■

■

)

℃

■

XC9206/XC9207/XC9208

Series

ETR0503_002

PWM, PWM / PFM Switchable Step-Down

DC / DC Converters With Driver Transistor Built-In

GENERAL DESCRIPTIO N

The XC9206/XC9207/XC9208 series is a group of DC/DC converters with a built-in 0.4Ω P-channel driver transistor, offered

in a SOT-25 package. The ICs are designed to provide high efficiencies and a stable power supply with an output current of

500mA using only a coil, a diode and two ceramic capacitors connected externally.

Minimum operating voltage of the XC9206/9207 is 1.8V and 2.0V for XC9 208. Output voltage is internally programmable in

a range from 0.9V to 4.0V in 100mV increments (accuracy: ±2.0%). Oscillation frequency i s selectable fro m 300k Hz, 600 kHz

and 1.2MHz so that the frequency best suited to your particular applic ation can be selected. Each series features different

operation modes: PWM control (XC9206 series), automatic PWM/PFM switching control (XC9207 series) and manual

PWM/PFM switching control (XC9208 series). The series gives fast transient response, low ripple and high efficiency over

the full range of load (from light load to high output curre nt conditions). The soft start and current control functions are

internally optimized. During stand-by, all circuits are shutdown to reduce current consumption to as low as 1.0μA or less.

With the built-in U.V.L.O. (Under Voltage Lock Out) function, the internal P-channel driver transistor is forced OFF when input

voltage becomes 1.4V or lower.

■APPLICATIONS

●Mobile phones

(PDC, GSM, CDMA, IMT2000 etc.)

●PDAs, Portable communication modems

●Portable games

●Cameras, digital cameras

●Cordless phones

●Note book computers

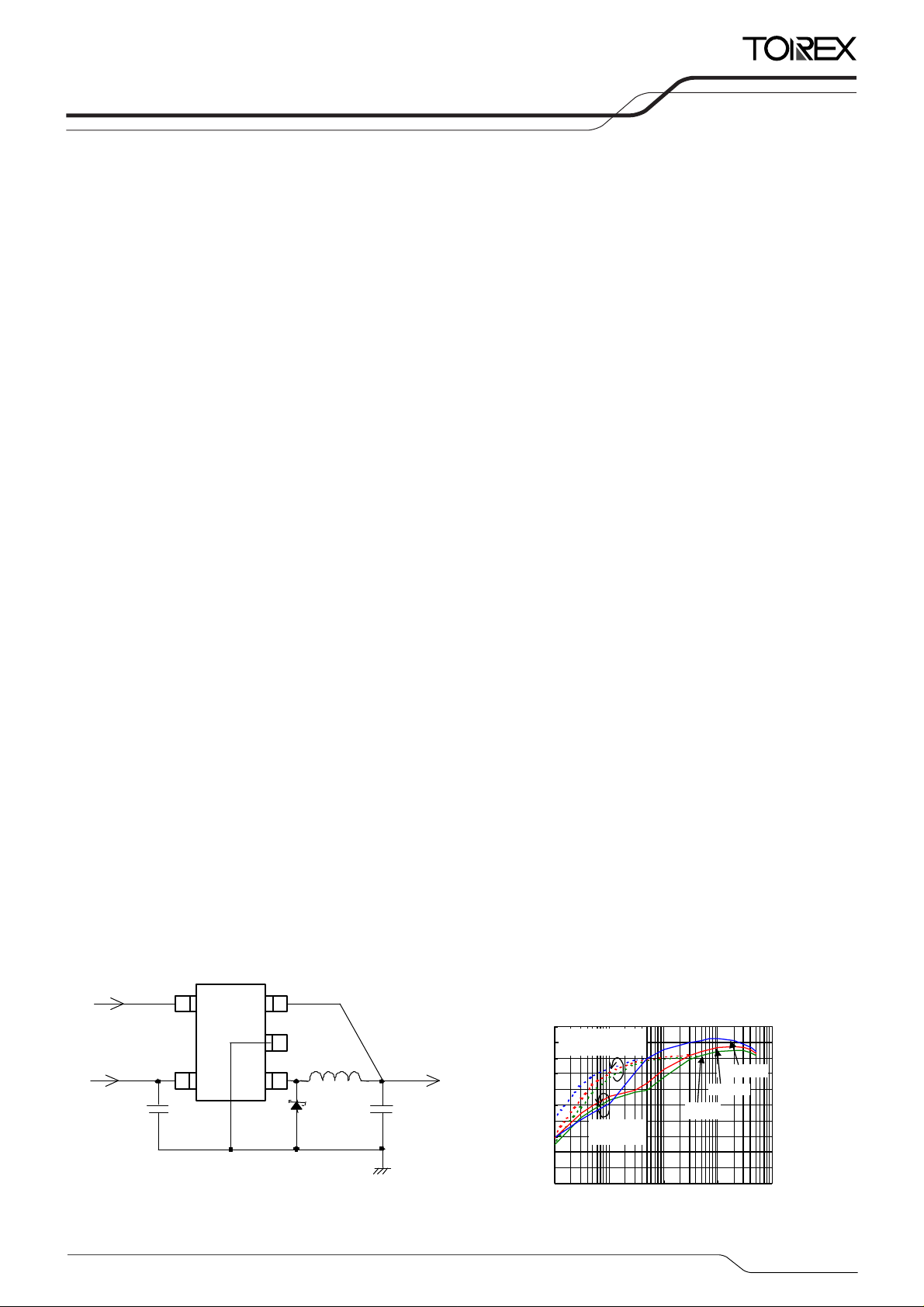

TYPICAL APPLICATION CIRCUIT

CE/MODE

VIN

(ceramic)

L :4.7μF (CDRH 3D16,SUMIDA)

SD :CRS02 (SCHOTTKY DIODE,TOSHIBA)

CL :10μF (ceramic)

C

4

5

IN :4.7μF (ceramic)

CE/

MODE

VIN

VOUT

VSS

3

2

L

Lx

1

SDCIN

VOUT

(500mA)

CL

(ceramic)

FEATURES

P-ch driver Tr. Built-in : ON resistance 0.4Ω

Output Voltage Range : 0.9V ~ 4.0V

(100mV increments)

Oscillation Frequency : 300kHz, 600kHz, 1.2MHz

Fixed oscillation frequency

Accuracy ±15%

Stand-by function : Istb = 1μA (MAX.)

Current Limiter built-in : 600mA

Input Voltage Range : 1.8V ~ 6.0V(XC9206/XC9207)

Output Current : 500mA

Maximum Duty Ratio : 100%

PWM/PFM Switching Control (XC9207 / XC9208)

Ceramic Capacitor Compatible

Soft start circuit built-in

Small Package : SOT-25

■TYPICAL PERFORMANCE

CHARACTERISTICS

●Efficiency vs. Output Current

VOUT=1.8V (Oscillation Frequency 1.2MHz)

100

90

80

70

60

50

40

30

Efficiency EFFI (%

20

10

0

0.1 1 10 100 1000

XC9208A18C

CIN:4.7μF,CL:10μF, L:4.7μH(CDRH3D16),

PWM/PFM

Switchin g Co ntrol

PWM Control

Output Current IOUT (mA)

☆GO-Compatible

Fixed output voltage accuracy ±2%

2.0V ~ 6.0V (XC9208)

