Torit HPW, HPT, HPH Installation And Operation Manual

Torit® Installation

and Operation Manual

Torit Dust Collector

Models HPW, HPT, and HPH

Includes Installation, Operation, and Service Instructions

HPW

HPT

HPH

IMPORTANT

This manual contains specific precautionary statements relative to worker

safety in appropriate sections. Read this manual thoroughly and comply as

directed. It is impossible to list all of the potential hazards of dust control

equipment or systems. It is imperative that use of the equipment be discussed

with a Torit representative. Personnel involved with the equipment or systems

should be instructed to conduct themselves in a safe manner.

Donaldson Company, Inc. © 1995

IOM-29349-00

Revision 5

1

NOTE

CAUTION

Statements indicate precautions necessary

to avoid potential equipment failure.

CAUTION

APPLICATION OF DUST CONTROL EQUIPMENT:

• Special care must be exercised in the use of

dust collection equipment when combustible

material, such as buffing lint, paper, wood

dust, aluminum, or magnesium dust are

present. These materials may present a fire

or explosion hazard. A prudent user of Torit

equipment should consult and must comply

with all National and Local Fire Codes and/

or other appropriate codes when

determining the location and operation of

dust collection equipment.

• Under no conditions should anyone,

including the machine operator, allow

burning objects or lit cigarettes to enter the

hood or ducting of any dust control system.

• Avoid mixing combustible materials with

dust generated from grinding of ferrous

metals due to the potential fire hazard

caused by sparks being pulled into the dust

collection equipment.

• When collection equipment is used to collect

flammable or explosive dusts, as a minimum,

the dust collection equipment should be

Statements indicate potential safety hazards.

located outside the building. Also, an

installer of fire extinguishing equipment,

familiar with the type of fire hazard and

local fire codes, should be consulted for

recommendations and installation of the

proper fire extinguishing equipment. Torit

equipment does NOT contain fire

extinguishing equipment.

• Explosion relief vents are required on some

applications. Consult with an insurance

underwriter or a NFPA Manual to

determine proper vent sizing requirements.

Vents installed on dust collection

equipment must relieve to the outside of the

building to minimize chances of a

secondary explosion. Consult the proper

authority to determine proper method of

venting the dust collection equipment. Torit

equipment does NOT contain explosion

relief vents, except on special order.

• To insure optimum collector performance,

always use Torit-Built

filters.

®

replacement

Portions of your Torit baghouse, including the clean and dirty chambers of the baghouse, may be considered

"OSHA Permit Required Confined Spaces." OSHA Regulations, found in the Code of Federal Regulations, 29

CFR Section 1910.146 control the entry of "confined spaces." Please refer to this regulation to determine if your

use of the baghouse requires a permit program.

Methods of determining "acceptable entry conditions" vary depending upon the application and the type of dust

collected. In some cases, a visual inspection of airborne dust in the baghouse may be sufficient. In other cases,

chemical tests may be necessary to insure safe entry and occupancy.

Torit recommends that employers follow safe work practices during installation and use of all dust collection

equipment. This includes following applicable OSHA regulations and any other applicable local, state, or

federal laws. Copies of OSHA Regulations can be obtained from your local OSHA office or:

Superintendent of Documents

US Government Printing Office

Washington D.C. 20402 Phone: (202) 783-3238

As always, if you have any questions about your Torit dust collector, do not hesitate to contact your local sales

representative or the Torit headquarters office.

