XC9515 Series

ETR0706-012b

2 channel Synchronous Step-Down DC/DC Converter with Manual Reset

■GENERAL DESCRIPTION

The XC9515 series consists of 2 channel synchronous step-down DC/DC converters and a voltage detector with delay circuit

built-in. The DC/DC converter block incorporates a P-channel 0.35Ω (TYP.) driver transistor and a synchronous N-channel

0.35Ω (TYP.) switching transistor. By minimizing ON resistance of the built-in transistors, the XC9515 series can deliver

highly efficient and a stable output current up to 800mA. With high switching frequencies of 1MHz, a choice of small inductor

is possible. The series has a built-in UVLO (under-voltage lock-out) function, therefore, the internal P-channel driver

transistor is forced OFF when input voltage becomes 1.8V or lower (for XC9515A, 2.7V or lower). The voltage detector block

can be set delay time freely by connecting an external capacitor. With the manual reset function, the series can output a

reset signal at any time.

■APPLICATIONS

●DVDs

●Blue-ray Disk

●LCD TVs, LCD modules

●Multifunctional printers

●Photo printers

●Set top boxes

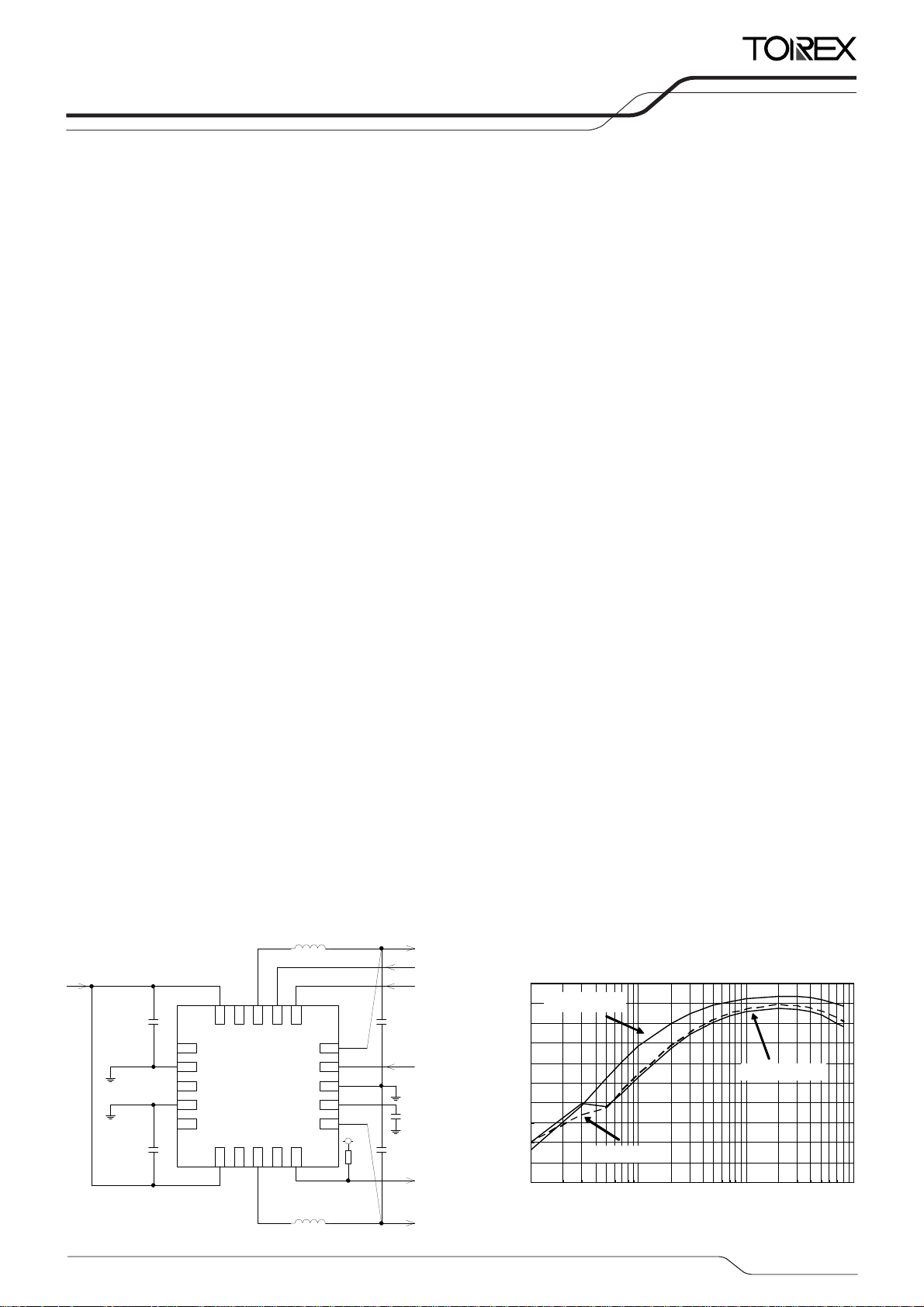

■TYPICAL APPLICATION CIRCUIT

VIN

NC

PVSS

1

NC

PVSS

2

NC

1

PVDD

PVDD2NC

NC

CIN1 CL1

CIN2

L1

LX1

EN1

EN2

VOUT

1

MR

AVSS

Cd

VOUT

LX2

2

NC

VDOUT

L2

RUP

VOUT1

EN1

EN2

MR

Cd

CL2

VDOUT

VOUT2

■FEATURES

DC/DC Block

Input Voltage Range : 2.5V~5.5V

Output Voltage

: V

=1.2V~4.0V

OUT1

V

=1.2V~4.0V

OUT2

(Accuracy ±2%)

Oscillation Frequency : 1MHz (Accuracy ±15%)

High Efficiency : 95% (VIN=5V, V

OUT

=3.3V)

Output Current : 800mA

Control : PWM control

Protection Circuits : Thermal Shutdown

: Integral Latch (Over Current Limit)

: Short Protection Circuit

Ceramic Capacitor Compatible

Voltage Detector (VD) Block

Detect Voltage Range : 2.0~5.5V(Accuracy ±2%)

Delay Time : 173 ms

(When Cd=0.1μF is connected)

Output Configuration : N-channel open drain

Operating Ambient Temperature :

-40℃ ~ +85℃

Package : QFN-20

Environmentally Friendly : EU RoHS Compliant, Pb Free

■ TYPICAL PERFORMANCE

CHARACTERISTICS

● Efficiency vs. Output Current

VIN=5V, f

100

90

80

70

60

50

40

Efficiency[%]

30

20

10

VOUT=3.3V

VOUT=1.8V

0

1 10 100 1000

=1MHz, L=4.7μH (CDRH4D28C)

OSC

L=4.7uH(CDRH4D28C),CIN=10uF(ceramic),CL=10uF(ceramic)

CIN=10μF (ceramic), CL=10μF (ceramic)

Output Current : IOUT [mA]

VIN=5V,FOSC=1MHz

VOUT=1.5V

1/21

XC9515 Series

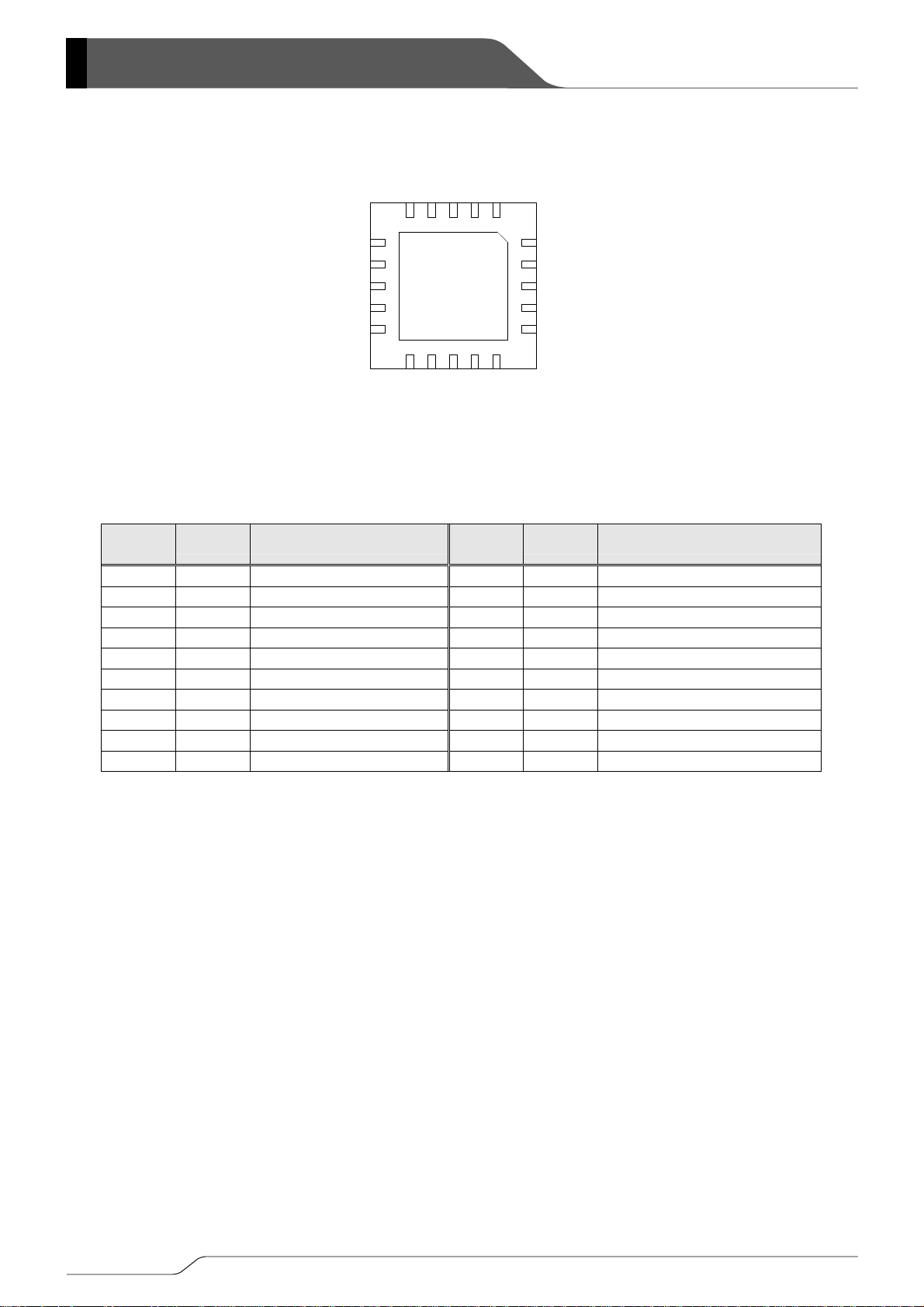

■PIN CONFIGURATION

VDD1

NC

LX1

EN1

EN2

17

16

15

V

out1

MR

14

A

13

VSS

CD

12

V

11

out2

※1

QFN-20

(BOTTOM VIEW)

9

10

NC

DOUT

V

P

20

19

18

NC

1

P

2

VSS1

NC

3

P

4

VSS2

NC

5

6

7

8

NC

LX2

VDD2

P

■ PIN ASSIGNMENT

QFN-20

PIN

NUMBER

1 NC No Connection 11 V

2 P_V

PIN NAME FUNCTION

Power Ground 1 12 Cd Delay Capacitor Connection

SS1

PIN

NUMBER

PIN NAME FUNCTION

Output Voltage Sense 2

OUT2

3 NC No Connection 13 A_VSS Analog Ground

4 P_V

5 NC No Connection 15 V

6 P_V

Power Ground 2 14 MR Manual Reset

SS2

Output Voltage Sense1

OUT1

Power Supply 2 16 EN2 CH2 ON/OFF Control

DD2

7 NC No Connection 17 EN1 CH1 ON/OFF Control

8 LX2 Switching Output 2 18 LX1 Switching Output 1

9 NC No Connection 19 NC No Connection

10 V

*1 Back metal pad voltage :VSS level

(The back metal pad should be soldered to enhance mounting strength and heat release. If the pad needs to be connected to

other circuit, care should be taken for the pad voltage level.)

