TorcUP ULTRA series, ULTRA UT-3, ULTRA UT-2, ULTRA UT-7, ULTRA UT-11 Operating And Maintenance Instructions Manual

Version 1-2008

September 2008

OPERATION AND MAINTENANCE MANUAL

FOR TorcUP ULTRA UT-2, UT-3, UT-7, UT-11,

SQUARE DRIVE HYDRAULIC TORQUE WRENCHES

UTLRA Series UT-2, UT-3, UT-7, UT-11, Square Drive Hydraulic Torque Wrenches are designed for

installing and removing threaded fasteners requiring precise high torque during bolt makeup and

maximum torque during bolt breakout.

TorcUP Inc. is not responsible for customer modification of tools for applications on which TorcUP Inc.

IMPORTANT SAFETY INFORMATION ENCLOSED.

READ THIS MANUAL BEFORE OPERATING TOOL.

IT IS THE RESPONSIBILITY OF THE EMPLOYER TO PLACE THE INFORMATION IN THIS

MANUAL INTO THE HANDS OF THE OPERATOR.

FAILURE TO OBSERVE THE FOLLOWING WARNINGS COULD RESULT IN INJURY

PLACING TOOL IN SERVICE

• Always operate, inspect and maintain this tool in

accordance with American National Standards Safety

Code for Hydraulic Rams and Jacks (ANSI B30.1)

• This tool will function using an air or electric powered

hydraulic pump. Adhere to the pump safety

requirements and follow instructions when connecting

the pump to the tool.

• Use only equipment rated for the same pressure and

torque.

• Use only a hydraulic pump capable of gener a t i ng

10,000 PSI (681 bar) maximum pressure with this tool.

• Use only twin line hydraulic hose rated for 10,000 PSI

(681 bar) pressure with this tool.

• Do not interchange the male and female swivel inlets

on the tool or the connections on one end of the hose.

Reversing the inlets will reverse the power stroke cycle

and may damage the tool.

• Do not use damaged, frayed or deteriorated hoses and

fittings. Make certain there are no cracks, splits

or leaks in the hoses.

The use of other than genuine TorcUP replacement parts may result in safety hazards, decreased tool performance,

and increased maintenance, and may invalidate all warranties.

Repairs should be made only by authorized personnel. Consult your nearest TorcUP Authorized Service Center.

Refer All Communications to the Nearest TorcUP Office or Distributor.

TorcUP Inc.

Printed in U.S.A.

For Technical Support and Information Contact:

1025 Conroy Place, Easton, PA 18040

Phone: (610) 250-5800 Fax: (610) 250-2700

- 1 -

NOTICE

was not consulted.

WARNING

• Use the quick connect system to attach the hoses to the

tool and pump. Make certain the spring-loaded retaining

rings are fully engaged to prevent the connectors from

disengaging under pressure.

• When connecting hoses that have not been preloade d

with hydraulic oil, make certain the pump reservoir is

not drained of oil during start-up.

• Do not remove any labels. Replace any damaged label.

USING THE TOOL

• Do not handle pressurized hoses. Escaping oil under

pressure can penetrate the skin, causing serious injury. If

oil is injected under the skin, see a doctor immediately.

• Never pressurize uncoupled couplers. Onl y use

hydraulic equipment in a coupled system.

• Always wear eye protection when operating or

performing maintenance on this tool.

• Always wear head and hand protection and protective

clothing when operating this tool.

NOTICE

TorcUP, Inc.

E-mail: info@torcup.com

.

FAILURE TO OBSERVE THE FOLLOWING WARNING COULD RESULT IN INJURY

WARNING

USING THE TOOL

*Keep hands, loose clothing and long hair away from the

reaction arm and working area during operation. Do not

attempt to support the tool with your hands during operation.

*This tool will exert a strong reaction force. Use proper

mechanical support and correct reaction arm positioning to

control these forces. Do not position the reaction arm so that

it tilts the tool off the axis of the bolt and never use the swivel

inlets as a reaction stop.

*Avoid sharp bends and kinks that will cause severe back-up

pressure in hoses and lead to premature hose failure.

*Use accessories recommended by TorcUP.

*Use only impact sockets and accessories. Do not use hand

(chrome) sockets or accessories.

*Use only sockets and accessories that correctly fit the

bolt or nut and function without tilting the tool off the axis

of the bolt.

*This tool is not designed for working in explosive atmo-

spheres

*This tool is not insulated against electric shock. When

using this tool with a pump having an electrical power

source or circuits, follow the pump instructions for proper

grounding.

* Use only impact sockets and accessories that are appro-

priately rated for the output of the tool.

*Always use retaining pin and ring to engage the socket

to the square drive.

*Inspect sockets for signs of over use before utilizing with

tool.

CONNECTING THE TOOL

1. Attach the twin line hose to the swivel inlets of the

Square Drive Torque Wrench using the spring - loaded

quick connects ends. After making certain that they are

fully engaged, thread the safety rings tightly against the

spring–loaded retainer rings.

2. Connect the opposite ends of the hose to the Pump in the

same manner.