ATTENTION

Donaldson Company, Inc. © 19952

Table of Contents Figures

Notes and Cautions ...................................... 2

Data Sheet ................................................... 3

1.0 Introduction ................................................. 5

1.1 Operational Explanation .............................. 5

1.1.1 Normal Operation ....................................... 5

1.1.2 Filter Cleaning ............................................. 6

2.0 Installation................................................... 6

2.1 Inspection..................................................... 6

2.2 Ship Loose Items .......................................... 6

2.3 Equipment/Tools Required ........................... 7

2.4 Preinstallation .............................................. 7

2.5 Assembly of Standard Equipment ................. 8

2.5.1 General Safety Precautions........................... 8

2.5.2 Erection (Major Collector Components) ....... 9

2.5.3 Filter Tube Installation ............................... 11

2.6 Assembly of Optional Equipment ............... 13

2.6.1 55-Gallon Drum Cover Pack

With or Without Slide Gate .................. 13

2.6.2 Transition Pack.......................................... 14

2.6.3 Transition and Airlock ............................... 15

2.6.4 Magnehelic®* Gage ................................... 16

2.6.5 Photohelic®* Gage ..................................... 17

2.6.6 Level Indicator ........................................... 19

2.6.7 Platform and Handrails.............................. 19

2.6.8 Ladder/Cage .............................................. 20

2.6.9 Light Pack (HPW Only) ............................. 20

2.6.10 Blower Fan Mounting Instructions .............. 21

2.6.11 Damper Pack ............................................. 23

2.7 Electrical Installation ................................. 23

2.7.1 Electrical Operation................................... 24

2.7.2 Solid-State Control Timer Specifications .... 24

2.8 Installation—Compressed Air Supply ......... 26

3.0 Prestart-Up Check ...................................... 27

4.0 Start-Up ..................................................... 27

5.0 Routine Maintenance ................................. 27

5.1 Operating Checks ...................................... 28

6.0 Service ....................................................... 28

6.1 Dust Removal ............................................ 29

6.2 Compressed Air Components ...................... 29

7.0 Troubleshooting Guide ............................... 30

Parts Ordering Information ........................ 36

Warranty ................................................... 36

Figure 1 - Typical Installation View ..................... 4

Figure 2 - Operational Schematic ......................... 5

Figure 3 - Hopper Joint and Leg Attachment ...... 10

Figure 4 - Leg Bracing ....................................... 10

Figure 5 - Sealing Details ................................... 11

Figure 6 - Filter Tube Installation ....................... 12

Figure 7 - Hose Drum Cover Pack with Gate ...... 13

Figure 8 - Hose Drum Cover Pack without Gate . 14

Figure 9 - Transition Pack, Transition,

Figure 10 - Installation of Magnehelic Gage ......... 16

Figure 11 - Installation of Photohelic Gage ........... 17

Figure 12 - Photohelic Gage Wiring Diagram ...... 18

Figure 13 - Weatherproof NEMA 4 Enclosure ...... 18

Figure 14 - Blower Transition Assembly ............... 22

Figure 15 - Damper Assembly .............................. 23

Figure 16 - Solid-State Control Timer

Figure 17 - Compressed Air Manifold .................. 26

* Photohelic and Magnehelic are registered trademarks

of Dwyer® Instruments, Inc.

Torit is the leading designer and manufacturer

of air filtration systems for the control of

industrial air pollution. Its systems are designed

to help reduce occupational hazards, lengthen

machine life, reduce in-plant maintenance

requirements, and improve product quality.

and Airlock................................... 15

Wiring Diagram ........................... 24

Data SheetData Sheet

Data Sheet

Data SheetData Sheet

Customer Name

Address

Shipping Date Installation Date

Model Number Serial Number

Filter Medium

Accessories

Other

Donaldson Company, Inc. © 1995

3

* Asterisk items (*) are not included with Dust Collector.

* Sprinklers.

* Explosion Relief Panels.