Voltage Detector output 20 P_V

DOUT

Power Supply 1

DD1

2/21

■FUNCTION CHART

●EN1, EN2 and MR pins are internally pulled up. *2)

PIN LEVEL OPERATIONAL STATUS

EN1

EN2

MR

EN1, EN2 and MR pins are internally pulled up so that the levels of High and Open are same function.

●EN1, EN2 and MR pins are left open internally. *

PIN LEVEL OPERATIONAL STATUS

EN1

EN2

MR

EN1, EN2 and MR pins are floated inside so that these pins shall not be left open outside.

2)

*

Please refer to the PRODUCTION CLASSIFICATION to see the combination of pull-up status regarding the EN1, EN2, and MR pins.

■PRODUCT CLASSIFICATION

●Ordering Information (Standard products)

XC9515①②③④⑤⑥-⑦

High , Open DC/DC_CH1 Operation

Low DC/DC_CH1 Stop

High , Open DC/DC_CH2 Operation

Low DC/DC_CH2 Stop

High , Open VD_OUT Detect RESET Signal Output

Low VD_OUT Force RESET Signal Output

2)

High DC/DC_CH1 Operation

Low DC/DC_CH1 Stop

High DC/DC_CH2 Operation

Low DC/DC_CH2 Stop

High VD_OUT Detect RESET Signal Output

Low VD_OUT Force RESET Signal Output

(*1)

XC9515

Series

DESIGNATOR ITEM SYMBOL DESCRIPTION

① Input Voltage & UVLO

② EN & MR logic control conditions

③④ Set Voltage Combinations 01~ Based on Torex Standard Product Number

⑤⑥-⑦ Package (Order Unit) ZR-G QFN-20 (1,000/Reel)

(*1)

The “-G” suffix denotes Halogen and Antimony free as well as being fully RoHS compliant.

About ①②③④(Output Voltage, Detect Voltage)

XC9515①②③④ VOUT1 [V] VOUT2 [V] VDF(Detect Voltage) [V]

XC9515AB02 1.2 3.3 3.5

XC9515AB04 1.5 3.3 3.5

XC9515AB05 1.8 3.3 3.5

XC9515BA06 1.2 1.8 3.0

XC9515AA07 1.2 3.3 4.2

XC9515AA08 3.3 1.8 4.5

*This series are semi-custom products. For other combinations, output voltages, detect voltage and etc., please ask Torex sales contacts.

A Input Voltage Range 5V±10%, UVLO Voltage 2.7V (TYP.)

B Input Voltage Range 2.5V~5.5V, UVLO Voltage 1.8V (TYP.)