ADJUSTMENTS

SETTING THE SQUARE DRIVE FOR ROTATION

The position of the Square Drive when looking toward the

Shroud will determine if the tool is set to tighten or loosen

the nut. When the Square Drive extends to the left when

looking at the Shroud with the inlets away from you, the

tool is set to loosen the nut. When the Square

Drive extends to the right, the tool is set to tighten the nut. To

change the direction of rotation forModels UT-2 UT-3, UT-7

and UT-11simply push the Square Drive into the housing

until the Drive projects out the opposite side of the tool.

SETTING THE TORQUE

After determining the desired torque, use the torque con-ver-

sion chart on the Shroud or the torque conversion charts on

page 5 to determine the pressure that is necessary to achieve

that torque.

1. Connect the tool to the power supply and turn the pump on.

2. Depress the remote control button causing the pressure to

be shown on the gauge.

3. Adjust the pressure by loosening the wing nut that locks the

pressure adjustment thumbscrew. Rotate the thumbscrew

clockwise to increase the pressure and counterclockwise to

decrease the pressure. Con’t...

PLACING THE TOOL IN SERVICE

PLACING THE TOOL IN SERVICE

When decreasing pressure, always lower the pressure

below the desired point and then bring the gauge back up

to the desired pressure.

4. When the desired pressure is reached, retighten the

wing nut and cycle the tool again to confirm that the

desired pressure setting has been obtained.

SETTING THE REACTION ARM

The function of a reaction device is to hold the tool in

position against the forces generated to tighten or loosen

bolts or nuts. Hydraulic wrenches generate tremendous

force.

An improperly positioned reaction arm may

result in operator injury or damaged tooling.

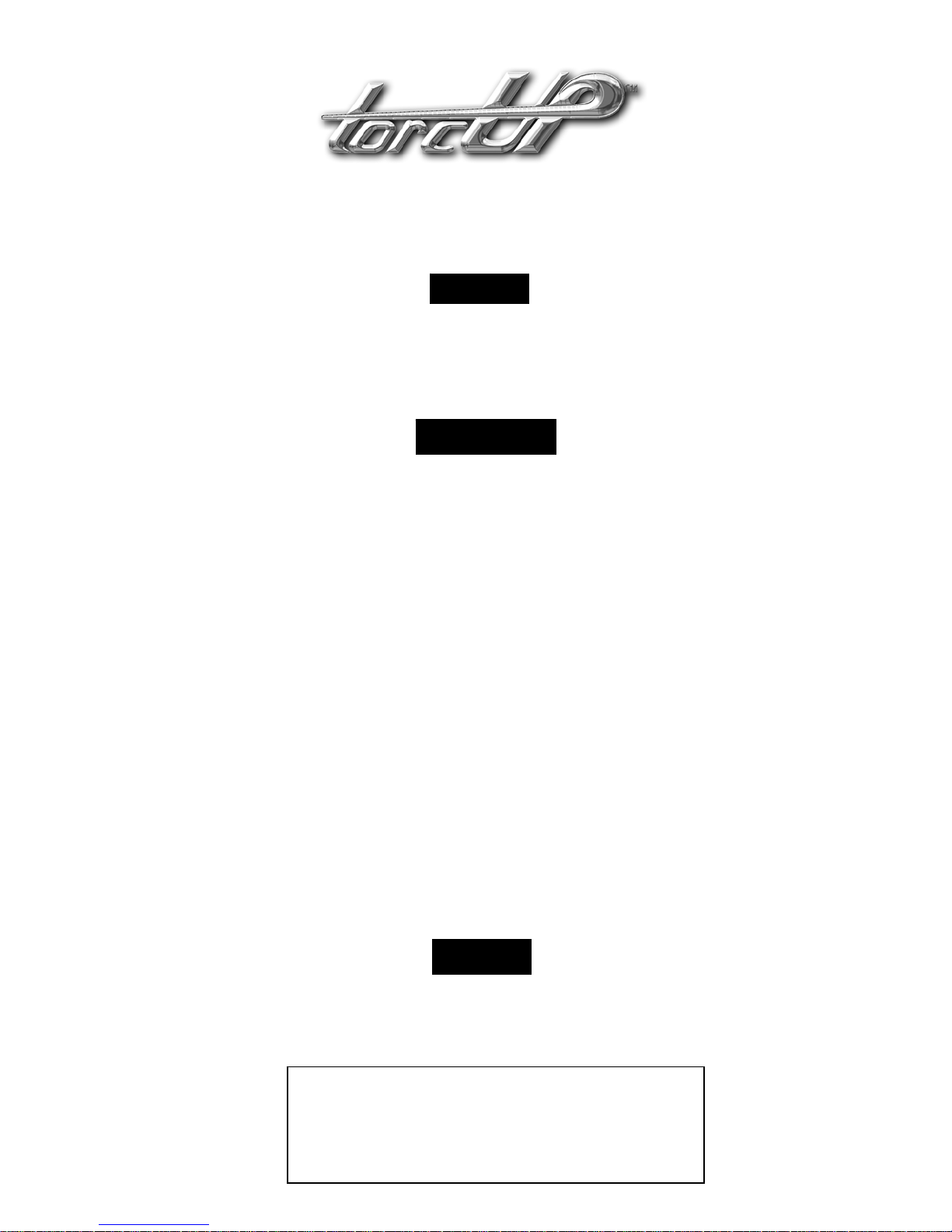

Square Drive Hydraulic Wrench

Reaction Points (Dwg. 01)

Make sure the Reaction Arm is positioned correctly.

