User’s Manual for

TL-403 Laser Engraving

and Cutting Control

System

Shenzhen Topwisdom Technology Co., Ltd

Add: 4F, NO.58, East Side of Yousong Road, New Longhua District, ShenZhen, China,

518109

Tel: +86-0755-82057902

Fax: +86-0755-82057892

Website: http://www.topwisdom.com.cn

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

Copyright Statement

Shenzhen Topwisdom Technology Co., Ltd.

All rights reserved.

Shenzhen Topwisdom Technology Co., Ltd. (Topwisdom Technology hereinafter)

reserves the rights of final interpretation and modification for this manual and

declaration. Topwisdom Technology owns the patents, copyright and other intellectual

property rights for its product and software. Without authorization, no one is allowed to

copy, excerpt, reproduce, process, disseminate and use this product and its relative

parts directly or indirectly.

Disclaimer

Topwisdom Technology reserves the right to modify the content described in this

manual without advance notice. Topwisdom Technology is not responsible to any direct,

indirect, or consequential damage or liability caused by improper use of this manual or

the product. Machinery in motion can be dangerous! It is the responsibility of the user

to design effective error handling and safety protection as part of the machinery.

Topwisdom Technology shall not be liable or responsible for any incidental or

consequential damages.

Technical Support

To get our technical support and after-sale service:

Tel: +86-0755-82057902

Fax: +86-0755-82057892

Website: http://www.topwisdom.com.cn

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

I

Content

Part 1 Overview ............................................................................................................... 1

1.1 System Overview ............................................................................................... 1

1.2 Notes and Warning............................................................................................. 2

1.3 Work Environment .............................................................................................. 2

1.4 Power Supply and Grounding ............................................................................ 2

1.4.1 Power supply requirements ..................................................................... 2

1.4.2 Grounding requirements .......................................................................... 2

1.5 Accessory List .................................................................................................... 3

Part 2 Wiring Installation Instruction................................................................................ 5

2.1 System Wiring Diagram ..................................................................................... 5

2.2 Installation Dimension ........................................................................................ 6

2.2.1 Panel ........................................................................................................ 6

2.2.2 Mainboard ................................................................................................ 7

2.3 Wiring Instruction................................................................................................ 9

2.3.1 Interface Broad ........................................................................................ 9

2.3.2 Wiring Diagram ........................................................................................ 9

2.4 Interface Instruction .......................................................................................... 13

2.4.1 Power Signal .......................................................................................... 13

2.4.2 U-DISK Port ........................................................................................... 14

2.4.3 PC Connection Port ............................................................................... 14

2.4.4 NETWORK Port ..................................................................................... 14

2.4.5 Output ..................................................................................................... 14

2.4.6 Laser Power Interface............................................................................ 16

2.4.7 Input ....................................................................................................... 17

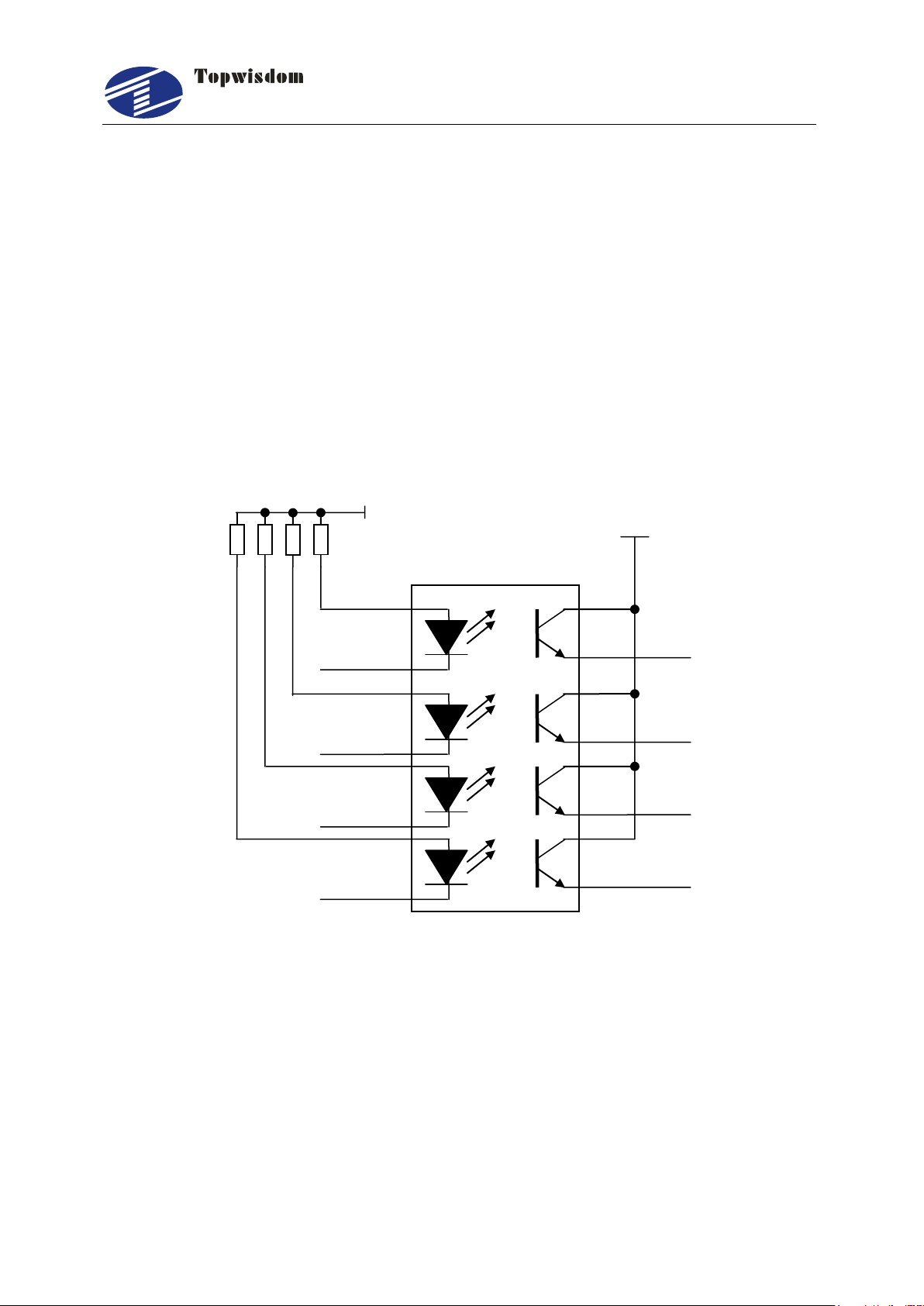

2.4.8 Input Signal Diagram ............................................................................. 19

Part 3 Software Installation ............................................................................................ 20

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

II

3.1 Installing CoreDRAW Direct Output................................................................. 20

3.1.1 Manual Install ......................................................................................... 21

3.1.2 Auto install .............................................................................................. 22

3.2 Uninstalling CorelDRAW Direct Output ........................................................... 23

3.3 Installing CAD Direct Output ............................................................................ 23

3.4 Uninstalling CAD Direct Output ....................................................................... 25

3.5 USB Driver Installation ..................................................................................... 26

3.6 USB Port Setting .............................................................................................. 29

3.6.1 View the assigned COM Port by Computer .......................................... 29

3.6.2 Change the Assigned COM port by Computer ..................................... 32

3.7 IP Setting .......................................................................................................... 33

Part 4 Software Operation Guide .................................................................................. 37

4.1 CorelDRAW Direct Output Software Operation .............................................. 37

4.1.1 Layer Parameter Setting........................................................................ 38

4.1.2 Coordinate Setting ................................................................................. 42

4.1.3 Track Setting .......................................................................................... 43

4.1.4 Single Axis Operation ............................................................................ 44

4.1.5 Output Engrave ...................................................................................... 45

4.2 The Equipment Management .......................................................................... 49

4.2.1 Toolbar .................................................................................................... 50

4.2.2 Parameter Setting .................................................................................. 50

4.2.3 Embroidery Import ................................................................................. 55

4.2.4 Import bitmap ......................................................................................... 56

4.2.5 Curve Precision...................................................................................... 57

4.3 CAD Direct Output Software Operation ........................................................... 57

4.4 CAD Direct Output Software Supplementary Description .............................. 58

4.4.1 The Support of AutoCAD Direct Output Annotation Text ...................... 58

4.4.2 Carving Gradient Sketch Map ............................................................... 60

4.4.3 Coordinate System ................................................................................ 60

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

III

4.4.4 Supplementary Description of Carving ................................................. 61

4.4.5 Supplementary Description of Software and CAD Direct Output ......... 62

Part 5 The Operation Panel ........................................................................................... 66

5.1 The Panel Operation and Buttons Function Introduction ................................ 66

5.1.1 The Panel ............................................................................................... 66

5.1.2 Buttons Function Introduction................................................................ 66

5.2 The Main Interface Introduction ....................................................................... 69

5.2.1 Power Interface ...................................................................................... 69

5.2.2 Standby Interface ................................................................................... 69

5.2.3 Speed Setting Interface ......................................................................... 71

5.2.4 Power Light Intensity Interface .............................................................. 71

5.2.5 Range Preview Interface ....................................................................... 72

5.2.6 Single Axis Movement Interface ............................................................ 73

5.2.7 File Selection Interface .......................................................................... 73

5.2.8 U disk File Interface ............................................................................... 74

5.2.9 The Main Menu Setting.......................................................................... 75

5.3 File Setting ........................................................................................................ 76

5.4 The Integrate Settings ...................................................................................... 77

5.4.1 Laser Set ................................................................................................ 77

5.4.2 Equipment Set ....................................................................................... 78

5.4.3 Axis Set .................................................................................................. 80

5.4.4 Back Set ................................................................................................. 83

5.4.5 User Set ................................................................................................. 85

5.5 System Information .......................................................................................... 87

5.5.1 The Password Setting............................................................................ 88

5.6 System Test ...................................................................................................... 89

Part 6 the Frequently Asked Question Help.................................................................. 91

6.1 Power-on Reset Question ................................................................................ 91

6.2 The Laser Light Question ................................................................................. 92

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

IV

6.3 The PC Connection Question .......................................................................... 92

6.4 The Reading and Writing of U disk Question .................................................. 93

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

1

Part 1 Overview

1.1 System Overview

Thank you very much for using laser engraving control system of our company!

This system can be used with various types of laser engraving cutting machine, meets

your different requirements for processing.

Use High-Performance 32-Bit CPU with Single-Precision Floating-Point Unit (FPU),

the main frequency is up to 150MH. Setting device parameter out of PC completely.

All coupler completely isolated from outside interference, the system is reliable.

Support USB2.0 port, U disk reading and writing, support U disk system upgrade;

Support network , PC-communication is more convenient, safe, and reliable.

With 64MB storage, work independently form PC, which is useful for the quantities

of engraving and cutting production.

Support 5 axises motion control(X Y Z U V, XY is for laser cutting control, Z is

feeding axis, U is lift axis, V is for the second laser cutting head).

Support double laser head cutting, support leftover cutting. Each laser power is

able to be control independently.

Support feeding, lifting, rotating engraving, metal cutting, scale cutting, automatic

blowing, automatic focusing, foot switch, cover protect, power-off cutting

restoration, system lock, device management.

S-shape acceleration and deceleration and adjustable velocity profile, meet the

demand of smooth cutting and high speed working.

Before using, please read our manual carefully, ensure to operate our system

correctly.

Please keep the manual well, and it’s convenient for your future references.

Because of different configuration, some devices have not some of the

functions listed in the manual, the details subject to appropriate operation

functions.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

2

1.2 Notes and Warning

Prohibit the non-professionals to maintenance and debug the electrical system, if

not, this will reduce device’s safety performance, and expand failure, even cause

accident and property loss.

Please do not piles up debris on the control box, and in the course of using,

regularly remove the dust of the control box surface and filters, to keep good

ventilation.

When users have to open the cover of the control box, must cut off the power after

5minutes and under the professionals’ guidance, only can be allowed to touch the

components in the electrical control box!

Prohibit touching any motion parts or opening the control equipments when the

machine is working, or it maybe bring about the accident and machine can’t work.

Prohibit using the electrical equipment in the damp, dust, corrosive gas, flammable

gas area, or it maybe cause the electrical shock or fire!

1.3 Work Environment

Ventilation, sanitation, and less dust

Storage temperature: 0-50℃

Work temperature: 5-40℃

Work relative humidity: 30%-90%(no condensation)

1.4 Power Supply and Grounding

1.4.1 Power supply requirements

Core power supply: DC 5V, 3A; External power supply: DC 5V, 3A

According to different machine configurations, power consumption is between

0.1-0.2KW

1.4.2 Grounding requirements

In order to prevent electrical equipment due to leakage, over-voltage, insulation etc

causes of the electrical shock or fire, please make the electrical control reliable

