FemtoFiber smart

Ultrafast

Fiber Laser

Manual

Manual: M-056 Version 08

Copyright

2018 TOPTICA Photonics AG

TOPTICA Photonics AG

Lochhamer Schlag 19

D-82166 Graefelfing/Munich

Tel.: +49 89 85837-0

Fax: +49 89 85837-200

email: info@toptica.com

http://www.toptica.com

(September 2018 Subject to change without notice)

Dear Customer,

FemtoFiber smart Manual

Welcome to the T

OPTICA community!

We have designed this product to be easy to use and reliable so that you can focus on your work. If you

have questions or need advice on how to integrate it into your setup, please contact us immediately so

we can walk you through the process. We will provide you with quick and competent help through our

service staff and product managers.

You can contact us in the following ways:

- Internet: service.toptica.com. In our support section you can find a list of frequently asked questions and a service contact form

- Email: service@toptica.com

- Phone: +49-89-85837-150

Our customers in the USA and Canada may contact T

OPTICA Photonics Inc.:

- Phone: +1-585-657-6663

Our customers in Japan may contact T

OPTICA Photonics K.K.:

- Phone: +81-42-306-9906

Please have your product ID and serial number ready when contacting us-so we can quickly retrieve all

relevant information.

As we are constantly improving our products, we greatly value all customer feedback. We encourage

you to tell us what you like about our products as well as any suggestions for improvement.

Best regards,

Harald Ellmann

Director Service

T

OPTICA Photonics AG

Statu s: 6.9.18

FemtoFiber smart Manual

Contents

1 General Description of the FemtoFiber smart System 3

1.1 Ytterbium Fiber Lasers 3

1.2 Erbium Fiber Lasers 4

1.3 FemtoFiber smart Switch Box (Optional) 5

1.3.1 USB-Control 5

2 Safety Instructions and Warnings 6

2.1 General Safety Terms 6

2.2 Safety Labels 8

2.2.1 Laser Beam 8

2.2.2 Apertures 8

2.2.3 CFR Compliance 9

2.3 Identification of Manufacturer 9

2.4 Safety Features 10

2.4.1 External Interlock 10

2.4.2 Shutter (Free Beam Version) 10

2.4.3 Protection Cap on Fiber Pigtail or FC/APC Connector 10

3 Installation 11

3.1 Package Contents 11

3.2 Installation Instructions 12

4Operation 13

4.1 Operator Controls FemtoFiber smart Laser 13

4.2 Operator Controls FemtoFiber smart Switch Box 15

4.3 FemtoFiber smart System Quickstart 18

4.3.1 OEM Integrated Environment 18

4.3.2 Manual Operation via Switch Box 19

4.3.3 FemtoFiber smart Operation via Software Commands 20

4.3.4 FemtoFiber smart Operation with Graphical User Interface 23

4.3.5 System Requirements 23

5 TOPAS FemtoFiber smart Control Software 27

5.1 Upper and Lower Screen Section 27

5.1.1 Header 27

5.1.2 Footer 27

5.1.3 Menu 28

5.1.4 Help 31

5.2 Control Section 32

5.2.1 System Info Tab 33

5.2.2 Micro Mover Tab (only FYb Systems) 34

Status: 6.9.18

6Appendix 35

6.1 Specifications 35

6.2 Pin Assignment D-Sub 9 Input/Output Connector 35

6.3 Operation without Switch Box (Control via TTL/Analog Pins) 36

6.4 Pin Assignment of Laser On Input Connector (Switch Box) 37

6.5 Pin Assignment of Power Supply Connector (Switch Box) 37

6.6 Firmware Update 38

6.7 USB Connection (Installation of FTDI CDM Drivers) 39

6.8 Precautions for Non-Condensing Operation Conditions 41

6.9 Declaration of CE Conformity 42

6.10 Main Dimensions of the FemtoFiber smart System Versions 43

6.10.1 FemtoFErb Free Beam 43

6.10.2 FemtoFErb with Fiber Pigtail 44

6.10.3 FemtoFErb with FC/APC Fiber Connector 45

6.10.4 Femto/PicoFYb with Fiber Pigtail 46

6.11 License and Copyright Information associated with Third Party Software 47

6.12 EU Legislation for Electrical and Electronic Equipment (EEE) 47

7 Guarantee and Service 48

Status: 6.9.18

FemtoFiber smart Manual

1 General Description of the FemtoFiber smart System

Ultrafast fiber lasers provide an ideal combination of system parameters: Small form factor at low cost,

but on the other hand reliable and having brilliant laser performance. Various bulky and cost-consuming

solid-state laser concepts are therefore getting more and more replaced by robust and reliable turnkey

fiber lasers.

T

OPTICA´s FemtoFiber smart lasers are the most compact and cost-effective laser sources for Terahertz

generation. Other applications benefiting from the FemtoFiber smart laser solutions are e.g. metrology

systems, light sources for microscopy, ophthalmology or medical surgery/ examination.

The FemtoFiber smart laser systems are based on rare earth doped fibers and saturable absorber mirror (SAM) mode-locking technology. Generally, the fiber technology ensures a very compact design and

highest robustness against vibration or mechanical shocks. The use of mass produced fiber components

with the proof of Telcordia standards provides an unique cost-benefit ratio. The passive SAM device

ensures self-starting and reliable mode-locking.

Key Features for all systems of the FemtoFiber smart family:

•Turnkey

•Compact

• State of the art FemtoFiber technology: robust and reliable all- fiber setup

• Fiber coupled output

• All necessary control electronics inside

• Telcordia proved components

NOTE ! Please refer to the website www.toptica.com for detailed specifications of the FemtoFiber

smart.

For individual laser system specifications, please refer to the Production and Quality Control Data Sheet.

The FemtoFiber smart lasers are plug & play systems for both OEM integrators and single unit customers.

They provide an electrical interface for remote control and only need 12 ± 2 V DC filtered supply input for

all internal electronics. For single system users the supplied Switch Box provides all switches, supply and

status lines to run a FemtoFiber smart as a stand-alone system without integration environment.

Alternatively, FemtoFiber smart laser heads can also be controlled via an USB-interface.

1.1 Ytterbium Fiber Lasers

PicoFYb 1030/1064

The PicoFYb laser systems are fiber-based picosecond oscillators for seeding industrial laser systems, e.g.

for micro-machining. The PicoFYb laser pulses with excellent amplitude and frequency jitter parameters

are amplified to typical multi-Watt levels in the MOPA (master oscillator, power amplifier) laser or regenerative amplifier systems of our customers. Typical amplifiers are slab, rod and disc lasers operating in the

1 µm wavelength regions.

FemtoFYb 1030

The FemtoFYb laser systems are fiber-based sub-picosecond to femtosecond oscillators for seeding

industrial laser systems, e.g. for micro-machining. The FemtoFYb laser pulses with excellent amplitude and

frequency jitter parameters are amplified to typical multi-Watt levels in the MOPA (master oscillator,

power amplifier) laser or regenerative amplifier systems of our customers. Typical amplifiers are slab, rod

and disc lasers operating in the 1 µm wavelength regions.

Page 3

Statu s: 6.9.18

FemtoFiber smart Manual 1. General Description of the FemtoFiber smart System

1.2 Erbium Fiber Lasers

FemtoFErb 1560

The FemtoFErb 1560 is a very robust all fiber-based femtosecond laser system with excellent amplitude

and frequency jitter parameters. Applications benefiting from the most stable, compact and cost-effective FemtoFErb 1560 are e.g. Terahertz or metrology systems, light sources for microscopy, ophthalmology

or medical surgery/examination.

FemtoFErb 1560 FD6.5

The FemtoFErb 1560 FD6.5 is the fiber delivery version of the FemtoFErb 1560 providing a 6.5 m external

SM PM 1560 fiber and transform-limited pulses at the fiber end. This allows replacing complex beam delivery setups by flexible and convenient fiber solutions. Applications benefiting from the most stable, compact and cost-effective FemtoFErb FD6.5 are e.g. Time-Domain Terahertz, medical applications like

endoscopy or metrology systems.

FemtoFErb 1560 and FemtoFErb 1560 FD6.5 with THz Option

This option includes a special technology called QuTE (Qu

connected permanently and directly to the THz antennas. This option prevents possible Q-switch pulses

to reach the antennas, which may occur at the laser start-up procedure.

FemtoFErb 780

The FemtoFErb 780 is a very compact all fiber-based femtosecond laser system with integrated miniaturized second-harmonic generation unit. It unites both supply electronics and laser unit in one box, being

thus one of the smallest fiber laser units on the market. The system only needs 12 ± 2 V DC filtered power

supply and comprises a free-beam output with mechanical shutter.

FemtoFErb 1950

The FemtoFErb 1950 laser is a very robust all fiber-based femtosecond laser system with excellent amplitude and frequency jitter parameters. A frequency shifted solitonic pulse is generated by nonlinear

effects. The unit is used for seeding Thulium doped amplifiers and also for other purposes in the 2 µm

wavelength range

-Switch Termination) allowing the laser to be

Page 4

Statu s: 6.9.18

FemtoFiber smart Manual 1. General Description of the FemtoFiber smart System

1.3 FemtoFiber smart Switch Box (Optional)

The FemtoFiber smart Switch Box is a small tool which provides all switches as well as supply and status

lines necessary to run a FemtoFiber smart laser as a stand-alone system without integration environment

and therefore is recommended especially for single-system users.

