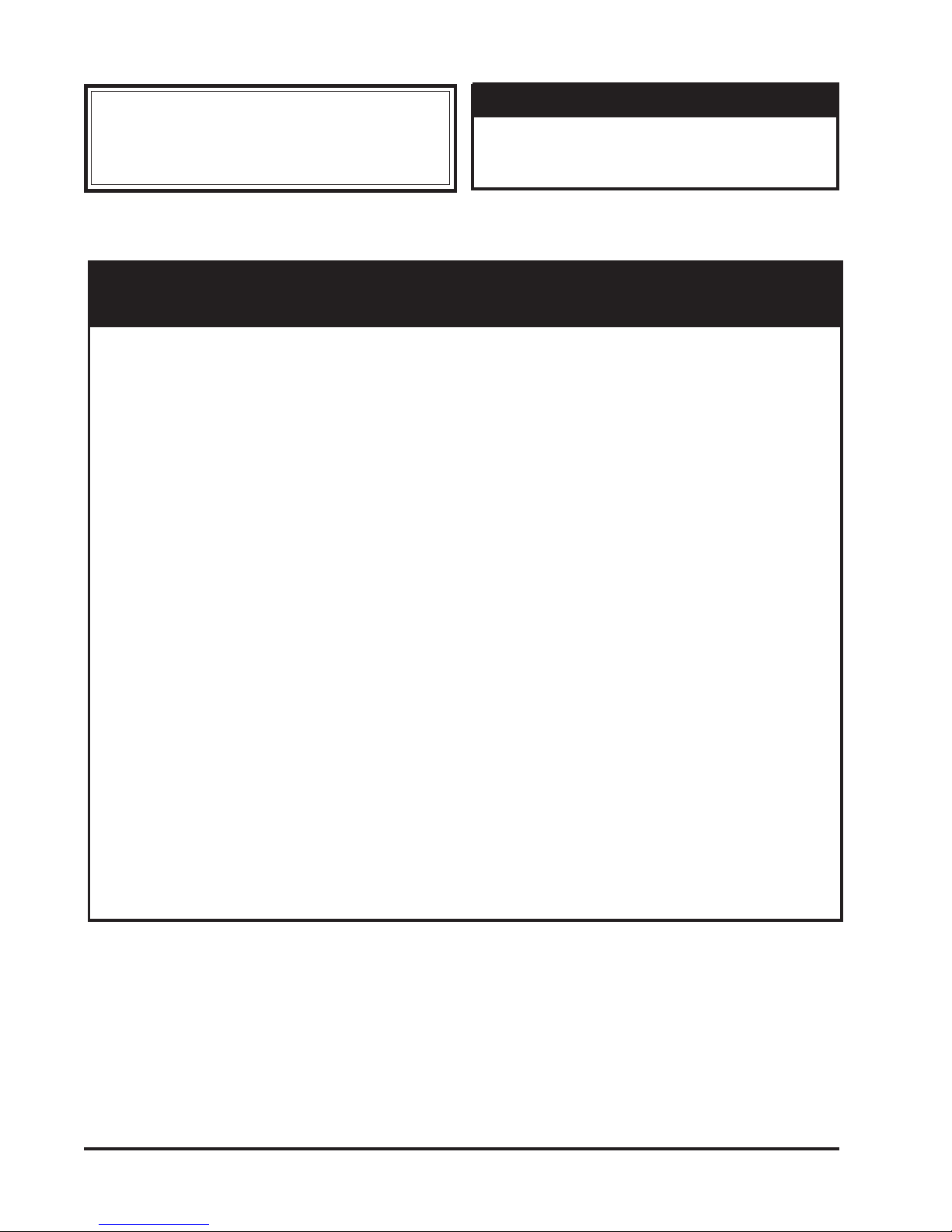

Torit Downflo SDF-2, Downflo SDF-4, Downflo SDF-6 Installation And Operation Manual

Torit® Installation

and Operation Manual

FOR TORIT FILTER CARTRIDGE SYSTEM DUST COLLECTORS

Torit Downflo® Models SDF–2, SDF–4, SDF–6

Includes Installation, Operation, and Service Instructions

WITH QUICK-CHANGE

ULTRA-WEB® II

FIBRA-WEB

ULTRA-TEK

FILTER ELEMENTS

®

®

This manual contains specific precautionary statements relative to worker

safety in appropriate sections. Read this manual thoroughly and comply as

directed. It is impossible to list all of the potential hazards of dust control

equipment. It is imperative that use of the equipment be discussed with a Torit

representative. Personnel involved with the equipment or systems should be

instructed to conduct themselves in a safe manner.

Donaldson Company, Inc. © 1995

IMPORTANT

IOM-46740-00

Revision 5

1

NOTE

CAUTION

Statements indicate precautions necessary

to avoid potential equipment failure.

CAUTION

Application of Dust Control Equipment:

• Special care must be exercised in the use of

dust collection equipment when combustible

equipment, such as buffing lint paper, wood

dust, aluminum, and magnesium are present.

These materials may present a fire or

explosion hazard. A prudent user of Torit

equipment should consult and must comply

with all National and Local Fire Codes and/

or other appropriate codes when determining

the location and operation of dust collection

equipment.

• Under no conditions should anyone, including

the machine operator, be allowed to put

burning objects or lit cigarettes into the hood

or ducting of any dust control system.

• Avoid mixing combustible materials with

dust generated from grinding of ferrous

metals due to the potential fire hazard caused

by sparks being pulled into the dust collection

equipment.

Statements indicate potential safety hazards.

collection equipment should be located

outside the building. Also, an installer of

fire extinguishing equipment, familiar with

this type of fire hazard and local fire codes,

should be consulted for recommendations

and installation of the proper fire

extinguishing equipment. Torit

does NOT contain fire extinguishing

equipment.

• Explosion relief vents are required on some

applications. Consult with an insurance

underwriter or a NFPA Manual to

determine proper vent sizing requirements.

Vents installed on dust collection equipment

within a building must relieve to the outside

of the building to minimize chances of a

secondary explosion. Consult the proper

authority to determine proper method of

venting the dust collection equipment. Torit

equipment does NOT contain explosion

relief vents, except on special order.

equipment

• When collection equipment is used to collect

flammable or explosive dusts, the dust

2

• To insure optimum collector performance,

always use Torit-Built® replacement

filters.

TORIT PRODUCTS is the leading designer and

manufacturer of dust collector systems for the

control of industrial air pollution. Its systems are

designed to help reduce occupational hazards,

lengthen machine life, reduce in-plant maintenance

requirements, and improve product quality.

