TOREX XC9120, XC9121, XC9122 User Manual

)

V

XC9120/XC9121/XC9122

Series

ETR0409-003

Step-Up DC/DC Controller IC, MAXDUTY: 93%

■GENERAL DESCRIPTION

XC9120/9121/9122 Series are PWM, PWM/PFM auto/external switching controlled step-up DC/DC converter controller ICs.

Since maximum duty ratio is as large as 93%, the series is the best for the applications used as high step-up ratios, such as

the LCD panels and OLED. In this series, even if it is a high step-up ratio, the output voltage stabilized at high efficiency can

be obtained. With 0.9V (±2.0%) of reference voltage supply internal, and using external resistors, RFB1 and 2, output

voltage can be set up freely within a range of 1.5V to 30V. For a current sense, with the use of RSENSE, ceramic capacitors

can be used as load capacitors and allows for lower output ripple and reduced PCB area requirements.

Control automatically switches from PWM to PFM during light loads with the XC9121 series and the XC9122 series can

switch the control from PWM to PFM using external signals depending on the circuit conditions..

During stand-by (when the CE pin is low), all circuits are shutdown to reduce current consumption to as low as 1.0μA or less.

The overcurrent limit circuit of this IC is designed to monitor the ripple voltage of the FB pin and operates the IC to stop when

the ripple voltage runs over 250mV. The IC resumes its operation with a toggle of the CE pin or by turning the power supply

back on.

■APPLICATIONS

●Power Supply for the LCDs.

●High Step-Up Ratio Equipment (OLED, etc.)

