Torin BIG RED TR4076 Owner's Manual

OWNER’S MANUAL

1/2 TON LOW PROFILE TRANSMISSION JACK

Item: TR4076

Questions, problems, missing parts? Before returning to your retailer, call our customer service department at

1-888-44-TORIN (1-888-448-6746), 8 a.m.- 5 p.m., PST, Monday-Friday.

Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure

to follow the safety rules and other basic safety precautions may result in serious personal injury.

Version 20161217

2

IMPORTANT

OWNER / USER RESPONSIBILITY

INTENDED USE

TECHNICAL SPECIFICATIONS

Before You Begin Register This Product.

For future reference, record the model name, model number, date of manufacture and purchase date of this

product. You can nd this information on the product.

Model Name

Model Number

Date of Manufacture

Date of Purchase

DO NOT OPERATE OR REPAIR THIS PRODUCT WITHOUT READING THIS MANUAL.

Read and follow the safety instructions. Keep Instructions readily available for operators. Make certain all

operators are properly trained and understand how to safely and correctly operate the product. By proceeding

you agree that you fully understand and comprehend the full contents of this manual. Failure to operate this

product as intended may cause injury or death. The manufacturer is not responsible for any damages or injury

caused by improper use or neglect. Allow product operation only with all parts in place and operating safely.

Use only genuine replacement parts. Service and maintain the product only with authorized or approved

replacement parts; negligence will make the product unsafe for use and will void the warranty. Carefully

inspect the product on a regular basis and perform all maintenance as required. Store these instructions

in a protected dry location. Keep all decals on the product clean and visible. Do not modify and/or use for

any application other than that for which this product was designed. If you have any questions relative to a

particular application, DO NOT use the product until you have rst contacted the distributor or manufacturer to

determine if it can or should be performed on the product.

For technical questions please call 1-888-448-6746.

This 1/2 Ton Low Prole Transmission Jack for is designed for transmission installation and removal. It

features a 360° handle that offers rotational mobility for hard-to-reach lifting points. Universal mounting head

provides a wide fore and aft tilt range. Manual operated hydraulic system that includes a bypass system to

prevent over-extension and accidental overloading. Low prole design; four heavy-duty steel swivel casters

provide easy maneuvering throughout the shop. Fits most transmissions. This product is tested for reliability

and safety to meet ASME PASE Standards.

Item

TR4076

Capacity 1000 lbs.

Lifting Range 8-1/2 inch ~ 22-1/4 in.

Saddle Forward Tilt 13°

Saddle Backward Tilt 71°

Left Saddle Tilt 30°

Right Saddle Tilt 46°

____________________________

____________________________

____________________________

____________________________

3

GENERAL SAFETY RULES

JACK USE AND CARE

INSPECTION

GENERAL SAFETY RULES

IMPORTANT SAFETY CONSIDERATIONS

WARNING: Read and understand all instructions.

Failure to follow all instructions listed below may

result in serious injury.

WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot

cover all possible conditions or situations that could occur.

It must be understood by the operator

that common sense and caution are factors that cannot be built into this product, but must be supplied by

the operator.

CAUTION: Do not allow persons to operate or assemble this jack until they have read this manual

and have developed a thorough understanding of how the jack works.

• Inspect the jack carefully before each use. Ensure the jack is not damaged, excessively worn, or missing

parts.

• Do not use the jack unless it is properly lubricated.

• Using a jack that is not in good clean working condition or properly lubricated may cause serious injury.

• Inspect the work area before each use. Make sure it is free and clear of any potential hazards.

•

Do not modify the Jack in any way.

Unauthorized modication may impair the function and/or safety and

could affect the life of the equipment. There are specic applications for which the Jack was designed.

•

Always check of damaged or worn out parts before using the Jack.

Broken parts will affect the Jack

operation. Replace or repair damaged or worn parts immediately.

•

Store idle Jack.

When Jack is not in use, store it in a secure place out of the reach of children. Inspect it for

good working condition prior to storage and before re-use.

•

Not for use by children

or people with reduced mental capacity.

•

Do not use under the inuence of drugs or alcohol.

•

Ensure children and other bystanders are

kept at a safe distance when using product.

DO NOT OPERATE OR REPAIR THIS EQUIPMENT WITHOUT READING THIS MANUAL.

To maintain the Transmission Jack and user safety, the owner is responsible for reading and following

these instructions.

• Inspect the service jack for proper operation and function.

• Keep instructions readily available for equipment operators. Make certain all equipment operators are

properly trained; understand how to safely and correctly operate the unit.

• Allow unit operation only with all parts in place and operating properly.

• Use only genuine replacement parts. Service and maintain the unit only with authorized or approved

replacement parts negligence will make the jack unsafe for use and void the warranty.

• Carefully inspect the unit on a regular basis and perform all maintenance as required.

• Store these instructions in the handle of your jack. Keep all decals on the unit clean and visible.

• Safety: always follow safety precautions when installing and operating this jack.