grounding.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

3

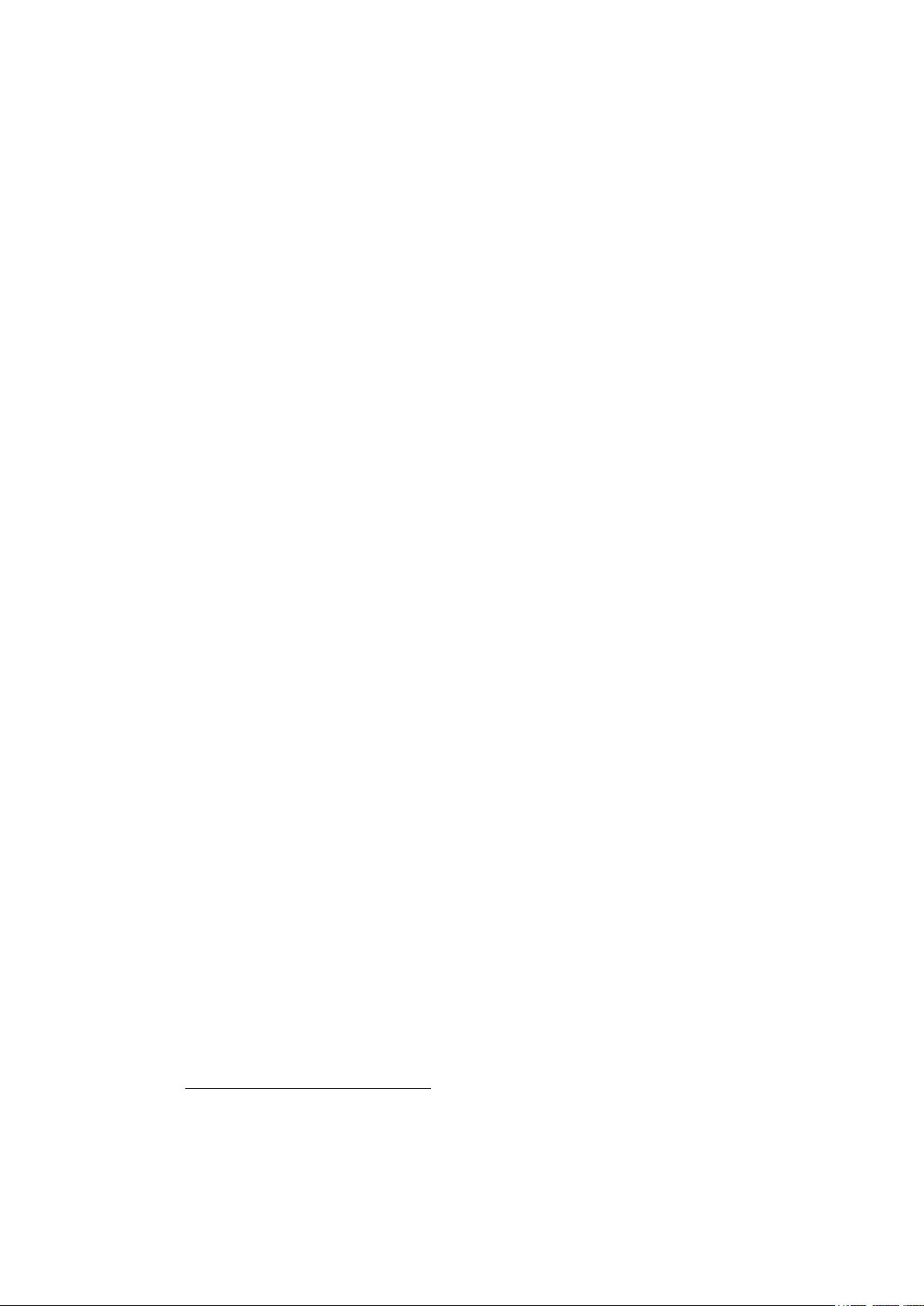

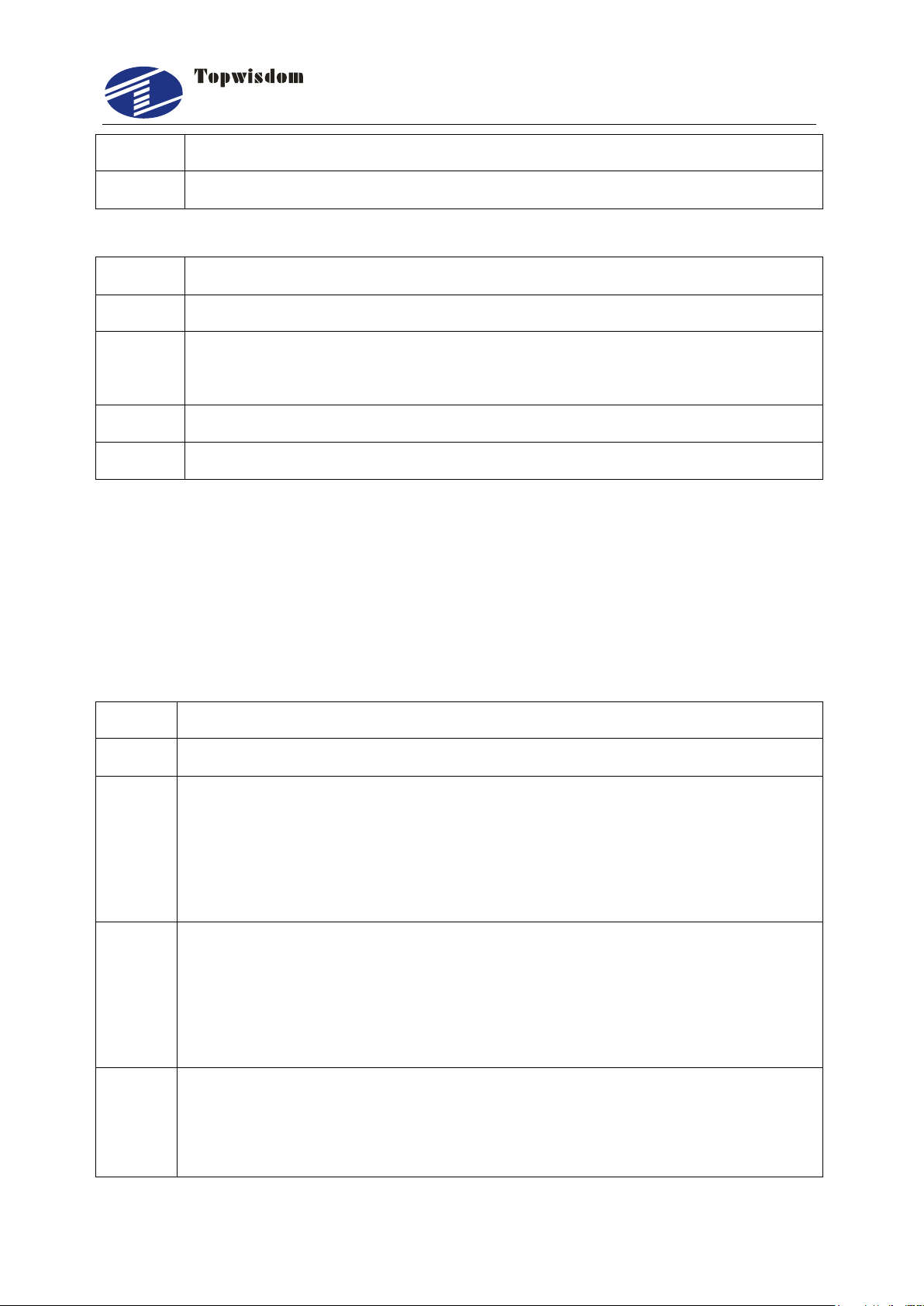

Name

Qty

Introduction

Photo

Operation

Panel

1

For user

operation

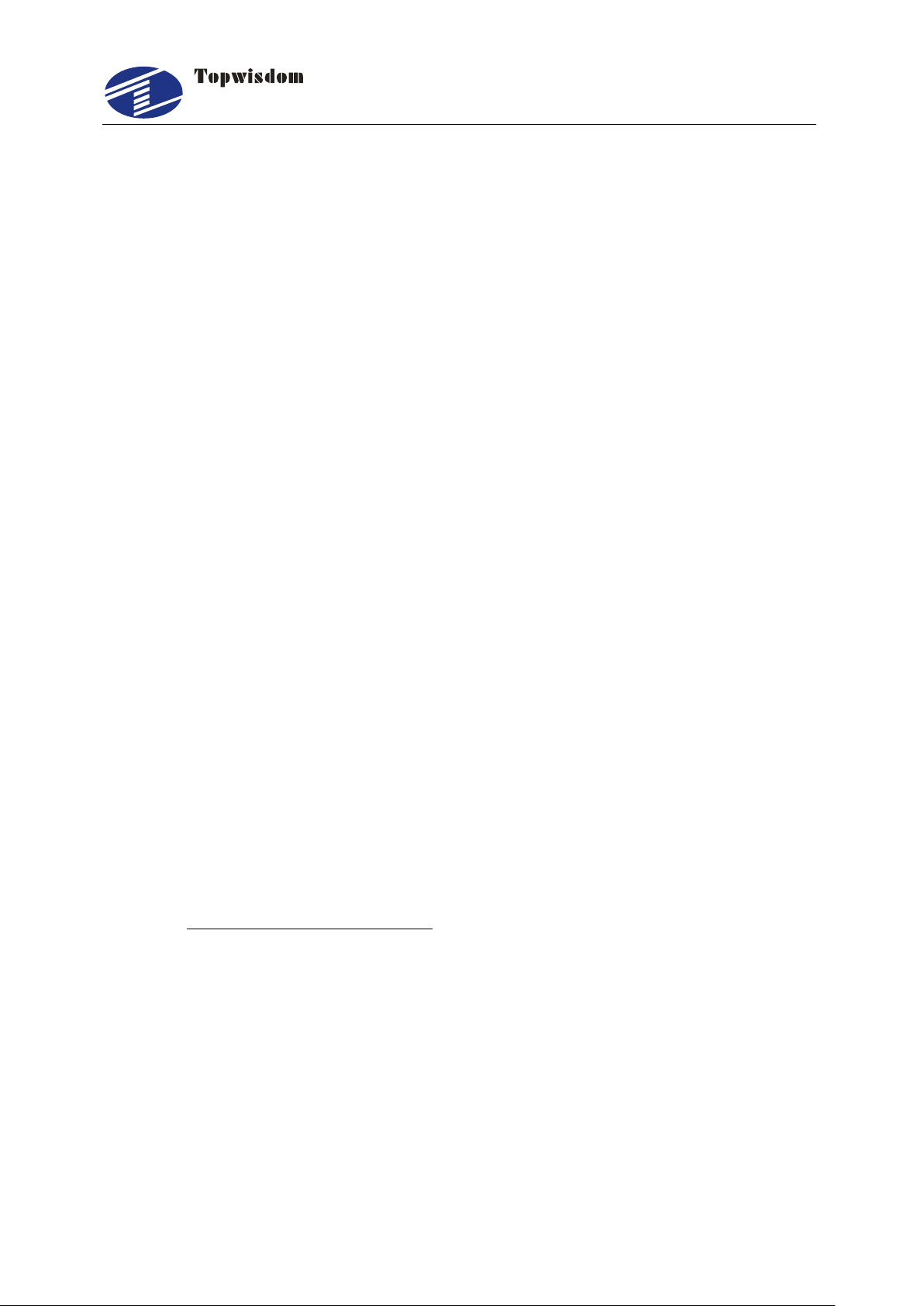

Controller

1

The Motion

Control Card

Connection

cable

3

1.Panel

Connection

cable for

connecting

controller and

panel.

2.USB

communication

cable for

connecting

controller and

Grounding resistance is less than 100 ohms; the length of wire cable is within the

20meters, the cross-sectional area of the wire cable is larger than 1.0 mm2.

1.5 Accessory List

The Laser Engraving Control System-TL-403 contained the accessories as below:

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

4

PC

3.USB

communication

extended cable

Crossover

Ethernet

Cable

2

1.Crossover

Ethernet Cable

2.Network

communication

extended cable

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

5

PC

U-DISK

EX5V

EX5V

XGND

IN-5

XGND

OUT6

OUT5

OUT2

OUT1

EX5V

IN-2

IN-3

IN-4

XGND

EX5V

EX5V

PWM4

DIR4

XGND

IN 6

GND

+5V

EX5V

PWM3

DIR3

XGND

IN 1

LASER-2 LASER-1

EX5V

XGND

IN10

IN-7

IN-8

IN-9

EX5V

XGND

IN11

IN12

IN13

EXV+

EXV-

OUT7

OUT8

EX5V

XGND

PWM6

DIR6

EX5V

XGND

PWM5

DIR5

EX5V

XGND

PWM2

DIR2

EX5V

XGND

PWM1

DIR1

X-DRIVERY-DRIVERZ-DRIVERV-DRIVER

DIR

PUL

EX5V

TL-403C

HANDSET

NETWORK

Air Control

Pen Control

5V Relay

5V Relay

EX5V

DIR

PWM

DIR

PWM

- - + +

DIR

PWM

DIR

PWM

- - + +

DIR

PWM

DIR

PWM

- - + +

DIR

PWM

DIR

PWM

- - + +

Axis V Driver

(Laser head2 motor)

Axis Z Driver

(Feeding motor)

Axis Y Driver

(Y motor)

Axis X Driver

(X motor)

U-DRIVER

V Origin Limit

Z Origin Limit

U Origin Limit

Cover Protect

Foot Switch

X Origin Limit

Y Origin Limit

PWM

DIR

PWM

DIR

- - + +

Mechanical

Switch

DC 5V/3A

DC 5V/3A

Water Protect

Water Protect

TH

TL

WP

G

IN

5V

Two way

switch

RP100R

CO2

Laser

power

1

TL

G

IN

CO2

Laser

power

2

Axis U Driver

(Lifting motor)