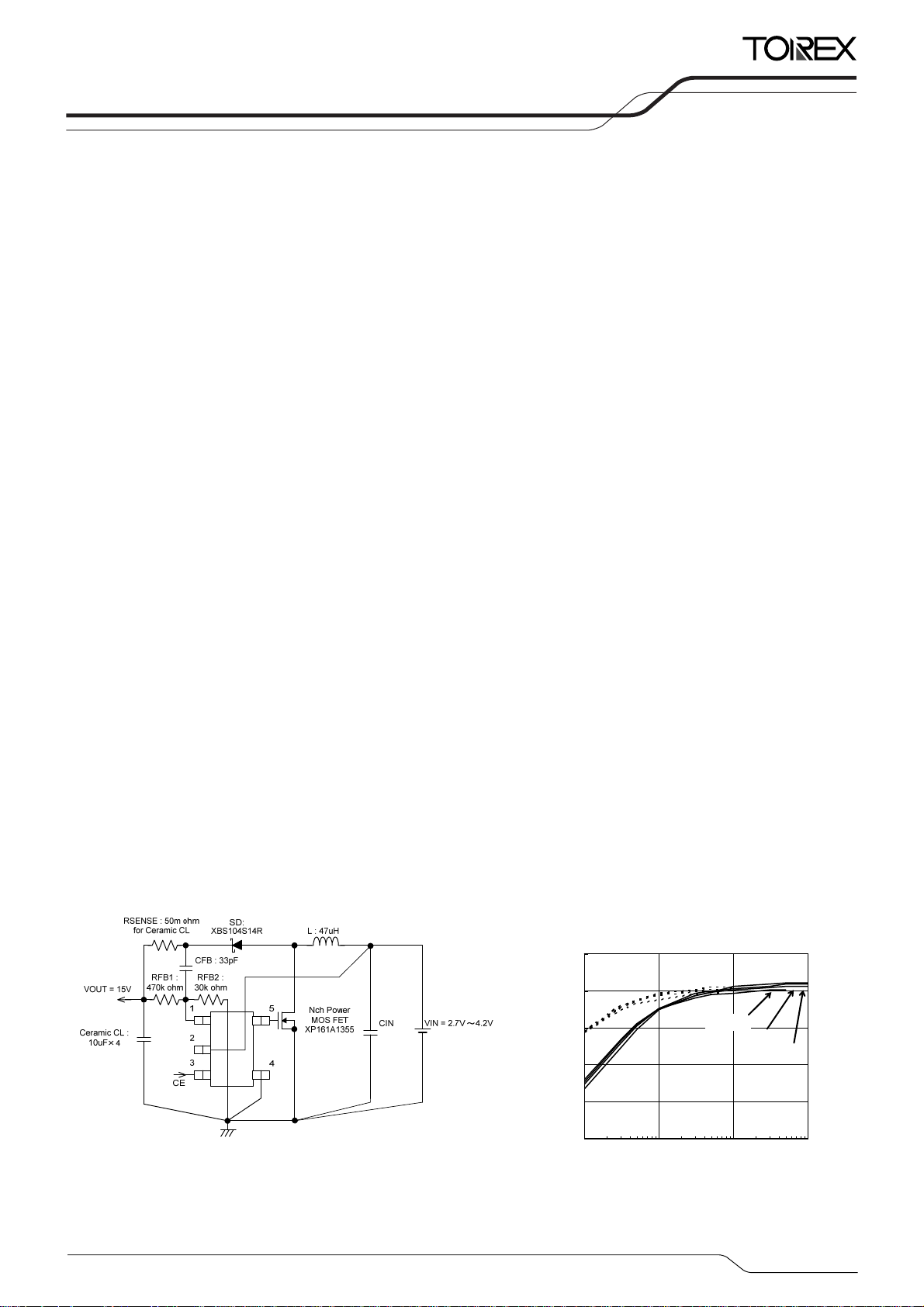

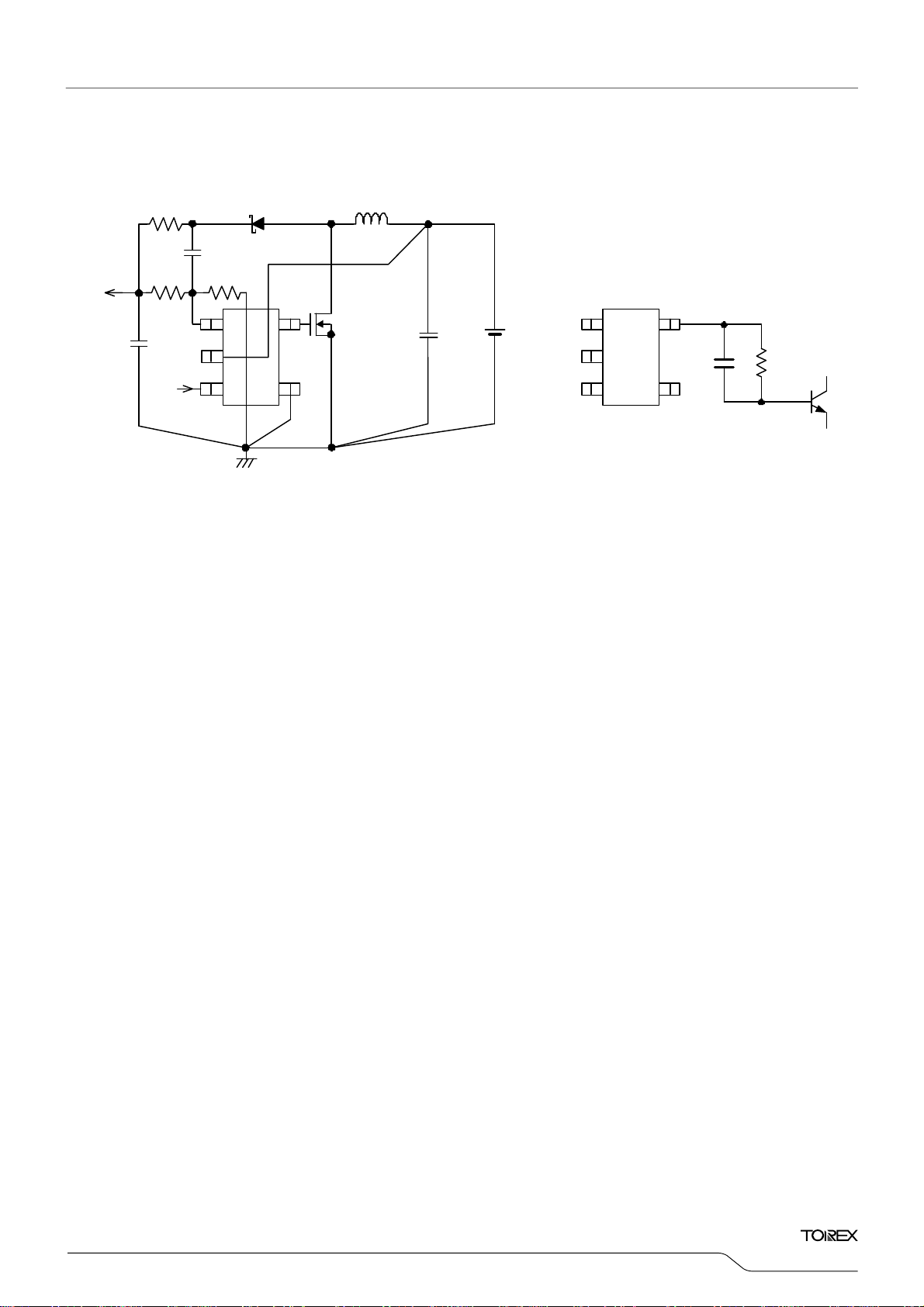

■TYPICAL APPLICATION CIRCUIT

■FEATURES

Input Voltage Range : 0.9V~6.0V

Operating Voltage Range

Output Voltage Range : 1.5V~30V (externally set)

Reference voltage 0.9V (±2.0%)

Oscillation Frequency : 100kHz (±15%)

Output Current : ≥80mA (V

Control : XC9120 (PWM)

High Efficiency : 85% (TYP.)

: (V

Stand-by Function : I

Load Capacitors : Low ESR capacitor compatible

Current Limiter : Operates when ripple is 250mV

Maximum Duty Cycle : 93% (TYP.) for High Step-up Ratio

Packages : SOT-25, USP-6C

* When using external components showing in the circuit below.

■TYPICAL PERFORMANCE

CHARACTERISTICS

XC9122D091 (100kHz, 15.0V)

100

PWM/PF M

80

60

40

Efficiency: EFFI(%

20

0

0.1 1 10 100

☆GreenOperation-Compatible

: 1.8V~6.0V

=3.6V, V

IN

OUT

=15V)*

: XC9121 (PWM/PFM Automatic)

: XC9122 (PWM/PFM Externally)

=3.6V, V

IN

=1.0μA (MAX. )

STB

L=47uH (CDRH5D28),SD:XB01SB04A2

CL= 40uF( Cerami c), Tr:161A11A 1

PWM

Output Current: IOUT(mA)