SD: C R S02, Topr=25

VIN=2.4V

3.6V

4.2V

1/16

■

■

■

XC9206/XC9207/XC9208

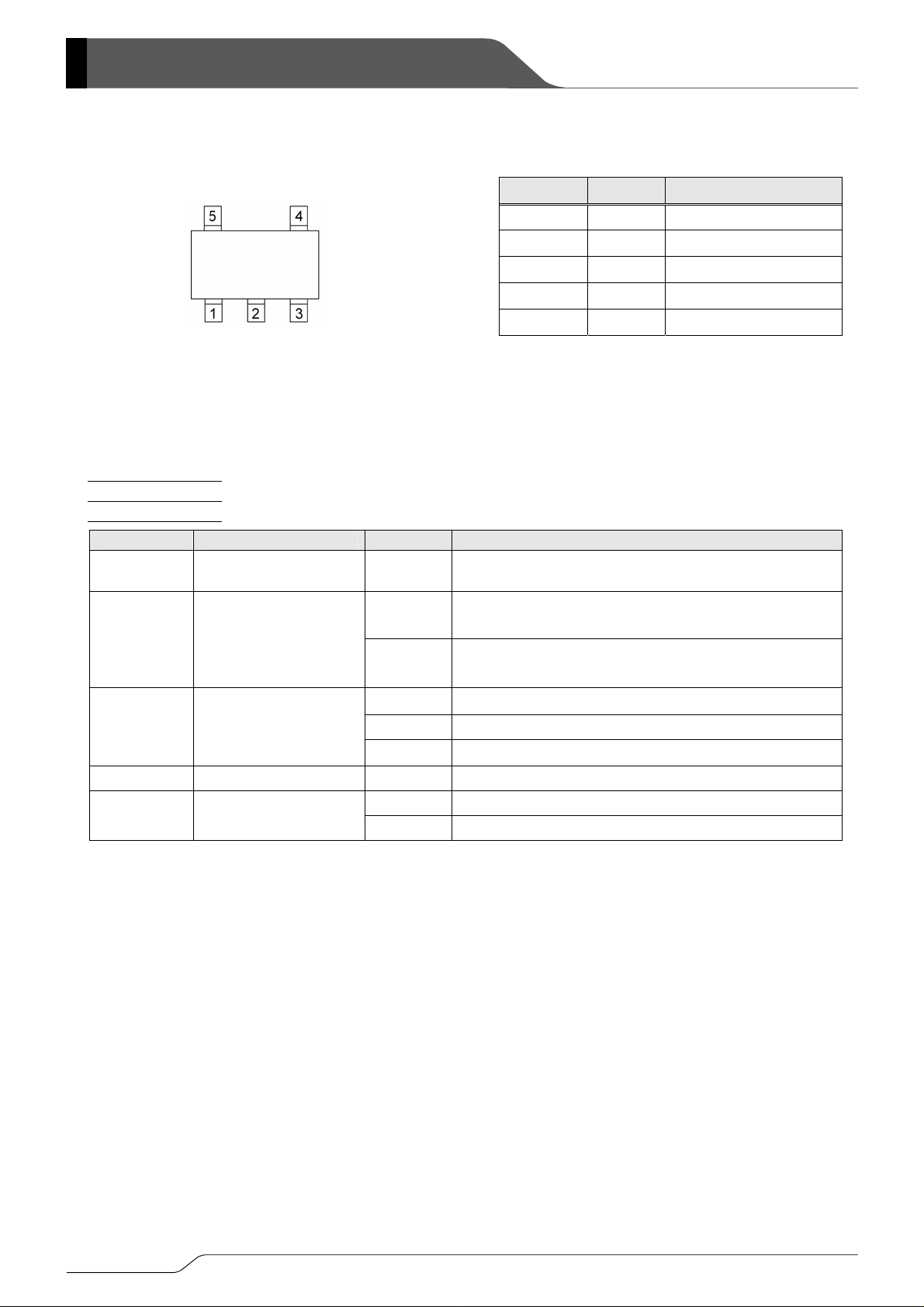

PIN CONFIGURATION

PRODUCT CLASSIFICATION

●Ordering Information

XC9206①②③④⑤⑥: PWM Control

XC9207①②③④⑤⑥: PWM / PFM Automatic Switching Control

XC9208①②③④⑤⑥

DESIGNATOR

①

②③

VIN CE/MODE

Lx V

(TOP VIEW)

Type of DC/DC Converter A

V

SS

SOT-25

OUT

: PWM Control, PWM / PFM Automatic Switching Control Manually Selectable

DESCRIPTION SYMBOL DESCRIPTION

Output Voltage

Series

09~40

09~40 & L

PIN ASSIGNMENT

PIN NUMBER PIN NAME FUNCTION

1 LX Switching Output

2 VSS Ground

3 VOUT Output Voltage Sense

4 CE/MODE Chip Enable/Mode Switch

5 VIN Power Input

: 600mA current limiter, Transistor built-in, output voltage

internally set (V

: 100mV increments

e.g. VOUT=1.5V→②=1, ③=5

: 1.85V V

2.85V VOUT →②=2, ③=L

OUT →②=1, ③=L

OUT product), soft start internally set.

3 : 300kHz

④

⑤ Package M : SOT-25 (SOT-23-5)

⑥

* Output voltage 0.9V ~ 4.0V (100mV increments), 1.85V and 2.85V are standard products.

Output voltage other than these are available as semi-custom products.

Oscillation Frequency

Device Orientation

6 : 600kHz

C : 1.2MHz

R : Embossed tape, standard feed

L : Embossed tape, reverse feed

2/16

■

■

A

XC9206/XC9207/XC9208

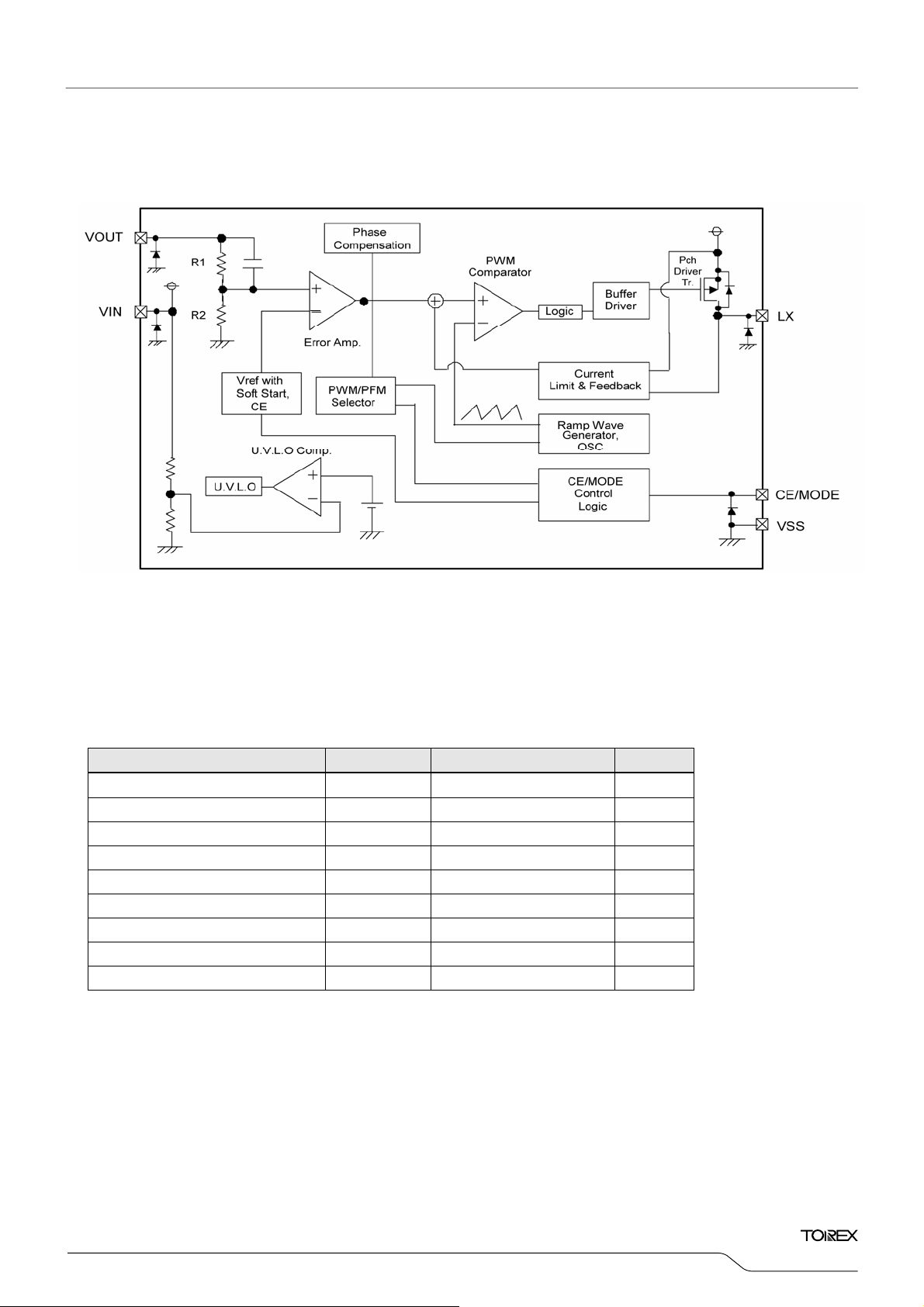

BLOCK DIAGRAM

Note: The signal from CE/MODE Control Logic to PWM/PFM Selector is being fixed to "L" level inside, and XC9206 series chooses

PWM control.