Donaldson Company, Inc. © 1995

Table of Contents

Notes and Cautions ............................. 2

Data Sheet ........................................... 3

Figures ................................................. 4

1.0 Introduction ......................................... 6

1.1 Operational Explanation ..................... 6

1.1.1 Normal Operation ............................... 6

1.1.2 Filter Cleaning ..................................... 7

2.0 Installation ........................................... 7

2.1 Inspection............................................. 7

2.2 Ship Loose Items .................................. 7

2.3 Equipment/Tools Required................... 7

2.4 Assembly of Standard Equipment ........ 7

2.5 Assembly of Optional Equipment ........ 8

2.5.1 Compressed Air Inlet Adapter ............. 8

2.5.2 Leg Levelers ......................................... 8

2.5.3 Inlet Collar ........................................... 8

2.5.4 Adapter to Round Outlet ..................... 8

2.5.5 Adapter Auto-Lok™/Ultra-Lok™ ....... 8

2.5.6 Adapter HEPA/Activated Carbon ...... 12

2.5.7 Leg Pack SDF ..................................... 12

2.5.8 55-Gallon Drum Pack ......................... 14

2.5.9 5-Gallon Pail Pack .............................. 14

2.5.10 Bin Vent Base Pack ............................. 14

2.5.11 Flex-Trunk™ Assembly

7-Foot/10-Foot SDF ............................ 16

2.5.12 Weather Hood Pack ........................... 16

2.5.13 Explosion Vent Pack ........................... 16

2.5.14 Explosion Vent Cabinet ...................... 20

2.6 Electrical Installation ............. 20-23,29-30

2.6.1 Electrical Operation ............................ 30

2.6.2 Checker

Control Panel Specifications ............... 30

2.6.3 Solid State Control Timer

Specifications ................................... 30-31

2.6.4 Magnehelic

2.6.5 Torit ∆P Control .............................. 33-35

2.6.6 Photohelic

2.7 Compressed Air Supply Installation.... 38

2.7.1 Air Manifold Assembly ....................... 39

2.7.2 Blower Compartment ......................... 39

2.7.3 Dust Storage Compartment ................ 39

4.0 Start-up ............................................... 39

5.0 Operating Adjustment ........................ 40

5.1 Checker Board .................................... 40

5.2 Solid State Control Timer ................... 40

5.3 ∆P Control Calibration ....................... 41

5.4 Outlet Damper Adjustment................. 41

5.5 Operating Checks ............................... 41

6.0 Service ................................................ 42

6.1 Filter Element Removal ...................... 42

6.2 Filter Element Installation ................... 42

6.3 Bag-Out Filter Element Removal .....42-43

6.4 Dust Removal Dust Container ........ 43-44

6.4.1 Dust Removal—Hopper Model .......... 44

6.5 Compressed Air Components ............. 45

6.6 Electrical Service ................................ 45

7.0 Troubleshooting Guide .................... 46-52

Parts Ordering Information ................ 54

Warranty ............................................ 54

™

Board, Diagnostics and

®

* Gage ............................ 31

®

* Gage .............................. 37

Data Sheet

* Magnehelic and Photohelic are registered trademarks

of Dwyer® Instruments, Inc..