Control

damper

Control

damper

Auto

Manual

Y Up Limit

X Up Limit

5Vo0V

Optoelectronic

Switch

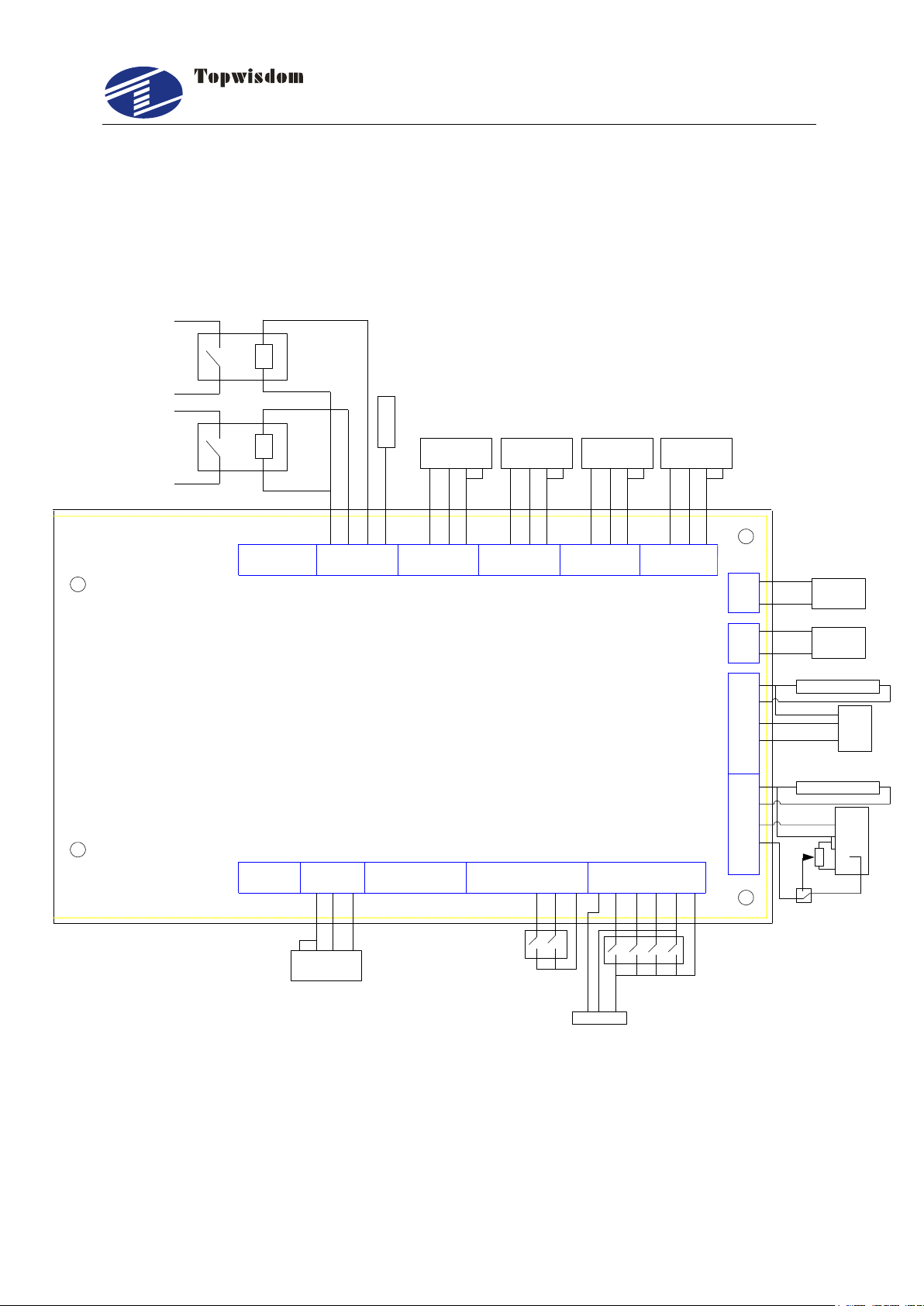

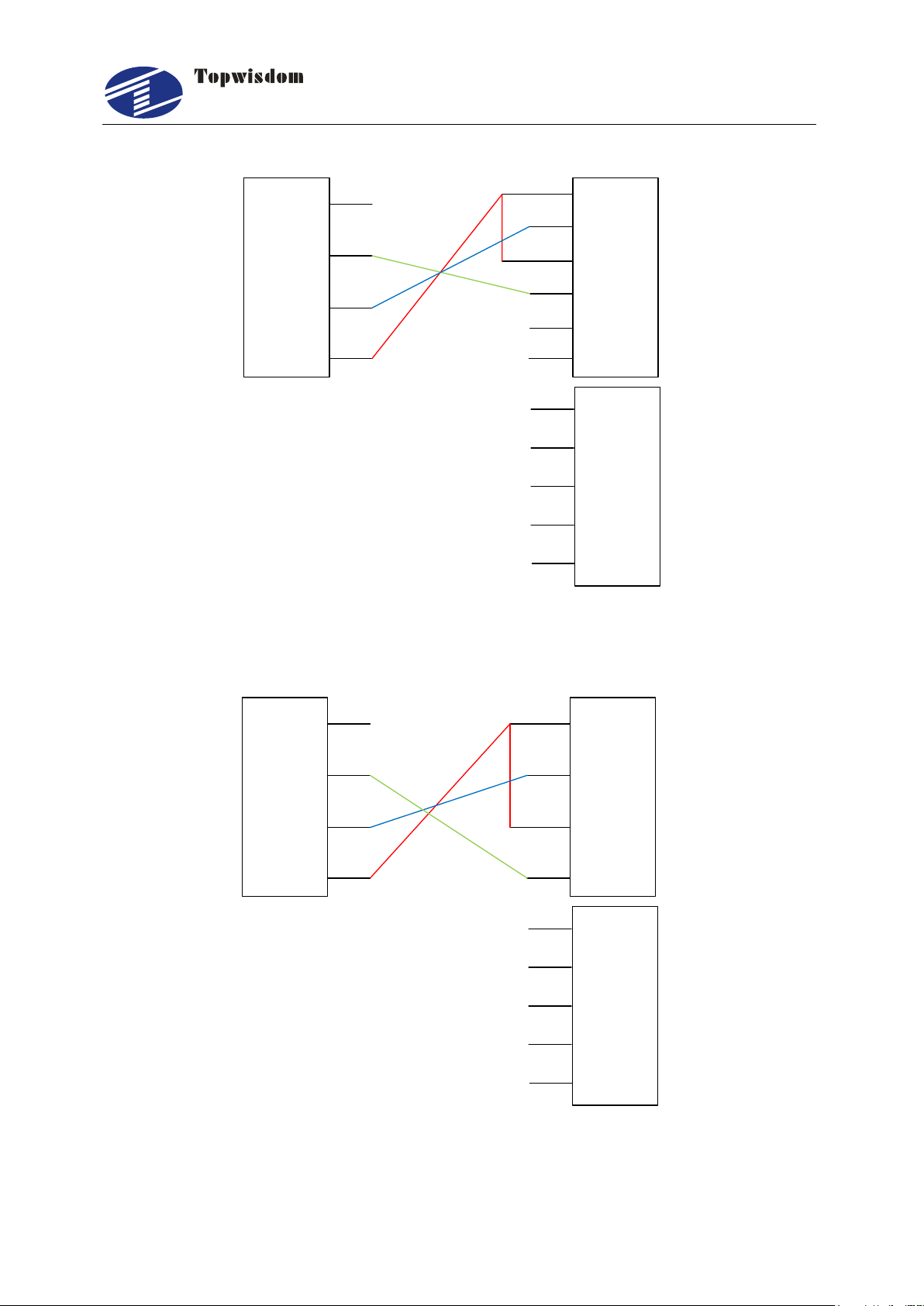

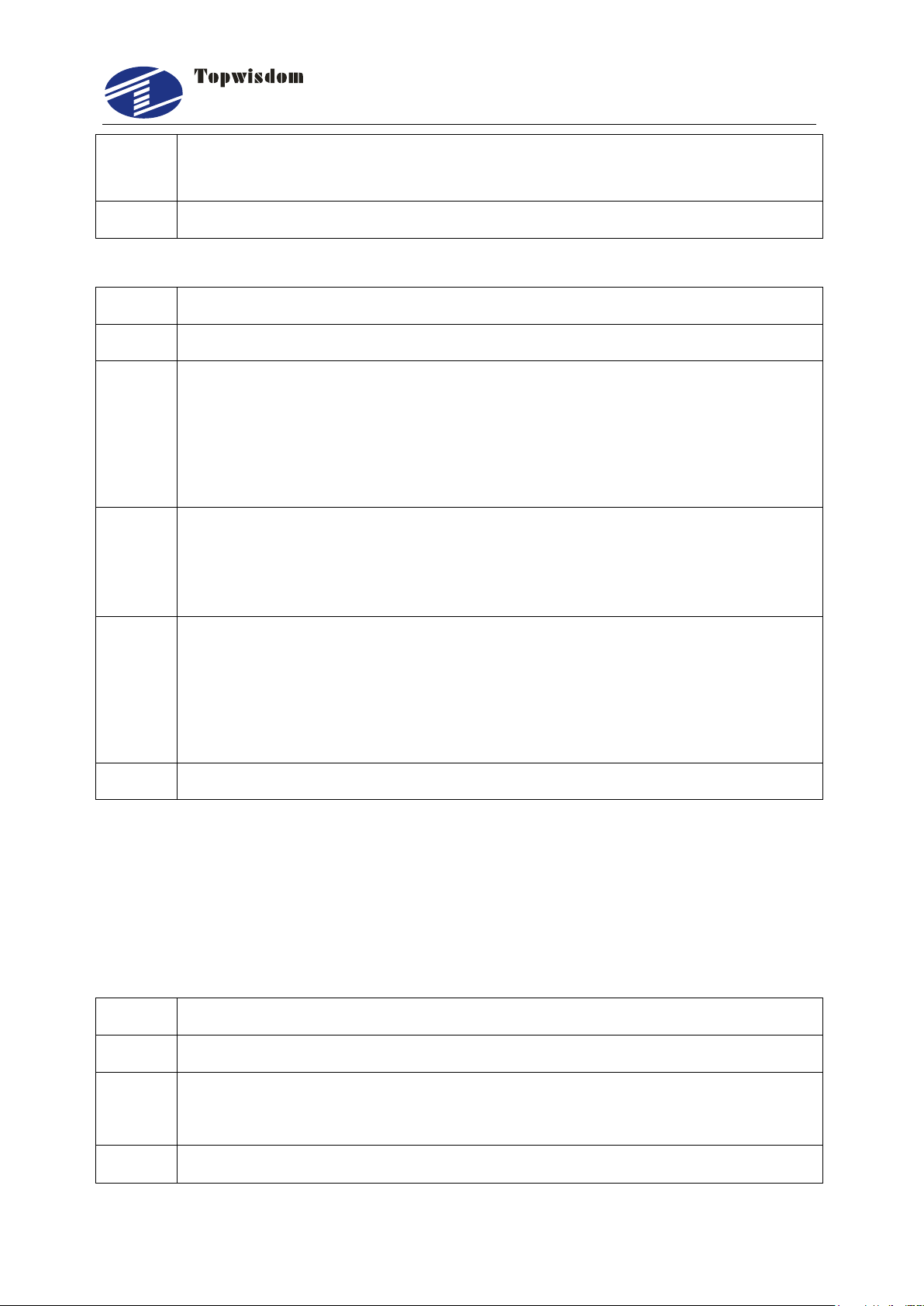

Part 2 Wiring Installation Instruction

2.1 System Wiring Diagram

Fig. 2-1

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

6

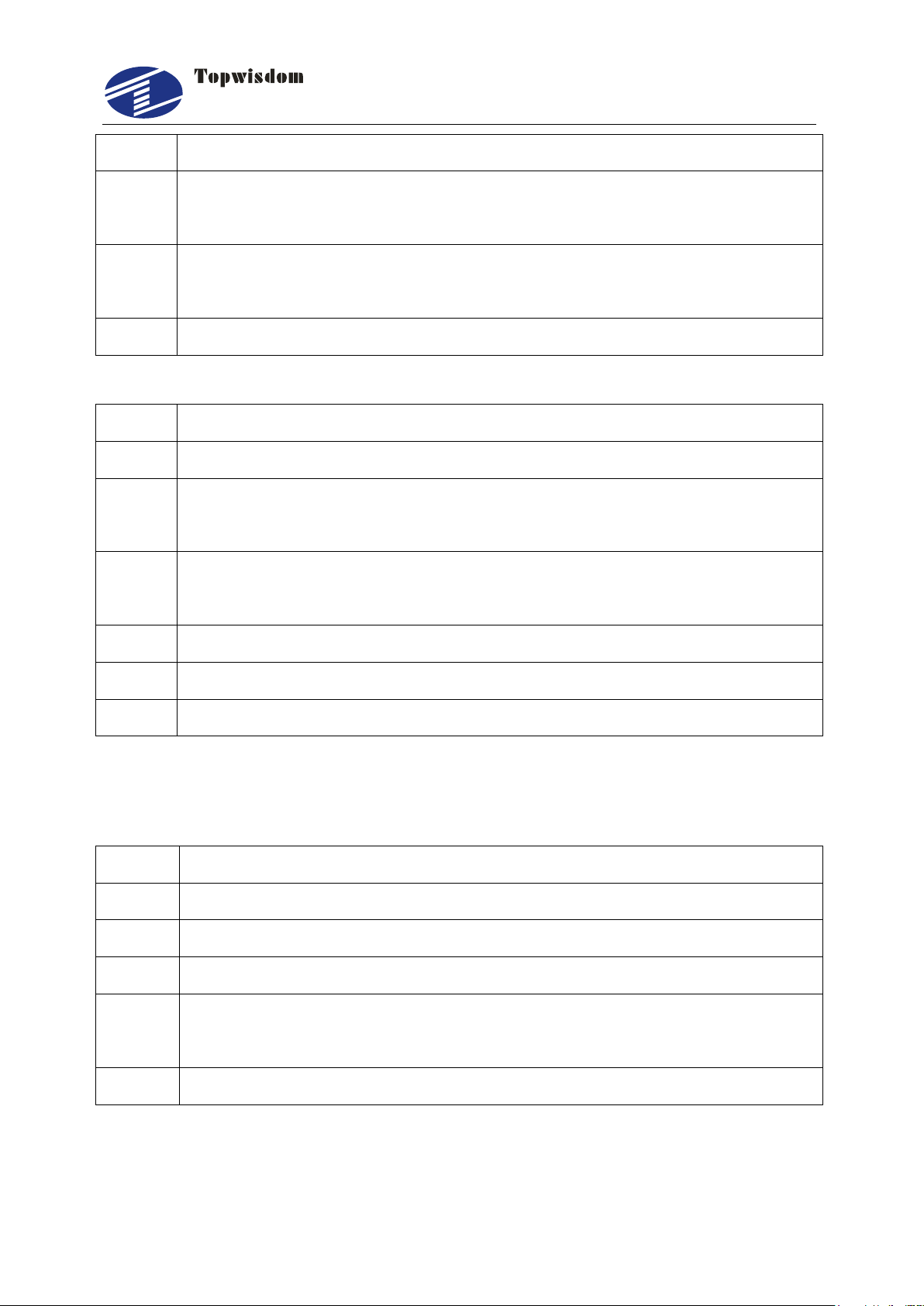

2.2 Installation Dimension

2.2.1 Panel

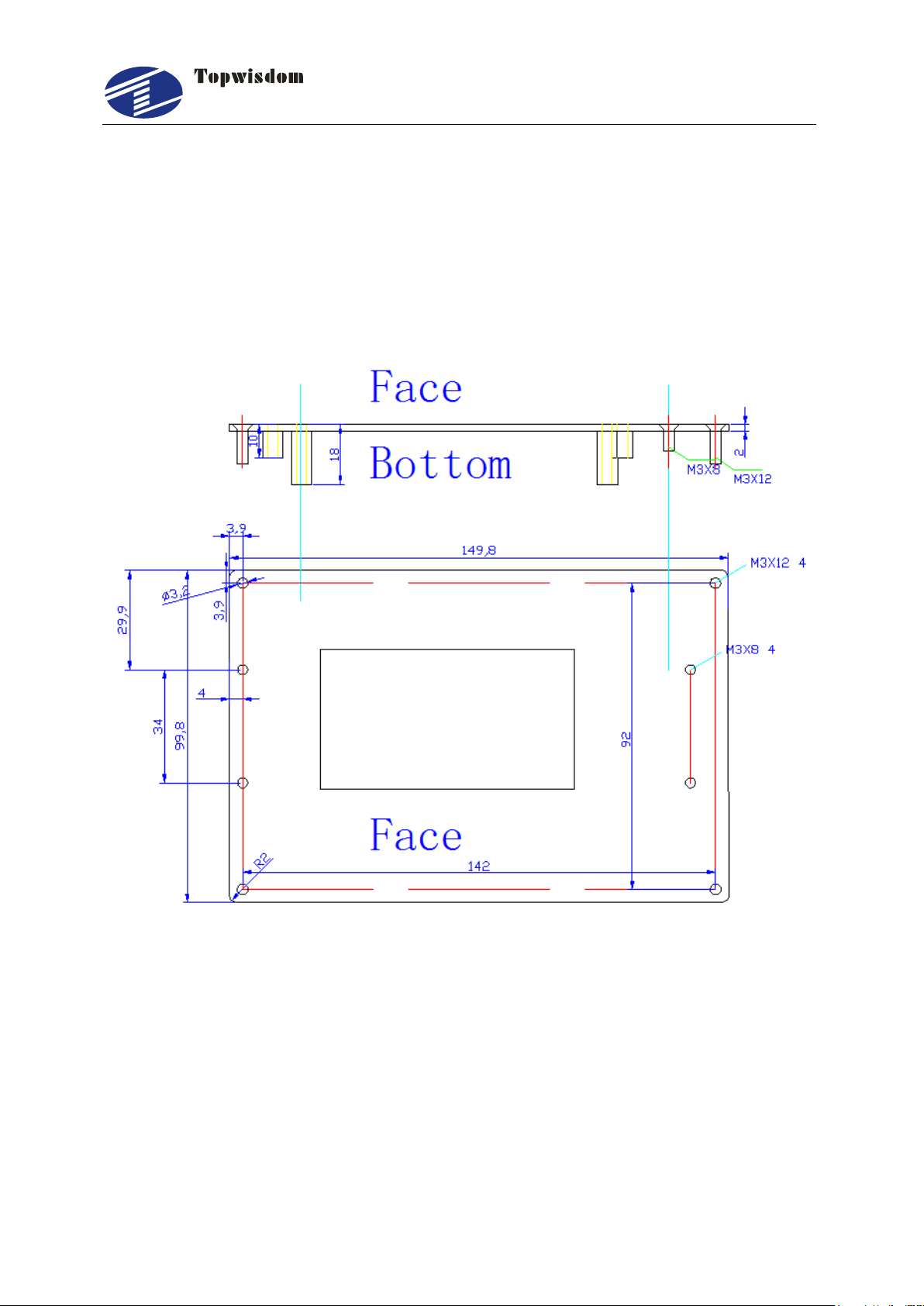

The installation dimension of operation panel (the unit is MM):

Face:

Fig. 2-2

Bottom:

