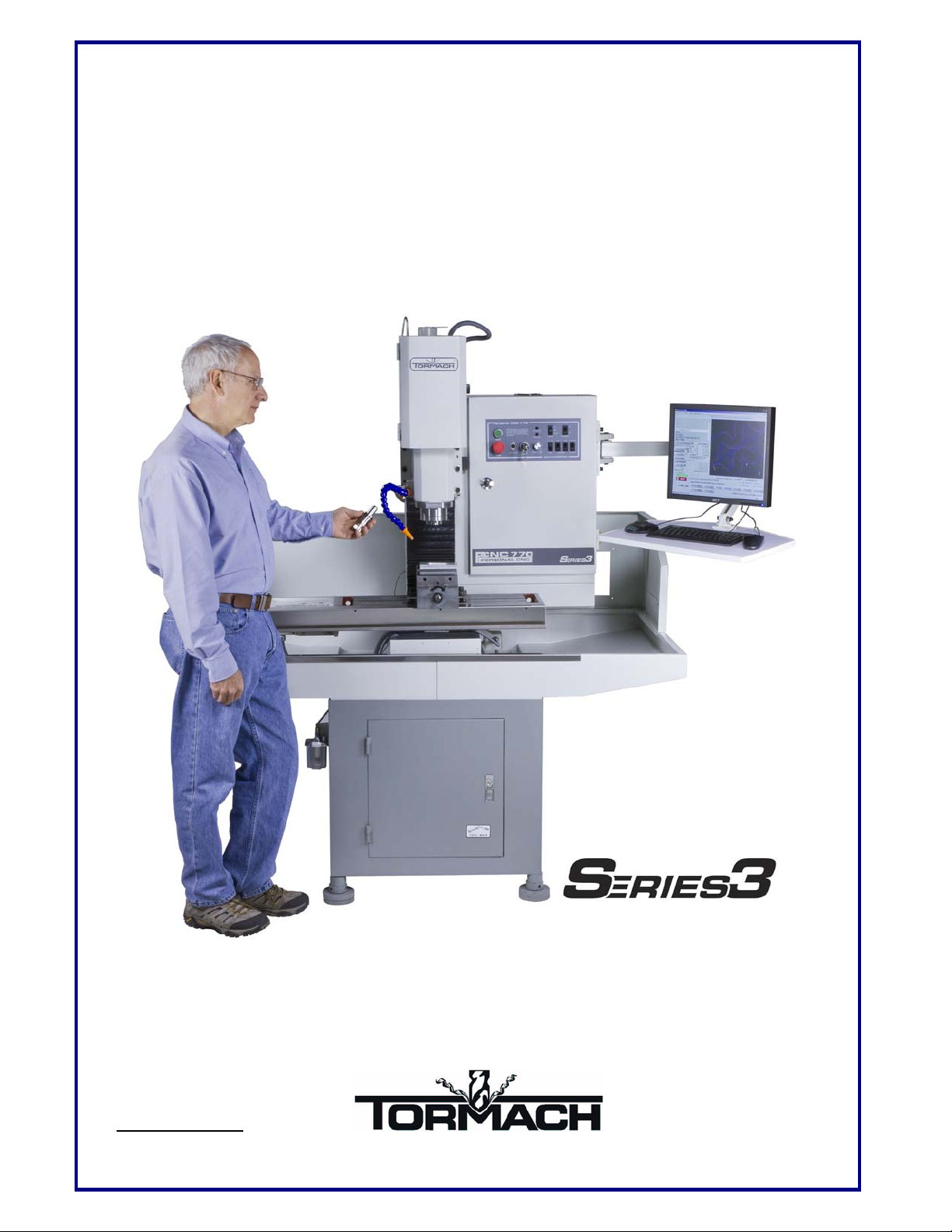

Page 1

-

PCNC 770 Manual

Part Number 32426 – 0412A

Questions or comments?

Using the Tormach

PCNC 770

Programmer’s and Operator’s Guide to the Personal CNC 770

Please email us at:

info@tormach.com

©2011 Tormach® LLC. All rights reserved.

Page 2

iiContents

Using Tormach PCNC 770 ii 32426 Rev C1-1

Page 3

Contents

1. Preface ............................................................................................. 1-1

1.1 Safety ............................................................................................................................... 1-1

1.1.1 Electrical Safety ................................................................................................................ 1-1

1.1.2 General Operating Safety .................................................................................................. 1-1

1.1.3 Safety Publications ........................................................................................................... 1-2

1.1.4 Safety Precautions............................................................................................................. 1-2

1.2 Personal CNC Concept ................................................................................................... 1-3

1.3 Performance Expectations .............................................................................................. 1-3

1.3.1 Cutting Ability .................................................................................................................. 1-3

1.3.2 Understanding Accuracy ................................................................................................... 1-4

1.3.3 Resolution, Accuracy and Repeatability of the PCNC ........................................................ 1-4

1.4 Scope and Intellectual Property...................................................................................... 1-4

1.5 Nomenclature .................................................................................................................. 1-5

2. Preparation ...................................................................................... 2-1

2.1 Planning for Your PCNC ................................................................................................ 2-1

2.1.1 Electrical Connection ........................................................................................................ 2-1

2.1.2 Location and Mounting ..................................................................................................... 2-1

2.1.3 Computer Mounting Arrangement ..................................................................................... 2-2

2.1.4 Learning and Training ....................................................................................................... 2-3

2.2 Receiving, Unpacking and Checking Shipment.............................................................. 2-4

2.2.1 Moving the Crate .............................................................................................................. 2-4

2.2.2 Uncrating and Inspection................................................................................................... 2-4

2.3 Mounting the PCNC ....................................................................................................... 2-4

2.3.1 Lifting onto Stand ............................................................................................................. 2-4

2.3.1.1 Lifting from Below ................................................................................................ 2-5

2.3.1.2 Lifting from Above ................................................................................................ 2-5

2.3.2 Fixing to Stand ................................................................................................................. 2-5

2.3.3 Installing central lubrication pump .................................................................................... 2-6

2.3.4 Accessories ....................................................................................................................... 2-6

2.4 Power to the PCNC ......................................................................................................... 2-6

2.5 Power for Machine Accessories ...................................................................................... 2-7

2.6 Tormach Machine Controller and Software Installation ............................................... 2-7

2.6.1 Control Computer ............................................................................................................. 2-7

2.6.2 Setting Up Your Controller ............................................................................................... 2-7

2.6.2.1 Positioning the Controller ....................................................................................... 2-7

2.6.2.2 Keyboard and Mouse ............................................................................................. 2-8

2.6.2.3 Display .................................................................................................................. 2-8

2.6.2.4 Speaker and Microphone Connections .................................................................... 2-8

2.6.2.5 Power Connections ................................................................................................ 2-8

2.6.3 Operating the Controller.................................................................................................... 2-8

2.6.3.1 About the Operating System ................................................................................... 2-8

2.6.3.2 Starting the controller ............................................................................................. 2-8

2.6.3.3 Stopping the controller ........................................................................................... 2-8

2.6.3.4 Mach3 License Installation ..................................................................................... 2-8

2.6.4 Machine Controller Maintenance and Configuration .......................................................... 2-9

2.6.4.1 Login and Software Installation .............................................................................. 2-9