A EN1, EN2, MR pins are not pulled up internally

B

C

D

EN1, EN2 pins have built-in pull-up resistors,

MR pin has a built-in pull-up resistor

EN1, EN2 Pins are not pulled up internally,

MR pin has a built-in pull-up resistor

EN1, EN2 pins have built-in pull-up resistors,

MR pin are not pulled up internally

3/21

XC9515 Series

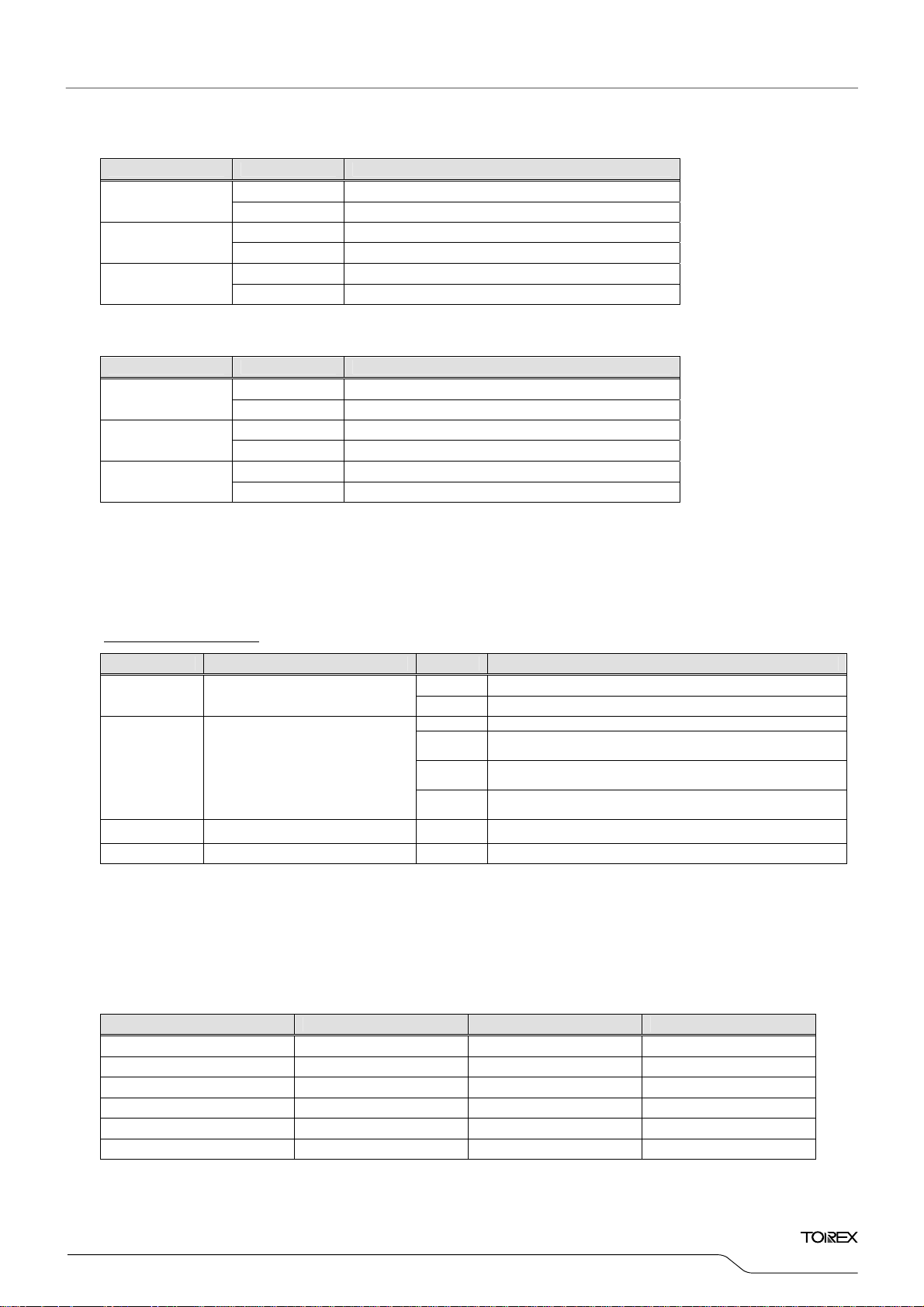

■BLOCK DIAGRAM

●EN1 Pin, EN2 Pin, MR Pin,

Pull-up Inside ●EN1 Pin, EN2 Pin, MR Pin, internally floating

V

OUT1

PVDD1

EN1

EN2

ON/OF

Control

Soft

Start

F

V

OUT2

Soft

Start

PVDD1

MR

Error Amp

Error Amp

Ramp

Wave

OSCVref

Ramp

Wave

PWM

Comparator

PWM

Comparator

Rdelay

Current

Limit

Current

Feedback

Logic

Thermal

Shutdown

Current

Limit

Current

Feedback

Logic

Buffer

Drive

Buffer

Drive

P

LX1

P

P

LX2

P

VDD1

VSS1

VDD2

VSS2

V

DOUT

A

Vref

VSS

Cd

■ABSOLUTE MAXIMUM RATINGS

P

LX1

P

P

LX2

P

VDD1

VSS1

VDD2

VSS2

V

DOUT

V

OUT1

Error Amp

EN1

EN2

V

OUT2

PVDD1

MR

ON/OF

Control

Soft

Start

F

Soft

Start

Error Amp

A

VSS

Comparator

Ramp

Wave

OSCVref

Ramp

Wave

Comparator

Vref

PWM

PWM

Cd

Rdelay

Current

Limit

Current

Feedback

Logic

Thermal

Shutdown

Current

Limit

Current

Feedback

Logic

Buffer

Drive

Buffer

Drive

Ta=25℃

4/21

PARAMETER SYMBOL RATINGS UNITS

P_V

DD1

V

OUT1・VOUT2

・P_V

Pin Voltage

DD2

Pin Voltage

P_V

V

DD1

OUT1

Cd Pin Voltage VCd

V

Pin Voltage V

DOUT

V

Pin Current I

DOUT

EN1・EN2・MR Pin Voltage

LX1・LX2 Pin Voltage

LX1・LX2 Pin Current

Power Dissipation QFN-20

V

EN1,VEN2,VMR

V

Lx1

I

Lx1

Pd (Free air) 300

Pd (PCB mounted) 1000

Operating Ambient Temperature Topr

Storage Temperature Tstg

* P_V

A_VSS=P_V

DD1・2

SS1

stands for P_V

=P_V

=0V

SS2

DD1

=P_V

DD2

, P_V

DD2

, V

OUT2

DOUT

10 mA

DOUT

, V

Lx2

, I

1500 mA

Lx2

A_V

A_V

A_V

SS

A_V

SS

-0.3~P_V

SS

A_V

SS

A_V

SS

-0.3~P_V

SS

-0.3~6.5

-0.3~6.5

DD1・2

-0.3~6.5

-0.3~6.5

DD1・2

+ 0.3

+0.3

V

V

V

V

V

V

mW

o

-40 ~ +85

-55 ~ +125

C

o

C

y

XC9515

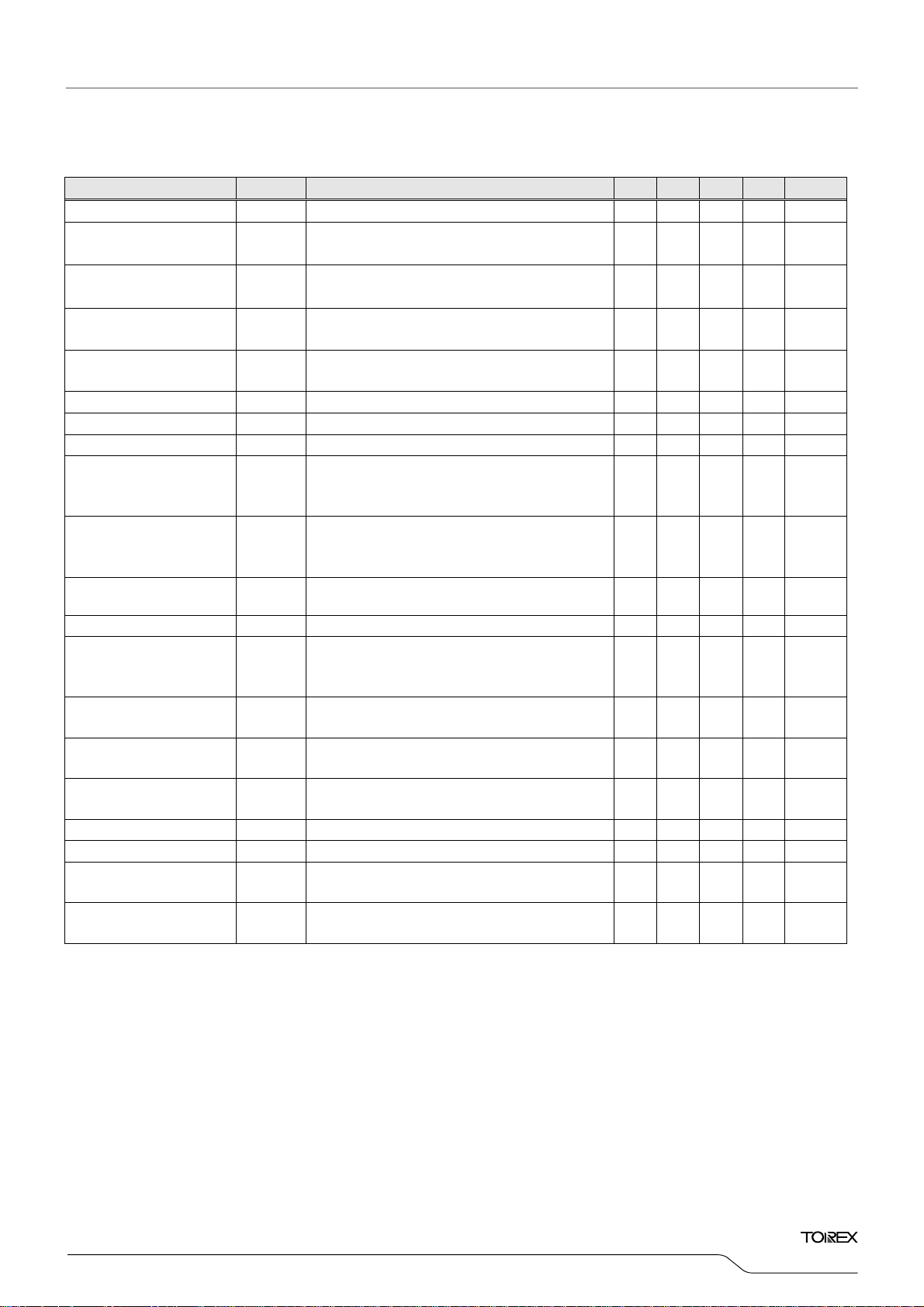

■ELECTRICAL CHARACTERISTICS

XC9515AB04xx

● DC/DC CH1, CH2 (V

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNITS CIRCUIT

Input Voltage VIN 4.5 5.0 5.5 V

Output Voltage 1 VOUT1

Output Voltage 2 VOUT2

Maximum Output Current 1・2

Current Limit 1・2

Oscillation Frequency f

Maximum Duty Cycle D

Minimum Duty Cycle D

Efficiency 1

Efficiency 2

LX1・2 "H" ON Resistance

LX1・2 "L" ON Resistance

Integral Latch Time 1・2

Soft-Start Time 1・2

EN1・2 "H" Level Voltage

EN1・2 "L" Level Voltage

EN1・2 "H" Level Current

EN1・2 "L" Level Current

LX1・2 "H" Leakage Current

LX1・2 "L" Leakage Current

Test Conditions:

* P_V

DD1・2

**Unless otherwise stated, P_V

*** A_VSS=P_V

NOTE :

*1

:When the difference between the input and the output is small, some cycles may be skipped completely before current maximizes.

If current is further pulled from this state, output voltage will decrease because of P-ch driver ON resistance.

*2:EFFI = { ( output voltage x output current ) / ( input voltage x input current) } x 100

*3

:On resistance (Ω)= (V

*4:Designed value.

*5:Time until it short-circuits LX1 (LX2 in the side of 2CH) with GND via 1Ωof resistor from an operational state and is set to Low level from

current limit pulse generating.

*6:”H” is judged as “H”>VIN-0.1V, ”L” is judged as ”L”<0.1V.

*7

:When temperature is high, a current of approximately 20μA (maximum) may leak.

*8

:Current which EN1 and EN2 are measured separately.

:Lead current which LX1 and LX2 are measured separatel

*9

(*2)

EFFI1

(*2)

EFFI2

stands for P_V

=P_V

SS1

OUT1

=1.5V, V

OUT2

=3.3V, f

OSC

Connected to the external components,

P_V

DD1・2=VEN1=VEN2

Connected to the external components,

P_V

DD1・2=VEN2=VEN1

IOUTMAX1

(*1)

IOUTMAX2

LIM1,

I

I

LIM 2

Connected to the external components, I

OSC

V

MAX

V

MIN

Connected to the external components,

P_V

Connected to the external components,

P_V

LX1H

・RLX2H

R

R

LX1L

・RLX2L

V

OUT1=VOUT2

LX1 and LX2 are pulled down by a resistor of 200Ω

, t

LAT1

t

SS1

LAT2

Time until EN1, EN2 or both pins changes from 0V to

, t

SS2

V

and voltage becomes V

IN

V

V

OUT2

t

VEN1H,

V

EN2H

Voltage which LX1 or LX2 becomes ”H”

VEN1L,

V

EN2L

IEN1H, IEN2H

IEN1L, IEN2L

ILEAK1H,

(*7)

LEAK2H

I

ILEAK1L,

I

LEAK2L

=P_V

DD1

DD2

=5V, V

DD1・2

=0V

SS2

- Lx pin measurement voltage) / 100mA

IN

Voltage which LX1 or LX2 becomes ”L”

P_V

P_V

DD1・2=VLX1=VLX2

P_V

DD1・2

= P_V

EN1=VEN2

=1MHz, EN1・2 Pull-up inside) Ta =25 oC

=0V, I

=0V, I

OUT1=VOUT2

OUT1=VOUT2=VIN

DD1・2=VEN1

=1.5V, I

V

OUT1

DD1・2=VEN2

=3.3V, I

V

OUT2

=0V 100

=5.0V, V

1=200mA

OUT

=5.0V, V

=200mA

OUT2

=0V, ILx1=ILx2=100mA

=Setting Voltage×0.9,

OUT1

= Setting Voltage ×0.9

×0.95, I

OUT1・2

V

OUT1=VOUT2

V

OUT1=VOUT2

P_V

DD1・2=VEN1=VEN2

=5.5V, V

DD1・2

=0V

=0V

EN1=VEN2

=5.5V, V

=5.5V, V

DD1・2

LX1=VLX2=VEN1=VEN2

.

=30mA

OUT1

=30mA

OUT2

=10mA 0.85 1.00 1.15 MHz

OUT

=0V,

EN2

=0V,

EN1

(*3)

(*5)

=10mA

OUT1・2

(*6)

(*6)

=5.5V -

=0V -

=0V - -

EN1=VEN2

=0V

1.470 1.500 1.530 V

3.234 3.300 3.366 V

800

1000

- -

- -

- -

- -

89

-

94

-

0.35

-

0.35

-

6

-

1.3

-

1.2

AVSS

-

-

-6

(*9)

-3.0

- - μA ④

0 %

-

-

(*4)

- Ω ③

(*4)

- Ω -

-

-

V

V

IN

0.4 V

(*8)

0.1

(*8)

- μA ④

(*9)

1.0

mA

mA

%

%

%

ms

ms

μA ④

μA ④

Series

-

①

①

①

②

①

②

②

①

①

⑦

①

④

④

5/21

XC9515 Series

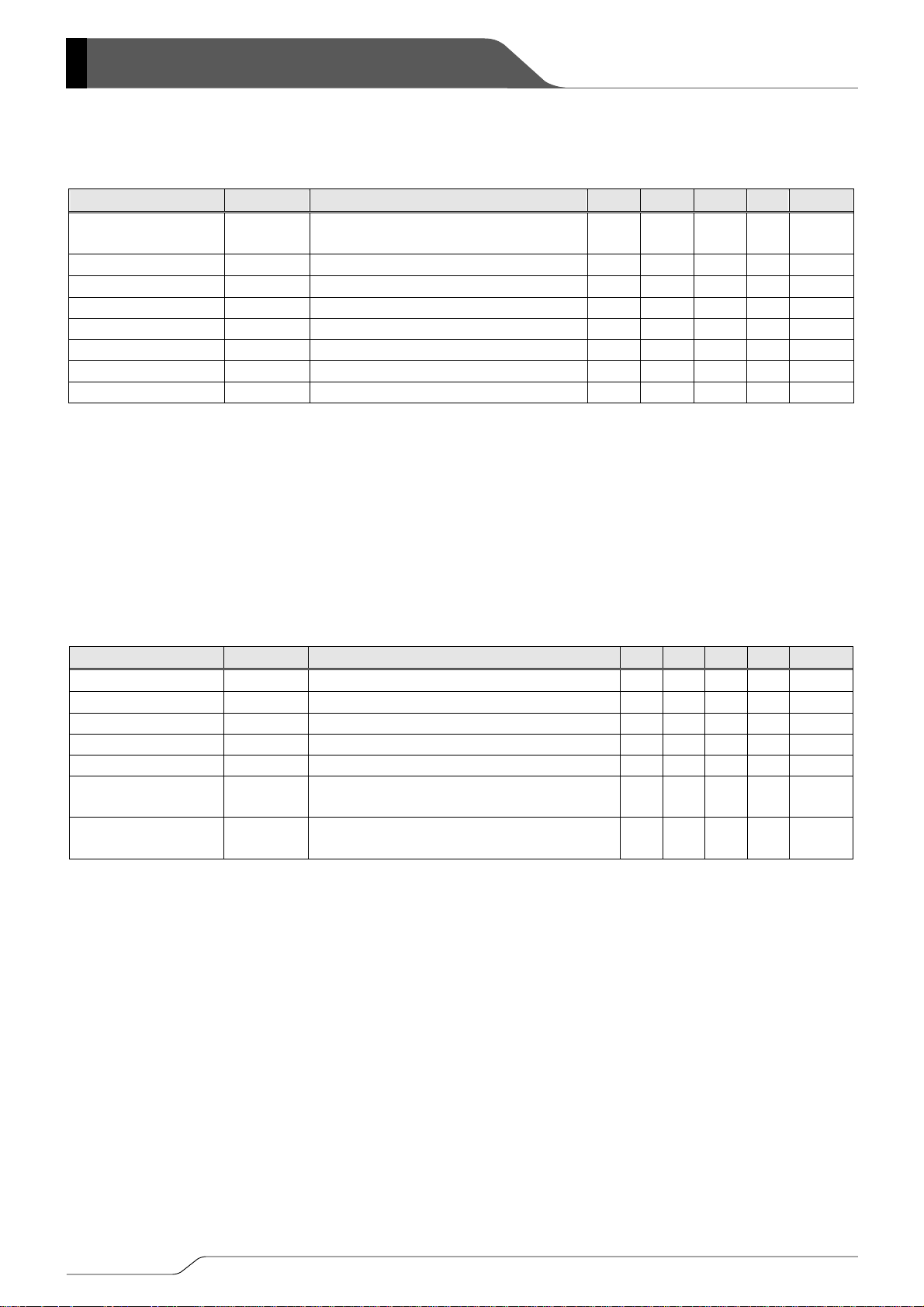

■ELECTRICAL CHARACTERISTICS (Continued)

XC9515AB04xx

●Voltage Detector (VD) (MR pin Pull-up Inside) Block

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNITS CIRCUIT

Detect Voltage V

Hysteresis Width V

VD Output Current I

Delay Resistance R

MR "H" Level Voltage V

MR "L" Level Voltage V

MR "H" Level Current I

MR "L" Level Current I

Test Conditions:

* P_V

**Unless otherwise stated, P_V

*** A_VSS=P_V

NOTE :