(Refer to Drawing 01).

The Reaction Arm can be positioned numerous places

within a 360

correctly positioned, it must be set within a 90

of that circle. That quadrant is the area located between

the protruding Square Drive and the bottom of the

Housing away from the Swivel Inlets. It will always be

toward the lower half of the Housing and on one side of

the Housing when tightening and the other side when

loosening.

OPERATING THE WRENCH

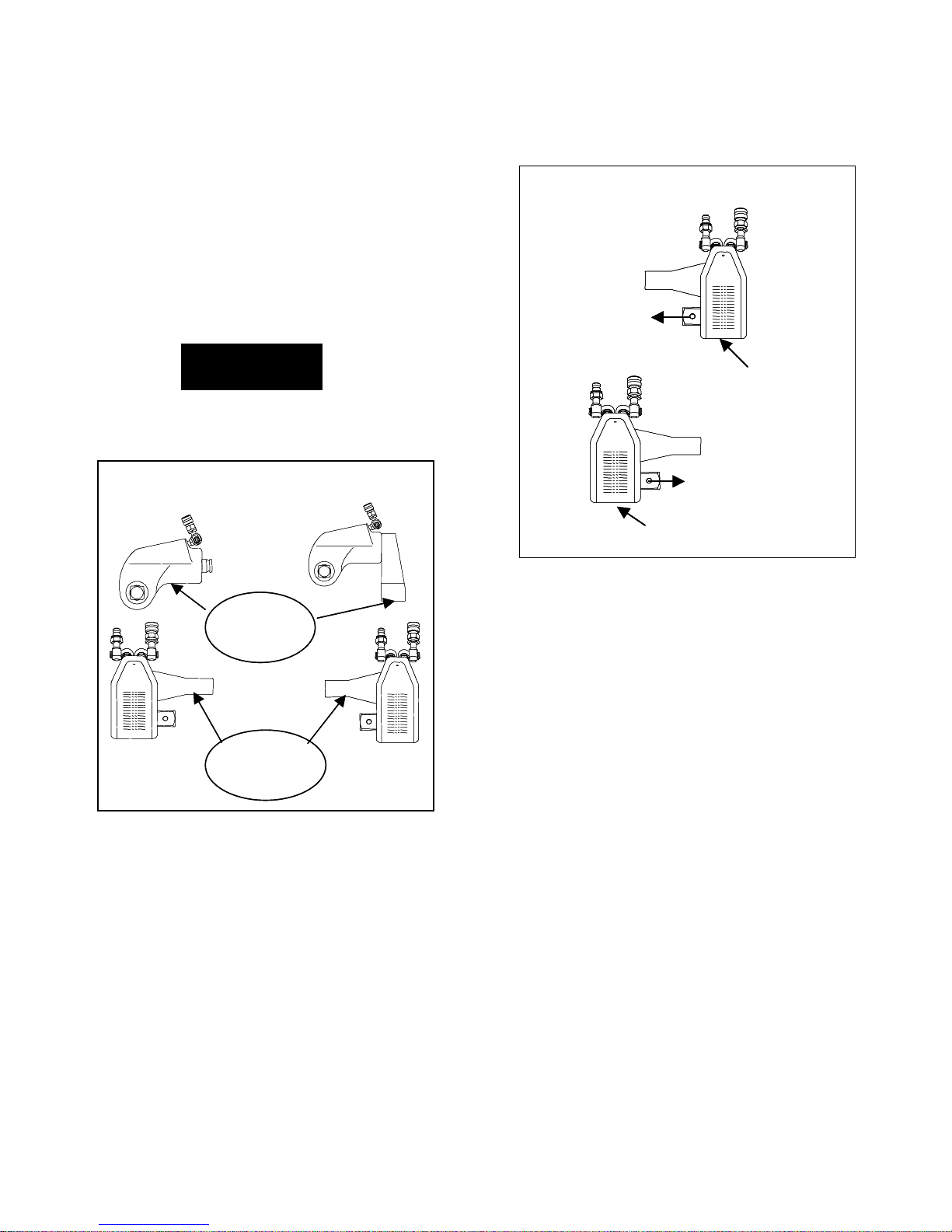

The position of the Square Drive relative to the Shroud

determines whether the action will tighten or loosen the

nut. (Refer to Dwg. 02 for application examples).

The power stroke of the Piston Assembly will always

turn the Square Drive toward the Shroud.

WARNING

REACTION

REACTION

CONTACT

CONTACT

POINTS

POINTS

REACTION

REACTION

CONTACT

CONTACT

POINTS

POINTS

O

circle. However, for the Arm to be

O

quadrant

WRENCH POSITIONS

Square Drive Position for Loosening and

Tightening (Dwg. 02)

FOR LOOSENING

FOR LOOSENING

FOR LOOSENING

SHROUD

SHROUD

SHROUD

FOR TIGHTENING

FOR TIGHTENING

FOR TIGHTENING

SHROUD

SHROUD

SHROUD

1. Place the Square Driver in the socket and the socket

on the nut. Make certain the Square Driver and socket

are the correct size for the nut and that the Driver fully

engages the socket and that the socket is pinned to the

Driver with retaining ring and pin.