The signal from CE/MODE Control Logic to PWM/PFM Selector is being fixed to "H" level inside, and XC9207 series chooses

only PWM/PFM automatic switching control.

BSOLUTE MAXIMUM RATINGS

Ta=25℃

PARAMETER SYMBOL RATINGS UNITS

VIN Pin Voltage VIN - 0.3 ~ + 6.5 V

VSS Pin Voltage VSS - 0.3 ~ + 6.5 V

Lx Pin Voltage VLx - 0.3 ~ VIN + 0.3 V

VOUT Pin Voltage VOUT - 0.3 ~ + 6.5 V

CE / MODE Pin Voltage VCE - 0.3 ~ VIN + 0.3 V

Lx Pin Current ILx ± 1000 mA

Power Dissipation Pd 250 mW

Operating Temperature Range Topr - 40 ~ + 85

Storage Temperature Range Tstg - 55 ~ + 125

℃

℃

Series

3/16

■

℃

XC9206/XC9207/XC9208

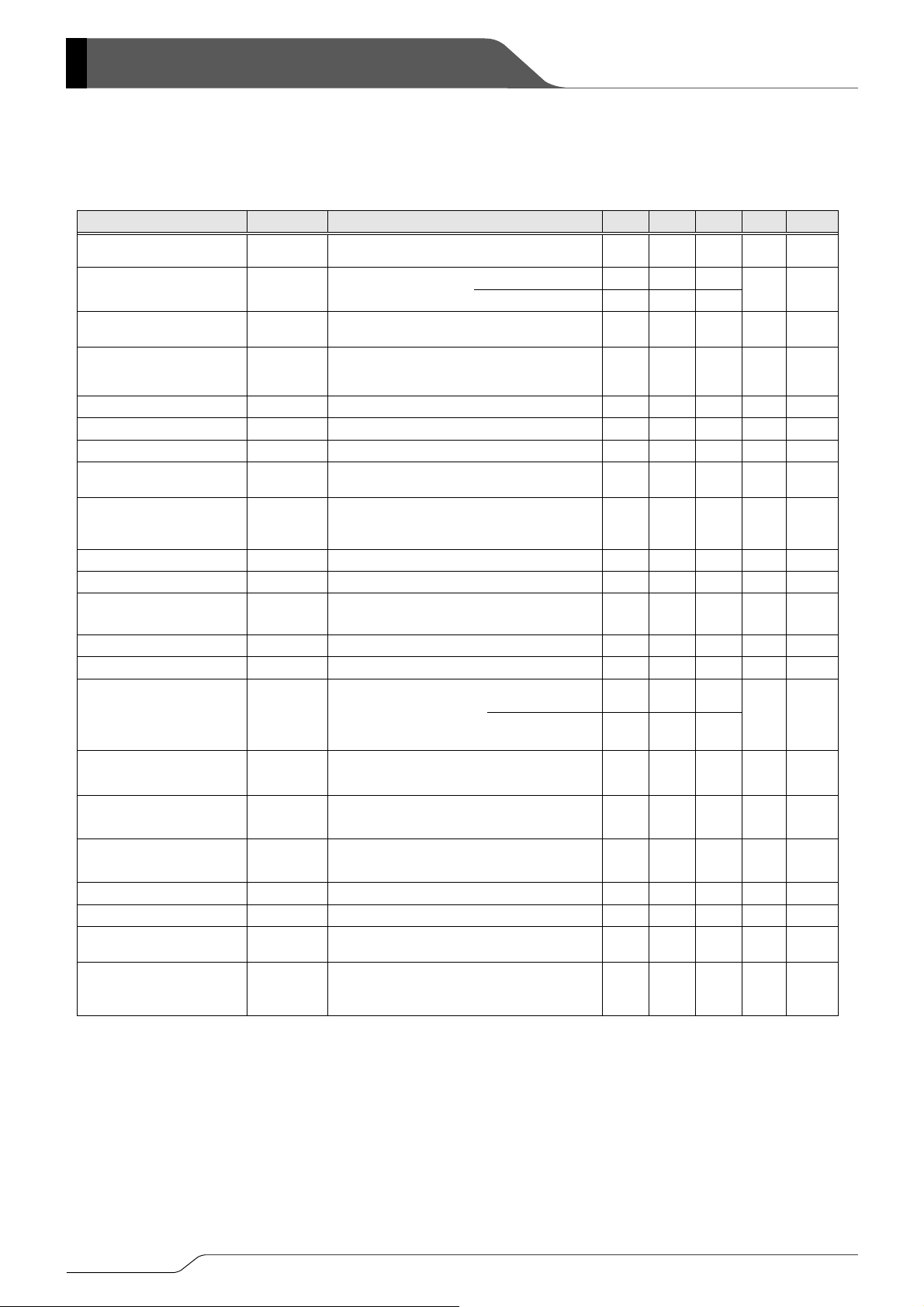

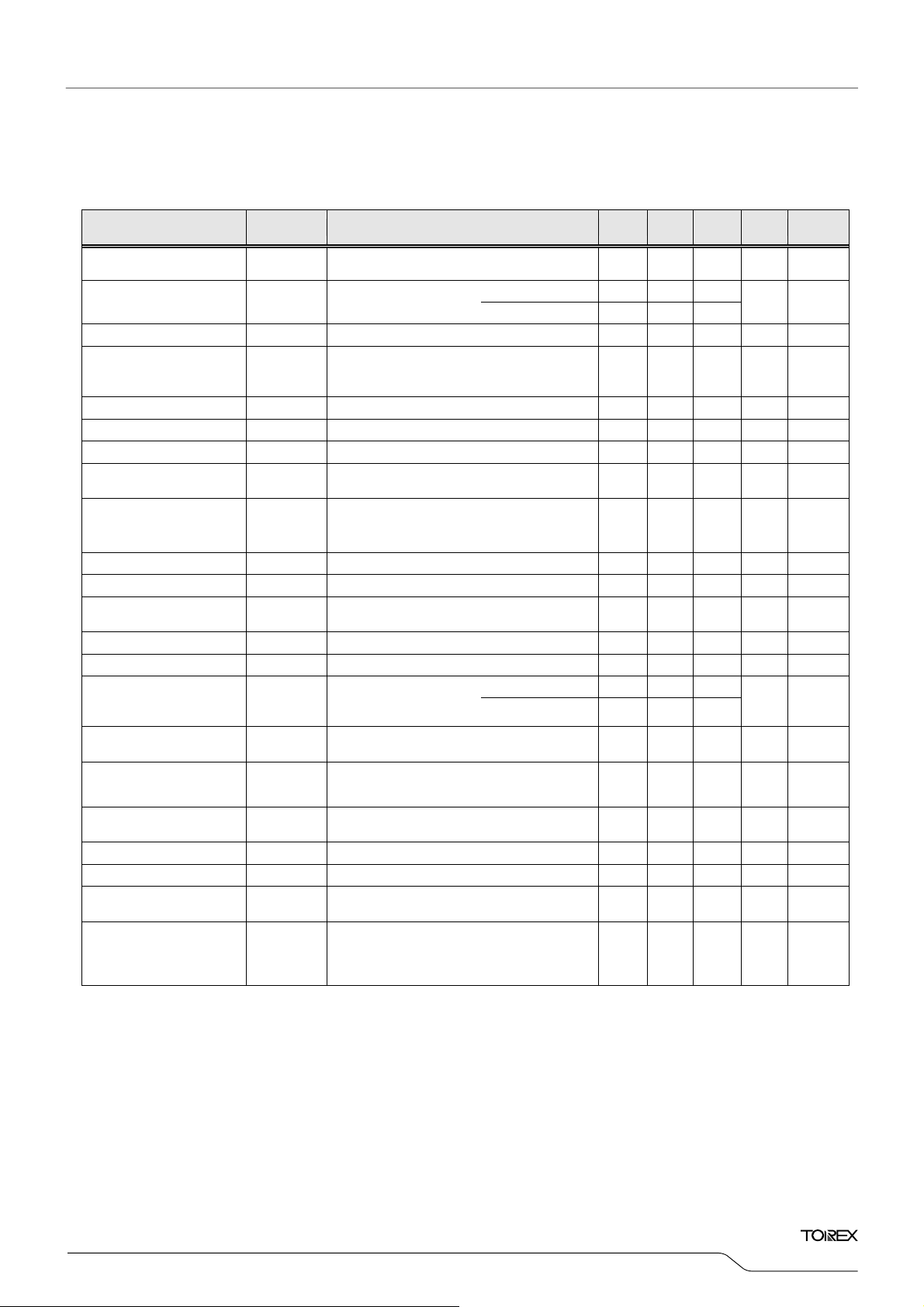

ELECTRICAL CHARACTERISTICS

XC9206A18CMR, XC9207A18CMR, XC9208A18CMR

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNIT

Output Voltage VOUT

Operating Voltage Range VIN

When connected to ext. components

IN, IOUT=30mA

CE=V

Series

(XC9206, 9207)

(XC9208)

VOUT=1.8V, FOSC=1.2MHz, Ta=25

CIRCUIT

1.764 1.800 1.836 V

1.8 - 6.0

2.0 - 6.0

V

①

①

Maximum Output Current IOUTMAX When connected to ext. components 500 - - mA

CE=V

IN, VOUT=0V,

U.V.L.O. Voltage VUVLO

Supply Current 1 IDD1

Supply Current 2 IDD2 CE=VIN, VOUT=fixed voltage x 1.1V - 98 158

Stand-by Current ISTB CE=VSS, VOUT=fixed voltage x 1.1V - 0 1

Oscillation Frequency FOSC

Voltage which Lx pin voltage holding "L"

(*1)

level

CE=V

IN, VOUT=fixed voltage x 0.9V

When connected to ext. components

IN, IOUT=30mA

CE=V

1.00 1.40 1.78 V

- 255 413

μA ③

μA ③

μA ③

1.020 1.200 1.380 MHz

①

②

①

When connected to ext. components

PFM Pulse Width Rate PFMDTY

(XC9207, XC9208 only), CE=V

OUT=1mA

I

Maximum Duty Cycle MAXDTY CE=VIN, VOUT=0V 100 - %

Minimum Duty Cycle MINDTY CE=VOUT=VIN - - 0 %

Efficiency

(*2)

EFFI

When connected to ext. components,

CE=V

IN, IOUT=100mA

Lx SW ON Resistance RLx CE=VIN, VOUT=0V, ILx=400mA

Current Limit ILIM VIN=CE=5.0V, VOUT=0V - 600 - mA

OUT=0V, When CE

V

CE "H" Voltage VCEH

voltage is applied Lx

determine "H"

V

CE "L" Voltage VCEL

OUT=0V, When CE voltage is applied Lx

determine "L"

IN,

24 30 36 %

- 86 %

(*3)

- 0.4 0.9

(XC9206, 9207)

1.2 - V

(XC9208) 0.9 - V

SS - 0.3 V

V

IN

IN

①

②

②

①

Ω ④

④

V

⑤

⑤

PWM "H" Voltage VPWMH

PWM "L" Voltage VPWML

CE "H" Current ICEH CE=VIN=5.5V, VOUT=0V -0.1 - 0.1

CE "L" Current ICEL CE=0V, VIN=5.5V, VOUT=0V -0.1 - 0.1

Soft-Start Time TSS

When connected to ext. components