:V

*1

:V

*2

*3

:”H” is judged as “H”>V

stands for P_V

DD1・2

=P_V

SS1

=Detect Voltage

DF(E)

=Release Voltage

DR(E)

(*1)

DF(E)

V

HYS

DOUT

DLY

V

MRH

V

MRL

MRH

MRL

=P_V

DD1

DD2

=5V, V

DD1・2

=0V

SS2

-0.1V, ”L” is judged as “L”<0.1V

IN

P_V

EN1=VEN2

=(V

HYS

DR(E)

DD1・2=VDF

DOUT

DOUT

P_V

P_V

= P_V

(*3)

- V

) / V

DF(E)

-0.01V, Apply 0.5V to V

=”H” Level Voltage

=”L” Level Voltage

DD1・2=VMR

DD1・2

DD1・2

=5.5V - -

=5.5V, VMR=0V -

×100

DF(E)

DOUT

(*3)

1.2 - VIN V

(*3)

AVSS

V

DF(T)

DF(T)

×0.98

V

-

5.0 6.6 8.0 mA

-

-6.0

5.0

2.5

-

V

DF(T)

(*2)

×1.02

-

- MΩ -

0.4 V

0.1

- μA ④

XC9515AB04xx

●Whole Circuit (V

OUT1

=1.5V, V

OUT2

=3.3V, f

=1MHz, EN1・2 Pull-up Inside)

OSC

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNITS CIRCUIT

Supply Current 1 IDD1 V

Supply Current 2 IDD2

V

OUT1=VOUT2

OUT1=VOUT2

=Setting Voltage x 1.1 (Oscillation stops) -

Stand-by Current ISTB V

UVLO Detect Voltage VUVLOF VIN voltage which V

UVLO Release Voltage VUVLOR VIN voltage which V

Thermal Shutdown

Temperature

Thermal Shutdown

Hysteresis Width

Test Conditions:

* P_V

**Unless otherwise stated, P_V

*** A_VSS=P_V

NOTE :

*1:”H” is judged “H”>V

stands for P_V

DD1・2

SS1

=P_V

TSD

T

HYS

T

=P_V

DD1

=0V

SS2

-0.1V, ”L” is judged “L”<0.1V

IN

DD1・2

DD2

=5V, V

EN1=VEN2

= P_V

=Setting Voltage x 0.9

EN1=VEN2

OUT1

OUT1

DD1・2

=0V

=0V and LX pin becomes ”L”

=0V and LX pin becomes ”H”

950 1500

-

75 145

18 33

-

(*1)

2.4 2.7 3.0 V

(*1)

- -

150

-

20

-

3.5 V

-

-

Ta =2 5oC

V

%

μA ④

⑤

-

④

④

④

Ta =2 5oC

μA ⑥

μA ⑥

μA ⑥

②

②

o

C

o

C

-

-

6/21

■ELECTRICAL CHARACTERISTICS (Continued)

XC9515BA06xx

●DC/DC CH1, CH2 (V

=1.5V, V

OUT1

OUT2

=3.3V, f

=1MHz, EN1 and EN2 pins are internally floating)

OSC

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNITS CIRCUIT

Input Voltage VIN 2.5

5.5 V

-

Connected to the external components,

Output Voltage1 VOUT1

P_V

DD1・2=VEN1

=30mA

I

OUT1

, V

EN2

=0V

1.470 1.500 1.530 V

Connected to the external components,

Output Voltage2 VOUT2

IOUTMAX1

Maximum Output Current 1・2

Current Limit 1・2

Oscillation Frequency f

Maximum Duty Cycle D

Minimum Duty Cycle D

Efficiency 1

Efficiency 2

LX1・2 "H" ON Resistance

LX1・2 "L" ON Resistance

Integral Latch Time 1・2

Soft-Start Time 1・2

EN1・2 "H" Voltage

EN1・2 "L" Voltage

EN1・2 "H" Current

EN1・2 "L" Current

LX1・2 "H" Leak Current

LX1・2 "L" Leak Current

Test Conditions:

* P_V

**Unless otherwise stated, P_V

*** A_VSS=P_V

NOTE :

*1

:When the difference between the input and the output is small, some cycles may be skipped completely before current maximizes.

*2:EFFI = { ( output voltage x output current ) / ( input voltage x input current) } x 100

*3

:On resistance (Ω)= (V

*4:Designed value.

*5:Time until it short-circuits LX1 (LX2 in the side of 2CH) with GND via 1Ωof resistor from an operational state and is set to Low level

*6:”H” is judged as “H”>VIN-0.1V, ”L” is judged as ”L”<0.1V.

:When temperature is high, a current of approximately 20μA (maximum) may leak.

*7

*8

:Current which EN1 and EN2 are measured separately.

*9

:Lead current which LX1 and LX2 are measured separately.

stands for P_V

DD1・2

If current is further pulled from this state, output voltage will decrease because of P-ch driver ON resistance.

from current limit pulse generating.

(*1)

IOUTMAX2

LIM1, ILIM 2 1000

I

Connected to the external components, I

OSC

V

MAX

V

MIN

(*2)

EFFI1

(*2)

EFFI2

RLX1H, RLX2H V

RLX1L, RLX2L

LAT1, tLAT 2

t

SS1, tSS2

t

EN1H, VEN2H

V

EN1L, VEN2L

V

, I

, I

, I

, I

DD1・2

EN2H

EN2L

leak2H

leak2L

DD2

=5V, V

SS1

=P_V

I

EN1H

I

EN1L

(*7)

I

leak1H

I

leak1L

=P_V

DD1

=0V

SS2

- Lx pin measurement voltage) / 100mA

IN

LX1 and LX2 are pulled down by a resistor of 200Ω

V

= Setting Voltage×0.9, V

OUT1

Time until EN1, EN2 or both pins changes from 0V to V

and voltage becomes V

Voltage which LX1 or LX2 becomes ”H”

Voltage which LX1 or LX2 becomes ”L”

EN1=VEN2

P_V

DD1・2=VEN2

OUT1=VOUT2

OUT1=VOUT2=VIN

Connected to the external components,

P_V

DD1・2=VEN1

=1.5V, I

V

OUT1

Connected to the external components,

P_V

DD1・2=VEN2

=3.3V, I

V

OUT2

OUT1=VOUT2

V

OUT1=VOUT2

V

OUT1=VOUT2

P_V

DD1・2=VEN1=VEN2

P_V

DD1・2

P_V

DD1・2=VLX1=VLX2

P_V

DD1・2

= P_V

=5.5V, V

DD1・2

, V

EN1

=30mA

I

OUT2

=0V 100

=5.0V, V

=200mA

OUT1

=5.0V, V

=200mA

OUT2

=0V, I

=100mA

Lx1=ILx2

= Setting Voltage×0.9

OUT2

×0.95, I

OUT1・2

=0V

=0V

=5.5V - -

=5.5V, V

EN1=VEN2

=5.5V, V

LX1=VLX2=VEN1=VEN2

=0V

=10mA 0.85 1.00 1.15 MHz

OUT

=0V

EN2

=0V

EN1

(*3)

=10mA

OUT1・2

(*6)

(*6)

=0V

=0V - -

EN1=VEN2

=0V

3.234 3.300 3.366 V

800

- -

- -

- -

- -

89

-

94

-

0.35

-

0.35

-

-

(*5)

IN

AVSS

-0.1

-3.0

6

-

1.3

-

1.2

-

(*8)

- - μA ④

(*9)

- - μA ④

0 %

-

-

(*4)

- Ω ③

(*4)

- Ω

-

-

V

V

IN

0.4 V

(*8)

0.1

(*9)

1.0

mA

mA

%

%

%

ms

ms

μA ④

μA ④

XC9515

Series

Ta =2 5 oC

①

①

①

②

①

②

②

①

①

-

⑦

①

④

④

7/21

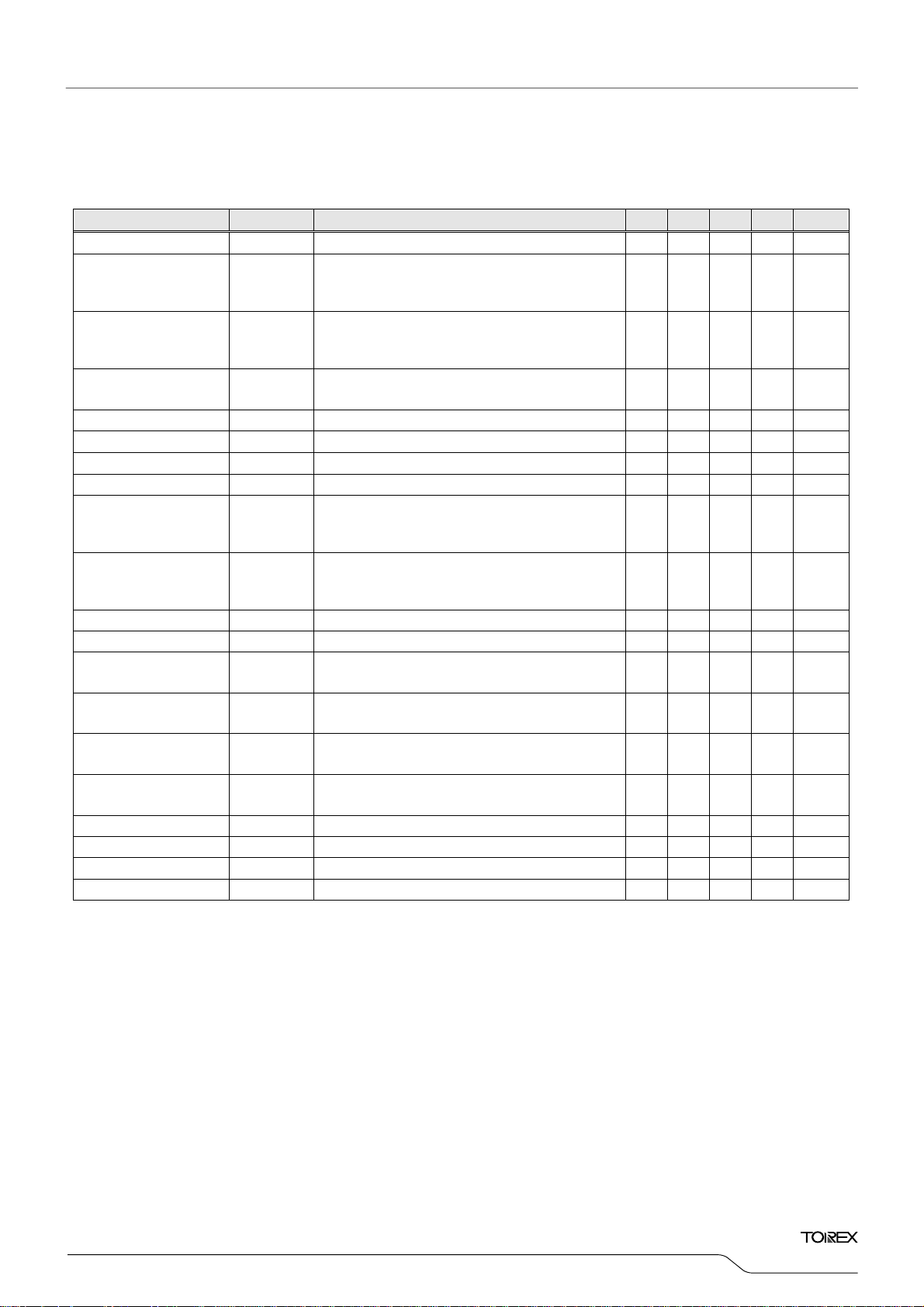

XC9515 Series

■ELECTRICAL CHARACTERISTICS (Continued)