* Air Line to Manifold

* Solenoid Electrical Connection

* Power Supply Disconnect Switch

Solid-State Control Timer

* Air Supply Line

* Air Regulator

* Air Filter (Bleed Type)

* Shut-Off Valve

* Automatic Condensate Valve

Hopper

* Blower Fan with Transition

Magnehelic or Photohelic* Gage

* Low Voltage (120 VAC)

Magnetic Starter (Blower Motor)

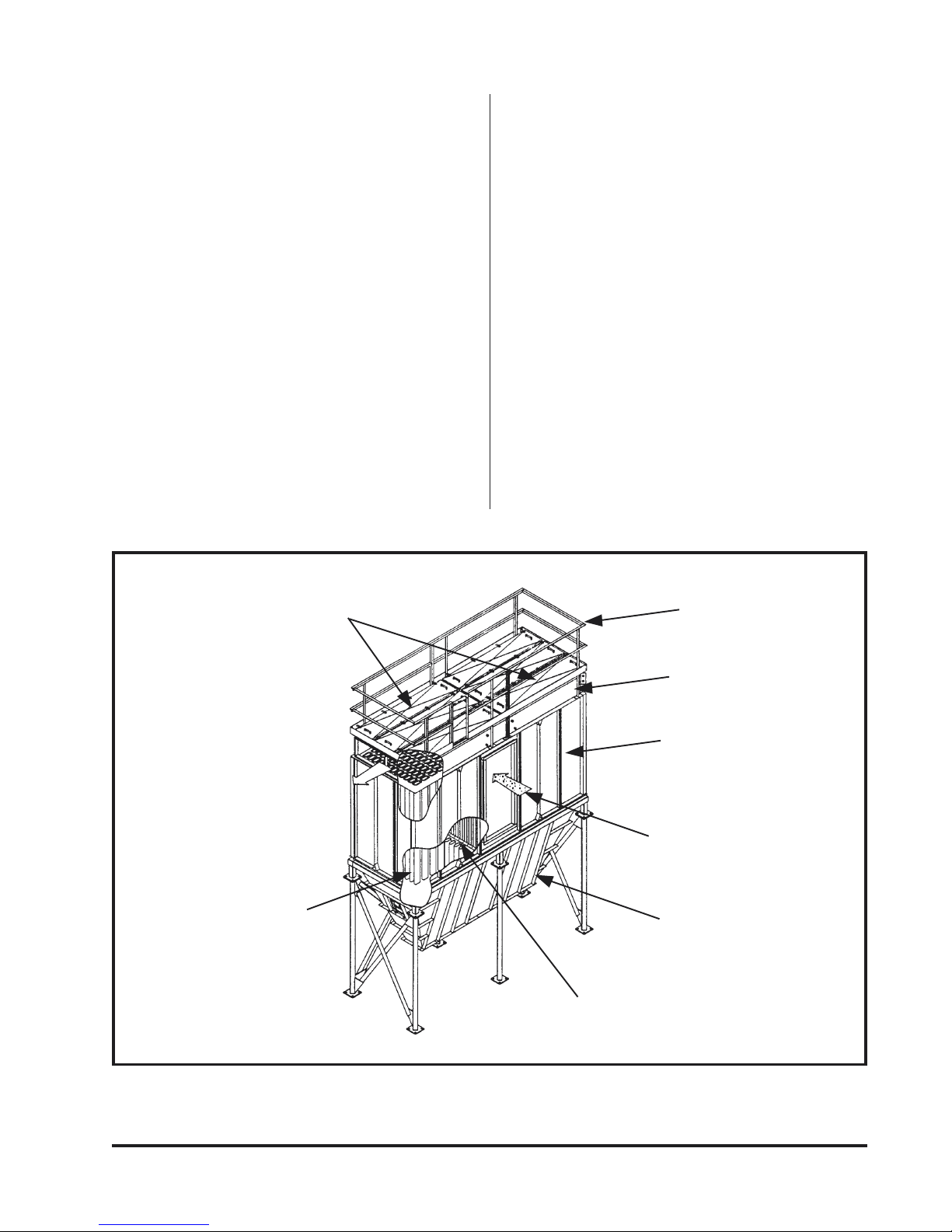

Figure 1

Typical Installation View (HPH Shown)

Donaldson Company, Inc. © 19954

1.0 Introduction

1.1 Operational Explanation

The Torit HPH, HPT, and HPW are used for

the collection of airborne dust and particulate.