OUT

VIN =2.7V

=15V, I

4.2V

3.2V

OUT

3.6

=10mA)*

1/17

XC9120/XC9121/XC9122

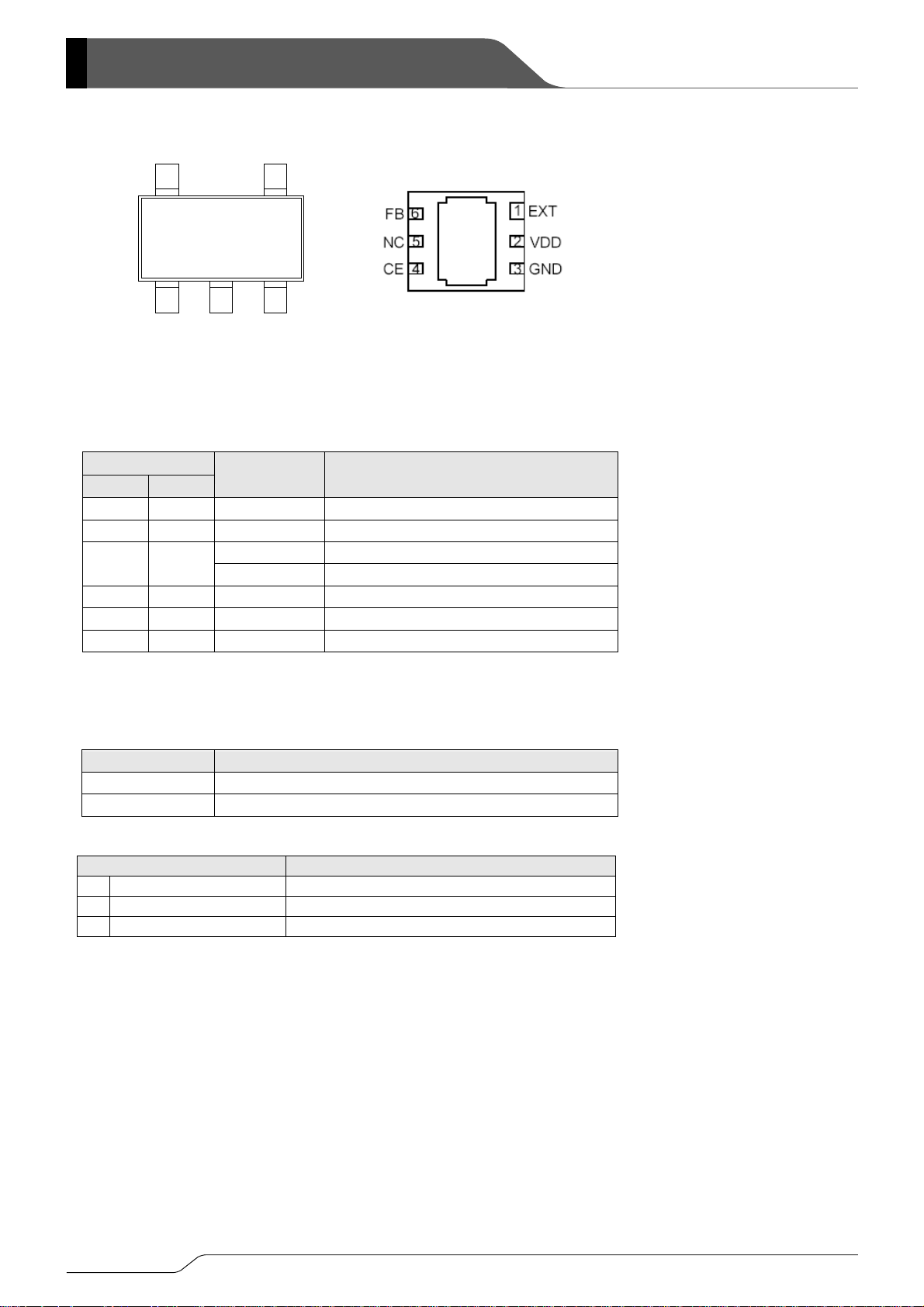

■PIN CONFIGURATION

■PIN ASSIGNMENT

PIN NUMBER

SOT-25 USP-6C

EXT

5

5 4

1 2 3

132

FB

DD

V

SOT-25 (TOP VIEW)

GND

4

CE

USP-6C (BOTTOM VIEW)

PIN NAME FUNCTION

Series

1 6 FB Output Voltage Setting Resistor Connection

2 2 VDD Supply Voltage

3 4

CE Chip Enable (Operates when "H" Level)

CE (/PWM) PWM/PFM Switch*

4 3 GND Ground

5 1 EXT External Transistor Drive Connection

- 5 NC No Connection

* The XC9122 series combines the CE pin and PWM/PFM switch pin.

■FUNCTION

XC9120/9121 Series

CE PIN IC OPERATIONAL STATE

H Operation

L Shut-Down

XC9122 Series

CE/PWM PIN IC OPERATIONAL STATE

H More than VDD - 0.2 (V) Operation (PWM control)

M 0.65 ~ VDD – 1.0 (V) Operation (PWM/PFM automatic switching control

L 0 ~ 0.2 (V) Shut-Down

2/17

* The dissipation pad for the

USP-6C package should be

solder-plated in recommended

mount pattern and metal masking

so as to enhance mounting strength

and heat release. If the pad needs

to be connected to other pins, it

should be connected to the V

(Pin #2).

DD pin

r

XC9120/XC9121/XC9122

■ PRODUCT CLASSIFICATION

●Ordering Information

XC9120①②③④⑤⑥-⑦

XC9121①②③④⑤⑥-⑦

XC9122①②③④⑤⑥-⑦

DESIGNATOR DESCRIPTION SYMBOL DESCRIPTION

① Type of DC/DC Controller

② ③ Output Voltage 09 : FB Voltage (ex. FB Voltage=0.9V→②=0, ③=9)

④ Oscillation Frequency 1 : 100kHz

⑤⑥-⑦

(*1)

The “-G” suffix indicates that the products are Halogen and Antimony free as well as being fully RoHS compliant.