2. Position the reaction arm or surface against an

adjacent nut, flange or solid system component. Make

certain that there is clearance for the hoses, swivels,

inlets and End Plug. DO NOT allow the tool to react

against the hoses, swivels, inlets or End Plug.

3. After having turned the Pump on and presetting the

pressure for the correct torque, depress the remote

control button to advance the Piston Assembly

4. When the wrench is started, the reaction surface of the

wrench or Reaction Arm will move against the contact

point and the nut will begin to turn.

5. When the nut is no longer turning and the Pump

Gauge reaches the preset pressure, release the remote

control button. The piston rod will retract when the

button is released and under normal conditions, an

audible “click” will be heard as the tool resets itself.

6. Continue to cycle the tool until it “stalls” and the

preset PSI/torque has been attained.

7. Once the nut stops rotating, cycle the tool one last

time to achieve total torque.

- 3 -

PLACING THE TOOL IN SERVICE

LUBRICATION

Marine Moly Grease

Lubrication frequency is dependent on factors known only to the user. The amount of contaminants in the work area is one

factor. Tools used in a clean room environment will obviously require less service than a tool used out-doors and dropped

in loose dirt or sand. Marine Moly Grease is formulated not to wash out of the tool in areas where lubrication is critical.

Whenever lubrication is required, lubricate as follows:

1. Remove the Drive Plate, Ratchet, Segment Pawl and Drive Sleeves as instructed in the Maintenance Section and wash

the components in a suitable cleaning solution in a well–ventilated area.

2. After drying the components, wipe a film of Marine Moly Grease onto the wear surface of both Drive Sleeves and the

ends of the Ratchet.

3. Spread a light film of Marine Moly Grease onto the inner face and both sides of the Drive Plate.

Do not pack the teeth of the Segment Pawl or Ratchet with lube. It can prevent the teeth from engaging properly.

4. Place a daub of Marine Moly Grease in the piston rod recess of the Drive Plate before linking the Piston Rod to the

Drive Plate at assembly.

CRITICAL LUBRICATION

It is imperative to lubricate the piston rod recess of the Drive Plate to Piston Rod

contact area every 20 hours of continuous duty cycling.

Lubricate as follows:

1. Remove Shroud Screws, Shroud, and Roll Pin.

2. Pry the Drive Plate assembly forward from the Piston Rod to expose the recessed contact area in the Drive Plate.

3. With a rag, wipe clean the area and apply a sizeable amount of Marine Moly Grease.

4. Reassemble as instructed in the maintenance section.

- 4 -

UT Series Torque Conversion Chart

P.S.I./FT./lbs Bar/N.M.

UT-2

P.S.I.