Page 4

iiContents

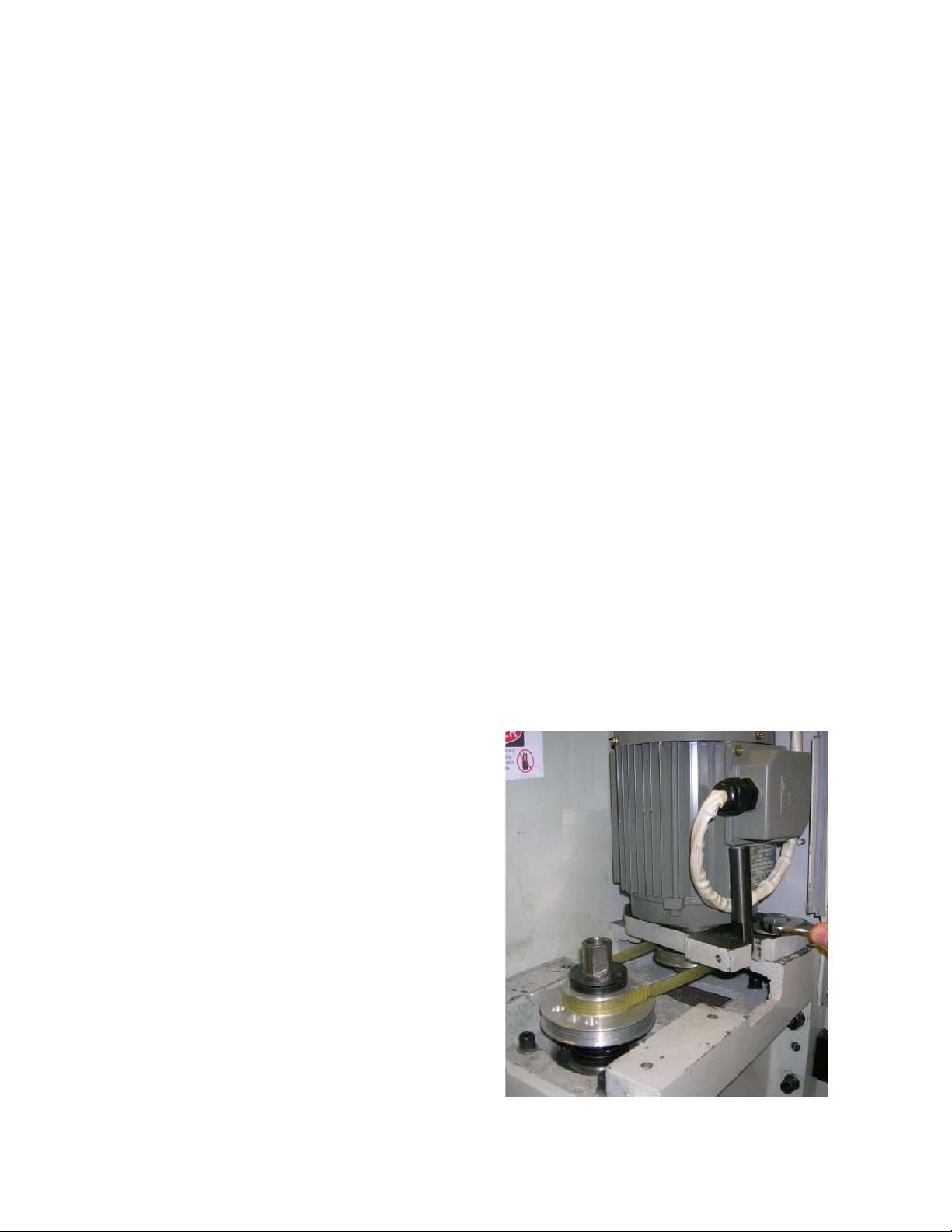

2.7 Connecting and Running the PCNC ............................................................................... 2-9

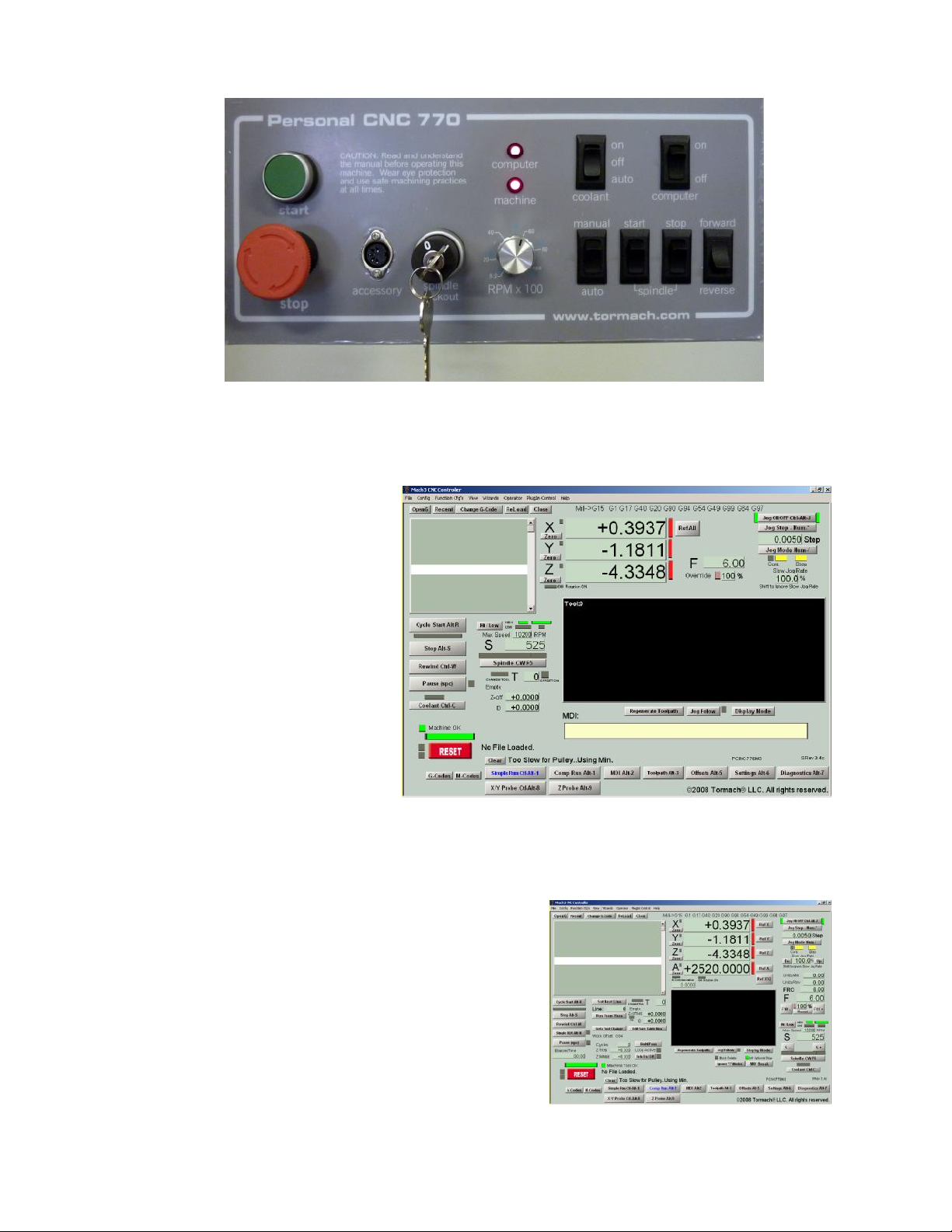

2.7.1 Main Switch and Control Panel ......................................................................................... 2-9

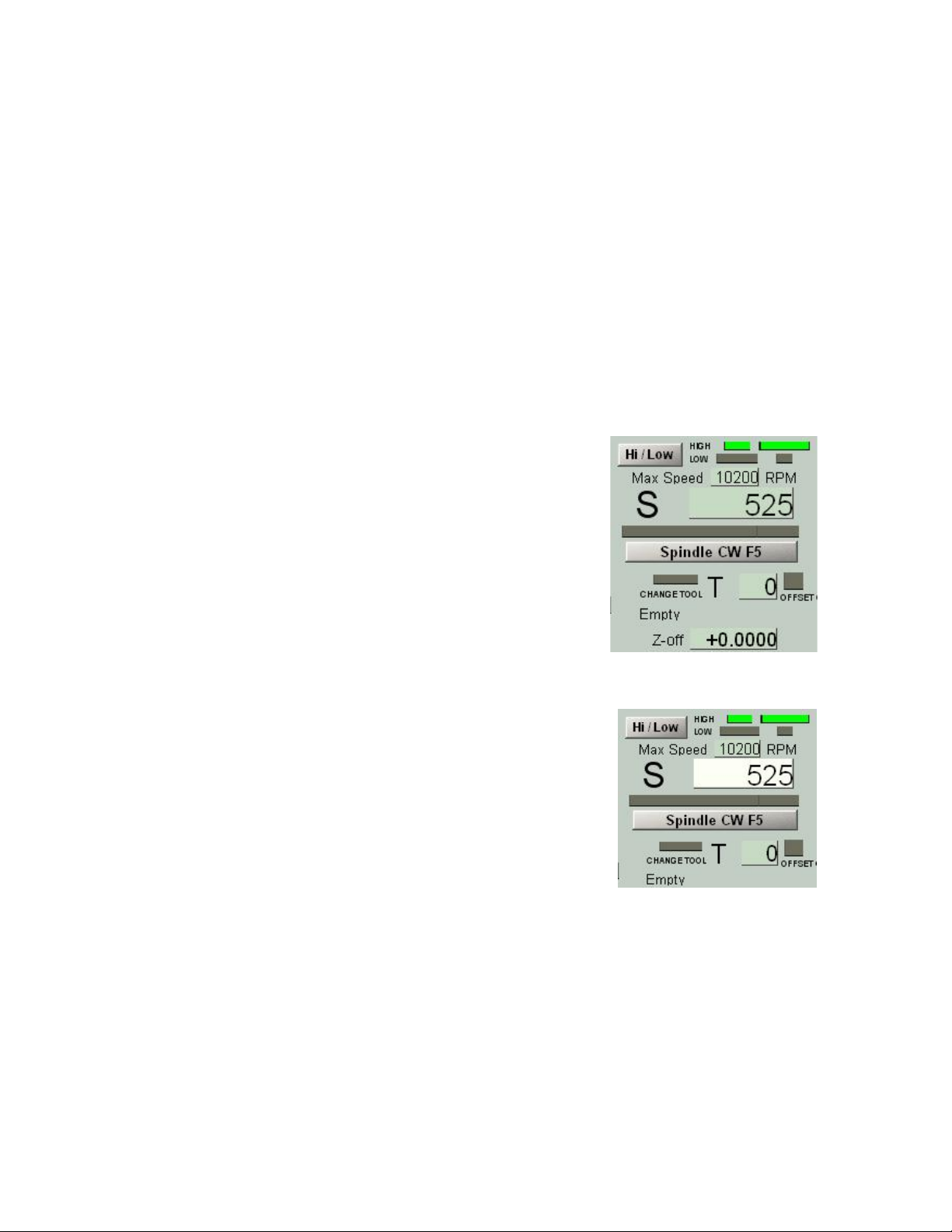

2.7.2 Changing the Spindle Speed Range ................................................................................. 2-11

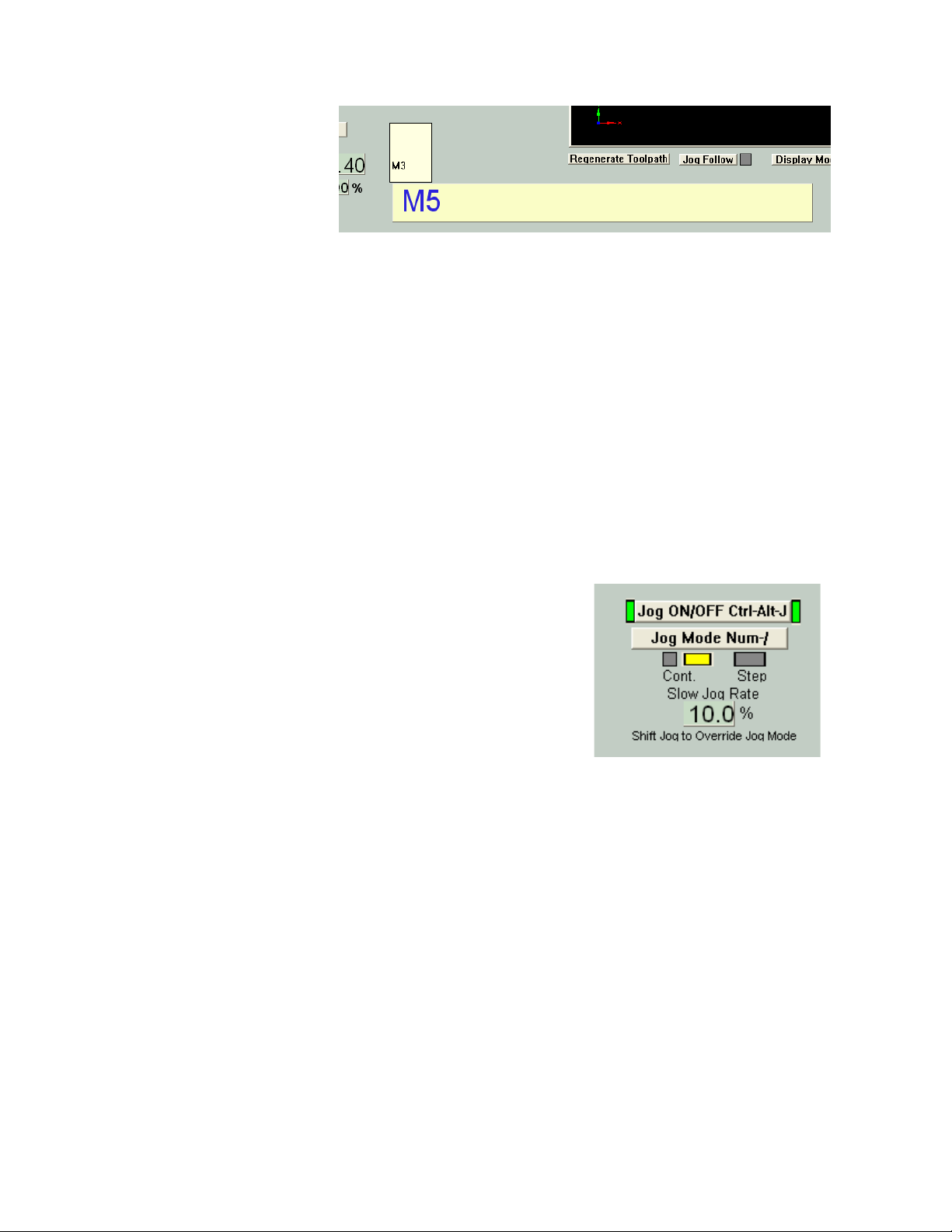

2.7.3 Computer Control of the Spindle and Coolant .................................................................. 2-12

2.7.4 MDI for Entering G- and M-code Commands .................................................................. 2-13

2.7.5 Jogging the Axes............................................................................................................. 2-13

2.8 Summary ....................................................................................................................... 2-14

3. Making Your First Part .................................................................... 3-1

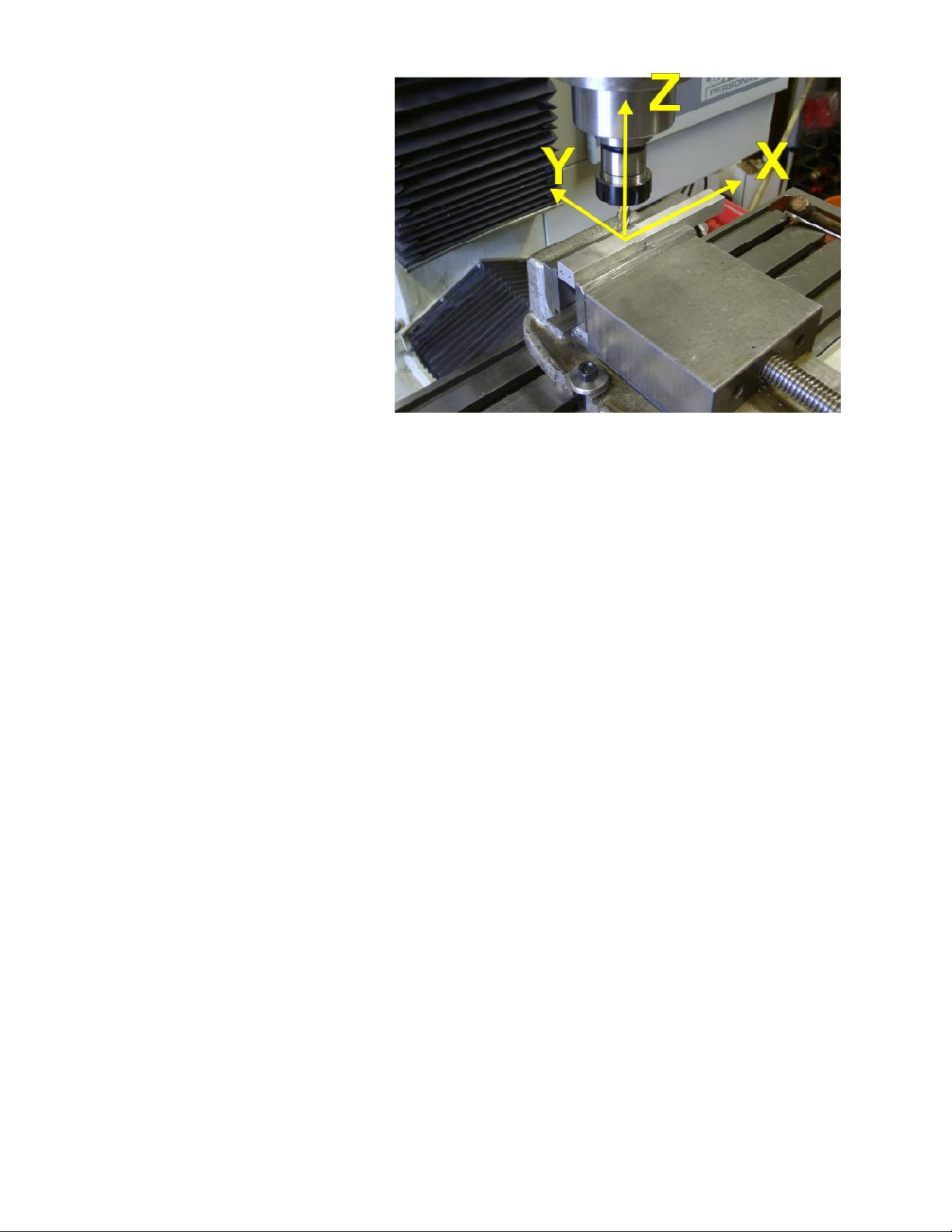

3.1 Coordinates ..................................................................................................................... 3-1