(*2)

The device orientation is fixed in its embossed tape pocket. For reverse orientation, please contact your local Torex sales office o

representative. (Standard orientation: ⑤R-⑦, Reverse orientation: ⑤L-⑦)

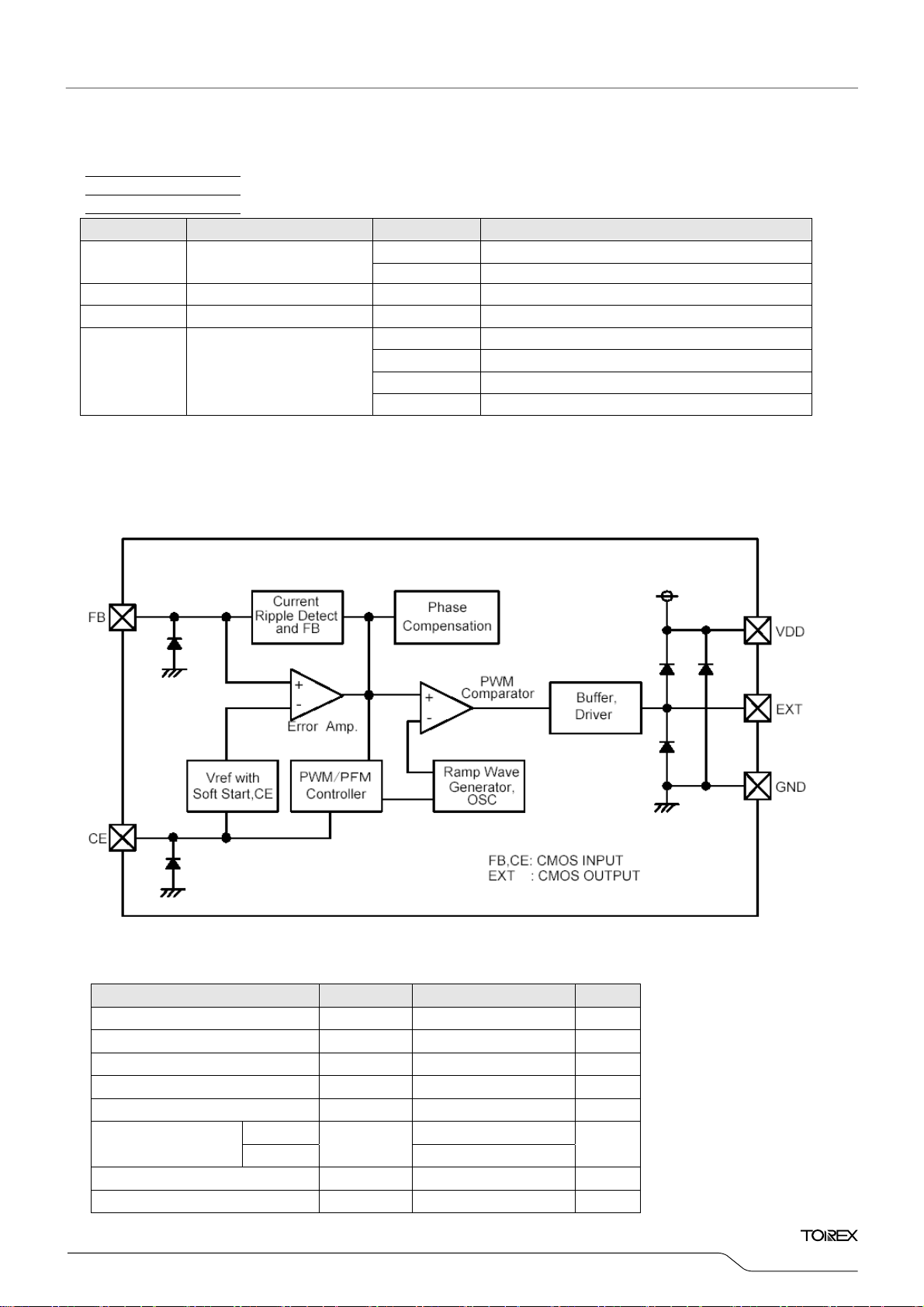

■ BLOCK DIAGRAM

■ ABSOLUTE MAXIMUM RATINGS

Power Dissipation

Operating Temperature Range Topr -40 ~ +85

* Voltage is all ground standardized.