As part of a manufacturing process, the HP

collector series provides highly efficient,

continuous, on-line dust collection.

Standard HP models are available in sizes

ranging from 36 to 320 filter tubes. Other sizes

are available as specials. The standard filter

length is 8 feet. The HPH is a low profile

horizontal filter removal collector; the HPT is a

vertical filter removal collector; and the HPW is

a vertical filter removal collector with a walk-in

top section.

If, after reading this manual, you have further

questions or are in need of technical or field

support, contact your local Torit representative.

1.1.1 Normal Operation

(See Figure 2)

During normal operation, dust-laden air enters

the HP inlet section next to the filter tubes. The

airflow must turn 90° to pass through the filter

tube section. The energy loss from turning and

the reduced velocity in the inlet section causes

the heavier dust particles to drop directly into

the hopper below. A standard inlet baffle helps

evenly distribute the dust-laden air around the

filter tubes. The dust is collected on the outside

surface of each filter tube where it forms a cake

that aids in filtering efficiency. Filtered (clean)

air passes through each filter tube into the clean

air plenum where it is discharged through the

clean air outlet.

Filter Tube Access Doors

Clean Air Outlet

Filter Tubes

Handrail

Clean Air Plenum

Dirty Air Plenum

Dirty Air Inlet

Hopper

Inlet Baffle

Donaldson Company, Inc. © 1995

Figure 2

Operational Schematic (HPT Shown)

5

1.1.2 Filter Cleaning

Filter tubes are cleaned automatically and

sequentially. Only one row of filter tubes is

cleaned per pulse. During the filter tube cleaning

purge, the solid-state timer energizes a solenoid

valve. This action causes the corresponding

diaphragm valve to send a pulse of compressed

air out into the blowpipe. The blowpipe is

equipped with two high pressure nozzles

centered over each oval shaped filter tube. The

high pressure pulse enters the inside of the filter

tube forcing air through the filter. The collected

contaminants are blown away from the outside

surface of the filters. The dust falls into the

hopper where it is discharged into drums, screw

conveyor, or rotary valve.

2.0 Installation

2.1 Inspection

The collector is normally shipped with major

components preassembled when possible.

However, due to space restrictions and/or to

minimize freight costs, some components may be

shipped unassembled and nested. On most

HPW/T models, the clean air plenum, dirty air

plenum, and hopper/support weldment are

unassembled.

A crane is recommended for unloading,

assembly, and installation of the dust collector.

Before unloading major components, such as

housing and hopper, check inside for smaller

items that could be damaged if not removed

first. Unload components in a location that

allows for parts identification and assembly.

The filter tubes should be stored in a dry,

rodent-proof area until ready for installation.

2.2 Ship Loose Items

Items shipped loose with the HP dust collector

may include:

• Hopper

• Legs and Cross Bracing

• 55-Gallon Drum Cover Pack

• Transition Pack

• Magnehelic Gage or Photohelic Gage

• Control Box

• Hardware/Sealant

• Explosion Vent

• Weather Cover

• Platforms

• Ladders

• Ladder Cages

• Air Locks

• Tubesheet

• Filter Tubes

• Filter Cages

• Blowpipes (HPH only)

On most HPH models, the clean air plenum is

assembled to the dirty air plenum and the

hopper and support are unassembled. Also, the

blowpipes are unassembled to facilitate filter

tube installation. In most cases, the filter tubes

and frames are shipped separate (unassembled)

for all models.

A packing list is enclosed with each dust

collector. If there are any questions about

completeness of a shipment or obvious damage

to packaged parts, notify the carrier

immediately. Also, damage to any section of the

shipment should be noted on the carrier's Bill of

Lading.