3.1.1 Referencing the Machine................................................................................................... 3-1

3.2 Loading a Demonstration Program ................................................................................ 3-2

3.3 Running the Demonstration Part-program .................................................................... 3-3

3.3.1 Part Material ..................................................................................................................... 3-3

3.3.2 Setting Work Offsets ......................................................................................................... 3-3

3.3.3 Cutting in Air.................................................................................................................... 3-4

3.3.4 Cutting the Actual Part ...................................................................................................... 3-4

3.3.5 Summary .......................................................................................................................... 3-5

4. Routes from an Idea to a Part ........................................................ 4-1

4.1 Controlling the PCNC ..................................................................................................... 4-1

4.2 Choosing the Appropriate Design Software ................................................................... 4-2

4.3 Software for CAD/CAM ................................................................................................. 4-2

4.3.1 3D CAD ........................................................................................................................... 4-3

4.3.2 2D CAD ........................................................................................................................... 4-3

4.3.3 CAM ................................................................................................................................ 4-4

4.3.4 Running the G-code .......................................................................................................... 4-6

4.3.5 CAD/CAM Systems.......................................................................................................... 4-6

4.4 Programming with Wizards ........................................................................................... 4-9

4.4.1 Machining Wizard Concept ............................................................................................... 4-9

4.4.1.1 Selecting and Running a Wizard ............................................................................. 4-9

4.4.1.2 Standard Wizard Features ....................................................................................... 4-9

4.4.1.3 G-code from a Wizard .......................................................................................... 4-10

4.4.1.4 Commercial Wizards ............................................................................................ 4-10

5. Machine Controls ............................................................................ 5-1

5.1 Machine Operation ......................................................................................................... 5-1

5.1.1 Operator’s Panel ............................................................................................................... 5-1

5.1.2 Tool Changing .................................................................................................................. 5-3

5.1.2.1 Tooling Strategy .................................................................................................... 5-3

5.1.2.2 Changing R8 Tools ................................................................................................ 5-3

5.1.2.3 Changing TTS Tools .............................................................................................. 5-4

5.1.3 Spindle Speed Ranges ....................................................................................................... 5-4

5.2 Screen Control Panels ..................................................................................................... 5-5

5.2.1 Using the Screens ............................................................................................................. 5-5

5.2.2 Families of Related Controls ............................................................................................. 5-5

5.2.2.1 Screen Switching Controls ..................................................................................... 5-5

5.2.2.2 Axis Control Family ............................................................................................... 5-6

5.2.2.3 Jogging Control Family .......................................................................................... 5-7

5.2.2.4 Spindle Speed Control Family ................................................................................ 5-8

5.2.2.5 Feed Control Family .............................................................................................. 5-9

5.2.2.6 Program Running Control Family ......................................................................... 5-10

5.2.2.7 Toolpath Control Family ...................................................................................... 5-11

Using Tormach PCNC 770 ii 32426 Rev C1-1

Page 5

Contents

5.2.2.8 File Control Family .............................................................................................. 5-12

5.2.2.9 Work Offset and Tool Table Control Family ......................................................... 5-12

5.2.2.10 MDI and Teach Control Family ............................................................................ 5-12

5.2.2.11 Loop Control Family ............................................................................................ 5-13

5.2.2.12 Modes and Mode Alarm Control Family ............................................................... 5-13

5.2.2.13 Rotational Diameter Control Family ..................................................................... 5-13

5.2.2.14 Toolchange Position Control Family..................................................................... 5-14

5.2.2.15 Inhibits and Overrides Control Family .................................................................. 5-14

5.2.2.16 Feeds and Speeds Calculator ................................................................................ 5-14

5.2.2.17 Tapping Configuration Family.............................................................................. 5-15

5.2.2.18 Misc. Settings Control Family .............................................................................. 5-15

5.3 USB Jogging Pendants .................................................................................................. 5-16

5.3.1 Jog/Shuttle Controller ..................................................................................................... 5-16

5.3.2 Keypad Pendant .............................................................................................................. 5-16

6. Using Multiple Tools ....................................................................... 6-1

6.1 Offsets and Coordinate Systems ..................................................................................... 6-1

6.2 Tool Length Offsets and the Tool Table ......................................................................... 6-1

6.2.1 Example Operation of Multiple Tools ................................................................................ 6-1

6.2.1.1 To fill the table: ..................................................................................................... 6-2

6.2.1.2 Zeroing to work height ........................................................................................... 6-3

6.2.1.3 Using tool #2 ......................................................................................................... 6-4

6.2.1.4 Using other tools .................................................................................................... 6-4

6.2.1.5 Changing to a different work-piece ......................................................................... 6-4

6.2.2 How this multiple tooling setup works ............................................................................... 6-4

6.2.3 Programming, Buttons, or Direct Entry ............................................................................. 6-5

6.3 Alternative Methods Setting Up Tools ............................................................................ 6-6

6.3.1 Measuring techniques ....................................................................................................... 6-6

6.3.1.1 “Roll-Your-Own” Gauge Method ........................................................................... 6-7

6.3.1.2 Roller Gauge Method ............................................................................................. 6-7

6.3.1.3 Adjustable Parallel Method .................................................................................... 6-8

6.3.2 Comments on Accuracy .................................................................................................... 6-8

6.3.3 Working without the tool table .......................................................................................... 6-8

6.3.3.1 Direct Entry to Axis DRO ...................................................................................... 6-9

6.3.3.2 Using the Touch Buttons ........................................................................................ 6-9

6.3.4 Tool Table with General Tooling..................................................................................... 6-10

6.3.5 Tool table with the Tool Setter ........................................................................................ 6-10

6.4 Comments on Tool Offsets ............................................................................................ 6-10

6.5 Setting X and Y Offsets ................................................................................................. 6-11

6.5.1 By eye ............................................................................................................................ 6-11

6.5.2 With a Probe ................................................................................................................... 6-11

6.5.3 Measuring Off an Edge ................................................................................................... 6-11

6.5.4 Laser Centering Techniques ............................................................................................ 6-12

6.6 How Work Offsets work ............................................................................................... 6-12

6.7 Multiple Work Origins ................................................................................................. 6-14

6.7.1 G54 Work Offset ............................................................................................................ 6-14

6.7.2 Other Work Offsets ......................................................................................................... 6-14

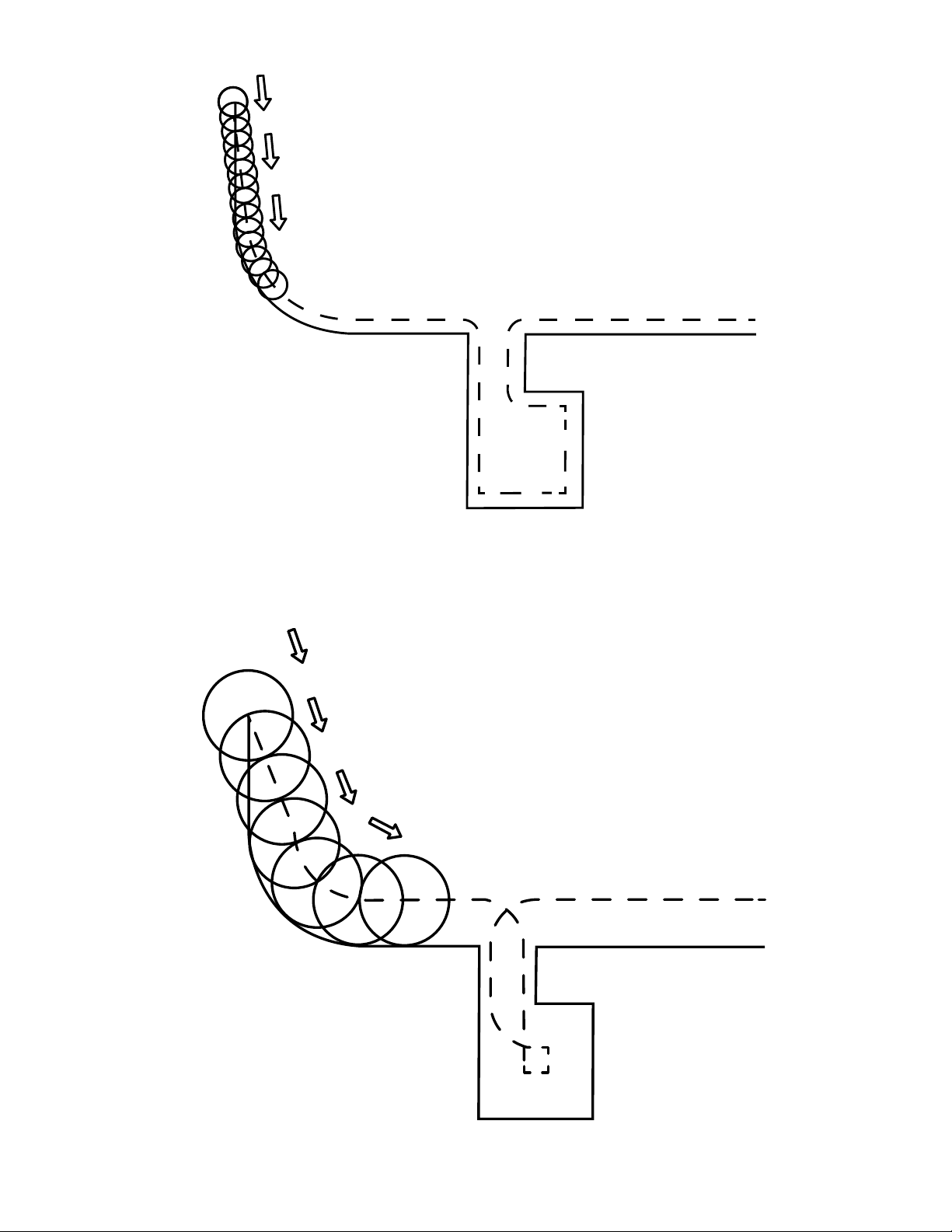

6.8 Cutter Diameter Compensation .................................................................................... 6-15

6.8.1 CAD/CAM and Wizards ................................................................................................. 6-15

6.8.2 Concepts for Cutter Diameter/Radius Compensation........................................................ 6-15

6.8.3 Caveats in the Use of Cutter Compensation ..................................................................... 6-15

6.8.4 Examples of Operation .................................................................................................... 6-16

6.8.5 Look Ahead Issues .......................................................................................................... 6-19

6.8.6 Other Restrictions ........................................................................................................... 6-21

32426 Rev C1-1 iii Using Tormach PCNC 770

Page 6

ivContents

6.8.7 Perspective on Cutter Compensation ............................................................................... 6-21

6.8.8 Resources for Debugging Cutter Compensation ............................................................... 6-21

7. Part-programming Language Reference ....................................... 7-1

7.1 Definitions ....................................................................................................................... 7-1