• Before proceeding ensure that you fully understand and comprehend the full contents of this manual.

• Failure to operate this equipment as directed may cause injury or death.

• The distributor is not responsible for any damages or injury caused by improper use or neglect.

4

SAFETY

SAFETY MARKINGS

Always follow safety precautions when installing and operating this jack. Keep all decals on the unit clean and

visible. Before proceeding ensure that you fully understand and comprehend the full contents of this manual.

Failure to operate this equipment as directed may cause injury or death. The distributor is not responsible for

any damages or injury caused by improper use or neglect.

Always use Jack Stands!

DO NOT USE

wood blocks or any other non-approved load sustaining devices. The manufacturer only

warrants loads to be sustained by jack stands that meet current ASME standards.

DO NOT USE

wood blocks or any other non-approved lifting devices for a means of lifting with the jack and or

load being raised. Failure to head these warnings may cause injury or death.

WARNING!

WARNING!

1. Study, understand, and follow all instructions before operating this device.

2. Do not exceed rated capacity.

3. Use only on hard, level surfaces, with less than 3 degrees of slope.

4. Adequately support the vehicle before starting repairs.

5. Use of this product is limited to the removal, installation, and transportation in the lowered position, of

transmissions, transfer cases, and transaxles.

6. No alterations shall be made to this product.

7. Only attachments and/or adapters supplied by the manufacturer shall be used.

8. Do not get under or allow anyone under the vehicle until it has been supported by jack stands.

9. Center load on saddle prior to lifting.

10. Never use on a lawn mower or lawn tractor.

11. Do not use this jack for any use other than the manufacturer specied usage.

12. Failure to heed these markings may result in personal injury and/or property damage.

5

GENERAL SAFETY INSTRUCTIONS

Position the Jack

Position the jack to only lift on the areas of the vehicle as specied by the vehicle manufacturer.

Always Use Jack Stands

After lifting the vehicle always support the load with appropriately rated vehicle Jacks stands before working

on the vehicle.

Do Not Overload Jack

Do not overload this jack beyond its rated capacity. Overloading this jack beyond its rated capacity can cause

damage to or failure of the jack.

Always Use on Hard Level Surfaces

This jack is designed only for use on hard level surfaces capable of sustaining the load. Use on unstable or

other possible loss of load.

Chock and Block (Stabilize)

Apply parking brake in vehicle before operating jack.

A chock is a wedge for steadying an object and holding it motionless, or for preventing the movement of a

wheel Chock the wheel opposite the end being lifted.

When you block a load, you secure and support a load that is being lifted. The block(s) or stabilizer(s) should

have a weight capacity that is greater than the weight of the load which is being lifted.

Center Load on Jack Saddle

Center load on jack saddle before lifting vehicle.

Off-center loads and loads lifted when the jack is not level can cause loss of load or damage to the jack.

Do not raise or lower the vehicle unless tools, materials and people are clear.

When the lift is being lowered, make sure everyone is standing at least six feet away. Be sure there are no

tools or equipment left under or around the jack before lowering.

Always lower the jack slowly.

DO NOT USE THE JACK TO SUPPORT OR STABILIZE A LOAD.

Using the jack to support or stabilize a load may result in unexpected movement and result in serious injury,

being crushed and death. Always securely chock and block (stabilize) the load to be lifted. Never place any

part of the body under a raised load without properly chocking and supporting the load.

Never use the jack on curved or tubular vehicle

Bumpers, this will result in the vehicle slipping off the jack and falling, causing serious injury or death. Use a

bumper lift to lift most vehicles with curved bumpers or plastic bumpers.

Wear ANSI-approved safety glasses and heavy-duty work gloves during use.

Do not adjust the safety valve.

Do not move or dolly vehicle while jack is in use.

Stay alert. Use caution and common sense when operating jack.

Do not use a jack when tired,

incoherent, dizzy, under the use or drugs or alcohol.

Training

Read this manual before use. Do not allow anyone who has not read this manual, and/or does not understand

the requirements, to use the jack.

Spectators

Do not allow bystanders around the jack or under the load supported only by the jack. -Do not allow anyone in

the vehicle while the jack is in use. Keep all bystanders away from vehicle when in use.

Inspection

Inspect the jack carefully before each use. Ensure the jack is not damaged, excessively worn, or missing

parts. -Do not use the jack unless it is properly lubricated. -Using a jack that is not in good clean working

condition or properly lubricated may cause serious injury.

Additional Notes:

Save the receipt, warranty and these instructions.

Do not modify the jack in any way.

Unauthorized modication may impair the function and/or safety and

could affect the life of the equipment. There are specic applications for which the jack was designed.

Always check for damaged or worn out parts before using the jack.

Broken parts will affect the

equipment operation. Replace or repair damaged or worn parts immediately.

When jack is not in use, store it in a secure place out of the reach of children. Inspect it for good working

condition prior to storage and before re-use.