(XC9208 only), I

OUT=1mA

When connected to ext. components

(XC9208 only), I

OUT=1mA

(*4)

(*4)

When connected to ext. components

CE=0V → V

IN, IOUT=1mA

IN-0.3 - - V

V

- - V

IN-1.0 V

μA ⑤

μA ⑤

0.8 - 6.0 ms

When connected to ext. components

Latch Time Tlat

Test condition: Unless otherwise stated, VIN = 3.6V

NOTE:

*1: Including hysteresis operating voltage range.

*2: EFFI = [ (output voltage x output current) / (input voltage x input current) ] x 100

*3: On resistance = V

*4: The CE/MODE pin of the XC9208A series works also as an external PWM control and PWM/PFM control switching pin. When the

IC is in the operation, control is switched to the PWM mode when the CE/MODE pin voltage is equal to or greater than V

V, and to the automatic PWM/PFM switching mode when the CE/MODE pin voltage is equal to or lower than V

equal to or greater than V

*5: Time until it short-circuits V

pulse generating.

Lx (measurement voltage) / 0.4

CEH.

OUT with GND through 1Ωof resistance from a state of operation and is set to VOUT=0V from current limit

VIN=CE=5.0V, short VOUT by 1Ω

resistance

(*5)

- - 12.0 ms

IN minus 1.0 V and

①

①

①

⑥

IN minus 0.3

4/16

℃

■

ELECTRICAL CHARACTERISTICS (Continued)

XC9206A25CMR, XC9207A25CMR, XC9208A25CMR

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNIT CIRCUIT

XC9206/XC9207/XC9208

Series

VOUT=2.5V, FOSC=1.2MHz, Ta=25

Output Voltage VOUT

Operating Voltage Range VIN

When connected to ext. components

IN, IOUT=30mA

CE=V

(XC9206, 9207) 1.8 - 6.0

(XC9208) 2.0 - 6.0

2.450 2.500 2.550 V ①

V ①

Maximum Output Current IOUTMAX When connected to ext. components 500 - - mA ①

CE=V

U.V.L.O. Voltage VUVLO

IN, VOUT=0V,

Voltage which Lx pin voltage holding "L"

(*1)

level

1.00 1.40 1.78 V ②

Supply Current 1 IDD1 CE=VIN, VOUT=fixed voltage x 0.9V - 255 413 μA ③

Supply Current 2 IDD2 CE=VIN, VOUT=fixed voltage x 1.1V - 98 158 μA ③

Stand-by Current ISTB CE=VSS, VOUT=fixed voltage x 1.1V - 0 1 μA ③

Oscillation Frequency FOSC

When connected to ext. components

CE=VIN, IOUT=30mA

1.020 1.200 1.380 MHz ①

When connected to ext. components

PFM Pulse Width Rate PFMDTY

(XC9207, XC9208 only), CE=VIN,

I

OUT=1mA

24 30 36 % ①

Maximum Duty Cycle MAXDTY CE=VIN, VOUT=0V 100 - % ②

Minimum Duty Cycle MINDTY CE=VOUT=VIN - - 0 % ②

Efficiency

(*2)

EFFI

Lx SW ON Resistance RLx CE=VIN, VOUT=0V, ILx=400mA

When connected to ext. components,

IN, IOUT=100mA

CE=V

(*3)

