58 0 * No power close for electric strike release

58 1 Power close for electric strike release

59 0...b Delay time to open (or until response "R" for motorised lock)

0 * 1 2 3 4 5 6 7 8 9 A b code

0,1 0.2 0.4 0.8 1.2 1.6 2 2.5 3 4 R/NO R/NC sec. / Response

60 0 in4 BDM: No function

60 1 * in4 BDM: Safety swing area

60 2 in4 BDM: Safety closing with reversing function

60 3 in4 BDM: Safety closing with creeping function

60 4 in4 BDM: Safety opening with stop function

60 5 in4 BDM: Safety opening with creeping function

60 6 in4 BDM: Power-assistance pre-triggering

61 0 out1 BDM: No function

61 1 * out1 BDM: Message “General fault”

61 3 out1 BDM: Message "door closed"

61 4 out1 BDM: Message “door closed and locked”

61 5 out1 BDM: Message “door open”

61 6 out1 BDM: Message “Mode of operation OFF”

62 0 * in1 PDM: No function

62 1 in1 PDM: Emergency closing

62 2 in1 PDM: Emergency opening

64 0 * in3 PDM: Safety opening with stop function

64 1 in3 PDM: Safety opening with function "Low-Energy"

64 2 in3 PDM: Safety stop

64 3 in3 PDM: Safety swing area

65 0 * in4 PDM: Safety closing with reversing function

65 1 in4 PDM: Safety closing with function "Low-Energy"

65 2 in4 PDM: Safety stop

65 3 in4 PDM: Safety swing area

UP=(P) Program mode. UR=(R) Read parameter mode

Connect power of sensor to GNDct (PDM)

Connect power of sensor to GNDct (PDM)

Connect power of sensor to GNDct (EDM)

Connect power of sensor to GNDct (EDM)

Connect power of sensor to GNDct (EDM)

LEDs switch on when needed

When using electric. strikes: 100% duty ratio required

When using electric. strikes: 100% duty ratio required

When using electric. strikes: 100% duty ratio required

Only for electric strike with 100% duty ratio

With return signal: Programm P59A or B

Requires min. unlocking time of 0,2s (P591)

Only valid if electric strike has to unlock

Safety functions use only once with 60x, 64x, 65x!

Contact type NO, NC detect with code P023 or OB 3

Contact type NO, NC detect with code P023 or OB 3

Contact type NO, NC detect with code P023 or OB 3

Contact type NO, NC detect with code P023 or OB 3

Contact type NO, NC detect with code P023 or OB 3

Function depending of op. mode and P85x-87x, x>=2

Only with response of motorised lock

Contact type NC

Contact type NC

Contact type NC+test, NC, NO detect with P023 or OB 3

Contact type NC+test, NC, NO detect with P023 or OB 3

Contact type NC+test, NC, NO detect with P023 or OB 3

Contact type NC+test, NC, NO detect with P023 or OB 3

Contact type NC+test, NC, NO detect with P023 or OB 3

Contact type NC+test, NC, NO detect with P023 or OB 3

Contact type NC+test, NC, NO detect with P023 or OB 3

Contact type NC+test, NC, NO detect with P023 or OB 3

* = Default value

34

Programming Table

Code Function Note

70 0 * out1 MDM: Message “door open”

70 1 out1 MDM: Battery in service

71 0 * out2 MDM: Message "door closed"

72 0 * out3 MDM: Message “door closed and locked”

72 1 out3 MDM: Message “General fault”

73 0 * out4 MDM: Door ready for operation

73 1 out4 MDM: Mode of operation OFF

74 0 in1 MDM: no function

74 1 * in1 MDM: Mode of operation OFF

75 0 in2 MDM: no function

75 1 * in2 MDM: Mode of operation OPEN

76 0 in3 MDM: no function

76 1 * in3 MDM: Mode of operation EXIT

77 0 in4 MDM: no function

77 1 * in4 MDM: Passage for beds

77 2 in4 MDM: Operation mode MANUAL

80 0 * UP out3 EDM: Bell trigger: Activator outside

80 1 UP out3 EDM: Bell trigger: Activator inside

80 2 UP out3 EDM: Bell trigger: Key switch

81 0...4 UP Button pressed time for handicapped

0 * 1 2 3 4 code

0 1 2 3 5 sec.