Customer Name

Address

Shipping Date Installation Date

Model Number Serial Number

Filter Medium

Accessories

Other

Donaldson Company, Inc. © 1995

3

Figures

Figure 1 – SDF-4 Phantom View .............. 5

Figure 2 – Operational Schematic ............ 6

Figure 3 – Compressed Air Inlet Adapter 8

Figure 4 – Leg Levelers ............................ 8

Figure 5 – Inlet Collar .............................. 9

Figure 6 – Adapter Pack to

Round Outlet .......................... 9

Figure 7 – Adapter Pack

Auto-Lok/Ultra Lok ................10

Figure 8 – Adapter Pack HEPA/

Activated Carbon.................... 11

Figure 9 – Leg Pack SDF .......................... 12

Figure 10 – 55-Gallon Drum Pack &

5-Gallon Pail Pack................... 13

Figure 11 – Bin Vent Base Pack ................. 14

Figure 12 – Flex-Trunk Assembly

7-Foot/10-Foot SDF................. 15

Figure 13 – Weatherhood Pack .................. 17

Figure 14 – Explosion Vent Pack ............... 18

Figure 15 – SDF-4 with Explosion Vents—

Phantom View ......................... 19

Figure 16 – Prewired with Checker Board

on Unit .................................... 21

Figure 17 – Unwired with Checker Board

on Unit .................................... 21

Figure 18 – Prewired with Checker Board

in Remote Enclosure ...............22

Figure 19 – Unwired with Checker Board

in Remote Enclosure ...............23

Figure 20 – Wiring Diagram 575V 60Hz

3PH 3, 5, 7-1/2, 10 hp ............ 24

Figure 21 – Wiring Diagram 380V 50Hz

3PH 3, 5 hp .............................24

Figure 22 – Wiring Diagram 380V 50Hz

3PH 7-1/2 hp ........................... 25

Figure 23 – Wiring Diagram 230V 60Hz

3PH 3, 5, 7-1/2, 10 hp ............ 25

Figure 24 – Wiring Diagram 200V 50/60Hz

3PH 3, 5 hp .............................26

Figure 25 – Wiring Diagram 200V

50/60Hz 3PH 7-1/2, 10 hp ...... 26

Figure 26 – Wiring Diagram 460V 60Hz

3PH 3, 5, 7-1/2, 10 hp ............. 27

Figure 27 – Wiring Diagram 208 V

60Hz 3PH 3, 5, 7-1/2, 10 hp ... 27

Figure 28 – Remote Checker Board

Assembly ................................. 28

Figure 29 – SDF Solid-State Timer Wiring

Diagram .................................. 29

Figure 30 – Magnehelic Gage .................... 32

Figure 31 – Remote-Mounted Magnehelic

Gage .......................................32

Figure 32 – ∆P Control Display ................. 33

Figure 33 – Printed Circuit Board ..............35

Figure 34 – Photohelic Gage ......................36

Figure 35 – Remote-Mounted Photohelic

Gage .......................................36

Figure 36 – Photohelic Gage

Wiring Diagram ...................... 37

Figure 37 – Air Manifold Assembly ........... 38

Figure 38 – Bag-Out Assembly .................. 43

Figure 39 – Bag-Out Filter Removal .......... 43

Figure 40 – Dust Container Support

System..................................... 44

Figure 41 – Typical Electrical

Component Assembly ............. 45

4

Donaldson Company, Inc. © 1995

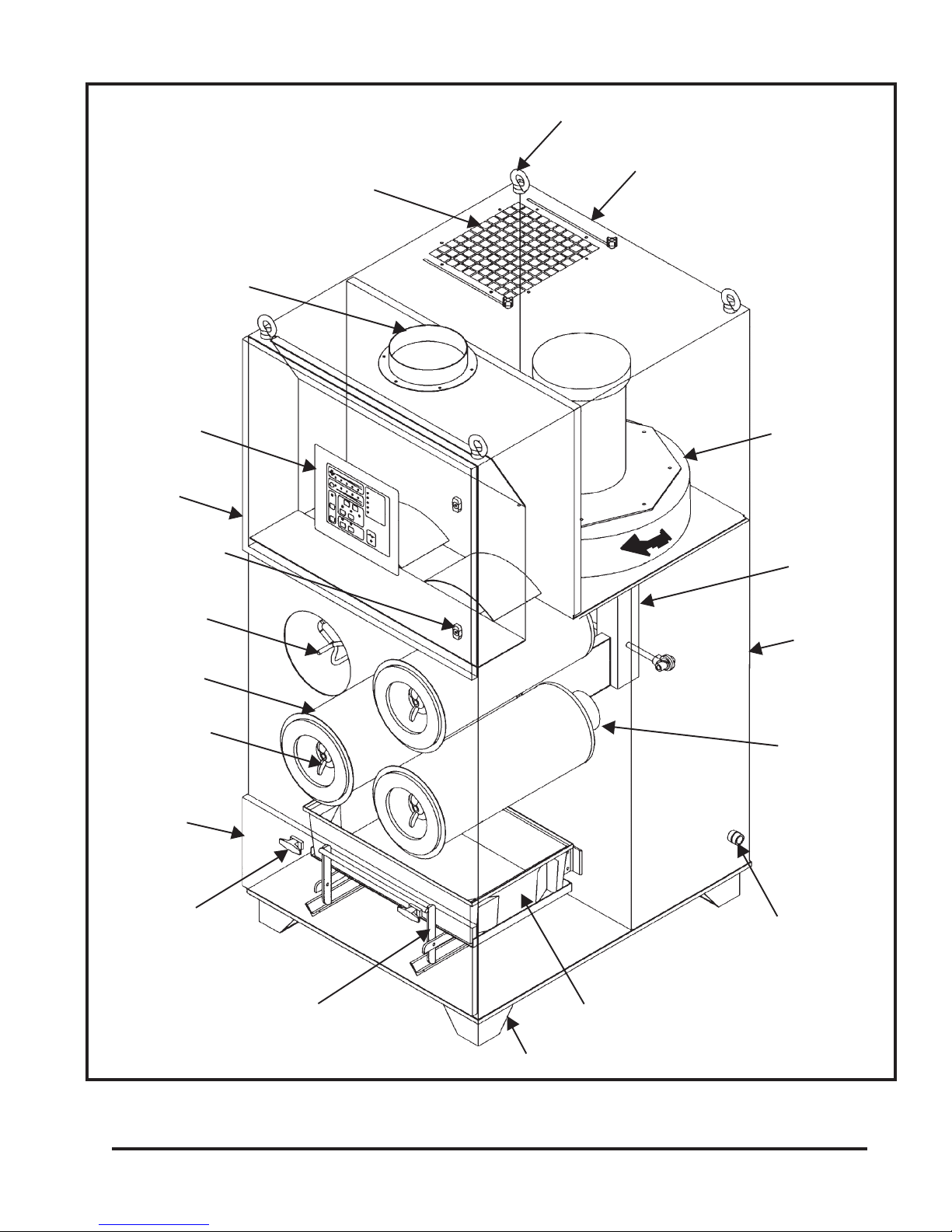

Sprinkler Taps (not shown) (not supplied standard with the SDF)