XC9515BA06xx

●VD (MR pin is) internally floating

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNITS CIRCUIT

Detect Voltage V

Hysteresis Width VHYS V

VD Output Current IDOUT

Delay Resistance RDLY

MR "H" Level Voltage VMR V

MR "L" Level Voltage VMR V

MR "H" Level Current IMR

MR "L" Level Current IMR

(*1)

2.94 3.00 3.06 V

DF(E)

HYS

P_V

DOUT

DOUT

P_V

P_V

(*2)

={V

-V

}/ V

DR(E)

DD1・2=VDF

DF(E)

-0.01V, Apply 0.5V to V

=”H” Level Voltage

=”L” Level Voltage

=MR=5.5V - -

DD1・2

=5.5V,MR=0V -0.1

DD1・2

×100

DF(E)

DOUT

(*3)

1.2

(*3)

AVSS

5.0 6.6 8.0 mA

5.0

-

2.5

-

-

-

(*8)

- - μA ④

-

- MΩ

VIN V

0.4 V

0.1

Test Conditions:

* P_V

**Unless otherwise stated, P_V

*** A_VSS=P_V

NOTE :

:V

*1

:V

*2

*3

:”H” is judged as “H”>V

stands for P_V

DD1・2

=P_V

SS1

=Detect Voltage

DF(E)

=Release Voltage

DR(E)

=P_V

DD1

=0V

SS2

-0.1V, ”L” is judged as “L”<0.1V

IN

DD1・2

DD2

=5V, V

EN1=VEN2

= P_V

DD1・2

XC9515BA01xx

●Whole Circuit (V

OUT1

=1.5V, V

OUT2

=3.3V, f

=1MHz, EN1 and EN2 pins are internally floating)

OSC

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNITS CIRCUIT

Supply Current 1 IDD1

Supply Current 2 IDD2

V

OUT1=VOUT2

V

OUT1=VOUT2

= Setting Voltage×0.9 -

= Setting Voltage×1.1 (Oscillation stops) -

Stand-by Current ISTB EN1=EN2=0V

UVLO Detect Voltage VUVLOF VIN voltage which V

UVLO Release Voltage VUVLOR VIN voltage which V

Thermal Shutdown

Temperature

Thermal Shutdown

Hysteresis Width

T

TSD

HYS

T

=0V and LX pin becomes ”L”

OUT1

=0V and LX pin becomes ”H”

OUT1

(*1)

(*1)

950 1500

75 145

5.5 11

-

1.5 1.8 2.1 V

150

20

2.3 V

-

-

- -

-

-

Test Conditions:

* P_V

**Unless otherwise stated, P_V

*** A_VSS=P_V

NOTE :

*1:”H” is judged “H”>V

stands for P_V

DD1・2

SS1

=P_V

DD1

=P_V

=0V

SS2

-0.1V, ”L” is judged “L”<0.1V

IN

DD1・2

DD2

=5V, V

EN1=VEN2

= P_V

DD1・2

8/21

Ta =2 5 oC

⑤

% -

④

-

④

④

μA ④

Ta =2 5 oC

μA ⑥

μA ⑥

μA ⑥

②

②

o

C -

o

C -

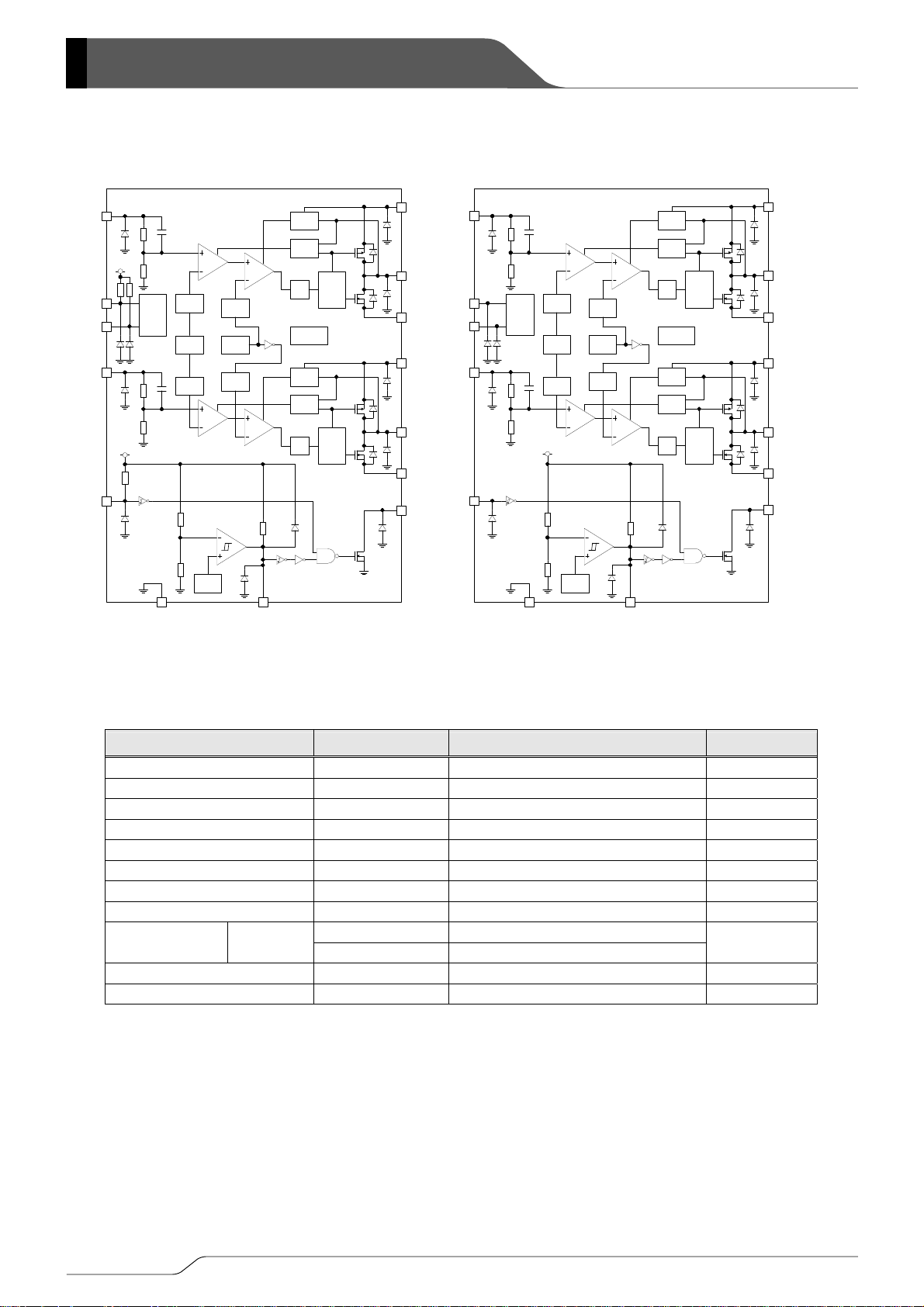

■TYPICAL APPLICATION CIRCUIT

VIN

CIN1 CL1

PVDD

NC

PVSS

1

NC

PVSS

2

NC

PVDD2NC

CIN2

<Example of the External Components>

L1 :4.7μH(CDRH4D28C, SUMIDA)

L2 :4.7μH(CDRH4D28C, SUMIDA)

:10μF(ceramic)

C

IN1

:10μF(ceramic)

C

IN2

:10μF(ceramic)

C

L1

:10μF(ceramic)

C

L2

RUP :100kΩ

XC9515

Series

L1

1

NC

LX1

EN1

EN2

VOUT

1

MR

AVSS

Cd

VOUT

2

LX2

NC

VDOUT

RUP

L2

VOUT1

EN1

EN2

MR

Cd

CL2

VDOUT

VOUT2

9/21

DD1

and P_V

Limit < # ms

pin through split resistors, R

OUT

and R

FB1

voltages drop below the low level of EN1 and EN2 pin.)The latch operation

DD2

. When a voltage lower than the reference is fed back, the output

FB2

Limit < # ms

and R

FB1

. Phase

FB2

XC9515 Series

■OPERATIONAL EXPLANATION

XC9515 series consists of a reference voltage source, ramp wave circuit, error amplifier, PWM comparator, phase

compensation circuit, output voltage adjustment resistors, P-channel driver transistor, N-channel synchronous switching

transistor, current limit circuit, UVLO circuit and others. The series ICs compare, using the error amplifier, the voltage of the

internal voltage reference source with the feedback voltage from V

compensation is performed on the resulting error amplifier output, to input a signal to the PWM comparator to determine the

turn-on time during PWM operation. The PWM comparator compares, in terms of voltage level, the signal from the error

amplifier with the ramp wave from the ramp wave circuit, and delivers the resulting output to the buffer driver circuit to cause

the Lx pin to output a switching duty cycle. This process is continuously performed to ensure stable output voltage. The

current feedback circuit monitors the P-channel driver transistor current for each switching operation, and modulates the error

amplifier output signal to provide multiple feedback signals. This enables a stable feedback loop even when a low ESR

capacitor, such as a ceramic capacitor, is used, ensuring stable output voltage.

<Reference Voltage Source>

The reference voltage source provides the reference voltage to ensure stable output voltage of the DC/DC converter.

<Ramp Wave Circuit>

The ramp wave circuit determines switching frequency. The frequency is fixed internally at 1MHz. Clock pulses generated

in this circuit are used to produce ramp waveforms needed for PWM operation, and to synchronize all the internal circuits.

<Error Amplifier>

The error amplifier is designed to monitor output voltage. The amplifier compares the reference voltage with the feedback

voltage divided by the internal split resistor, R

voltage of the error amplifier increases. The gain and frequency characteristics of the error amplifier output are fixed

internally to deliver an optimized signal to the mixer.

<Current Limit>

The current limiter circuit of the XC9515 series monitors the current flowing through the P-channel MOS driver transistor

connected to the Lx pin, and features a combination of the current limit mode and the latch mode.

①When the driver current is greater than a specific level (peak value of coil current), the current limit function operates to off

the pulses from the Lx pin at any giving timing.

②When the driver transistor is turned off, the limiter circuit is then released from the current limit detection state.

③At the next pulse, the driver transistor is turned on. However, the transistor is immediately turned off in the case of an

over current state.

④When the over current is eliminated, the IC resumes its normal operation.

The IC waits for the over current state to end by repeating the steps ① to ③. If an over current state continues for a few

ms and the above three steps are repeatedly performed, the IC performs the function of latching the OFF state of the

driver transistor. Both two DC/DC blocks stop operations when either CH1 or CH2 of protection circuit is activated. At

this time, both Lx1 and Lx2 become high impedance. Once the IC is in latch mode, operations can be resumed by either

turning the IC off after letting EN1 and EN2 pins down to low level, or by restoring power. For restoring power, the IC

should be turned off after P_V

can be released from the current limit detection state because of the circuit’s noise. Also, depending on the state of the

PC Board, latch time may become longer and latch operation may not work. In order to avoid the effect of noise, the

board should be laid out so that capacitors are placed as close to the chip as possible.

10/21

XC9515

■OPERATIONAL EXPLANATION (Continued)

<Thermal Shutdown>

For protecting the IC from heat damage, the thermal shutdown circuit monitors the chip temperature. When the chip

temperature reaches 150℃, the thermal shutdown circuit operates and the driver transistor will be set to OFF. As the chip

temperature drops to 130℃ by stopping current flow, the soft-start function operates to turn the output on.