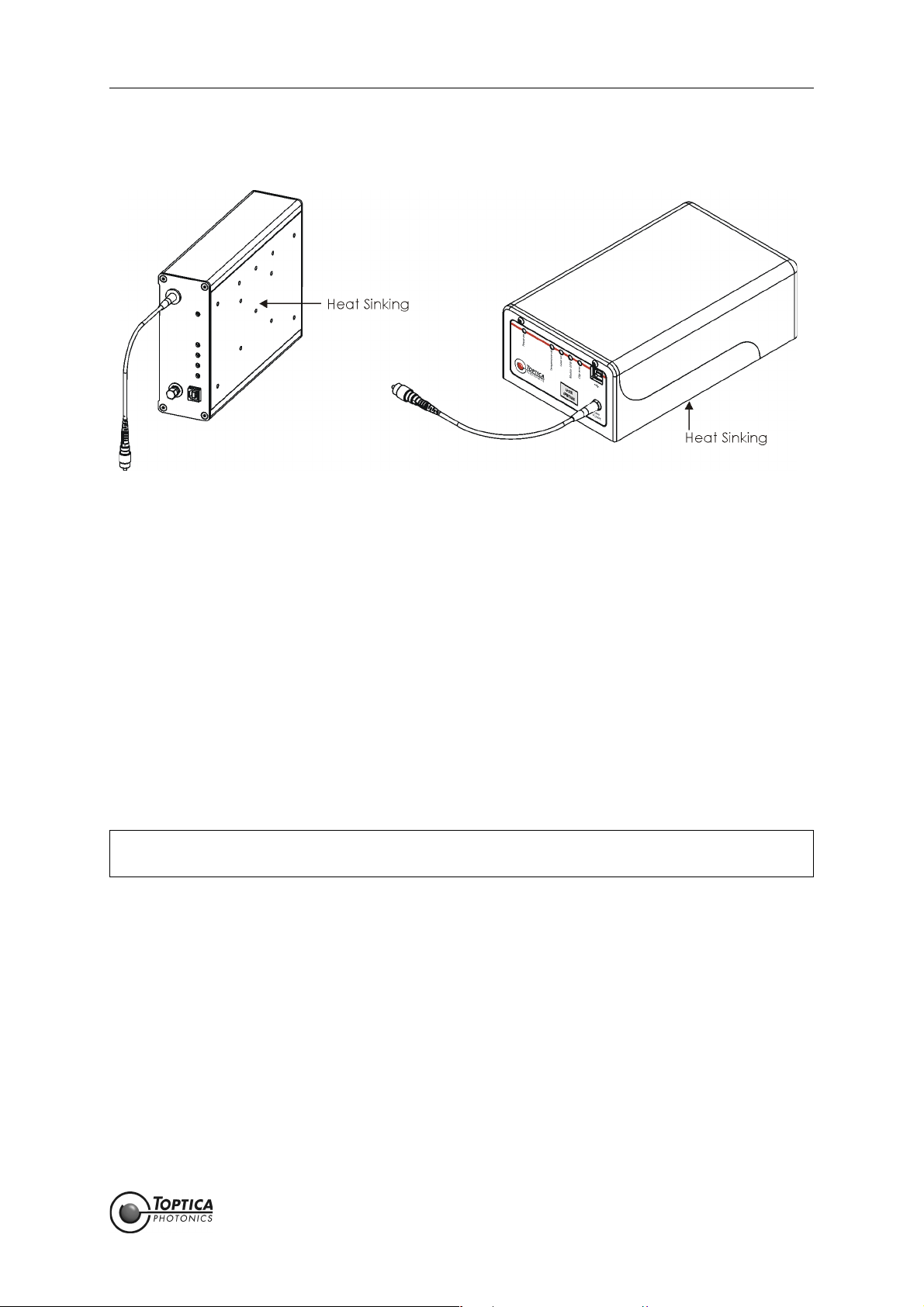

Figure 1 FemtoFiber smart Switch Box

NOTE ! All FemtoFiber smart lasers are principally designed for OEM integration.

For stand-alone operation of a FemtoFiber smart: In order to achieve full accordance with

general and nation-specific laser safety regulations (IEC 60825, CDRH, etc.), it is necessary

to supply a FemtoFiber smart laser with a Switch Box at all time !

1.3.1 USB-Control

All FemtoFiber smart laser heads are equipped with a serial USB interface for remote control of the laser

and to integrate it into software environments.

In order to establish an USB connection a USB cable (max. 2 meters length) and a suitable computer

with a free USB 2.0 port are needed. For further details of the USB-Control please refer to section 4.3.3.

NOTE ! A FemtoFiber smart laser system operated without Switch Box, but instead with 12 V direct

power supply and USB remote control, is officially not approved by T

applications. This combination would circumvent the general laser safety regulations (no

interlock mechanism, no lockable power key-switch etc.). T

such setups.

This note is not valid for OEM integrators.

OPTICA waives all liabilities for

OPTICA for stand-alone

Page 5

Statu s: 6.9.18

FemtoFiber smart Manual 2. Safety Instructions and Warnings

2 Safety Instructions and Warnings

The following Safety Instructions and Warnings should be read and complied with during operation or

maintenance of FemtoFiber smart. Failure to do so could result in damage to FemtoFiber smart or/and

personal injury or death.

2.1 General Safety Terms

FemtoFiber smart is manufactured according to the Laser Safety Standard EN 60825-1:2014 and complies

with US law 21 CFR §1040.10 and §1040.11.

The following safety terms are used in this manual:

The DANGER ! heading in this manual explains hazards that could result in personal injury or death.

The CAUTION ! heading in this manual explains hazards that could damage the instrument.

In addition, a NOTE ! heading gives information to the user that may be beneficial when using the

device.

DANGER ! Before operating the FemtoFiber smart please read this manual carefully to prevent personal

CAUTION ! injury and damage to the device. The following safety instructions must be followed at all

times.

DANGER ! Possibility of electrical shock ! Wherever this symbol is attached, the possibility of an

CAUTION ! electrical shock may appear. Use only equipment and accessories supplied

by T

OPTICA.

Caution ! Wherever this symbol is attached read and understand the manual before

operating the device. The manual must be consulted in order to find out the nature

of the potential HAZARDS and any actions which have to be taken to avoid them.

DANGER ! OEM use of the FemtoFiber smart Laser Source (integration into an end device, operation

CAUTION ! without Switch Box): The operator or designer of the end device is responsible for integration

of a key switch and an interlock circuit to the 12 ± 2 V DC Supply as well as to install redundant laser emission warning lamps, a shutter and to apply the according laser safety labeling

according to the Laser Safety Standard EN 60825-1:2014.

DANGER ! The Laser Driver Electronics (Switch Box) and the Laser Head are both equipped with LEDs

CAUTION ! that indicate laser emission. (Please refer to sections 4.1 and 4.2 in this manual for detailed

information).

Be aware of laser emission when at least one of these LEDs lights up.

Page 6

Statu s: 6.9.18

FemtoFiber smart Manual 2. Safety Instructions and Warnings

DANGER ! During installation, maintenance and service, all persons in the room must wear appropriate

laser safety goggles while the laser is in operation. The recommended protection stage is

dependent on the laser system.

Use appropriate eyewear and other protective means in order to keep radiation exposure

below the maximum permissible levels allowed by applicable regulations (examples: OSHA

limits in the US, BGV B2, BGI5092, TROS Laserstrahlung in Germany).

To determine the protection level of the laser safety goggles required for e.g. FemtoFErb 780

laser system, please refer to the following example: FemtoFErb 780 with collimated beam,

beam diameter 1.6 mm, wavelength = 780 nm, repetition rate 100 MHz, laser power up to 6070 mW generates a peak power density of H

BGI5092 this leads to a required protection level of 780 D LB 4 + M LB 1 for your eyewear.

DANGER ! Laser safety goggles selected for adjustment purposes do not protect against an intention-

ally focused direct beam which will increase the optical power densities by a few orders of

magnitude.

DANGER ! Regular functional checks and performance inspections at the supplier are recommended

for all laser safety goggles.

DANGER ! Do not position the equipment so that it is difficult to operate the disconnecting device.

DANGER ! Use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

~ 0.3 mJ/m² (approximately). From Table 3 in

M

DANGER ! If the equipment is used in a manner not specified by the manufacturer, the protection pro-

vided by the equipment may be impaired.

DANGER ! The FemtoFiber smart uses very powerful lasers (up to class 3B). Therefore, it is imperative to

take great care and observe the statutory warning labels on the unit.

DANGER ! Do not open the device at any time, FemtoFiber smart is a hands-off laser system. Reflections

of the laser beam may cause serious injury to your eyes. Internal tuning as well as the replacing of components may only be carried out by T

OPTICA. Under certain circumstances there

may be dangerous voltages, even if the device is disconnected from the mains supply.

DANGER ! Do not look into the beam from the Laser Output (depending on the version: free beam, FC/

APC connector(s) on front panel or FC/APC connector at the fiber pigtail) as the output can

exceed the limits for class 1 specified by US laws 21 CFR 1040.10 and 2 CFR 1040.11 and the

Laser Safety Standard EN 60825-1:2014. Take precautions to eliminate exposure to a direct or

reflected beam.

DANGER ! FemtoFiber smart may not be operated in surroundings of flammable gases or fumes.

CAUTION ! Special precautions are necessary if FemtoFiber smart is to be operated in surroundings of

high electro-magnetic radiation such as close to a plasma discharge. Please refer to T

OPTICA

for technical support.

CAUTION ! Since the FemtoFiber smart has power levels which may already destroy optical fibers, please

pay special attention to a clean fiber facet at the output fiber connector. We also recommend to always switch-off the laser emission before the fiber connector is opened/closed!

CAUTION ! FemtoFErb 1560 standard version: While starting the laser it may occur that higher level pulses

are sent out by the laser. This transient phenomenon is due to the fact that the amplifier of

the system starts simultaneously with the oscillator. We therefore recommend blocking the

output beam at the moment when the laser is switched on, or adding the THz option.