6

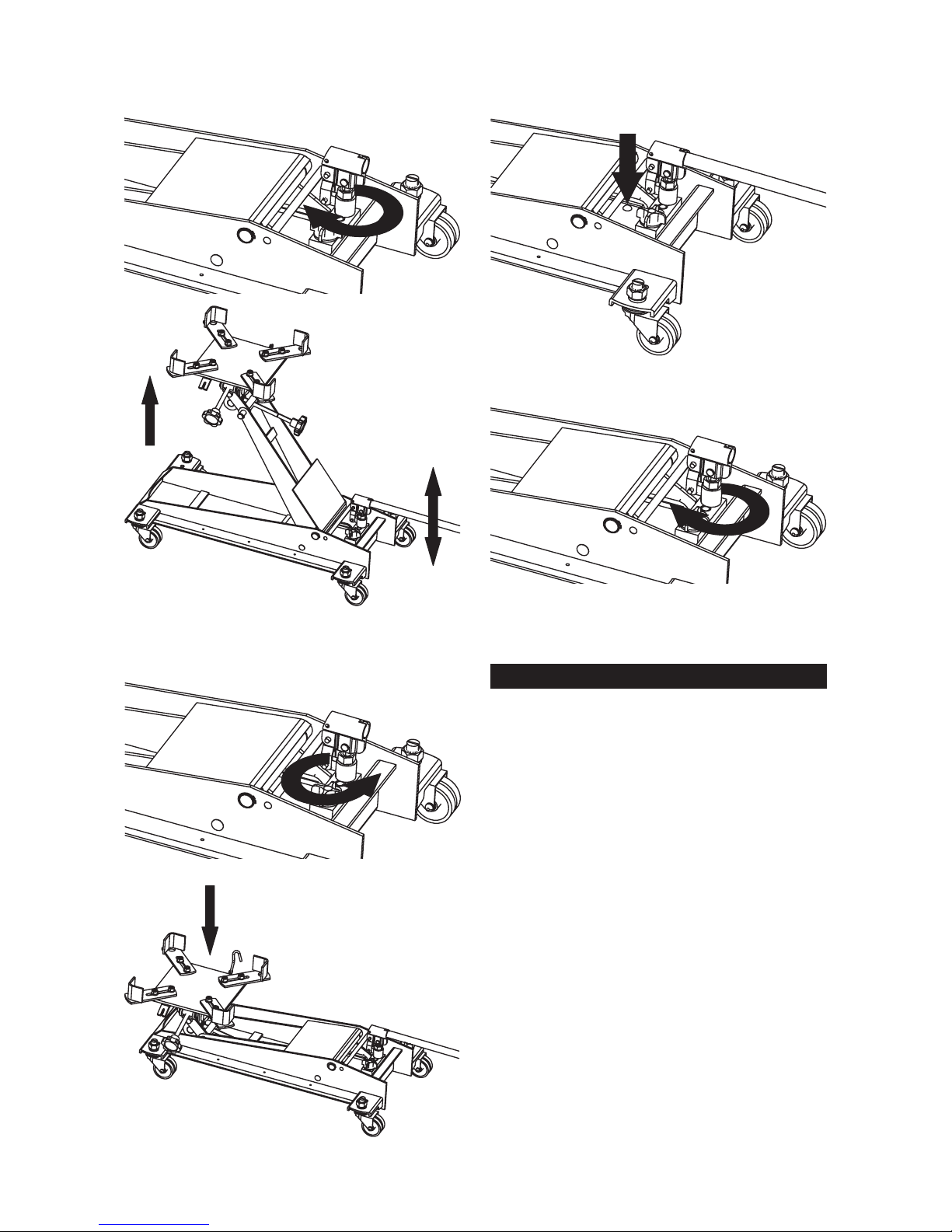

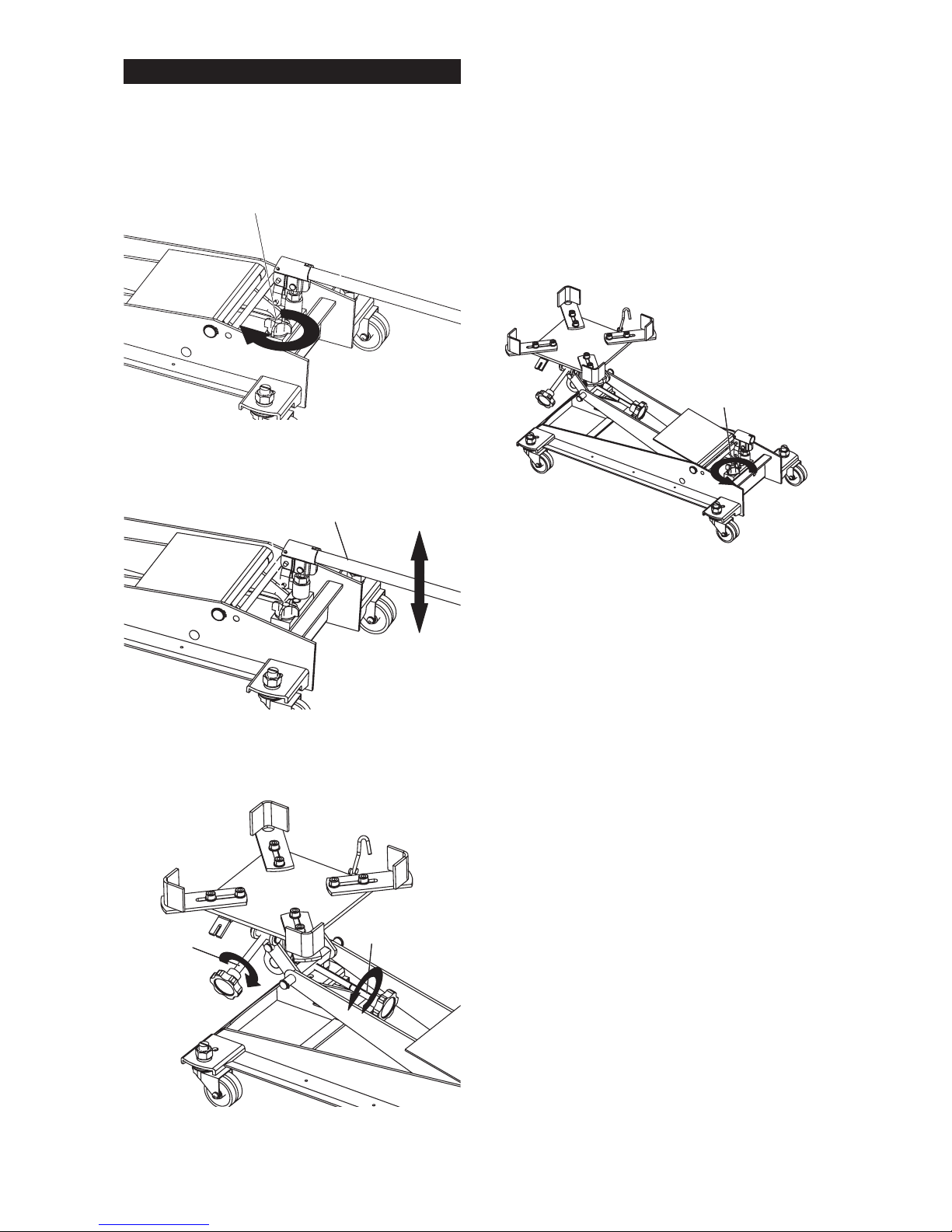

ASSEMBLY

All numbers in parenthesis () refer to the index

number from the parts breakdown.

1. Mount the four sliding plate assembly (16) to the

saddle, using eight bolt (21) and eight washers

(22).

2. Thread buttery nut (17) part way up the chain

hook (18) , and buttery nut (17).

SYSTEM AIR PURGE PROCEDURE

IMPORTANT: BEFORE FIRST USE

Perform the following Air Purge Procedure to

remove any air that may have been introduced into

the hydraulic system as a result of product shipment

and handing. This step is to be completed without

any weight on the jack.

3. Screw the pump handle (5) into the socket.

4. Tighten release valve assembly (7) clockwise

to close the pump release valve. Pump handle

up and down to lift the whole stroke. Release

release valve assembly (7) for lowering. Test

jack raising and lowering operation several times

before use.

16

22

21

17

17

18

17

5

5

7

1. Turn release valve counterclockwise one full turn

to the open position.

2. Quickly pump the jack about 10 to 20 times.

1. Before using this product, read the owner's

manual completely and familiarize yourself

thoroughly with the product and the hazards

associated with its improper use.

2. Perform the air purge procedure. (See previous

instructions for system purge procedure.)

3. Inspect before each use. Do not use if bent,

broken or cracked components are noted.

BEFORE USE

3. Turn release valve clockwise to the closed

position, pump the jack and the lift arm will rise,

until the jack reaches maximum height.

4. Turn release valve counterclockwise one full turn

to the open position, lift arm will fall , until the jack

reaches minimum height.

5. Carefully and slowly pinch oil ll plug to release

trapped air. (Use caution not to tear or puncture

the oil plug.).

6. Turn release valve clockwise to the closed

position.

7. Jack is now ready for use. Check for proper pump

action.