<Short-Circuit Protection>

The short-circuit protection circuit monitors the FB voltage. If the output is shorted incorrectly with the ground, the

short-circuit protection circuit operates and turns the driver transistor off to latch when the FB voltage becomes less than half

of the setting voltage. Both two DC/DC blocks stop operations when either CH1 or CH2 of protection circuit is activated. At

this time, both Lx1 and Lx2 become high impedance. Once the IC is in latch mode, operations can be resumed by either

turning the IC off after letting both ends of EN1 and EN2 pins down to low level, or by restoring power. (The P_V

voltages should be less than the low level of the EN1 and EN2 pins when restoring power.)

P_V

DD2

<Soft Start Function>

The soft-start circuit protects against inrush current, when the power is switched on, and also to protect against voltage

overshoot. It should be noted, however, that this circuit does not protect the load capacitor (C

L) from inrush current. With

the Vref voltage limited and depending upon the input to the error amps, the operation maintains a balance between the two

inputs of the error amps and controls the EXT1 pin's ON time so that it doesn't increase more than is necessary.

<UVLO Circuit>

When the V

forced OFF to prevent false pulse output caused by unstable operation of the internal circuitry. When the V

IN pin voltage becomes1.8V (TYP.) or lower (for XC9515A, 2.7V or lower), the P-channel output driver transistor is

IN pin voltage

becomes 1.9V (TYP.) or higher (for XC9515A, 3.0V or lower), switching operation takes place. By releasing the UVLO

function, the IC performs the soft-start function to initiate output startup operation.

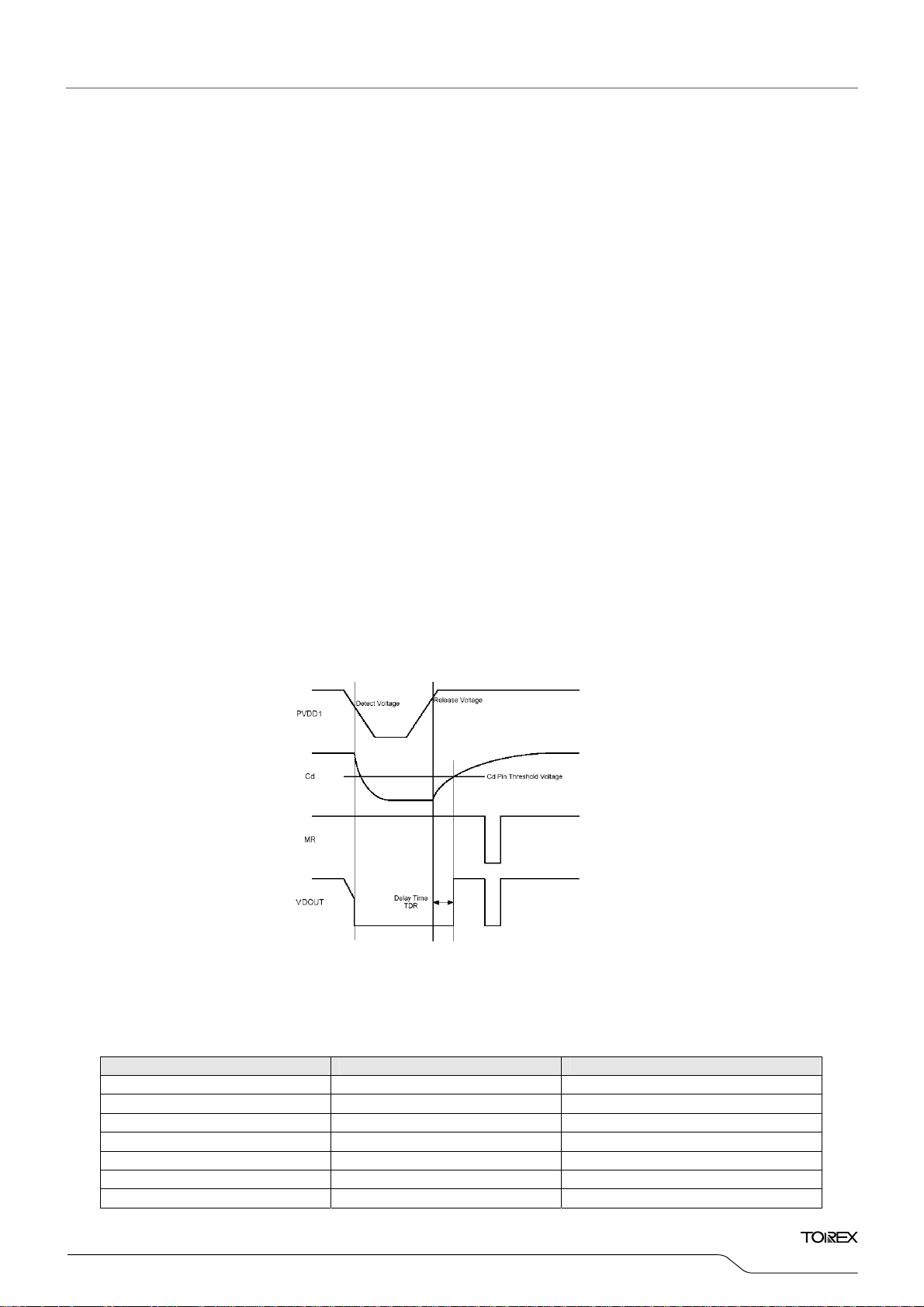

<Voltage Detector Block>

The series' detector function monitors the voltage divided by resistors connected to the P_V

DD1 pin, as well as monitoring the

voltage of the internal reference voltage source via the comparator. Because of hysteresis at the detector function, output at

the V

of the detect voltage). The output configuration of the V

required. The voltage detector block has a manual reset (MR) pin. By setting the MR pin at low level, the V

pin will invert when the sense pin voltage of the detector block (P_VDD1) increases above the release voltage (105%

DOUT

pin is N-channel open drain, therefore, a pull-up resistor is

DOUT

pin is forced

DOUT

to be at low level.

By connecting a capacitor (Cd) to the Cd pin, the XC9515 series can set a delay time to VDOUT pin’s output signal when

releasing voltage. The delay time can be calculated from the internal resistance, Rdelay (2.5MΩ fixed TYP.) and the

value of Cd as per the following equation. As selecting the capacitor (Cd), the delay time can be set freely.

t

(Delay time) =Cd x Rdelay x 0.69

DR

●Release Delay Ta=25oC

Delay Capacity Cd [μF] Release Delay tDR (TYP.) [ms] Release Delay tDR (MIN.~MAX.) [ms]

0.01 17 10~24

0.022 38 23~53

0.047 81 49~113

0.1 173 103~242

0.22 380 228~532

0.47 811 487~11 35

1 1725 1035~2415

Series

and

DD1

11/21

XC9515 Series

■NOTES ON USE

1. Please use this IC within the stated maximum ratings. The IC is liable to malfunction should the ratings be exceeded.

2. Please apply the same electrical potential to the P_V

P_V

and P_V

3. The XC9515 series is designed for use with ceramic output capacitors. If, however, the potential difference between

4. When the peak current, which exceeds limit current flows within the specified time, the built-in driver transistor is turned off

5. When the input voltage is low, limit current may not be reached because of voltage falls caused by ON resistance or serial

6. Since the potential difference for input voltage has occurred to the both ends of a coil, the time changing rate of the coil

DD1

causes malfunction. Also the same electrical potential should be applied to the P_V

dropout voltage or output current is too large, a ceramic capacitor may fail to absorb the resulting high switching energy and

the output could be unstable. If the input-output potential difference is large, use a larger output capacitor to compensate for

insufficient capacitance.

(the integral latch circuit). During the time until it detects limit current and before the built-in transistor can be turned off, the

current for limit current flows; therefore, care must be taken when selecting the rating for the coil.

resistance of the coil.

current is large when the P-channel driver transistor is ON. On the other hand, since the V

when the N-channel transistor is ON and there is almost no potential difference of the coil both ends, the time changing rate

of the coil current becomes very small.

This operation is repeated and the delay time of the circuit also influences, therefore, the coil current is converged on the

current value beyond the amount of current which should be restricted essentially.

The short-circuit protection does not operate during the soft-start time. As soon as the soft-start time finishes, the

short-circuit protection starts to operate and the circuit becomes disable.

The delay time of the circuit also influences when step-down ratio is large, as the result, a current more than over current

limit may flow. Please do not exceed the absolute maximum ratings of the coil.

① A current flows to the driver transistor up to the current limit (I

② For the delay time of the circuit, a current more than the I

transistor turns off.

③ Time changing rate of the coil current becomes very small because there is no potential difference between both ends

of the coil.

④ The Lx pin oscillates a narrow pulse during the soft-start time because of the current limit.

⑤ The circuit is latched since the short-circuit protection operates and the P-channel driver transistor is turned off.

pins should have the same electrical potential. Applying the electrical potential to only one side

DD2

and P_V

DD1

pins. Even where either CH1 or CH2 is used, both

DD2

).

LIM

flows after the I

LIM

# ms

, P_V

SS1

decide until the P channel driver

LIM

and A_VSS pins.

SS2

pin short-circuits to the GND

OUT

12/21

XC9515

Series

■NOTES ON USE (Continued)

7. Driving current below the minimum operating voltage may lead malfunction to the UVLO circuit because of the noise.

8. Depending on the PC board condition, the latch function may be released from limit current detection state and the latch

time may extend or fail to reach the latch operation. Please locate the input capacitance as close to the IC as possible.

9. Spike noise and ripple voltage arise in a switching regulator as with a DC/DC converter. These are greatly influenced by

external component selection, such as the coil inductance, capacitance values, and board layout of external components.

Once the design has been completed, verification with actual components should be done.

10. With the DC/DC converter block of the IC, the peak current of the coil is controlled by the current limit circuit. Since the

peak current increases when dropout voltage or load current is high, current limit starts operating, and this can lead to

instability. When peak current becomes high, please adjust the coil inductance value and fully check the circuit operation.

In addition, please calculate the peak current according to the following formula:

Peak current: Ipk = (V

L: Coil Inductance Value, f

IN - V

) x OnDuty / (2 x L x fosc) + I

OUT

: Oscillation Frequency

OSC

OUT

11. When the load current is light in PWM control, very narrow pulses will be outputted, and there is the possibility that some

cycles may be skipped completely.

12. When the difference between V

IN and VOUT is small, and the load current is heavy, very wide pulses will be outputted and

there is the possibility that some cycles may be skipped completely.

13. If the power input pin voltage is assumed to decrease rapidly (ex. from 6.0V to 0V) at the release of the operation

although delay capacitance (Cd) pin is connected, please connect an Shottky barrier diode between the power input

(P_V

) pin and the delay capacitance (Cd) pin.

DD1

14. Please connect a pull-up resistor with 100 to 200kΩ to the output pin of the voltage detector block (V

DOUT

).

15. The delay time of the voltage detector block in heavy load may extend because of the noise of the DC/DC block.

Precipitous and large voltage fluctuation at the power input pin may cause malfunction of the IC.

16. Use of the IC at voltages below the minimum operating voltage may lead the output voltage drop before achieving over

current limit.

17. When P_VDD1 and P_VDD2 power supply pins and EN1 and EN2 enable pins are in undefined states, the latch

protection circuit may not be reset so that the IC operation does not start correctly. Power supply and enable pins

(EN1,EN2) should be grounded before starting the IC operation.

【Undefined state conditions for each pin】

P_V

=P_VDD2=0.1V ~ 1.2V

DD1

V

EN1=VNE2

= 0.4V ~ 1.2V

18. UVLO function works even if when V

input voltage falls below the UVLO voltage in very short time period like a few ten

IN

nanoseconds.