- 0.4 0.9 Ω ④

- 91 % ①

Current Limit ILIM VIN=CE=5.0V, VOUT=0V - 600 - mA ④

OUT=0V, When CE

CE "H" Voltage VCEH

CE "L" Voltage VCEL

PWM "H" Voltage VPWMH

PWM "L" Voltage VPWML

V

voltage is applied Lx

determine "H"

OUT=0V, When CE voltage is applied Lx

V

determine "L"

When connected to ext. components

(XC9208 only), IOUT=1mA

When connected to ext. components

(XC9208 only), I

OUT=1mA

(XC9206, 9207) 1.2 - VIN

(XC9208) 0.9 - V

V

SS - 0.3 V ⑤

(*4)

(*4)

VIN-0.3 - - V ①

- - V

IN

IN-1.0 V ①

V ⑤

CE "H" Current ICEH CE=VIN=5.5V, VOUT=0V -0.1 - 0.1 μA ⑤

CE "L" Current ICEL CE=0V, VIN=5.5V, VOUT=0V -0.1 - 0.1 μA ⑤

Soft-Start Time TSS

When connected to ext. components

CE=0V →V

IN, IOUT=1mA

0.8 - 6.0 ms ①

When connected to ext. components

Latch Time Tlat

Test condition : Unless otherwise stated, VIN = 3.6V

NOTE:

*1 : Including hysteresis operating voltage range.

*2 : EFFI = [ (output voltage x output current) / (input voltage x input current) ] x 100

*3 : On resistance = V

*4 : The CE/MODE pin of the XC9208A series works also as an external PWM control and PWM/PFM control switching pin. When the

IC is in the operation, control is switched to the PWM mode when the CE/MODE pin voltage is equal to or greater than V

V, and to the automatic PWM/PFM switching mode when the CE/MODE pin voltage is equal to or lower than V

equal to or greater than V

*5 : Time until it short-circuits V

limit pulse generating.

LX (measurement voltage) / 0.4

CEH.

OUT with GND through 1Ω of resistance from a state of operation and is set to VOUT=0V from current

VIN=CE=5.0V, short VOUT by 1Ω

resistance

(*5)

- - 12.0 ms ⑥

IN minus 0.3

IN minus 1.0 V and

5/16

℃

■

XC9206/XC9207/XC9208

ELECTRICAL CHARACTERISTICS (Continued)

XC9206A33CMR, XC9207A33CMR, XC9208A33CMR

Series

VOUT=3.3V,FOSC=1.2MHz, Ta=25

PARAMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNIT CIRCUIT

Output Voltage VOUT

Operating Voltage Range VIN

When connected to ext. components

CE=VIN, IOUT=30mA

(XC9206, 9207) 1.8 - 6.0

(XC9208) 2.0 - 6.0

3.234 3.300 3.366 V ①

V ①

Maximum Output Current IOUTMAX When connected to ext. components 500 - - mA ①

CE=V

U.V.L.O. Voltage VUVLO

IN, VOUT=0V,

Voltage which Lx pin voltage holding "L"

(*1)

level

1.00 1.40 1.78 V ②

Supply Current 1 IDD1 CE=VIN, VOUT=fixed voltage x 0.9V - 370 585 μA ③

Supply Current 2 IDD2 CE=VIN, VOUT=fixed voltage x 1.1V - 120 180 μA ③

Stand-by Current Istb CE=VSS, VOUT=fixed voltage x 1.1V - 0 1 μA ③

Oscillation Frequency FOSC

When connected to ext. components

IN, IOUT=30mA

CE=V

1.020 1.200 1.380 MHz ①

When connected to ext. components

PFM Pulse Width Rate PFMDTY

(XC9207, XC9208 only),

IN, IOUT=1mA

CE=V

26 32 38 % ①

Maximum Duty Cycle MAXDTY CE=VIN, VOUT=0V 100 - % ②

Minimum Duty Cycle MINDTY CE=VOUT=VIN - - 0 % ②

Efficiency

(*2)

EFFI

Lx SW ON Resistance RLx CE=VIN, VOUT=0V, ILx=400mA

When connected to ext. components,

IN, IOUT=100mA

CE=V

(*3)

- 0.4 0.9 Ω ④

- 92 % ①

Current Limit ILIM VIN=CE=5.0V, VOUT=0V - 600 - mA ④

CE "H" Voltage VCEH

CE "L" Voltage VCEL

PWM "H" Voltage VPWMH

PWM "L" Voltage VPWML

OUT=0V, When CE

voltage is applied Lx

determine "H"

OUT=0V, When CE voltage is applied

V

Lx determine "L"

When connected to ext. components

(XC9208 only), I

OUT=1mA

When connected to ext. components

(XC9208 only), I

OUT=1mA

(XC9206, 9207) 1.2 - VIN

(XC9208) 0.9 - V

V

SS - 0.3 V ⑤

V

(*4)

(*4)

IN-0.3 - - V ①

- - V

IN

IN-1.0 V ①

V ⑤

V

CE "H" Current ICEH CE=VIN=5.5V, VOUT=0V -0.1 - 0.1 μA ⑤

CE "L" Current ICEL CE=0V, VIN=5.5V, VOUT=0V -0.1 - 0.1 μA ⑤

Soft Start Time TSS

When connected to ext. components

CE=0V → V

IN, IOUT=1mA

0.8 - 6.0 ms ①

When connected to ext. components

Latch Time Tlat

Test condition: Unless otherwise stated, VIN = 5.0V

NOTE:

*1: Including hysteresis operating voltage range.

*2: EFFI = [ (output voltage x output current) / (input voltage x input current) ] x 100

*3: On resistance = V

*4: The CE/MODE pin of the XC9208A series works also as an external PWM control and PWM/PFM control switching pin. When the

IC is in the operation, control is switched to the PWM mode when the CE/MODE pin voltage is equal to or greater than V

V, and to the automatic PWM/PFM switching mode when the CE/MODE pin voltage is equal to or lower than V

equal to or greater than V

*5: Time until it short-circuits V

pulse generating.

LX (measurement voltage) / 0.4

CEH.

OUT with GND through 1Ω of resistance from a state of operation and is set to VOUT=0V from current limit

VIN=CE=5.0V, short VOUT by 1Ω

resistance

(*5)

- - 12.0 ms ⑥

IN minus 1.0 V and

6/16

IN minus 0.3

■

XC9206/XC9207/XC9208

Series

TYPICAL APPLICATION CIRCUIT

CE/MODE

VIN

(ceramic)

* XC9206/9207/9208 series wire connection

■OPERATIONAL EXPLANATION

Each unit of the XC9206/9207/9208 series consists of a reference voltage source, ramp wave circuit, error amplifier, PWM

comparator, phase compensation circuit, output voltage adjustment resistors, driver transistor, current limiter circuit, U.V.L.O.

circuit and others. The series ICs compare, using the error amplifier, the voltage of the internal voltage reference source with

the feedback voltage from the VOUT pin through resistors R1 and R2. Phase compensation is performed on the resulting error

amplifier output, to input a signal to the PWM comparator to determine the turn-on time during PWM operation. The PWM

comparator compares, in terms of voltage level, the signal from the error amplifier with the ramp wave from the ramp wave

circuit, and delivers the resulting output to the buffer driver circuit to cause the Lx pin to output a switching duty cycle. This

process is continuously performed to ensure stable output voltage. T he current feedbac k circuit monito rs the P-channel MOS

driver transistor current for each switching operation, and modulates the error amplifier output signal to provide multiple

feedback signals. This enables a stable fee dback loop even when a low ESR capacitor, such as a ceramic capacitor, is used,

ensuring stable output voltage.

< Reference Voltage Source >

The reference voltage source provides the reference voltage to ensure stable output voltage of the ICs.

< Ramp Wave Circuit >

The ramp wave circuit determines switching frequency. The frequency is fixed internally and can be selected from 300k Hz,

600 kHz and 1.2 MHz. Clock pulses generated in this circuit are used to produce ramp waveforms needed for PWM

operation, and to synchronize all the internal circuits.

