A

XBP06V4E4GR-G

ETR2903-005

Transient Voltage Suppressor (TVS)

■GENERAL DESCRIPTIO N ■APPLICATIONS

Four elements in USP-4 package (Anode Common)

High ESD

■

BSOLUTE MAXIMUM RATINGS

Ta=25℃

PARAMETER SYMBOL RATINGS UNITS

Peak Pulse Power

Power Dissipation Pd

(*1)

Ppk 70 W

120

1000

(*2)

mW

Junction Temperature Tj 150 ℃

Storage Temperature Tstg -55~+150 ℃

ESD Durability

Contact Discharge

(*1): tp=8/20μs

(*2): This is a reference data taken by using the test board.

(*3): Test Condition IEC61000-4-2 Standard

(*4): Criterion: No damage to device elements

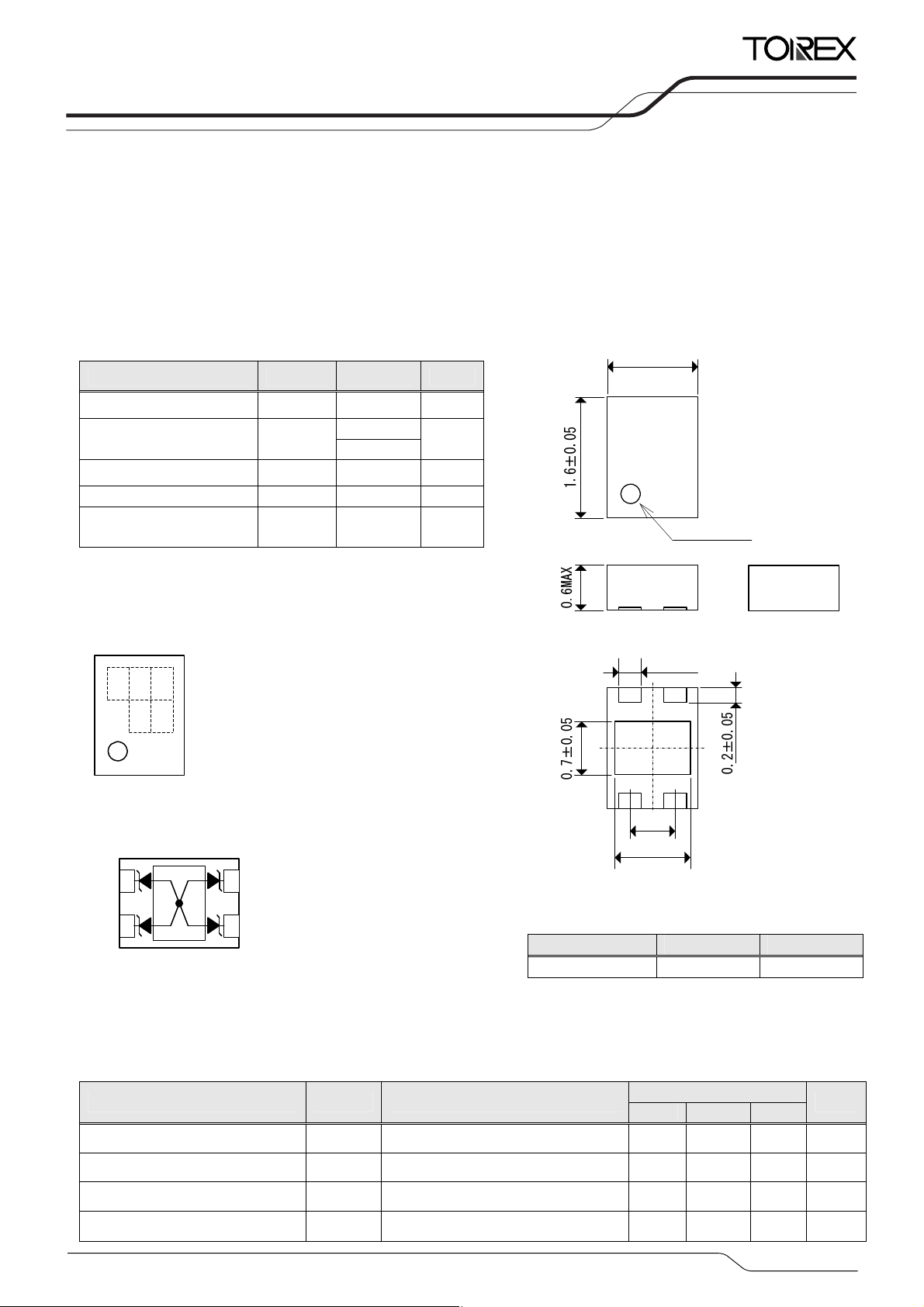

■MARKING RULE

①

■PIN CONFIGURATION

2

1

■ ELECTRICAL CHARACTERISTICS

(*3)(*4)

②③

⑤

④

BOTTOM VIEW

Vpp 30 kV

①②③:BP2(Product Number)

④⑤:Lot Number

3

4

1. Cathode

2. Cathode

3. Cathode

4. Cathode

TAB. Anode

PARAMETER SYMBOL TEST CONDITION

Breakdown Voltage VBR IR =5mA 6.4 6.8 7.2 V

ESD protection

■PACKAGING INFORMATION

■PRODUCT NAME

PRODUCT NAME PACKAGE ORDER UNIT

XBP06V4E4GR-G

*

The “-G” suffix indicates that the products are Halogen and Antimony free

as well as being fully RoHS compliant.