1,000 127 330 740 1,090 68 172 447 1,003 1,478

1,200 152 395 888 1,308 82 206 535 1,204 1,773

1,400 178 460 1,036 1,526 95 241 624 1,404 2,069

1,600 203 525 1,185 1,745 109 275 712 1,606 2,366

1,800 229 590 1,332 1,962 122 310 800 1,806 2,660

2,000 255 655 1,470 2,210 136 346 888 1,993 2,996

2,200 279 722 1,617 2,430 150 378 979 2,192 3,294

2,400 305 789 1,765 2,652 163 413 1,070 2,393 3,595

2,600 330 856 1,911 2,873 177 447 1,160 2,591 3,895

2,800 356 923 2,058 3,095 190 483 1,251 2,790 4,196

3,000 380 990 2,210 3,340 204 515 1,342 2,996 4,528

3,200 406 1,058 2,358 3,560 218 550 1,434 4,826 4,826

3,400 432 1,126 2,505 3,785 231 586 1,526 3,395 5,131

3,600 457 1,194 2,652 4,005 245 620 1,619 3,595 5,429

3,800 483 1,262 2,800 4,230 258 655 1,711 3,796 5,734

4,000 510 1,330 2,960 4,400 272 691 1,803 4,013 5,965

4,200 533 1,397 3,108 4,620 286 723 1,894 4,213 6,263

4,400 559 1,464 3,256 4,840 299 758 1,985 4,414 6,561

4,600 584 1,531 3,405 5,060 313 792 2,075 4,616 6,859

4,800 609 1,598 3,552 5,280 326 826 2,166 4,815 7,158

5,000 635 1,665 3,716 5,500 340 861 2,257 5,037 7,456

5,200 660 1,732 3,865 5,720 354 895 2,348 5,239 7,754

5,400 686 1,799 4,013 5,940 367 930 2,439 5,440 8,052

5,600 711 1,856 4,162 6,160 381 964 2,516 5,642 8,350

5,800 737 1,933 4,311 6,380 394 999 2,620 5,843 8,649

6,000 760 2,000 4,440 6,620 408 1,030 2,711 6,019 8,974

6,200 787 2,065 4,588 6,838 422 1,067 2,799 6,219 9,270

6,400 813 2,130 4,736 7,060 435 1,102 2,887 6,420 9,571

6,600 838 2,195 4,884 7,280 449 1,136 2,976 6,621 9,869

6,800 864 2,260 5,032 7,500 462 1,171 3,064 6,821 10,167

7,000 890 2,325 5,180 7,710 476 1,206 3,152 7,022 10,452

7,200 914 2,398 5,328 7,927 490 1,239 3,251 7,223 10,746

7,400 940 2,461 5,476 8,147 503 1,274 3,336 7,423 11,044

7,600 965 2,529 5,625 8,368 517 1,308 3,428 7,625 11,344

7,800 991 2,597 5,772 8,588 530 1,343 3,520 7,825 11,642

8,000 1,015 2,665 5,920 8,820 544 1,376 3,613 8,025 11,956

8,200 1,041 2,731 6,068 9,045 558 1,411 3,702 8,226 12,261

8,400 1,067 2,797 6,216 9,265 571 1,446 3,792 8,426 12,560

8,600 1,092 2,863 6,365 9,485 585 1,480 3,881 8,628 12,858

8,800 1,118 2,929 6,512 9,705 598 1,516 3,971 8,828 13,156

9,000 1,145 2,995 6,660 9,930 612 1,552 4,060 9,028 13,461

9,200 1,168 3,062 6,808 10,148 626 1,583 4,151 9,229 13,757

9,400 1,194 3,129 6,956 10,368 639 1,619 4,242 9,430 14,055

9,600 1,219 3,196 7,105 10,588 653 1,652 4,332 9,632 14,353

9,800 1,245 3,263 7,252 10,810 666 1,688 4,423 9,831 14,654

10,000 1,270 3,330 7,400 11,010 680 1,722 4,514 10,031 14,925

UT-3 UT-7 UT-11

ft./lbs. ft./lbs. ft./lbs. ft./lbs.

UT-2 UT-3 UT-7 UT-11

Bar

N.m. N.m. N.m. N.m.

- 5 -

UT – 2, 3, 7 and 11 Series Wrench

- 6 -

Part Numbers for Ordering

1 Housing UT-2-01 UT-3-01 UT-7-01 UT-11-01

2 Housing Threaded Plug N/A N/A TU-7-39 UT-11-39

3 Reaction Arm TU-2-03-1 TU-3-03-1 TU-7-03-1 TU-11-03-1

4 Reaction Arm Cover TU-2-03-7 TU-3-03-7 TU-7-03-7 TU-11-03-7

5 Cover Screws TU-2-03-8 TU-3-03-8 TU-7-03-8 TU-11-03-8

6 Reaction Arm Spring TU-2-03-6 TU-3-03-6 TU-7-03-6 TU-11-03-6

7 Locking Pin UT-2-03-3 UT-3-03-3 UT-7-03-3 UT-11-03-3

8 Retract Button UT-2-03-4 UT-3-03-4 UT-7-03-4 UT-11-03-4

9 Reaction Arm Screw UT-2-03-5 UT-3-03-5 UT-7-03-5 UT-11-03-5

10 Spline sleeve UT-2-03-2 UT-3-03-2 UT-7-03-2 UT-11-03-2

11 Square Drive TU-2-11-1 TU-3-11-1 TU-7-11-1 TU-11-11-1

12 Ball Plunger TU-2-11-3 TU-3-11-3 TU-7-11-3 TU-11-11-3

14 Locking Pin TU-2-11-2 TU-3-11-2 TU-7-11-2 TU-11-11-2

16 Sleeve UT-2-13 UT-3-13 UT-7-13 UT-11-13

17 Ratchet UT-2-05 UT-3-05 UT-7-05 UT-11-05

18 Drive Plate UT-2-09 UT-3-09 UT-7-09 UT-11-09

19 Drive Segment UT-2-07 UT-3-07 UT-7-07 UT-11-07

20 Drive Segment Spring TU-2-27 TU-3-27 TU-7-27 TU-11-27

21 Roll Pin TU-2-19 TU-3-19 TU-7-19 TU-11-19

22 N/A

23 Smalle y Ring TU-2-43 TU-3-43 TU-7-43 N/A

24 End Plug UT-2-15 UT-3-15 UT-7-15 UT-11-15

25 End Plug Seal TU-2-37 TU-3-37 TU-7-37 TU-11-37

26 Piston Seal TU-2-33 TU-3-33 TU-7-33 TU-11-33

27 Piston Rod Assembly TU-2-17 TU-3-17 TU-7-17 TU-11-17

28 Gland Seal TU-2-35 TU-3-35 TU-7-35 TU-11-35

29 Cylinder Gland TU-2-21 TU-3-21 TU-7-21 TU-11-21

30 Rod Seal TU-2-31 TU-3-31 TU-7-31 TU-11-31

31 Shroud TU-2-23 TU-3-23 TU-7-23 TU-11-23

32 Shroud Screws TU-2-25 TU-3-25 TU-7-25 TU-11-25

33 Swivel (2 req) STU-4M-4M STU-4M-4M STU-4M-4M STU-4M-4M

34 Coupler Set HC-S-100 HC-S-100 HC-S-100 HC-S-100

35

36

40 Gland Wrench TU-2-GW TU-3-GW TU-7-GW TU-11-GW

~ Reaction Arm Assembly UT-2-03 UT-3-03 UT-7-03 UT-11-03

~ Square Drive Assembly UT-2-11 UT-3-11 UT-7-11 UT-11-11

Part UT-2 UT-3 UT-7 UT-11

- 7 -

Maintenance Section

Always turn off the power supply, bleed off hydraulic

fluid from the hose connections on the cylinder

assembly and disconnect the hoses before attempting

to repair or perform maintenance on this tool.