Page 7

Statu s: 6.9.18

FemtoFiber smart Manual 2. Safety Instructions and Warnings

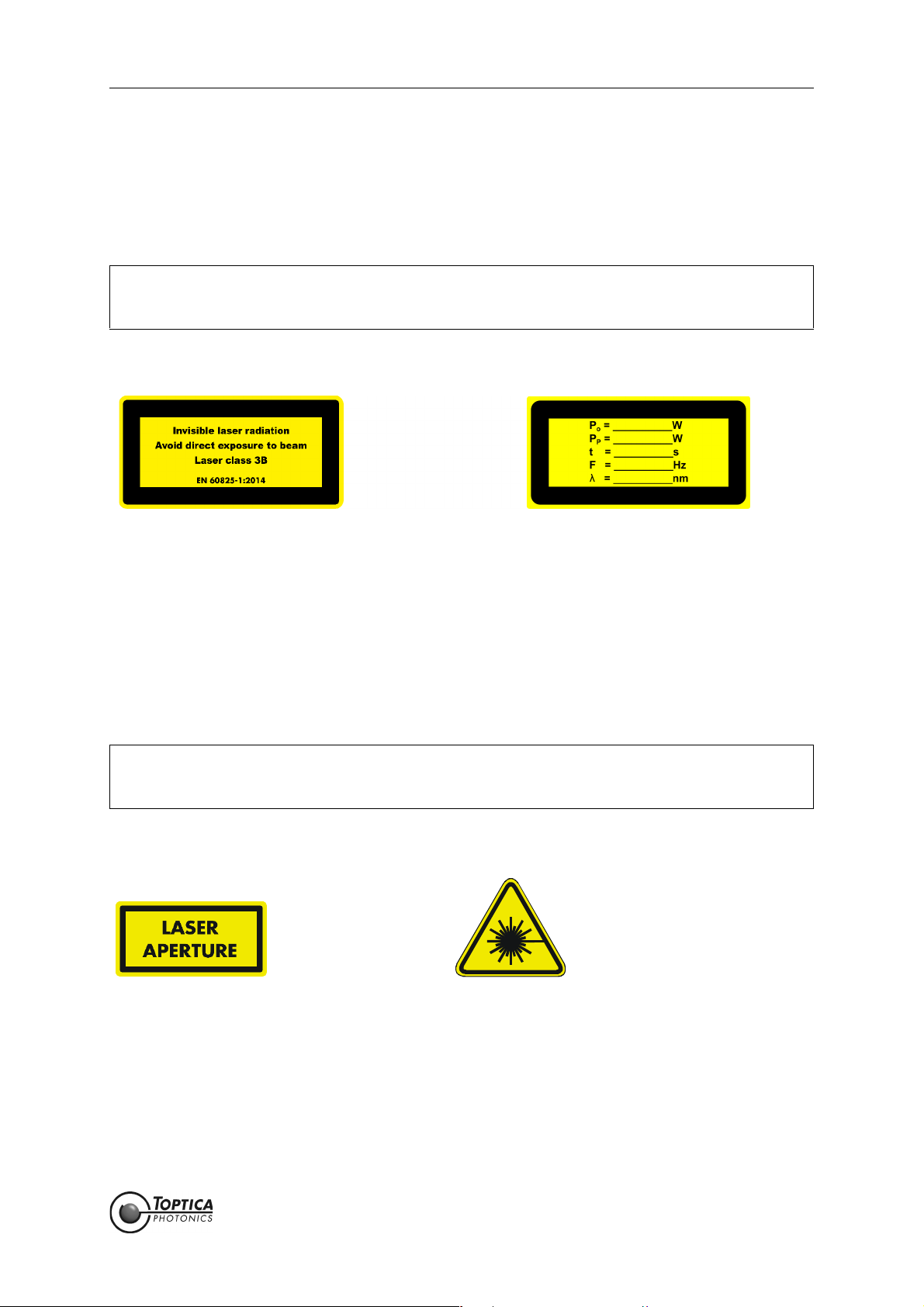

2.2 Safety Labels

2.2.1 Laser Beam

FemtoFiber smart emits invisible pulsed laser radiation of up to 170 mW power. It is classified as Class 3B

product.

DANGER ! FemtoFiber smart emits invisible pulsed laser radiation of up to 170 mW power (Class 3 B

laser product). Avoid exposing eyes and skin to the laser beam, including any laser stray

light !

The following labels are affixed to the outer side of the FemtoFiber smart laser protective housing according to EN 60825-1:2014:

Size: 52 mm x 26 mm

Color: yellow/black

Location: Outer side of the FemtoFiber smart laser protective housing

2.2.2 Apertures

During operation, depending on the individual system, the laser beam is emitted at the laser beam aperture(s), either free beam, from the FC/APC fiber connector at the front panel or from the fiber pigtail.

DANGER ! FemtoFiber smart emits invisible pulsed laser radiation of up to 170 mW power (Class 3B

laser product). Avoid exposing eyes and skin to the laser beam, including any laser stray

light !

The following labels are affixed to the outer side of the FemtoFiber smart laser protective housing next to

the laser beam aperture(s) according to EN 60825-1:2014:

Size: 26 mm x 13 mm Size: 15 mm x 15 mm

Color: Yellow/black Color: Yellow/black

Location: Besides laser beam aperture(s) Location: FemtoFiber smart laser protective

housing

Page 8

Statu s: 6.9.18

FemtoFiber smart Manual 2. Safety Instructions and Warnings

2.2.3 CFR Compliance

Compliance with US laws 21 CFR §1040.10 and §1040.11 is declared by the following label:

Size: 38 mm x 19 mm

Color: silver/black

Location: FemtoFiber smart Laser Head

housing

2.3 Identification of Manufacturer

Manufacturer (name and address), production date, FemtoFiber smart model, serial number, article

number and compliance with CE standards are noted on the identification label:

Size: 38 mm x 19 mm

Color: Silver/black

Location: Outer side of the FemtoFiber smart laser protective housing

Page 9

Statu s: 6.9.18

FemtoFiber smart Manual 2. Safety Instructions and Warnings

2.4 Safety Features

2.4.1 External Interlock

An interlock circuit to connect e.g. a door switch can be set up by using the Interlock Connector on the

Switch Box (for location please refer to Section 4.2). For first operation, a bridged interlock plug is supplied

to close the interlock circuit. For safety reasons the installation of an external interlock circuit is strongly

recommended.

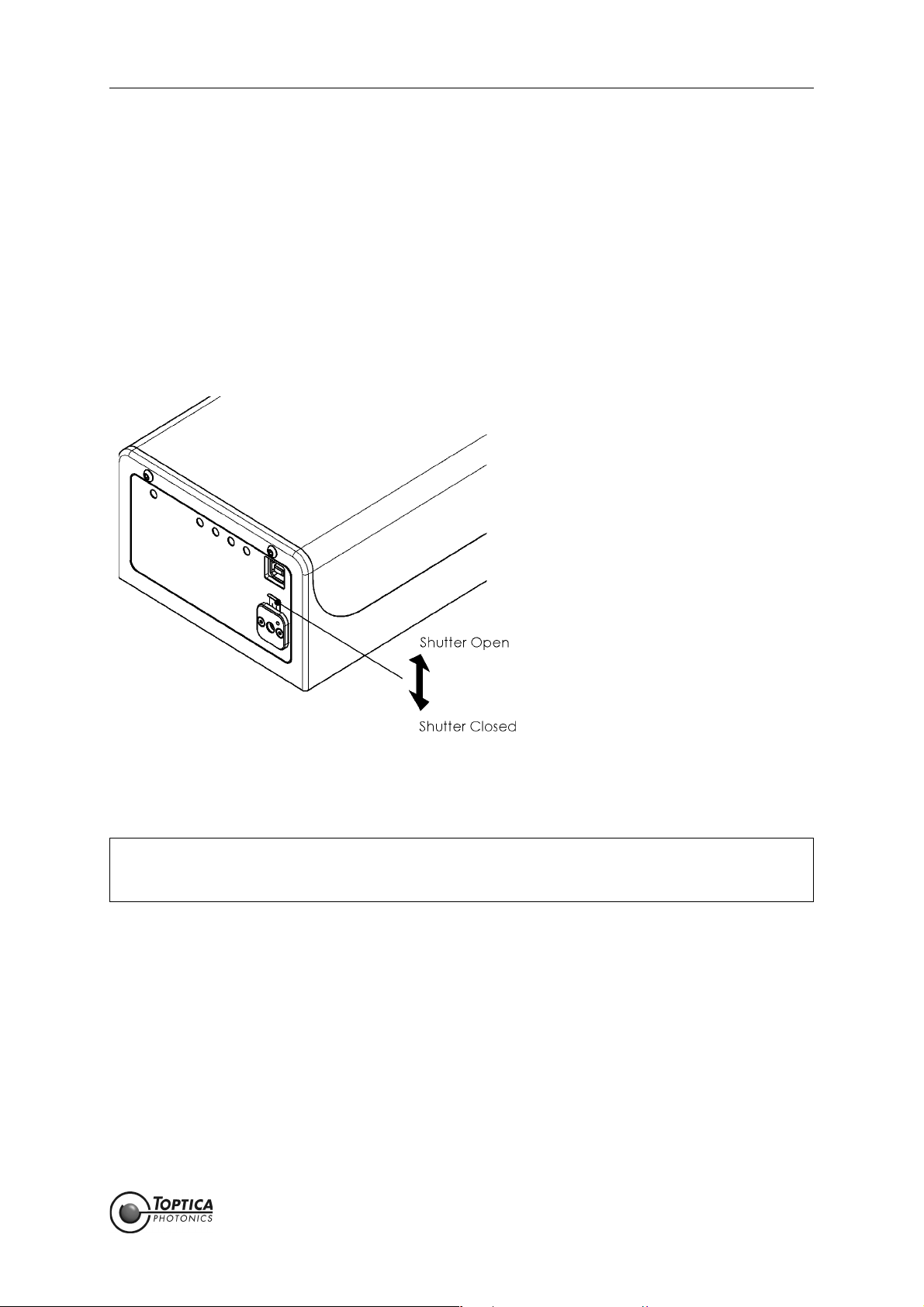

2.4.2 Shutter (Free Beam Version)

Figure 2 FemtoFiber smart shutter operation (only free beam version)

Shift shutter lever up/down as shown in Figure 2 to open/close the laser beam shutter.