Lifting Eyes

Inlet Collar

Checker™ Board

Diagnostic and

Control Panel

Hinged Access

to Electrical

Compartment

Tool Operated

Fastener

Filter Yoke

Filter Element

Outlet with Damper

Screwed-on Rear

Access Panel to

Blower Compartment

Blower Pack

Air Manifold

Assembly

Screwed-on

Rear Access

Panel to Clean

Air Manifold

Filter Wing

Nut

Hinged Access

Door to Dust

Container

T–Handle

Quick Latch

Lift Assembly Dust

Container

Donaldson Company, Inc. © 1995

Venturi

Compressed Air Inlet—

1/2 National Pipe

Threads or British Pipe

Threads

Dust Container

Legs or Casters

Figure 1

SDF–4 Phantom View

5

1.0 Introduction

1.1 Operational Explanation

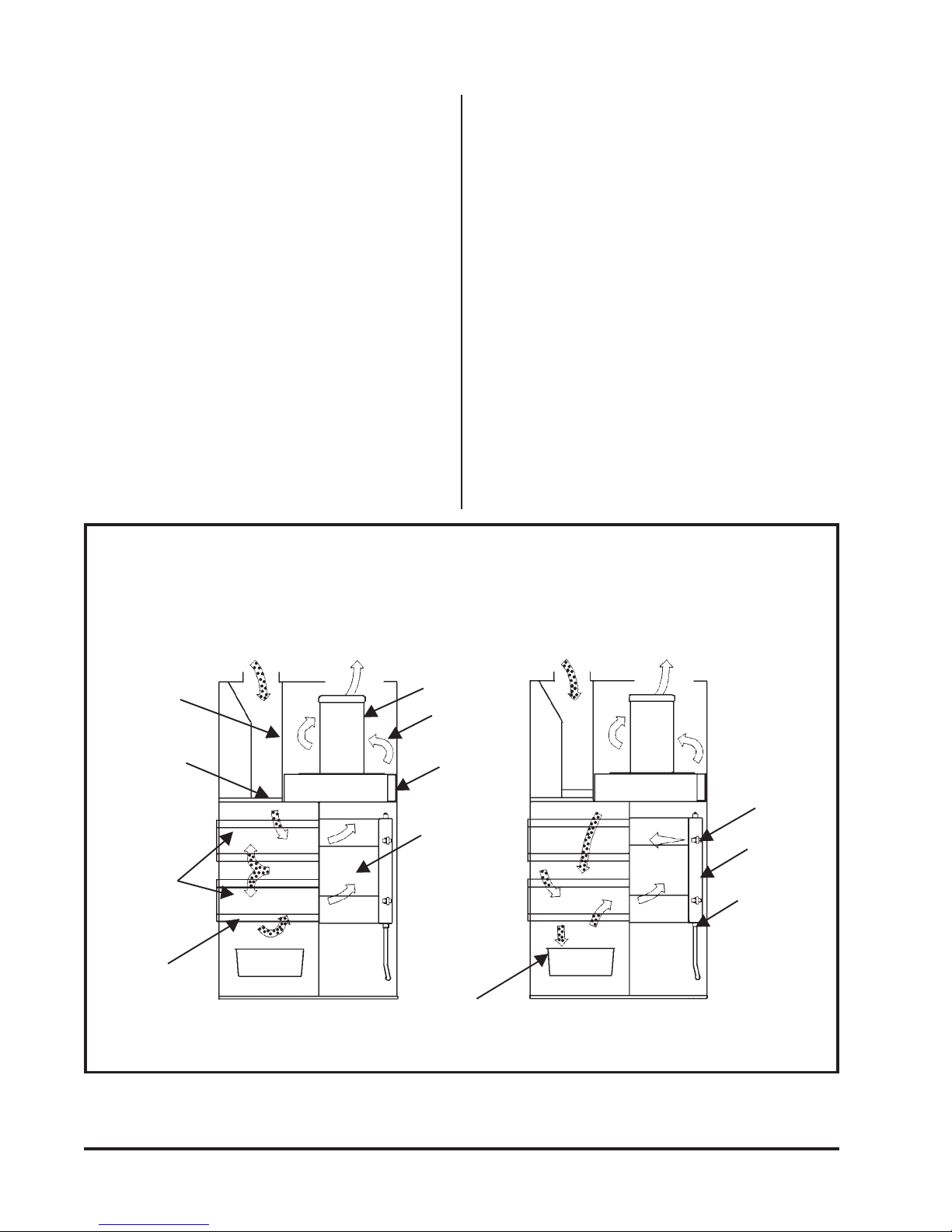

(See Figure 2 Operational Schematic)

The Torit® Downflo® model SDF dust collector

is used for the collection of airborne dust and

particulate. The model SDF collector provides

highly efficient, continuous, on-line dust

collection.

®

The Torit-Built

filter elements are the heart of

the model SDF dust collector. These filter

elements help ensure that clean air is returned to

the plant environment.

Technical and field support are always available

from your local Torit representative and

distributors.

Normal Operation

1.1.1 Normal Operation

During normal operation, contaminated air

enters through the top inlet area and passes

down and through the filter elements. Dust is

collected on the outside surface of the filter

elements. The clean, filtered air flows through

the center of the filter elements and into the

clean air plenum, where it exits through the

clean air outlet.

Filter Element Purge

Dirty Air Plenum

Deflector

Filter

Elements

Filter Section

Dirty Air Inlet

Clean Air Outlet

Blower Pack

Silencer

Section

Fan Outlet

Clean Air

Plenum

Dirty Air Inlet

Diaphragm

Cleaning Air

Valve

Compressed

Air Manifold

Compressed

Air Inlet Fitting

(Purge Air)

6

Figure 2

Operational Schematic

Donaldson Company, Inc. © 1995

1.1.2 Filter Cleaning

2.3 Equipment/Tools Required

Filter elements are cleaned automatically and

sequentially. The result is that only one filter

cartridge will be off-line for cleaning at any

given time.

During the filter element cleaning purge, a

solenoid valve is energized, causing the

corresponding diaphragm valve to send a pulse

of compressed air through the filter element

(from the inside outward), removing the

collected dust from the outside surfaces of the

filter element. The dust falls into the dust storage

container.

2.0 Installation

2.1 Inspection

The Downflo SDF is normally shipped by

common carrier and should be checked for

damage that may have occurred en route. Any

damage should be noted and the carrier notified

immediately.

The following is a list of typical tools and

equipment required to install and assemble a

Downflo SDF unit.

• Crane/Lift Truck

• Pipe Wrenches

• Socket Wrenches

• Pipe Sealant

2.4 Assembly of Standard Equipment

NOTE

A crane or forklift truck is recommended

for the unloading of the dust collector.

CAUTION

• Connect lifting slings to the four lift

lugs on top of the dust collector when

using a crane to unload the unit.

2.2 Ship Loose Items

Items shipped loose with the dust collector may

include:

• Bag-out Assembly

• Inlet Collar

• Compressed Air Inlet Adapter

• (4) Leveling Mount Foot Pads

• (4) Metric Hex Bolts

• Hopper

• Legs and Crossbracing

• Outlet Adapters

• Auto-Lok/Ultra-Lok/HEPA/Carbon Filter

• Remote Checker Board/

Magnehelic Gage/Photohelic Gage

• Slide Gate/55-Gallon Drum Cover Pack

• 5-Gallon Pail Pack

• Flex-Trunk Assembly

• Weather Hood

• Explosion Vents

• Insert the fork under the dust

collector between the casters or legs

when using a forklift truck to unload

the unit.

Remove all crating and strapping from the unit.

Remove all miscellaneous parts (bolts, nuts, etc.)

before lifting the unit off of the truck. Check the

parts received against the packing list. If there

are parts missing, the carrier and your local

Torit representative should be notified

immediately.

NOTE

If the lift lugs are removed, they must be

replaced with the four (4) metric hex

bolts (provided) before the dust collector

is operated.

Most cabinets are shipped completely assembled

with the filter cartridges installed.

Donaldson Company, Inc. © 1995

7

2.5 Assembly of Optional Equipment

2.5.4 Adapter to Round Outlet (See Figure 6

Adapter Pack to Round Outlet)

2.5.1 Compressed Air Inlet Adapter

(See Figure 3 Compressed Air Inlet

Adapter)

The compressed air inlet adapter is used for

converting the compressed air inlet from

National Pipe Threads to British Pipe Threads.

Install the compressed air inlet adapter as shown

in Figure 3 Compressed Air Inlet Adapter. Use

thread-sealing tape or pipe sealant on the

threaded adapter before screwing it into the

compressed air inlet.

2.5.2 Leg Levelers (See Figure 4 Leg Levelers)

The leveling mount foot pads screw into the

bottom of the collector legs as illustrated in

Figure 4 Leg Levelers.

2.5.3 Inlet Collar (See Figure 5 Inlet Collar)

Place 1/4" diameter sealant between the cabinet

side or top and the inlet collar. Attach the collar

using the eight (8) #6-32 thread cutting screws

provided.

Place the 3/16" x 1/2" rubber seal between the

cabinet top and the outlet adapter. Attach the

outlet adapter to the cabinet using the clamp

hook, wing nut, and washer as shown. The

sliding damper will still operate with this

adapter.

2.5.5 Adapter Auto-Lok / Ultra-Lok

(See Figure 7 Adapter Pack

Auto-Lok / Ultra-Lok )

Remove the lift lug on the cabinet top and

replace it with the set screw. Place the 3/16" x

1-1/4" gasket between the cabinet top and the

adapter. Attach the adapter to the cabinet top

using the clamp hooks, wing nuts, and washers

as shown. Place the 3/8" x 1-1/4" gasket

between the adapter and the Auto-Lok or UltraLok filter as shown. Use the 10-24 x 7/16 screws

to attach the filter to the adapter. The sliding

damper will not operate with these adapters.