Always wear eye protection when operating or

performing maintenance on this tool.

General Instructions

1. Do not disassemble the tool any further than necessa ry

to replace or repair damaged parts.

2. Use extra care not to score, nick or damage surfaces

that will contain hydraulic oil under pressure.

3. Whenever grasping a tool in a vise, always use

leather–covered or copper–covered vise jaws to protect

the surface of the part and help prevent distortion. This is

particularly true of threaded members and housings.

4. Do not remove any part that is a press fit in or on an

assembly unless the removal of that part is necessary for

repairs or replacement.

5. Do not disassemble the hydraulic cylinder assem bly

unless you have a complete set of seals and o–rings for

replacement.

6. Use only British Standard fractional size tools when

disassembling these tools.

Disassembly of the Reaction Arm Assembly

1. Push the Reaction Arm Retract Button (8) toward the

Reaction Arm Boot (4) and separate the Reaction

Arm Assembly from the Housing (1).

2. While holding the Button down, use a hex wre nc h to

unscrew and remove the Reaction Arm Spline Screw (9).

3. Apply some downward pressure to the Reaction Arm

Engagement Pin (7) and unscrew the Reaction Arm

Retract Button from the Engagement Pin.

4. Remove the Engagement Pin by sliding it out of the

top of the Reaction Arm (3).

5. Pull the Reaction Arm Splined Sleeve (10) out of the

Reaction Arm.

6. Using a hooked tool through the Spline Screw

opening, pull the Reaction Arm Pin Spring (6) out of the

Reaction Arm.

7. To remove the Reaction Arm Boot, use a hex wrench

to unscrew the two Boot Mounting Screws (5) and pull

the Boot off the Reaction Arm.

Disassembly of the Square Drive Tool

1. Before attempting to disassemble a square drive tool,

connect the tool to a pump and operate the tool until the

Piston Assembly (27) is in the fully retracted position.

2. Grasp the Housing (1) in copper–covered or leather–

covered vise jaws with the inlet end upward and using a

WARNING

DISASSEMBLY

3/4” wrench, unscrew and remove the two Swivel Inlets

(33) with their attached Couplers (34).

3. Remove the Housing from the vise jaws and with the

inlet openings over a container to catch the oil, drain as

much hydraulic oil as possible from the Housing.

4. Grasp the Cylinder Housing in copper–covered or

leather–covered vise jaws with the Shroud (31) upward.

In the following step the Shroud will spring to a

straightened position when the Screws at one end are

removed. Hold the Shroud in position until the

Screws are removed and control the flex of the loose

end.

5. Use a hex wrench to unscrew and remove the Shroud

Mounting Screws (32). Remove the Shroud.

6. If the Piston Assembly is not fully retracted, use a

brass drift or brass hammer to tap the Assembly inward

until the Retract Pin (21) aligns with the cross holes in

the Housing. Use a small drift to tap the Retract Pin out

of the Drive Plate (18) and Piston Assembly through the

openings in the Housing.

7. For UT-2, UT-3, UT-7 and UT-11 models, insert a

hex wrench through the larger opening in the Square

Drive and unscrew the Square Drive Locking Pin (14)

inward against the Square Drive Spring (13) while

pulling or pushing the Square Drive out of the tool.

8. For UT-2, UT-3, UT-7 and UT-11 models, remove

the Drive Plate, assembled with the Ratchet (17),

Segment Pawl (19) and Segment Pawl Springs (20) from

between the ears of the Housing. Using finger press u re,

push the Drive Sleeves (16) inward to remove them from

the Housing.

9. Being careful not to let the springs eject from the

assembly, slide the Ratchet, Segment Pawl and Segment

Pawl Springs out of the Drive Plate.

- 8 -

CAUTION

NOTICE

The Cylinder Gland is staked into the Housing to

prevent it from loosening due to vibration or

turbulence in the hydraulic oil flow. The stake point

must be drilled out before attempting to remove the

Cylinder Gland.

10. Locate the stake point on the threads of the Cylinder

Gland (29) and Housing. Using a 1/16” drill bit centered

on the stake point, drill approximately 3/32” deep in one

continuous motion to remove the thread and interference

at that point.

11. Engage the pins of the Cylinder Gland Wrench (40)

with the holes in the Cylinder Gland and using a socket

on the hex of the Wrench unscrew and remove the

Cylinder Gland. Should the Gland not rotate freely a fte r

initial breakout, additional drilling, in small increments,

may be required to remove the obstruction.

12. If the Piston Rod Seal (30) must be replaced, remove

it from the central opening of the Gland.