NOTE ! When the emission of the FemtoFiber smart laser is switched on with closed shutter, back

reflections from the shutter may disturb the internal photo diode/power regulation. This

may lead to unexpected error messages, but is not harmful to the laser.

2.4.3 Protection Cap on Fiber Pigtail or FC/APC Connector

Due to transport and laser safety, depending on the specification the end of the fiber pigtail at the

FemtoFiber smart or the FC/APC connector is protected by a cap. It must be removed before the first

usage of the laser module.

Page 10

Statu s: 6.9.18

FemtoFiber smart Manual 3. Installation

3 Installation

3.1 Package Contents

Depending on the order, the complete FemtoFiber smart System consists of the following parts:

1 FemtoFiber smart Laser

1 FemtoFiber smart Manual (optional)

1 Production and Quality Control Data Sheet

when ordered with Switch Box (optional):

1Switch Box

1 D-Sub 9 Cable (Switch Box/FemtoFiber smart Laser)

1 FemtoFiber smart Power Supply with mains cable

when ordered wit F

1F

only FemtoFErb 1560 FD6.5

1 Single Mode PM 1560 Fiber with FC/APC connectors on both sides (optional)

IBEROUT FemtoFiber smart IR Fiber Collimator (optional)

IBEROUT option:

Page 11

Statu s: 6.9.18

FemtoFiber smart Manual 3. Installation

3.2 Installation Instructions

Figure 3 FemtoFiber smart laser (Femto/PicoFYb (left), FemtoFErb (right))

When installing the FemtoFiber smart laser the following instructions have to be observed:

• The FemtoFiber smart laser can be installed in any position. The protective housing has M4 threads

for fixing the FemtoFiber smart laser with screws (for main dimensions of the FemtoFiber smart lasers

and the location and depth of the M4 threads please see section 6.10).

• The FemtoFiber smart laser should only be installed at place free from vibrations.

• The FemtoFiber smart laser is designed for indoor usage, at altitudes below 2000 m.

• Environmental operating conditions: +15 °C .. +40 °C, the air humidity may not lead to condensation at or inside the laser housing. For a dew point table please refer to section 6.8.

Environmental transport/storage conditions: 0 °C .. +40 °C, non condensing.

• Weight: < 2.2 kg

• Depending on the individual system, the laser beam emits from the FC/APC connector(s) at the

FemtoFiber smart front panel, from the FC/APC-connector at the end of the fiber pigtail or free

beam. For location of the laser beam apertures please refer to section 6.10.

• For maximum stability, heat sinking of the base plate of the FemtoFiber smart laser to a typical

temperature of 22 ± 2° C is recommended.

Heat Dissipation: FYb laser heads typ. < 10 W, FErb laser heads typ. < 20 W.

CAUTION ! Avoid back reflection of the laser beam above 100 % (caused e.g. by a connected laser

amplifier).

Page 12

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

4Operation

4.1 Operator Controls FemtoFiber smart Laser

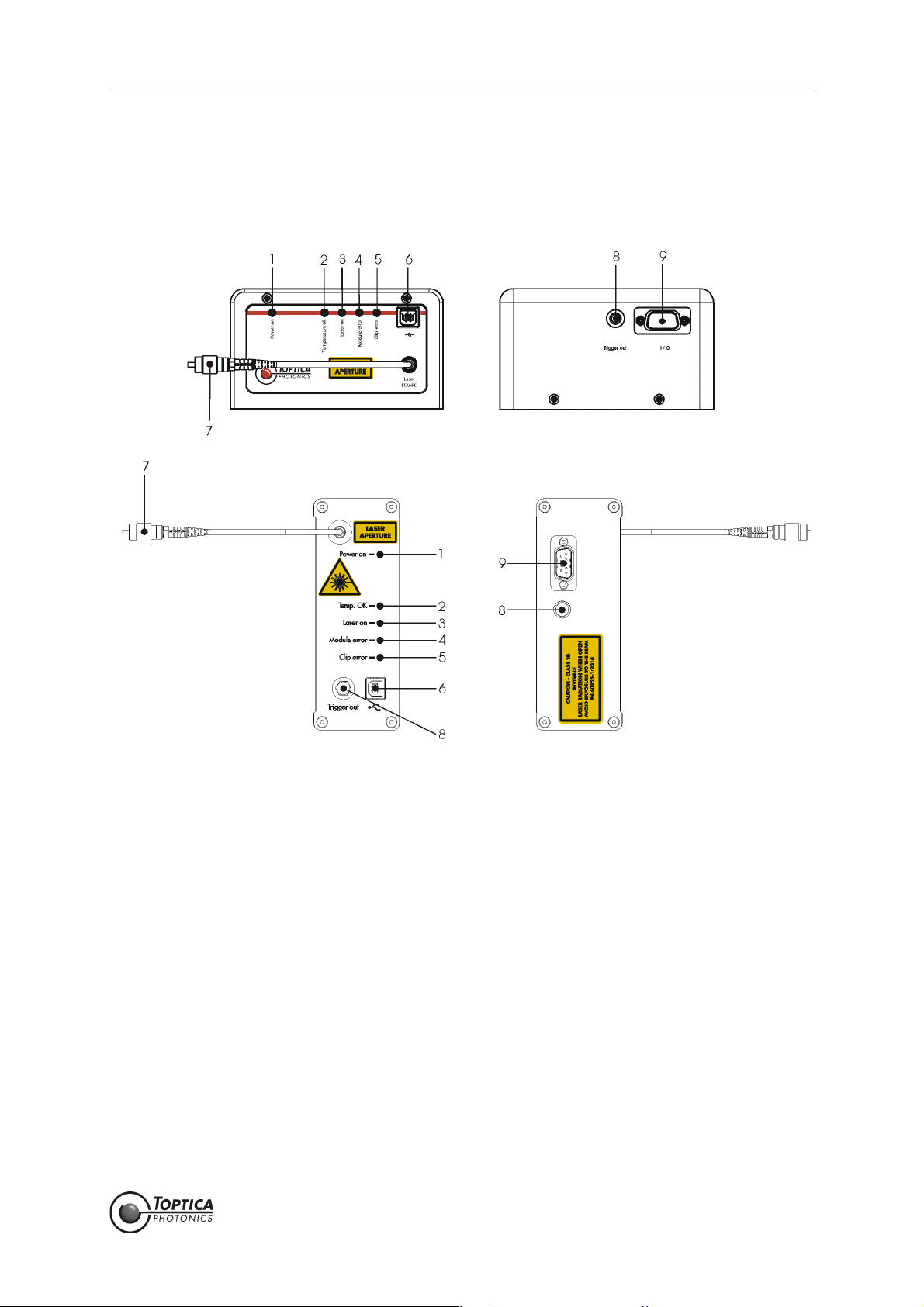

Figure 4 Front and rear panel of FemtoFiber smart laser (FemtoFErb (top), Femto/PicoFYb (bottom))

1 Power ON LED 4 Module Error LED 7 Laser Output

2 Temperature OK LED 5 Clip Error LED 8 Trigger Out

3 Laser ON LED

(Laser Radiation Emission

Warning LED)

6 USB-connector 9 I/O D-Sub 9 Connector

Page 13

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

1 Power ON LED The Power ON LED (blue, 1) lights up when the supply voltage

(12 ± 2 V DC filtered) is applied to the respective pins of the D-Sub 9-connector (9). For pin assignment please see section 6.2.

2 Temperature OK LED The Temperature OK LED (green, 2) lights up after the system is internally

stabilized and ready for operation.

3Laser ON LED

(Laser Radiation

Emission Warning

The Laser ON LED (orange, 3) indicates that the TTL input (Pin 7 of Input/

Output connector (9)) is in state high, i.e. the laser is ON and the laser

beam is emitted from the Laser Output (7).

LED)

DANGER ! When the orange Laser ON LED (Laser Radiation Emission

Warning LED) lights up, one has to be aware of laser emission.

4 Module Error LED The Module Error LED (red, 4) indicates a faulty connection between

Switch Box and laser head or a laser internal error. When the LED (4) lights

up continuously, please contact T

OPTICA.

5 Clip Error LED The Clip Error LED (yellow, 5) indicates that the laser did not start to oper-

ate after the TTL input (Pin 7 of Input/Output connector (9)) was set to

state high. When the LED (5) lights up continuously, please contact T

TICA.

OP-

6 USB-connector USB output connector type B for computer connection and control via

terminal program.

7 Laser Output FemtoFErb 780 Free beam laser output with mechanical shutter.

PicoFYb 1030/1064 FC/APC connector with connector tolerance for

FemtoFYb 1030 polarization maintaining fibers (narrow key,

2.02 mm)

FemtoFErb SC

FemtoFErb 1560 FD6.5 One FC/APC connector with connector tolerance

for polarization maintaining fibers (narrow key,

2.02 mm).

8Trigger Output

• SMA-connector

9 Input/Output

•D-Sub 9-connector

FemtoFErb 1560 Fiber pigtail (approx 20 cm long) with 3 mm cevlar

reinforced tubing and FC/APC-connector at the

end.

Output synchronous to the laser pulses for monitoring or triggering purposes (please refer to the Production and Quality Control Data Sheet for

signal properties).