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

7

Fig. 2-3

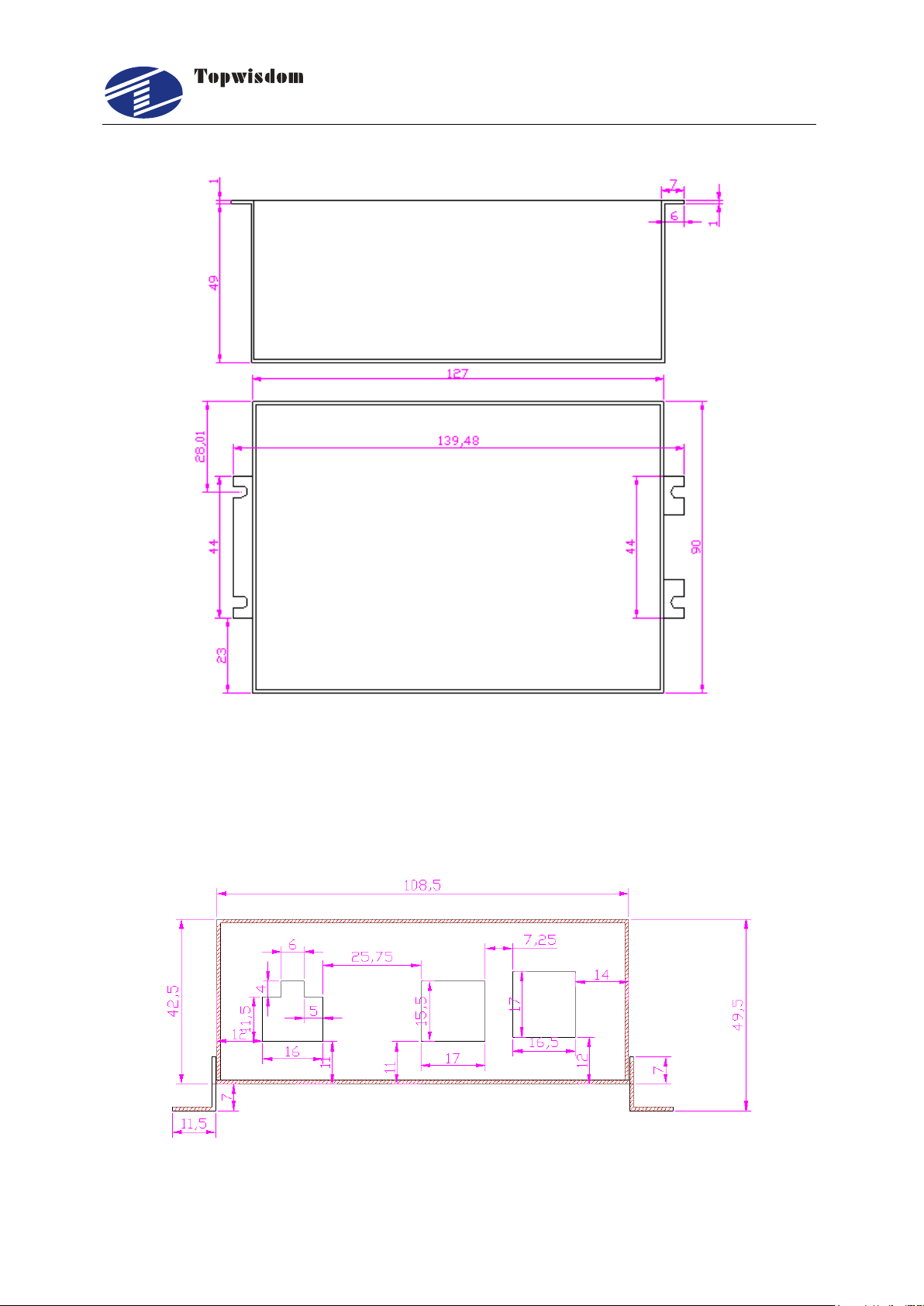

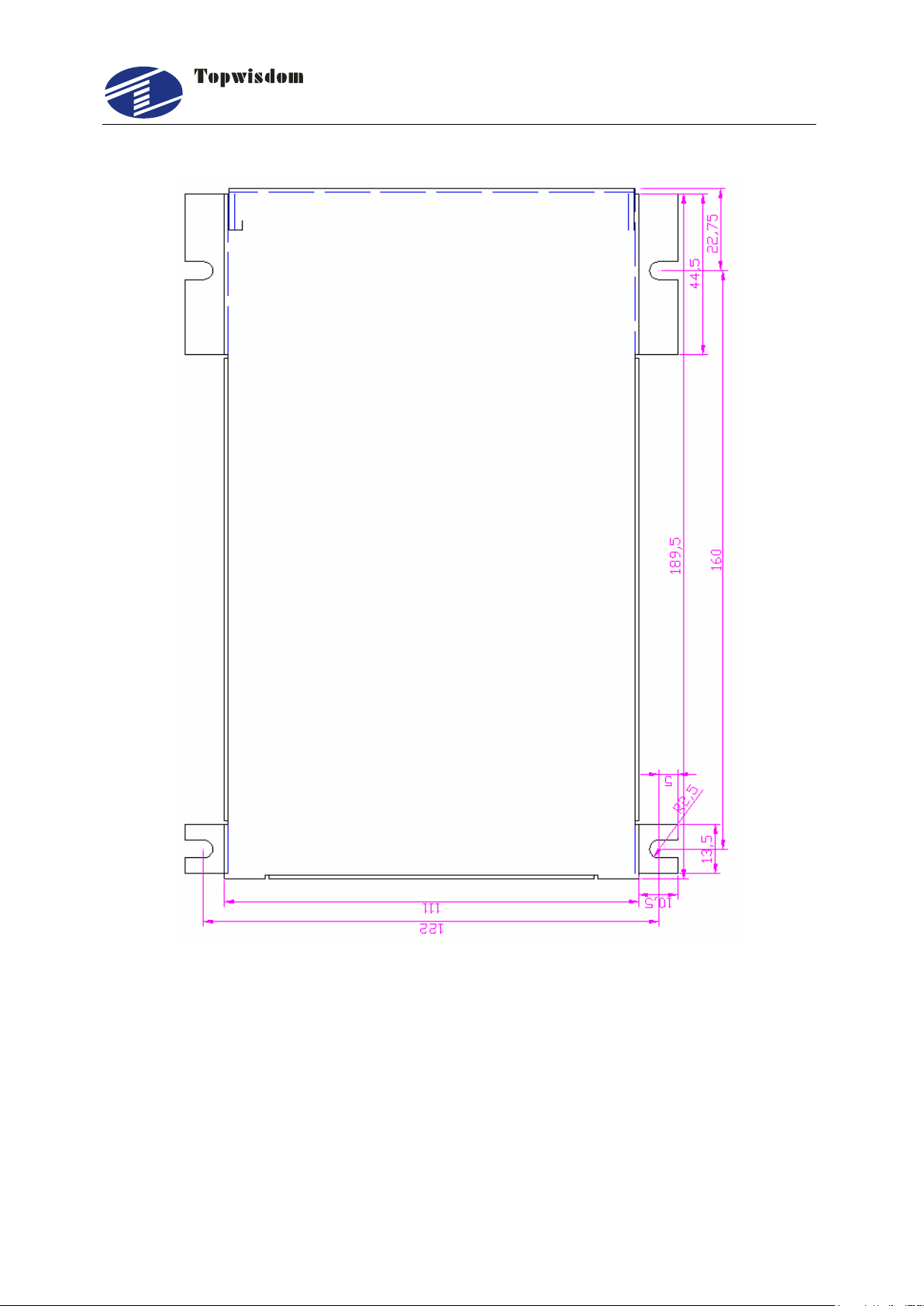

2.2.2 Mainboard

The installation dimension of mainboard (the unit is MM):

Fig.2-4

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

8

Fig.2-5

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

9

PC

U-DISK

EX5V

EX5V

XGND

IN-5

XGND

OUT6

OUT5

OUT2

OUT1

EX5V

IN-2

IN-3

IN-4

XGND

EX5V

EX5V

PWM4

DIR4

XGND

IN 6

GND

+5V

EX5V

PWM3

DIR3

XGND

IN 1

LASER-2 LASER-1

EX5V

XGND

IN10

IN-7

IN-8

IN-9

EX5V

XGND

IN11

IN12

IN13

EXV+

EXV-

OUT7

OUT8

EX5V

XGND

PWM6

DIR6

EX5V

XGND

PWM5

DIR5

EX5V

XGND

PWM2

DIR2

EX5V

XGND

PWM1

DIR1

X-DRIVERY-DRIVERZ-DRIVERV-DRIVER

DIR

PUL

EX5V

TL-403C

HANDSET

NETWORK

U-DRIVER

2.3 Wiring Instruction

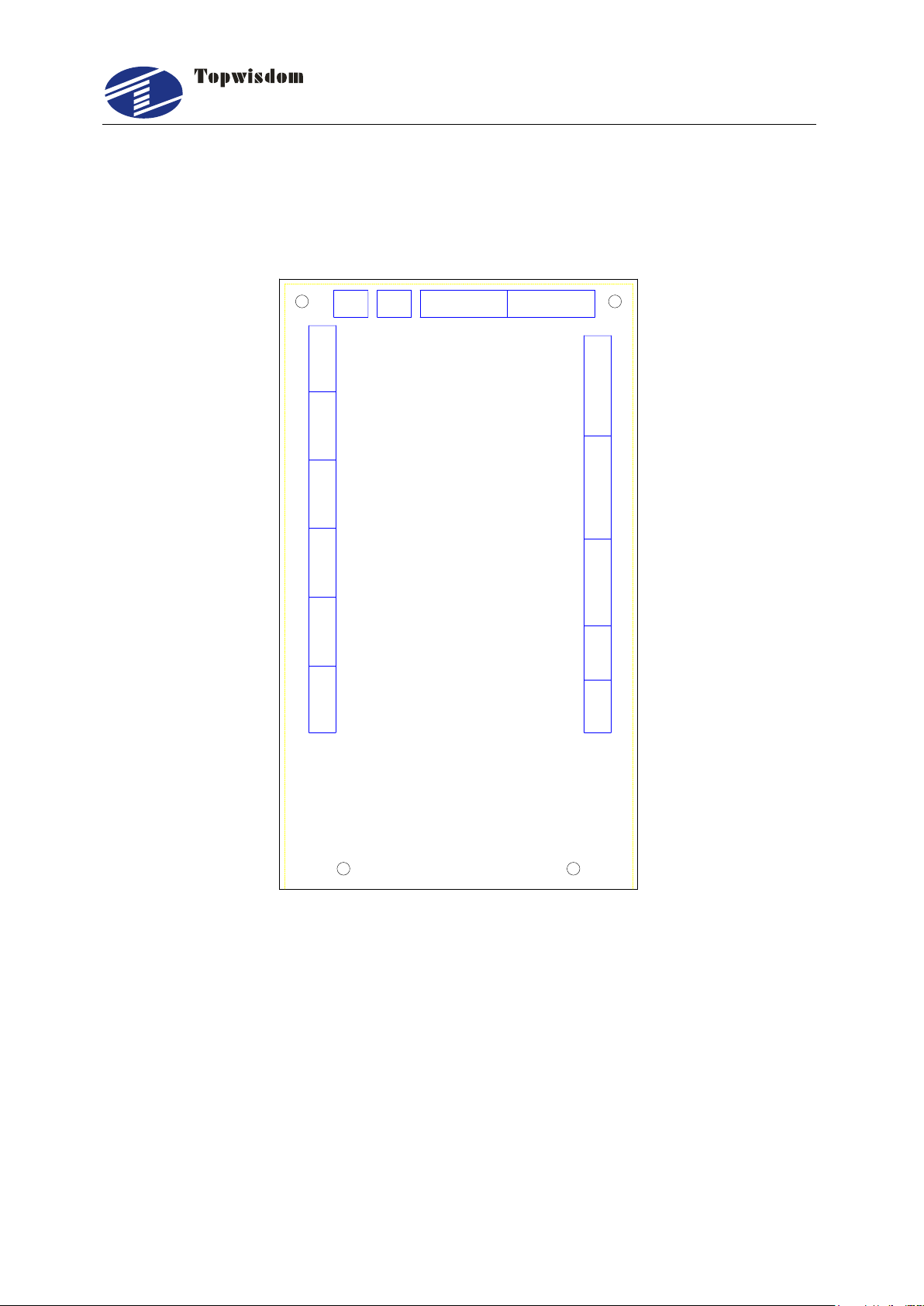

2.3.1 Interface Broad

2.3.2 Wiring Diagram

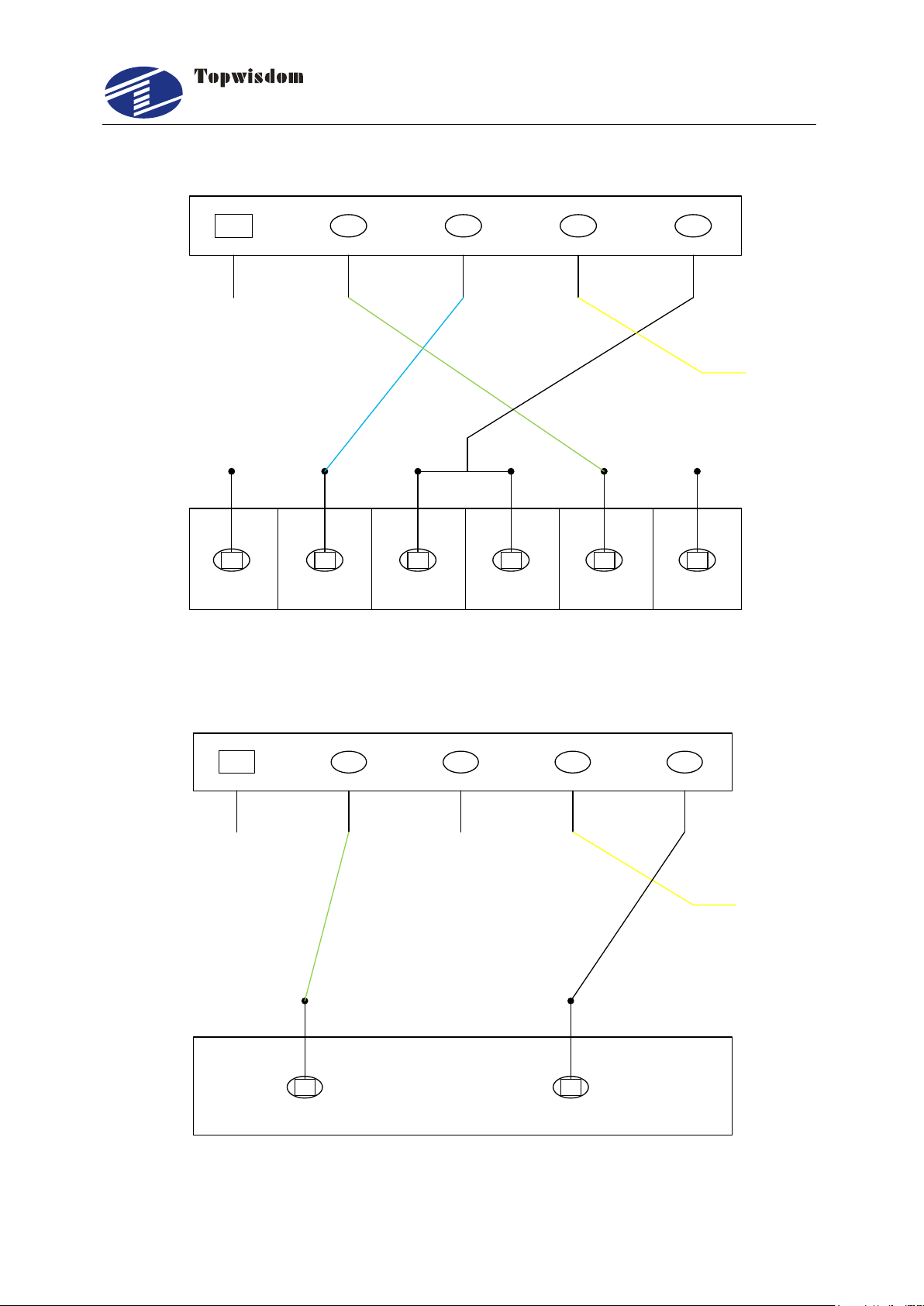

2.3.2.1 Motor Wiring

The following is X axis motor wiring, other axis are similar.

Fig. 2-6

1. Step Motor Wiring

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

10

PUL+

PULDIR+

DIRENA+

ENA-

GND

DIR1

PWM1

+5V

GND

U

V

W

Vdc

36V-

To

Motor

36V+

J20 X Driver

PULS1

PULS2

SIGN1

SIGN2

GND

DIR1

PWM1

+5V

COM-

U

V

W

COM+

24V-

To

Motor

24V+

J20

Panasonic servo

3

6

5

4

41

7

2. Panasonic Servo Wiring

Fig. 2-7

Fig. 2-8

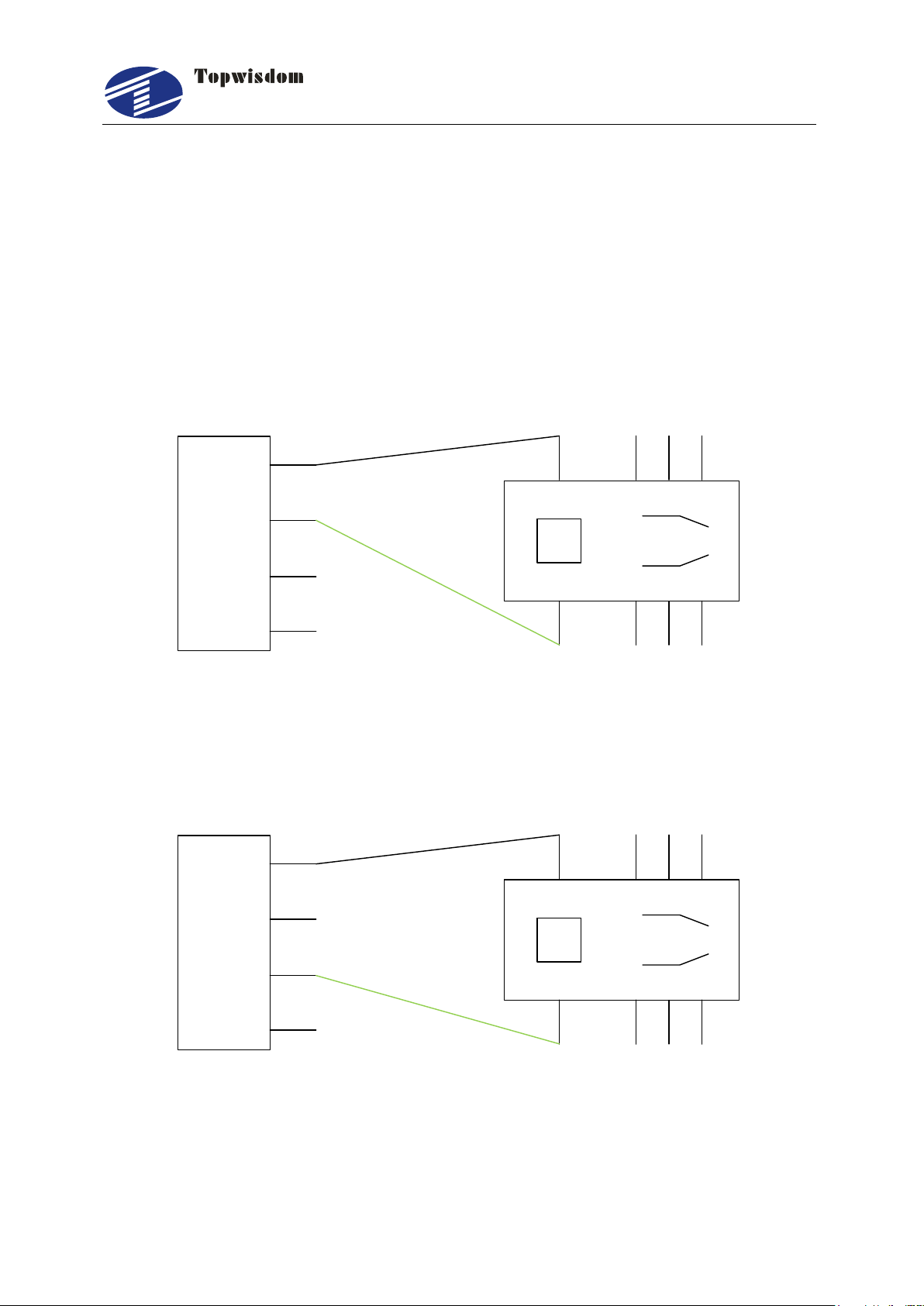

2.3.2.2 Laser Power Supply Wiring

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

11

TTL-H TTL-L WP GND

DAC

1 3 4 5 62

Water Potect

EX5V PWM3 DIR3 IN-1 XGND

J2

Laser

Power

Supply

Active low

Power

Water Protect

EX5V PWM3 DIR3 IN-1 XGND

J2

Laser

Power

Supply

GND

1. CO2 Laser Power Supply Wiring

2.RF Laser Wiring

Fig. 2-9

Fig. 2-10

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

12

EXV-

OUT8

OUT7

EXV+

J9

5V/24V Relay

5V+/24V+

EXV-

OUT8

OUT7

EXV+

J9

5V/24V Relay

5V+/24V+

The wiring of laser 2 is similar.