< Error Amplifier >

The error amplifier is designed to monitor output voltage. The amplifier compares the reference voltage with the feedback

voltage divided by the internal resistors (R1 and R2). When a voltage lower than the reference voltage is fed back, the outpu t

voltage of the error amplifier increases. The gain and frequency characteristics of the error amplifier output are fixed internally

to deliver an optimized signal to the mixer.

<Current Limit>

The current limiter circuit of the XC9206/9207/9208 series monitors the current flo wing through the P-channel MOS driver

transistor connected to the Lx pin, and features a combination of the constant-current type current limit mode and the operation

suspension mode.

①When the driver current is greater than a specific level, the constant-current type current limit function operates to turn off the

VOUT

CE/

4

MODE

VIN

5

VSS

3

2

Lx

1

L

SDCIN

VOUT

(500mA)

CL

(ceramic)

pulses from the Lx pin at any given timing.

②When the driver transistor is turned off, the limiter circuit is then released from the current limit detection state.

③At the next pulse, the driver transistor is turned on. However, the transistor is immediately turned off in the case of an over

current state.

④When the over current state is eliminated, the IC resumes its normal operation.

The IC waits for the over current state to end by repeating the steps ① through ③ . If an over current state continues for

several msec and the above three steps are repeatedly performed, the IC performs the function of latching the OFF state of the

driver transistor, and goes into operation suspension mode. Once the IC is in suspension mode, operations can be resumed

by either turning the IC off via the CE /MODE pin, or by restoring power to the VIN pin. The suspension mode does not mean a

complete shutdown, but a state in which pulse output is suspended; therefore, the internal circuitry remains in operation. The

constant-current type current limit of the XC9206A/9207A/9208A series can be set at 600 mA.

●FOSC=1.2MHz ●FOSC=600kHz

L : 4.7μH (CDRH3D16, L : 10μH (CDRH4D18C,

SUMIDA) SUMIDA)

SD : CRS02 (TOSHIBA) SD : CRS02 (TOSHIBA)

CIN : 4.7μF (Ceramic) CIN : 4.7μF (Ceramic)

CL : 10μF (Ceramic) CL : 10μF (Ceramic)

●FOSC=300kHz

L : 22μH (CDRH4D18,

SUMIDA)

*SD : Schottky diode

SD : CRS02 (TOSHIBA)

CIN : 4.7μF (Ceramic)

CL : 10μF (Ceramic)

IOUT

VOUT

CE/MODE

Limit < #ms

Limit< #mS Limit> #mS

LX

VIN

Limit > #ms

Cur ren t L im it LEVEL

0mA

VSS

Restart

7/16

■

XC9206/XC9207/XC9208

OPERATIONAL EXPLANATION (Continued)

< U.V .L.O. Circuit>

When the V

output caused by unstable operation of the internal circuitry. W hen the V

operation takes place. By releasing the U.V.L.O. function, the IC performs the soft start function to initiate output startup

operation. The soft start function operates even when the VIN pin voltage falls momentarily below the U.V.L.O. operating

voltage. T he U.V.L.O. circuit does not cause a complete shutdown of the IC, but causes pulse output to be suspended;

therefore, the internal circuitry remains in operation.

< Function of CE/MODE pin >

The XC9206/9207/9208 series will enter into shut down state by inputting a low level signal to the CE/ MODE pin. During a

shut down state, the current consumption of the IC becomes 0μA (TYP.), with a state of high impedanc e at the Lx pin and

V

OUT pin. The IC starts its operation by inputting a high level signal to the CE/MODE pin. The input of the CE/MODE pin is

a CMOS input and the sink current is 0μA (TYP.).

●XC9206A / 07A series - Examples of how to use CE/MODE pin

●XC9208A series - Examples of how to use CE/MODE pin

Intermediate voltage can be generated by RM1 and RM2. Please set the value of each R1, R2, RM1, RM2 at around 100kΩ.

For switches, CPU open-drain I/O port and transistor can be used.

< PWM / PFM >

XC9207/9208 series features PWM/PFM automatic switching control.

With the automatic PWM/PFM switching control function, the series ICs are automatically switched from PWM control to

PFM control mode under light load conditions. If during light load conditions the coil current becomes discontinuous and

on-time rate falls lower than PFM duty, the PFM circuit operates to output a pulse with a fixed on-time rate from the Lx pin.

During PFM operation with this fixed on-time rate, pulses are gener ated at different frequencies according to condition s of

the moment. This causes a reduction in the number of switching operations per unit of time, resulting in efficiency

improvement under light load conditions. However, since pulse output frequency is not constant, consideration should be

given if a noise filter or the like is needed. Necessary conditio ns for switching to PFM operati on depend on inp ut voltage,

load current, coil value and other factors.

IN pin voltage becomes 1.4 V or lower, the P-channel output driver transistor is forced OFF to prevent false pulse

(A) (B)

(A) (B)

Series

IN pin voltage becomes 1.8 V or higher, switching

SW_CE STATUS

ON Chip Disable

A

OFF

ON

B

PWM/PFM automatic switching control (XC9207

PWM/PFM automatic switching control (XC9207)

OFF Chip Disable

SW_CE SW_PMW/PFM STATUS

ON * Synchronous PWM control

OFF ON

A

OFF OFF Chip Disable

ON * Chip Disable

OFF ON

B

OFF OFF Synchronous PWM control

PWM control (XC9206),

PWM control (XC9206),

Non-synchronous PWM/PFM

automatic switching control

Non-synchronous PWM/PFM

automatic switching control

8/16

)

■

y

y

XC9206/XC9207/XC9208

NOTES ON USE

●Application Information

1. The XC9206/9207/9208 series are designed for use with an output ceramic capacitor. If, however, the potential

difference between input and output is too large, a ceramic capacitor may fail to absorb the resulting high switching

energy and oscillation could occur on the output. If the input-output potential difference is large, connect an

electrolytic capacitor in parallel to compensate for insufficient capacitance.

2. Spike noise and ripple voltage arise in a switching regulator as with a DC/DC converter. These are greatly influenced

by external component selection, such as the coil inductance, capacitance values, and board layout of external

components. Once the design has been completed, verific ation with actual components should be done.

3. When the difference between V

and there is the possibility that some cycles may be skipped completely.