PAR AMETER SYMBOL RATINGS UNIT

VDD Pin Voltage VDD -0.3 ~ 12.0 V

FB Pin Voltage VFB -0.3 ~ 12.0 V

CE Pin Voltage VCE -0.3 ~ 12.0 V

EXT Pin Voltage VEXT -0.3 ~ VDD + 0.3 V

EXT Pin Current IEXT ±100 mA

Storage Temperature Range Tstg -55 ~ +125

(*1)

: PWM Control

(*1)

: PWM/PFM Automatic Switching Control

(*1)

: PWM/PFM Externally Switching Control

B

: With current limiter

D : No current limiter

: SOT-25

: SOT-25 (Halogen & Antimony free)

Packages

Taping Type

(*2)

MR

MR-G

ER : USP-6C

ER-G : USP-6C (Halogen & Antimony free)

Ta =2 5℃

SOT-25 250

USP-6C

Pd

120

mW

℃

℃

Series

3/17

(

XC9120/XC9121/XC9122

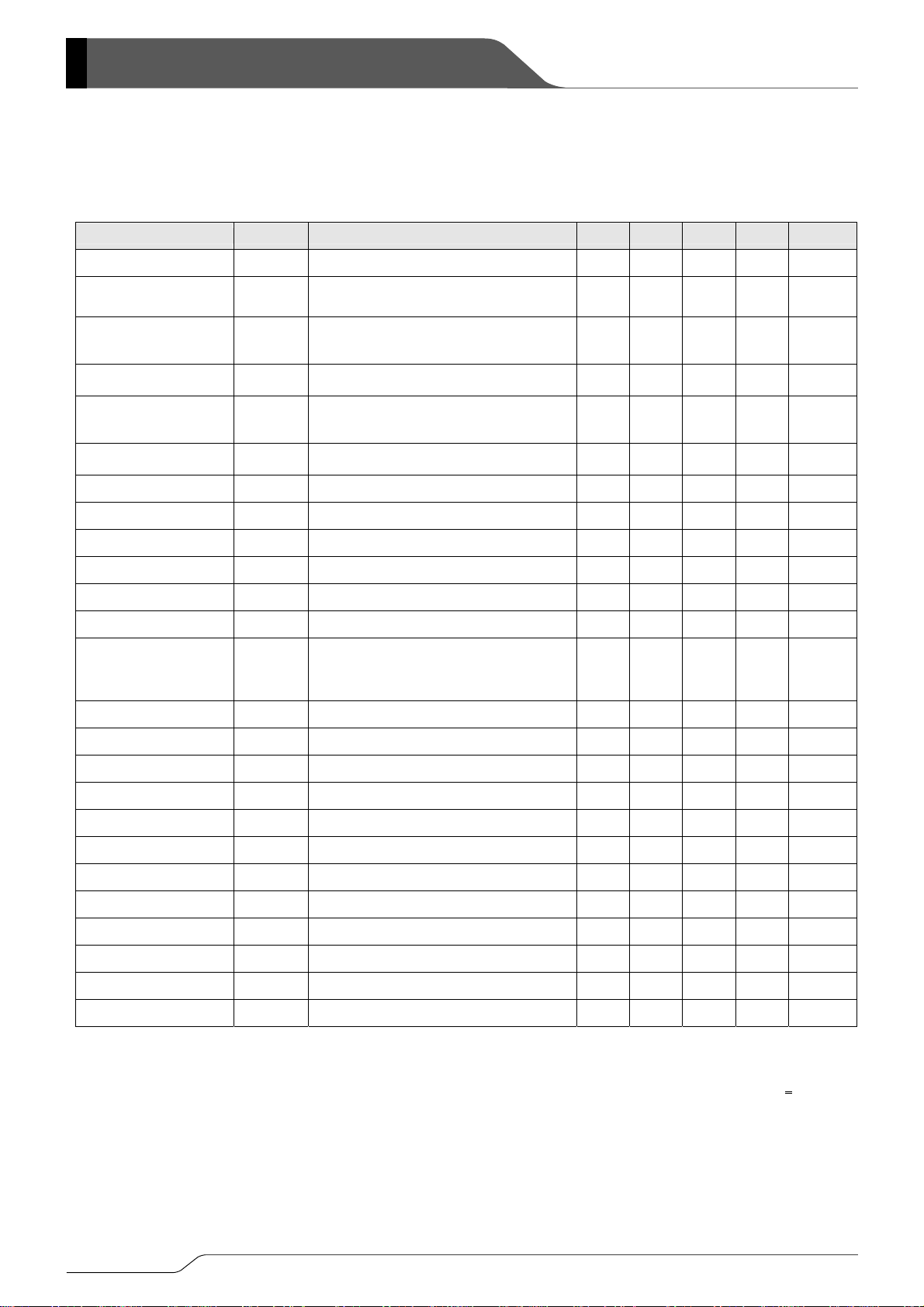

■ELECTRICAL CHARACTERISTICS

XC9120B091, XC9121B091, XC9122B091

XC9120D091, XC9121D091, XC9122D091

PAR AMETER SYMBOL CONDITIONS MIN. TYP. MAX. UNIT

V

NOTE:

*1: Although the IC starts step-up operations from a V

Therefore, a V

*2: The overcurrent limit circuit of this IC is designed to monitor the ripple voltage so please select your external components carefully to

FB Voltage

Supply Voltage Range

(*1)

Output Voltage Setting

Range

Operation Start Voltage VST1

Oscillation Start Voltage

(*1)

Operation Hold Voltage VHLD

Supply Voltage 1 IDD1 Same as VST2, VDD=3.0V - 25 50 μA ④

Supply Voltage 2 IDD2 Same as IDD1, FB=1.2V - 13 30 μA ④

Stand-by Current ISTB Same as IDD1, CE=0V - - 1.0 μA ⑤

Oscillation Frequency fOSC Same as IDD1 85 100 115 kHz ④

Maximum Duty Ratio MAXDTY Same as IDD1 89 93 96 % ④

PFM Duty Ratio

Over Current Sense

Voltage (*2)

Efficiency (*3) EFFI IOUT=10mA - 85 - % ①

Soft-Start Time tSS 5.0 10.0 20.0 ms ①

CE "H" Voltage VCEH Same as IDD1 0.65 - - V ⑤

CE "L" Voltage VCEL Same as IDD1 - - 0.20 V ⑤

EXT "H" ON Resistance REXTH Same as IDD1, VEXT=VOUT-0.4V - 24 36 Ω ④

EXT "L" ON Resistance REXTL Same as IDD1, VEXT=0.4V - 16 24 Ω ④

PWM ‘H’ Voltage (*4) VPWMH IOUT=1mA (XC9122B/D type) VDD-0.2 - - V ①

PWM ‘L’ Voltage (*4) VPWML IOUT=1mA (XC9122B/D type) - - VDD-1.0 V ①

CE "H" Current ICEH Same as IDD2, CE=VDD - - 0.1 μA ⑤

CE "L" Current ICEL Same as IDD2, CE=0V - - -0.1 μA ⑤

FB "H" Current IFBH Same as IDD2, FB=VDD - - 0.1 μA ⑤

FB "L" Current IFBL Same as IDD2, FB=0V - - -0.1 μA ⑤

Test Conditions: Unless otherwise stated, CL: ceramic, recommended MOSFET should be connected.

When V

DD of more than 1.8V is recommended when VDD is supplied from VIN or other power sources.

prevent V

operation, which in turn causes the IC’s operations to stop, the IC resumes its operation with a toggle of the CE pin or by turning the power

supply back on.

*3: EFFI: {(output voltage) x (output current)} / {(input voltage) x (input current)} x 100

*4: The XC9122 series’ CE pin combines PWM/PFM external switch pin. In the operation state, PWM control becomes effective when the CE

pin is more than V

effective with 32% duty.

LMT being reached under low temperature conditions as well as normal operating conditions. Following current limiter circuit

DD-0.2V. When the CE pin is less than VDD-1.0V and more than VCEH, PWM/PFM automatic switching control becomes

FB 0.882 0.900 0.918 V ④

VDD 1.8 - 6.0 V ①

Recommended circuit using 2SD1628,

V

OUTSET

VIN=VOUTSET×0.6, VDD=3.0V,

I

OUT=1.0mA

Recommended circuit using 2SD1628

VOUT=3.3V, IOUT=1.0mA

No external components,

V

ST2

CE connected to VDD, Voltage applied,

FB=0V

Recommended circuit using 2SD1628

VOUT=3.3V, IOUT=1.0mA

PFMDTY No Load (XC9121B/D, XC9122B/D types) 24 32 40 % ⑥

Step input to FB

VLMT

(Pulse width: 2.0μs or more)

EXT= Low level voltage

(XC9120/9122/9122B type)

OUT is set at 15V, VIN=VDD=3.6V.

DD=0.8V, the output voltage and oscillation frequency are stabilized at VDD>1.8V.