7.1.1 Control Software ............................................................................................................... 7-1

7.1.2 Linear Axes ...................................................................................................................... 7-1

7.1.3 Rotational Axes ................................................................................................................ 7-1

7.1.4 Scaling Input..................................................................................................................... 7-1

7.1.5 Controlled Point ................................................................................................................ 7-2

7.1.6 Coordinated Linear Motion ............................................................................................... 7-2

7.1.7 Feed Rate.......................................................................................................................... 7-2

7.1.8 Arc Motion ....................................................................................................................... 7-2

7.1.9 Coolant ............................................................................................................................. 7-3

7.1.10 Dwell................................................................................................................................ 7-3

7.1.11 Units ................................................................................................................................. 7-3

7.1.12 Current Position ................................................................................................................ 7-3

7.1.13 Selected Plane ................................................................................................................... 7-3

7.1.14 Tool Table ........................................................................................................................ 7-3

7.1.15 Path Control Modes .......................................................................................................... 7-3

7.2 Interpreter Interaction with Controls ............................................................................ 7-4

7.2.1 Feed and Speed Override controls ..................................................................................... 7-4

7.2.2 Block Delete Control ........................................................................................................ 7-4

7.2.3 Optional Program Stop Control ......................................................................................... 7-4

7.3 Tool File .......................................................................................................................... 7-4

7.4 Part-programs Language ................................................................................................ 7-4

7.4.1 Overview .......................................................................................................................... 7-4

7.4.2 Parameters ........................................................................................................................ 7-5

7.4.3 Coordinate Systems .......................................................................................................... 7-5

7.5 Formatting Code Lines (Block) ...................................................................................... 7-5

7.5.1 Line Number..................................................................................................................... 7-6

7.5.2 Subroutine Labels ............................................................................................................. 7-7

7.5.3 Word ................................................................................................................................ 7-7

7.5.3.1 Number.................................................................................................................. 7-7

7.5.3.2 Parameter Value ..................................................................................................... 7-7

7.5.3.3 Expressions and Binary Operations ........................................................................ 7-8

7.5.3.4 Unary Operation Value .......................................................................................... 7-8

7.5.4 Parameter Setting .............................................................................................................. 7-8

7.5.5 Comments and Messages .................................................................................................. 7-9

7.5.6 Item Repeats ..................................................................................................................... 7-9

7.5.7 Item Order ........................................................................................................................ 7-9

7.5.8 Commands and Machine Modes ...................................................................................... 7-10

7.6 Modal Groups ............................................................................................................... 7-10

7.7 G-codes .......................................................................................................................... 7-11

7.7.1 Rapid Linear Motion – G00............................................................................................. 7-11

7.7.2 Linear Motion at Feed Rate – G01 ................................................................................... 7-13

7.7.3 Arc at Feed Rate – G02 and G03 ..................................................................................... 7-14

7.7.3.1 Radius Format Arc ............................................................................................... 7-15

7.7.3.2 Center Format Arc ............................................................................................... 7-16

7.7.4 Dwell – G04 ................................................................................................................... 7-17

7.7.5 Coordinate System Data Tool and Work Offset Tables – G10 .......................................... 7-17

7.7.6 Clockwise/Counterclockwise Circular Pocket – G12 and G13 .......................................... 7-18

7.7.7 Exit and Enter Polar Mode – G15 and G16 ...................................................................... 7-18

7.7.8 Plane Selection – G17, G18 and G19 ............................................................................... 7-19

7.7.9 Length Units – G20 and G21 ........................................................................................... 7-19

7.7.10 Return to Home – G28 and G30 ...................................................................................... 7-20

Using Tormach PCNC 770 iv 32426 Rev C1-1

Page 7

Contents

7.7.11 Reference Axes – G28.1.................................................................................................. 7-20

7.7.12 Straight Probe – G31 ....................................................................................................... 7-20

7.7.12.1 Straight Probe Command ..................................................................................... 7-20

7.7.12.2 Using the Straight Probe Command ...................................................................... 7-21

7.7.12.3 Example Code ...................................................................................................... 7-21

7.7.13 Cutter Radius Compensation – G40, G41 and G42 .......................................................... 7-22

7.7.14 Tool Length Offsets – G43, G44 and G49 ....................................................................... 7-23

7.7.15 Scale Factors – G50 and G51 .......................................................................................... 7-23

7.7.16 Temporary Coordinate System Offset – G52 ................................................................... 7-23

7.7.17 Move in Absolute Coordinates – G53 .............................................................................. 7-24

7.7.18 Select Work Offset Coordinate System – G54 to G59 & G59 P~...................................... 7-24

7.7.19 Set Path Control Mode – G61 and G64 ............................................................................ 7-25

7.7.20 Coordinate system rotation – G68 and G69 ...................................................................... 7-25

7.7.21 Canned Cycle – High Speed Peck Drill – G73 ................................................................. 7-25

7.7.22 Cancel Modal Motion – G80 ........................................................................................... 7-26

7.7.23 Canned Cycles – G81 to G89 .......................................................................................... 7-26

7.7.23.1 Preliminary and In-Between Motion ..................................................................... 7-27

7.7.23.2 G81 Cycle ............................................................................................................ 7-28

7.7.23.3 G82 Cycle ............................................................................................................ 7-29

7.7.23.4 G83 Cycle ............................................................................................................ 7-29

7.7.23.5 G85 Cycle ............................................................................................................ 7-30

7.7.23.6 G86 Cycle ............................................................................................................ 7-30

7.7.23.7 G88 Cycle ............................................................................................................ 7-30

7.7.23.8 G89 Cycle ............................................................................................................ 7-30

7.7.24 Distance Mode – G90 and G91 ........................................................................................ 7-30

7.7.25 G92 Offsets – G92, G92.1, G92.2 and G92.3 ................................................................... 7-31

7.7.26 Feed Rate Mode – G93, G94 and G95 ............................................................................. 7-31

7.7.27 Canned Cycle Return Level – G98 and G99 .................................................................... 7-32

7.8 Built-in M-codes ........................................................................................................... 7-32

7.8.1 Program Stopping and Ending – M0, M1, M2 and M30 ................................................... 7-32

7.8.2 Spindle Control – M3, M4 and M5 .................................................................................. 7-33

7.8.3 Tool change – M6 ........................................................................................................... 7-33

7.8.4 Coolant Control – M7, M8 and M9 ................................................................................. 7-34

7.8.5 Re-run from First Line – M47 ......................................................................................... 7-34

7.8.6 Override Control – M48 and M49 ................................................................................... 7-34

7.8.7 Call Subroutine – M98 .................................................................................................... 7-34

7.8.8 Return from Subroutine – M99 ........................................................................................ 7-34

7.9 Application Defined M-codes ........................................................................................ 7-34

7.9.1 Self-reversing Tapping Cycles......................................................................................... 7-34

7.9.2 Goto Toolchange Position – M998 .................................................................................. 7-35

7.9.3 User Defined M-codes .................................................................................................... 7-35

7.10 Other Input Codes ........................................................................................................ 7-35

7.10.1 Feed Rate – F .................................................................................................................. 7-35

7.10.2 Spindle Speed – S ........................................................................................................... 7-36

7.10.3 Select Tool – T ............................................................................................................... 7-36

7.11 Order of Execution ....................................................................................................... 7-36

7.12 Error Handling ............................................................................................................. 7-37

8. Machine Upgrades and Configuration........................................... 8-1

8.1 Fourth Axis – Rotary Table ............................................................................................ 8-1

8.1.1 Installing the Electronics ................................................................................................... 8-1

8.1.2 Utilizing the Fourth Axis ................................................................................................... 8-1

8.1.2.1 Referencing and Zeroing the Fourth Axis ............................................................... 8-1

8.1.2.2 Diameter Compensation Feature ............................................................................. 8-1

8.1.3 Fourth Axis Applications .................................................................................................. 8-1

8.1.3.1 Engraving on a Periphery of a Cylinder .................................................................. 8-2

32426 Rev C1-1 v Using Tormach PCNC 770

Page 8

viContents

8.1.3.2 Gear Cutting .......................................................................................................... 8-3

8.2 Probes (Active and Passive) and Tool Setters ................................................................. 8-3

8.2.1 Introduction to Uses of Probes and Tool Setters ................................................................. 8-3

8.2.2 Probing for Work/Tool Setting .......................................................................................... 8-4

8.2.2.1 Simple X/Y Probing ............................................................................................... 8-5

8.2.2.2 Z Probing ............................................................................................................... 8-7

8.2.2.3 Comprehensive X/Y Probing .................................................................................. 8-9

8.2.2.4 Probe Calibration ................................................................................................. 8-12

8.2.3 Digitizing parts from a model or for reverse engineering .................................................. 8-13

8.2.4 The Probe Electrical Interface ......................................................................................... 8-13

8.2.5 Other .............................................................................................................................. 8-14

8.3 Auto-reverse tapping .................................................................................................... 8-14

9. Specifications, Customization and Troubleshooting ................... 9-1

9.1 Intended Use Statement .................................................................................................. 9-1

9.2 Support............................................................................................................................ 9-1

• This manual – ALWAYS the first place to check!! ................................................. 9-1

• Related documents found at: http://www.tormach.com/documents.html .................. 9-1

• Our website at: www.tormach.com ......................................................................... 9-1

• Email to: info@tormach.com .................................................................................. 9-1

• Telephone Tormach at: 608-849-8381 .................................................................... 9-1

• Fax Tormach at: 209-885-4534............................................................................... 9-1

9.3 Outside of the Scope of Intended Use ............................................................................. 9-1

9.4 Specifications................................................................................................................... 9-2

9.4.1 Mechanical ....................................................................................................................... 9-2

9.4.2 Electrical .......................................................................................................................... 9-2

9.4.3 System .............................................................................................................................. 9-3

9.4.4 Options ............................................................................................................................. 9-3

9.5 Maintenance .................................................................................................................... 9-3

9.5.1 Foreword – Understanding Machine Design ...................................................................... 9-3

9.5.1.1 Machine Stiffness................................................................................................... 9-3

9.5.1.2 Backlash, Friction, and Lost Motion ....................................................................... 9-4

9.5.1.3 Factors Combine .................................................................................................... 9-4

9.5.1.4 Adjusting Geometry ............................................................................................... 9-4

9.5.1.5 Achieving Accuracy in Machining.......................................................................... 9-5

9.5.2 Protecting from Rust ......................................................................................................... 9-5

9.5.3 Gibs, Dovetail Slideways and Lubrication ......................................................................... 9-5

9.5.4 Way Covers ...................................................................................................................... 9-6

9.5.5 Axis Gib Adjustment ........................................................................................................ 9-6

9.5.6 Adjusting Ballscrew Preload ............................................................................................. 9-8

9.5.6.1 Understanding Preloaded Angular Contact Bearings ............................................... 9-9

9.5.6.2 Making the Adjustment .......................................................................................... 9-9

9.5.7 Adjusting Mating Surfaces .............................................................................................. 9-11

9.5.8 Speed Calibration............................................................................................................ 9-11

9.5.9 Using a Non-standard Printer Port ................................................................................... 9-13

9.5.10 Defining Your Own Sizes for Step-mode Jogging ............................................................ 9-14

9.5.11 Defining Probe Type ....................................................................................................... 9-15

9.5.12 Enabling 4th axis homing ................................................................................................ 9-15

9.5.13 Configuring to start in Metric units .................................................................................. 9-15

9.6 Troubleshooting ............................................................................................................ 9-16

9.6.1 Overview ........................................................................................................................ 9-16

9.6.2 Philosophy of Troubleshooting ........................................................................................ 9-16

9.6.3 Tips and Tools for Troubleshooting (Equipment and Procedures)..................................... 9-19

9.6.3.1 Safety .................................................................................................................. 9-19

9.6.3.2 Tip on Computer Diagnostics ............................................................................... 9-19

Using Tormach PCNC 770 vi 32426 Rev C1-1

Page 9

Contents

9.6.3.3 Tools ................................................................................................................... 9-20

9.6.3.4 Using the digital multi meter for electrical tests .................................................... 9-20

9.6.3.5 Contacting Technical Support............................................................................... 9-21

9.6.4 Frequently Found Problems (Repeat Offenders) .............................................................. 9-21

9.6.4.1 Loose Wires ......................................................................................................... 9-21