Note:When “RF1 or RF2” is selected, please set the PWM Frequency according

to the data sheet of the laser. Generally, PWM Frequency is 5000Hz. And set the

Laser Max parameter not larger than 95%, especially not to set as 100%,

otherwise it works improperly.

2.3.2.3 Blowing Air Signal Wiring

Fig. 2-11

2.3.2.4 Pen UP/Down Signal Wiring

Fig. 2-12

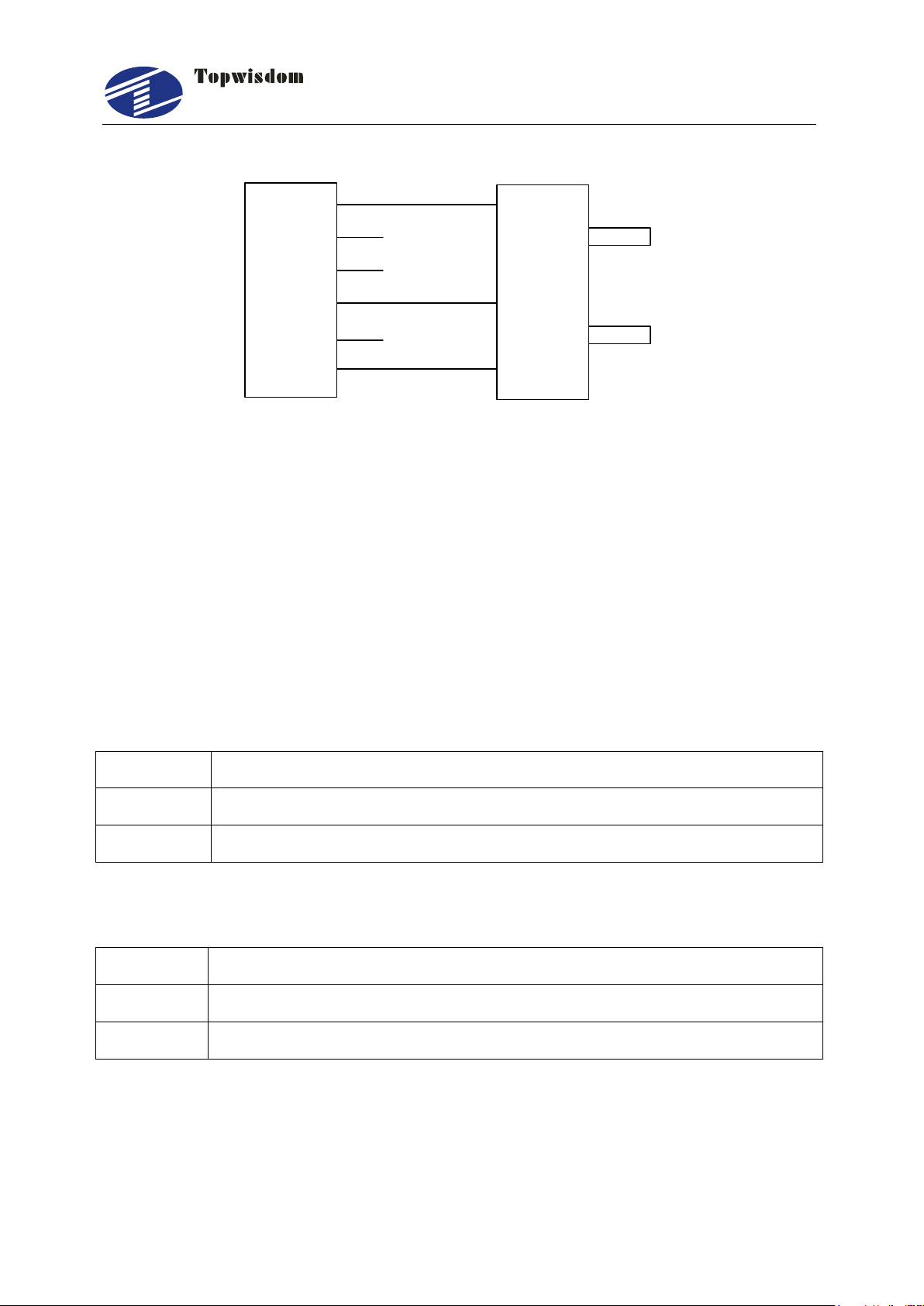

2.3.2.5 Limit Switch Signal Wiring

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

13

XGND

IN-5

IN-4

IN-3

IN-2

EX5V

0V

OUT

5V

J3

Photoelectric limit switch

X Origin limit switch

Pin

Definition

1

+5V Internal 5V power source positive (input)

2

GND Internal 5V power source grounding (input)

Pin

Definition

1

EX5V External 5V power source positive (output)

2

XGND External 5V power source grounding (output)

Other limit switch wirings are similar.

Fig. 2-13

2.4 Interface Instruction

2.4.1 Power Signal

The system is dual 5V power supply

The system internal 5V power interface J24 (switching power interface)

The system external power interface J23 (switching power interface)

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

14

Pin

Definition

1

EX5V External 5V power source positive (output) PUL+, DIR+

2

PWM1 Step pulse (output) PUL-

3

DIR1 Direction signal (output) DIR-

4

GND External 5V power source grounding (output)

Pin

Definition

1

EX5V External 5V power source positive (output) PUL+, DIR+

2

PWM2 Step pulse (output) PUL-

3

DIR2 Direction signal (output) DIR-

4

GND External 5V power source grounding (output)

Pin

Definition

2.4.2 U-DISK Port

Label U-DISK, can directly insert the U disk to read and write.

2.4.3 PC Connection Port

Label PC connection port, can connect PC to read and write with USB.

2.4.4 NETWORK Port

Label NETWORK, can connect PC to read and write by network.

2.4.5 Output

The driver interface

X axis interface J20

Y axis interface J18

Z axis interface J21

泰智科技

15

1

EX5V External 5V power source positive (output) PUL+, DIR+

2

PWM5 Step pulse (output) PUL-

3

DIR5 Direction signal (output) DIR-

4

GND External 5V power source grounding (output)

V axis interface J22

Pin

Definition

1

EX5V External 5V power source positive (output) PUL+, DIR+

2

PWM6 Step pulse (output) PUL-

3

DIR6 Direction signal (output) DIR-

4

GND External 5V power source grounding (output)

Pin

Definition

1

EX5V External 5V power source positive (output) PUL+, DIR+

2

OUT3 Step pulse (output) PUL -

3

OUT4 Direction signal (output) DIR--

Pin

Definition

1

EX5V External 5V power source positive (output)

2

OUT1 Work finish output signal

3

OUT2 Feeding output signal. When feeding, it outputs <1.0V voltage,

otherwise it outputs >3.0V voltage

Pin

Definition

1

EX5V External 5V power source positive (output)

2

OUT5 Press material output signal while feeding

U axis interface J11

Shenzhen Topwisdom Technology Co., Ltd

The general output interface

The general IO output interface J17

The general IO output interface J10 (expansion port)

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

16

3

OUT6 Reserved

4

XGND External 5V power source grounding (output)

Pin

Definition

1

EXV+ Connect to pin 1 of J10 or external 5V/24V power source

2

OUT7 In the brush mode, lifting signal, high effective, connect to the

relay coil ―+‖ side

3

OUT8 Blow air signal, high effective, connect to the relay coil ―+‖ side

4

EXV- Connect to the relay coil ―-‖ side

Pin

Definition

1

EX5V External 5V power source positive (output)

2

PWM3 Be used to control the laser

When the laser is RF laser, used to control the power intensity and light of

the laser.

When the laser is domestic glass tube, used to control the electric current.

3

DIR3 Laser enable control (DIR3 jumper to H, the signal is high and

effective, to L, the signal is low and effective.)

When the laser is RF laser, used to control the enable function of laser.

When the laser is domestic glass tube, used to control laser On/Off.

4

IN-1 Laser status, the corresponding instruction is LED D1

When the laser is RF laser, used to the state input of laser.

When the laser is domestic glass tube, used to the state input of water

The relay control signal interface J9

The input voltage of relay has many kinds, such as 5V, 12V, 24V, but the 5V is the best.

2.4.6 Laser Power Interface

The interface of laser power 1 – J2

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

17

conservation (active low).

5

XGND External 5V power source grounding(output)

Pin

Definition

1

EX 5V External 5V power source positive (output)

2

PWM4 Be used to control the laser

When the laser is RF laser, used to control the power intensity of the laser.

And Put the Jumper of s2/s4 to far away to battery.

When the laser is domestic glass tube, used to control the electric current.

3

DIR4 Laser enable control (DIR3 jumper to H, the signal is high and

effective, to L, the signal is low and effective.)

When the laser is domestic glass tube, used to control laser On/Off.

4

IN-6 Laser status, the corresponding instruction is LED D6

When the laser is RF laser, used to the state input of laser.

When the laser is domestic glass tube, used to the state input of water

conservation (active low).

5

XGND External 5V power source grounding(output)

Pin

Definition

1

EX 5V External 5V power source positive (output)

2

IN-2 X upper limit, axis movement to the max coordinate limit sensor

input

3

IN-3 X origin limit, axis movement to the minimum coordinate(0)limit

The interface of laser power 2 – J5

2.4.7 Input

The limit interface

X, Y axis limit interface J3

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

18

sensor input

4

IN-4 Y upper limit, axis movement to the max coordinate limit sensor

input

5

IN-5 Y origin limit, axis movement to the minimum coordinate(0)limit

sensor input

6

XGND External 5V power source grounding (output)

Pin

Definition

1

EX 5V External 5V power source positive (output)

2

IN-7 Z origin limit, axis movement to the minimum coordinate(0)limit

sensor input

3

IN-8 U origin limit, axis movement to the minimum coordinate(0)limit

sensor input

4

IN-9 Opening protection signal input

5

IN-10 Foot switch signal input

6

XGND External 5V power source grounding (output)

Pin

Definition

1

EX 5V External 5V power source positive (output))

2

IN-11 U axis upper limit switch input

3

IN-12 U axis lower limit switch input

4

IN-13 V origin limit, axis movement to the minimum coordinate(0)limit

sensor input

5

XGND External 5V power source grounding (output)

Z, U axis limit interface J7

The general input interface

Input interface J4

When using the single laser control, the water protection signal of another laser must

be shorted with XGND, otherwise, the machine don’t work.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

19

IN-1

IN-4

IN-2

IN-3

Input signal

+5V

+3.3V

The connection ways of switch input signal:

When using approaching switch, the corresponding parameters of upper PC must

be set as ―Negative‖ by NPN; the corresponding parameters of upper PC must be

set as ―Positive‖ by PNP.

When using straight or magnetic induction switch, the corresponding parameters

of upper PC must be set as ―Negative‖ while receiving signal + XGND;the

corresponding parameters of upper PC must be set as ―Positive‖ while receiving

signal + EX5V.

2.4.8 Input Signal Diagram

Fig 2-14

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

20

Part 3 Software Installation

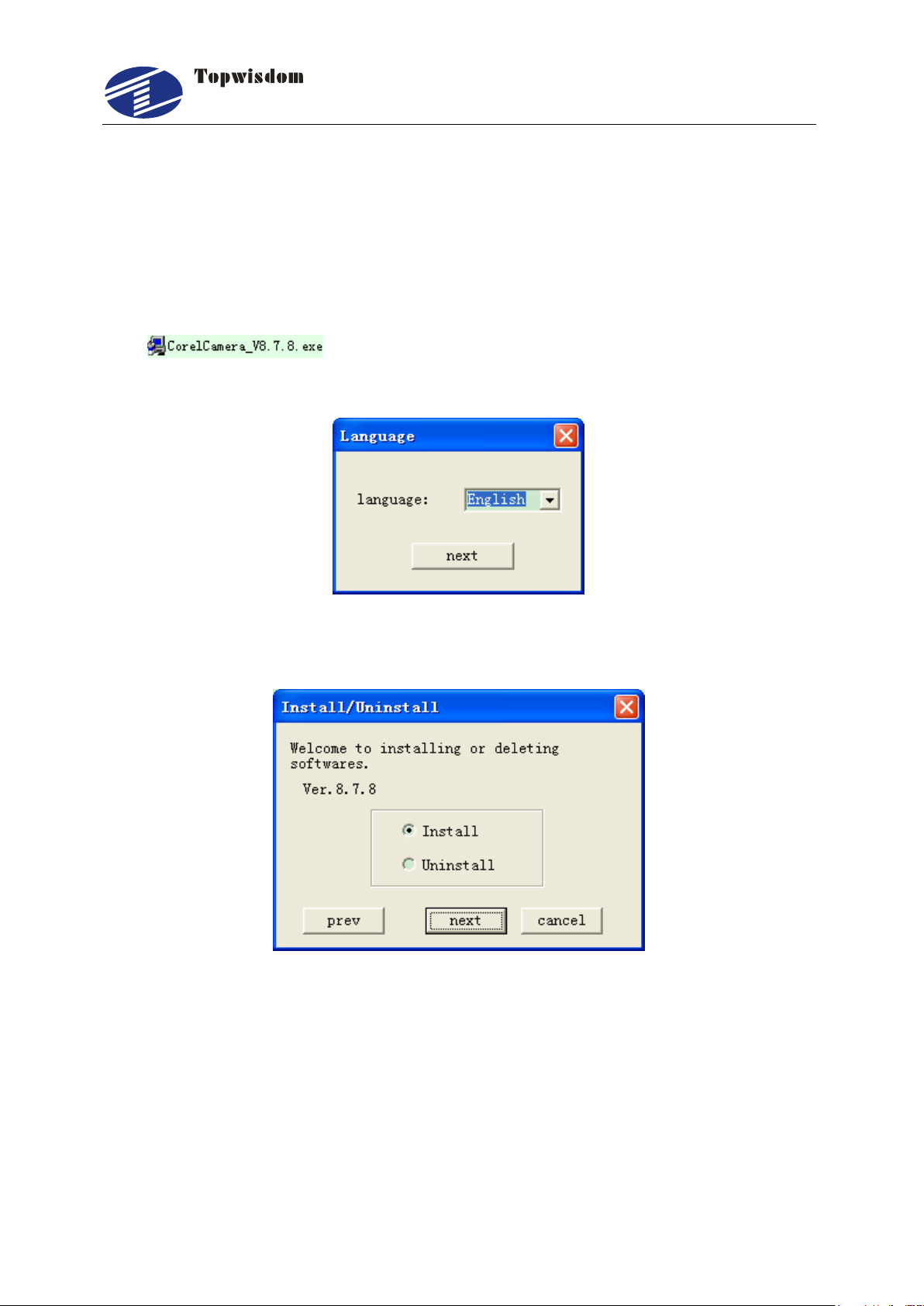

3.1 Installing CoreDRAW Direct Output

CorelDRAW12 or a higher version needs to be installed firstly. Then double click the

icon (below CorelCamera_V8.7.8 is used to introduce), a screen

shown in Fig. 3-1 will be displayed for selecting installing language.

Fig. 3-1

Click ‖next‖ to proceed with installation.