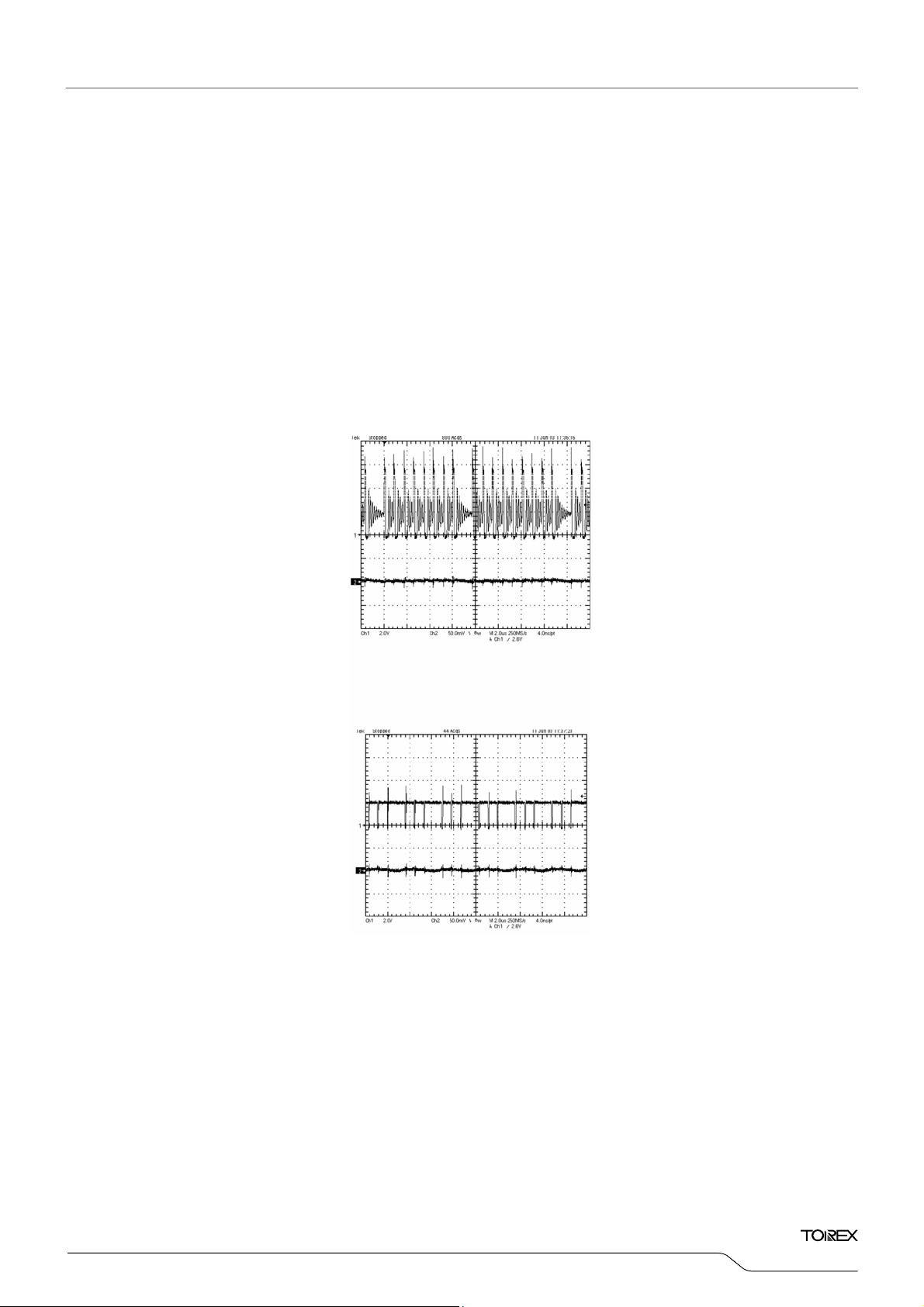

●Oscillation Wave Form (FOSC=1.2MHz)

① VIN = 5.5V, VOUT=1.8V, IOUT=10mA

4. When the difference between VIN and VOUT is small, and the load current is heavy, very wide pulses will be outputted

and there is the possibility that some cycles may be skipped completely: in this case, the Lx pin may not go low at all.

●Oscillation Wave Form (FOSC=1.2MHz)

② VIN = 2.0V, VOUT=1.8V, IOUT=60mA

5. With the IC, the peak current of the coil is controlled by the current limit circuit. Since the peak current increases when

dropout voltage or load current is high, current limit starts operating, and this can lead to instability. When peak current

becomes high, please adjust the coil inductance value and fully check the circuit operation. In addition, please

calculate the peak current according to the following formula:

Ipk = (V

IN - VOUT) x On Duty / (2 x L x FOSC) + IOUT

OnDut

: OnDuty ratio of Pch Driver Transistor

L : Coil Inductance Value

FOSC : Oscillation Frequenc

6. When the peak current which exceeds limit current flows within the specified time, the built-in P-ch driver transistor is

turned off. During the time until it detects limit current and before the built-in transistor can be turned off, the current

for limit current flows; therefore, care must be taken when selecting the rating for the coil or the schottky diode.

7. When V

IN is less than 2.4V, limit current may not be reached because voltage falls caused by ON resistance.

IN and VOUT is large and the load current is light, very narrow pulses will be outputted,

CH1 : Lx

L

: 4.7μH

(CDRH3D16,

SUMIDA)

OUT

CH2 : V

AC-COUPLED

CH1 : Lx

SD : CRS02 (TOSHIBA)

CIN

CL

L

: 4.7μF

: 10μF

: 4.7μH

(Ceramic)

(Ceramic)

(CDRH3D16,

SUMIDA)

SD : CRS02 (TOSHIBA)

CH2 : V

OUT

AC-COUPLED

CIN

CL

: 4.7μF

: 10μF

(Ceramic)

(Ceramic)

Series

9/16

■

XC9206/XC9207/XC9208

NOTES ON USE (Continued)

●Application Information (Continued)

8. Care must be taken when laying out the PC Board, in order to prevent misoperation of the current limit mode.

Depending on the state of the PC Board, latch time may become longer and latch operation may n ot work. In order to

avoid the effect of noise, the board should be laid out so that capacitors are placed as close to the chip as possible.

9. Use of the IC at voltages below the recommended voltage range may lead to instability.

10. This IC should be used within the stated absolute maximum ratings in order to prevent damage to the device.

11. Depending on the input-output voltage differential, or load current, some pulses may be skipped, and the ripple voltage

may increase. When the series' duty cycle is digitally s ignalized, the linear duty cycle and the digitally signalized dut y

cycle cannot carry out completely the same change, which means that the duty cycle does not change li nearly. T he

output is stabilized by applying the phase compensation and adjusting the duty cycle, even when the duty cycle loses the

linear change in the whole circuit. When the state where the output was stabilized is continued by applying phase

compensation to duty cycle which lost linearity, ripple voltage does not increase more than it. The ripple voltage may

increase to about several 10mV according to operating conditions. It is possible, by increasing the capacitance values,

to reduce the ripple voltage. The operating conditions are greatly influenced by the dropout voltage, the load current, the

delay-time, or the external components, such as the coil inductance, and the capacitance values. Verification with actual

parts should be done.

●The Increase of Ripple Voltage (1.2MHz)

CH2: V

AC-COUPLED

CH2: V

AC-COUPLED

CH1: Lx

OUT

③ V

CH1: Lx

OUT

① V

IN=4.2V, VOUT=1.8V, IOUT=180mA ② VIN=4.2V, VOUT=1.8V, IOUT=60mA

IN=3.6V, VOUT=1.8V, IOUT=30mA

Series

AC-COUPLED

CH1: Lx

CH2: V

OUT

L

: 4.7μH

(CDRH3D16,

SUMIDA)

SD : CRS02 (TOSHIBA)

CIN

CL

: 4.7μF

: 10μF

(Ceramic)

(Ceramic)

10/16

■

NOTES ON USE (Continued)

●Instructions on Pattern Layout

1. In order to stabilize VDD's voltage level, we recommend that a by-pass capacitor (CIN) be connected as

close as possible to the V

2. Please mount each external component as close to the IC as poss ible, and connect it to GND with the

shortest possible PCB traces.

3. Wire external components as close to the IC as possible and use thick, short connecting traces to reduce

the circuit impedance.

4. Make sure that the PCB GND traces are as thick as possible, as variations in groun d potential caused by

high ground currents at the time of switching may result in instability.

5. Please connect SD anode directly to the by-pass capacitor C

the V

pin of the IC. Also, take distance between the VSS pin and the SD anode for having large impedance

SS

as possible. We recommend that a ferrite bead mount pattern be arranged for the case that the SD noise

can not be reduced by using the pattern layout as shown below.

6. Please do not make the traces under the IC to carry switching main current. It may cause a malfunction of

the IC.

IN & VSS pins.