9.6.4.2 Wire Hairs ........................................................................................................... 9-22

9.6.4.3 Poor Cable Connections ....................................................................................... 9-22

9.6.4.4 Software Restart ................................................................................................... 9-22

9.6.4.5 Sensors (on the PCNC770 the End of Travel Sensors aka Limit Switches) ............ 9-22

9.6.4.6 Flaky Computer ................................................................................................... 9-22

9.6.4.7 Control Software license not installed ................................................................... 9-22

9.6.4.8 Unexplained stop or limit switch error while running ............................................ 9-23

9.6.5 Which sub-system should I troubleshoot .......................................................................... 9-23

9.6.5.1 Computer and Coolant Power Distribution Sub-system ......................................... 9-24

9.6.5.2 Control Power Sub-system Overview ................................................................... 9-26

9.6.5.3 9.6.5.3 Computer Control Communication Sub-Section ........................................ 9-29

9.6.5.4 Axes Drive Sub-system ........................................................................................ 9-31

9.6.5.5 Spindle Drive Sub-system .................................................................................... 9-46

9.7 Mechanical maintenance.............................................................................................. 9-56

9.8 Electrical maintenance .................................................................................................. 9-56

9.9 Preparation for Transport ............................................................................................ 9-57

9.10 Disassembly for Transport ........................................................................................... 9-57

10. Appendices .................................................................................... 10-1

10.1 Appendix 1 – Not Used.................................................................................................. 10-1

10.2 Appendix 2 – Exploded Parts Views ............................................................................. 10-1

10.3 Appendix 3 - Use of a Standard PC to control PCNC ................................................ 10-14

10.3.1 Choice of computer ....................................................................................................... 10-14

10.3.2 Optimizing the Windows Installation............................................................................. 10-15

10.3.3 Installing the Control Software ...................................................................................... 10-15

10.3.3.1 Installing .............................................................................................................10-15

10.3.3.2 Vital Re-boot ......................................................................................................10-16

10.3.3.3 Testing the Installation ........................................................................................10-16

10.3.3.4 DriverTest After a Software Crash .......................................................................10-17

10.3.3.5 Manual Driver Installation and Un-installation.....................................................10-17

10.3.4 Optimization of Windows XP ....................................................................................... 10-18

10.3.4.1 Remove Unnecessary Services and Startup Programs...........................................10-19

10.3.4.2 Disable Power Management ................................................................................10-19

10.3.4.3 Disable sound card ..............................................................................................10-19

10.3.4.4 Disable Automatic Updates .................................................................................10-20

10.3.4.5 Set Computer to Standard PC not ACPI PC .........................................................10-20

10.4 Revision history ........................................................................................................... 10-21

11. Index .................................................................................................. 23

32426 Rev C1-1 vii Using Tormach PCNC 770

Page 10

Page 11

1. Preface

1.1 Safety

Any machine tool is potentially dangerous. Computer controlled machines are potentially more

dangerous than manual ones because, for example, a computer is quite prepared to plunge a 3"

diameter facing cutter at 50 inches per minute into a block of high-carbon steel or to mill the

clamps off your table.

1.1.1 Electrical Safety

The PCNC 770 can deliver sufficient force to break brittle tools, to crush bones and to tear

flesh.

This manual tries to give you guidance on safety precautions and techniques but because we do

not know the details of your workshop or other local conditions we can accept no responsibility

for the performance of the machine or any damage or injury caused by its use. It is your

responsibility to ensure that you understand the implications of what you are doing and to

comply with any legislation and codes of practice applicable to your country or state.

Power Input: The PCNC 770 supply is 115 VAC. A circuit rated at 20 amps is required. This

power supply can provide lethal electrical shocks. The power input should be unplugged before

working in the electrical cabinet.

Preface

Grounding: The power input must be grounded. During installation it is not enough to assume

that the ground line of a wall outlet is properly grounded. Check continuity between the

machine frame and true earth ground (water pipe or similar) to ensure a good ground

connection.

A Ground Fault Interrupt or GFI (i.e., Residual Current Circuit Breaker or RCCB in Europe)

outlet is not recommended as the filters in the spindle drive can give leakage currents sufficient

to trip a normal 30 mA breaker.

Electrical Panel: NEVER operate the machine tool with the cabinet door open. NEVER allow

a coolant pump to operate with the cabinet door open. DO NOT allow the coolant system to

flow coolant directly at the cabinet door seal or on the operator console controls. Neither the

cabinet door seal nor the electrical controls are sealed against liquids.

Retained Electrical Power: Electronic devices within the electrical cabinet may retain

dangerous electrical voltages after the power has been removed.

Electrical Service: Certain service and troubleshooting operations require access to the

electrical cabinet while the electrical power is on. Only qualified electrical technicians should

perform such operations.

1.1.2 General Operating Safety

Safe operation of the machine depends on its proper use and the precautions taken by each

operator.

Read and understand this manual. Be certain every operator understands the operation and

safety requirements of this machine before operating the machine.

Always wear safety glasses and safety shoes.

Always stop the spindle and check to ensure the CNC control is in the stop mode before

changing or adjusting the belt/pulley position, tool or work piece.

32426 Rev C1-1 1-1 Using Tormach PCNC 770

Page 12

Preface

Never wear rings, watches, gloves, long sleeves, neckties, jewelry or other loose items when

operating or working around the machine. Long hair should be bound or kept under a hat.

Use adequate safeguarding around the operating envelope. It is the responsibility of the

employer to provide and ensure point of operation safeguarding per OSHA 1910.212 – Milling

Machine.

1.1.3

1.1.4

Safety Publications

Tormach recommends the following publications for assistance in enhancing the safe use of

this machine.

• Safety Requirements for The Construction, Care and Use of Drilling, Milling and Boring

Machines (ANSI B11.8-1983). Available from The American National Standards

Institute, 1430 Broadway, New York, New York 10018.

• Concepts and Techniques of Machine Safeguarding (OSHA Publication Number 3067).

Available from The Publication Office – O.S.H.A., U.S. Department of Labor, 200

Constitution Avenue, NW, Washington, DC 20210.

Safety Precautions

1. Do not run this machine without knowing the function of every control key, button, knob or

handle. Refer to the manual or contact Tormach if any function is not understood.

2. Protect your eyes. Wear approved safety glasses (with side shields) at all times. You should

never use compressed air to remove chips or to clean the machine. An air blast will often

launch a metal chip into a place it should not be.

3. Ear protection should be used on any operations that exceed sound levels of 85dBa.

4. Avoid moving parts. Before operating this machine remove all jewellery including watches

and rings, neckties and any loose-fitting clothing.

5. Keep your hair away from moving parts.

6. Take off gloves before you operate the machine. Gloves are easily caught in moving parts

or cutting tools.

7. Never operate with unbalanced tooling or spindle fixtures.

8. Remove all tools (wrenches, chuck keys, etc.) from the spindle and machine surface before

you begin. Loose items can become dangerous flying projectiles.

9. Use adequate work clamping. Do not allow your work piece to become a projectile.

10. Never operate a milling machine after consuming alcoholic beverages or taking strong

medication.

11. Protect your hands. Stop the machine spindle and ensure that the computer control is

stopped before you:

• Change tools;

• Change parts or adjust the work piece;

• Change the belt/pulley position;

• Clear away chips, oil or coolant – always use a chip scraper or brush;

• Make an adjustment to the part, fixture, coolant nozzle or take measurements;

• Remove protective shields or safeguards – do not reach for the part, tool or fixture around

a guard.

12. Keep work area well lit. Ask for additional light if needed.

13. Keep the computer area clear of clutter. Recognize that machine motion can occur when

certain keys are pressed. Objects falling on the keyboard can result in unexpected motion.

14. Avoid getting pinched in places where the table, saddle or spindle head create “pinch

points” while in motion.

Using Tormach PCNC 770 1-2 32426 Rev C1-1

Page 13

15. Securely clamp the work piece in a vise, on the table or in the fixture. Use proper holding

clamping attachments and position them clear of the toolpath. Be aware of larger pieces that

will be cut free during operations – loose parts can become projectiles.

16. Always use proper feeds and speeds, as well as depth and width of cut, to prevent tool

breakage.

17. Use proper cutting tools for the job.

18. Do not use dull or damaged cutting tools. They break easily and become dangerous

projectiles. Never use longer or larger tools than necessary.

19. Chips and dust from certain materials (e.g., magnesium) can be flammable. Fine dust from

normally non-flammable materials can be flammable or even explosive.

20. Chips and dust from certain materials can be toxic. Vapours from certain overheated

materials can be toxic. Always check a Materials Safety Data Sheet (MSDS) of suspect

materials. Refuse machining work requests of unknown materials.

21. If you are in any doubt you must seek guidance from a professionally qualified expert

rather than risk injury to yourself or to others.

1.2 Personal CNC Concept

The PCNC 770 is a machine tool intended to make CNC machining more personal. As with the

evolution of personal computers, the evolution of personal CNC alters the paradigm of what a

machine tool is about. We aim for a machine tool so affordable that anyone can have one.

We feel that the work of engineers, inventors, technicians, hobbyists, educators and others will

be enhanced when they have access to CNC machinery. In education, each student can run his

own machine instead of waiting in line when the machine tool costs less than 20% of a small

machining center. In R & D, turn-around on prototype design takes minutes instead of days

when a machine is “at the ready” and on site. In general engineering, designs sent to the

production machine shop are improved when the design engineer has been more involved in the

prototype creation.

Preface

The PCNC offers the precision of a production machine but with cost/performance optimized

for short run operation.

1.3 Performance Expectations

1.3.1 Cutting Ability

The machine is capable of cutting most materials at or near their recommended feeds and

speeds. For example, for fast metal removal on 6061 aluminium we will run a 1/2" diameter 2

flute cutter at around 18 IPM (inches per minute) and 3000 RPM, using a full 1/2" depth of cut.;

that is a pretty good volumetric rate of metal removal so it is essential to clear chips with a

flood coolant. We will run smaller cutters when we are not trying to remove large amounts in a

hurry. For most aluminium work we use 3/8". The example above, using a 1/2" cutter, results in a

surface speed of 390 SFM (surface feed per minute), a 1/4" cutter needs 6000 RPM to get the

same surface speed, well within the performance envelope of the machine.

Cutting steel and iron needs a lower volumetric rate, thus slower feed and speed. The PCNC

will run best using smaller cutters when working with tougher materials. For example, the

general machining recommendation for some oil hardening steels is 30 SFM. Doing this with a

¾" end mill, the surface speed calculation indicates 150 RPM, but that is below the minimum

spindle speed of the PCNC 770 and certainly at minimum speed limited power is available. By

switching to a 1/4" end mill the recommended spindle speed becomes 460 RPM, well within the

capability of the PCNC. By keeping close to general machining recommendations your tools

will last longer and you will have a better cut.

32426 Rev C1-1 1-3 Using Tormach PCNC 770

Page 14

Preface

1.3.2 Understanding Accuracy

While a machine tool may seem absolutely rigid, the truth of the matter is that everything has

some elasticity. Related to elasticity is the compressibility of components such as ball nuts and

bearings. Preloading of bearings and ballscrews can remove the physical open space between

moving parts, but the technique cannot eliminate compressibility. The key to achieving

maximum accuracy is understanding and controlling the magnitude and direction of forces.

Maximum accuracy is achieved when the forces are minimized, as occurs in a finishing cut.

Maximum repeatability is achieved when the forces are repeatable, both in magnitude and

direction.

1.3.3 Resolution, Accuracy and Repeatability of the PCNC

The minimum discrete position move is 0.0001", this is the resolution of motion. Machine

accuracy is closely related to ballscrew accuracy. Our ballscrews are accurate to 0.0006" per

foot, but considering all the other factors that come into play, we prefer to keep accuracy

expectations to 0.0013" per foot. Repeatability will be better than 0.001" per foot.

Machining is a mix of science, skill and art. The caveat in stating accuracy and repeatability is

that these factors depend on the techniques used by the machinist. A skilled machinist can often

deliver accuracy that exceeds the accuracy specified by the machine builder, while an

inexperienced machinist may have difficulty delivering the expected accuracy. With this

understanding, we cannot tell you what accuracy you will be able to achieve in your own work.

Nevertheless, the accuracy specified by a machine builder remains an important reference

point.