Compressed Air Inlet

Collector

Leg or Caster

Figure 3

Compressed Air Inlet Adapter

8

Sealant

Compressed Air

Inlet Adapter

Collector

Leg

Leveling

Mount Foot

Pad

Figure 4

Leg Levelers

Donaldson Company, Inc. © 1995

#6-32 Screws

Inlet Collar

Cabinet Top or Side

1/4" Diameter Sealant

Figure 5

Inlet Collar

Wing Nut

3/8 Flat Washer

Rubber Seal

Cabinet Top

(Ref)

Adapter Pack to Round Outlet

Donaldson Company, Inc. © 1995

Outlet Adapter

Clamp Hook

Figure 6

9

3/8 x 1-1/4 Gasket

Adapter

Auto-Lok /

Ultra-Lok

Assembly

10-24 x 7/16 Screw

3/16 x 1-1/4 Gasket

Cabinet Top (Ref)

10

Wing Nut

3/8 Flat Washer

Set Screw

Clamp Hook

Figure 7

Adapter Pack Auto-Lok / Ultra-Lok

Donaldson Company, Inc. © 1995

Filter Retainer Bar

Adapter

1/4-20 x 3/4 Bolt

1/4 Flat Washer

HEPA /

Carbon Filter

1/4 x 3/4

Gasket

3/16 x 1-1/4 Gasket

Cabinet Top (Ref)

Wing Nut

3/8 Flat Washer

Set Screw

Clamp Hook

Figure 8

Adapter Pack HEPA / Activated Carbon

Donaldson Company, Inc. © 1995

11

2.5.6 Adapter HEPA / Activated Carbon

(See Figure 8 Adapter Pack HEPA /

Activated Carbon)

Remove the lift lug on the cabinet top and

replace it with the set screw. Place the 3/16" x

1-1/4" gasket between the cabinet top and the

adapter. Attach the adapter to the cabinet using

the clamp hooks, wing nuts, and washers as

shown. Place the 1/4" x 3/4" gasket between the

adapter and the HEPA or Activated Carbon

filter as shown. Use the filter retainer bar and

the 1/4" bolts and washers to attach the filter to

the adapter. The sliding damper will not operate

with these adapters.