13. If the Cylinder Gland Seal (28) must be replaced,

remove it from the groove at the bottom of the threads in

the Housing.

In the following step, DO NOT grasp the shaft of the

Piston Assembly with any device that will mar, bur or

otherwise damage the shaft or the drive plate end of

the shaft.

14. Pull the Piston Assembly out of the Housing. If the

Assembly is tight in the Housing and difficult to pull,

inject air into the inlet opening while holding the

Housing over a container that will not damage the

Piston when it is expelled. If an air hose is not available,

temporarily attach the advance line from the pump and

cycle the tool to advance the Piston out of the Housing.

Hydraulic oil will be emitted with the Piston, so the

assembly must be held over a non–damaging container.

15. If the Piston Seal (26) must be replaced, remove it

from the Piston.

16. Push on the small end of the End Plug (24) to

remove it from the Housing. If the End Plug is tight in

the Housing, insert a flat face drift into the hole in the

center of the small shaft, and without cocking the Plug,

tap it out of the Housing.

17. If the End Plug Seal (25) must be replaced, remove it

from the End Plug.

18. If the Splined Sleeve Seat (23) needs replacement,

use a thin blade screwdriver to work it out of the groove

in the Housing.

ASSEMBLY

General Instructions

1. Use extra care not to score, nick or damage surfaces

that will contain hydraulic oil under pressure.

2. Whenever grasping a tool in a vise, always use

leather–covered or copper–covered vise jaws to protect

the surface of the part and help prevent distortion. This is

particularly true of threaded members and housings.

3. Apply o–ring lubricant to all o–rings before final

assembly.

Assembly of the Square Drive Tool

1. If the Splined Sleeve Seat (23) was removed from the

Housing (1), install it in the internal groove near the inlet

end of the Housing.

2. Grasp the Housing in leather–covered or cop per–

covered vise jaws with the inlet end downward.

3. Apply o–ring lubricant to the End Plug Seal (25) and

install it in the annular groove at the large end of the

End Plug (24).

4. Insert the assembled End Plug, small end leading, into

the piston bore of the Housing and using a brass drift in

the center of the End Plug; tap the assembly to the

bottom of the bore without cocking it.

5. Apply o–ring lubricant to the Piston Seal (26) and

install it in the annular groove at the large end of the

Piston Assembly (27).

6. If the Piston Rod Seal (30) was removed from the

Cylinder Gland (29), install a new Seal, lip end trailing,

into the central opening of the Gland.

7. Apply o–ring lubricant to the Cylinder Gland Seal

(28) and install it in the housing recess at the bottom of

the threads for the Cylinder Gland.

8. Insert the Piston Assembly, shaft end leading, into the

threaded end of the Gland through the Gland Seal and

push it inward until the large end of the Piston is against

the end of the Gland.

9. Start threading the Cylinder Gland into the Housing.

Using the Cylinder Gland Wrench (40) and a socket,

tighten the Gland in the Housing.

10. Reposition the assembled tool in the vise jaws with

the inlet end upward.

11. Wrap the threads of the Swivel Sets (33) with Teflon

Tape. Thread the swivel with the male hose Coupler (34)

into the threaded hole on the right (Marked A) side of

the Housing when looking from the inlet end of the tool

with the Square Drive downward. Thread the swivel

with the female hose Coupler into the other hole

(Marked R).

12. Connect the hoses from the pump, turn the power on

and cycle the tool several times to determine if the Gland

is leaking fluid.

13. If the Gland is leaking, disconnect the hoses and

power supply, determine the cause of the leak and take

whatever steps are necessary to correct the problem.

If the Gland is not leaking, operate the tool to fully

retract the Piston Assembly, disconnect the hoses and

power supply and reposition the tool in the vise jaws

with the inlet end downward.

- 9 -

NOTICE

In the following step, the Cylinder Gland must be

staked into the Housing to prevent it from loosening

due to vibration or turbulence in the hydraulic oil

flow. Use a center punch with a 60 degree included

angle and do not deform the stake point beyond 3/64”

deep. Do not attempt to use the previously staked

position and leave housing clearance at the new

position for a 1/16” drill bit should the Gland require

removal in the future.

14. Stake the thread of the Gland and Housing at the

open area between the ears of the Housing that holds the

Square Drive (11). Make certain both the Housing and

Gland are deformed at the stake point.

15. If the Ball Plungers (22) were removed, install them

in the Housing and thread them inward until only the ball

projects into the driver sleeve opening.

16. Wipe a thin film of Marine Moly Grease on the sides

of the Drive Plate (18), as well as the inner race and

piston rod recess of the Drive Plate.

17. Insert the Ratchet (17) in the Drive Plate.

18. Position the Segment Pawl (19) at the cavity in the

Drive Plate. Make certain the teeth of the Pawl will

properly engage the teeth of the Ratchet. If they will not

engage properly, reverse the Ratchet in the Drive Plate.

Insert the Segment Pawl Springs (20) into the holes in

the Pawl, and while compressing the springs with finger

pressure, slide the Pawl and springs into the Drive Plate.