●Instruction on Pattern Layout

1. In order to stabilize VIN's voltage level, we recommend that a by-pass capacitor (CIN1 and CIN2) be connected as close

as possible to the P_V

2. Please mount each external component as close to the IC as possible.

3. Wire external components as close to the IC as possible and use thick, short connecting traces to reduce the circuit

impedance.

4. Make sure that the V

at the time of switching may result in instability of the DC/DC converter.

・P_V

DD1

traces are as thick as possible, as variations in the VSS potential caused by high VSS currents

SS

pins and P_V

DD2

SS1

・P_V

SS2

pins.

13/21

XC9515 Series

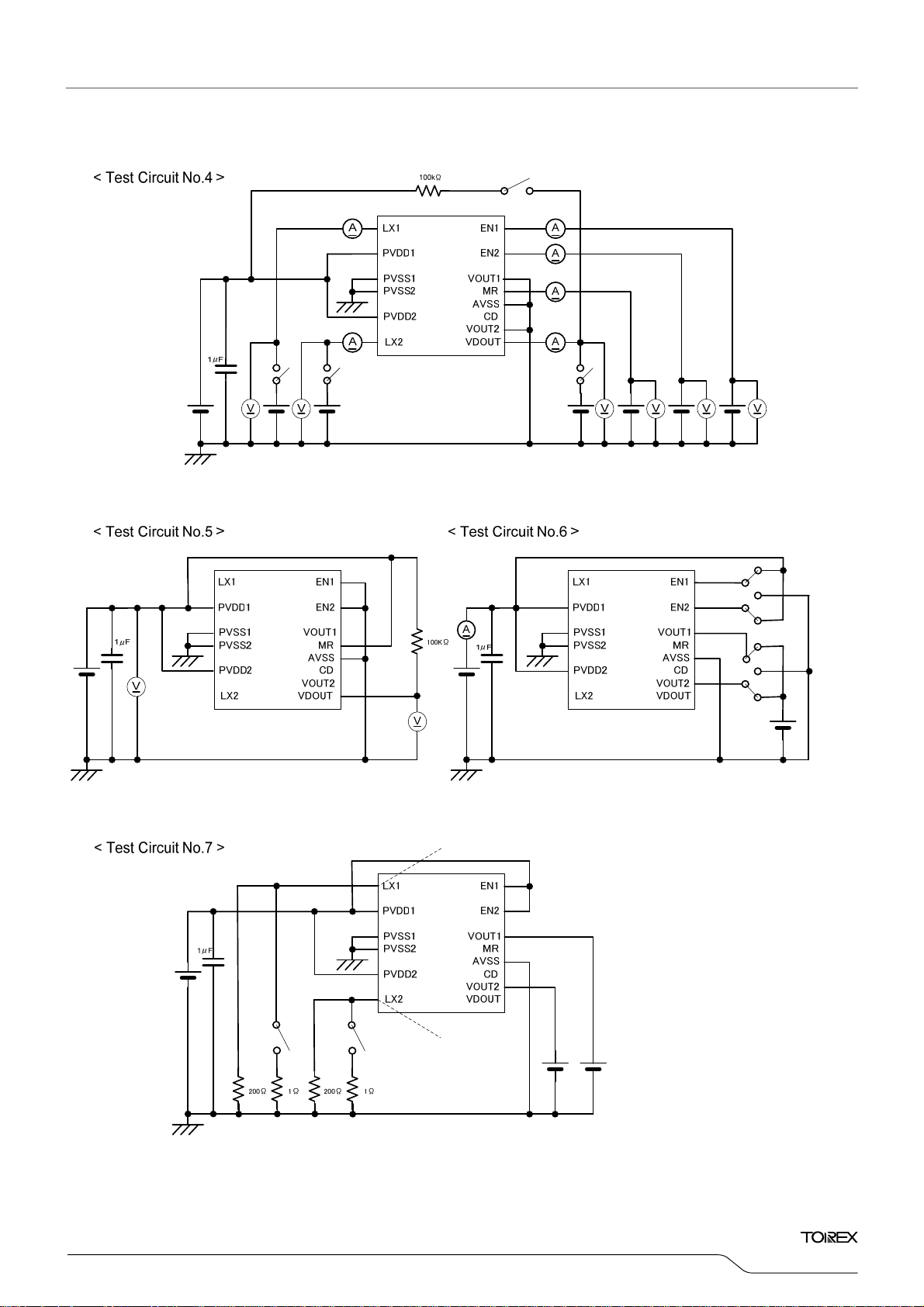

■TEST CIRCUITS

< Test Circuit No.1 >

CL

CL

Wave Form Measurement Point

Wave Form Measurement Point

L

CIN

CIN

L

Wave Form Measurement Point

Wave Form Measurement Point

LX1

PVDD1

PVSS1

PVSS2

PVDD2 CD

LX2 VDOUT

EN1

EN2

VOUT1

MR

AVSS

VOUT2

A

V

※ External Components

L : 4.7μH(CDRH4D28C : SUMIDA)

CIN : 10μF (ceramic)

CL : 10μF (ceramic)

A

V

< Test Circuit No.2 >

A

1μF

V

< Test Circuit No.3 >

1μF

Wave Form Measurement Point

Wave Form Measurement Poi nt

A

V

A

m100 A

A

V

V

m100 A

A

LX1

PVDD1

PVSS1

PVSS2

PVDD2 CD

LX2 VDOUT

V

Wave Form Measurement Point

Wave Form Measurement Poi nt

LX1

PVDD1

PVSS1

PVSS2

PVDD2 CD

LX2 VDOUT

EN1

EN2

VOUT1

MR

AVSS

VOUT2

EN1

EN2

VOUT1

MR

AVSS

VOUT2

14/21

■TEST CIRCUITS (Continued)

XC9515

Series

Wave Form Measurement Point

Wave Form Measurement Point

15/21

XC9515 Series

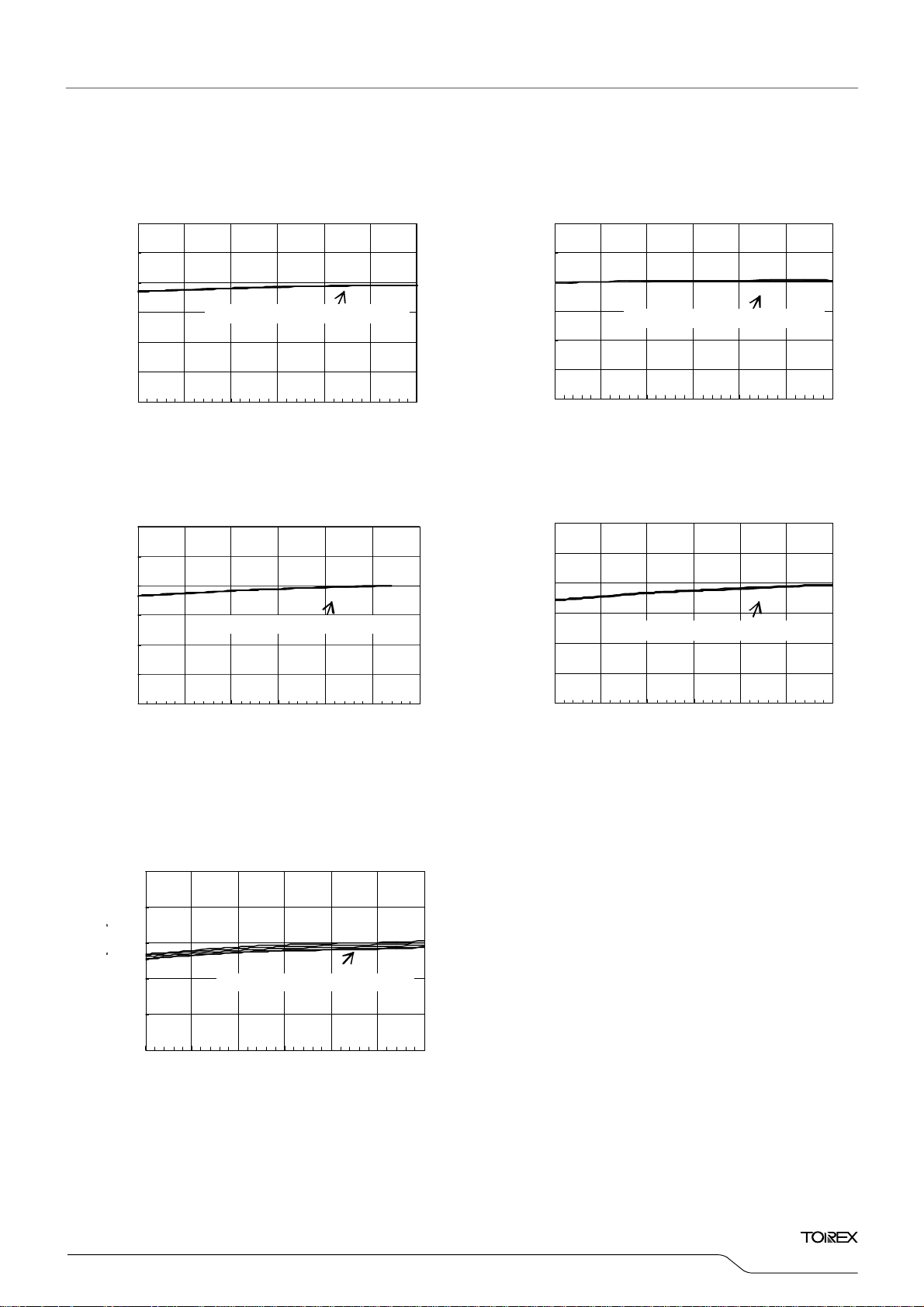

■TYPICAL PERFORMANCE CHARACTERISTICS

(1) Efficiency vs. Output Current

100

90

80

70

60

50

40

Efficiency[%]

30

Efficiency: EFFI (%)

20

10

(2) Output Voltage vs. Output Current

Output Voltage: VOUT (V)

Output Vo ltage : VOUT[V]

(V)

OUT

Output Voltage: V

Output V olta ge : V OUT[V ]

VOUT=3.3V

0

1 10 100 1000

1.60

1.55

1.50

1.45

1.40

1 10 100 1000

3.40

3.35

3.30

3.25

3.20

1 10 100 1000

L=4.7uH(CDRH4D28C),CIN=10uF(c eramic ),C L=10uF( cerami c)

VOUT=1.8V

Output Current: I

Output Current : IOUT [mA]

VOUT=1.5V VOUT=1.8V

L:4.7 uH(CDRH4 D28C),CIN= 10uF(ce ra mic) ,CL=10uF(ce ramic)

Output Current : IOUT[m A]

Output Current: I

VOUT= 3.3V

L:4.7 uH(CDRH4 D28C),CIN= 10uF(ce ra mic) ,CL=10uF(ce ramic)

Output Current : IOUT[m A]

Output Current: I

OUT

OUT

(mA)

(mA)

OUT

(mA)

VIN=5V,FOSC=1MHz

VOUT=1.5V

VIN=5.0V

1.90

1.85

1.80

1.75

Output V oltage : VOUT[V]

1.70

1 10 100 1000

VIN=5.0V

L:4.7uH(CDRH4D28C),CIN=10uF(ceramic), CL=10uF(ceramic)

Output Current : IOUT[mA]

Output Current: I

OUT

(mA)

VIN=5.0V

16/21

■TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

(3) Output Voltage vs. Ambient Temperature

V

1.30

=1.2V V

OUT

Vout =1.2V Vout= 1.5V

L:4.7uH( CDRH4D28C ),C IN=10uF(c eram ic),CL=10uF(ce ramic)

VIN=2.5V,3. 0V,4. 0V,5.0V, 5.5V

1.60

=1.5V

OUT

L:4.7 uH(CDRH 4D28C),CIN =10uF(ceramic) ,CL=10uF(ceramic)