Donaldson Company, Inc. © 19956

2.3 Equipment/Tools Required

The following is a list of typical tools and

equipment required to install and assemble an

HP dust collector:

• Crane/Lift Truck

• Slings/Spreader Bars/Clevice Pins

• Drift Pins

• Clamps

• Screwdrivers

• Pipe Wrenches

• Socket Wrenches

• End Wrenches

• Large Crescent Wrench

• Drill and Drill Bits

• Pipe Sealant

• Extension Cords

• Trouble Light

2.4 Preinstallation

(See Figure 1)

The HP dust collector is usually mounted on a

reinforced concrete foundation. However, roof

mounting is also possible. When calculating for

foundation or roof mounting, the weight of both

the dust collector, the material being collected,

and all auxiliary equipment must be considered

together with wind, seismic and other live loads.

See the Specification Control Drawing for the

dust collector weight.

CAUTION

• Location must be clear of all

obstructions such as utility lines or roof

overhang (see Specification Control

Drawing).

NOTE

Wearing safety equipment such as helmets

and glasses is recommended for all persons

while working in or around the collector.

CAUTION

Use appropriate lifting equipment and

adopt all the safety precautions needed for

moving and handling the equipment.

• A crane must be used to move the

collector into position.

To avoid delay, install foundation in the proper

location. Pay particular attention to the anchor

bolt location. Anchor bolts must extend at least

1-3/4" above foundation. The collector should

be located with consideration for emptying

hopper storage area, shortest runs of inlet and

outlet ductwork, electrical and compressed air

connections, and convenience of maintenance.

In case of hazardous dust collection, consult

with local authorities for the proper location of

the dust collector.

Donaldson Company, Inc. © 1995

7

2.5 Assembly of Standard Equipment

(See Figure 1)

CAUTION

• A crane is recommended for the

unloading, assembly, and installation

of the dust collector.

• Connect lifting sling to a minimum of 4

lifting lugs. Distribute loads equally.

Use clevices, not hooks, on lifting sling.

Use spreader bars on lifting sling.

2.5.1 General Safety Precautions

1. Be certain that the crane has sufficient

capacity to lift sections, sub-assemblies and

complete units, if that applies. Check

weights and dimensions of dust collector

components on specification drawings

furnished by Torit. Spreader bars are

recommended between lifting cables;

shallow cable angles should be avoided.

2. No person shall operate the crane or other

erection equipment except those qualified by

training and experience.

3. Do not install during gusty or heavy winds.

Remove all crating and strapping from the unit.

Remove all miscellaneous parts (bolts, nuts, etc.)

before lifting unit off of the truck. Check the

parts received against the packing slips. If there

are parts missing, the carrier and your local

Torit Representative should be notified

immediately.

NOTE

Each item to be attached to your collector

is accompanied by a drawing that shows

the attachment process. Refer to both the

drawing and this manual when erecting

your collector.

4. Note location of adjacent structures, power

lines, traffic, unstable ground, and ground

obstacles in the erection area.

5. Never swing loads over personnel.

6. Use conventional hand signals for crane

operators.

7. Always consider electrical lines to be live

(hot).

8. Provide an observer to assist crane operator

for periods of impaired visibility.

9. Refer to applicable OSHA regulations and

local rules in using cranes, forklifts, and

other erection equipment.

10. Make liberal use of drift pins to align holes

in section flanges during assembly.

11. Wear appropriate safety gear including hard

hats and safety glasses.

Donaldson Company, Inc. © 19958

2.5.2 Erection (Major Collector Components)

HPT/W Units Only - (Hopper & Legs)

CAUTION

Do not disconnect crane until the lifted

component is securely fastened in place.

The following general procedure is

recommended for assembly:

NOTE

• If the dust collector is shipped

preassembled, including support legs, it

may be lifted directly from the truck

onto the foundation.

• If the dust collector is shipped

unassembled, see Specification Control

Drawing for correct orientation and

location of components.

1. The HPT/HPW hopper/leg arrangements

come totally assembled.

2. Lift the hopper/leg assembly, using a crane,

into position over the anchor bolts and lower

down onto the anchor bolt pads. Fasten the

legs to the anchor bolts with washers and

nuts (provided by customer). Level the

hopper at the top flange in all directions by

placing solid steel shims under the leg pads.