19. For UT-2, UT-3, UT-7 and UT-11 models, proceed

as follows:

a) a) From inside the housing ears, insert a Driver

Sleeve (16) into each ear with the detent end of the

Sleeve trailing. The ball of the Ball Plunger must

engage the detent holes encircling the Sleeve.

b) b) Position the assembled Drive Plate between the

ears of the Housing with the notch for the piston rod

toward the rod end.

c) c) Insert a wire rod or hex wrench through the

opening of the Square Drive Hollow Lock ( 15 ) and

push the Square Drive Locking Pin (14) inward

against the Square Drive Spring (13) while inserting

the Square Drive (11) into the Ratchet. It may be

necessary to individually rotate the Driver Sleeves

and Ratchet to align the squares for the Square

Drive.

In the following step, the side of the Housing that the

square protrudes from will determine the direction of

square drive rotation. If the square extends to the

left side when looking from the inlet end of the

NOTICE

Housing, rotation will be clockwise to tighten. A

right side extension is counterclockwise for loosening.

a) Insert the splined end of the Square Drive (11)

through the Driver Sleeves and Ratchet. Install the

Square Drive Retaining Screw (35) in the end of the

Square Drive and tighten it.

20. Insert the Retract Pin (21) into the hole in the Drive

Plate through the hole in the Housing. Use a drift and

hammer to tap the Pin into the Plate and rod to secure the

assembly. Make certain the Pin does not protrude

beyond the sides of the Drive Plate.

21. For UT-11 model , use a hex wrench to install the

two Retract Pin Hole Plugs (2) flush with the sides of the

Housing.

22. Place one end of the Shroud (31) on the Housing and

using a hex wrench, install the Shroud Mounting Screws

(32) at that end.

23. Bend the Shroud around the Housing and install the

remaining Mounting Screws.

Assembly of the Reaction Arm Assembly

1. If the Reaction Arm Boot (4) was removed, push it

onto the end of the Reaction Arm (3) and using a hex

wrench, secure it by installing the two Boot Mounting

Screws (5).

2. Insert the Reaction Arm Pin Spring (6) in the

downward, blind hole below the bore for the Reaction

Arm Splined Sleeve (10).

3. Position the Reaction Arm Splined Sleeve in the bore

of the Reaction Arm with the small hub end trailing and

the slightly larger hole through the side of the Sleeve

upward. Align the holes through the Sleeve with the

holes in the Reaction Arm.

4. Insert the Reaction Arm Engagement Pin (7), flat end

leading, through the Sleeve into the hole against the Pin

Spring. Rotate the Pin so that the vertical flat on the end

of the Pin faces away from the tool end of the Arm.

5. Push downward on the Engagement Pin until the

threaded hole in the side of the Pin is visible through the

slot in the end of the reaction arm away from the tool.

6. For UT-2, UT-3, UT-7 and UT-11 models, apply a

suitable thread–locking compound to the threads of the

Reaction Arm Retract Button (8) and using a

screwdriver, screw the Button tightly into the threaded

hole in the Engagement Pin.

7. Using a hex wrench, thread the Reaction Arm Spline

Screw (9) into the top of the Reaction Arm until the

unthreaded end enters the hole in the Splined Sleeve and

the threads bottom out.

- 10 -

Trouble Probable Cause Solution

Piston will not advance or retract

Piston will not retract

Cylinder will not build up

pressure

Square Drive will not turn

Tool tightens immediately when

turned on

Pump will not build up pressure

Troubleshooting Guide

Couplers are not securely

attached to the tool or pump

Coupler is defective Replace any defective Coupler.

Defective remote control switch

Dirt in the direction-control valve

of the pump unit

Hose connections reversed

Retract hose not connected Connect the retract hose securely

Retract pin broken Replace the broken pin and/or spring

Piston Seal and/or End Plug Seal

leaking

Coupler is defective Replace any defective Coupler

Grease or dirt build up in the

teeth of the Ratchet and Segment

Pawl

Worn or broken teeth on Ratchet

an/or Segment Pawl

Hose connections are reversed

Defective relief valve

Air supply too low or air hose too

small

Electric power source is too low

Check the Coupler connections and

make certain that they are connected.

Replace the switch and/or control

pendent

Disassemble the pump and clean the

direction-control valve.

Make certain the advance on the

pump is connected to the advance on

the tool and retract on the pump is

connected to the retract on the tool.

Replace any defective O-rings

Disassemble the Ratchet and clean the

grease or dirt out of the teeth

Replace any worn or damaged parts

Depress the advance button to release

the tool; shut the pump off in the

advance position and reverse the hose

connection

Inspect, adjust or replace the relief

valve

Make certain the air supply and hose

size comply with the pump manual

recommendations.

Make certain the amperage, voltage

and any extension cord size comply

with the pump manual requirements

Pressure reading erratic Defective Gauge Replace the Gauge

Nut Returns with retract stroke

SAVE THESE INSTRUCTIONS. DO NOT DESTROY.

Defective Gauge Replace the Gauge

Low oil level Check and fill the pump reservoir

Clogged filter

Ball Plungers are not engaging

the Drive Sleeves

Inspect, clean and/or replace the

pump filter

Thread the Ball Plungers to the

correct depth in the Housing.

- 11 -

Loading...

Loading...