Fig. 3-2

Select ―Install‖ to install software, or select ―Uninstall‖ to uninstall software. Then click

next. And the screen shown in Fig. 3-3 is displayed.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

21

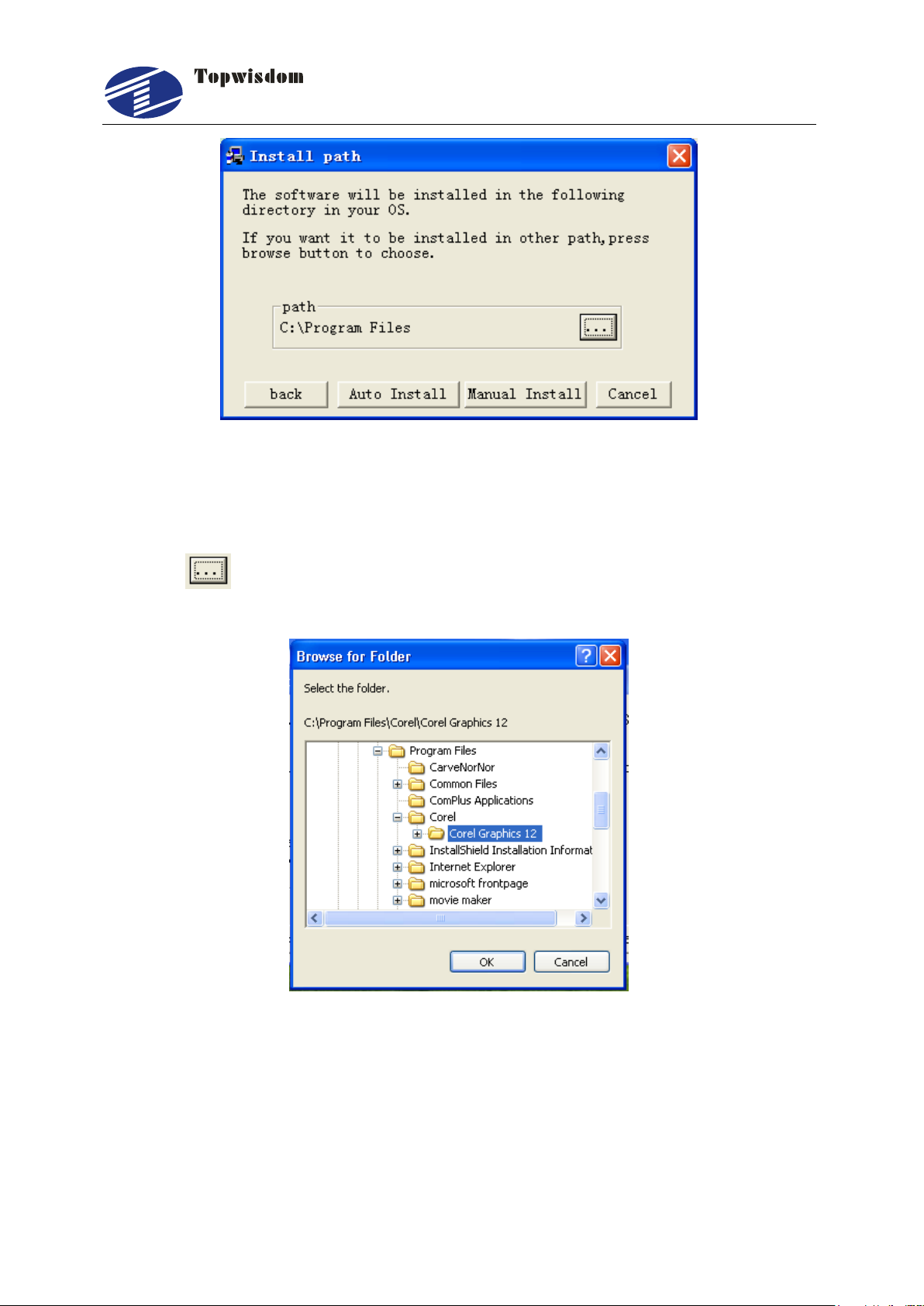

3.1.1 Manual Install

Fig. 3-3

Click the button to find the CorelDRAW install path, as shown in Fig.3-4, select

the Corel Graphics 12 folder as below.

Fig. 3-4

When the installed path is found, click the Confirm to go back to the screen shown in

Fig.3-3. Then click the ―Manual install‖ to install. W hen installation is finished, the

screen shown in Fig. 3-5 is displayed. Click ―OK‖ to finish.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

22

Fig. 3-5

3.1.2 Auto install

Click the ―Auto install‖ button shown in Fig. 3-3, the program will find the install path

automatically. When installation is finished, the screen shown in Fig. 3-5 is displayed.

Click ―OK‖ to finish.

However, the installation is not really completed then, as you need to make

configurations for the CorelDRAW software, after the configuration the total installation

will be completed, then open CorelDRAW, it’ll show as below.

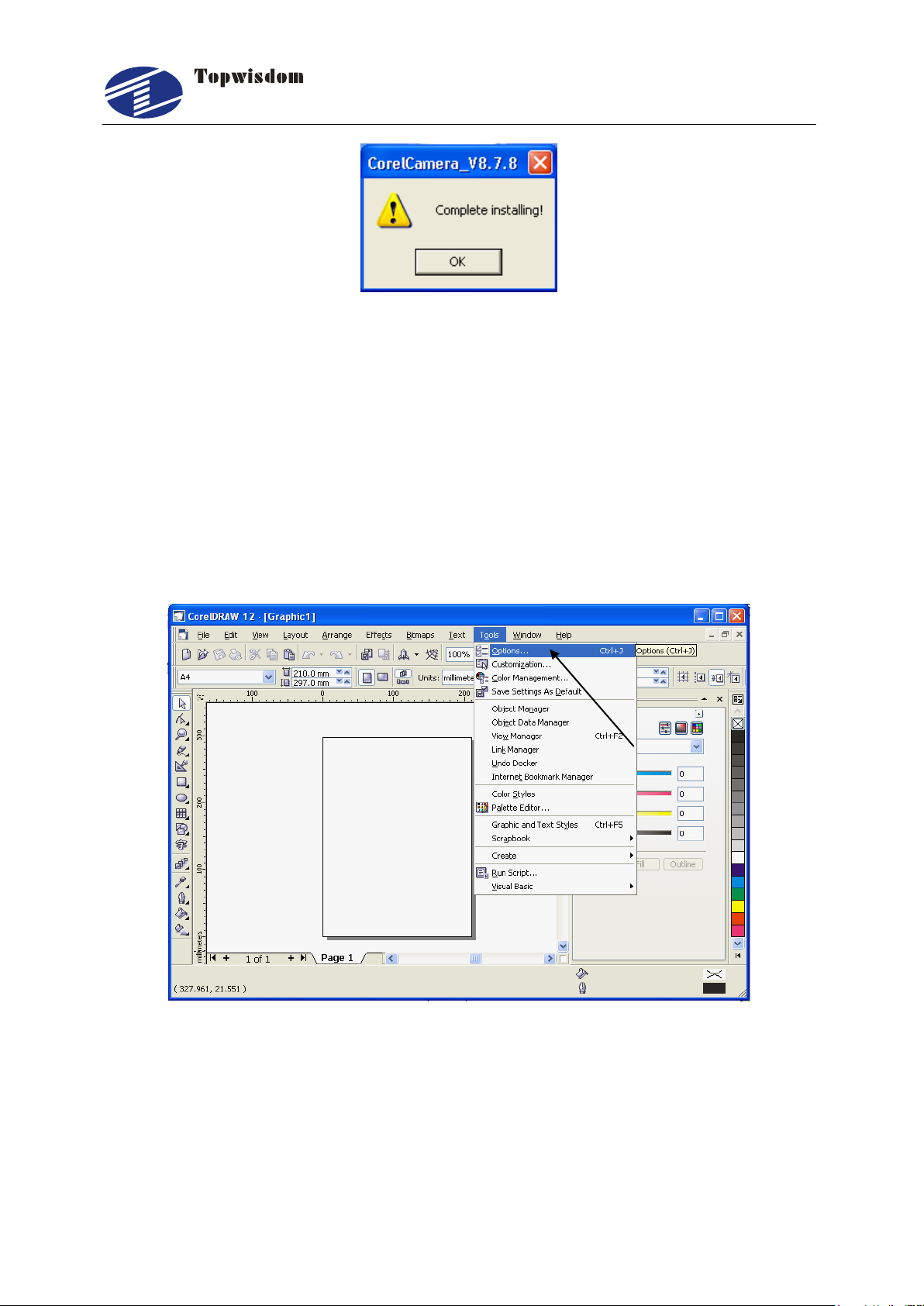

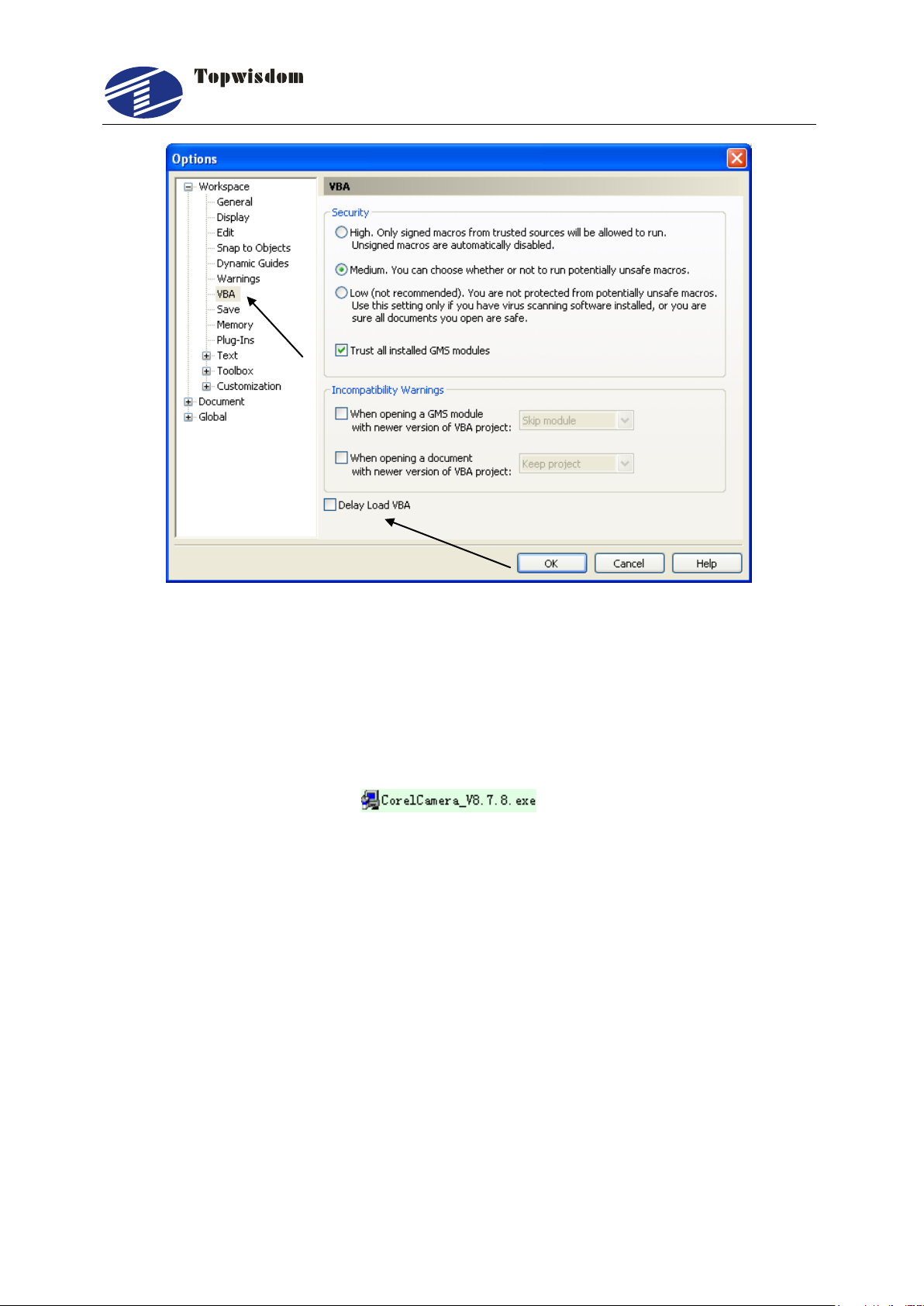

Fig. 3-6

Select ―Options‖ from ―Tools‖ in the toolbar shown in Fig. 3-6 to enter the menu shown

in Fig. 3-7.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

23

Fig. 3-7

In Fig. 3-7, first click on the ―VBA‖ as pointed out by the arrow in the left, then choose

the "Delay Load VBA" at the bottom, the installation is thoroughly completed.

3.2 Uninstalling CorelDRAW Direct Output

Double click on the icon of CorelDRAW Direct Output

installation software for uninstall, select ―Uninstall‖ and click the ―next‖ to uninstall the

software. The CarveNorNor folder in the root folder of CoreDRAW application and the

CORELSAVE_NOR folder in Draw folder can be manually deleted if it was needed.

3.3 Installing CAD Direct Output

Now there are two CAD Direct output software available.

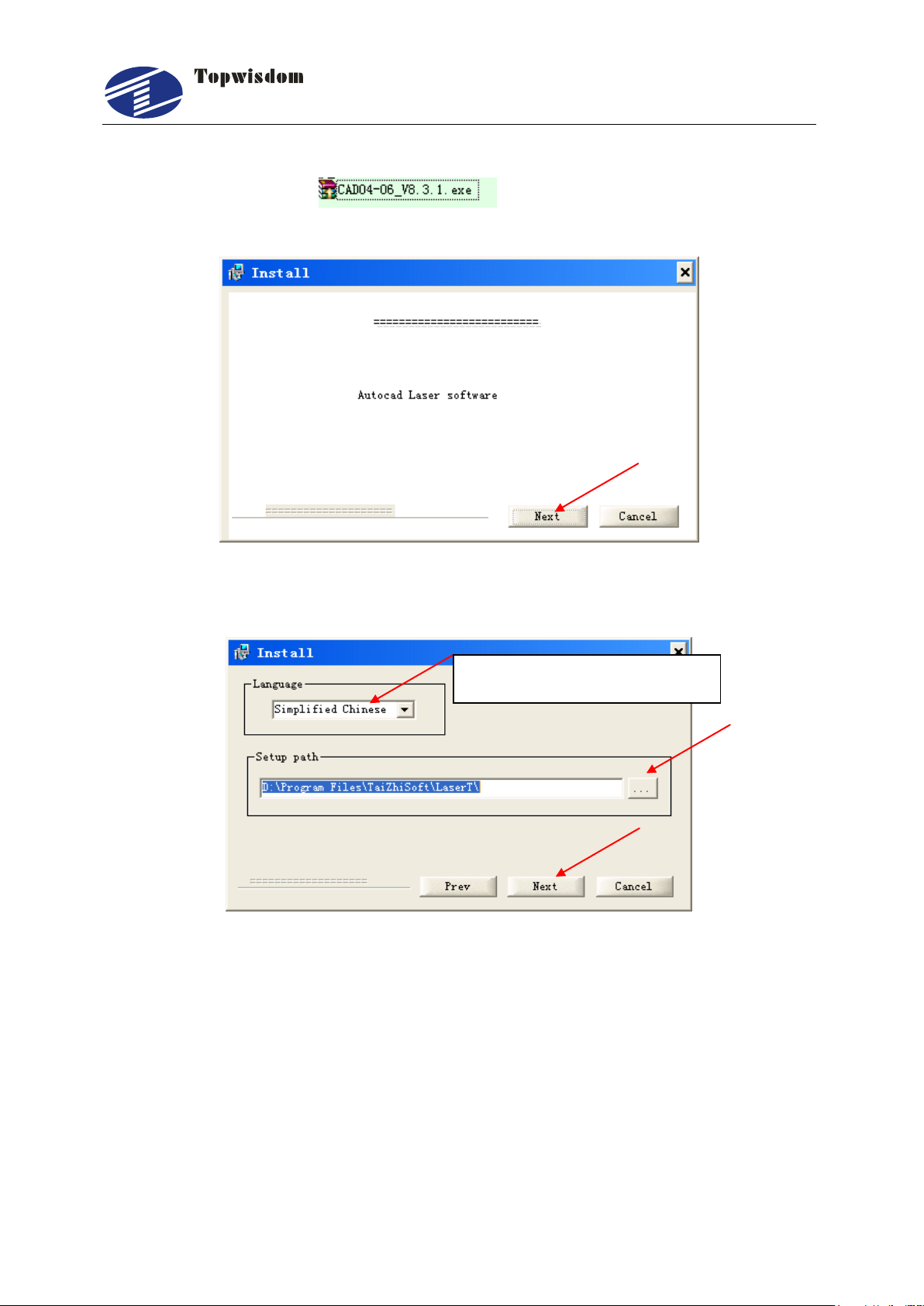

CAD04-06_V8.3.1.exe

CAD07-09_V8.3.1.exe

CAD04-06_V8.3.1.exe is for installing on AutoCAD2004-2006, now the current

software version is V8.3.1—the version is according which program you installed. The

version is shown in the installing program name, as you can see in

CAD04-06_V8.3.1—the version is V8.3.1. CAD07-09_V8.3.1.exe is for installing on

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

24

Select the installing language

AutoCAD2007-2009.