7

8

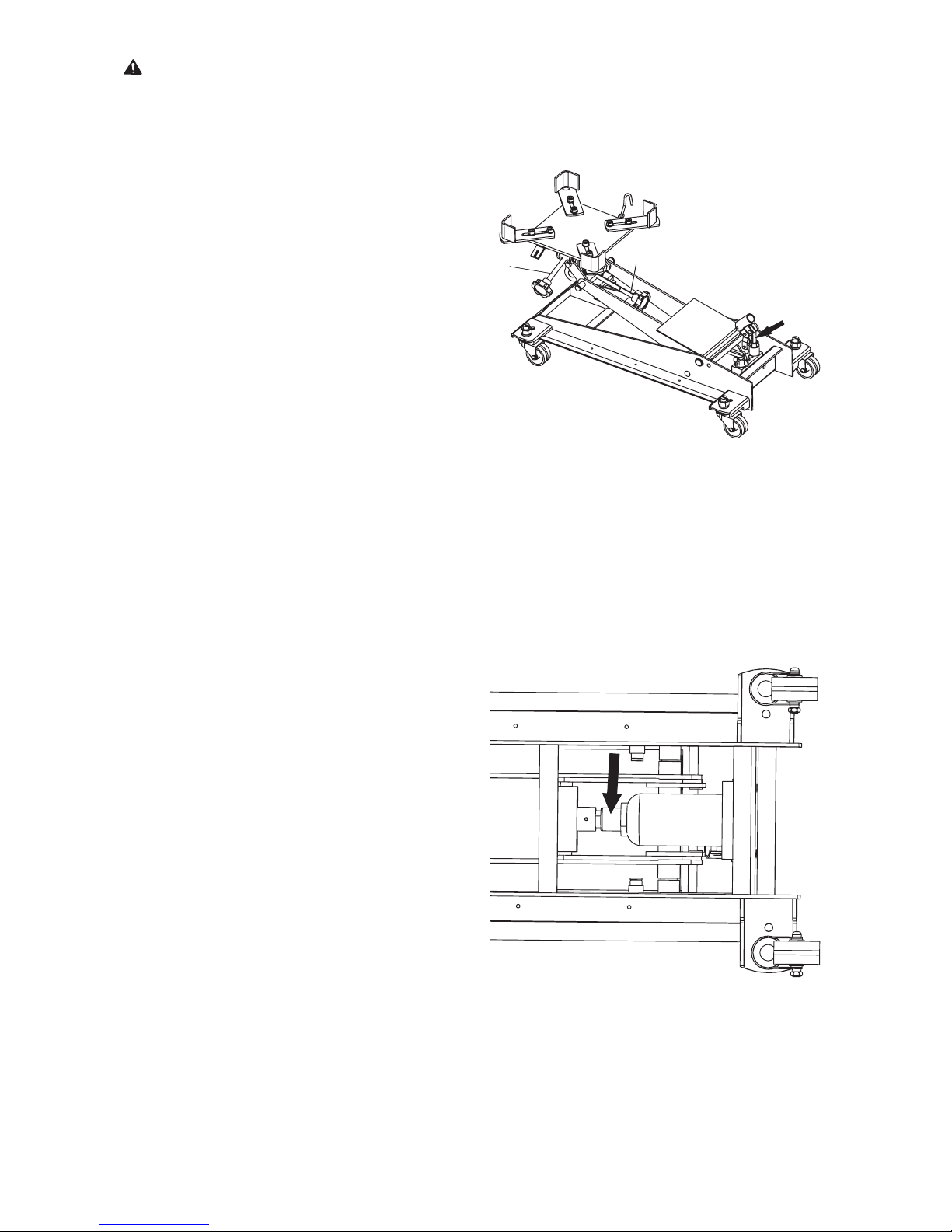

All numbers in parenthesis () refer to the index

number from the parts breakdown.

1. Move the jack into position.

2. Turn the release valve assembly (7) clockwise

fully to close the valve.

OPERATION

3. Move the handle(5) up and down to raise the

saddle.

4. Adjust the adjustable screw (13&14) to align with

the shape of the transmission.

5. Adjust the angle brackets and the chain to secure

the transmission on the saddle.

8. Reverse this procedure when mounting the

transmission.

6. Remove the transmission from the vehicle.

7. Turn the release valve assembly (7) counterclockwise slowly to lower the saddle. Always

lower the saddle slowly. Always transport the load

in the lowered position with the chains securely

fastened.

NOTE: Use a tie-down or chain to stabilize the

transmission before removing the transmission

or gear box from the vehicle.

7

5

14

13

7

9

MAINTENANCE INSTRUCTIONS

If you use and maintain your equipment properly, it will give you many years of service. Follow the

maintenance instructions carefully to keep your equipment in good working condition. Never perform any

maintenance on the equipment while it is under a load.

Inspection

You should inspect the product for damage, wear, broken or missing parts (e.g.: pins) and that all components

function before each use. Follow lubrication and storage instructions for optimum product performance.

Binding

If the product binds while under a load, use equipment with equal or a larger load capacity to lower the load

safely to the ground. After un-binding; clean, lubricate and test that equipment is working properly. Rusty

components, dirt, or worn parts can be causes of binding Clean and lubricate the equipment as indicated in

the lubrication section. Test the equipment by lifting without a load. If the binding continues contact Customer

Service.

Cleaning

If the moving parts of the equipment are obstructed, use cleaning solvent or another good degreaser to clean

the equipment. Remove any existing rust, with a penetrating lubricant.

Lubrication

This equipment will not operate safely without proper lubrication. Using the equipment without proper

lubrication will result in poor performance and damage to the equipment. Some parts in this equipment are not

self-lubricating inspect the equipment before use and lubricate when necessary. After cleaning, lubricate the

equipment using light penetrating oil, lubricating spray.