NOTE ! FemtoFErb systems are using the direct output of a photo

diode as Trigger signal. There is no further (amplifying) electronics in order not to increase the signal jitter. Hence the

amplitudes of the signal are low, in the range of a few tens of

millivolts by nature. Please refer to the Production and Quality

Control Data Sheet for individual values.

General I/O connector for FemtoFiber smart operation. For pin assignment

please see section 6.2.

Page 14

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

4.2 Operator Controls FemtoFiber smart Switch Box

Figure 5 Front and rear panel of FemtoFiber smart Switch Box

10 ON/OFF Switch 15 Power LED 21 Laser Power Input

11 Main Power Key Switch 16 FemtoFiber smart Supply LED 22 FemtoFiber smart Connector

12 Laser ON Push Button 17 FemtoFiber smart Error LED 23 Power Supply Connector

13 Micro Mover Push Button 18 Laser ON LED

(Laser Radiation Emission

Warning LED)

14 Pump Laser Power 19 Micro Mover LED 25 Interlock Connector

Adjustment 20 Power Monitor Output

24 Laser ON Input

Page 15

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

10 ON/OFF Switch FemtoFiber smart Switch Box voltage supply and laser voltage supply are

switched ON/OFF by switch (10).

11 Main Power Key

General Switch for Switch Box voltage supply.

Switch

12 Laser ON Push Button Push button switches laser emission ON/OFF. Laser emission is indicated by

the Laser ON LED (18).

13 Micro Mover Push

Button

FYb Systems: When the laser does not start after the Laser ON Push But-

ton (12) has been pressed (i.e. the Clip Error LED (5) lights

up), the mirror chip inside the laser head can be moved

slightly by pressing the push button (13) twice.

Please note that the mirror chip can only be moved with

the laser emission switched off.

FErb Systems: Not supported.

14 Pump Laser Power

Adjustment

FErb Systems: Adjustment of the pump diode current from 90 % to 110 %

of the nominal pump diode current.

The zero position on the dial is equal to 90 %, while position 10 is equal to 110 %. The pump laser current adjustment can be used for fine tuning of the pulse

characteristics.

NOTE ! For normal operation, please leave the trimpot in mid position

(5 = 100 %) ! The system is checked and certified only for trimpot position 5. T

OPTICA Photonics AG does not guarantee that

the specifications of the laser are met at all other trimpot settings. Please refer to the Production and Quality Control Test

Data Sheet for specified values

FYb Systems: Adjustment of the pump diode current from 90 % to 100 %

of the nominal pump diode current.

The zero position on the dial is equal to 90 %, while position 10 is equal to 100 %. The pump laser current adjustment can be used for fine tuning of the pulse

characteristics.

NOTE ! For normal operation, please leave the trimpot in end position

(10 = 100 %) ! The system is checked and certified only for trimpot position 10. T

OPTICA Photonics AG does not guarantee that

the specifications of the laser are met at all other trimpot settings. Please refer to the Production and Quality Control Test

Data Sheet for specified values

15 Power LED This green LED indicates proper voltage supply of the Switch Box.

16 Supply LED The Supply LED (blue, 16) lights up when the supply voltage is applied to

the FemtoFiber smart laser.

17 Error LED The Error LED (red, 17) indicates a faulty connection between Switch Box

and laser head or a laser internal error. When the LED (17) lights up contin-

18 Laser ON LED

(Laser Radiation

uously, please contact T

The Laser ON LED (orange, 18) indicates that the laser is ON and the laser

beam is emitted from the Laser Output (7).

OPTICA.

Emission Warning

LED)

DANGER ! When the orange Laser ON LED (Laser Radiation Emission

Warning LED) lights up, one has to be aware of laser emission.

Page 16

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

19 Micro Mover LED FYb Systems: The Micro Mover LED (19) lights up after one push at the

Micro Mover Push Button (13) and goes off after the second push, when the mirror chip has been moved.

FErb Systems: Not supported.

20 Power Monitor Output

• SMA-connector

21 Laser Power Input

• SMA-connector

22 FemtoFiber smart

Connector

•D-Sub 9-connector

23 Power Supply

Connector

24 Laser ON Input

• Tyco AMP 828549

connector

Oscillator Power Monitoring, Output Voltage 0 .. 4.5 V for 0 .. 100 %

(does not represent the laser output power exactly)

Input for Analog Laser Power Control (for details please refer to section

6.3).

FErb Systems: 0..5mA via R=1kΩ, Range 90 - 110 % additional to the

Pump Laser Power Adjustment (14).

FYb Systems: 0..5mA via R=1kΩ, Range 90 - 100 % additional to the

Pump Laser Power Adjustment (14).

NOTE ! When the laser power is controlled via the Laser Power Input

(21), the Pump Laser Power Adjustment potentiometer (14)

should be turned to min. position to avoid interference

between the two controls.

Connection to the FemtoFiber smart laser.

Connection to the FemtoFiber smart Power Supply.

For pin assignment please refer to section 6.5.

Input to switch laser emission ON/OFF.

TTL high (+ 3.3 V..+ 5 V) Laser ON, TTL low (0 V..+ 0.8 V) Laser OFF.

Laser emission is indicated by the Laser ON LED (18).

For pin assignment please refer to section 6.4.

25 Interlock Connector

• Phoenix MC0.5/2-G-

2.5 connector

Connector for installation of an external interlock circuit. For first operation,

an interlock plug is supplied to close the interlock circuit. For safety reasons, the installation of an external interlock circuit is strongly recommended.

Page 17

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

4.3 FemtoFiber smart System Quickstart

CAUTION ! Since the FemtoFiber smart has power levels which may already destroy optical fibers,

please pay special attention to a clean fiber facet at the output fiber connector. We also

recommend to always switch-off the laser emission before the fiber connector is opened/

closed!

CAUTION ! While starting the laser it may occur that higher level pulses are sent out by the laser. This

transient phenomenon is due to the fact that the amplifier of the system starts simultaneously with the oscillator. We therefore recommend blocking the output beam at the

moment when the laser is switched on, or adding the THz option.

NOTE ! The FemtoFiber smart is specified to be ready for operation within 15 seconds after switch-

on, provided that the laser emission start signal is given right after the boot-up sequence,

which takes approx. 3 seconds. The end of the boot-up sequence is indicated at the laser

head when the Power ON LED (1, blue) and the Temperature OK LED (2, green) light up

(all other LEDs are off).

If laser emission is activated before reaching this state, an error may occur, indicated by

the Clip Error LED (3, yellow) or Module Error LED (4, red).

4.3.1 OEM Integrated Environment

1. Connect the FemtoFiber smart laser to the application via the I/O connector (9). For pin assign-

ment please see section 6.2.

2. Connect the FemtoFiber smart laser Output FC/APC connector (7) to the application.

3. When the FemtoFiber smart laser supply voltage (pin 1 of the I/O connector (9)) is applied and the

TTL input (pin 7 of the I/O connector (9)) is in state high, the laser emission is ON.

Page 18

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

4.3.2 Manual Operation via Switch Box

NOTE ! For Switch Box operator controls please refer to section 4.2.

1. Unpack all system items.

Systems with fixed fiber: Remove the protection cap from the fiber pigtail and plug in the FC/APC

connector into the receptacle of the application, optionally to the F

orientated parallel to the slow axis of the fiber.

Systems with FC/APC fiber connector: Use the supplied fiber to connect the FemtoFiber smart to

the application. Remove the protection caps from both ends of the fiber. Connect the fiber to the

FC/APC connector of the FemtoFiber smart laser and to the receptacle of the application, optionally to the F

IBEROUT. The connector key is orientated parallel to the slow axis of the fiber.

Systems with free beam laser output: Make sure the laser beam shutter is closed for safety reasons

(please refer to section 2.4.2).

2. Connect the FemtoFiber smart laser to the Switch Box via the D-Sub 9 cable and fix it with the

screws.

3. Make sure that the Main Power Key switch (11) is in OFF position. Connect the power supply to the

Switch Box and to mains.

IBEROUT. The connector key is

4. Remove the protection cap from the Trigger Output (8) and connect to the trigger input of the

application (if necessary).

5. Turn the Main Power Key switch (11) into position ON.

6. Set the Pump Laser Power Adjustment potentiometer (14) on the Switch Box to position 10 (FYb

systems), respectively 5 (FErb systems).

7. Switch ON the FemtoFiber smart system with the ON/OFF Switch (10) and wait until the green Temperature OK LED (2) on the FemtoFiber smart laser head lights up.

8. To enable the laser emission, press the Laser ON Push Button (12). The Laser On LED (18) will light up

and laser light is emitted. The FemtoFiber smart laser can be operated via the operator controls at

the Switch Box (see section 4.2).

Systems with free beam laser output: Open the laser beam shutter (please refer to section 2.4.2).

When the laser is disabled, close the laser beam shutter for safety reasons.

NOTE ! When the emission of the FemtoFiber smart laser is switched on with closed shutter, back

reflections from the shutter may disturb the internal photo diode/power regulation. This

may lead to unexpected error messages, but is not harmful to the laser.

Page 19

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

4.3.3 FemtoFiber smart Operation via Software Commands

4.3.3.1 Installation of USB Connection

NOTE ! For Switch Box operator controls please refer to section 4.2.

In order to connect a FemtoFiber smart to a computer for the first time, please follow the instructions

noted below for the initial installation:

1. Switch ON the computer.

2. Switch ON the FemtoFiber smart.

Switch Box: Switches (10) and (11) in position ON.

OEM: I/O connector (9) connected, 12 ± 2 V DC applied at pin 1

3. Connect the USB cable to the USB-connector (6) on the FemtoFiber smart first and then connect it

to the computer (Windows 7 or higher required).

4. Please install the USB driver as described in section 6.7.

5. Open a terminal program and select a serial connection with the following settings:

Baud rate 9600

8 bits

no parity

1 stop bit

no hardware handshake

The COM port for communication with the FemtoFiber smart is usually the newest added USB Serial

Port or the one with highest COM port number.