Tighten the nuts on the anchor bolts. Recheck level and adjust as required. Remove

the crane from the hopper.

3. Apply 1/4" diameter sealant to the top

flange all around toward the inside edge of

the bolt pattern (see Figure 5, Sealing

Details).

• All flanged connections of components

providing air seals, including clean air

plenum, tube section, and hopper, must

be sealed before assembly with sealant

as shown in Figure 5, Sealing Details

unless they are factory assembled.

• Use spreader bars for lifting sections of

collector.

• Use drift pins to align holes during

erection.

• Filter tubes and cages can be installed

before or after collector is erected.

Donaldson Company, Inc. © 1995

9

HPH Units Only - (Hopper & Legs)

(See Figures 3 and 4)

1. HPH units have unassembled leg sets.

Locate and identify all legs, bracing, and

hardware required for leg set. Organize the

legs and bracing for assembly.

2. Lift the hopper using a crane and position

over the four legs. Stand each leg up on its

pad, one at a time, and position the hopper

gusset holes to line up with the holes in the

leg. Use a drift pin to assist in hole

alignment. Fasten each leg using the proper

bolts, washers, and nuts provided. Do not

tighten any hardware at this time. Do not

disconnect the crane.

3. Position the inside angle of the cross bracing

and bolt in place using the proper bolts,

washers, and nuts provided. Do not tighten.

Position the outside angle of the cross

bracing and bolt in position. Where the two

angles cross, bolt through each hole with a

bolt, washers, and nut. Repeat this sequence

on the opposite side of the hopper. Do not

tighten hardware.

4. Lift the hopper leg assembly into position

over the anchor bolts and lower down onto

the anchor bolt pads. Fasten the legs to the

anchor bolts with washers and nuts

(provided by customer). Level the hopper at

the top flange in all directions by placing

solid steel shims under the leg pads. Tighten

all hardware on the gussets, cross bracing,

and anchor bolts. Re-check level and adjust

as required. Remove the crane from the

hopper.

5. Apply 1/4" diameter sealant to the top

flange all around toward the inside edge of

the bolt pattern (see Figure 5, Sealing

Details).

Dirty Air Plenum

Hopper

Leg

Figure 3

Hopper Joint and Leg Attachment

(HPH Only)

Cross Bracing

Figure 4

Leg Bracing

(HPH Only)

Donaldson Company, Inc. © 199510

Dirty Air Plenum

Clean Air Plenum

Dirty Air Plenum to

Hopper Joint

1/4" Dia.

Sealant

Hopper

1/4" Dia. Sealant

Tubesheet

Sealant

Dirty Air Plenum

Clean Air Plenum to

Dirty Air Plenum Joint

Figure 5

Sealing Details

Apply Sealant Between

Flanges, on Inside of Bolt

Pattern

Sealing Detail

2.5.3 Filter Tube Installation

(See Figure 6)

Several filter medias are available to meet the

filtration needs for many different types of dust.

Contact your local Torit representative for

assistance in choosing the correct media for

your dust collection requirements.

The cages will arrive on site packaged in crates.

The filters will arrive on site packaged in boxes.

Choose a clean area for pre-assembly of the

filters onto the cages.

Installing the filters before the filter section is

raised will be easier and save time. Install the

filter tubes as shown in Figure 6, Filter Tube

Installation. Slip the filter tube over the filter

tube frame until it touches the top flange of the

Donaldson Company, Inc. © 1995

frame. Slide this filter assembly through the

tubesheet. Align the two bolts with the threaded

inserts in the tubesheet. Secure each filter tube

and frame assembly with the Boltsafe™

hardware provided.

NOTE

• Use a speed wrench to tighten the

screws. Do not use a power driver or

impact nut driver. These may strip

threads or shear screws.

• Only tighten screws until the top flange

rests on the tubesheet, about 8-10 ft. lbs

torque.

11

Loading...

Loading...