• Use a good lubricant on all moving parts.

• For light duty use lubrication once a month.

• For heavy and constant use lubrication recommended every week.

• NEVER USE SANDPAPER OR ABRASIVE MATERIAL ON THESE SURFACES!

Rust Prevention:

Check rams and pump plungers on the power unit assemblies daily for any signs of rust or corrosion.

Without a load lift the equipment as high as it goes and look under and behind the lifting points. If signs of rust

are visible clean as needed.

Grease Fittings

Some models contain grease ttings the will regularly need to be greased and lubricated.

How the Jack Operates

With release valve closed, an upward stroke of the jack handle draws oil from the reservoir tank into the

plunger cavity. Hydraulic pressure holds the valve closed, which keeps the oil in the plunger cavity. A

downward stroke of the jack handle releases oil into the cylinder, which forces the ram out. This raises the

saddle. When the ram reaches maximum extension, oil is bypassed back into the reservoir to prevent an over

extended ram stroke and possible damage to the jack. Opening the release valve allows oil to ow back into

reservoir. This releases hydraulic pressure on the ram, which results in lowering the saddle.

Storing the Jack

1. Lower the hydraulic ram to lowest position.

2. Leave lowering valve open.

3. Store in a dry location, recommended indoors.

Note: If the jack is stored outdoors, be sure to lubricate all parts before and after use to ensure the jack stays

in good working condition. Always store jack in the fully retracted postion when stored in outdoor or caustic

enviroments that can cause corrosion and/or rust.

10

TO ADD JACK OIL

TO REPLACE JACK OIL

The hydraulic cylinder assembly contains hydraulic

uid that must be kept at approximately 80% full at

all times for proper operation. To check the level and

to ll remove oil ller plug.

1. Position the jack on level ground and lower the

saddle.

2. Remove the oil plug.

3. Fill the oil case until oil level to 80% full.

4. Replace oil plug.

5. Perform the Air Purge Procedure.

1. Position the jack on level ground and lower the

saddle.

2. Open release valve by turning handle counterclockwise (4 full turns).

3. Remove the oil ll plug.

4. Turn the jack on its side so that old oil will drain

from the oil ll hole.

5. Position the jack on level ground and lower the

saddle.

6. Fill the oil case until oil level to 80% full.

KEEP DIRT AND OTHER MATERIALS CLEAR

WHEN POURING.

7. Replace oil plug.

8. Perform the Air Purge Procedure.

on level ground and lower the saddle

7

11

ADDITIONAL WARNINGS:

Important: Use only a quality grade hydraulic jack

oil. Avoid mixing different types of uid and NEVER

use brake uid, turbine oil, transmission uid, motor

oil or glycerin. Improper uid can cause failure of the

jack and the potential for sudden and immediate loss

of load.

LUBRICATION

1. Lubricate the shaft threads of the adjustable

screw assembly (13&14) with #2 tube grease

when necessary.

• DO NOT USE MOTOR OIL IN THE JACK.

• ONLY USE ANTI-FOAMING JACK OIL.

• ALWAYS USE A GOOD GRADE HYDRAULIC

JACK OIL.

• DO NOT USE HYDRAULIC BRAKE FLUID,

ALCOHOL, GLYCERINE, DETERGENT, MOTOR

OIL OR DIRTY OIL.

• USE OF A NON-RECOMMENDED FLUID CAN

CAUSE DAMAGE TO A JACK.

• AVOID MIXING DIFFERENT TYPES OF FLUID

AND NEVER USE BRAKE FLUID, TURBINE

OIL, TRANSMISSION FLUID, MOTOR OIL OR

GLYCERIN. IMPROPER FLUID CAN CAUSE

PREMATURE FAILURE OF THE JACK AND THE

POTENTIAL FOR SUDDEN AND IMMEDIATE

LOSS OF LOAD.

• DISPOSE OF HYDRAULIC FLUID IN

ACCORDANCE WITH LOCAL REGULATIONS.

2. A coating of light lubricating oil to pivot points.

Axles and hinges will help to prevent rust and

assure that wheels, casters and pump assemblies

move freely.

3. Periodically check the pump piston and ram for

signs of rust or corrosion. Clean as needed and

wipe with an oil cloth.

4. When not in use, store the Jack with pump piston

and ram fully retracted.