1.4 Scope and Intellectual Property

This document is intended to provide sufficient information and detail to allow you to install,

setup and use your Tormach mill. It assumes that you have appropriate experience and/or

access to training for any Computer Aided Design/Manufacture software that you intend to use

with the machine. This document also assumes familiarity with typical Microsoft Windows

applications programs as the control software for the PCNC runs under the Windows operating

system.

Tormach LLC is dedicated to continual improvement of its products, so suggestions for

enhancements, corrections and clarifications will be gratefully received.

Tormach LLC, Art Fenerty and John Prentice assert their right to be identified as the authors of

this work. This work is copyrighted by Tormach LLC. The right to make copies of this manual

is granted solely for the purpose of training courses related to, evaluation of and/or use of the

PCNC. It is not permitted, under this right, for third parties to charge for copies of this manual

beyond the cost of printing.

Every effort has been made to make this manual as complete and as accurate as possible but no

warranty or fitness is claimed or implied. All information provided is on an “as is” basis. The

authors, publisher, and Tormach LLC shall not have any liability for, or responsibility to, any

person or entity for any reason for any loss or damage arising from the information contained in

this manual.

Tormach, PCNC1100 Personal CNC, PCNC770 Personal CNC, and Tormach Tooling System

are registered trademarks of Tormach. Windows XP and Windows 7 are registered trademarks

of Microsoft Corporation. If other trademarks are used in this manual, but not acknowledged,

please notify Tormach LLC so this can be remedied in subsequent editions.

Tormach milling machines and accessories are covered by one or more of the following U.S.

Patents: 7,386,362, D606,568, D612,406, D621,859 and Patent(s) Pending.

Using Tormach PCNC 770 1-4 32426 Rev C1-1

Page 15

1.5 Nomenclature

This manual uses the following typographical nomenclature:

Software control

Refers to a Control Software “soft” control. (i.e., a Windows control on the PC screen).

Hardware Control

Refers to a physical button or switch on the Operator’s Panel of the machine.

G-code (e.g., G01X34.8)

Used to show G-code programs.

Key name (e.g., Enter)

Tells you to press the indicated key.

Preface

32426 Rev C1-1 1-5 Using Tormach PCNC 770

Page 16

Page 17

2. Preparation

This chapter describes the work required to unpack and to commission the

hardware and software of the PCNC.

It contains a lot of detail but can be completed in one or two hours by a person

familiar with CNC machines. Enough detail is given here so that a beginner

should be successful but some users may prefer to arrange for a machine tool

expert to do this work.

If your machine has already been set-up then you can skip this chapter

2.1 Planning for Your PCNC

2.1.1 Electrical Connection

The PCNC 770 is shipped with a 3-wire cord and no electrical plug. There are several different

NEMA (National Electric Manufacturers Association) and non-NEMA plug patterns that can be

used. Straight blade patterns are common in household use; twist-lock patterns are more

common in industrial locations. Power required is 115 to 130 VAC, 50 or 60 Hz. Continuous

current is below 15 amps, but a 20 amp breaker or slow blow fuse is recommended.

Preparation

The power input must be grounded. During installation it is not enough to assume that the

ground line of a wall outlet is properly grounded. Check continuity between the machine frame

and true earth ground (water pipe or similar) to ensure a good ground connection.

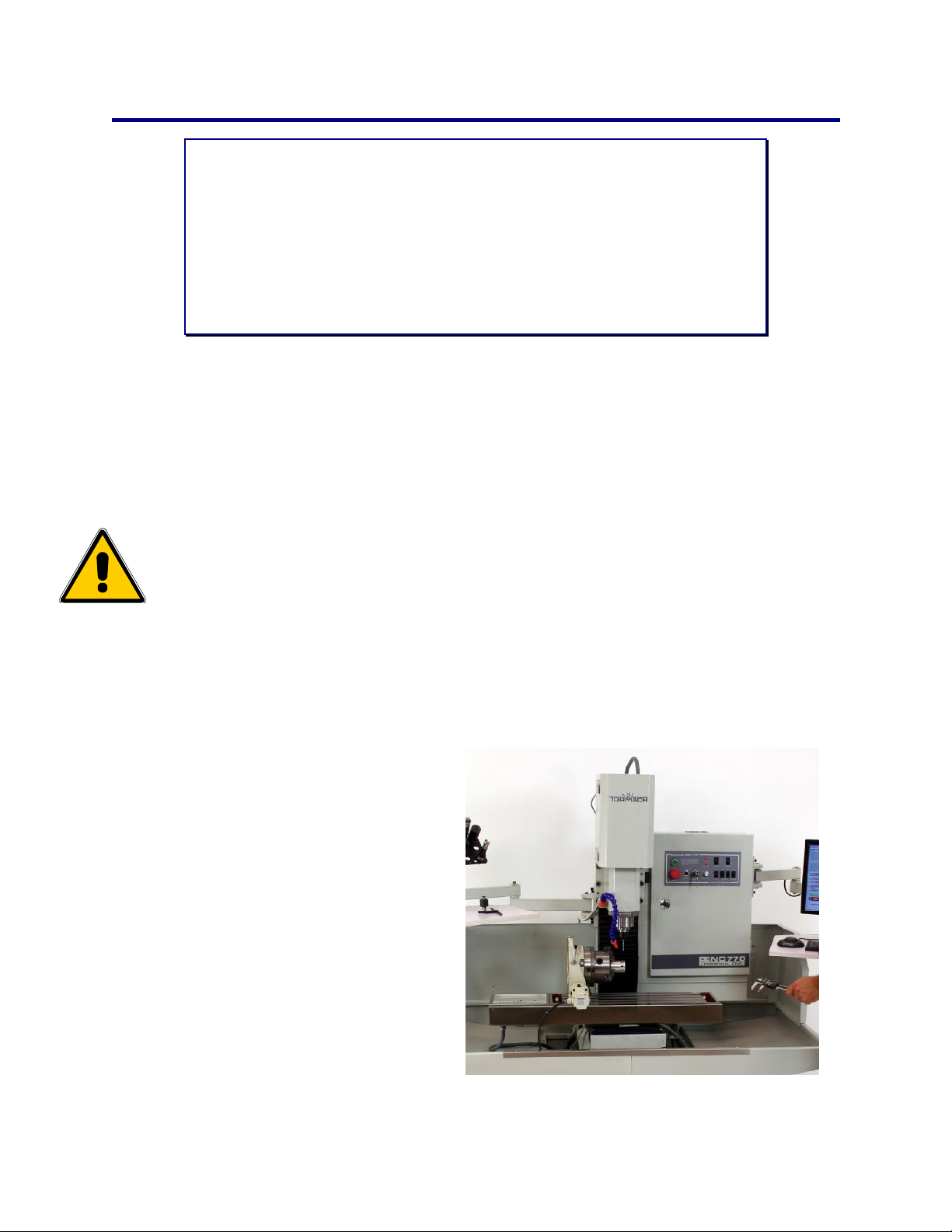

2.1.2 Location and Mounting

People experienced with CNC machining will undoubtedly have ideas as to how they want to

setup their PCNC (figure 2.1). While the machine can be configured in many different ways,

there are a few limitations. Many fully enclosed vertical machining centers incorporate high

volume coolant systems that make the inside of the machine look like the inside of a

dishwasher. The PCNC electrical

cabinet and operator console should

not be exposed to such conditions.

Additionally, there should never be

an enclosure or accessory that limits

access to the emergency stop. Please

keep these limitations in mind when

you plan your configuration.

If your prior experience is limited to

manual mills then keep in mind that,

as CNC dramatically extends your

machining capabilities, it will also

change the way you cut metal. When

your metal cutting is done by turning

handles on a manual mill your

operations will generally be limited to

cleaning up a surface, drilling a hole

pattern or cutting to a dimensional

outline. With manual milling many

people are accustom to dry cutting, clearing chips with a small brush as they go.

Figure 2.1 – An example mounting on stand

32426 Rev C1-1 2-1 Using Tormach PCNC 770

Page 18

Preparation

With CNC you have a whole new world open to you. In many cases you may turn the majority

of the stock into chips, cutting a shape out of a solid block of metal the way Michelangelo

would cut a sculpture from a block of marble. Unless you are limiting yourself to cutting cast

iron, wood, printed circuit boards or certain other materials, you will probably want a coolant

system on your machine. Mist coolant can be effective for keeping your cutting tools cool, but

it does little for clearing chips. Flood coolant will cool the cutting tools while clearing chips,

but is more challenging to contain. We strongly recommend that you plan your setup with a full

motion tray and splash guards, such that coolant will be captured as it overflows the machine

table within the full operating envelope of the machine.

Another reason to use a full motion tray is to reserve the space that will be required when the

machine moves. If you use a narrow drip tray or none at all, you should plan for full machine

motion plus some human space when you place the machine in your workshop. You do not

want to locate it where you can create crush points between the machine table and a wall. When

in operation, the X, Y and Z motions will not stop when they hit something. The machine will

move with hundreds of pounds of force, enough to punch through a wall, tip over the machine

or crush someone in the way.

Machine safety is the responsibility of the operator. This includes all aspects of safety: setup,

location, operation, security and all other factors that involve safety.

The PCNC 770 requires a minimum plan area of 60" wide by 40" deep. This gives clearance for

the full motion of the table and for minimal access for cabling etc. The overall height required

is 73" assuming that it is installed with the table at a working height of 36".

Tormach offers a suitable heavy duty stand with built in storage for tooling and the control

computer. It is also available with a coolant sub-system.

You should choose a well lit location and provide any additional task-lighting to make it easy to

setup work on the table.

Over time you will find that you accumulate a range of tools and tool holders so you should

allocate space for storage of these near the machine. A rack with numbered slots is convenient

to avoid errors when doing tool changes during a job.

5

USB jogging

pendant

4

LCD

Screen

Keyboard

6

3

2

1

Personal

computer

Personal

computer

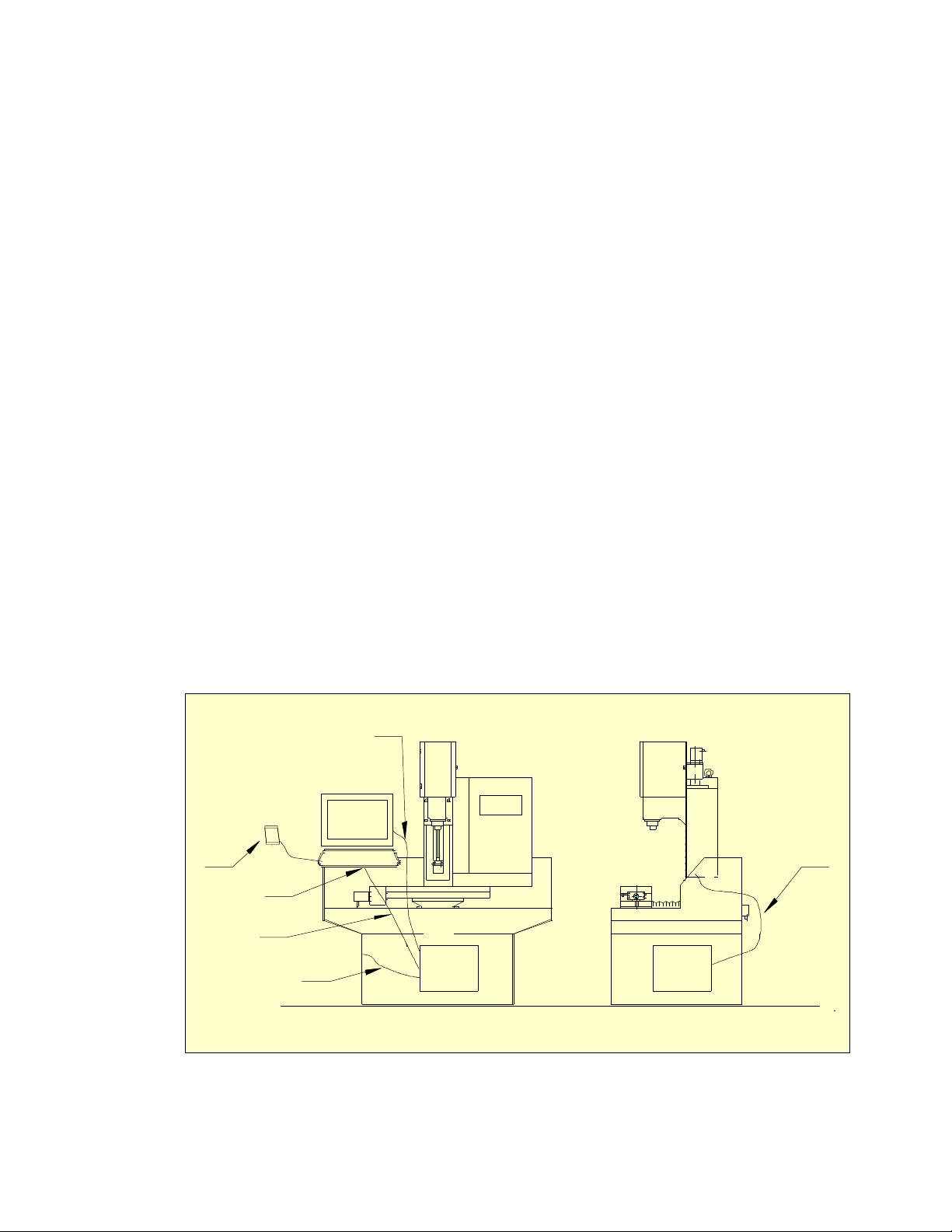

Figure 2.2 Computor and Display

2.1.3 Computer Mounting Arrangement

Keep the computer in a clean location, preferably inside the stand of the milling machine.