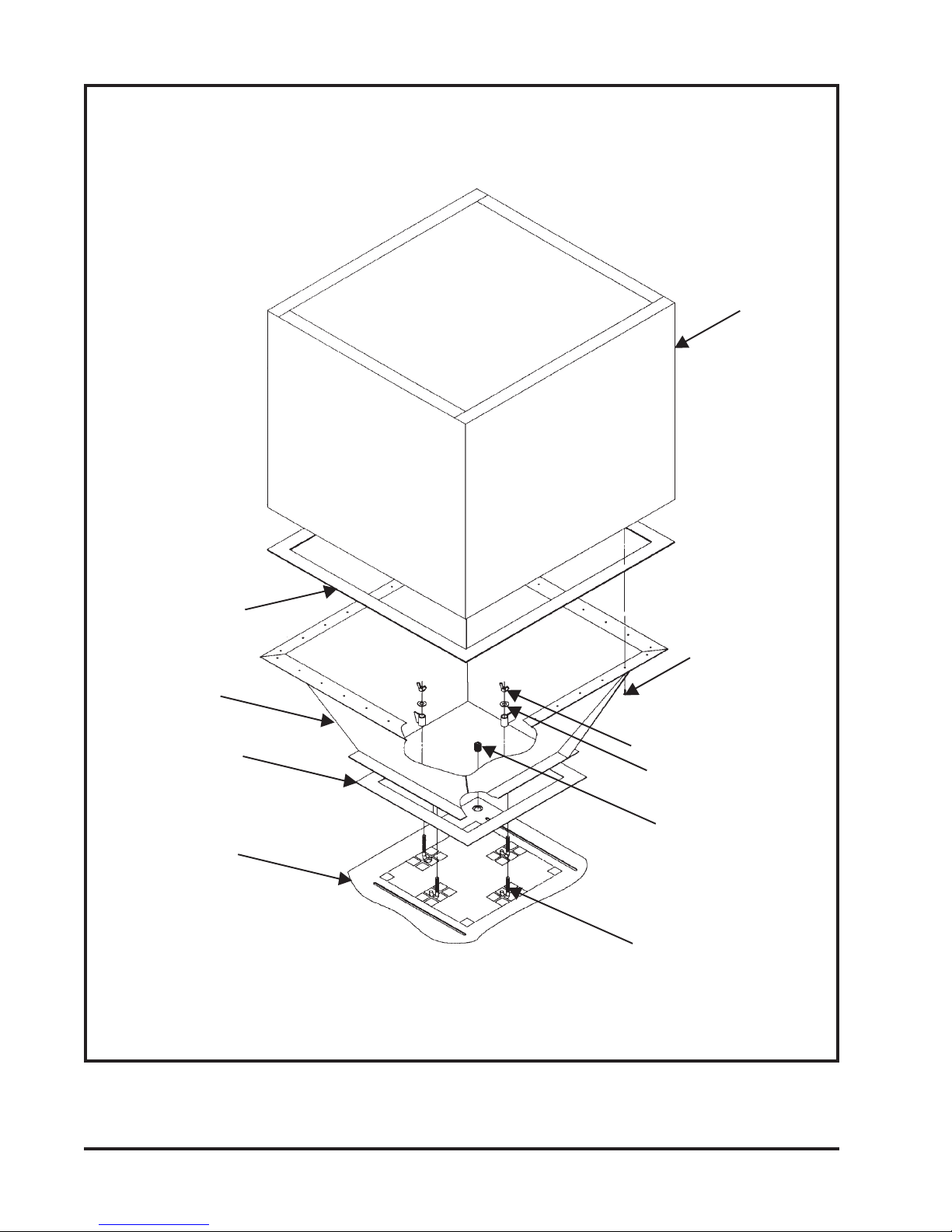

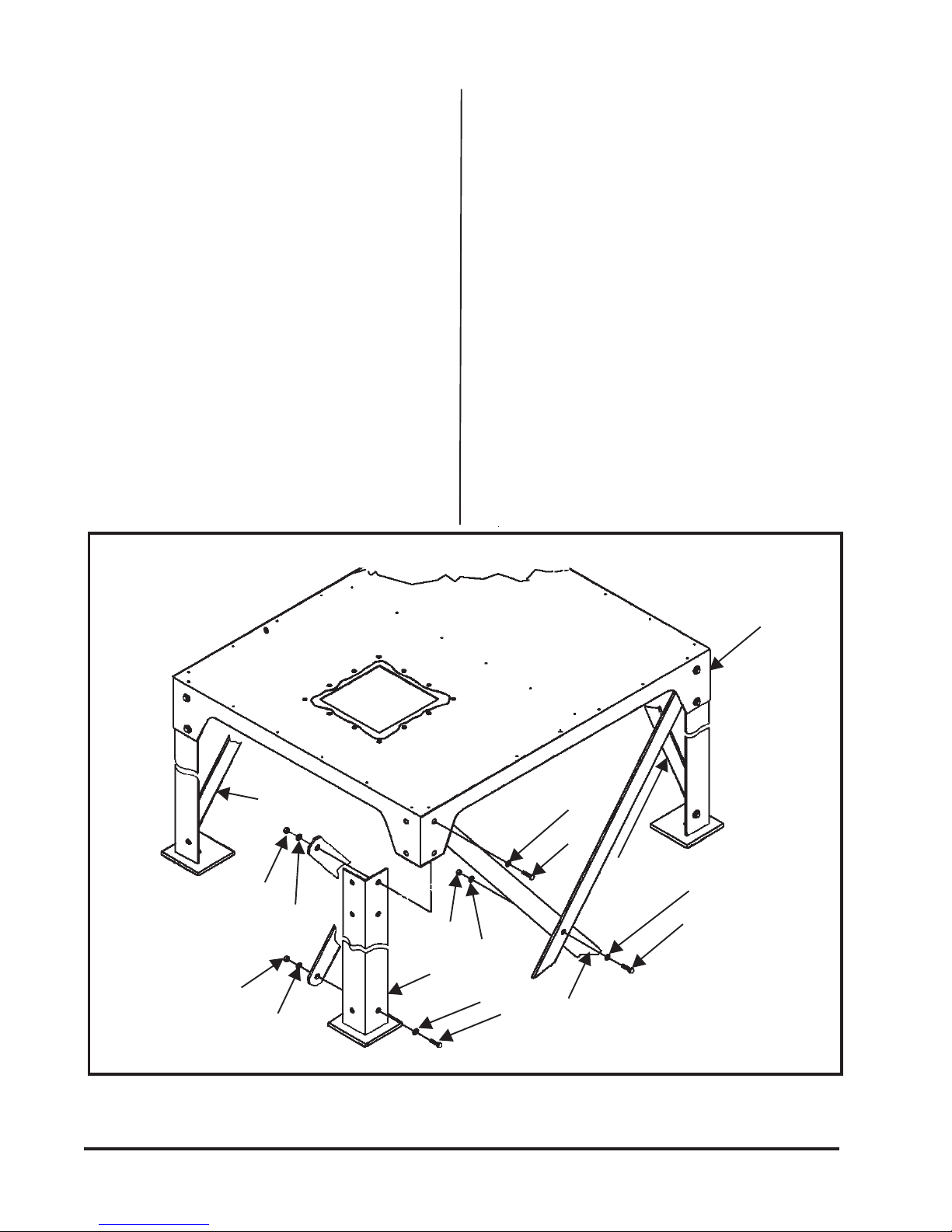

2.5.7 Leg Pack SDF

(See Figure 9 Leg Pack SDF)

The SDF units that are not furnished with a dust

container will have an internal hopper with a

base to attach to legs and crossbracing.

Assemble the legs and crossbracing to the SDF

base as shown in Figure 9 Leg Pack SDF. The

55-gallon drum pack leg crossbraces should be

installed on the three sides only, in order to

allow access to the drum. The 5-gallon pail pack

does not require crossbracing.

Nut

Washer

Crossbrace

Nut

Washer

Nut

Leg

Washer

Washer

Bolt

SDF Base

Washer

Bolt

Crossbrace

Washer

Bolt

Crossbracing

12

Figure 9

Leg Pack SDF

Donaldson Company, Inc. © 1995

Attach to SDF Base as Shown

SDF Base

1/4" Dia. Seal

Bolts, Washers,

& Nuts

55-Gallon Drum Pack

With or Without Gate

With or Without Latches

55-Gallon Drum Pack and 5-Gallon Pail Pack

Donaldson Company, Inc. © 1995

5-Gallon Pail Pack

With or Without Gate

Figure 10

13

Bin Vent Base

1/2" Diameter Holes (28)

Figure 11

Bin Vent Base Pack

2.5.8 55-Gallon Drum Pack

(See Figure 10 55-Gallon Drum Pack

and 5-Gallon Pail Pack)

The 55-gallon drum cover and the 55-gallon

drum cover with gate can be attached to the

base as shown in Figure 10 55-Gallon Drum

Pack and 5-Gallon Pail Pack. Use the existing

bolts, washers, and nuts that are on the base.

Access to the bolts is through the hinged door.

Be sure to use sealant to seal between the drum

cover and the base.

2.5.9 5-Gallon Pail Pack

(See Figure 10 55-Gallon Drum Pack

and 5-Gallon Pail Pack)

Attach the 5-gallon pail cover and the 5-gallon

pail cover with gate as shown in Figure 10

55-Gallon Drum Pack and 5-Gallon Pail Pack.