1.25

1.20

1.55

1.50

1.15

1.10

VIN=2.5V,3.0V,4. 0V,5. 0V,5.5 V

1.45

1.40

VIN=2 .5V,3.0V,4.0V,5.0V,5. 5V

1.05

Output V olta ge:Vo ut1[v]

1.00

-50 -25 0 25 50 75 100

Ambi ent Tem perature:T a[℃ ]

1.35

Outpu t Voltage: Vou t1[v]

1.30

-50-25 0 255075100

Ambient T emp erature: Ta[℃ ]

1.90

1.85

1.80

1.75

Voltage: Vout1 [v]

1.70

1.65

Output

1.60

-50-250 255075100

V

=1.8V V

OUT

Vout=1.8V Vout=3.3V

L:4.7uH( CDRH4D28C ),C IN=10uF(c eram ic),CL=10uF(ce ramic)

VIN=2.5V,3.0V,4.0V,5.0V ,5.5V

Ambi ent Tempe rature:Ta[℃ ]

VIN=2.5V,3. 0V,4. 0V,5.0V, 5.5V

L:4.7uH(CDRH 4D28C),CIN =10uF (ceramic) ,CL =10uF(ceramic)

3.40

3.35

3.30

3.25

3.20

3.15

Output V olta ge:Vou t2[v ]

3.10

-50 -25 0 25 50 75 100

Ambient Temperature:Ta[℃ ]

=3.3V

OUT

VIN=4.0V,5 .0V,5.5V

(4) Oscillation Frequency vs. Ambient Temperature

f

=1MHz

1.2

(MHz)

OSC

1.1

OSC

FOSC=1MHz

L:4.7uH(CDRH4D28C),CIN=10uF(ceramic),CL=10uF(ceramic)

VIN=2.5V,3.0V,4.0V,5.0V,5.5V

1.0

0.9

:FOSC[MHz]

0.8

Oscillation Frequency

Oscillation Frequency: f

0.7

-50 -25 0 25 50 75 100

VIN=2.5V,3.0V,4.0V, 5.0V,5.5V

Ambient Temperature:Ta[℃ ]

XC9515

Series

VIN=2.5V, 3.0V,4.0V,5.0 V,5.5V

VIN =4.0V,5.0 V,5.5V

17/21

OSC

=1MHz

=1MHz

OSC

=1MHz

OSC

VOUT1= 200mV/div

VOUT2= 200mV/div

IOUT1=200mA

IOUT1=1mA

VOUT1= 200mV/div

VOUT2= 200mV/div

IOUT1=800mA

IOUT1=200m A

VOUT1= 200mV/div

VOUT2= 200mV/div

XC9515 Series

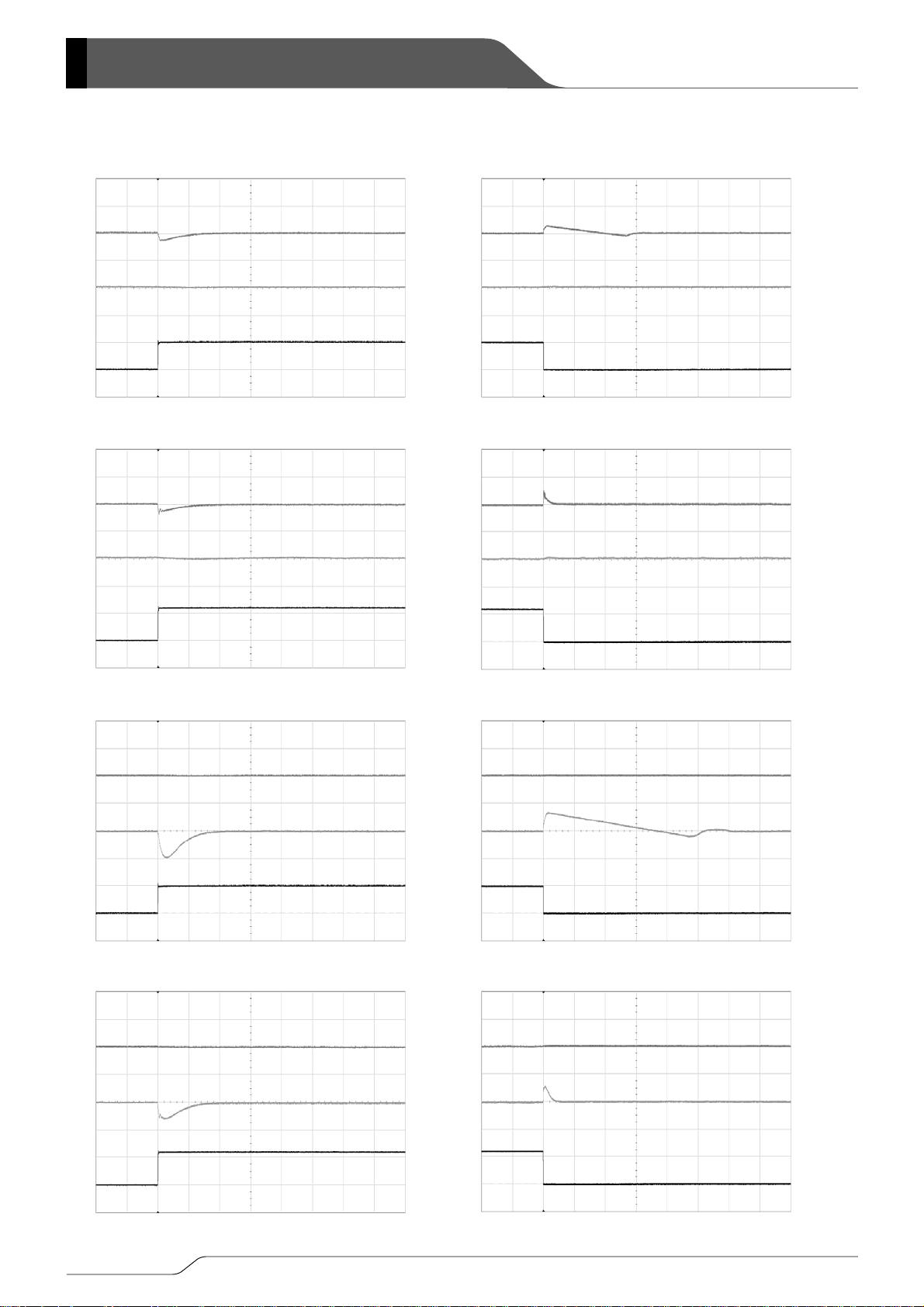

■TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

(5) Load Transient Response

V

=5V, V

IN

VIN=5V,VOUT1=1.5V,VOUT2=3.3V,FOSC=1MHz,

VOUT1=20 0mV/div

VOUT2=20 0mV/div

IOUT1=1mA

VIN=5V, V

VIN=5V,VOUT1=1.5V,VOUT2=3.3V,FOSC=1MHz,

VOUT1=20 0mV/div

VOUT2=20 0mV/div

IOUT1=200mA

VIN=5V, V

VIN=5V,VOUT1=1.5V,VOUT2=3.3V,FOSC=1MHz,

VOUT1=20 0mV/div

VOUT2=20 0mV/div

=1.5V, V

OUT1

IOUT1=200mA

=1.5V, V

OUT1

IOUT1=800mA

OUT1

=3.3V, f

OUT2

50μs/div 200μs/div

50μs/div 200μs/div

=3.3V, f

OUT2

50μs/div 200μs/div

50μs/div 200μs/div

=1.5V, V

OUT2

=3.3V, f

IOUT2=200mA

IOUT2=1mA

50μs/div 200μs/div

50μs/div 200μs/div

VIN=5V, V

VIN=5V,VOUT1=1.5V,VOUT2=3.3V,FOSC=1MHz,

VOUT1=20 0mV/div

VOUT2=20 0mV/div

IOUT2=200mA

=1.5V, V

OUT1

IOUT2=800mA

50μs/div 200μs/div

50μs/div 200μs/div

OUT2

=3.3V, f

OSC

18/21

IOUT2=200mA

IOUT2=1mA

=1MHz

VOUT1= 200mV/div

VOUT2= 200mV/div

IOUT2=800mA

IOUT2=200m A

■PACKAGING INFORMATION

●QFN-20 Unit: mm

1 PIN INDENT

4.00±0.10

2.70±0.05

4.00±0.10

0.40±0.05

106789

(0.2)

+0.03

0.02

-0.02

0.75±0.05

XC9515

Series

0.20±0.05

5

4

3

2

2.70±0.05

1

11

12

13

14

15

*The solder filet may not be formed because of no plating at side.

(0.5)

20

19

161718

●QFN-20 Reference Pattern Layout ●QFN-20 Reference Metal Mask Design

4.6

3.2

0.3

3.2

4.6

2.7

4.5

3.3

4.5

3.3

0.3 1.1

0.5

2.7

0.3

Thickness of solder paste:120μm (reference)

0.5

1.10.3

19/21

XC9515 Series

■MARKING RULE

●QFN-20

1pin

①②③④⑤⑥

⑦⑧⑨

20/21

QFN-20

(TOP VIEW)

●Standard Product

①②③ represent product series

MARK

① ② ③

PRODUCT SERIES

5 1 5 XC9515******-G

④Input Voltage Range, UVLO Voltage

MARK PRODUCT SERIES OPTIONAL FUNCTIONS

A XC9515A*****-G

B XC9515B*****-G

⑤EN Pin, MR Pin, Internal Control

MARK

PRODUCT SERIES OPTIONAL FUNCTIONS

A XC9515*A****-G

B XC9515*B****-G

C XC9515*C****-G

D XC9515*D****-G

⑥⑦ represents integer number of setting voltage

MARK

⑥ ⑦

0 1 XC9515**01**-G

⑧⑨ represents production lot number

Order of 01, …09, 10, 11, …99, 0A, …0Z, 1A, …9Z, A0, …Z9, AA, …ZZ.

(G, I, J, O, Q, W excluded)

*No character inversion used.

Input Voltage Range 5V±10%, UVLO

Voltage 2.7V (TYP.)

Input Voltage Range 2.5V~5.5V, UVLO

Voltage 1.8V (TYP.)

EN1, EN2 Pin Open

MR Pin Open

Built-in EN1, EN2 Pin Pull-up Resistance

Built-in MR Pin Pull-up Resistance

EN1, EN2 Pin Open

Built-in MR Pin Pull-up Resistance

Built-in EN1, EN2 Pin Pull-up Resistance

MR Pin Open

PRODUCT SERIES

XC9515

Series

1. The products and product specifications contained herein are subject to change without

notice to improve performance characteristics. Consult us, or our representatives

before use, to confirm that the information in this datasheet is up to date.

2. We assume no responsibility for any infringement of patents, patent rights, or other

rights arising from the use of any information and circuitry in this datasheet.

3. Please ensure suitable shipping controls (including fail-safe designs and aging

protection) are in force for equipment employing products listed in this datasheet.

4. The products in this datasheet are not developed, designed, or approved for use with

such equipment whose failure of malfunction can be reasonably expected to directly

endanger the life of, or cause significant injury to, the user.

(e.g. Atomic energy; aerospace; transport; combustion and associated safety

equipment thereof.)

5. Please use the products listed in this datasheet within the specified ranges.

Should you wish to use the products under conditions exceeding the specifications,

please consult us or our representatives.

6. We assume no responsibility for damage or loss due to abnormal use.

7. All rights reserved. No part of this datasheet may be copied or reproduced without the

prior permission of TOREX SEMICONDUCTOR LTD.

21/21

Loading...

Loading...