XC9206/XC9207/XC9208

(-) in order to minimize SD noise affect on to

IN

Series

<TOP VIEW>

VSS

CE

VIN

Ferrite Bead

<BOTTOM VIEW>

VOUT

L

XC9206/07/08

R.1.1 SD

SOT-25

Figure XC9206/07/08Series Pattern Layout

11/16

■

②

/

V

A

V

/

/

V

A

④

⑥

XC9206/XC9207/XC9208

Series

TEST CIRCUITS

Circuit ① Circuit

CIN

CE

VOUT

4

/MODE

5

VSS

3

2

LxVIN

1

L

SD

CL

RL

1μF

VOUT

CE

4

MODE

VI

5

VSS

3

2

Lx

1

200

Ω

Circuit ③ Circuit

CE

/MODE

VOUT

VSS

34

2

Lx

VIN

5

1

1μF

1μF

VOUT

CE

4

MODE

VIN

5

VSS

3

2

Lx

1

L

Circuit ⑤ Circuit

H

CE

VOUT

VSS

34

2

Lx

1

1k

Ω

/MODE

L

VIN

5

1μF

CIN

CE

VOUT

4

MODE

5

VSS

3

2

LxVI

1

L

SD

CL

1

Ω

1.2MHz 600kHz 300kHz

12/16

CIN

CL

4.7μF (ceramic) 4.7μF (ceramic) 4.7μF (ceramic)

10μF (ceramic) 10μF (ceramic) 10μF (ceramic)

L

4.7μH 10μH 22μH

SD Schottky Diode Schottky Diode Schottky Diode

■

TYPICAL PERFORMANCE CHARACTERISTICS

(1) Output Voltage vs. Output Current

VOUT=1.8V (Oscillation Frequency1.2MHz)

CIN:4.7μF,CL:10μF, L: 4. 7μH(CDRH3D16),

2

1.9

(V)

OUT

1.8

1.7

XC9208A18C

PWM/PFM

Switching Control

PWM Control

SD:CRS02, Topr=25

VIN=2.4V

3.6V

4.2V

℃

(V)

OUT

2

1.9

1.8

1.7

1.6

Output Voltage VOUT (V)

Output Voltage: V

1.5

0.1 1 10 100 1000

Output Current: I

Output Current IOUT (mA)

OUT

XC9208A183

VOUT=1.8V (Oscillation Frequency 300kHz)

CIN:4.7μF,CL:10μF, L: 22μH(CDRH4D28C),

2

SD:CRS02, Topr=25

(mA)

(2) Efficiency vs. Output Current

℃

1.6

Output Voltage VOUT (V)

Output Voltage: V

1.5

1.9

(V)

OUT

1.8

1.7

1.6

Output Voltage: V

Output Voltage VOUT (V)

1.5

0.1 1 10 100 1000

PWM/PFM

Switching Control

PWM Control

Output Current: I

Output C urrent IOU T (m A)

3.6V, 4.2V

VIN=2.4V

Efficiency: EFFI (%) Efficiency: EFFI (%)

(mA) Output Current: I

OUT

Efficiency: EFFI (%)

XC9206/XC9207/XC9208

XC9208A186

VOUT=1.8V (Oscillation Frequency 600kHz)

CIN:4.7μF,CL:10μF, L:10μH(CDRH4D18C),

SD:CRS02, Topr=25

Switching Control

PWM

Control

3.6V, 4.2VPWM/PFM

VIN=2.4V

0.1 1 10 100 1000

Output Current: I

Output C urrent IOU T (m A)

Output Current: I

OUT

OUT

OUT

(mA)

(mA)

(mA)

℃

Series

Output Current: I

(mA) Output Current: I

OUT

OUT

(mA)

13/16

■

℃

℃

℃

●SOT

■

r

r

r

XC9206/XC9207/XC9208

Series

TYPICAL PERFORMANCE CHARACTERISTICS (Continued)

(3) Ripple Voltage vs. Output Current

VOUT=1.8V (Oscillation Frequency 1.2MHz)

(mV)

100

80

60

40

PWM/ PFM Sw i tching

20

Ripple Voltage Vr (mV)

Ripple Voltage: V

0

0.1 1 10 100 1000

XC9208A18C

CIN:4.7μF,CL:10μF, L: 4. 7μH(CDRH3D16),

Control

Output Current IOUT (mA)

Output Current: I

SD:CRS02, Topr=25

PWM Control

3.6V

VIN=2.4V

(mA)

OUT

4.2V

VOUT =1.8V (Oscillation Frequency 600kHz)

CIN:4.7μF,CL:10μF, L: 10μH(CDRH4D18C),

100

80

(mV)

60

PWM/ PFM Swit c hing Cont rol

40

20

Ripple Voltage: V

Ripple Voltage Vr (mV)

0

0.1 1 10 100 1000

XC9208A186

Output Current: I

Output Current IOUT (mA)

VOUT=1.8V (Oscillation Frequency 300kHz)

100

XC9208A183

CIN:4.7μF,CL:10μF, L: 22μH(CDRH3D28C),

SD:CRS02, Topr=25

(mV)

Ripple Voltage V r (mV)

Ripple Voltage: V

80

60

40

20

PWM/PFM Swit c hing

Control

VIN=2.4V

PWM Control

3.6V

4.2V

0

0.1 1 10 100 1000

Output Current IOUT (mA)

Output Current: I

OUT

(mA)

PACKAGING INFORMATION

-25

SD:C R S02, Topr=25

PWM Control

4.2V

3.6V

OUT

VIN=2.4V

(mA)

14/16

●SOT

■

XC9206/XC9207/XC9208

MARKING RULE

-25

54

① ② ③ ④

123

SOT-25

(TOP VIEW)

① Represents product name and type of DC/DC converters

MARK PRODUCT SERIES

6 XC9206AxxxMx

7 XC9207AxxxMx

8

* Character inversion is used.

② Represents integer of outp ut voltage and oscill ation frequency

MARK

FOSC=300kHz FOSC=600kHz FOSC=1.2MHz

XC920xx②x3Mx XC920xx②x6Mx XC920xx②xCMx

0 0 A 0.x

1 1 B 1.x

2 2 C 2.x

3 3 D 3.x

4 4 E 4.x

③ Represents decimal number of outpu t voltage and oscillation frequency

MARK

FOSC=300kHz FOSC=600kHz FOSC=1.2MHz

XC920xxx③3Mx XC920xxx③6Mx XC920xxx③CMx

0 A A x. 0

1 B B x. 1

2 C C x. 2

3 D D x. 3

4 E E x. 4

5 F F x. 5

6 H H x. 6

7 K K x. 7

8 L L x. 8

Z Y Y x. 85

9 M M x. 9

* Output voltage 0.9V ~ 4.0V (100mV increments), 1.85V and 2.85V are standard products.

Output voltages other than these are available as semi-custom products.

②③ example :

OSCILLATION

FREQUENCY

VOUT=3.3V VOUT=5.0V VOUT=1.85V

② ③ ② ③ ② ③

MARK

300kHz 3 3 5 0 1 Z

600kHz 3 D 5 A 1 Y

1.2MHz D D F A B Y

④ Represents production lot number

0 to 9, A to Z repeated (G, I, J, O, Q, W excepted)

Series

XC9208AxxxMx

OUTPUT VOLTAGE

(V)

OUTPUT VOLTAGE

(V)

15/16

XC9206/XC9207/XC9208

1. The products and product specifications containe d herein are subject to change without

notice to improve performance characteristics. Consult us, or our representatives

before use, to confirm that the information in this catalog is up to date.

2. We assume no responsibility for any infringement of patents, patent rights, or other

rights arising from the use of any information and circuitry in this catalog.

3. Please ensure suitable shipping controls (including fail-safe designs and aging

protection) are in force for equipment employing products listed in this catalog.

4. The products in this catalog are not developed, designed, or approv ed for use with such

equipment whose failure of malfunction can be reasonably expected to directly

endanger the life of, or cause significant injury to, the user.

Series

(e.g. Atomic energy; aerospace; transport; combustion and associated safety

equipment thereof.)

5. Please use the products listed in this catalog within the specified ranges.

Should you wish to use the products under conditions exceeding the specifications,

please consult us or our representatives.

6. We assume no responsibility for damage or loss due to abnormal use.

7. All rights reserved. No part of this catalog may be copied or reproduced without the

prior permission of Torex Semiconductor Ltd.

16/16

Loading...

Loading...