6. Switch the laser OFF and ON.

Switch Box: Switch (10) in position OFF and ON.

OEM: I/O connector (9) connected, 12 ± 2 V DC at pin 1 removed and applied.

You should see a prompt appearing at the terminal window which includes the current firmware

number.

Example:

FemtoFErb 2.0.87>

After the USB connection is installed and works properly, the laser can be remote controlled. For a command list, please refer to section 4.3.3.2.

DANGER ! When the FemtoFiber smart is remote controlled via software commands, the Laser ON LED

on the Switch Box does not show the actual status of the laser !

NOTE ! As per default after start-up, the FemtoFiber smart can only be controlled by the hardware

input lines (D-Sub-9 connector), i.e. via Switch Box.

To control a FemtoFiber smart via software commands, the hardware input lines (i.e.

Switch Box operation), have to be disabled by the corresponding command (please see

section 4.3.3.2). It is not possible to control the laser in both ways at the same time, either

hardware (D-Sub-9) or software (USB) control is possible.

NOTE ! After switching off the FemtoFiber smart power supply, all settings will be lost, i.e. the laser is

in hardware control mode again as per default.

Page 20

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

4.3.3.2 Commands for Remote Control

NOTE ! The syntax must include all shown characters and symbols (brackets, apostrophes, !, #, ...)

Mode W = write, Mode R = read.

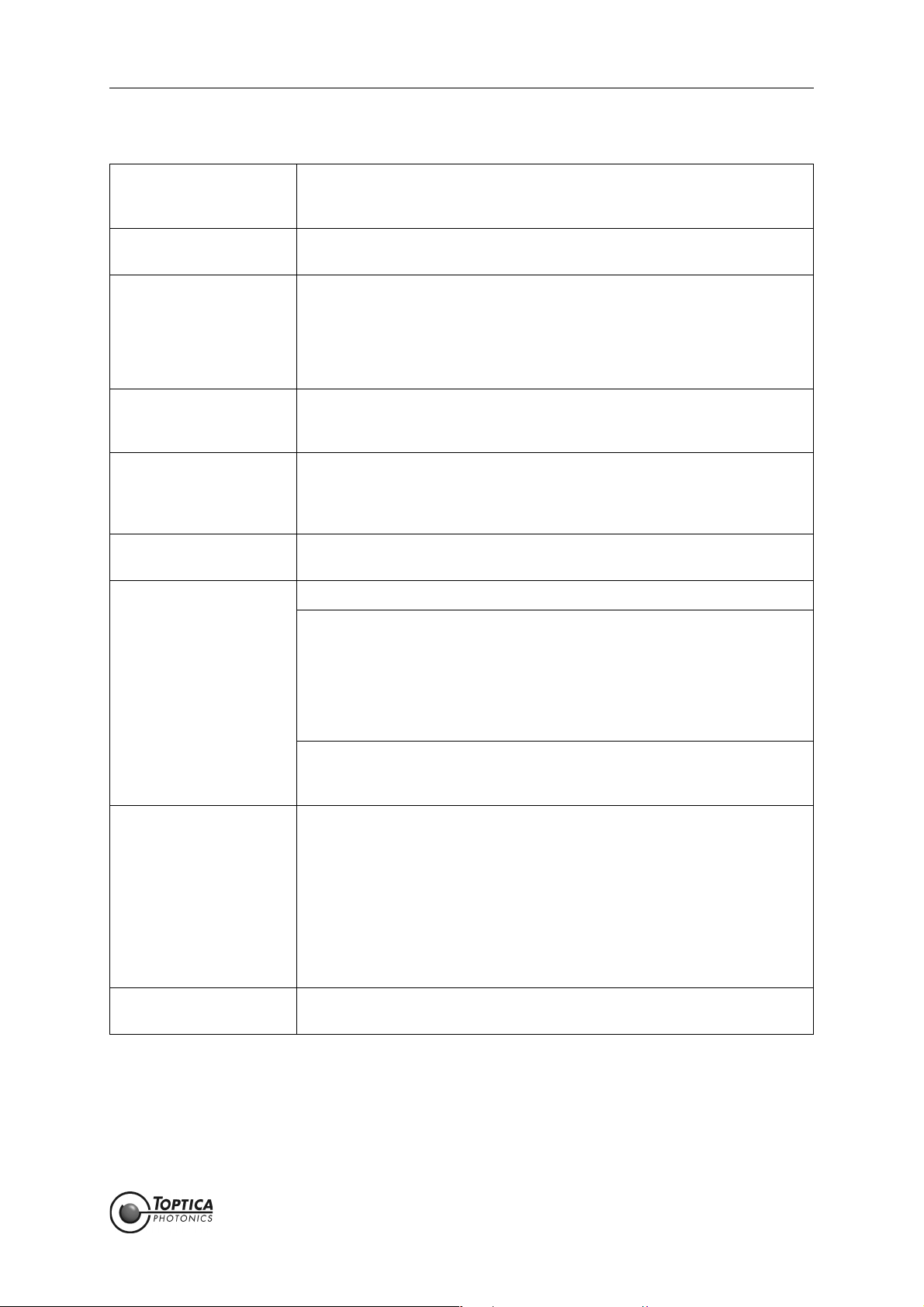

Command/Parameter Syntax Return Type Mode Description

(param-set! 'hw-input-dis #t) BOOLEAN W Enable remote control

(#t: true, #f: false)

(param-ref 'hw-input-dis) BOOLEAN R Remote control status

#t: write commands will be executed

#f: write commands disabled

(param-set! 'laser:en #t) BOOLEAN W Switch ON/OFF laser

(param-ref 'laser:en) BOOLEAN R Laser ON/OFF status

(param-ref 'laser:i) INTEGER R Laser current in Milliampere (mA)

(param-ref 'laser:pd-i) INTEGER R Photodiode monitor level in arb. units

(param-ref 'tec1:temp) INTEGER R Pump diode TEC temperature in 0.1

celsius degrees (°C).

(param-set! 'poti-pos xxxx) INTEGER W Set output power (0..1000)

(param-ref 'poti-pos) INTEGER R Output power (0..1000) corresponds

to:

0 > Switch Box Trimpot Position 0

1000 > Switch Box Trimpot Position

10.00

NOTE ! The system is checked

and certified only for

100 % nominal output

power. This is equal to

Switch Box Trimpot position 5 (FErb systems), or

10 (FYb systems). Please

refer to the Production

and Quality Control Test

Data Sheet for specified

values.

T

OPTICA Photonics AG

does not guarantee that

the specifications of the

laser are met at all other

trimpot settings

(param-set! 'powercontrol:en #t) BOOLEAN W Enable power control loop

Page 21

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

(param-ref 'powercontrol:en) BOOLEAN R Power control loop status

#t: Poti controls power value

#f: Poti controls current value

(param-ref 'laseron:time) STRING R Laser operation time in Seconds (s)

(param-ref 'laseron:cycles) STRING R Counter of "laser on" operations

(param-ref 'laseron.uptime) STRING R "Power-on" time in Seconds (s)

(param-ref 'serial-number) STRING R Readout of serial number

(param-ref 'system-type) STRING R Returns a string containing the

device type

(param-ref 'system-model) STRING R Returns a string describing the hard-

ware setup device

(param-ref 'fw-ver) STRING R Returns firmware number

(param-ref 'status) INTEGER R Status parameter bit code

bit 0 - Current error

bit 1 - Low voltage error

bit 2 - Laser current clip active

bit 3 - TEC1 error

bit 4 - Control loop overflow error

bit 5 - Modelock error

bit 6 - QML error

bit 7 - TEC 2 error

bit 8 - EEPROM error</description>

Page 22

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

4.3.4 FemtoFiber smart Operation with Graphical User Interface

4.3.5 System Requirements

Control computer with Windows operating system, up to Windows 10.

4.3.5.1 Installation of TOPAS FemtoFiber smart

NOTE ! You will need to have administrator rights to run the setup. If you don't have logged in with

such rights, you will need to logon as such first. As an alternative, you may also run

setup.exe under a different user while using right-mouse-click and select "run as..."

The following installation procedure is described with Windows 7/8, other operation systems may show different windows. In this case, please follow the steps accordingly.

For TOPAS FemtoFiber smart installation, please insert the supplied USB flash drive to the control computer

and start the installer (TOPAS FemtoFiber smart.exe). The installer will guide you through the installation

process.

Figure 6 TOPAS FemtoFiber smart installation

Start the installation by clicking Next and confirm the license agreement by clicking IAgree.

Figure 7 TOPAS FemtoFiber smart installation

Page 23

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

Select the folder where TOPAS FemtoFiber smart will be installed. Click Next to continue to the following

window.

In your software version, all components of TOPAS FemtoFiber smart will be installed. In the next window (Figure 7 right) you may choose the name of a program folder in the start menu. Click Install to continue.

Figure 8 TOPAS FemtoFiber smart installation

After the installation is completed, click Finish to close the TOPAS FemtoFiber smart installer.

Page 24

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

4.3.5.2 FemtoFiber smart Operation with TOPAS FemtoFiber smart

NOTE ! Please refer to section 4.1 for a detailed description of the operator controls on the

FemtoFiber smart front and rear panel and to section 5 for a detailed description of the

TOPAS FemtoFiber smart graphical user interface (GUI).

1. Connect the FemtoFiber smart to your OEM environment (see section 4.3.1) or to the Switch Box

(see section 4.3.2).

Connect the USB-connector on the FemtoFiber smart front panel with a USB connector of your PC

by using the supplied USB cable. Switch ON the FemtoFiber smart laser at the Switch Box.

NOTE ! When no USB serial port is detected, please check whether a FTDI driver is installed on the

computer. Verified FTDI drivers can be downloaded from the product pages on the T

TICA website.