Resist the temptation to expose the computer in any way. Providing access to floppy disks, CDs

Using Tormach PCNC 770 2-2 32426 Rev C1-1

Page 19

Preparation

or direct computer controls will also open the computer to contamination and risk. Tormach

offers accessories that will allow you to operate the system without exposing your computer.

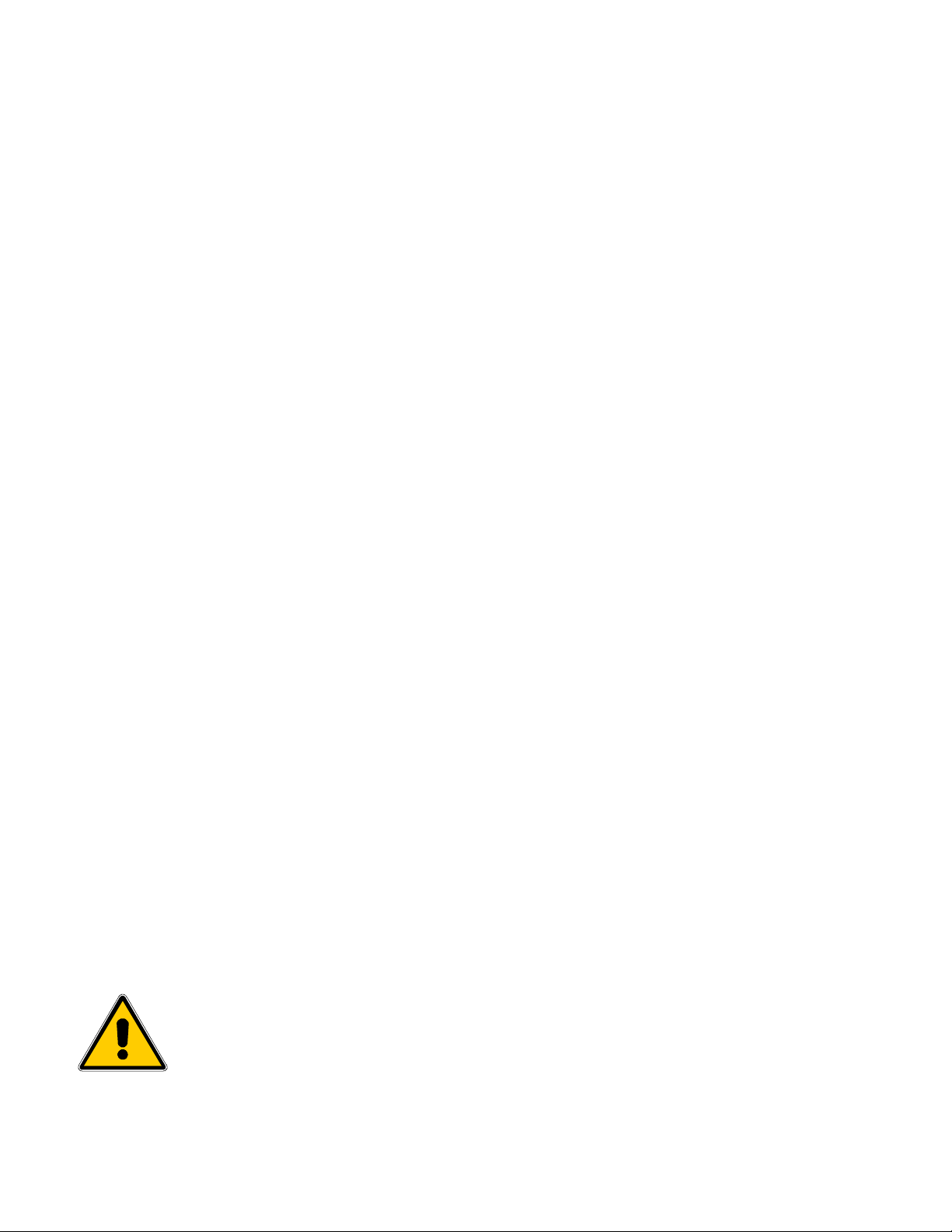

While there are many possible configurations for your machine control computer, we suggest

the following (figure 2.2):

1. USB bulkhead (panel mount) cable. This allows you to mount a USB socket directly on the

side of the cabinet. You can use a standard USB flash drive to transfer G-code programs

and other files to the machine controller. This is Tormach PN 30278 (USB bulkhead mount

cable – 3' Version 2.0 USB A to A extension M-F).

2. USB extension cable, extending the short cable normally found on keyboards and other

USB devices. Tormach PN 30279 (10FT USB 2.0 A to A Male/Female Extension Cable).

3. USB mini-keyboard. This is about the size of most laptop keyboards. The keyboard

includes a key which will power down the computer, allowing a convenient way to

shutdown the system. This is Tormach PN 31371 (Mini Keyboard). The keyboard can be

protected against coolant or chips by addition of Keyboard Cover PN 31384.

4. A Tormach USB jogging pendent is a very useful accessory for jogging, manual operations

and machine setup. Two options are available: a key based pendant (Tormach PN 30214

Pendent, 10 key USB keypad) and a jog/shuttle controller pendant that gives very fine

control of jogging speeds and distances. (Tormach PN 30616 Jog/Shuttle Controller).

5. LCD monitor signal cables are normally too short. Most inexpensive VGA signal extension

cables create serious signal degradation. This is particularly true with Super VGA screen

resolutions. Tormach PN 30280 (10FT SVGA Super VGA M/F Monitor Cable w/ ferrites)

is designed to extend Super VGA signals without degradation.

6. This is simply the AC power cord of the computer. The Computer switch on the operator

console controls a convenience outlet on the bottom of the machine control cabinet. If you

set the BIOS/CMOS configuration in your computer to start the computer when it sees AC

power then the console switch will allow you to start the computer from the console. You

should not shut off the computer from this switch due to issues with the Microsoft

Windows operating system, but you can turn the computer on from the keyboard/screen

controls.

There are several important points to bear in mind when using devices interfaced with USB

(Universal Serial Bus).

Do not attempt to run a G-code program that is stored on a USB drive (often called pen drives,

memory stocks, flash drives). Copy your G-code files into a folder on the hard drive (usually C:

of the control computer. Remove the USB drive after making the copy.

Do not use external USB hubs or devices like monitors or keyboards containing hubs.

USB devices can be affected by electrical noise on the computer mains power line. Devices

with large motors like compressors and ‘shop vacuum cleaners should not be plugged in to a

multiple outlet used by the control computer.

These rules minimize the chance of Windows deciding to manage USB devices when you are

running cuts on the mill.

The milling machine itself requires a 115 volt single phase wall power outlet rated at 20 amps.

2.1.4 Learning and Training

The final element of planning your installation is to consider the training that you and any other

users of the machine will need.

This manual will give you the basic information required to start manufacturing components

with you PCNC. You must, however, expect to have to invest time in learning how to achieve

the best results. The areas which you will find easy and those which will require more effort

will of course depend on your background; you might be most comfortable with machining or

with component design or even with information technology.

32426 Rev C1-1 2-3 Using Tormach PCNC 770

Page 20

Preparation

Figure 2.4

– Un-crated machine on pallet

We believe that you will find it highly cost-effective to acquire additional training materials for

areas of CAD/CAM/CNC which are new to you. Tormach sales can help point you in

appropriate directions.

2.2 Receiving, Unpacking and Checking Shipment

2.2.1 Moving the Crate

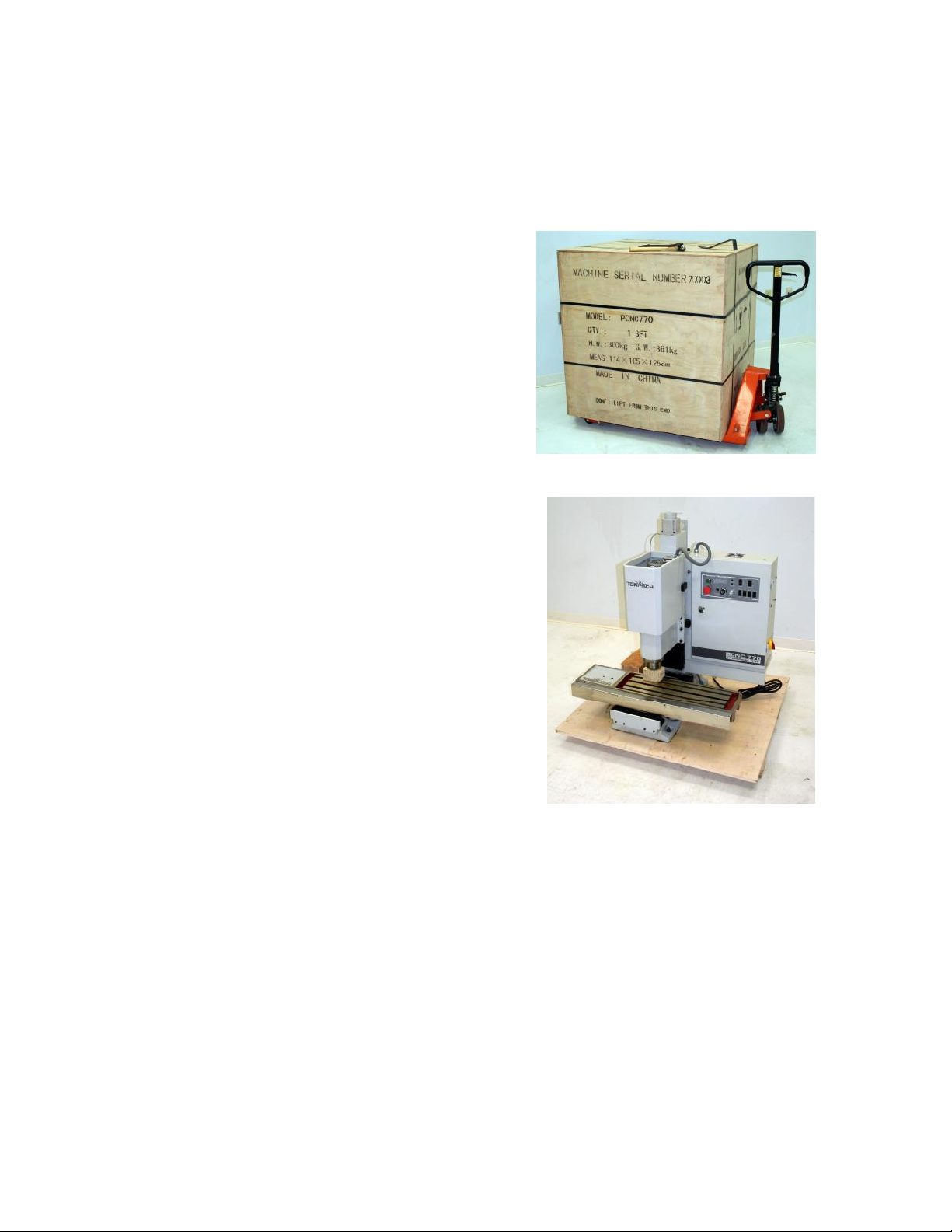

The PCNC is supplied on a standard pallet and

can be offloaded from a truck with a tailgate

lift and moved on smooth surfaces using a

hydraulic pallet jack. This makes delivery very

economical (figure 2.3).