82 0 * Emergency operation in case of faulty safety > for low risk

82 1 Safety operation in case of faulty safety > for high risk

83 0 Double wing door without overlapping, synchronous

83 1 * Double wing door with overlapping

83 2 Double wing door with "Door coordinator device" MDC

84 0 * Battery switches off after 10s

84 1 Battery operation in all modes of operation

84 2 Battery operation in AUTO, EXIT, OPEN

84 3 Opens with battery in OFF, AUTO, EXIT, OPEN

84 4 Opens with battery in AUTO, EXIT, OPEN

85 0 * No opening assistance in MANUAL

85 2 Power-assistance in MANUAL incl. pre-trigger by activator in-/outside

85 3 Power-assistance in MANUAL

86 0 No opening assistance in AUTO

86 1 * Push & Go in AUTO

86 2 Power-assistance in AUTO

87 0 No opening assistance in EXIT

87 1 * Push & Go in EXIT

87 2 Power-assistance in EXIT

90 0 * Programming button (BDM) released

90 1 Programming button (BDM) disabled

91 0...4 UP Access code lock for control unit

0 * 1 2 3 4 code

-- 111 222 333 123 code

92 0 * User parameter enabled

92 1 User parameter disabled

UP=(P) Program mode. UR=(R) Read parameter mode

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

MDM- A (Non Stocking part, special order)

Valid for inside/outside and key switch activations

At E31-36: Creep speed with force <67N

At E31-36: Manual operation

Application see T-1763, T1753

Application see T-1763, T1753

Application see T-1763, T1753

In all other modes, the battery switches off after 10s

In all other modes, the battery switches off after 10s

In all other modes, the battery switches off after 10s

+ Triggered by angle or in4 BDM (in4 only with P510)

Triggered by angle or pre-release by IN4 BDM

Triggered by angle or pre-release by IN4 BDM

Triggered by angle or pre-release by IN4 BDM

0 = off

* = Default value

35

Troubleshooting Codes

* E = Error | H = Hint

* No. Fault Behaviour of System Reset

E0x Internal test negative. Fatal error. Safety operating

E11 Motorised lock not unlocked Door blocked Automatically if OK

E12 Motorised lock not locked Automatically if OK

E23 CAN connection EDM interrupted Safety operating mode

E24 CAN connection PDM interrupted Safety operating mode

E25 CAN connection MDM interrupted Safety operating mode

E26 CAN connection primary - second. interrupted Primary continues, second. stays closed

E31 Safety open > 1 min. active, test neg. According safety function Automatically if OK

E32 Safety closing > 1 min. active, test neg. According safety function Automatically if OK

E33 Safety stop > 1 min. active, test neg. According safety function Automatically if OK

E34 Safety swing area > 1 min. active, test neg. According safety function Automatically if OK

E35 Safety open creep > 1 min. active, test neg. According safety function Automatically if OK

E36 Safety close creep > 1 min. active, test neg. According safety function Automatically if OK

E37 Safety open Low En. > 1min. active, test neg. According safety function Automatically if OK

E38 Safety clos. Low En. >1min. active, test neg. According safety function Automatically if OK

E41 Activator inside > 1min. active Door remains open Automatically if OK

E42 Activator outside > 1min. active Door remains open Automatically if OK

E43 Key switch > 1min. active Door remains open Automatically if OK

E45 Emergency open > 1 min. active Door remains open Automatically if OK

E46 Emergency close > 1 min. active Door closes and remains closed Automatically if OK.

E47 Inhibit switch > 1 min. active Door closes without hold open time Automatically if OK.

E48 Activator bed passage > 1min. active Door remains open Automatically if OK

E51 Encoder not working Safety operating mode Reset

E61 Power supply 40V outside of admissible range Safety operating mode Automatically if OK

E62 Power Supply 24V outside of permissible range Safety op. mode Automatically if OK

E63 Power Supply 24V short circuit Safety op. mode Automatically after 20s if OK

E64 Motor hot Safety operating mode Automatically after cooling down

E66 Motor faulty. Interruption of motor control. Safety operating mode. No braking! Replace motor

E68 Power failure (Power on)

E99 Error at secondary drive unit

H01 System was started Safety op. mode Reset

H02 Factory reset required (VEE unreadable) Safety mode Factory reset

H11 Parameter 06... not yet programmed Safety operation Enter parameter

H12 Parameter 07... not yet programmed Safety operation Enter parameter

H13 Parameter 08... not yet programmed Safety operation Enter parameter

H14 Commissioning not executed Safety operation Start commissioning

H15 Timeout moving. Door blocked. Motor faulty Commissioning is canceled Restart commissioning

H16 Mass detection faulty (wind, opening angle) Autom. detection is terminated Restart automatic detection

H17 Open endstop too soft. Motor may overheat

H18 Safety function is used more than once See P60x, P64x, P65x

H19 Detection of safety functions pending P023 or OB code 3

H21 Teach-In: Door moves >25 s before start Abort Teach-In New Teach-In

H22 Teach-In: No start within 60s Abort Teach-In New Teach-In

H23 Teach-In: Movement to slow. >60 s Abort Teach-In New Teach-In

H31 Obstacle detection at opening Door reverses Automatically, Display 20s.

H32 Obstacle detected at closing Door reverses Automatically, Display 20s.

H33 Permanent obstacle at opening Safety operation Reset

H34 Permanent obstacle at closing Safety operation Reset

H46 FW missmatch in primary and secondary

H62 Calibration run in closing direction Searches closed position At the end of movement

H67 Absolute position not found yet Slow opening movement

H71 Battery mode Door moves slowly Power supply return

H74 Motor current in open position too high E64 can trigger later P404. Avoid wind load. Install HM

Power OFF-ON. Possibly press button 5s

36