Double click the icon , to unzip files, then the screen shown

in Fig. 3-8 is displayed.

Fig. 3-8

Click ―Next‖ to proceed with installation.

Fig. 3-9

When finished selecting language, click ―…‖ button to select the install path. Then click

―Next‖ to start installing, the installing screen shown in Fig. 3-10 is displayed.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

25

Fig. 3-10

When the installation is finish, the installing program will be closed automatically.

3.4 Uninstalling CAD Direct Output

Click the LaserT Uninstall, show as Fig. 3-11.

Fig. 3-11

Click ―Yes‖ to uninstall in Fig. 3-12.

Fig. 3-12

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

26

Select ―No, not this time‖

Click the

"Next"

Fig. 3-13

3.5 USB Driver Installation

Insert the USB Cable, the power on, Fig. 3-14 will be shown on the Compute, and then

the Fig. 3-15 will be shown:

Fig. 3-14

Fig. 3-15

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

27

Select ‖Install

from a list or

specific

location

(Advance)‖

Click the

"Next"

Click ―Include this

location in the search‖

Click

―Browse‖

Click

―Next‖

Click the "Next", show as Fig. 3-16

Click the "Next", show as Fig. 3-17.

Fig. 3-16

Fig. 3-17

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

28

Select the usb

driver folder

Click OK

Browse to the USB driver folder by clicking the browse button. Once the file path has

been entered in the box, click next to proceed.

Fig. 3-18

The screen shown in Fig. 3-19 will be displayed as Windows XP copies the required

driver files.

After finishing, show as Fig. 3-20.

Fig. 3-19

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

29

Click

Finish

Fig. 3-20

USB driver must be installed twice. Repeat the installation steps above once again.

3.6 USB Port Setting

After the engraving card power on, connect the PC with USB cable, the computer will

assign a COM port to communicate. But when the assigned COM port is more than

COM8, the communication will have problem, so we need to change the COM port

number, the range is among COM3~COM9.

3.6.1 View the assigned COM Port by Computer

Enter the control panel.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

30

Fig. 3-21

Double click the "System", show as Fig. 3-22.

Fig. 3-22

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

31

The

assigned

COM port

Click the device management.

Fig. 3-23

Fig. 3-24

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

32

3.6.2 Change the Assigned COM port by Computer

On Fig. 3-24 USB Serial Port(COM4) is the assigned COM port, the way and the steps

that change the assigned COM port are as follow:

Double click USB Serial Port(COM4), show a window, single click Port settings, show

as Fig. 3-25

Fig. 3-25

Click "Advanced", show a Advanced Settings for COM4 window, choose the port

numbers on the COM Port Number, show as Fig. 3-26.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

33

Fig. 3-26

Click "OK", display a window of Communications Port Properties, as Fig. 3-27

Fig. 3-27

Click "Yes" to finish.

3.7 IP Setting

Enter the control panel

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

34

Double click network connection.

Fig. 3-28

Fig. 3-29

Double click "Local Connection".

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

35

Double click TCP/IP setting.

Fig. 3-30

Fig. 3-31

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

36

Select ―Use the following IP address‖, set the IP, Subnet mask, Default gateway, as

below figure.

Fig. 3-32

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

37

Part 4 Software Operation Guide

4.1 CorelDRAW Direct Output Software Operation

Open the CorelDRAW software, show as Fig. 4-1

Fig. 4-1After startup, our processing buttons will be automatically mounted on the

menu shown in Fig. 4-1 as pointed out by the arrow. After completing the figure, we

can click on the ―Laser Carve‖ button as pointed out by the arrow in Fig. 4-1 to show

the menu in Fig. 4-2.

Fig. 4-2

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

38

4.1.1 Layer Parameter Setting

It uses different colors for the configuration of engraving parameters, if there are

imported bitmaps, there will be independent bitmap settings. You can select a certain

color and double click or click on button ―Parameter Settings‖ for settings of these

drawings, and then the menu shown in Fig. 4-3 and Fig. 4-4 will be entered.

Fig. 4-3

Fig. 4-4

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

39

The two most important parameter settings are Outline output and Carve output. If

neither of the two is selected, ―output disabled‖ will be shown, i.e., no engraving output

for this kind of drawings will be carried out; if both are selected, data in this color will be

provided with possibility of both Outline and Carve output, pay attention that there must

be closed drawings for Carve. Otherwise, select one of them for one output condition.

PrecisionUnit: the unit of precision of engraving.

DPI(dots/inch): dots per inch

DPM(dots/mm): dots per millimeter

SpeedUnit: the work speed and the free speed unit.

m/minute: meter per minute

mm/s: millimeter per second

PRI: Is used for setting the engraving order of different colors, the smaller PRI, the

earlier to be exported, and vice versa.

Those are common settings for colors. ―Outline‖ and ―Carve‖ menus are respectively

corresponding to settings for Outline and Carve. For Outline, there are settings for

engraving features including speed, power intensity etc., for dots, the dotting time

settings are also available; and the settings for Carve follow the same way.

When the check box of ―default‖ is selected, no need to set the power intensity and

speed and the default values of the machine will be adopted; settings for power

intensity and speed are only available in case the check box of ―default‖ is not

selected.

Parameters description:

Output: W hen selected, engraving output for drawings in the current color will be

carried out.

Min. Power: W hen stroking curves, this power intensity applied for line start and the

corner of the curve .Or it applied for the top depth when gradient carving. The range is

0.00-100.00% (Min.Power1 is setting for min power of laser1, Min. Power2 is setting

for min power of laser2. Max. power is similar).

Max. Power: W hen stroking curves, this power intensity is applied as the work speed

was reached. Or it applied for the bottom depth when gradient carving. The range is

0.00-100.00%. If the is elbow too deep, it means the Min. power intensity is on the high

side or the speed is on the low side. When gradient carving is carried out, the min

power must not be set bigger than 30%, the max power can be set bigger, for getting a

better degree of gradient carving effect. The gradient rang is 0-3mm.

Work Speed: The work speed of the laser head is cutting. The rang is 0.000 to Axis

X,Y limit speed.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

40

Free speed: The move speed of laser head when the laser is off. he rang is 0.000 to

Axis X,Y limit speed.

Default: If selected, parameters like power intensity and speed etc. will be in

accordance with what displayed on the machine.

Open/Close delay: open delay is applied for the head of the cutting line. And the close

delay is applied fo the tail of the cutting line. The range is 0-15s.

Open Air: when open air check box is click, the blow air signal is active when work is

start. There is two ways of blow air, one is the blow air signal is always active. The

other is when laser is on the blow air signal is active otherwise not active.

Z_AxisMoveSize(mm): the moving distance of lift axis before work start. W hen work

is finish lift axis move back to the original position. The steps to enable the automatic

lifting function is below: Click the AxisControl button at the bottom, then select the

Allow_zAxis.,and set the SelectAxis as Z, click OK to back to the parameter setting

interface, now it is able to modify the Z_AxisMoveSize. Attention: This function is use

to the case of cutting the material with various thickness. By adjusting the position of

laser head, to make the laser head move to the position of the laser focal length is

reach.

Hit_point: for hit point or drill on material. Firstly click the ―Hit_Point‖ check box. Then

set the Point_Interval—interval between dots—and the Hit_Time—laser on timer, unit

is second.

Spot Compen.: Spot compensation is for compensating the size lose resulting f rom

the spot is too much big. The unit is mm.

Reseau: In the carve page, it can set the engraving mode to reseau mode. The reseau

mod is suitable for closed vector graphics.when the Open_Reseau check box is

selected, three parameters below can be set:

Pattern: Round, Square, Triangle

Interval(mm): Interval between dots

Size(mm): the size of dots. When the pattern is round, the size is the length of

diameter. W hen the pattern is square, it is length of edge. When pattern is

triangle, ti is the edge of external rectangle of triangle.

Carve method:

X_Unilateralism: Engraving from one horizontal side, when move inversely ,the

laser is off. It can eliminate backlash and the processing effect is good, but the

processing time is longer.

X_Bidirectiona(recommended): Engraving from both horizontal sides. The

processing time is short. But because the machine generally exist backlash leads

to dislocation. At this time you need to set up a backlash or backlash list.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

41

Y_Unilateralism: Engraving from one vertical side, when move inversely ,the laser

is off. It can eliminate backlash and the processing effect is good, but the

processing time is longer.

Y_Bidirectional: Engraving from both vertical sides. The processing time is short.

But because the machine generally exist backlash leads to dislocation. At this time

you need to set up a backlash or backlash list.

Gradient(mm): the gradient length of gradient engraving, as shown in figure below.

When carry out gradient engraving, the top depth is determined by the min power. The

larger the min power, the deeper the top depth. The Depth from top to bottom is

determined by the max power. The larger the max power, the deeper the depth. The

gradient length determines the distance from the top to the bottom, the greater the

distance, the slope more flat.

Fig. 4-5

Precision: the precision of engraving. The unit is DPI or DMP. It means how many

lines will be processed per inch or per millimeter. For example, 500 DPI means it will

process 20 lines within 1 millimeter length. The greater the precision value, the deeper

the engraved depth.

ReverseRepair: use to compensate the backlash of the machine. The debug step is

as follows.

Draw three 50X50 rectangle in CorelDRAW, select the carve output check box in

parameter setting window. And set precision as 2 DPI, ReverseRepair as 0. Then

output the file to control card.

The actual processing effect is similar to the figure below. The length of first line

and second line dislocation in the middle rectangle is the compensated length.

Generally it is negative, according to the engraving effect to set it. As the figure

shown below, the length is -0.2mm. So the ReverseRepair is -0.2.

Fig. 4-6

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

42

When finish setting the ReverseRepair, set the appropriate value of max power

and precision. Generally, 60W CO2 laser, 53.5 Focus lens, 350DPI is

recommended. The greater the precision, the longer the engraving time.

IntervalList: select the UseList check box then the IntervalList setting is applied to the

engraving file. In this case, the ReverseRepair is useless. The function of IntervalList is

similar to the ReverseRepair, use to adjust the engraving effect. In the list of

IntervalList, it can set the backlash in different speed. Because of working in different

speed, the backlash is different. The greater speed, the bigger the backlash.

After the parameter settings, the engraving output can be carried out, the

system will remember the last parameter settings to avoid repeated parameter

settings. For instance, if you set the red output power intensity at (50%, speed at

20%, no error compensation and PRI at 1), the same setting will be applied for

the use of the color red (if any) for the next time.

4.1.2 Coordinate Setting

According to actual situation, just click on the ―Coordinate‖ button in Fig. 4-2 to enter

the menu shown in Fig. 4-7. If the machine homing to the upper right, select Right-Top

in the group of coordinate.

Fig. 4-7

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

43

Laser head

There is 9 location can choose. If you set the location in upper right, the output file will

be processed in the lower left side of the laser head. As shown in Fig. 4-8.

Fig. 4-8

4.1.3 Track Setting

Click the ―TrackSet‖ button in Fig. 4-2, a track setting window will be shown. It can set

the cutting order and the cutting start point of the line in different shape or layer. As

shown in Fig. 4-9.

Fig. 4-9.

ColorLayer: Select the color layer number you want to adjust. It will display all the

shapes in this layer in the upper left window.

Shape: Each shape has a serial number. It means its processed order in this layer.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

44

Select a serial number in the shape drop-down box. Then the shape with this number

will be displayed in the upper right window. And the red arrow shows the start process

point and the direction of cutting.

Show Order: Select show order check box. The serial number of the shape will be

shown side by the shape in the upper left window.

Auto Order: click the auto order button, the program will automatically optimized

cutting sort all shapes.

Step: Specify the start processing point of the shape. The unit is the line number.

When set the step as 1, click the ―StartPos‖ button once, the start processing point will

move forward 1 line segment on cutting direction.

Sequence: Specify the process order of the select shape. Set the proper value of

sequence, then click ok button. At this time, the upper left window will display the new

processing order of shapes (the Show Order check box is selected).

Enter Line: When Selected the enter Line check box, an extension line will be added

before the shape. It is used to avoid the laser light is not stable, lead to processing

problems. Set into the angle and length of enter line, click ok button below to complete

setting.

Out Line: When Selected the enter Line check box, an extension line will be added

after the shape. It is used to avoid laser burn twice at the same place of the start

position of close shape, lead to overcut problem. Set into the angle and length of out

line, click ok button below to complete setting. Generally, the enter line and the out line

is less than 10mm.

When finish setting, click the ok button in right bottom to save the configure.

4.1.4 Single Axis Operation

Click the ―AxisControl‖ button in Fig. 4-2, a track setting window will be shown. It can

separately operate the single axis moving, show as Fig. 4-10:

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

45

Fig. 4-10

Firstly select the com port which is the USB port described in section 3.6. Then select

the axis you want to move. Set the move distance in MoveSize edit box and the move

speed in Speed edit box. If you need the laser on, set the laser power in Power edit

box and select the OpenLaser check box. Click Execute button to move. If you want

the axis move to the reverse direction, set a negative value in the MoveSize edit box.

4.1.5 Output Engrave

After the parameter settings, click on ―output‖ to enter Fig. 4-11

Fig. 4-11

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

46

Parameter description:

Out Rows: The rows of the output shape.

Out Columns: The Columns of the output shape. By defaut, the row and column is 1,it

means the shape will be processed once.

Row Interval (mm): The interval size of row. The unit is mm.

Columns Interval (mm): The interval size of column. The unit is mm.

FeedingTimes: After finish one process, the machine can feed once. The feeding

times parameter determines how many time it will feed.

FeedingPerSize(mm): the feeding length.

Feeding delay: The delay time after feeding. The Unit is second.

Attention: These parameters above are applied to array process or repeat process.

Here, the row and the column is array parameters. If row is 2 and column is 1, then

2X1 array work file will be outputted. The row interval determines the distance between

two rows. The columns interval determines the distance between two columns.

Feeding Times, FeedingPerSize, Feeding delay is applied to the machine with feeding

equipment. Feeding Times is repeat work parameters. Click the ―>>‖ button for more

array setting. As shown in figure below, it can set the table size—table width and length,

work start position, row, column, row interval, column interval. Click the Import button

or Auto-filled button to preview. Click ok to save configure.

Fig. 4-12

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

47

Translate Mode: The communication mode for download file from computer to control

card. If USB mode is selected, it can select the com port in the drop-down

box—corresponding to the visual serial port created in the Device Manager of the

computer. If Netware mode is selected, it can select the IP of the machine you want to

download file to. Or you can set click the button to add or modify the IP address of

the machine. If the control card is camera cutting card with the version is

V.L010.XXX, then the CCD Mode check box must be selected. Otherwise, the

output file will not be identified by the card.

Path:

Shortest path: The program will automatically calculate the shortest cutting path

of the output shapes. The following options can be set.

Work starting pos.: laser head work starting position (Left-Top, Left-Below,

Right-Top, Right-Below).

Convergence point: The data handle between ending position of the current

shape and starting position of next shape.

The starting point: The distance from ending position of current shape to

starting position of next shape is shortest. The free move time is shortest.

Smooth starting point: Select the optimal starting position of next shape

to realize smooth moving, avoid shake or dislocation

Original starting point: no change the starting position of the shape.

Sub-layer optimization: First according to layer order to sort. Then optimize

the cutting order inside the layer.

From the inside out: If the shapes have the containment relationship, the

inside shape will be cut first. This guarantee will not happen cutting error or

missing cutting.

Original Path: Not optimize the path, using drawing order.

Hori. Unidirectional: cutting from one horizontal direction for array process (T

shape).

Bi-level: cutting from bilateral horizontal direction for array process (S shape).

Row: When the select the Hor. Unidirectional or Bi-level, it can set the Row

parameter. It means the width of the partition optimization. If you want to cut

the shapes within 100mm range, set the row is 100mm. So the machine will

have cut all the shapes with 100mm row size, then it moves to cut next shape

within next row.

Merge adjacent: set this merged range so that two line will be merged into a line if

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

48

they meet the requirements. This is helpful to reduce the nodes within a shape and

make the not closed graph to closed graph.

ClosedRepair: Set the compensated line length for compensating the process error

leaded by the mechanical parts. This is helpful to make the not closed graph to closed

graph.

Dislocation treatment: For avoiding closed graph processing dislocation

phenomenon.

Offset repair: W hen feeding, material will send partial due to mechanical movement.

Offset repair parameter is used to correct the feeding error. The unit is %, the greater

the value you set, the greater the compensation.

Split feed: If the graph is so long, it needs to split feed. Set the split length. And the

graph within the split length range will not be split. Make sure the dimension of the

length is not greater than Y, otherwise it will be forced to split. Under the specified

length, cutting out a layout of the graphics, and then feed, and then cutting the next

layout of the graphics. Generally, the split length is length of the longest graphic.