2. Start TOPAS FemtoFiber smart.

3. Select Menu > Connection Settings

OP-

Figure 9 TOPAS FemtoFiber smart menu

To be continued on the next page.

Page 25

Statu s: 6.9.18

FemtoFiber smart Manual 4. Operation

Figure 10 TOPAS FemtoFiber smart Connection Settings window

4. In the Connection Settings window, select the USB Serial Port to which the device is connected.

Baudrate and Settings are preset and fixed for FemtoFiber smart operation. Click OK to save the

settings and to close the window.

NOTE ! If there is no USB serial port found in the TOPAS FemtoFiber smart list of available lasers -

although the laser is properly connected, switched on and ready to work, it probably

helps to try one of the following solutions:

1) Try to run TOPAS FemtoFiber smart in "XP compatibility mode" (right click on the TOPAS

icon > properties > compatibility). This feature is forcing Windows to emulate XP conditions

and may solve port access issues.

2) Try a "right-mouse-click" on the TOPAS icon and select "run as administrator". Independently from the individual user rights of the computer, TOPAS FemtoFiber smart is run under

administrator rights, without needing to have a password.

3) The USB cable is probably too long or the outputs at the USB port of the computer are

very low. The first problem may appear when the USB-cable is longer than 2 meters. The

second one often appears when a laptop or a tablet computer is used. In both cases, the

signal gets too weak at receiver's side and the communication may be disrupted. In our

experience, establishing the first connection is usually still possible, but in some cases

exchanged commands get lost and either GUI or laser are not operating properly. Do not

use a USB cable longer than the factory supplied one. Alternatively you can try to use a

powered USB hub with an external power supply.

5. Select Menu > Connect to establish a connection to the device.

6. The laser can now be operated with the Controls of the GUI (see section 5).

Page 26

Statu s: 6.9.18

FemtoFiber smart Manual 5. TOPAS FemtoFiber smart Control Software

5 TOPAS FemtoFiber smart Control Software

In this section all controls of the TOPAS FemtoFiber smart graphical user interface (GUI) are described in

detail.

5.1 Upper and Lower Screen Section

5.1.1 Header

Figure 11 TOPAS FemtoFiber smart header

Menu Please refer to section 5.1.3.

Help Please refer to section 5.1.4.

Connected Device Displays the connected device and its serial number.

Laser Warning Label The laser warning label appears when laser light is emitted by the

connected device (please refer to section 5.2).

Indicators The five indicators on top to the right correspond to the LEDs on the

FemtoFiber smart front panel (please refer to section 4.1).

5.1.2 Footer

Figure 12 TOPAS FemtoFiber smart footer

Connection: Displays the connection currently used for communication with the

device.

Device Communication: Bright green: Communication.

Dark green: No communication.

Page 27

Statu s: 6.9.18

FemtoFiber smart Manual 5. TOPAS FemtoFiber smart Control Software

5.1.3 Menu

Figure 13 TOPAS FemtoFiber smart menu

Menu > Connect Establishes a connection to the device selected in the Connection

Settings window.

Page 28

Statu s: 6.9.18

FemtoFiber smart Manual 5. TOPAS FemtoFiber smart Control Software

Menu > Connection Settings The Connection Settings window opens where the connection can

be configured.

Figure 14 TOPAS FemtoFiber smart Connection Settings Window

Serial Port Select the USB Serial Port where the device is connected to.

Baudrate The Baudrate is fixed to 9600 for FemtoFiber smart operation.

Settings The Settings for the communication are preset and fixed for

FemtoFiber smart operation.

Test Connection Clicking opens a window where details on the connected device

are shown.

Connect on Startup When checked, the connection saved by clicking OK is automati-

cally established at the next software start.

Search not active

Display Identification/Address not active

OK Saves the settings and closes the window.

Cancel Closes the window.

Menu > Disconnect Closes the connection to the device.

Page 29

Statu s: 6.9.18

FemtoFiber smart Manual 5. TOPAS FemtoFiber smart Control Software

Menu > Firmware Update Opens the Firmware Update window.

Figure 15 TOPAS FemtoFiber smart Firmware Update window

NOTE ! Please refer to section 6.6 for a detailed description of the firmware update procedure.

Serial Port Displays the USB Serial Port where the device is connected to.

Select Choose the firmware file (*.elf) to be installed. The selected firmware

file is displayed in the display field.

Start Starts the firmware update.

Abort Aborts the firmware update.

Log window Displays details on the process of the firmware update.

Close Closes the Firmware Update window.

Page 30

Statu s: 6.9.18

FemtoFiber smart Manual 5. TOPAS FemtoFiber smart Control Software

Menu > Log Adds the Log window to the bottom section of the screen.

Menu > Communication Adds the Communication window to the bottom section of the

screen.

NOTE ! When you display Log and Communication windows at the same time, you can display

one window at full size in the front for better viewing. Do this by picking the window at the

title bar and pulling it in the center of the screen area.

Each display window may also be moved to any screen position when picked at the title

bar.

Figure 16 TOPAS FemtoFiber smart Log and Communication window

Log Window The Log Window shows TOPAS FemtoFiber smart internal debug mes-

sages.

Loglevel Selection of the Loglevel displayed in the Log Window

Error Only Error messages are displayed.

Warning Error and Warning messages are displayed.

Info Error and Warning messages as well as additional

detailed information on the system operation are displayed.

Save Log The currently displayed log is saved.

Communications Window The Communications Window shows the communication between

TOPAS FemtoFiber smart and the FemtoFiber smart.

Show Monitoring Line/ Click to toggle between display of communication on the

Show Command Line monitoring or the command line.

NOTE ! Communication on monitoring line is not active with FemtoFiber smart lasers.

Hold Freezes the display of the communication. Click Hold again to con-

tinue the display.

Monitoring Line/ Display area for communication between TOPAS FemtoFiber smart

Command Line and the FemtoFiber smart.

Menu > About The About window opens, which provides information about the

manufacturer, contact details, software version, etc.

Menu > Exit Closes the TOPAS FemtoFiber smart software.

5.1.4 Help

Clicking opens a pdf version of the FemtoFiber smart manual.

Page 31

Statu s: 6.9.18

FemtoFiber smart Manual 5. TOPAS FemtoFiber smart Control Software

5.2 Control Section

Figure 17 TOPAS FemtoFiber smart controls (FErb system shown)

Emission Indicates and controls the emission of the laser.

Indicator OFF: No laser emission.

Indicator green: Laser emission is turned on.

Click the Emission button to toggle the emission state.

Hardware Disable Click the Hardware Disable button to toggle between GUI operation

(hardware disabled) or e.g. Switch Box operation of the FemtoFiber

smart. At software start, by default the button is set to hardware disabled.

When hardware is disabled, the Switch Box display and control elements are not active.

DANGER ! When the FemtoFiber smart is remote controlled via TOPAS FemtoFiber smart, the Laser ON

LED on the Switch Box does not show the actual status of the laser !

Page 32

Statu s: 6.9.18

FemtoFiber smart Manual 5. TOPAS FemtoFiber smart Control Software

Switchbox Trimpot Position Enter a number or move the slider to change the laser power similar

to a Laser Power trimpot adjustment on the Switch Box .

The adjustment can be used for fine tuning of the pulse characteristics.

NOTE ! The position of the Laser Power trimpot on the Switch Box is read out and displayed when

the FemtoFiber smart is connected (Menu > Connect) to the TOPAS FemtoFiber smart software. Small deviations due to component tolerances are possible.

NOTE ! The system is checked and certified only for 100 % nominal output power. This is equal to

Switch Box Trimpot position 5 (FErb systems), or 10 (FYb systems). Please refer to the Production and Quality Control Test Data Sheet for specified values.

T

OPTICA Photonics AG does not guarantee that the specifications of the laser are met at all

other trimpot settings

5.2.1 System Info Tab

The System Info section (see Figure 17) provides detailed information on the FemtoFiber smart system setup.

System Info Section

Temperatures

Pump Diode (°C) Displays the temperature of the pump diode.

System Status

Laser on Time (h) Displays the accumulated time where laser light was emitted.

Uptime (h) Displays the accumulated system uptime.

Start Counter Displays the number of emission ON cycles.

Firmware Version Displays the current firmware version.

Power Consumption Displays the internal power consumption index.

Page 33

Statu s: 6.9.18

FemtoFiber smart Manual 5. TOPAS FemtoFiber smart Control Software

5.2.2 Micro Mover Tab (only FYb Systems)

Figure 18 TOPAS FemtoFiber smart Micro Mover tab (only FYb systems)

Display The current spot position is shown with a yellow background.

Spot Runtime (h) Displays the accumulated operating time on the respective spot

position.

Laser Starts Displays the number of emission ON cycles on the respective spot

position.

Move one step A dialog windows opens. Select Execute to move the SAM to the

next spot position by the micro mover.

NOTE ! Moving the SAM to the next spot position is only possible with the laser emission switched

off !

Refresh The content of the display is refreshed.

Current Position Displays the current spot position.

Page 34

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6Appendix

6.1 Specifications

For current specifications of the FemtoFiber smart systems please refer to the TOPTICA website and to the

Production and Quality Control Data Sheet.

6.2 Pin Assignment D-Sub 9 Input/Output Connector

Figure 19 Input/output D-Sub 9 connector at FemtoFiber smart laser rear panel

Pin 1 12 ± 2 V DC filtered (supply)

Pin 2 GND (TTL)

Pin 3 TTL signal micro mover (optional)

Pin 4 GND (analog)

Pin 5 Analog Laser Power Control, Range 90 - 110 % (please refer to section 6.3 for details)

Pin 6 GND (supply)

Pin 7 TTL high (+ 2 V..+ 5 V) Laser ON, TTL low (0 V..+ 0.8 V) Laser OFF

Pin 8 Error low = error (monitor signal e.g. for external control)

Pin 9 Oscillator Power Monitoring, Output Voltage 0 .. 4.5 V for 0 .. 100 %

(does not represent the laser output power exactly)

Page 35

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.3 Operation without Switch Box (Control via TTL/Analog Pins)

If a FemtoFiber smart laser head is operated without Switch Box, the Pump Laser Power Adjustment trimpot setting has to be replaced by the Analog Laser Power Control applied to pin 5 of the Input/Output DSub 9 connector.