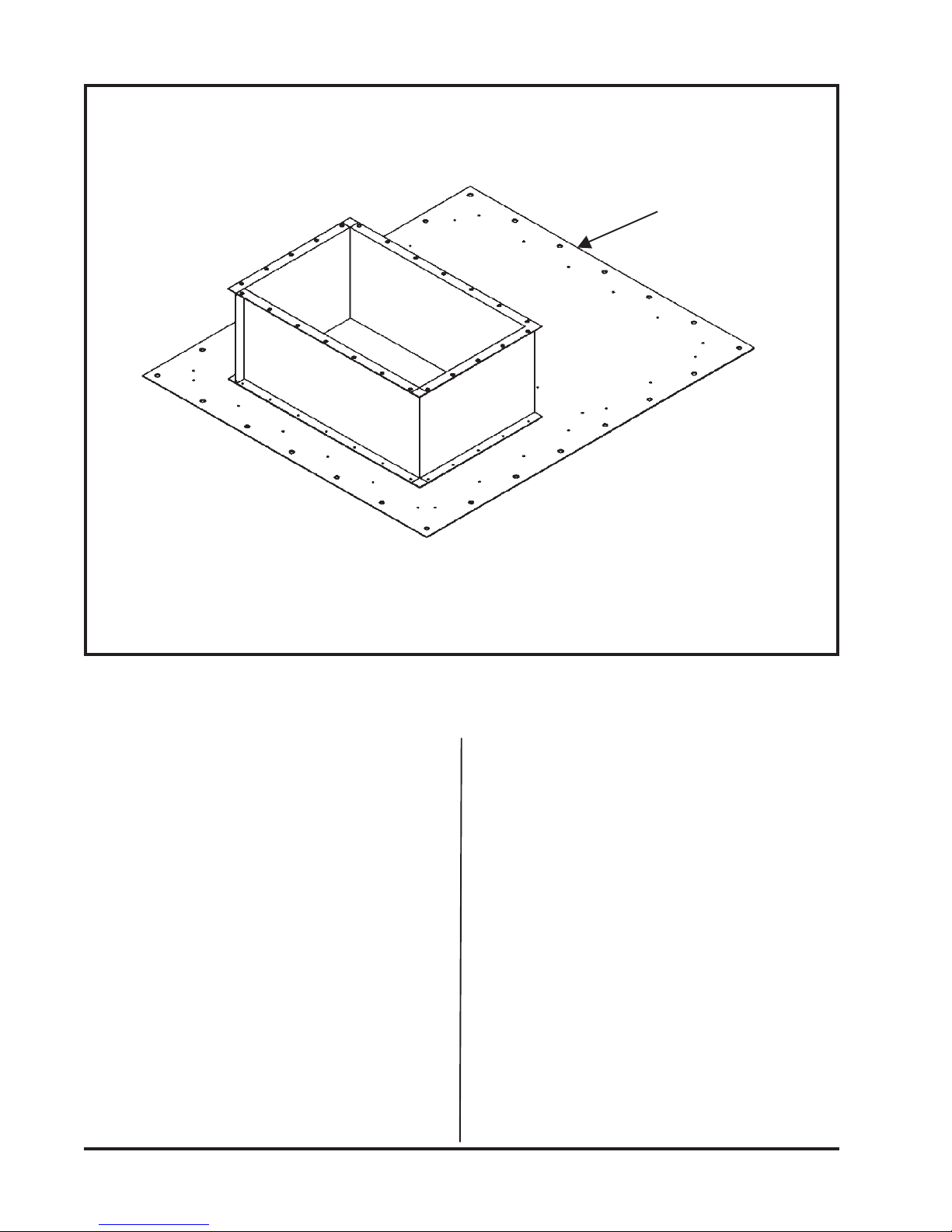

2.5.10 Bin Vent Base Pack

(See Figure 11 Bin Vent Base Pack)

The Bin Vent pack for the SDF consists of a

base, as shown in Figure 11 Bin Vent Base Pack.

The Bin Vent base has twenty-eight (28) 1/2"

diameter holes for attachment in the field.

14

Donaldson Company, Inc. © 1995

5/16 Screw

5/16 Washer

1/4" Diameter

Sealant

Flex-Trunk Assembly

(7-Foot Shown)

~

Swivel Base

M-6 Hex Bolts

(8 Req'd)

See Detail A

1/4" Diameter

M-6 Thread Cutting

Bolts (12 Req'd)

Cover Plate

Detail A

Sealant

Flex-Trunk

Adapter

Flex-Trunk Assembly 7-Foot/10-Foot SDF

Donaldson Company, Inc. © 1995

Use the bolts that are

removed from the cover

plate in Detail A

Figure 12

15

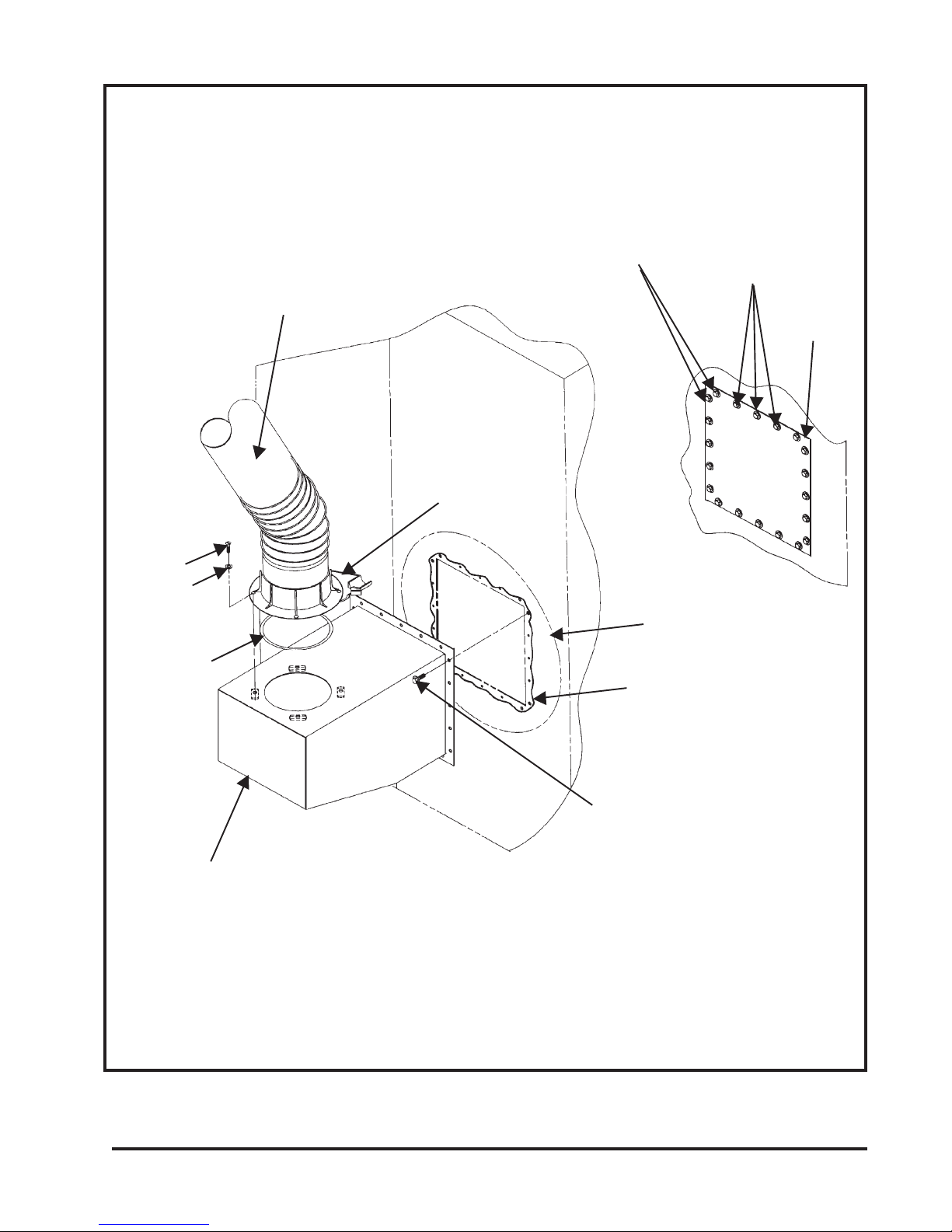

2.5.11 Flex-Trunk Assembly 7 Ft/10 Ft

(See Figure 12 Flex-Trunk Assembly)

Remove the cover plate bolts and the cover

plate from either the right or left side of the SDF

cabinet. Using the same cover plate bolts, attach

the Flex-Trunk Adapter to the side of the SDF

cabinet. Be sure to place 1/4" diameter sealant

between the adapter and the cabinet, as shown

in Figure 12 Flex-Trunk Assembly. Next, attach

the Flex-Trunk assembly to the adapter, being

sure to install more 1/4" sealant between the

adapter and the Flex-Trunk assembly. With the

swivel base positioned as shown in Figure 12

Flex-Trunk Assembly, secure the Flex-Trunk to

the adapter using the four (4) 5/16 slotted

screws and lock washers. For the adjustment

and operation of the Flex-Trunk, see the

Installation and Operation Manual for the FlexTrunk IOM-40779-00.