1.2±0.05

1pin INDENT

0.3±0.05

(0.6)

1.0±0.05

*

USP-4 3,000/Reel

LIMITS

MIN. TYP. MAX.

Ta=25℃

UNITS

Leakage Current IRM VRM=5V - - 1.0 μA

Forward Voltage VF IF=10mA - - 1.25 V

Inter-Terminal Capacity Ct VR=0V, f=1MHz - 40 - pF

1/4

XBP06V4E4GR-G

■TYPICAL PERFORMANCE CHARACTERISTICS

(1) Reverse Current vs. Breakdown Voltage (2) Reverse Current vs. Reverse Voltage

100

10

(mA)

R

1

75℃

25℃

1

0.1

(uA)

R

Ta=125℃ 25℃75℃

0.01

BR

Ta=125℃

(V)

0.001

Reverse Current I

0.0001

0123456

Reverse Voltage V

R

(V)

0.1

Reverse Current I

0.01

-25℃

0.001

5.0 5.5 6.0 6.5 7.0 7.5 8.0

Breakdown Voltage V

(3) Breakdown Voltage vs. Operating Temperature (4) Reverse Current vs. Operating Temperature

8.0

10

7.5

(V)

BR

7.0

I

=5mA

1

(uA)

R

-25℃

6.5

0.1

6.0

0.01

Breakdown Voltage V

5.5

5.0

-50 0 50 100 150

Operating Temperature Ta (℃)

Reverse Current I

0.001

-50 0 50 100 150

Operating Temperature Ta (℃)

(5) Inter-Terminal Capacity vs. Reverse Voltage (6) Forward Current vs. Forward Voltage

100

90

80

70

f=1MHz

100

10

(mA)

F

Ta=125℃ 75℃

60

50

1

40

30

20

Inter-Terminal Capacity Ct (pF)

10

0

0123456

Ta=25℃

0.1

Forward Current I

0.01

0 0.2 0.4 0.6 0.8 1 1.2

V

=5.25V

5V

3V

25℃

-25℃

2/4

Reverse Voltage V

R

(V)

Forward Voltage V

F

(V)

p

(

)

■PACKAGING INFORMATION

● USP-4 Power Dissipation

Power dissipation data for the USP-4 is shown in this page.

The value of power dissipation varies with the mount board conditions.

Please use this data as one of reference data taken in the described

condition.

1. Measurement Condition (Reference data)

Condition: Mount on a board

Ambient: Natural convection

Soldering: Lead (Pb) free

Board: Dimensions 40 x 40 mm (1600 mm

Material: Glass Epoxy (FR-4)

Thickness: 1.6 mm

Through-hole: 4 x 0.8 Diameter

Copper (Cu) traces occupy 50% of the board area

in top and back faces.

Package heat-sink is tied to the copper traces.

2

in one side)

2. Power Dissipation vs. Ambient temperature

Board Mount (Tj max = 150℃)

Ambient Temperature (℃)

Power Dissipation Pd (mW)

Evaluation Board (Unit: mm)

Thermal Resistance (℃/W)

XBP06V4E4GR-G

25 1000

150 0

125.00

1200

mW

1000

800

600

ation: Pd

400

Pd-Ta特性グラフ

Pd vs. Ta

200

許容損失Pd(mW)

Power Dissi

0

25 50 75 100 125 150

Ambient Temperature: Ta (℃)

周囲温度Ta(℃)

3/4

XBP06V4E4GR-G

1. The products and product specifications contained he rein are subject to change without

notice to improve performance characteristics. Consult us, or our representatives

before use, to confirm that the information in this datasheet is up to date.

2. We assume no responsibility for any infringement of patents, patent rights, or other

rights arising from the use of any information and circuitry in this datasheet.

3. Please ensure suitable shipping controls (including fail-safe designs and aging

protection) are in force for equipment employing products listed in this datasheet.

4. The products in this datasheet are not developed, designed, or approved for use with

such equipment whose failure of malfunction can be reasonably expected to directly

endanger the life of, or cause significant injury to, the user.

(e.g. Atomic energy; aerospace; transport; combustion and associated safety

equipment thereof.)

5. Please use the products listed in this datasheet within the specified ranges.

Should you wish to use the products under conditions exceeding the specifications,

please consult us or our representatives.

6. We assume no responsibility for damage or loss due to abnormal use.

7. All rights reserved. No part of this datasheet may be copied or reproduced without the

prior permission of TOREX SEMICONDUCTOR LTD.

4/4

Loading...

Loading...