In the bottom of the window, there are some buttons. The description is following:

WorkTime: Predicting the processing time.

SpeedCorrect: Click it then it shows a speed setting window. Set the speed limit when

cutting the little graph. It is useful to avoid shake.

Fig. 4-13

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

49

OutFromFile: Download the *.out work file to control card.

Save: Generate a work file from current drawing and save the work file in computer.

Output: Click it and a window is shown. Doc name is assigned by the program, can be

modified. Press ―OK‖ to download file to control card. After the completion of the

transfer, control card will beep on. Press File button on the card panel, you will find the

downloaded file at the last. Select it and press ―start‖ to process.

Exit: Close the output window.

Fig. 4-14

4.2 The Equipment Management

This section describes the parameter settings of the laser engraving software and the

operation of the parameter setting software. These settings are very important

because the parameters of the machine will decide the working status of the

engraver, therefore, please read carefully this chapter and do not make any

change before you completely understand the meanings of all the parameters.

Enter the machine parameter settings when clicking on the ―Equipment Manage‖ in Fig.

4-1 above.

Fig. 4-15

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

50

The equipment parameters are the core settings of the engraver, the user needs not to

modify them in normal cases, if the modification is necessary, please prepare a backup

for correct parameters in advance, if the equipment cannot work normally after the

modification, you can rewrite the backup data into the engraver.

Open the parameter settings menu (Fig. 4-16、4-17). This software functions to make

settings for the equipment parameters of Topwisdom laser engraving software.

4.2.1 Toolbar

There are 3 buttons in the tool bar , respectively

representing: factory settings, open file, save file and exit.

Factory Settings: Reference values or limit values for the parameters set by the

factory, the user cannot modify the factory settings but can use them as reference.

Open File: Opens the backup parameter files saved in the computer.

Save File: Saves current parameters to a file.

4.2.2 Parameter Setting

See Figure Fig.4-16 for the factory settings

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

51

Fig. 4-16

Port: It’s the communication interface between the computer and the equipment,

which is realized via the port, namely, the image information and the equipment

parameters on the computer are transmitted to the equipment via the port. Topwisdom

laser engraving software adopts USB interface or network for the connection with the

computer.

IP: Set the control card IP.

Netware mode: use network to communication.

CCD mode: for Camera cutting control card.

Read: Read the parameters saved in the equipment and display the values to the user

for reference. If you need to modify the parameters, you must read the parameters in

the equipment or open the parameter files already saved first, and then modify the

parameters (If read failure, please check if computer is connected to control card by

the USB cable or network cable).

Write: Write the parameter values set by the user into the equipment (authorizing code

provided by the manufacture is required: TZ0001), and then the equipment will operate

according to the parameters written into it. W hen the parameter settings of the

equipment is not completed, click on this button, and the ―Some Data is Invalidate‖ will

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

52

be shown in the status bar at the bottom, the parameters cannot be written into the

machine.

Clear: Besides the drop-down box option, the rest of the parameter value will be set to

null, which is no parameter values.

※ Topwisdom software uses serial ports for writing and reading, therefore, once a kind

of software is using a serial port, other software cannot use this serial port.

Equipment Type: type of the used machine. There are mainly general engravers and

brand engravers.

Open_cover safeguard: If Yes is selected, whenever the cover is open by user,

machine will start the safety protective measures, to pause working. In the case of

equipment with safety protection, which do not use the open protection, user can also

will set the Open_cover safeguard parameter as "No". Such as test equipment, test

process, but this operation must be performed by the professionals, generally don't

recommend customers to use.

Laser Type: Select proper laser device type according to the laser device used by the

machine.

PWM Frequency: I.e., the power intensity frequency of the laser tube, this value

differs according to different types of the laser tubes; please consult the instructions for

the laser tube for details.

Least Light: The min. duty ratio supported by the engraver.

Most Light: The max. duty ratio supported by the engraver.

Laser Open/Close Delay: the delay parameter set to avoid the uneven edges of the

first Outline and the last Outline when the laser is on or off.

Laser on Delay: Because it takes a short period to start the laser, in order to make the

power and the laser head be started synchronously, the laser device is started before

the laser head. I.e., the Laser On Delay.

Laser off Delay: Because it takes another period of time to shut off the laser after

receiving the instruction, in order to avoid excessive engraving, the laser is shut off in

advance.

Least Pulse Width: The min. pulse width to be recognized by the laser device.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

53

Fig. 4-17

Direction Polarity: Classified into positive and negative, when the motion direction of

the motor disaccords with the direction control buttons on the keyboard, you can

change the direction polarity to make them consistent with each other.

Limit Polarity: Classified into positive and negative, when the motor cannot return to

the original position, you can change the limit polarity to make it normal.

Key Polarity: The buttons on the control panel correspond to directions of the motion

of the axes, if it moves to the right when you press the left, change the polarity.

Note: set the limit polarity first, then direction polarity, and key polarity last.

Movement Precision (µm): The move distance per pulse, the unit is µm. The

resolution of machines may be changed slowly due to different abrasion and other

factors of machines, the user may get the optimal value after multiple times of

debugging and settings.

Calculation of Resolution: Accurate Resolution = Current Resolution × Real Size/

WishSize.

Current Resolution: The resolution set at current operation of the equipment, i.e., the

resolution in the parameter settings of the equipment, which can be read from the

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

54

equipment.

RealSize: The length on the effect drawing designed by the user, normally in whole

numbers but not exceeding the max. travel.

WishSize: The length of the track left by the engraver on the engraved material, which

can be measured by measuring tools.

Fig. 4-18

About the size of the measuring:

Draw a 30*30 rectangle to c alculate the resolution. When measuring, the width of the

laser beam needs to be considered. The processed reactangle is as shown in figure

below. Take the measured value of the X axis 34mm, and input 34 into the RealSize

edit box and 30 into the WiseSize edit box. Click ok the program will calcul ate out the

right resolution. Other Axis is similar. When calculate the resolution of Y, the RealSize

is the length of trace the beam moved.

Fig. 4-19

Test Precision(µm): This parameter is valid when the equipment is provided with the

closed-loop detection system, this parameter finally decides the errors between the

engraved dimensions and the designed dimensions, in this case, only the adjustment

of this parameter rather than the minute changes of the motion resolution will influence

the engraved dimensions.

This parameter is invalid when the equipment is not provided with the closed-loop

detection system. In this case, the minute changes of the motion resolution will directly

influence the engraved dimensions.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

55

Most Speed (mm/s): The max. speed allowed for single-axis movement. This value

decides the max. Engraving speed and cutting speed.

Stop Speed (mm/s): The speed of sudden stop during single-axis motion, i.e., the

motion stops speed.

If the stop speed is high, the equipment will get greater impact when stopping and

starting; the effect of engraving will be poor while the engraving efficiency will be high;

Most_Acc( mm/s2): Max acceleration of the axis, the ratio of change of speed. It is

the ability of speed change from one value to another value in unit time.

The higher the acceleration, the time of the speed from one variable to another is

shorter. And carving efficiency is high, but the impact of the equipment and equipment

abrasion is big;

Otherwise, efficiency is low, the impact of equipment and equipment abrasion is small.

The max acceleration must match the max speed. Then device will work in the best

state (that is, the equipment work with high speed and carved to obtain the very good

effect). In general, the user can set the parameters reasonable according to their

requirement for engraving speed and accuracy.

To meet the accuracy requirement of the user, it can improve the speed and

acceleration to make engraving efficiency.

If speed is now meet the requirements of users, or it was unable to reach the maximum

speed of current Settings, the user can appropriately reduce the speed value. Because

each user's environment and engraving requirement is different, so the device’s max

speed and the max acceleration will also be different. Users can obtain the best

parameters after repeated practice.

Max. Space: As either the bean or the guide rail has a fixed length, each machine has

a max working breadth (i.e., working range), which limits the motion of the machine

within the max working breadth and makes the trolley and the beam move within the

working range. The trolley and the beam will not hit the machine edge as there’s the

limitation of max space.

4.2.3 Embroidery Import

Embroideries Import is provided for the convenience of the user to import DST, DSB

files of format, the import of CAD files is opened here. Please see the figure below:

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

56

4.2.4 Import bitmap

Fig. 4-20

If have a bitmap for engraving, click on the import bitmap button in Fig. 4-20, a Import

set window will be shown. If you need to change the bitmap into reseau diagram,

select the NetMode check box. You can set the direction of net point or the size of point.

Click OK button to import the bitmap.

Fig. 4-21

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

57

4.2.5 Curve Precision

Set the curve accuracy with the software to improve the smoothness and speed of the

operation, you can select general, meddle, high, very high, most high, etc..

Fig. 4-22

4.3 CAD Direct Output Software Operation

Open the CAD software, show as Fig. 4-23

Fig. 4-23

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

58

4.4 CAD Direct Output Software Supplementary Description

4.4.1 The Support of AutoCAD Direct Output Annotation Text

Text and annotations in CAD system are normally exported as auxiliary information,

therefore, in usual cases, you need not select text and annotations in the window

shown in Fig. 4-24. However, in special cases, e.g., the user needs to engrave the text

in the graphics, and even the annotations, for output, you can select corresponding

options in the window shown in Fig. 4-24.

First, you’d like to announce that we do not support text and annotations to a fractional,

however, there are some limitations, for example, we support 5, 6 types of large fonts,

settings for large fonts are as follows: first enter the menu shown in Fig. 4-24, select

Text Style in the ―Format‖ menu.

Fig. 4-24

Then you’ll enter the menu shown in Figure Fig. 4-25, select Use Big Font (U). And

then select the font file you required from the pull-down menu of Big Fonts (B), we

currently supports the following font files for Chinese: Fs.shx, gbcbig.shx, HT.shx,

Hztxt.shx and Khz.shx. So you must select one of the aforesaid files.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

59

Fig. 4-25

After the steps above, the settings are completed, but please do note that when

inputting text, as shown in the figure below, after the text inputting tool is selected, the

menu shown in Figure Fig. 4-26 will appear when inputting text.

Fig. 4-26

Then you just let it adopt the default font shown in Figure Fig.4-26. Do not select the

English fonts or Song typeface or boldface etc. from the pull-down menu, for those

may not be supported by our software temporarily. After this, our software can support

the engraving output of text in CAD interface.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

60

4.4.2 Carving Gradient Sketch Map

Fig. 4-27

4.4.3 Coordinate System

Fig. 4-28

Coordinate: Coordinate must match original position of the machine. On the same

machine can't literally change the coordinate system

Location: The position of laser head is the start position before cutting. As shown in

figure below, there are 9 locations of laser head relative to the position of graphic. The

red cross is the position of laser head.

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

61

scan

drawing graphic

effect

Fig. 4-29

4.4.4 Supplementary Description of Carving

AutoCAD provides the Carving output, which only needs the contour of a drawing

instead of filling, which should be particularly paid attention to.

Please note that for drawings drawn in AutoCAD, the Carving in direct output is carried

out according to the contour, you need not to draw the drawings in the filled mode,

besides, there’s no difference between intaglio and incised inscription, Fig.4-30 shows

the effects of the origin drawing and the drawing after Carving output, as there’s no

difference of intaglio and incised inscription in vector graphics, you may get the effect

of incised inscription by drawing, please see Fig. 4-31 if there’s relation of inclusion

between two outline drawings in the same color, the effect shown in the drawing below

will be created. If multiple layers of drawings in the same color are included, the effect

will be as follows, its rule of Carving output is that: engraving the first layer, not

engraving the next layer, and then engraving the further next layer, and the rest may be

deduced by analogy. Please see Fig. 4-32

Fig. 4-30

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

62

scan

drawing graphic

effect

scan

drawing graphic

effect

scan

drawing graphic

effect

Fig. 4-31

Fig. 4-32

From what described above, we may see that for Carving out of vector graphics, filling

is not needed, and there’ll not be this kind of influence between drawings in different

colors, as shown in Figure Fig. 4-33 drawings in different colors are in the relation of

inclusion, no influence on each other. There’s overlay between the two parts of

Carvings. We believe you may have deeper understanding for the Carving modes of

AutoCAD.

Fig. 4-33

4.4.5 Supplementary Description of Software and CAD Direct

Output

Announcement: This document is mainly purposed to provide some methods of

analysis and solutions for the disorder of the engraving for vector graphics, as the

applications are diversified, some problems cannot be completely solved by our

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

63

3 1 2

software alone, Therefore, sometimes the user need to make improvements for the

drawing so as to make the operation of the machine in accordance with our ideas.

Some simple drawings may be connected and exported in order

See the figure below:

Fig. 4-34

In Fig. 4-34, we first draw the curve at the center from the left to the right, then draw the

line section on the right from right to left, finally, we draw the line section on the left

from left to right, according to the original output processing, the result will be as

follows.

Fig. 4-35

And the order of output by the equipment follows the numbers displayed in Fig. 4-35

the direction for each step of output is shown by the arrow. This effect is poor as its not

completed from the beginning to the end b one run.

There are 2 ways to solve this problem, 1: draw the drawings in order or combine them

with the merger operation provided in software like CorelDRAW or AutoCAD etc., 2:

our software engraving can change the order into a smooth and continuous way of

operating from the beginning to the end when processing the drawings.

The current software has make processing to drawings as shown in Figure 1 to mak e

them to be exported from the beginning to the end, i.e., this problem of output order

has been solved in the latest version of the software. However, we recommend our

users to draw the drawings in order when using AutoCAD or CorelDRAW etc., if you

fail to do that, you can combine them together with the merger operation provided in

the aforesaid software, which may provide higher fault tolerance.

Normalized output for complicated drawings are shown in Fig.4-36 below

Fig. 4-36

Fig.4-36 is not so complicated, however, according to our observation, many users will

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

64

draw the figure in several sections instead of drawing it continuously, therefore, the

software will create multiple effects of output (this is relevant to the order of drawing of

different users), however, may be none of the effects is what you expect.

Please see the following sample for different effects of cutting.

Cutting 1 Cutting 2 Cutting 3

Cutting 4 Cutting 5

Fig. 4-37

As you can see in the drawings above, it totally takes 5 times to cut the entire drawing,

and the procedure is disordered. The effect is not expected, seeing from the stroking in

the drawings above, each Outline reaches the end and stops till there’s no connected

line section, but it is hard to choice the path in this way, and there’s also great

randomness, therefore, the entire drawing is divided into several parts. There’s little

software, currently, is provided with the capacity to manage the problems as a whole

like human being, for instance, cutting the external rectangle before the internal part

etc.. Therefore, we must pay attention to this kind of drawing when drawing, e.g., if you

want to cut the two rectangles along the 4 sides, you must combine the separate line

sections of the rectangles together with software, thus the disordered engraving will be

avoided and a relatively neat path will be achieved. Many users just patch up the

drawings Outline by Outline in irregular order, therefore, multiple types of stroking will

be created for a drawing as shown in Fig.4-34, which is actually very simple, while in

fact, there are many drawings much more complicated than this one, one joint may be

connected with many line sections, and the stroking will be more disordered, so it’s

hard to arrange the order effectively by our software alone, and you must solve the

problem from the beginning, the method of drawing.

Disordered output for single lines without joint or crossing

Fig. 4-38

Fig. 4-38 seems to the same to Fig. 4-34 at first view; however, the engraving is

disordered, why? Let’s amplify the drawing and you can see that there’s no joint

泰智科技

Shenzhen Topwisdom Technology Co., Ltd

65

between the line sections, so the order cannot the arranged. Therefore, when drawing,

pay attention that the joints must be closed.

No display when opening the drawing in a 3rd party engraving software, or run into a

wall when using CAD for direct output.

For example, you draw a drawing in CAD, which looks normal, while it cannot be

displayed in a 3rd party engraving software, or run into a wall when exported to the

equipment. Why? This is normally caused by a small drawing or dot far away from the

drawing, which is not what the user expects to process but is just drawn by mistake,

this makes the whole drawing to be so large and cannot be seen when opened in

another software after zooming out, and the breadth of output will be far exceeding the

operation breadth of the equipment, which will also cause problems.

Part of the drawings of CAD direct output or in DXF files cannot be displayed and

processed

AutoCAD2005 is newly provided with region tools and table tools, parts of a closed

drawing can be processed into the drawing of a region via the region tools on the left.

Then the software cannot recognize and process it, so pay attention that there should

not be any region drawing when drawing, if there are some, they should be redrawn by

line sections or curves or be broken up with breakup operation. Tables drawn with the

table tools should follow the same way, they can be normally exported after being

broken up, those are all new features after AutoCAD2005.