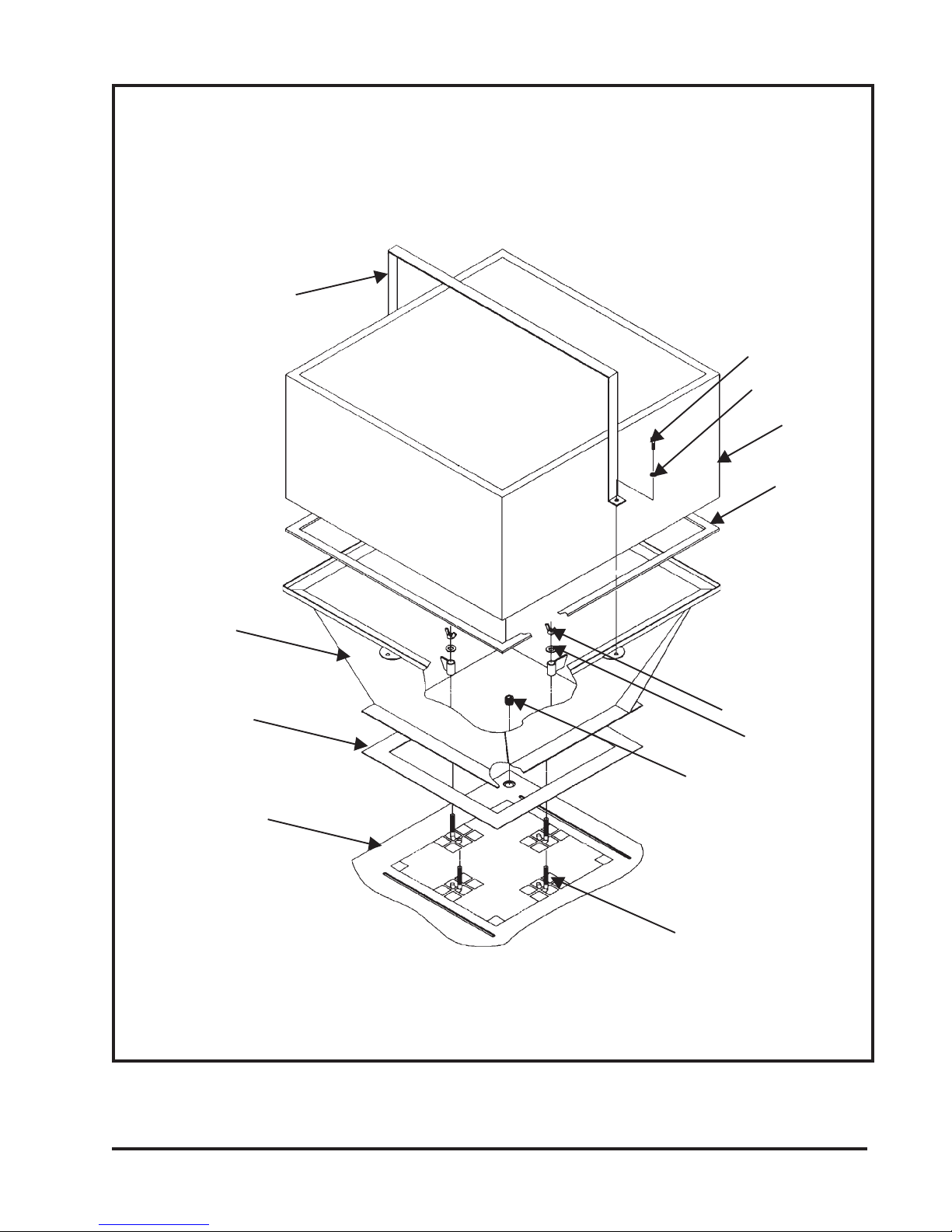

2.5.12 Weatherhood Pack

(See Figure 13 Weatherhood Pack)

Remove the bolts and the rear access panel to

the SDF. If the SDF is equipped with an outlet

damper (see Figure 1 SDF-4 Phantom View), this

damper must be removed. The weather hood

cannot be used with the outlet damper. Also,

remove the lift lug from the corner of the cabinet

and replace it with the M-16 set screw provided.

Place 1/4" diameter sealant between the cabinet

top and the weatherhood. Position the

weatherhood over the cabinet outlet, as shown

in Figure 13 Weatherhood Pack, and attach the

weather hood to the cabinet using the four M-6

bolts provided. These bolts should be inserted

through the slots on the cabinet roof and

screwed into the weld nuts on the weatherhood.

Replace the rear access panel and bolts.

2.5.13 Explosion Vent Cabinet (See Figure 15

SDF-4 with Explosion Vents—Phantom

View)

When explosion vents are furnished on an SDF,

a special cabinet is required (see Figure 15 SDF4 with Explosion Vents—Phantom View). Some

features on this cabinet include:

• A hinged access door to the dust container

with threaded handles and a reinforcing

bar.

• Two 1/8" NPT couplings for dirty air (high

pressure) and clean air (low pressure)

fittings.

• Two 3/4" NPT couplings for electrical

connections.

• Openings for two 12 x 12 explosion vents.

Options available with this SDF cabinet in

addition to the 12 x 12 explosion vents include:

• Explosion-Proof Motors.

• Aluminum Blower Wheels.

• NEMA 9 Explosion-Proof Solenoid

Enclosures.

• Checker board in remote enclosure with

unwired electrical only.

NOTE

• Explosion vent SDF units do not

contain an electrical compartment.

They are furnished from Torit

unwired.

16

• All electrical work must be done by a

qualified electrician according to local

codes.

Donaldson Company, Inc. © 1995

1/4" Dia Sealant

Weatherhood

Cabinet Shown with

Rear Access Panel

Removed

Donaldson Company, Inc. © 1995

M-6 Bolt

Replace Lift Lug

with Set Screw

Figure 13

Weatherhood Pack

17

Loading...

Loading...