14

13

12

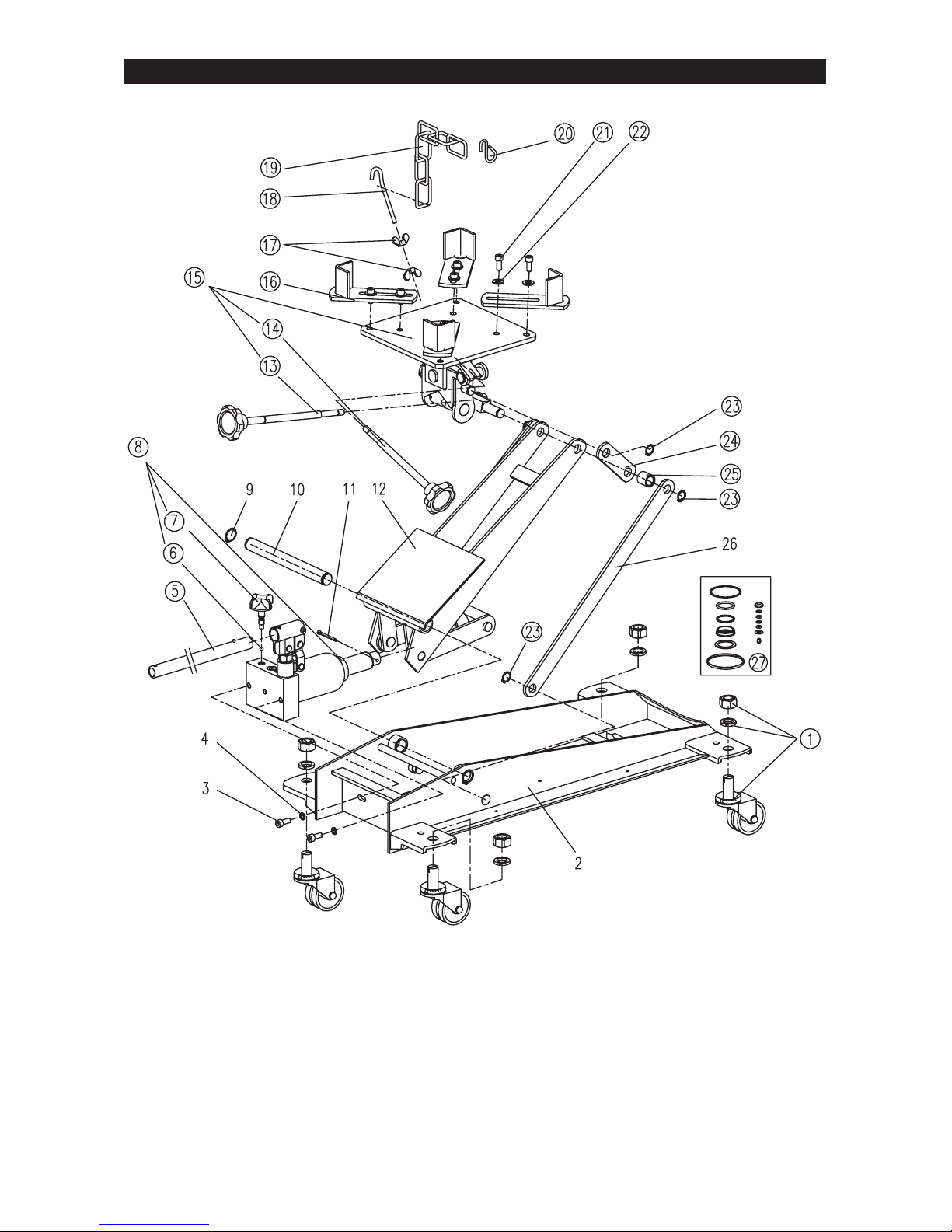

ASSEMBLY DIAGRAM

13

REF# PART # DESCRIPTION QTY

1 TE05001.5(ASM) Caster assembly 4

2 Frame assembly 1

3 Bolt M8X16mm 2

4 Spring washer M8 2

5 TE05001-01 Handle 1

6 GB308-6 Steel ball Ø6mm 1

7 QF4.2A(ASM) Release valve assembly 1

8 TE05001.3 Pump assembly 1

9 C-clip Ø22 2

10 Supporting shaft 1

11 Cotter pin Ø4X40mm 1

12 Lifting arm 1

13 TE05001.4-5(ASM) Adjustable screw(long) M12X268.5mm 1

14 TE05001.4-7(ASM) Adjustable screw(short) M12X228.5mm 1

15 TE05001.4(ASM) Platform assembly 1

16 TE05001.4-1(ASM) Sliding plate assembly 4

17 GB62-M6 Buttery nut M6 2

18 TE05001-04 Hook M6X105mm 1

19 TEL05001-02 Chain 1

20 TE05001-06 S-hook 1

21 GB5783-M10X16 Bolt M10X16mm 8

22 GB97.1-10 Washer M10 8

23 GB894.1-16 C-clip φ16 6

24 Connecting bar for platform assembly 2

25 TE05001.4-8 Shaft sleeve 2

26 Connecting bar 2

27 TE05001.MF Seal kit 1

14

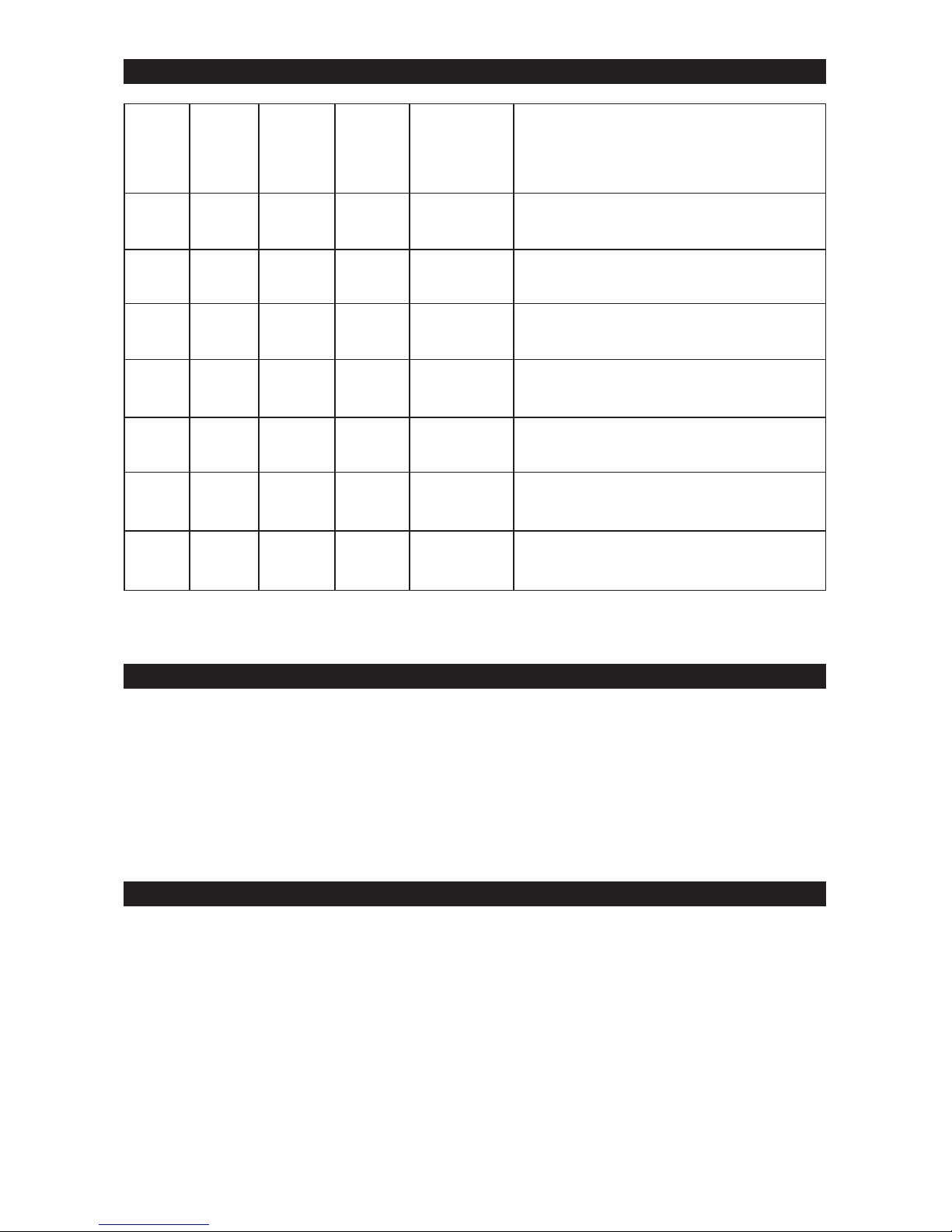

TROUBLESHOOTING

JACK

WILL

NOT

LIFT

LOAD

JACK

WILL

NOT

HOLD

LOAD

JACK

WILL

NOT

LOWER

POOR

JACK

LIFTING

WILL NOT

LIFT TO

FULL

EXTENSION

CAUSES AND SOLUTIONS

Release valve is not completely closed

(Turn handle clockwise).

Weight Capacity Exceeded.

Air is in the hydraulics.

Purge air from system.

Low oil level. Add oil as required.

Oil reservoir is overlled.

Drain excessive oil.

Lubricate moving parts.

Jack is binding or foreign obstruction

Power unit malfunctioning.

Replace the power unit.

X XX

X

X X

X X XX

X X X

X

X

Safe Operating Temperature is between 40°F – 105°F (4°C - 41°C)

This equipment is covered under a 1-year limited warranty when used as recommended. Only those

items listed with a Part # are available for purchase. For assistance with the operation or the availability of

replacement parts, contact our Parts and Warranty Department at 1-888-44-TORIN (1-888-448-6746). Please

have available a copy of your receipt, the model number of the product, serial number, and specic details

regarding your question.

Not all equipment components are available for replacement; illustrations provided are a convenient reference

of location and position in the assembly sequence.

The manufacturer reserves the rights to make design changes and or improvements to product lines

and manuals without notice.

WARRANTY NOTICE

We want to know If you have any concerns with our products. If so, please call toll-free for Immediate

assistance. For additional web customer support help inquiries visit the Customer Service section at:

http://www.torin-usa.com.

WARRANTY INFORMATION

Loading...

Loading...