Remove the crate top and sides with care as

the axis drive stepper motors are in vulnerable

places (figure 2.4).

The crated system weighs less than 800 lbs

(400 kg) nevertheless, it requires mechanical

handling to move it over rough ground. The

machine is designed to be modular so it can be

dismantled to move through small doorways

or along narrow corridors and has an optional

moving kit (Part number 31333) to facilitate this.

Some mechanical handling equipment will be

needed to lift it onto the stand. Tormach advises

you to employ the services of a specialist rigger if

the machine has to be moved in situations where

the pallet lifter cannot be used or where there is

no crane to lift the machine onto its stand. It is

possible to improvise using a small trailer, a

portable engine crane and similar tools if there is

no alternative but this risks injury to you and

damage to the machine.

Figure 2.3 – Crated machine as delivered

2.2.2 Uncrating and Inspection

After uncrating you should check the contents

against the parts listed on the packing slip and

inspect the machine for any damage incurred

during transit so any claims can be made within the carrier’s deadline.

2.3 Mounting the PCNC

2.3.1 Lifting onto Stand

The machine can be lifted onto an operating stand by either of two methods: from below using

the base connection points or from above using a slinging technique. In either case caution and

common sense are needed for the protection of the machine and the people involved. Lifting up

to 600 lbs can be simple with proper preparation and good equipment, but it is never trivial and

the dangers involved should be taken seriously.

The work of lifting and placing heavy equipment is called rigging. If you are not trained or

prepared then you should seek the advice of those who are. Professional riggers can be found in

most areas.

Using Tormach PCNC 770 2-4 32426 Rev C1-1

Page 21

2.3.1.1 Lifting from Below

The base of the machine has four 7/8" diameter holes. By sliding two steel bars into these holes,

at least 32" in length, you end up with some outrigger wings that can be used in combination

with a fork lift truck to lift the machine. These should be solid steel bars, not pipes and be ¾" or

7

/

" in diameter.

8

2.3.1.2 Lifting from Above

The alternative way to

mount your PCNC to a

stand involves lifting

from above. The eye in

the top of the column is

suitable for lifting the

machine, but it is not in

line with the center of

gravity. The machine

will tilt when lifted

solely from the eye. The

alternative is to sling the

machine using a

combination of the eye

and an eye in a T-nut on

the table using a

Tormach special tool

(part number 30576 -

Machine Hoist Bar) (figure 2.5).

Preparation

Figure 2.5 – Hoist bar for slinging the mill

Figure 2.6 shows the geometry of the

slinging. The table should be as far away

from the column and as far to the right as

possible to optimize the balance.

It is most important that the machine is not

lifted by the control cabinet or by any of the

protruding stepper motors or the head or the

table. Incorrect rigging of the sling will

likely result in serious damage to the

PCNC.

The optimal balance for lifting should be

checked with the machine an inch or two

off the floor.

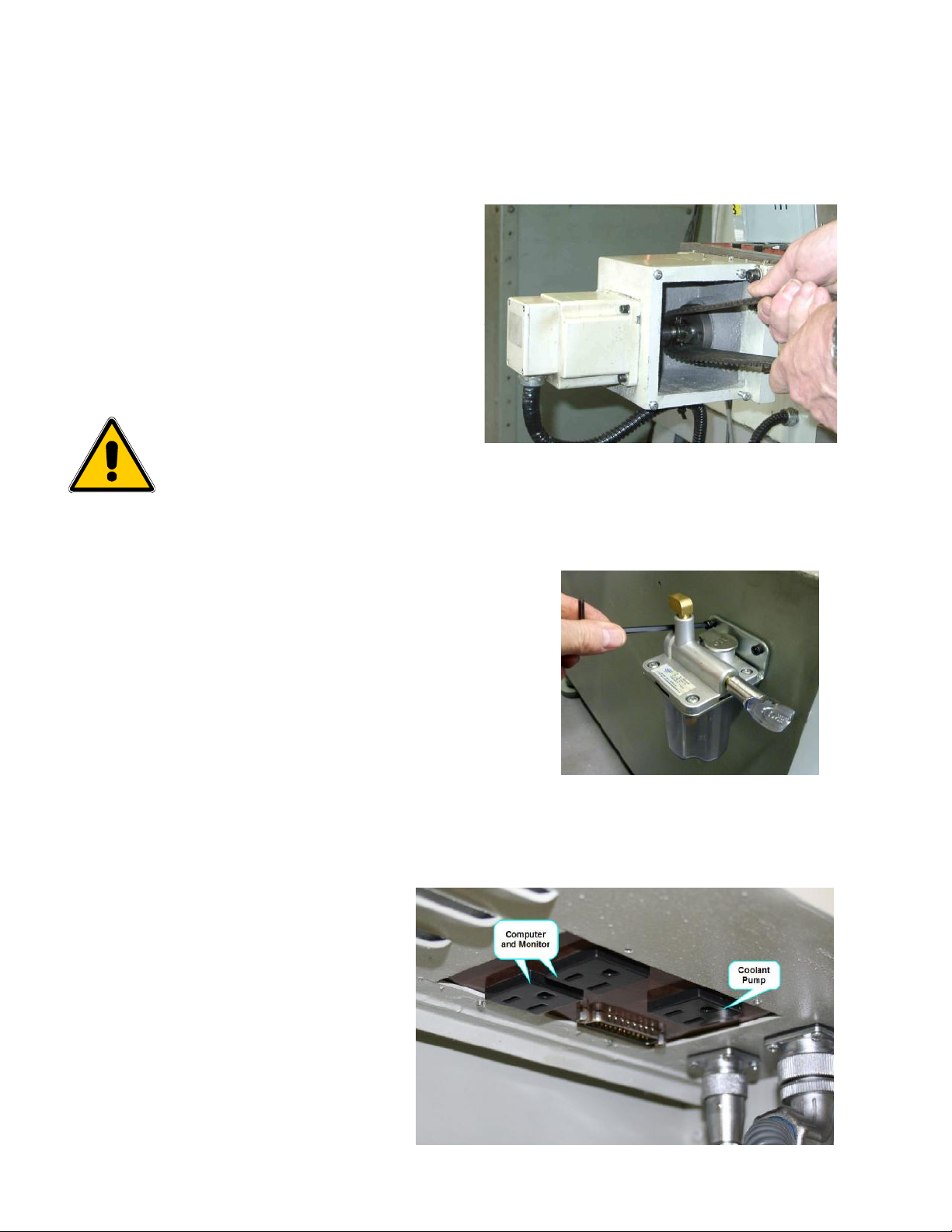

The X-, Y- and Z-axes can easily be moved

by hand if the covers on their coupling

boxes are removed. The smooth (i.e.,

outside face) of an old auto engine timing

belt or poly-vee auxiliary drive belt, which

has been cut to make a strip, can be used to

turn the coupling between the stepper motor

and ball screw (figure 2.7).

When you are ready to lift the machine you

should remove the nuts from the four

screws holding it down to the pallet.

2.3.2 Fixing to Stand

Figure 2.6 – Slinging geometry

Unlike very large mills, the level of your

32426 Rev C1-1 2-5 Using Tormach PCNC 770

Page 22

Preparation

mill does not significantly alter machine accuracy. Leveling should be sufficient to provide

proper coolant drainage, but precision leveling is not necessary.

The supports under the corners of the base of the mill are important to machine accuracy.

Despite the apparent stiffness of the base casting, it will respond to the weight of the machine.

The result will be errors in the left/right tram of the mill. For best accuracy, add shims under the

left front or right front corners of the machine as needed, such that the left/right tram is within

your desired tolerance. Something like

0.002” is usually all that is needed;

however it is certainly possible to do

even better.

A welded steel stand is unlikely to be

flat. Furthermore, if it is flat sitting on

its own, it will sag down as the 800 lb

machine is placed on it. Be aware that

welded steel stands are neither stress

relieved nor as stiff as the machine base

itself. If, for example, you place a

0.050” shim between the base of the

mill and the stand, you’re not actually

lifting the corner of the base up by

0.050”. It is more likely that you are moving the mill up by 0.005” and the corresponding point

on the stand down by 0.045”.

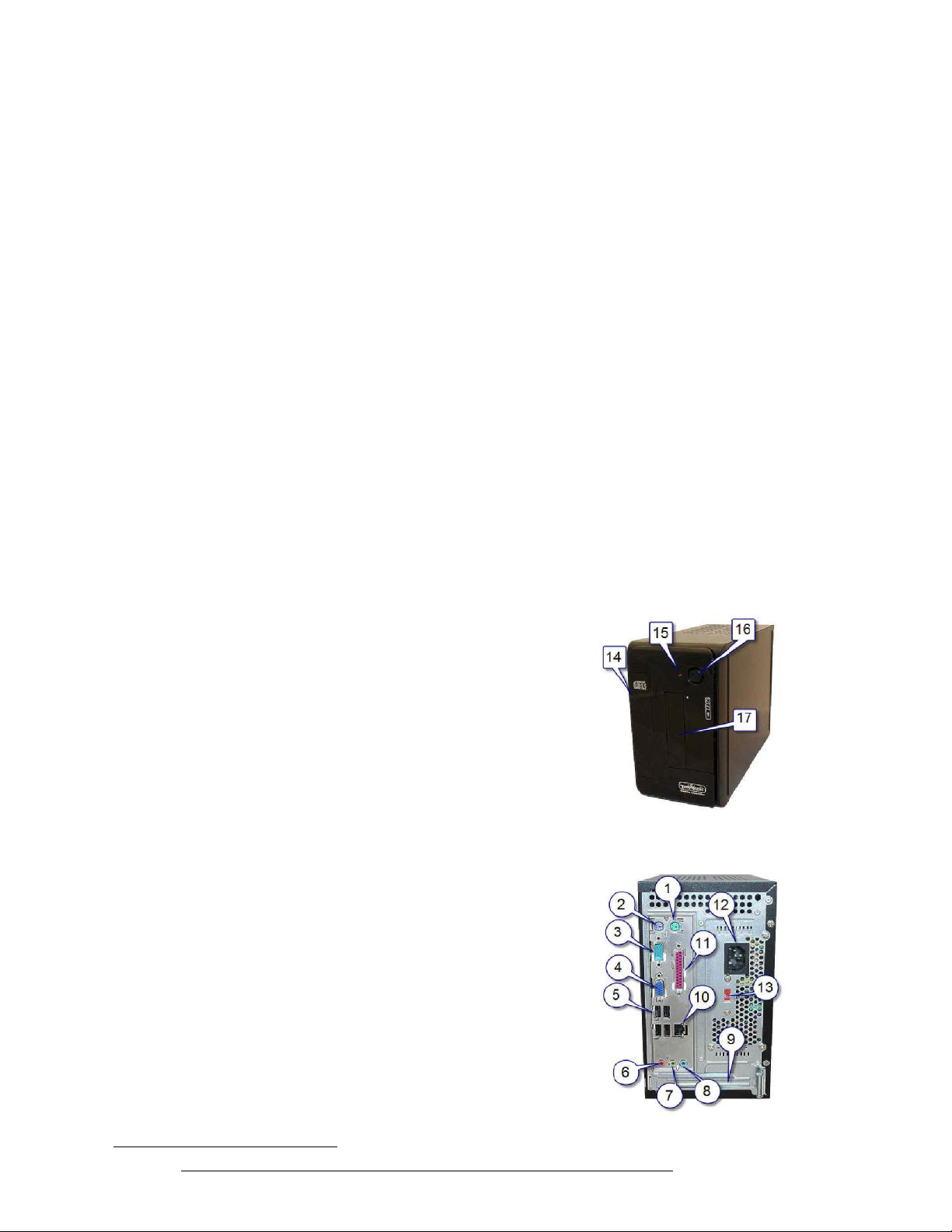

2.3.3 Installing central lubrication pump

The standard pump is manually operated. An

optional automatic pump is available. It comes with

its own installation instructions.

The manual pump is fixed by the two socket screws

provided to tapped holes on the left hand side of the

stand. You may find that your pump mount bracket

is oriented backwards.

Simply remove the 4 screws connecting the bracket