NOTE ! This information is not valid for OEM integrators intending to use USB control and not TTL/

analog signals to control the laser.

FErb Systems: All FErb laser heads are specified at 100 % laser power with trimpot setting 5/mid position.

To be within specification, 100 % laser power has to be adjusted by an external laser

power control circuit when the Switch Box is not used.

FYb Systems: All FYb laser heads are specified at 100 % laser power with trimpot setting 10/end posi-

tion. To be within specification, 100 % laser power has to be adjusted by an external laser

power control circuit when the Switch Box is not used.

Figure 20 Setup for FemtoFiber smart operation without Switch Box

Examples for Analog Laser Power Control voltages applied to pin 5 of the Input/Output D-Sub 9 connector and the corresponding laser power are noted in the table below:

FErb System

Laser Power

90 % 90 %

100 % 95 %

110 % 100 %

FYb System

Laser Power

R ext = 1 kΩ R ext = 0

0V 0V

5V 2.5V

10 V 5 V

Page 36

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.4 Pin Assignment of Laser On Input Connector (Switch Box)

Figure 21 Tyco AMP 828549 connector

Pin 1: TTL high (+ 3.3 V..+ 5 V) Laser ON, TTL low (0 V..+ 0.8 V) Laser OFF

Pin 2: GND

6.5 Pin Assignment of Power Supply Connector (Switch Box)

Figure 22 Power supply connector

Page 37

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.6 Firmware Update

The file (*.elf) for updating the FemtoFiber smart firmware is provided by TOPTICA. Please follow the

description below for updating the firmware.

Prerequisites:

• FTDI Driver installed on the control computer.

• TOPAS FemtoFiber smart software installed on the control computer.

• FemtoFiber smart laser head connected to the control computer.

• FemtoFiber smart laser head switched off.

• The firmware file (*.elf) is available on the control computer.

1. Run the TOPAS FemtoFiber smart software and select Menu > Firmware Update. The Firmware

Update window appears (see also section 5.1.3).

Figure 23 TOPAS FemtoFiber smart Firmware Update window

2. Click Select and chose In the firmware file (*.elf) on the control computer.

3. Move the mouse pointer over the Start button but do not click, yet.

4. Switch off the FemtoFiber smart laser head.

5. Switch the FemtoFiber smart laser head back on. Now click the Start button in the TOPAS FemtoFi-

ber smart Firmware Update window within one second - otherwise the update will not take place.

6. The firmware update takes about 2 minutes. A successful update is indicated by the message

“Update successful”. In case of an error, please repeat from step 3.

7. After a successful firmware update, please switch the FemtoFiber smart laser head off and back

on. Establish a connection to TOPAS FemtoFiber smart.

8. The Firmware Version can be checked in the System Info tab (System Status section) of

TOPAS FemtoFiber smart. Please note that the file name may be truncated.

Page 38

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.7 USB Connection (Installation of FTDI CDM Drivers)

NOTE ! You will need to have administrator rights to run the setup. If you don't have logged in with

such rights, you will need to logon as such first. As an alternative, you may also run

setup.exe under a different user while using right-mouse-click and select "run as..."

NOTE ! Since support of Windows XP has been terminated recently, T

or older operating systems. The following procedures are executed on a Windows 7 system, also including some special remarks on Windows 8.

Operation with Windows 10 has been verified at time of issuing this manual.

NOTE ! Newest and latest FTDI drivers can always be found at the manufacturer's website:

http://www.ftdichip.com/Drivers/VCP.htm

Insert the supplied USB flash drive to the control computer and select the folder FemtoFiber-smart-USB-

Driver_Windows (Figure 24).

OPTICA no longer supports this

Figure 24

For USB driver installation, please insert the supplied USB flash drive to the control computer and start the

installation wizard (CDM xxx.exe). The installation wizard will guide you through the installation process.

Figure 25 USB driver installation

Start the installation by clicking Extract. Continue to install by clicking Next.

Page 39

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

Figure 26 USB driver installation

Click Finish to complete the installation.

Page 40

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.8 Precautions for Non-Condensing Operation Conditions

For FemtoFiber smart lasers, the typical temperature inside the housing is approximately 4 °C above the

ambient temperature. This means, however, that especially in warm and humid surroundings, there

could be condensation at relatively cold parts of the FemtoFiber smart – this is a condition that has to be

prevented. Please refer to the dew point table below to see if the environmental conditions are appropriate for the operation of the FemtoFiber smart.

A safe operating condition for the FemtoFiber smart is reached when the dew point is below the typical temperature inside the housing. For safety reasons, there should be a small margin of 2 °C. Please

check with the dew point table whether at your ambient conditions there may be a risk of condensation.

Ambient Temperature in °C 15 20 25 30 35 40 45

Ambient Temperature in °F 59 68 77 86 95 104 113

Relative Ambient Humidity Dew Points at corresponding Ambient Conditions

90% 13,4 18,3 23,2 28,2 33,1 38,0 43,0

85% 12,5 17,4 22,3 27,2 32,1 37,0 41,9

80% 11,6 16,4 21,3 26,2 31,0 35,9 40,7

75% 10,6 15,4 20,3 25,1 29,9 34,7 39,5

70% 9,6 14,4 19,1 23,9 28,7 33,5 38,2

65% 8,5 13,2 18,0 22,7 27,4 32,2 36,9

60% 7,3 12,0 16,7 21,4 26,1 30,7 35,4

55% 6,0 10,7 15,3 20,0 24,6 29,2 33,9

50% 4,7 9,3 13,9 18,4 23,0 27,6 32,2

45% 3,2 7,7 12,2 16,8 21,3 25,8 30,3

40% 1,5 6,0 10,5 14,9 19,4 23,8 28,3

35% -0,3 4,1 8,5 12,9 17,3 21,6 26,0

30% -2,4 1,9 6,2 10,5 14,8 19,1 23,4

25% -4,9 -0,6 3,6 7,8 12,0 16,2 20,4

20% -7,8 -3,7 0,5 4,6 8,7 12,8 16,8

Table 1 Dew point table

Page 41

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.9 Declaration of CE Conformity

Page 42

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.10 Main Dimensions of the FemtoFiber smart System Versions

6.10.1 FemtoFErb Free Beam

Figure 27 Main dimensions of FemtoFErb with free beam laser output

Page 43

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.10.2 FemtoFErb with Fiber Pigtail

Figure 28 Main dimensions of the FemtoFErb with fiber pigtail

Page 44

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.10.3 FemtoFErb with FC/APC Fiber Connector

Figure 29 Main dimensions of the FemtoFErb with FC/APC fiber connector

Page 45

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.10.4 Femto/PicoFYb with Fiber Pigtail

Figure 30 Main dimensions of the Femto/PicoFYb with fiber pigtail

Page 46

Statu s: 6.9.18

FemtoFiber smart Manual 6. Appendix

6.11 License and Copyright Information associated with Third Party

Software

This product incorporates certain third party software. The license and copyright information associated

with this software is available in the folder Software License and Copyright Information on the supplied

USB flash drive.

Please address your request to T

82166 Graefelfing, Germany. This offer is valid during a 3-years-period beginning at the purchase date.

OPTICA Photonics AG, Head of Development, Lochhamer Schlag 19,

6.12 EU Legislation for Electrical and Electronic Equipment (EEE)

Companies selling electrical and electronic goods in the European Union must conform to the EU legislation for electrical and electronic equipment (EEE), which includes the Waste Electrical and Electronic

Equipment Directive (WEEE). Assigned duties affect product design of the equipment, disposal of used

appliances as well as organizational responsibilities, i.e. product registration.

There are different requirements for household WEEE and that which is sold business to business (B2B).

All equipment T

Authority (Stiftung Elektro-Altgeräte Register EAR) under No. DE70442884.

At end-of life return your product back to T

ner as to meet all relevant local, country and EU requirements and guideline.

OPTICA Photonics AG handles is classed as B2B. TOPTICA is registered at the Competent

OPTICA. TOPTICA will dispose used equipment in such a man-

To return products please mark them clearly with “intended for disposal”. Contact T

ping and send them to the following address:

T

OPTICA Photonics AG

Lochhamer Schlag 19

D-82166 Graefelfing

OPTICA prior to ship-

Page 47

Statu s: 6.9.18

FemtoFiber smart Manual 7. Guarantee and Service

7 Guarantee and Service

On the following page you will find the Guarantee Registration Form in which the warranty conditions are

defined. Please complete in the Guarantee Registration Form immediately after you receive your device

and return it to T

As a first step towards obtaining technical support, please contact your local distributor or visit the

support pages on our web site: http://www.toptica.com/support/.

In case you wish to return a product for diagnosis and/or repair, please contact us prior to sending it

so we can issue a Return Material Authorization (RMA) number for you.

You can contact us in the following ways:

- Internet: service.toptica.com. In our support section you can find a list of frequently asked ques-

- Email: service@toptica.com

- Phone: +49-89-85837-150

OPTICA Photonics AG by mail or fax.

tions and a service contact form.

Our customers in the USA and Canada may contact T

- Phone: +1-585-657-6663

Our customers in Japan may contact T

OPTICA Photonics K.K.:

- Phone: +81-42-306-9906

OPTICA Photonics Inc.:

Page 48

Statu s: 6.9.18

Loading...

Loading...