Series

f

=100kHz) Ta= 25 ℃

CIRCUIT

1.5 - 30.0 V ②

- - 0.9 V ③

- - 0.8 V ④

- - 0.7 V ③

150 250 400 mV ⑥

4/17

■ TYPICAL APPLICATION CIRCUIT

CFB

RFB2

SD

Nch Power

MOS FET

43

DD between the VDD

IN as close as to the VOUT and VDD

VOUT

RSENSE

RFB1

15

CL

2

CE

When obtaining VDD from a source other than VIN (VOUT),

please insert a by-pass capacitor C

pin and the GND pin in order to provide stable operations.

Please place CL and C

pins respectively and also close to the GND pin.

Strengthen the wiring sufficiently.

R

SENSE should be removed and shorted when the CL

capacitor except for ceramic or low ESR capacitor is

used.

CIN

VIN

XC9120/XC9121/XC9122

Insert R

NPN transistor.

B and CB when using a bipolar

Series

RB

CB

NPM Tr

5/17

XC9120/XC9121/XC9122

■ OPERATIONAL EXPLANATION

The XC9120/9121/9122 series consists of a reference voltage source, ramp wave circuit, error amplifier, PWM comparator,

phase compensation circuit, and current limiter circuit. The series ICs compare, using the error amplifier, the voltage of the

internal voltage reference source with the feedback voltage from the FB pin. Phase compensation is performed on the

resulting error amplifier output, to input a signal to the PWM comparator to determine the turn-on time during PWM operation.

The PWM comparator compares, in terms of voltage level, the signal from the error amplifier with the ramp wave from the

ramp wave circuit, and delivers the resulting output to the buffer driver circuit to cause the EXT pin to output a switching duty

cycle. This process is continuously performed to ensure stable output voltage.

<Error Amp.>

Error amplifier is designed to monitor the output voltage, comparing the feedback voltage (FB) with the reference voltage

Vref. In response to feedback of a voltage lower than the reference voltage Vref, the output voltage of the error amp.

decreases.

<OSC Generator>

The circuit generates the internal reference clock. The frequency is set to 100kHz (TYP.).

<Ramp Wave Generator>

The ramp wave generator generates a saw-tooth waveform based on outputs from the OSC Generator.

<PWM Comparator>

The PWM comparator compares outputs from the error amp. and saw-tooth waveform. When the voltage from the error

amp’s output is low, the external switch will be set to ON.

<PWM/PFN Comparator>

The circuit generates PFM pulses.

The XC9122 series can switch PWM control and PWM/PFM switching control by external signal. The PWM/PFM automatic

switching control becomes effective when the voltage of the CE pin is less than V

PWM and PFM automatically depending on the load. The PWM/PFM control turns into the PFM control when threshold

voltage becomes lower then voltage of error amps. The PWM control becomes effective when the CE pin voltage is more

than V

DD-0.2V. Noise is easily reduced with the PWM control since the switching frequency is fixed. Because of this, the

series gives the best control suitable for your application.

<Vref with Soft Start>

The reference voltage, Vref (FB pin voltage) =0.9V, is adjusted and fixed by laser trimming (for output voltage settings, please

refer to the output voltage setting.). Soft-start circuit protects against inrush current, when the power is switched on, and

also protects against voltage overshoot. It should be noted, however, that this circuit does not protect the load capacitor (C

form inrush current. With the Vref voltage limited and depending on the input to the error amps, the operation maintains a

balance between the two inputs of the error amps and controls the EXT pin’s ON time so that it does not increase more than

is necessary.

<Enable Function>

The function controls the operation and shutdown of the IC. When the voltage of the CE pin is 0.2V or less, the mode will be

disable, the channel’s operations will stop and the EXT pin will be kept at a low level (the external N-ch MOSFET will be

OFF). When the IC is in a state of disable, current consumption will be no more than 1.0μA. When the CE pin’s voltage is

0.65V or more, the mode will be enabled and operations will recommence.

<Current Limiter Circuit>

The current limiter circuit of the XC9120 series is designed to monitor a ripple output voltage. Following current limiter

circuit operation, which in turn causes the IC’s operations to stop, the IC resumes its operation with a toggle of the CE pin or

by turning the power supply back on.

Series

DD-1.0V, and the control switches between

6/17

L)

Loading...

Loading...